Page 1

273 Branchport Avenue

Long Branch, NJ 07740

(800) 631-2148 Thank you for using our products.

www.wheelockinc.com

INSTALLATION INSTRUCTIONS

MULTI-TONE HORN

Use this product according to this instruction manual. Please keep this instruction manual for future reference.

MODEL NUMBER: MTH-24

GENERAL:

The MTH-24 Multi-Tone Horn is a loud, attention getting alert designed for use in noisy and/or large locations where two different

audible appliances are required at one location.

The MTH-24 functions as a telephone extension alert because it provides a pulsed warble tone (1 second on and 7 seconds off) which

can be activated by a telephone systems interrupted or continuous dry contact closure. Additionally, it functions as an auxiliary alert

because it also provides a steady tone which follows the contact closure of a door/service push-button, time clock, alarm systems, etc.

When both alerting tones are activated, the steady tone will take priority over the warble tone.

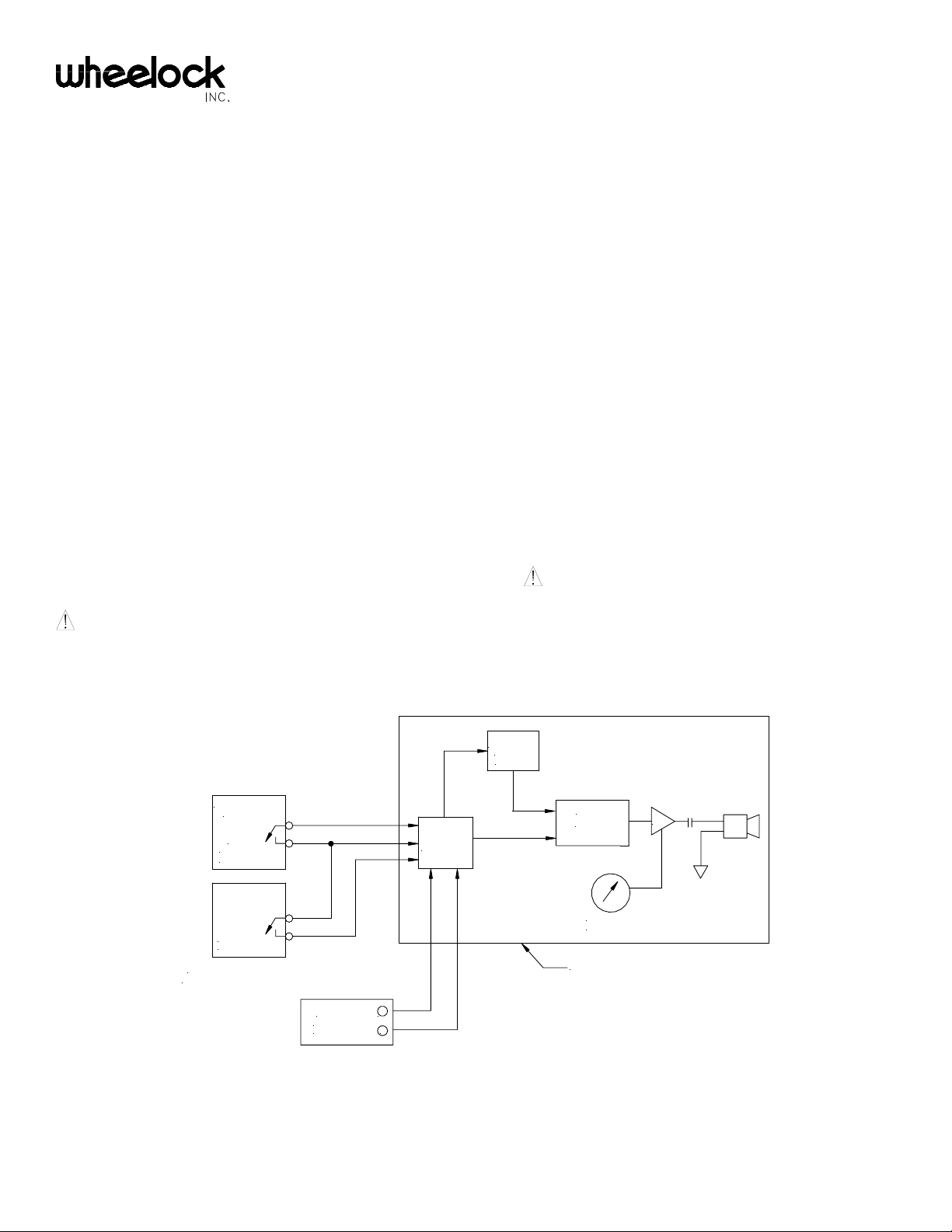

If required, the warble tone can be used as the auxiliary alert, and the priority tone can be used as the telephone alert. As shown in

Figure 1, the MTH-24 consists of dual tone generator, amplifier, timer for the warble tone, priority circuit and volume control built-in

to a weather resistant speaker horn for indoor and outdoor use. A Wheelock RPS-2406, 24VDC power supply is included to power

the MTH-24. Multiple units can be connected in parallel where required.

NOTE: All CAUTIONS and WARNINGS are identified by the symbol

. All warnings are printed in bold capital letters.

WARNING: READ THESE INSTRUCTIONS CAREFULLY. FAILURE TO COMPLY WITH ANY OF THE

FOLLOWING INSTRUCTIONS, CAUTIONS AND WARNINGS COULD RESULT IN IMPROPER APPLICATION,

