Page 1

POWERPATH

PS-12/24-8MP

(103046)

POWER BOOSTER

POWER SUPPLY

Installation Instructions

273 Branchport Avenue, Long Branch, NJ 07740-6899 Ph: (800) 631-2148 Fax: (732) 222-8707

Web Site: www.wheelockinc.com e-mail: info@wheelockinc.com

A84531 B

Copyright 2005 Wheelock, Inc. All rights reserved.

Page 2

Use this product according to this instruction manual.

Thank you for using our products.

Please keep this instruction manual for future reference.

TABLE OF CONTENTS

1.0 - INTRODUCTION AND SPECIFICATIONS 2

1.1 - INTRODUCTION 2

1.2 - SPECIFICATIONS 3

1.3 - TERMINOLOGY 3

1.4 - TERMINAL IDENTIFICATION 4

1.5 - LED STATUS 6

1.6 - BATTERY MAINTENANCE 6

2.0 - INSTALLATION INSTRUCTIONS 6

2.1 - UNPACKING 6

2.2 - MOUNTING 6

2.3 - WIRING 8

2.4 - RELAY STATUS CONNECTIONS 8

3.0 - OPERATION 10

3.1 - MODES OF OPERATION 10

3.2 - DIP SWITCH SETTINGS 10

3.3 - CLASS “B” OPERATION 11

3.4 - CLASS “A” OPERATION 14

3.5 - MASTER REMOTE OPERATION 18

4.0 - TROUBLESHOOTING 20

5.0 - BATTERY CALCULATION SHEET 21

6.0 - WARRANTY STATEMENT 22

WHEELOCK INC. COMPATIBLE APPLIANCES Appendix A

LIST OF FIGURES

FIGURE 1: TERMINAL LOCATIONS 5

FIGURE 2: MOUNTING DIMENSIONS 7

FIGURE 3: POWERPATH PS-12/24-8MP 9

FIGURE 4: OUTPUT DIP SWITCH(S) 10

LIST OF TABLES

TABLE 1: TERMINAL IDENTIFICATION 4

TABLE 2: LED STATUS DESCRIPTION 6

TABLE 3: DIP SWITCH SELECTION 8

P84333 K Sheet 2 of 23

TABLE 4: TROUBLESHOOTING 20

Page 3

NOTE: All CAUTIONS and WARNINGS are identified by the symbol

letters.

WARNING: READ THIS INSTRUCTION MANUAL CAREFULLY. FAILURE TO COMPLY WITH ANY OF THE

FOLLOWING INSTRUCTIONS, CAUTIONS, AND WARNINGS COULD RESULT IN IMPROPER APPLICATION

AND/OR OPERATION OF THESE PRODUCTS IN AN EMERGENCY SITUATION, WHICH COULD RESULT IN

PROPERTY DAMAGE AND SERIOUS INJURY OR DEATH TO YOU AND/OR OTHERS.

. All WARNINGS are printed in bold capital

1.0 INTRODUCTION AND SPECIFICATIONS:

1.1 INTRODUCTION

The PS-12/24-8MP POWERPATH is an 8 Amp, 12/24VDC, filtered and regulated, supervised remote power

supply/charger used for supervision and expanded power driving capability for Fire Alarm Notification

Appliance Circuits. The PS-12/24-8MP may be connected to any 12VDC or 24VDC Fire Alarm Control

Panel (FACP) by using a Notification Appliance Circuit (NAC) or a “Dry Contact”. Primary applications

include NAC expansion (supports ADA requirements) and auxiliary power to support system accessories.

This unit provides filtered and regulated 12VDC or 24VDC, 8 Amp up to four (4) Class "B", two (2) Class “A”,

or two (2) Class “B” and one (1) Class “A” Notification Appliance Circuits. Additionally, an auxiliary power

output of 3.5 Amps is provided, which can be reset. The PS-12/24-8MP also contains a battery charger

capable of charging either 7 or 12 Amp/Hour (AH) of battery backup.

Two FACP NAC circuits or two “Dry” contact closures can be connected to the POWERPATH inputs. These

inputs can then be directed to control supervision and power delivery to any combination of the four (4)

outputs.

Each output is rated at 3.0 Amps (Class "B") or 3.0 Amps (Class "A") and can be programmed to

generate a steady or Code 3 Temporal Horn sound and a strobe output under alarm condition. Total

load for the PS-12/24-8MP NAC circuits shall not exceed 8.0 Amps.

The PS-12/24-8MP under non-alarmed condition provides independent loop supervision for Class “A” and

Class “B” FACP NAC circuits. In the event of a loop trouble, the FACP will be notified via the POWERPATH

steered input (IN1 or IN2). In addition there are common trouble output terminals (used to indicate a loop

trouble) and common trouble input terminals (used generically by any initiating circuit).

Wheelock horns/strobes, strobes and horns with synchronizing capability can be utilized with the PS-12/248MP. Audibles can be silenced with only two wires. Additionally, the POWERPATH can provide a temporal

coded signal for appliances that can utilize it.

P84333 K Sheet 3 of 23

Page 4

1.2 SPECIFICATIONS

Approvals:

• UL Listed 864 Standard for Control Units for Fire Protective Signaling Systems

• FM

• MEA approved – NYC Dept. of Buildings

• California State Fire Marshall (CSFM) approved

• Pending: Bureau of Fire Protection (BFP) Chicago

• NFPA 72 compliant

Inputs:

• 120VAC, 50/60Hz, 5.0 Amps or 240VAC, 50/60Hz 3.0 Amps Operating Power in Alarm

• 12/24VDC Battery Backup Connection

• Two (2), 12VDC or 24VDC NAC Initiating Circuits (8-33VDC at 5mA)

• Two (2) “Dry” Contact initiating Circuits

• Accepts two Class “A” or two Class “B” circuit inputs

• Built in battery charger for sealed lead acid or gel type batteries

Outputs:

• Switch selectable 12VDC or 24VDC power limited outputs

• 8 Amp in alarm supply current at 12VDC or 24VDC

• Capable of four (4), Class "B" circuits (2.0 Amps each)

• Capable of two (2) Class “A” circuits (3.0 Amps each)

• Capable of one (1) Class “A” circuit (3.0 Amps) and two (2) Class “B” circuits (2.0 Amps each)

• Capable of two (2) Class “B” circuits (3.0 Amps each) and (2) Class “B” circuits (2.0 Amps total)

• Temporal (Code 3) or constant voltage output generation

• Built-in Wheelock synchronization mode that can be fed to any or all of the output circuits

• Input and output can be synchronized with “IN>OUT SYNC” mode (SM, DSM or 2

required)

• Audible silence capability

• Filtered and electronically regulated output

• 3.5 Amp auxiliary power limited output with reset capability. (Removed upon AC loss or alarm. Automatic

reset 30 seconds after AC power returns or the alarm condition is over)

Supervision:

• Compatible with 12VDC or 24VDC FACP

• Signaling appliance loops are supervised and steered to either IN1 or IN2

• 2.2K Ohm, 1 Watt (Wheelock Model #MPEOL) End of Line Resistor (EOLR) for supervision of all outputs

• Common input and output trouble circuits

• Automatic switchover to standby battery when AC fails

• Thermal and short circuit protection with auto reset

• Input and output status LED indicators

• AC fail supervision (Form C contact, 1 Amp 28VDC)

• Battery presence and low battery supervision (Form C contact, 1 Amp 28VDC)

• Ground Fault Detection

1.3 TERMINOLOGY

CLASS “A” = STYLE Z

CLASS “B” = STYLE Y

FACP = Fire Alarm Control Panel

EOLR = End of Line Resistor

NAC = Notification Appliance Circuit

SM = Wheelock Sync Module with single output.

DSM = Wheelock Dual Sync Module with two outputs.

