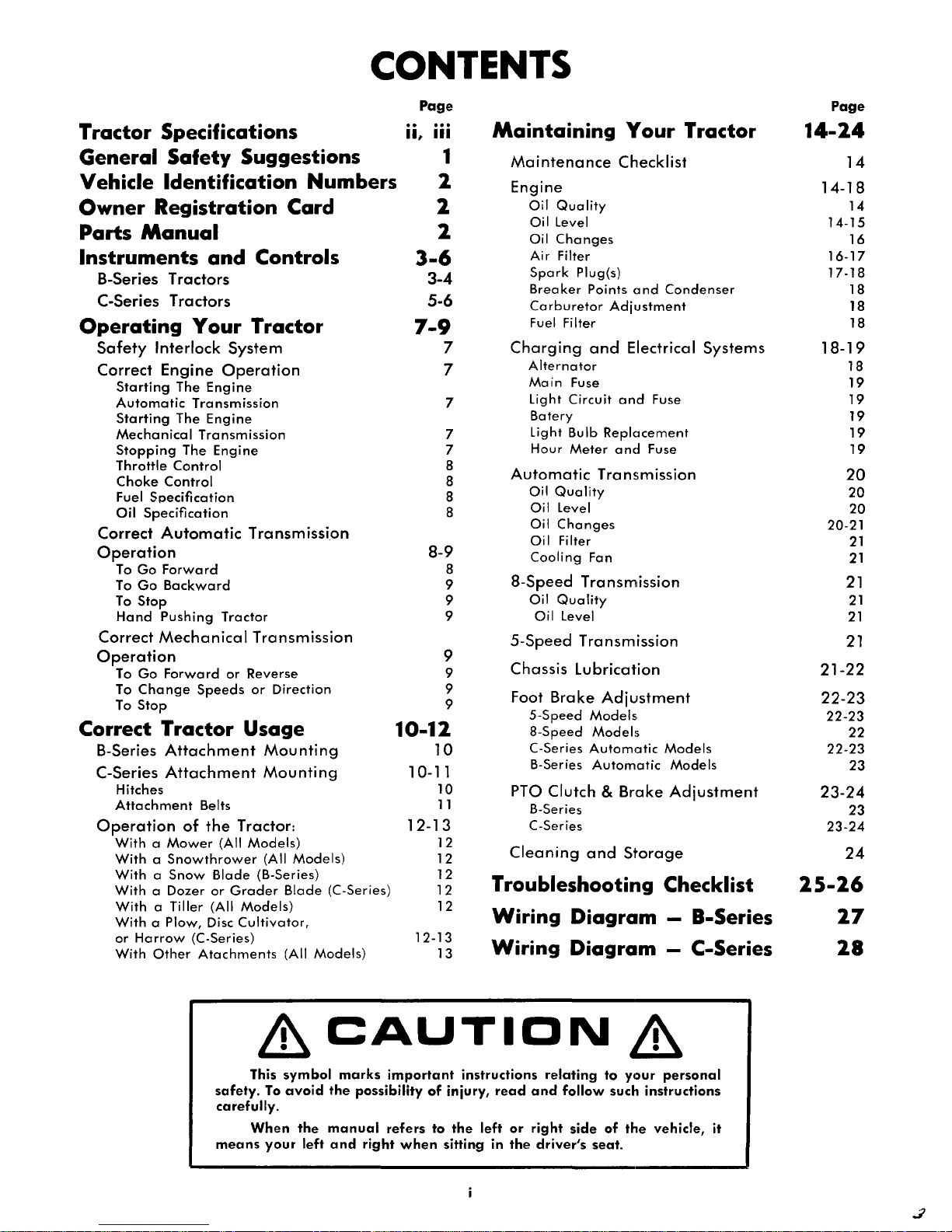

CONTENTS

Tractor

General

Vehicle

Owner

Parts

Instruments

Specifications

Safety

Identification

Registration Card

Manual

and

B-Series Tractors

C-Series Tractors

Operating

Safety

Correct

Starting

Automatic

Starting

Mechanical

Stopping

Throttle

Choke

Fuel

Oil

Specification

Correct

Your

Interlock

Engine

The

Engine

Transmission

The

Engine

Transmission

The

Control

Control

Specification

Automatic

Operation

To

Go

Forwa

rd

To

Go

Backward

To

Stop

Hand

Pushing

Correct

Mechanical

Operation

To

Go

Forward

To

Change

To

Stop

Correct

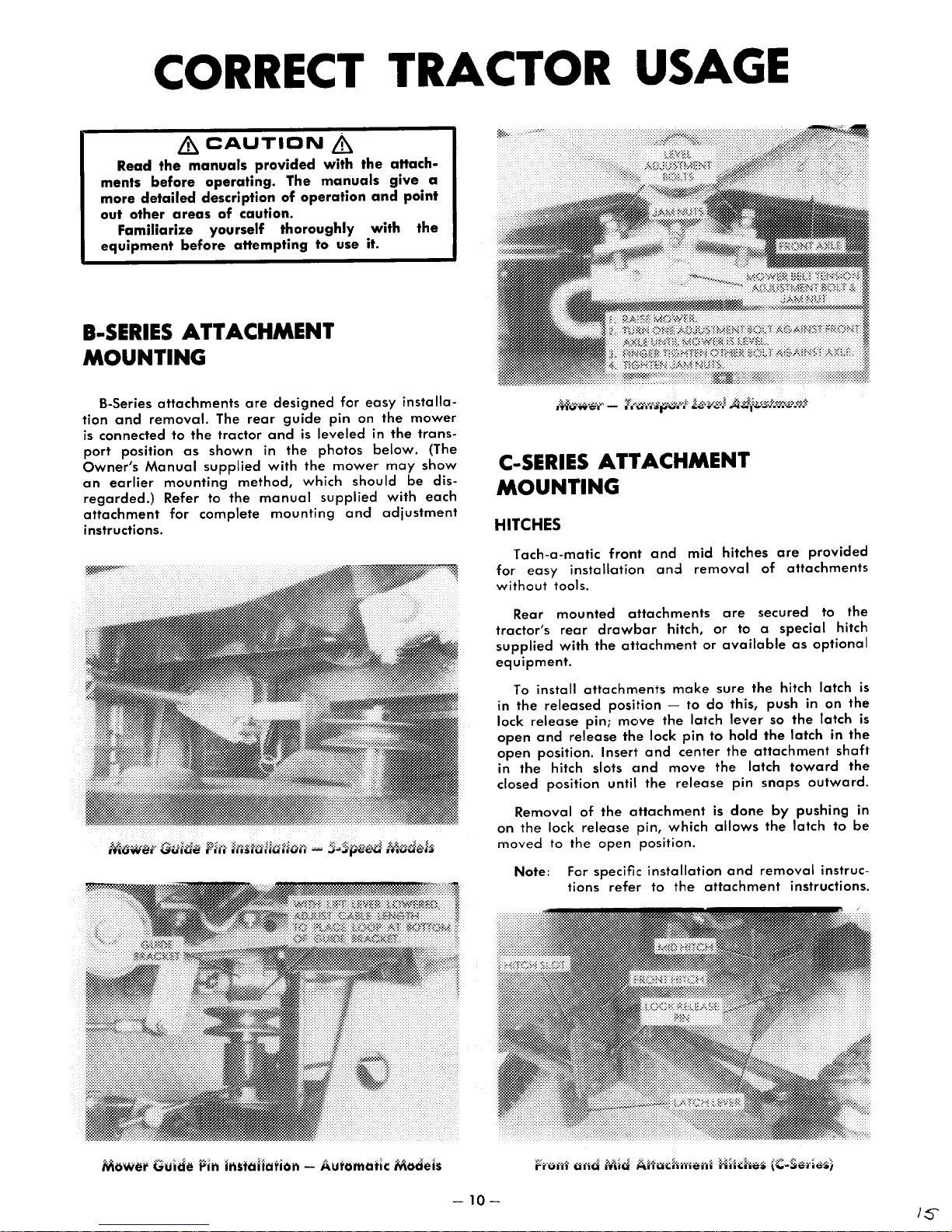

B-Series

C-Series

Hitches

Attachment

Operation

With a

With a

With a

With a Dozer

With a Tiller (All Models)

