Page 1

273 Branchport Avenue

Long Branch, NJ 07740 Thank you for using our products.

(732) 222-6880

INSTALLATION INSTRUCTIONS

MODEL PSC-2420-B AND PSC-2420-R

Use this product according to this instruction manual. Please keep this instruction manual for future reference.

DESCRIPTION:

The PSC-2420 is a special application 20 Amp, 24VDC Power Supply Battery Charger Unit. It is UL Listed under Standard 1481,

Power Supplies for Fire Protective Equipment, and is used to power the Dual Circuit SAFEPATH. Refer to the Dual Circuit

SAFEPATH Operation and Installation Manual for further information.

NOTE: All CAUTIONS and WARNINGS are identified by the symbol

. All warnings are printed in bold capital letters.

WARNING: QUALIFIED PERSONNEL MUST TEST THE SAFEPATH PANEL AFTER THE POWER SUPPLY

MODULE HAS BEEN INSTALLED AND BEFORE THE SAFEPATH PANEL IS PLACED IN SERVICE IN

ACCORDANCE WITH THE INSTRUCTIONS IN THE SAFEPATH OPERATION AND INSTALLATION MANUAL.

FAILURE TO TEST THE SAFEPATH PANEL OR CORRECT ANY TROUBLE CONDITION BEFORE THE SAFEPATH

PANEL IS PLACED IN SERVICE COULD RESULT IN A MESSAGE NOT BEING PLAYED WHEN AND WHERE

REQUIRED IN AN EMERGENCY SITUATION. THIS COULD RESULT IN PROPERTY DAMAGE AND SERIOUS

INJURY OR DEATH TO YOU AND/OR OTHERS.

SPECIFICATIONS:

Mechanical

Dimensions (H x W x D) 21 x 16 x 6 in.

Weight 40 lb.

Finish Black or red

Enclosure Construction Type 0.050” steel

Mounting Indoor surface mount

Wiring Entry Top and bottom knockouts (3/4”, 1”)

Door Lock Standard Wheelock key-lock

PC Boards Power Supply

Environmental

Operating Temperature 0 to 49 °C (32 to 120 °F)

Storage Temperature -20 to 70 °C (-4 to 158 °F)

Humidity, Non-condensing

Copyright 1997, 1998 Wheelock, Inc. All rights reserved.

Electrical (Power Supply)

Battery Charger

Fuse Block

85±5% @ 30±2 °C (86 ± 4 °F)

P83572 C

Sheet 1 of 8

Page 2

Input Parameters

Supply Voltage (Nominal) 120VAC

Supply Voltage Absolute Minimum 102VAC

Supply Voltage Absolute Maximum 132VAC

Input Frequency

60 ± 1Hz

Input Current at 120VAC, 20A 10AAC Max

Input Power at 120VAC, 20A 900W

Efficiency at 120VAC, 20A

Power Factor at 120VAC, 20A

87.6 ± 1.75%

.75 ± .015

Output Parameters

Output Power at 50o C Natural Convection Cooling 500W

Output Voltage at 120VAC, No Load

24.2 ± VDC

Total Regulation, Over Temperature Range 1.5% Min

Load Regulation .25% Min

Line Regulation .10% Min

Ripple and Noise 2% Max Peak to Peak

Temperature Coefficient -.01%/Degree C

Transient Response at 25 Ohm to 1.15 Ohm Load 2% for 10mS Max

Electrical (Battery Charger)

