Page 1

Remote SAFEPATH

Operation and Installation

Manual

Models:

RSAPE-B

RSAPE-R

273 Branchport Avenue

Long Branch, NJ 07740

Telephone: 800-631-2148

Fax: 732-222-8707

www.wheelockinc.com

Part Number A83666 Revision A

Thank you for using our products. Use this product according to this instruction manual. Please keep

this instruction manual for future reference.

ANY MATERIAL EXTRAPOLATED FROM THIS DOCUMENT OR FROM WHEELOCK MANUALS OR OTHER DOCUMENTS

DESCRIBING THE PRODUCT FOR USE IN PROMOTIONAL OR ADVERTISING CLAIMS, OR FOR ANY OTHER USE,

INCLUDING DESCRIPTION OF THE PRODUCT'S APPLICATION, OPERATION, INSTALLATION AND TESTING IS USED AT

THE SOLE RISK OF THE USER AND WHEELOCK WILL NOT HAVE ANY LIABILITY FOR SUCH USE.

Remote SAFEPATH Manual Sheet 1 of 50

Rev. C December 1998

Page 2

Conventions Used in This Manual

This manual uses the following conventions for notes, cautions, and warnings.

NOTE: All CAUTIONS and WARNINGS are identified by the symbol

CAUTION: Indicates a potentially hazardous situation which, if not avoided, could result in minor or moderate injury. It may

also be used to alert against unsafe practices.

WARNING: INDICATES A POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, COULD RESULT IN

PROPERTY DAMAGE AND SERIOUS PERSONAL INJURY OR DEATH TO YOU AND OR OTHERS.

All warnings are printed in bold capital letters.

.

Copyright 1998 Wheelock, Inc. All rights reserved.

P83665

Remote SAFEPATH Manual

Rev. C December 1998

Remote SAFEPATH Manual Sheet 2 of 50

Rev. C December 1998

Page 3

Preface

The Remote SAFEPATH panel provides remote amplification and live announcement capabilities. Live announcements can be

made at either the central or remote location. Pre-recorded messages, however, can only be initiated from the central SAFEPATH

panel.

This panel does not sense an emergency condition or hazardous fires; it is only a part of a system that does sense such conditions.

The Remote SAFEPATH panel, when activated by a central SAFEPATH panel, provides a pre-recorded tone and/or voice

message(s) to notification appliances. When used as part of a protective signaling system, the Remote SAFEPATH panel must be

properly connected to a central SAFEPATH panel and to LISTED compatible notification appliances for proper operation.

PERSONNEL PROPERLY QUALIFIED IN THE APPLICATION AND USE OF LIFE SAFETY EQUIPMENT MUST READ THIS

MANUAL CAREFULLY BEFORE PERFORMING ACTIONS TO SPECIFY, APPLY, INSTALL, MAINTAIN AND OPERATIONALLY

TEST SAFEPATH PRODUCTS IN ACCORDANCE WITH THE INSTRUCTIONS IN THIS MANUAL.

WARNING: IF SAFETY PRECAUTIONS, INSTALLATION AND TESTING INSTRUCTIONS ARE NOT PERFORMED

DO NOT assume any installation, operation and testing details not shown in this manual.

•

This SAFEPATH panel should only be operated with covers properly in place.

•

KEEP THIS MANUAL WITH THIS PANEL FOR FUTURE REFERENCE for the life of the system and make it available to all

•

qualified personnel who operate, test, maintain, or service this product. We strongly recommend that such personnel read and

understand this manual and all other relevant product instructions.

This panel WILL NOT WORK WITHOUT POWER. This panel is powered by 120VAC. Back-up power is provided by 24VDC

batteries. If both sources of power are cut off for any reason, the SAFEPATH panel will not provide the desired tone and/or voice

warning.

WHEELOCK EXPRESSLY DISCLAIMS ALL LIABILITY FOR THE CONTENT, CLARITY AND LANGUAGES OF, AND OUTPUT

CHANNEL AND PRIORITY LEVEL ASSIGNED TO, ANY AND ALL MESSAGES. IT IS ESSENTIAL THAT YOU HAVE MESSAGE

CONTENT AND LANGUAGE, SEQUENCE, OUTPUT CHANNEL AND PRIORITY ASSIGNMENTS REVIEWED AND APPROVED

BY QUALIFIED LEGAL AND SAFETY ADVISORS, QUALIFIED REPRESENTATIVE(S) OF OWNER(S) AND USER(S), AND

AUTHORITIES HAVING JURISDICTION.

CAUTION: This panel’s printed circuit boards are sensitive to static electricity and have delicate components mounted on them.

Before handling either a board or any component on a board, discharge any static electricity from your body by touching a grounded

object such as a metal screw which is connected to earth ground. Handle the board by its edges, and be careful not to twist or flex

it. This panel is to be installed in a static free area and the user is to properly attach grounded wrist straps before touching any static

sensitive areas. After handling this panel’s printed circuit boards, the panel should be tested in accordance with the “System

Checkout” guidelines in the “Installation” section of this manual to verify that the printed circuit boards are undamaged and

functioning properly.

COMPLY WITH ALL OF THE LATEST APPLICABLE CODES, REGULATIONS, LAWS, STANDARDS, GUIDELINES.

For emergency, hazardous, security, life safety and fire protective signaling system applications, the SAFEPATH products must be

used within their published specifications and only with a LISTED compatible control panel in accordance with sound engineering

judgment and the instructions of the manufacturer and in accordance with local, state and federal codes, regulations and laws.

SAFEPATH products must be PROPERLY specified, applied, installed, operated, maintained and operationally tested in accordance

with these instructions at the time of installation and at least twice a year or more often as required by local, state and federal codes,

regulations and laws. Installation, testing and maintenance must be performed by qualified personnel for proper operation in

accordance with all of the latest National Fire Protection Association (NFPA), Underwriters' Laboratories (UL), National Electrical

Code (NEC), Occupational Safety and Health Administration (OSHA), local, state, county, province, district, federal and other

applicable building and fire standards, guidelines, regulations, laws and codes including, but not limited to, all appendices and

amendments and the requirements of the local authority having jurisdiction (AHJ).

WARNING: IF THE PROTECTIVE SIGNALING SYSTEM SOUNDS AND/OR FLASHES, IT IS A WARNING OF A

PROPERLY, THIS SAFEPATH PANEL MAY NOT OPERATE IN AN EMERGENCY SITUATION WHICH

COULD RESULT IN PROPERTY DAMAGE AND SERIOUS INJURY OR DEATH TO YOU AND/OR OTHERS.

POSSIBLY SERIOUS SITUATION AND REQUIRES YOUR IMMEDIATE ATTENTION.

Remote SAFEPATH Manual Sheet 3 of 50

Rev. C December 1998

Page 4

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation

of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Request that the local authority having jurisdiction inspect the proposed placement of the notification appliances and receive their

approval.

The output of the audio system may not be heard in all cases. Sound can be blocked or reduced by walls, doors, carpeting, wall

covering, furniture, insulation, bed coverings, and other obstacles that may temporarily or permanently impede the output of the

audio system. Sound is also reduced by distance and masked by background noise. The output of the audio system may not be

sufficient to alert all occupants, especially those who are asleep, those who are hearing-impaired, those who are wearing devices

that plug or cover the ears, and those who have recently used drugs or alcohol. The output of the audio system may not be heard

by an alert person if the output device is placed in an area which is isolated by a closed door, or is located on a different floor from

the person in a hazardous situation or is placed too far away to be heard over ambient noise such as, but not limited to, running

water, traffic, air conditioners, machinery or musical appliances.

WARNING: AUDIBLE SIGNALS MAY MASK MEDICAL EQUIPMENT MONITORING ALARMS. WHERE MEDICAL

If audible tones and/or voice messages cannot be readily heard and understood clearly within the protected areas as intended, it is

necessary to increase the number and/or sound output intensity of speakers within those areas so that they are heard and

understood clearly when activated.

Notification equipment cannot last forever. Even though this panel is expected to last up to ten years, any of its parts or components

could fail before then. Therefore testing of the entire protective signaling system, including this panel, all notification equipment, as

well as all messages and their output channel, and priority assignment, must be conducted at least twice each year, or more often

as required by local, state and federal codes, regulations and laws, by qualified personnel. If the notification equipment is not

working properly, immediately contact the installer and have all/any problems corrected immediately. Malfunctioning components

should be replaced immediately. Do not attempt to repair malfunctioning components. Malfunctioning components should be

returned for factory repair or replacement. In the event you cannot contact the installer, contact the manufacturer.

WARNING: CERTAIN HARDWARE FUNCTIONS ON THIS SAFEPATH PANEL ARE NOT SUPERVISED. IF ANY SUCH

Additional copies of this manual may be obtained from the manufacturer.

EQUIPMENT MONITORING ALARMS ARE IN USE, DO NOT USE AUDIBLE SIGNALS; PROVIDE VISUAL

NOTIFICATION APPLIANCES IN HIGHLY VISIBLE LOCATIONS.

HARDWARE FUNCTIONS FAIL, THE REMOTE SAFEPATH PANEL MAY NOT PROVIDE THE INTENDED

WARNING AND/OR NOT INDICATE A TROUBLE CONDITION.