With a Plow, Disc

or

Harrow

With

Speeds

Tractor

Attachment

Attachment

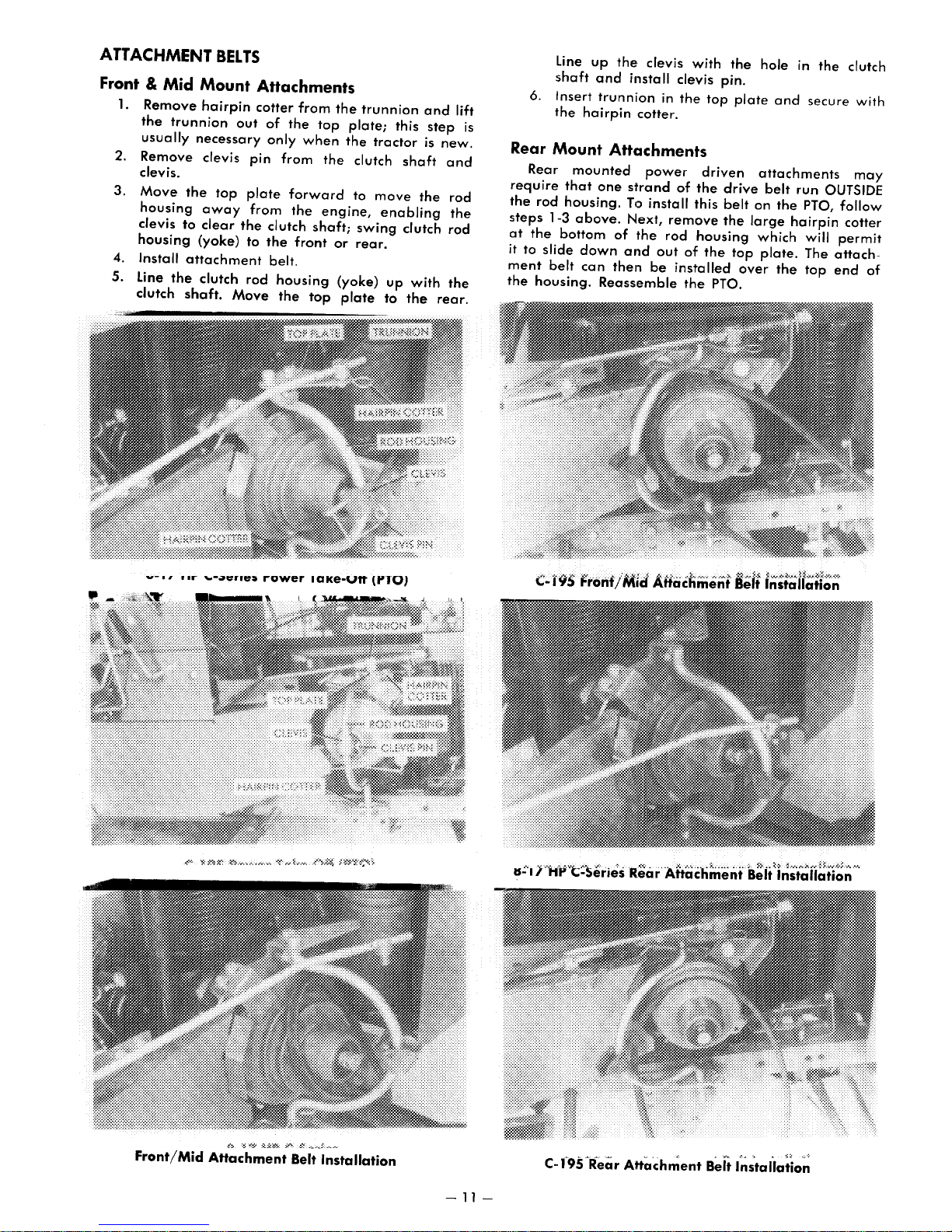

Belts

of

the

Mower

Snowthrower

Snow

or

(C-Series)

Other

Atachments

Suggestions

Controls

Tractor

System

Operation

Engine

Transmission

Tractor

Transmission

or

Reverse

or

Direction

Usage

Mounting

Mounting

Tractor:

(All

Models)

(All Models)

Blade

(B-Series)

Grader

Blade

Cultivator,

(All Models)

Numbers

(C-Series)

Page

ii, iii

1

2

2

2

3-6

3-4

5-6

7-9

7

7

7

7

7

8

8

8

8

8-9

8

9

9

9

9

9

9

9

10-12

10

10-11

10

11

12-13

12

12

12

12

12

12-13

13

Maintaining

Maintenance

Your

Checklist

Tractor

Engine

Oil

Quality

Oil Level

Changes

Oil

Air Filter

Spark

Breaker

Carburetor

Fuel Filter

Charging

Alternator

Main

Light Circuit

Batery

Light

Automatic

Oil

Oil Level

Oil

Oil Filter

Cooling

8-Speed

Oil

5-Speed

Chassis

Foot

5-Speed

8-Speed

C-Series Automcltic

B-Series

PTO

B-Series

C-Series

Cleaning

Plug(s)

Points

Adjustment

and

Fuse

and

Bu

Ib

Replclcement

Hour

Meter

and

Transmission

Quality

Changes

Fan

Transmission

Quality

Oil Level

Transmission

lubrication

Brake

Adjustment

Models

Models

Automatic

Clutch & Brake

and

Clnd

Condenser

Electrical

Fuse

Fuse

Models

Models

Adjustment

Storage

Systems

Troubleshooting Checklist

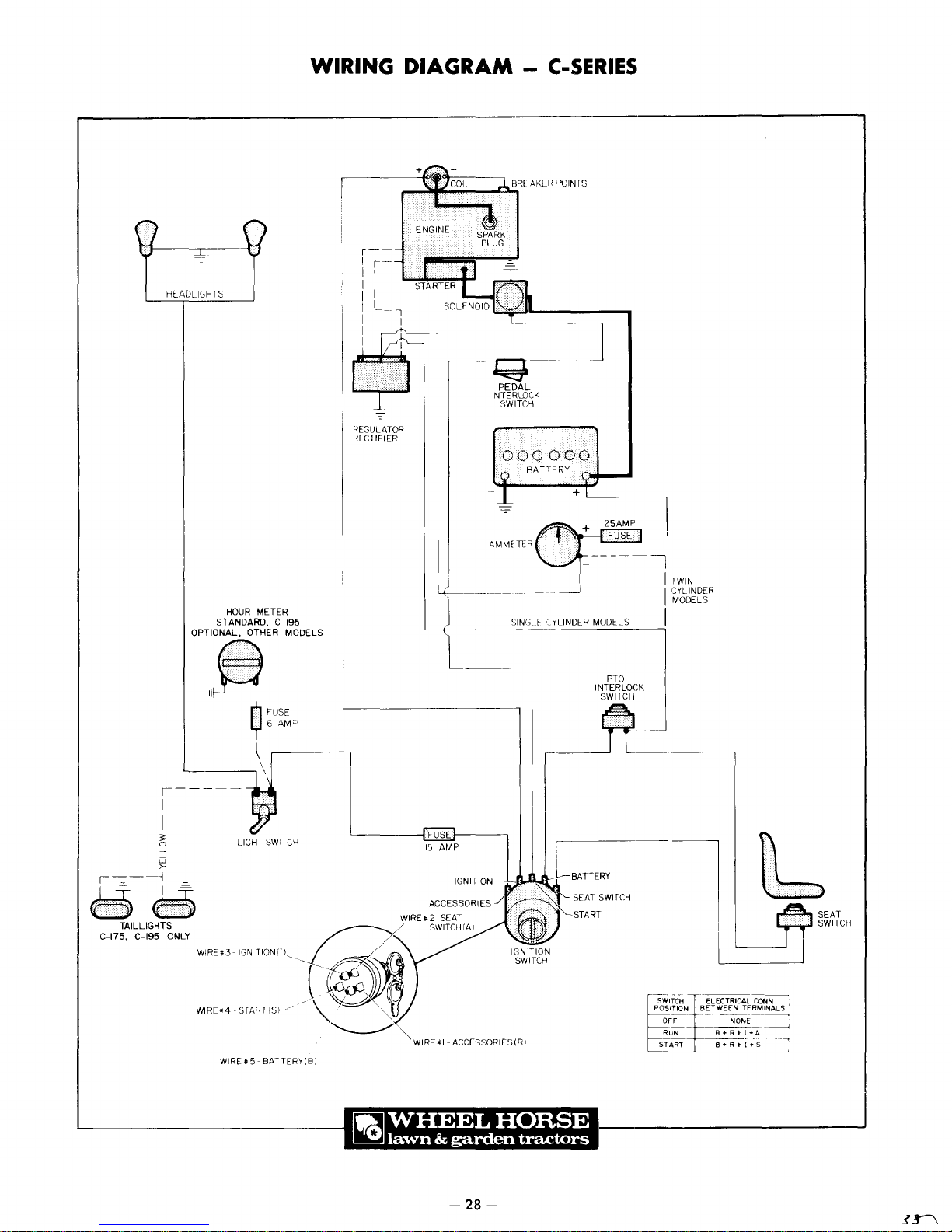

Wiring

Wiring

Diagram

Diagram

I-Series

C-Series

Page

14-24

14

14-18

14

14-15

16

16-17

17-18

18

18

18

18-19

18

19

19

19

19

19

20

20

20

20-21

21

21

21

21

21

21

21-22

22-23

22-23

22

22-23

23

23-24

23

23-24

24

25-26

27

28

&CAUTION

This

symbol

safety.

carefully.

means

To

When

your

avoid

the

left

marks

the

possibility

manual

and

right

important

of

refers

to

when

instructions

injury,

the

left

sitting

read

in

or

the

relating

and

follow

right

driver's

side

to

such

of

seat.