Line Input Voltage, Nominal 120VAC

Line Input Voltage, Minimum 102VAC

Line Input Voltage, Maximum 132VAC

Line Input Frequency

Line Input Current at 120VAC 10AAC Max

Power Supply Input Voltage, Nominal 24VDC

Power Supply Input Voltage, Minimum 20.4VDC

Power Supply Input Voltage, Maximum 26.4VDC

Power Supply Input Current at 24VDC, Standby

Power Supply Input Current at 24VDC, Float Charge State 1A Max DC

Power Supply Input Current at 24VDC, Bulk Charge State

Battery Charge Enable Voltage

Battery Float State Voltage

Battery Float State Voltage, 0o C to 65o C

Battery Overcharge Voltage

Battery Overcharge Termination Current

Battery Bulk Charge Rate at Vbat=26VDC

Battery Open Circuit Voltage

Battery Short Circuit Current

Battery Low Detect Voltage

Battery Open Detect Voltage

Battery Capacity 24 to 60 AH’s

Battery Type Sealed Lead Acid

Battery Charge Time, 24 AH’s 19 Hrs Max

Battery Charge Time, 38 AH’s 30 Hrs Max

Battery Charge Time, 48 AH’s 38 Hrs Max

Battery Charge Time, 60 AH’s 48 Hrs Max

Trouble Output Sink Current at .2V

Relay Delay, Turn On 25 to 100mS

Relay Delay, Turn Off 250 to 400mS

Relay Switching Time, Turn On 5 to 40mS

Relay Switching Time, Turn Off 5 to 40mS

INSTALLATION

Location

:

CAUTION: The maximum current of all output circuits must not exceed 20A.

Input Parameters

60Hz ± 1Hz

40 ± 4mADC

3.7 ± .56ADC

Output Parameters

20 ± .5VDC

27.34 ± .27VDC

V(Float)=(28.83-.047T) ± 2.5%

28.92 ± .29VDC

469 ± 188mADC

2.57 ± .39ADC

37.57 ± 1.88VDC

20 ± 2mADC

20.03 ± .50VDC

30.80 ± .77VDC

120 ± 12mADC

P83572 C

Sheet 2 of 8

Page 3

This panel shall be mounted in a location within the environmental limits specified in the latest UL Standard 864 for indoor

control panels. The panel shall not be located in a hazardous area.

CAUTION

: In order to comply with the latest NFPA and UL requirements for interconnection of fire alarm control equipment,

this panel must be located in the same room as, and within 20 feet of, listed compatible units with the wiring enclosed in conduit and

properly connected to such control panel.