INSTALLATION AND/OR OPERATION OF THESE PRODUCTS IN AN EMERGENCY SITUATION, WHICH COULD

RESULT IN PROPERTY DAMAGE, SERIOUS INJURY OR DEATH TO YOU AND/OR OTHERS.

TELEPHONE

SYSTEM

DRY

CONTACT

CLOSURE

CONTACT

CLOSURE

DOOR/SERVICE PUSHBUTTON,

TIMECLOCK OR ALARM SYSTEM

RPS-2406

POWER

SUPPLY

Figure 1: Circuit Block Diagram

Copyright 2002 Wheelock, Inc. All rights reserved.

WARBLE

TONE

TIMER

DUAL

TONE

PRIORITY

CIRCUIT

+

-

GENERATOR

VOLUME

CONTROL

MTH-24

AMP

P81543 G

Sheet 1 of 5

Page 2

Table 1 shows the sound pressure level performance of the MTH-24, and Table 2 provides a guide to horn spacing, area coverage,

and sound pressure level.

Table 1: Sound Pressure Level Performance

Sound Pressure Level (dB at 24 VDC)

Feet On

Axis

Full Power

(10 W)

1/2 Power

(5W)

1/4 Power

(2.5W)

4 115 112 109

8 109 106 103

16 103 100 97

32 97 94 91

64 91 88 85

128 85 82 79

Table 2: Horn Guide

Full Power (10W) Half Power (5W) Quarter Power (2.5W)

Noise

Level

Quiet

50-65dB

Moderate

65-75dB

*Spacing

& Distance

**SPL Area

*Spacing

& Distance

**SPL Area

N/A N/A N/A 120 Ft. 83dB 14,400 Sq. Ft. 120 Ft. 80dB 14,400 Sq. Ft.

110 Ft. 88dB 12,100 Sq. Ft. 110 Ft. 85dB 12,100 Sq. Ft. 110 Ft. 82dB 12,100 Sq. Ft.

*Spacing

& Distance

**SPL Area

90 Ft. 89dB 8,100 Sq. Ft. 90 Ft. 86dB 8,100 Sq. Ft. 90 Ft. 83dB 8,100 Sq. Ft. Noisy

75-85dB

Very Noisy

85-95dB

60 Ft. 92dB 3,600 Sq. Ft. 60 Ft. 89dB 3,600 Sq. Ft. 60 Ft. 86dB 3,600 Sq. Ft.

30 Ft. 98dB 900 Sq. Ft. 30 Ft. 95dB 900 Sq. Ft. 30 Ft. 92dB 900 Sq. Ft.

25 Ft. 100dB 600 Sq. Ft. 25 Ft. 97dB 600 Sq. Ft. 25 Ft 94dB 600 Sq. Ft

16 Ft. 103dB 250 Sq. Ft. 16 Ft. 100dB 250 Sq. Ft. 16 Ft. 97dB 250 Sq. Ft.

* Spacing between horns (side-to-side), and distance in front of horn at which a clear audible tone will be heard.