&

your

personal

instructions

the

vehicle,

it

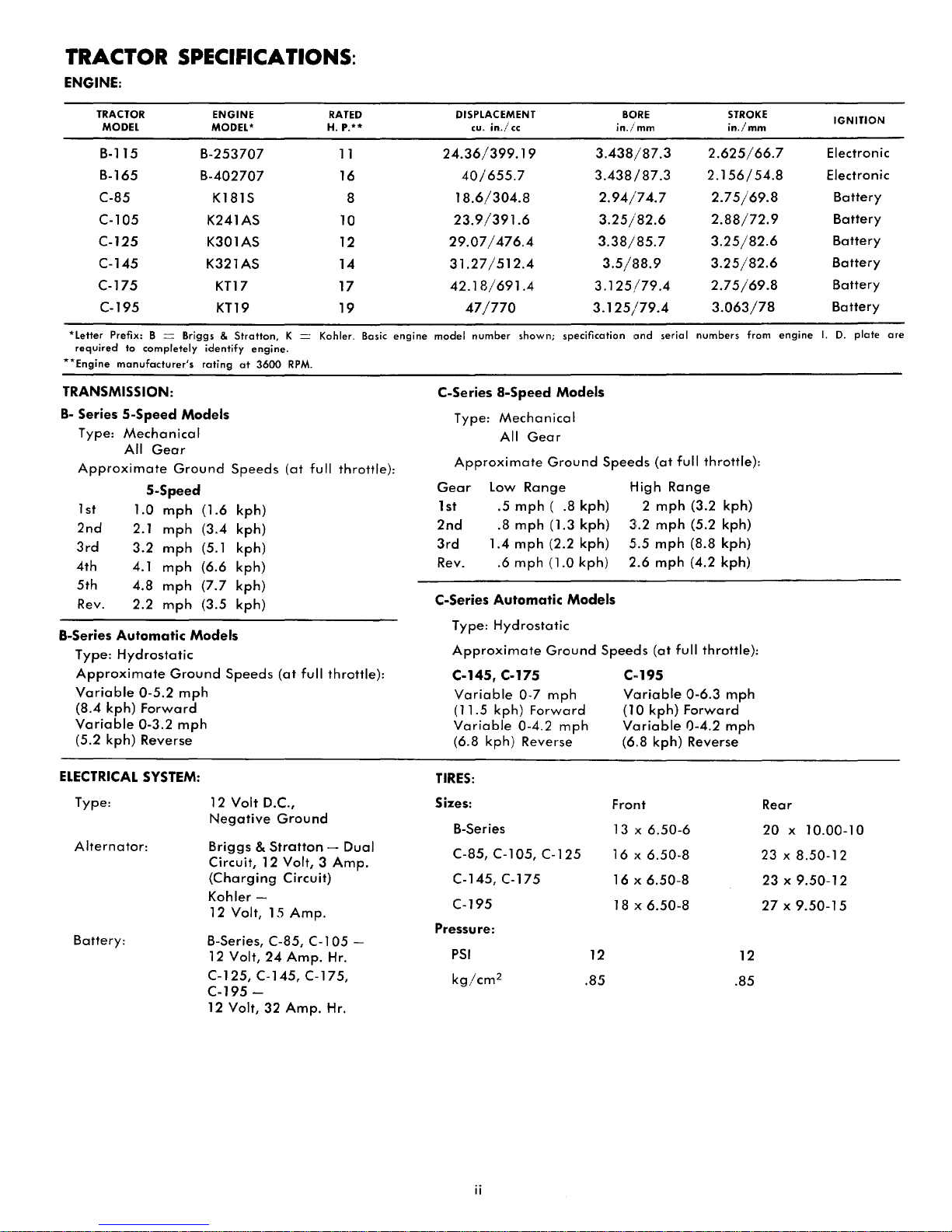

TRACTOR SPECIFICATIONS:

ENGINE:

TRACTOR

MODEL

B-115

B-165

C-85

C-I05

C-125

C-145

C-175

C-195

'Letter

Prefix: B = Briggs &

required

'*Engine

to

completely

manufacturer's

TRANSMISSION:

B-

Series

5-Speed

Type:

Mechanical

All

Gear

Approximate

5-Speed

1

st

2nd

3rd

4th

5th

1.0

2.1

3.2

4.1

4.8

Rev. 2.2

Type:

Automatic

Hydrostatic

B-Series

Approximate

Variable

(8.4 kph)

Variable

0-5.2

Forward

0-3.2

(5.2 kph) Reverse

Models

Ground

mph

mph

mph

mph

mph

mph

Models

Ground

mph

mph

ENGINE

MODEL'

B-253707

B-402707

K181S

K241AS

K301AS

K321

AS

KTl7

KTl9

Stratton,

identify

engine.

rating

at

3600

Speeds

(1.6

kph)

(3.4 kph)

(5.1 kph)

(6.6 kph)

(7.7

kph)

(3.5 kph)

Speeds

RATED

H.

P."

1 1

16

8

10

12

14

17

19

K = Kohler. Bosic

RPM.

(at

full throttle):

(at

full throttle):

engine

DISPLACEMENT

cu.

in.;'

cc

24.36/399.19

40/655.7

18.6/304.8

23.9/391.6

29.07/476.4

31.27/512.4

42.18/691.4

47/770

model

number

C-Series

Type:

shown;

a-Speed

Mechanical

All

Approximate

Gear

1st .5

2nd

3rd

Rev. .6

C-Series

Type:

Low

Range

mph

.8

mph

1.4

mph

mph

Automatic

Hydrostatic

Approximate

C-145, C-175

Variable

0-7

(11.5 kph)

Variable

0-4.2

(6.8 kph) Reverse

3.125/79.4

specification

Models

Gear

Ground

( .8 kph) 2

(1.3 kph)

(2.2 kph)

(1.0 kph)

Models

Ground

mph

Forward

mph

BClRE

in./mm

3.438/87.3

3.438/87.3

2.94/74.7

3.25/82.6

3.38/85.7

3.5/88.9

3.125/79.4

Ilnd

serial

Speeds

High

(at

Range

mph

3:.2

mph

5.5

mph

2.6

mph

Speeds

(at

full throttle):

C··195

VClriable

(10 kph)

Vcuiable

(6.8 kph) Reverse

STROKE

in./mm

2.625/66.7

2.156/54.8

2.75/69.8

2.88/72.9

3.25/82.6

3.25/82.6

2.75/69.8

3.063/78

numbers

from

full throttle):

(3.2 kph)

(5.2 kph)

(8.8 kph)

(4.2 kph)

0-6.3

mph

Forward

0-4.2

mph

engine

IGNITION

Electronic

Electronic

Battery

Battery

Battery

Battery

Battery

Battery

I.

D.

plate

are

ELECTRICAL

Type:

Alternator:

SYSTEM:

12

Volt D.C.,

Negative

Briggs &

Ground

Stratton

Circuit, 12 Volt, 3

Battery:

(Charging

Kohler

12 Volt, 15

B-Series, C-85, C-105 -

12 Volt,

-

24

Circuit)

Amp.

Amp.

C-125, C-145, C-175,

C-195

-

12 Volt,

32

Amp.

- Dual

Amp.

Hr.

Hr.

TIRES:

Sizes:

B-Series

C-85, C-l

C-145, C-175

C-195

Pressure:

PSI

kg/cm

ii

05, C-125

2

Front

13

16 x 6.50-8

16

18 x

12

.85

x

6.50-6

)(

6.50-8

6.50-8

Rear

20 x 10.00-10

23 x

8.50-12

23 x 9.50-12

27x9.50-15

12

.85

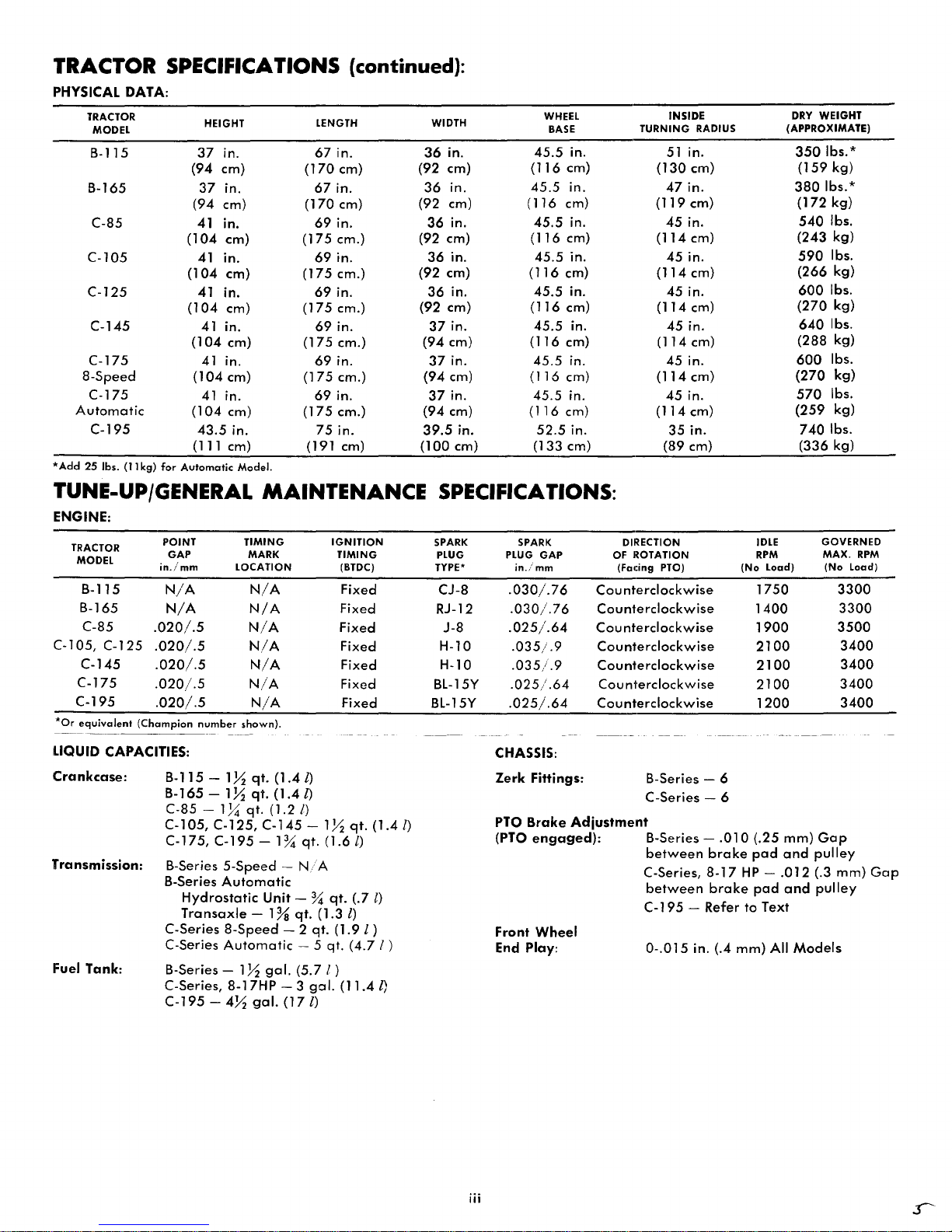

TRACTOR SPECIFICATIONS (continued):

PHYSICAL

Automatic

*Add

DATA:

TRACTOR

MODEL

B-115

B-165

C-85

C-l05

C-125

C-145

C-175

8-Speed

C-175

C-195

25

Ibs.

(11

kg)

for

HEIGHT

37

in.

(94 em)

37

in.

(94 em)

41

in.

(104

em) (175 em.)

41

in.

(104

em) (175 em.)

41

in.

(104

em) (175 em.)

41 in.

(104

em)

41

in.

(104

em)

41

in.

(104

em)

43.5

in.

(111 em)

Automatic

Model.

LENGTH WIDTH

67

(170

67

(170

69

in.

em)

in.

em)

in.

36

(92 em)

36

(92 em)

36

(92 em)

69

in.

36

(92 em)

69

in.

36

(92 em)

69

in.

(175 em.)

69

in.