Procedure

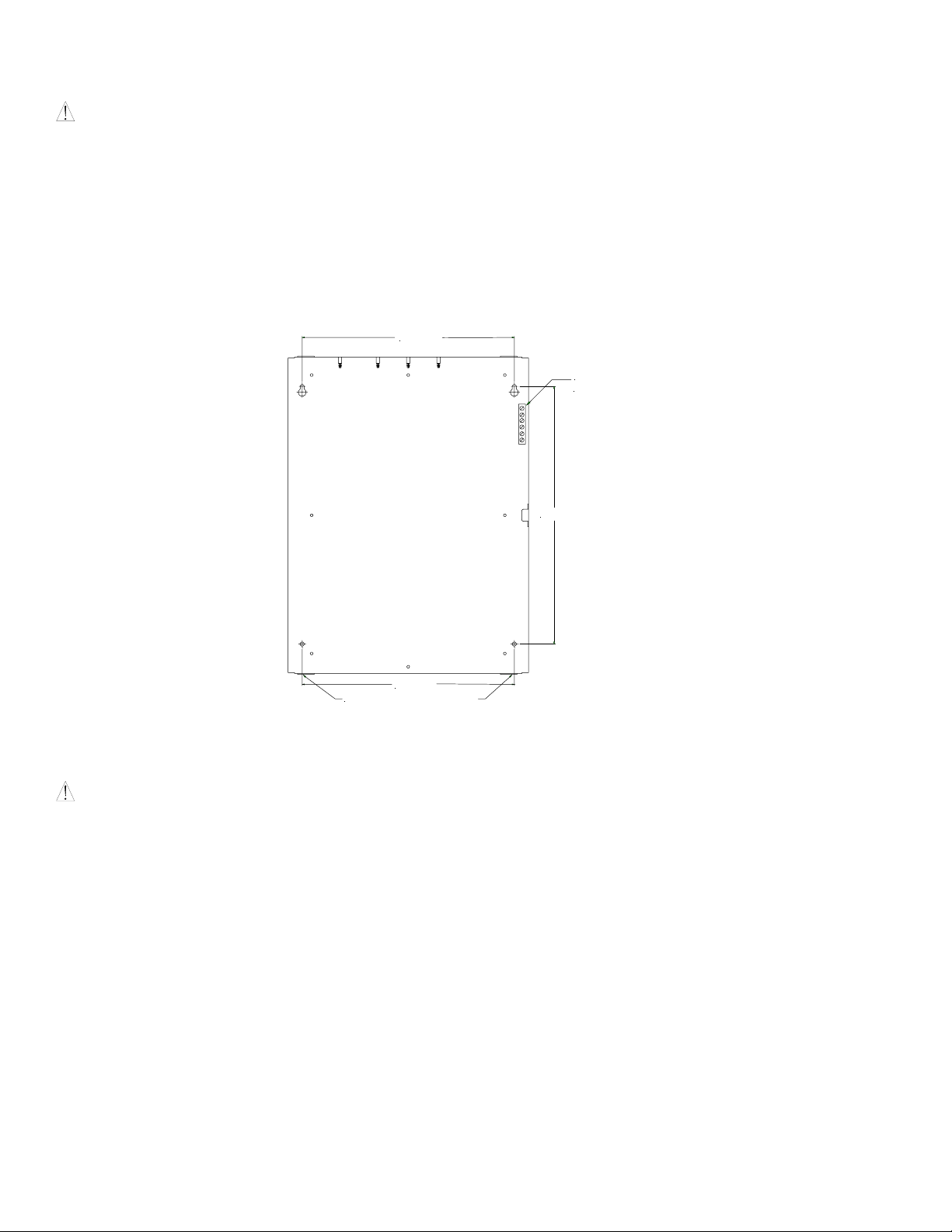

1. See Figure 1 for mounting hole layout.

2. Drill mounting holes for appropriate screws and anchors to ensure secure mounting to the type of surface at the selected

location.

3. Prevent dust and dirt contamination of the panel during installation. This contamination can interfere with the operation and

reduce the life of the equipment.

4. Open the door. Mount the panel.

14.00"

GROUND

TERMINALS

17.00"

CONDUIT ENTRANCES (TYP. TOP & BOTTOM)

14.00"

Figure 1.

Panel Mounting

WIRING GUIDELINES:

CAUTION:

The National Electric Code limits the maximum number of conductors that can be installed in conduit and wiring

boxes depending on the size of the conduit, the volume of the boxes, and the gauge of the wire used. Make sure that wiring used for

installation complies with the latest NEC, NFPA, Local, State, County or Province requirements.

The National Electrical Code defines the types of circuits for protective signaling systems as either power limited circuits or non-

power limited circuits. The SAFEPATH circuits have been designed as non-power limited circuits.

Field Wiring:

Before installation, the system specifier shall determine the proper wire gauge for all field wiring and ensure that all wiring

complies with the latest NEC, NFPA, Local, State, County of Province Requirements.

The wiring terminals are designed to accept #12 to #22 American Wire Gauge (AWG) (one wire per terminal). When connecting

field wiring to terminals, refer to Figure 2.

Check the integrity of all field wiring following directions in the "Field Wiring Checkout" section. Confirm that the specified

cable is installed and there is continuity between required points (no "open circuits"), with no unwanted shorts to other conductors,

chassis, or earth ground. Perform the field wiring checkout before making any connections to the wiring terminals.

P83572 C

Sheet 3 of 8

Page 4

Field Wiring Checkout:

Refer to NFPA for guidelines on testing signaling system wiring.

CAUTION:

Verify that the field wiring is in full agreement with this manual and with the wiring layout prepared for this installation.

Do not connect input voltage to any equipment until the field wiring has been inspected and approved.

Ensure that no unwanted voltages are present on circuit conductors and ground. Test all ungrounded connectors for electrical

isolation from ground. Test all wires that are not intentionally connected for electrical isolation from each other. Measure and

record the resistance of each circuit pair (this can be done by temporarily short circuiting one end of the circuit).