** Horn sound pressure level (SPL) should exceed the locations noise level by at least 6dB.

SPECIFICATIONS:

Table 3.

Nominal Input Voltage 24VDC

Input Voltage Range 21.6VDC TO 26.4VDC

Input Current at 24VDC with Maximum Volume 0.6A

Sound Pressure Level (On Axis at 24VDC at Full Rated Output) 117dB at 1 Meter

Contact Closure Current Requirement 0.01A

Amplifier Rated Power Output 10 Watts

Speaker Voice Coil Impedance 8 Ohms

Tone Appliances Warble and Single Tone

Operating Duty Cycle See Table 4 and Notes

Table 4: Operating Duty Cycle

Contact Closure Duty Cycle Warble Tone Priority Tone

Continuous

(Minimum 5 Seconds On)

Interrupted

1 Second On

7 Seconds Off

Follows Contact Closure

(See Notes Below)

Follows Contact Closure

(Takes Priority Over Warble Tone)

Follows Contact Closure

(Takes Priority Over Warble Tone)

NOTES:

1) A continuous closure duty cycle is defined as having a minimum "On" time of 5 seconds.

2) Maximum warble tone "on" time, during any "On-Off" cycle

tone will operate as follows:

Interrupted Closure Duty Cycle "On" Time Warble Tone Operation

1 second Follows closure

Less than 1 second Follows closure

More than 1 second (and less than 5 seconds) 1 second on

, is 1 second. For interrupted contact closure duty cycles, warble

Table 5.