(175

em.)

69

in.

(175

em.)

75

in.

(191 em)

37

(94

37

(94

37

(94 em)

39.5

(100 em) (133 em) (89 cm)

in.

in.

in.

in.

in.

in.

em)

in.

em)

in.

in.

WHEEL

BASE

45.5

in.

(116

em)

45.5

in.

(116 em)

45.5

in.

(116

em)

45.5

in.

(116

em)

45.5

in.

(116

em)

45.5

in.

(116

em)

45.5

in.

(116

cm)

45.5

in.

(116

cm)

52.5

in.

INSIDE

TURNING

51

(130

47

(119

45

(114

45

(114

45

(114

45

(114 em)

45

(114

45

(114

35

RADIUS

in.

em)

in.

em)

in.

em)

in.

em)

in.

em)

in.

in.

em)

in.

em)

in.

DRY

WEIGHT

(APPROXIMATE)

350

Ibs. *

(159

kg)

380

Ibs.*

(172

kg)

540

Ibs.

(243

kg)

590

Ibs.

(266

kg)

600

Ibs.

(270

kg)

640

Ibs.

(288

kg)

600

Ibs.

(270

kg)

570

Ibs.

(259

kg)

7401bs.

(336 kg)

TUNE-UP/GENERAL

ENGINE:

(Champion

--------

POINT

GAP

in./mm

N/A

N/A

.020/.5

.020/.5

.020/.5

.020/.5

.020/.5

B-115 - 1 X

TRACTOR

MODEL

B-115

B-165

C-85

C-l05,

C-125

C-145

C-175

C-195

*Or

equivalent

---

--~--

LIQUID

CAPACITIES:

Crankcase:

B-165 -

C-85 C-l05,

C-175, C-195

Transmission:

B-Series

B-Series

Hydrostatic

Transaxle

C-Series

C-Series

Fuel Tank: B-Series - 1 X

C-Series,

C-195 -4X

TIMING

LOCATION

number

shown).

IX

1~

C-125,

5-Speed -N/

Automatic

8-Speed

Automatic

8-17HP

MAINTENANCE

I)

- 1 X

qt.

(1.6l)

A

qt.

(1.3

qt.

- 5 qt.

(5.7 I )

gal.

IGNITION

TIMING

(BTDC)

Fixed

Fixed

Fixed

Fixed

Fixed

Fixed

Fixed

qt.

qt.

(.7 l)

I)

(1.9l)

(4.71

(11.4

(1.4

I)

MARK

N/A

N/A

N/A

N/A

N/A

N/A

N/A

qt.

(1.4

qt.

(1.41)

qt.

(1.2/)

C-145

-1%

Unit - %

- 1 %

gal.

gal.

- 2

- 3

(171)

SPECIFICATIONS:

mm)

and

and

Models

GOVERNED

MAX.

(No

Load)

3300

3300

3500

3400

3400

3400

3400

Gap

pulley

(.3

mm)

pulley

RPM

Gap

SPARK

PLUG

TYPE'

CJ-8

RJ-12

J-8

H-l0

H-l0

BL-15Y

BL-15Y

SPARK

PLUG

GAP

in./mm

.030/.76

.030/.76

.025/.64

.035/.9

.035/.9

.025/.64

.025/.64

DIRECTION IDLE

OF ROTATION

(Facing PTO)

Cou

nterclockwise

Counterclockwise

Cou

nterclockwise

Counterclockwise

Counterclockwise

Counterclockwise

Counterclockwise

(No

RPM

Load)

1750

1400

1900

2100

2100

2100

1200

CHASSIS:

Zerk

Fittings:

B-Series - 6

C-Series - 6

PTO

Brake

I)

(PTO

Front

)

End Play:

Adjustment

engaged):

Wheel

B-Series between

C-Series,

between

.010

brake

8-17

brake

C-195 - Refer

0-.015

in. (.4

(.25

pad

HP -.012

pad

to

Text

mm)

All

iii

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

Know

the

READ

THE

Do

not

allow

adults

tion.

Do

not

a

safe

distance

Clear

work

up

and

Disengage

neutral

Disengage

gine

(motor)

Disengage

gine

(motor)

justments.

Disengage

ing

or

not

Take

all

hicle

unattended;

take-off,

tral,

setting

removing

Do

not

stop

or

downhill.

slopes;

be

when

Reduce

slopes

loss

changing

Stay

which

Use

equipment.

a.

b.

c.

d.

Watch

ways.

When

charge

anyone

never

ascended,

descending.

and

of

alert

may

care

Use

only

Limit

Do

not

Use

counterweight(s)

suggested

out

using

of

controls

OWNER'S

allow

children

to

operate

carry

passengers.

away.

area

thrown.

all

attachment

before

speed a nd

near

power

before

power

before

power

in

use.

possible

lowering

parking

key.

or

Mow

across

in

control.

directions

for

holes,

cause

when

approved

loads

turn

in

for

any

material

vehicle

attempting

start

back

sharp

to

sharply.

owner's

traffic

and

MANUAL.

to

it

of

objects

to

attachments

leaving

to

attachment(s)

making

to

attachments

precautions

such

attachments,

brake,

suddenly

up

and

the

face.

up

exercise

turns

Be

especially

on

slopes.

rocks

the

vehicle

pulling

drawbar

those

you

Use

or

when

attachments

toward

while

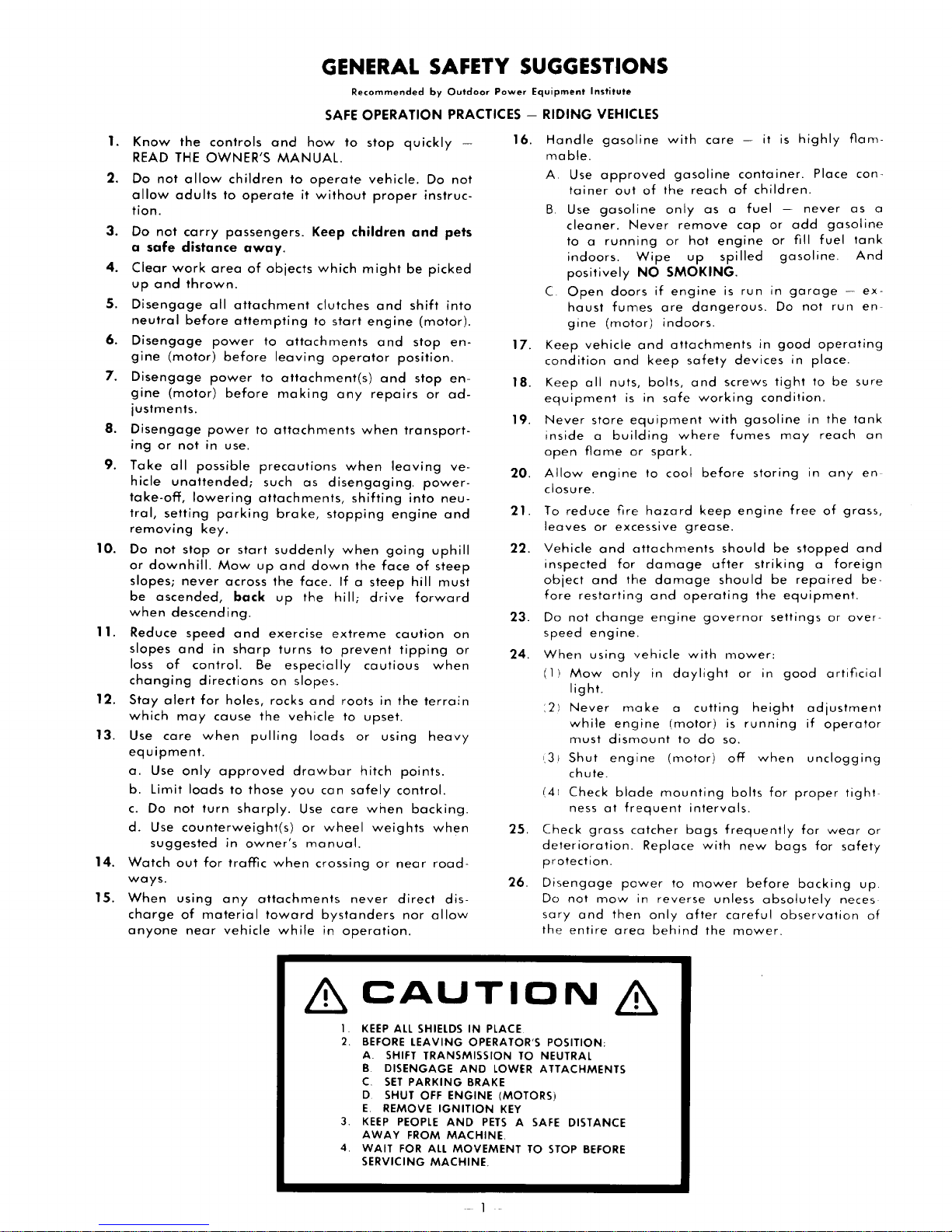

GENERAL SAFETY SUGGESTIONS

SAFE

how

operate

without

Keep

which

clutches

to

start

operator

any

as

disengaging.

stopping

when

down

If a steep

the

hill;

extreme

to

prevent

and

roots

to

loads

can

care

wheel

manual.

crossi

bystanders

in

operation.

Recommended

OPERATION

to

stop

vehicle.

proper

children

might

and

engine

and

and

repairs

when

when

shifting

the

face

drive

cautious

in

upset.

or

using

hitch

safely

when

weights

ng

or

never

by

quickly

Do

instruc-

and

be

picked

shift

(motor).

stop

position.

stop

or

transport-

leaving

power-

into

engine

going

of

hill

forward

caution

tipping

the

terrain

heavy

points.

control.

backing.

nea r road-

direct

nor

allow

Outdoor

PRACTICES -

-

not

pets

into

en-

en-

ad-

ve-

neu-

and

uphill

steep

must

on

or

when

when

dis-

Power

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

Equipment

RIDING

1.31

(41

Check

deterioration.

protection.

Disengage

Do

sary

the

Institute

VEHICLES

Handle

mabie.