WARNING: TO REDUCE THE RISK OF ELECTRICAL SHOCK, NEVER CONNECT OR DISCONNECT FIELD WIRING

WHEN INPUT VOLTAGE IS CONNECTED TO THE PANEL

TO DUAL

CIRCUIT

SAFEPATH

(NOTE 2)

LT

RET

ALM

TRB

+

20A MAX @ 24VDC OUT

24V BATTERIES

24V

COM

-

BAT+

+

BAT-

-

PS+

PS-

L

N

BATT CHG BOARD

NEUTRAL

8A MAX

@ 120VAC

60Hz LINE

N

L

PS-

PS+

PS BOARD

FUSE

BOARD

87654

3

2

1

+ -

OUTPUTS (+)

24VDC, 3A (NOTE 1)

24VDC INPUT

+

FROM

-

BATTERY CHARGE

BOARD

OUTPUTS (- )

Figure 2.

Wiring Diagram

Notes:

1. The maximum current of all output circuits must not exceed 20A.

2. For installations other than Dual Circuit SAFEPATH, ALM signal from the header J1 must be wired to Power COM.

P83572 C

Sheet 4 of 8

Page 5

INSTALLATION AND CARE OF SEALED LEAD ACID BATTERIES

Sealed lead acid batteries are designed to operate in standby service for approximately five years. This is based upon a normal service

condition where there is an ambient of 20 degrees C (68 degrees F) and batteries are completely discharged once every three months.

LENGTH OF SERVICE LIFE WILL BE DIRECTLY EFFECTED BY THE NUMBER OF DISCHARGE CYCLES, DEPTH OF

DISCHARGE, AND AMBIENT TEMPERATURE.

Use Guidelines:

1. Avoid installation and/or operation in close proximity to heat source. While the operating temperature range is 0 to 49 degrees C

(32-120 degrees F), battery life will be maximized at an ambient of 20 degrees C (69 degrees F).

2. Batteries may generate ignitable gases. Because of this, batteries shall be installed in a well ventilated location, away from spark

producing equipment.

3. Batteries shall not be installed in an atmosphere where organic solvents or adhesives may be present. The batteries shall not be

cleaned with oils, thinners, or similar substances. The case and cover of the batteries are ABS plastic resin which may suffer

damage from these chemicals.

4. Batteries shall not be installed in a heavy vibration or shock location.

5. Batteries shall have a 1/4” minimum separation between cells.

6. Insulated gloves shall always be worn when handling batteries.

7. Batteries shall not be crushed, incinerated, or dismantled. The electrolyte contains sulfuric acid which can cause serious damage

to eyes and skin. If contact does occur, flush with water and seek immediate medical attention.

8. Batteries of different capacities, age, or manufacturer shall not be used together.

Battery Storage:

Batteries which are to be stored for an extended period of time should be given a supplementary charge monthly. Batteries should

never be stored in a discharged condition.

The self-discharged rate of batteries is approximately 3% per month when the storage temperature is maintained at 20 degrees C (68

degrees F). The self-discharge rate will vary depending upon temperature. Cooler temperatures cause the self-discharge rate to

decrease. Warmer temperatures cause the self-discharge rate to increase.

PSC-2420 OPERATING INSTRUCTIONS (PER UL)

P83572 C

Sheet 5 of 8

Page 6

The PSC-2420 is a special application power supply and battery charger unit that provides 24VDC up to 20 amps output.

Input and Output Ratings:

Input Voltage 120VAC

Input Current 10A Maximum

Output Voltage 24VDC

Output Current 20A Maximum

Maximum Load 1.2 Ohms

Maximum Charging Current 3.0A

Maximum Amp-Hour Capacity 72AH

IN THE EVENT OF TROUBLE CONTACT-

NAME:

ADDRESS:

PHONE:

FRAME AND MOUNT THESE OPERATING INSTRUCTIONS ADJACENT

TO THE CONTROL PANEL.