C = Common

NC = Normally Closed

NO = Normally Open

AH = Ampere/Hour

nd

PS-12/24-8MP is

P84333 K Sheet 4 of 23

Page 5

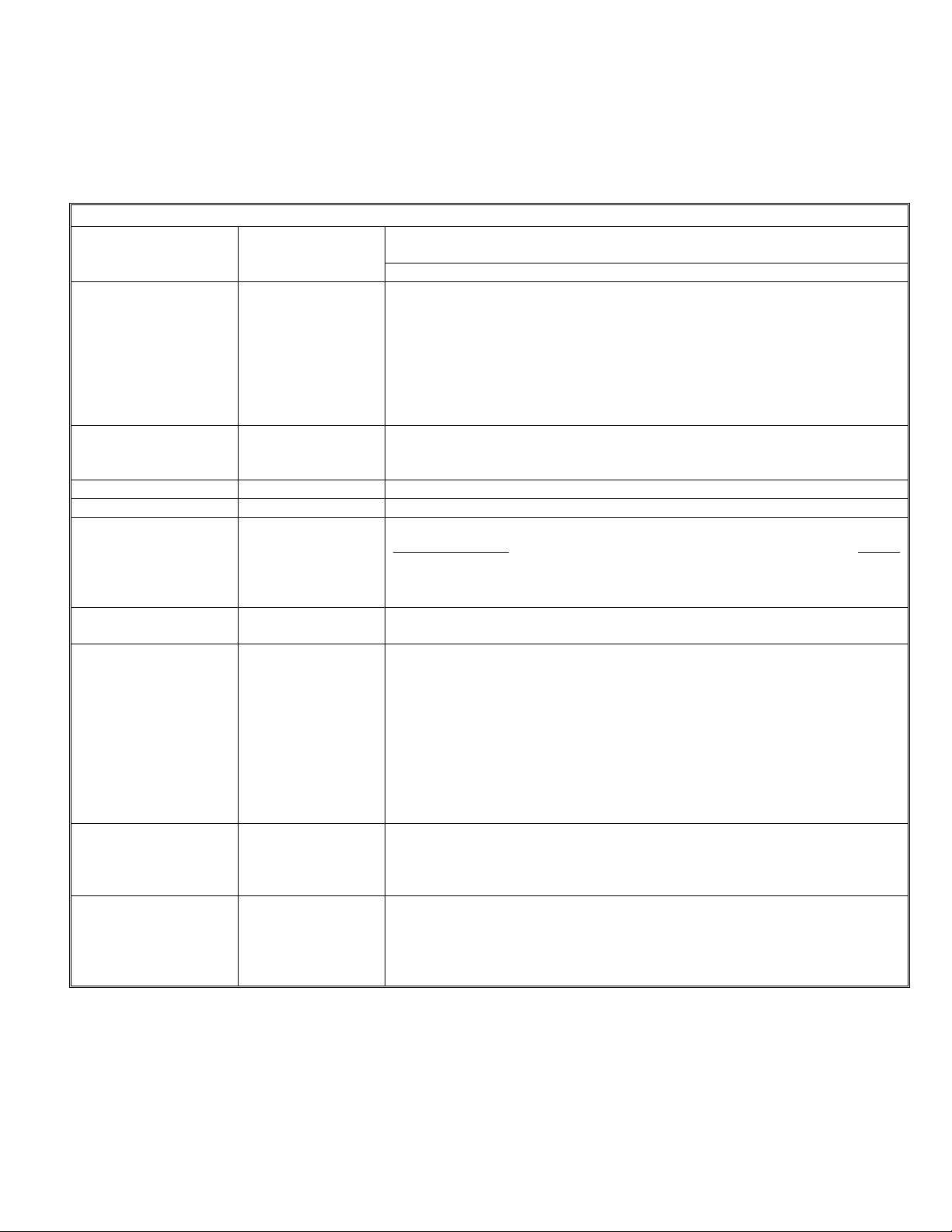

1.4 TERMINAL IDENTIFICATION

Table 1: Terminal Identification

Terminal Block

Identification

Numbers (Figure 1) Identification

TB4-1, 2

TB4-3, 4,

TB5-1, 2

TB5-5, 4

TB4-5, 6

TB5-5, 6

TB6-1, 2

TB6-3, 4

TB6-5, 6

TB6-7, 8

TB7-1-3

TB7-4, 5

Terminal Function/Description

IN1+,IN1- These terminals connect to the input voltage source (i.e. 12VDC or

24VDC FACP). The FACP will supply a voltage from 8-33VDC at 5mA.

During the alarm condition these inputs will cause the designated outputs

to drive the notification appliances (designated outputs are set by output

DIP switch banks). During Stand-by on a FACP, a trouble condition on

the designated loop will cause these inputs to trip the FACP by opening

the FACP loop. Alarm condition always overrides trouble to drive output

indicating appliances.

RET1+, RET1- EOLR is connected on these terminals corresponding to IN1+ and IN1-,

or the loop may be continued to other power supplies or appliances

before terminating.

IN2+, IN2- Same as IN1+, IN1- for corresponding terminals.

RET2+, RET2- Same as RET1+, RET1- for corresponding terminals.

C “DRY1” NC Dry contacts are used to actuate the designated outputs. Contacts are

normally closed

and actuate the power supply on contact Open.

Designated outputs correspond to IN1+,IN1-. NOTE: FACP NAC circuit

cannot energize the power supply by these contacts. NOTE: When these

terminals are not in use, a jumper must be connected across them.

C “DRY2” NC Operates the same as IN2+,IN2- for corresponding terminals. When

these terminals are not in use, a jumper must be connected across them.

+OUT1+OUT2+OUT3+OUT4-

Indicating appliances are connected to these outputs (See Examples in

Operation Section). Each output can supply a maximum load of 3.0

Amps, Class "B" or 3.0 Amps Class "A" and can be individually

programmed for Normal Mode, Temporal Mode, IN>OUT SYNC Mode, or

WHEELOCK SYNC Mode. The outputs can be configured as four Class

"B" circuits, two Class "A" circuits, or two Class "B" and one Class "A"

circuits. Outputs are controlled by a designated input (INPUT 1 or 2) as

selected by the DIP switch for that output. NOTE: When the panel has

been set to synchronization mode, IN1 is used for strobe activation and

IN2 is used for audible silence. Individual output control is disabled.

“NO” “C” “NC”

(COMMON

Typically used to trigger remote alerts or other reporting appliances.

Form C contacts rated 28VDC at 1 Amp.

TROUBLE

OUTPUT)

+ AUX - This output is capable of 3.5 Amps which can be used for door holders

and can be reset by a momentary switch on the board. The 3.5 Amps of

power is disconnected when AC power is lost or the unit is in alarm. The

3.5 Amps of power is reconnected 30 seconds after AC power returns or

the alarm condition is over.

P84333 K Sheet 5 of 23

Page 6

(NONPOWER-LIMITED, SUPERVISED)

(LINE OR BLACK LEAD) L1

(NEUTRAL OR WHITE LEAD) L2

(GROUND OR GREEN LEAD) EARTH

(NONPOWER-LIMITED, SUPERVISED)

AC POWER

120VAC, 50/60Hz

240VAC, 50/60Hz

TB1

F1

10 AMP

250V

AC POWER

FUSE

OR

G L2

G L1

MADE IN USA

WITH PRIDE

SEE INSTALLATION INSTRUCTION (P84333) FOR DETAILS

AC POWER

SELECTION

120/240VAC

SW1

115V

CONTROL 1

NAC

ACTIVATION

FROM FACP

TO NEXT

BOOSTER

SHORTED (NO ALARM)

OPEN (ALARM)

CONTROL 2

NAC

ACTIVATION

FROM FACP

TO NEXT

BOOSTER

SHORTED (NO ALARM)

OPEN (ALARM)

OUTPUT1

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

OUTPUT2

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

P84230

REV.

TB4

+

-

IN1

+

RET1

-

DRY1

+

-

IN2

+

RET2

-

DRY2

OUT TRB

D8

D13

D14

D18

ON

D70

SW8

SYS

RESET

IN1+

IN1-

OUT1

OUT2

OUT3

OUT4

SW2

2 3 41

41 2 3

SW5

OFF

RET1+

MICRO

FAULT

D9

D15

D16

D19

SW3

SW6

D10

INP1

INP2

GND

FAULT

BATT

ON OFF

DRY1RET1-

C NC

AC

D71

OUTPUT3

IN>OUT SYNC

WHEELOCK SYNC

2 3 41

TEMPORAL

INPUT SELECT

OUTPUT4

41 2 3

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

CLASS A/B

SELECTION

SWITCHES

IN2-

IN2+

TB5

POWER SUPPLY DC

SW4

O

N

1 2

3

4

DRY2

RET2-

C

RET2+

NC

DC POWER OUT

12V

SELECTION

24V

12Vdc OR 24Vdc

SW9

OUT1

+

TB6

AUXILIARY POWER

RESET

SW7

(MP VERSION)

OUT2

-

OUT3

+

- + - + -

OUT4

NO C NC

AUX

+ -

TB3

BATTERY CONNECTION

-

BATT

7AH-12AH

+

(NONPOWER-LIMITED,

SUPERVISED)

W1

TB7

AUXILIARY POWER OUTPUT

(MP VERSION)

3.5A

0.2A 24HR or 0.06A 60HR (CP VERSION)

(POWER-LIMITED, FAIL-SAFE)

NC TROUBLE RELAY

C FORM-C

NO (NONSUPERVISED)

-

NAC4

+

+

+

+

28VDC 1 AMPPOWER-LIMITED

NAC OUTPUTS

NAC3

EOLR 2.2K

CLASS A OR B

NAC2

(POWER-LIMITED, SUPERVISED)

NAC1

TWO DIFFERENT SOURCES OF POWER MAY BE CONNECTED TO THIS UNIT.

WAR NIN G

DISCONNECT BOTH SOURCES OF POWER BEFORE SERVICING.

FAILURE TO DISCONNECT BOTH SOURCES OF POWER BEFORE SERVICING

COULD RESULT IN PROPERTY DAMAGE, SERIOUS INJURY OR

DEATH TO YOU AND/OR OTHERS

FCC COMPLIANCE:

1) THIS DEVICE MAY NOT CAUSE HARMFUL INTERFERENCE; AND 2) THIS DEVICE MUST ACCEPT ANY INTERFERENCE

RECEIVED, INCLUDING INTERFERENCE THAT MAY CAUSE UNDESIRED OPERATION.