A Use

B.

C

Keep

condition

Keep

equipment

Never

inside a building

open

Allow

closure.

To

leaves

Vehicle

inspected

object

fore

Do

speed

When

(1)

:2)

gasolline

approved

tainer

out

Use

gasoline

cleaner.

to a running

indoors.

positively

Open

doors

haust

fumes

gine

(motor)

vehicle

and

all

nuts,

store

flame

engine

reduce

not

Mow

light.

Never

while

must

Shut

chute.

Check

ness

not

entire

fire

or

excessive

and

for

and

restartin';J

change

engine.

using

onl)!

moke

en9ine

dismount

engine

blade

at

grass

power

mow

and

then

area

with

gasoline

of

the

only

!'-Iever

is

or

the

frequent

remove

or

Wipe

NO

SMOKING.

if

engine

are

indoors.

and

attachments

keep

bolts,

in

safe

equipment

where

spark.

to

cool

hazard

Cltlachments

damage

damage

and

engine

vehicle

in

daylight

a

(motor)

to

(motor)

mounting

catcher

Replace

to

in

reverse

only

behind

care -it

reach

as a fuel

hot

engine

up

spilled

is

dangerous.

safety

and

screws

working

with

fumes

before

keep

grease.

should

ufter

should

operating

governar

with

mower:

cutting

IS

do

so.

off

bolts

intervals.

bags

frequently

with

mower

unless

after

careful

the

container.

of

children.

cap

ar

or

run

in

Do

in

devices

tight

condition.

gasoline

storing

engine

be

striking

be

the

settings

or

in

height

running

when

for

new

bags

before

absolutely

mower.

is

highly

add

fill

gasoline.

garage .-ex·

not

good

in

may

free

stopped

repaired

equipment.

gaod

proper

for

backing

observation

flam·

Place

never

gasoline

fuel

run

operating

place.

to

be

in

the

reach

in

any

of

grass,

a

foreign

or

over·

artificial

adjustment

if

operator

unclogging

tight

wear

for

safety

neces

con·

as

tank

And

en-

sure

tank

en-

and

be·

up

a

an

or

of

&CAUTION

1

KEEP

ALL

2.

3.

4.

BEFORE

A.

B.

C.

D

E.

KEEP

AWAY

WAIT

SHIELDS

LEAVING OPERATOR'S POSITION:

SHIFT

TRANSMISSION

DISENGAGE AND

SET

PARKING

SHUT

OFF ENGINE (MOTORS)

REMOVE

PEOPLE

FROM

FOR

ALL

SERVICING MACHINE.

IN

BRAKE

IGNITION

AND

PETS A SAFE

MACHINE.

MOVEMENT

PLACE.

LOWER

KEY

TO

NEUTRAL

ATTACHMENTS

DISTANCE

TO

STOP

&

BEFORE

VEHICLE

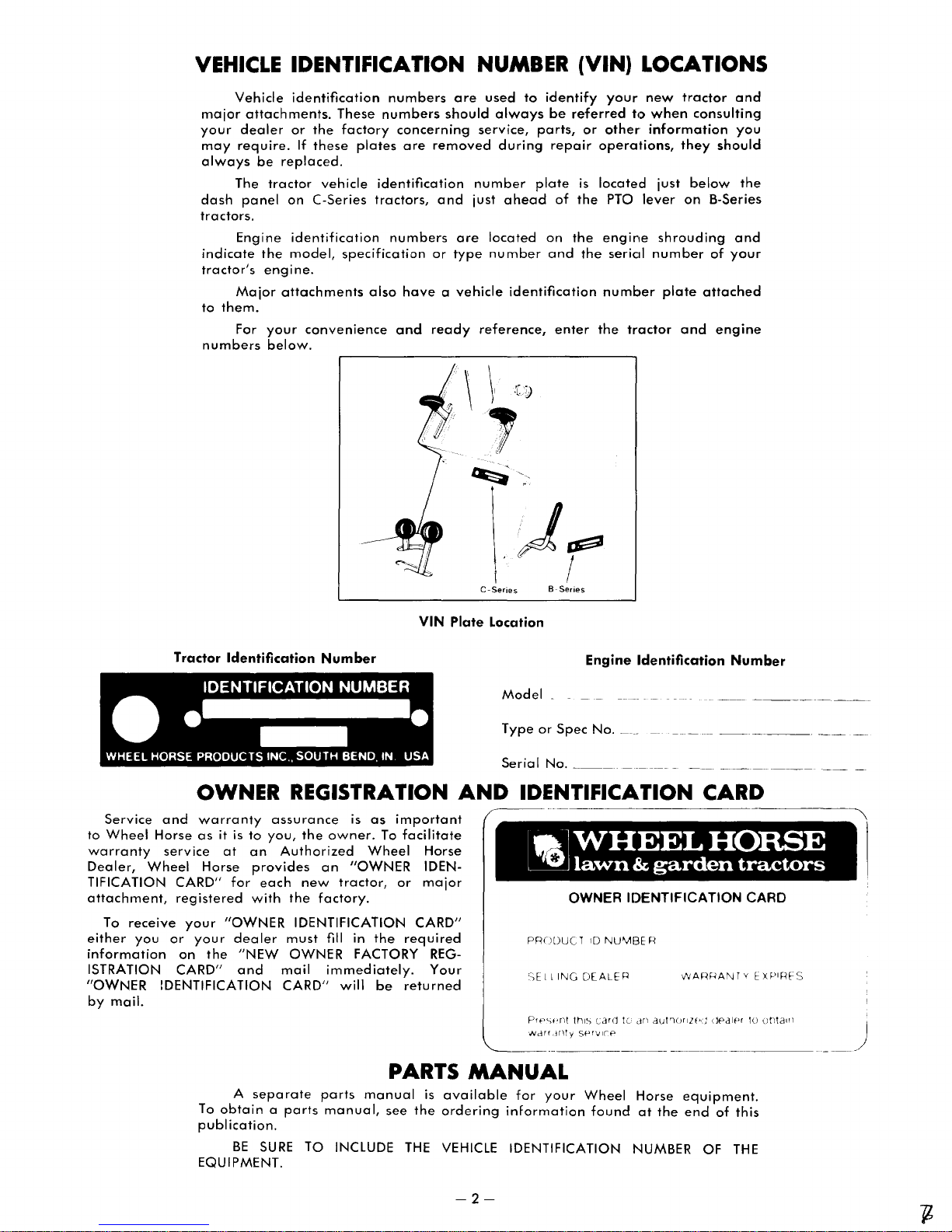

IDENTIFICATION NUMBER (VIN) LOCATIONS

Vehicle

major

your

dealer

may

require.

always

The

dash

panel

tractors.

Engine

indicate

tractor's

Major

to

them.

For

numbers

identification

attachments.

or

the

If

these

be

replaced.

tractor

on

C-Series

identification

the

model,

engine.

attachments

your

convenience

below.

These

factory

plates

vehicle

specification

also

numbers

numbers

concerning

are

removed

identification

tractors,

numbers

and

or

have a vehicle

and

ready

are

should

number

just

are

type

used

to

always

service,

during

ahead

located

number

identification

reference,

identify

be

parts,

repair

plate

of

on

and

enter

your

referred

or

other

operations,

is

located

the

PTO

the

engine

the

seriCiI

number

the

new

t,:>

when

information

just

lever

shrouding

number

plate

tractor

tractor

consulting

they

should

below

on

B-Series

of

attached

and

engine

and

you

the

and

your

Service

to

Wheel

warranty

Dealer,

TIFICATION

attachment,

To

either

information

ISTRATION

"OWNER

by

Horse

Wheel

receive

you

mail.

Tractor

Identification

Number

OWNER REGISTRATION

and

warranty

as

it

service

CARD"

registered

or

CARD"

IDENTIFICATION

your

on

at

Horse

"OWNER

your

the

is

to

an

provides

for

each

with

dealer

"NEW

and

assurance

you,

the

owner.

Authorized

an

new

tractor,

the

factory.

IDENTIFICATION

must

fill

OWNER

mail

immediately.

CARD"

will

is

Wheel

"OWNER

in

FACTORY

as

important

To

the

be

VIN

facilitate

Horse

IDEN-

or

major

CARD"

required

REGYour

returned

Plate

AND

Location

Model

Type

Serial

Engine

or

Spec

No.

___________________

No.

Identification

__

_

IDENTIFICATION CARD

lalWHEEL

~

lawn & garden

OWNER IDENTIFICATION CARD

PRODUCT

C,E

PfI-·'").·nt

Wdrr

I

liNG

,H~ty

10

DEALE

thl~

card

SPr-,/I('P

NU'V113E

R

te-

R

drl

autr")()rllf"U

Number

_

HORSE

tractors

dpdlpr

tu

tJt)talfl

)

A

separate

To

obtain a parts

publication.

BE

SURE

EQUIPMENT.

TO INCLUDE

parts

manual,

PARTS

manual

see

the

THE

MANUAL

is

available

ordering

VEHICLE

-2-

for

your

Wheel

information

IDENTIFICATION

found

Horse

NUMBER OF THE

at

equipment.

the

end

of

this

INSTRUMENTS

AND

CONTROLS

B-SERIES

TRACTORS

S-SPEED

2

/

/

~

5

MODELS

10

AUTOMATIC

-3-

MODELS

1. THROnLE CONTROL

The

the

Raise

to

start

2.

The

dash

tien

after

been

start

throttle

dash

the

the

CHOKE

choke

panel.

when

the

running,

it.

panel.

lever

engine.

control

Raise

starting

engine

control

to

is

This

operate

CONTROL

is

located

the

choke

the

engine.

starts.

choking

If

3. IGNITION SWITCH

The

ignition

the

dash

tion

switch

(1) Off, (2) Run, (3)

key

all

the

the

engine

the

Run

engine

off.

the

brake

and

engage,

therefore,

pesition

seat

switch

seat,

and

brake

back

brake

foot

and

foot

6.

tractor.

Note:

clutch

transmission

7.

tractor.

things:

necting

ates a safety

operate.

stops

4.