THE FOLLOWING HARDWARE FAILURES WOULD PREVENT THE REMOTE SAFEPATH PANEL FROM

PROVIDING THE INTENDED WARNING:

1. THE POLARITY DETECTION CIRCUITRY FOR THE LINE LEVEL INPUT.

2. THE ALARM CONTACT.

THE FOLLOWING HARDWARE FAILURES WOULD PREVENT THE REMOTE SAFEPATH PANEL FROM

INDICATING A TROUBLE CONDITION.

1. THE "OPEN CIRCUIT" AND "SHORT CIRCUIT" DETECTION CIRCUITRY FOR ANY ONE OR ALL OF

THE NOTIFICATION APPLIANCE OUTPUT CIRCUITS.

2. THE AMPLIFIER SUPERVISION CIRCUITRY FOR ANY ONE OR ALL OF THE AMPLIFIERS.

3. THE STATUS CONTACT.

THESE HARDWARE FUNCTIONS MUST BE PERIODICALLY CHECKED FOR PROPER OPERATION.

Remote SAFEPATH Manual Sheet 4 of 50

Rev. C December 1998

Page 5

CONTENTS

Page

Introduction................................................................................................................................. 7

Operation.................................................................................................................................... 8

Operator's Console.................................................................................................................. 8

Input and Output Options.......................................................................................................... 8

Supervision............................................................................................................................. 8

Operator Instructions................................................................................................................ 10

Power Calculations............................................................................................…................... 12

Installation.................................................................................................................................. 14

Wiring Guidelines..................................................................................................................... 15

Mounting................................................................................................................................ 15

Grounding............................................................................................................................... 15

Field Wiring............................................................................................................................. 17

Field Wiring Checkout............................................................................................................... 29

System Checkout..................................................................................................................... 29

Installation and Care of Sealed Lead Acid Batteries...................................................................... 30

Troubleshooting........................................................................................................................... 31

Procedures A, B, C, D.............................................................................................................. 34

Procedures E, F, G, H............................................................................................................... 35

Procedures I, J, K, L................................................................................................................. 36

Procedures M-V, W, X, Y, Z...................................................................................................... 37

Periodic Testing........................................................................................................................... 38

Module Description...................................................................................................................... 39

Introduction............................................................................................................................. 39

Supervised Audio System Mother Board (SAMB-A)...................................................................... 42

Supervised Audio System Common Control Module (SADC).......................................................... 43

Self Amplified Speaker Control/Signal Circuit Module (SALL-15S).................................................. 45

Supervised Audio System Power Supply Module (SAPS).............................................................. 47

Supervised Audio System Battery Charger Module (SABC)............................................................ 48

Technical Specifications............................................................................................................... 49

Limited Warranty......................................................................................................................... 50

Limitation of Liability.................................................................................................................... 50

Appendix A. ............................................................................................................................. Reserved

Appendix B. ............................................................................................................................. Reserved

Appendix C. ............................................................................................................................. Reserved

Appendix D. ............................................................................................................................. Reserved

Appendix E. Compatible Signaling Devices................................................................................... E-1

Remote SAFEPATH Manual Sheet 5 of 50

Rev. C December 1998

Page 6

List of Figures

Page

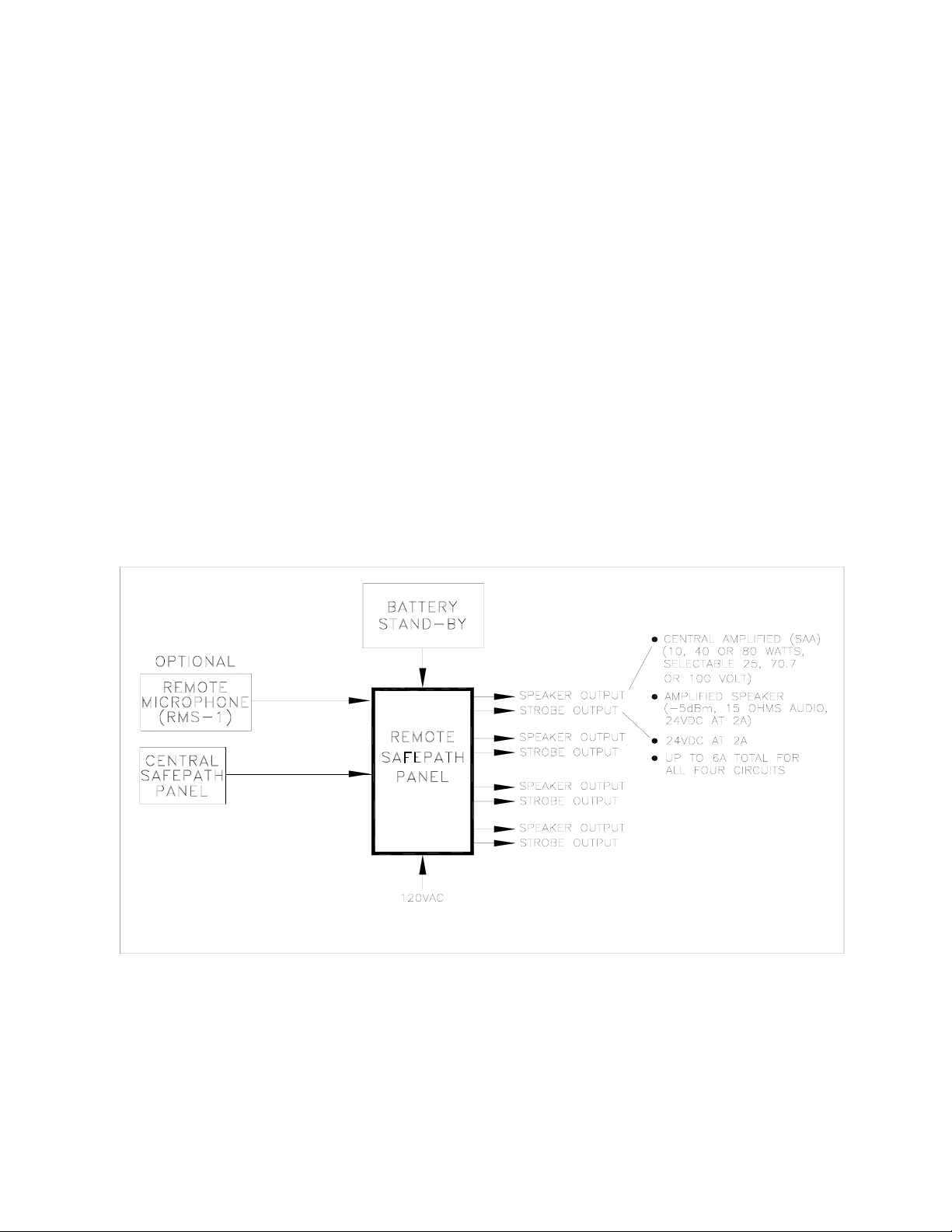

Figure 1 Basic Capabilities of the Remote SAFEPATH Panel...................................................... 7

Figure 2 Operator's Console.................................................................................................. 11

Figure 3 Panel Mounting....................................................................................................... 16

Figure 4 Typical System Block Diagram.................................................................................. 20

Figure 5 Field Wiring Input/Output Terminal Block Locations...................................................... 21

Figure 6 Power Supply, Battery Charger, and Earth Ground Terminal Blocks................................ 22

Figure 7 Line Level Input Wiring............................................................................................. 23

Figure 8 Typical AC Input Voltage Wiring................................................................................ 23

Figure 9 Typical Battery Wiring.............................................................................................. 23

Figure 10 Typical Earth Ground Wiring..................................................................................... 23

Figure 11 Output Terminal Block Detail..................................................................................... 24

Figure 12 Alarm Output Contact Connection Diagram................................................................. 25

Figure 13 System Trouble Output Contact Connection Diagram................................................... 25

Figure 14 Trouble Audible Output Wiring Diagram...................................................................... 25

Figure 15 Visual Notification Appliance Output Wiring Diagram................................................... 26

Figure 16 Audio Notification Appliance Output Wiring Diagram

Using Audio Only Appliances in Central Amplified Applications..................................... 26

Figure 17 Audio Notification Appliance Output Wiring Diagram

Using Audio Only Appliances in Amplified Speaker Applications.................................... 26

Figure 18 Notification Appliance Output Wiring Diagram

Using Combination Audio/Visual Appliances in Central Amplified Applications................ 27

Figure 19 Notification Appliance Output Wiring Diagram

Using Combination Audio/Visual Appliances in Amplified Speaker Applications............... 27

Figure 20 Optional Remote Microphone (RMS-1) Wiring Diagram................................................. 28

Figure 21 Trouble Location Indicator Locations.......................................................................... 33

Figure 22 Module Layout of the Panel...................................................................................... 40

Figure 23 Panel Block Diagram................................................................................................ 41

Figure 24 Supervised Audio System Mother Board..................................................................... 42

Figure 25 Supervised Audio System Common Control Module..................................................... 44

Figure 26 Self Amplified Speaker Control/Signal Circuit Module................................................... 46

Figure 27 Supervised Audio System Power Supply Module......................................................... 47

Figure 28 Supervised Audio System Battery Charger Module...................................................... 48

Remote SAFEPATH Manual Sheet 6 of 50

Rev. C December 1998

Page 7

Introduction

Remote SAFEPATH provides remote amplification and remote live announcement capabilities to a centrally located SAFEPATH

panel. Remote SAFEPATH is capable of providing up to four zones of audible and visual signals. Figure 1 illustrates the basic

capabilities of the remote SAFEPATH panel.