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES. OPERATION IS SUBJECT TO THE FOLLOWING TWO CONDITIONS:

PAT. PEND. PAT. 5400009, 5608375, 5751210, 5982275 FGN PAT. 185360, 2282717

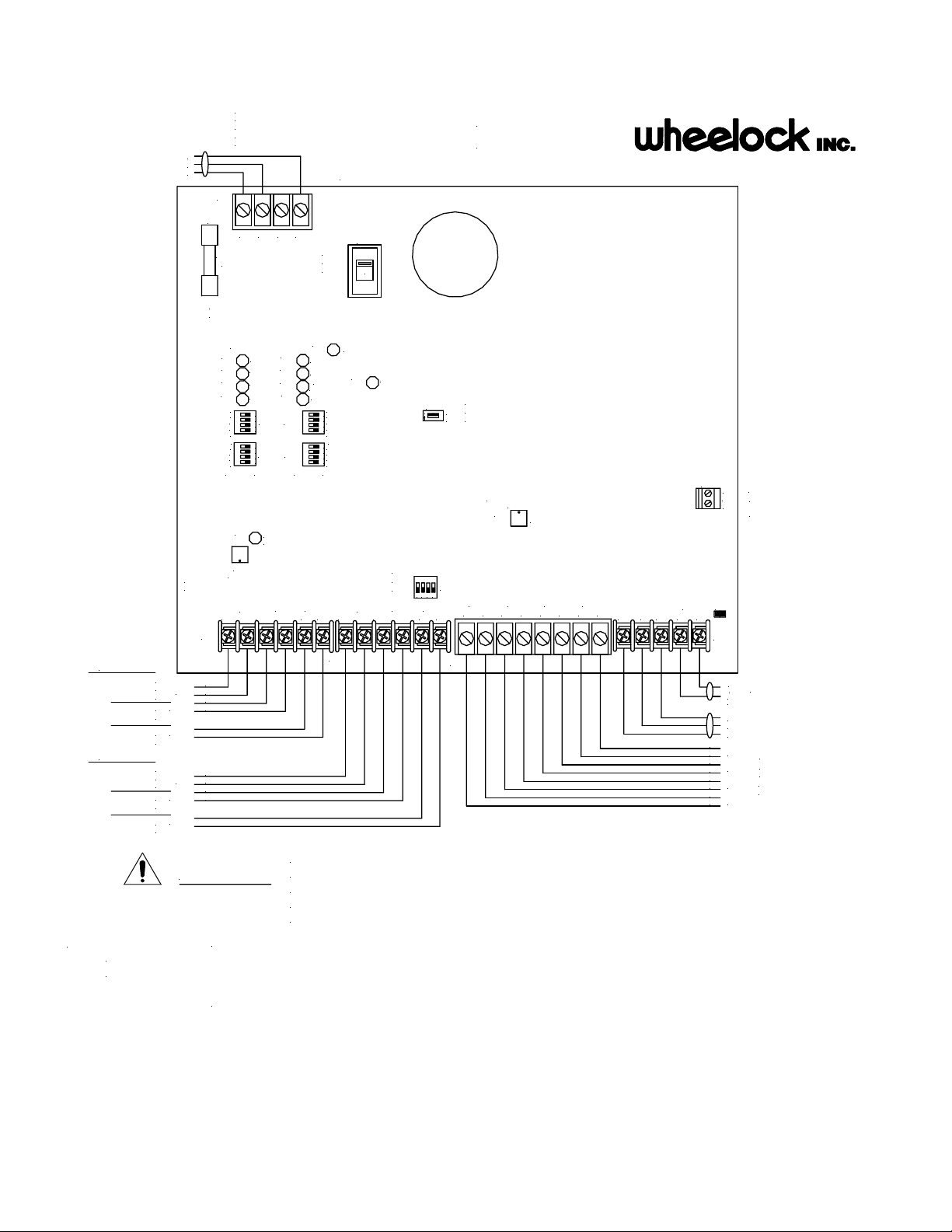

Figure 1:

Terminal Locations

P84333 K Sheet 6 of 23

Page 7

1.5 LED STATUS

Table 2 lists status of the LED indicators. The ALARM condition occurs when the input causes the output

circuits to energize. TROUBLE condition occurs when the circuit is no longer supervised correctly. The

TROUBLE LED’s for OUT1, OUT2, OUT3, OUT4 and, GND FAULT latch ON when the trouble occurs.

They are turned OFF when an alarm condition occurs or the PS12/24-8MP system rest (SW8) is pressed.

The trouble relay follows any trouble condition and is not latching.

NOTE: An alarm condition overrides a trouble condition.

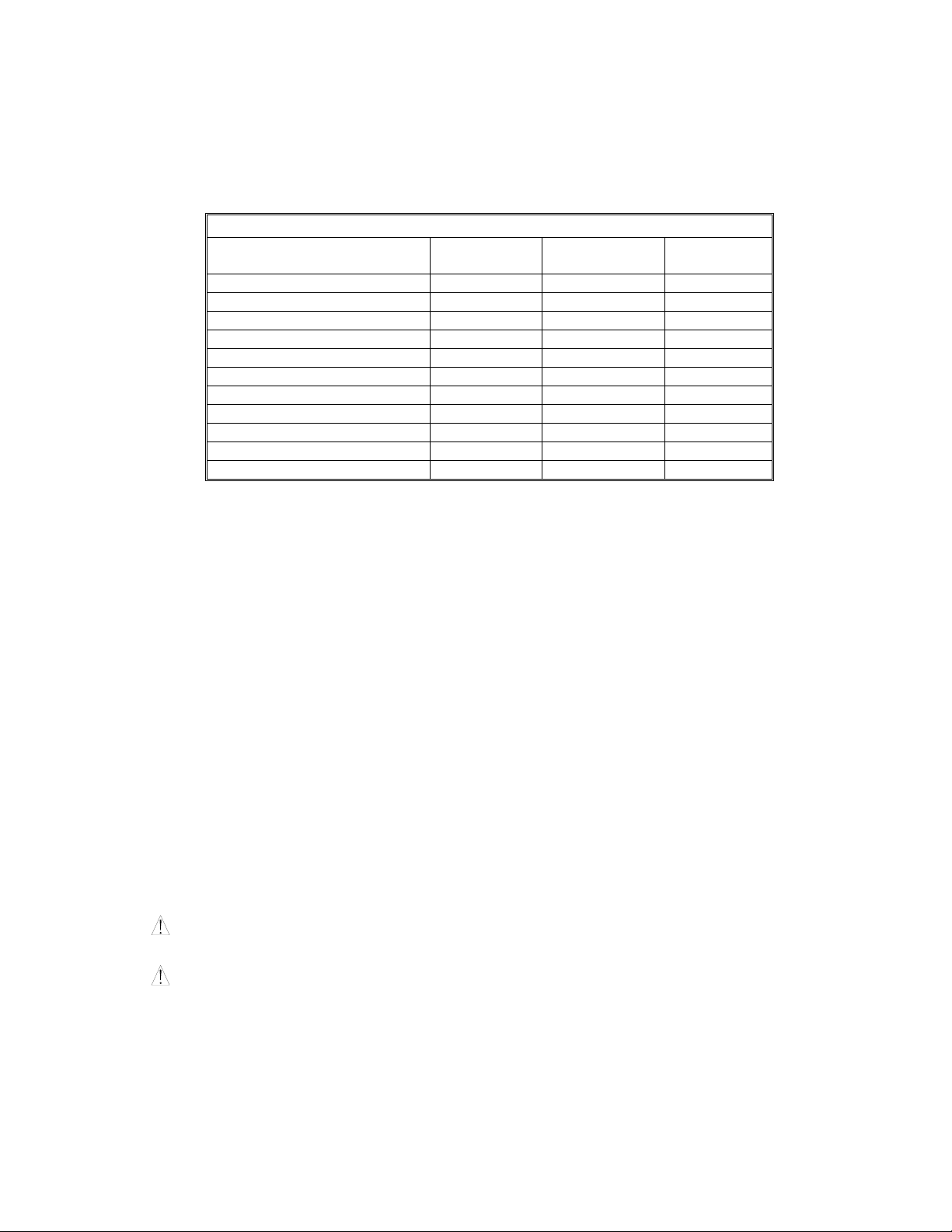

Table 2: LED Status Description

LED

OUT1 STANDBY -------- TROUBLE

OUT2 STANDBY -------- TROUBLE

OUT3 STANDBY -------- TROUBLE

OUT4 STANDBY -------- TROUBLE

INP1 STANDBY ALARM TROUBLE*

INP2 STANDBY ALARM TROUBLE*

GND FAULT -------- TROUBLE -------AC No AC AC Present -------BATT -------- TROUBLE -------MICRO FAULT -------- TROUBLE -------POWER SUPPLY DC TROUBLE DC PRESENT --------

* NOTE: If INP1 or INP2 LED and OUT1-OUT4 TROUBLE LED are on, TROUBLE exists currently.

1.6 BATTERY MAINTENANCE

Battery Replacement: Power-Sonic (or equal) 12VDC, replace with new batteries every four (4) years or as

needed if battery will no longer accept full charge. Two 12V batteries are required for 24VDC setting. Use

either a 7AH battery or a 12AH battery in accordance with the proper battery calculation for the application

using BATTERY CALCULATION SHEET provided on Sheet 23.

