Networked AoIP Broadcast Console

Manufactured by Wheatstone Corporation

1

Publication Information

©2018 Wheatstone Corporation

Wheatstone con s ide r s this document and its contents to be proprietary and confidential. Except for making a reasonable number of copies for your own

internal use, you may not reproduce this publication, or any part there of, in any for m , by any method, for any purpose, or in a ny language other tha n English

without the written consent of Wh eatstone Corporation. All others uses are illegal.

This publication is de s igned to assist in the installation and use of the product as it exists on the date of publication of this manual, and may not reflect the

product at the cur r ent time or an unkn own time in the fu ture. This publication does not in any way warrant description accurac y or guarantee the use for the

product to which it r efers.

Wheatstone reser ves the right, without notice, to make such changes in equipment, de s ign, specificati ons, components, or documentation, as progress may

warrant, improving the perf orm a nce of the product.

Trademarks

Product names and other appropriate trademarks, e.g. WheatNet-IP™, VoxPro®, PR&E® are registered trademarks of Wheatstone Corporation or its

subsidiaries. Mic r osoft

respective companies.

®

and Windows® are registered tr a d em arks of Microsoft Corporation. All other tradem arks and trade n ames are the property of their

Customer Servi c e Contact Information

Wheatstone

600 Industrial Drive

New Bern, NC 28562 USA

For technical support, including on-site service, general product training, repair and parts, contact Wheatston e / PR&E through the webpage:

www.wheatstone.com; through email at techsupport@wheatstone.com; or by phone,+01 252-638-7000.

Manual Revisions

A = Initial release, Octobe r 2017

B = technical corrections, PR&E IP Navigator addition s , operational clar ifications, O c tober 2017

C = Appendix A on networking multiple consoles added; some technical corrections; consolidated software app info into chapter 3, July 2018

D = Added info on a new feature: saving/loading EQ Configuration files (DMX Surface S etup, build 1.0.29 and later), September 2018

D.1 = Added info a bout saving two Studio EXT selections, October 2018

D.2 = Changed exclamation point graphic to display pr op erly in a PDF, October 2018

2

TABLE OF CONTENTS

Publication Information .................................................................. 2