This manual describes the remote SAFEPATH panel, which features:

A multitone generator with field selectable sounds for a manual evacuation signal.

•

Field upgradable.

•

Up to four audio and strobe circuits, zone selectable.

•

Supervision of input and output lines and many internal operations with trouble diagnosis and notification.

•

An optional Remote Microphone (RMS-1).

•

An optional Zone Splitter Module (SPL).

•

THE REMOTE SAFEPATH PANEL MUST BE PROPERLY INSTALLED, PROGRAMMED AND CONNECTED TO A CENTRALLY

LOCATED SAFEPATH PANEL TO FUNCTION IN A VOICE EVACUATION SYSTEM.

Figure 1.

Basic Capabilities of the Remote SAFEPATH Panel

Remote SAFEPATH Manual Sheet 7 of 50

Rev. C December 1998

Page 8

Operation

This chapter describes the operating characteristics of the remote SAFEPATH panel. Included is information about the following

features:

• Operator's Console

Input and Output Options

•

Supervision

•

Operators Instructions

•

Back-up Battery Requirements

•

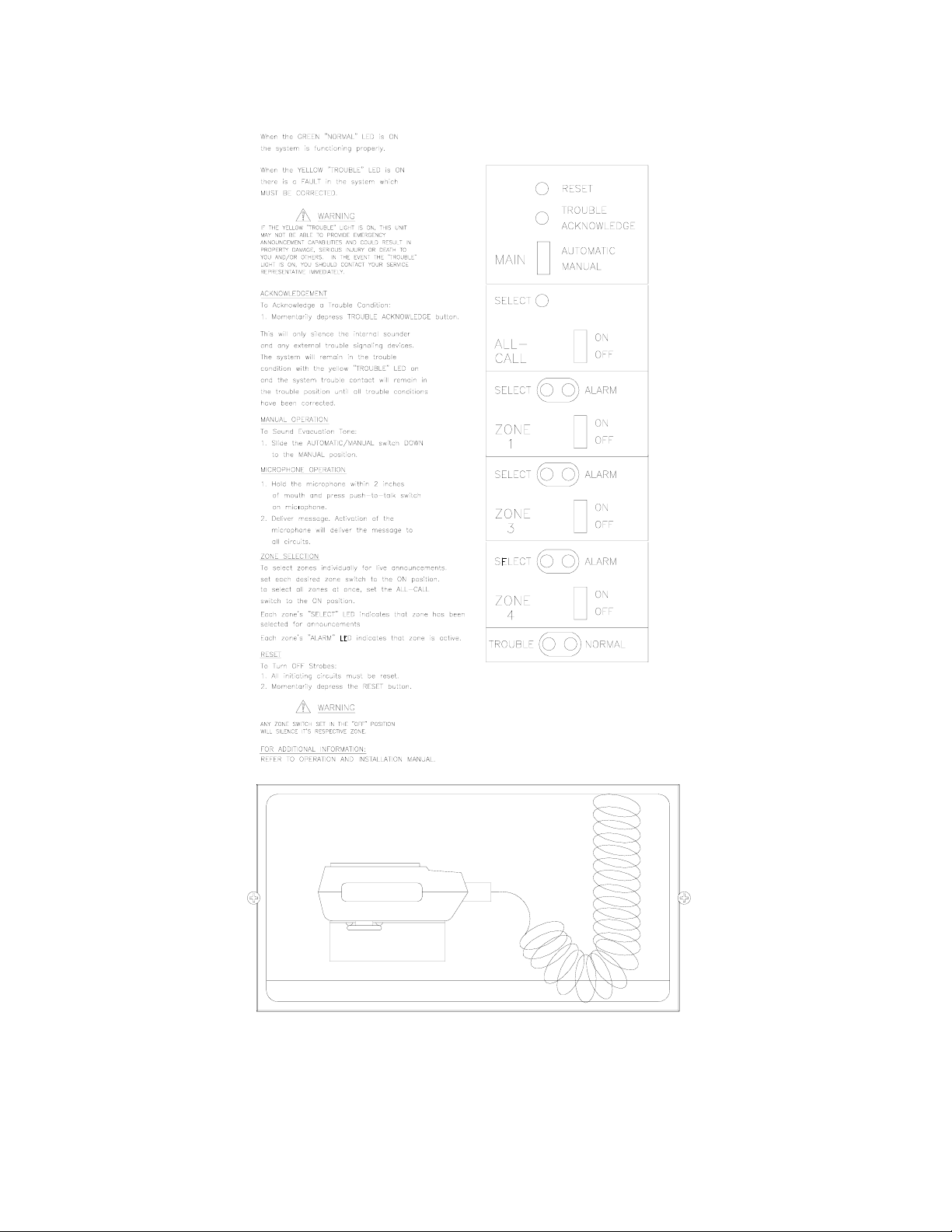

Operator's Console

An operator's console, which allows for manual override of the automatic message playing, is provided. The operator's console

includes a microphone, an "ACKNOWLEDGE" push-button, a "MANUAL/AUTOMATIC " switch, “ALL-CALL” switch, four “ZONE

DISARRANGEMENT” switches, and "NORMAL" and "TROUBLE" indicators. The operator's console is accessed by opening the

enclosure door. See Figure 2.

Input and Output Options

One line level input is provided for connecting to the central SAFEPATH panel.

Up to four audio outputs are available. Each output may be either a 15 Ohm line level output or a 25V, 70.7V or 100V amplifier

output. The 15 Ohm line level output can drive up to twenty 600 Ohm line level input appliances. The 25V, 70.7V or 100V amplifier

can drive up to 10, 40 or 80 Watts of speaker notification appliances.

Up to four visual appliance outputs are available. These outputs are rated for 24VDC and can each supply up to 2 amps of current.

Total current for all four outputs may not exceed 6 amps.

Up to four amplified speaker notification appliance power outputs are available. Each output is rated for 24VDC and can supply up

to 2 amps of current. Total current for all four outputs may not exceed 8 amps.

Supervision

A trouble condition indicates that the supervision functions have detected a malfunction in this panel. When a trouble condition is

detected, the panel may not be capable of playing emergency announcements.

If a trouble condition is detected by any of the supervision functions, the Form C status relay (normally energized) will change state,

the green system normal LED will turn off, and the amber trouble LED will turn on. The status relay contact closure must be properly

connected to and used by the control panel to indicate a system trouble. At the same time, an amber trouble location LED will

identify the location of the trouble condition. If a trouble condition is indicated, follow the procedures in the "Troubleshooting and

Servicing" section.

WARNING: DO NOT LEAVE THIS SAFEPATH PANEL IN A TROUBLE CONDITION AS, IT MAY NOT PLAY WARNING

WARNING: MESSAGES MADE BEFORE AND DURING A TROUBLE CONDITION MAY NOT BE HEARD, WHICH COULD

Input Voltage Supervision

Input voltage is supervised, and if the input voltage drops below the operating minimum voltage, this panel will transfer to battery

back-up power and indicate a trouble condition.

MESSAGES WHICH COULD RESULT IN PROPERTY DAMAGE AND SERIOUS INJURY OR DEATH TO YOU

AND/OR OTHERS. IF SAFEPATH INDICATES A TROUBLE CONDITION: (1) PROVIDE UL REQUIRED

ALTERNATIVE SIGNALING AND (2) HAVE QUALIFIED SERVICE PERSONS IMMEDIATELY REPLACE UNIT(S)

THAT HAVE MALFUNCTIONED.

RESULT IN PROPERTY DAMAGE AND SERIOUS INJURY OR DEATH TO YOU AND/OR OTHERS. IF MESSAGES

MADE BEFORE AND DURING A TROUBLE CONDITION ARE STILL NECESSARY, THEY SHOULD BE REPEATED

WHEN THIS SAFEPATH PANEL IS RETURNED TO NORMAL.

Remote SAFEPATH Manual Sheet 8 of 50

Rev. C December 1998

Page 9

Microprocessor Supervision

Each microprocessor within this panel has a watchdog circuit that supervises the processor and resets it (if necessary) or maintains

a trouble condition if the microprocessor cannot be restarted. Each watchdog circuit constantly monitors the functioning of its

microprocessor and, if the microprocessor fails to function properly, will attempt to reset and restart the microprocessor.

Line Level Input Supervision

The line level input wiring is supervised by the central panel only. If either an open or short in the wiring should occur, the remote

panel will indicate an alarm condition.

Visual Notification Appliance Output Line Supervision

All visual notification appliance output lines are supervised. The lines are supervised for open circuits, short circuits, and ground

faults when the output is de-energized; and ground faults only when the output is energized. Output line supervision requires a

LISTED 10K end-of-line resistor to be installed on each output circuit and across the terminals of unused output circuits.

Audio Notification Appliance Output Line Supervision

All audio notification appliance output lines are supervised. The lines are supervised for open circuits, short circuits, and ground

faults when the output is de-energized. The lines are unsupervised when the output is energized. Output line supervision requires a

LISTED 10K end-of-line resistor to be installed on each output circuit and across the terminals of unused output circuits.

