Wheeler Engineering Digital F.a.t. Wrench User Manual

DIGITAL

Instructions #1056501 Rev. C

Product #710909

CONTENTS:

Digital F.A.T. Wrench

9 drive bits

1 square drive adapter

1 Spare battery

Storage case

®

sales@btibrands.com

The Wheeler® Engineering Digital F.A.T. Wrench® is a hand driven torque wrench with a

digital LCD that is very useful for applying the necessary torque to most rearm and rearm

accessory fasteners. The Digital F.A.T. Wrench® features an ergonomic rubber overmolded

handle, a standard ¼” hex drive tip, and can be used to apply torque from 15-100 lb-in at 0.1

lb-in increments. Units of measurement can be changed from lb-in to kg-cm or N-m. The

digital display is capable of two different modes. The “LIVE” mode displays the torque being

applied and increases/decreases as the torque load changes. The “PEAK” mode displays the

highest torque applied and will hold this value on the LCD for approximately 5 seconds.

Common uses include, but are not limited to; installation of scope ring and base screws,

action screws and trigger guard screws. With proper care and use, the Digital F.A.T. Wrench®

will provide you with a lifetime of reliable service. Package includes: Digital F.A.T. Wrench®, 9

drive bits, 1 square drive adapter, and a storage case.

NOTE: BEFORE USE

Remove battery discharge prevention strip from battery compartment. Loosen screws

enough to allow strip to be pulled from the compartment. DO NOT PULL STRIP WHILE

SCREWS ARE TIGHT. Once strip is removed, re-tighten screws.

ADJUSTING AND USING THE DIGITAL F.A.T. WRENCH

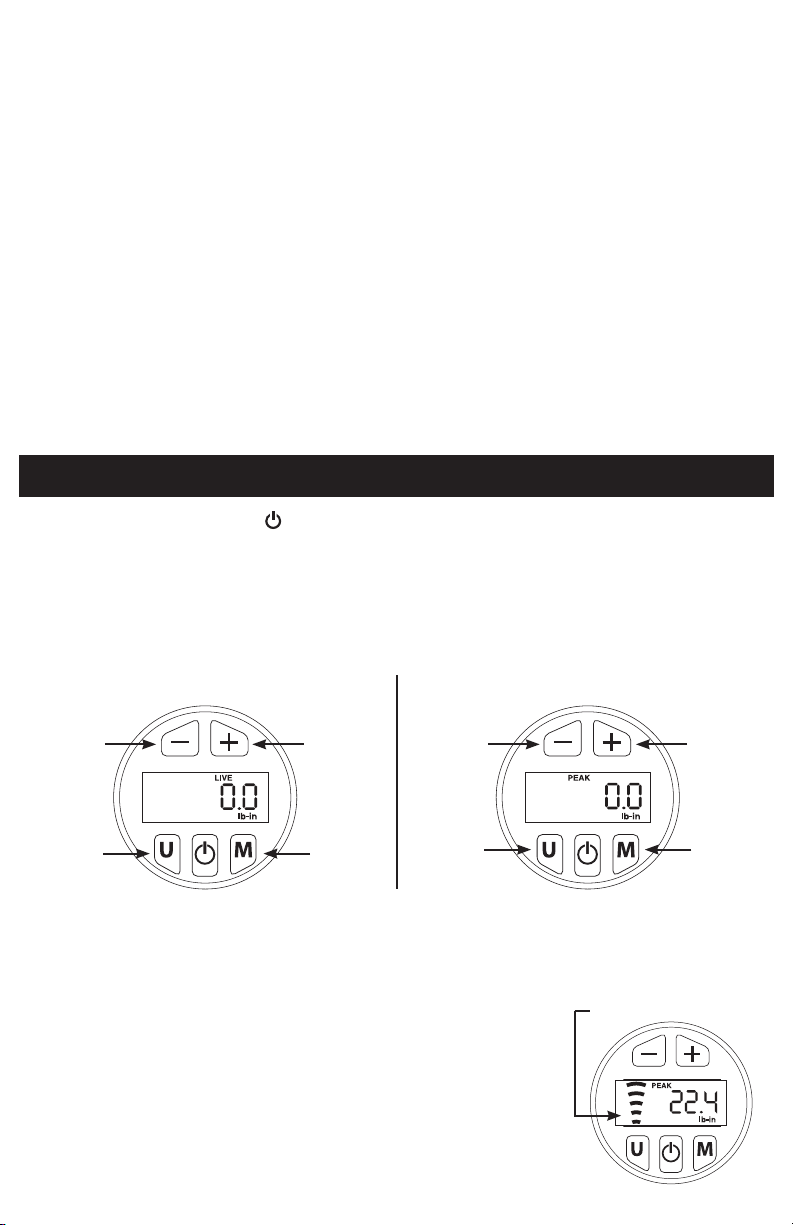

1. To power the unit ON, press the bottom middle button once. The same button will power the unit OFF.

2. Select the units of torque measurement by depressing the bottom left button labeled “U”. By default, the units

are set to lb-in and can be changed to kg-cm or N-m.

3. Select the display mode by depressing the bottom right button labeled “M”. The “LIVE” mode displays the

torque being applied and increases/decreases as the torque load changes. The “PEAK” mode displays the

highest torque applied and will hold this value on the LCD for approximately 5 seconds.

PEAK MODELIVE MODE

TORQUE

VALUE

DOWN

UNIT OF

MEASURE

5. Select the target torque value by depressing either of the top two buttons labeled “-” and “+”. Depressing the

top left button labeled “-“ will decrease the torque setting. Depressing the top right button labeled “+” will

increase the torque setting. Pressing and holding either button will rapidly change the value. When the lowest

or highest setting is reached, it will loop to the highest or lowest setting and continue until the button is

released.

6. Insert the bit needed into the hex drive tip. The Digital F.A.T. Wrench® can now

be used to apply torque to the fastener.

7. Tighten the fastener by turning clockwise. As the fastener begins to get tight,

you will see the number displayed on the LCD increase as well as the number

of bars on the far left side. When 80%-95% of the target torque is reached

a slow audible beep can be heard. When 95%-105% of the target torque is

reached a solid audible tone can be heard. If you exceed 105% of the target

torque a fast audible beep can be heard.

TORQUE

VALUE

UP

MODE

TORQUE

VALUE

DOWN

UNIT OF

MEASURE

BARS THAT CORRESPOND

WITH AUDIBLE BEEP

TORQUE

VALUE

UP

MODE

Loading...

Loading...