P81543 G

Sheet 2 of 5

Page 3

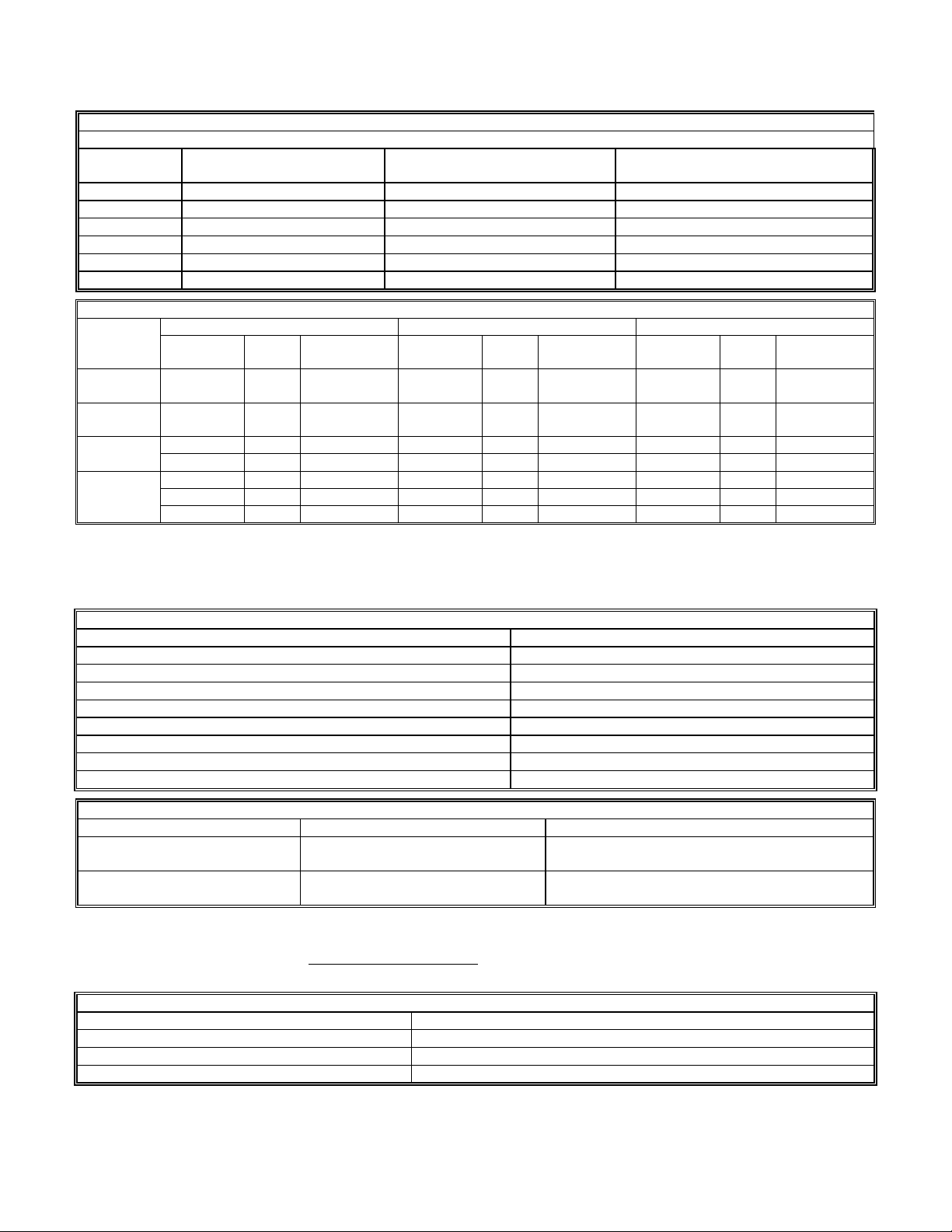

MOUNTING INFORMATION:

)

The MTH-24 may be surface mounted by simply using the holes in the swivel base to locate and drill mounting holes. The mounting

base is also fully adjustable in both the vertical and horizontal planes; See Figure 2.

HORN VIEWED

FROM REAR

TOP WING NUT

(VERTICAL ADJUSTMENT)

TO DETACH BASE FROM HORN

EMOVE TOP WING NUT AND BOLT

BOTTOM WING NUT

(HORIZONTAL ADJUSTMENT

(4) MOUNTING HOLES

Figure 2: Mounting And Adjustments

CAUTION: When removing horn from base, be careful not to lose adjusting hardware. Mount RPS-2406 Power Supply

(provided with horn) as shown on its Installation Instructions.