Amplified Speaker Notification Appliance Power Output Line Supervision

All amplified speaker notification appliance power output lines are supervised. The lines are supervised for open circuits, short

circuits, and ground faults when the output is de-energized, and ground faults only when the output is energized. Output line

supervision requires a LISTED 10K end-of-line resistor to be installed on each output circuit and across the terminals of unused

output circuits.

Battery Back-Up Line Supervision

The battery back-up lines are supervised for open circuits, short circuits and ground faults.

Back-Up Battery Supervision

The back-up battery is supervised for low voltage conditions.

Remote Microphone Supervision

The optional remote microphone is supervised for proper operation and for open circuits, short circuits and ground faults.

Remote SAFEPATH Manual Sheet 9 of 50

Rev. C December 1998

Page 10

Operator Instructions

The SAFEPATH panel provides an operator console for manually activating the panel. The operator console includes a

microphone, a green “NORMAL” indicator, a yellow “TROUBLE” indicator, an “ACKNOWLEDGE” push-button switch, a “RESET”

push-button, a “MANUAL/AUTOMATIC” switch, an “ALL-CALL” switch and four “ZONE SELECT” switches. The operator interface

allows the operator to manually override automatically playing pre-recorded messages with live announcements or an evacuation

tone, to silence internal and external trouble audibles, and to ascertain if the panel has detected a trouble condition. The operator

interface is shown in Figure 3.

The “TROUBLE” and “NORMAL” indicators are visible through a window on the panel door, when door is closed. All other operator

controls are only accessible by opening the panel door.

The “SELECT” LED’s indicate the zones selected for live announcements.

The ”ALARM” LED’s indicate the zones actively in alarm.

The two indicators identify to the operator when the SAFEPATH panel has detected a trouble condition. The yellow “TROUBLE”

indicator will be illuminated whenever there is a trouble detected by the SAFEPATH panel. If no troubles are detected, the green

“NORMAL” indicator will be illuminated.

The “ACKNOWLEDGE” push-button allows the operator to silence the trouble audibles, both internal and external. When a trouble

condition is detected, both the internal and external trouble audibles are sounded. When the “ACKNOWLEDGE” push-button is

depressed, the internal and external trouble audibles will be silenced. The trouble audibles will resound for subsequent trouble

conditions. The Form C trouble output contact will remain in the trouble condition and the “TROUBLE” indicator will remain

illuminated until all trouble conditions have been corrected.

The “RESET” push-button resets the strobe circuits after all initiating circuits are reset.

The “MANUAL/AUTOMATIC” switch has two positions, manual (down) and automatic (up). When the “MANUAL/AUTOMATIC”

toggle switch is in the automatic position, pre-recorded messages may be selected to play in individual circuits via dry contact inputs

and/or a serial communication interface. When the “MANUAL/AUTOMATIC” switch is in the manual position, pre-recorded

messages will not play, and the visual notification appliances are energized and the evacuation tone sounds in all circuits.

The “ALL-CALL” switch overrides any zone selection and allows audible signals to be heard regardless of the position of the four

zone select switches.

The four “ZONE SELECT” switches are numbered 1 through 4. They are used to silence any audible signal and turn off visual

signals in the respective zones, for live announcements only.

Operation Instructions

To make a live announcement:

1. Select specific zones or use “ALL-CALL” as necessary.

2. Remove microphone from its holder.

3. Hold down microphone’s push-to-talk button and talk into microphone.

To manually sound evacuation tone:

1. Move “MANUAL/AUTOMATIC” switch to the manual position.

The evacuation tone will sound in all circuits.

To silence trouble audibles:

1. Depress the “ACKNOWLEDGE” push-button.

To reset strobes:

1. All initiating circuits must be reset.

2. Momentarily depress the “RESET” push-button.

Remote SAFEPATH Manual Sheet 10 of 50

Rev. C December 1998

Page 11

Figure 2.

Operator’s Console

Remote SAFEPATH Manual Sheet 11 of 50

Rev. C December 1998

Page 12

Power Calculations

It is necessary to calculate the current draw for battery back-up requirements. The current requirements depend on the system

configuration and the options installed. The total current is the sum of the currents of all the components in the system. There are

two different system current ratings:

Standby Current

Alarm Current

Standby Current Calculations:

System Controller Board 150mA

Amplifier 1 See Note 1

Amplifier 2 See Note 1

Amplifier 3 See Note 1

Amplifier 4 See Note 1

Optional RMS-1 40mA (If Installed)

Optional Trouble Audible See Note 2

Optional SPL 40maA (If Installed)

________

Total:

Note 1: If no amplifier is installed in the slot then the current for that amplifier is zero. If there is an amplifier the standby current

depends on the model of the amplifier installed in the slot and the pre-selected 1 of 8 evacuation tones.

Model Standby Current Temporal Worst case

As per UL full power CODE-3 tone

SIN wave testing TONE HI/LO

SALL-15S 100mA 100mA 100mA

SAA10S/SE Series 240mA 125mA 150mA

SAA40S/SE Series 400mA 300mA 300mA

SAA80S/SE Series 600mA 300mA 400mA

Note 2: Use the rated current for the optional trouble audible attached to the system.

Alarm Current Calculations:

System Controller Board 150mA

Amplifier 1 See Note 4

Amplifier 2 See Note 4

Amplifier 3 See Note 4

Amplifier 4 See Note 4

Digital Voice See Note 5

Optional RMS-1 75mA (If Installed)

Optional Trouble Audible See Note 6

Zone 1 Strobes See Note 7

Zone 2 Strobes See Note 7

Zone 3 Strobes See Note 7

Zone 4 Strobes See Note 7

Optional SPL 190mA (If Installed)

________

Total:

Remote SAFEPATH Manual Sheet 12 of 50

Rev. C December 1998

Page 13

Note 3: If no amplifier is installed in the slot then the current for that amplifier is zero. If there is an amplifier the alarm current

depends on the model of the amplifier installed in the slot and the signal used for evacuation.

Model Alarm Current full power SIN wave as per UL testing

SALL-15S Series The sum of the currents of the self amplified speakers.

SAA-10S/SE Series (total wattage of connected speakers) x 69 + 240mA

SAA-40S/SE Series (total wattage of connected speakers) x 55 + 400mA

SAA-80S/SE Series (total wattage of connected speakers) x 56 + 600mA

Alarm Current for: Temporal Worst case

CODE-3 tone

Typical Voice TONE HI/LO

SAA10S/SE Series 250mA 350mA 750mA

SAA40S/SE Series 600mA 750mA 1600mA

SAA80S/SE Series 1000mA 1050mA 2500mA

Note 4: Use the rated current for the optional trouble audible attached to the system.

Note 5: If no strobes are installed in the zone the current is zero. If strobes are installed, the current is the sum of the current ratings

of all the strobes attached to the zone.

Battery Capacity Calculations:

The battery capacity depends on two factors; the current being drawn from the battery and the amount of time that the current is

being drawn. The battery capacity is measured in amp hours. The total amp hours of batteries needed is (the standby current) x

(time in standby) + (the alarm current) x (time in alarm).

Sample Calculation:

The system is equipped with an RMS-1, a remote trouble audible that is rated for 100mA, and three amplifiers. The first amplifier is

an SAA-10S Series with 10 watts of speakers attached and 1 amp of strobes attached. The second amplifier is an SAA-80S Series

with 60 watts of speakers attached and 2 amps of strobes attached. The third amplifier is an SALL-15S Series with 10, 100mA self

amplified speakers attached and no strobes attached. The system is designed for 24 hours of standby and 15 minutes of alarm.

Standby Calculations:

System Controller Board 150mA

Amplifier 1 125mA

Amplifier 2 300mA

Amplifier 3 100mA

Amplifier 4 0mA

Optional RMS-1 40mA

Optional Trouble Audible 100mA

_______

Total: 815mA = .815 amps

Alarm Current Calculations:

System Controller Board 150mA

Amplifier 1 350mA

Amplifier 2 1050mA

Amplifier 3 1000mA

Amplifier 4 None 0mA

Optional RMS-1 750mA

Optional Trouble Audible 100mA

Zone 1 Strobes 1000mA

Zone 2 Strobes 2000mA

Zone 3 Strobes 0mA

Zone 4 Strobes 0mA

________

Total: 5725mA = 5.725 amps

Battery Capacity Calculations:

24 hours x .815 amps + 1/12 hour (5 minutes) x5.725 amps = 20.04 amp hours minimum capacity. Any de-rating factor must also

be included.

Remote SAFEPATH Manual Sheet 13 of 50

Rev. C December 1998

Page 14

Installation

The lives of people depend upon your safe installation of this panel. Please read, understand and carefully follow the specific

installation instructions set forth below to avoid damage to this panel and the equipment connected to it. Installation should be

conducted only by qualified persons in accordance with the procedures in this manual.

WARNING: SHUT OFF ALL POWER BEFORE STARTING THE INSTALLATION. ELECTRICAL SHOCK CAN CAUSE

CAUTION: This panel’s printed circuit boards are sensitive to static electricity and have delicate components mounted on

CAUTION: The Authorities Having Jurisdiction (AHJ) should be consulted by the installer prior to installation.

1. Prepare a drawing of the complete system wiring (Keep a copy of the system wiring drawing with this manual as a

permanent record of the system wiring). See the "Wiring Guidelines" and the "Field Wiring" sections to help develop

this drawing.