NOTE: Battery compartment measures 4-1/2" High X 11-1/2" Wide X 4-1/2" Deep.

2.0 INSTALLATION INSTRUCTIONS:

NOTE: The PS-12/24-8MP POWERPATH shall be installed in accordance with the National Fire Protection

Association (NFPA), National Electrical Code (NEC) and all applicable state and local regulations.

2.1 UNPACKING

The POWERPATH was carefully checked before leaving the factory. Inspect shipping container and unit

carefully for indications of improper handling. If damage is detected, make an immediate claim to the

carrier.

Remove the POWERPATH from the shipping container and check that the door lock keys, door lock, and

battery connection wires are inside. Make sure the printed circuit board is securely mounted to the rear of

the enclosure.

2.2 MOUNTING

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS UNIT

TO RAIN OR MOISTURE.

CAUTION: This product is not intended for use in hazardous locations as defined by the National

Electrical Code (NEC) and by the National Fire Protection Association (NFPA).

Mount the POWERPATH in the desired location using the mounting dimensions in Figure 2.

Mount the panel in a location that does not exceed a temperature range of 0° C to 49° C (32° F to 120° F)

and a humidity equal to 10% to 85% at 30° C (86° F) non-condensing.

When mounting on interior walls, use proper screw anchors in plaster. When mounting to concrete,

especially when moisture is expected, first attach a piece of ¾ inch plywood to the concrete surface. Attach

the POWERPATH to the plywood.

P84333 K Sheet 7 of 23

OFF

ON

ON

Page 8

13.950"

.544"

1.060"

10.000"

Figure 2:

Mounting Dimensions

DIMENSIONS (H x W x D) - 16” x 12.25” x 5”

NOTE: All dimensions shown are measured in inches.

P84333 K Sheet 8 of 23

Page 9

2.3 WIRING

Review the Operation Section (3.0) in order to select the proper hook-up and use of the POWERPATH.

Set switches and wire the POWERPATH as follows: Terminal locations are shown in Figure 1.

Set Power Supply switch (SW1) for 120VAC or 240VAC operation. See Figure 1.

A. Set Power Supply switch (SW4) for desired output voltage (Down for 24VDC, Up for 12VDC). See

Figure 1.

B. Set output DIP Switch(s) to follow corresponding input (IN1, IN2) and desired output mode. See Table

3 DIP Switch Selection and DIP Switch Settings Section (3.2).

C. Set DIP Switch SW9 position 1 & 2 to select Class “A” or Class “B” operation (Off for Class "B", On for

Class "A"). See Figure 1.

D. Dress battery wire down to the back of the enclosure, observing ¼” separation of power limited wire

V.S. non-power limited wiring. See Figure 3.

E. Connect notification appliances to desired outputs OUT1 – OUT4. See Operation Section (3.0).

• The POWERPATH has in-out wiring terminals that accept two #18 to #12 American Wire Gauge

(AWG) wires at each screw terminal. Strip leads 3/8 inches and connect to screw terminals.

• Separate all in-out wire runs on supervised circuits to insure integrity of circuit supervision. The

polarity shown in the wiring diagrams and on the circuit boards is for operation of the appliances.

The polarity is reversed by the FACP during supervision.

• Total load for the PS-12/24-8MP NAC circuits shall not exceed 8.0 Amps.

• Total load of any Class “B”output circuit shall not exceed 3.0 Amps.

• Total load of any Class “A”output circuit shall not exceed 3.0 Amps.

• Terminate unused outputs with a 2.2K Ohm EOLR.

F. Connect the indicating circuit(s) from the FACP to the desired input(s), IN1 and IN2. Connect EOLR to

RET1 and RET2. The value is determined by FACP.

G. Connect desired auxiliary equipment (Door Holder) to the auxiliary output terminals +AUX-. This output

is disconnected upon AC loss or alarm condition. The power is reconnected 30 seconds after AC

power returns or the alarm condition is over.

H. Connect trouble relays as desired.

I. Connect backup batteries. Observe correct polarity and voltage. For 12VDC, use a single 12V battery.

For 24VDC, use two of the same connected in series. Use either a 7AH or a 12AH battery depending

on circuit loading, BATTERY CALCULATION SHEET is provided on Sheet 23.

J. Install battery cover between both battery wires and Power Limited Wiring. See Figure 3.

K. Connect AC source. The AC source shall be connected to a dedicated, non-switch power source. The

AC must first be wired into the buildings main electrical power. The conduit entry can be either from the

top or left hand side using the knock-outs. See Figure 3. Connect Earth Ground First.

L. Press Auxiliary Power Reset, SW7 to ensure that Auxiliary Power is present.

M. Close door and secure with 2 screws on side.

Table 3: DIP Switch Selection

Function Switch Position Description Note

INPUT

SELECT

ON

OFF

Selected output to be controlled by Input 1 (IN1+, IN1-) (DRY1)

Selected output to be controlled by Input 2 (IN2+, IN2-) (DRY2)

------

------

TEMPORAL ON Generates Code 3 temporal signal on this output. 1

IN>OUT SYNC ON Allows a sync signal on the input to be used by the output. -----WHEELOCK

SYNC MODE

WHEELOCK SYNC “ON”

IN>OUT SYNC “ON”

Generates Wheelock sync signal for synchronizing Wheelock horns

and strobes.

NOTE 1: Use only with appliances that can operate using a coded horn appliance. (Example: Wheelock Series

CH, and Series MT)

NOTE 2: Use only with Wheelock Series AS/AH, Series NS/NS4/NH, Series RSS and products with SL/SLM

strobes.

2.4 RELAY STATUS CONNECTIONS

COMMON TROUBLE TERMINALS – The common trouble terminals are located on the right bottom side of the PC

Board. The three terminals are labeled “NO”, “C” and “NC”. When the PS-12/24-8MP is operating normally the “NC”

“C” terminals are shorted, and the “C” “NO” terminals are open. There are five trouble conditions that will cause these

terminals to change state. The relay follows the trouble condition and is not latching.

• Supervision trouble on any output

• Battery Fail

(+OUT1-, +OUT2-, +OUT3-, +OUT4-)

• AC Loss • GND Fault

• Micro Processor Fault

P84333 K Sheet 9 of 23

2

Page 10

INPUT CIRCUITS

POWER-LIMITED

BATTERY

COVER

RESTS ON

TOP OF

BATTERIES

AC POWER

NON-POWER LIMITED

120VAC, 5 AMPS, 50/60Hz

240VAC, 3 AMPS, 50/60Hz

F1

AC POWER

FUSE

OUTPUT1

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

OUTPUT2

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

P84230

REV.

TB4

TB1

10 AMP

250V

OUT TRB

D8

D13

D14

D18

ON OFF

RESET

IN1+

SW8

SYS

D70

G L2

OUT1

OUT2

OUT3

OUT4

IN1-

3 4

SW2

2

1

4

3

SW5

1 2

MICRO

FAULT

RET1+

G L1

SELECTION

D9

D15

D16

D19

SW3

SW6

ON OFF

AC POWER

120/240VAC

D10

INP1

INP2

GND

FAULT

BATT

OUTPUT3

IN>OUT SYNC

3 4

WHEELOCK SYNC

2

TEMPORAL

1

INPUT SELECT

OUTPUT4

4

IN>OUT SYNC

3

WHEELOCK SYNC

TEMPORAL

1 2

INPUT SELECT

DRY1RET1-

C NC

TB5

AC

D71

IN2+

SW1

115V

CLASS A/B

SELECTION

SWITCHES

POWER SUPPLY DC

SW4

O

N

1 2

3

4

DRY2

RET2-IN2-

C

RET2+

+ YELLOW -

12V

24V

SW9

NC

TB6

DC POWER OUT

SELECTION

12Vdc OR 24Vdc

AUXILIARY POWER

RESET

SW7

OUT2

OUT1

+

- +

(MP VERSION)

OUT3

- + - + -

OUT4

BLACK -

NO C

RED +

RELAY CONTACTS

AUX OUTPUT

POWER-LIMITED

TB3

-

BATT

+

AUX

+ -

W1

TB7

OUTPUT CIRCUITS

POWER-LIMITED

BATTERY WIRES

TO BE DRESSED

TO BACK OF

ENCLOSURE

TO ENSURE

POWER LIMITED

V.S. NON POWER

LIMITED 1/4"

SEPARATION.

NC

RED +

+

-

+

BLACK -

+ YELLOW -

-

BATTERY TERMINALS

TOP VIEW

Figure 3:

POWERPATH PS-12/24-8MP

P84333 K Sheet 10 of 23

Page 11

3.0 OPERATION:

3.1 MODES OF OPERATION

The PS-12/24-8MP POWERPATH can provide a 12VDC or 24VDC output when initiated by a 8VDC to

33VDC appliance (IN1 or IN2) or an open contact (DRY1 or DRY2). The output will remain on until the

deactivation of the input returns it to standby mode.

The outputs can be configured as four Class “B” circuits, two Class “A” circuits, or two Class “B” and one

Class “A” circuits.

Each Class "A" circuit is 3.0 Amps and each Class "B" circuit is 3.0 Amps. Total load for the PS-12/24-8MP

NAC circuits shall not exceed 8.0 Amps.