PTO

The

PTa

tractor,

pedal.

disengaged

To

engage

pull

The

PTa

before

is

vacated

will

5.

PARKING

The

parking

to

to

the

ToO

engage

solidly

(Automatic)

On.

To

release

brake.

will

brake

BRAKE

The

brake

Pushing

When

pedal

CLUTCH

The clutch

Pushing

(1)

the

Engaging

switch

panel,

has

way

starts

position.

and

above

three

Start.

to

the

and

When

all

is

it will

electrical

(POWER TAKE-OFF)

clutch

lever

is

between

Power

the

the

lever

the

autematically

the

driven

with

the

PTa,

lever

back.

actuates a safety

PTa

lever

the

engine

while

the

BRAKE

brake

the

right

left

on

the

and

the

The

return

is

applied.

PEDAL

pedal

coming

as

will

PEDAL

pedal

Declutches

engine

interleck

lever

on

manual

automatic

parking

then

move

or

forward

parking

parking

toO

the

disengaged

(5-Speed Models)

is

lecated

down

en

to a stop

well

as

be

disconnected

(5-Speed Models)

is

located

down

on

the

frem

the

clutch

located

lever

controls

the

lever

the

engine

may

net

located

the

throttle

positions

To

start

right.

automatically

the

switch

located

parking

attachments

PTa

push

lever

must

will

PTa

shut

LEVER

is

lecated

transmissien

brake,

the

brake,

brake

at

the

pedal

the

brake

at

the

clutch

tractor

the

transmission;

switch,

is

on

the

tractor;

on

Siewly

Release

accessories

the

to

be

en

control.

from

the

is

lower

left

lower

is

necessary

the

engine,

turned

CLUTCH

on

the

brake

lever.

forward.

interlock

be

in

the

start.

If

is

engaged,

off

the

engine.

in

transmission

first

apply

parking

(5-Speed)

push

lever

is

spring

pesition

the

right

applies

always

pedal

from

the

left

pedal

drive

so

the

doOne

by

right

engine

the

side

the

Cold

the

warm

right

The

left

to

the

key

return

are

LEVER

right

lever

are

engaged

disengaged

the

operator's

front

tractors,

tractors.

the

brake

toO

leck

dewn

when

side

the

depress

so

that

the

side

dees

belt,

(2) Actu-

starter

releasing

side

speed.

lever

of

the

posilever

and

has

toO

re-

side

igni-

right:

turn

the

when

off,

the

turned

side

and

the

To

dis-

switch;

a

seat

of

the

foot

lever

the

on

the

loaded

the

ef

the

brake.

the

the

engine.

of

the

two

discon-

will

the

of

of

to

of

pedal

the

depress

or

pedal

out

which

slowly

the

of

gear

tightens

pedal

and

the

when

when

when

8. BRAKE/RETURN

(Automatic Models)

The

brake

tractor,

through

pedal

is

tral.

When

mechanical

ing

action.

the

engine,

switch,

9.

GEAR

The

gear

seat.

Select

the

lever

tern

decal.

pedal,

provides

the

automatic

depressed,

the

brake

The

as

allowing

SHIFT

shift

any

to

the

dynamic

the

brake

is

pedal

the

the

lever

forward

pesition

located

transmission

also

must

pedal

starter

LEVER

is

10. MOTION CONTROL

(Automatic Models)

The

motion

steering

meved

right

and

control

control

independent

speed,

power

left

and

pull

lever

move

by

wheel.

and

ahead

back

lever

moving

contrcil

right

to

to

varies

of

lever

The,

in

to

go

reverse.

neutral

ground

engine

away

lever

lever

motion

the

11. TRANSMISSION

(Automatic Models)

The

transmission

of

the

seat

disconnects

the

lever

down

missien.

transmission.

Always

starting

12.

The

steering

the

attachments

tachments

13.

The

dash

toggle

eff.

ning.

14.

The

the

epen,

necessary.

Push

the

LIFT

manual

wheel.

lever

LIGHT

light

panel,

to

turn

The lights will

FUEL

fuel

fuel

tank.

except

to

the

disengage

engine

LEVER

ferward

used

before

switch

above

shut-off

when

clutch

the

right.

engiine

and

to

the

the

lever

the

in cold

lift

lever

Depress

or

with

lelJving

SWITCH

is.

located

the

choke

lights

on.

work

SHUT-OFF

valve

The

fuel

se·rvice

backward

the

Lower

shut-eff

drive

belt.

Always

engaging

shifting

starting

TO

braking

transmission.

pedal

appled

be

actuates a safety

the

the

transmission

the

NEUTRAL

at

the

to

beth

is

is

fully

for

additional

depressed

to

operate.

clutch.

engine.

PEDAL

left

side

rear

As

shifted

depressed,

when

the

(5-Speed Models)

lecated

speed

indicated

or

just in

reverse

en

the

front

by

shift

LEVER

is

located

control

neutral

ferward.

The

brake

fer

dynamic

speed

speed.

from

neutral.

toward

CLUTCH

lever

is

The

tra

from

the

left

to

to

the

transmission

weather.

is

lecated

the

release

tractor.

the

tracter

on

contrel.

the

enly

while

nsmission

just

lever

slot.

Push

Move

the

pedal

braking.

and

pulling

To

increase

Increase

neutral.

LEVER

located

transmission.

disconnect

right

to

clutch

just left

button

to

lower

Always

unattended.

the

left

Raise

teggle

toO

the

engine

below

lever

moves

just

clutch

the

engage

and

lower

side

the

turn

VALVE (Not Shown)

is

located

on

the

valve

fuel

at

the

is

system

bettem

normally

becomes

release

Always

into

of

the

wheels

brake

toO

neu-

brak-

starting

interlock

ef

the

meving

pat-

the

may

the

lever

left

the

The

power

ground

pulling

in

frent

lever

Push

trans-

the

when

of

the

move

er

raise

at-

ef

the

switch

lights

is

run-

of

left

a

be

-4-

INSTRUMENTS

AND

CONTROLS

8-SPEED

C-SERIES

16

MODELS

16

TRACTORS

1.

AMMETER

The

ammeter

the

right

of

7

gauge

ing

4

charged

2. THROnLE

The

the

dash

the

lever

to

start

3.

CHOKE

The

dash

panel.

when

starting

the

engine

running,

the

indicating

(+)

throttle

panel.

fully

the

engine

choke

control

Raise

starts.

choking

is

located

steering

the

rate

or

discharged

CONTROL

control

This

lever

to

operate

..

CONTROL

is

the

choke

the

engine.

Ii:

the

may

on

column.

at

is

located

controls

the

located

Slowly

engine

not

be

the

which

(-).

on

tractor;

on

lever

lower

is

warm

necessary

dash

The

the

the

engine

lower

the

left

to

the

panel,

ammeter

battery

right

speed.

the

side

Cold

the

lever

and

has

to

restart

just to

is

is

be-

side

of

Raise

lever

of

the

position

after

been

it.

a

C-195 AUTOMATIC MODEL

16

C-145, C-175 AUTOMATIC MODELS

10

4.

BRAKE

The

brake

tractor.

Note:

clutch

transmission

tractor.

things:

necting

a

Engaging

which

pedal

depress

or

Pushing

When

pedal

5.

CLUTCH

The

cI

Pushing

(1)

the

safety

tightens

slowly

the

out

of

6.

BRAKE/RETURN

pedal

coming

as

will

utch

peda I is

Declutches

engine

interlock

the

pedal

gear

PEDAL

clutc:h

(Automatic Models)

The

brake

tractor,

through

pedal

is

tral.

When

mechanical

ing

action.

the

engine,

interlock

pedal,

provides

the

automatic

depressed,

the

brake

The

as

switch,

is

down

well

be

PEDAL

down

from

switch,

thEl

when

when

and

when

d)rnamic

the

brake

is

pedal

the

allowing

(S-Speed Models)

located

on

to a stop

as

disconnected

the

the

at

pedal

brake

the

applies

always

pedal

from

(S-Speed Models)

located

on

the

is

done

drive

engaging

located

transmission

also

must

pedal

at

the

the

clutch

tractor

the

so

belt.

shifting

starting

TO

braking

transmission.

pedal

applied

be

linkage

the

drive

transmission;

the

starter

by

releasing

Always

the

the

NEUTRAL

at

the

to

is

fully

for

depressed

starter

the

actuates a safety

right

side

the

depress

so

that

the

engine.

left

side

pedal

does

belt,

discon-

(2)

Actuates

will

operate.

the

release

clutch.

transmission

engine.

Always

PEDAL

left

side

both

rear

As

is

shifted

additional

when

to

wheels

the

to

depressed,

starting

operate.

of

the

brake.

the

the

of

the

two

pedal

the

into

of

the

brake

neu-

brak-

a

-5-

7.

PTO

(POWER

The

PTO clutch

the

tractor.

and

disengaged

forward

back

lever

circuit;

lever

seat

switch

S.

The

seat.

moving

shift

9.

The

just

or

position

range

pulling

three

mid-point

with

to

to

disengage

actuates a safety

therefore,

is in

the

is

vacated

will

GEAR

gear

Select

any

the

pattern

RANGE

range

forward

low

range

indicated

provides

power

forward

position

the

gear

10. MOTION

lever

Power

engage

automatically

driven

with

the

disengaged

while

SHIFT

shift

lever

of

three

lever

to

decal.

SELECTOR

selector

of

the

gear

by

moving

on

a 4

for

moving

speeds

for

shift

lever.

CONTROL

(Automatic Models)

The

steering

tractor

the

brake

tion

ground

pendent

move

by

is

ceptible

neutral.

motion

forward.

lever

pedal

for

lever

moving

provided

11. PARKING

The

To

To

parking

to

the

engage

solidly

to

release

brake.

return

is

seat

brake

back

foot

will

brake

control

wheel.

to

the

moves

dynamic

speed

and

of

engine

away

lever

with a detent

feel'

as

brake

left.

the

and

lock

the

the

The

to

the

applied.