2. Carefully unpack the panel and make sure each item described on the packing slip is present and undamaged.

3. Mount the panel in the desired location as described in the "Mounting" section.

4. Mount any additional wiring boxes or junction boxes needed to interconnect field wiring.

5. Connect conduit fittings or bushings as needed using knockouts provided on the top and bottom of the panel.

6. Install field wiring in conduit when necessary, following the National Electrical Code and local codes for the type of

system being installed. Make all necessary connections at any additional wiring or junction boxes.

CAUTION: Provide proper strain relief for all wiring not in conduit.

7. Connect the panel to earth ground, following the National Electrical Code and local codes for the type of system being

installed, as described in the “Grounding “ section.

8. Check the integrity of all field wiring following the directions in the "Field Wiring Checkout'' section. Confirm that the

specified cable is installed and that there is continuity between required points (no open circuits), with no unwanted

connections (shorts) to other conductors, chassis, or earth ground.

9. Connect the wiring to the appropriate terminals of the panel’s modules following the directions in the "Field Wiring"

section and the system wiring drawing created in Step 1.

10. Install the appropriate amplifier modules into slots 1 thru 4 of the mother board.

11. Configure the dip switches on the controller module and install into slot 5 of the mother board.

12. Apply power and perform the operational tests described in the "System Checkout" section.

DEATH OR SERIOUS INJURY.

them. Before handling either a board or any component on a board, discharge any static electricity from your

body by touching a grounded object such as a metal screw which is connected to earth ground. Handle the

board by its edges, and be careful not to twist or flex it. This panel is to be installed in a static free area and the

user is to properly attach grounded wrist straps before touching any static sensitive areas. After handling this

panel’s printed circuit boards, the panel should be tested in accordance with the “System Checkout” guidelines

in the “Installation” section of this manual to verify that the printed circuit boards are undamaged and functioning

properly.

Remote SAFEPATH Manual Sheet 14 of 50

Rev. C December 1998

Page 15

Wiring Guidelines

WARNING: ALL AUDIO WIRING SHOULD BE ROUTED AWAY FROM ANY HIGH VOLTAGE OR HIGH CURRENT

The National Electrical Code defines two types of circuits for protective signaling systems: power limited circuits and non-power

limited circuits. All circuits in this panel are non-power limited.

CAUTION: The National Electric Code limits the maximum number of conductors that can be installed in conduit and wiring

See the “Field Wiring Connection” section for recommended wire sizes and wire type to use for all input and output circuits.

LINES (SUCH AS AC OR DC POWER LINE, AUDIO POWER LINES, AND MOTOR OR RELAY ACTUATION

LINES) AND SHOULD BE INSTALLED IN SEPARATE CONDUIT FROM HIGH VOLTAGE OR HIGH

CURRENT LINES. FAILURE TO DO SO MAY CAUSE ELECTRICAL SHOCK RESULTING IN PROPERTY

DAMAGE AND SERIOUS INJURY OR DEATH TO YOU AND/OR OTHERS.

boxes depending on the size of the conduit, the volume of the boxes, and the gauge of the wire used. Make

sure that wiring used for installation complies with the latest NEC requirements.

Mounting

This panel shall be mounted in a location within the environmental limits specified in the latest UL Standard for indoor control

panels. This panel shall not be located in a hazardous location. Refer to the "Technical Specifications'' section.

Refer to Figure 3 for panel mounting hole layout. Drill mounting holes for appropriate screws and anchors to ensure secure

mounting to the type of surface at the selected location. Keep out dust and dirt during installation, as they can interfere with the

operation and reduce the life of the equipment.

Remove the door and mount the panel at the selected location. Use care to avoid damage to the module PC boards during

installation. Do not apply excessive pressure to any PC board or its components, including field wiring terminals and connectors.

Grounding

This panel should be connected to earth ground in accordance with the National Electrical Code. Connecting this panel to earth

ground will reduce static discharge failures, improve transient protection, and reduce the chance of electrical shock. This panel

should be grounded as follows:

1. Connect a wire between the ground lug (labeled “EARTH GROUND”) in Figure 6 and earth ground.

Remote SAFEPATH Manual Sheet 15 of 50

Rev. C December 1998

Page 16

Figure 3.

Panel Mounting

Remote SAFEPATH Manual Sheet 16 of 50

Rev. C December 1998

Page 17

Field Wiring

Before installation, the system specifier must determine the proper wire gauge for all field wiring. The field wiring is broken down

into two categories, inputs and outputs.

NOTE: All field wiring shall conform to applicable codes and standards including NFPA, UL, local, state, county, province, district

and federal codes and standards.

Field Wiring Connection

All wiring terminals are designed to accept #22 AWG to #12 AWG wiring (one wire per terminal). Connect the field wiring to the

terminals while referring to the following sections.

Install field wiring following the latest National Electrical Code and local codes for the type of system being installed. Make all

necessary connections. See Figure 4 for typical system block diagram.

Check the integrity of all field wiring following directions in the "Field Wiring Checkout" section. Confirm that the specified cable is

installed and there is continuity between required points (no "open circuits"), with no unwanted connections ("shorts") to other

conductors, chassis, or earth ground. Perform the field wiring checkout before continuing with any connections to the wiring

terminals.

WARNING: TO REDUCE THE RISK OF ELECTRICAL SHOCK, NEVER CONNECT OR DISCONNECT FIELD WIRING

Input Wiring Descriptions

This panel has four types of inputs, the locations of which are shown in Figure 5. Detail of the power input and ground terminals is

shown in Figure 6.

Line Level Input Wiring

Determination of the wire gauge for the line level input wiring should consider all factors, including wire loop length and the

maximum allowable wire loop resistance of 10 ohms. The line level input wiring diagram’s are shown in Figure 7.

AC Input Voltage Wiring

Determination of wire gauge for the input voltage wiring should consider all factors, including wire loop length, AC power line

voltage, the panel’s maximum AC current consumption, and the panel’s AC input voltage range.

IT IS IMPORTANT THAT THE WIRING USED FOR INPUT VOLTAGE WIRING IS LARGE ENOUGH TO CARRY THE MAXIMUM

CURRENT REQUIRED BY THIS SAFEPATH PANEL WITHOUT EXCESSIVE VOLTAGE DROP. IF VOLTAGE DROPS FROM AC

POWER LINE LOADING AND WIRING RESISTANCE ARE NOT WITHIN THE SPECIFIED OPERATING VOLTAGE RANGE, THE

SAFEPATH PANEL WILL NOT FUNCTION PROPERLY.

A typical AC input voltage wiring diagram is shown if Figure 8. This panel shall have its own branch circuit on the main power panel.

The wiring from the main power panel shall terminate in the SAFEPATH panel on the power supply terminals as shown in Figure 8.

Wire jumpers shall then be run from the battery charger terminals to the power supply terminals as shown in Figure 8. The wire

jumpers between the battery charger terminals and the power supply terminals shall be the same gauge as the wire between the

main power panel and this panel.

Battery Wiring

Determination of the wire gauge for the battery wiring should consider all factors, including wire loop length and the maximum

allowable wire loop resistance. The maximum wire loop resistance is 0.05 ohms. A typical battery wiring diagram is shown in Figure

9.

Earth Ground Wiring

Determination of the wire gauge for the earth ground wiring should consider all factors, including wire length and the maximum

allowable wire resistance. A typical earth ground wiring diagram is shown in Figure 10.

If the RSAPE is connected to the direct output of the amplifier at the audio outputs on the SAMB-A, then wire to the LLIM as shown

in Figure 7A. If the RSAPE is connected to the output of a splitter (SPL, SC-SPL), then wire to the LLIM as shown in Figure 7B.

WHEN INPUT VOLTAGE OR BACK-UP BATTERIES ARE CONNECTED TO THIS SAFEPATH PANEL.

Remote SAFEPATH Manual Sheet 17 of 50

Rev. C December 1998

Page 18

Output Wiring Descriptions

This panel has six types of outputs. The location of the outputs’ terminal blocks within this panel are shown in Figure 5. Detail of

the terminal blocks is shown in Figure 11.

Alarm Output Contact Wiring

One alarm output contact is provided. It is Form C and is rated for 0.5A at 24VDC, resistive load. A detail of the alarm output

contact terminal connections is shown in Figure 12. The contact in Figure 12 is shown in the non-alarm position. Determination of

wire gauge for the alarm output contact wiring should consider all factors, including wire loop length, maximum current capacity, and

maximum voltage drop allowable.

System Trouble Output Contact Wiring

One system trouble output contact is provided. It is Form C and is rated for 0.5 amps at 24VDC, resistive load. A detail of the

system trouble output contact terminal connections is shown in Figure 13. The contact in Figure 13 is shown in the trouble position.

Determination of wire gauge for the system trouble output contact wiring should consider all factors, including wire loop length,

maximum current capacity, and maximum voltage drop allowable.

Trouble Audible Output Wiring

One trouble audible output is provided. The output is rated for 24VDC, 0.1 amps maximum. The output is unsupervised. The

wiring diagram for the trouble audible output is shown in Figure 14. Determination of wire gauge for the trouble audible output wiring

should consider all factors, including wire loop length, maximum current capacity, and maximum voltage drop allowable.