There are four output modes which can be used with either Class “A” or Class “B” circuits.

NORMAL MODE Used for a constant 12VDC or 24VDC output.

TEMPORAL MODE Provides a temporal output for appliances that can utilize a coded

signal. (i.e. single stroke bells and chimes and some horns) (NOTE:

Do not use with Wheelock AS, NS, RSS appliances.)

IN>OUT SYNC MODE Allows a coded signal or synchronization signal input to be utilized by

the POWERPATH. This signal may come from a FACP, another PS12/24-8MP or a Wheelock Synchronization Module (SM-12/24 or DSM12/24). Audibles can also be silenced.

WHEELOCK SYNC MODE Activates the built-in Wheelock Synchronization Mode for use with

patented synchronized horns and strobes. Audibles can also be

3.2 DIP SWITCH SETTINGS

The following is the DIP Switch settings for Output 1. Each of the remaining outputs is controlled similarly.

When switches are changed, press SYS RESET and wait 30 seconds before activating.

silenced.

Figure 4:

MODE DIP SWITCH SETTING

NORMAL MODE INPUT SELECT (1) “ON” for “IN1” or “DRY1”

“OFF” for “IN2” or “DRY2”

TEMPORAL (2) “OFF”

WHEELOCK SYNC (3) “OFF”

IN>OUT SYNC (4) “OFF”

TEMPORAL INPUT SELECT (1) “ON” for “IN1” or “DRY1”

“OFF” for “IN2” or “DRY2”

TEMPORAL (2) “ON”

WHEELOCK SYNC (3) “OFF”

IN>OUT SYNC (4) “OFF”

IN>OUT SYNC INPUT SELECT (1) “ON” for “IN1” or “DRY1”

“OFF” for “IN2” or “DRY2”

TEMPORAL (2) “OFF”

WHEELOCK SYNC (3) “OFF”

IN>OUT SYNC (4) “ON”

WHEELOCK SYNC INPUT SELECT (1) “ON” for “IN1” or “DRY1”

“OFF” for “IN2” or “DRY2”

TEMPORAL (2) “OFF”

WHEELOCK SYNC (3) “ON”

IN>OUT SYNC (4) “ON”

P84333 K Sheet 11 of 23

Output DIP Switch(s)

OUT1-4

4

IN>OUT SYNC

3

WHEELOCK SYNC

2

TEMPORAL

1

ON

INPUT SELECT

Page 12

3.3 CLASS “B” OPERATION

Class “B” outputs can be controlled from either IN1 or IN2. Switch SW9 position 1 & 2 on the board are in

the “OFF” position.

The following are examples of Class “B” connections. A FACP is used as a representative input.

• IN1 and/or IN2 can be used for connection to the FACP. The INPUT SELECT Switch (1) selects which

input is to be used to activate the output.

• Board switch SW9 position 1 & 2 control Class “A” or Class “B” configuration. SW9 position 1 controls

Outputs 1 and 3. SW9 position 2 controls Outputs 2 and 4.

• The PS-12/24-8MP requires a 2.2K Ohm End of Line Resistor (EOLR) on each output for proper

supervision.

Example 1: NORMAL MODE (CLASS B)

OUT1-4

4

IN>OUT SYNC

3

WHEELOCK SYNC

2

ON

TEMPORAL

1

INPUT SELECT

+

IN1

-

F

A

C

TO NEXT APPLIANCE

OR EOLR

+

RET1

-

POWERPATH

P

SW9

ON

4

2

3

1

LEGEND

OUT1

OUT2

OUT3

OUT4

+

TO NEXT APPLIANCE

OR EOLR

-

+

(2.2K OHMS)

TO NEXT APPLIANCE

OR EOLR

-

+

(2.2K OHMS)

TO NEXT APPLIANCE

OR EOLR

-

+

(2.2K OHMS)

TO NEXT APPLIANCE

OR EOLR

-

(2.2K OHMS)

STROBE

Example 2: TEMPORAL MODE (CLASS B)

OUT1

4

F

A

C

TO NEXT APPLIANCE

OR EOLR

+

IN1

-

+

RET1

-

POWERPATH

ON

ON

IN>OUT SYNC

WHEELOCK SYNC

23

TEMPORAL

1

INPUT SELECT

OUT2-4

4

IN>OUT SYNC

WHEELOCK SYNC

23

TEMPORAL

1

INPUT SELECT

P

SW9

ON

4

2

3

1

OUT1

OUT2

OUT3

OUT4

+

-

+

-

+

-

+

-

EOLR

2.2K OHMS

EOLR

2.2K OHMS

AUDIBLE

TO NEXT APPLIANCE

OR EOLR

(2.2K OHMS)

TO NEXT APPLIANCE

OR EOLR

(2.2K OHMS)

CAUTION: Strobes require constant voltage and will not operate properly in the TEMPORAL MODE. A second

output set in the NORMAL MODE will provide the constant voltage.

CAUTION: Only use audible appliances that can use a coded signal. Do not use with Wheelock Series AS/AH,

NS/NH or HS4/HS appliances.

P84333 K Sheet 12 of 23

Page 13

Example 3: IN>OUT SYNC MODE from CODED INPUT SOURCE (CLASS B)

F

A

C

P

CODED

TO NEXT APPLIANCE

OR EOLR

CONSTANT

TO NEXT APPLIANCE

OR EOLR

+

IN1

-

+

-

+

-

+

-

ON

RET2

ON

IN2

POWERPATH

RET2

SW9

ON

2

3

1

4

IN>OUT SYNC

WHEELOCK SYNC

23

TEMPORAL

1

INPUT SELECT

4

IN>OUT SYNC

WHEELOCK SYNC

23

TEMPORAL

1

INPUT SELECT

4

OUT1

OUT2-4

OUT1

OUT2

OUT3

OUT4

+

TO NEXT APPLIANCE

OR EOLR

-

+

SW9

(2.2K OHMS)

TO NEXT APPLIANCE

OR EOLR

-

+

EOLR

-

2.2K OHMS

+

EOLR

-

2.2K OHMS

(2.2K OHMS)

Minimum pulse duration for coded signals must be greater than 0.4 seconds.

CAUTION: Strobes require constant voltage and will not operate properly in the IN>OUT SYNC MODE with a

coded input source. A second constant input with a second output set in the NORMAL MODE will provide the

constant voltage.

CAUTION: Only use audible appliances that can use a coded signal. Do not use with Wheelock Series AS/AH,

NS/NH or HS4/HS appliances.

Example 4: IN>OUT SYNC MODE with External Sync Module without Audible Silence

(CLASS B)

SM/DSM

OUT1

OUT2

OUT3

OUT4

+

-

+

-

+

-

+

-

EOLR

2.2K OHMS

EOLR

2.2K OHMS

EOLR

2.2K OHMS

+

F

+ OUT1

+ IN1

MINUS 1

TO NEXT APPLIANCE

OR EOLR

IN1

-

+

RET1

-

4

23

1

ON

OUT1-4

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

A

+ AUDIBLE

C

- AUDIBLE

POWERPATH

P

SW9

ON

4

2

3

1

NOTE: When using the Wheelock external Sync Module (SM or DSM), synchronization will only occur with

Wheelock sync appliances.

P84333 K Sheet 13 of 23

TO NEXT

APPLIANCE

OR EOLR

(2.2K OHMS)

Page 14

Example 5: IN>OUT SYNC MODE with External Sync Module with Audible Silence

(CLASS B)

F

A

C

P

SM/DSM

+ OUT1

+ IN1

MINUS 1

EOLR

+ AUDIBLE

- AUDIBLE

TO NEXT

APPLIANCE

OR EOLR

OUT1-4

4

4

4

+

IN1

-

+

RET1

-

IN>OUT SYNC

23

23

23

WHEELOCK SYNC

1

1

1

TEMPORAL

ON

ON

ON

INPUT SELECT

POWERPATH

SW9

ON

4

2

3

1

OUT1

OUT2

OUT3

OUT4

+

-

+

-

+

-

+

-

TO NEXT APPLIANCE

OR EOLR

(2.2K OHMS)

EOLR

2.2K OHMS

EOLR

2.2K OHMS

EOLR

2.2K OHMS

NOTE: When using the Wheelock external Sync Module (SM or DSM), synchronization will only occur

Wheelock sync appliances.

Example 6: WHEELOCK SYNC MODE without Audible Silence (CLASS B)

with

F

+

-

-

+

IN1

RET1

ON

ON

ON

4

4

4

OUT1-4

IN>OUT SYNC

23

23

23

WHEELOCK SYNC

1

1

1

TEMPORAL

INPUT SELECT

OUT1

OUT2

+

-

+

-

EOLR

2.2K OHMS

TO NEXT APPLIANCE

OR EOLR

(2.2K OHMS)

A

POWERPATH

C

P

+

-

+

-

SW9

IN2

RET2

ON

TO NEXT APPLIANCE

OR EOLR

4

2

3

1

• This mode will only synchronize Wheelock horns, horn strobes, and strobes with the synchronization capability.

• If only strobes are connected to the POWERPATH outputs, the initiating input to IN2 is not required.