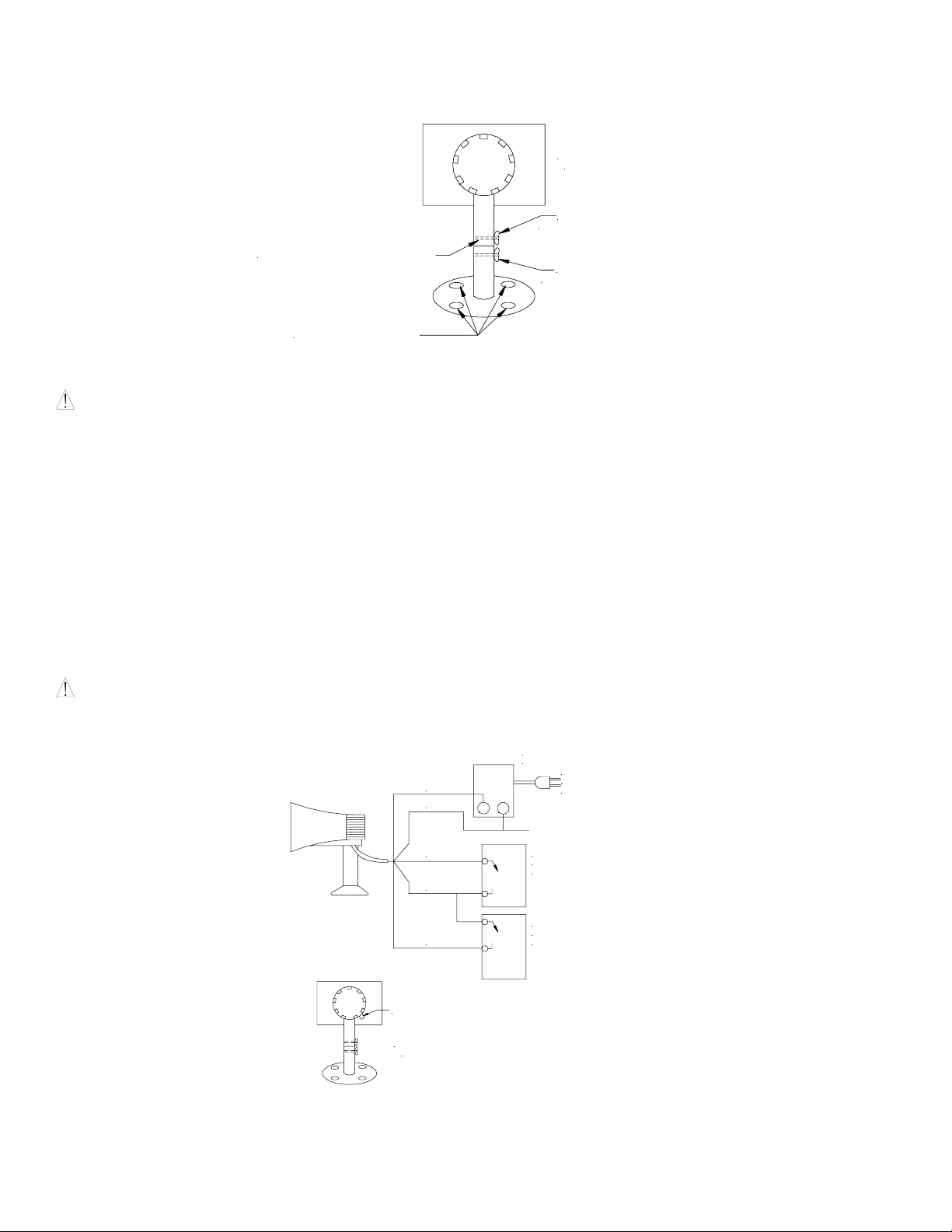

WIRING INFORMATION: (As shown in Figure 3.)

1. Connect orange and blue leads to the contact closure which will activate the warble tone.

2. Connect yellow and blue leads to the contact closure which will activate the steady priority tone.

Note: If only one tone appliance is used, then cut off and insulate unused wire (orange or yellow) to prevent shorting.

3. Be sure the power cord of the RPS-2406, 24VDC power supply is not plugged in.

4. Connect grey lead to power supply positive (+) terminal and white lead to power supply negative (-) terminal.

5. Plug the power supply cord into a 117VAC outlet.

6. Be sure volume control is turned all the way down (counter clockwise).

7. Check for operation by activating appropriate contact closures. If both tone appliances were connected, check that priority tone

takes precedence over warble tone when both are activated.

8. Adjust volume control (clockwise) to desired sound level.

CAUTION: These devices are not intended for use in hazardous locations as defined by the National Electrical Code (NEC) and

by the National Fire Protection Association (NFPA). Contact Wheelock Inc. for information on explosion-proof devices designed for

hazardous locations.

WHITE

BLACK

RPS 2406 POWER SUPPLY

(PROVIDED WITH HORN)

+

-

TO

117VAC

60 Hz.

ORANGE

BLUE

YELLOW

VOLUME CONTROL

HORN VIEWED

FROM REAR

CONTACT CLOSURE

ACTIVATES

WARBLE TONE

CONTACT CLOSURE

ACTIVATES

PRIORITY TONE

Figure 3: Wiring Diagram

P81543 G

Sheet 3 of 5

Page 4

TROUBLESHOOTING CHART:

PROBLEMS POSSIBLE CAUSE AND CORRECTION

No Sound

1) Check presence and polarity of -24VDC and GND at the unit.

2) Check connections to contact closures.

3) Check the external contact closure for continuity.