P83572 C

Sheet 6 of 8

Page 7

MEA INFORMATION:

Recommendations - That the above units be accepted on condition that all uses, configurations, arrangements and functions, locations

and installations comply with the New York City Building Code, specifically Subchapter 17 and with the Referenced Standard RS 173 through 17-3C including the NFPA as appropriate, the UL Listing, the manufacturer’s instructions, the Fire Department Rules and

the Electrical Code of the City of New York, and on further condition that:

(a) The use, installation and application of the SAFEPATH System shall be restricted exclusively to connection with an BSA/MEA

approved compatible Class E, Class J or Class C Fire Command Station.

(b) The Fire Command Station shall have the capability of overriding any function of the SAFEPATH system.

(c) Prior to the installation of any SAFEPATH System, a specific approval for a specific installation must be obtained from the Fire

Department.

(d) A priority voice message matrix must be submitted to the Fire Department for approval before the installation is performed and

shall include the following information:

1. The duration of each message.

2. The content of each message.

3. The duration of the audible and visual alarm signals prior to the initiation of the subsequent prerecorded message

transmission.

4. The interval between the cessation of the audible and visual alarm signals and the generation of prerecorded message.

(e) The SAFEPATH panel must be located in the room as, and within 20 feet of a BSA/MEA approved Fire Command Station. The

wiring between the SAFEPATH Control Unit and the Fire Command Station must be enclosed in conduit.

(f) Power supply wiring to the SAFEPATH Control Unit shall be installed in the same conduit containing the input and output

wiring.

(g) When used with central office communicator or transmitter, the installation and operation of the equipment and devices listed

herein shall comply with Fire Department Rule #3 - RCNY 17-01, NFPA 71, and shall have the capability of transmitting

separate and distinct signals to indicate manual pull station alarm, automatic smoke/heat detection alarm, sprinkler waterflow

alarm, supervisory signal indications and trouble indications.

(h) The connection of security/burglar devices and equipment to that submitted for acceptance for fire alarm usage under this MEA

application is prohibited within New York City and such equipment and devices shall be so permanently labeled.

All shipments and deliveries of such equipment shall be provided with a metal tag suitably placed, certifying that the equipment

shipped or delivered is equivalent to that tested and accepted for use, as provided for in Section 27-131 of the Building Code.

Limited Warranty

Wheelock products must be used within their published specifications and must be PROPERLY specified, applied, installed, operated,

maintained and operationally tested in accordance with these instructions at the time of installation and at least twice a year or more

P83572 C

Sheet 7 of 8

Page 8

often and in accordance with local, state and federal codes, regulations and laws. Specification, application, installation, operation,

maintenance and testing must be performed by qualified personnel for proper operation in accordance with all of the latest National

Fire Protection Association (NFPA), Underwriters' Laboratories (UL), Underwriters' Laboratories of Canada (ULC), National

Electrical Code (NEC), Occupational Safety and Health Administration (OSHA), local, state, county, province, district, federal and

other applicable building and fire standards, guidelines, regulations, laws and codes including, but not limited to, all appendices and

amendments and the requirements of the local authority having jurisdiction (AHJ). Wheelock products when properly specified,

applied, installed, operated, maintained and operationally tested as provided above are warranted against mechanical and electrical

defects for a period of three years from date of manufacture (as determined by date code). Correction of defects by repair or

replacement shall be at Wheelock's sole discretion and shall constitute fulfillment of all obligations under this warranty. THE

FOREGOING LIMITED WARRANTY SHALL IMMEDIATELY TERMINATE IN THE EVENT ANY PART NOT FURNISHED

BY WHEELOCK IS INSTALLED IN THE PRODUCT. THE FOREGOING LIMITED WARRANTY SPECIFICALLY

EXCLUDES ANY SOFTWARE REQUIRED FOR THE OPERATION OF OR INCLUDED IN A PRODUCT. WHEELOCK

MAKES NO REPRESENTATION OR WARRANTY OF ANY OTHER KIND, EXPRESS, IMPLIED OR STATUTORY

WHETHER AS TO MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR ANY OTHER MATTER.