• When synchronized horns are used on the two wire output of the POWERPATH, IN2 must be connected as

shown or the horns will not operate.

OUT3

OUT4

+

-

+

-

EOLR

2.2K OHMS

EOLR

2.2K OHMS

P84333 K Sheet 14 of 23

Page 15

Example 7: WHEELOCK SYNC MODE with Audible Silence (CLASS B)

F

A

C

P

TO NEXT APPLIANCE

OR EOLR

AUDIBLE

SILENCE

TO NEXT APPLIANCE

OR EOLR

+

-

+

-

IN1

RET1

ON

ON

ON

4

4

4

OUT1-4

IN>OUT SYNC

23

23

23

WHEELOCK SYNC

1

1

1

TEMPORAL

INPUT SELECT

POWERPATH

+

IN2

-

+

RET2

-

SW9

ON

4

2

3

1

OUT1

OUT2

OUT3

OUT4

+

-

+

-

+

-

+

-

TO NEXT APPLIANCE

OR EOLR

(2.2K OHMS)

EOLR

2.2K OHMS

EOLR

2.2K OHMS

EOLR

2.2K OHMS

• This mode will only synchronize Wheelock horns, horn strobes, and strobes with the synchronization capability.

3.4 CLASS “A” OPERATION

Class “A” circuit 1 uses “OUT1” and “OUT3”. Class “A” circuit 2 uses “OUT2” and “OUT4”. When operating

in Class “A” the two circuits must have the same switch settings for the operational mode selected. Switch

SW9 position 1 & 2 on the PC board are in the “ON” position.

• IN1 and/or IN2 can be used for connection to the FACP. The INPUT SELECT Switch (1) selects which

input is to be used to activate the output.

• Board switch SW9 position 1 & 2 control Class “A” or Class “B” configuration. SW9 position 1 controls

Outputs 1 and 3. Switch SW9 position 2 controls Outputs 2 and 4.

• DIP Switch settings for each circuit in the Class “A” output must be set identically.

Example 8: NORMAL MODE (CLASS A)

F

A

TO NEXT APPLIANCE

OR EOLR

OR RETURN

TO FACP

(CLASS "A")

+

IN1

-

+

RET1

-

ON

OUT1-4

4

IN>OUT SYNC

3

WHEELOCK SYNC

2

TEMPORAL

1

INPUT SELECT

OUT1

OUT2

+

-

+

-

POWERPATH

C

OUT3

-

+

P

SW9

ON

-

OUT4

4

2

3

1

P84333 K Sheet 15 of 23

+

Page 16

Example 9: TEMPORAL MODE (CLASS A)

OUT3

OUT4

4

+

OUT1

3

2

1

ON

4

ON

3

2

1

OUT2

OUT3

-

+

-

-

+

F

A

C

TO NEXT APPLIANCE

OR EOLR

OR RETURN

TO FACP

(CLASS "A")

OUT1

4

+

IN1

-

+

RET1

-

3

2

1

ON

4

3

2

ON

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

OUT2

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

1

INPUT SELECT

POWERPATH

P

SW9

ON

4

2

3

1

CAUTION: Strobes require constant voltage and will not operate properly in the TEMPORAL MODE. A second

Class “A” output set in the NORMAL MODE will provide the constant voltage for the strobe circuit. Only use sounding

appliances that can use a coded signal. Do not use Wheelock AS/AH or NS/NS4/NH appliances with TEMPORAL

MODE.

Example 10: IN>OUT SYNC MODE from CODED INPUT SOURCE (CLASS A)

OUT4

-

+

OUT3

OUT4

+

4

OUT1

-

3

2

1

ON

+

4

OUT2

-

3

2

1

ON

-

OUT3

+

-

OUT4

+

F

A

C

P

CODED

TO NEXT APPLIANCE

OR EOLR

OR RETURN

TO FACP

(CLASS "A")

CONSTANT

TO NEXT APPLIANCE

OR EOLR

OR RETURN

TO FACP

(CLASS "A")

OUT1

+

IN1

-

+

RET1

-

+

IN2

-

+

RET2

-

SW9

4

IN>OUT SYNC

3

WHEELOCK SYNC

2

TEMPORAL

1

INPUT SELECT

ON

OUT2

4

IN>OUT SYNC

3

WHEELOCK SYNC

2

TEMPORAL

1

INPUT SELECT

ON

POWERPATH

ON

4

2

3

1

CAUTION: Strobes require constant voltage and will not operate properly in the IN>OUT SYNC MODE with a

coded input. A second Class “A” output set in the NORMAL MODE will provide the constant voltage for the strobe

circuit. Only use audible appliances that can use a coded signal. Do not use Wheelock AS/AH or NS/NS4/NH

appliances with a coded input.

P84333 K Sheet 16 of 23

Page 17

Example 11: IN>OUT SYNC MODE with External Sync Module without Audible Silence

(CLASS A)

SM/DSM

+

IN1

-

+

RET1

-

F

+ OUT1

+ IN1

MINUS 1

TO NEXT APPLIANCE

OR EOLR

A

+ AUDIBLE

C

- AUDIBLE

POWERPATH

P

SW9

ON

NOTE: When using the Wheelock external Sync Module (SM or DSM), synchronization will only occur

Wheelock sync appliances.

Example 12: IN>OUT SYNC MODE with External Sync Module with Audible Silence

(CLASS A)

OUT1-4

4

IN>OUT SYNC

3

WHEELOCK SYNC

2

TEMPORAL

1

INPUT SELECT

ON

4

2

3

1

OUT1

OUT2

OUT3

OUT4

+

-

+

-

-

+

-

+

with

SM/DSM

F

A

C

AUDIBLE

SILENCE

EOLR

+ OUT1

+ IN1

MINUS 1

+ AUDIBLE

- AUDIBLE

TO NEXT APPLIANCE

OR EOLR

+

IN1

-

+

RET1

-

POWERPATH

ON

OUT1-4

4

IN>OUT SYNC

3

WHEELOCK SYNC

2

TEMPORAL

1

INPUT SELECT

P

SW9

ON

4

2

3

1

NOTE: When using the Wheelock external Sync Module (SM or DSM), synchronization will only occur

Wheelock sync appliances.

P84333 K Sheet 17 of 23

OUT1

OUT2

OUT3

OUT4

+

-

+

-

-

+

-

+

with

Page 18

Example 13: WHEELOCK SYNC MODE without Audible Silence (CLASS A)

OUT1-4

F

A

+

-

-

+

IN1

RET1

ON

4

IN>OUT SYNC

3

WHEELOCK SYNC

2

TEMPORAL

1

INPUT SELECT

OUT1

OUT2

+

-

+

-

C

P

TO NEXT APPLIANCE

OR EOLR

OR RETURN

TO FACP

(CLASS "A")

POWERPATH

+

IN2

-

-

RET2

+

SW9

ON

4

2

3

1

OUT3

OUT4

-

+

-

+

• This mode will only synchronize Wheelock horns, horn strobes, and strobes with the synchronization capability.

• If only strobes are connected to the POWERPATH outputs, the initiating input to IN2 is not required.

• When synchronized horns are used on the two wire output of the POWERPATH, IN2 must be connected as

shown or the horns will not operate.

Example 14: WHEELOCK SYNC MODE with Audible Silence (CLASS A)

ON

OUT1-4

4

IN>OUT SYNC

3

WHEELOCK SYNC

2

TEMPORAL

1

INPUT SELECT

OUT1

OUT2

+

-

+

-

F

A

TO NEXT APPLIANCE

OR EOLR

OR RETURN

TO FACP

(CLASS "A")

+

IN1

-

+

RET1

-

C

AUDIBLE SILENCE

P

TO NEXT APPLIANCE

OR EOLR

OR RETURN

TO FACP

(CLASS "A")

• This mode will only synchronize Wheelock horns, horn strobes, and strobes with the synchronization capability.

COMBINATION CLASS “A” AND CLASS “B” HOOKUP

POWERPATH

+

IN2

-

+

RET2

-

SW9

ON

4

2

3

1

OUT3

OUT4

-

+

-

+

The PS-12/24-8MP POWERPATH can be configured to have one Class “A” (3.0 Amps) and two Class “B” (2.0 Amps

each circuit) Outputs at the same time. This is done by Switch SW9 position 1 & 2. NOTE: When SW9 position 1 is

on, OUTPUTS 1 and 3 are the Class “A” circuit. When SW9 position 2 is on, OUTPUTS 2 and 4 are the Class “A”

circuit.

COMBINATION OF MODES

• In Class “B” configuration, each output can be set to an independent mode as desired.

• In Class “B”, IN1 or IN2 can be selected to activate any of the outputs desired.

• In Class “A”, OUTPUT DIP Switches must be set identically for each Class “A” output.

P84333 K Sheet 18 of 23

Page 19

3.5 MASTER REMOTE OPERATION:

4

5

5

Example 15: Synchronized Multiple PS-12/24-8MP or PS-12/24-8CP Using a Master

PS-12/24-8MP or PS-12/24-8CP (in the WHEELOCK SYNC MODE) Without Audible Silence,

and Using Input #1.

NOTE 2

FACP

NAC INPUT IN

ALARM CONDITION

-

+

P84230 REV.

P84230 REV.