Low Volume

1) Check that volume control is turned up (clockwise).

2) Be sure at least 21.6VDC is present at the unit (white and black leads) during

operation.

CAUTION: If these appliances are operated within 15 inches of a person's ear, they can produce a sound pressure level that

exceeds the maximum 120dBA permitted by ADA and OSHA rules. Exposure to such sound levels can result in damage to a person's

hearing.

CAUTION: Check the installation instructions of the manufacturers of other equipment used in the system for any guidelines or

restrictions on wiring and/or locating Notification Appliance Circuits (NAC) and notification appliances. Some system

communication circuits and/or audio circuits, for example, may require special precautions to assure immunity from electrical noise

(e.g. audio crosstalk).

The Series MTH products and these instructions are copyrighted by Wheelock and the Series MTH products contain proprietary,

confidential and trade secrets of Wheelock. No part of the Series MTH products and these instructions may be photocopied, printed

or reproduced in any form or modified, adapted, changed or enhanced, or converted to another programming language, or used to

create updated, related or derivative works, without the prior written consent of Wheelock. No part of the Series MTH products shall

be decomposed, disassembled or reverse engineered.

ANY MATERIAL EXTRAPOLATED FROM THIS DOCUMENT OR FROM WHEELOCK MANUALS OR OTHER

DOCUMENTS DESCRIBING THE PRODUCT FOR USE IN PROMOTIONAL OR ADVERTISING CLAIMS, OR FOR

ANY OTHER USE, INCLUDING DESCRIPTION OF THE PRODUCT'S APPLICATION, OPERATION, INSTALLATION

AND TESTING IS USED AT THE SOLE RISK OF THE USER AND WHEELOCK WILL NOT HAVE ANY LIABILITY

FOR SUCH USE.

IMPORTANT: READ SEPARATE "GENERAL INFORMATION" SHEET FOR INFORMATION ON THE

PLACEMENT, LIMITATIONS, INSTALLATION, FINAL CHECKOUT, AND PERIODIC TESTING OF NOTIFICATION

APPLIANCES.

P81543 G

Sheet 4 of 5

Page 5

Limited Warranty

Wheelock products must be used within their published specifications and must be PROPERLY specified, applied, installed, operated,

maintained and operationally tested in accordance with these instructions at the time of installation and at least twice a year or more

often and in accordance with local, state and federal codes, regulations and laws. Specification, application, installation, operation,

maintenance and testing must be performed by qualified personnel for proper operation in accordance with all of the latest National

Fire Protection Association (NFPA), Underwriters' Laboratories (UL), Underwriters’ Laboratories of Canada (ULC), National

Electrical Code (NEC), Occupational Safety and Health Administration (OSHA), local, state, county, province, district, federal and

other applicable building and fire standards, guidelines, regulations, laws and codes including, but not limited to, all appendices and

amendments and the requirements of the local authority having jurisdiction (AHJ). Wheelock products when properly specified,

applied, installed, operated, maintained and operationally tested as provided above are warranted against mechanical and electrical

defects for a period of three years from date of manufacture (as determined by date code). Correction of defects by repair or

replacement shall be at Wheelock's sole discretion and shall constitute fulfillment of all obligations under this warranty. THE

FOREGOING LIMITED WARRANTY SHALL IMMEDIATELY TERMINATE IN THE EVENT ANY PART NOT FURNISHED

BY WHEELOCK IS INSTALLED IN THE PRODUCT. THE FOREGOING LIMITED WARRANTY SPECIFICALLY

EXCLUDES ANY SOFTWARE REQUIRED FOR THE OPERATION OF OR INCLUDED IN A PRODUCT. WHEELOCK

MAKES NO REPRESENTATION OR WARRANTY OF ANY OTHER KIND, EXPRESS, IMPLIED OR STATUTORY

WHETHER AS TO MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR ANY OTHER MATTER.