USERS ARE SOLELY RESPONSIBLE FOR DETERMINING WHETHER A PRODUCT IS SUITABLE FOR THE USER'S

PURPOSES, OR WHETHER IT WILL ACHIEVE THE USER'S INTENDED RESULTS. THERE IS NO WARRANTY AGAINST

DAMAGE RESULTING FROM MISAPPLICATION, IMPROPER SPECIFICATION, ABUSE, ACCIDENT OR OTHER

OPERATING CONDITIONS BEYOND WHEELOCK'S CONTROL.

SOME WHEELOCK PRODUCTS CONTAIN SOFTWARE. WITH RESPECT TO THOSE PRODUCTS, WHEELOCK DOES

NOT WARRANT THAT THE OPERATION OF THE SOFTWARE WILL BE UNINTERRUPTED OR ERROR-FREE OR THAT

THE SOFTWARE WILL MEET ANY OTHER STANDARD OF PERFORMANCE, OR THAT THE FUNCTIONS OR

PERFORMANCE OF THE SOFTWARE WILL MEET THE USER'S REQUIREMENTS. WHEELOCK SHALL NOT BE LIABLE

FOR ANY DELAYS, BREAKDOWNS, INTERRUPTIONS, LOSS, DESTRUCTION, ALTERATION, OR OTHER PROBLEMS

IN THE USE OF A PRODUCT ARISING OUT OF OR CAUSED BY THE SOFTWARE.

THE LIABILITY OF WHEELOCK ARISING OUT OF THE SUPPLYING OF A PRODUCT, OR ITS USE, WHETHER ON

WARRANTIES, NEGLIGENCE, OR OTHERWISE, SHALL NOT IN ANY CASE EXCEED THE COST OF CORRECTING

DEFECTS AS STATED IN THE LIMITED WARRANTY AND UPON EXPIRATION OF THE WARRANTY PERIOD ALL

SUCH LIABILITY SHALL TERMINATE. WHEELOCK IS NOT LIABLE FOR LABOR COSTS INCURRED IN REMOVAL,

REINSTALLATION OR REPAIR OF THE PRODUCT BY ANYONE OTHER THAN WHEELOCK OR FOR DAMAGE OF ANY

TYPE WHATSOEVER, INCLUDING BUT NOT LIMITED TO, LOSS OF PROFIT OR INCIDENTAL OR CONSEQUENTIAL

DAMAGES. THE FOREGOING SHALL CONSTITUTE THE SOLE REMEDY OF THE PURCHASER AND THE EXCLUSIVE

LIABILITY OF WHEELOCK.

IN NO CASE WILL WHEELOCK'S LIABILITY EXCEED THE PURCHASE PRICE PAID FOR A PRODUCT.

Limitation of Liability

WHEELOCK'S LIABILITY ON ANY CLAIM OF ANY KIND, INCLUDING NEGLIGENCE AND BREACH OF WARRANTY,

FOR ANY LOSS OR DAMAGE RESULTING FROM, ARISING OUT OF, OR CONNECTED WITH THIS CONTRACT, OR

FROM THE MANUFACTURE, SALE, DELIVERY, RESALE, REPAIR OR USE OF ANY PRODUCT COVERED BY THIS

ORDER SHALL BE LIMITED TO THE PRICE APPLICABLE TO THE PRODUCT OR PART THEREOF WHICH GIVES RISE

TO THE CLAIM. WHEELOCK'S LIABILITY ON ANY CLAIM OF ANY KIND SHALL CEASE IMMEDIATELY UPON THE

INSTALLATION IN THE PRODUCT OF ANY PART NOT FURNISHED BY WHEELOCK. IN NO EVENT SHALL

WHEELOCK BE LIABLE FOR ANY CLAIM OF ANY KIND UNLESS IT IS PROVEN THAT OUR PRODUCT WAS A

DIRECT CAUSE OF SUCH CLAIM. FURTHER, IN NO EVENT, INCLUDING IN THE CASE OF A CLAIM OF

NEGLIGENCE, SHALL WHEELOCK BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES

DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE

PRECEDING LIMITATION MAY NOT APPLY TO ALL PURCHASERS.

8/98

P83572 C

Sheet 8 of 8

Loading...

Loading...