TB1

F1

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

TB4

MH8

NOTE 5

TB1

F1

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

TB4

OUTPUT1

OUTPUT2

IN1+

OUTPUT1

OUTPUT2

IN1+

MH8

L1

ON OFF

D70

SW8

IN1-

L1

ON OFF

D70

SW8

IN1-

GND L2

RET1+

SW2

SW5

GND L2

D8

D13

D14

SW2

SW5

RET1+

GND

115V

SW1

D10

OUT TRB

AC

D9

D8

INP1

OUT1

D15

D13

OUT2

INP2

D14

D16

OUT3

FAULT

D18

D19

OUT4

BATT

SW3

OUTPUT3

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

OUTPUT4

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

SW6

ON OFF

NCC

RET2-

RET2+

IN2+

RET1-

IN2-

DRY1

TB5

GND

115V

SW1

D10

OUT TRB

AC

D9

INP1

OUT1

D15

OUT2

INP2

D16

OUT3

FAULT

D18

D19

OUT4

BATT

SW3

OUTPUT3

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

OUTPUT4

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

SW6

ON OFF

NC

C

RET2-

RET2+

IN2+

RET1-

IN2-

DRY1

TB5

MASTER

R40

SW4

12V

24V

AUX

RESET

SW7

SW9

NC

C

+ -

+ -

TB6

OUT1

OUT2

DRY2

NOCNC

+ -

+ -

OUT4

OUT3

TB2

DC

+

TB3

W1

-

+

MH9

AUX

NOTE

REMOTE

NOTE 6

R40

SW4

12V

24V

AUX

RESET

SW7

SW9

NC

C

+ -

TB6

OUT1

DRY2

+ -

+ -

+ -

OUT4

OUT3

OUT2

NOCNC

TB2

DC

+

TB3

W1

-

+

MH9

AUX

NOTE

GND L2

GND

L1

TB1

F1

115V

SW1

D10

OUT TRB

AC

D9

D8

INP1

OUT1

D15

D13

OUT2

INP2

D14

D16

OUT3

FAULT

D18

D19

OUT4

BATT

SW3

SW2

OUTPUT1

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

OUTPUT2

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

SW5

ON OFF

D70

SW8

P84230 REV.

TB4

IN1+

IN1-

RET1+

MH8

See Figure 1 on Sheet 5 for larger view of PC Board.

OUTPUT3

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

OUTPUT4

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

SW6

ON OFF

SW9

NCC

RET2-

RET2+

IN2+

RET1-

IN2-

DRY1

TB5

REMOTE

NOTE 6

R40

SW4

12V

24V

AUX

RESET

SW7

NC

C

+ -

TB6

OUT1

DRY2

+ -

+ -

+ -

OUT4

OUT3

OUT2

TB2

DC

+

TB3

W1

-

+

NC

NO

C

MH9

AUX

NOTE

NOTE 1: NAC Input Voltage 8.0VDC to 33.0VDC Constant.

NOTE 2: OBSERVE DIP SWITCH SETTINGS

Input Selection Switch (Position 1) on OUT1 to OUT4 DIP Switches are shown in the "ON"

Position allowing Input #1 to activate Outputs 1-4, Positions 2-4 are set for "WHEELOCK SYNC MODE"

NOTE 3: Jumper "RET 1-" to "IN 2-" and "RET 1+" to "IN 2+ " only on the Master PS-12/24-8MP.

NOTE 4: Diagram shown with an output circuit (OUT4) on Master POWERPATH used to synchronized the Remote

POWERPATHS.

NOTE 5: Jumpers must be placed across "DRY 1" and "DRY 2" terminals when operating Power Supply using "IN 1" or "IN 2".

NOTE 6: OBSERVE DIP SWITCH SETTINGS

Input Selection Switch (Position 1) on OUT 1 to OUT 4 DIP Switches are shown in the "ON" Position allowing Input #1 to

activate Outputs 1-4. Positions 2-4 are set for "IN>OUT SYNC MODE".

P84333 K Sheet 19 of 23

Page 20

Example 16: Synchronized Multiple PS-12/24-8MP or PS-12/24-8CP Using a Master PS-12/24-8MP

or PS-12/24-8CP (in the WHEELOCK SYNC MODE) With Audible Silence, and Using

Input #1

FACP

AUDIBLE SILENCE

ALARM CONDITION

FACP

PROGRAMMED

NAC

NAC INPUT IN

NOTE 2

GND L2

GND

L1

TB1

F1

115V

SW1

D10

AC

OUT TRB

D9

D8

INP1

OUT1

D15

D13

OUT2

INP2

D14

D16

OUT3

FAULT

D18

D19

OUT4

BATT

SW3

SW2

OUTPUT1

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

OUTPUT2

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

SW5

P84230 REV.

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

P84230 REV.

OUTPUT1

OUTPUT2

TB4

F1

ON OFF

TB4

ON OFF

MH8

TB1

SW2

SW5

IN1+

MH8

F1

D70

SW8

IN1-IN1+

L1

OUT TRB

D8

D13

D14

D18

D70

SW8

IN1-

L1

TB1

-

+

-

+

OUTPUT3

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

OUTPUT4

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

SW6

ON OFF

SW9

NCC

SW3

SW6

ON OFF

GND

RET2-

C

RET2+

IN2+

IN2-

TB5

DRY2

115V

SW1

D10

AC

NOTE 4

OUTPUT3

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

OUTPUT4

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

SW9

NCC

RET2-

C

RET2+

IN2+

IN2-

TB5

DRY2

115V

SW1

RET1+

RET1-

DRY1

GND L2

GND

D9

INP1

OUT1

D15

OUT2

INP2

D16

OUT3

FAULT

D19

OUT4

BATT

RET1+

RET1-

DRY1

GND L2

MASTER

R40

SW4

12V

24V

AUX

RESET

SW7

NC

+ -

+ -

TB6

OUT1

OUT2

NOCNC

+ -

+ -

OUT4

OUT3

NOTE 5

TB2

DC

+

TB3

W1

-

+

MH9

AUX

NOTE 3

REMOTE

R40

SW4

12V

24V

AUX

RESET

SW7

NC

+ -

+ -

TB6

OUT1

OUT2

NO

+ -

+ -

OUT4

OUT3

TB2

DC

+

TB3

W1

-

+

NC

C

MH9

AUX

NOTE 5

REMOTE

D10

OUT TRB

AC

D9

D8

INP1

OUT1

D15

D13

OUT2

INP2

D14

D16

OUT3

FAULT

D18

D19

OUT4

BATT

SW3

SW2

OUTPUT1

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

OUTPUT2

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

SW5

ON OFF

SW8

P84230 REV.

TB4

IN1+

IN1-

MH8

See Figure 1 on Sheet 5 for larger view of PC Board.

OUTPUT3

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

OUTPUT4

IN>OUT SYNC

WHEELOCK SYNC

TEMPORAL

INPUT SELECT

SW6

ON OFF

D70

NC

C

RET1+

IN2+

RET1-

IN2-

DRY1

TB5

R40

NOTE 4

SW4

12V

24V

AUX

RESET

SW7

SW9

NC

RET2-

C

RET2+

+ -

+ -

TB6

OUT1

OUT2

DRY2

NOCNC

+ -

+ -

OUT4

OUT3

TB2

DC

+

TB3

W1

-

+

MH9

AUX

NOTE 5

NOTE 1: NAC Input Voltage 8.0 to 33.0VDC Constant.

NOTE 2: OBSERVE DIP SWITCH SETTINGS

Input Selection Switch (Position 1) on OUT1 to OUT4 DIP Switches are shown in the "ON"

Position allowing Input #1 to activate Outputs 1-4, Positions 2-4 are set for "WHEELOCK SYNC MODE"

NOTE 3: Diagram shown with an output circuit (OUT4) on Master POWERPATH used to synchronize the Remote PowerPaths.

In this configuration the Master PowerPath can only have three NAC circuits.

NOTE 4: OBSERVE DIP SWITCH SETTINGS

Input Selection Switch (Position 1) on OUT 1 to OUT 4 DIP Switches are shown in the "ON" Position allowing Input #1 to

activate Outputs 1-4. Positions 2-4 are set for "IN>OUT SYNC MODE".

NOTE 5: Jumpers must be placed across “DRY1” and “DRY2” terminals when operating Power Supply using “IN1” or “IN2”.

P84333 K Sheet 20 of 23

Page 21

4.0 TROUBLESHOOTING:

WARNING: THE PS-12/24-8MP POWERPATH CONTAINS VOLTAGES THAT CAN CAUSE DEATH OR

SERIOUS INJURY. ALWAYS OBSERVE PROPER ELECTRICAL SAFETY PRECAUTIONS AND WARNINGS.

Always follow good troubleshooting procedures:

• AUX power is available after a 30 second delay on power up and when coming out of alarm.

• When trouble occurs, observe all visual indications and note them.

• If the problem is obvious or it can be located on the Troubleshooting Table, note it.

• Press SYS RESET (SW8) and wait 30 seconds check for a trouble indication.

• Always de-energize the POWERPATH completely (Remove both AC and DC power) repairs.

• While the POWERPATH is de-energized, perform a visual and hands on check of all terminals and wires to

ensure proper termination.