Push

Pull

neutral

braking.

pulling

speed.

from

toward

the

BRAKE

parking

then

brake

parking

parking

disengaged

12. TRANSMISSION

(Automatic Models)

The

the

seat

clutch

transmission

and

the

lever

disconnects

clutch

motion

TAKE-OFF)

is

located

attachments

the

PTO

the

attachment.

the

attachment.

interlock

tractor

position.

the

PTO

shut

LEVER

(S-Speed Models)

is

located

forward

the

position

(S-Speed Models)

is

located

shift

the

the

range

to 1 speed

heavy

and

neutral;

lever

is

the

lever

the

lever

(center)

the

lever

The

power

To

neutral.

neutral.

type

control

LEVER

lever

is

brake,

move

On.

brake,

lever

CLUTCH

lever

control

the

engine

on

lever.

switch

will

not

is

off

just

speeds

in

lever.

lever

selector

reduction

loads

reverse.

neutral

LEVER

located

ahead

back

position

to

control

of

increase

Increase

The

stop

lever

located

first

the

parking

push

is

spring

position

is

lever.

CLUTCH

the

right

are

Push

Pull

The

in

start

If

the

engaged,

the

engine.

in

front

or

indicated

front

of

Select

either

right

or

decal.

and

in

each

Do

not

must

just

right

to

for

reverse.

to

the

neutral

lever

the

tractor

ground

pulling

neutral

to

give a 'per-

passes

in

front

apply

brake

down

loaded

when

LEVER

located

The

transmission

from

LEVER

side

engaged

the

lever

the

lever

PTO

clutch

the

starter

unless

operator's

a

of

reverse

on

the

seat,

high

left

to

greater

of

use

be

selected

of

drive

Move

stop.

posi-

varies

inde-

speed,

power

position

through

of

the

foot

lever

on

and

the

foot

between

the

trans-

of

this

seat

the

by

the

the

low

the

a

the

the

The

the

the

mIssIon. Pull

connect

Push

transmission.

Always

the

engine

the

the

transmission.

the

lever

disengage

in cold

13. MANUAL

The

manual

steering

the

attachments

to

ground,

be

knob

desired

leaving

14.

just

and

on

Pull

to

to

an

down.

tractor

trolling

lower

a

II

This

and

15.

dash

to

work

position.

wheel.

lever

hold

an

the

limited

right

position.

the

HYDRAULIC

On

C-195

below

C-175

the

lower

the

lever

hold

attachment

lower

attachment

Always

unattended.

The

C-195

the

optration

the

way

permits a rear

down

LIGHT

The

light

panel,

turn

on

only

lift Ilever

Depress

forward

used

attachment

forward

by

the

or

left

tractor

models,

the

left

models

dash

back

attachment.

at

lower

is

also

optional

described

forward

freely

SWITCH

switch

just

above

lights.

when

16. IGNITION

The

ignition

the

dash

ignition

(1) Off, (2) Run, (3)

key

engine

Run

engine

off.

17.

column

ating

lS.

the

open,

comes

switch

all

the

starts

position.

stops

HOUR

The

hour

and

time

FUEL

The fuel

fuel

tank.

except

necessary.

switch

panel,

has

way

to

and

When

and

METER

meter

is a convenient

between

SHUT-OFF

shut-off

The

when

lever

up

forward

the

transmission

weather.

LIFT

(S-Speed Models)

is

the

lor

backward

with

the

at a certain

(down)

Dial-A-Hite

until

the

AI:ways

unattended.

LIFT

the

hydraulic

front

corner

the

hydraulic

panel,

to

lift

in

position.

The

any

position

attachments

equipped

3-point

above,

it will lock in a

mounted

during

lower

is

the

use.

located

the

toggle

ignition

SWITCH

is

located

just

above

three

positions

Start.

To

the

right.

it will

all

automatically

the

switch

electrical

(C·195 Only)

is

located

maintenance

VALVE (Not Shown)

valve

is

fuel

shut-off

service

and

to

the

rear

to

and

down

to

engage

when

starting

located

release

tractor.

travel

selector.

lift

lower

just

button

to

lower

When

it is

height

of

the

Turn

lever

is

attachments

left

and

or

desired

above

lever

the

held

(Automatic Models)

lift

lever

is

located

of

the

seat.

On

lift

lever

is

located

below

attachment.

neutral

choke

start

Release

to

located

the

Push

position

from

before

with a lever

hitch.

if

the

attachment

on

the

control.

to

turn

switch

on

the

the

throttle

from

the

the

is

accessorie<;

the

left

way

to

periods.

at

valve

on

the

choke

Release

lever

will

full

up

leaving

Beside

lever

is

"float"

to

left

side

Raise

lights

off.

is

in

right

control.

left

engine,

key

when

return

turned

are

of

the

determine

the

bottom

is

normally

fuel

system

control.

forward

to

for

the

pushed

posision.

move

the

side

to

turn

off,

turned

steering

dis-

the

of

the

move

raise

the

can

hand

in

the

before

C-145

lever

hold

full

the

con-

lift/

up

of

the

toggle

lights

Run

of

The

right:

the

the

to

the

the

oper-

of

left

be-

-6-

I(

OPERATING YOUR TRACTOR

SAFETY INTERLOCK SYSTEM

The

safety

switches,

The

left

will

and

not

The

switch

seat

two

foot

not

the

start

tractor

shuts

while

for

pedal

start,

left

unless

CORRECT

Before

with

all

thoroughly.

before

oil

level

starting.

safe

starting

and

check

foot

is

also

off

the

PTO

interlock

starting.

the

that

pedal

both

equipped

the

switches

PTO clutch

the

is

switches

engine

is

engaged.

system

are

control.

PTO

clutch

depressed.

are

with a seat

if

the

driver

properly

ENGINE OPERATION

&

CAUTION

starting

controls.

starting.

(automatic

Always

Always

the

engine,

Read

this

check

transmission

the

check

become

owner's

engine

the

incorporates

actuated

If

is

disengaged,

The

engine

switch.

rises

&

transmission

models)

by

the

tractor

actuated.

off

familiar

manual

oil

level

before

two

the

will

This

the

Once

the

control

at

choke

reaches

be

up

"Correct

placing

low

should

When

sure

the

to

speeds,

normal

starting

to

engine

Automatic:

the

STARTING

engine

its

follow

tractor

normal

be

and

THE

has

started,

or

hesitates

applied

operating

IIhe

the

special

the

transmission

Transmission

into

ENGINE

position.

during

as

necessary

temperature.

engine

procedures

operation.

slowly

If

the

during

as

Operation",

Mechanical Transmission Models

Because

new

is

depressed

To

disengage

about

choke

Wheel

start

half

control

of

a buiilt·in

Horse will

and

the

the

engine

the

PTO.

way

to

all

the

not

PTO

depress

Move

the

way

safety

start

is

disengaged.

the

Operate

to

the

interlock

until

the

clutch

throttle

position.

Cold position.

return

the

engine

acceleration,

until

the

engine

cold

weather,

for

warming

described

before

system,

the

clutch

pedal

control

Move

choke

stalls

the

under

your

pedal

and

lever

the

Care

haust

gases

gas

which

monoxide

unconsciousness

Do

not

as a closed

STARTING

Automatic

Because

new

Wheel

is

depressed

To

start

disengage

about

choke

engages.

The

Run

half

control

Turn

switch

position

If

of

continuous

Off

position

for

one

consult

the

When

the

minute.

the

WARNING &

should

as

is

is a

run

garage.

THE

be

taken

they

colorless

dangerous

and

the

engine

ENGINE

to

contain

and

is

potentially

in

gas

confined

Transmission Models

of a built·in

Horse will not

and

the

engine

the

PTO.

way

to

all

the

ignition

the

is

spring

automatically.

engine

and

Troubleshooting

safety

the

PTO

depress

Move

the

Operate

way

key

engine

loaded

fails

to

cranking,

allow

Check

for

interlock

start

is

disengaged.

the

the

to

the

clockwise

starts,

and

start

turn

the

starter

cause

Checklist.

avoid

carbon

odorless.

that

until

the

brake

throttle

position.

Cold

until

release

will

after

the

motor

of

hard

inhaling

monoxide

can

lethal.

areas

system,

brake

pedal

control

Start

the

return

10

seconds

key

starting;

ex·

Carbon

cause

such

pedal

lever

Move

position.

starter

the

to

to

the

to

cool

your

and

the

key.

the

Always

in

the

start

the

Turn

the

engages.

switch

The

Run

position

If

the

of

continuous

Off

position

cool

for

starting;

Once

the

control

low

should

reaches

to

speeds,

be

normal

STOPPING

To

stop

Idle

position

position.

the

time

to cool

If

engine

before

the

&CAUTION

place

the

neutral

engine.

ignition

When

its

the

the

is

sprin9

automl::ltically.

engine

cranking,

anell

one

minute.

consult

engine

or

applied

is

engine

normal

hesitcltes

operating

THE

ENGINE

engine,

and

the

engine

hot, cdlow

turning

has

tlJrn

before

transmission

position

key

clockwise

engine

loaded

fails

to

start

allow

Check

the

Troubleshooting

started,

position.

during

as

necessary

temperature.

return

the

has

the

Ilhe

key

off. This

stopping.

&

gear

before

starts,

and

turn

the

the

ignition

been

attempting

until

release

will

after

the

starter

for

cause

slowly

If

the

acceleration,

until

throttle

working

engine

practice

shift

the

return

10

seconds

key

to

motor

of

Checklist.

return

the

engine

the

the

lever

key

to

hard,

to

idle a short

lever

starter

the

to

the

hard

choke

stalls

choke

engine

to

the

will

to

key.

the

to

at

the

Off

or

help

-7-

Note:

stopped

brake

if

don't

opportunity

In

by

Always

when

for

just a

give

THROTTLE

The

engine

This control

speed

designed

mum

the

and

Always

set

throttle

as

measured

of

the

The

engine

with a special

RPM.

engine

protects

operate

at % to

The

engine

of % throttle

Using

the

at

less

than % throttle

transmission

well

as

models.

case

of

turning

the

&CAUTION

remove

leaving

few

children

to

operate

CONTROL

control

should

Unlike

to

poor

tractor.

in

operate

it

from

the

full

speed.