Visual Notification Appliance Output Wiring

Up to four visual notification appliance outputs may be provided. Each output provided is rated for 24VDC, 2.0 amps maximum. All

four outputs combined may not exceed 6.0 amps maximum. Each output meets Class B, Style Y supervision requirements for

notification appliance circuits.

The wiring diagram for the visual notification appliance output using visual only appliances is shown in Figure 15. The wiring

diagram for a notification appliance output using combination audio/visual appliances in central amplified applications is shown in

Figure 18. The wiring diagram for a notification appliance output using combination audio/visual appliances in amplified speaker

applications is shown in Figure 19.

Each output circuit must have a LISTED 10K end-of-line resistor installed across the last visual notification appliance. All unused

outputs must have a LISTED 10K end-of-line resistor across the output terminals. The LISTED 10K end-of-line resistors must have

a 1/8W minimum power rating and a 5% maximum tolerance

The gauge of the wire necessary for the wiring may vary for each visual notification appliance output on the SAFEPATH panel.

Determination of wire gauge should consider all factors including wire loop length, the maximum current draw of each appliance, the

number of appliances, and the maximum voltage drop allowable.

Audio Notification Appliance Output Wiring

Up to four audio notification appliance outputs may be provided. Each output is either a central amplified output or an amplified

speaker output. Central amplified outputs are a 25V, 70.7V or 100V audio output, rated for 10, 40, or 80 watts maximum. Amplified

speaker outputs are 15 Ohm, -5dBm maximum. Each output meets Class B, Style Y supervision requirements for notification

appliance circuits.

The wiring diagram for the audio notification appliance output using audio only appliances in central amplified applications is shown

in Figure 16. The wiring diagram for the audio notification appliance output using audio only appliances in amplified speaker

applications is shown in Figure 17. The wiring diagram for a notification appliance output using combination audio/visual appliances

in central amplified applications is shown in Figure 18. The wiring diagram for a notification appliance output using combination

audio/visual appliances in amplified speaker applications is shown in Figure 19.

Each output circuit must have a LISTED 10K end-of-line resistor installed across the last audio notification appliance. All unused

outputs must have a LISTED 10K end-of-line resistor across the output terminals. The LISTED 10K end-of-line resistors must have

a 1W minimum power rating and a 5% maximum tolerance

The gauge of the wire necessary for the wiring may vary for each audio notification appliance output on the SAFEPATH panel.

When speaker with transformer appliances are used (central amplified outputs), determination of wire gauge should consider all

factors including wire loop length, appliance power ratings, the number of appliances, and the maximum voltage drop allowable.

When amplified speaker appliances are used, determination of wire gauge should consider all factors including wire loop length,

output level, the output resistance, the input resistance of each appliance, the number of appliances, and the appliance input

sensitivity.

Remote SAFEPATH Manual Sheet 18 of 50

Rev. C December 1998

Page 19

Amplified Speaker Notification Appliance Power Output Wiring

Up to four amplified speaker notification appliance power outputs may be provided. Each output is rated for 24VDC, 2.0 amps

maximum. Each output meets Class B, Style Y supervision requirements for notification appliance circuits. The wiring diagram for

the amplified speaker notification appliance power output using audio only appliances is shown in Figure 17. The wiring diagram for

the amplified speaker notification appliance power output using combination audio/visual appliances is shown in Figure 19.

Each output circuit must have a LISTED 10K end-of-line resistor installed across the last appliance. All unused outputs must have a

LISTED 10K end-of-line resistor across the output terminals. The LISTED 10K end-of-line resistors must have a 1W minimum

power rating and a 5% maximum tolerance

The gauge of the wire necessary for the wiring may vary for each amplified speaker notification appliance power output on the

SAFEPATH panel. Determination of wire gauge should consider all factors including wire loop length, the maximum current draw of

each appliance, the number of appliances, and the maximum voltage drop allowable.

Remote Microphone Station (RMS-1) Wiring

Use twisted shielded wiring between the remote microphone station and the SAFEPATH panel. Connect shield to the panel ground

connection only. The maximum distance between the RMS-1 and the SAFEPATH panel is 1000 Ft. with a minimum wire size of 22

AWG, with a maximum capacitance of 50pF/Ft. or .05uF/Total run. The wiring diagram for the remote microphone station is shown

in Figure 20.

Remote SAFEPATH Manual Sheet 19 of 50

Rev. C December 1998

Page 20

Figure 4.

Typical System Block Diagram

Remote SAFEPATH Manual Sheet 20 of 50

Rev. C December 1998

Page 21

Figure 5.

Field Wiring

Input/Output Terminal Block Locations

Remote SAFEPATH Manual Sheet 21 of 50

Rev. C December 1998

Page 22

Figure 6.

Power Supply, Battery Charger And Earth Ground Terminal Blocks

Remote SAFEPATH Manual Sheet 22 of 50

Rev. C December 1998

Page 23

Figure 7A.

Line Level Input Wiring Diagram From Splitter

Output Diagram

Typical AC Input Voltage Wiring

Figure 8.

Figure 7B.

Line Level Input Wiring Diagram From Amplifier

Output Diagram

Figure 9.

Typical Battery Wiring

Figure 10.

Typical Earth Ground Wiring

Remote SAFEPATH Manual Sheet 23 of 50

Rev. C December 1998

Page 24

Figure 11.

Output Terminal Block Detail

Remote SAFEPATH Manual Sheet 24 of 50

Rev. C December 1998

Page 25

Figure 12.

Alarm Output Contact Connection Diagram

Figure 13.

System Trouble Output Contact Connection Diagram

(Contact shown in trouble condition)

Figure 14.

Trouble Audible Output Wiring Diagram

CAUTION: Do not loop wire under terminals. Break wire run to provide supervision of connection.

Remote SAFEPATH Manual Sheet 25 of 50

Rev. C December 1998

Page 26

Figure 15.

Visual Notification Appliance Output Wiring Diagram

CAUTION: Do not loop wire under terminals. Break wire run to provide supervision of connection.

Figure 16.

Audio Notification Appliance Output Wiring Diagram

Using Audio Only Appliances In Central Amplified Applications

CAUTION: Do not loop wire under terminals. Break wire run to provide supervision of connection.

Figure 17.

Audio Notification Appliance Output Wiring Diagram

Using Audio Only Appliances In Amplified Speaker Applications

Remote SAFEPATH Manual Sheet 26 of 50

Rev. C December 1998

CAUTION: Do not loop wire under terminals. Break wire run to provide supervision of connection.

Page 27

Figure 18.

Notification Appliance Output Wiring Diagram

Using Combination Audio/Visual Appliances In Central Amplified Applications

CAUTION: Do not loop wire under terminals. Break wire run to provide supervision of connection.

Figure 19.

Notification Appliance Output Wiring Diagram

Using Combination Audio/Visual Appliances In Amplified Speaker Applications

Remote SAFEPATH Manual Sheet 27 of 50

Rev. C December 1998

CAUTION: Do not loop wire under terminals. Break wire run to provide supervision of connection.

Page 28

Figure 20.

Optional Remote Microphone Station (RMS-1) Wiring Diagram

Remote SAFEPATH Manual Sheet 28 of 50

Rev. C December 1998

Page 29

Field Wiring Checkout

Refer to NFPA for guidelines on testing signaling system wiring.

CAUTION: Do not connect input voltage to any equipment until the field wiring has been inspected and approved.

Verify that the field wiring is in full agreement with this manual and with the detailed wiring layout prepared for this installation.

Ensure that no unwanted voltages are present on circuit conductors and ground. Test all ungrounded connectors for electrical

isolation from ground. Test all wires that are not intentionally connected for electrical isolation from each other. Measure and record

the resistance of each circuit pair (this can be done by temporarily short circuiting one end of the circuit).

System Checkout

Refer to NFPA for guidelines on testing signaling systems.

When rated input voltage is applied to this panel, the unit initializes its program and broadcasts a tone signal through each output

channel for several seconds. The green system normal LED indicator should be on to indicate normal operation. If the amber

system trouble LED is on, a trouble condition is indicated. Refer to the "Troubleshooting and Servicing" section to diagnose and

correct the trouble condition.

The system checkout should include:

1. Testing all inputs and outputs.

2. Testing all connections to equipment that is interconnected with this panel.

3. Testing all message files for proper audibility, intelligibility, content, and priority (message files are stored in the central panel).

If a malfunction is discovered during testing, the problem should be corrected immediately before continuing with testing.

WARNING: ALL PROTECTIVE SIGNALING SYSTEMS REQUIRE PERIODIC TESTING. ALL PROTECTIVE SIGNALING

SYSTEM EQUIPMENT SHALL BE TESTED BY QUALIFIED PERSONNEL AT LEAST TWICE A YEAR FOR

PROPER OPERATION, OR MORE OFTEN IF REQUIRED BY CODES, REGULATIONS AND LAWS.

FAILURE TO MAINTAIN AND TEST PROTECTIVE SIGNALING SYSTEM EQUIPMENT CAN RESULT IN AN

INABILITY TO DETECT EQUIPMENT FAILURE THAT CAN RESULT IN PROPERTY DAMAGE AND

SERIOUS PERSONAL INJURY OR DEATH TO YOU AND/OR OTHERS DURING AN EMERGENCY

SITUATION.