USERS ARE SOLELY RESPONSIBLE FOR DETERMINING WHETHER A PRODUCT IS SUITABLE FOR THE USER'S

PURPOSES, OR WHETHER IT WILL ACHIEVE THE USER'S INTENDED RESULTS. THERE IS NO WARRANTY AGAINST

DAMAGE RESULTING FROM MISAPPLICATION, IMPROPER SPECIFICATION, ABUSE, ACCIDENT OR OTHER

OPERATING CONDITIONS BEYOND WHEELOCK'S CONTROL.

SOME WHEELOCK PRODUCTS CONTAIN SOFTWARE. WITH RESPECT TO THOSE PRODUCTS, WHEELOCK DOES

NOT WARRANTY THAT THE OPERATION OF THE SOFTWARE WILL BE UNINTERRUPTED OR ERROR-FREE OR

THAT THE SOFTWARE WILL MEET ANY OTHER STANDARD OF PERFORMANCE, OR THAT THE FUNCTIONS OR

PERFORMANCE OF THE SOFTWARE WILL MEET THE USER'S REQUIREMENTS. WHEELOCK SHALL NOT BE LIABLE

FOR ANY DELAYS, BREAKDOWNS, INTERRUPTIONS, LOSS, DESTRUCTION, ALTERATION, OR OTHER PROBLEMS

IN THE USE OF A PRODUCT ARISING OUT OF OR CAUSED BY THE SOFTWARE.

THE LIABILITY OF WHEELOCK ARISING OUT OF THE SUPPLYING OF A PRODUCT, OR ITS USE, WHETHER ON

WARRANTIES, NEGLIGENCE, OR OTHERWISE, SHALL NOT IN ANY CASE EXCEED THE COST OF CORRECTING

DEFECTS AS STATED IN THE LIMITED WARRANTY AND UPON EXPIRATION OF THE WARRANTY PERIOD ALL

SUCH LIABILITY SHALL TERMINATE. WHEELOCK IS NOT LIABLE FOR LABOR COSTS INCURRED IN REMOVAL,

REINSTALLATION OR REPAIR OF THE PRODUCT BY ANYONE OTHER THAN WHEELOCK OR FOR DAMAGE OF ANY

TYPE WHATSOEVER, INCLUDING BUT NOT LIMITED TO, LOSS OF PROFIT OR INCIDENTAL OR CONSEQUENTIAL

DAMAGES. THE FOREGOING SHALL CONSTITUTE THE SOLE REMEDY OF THE PURCHASER AND THE EXCLUSIVE

LIABILITY OF WHEELOCK.

IN NO CASE WILL WHEELOCK'S LIABILITY EXCEED THE PURCHASE PRICE PAID FOR A PRODUCT.

Limitation of Liability

WHEELOCK'S LIABILITY ON ANY CLAIM OF ANY KIND, INCLUDING NEGLIGENCE AND BREACH OF WARRANTY,

FOR ANY LOSS OR DAMAGE RESULTING FROM, ARISING OUT OF, OR CONNECTED WITH THIS CONTRACT, OR

FROM THE MANUFACTURE, SALE, DELIVERY, RESALE, REPAIR OR USE OF ANY PRODUCT COVERED BY THIS

ORDER SHALL BE LIMITED TO THE PRICE APPLICABLE TO THE PRODUCT OR PART THEREOF WHICH GIVES RISE

TO THE CLAIM. WHEELOCK'S LIABILITY ON ANY CLAIM OF ANY KIND SHALL CEASE IMMEDIATELY UPON THE

INSTALLATION IN THE PRODUCT OF ANY PART NOT FURNISHED BY WHEELOCK. IN NO EVENT SHALL

WHEELOCK BE LIABLE FOR ANY CLAIM OF ANY KIND UNLESS IT IS PROVEN THAT OUR PRODUCT WAS A

DIRECT CAUSE OF SUCH CLAIM. FURTHER, IN NO EVENT, INCLUDING IN THE CASE OF A CLAIM OF

NEGLIGENCE, SHALL WHEELOCK BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES

DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE

PRECEDING LIMITATION MAY NOT APPLY TO ALL PURCHASERS.

2/02

P81543 G

Sheet 5 of 5

Loading...

Loading...