MUST

tractor

damage

overall

not

your

an

damage

whenever

emergency,

ignition

the

the

minutes.

or

regulates

in

RPM

be

new

automobile,

most efficiently

tractor

be

while

tractor

key

key

and

tractor

unauthorized

this

machine.

(Revolutions Per Minute).

used

to

Wheel

governor

caused

with

operating

the

the

engine

may

on

automatic

performance

the

engine

to

the

&

set

the

unattended,

Prevent

persons

the

speed

regulate

Horse

that

this

governor

at a set

by

excessive

the

throttle

at a minimum

tractor

is

result

in

models,

may

Off

position.

parking

even

accidents,

an

of

the

ground

has

been

limits

maxiallows

speed,

RPM.

control

is in use.

operating

extensive

as

on

all

be

the

For

convenience

of

fuel

spills, it is

plastic

with

When

with a good

gasoline.

tractors

unleaded

engines.

lines.

fuel is

manufacturers.

In

buildup

tributes

Briggs

regular

operation,

leaded

OIL

To

oil level

cerning

level

tion of this

funnel

under-seat

the

Use

with Briggs &

regular

Do

Do

not

not

recommended

general,

of

combustion

to long

&

Stratton

gasoline

while

fuel

SPECIFICATION

protect

before

recommended

is

given

manual.

be

used

fuel

tractor

grade

not

mix

the

thereafter.

your

requires

(85

only

leaded

may

intermix

oil

with

use of

valve

en!~ines,

be

used

the

piston rings

new

each

in

the

"Maintaining

and

to

minimize

recommended

when

refueling

tanks.

refueling,

octane

Stratton

be

regular

gasoline.

unleaded

deposits

life. Except for

Wheel

use.

oils

minimum)

or

low-lead

used

in

by

either

in

it is

suggested

for

the

are

Horse, check

Complete

and

how

engines.

and

the

the

chance

that a large

tractors

fill

the

of

regular

regular

Leaded

tractors

The use

fuel will

with

Kohler

unleaded

of

these

engine

tractors

first 25

seating,

information

to check

Your Tractor" sec-

of

gasohol

reduce

and

that

hours

and

the

gaso-

engine

leaded

engine

the

tank

in

or

the

conwith

of

un-

con-

oil

CHOKE

the

pletely

results

easier

engines

FUEL

CONTROL

The

choke

carburetor.

closed, less

in a higher

to

ignite

may

A

special

cylinder

instructions

for

winter

The

the

chance

is

operated

weather.

In

the

directly

tion

heated

the

muffler.

Place

at

the

start

Summer

SPECIFICATION

Handle

mable.

add

fuel

tank

outdoors

tank

indoors.

wipe

up

control

not

activates a "butterfly"

When

when

the

air

is

fuel-to-air

the

need

WINTER

TWIN

tractors. A decal

purpose

Summer

into

the

position

air

on

use.

of

of

carburetor

in

the

outside

air

of

the

CYLINDER

intake

how

this

near-freezing,

position

air

cleaner.

air

intake

snow

in

the

&CAUTION

fuel

with

Use

only

approved

while

the

engine

with

extreme

Replace

all

spilled

fuel.

choke

admitted

engine

choking.

is

to

(richer)

is

started

OPERATION,

MODELS

system

to

set

system

is

in

season.

Spring.

care

gasoline

on

up

icing

outside

In

drawn

the

- it is

fuel

is

care.

is

the

is

to

when

the

in

Winter

Return it

container.

running.

cap

partially

the

engine.

mixture

cold.

used

engine

the

air

help

the

high

humidity

air

is

Winter

from

&

highly

Never

securely

valve

or

com-

that

Warm

on

twin

gives

intake

prevent

tractor

drawn

posi-

around

position

to

the

flam-

Never

Fill

fuel

fill

fuel

and

in

This

is

TRANSMISSION OPERATION

During cold

parking

clutch

least

two

up;

engage

engine

o

and

mission

attempting

peratures

mission

attempting

do

so

mission

TO

GO

Before

or

backward,

engaged.

neutral

brake.

The motion

single

"Motion

push

the lever forwclrd. The

is

pushed,

CORRECT

AUTOMATIC

weather,

brake

lever

at

30°F

to

to

may

damage.

FORWARD

pedal

the

engaged

disengaged.

minutes

full

run

to

below

run

to

to

the

transmission

throttle.

(18C and

in

neutral

set

the

OaF

in

neutral

set

the

result

&CAUTION

the

tractor

thE!

ALWAYS

when

of

your

Control

faster

the

start

and

Run

allow

For

temperatures

_2

unit

(-18

for

unit

in

extensive

will

parking

depress

disengaging

tractor

lever".

farther

tractor

the

engine

the

transmission

the

engine

the

engine

clutch

C

e)

allow

for 5 minutes

into

motion.

n

e)

allow

10

in

motion.

to

with

the

the

minutes

Failure

internal

&

move

either

brake

must

the

brake/return

the

is

controlled

To

go

forward,

forward

will go.

with

the

for

at

warm-

the

between

trans-

before

For

tem-

trans-

before

to

trans-

forward

be

dis-

to

parking

by

simply

the

lever

a

-8-

For

control

By

adjusting

speed

of

ing

the

moving

tractor

much

mechanical

TO

motion

the

faster

speed

ing

TO

reverse

methods:

the

applies

hold

The

lever

action

mechanical

(at a very

neutral.

when

though

in

the

when

HAND

ground

the

GO

To

reverse

control

lever

the

For

control

By

adjusting

of

the

engine

STOP

Stopping

direction

1.

Return

position.

2.

Depress

Activating

motion

a

the

pedal

can

The

tractor

inside

Therefore,

the

B-Series

neutral

brake

stopped

PUSHING TRACTOR

Hand

can

cause

transmission.

&

CAUTION

safe

operation,

lever

too

rapidly,

the

motion

the

tractor

engine

the

same

transmission.

throttle

control

speed

as

can

shifting

BACKWARD

the

motion

lever

to

back.

The

tractor

will

&CAUTION

safe

operation,

lever

too

rapidly,

the

motion

the

tractor

the

the

the

control

mechanical

motion

must

be

broke.

slow

tractor

even

is

recommended

push

throttle

tractor

can

motion

the

brake

brake

control

be

moved

is

stopped

the

speed)

is

tractors

when

on

tractor

severe

can

lever

released

either

hydrostatic

C-Series

always

stopped

unlevel

never

especially

control

be

regulated

control.

lever

toward

and

increases

to a lower

of

the

the

neutral

farther

go

control.

be

brake.

the

damage

back

in

reverse.

never

especially

control

be

regulated

from

achieved

control

pedal.

pedal

to

its

lever

in

before

forward

by a "dynamic

tractors

when

depress

on

will

tend

brake

to

terrain.

only.

Do

&

move

the

on

lever,

without

For

heavy

neutral

pulling

tractor,

position,

the

&

move

either

automatically

neutral

The

transmission

the

avoid

to

the

on

lever,

without

the

by

lever

to

brake

the

neutral

the

motion

or

back.

are

transmission

the

unlevel

to

remain

is

released,

accidental

not

tow.

the

hydrostatic

motion

grades.

the

forward

adjustpulling,

reduces

gear

with

return

and

lever

motion

grades.

the

reverse

adjust-

forward

one

of

its

neutral

returns

position

pedal

position.

control

braking"

and

free

to

brake

terrain.

stationary

use

Towing

power

the

pull

is

the

two

and

will

roll

is

pedal

Al-

of

starts

a

or

a

in

CORRECT

MECHANICAL

TRANSMISSION

TO

GO

FORWARD OR

With

the

engine

and

the

brake

Series

Move

ward,

the

release

ed,

Only)

the

or

various

the

the

tractor

Always

starting

be

damaging

loss

of

gear

to

speeds.

clutch

the

operatol'

TO CHANGE

When a change

quired,

by

Series)

each

of

or

motion

in

selected

gear

TO

the

fully

always

depressing

Never

motion.

may

Change

this

It

is

"down"

any

should

result.

as

gear

manual.

not

The

gear.

gear

attempt

Severe

the

desired.

is

necessary

STOP

To

stop

the

brake

pedal.

before

When

stopping

clutch

pedal

ing

the

broke

cessive

transmission

pedal

NOT

brake

without

STOP

through

tractor

be

the

to

&CAUTION

running,

pedals.

either

shift

lever

reverse.

will

release

trador

peda

tel

the

control.

The

Release

begin

the

in

SPEEDS

in

ground

br.ing

both

the

to

internal

gear

shift

The

shown

&

THE

in

or

the

has

If

the

tractor

with a heavy

used.

tractC)r,

The clutch

brake

CAUTION

the

first,

then

without

lining

damage.

depressing

TRACTOR.

OPERATION

REVERSE

depress

Move

the

range

the

High

or

the

to

the

desired

gear

shift

the

brake

I.

As

the

clutch

to

move.

&

clutch

pedal

motion.

equipment

OR

the

clutch

shift

approximate

the

recommended

gears

sufficient

depress

pedal

tractor

the

the

wear,

Sudden

and

DIRECTION

speed

or

tractor

lever

to a complete

and

the

gears

with

transmission

or

range

ground

specifications

with

power

will

not

load

attached, a lower

the

cI

pedal

must

is

depressed.

&

always

brake

pedal.

clutch

may

or

extensive

Depressing

the

brake

utch

both

the

selector

low

speed

decal

pedal.

peda I is

slowly

starts

could

direction

broke

the

damage

selector

in

to

shift

the

tractor

to

move

pedal,

be

depressed

depress

Depress-

cause

internal

the

pedal

clutch

(C-

position.

for-

identifies

Slowly

releas-

when

can

cause

is

re-

halt

pedals.

unit

in

(C-

speed

for

the

front

"up"

move

out

out

in

then

the

ex-

clutch

WILL

in

a

C-Series

pushed

faster,

for a moment,

slower

S-Series