Table 4: Troubleshooting

Trouble Cause Action

INP1, INP2 LED’s do not light in

ALARM.

GND FAULT LED ON GND FAULT Check output circuits.

DC LED OFF No DC output. Check wiring to AC power source.

AC LED OFF No AC power. Check AC power source.

No audible output in

WHEELOCK SYNC MODE.

Horn, horn strobes, or strobes

do not synchronize.

CLASS “A” circuit is not

functioning properly.

CLASS “B” circuit is not

functioning properly.

OUT1, OUT2, OUT3, OUT4

LED's on during standby.

No input signal on terminals

IN1+IN1-, IN2+IN2-.

No input to IN2+,IN2-. See Example 13 and 14 for proper

Improper MODE selection

Improper appliances.

Improper MODE selection or

SW9 settings.

Improper MODE selection or

SW9 settings.

Trouble on output. Check output supervision voltage.

Check input and input wiring.

input connections.

Check MODE selection.

Check appliances to ensure proper

type for synchronization. For

IN>OUT MODE check input

appliance (DSM, SM or PS-12/248MP).

Check to be certain MODE

selection is identical for each Class

“A” output circuit. Class “A” OUT1

uses outputs 1 and 3. Class “A”

OUT2 uses outputs 2 and 4.

Check SW9 POS 1 and POS 2 on

board for “ON” position.

Check SW9 POS 1 and POS 2 on

board for “OFF” position.

Check output EOLR.

P84333 K Sheet 21 of 23

Page 22

5.0 BATTERY CALCULATION SHEET:

PS-12/24-8MP BATTERY CALCULATION SHEET

STANDBY CURRENT CALCULATIONS

Amps

1. The Standby Current for the PS-12/24-8MP is .060 Amps.

Amps

2. Multiply by the number of hours required.

60 Hours - Multiply by 60

TOTAL STANDBY CURRENT IN Amp HOURS. AH

ALARM CURRENT CALCULATIONS

1. List notification appliance requirements.

CURRENT

ALARM CURRENT FOR THE PS-12/24-8MP 0.100

NOTIFICATION APPLIANCE

2. Calculate total notification appliance current plus alarm current for PS-12/24-8MP. Amps

3. Multiply Step 2 by alarm time required. AH

BACKUP BATTERY REQUIREMENTS

1. Enter Standby Current. AH

2. Enter Alarm Current from Step 3 above. AH

3. Add Steps 1 and 2 together. AH

Multiply Step 3 by 1.2 for minimum Backup Battery Requirements. AH

24 Hours - Multiply by 24

15 Min – Multiply by 0.25

5 Min – Multiply by 0.0833

P84333 K Sheet 22 of 23

Page 23

ANY MATERIAL EXTRAPOLATED FROM THIS DOCUMENT OR FROM WHEELOCK MANUALS OR OTHER

DOCUMENTS DESCRIBING THE PRODUCT FOR USE IN PROMOTIONAL OR ADVERTISING CLAIMS, OR FOR

ANY OTHER USE, INCLUDING DESCRIPTION OF THE PRODUCT’S APPLICATION, OPERATION.

INSTALLATION AND TESTING IS USED AT THE SOLE RISK OF THE USER, AND WHEELOCK WILL NOT

HAVE ANY LIABILITY FOR SUCH USE.

6.0 WARRANTY STATEMENT:

Limited Warranty

Wheelock products must be used within their published specifications and must be PROPERLY specified, applied,

installed, operated, maintained and operationally tested in accordance with these instructions at the time of installation

and at least twice a year or more often and in accordance with local, state and federal codes, regulations and laws.

Specification, application, installation, operation, maintenance and testing must be performed by qualified personnel

for proper operation in accordance with all of the latest National Fire Protection Association (NFPA), Underwriters'

Laboratories (UL), Underwriters’ Laboratories of Canada (ULC), National Electrical Code (NEC), Occupational Safety

and Health Administration (OSHA), local, state, county, province, district, federal and other applicable building and fire

standards, guidelines, regulations, laws and codes including, but not limited to, all appendices and amendments and

the requirements of the local authority having jurisdiction (AHJ). Wheelock products when properly specified, applied,

installed, operated, maintained and operationally tested as provided above are warranted against mechanical and

electrical defects for a period of three years from date of manufacture (as determined by date code). Correction of

defects by repair or replacement shall be at Wheelock's sole discretion and shall constitute fulfillment of all obligations

under this warranty.

THE FOREGOING LIMITED WARRANTY SHALL IMMEDIATELY TERMINATE IN THE EVENT ANY

PART NOT FURNISHED BY WHEELOCK IS INSTALLED IN THE PRODUCT. THE FOREGOING LIMITED WARRANTY

SPECIFICALLY EXCLUDES ANY SOFTWARE REQUIRED FOR THE OPERATION OF OR INCLUDED IN A PRODUCT.

WHEELOCK MAKES NO REPRESENTATION OR WARRANTY OF ANY OTHER KIND, EXPRESS, IMPLIED OR

STATUTORY WHETHER AS TO MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR ANY OTHER

MATTER.

USERS ARE SOLELY RESPONSIBLE FOR DETERMINING WHETHER A PRODUCT IS SUITABLE FOR THE USER'S

PURPOSES, OR WHETHER IT WILL ACHIEVE THE USER'S INTENDED RESULTS. THERE IS NO WARRANTY

AGAINST DAMAGE RESULTING FROM MISAPPLICATION, IMPROPER SPECIFICATION, ABUSE, ACCIDENT OR

OTHER OPERATING CONDITIONS BEYOND WHEELOCK'S CONTROL.

SOME WHEELOCK PRODUCTS CONTAIN SOFTWARE. WITH RESPECT TO THOSE PRODUCTS, WHEELOCK DOES

NOT WARRANTY THAT THE OPERATION OF THE SOFTWARE WILL BE UNINTERRUPTED OR ERROR-FREE OR

THAT THE SOFTWARE WILL MEET ANY OTHER STANDARD OF PERFORMANCE, OR THAT THE FUNCTIONS OR

PERFORMANCE OF THE SOFTWARE WILL MEET THE USER'S REQUIREMENTS. WHEELOCK SHALL NOT BE

LIABLE FOR ANY DELAYS, BREAKDOWNS, INTERRUPTIONS, LOSS, DESTRUCTION, ALTERATION, OR OTHER

PROBLEMS IN THE USE OF A PRODUCT ARISING OUT OF OR CAUSED BY THE SOFTWARE.

THE LIABILITY OF WHEELOCK ARISING OUT OF THE SUPPLYING OF A PRODUCT, OR ITS USE, WHETHER ON

WARRANTIES, NEGLIGENCE, OR OTHERWISE, SHALL NOT IN ANY CASE EXCEED THE COST OF CORRECTING

DEFECTS AS STATED IN THE LIMITED WARRANTY AND UPON EXPIRATION OF THE WARRANTY PERIOD ALL

SUCH LIABILITY SHALL TERMINATE. WHEELOCK IS NOT LIABLE FOR LABOR COSTS INCURRED IN REMOVAL,

REINSTALLATION OR REPAIR OF THE PRODUCT BY ANYONE OTHER THAN WHEELOCK OR FOR DAMAGE OF

ANY TYPE WHATSOEVER, INCLUDING BUT NOT LIMITED TO, LOSS OF PROFIT OR INCIDENTAL OR

CONSEQUENTIAL DAMAGES. THE FOREGOING SHALL CONSTITUTE THE SOLE REMEDY OF THE PURCHASER

AND THE EXCLUSIVE LIABILITY OF WHEELOCK.

IN NO CASE WILL WHEELOCK'S LIABILITY EXCEED THE PURCHASE PRICE PAID FOR A PRODUCT.

Limitation of Liability

WHEELOCK'S LIABILITY ON ANY CLAIM OF ANY KIND, INCLUDING NEGLIGENCE AND BREACH OF WARRANTY,

FOR ANY LOSS OR DAMAGE RESULTING FROM, ARISING OUT OF, OR CONNECTED WITH THIS CONTRACT, OR

FROM THE MANUFACTURE, SALE, DELIVERY, RESALE, REPAIR OR USE OF ANY PRODUCT COVERED BY THIS

ORDER SHALL BE LIMITED TO THE PRICE APPLICABLE TO THE PRODUCT OR PART THEREOF WHICH GIVES

RISE TO THE CLAIM. WHEELOCK'S LIABILITY ON ANY CLAIM OF ANY KIND SHALL CEASE IMMEDIATELY UPON

THE INSTALLATION IN THE PRODUCT OF ANY PART NOT FURNISHED BY WHEELOCK. IN NO EVENT SHALL

WHEELOCK BE LIABLE FOR ANY CLAIM OF ANY KIND UNLESS IT IS PROVEN THAT OUR PRODUCT WAS A

DIRECT CAUSE OF SUCH CLAIM. FURTHER, IN NO EVENT, INCLUDING IN THE CASE OF A CLAIM OF

NEGLIGENCE, SHALL WHEELOCK BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES

DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE

PRECEDING LIMITATION MAY NOT APPLY TO ALL PURCHASERS.

5/05

P84333 K Sheet 23 of 23

Loading...

Loading...