Remote SAFEPATH Manual Sheet 29 of 50

Rev. C December 1998

Page 30

Installation and Care of Sealed Lead Acid Batteries

Sealed lead acid batteries are designed to operate in standby service for approximately five years. This is based upon a normal

service condition where there is an ambient of 20 degrees C (68 degrees F) and batteries are completely discharged once every

three months. LENGTH OF SERVICE LIFE WILL BE DIRECTLY EFFECTED BY THE NUMBER OF DISCHARGE CYCLES,

DEPTH OF DISCHARGE, AND AMBIENT TEMPERATURE.

Use Guidelines:

1. Avoid installation and/or operation in close proximity to heat sources. While the operating temperature range is 0 to 49

degrees C (32-120 degrees F), battery life will be maximized at an ambient of 20 degrees C (68 degrees F).

2. Batteries may generate ignitable gases. Because of this, batteries shall be installed in a well ventilated location, away from

spark producing equipment.

3. Batteries shall not be installed in an atmosphere where organic solvents or adhesives may be present. The batteries shall not

be cleaned with oils, thinners, or similar substances. The case and cover of the batteries are ABS plastic resin which may

suffer damage from these chemicals.

4. Batteries shall not be installed in a heavy vibration or shock location.

5. Batteries shall have a 1/4” minimum separation between cells.

6. Insulated gloves shall always be worn when handling batteries.

7. Batteries shall not be crushed, incinerated, or dismantled. The electrolyte contains sulfuric acid which can cause serious

damage to eyes and skin. If contact does occur, flush with water and seek immediate medical attention.

8. Batteries of different capacities, age, or manufacturer shall not be used together.

Battery Storage

Batteries which are to be stored for an extended period of time should be given a supplementary charge monthly. Batteries should

never be stored in a discharged condition.

The self-discharge rate of batteries is approximately 3% per month when the storage temperature is maintained at 20 degrees C (68

degrees F). The self-discharge rate will vary depending upon temperature. Cooler temperatures cause the self-discharge rate to

decrease. Warmer temperatures cause the self-discharge rate to increase.

Remote SAFEPATH Manual Sheet 30 of 50

Rev. C December 1998

Page 31

Troubleshooting

WARNING: SOME ELECTRONIC COMPONENTS STORE A HIGH VOLTAGE CHARGE, EVEN THOUGH POWER IS

WARNING: PROVIDE UL REQUIRED ALTERNATIVE SIGNALING MEANS DURING TROUBLE CONDITIONS AND

CAUTION: Troubleshooting and servicing should be conducted only by qualified persons in accordance with the

CAUTION: User servicing of this is limited to the following:

- Field wiring changes following the instructions in the "Installation" section of this manual.

- The procedures set forth in this section.

CAUTION: Do not paint or in any way cover window or LED's.

AFTER ANY TROUBLESHOOTING PROCEDURE IS COMPLETED, PERFORM A COMPLETE SYSTEM CHECKOUT.

This SAFEPATH panel monitors system integrity. Items monitored for integrity are:

1. Strobe circuit field wiring.

2. Speaker circuit field wiring.

3. Amplified speaker audio circuit field wiring.

4. Amplified speaker power circuit field wiring.

5. AC input voltage.

6. Battery voltage level.

7. Battery circuit field wiring.

8. Amplifier functionality.

9. Internal wiring.

10. Internal fuses.

11. Remote microphone functionality and wiring.

System status is indicated to the operator via the NORMAL and TROUBLE indicators. If a trouble condition is detected, this

SAFEPATH panel will respond as follows:

1. Turn off the NORMAL indicator.

2. Turn on the TROUBLE indicator.

3. Transfer the Form C trouble contact to the trouble position.

4. Turn on the internal trouble sounder.

5. Turn on the external trouble audible.

6. Turn on a trouble location indicator, if appropriate.

If the ACKNOWLEDGE push-button is pressed, the internal trouble sounder and the external trouble audible will be silenced. All

other trouble indicators will still indicate a trouble condition. The internal trouble sounder and the external trouble audible will not

resound for subsequent trouble conditions, until all trouble conditions have cleared. If the main power fuse on the controller board is

blown, the internal trouble sounder and the external trouble audible will not sound. All other trouble indications occur normally.

When there are no trouble conditions detected, the NORMAL indicator will always be on and the TROUBLE indicator will always be

off. When a trouble condition is detected, the NORMAL indicator will always be off and the TROUBLE indicator will always be on.

NOT CONNECTED, AND CAN CAUSE A DANGEROUS SHOCK IF TOUCHED. DO NOT TOUCH EXPOSED

CIRCUITRY ON THIS PANEL UNLESS THE CIRCUITRY HAS DISCHARGED FOR ONE HOUR AND A SAFE

DISCHARGE PROCEDURE IS USED.

SERVICING TO ASSURE ADEQUATE PROTECTION OF PEOPLE AND PROPERTY. HAVE QUALIFIED

SERVICE PERSONS IMMEDIATELY REPLACE ANY MODULES THAT HAVE MALFUNCTIONED.

procedures in this manual. Do not attempt to make other adjustments, modifications, or repairs. Never use

water, steam, cleaning liquids or sprays on this SAFEPATH panel.

Remote SAFEPATH Manual Sheet 31 of 50

Rev. C December 1998

Page 32

This panel has trouble location indicators which provide information as to what trouble condition has been detected and on which

part of the system the trouble is located. Figure 21 shows the location of all trouble location indicators within the panel. Table 1

cross references the trouble location indicators on the SABC, SALL-15S and SAA modules to the proper troubleshooting procedure.

NORMAL TROUBLE Troubleshooting

Indicator Indicator Module Indicator What it Means Procedure

On Off ---- ---- Normal ---Off Off ---- ---- Power Loss A

On On ---- ---- Faulty Controller Module B

PWR LOW Input Power Low C

SABC BAT LOW Battery Voltage Low D

BAT OPEN Battery Trouble E

AMP Amplifier Trouble F

SAA SPK Audio Output Wiring Trouble G

Off On STR Visual Notification Output Wiring Trouble H

AMP Amplifier Trouble I

SALL-15S AUDIO Audio Output Wiring Trouble J

STROBE Visual Notification Output Wiring Trouble K

AMP Amplifier Trouble L

D10 DV CH Play 10K Resistor Missing W

Off On SADC D11 Battery Charger Trouble X

D12 Remote Microphone Trouble Y

Trouble Location Indicator/Troubleshooting Procedure Cross Reference

Table 1.

Module Replacement Procedure

Return any modules that are malfunctioning, after all troubleshooting operations have been performed, for factory repair or

replacement. If it is necessary to return an individual module, replace the malfunctioning modules immediately in the following

manner:

1. Disconnect AC input power from the panel.

2. Disconnect battery back-up power from the panel.

3. Identify all wiring connections to make sure they will be reconnected identically on the replacement.

4. Disconnect all wiring connections.

5. Remove the malfunctioning module(s) and install the replacement module(s). Perform all checkout procedures described in

the “Installation” section of this manual to make sure the replacement module(s) is (are) operating properly.

Remote SAFEPATH Manual Sheet 32 of 50

Rev. C December 1998

Page 33

Figure 21.

Trouble Location Indicator Locations

Remote SAFEPATH Manual Sheet 33 of 50

Rev. C December 1998

Page 34

BEFORE PERFORMING ANY OF THE FOLLOWING TROUBLESHOOTING PROCEDURES, THE PRELIMINARY

TROUBLESHOOTING INFORMATION AT THE BEGINNING OF THIS “TROUBLESHOOTING” SECTION MUST BE READ,

UNDERSTOOD, AND FOLLOWED.

Procedure A

If the green NORMAL indicator is off, the yellow TROUBLE indicator is off, and no module indicators are on, a power loss condition

has occurred. A power loss condition may be caused by:

1. A blown fuse on the SAPS module.

2. A blown fuse on the SADC module

3. Loss of AC input power and battery back-up power.

4. Faulty internal wiring between the SAPS module and the SABC module.

5. Faulty internal wiring between SABC module and the backplane module.

6. Faulty SAPS module.

7. Faulty SABC module.

8. Faulty SADC module.

9. Faulty backplane module.

Perform the following:

1. Verify that all fuses on the SAPS module are intact.

2. Verify that all fuses on the SADC module are intact.

3. Verify that AC input power and battery back-up power are present.

4. Verify that the wiring between the SAPS module and the SABC module is intact.

5. Verify that the wiring between the SABC module and the backplane module is intact.

6. Verify that the output voltage of the SAPS module is within its specification.

7. Verify that the output voltage of the SABC module is within its specification.

8. Swap SADC module with a known good module.

9. Replace the backplane module.

Procedure B

If the green NORMAL indicator is on and the yellow TROUBLE indicator is on, a faulty controller module condition has occurred. A

faulty controller module condition may be caused by:

1. A faulty SADC module.

Perform the following:

1. Replace the SADC module.

Procedure C

If the green NORMAL indicator is off, the yellow TROUBLE indicator is on, and the PWR LOW indicator on the SABC is on, an input

power low condition has occurred. An input power low condition may be caused by:

1. A fuse on the SABC module is blown.

2. Low AC input power.

3. A faulty SABC module.

Perform the following:

1. Verify that all fuses on the SABC module are intact.

2. Verify that the AC input power is within the correct operating range.

3. Replace the SABC.

Procedure D

If the green NORMAL indicator is off, the yellow TROUBLE indicator is on, and the BAT LOW indicator on the SABC module is on, a

battery voltage low condition has occurred. A battery voltage low condition may be caused by:

1. Fully discharged batteries.

2. Faulty batteries.

3. A faulty SABC module.

Perform the following:

1. Charge the batteries for 24 hours.

2. Replace the batteries.

3. Replace the SABC module.

Remote SAFEPATH Manual Sheet 34 of 50

Rev. C December 1998

Page 35

Procedure E

If the green NORMAL indicator is off, the yellow TROUBLE indicator is on, and the BAT OPEN indicator on the SABC module is on,

a battery trouble condition has occurred. A battery trouble condition may be caused by:

1. A fuse on the SABC module is blown.

2. Faulty field wiring to batteries.

3. A faulty SABC module.

Perform the following:

1. Verify that all fuses on the SABC module are intact.

2. Verify that the field wiring to the batteries is intact.

3. Replace the SABC module.

Procedure F

If the green NORMAL indicator is off, the yellow TROUBLE indicator is on, and the AMP indicator on the SAA module is on, an

amplifier trouble condition has occurred. An amplifier trouble condition may be caused by:

1. Faulty internal wiring between the backplane module and the digital voice module.

2. A faulty SAA module.

3. A faulty SADC module.

4. A faulty backplane module.

Perform the following:

1. Verify that the wiring between the backplane module and the digital voice module is intact.

2. Replace the SAA.

3. Replace the SADC module.

4. Replace the backplane module.

Procedure G

If the green NORMAL indicator is off, the yellow TROUBLE indicator is on, and the SPK indicator on the SAA module is on, an audio

output wiring trouble condition has occurred. An audio output wiring trouble condition may be caused by:

1. Missing end-of-line resistor on the audio output.

2. The audio output field wiring is open or shorted.

3. A fuse on the SAA module is blown.

4. A faulty SAA module.

5. A faulty backplane module.

Perform the following:

1. Verify that the end-of-line resistor is properly in place.

2. Verify that the audio output field wiring is intact.

3. Verify that all fuses on the SAA module are intact.

4. Replace the SAA module.

5. Replace the backplane module.

Procedure H

If the green NORMAL indicator is off, the yellow TROUBLE indicator is on, and the STR indicator on the SAA module is on, a visual

notification output wiring trouble condition has occurred. A visual notification output wiring trouble condition may be caused by:

1. Missing end-of-line resistor on the visual notification output.

2. The visual notification output field wiring is open or shorted.

3. A fuse on the SAA module is blown.

4. A faulty SAA module.

5. A faulty backplane module.

Perform the following:

1. Verify that the end-of-line resistor is properly in place.

2. Verify that the visual notification output field wiring is intact.

3. Verify that all fuses on the SAA module are intact.

4. Replace the SAA module.

5. Replace the backplane module.

Remote SAFEPATH Manual Sheet 35 of 50

Rev. C December 1998

Page 36

Procedure I

If the green NORMAL indicator is off, the yellow TROUBLE indicator is on, and the AMP indicator on the SALL-15S module is on, an

amplifier trouble condition has occurred. An amplifier trouble condition may be caused by:

1. Faulty internal wiring between the backplane module and the digital voice module.

2. A faulty SALL-15S module.

3. A faulty SADC module.

4. A faulty backplane module.

Perform the following:

1. Verify that the wiring between the backplane module and the digital voice module is intact.

2. Replace the SALL-15S module.

3. Replace the SADC module.

4. Replace the backplane module.

Procedure J

If the green NORMAL indicator is off, the yellow TROUBLE indicator is on, and the AUDIO indicator on the SALL-15S module is on,

an audio output wiring trouble condition has occurred. An audio output wiring trouble condition may be caused by:

1. Missing end-of-line resistor on the audio output.

2. The audio output field wiring is open or shorted.

3. A fuse on the SALL-15S module is blown.

4. A faulty SALL-15S module.

5. A faulty backplane module.

Perform the following:

1. Verify that the end-of-line resistor is properly in place.

2. Verify that the audio output field wiring is intact.

3. Verify that all fuses on the SALL-15S module are intact.

4. Replace the SALL-15S module.

5. Replace the backplane.

Procedure K

If the green NORMAL indicator is off, the yellow TROUBLE indicator is on, and the STROBE indicator on the SALL-15S module is

on, a visual notification output wiring trouble condition has occurred. A visual notification output wiring trouble condition may be

caused by:

1. Missing end-of-line resistor on the visual notification output.

2. The visual notification output field wiring is open or shorted.

3. A fuse on the SALL-15S module is blown.

4. A faulty SALL-15S module.

5. A faulty backplane module.

Perform the following:

1. Verify that the end-of-line resistor is properly in place.

2. Verify that the visual notification output field wiring is intact.

3. Verify that all fuses on the SALL-15S module are intact.

4. Replace the SALL-15S module.

5. Replace the backplane module.

Procedure L

If the green NORMAL indicator is off, the yellow TROUBLE indicator is on, and the PWR indicator on the SALL-15S module is on,

an amplified speaker power output wiring trouble condition has occurred. An amplified speaker power output wiring trouble condition

may be caused by:

1. Missing end-of-line resistor on the amplified speaker power output.

2. The amplified speaker power output field wiring is open or shorted.

3. A fuse on the SALL-15S module is blown.

4. A faulty SALL-15S module.

5. A faulty backplane module.

Perform the following:

1. Verify that the end-of-line resistor is properly in place.

2. Verify that the amplified speaker power output field wiring is intact.

3. Verify that all fuses on the SALL-15S module are intact.

4. Replace the SALL-15S module.

5. Replace the backplane module.

Procedures M thru V

Reserved for future use

Remote SAFEPATH Manual Sheet 36 of 50

Rev. C December 1998

Page 37

Procedure W

If the green NORMAL indicator is off, the yellow TROUBLE indicator is on, and SADC D10 is on, the wiring between the DV channel

play contacts and the backplane is defective or the 10K ohm resistor attached to the DV channel play contacts is defective or

missing.

Perform the following:

1. Verify field wiring between the backplane and the DV is intact.

2. Verify the 10K ohm resistor across the DV channel play contacts is intact. Refer to procedures C, D and E.

Procedure X

If the green NORMAL indicator is off, the yellow TROUBLE indicator is on, and SADC D11 is on, the Battery Charger is defective or

mis-wired

Perform the following:

1. Check the wiring between the backplane and the Battery Charger board.

2. Refer to procedures C, D and E.

Procedure Y

If the green NORMAL indicator is off, the yellow TROUBLE indicator is on, and SADC D12 is on, the Remote Microphone (RMS-1)

has 1 or more troubles.

Perform the following:

1. Verify that field wiring between the backplane and Remote Microphone Station is intact.

2. Verify that all fuses on the SADC are intact.

Remote SAFEPATH Manual Sheet 37 of 50

Rev. C December 1998

Page 38

Periodic Testing

IMPORTANT: Periodic testing, including this panel, all notification equipment and all messages, including their audibility and

intelligibility, content and language, sequence, output channel, and priority assignment, must be conducted frequently, at least twice

each year, or more often as required by local, state and federal codes, regulations and laws, by qualified personnel to ensure proper

operation of all equipment. If the notification equipment is not working properly, immediately contact the installer and have all/any

problems corrected immediately. Malfunctioning units should be replaced immediately. Do not attempt to repair malfunctioning

units. Malfunctioning units should be returned for factory repair or replacement. In the event you cannot contact the installer,

contact the manufacturer.

WARNING: PROVIDE ALTERNATIVE SIGNALING MEANS DURING PERIODIC TESTING TO ASSURE ADEQUATE

In addition to testing required by relevant fire codes, regulations and laws, several hardware functions should also be tested. The

hardware functions that should be tested are as follows:

1. The polarity detection circuitry for line level input.

2. The alarm contact.

3. The "open circuit" and “short circuit” detection circuitry for any one or all of the notification appliance output circuits.

4. The amplifier supervision circuitry for any one or all of the amplifiers.

5. The status contact.

These hardware functions may be tested as follows:

1. Make a live announcement from the central SAFEPATH and verify that the proper message plays.

2. Monitor the alarm contact to verify proper operation while making a live announcement from the remote panel.

3. While in the standby condition, open and short circuit each notification appliance circuit and verify that the proper trouble

condition is indicated.

4. Listen to a message playing out each zone and check for audibility of message.

5. Monitor the status contact while causing the panel to alternate between trouble and normal states to verify proper operation.

If the Remote SAFEPATH panel fails to perform any of the above tests correctly, immediately replace the malfunctioning module(s)

following the Module Replacement Procedure given in the “Troubleshooting” section.

PROTECTION OF PEOPLE AND PROPERTY. FAILURE TO PROVIDE ALTERNATIVE SIGNALING MAY

CAUSE PEOPLE TO NOT BE WARNED OF AN EMERGENCY CONDITION WHICH COULD RESULT IN

PROPERTY DAMAGE AND SERIOUS INJURY OR DEATH TO YOU AND/OR OTHERS.

Remote SAFEPATH Manual Sheet 38 of 50

Rev. C December 1998

Page 39

Module Description