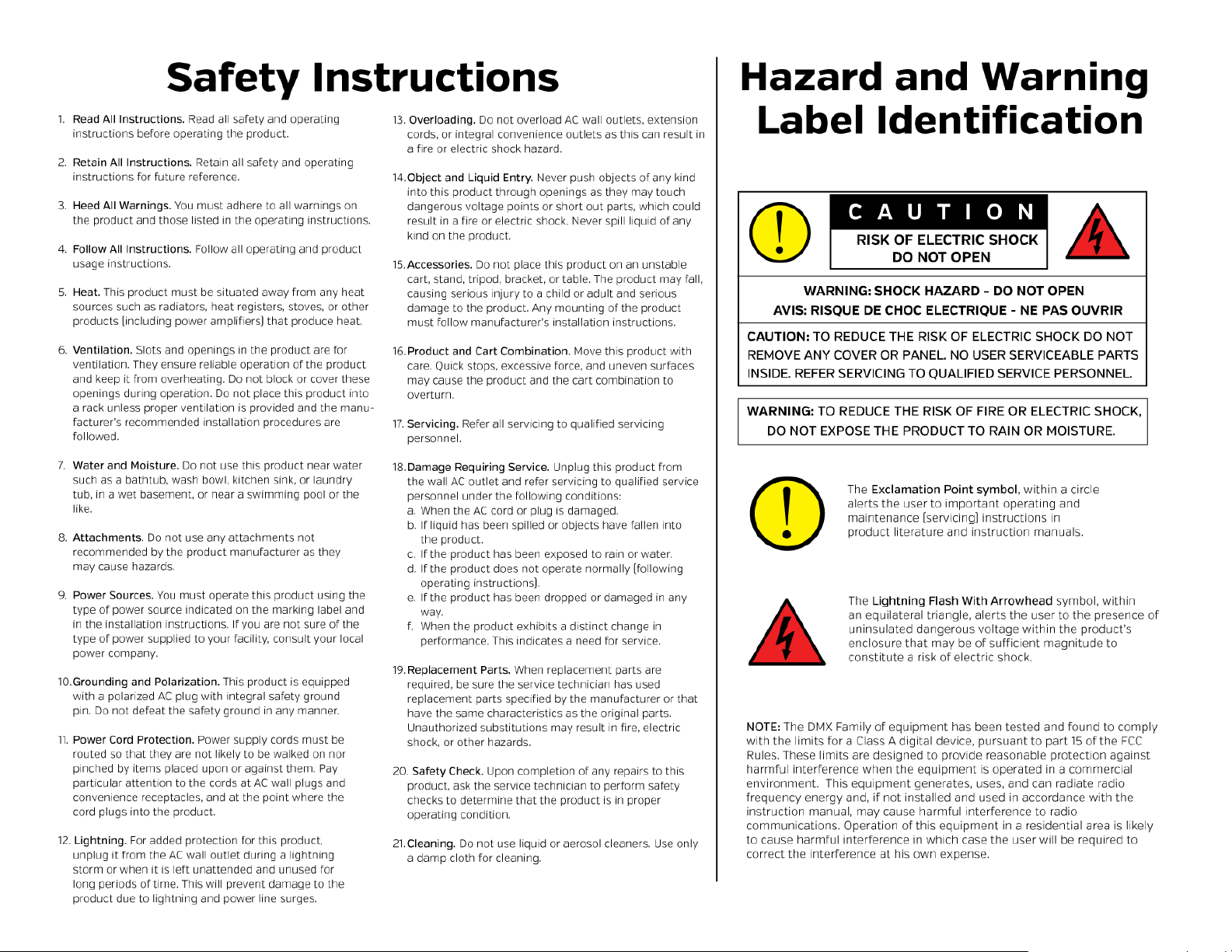

Safety Instructions & Hazard/Warning Labels .................................. 4

1 – Introducing the DMX Console .................................................... 5

DMX Overview ..................................................................... 6

DMX Specifications ............................................................ 7

Warranty Statement ............................................................ 9

FCC Compliance Statement ................................................. 9

2 – DMX Hardware Installation ........................................................ 10

Locating the DMX Components ............................................ 10

PR&E Mix Engine Connections ............................................. 12

DMX Power Up .................................................................... 13

Checking Out the DMX Features ........................................... 14

PR&E Mix Engine Signal Notes ............................................. 16

Additional DMX Features ..................................................... 17

Razor I/O Interface Notes ................................................... 19

3 – PR&E Apps and Console Configuration ........................................ 20

DMX Surface Setup App ...................................................... 20

PR&E Navigator App ............................................................ 31

PR&E System Configuration Tool .......................................... 43

Software Updates ............................................................... 44

4 – DMX Operation and Applications ................................................ 45

Console Operation .............................................................. 45

Using the Advanced Channel Features .................................. 51

DMX Applications ............................................................... 55

Razor I/O Interface ............................................................. 57

5 – DMX Service Information ........................................................... 58

Appendix A – Creating a PRE-IP Network ........................................... 60

3

4

1 – INTRODUCING THE DMX CONSOLE

T

hanks for joining the growing ranks of broadcasters

employing PR&E products, now designed, manufactured,

and supported by the Wheatstone Corporation.

Throughout PR&E’s long history we’ve endea v or ed to

provide the finest quality products , documentation , and after-sale support.

To obtain maximum be nefit from the DMX console’s capabil ities, please

read through this introduction and Chapters 2 and 3 prior to installing the

DMX console. For those in a hurry, a DMX Quick Guide (a PDF file on the

USB thumb drive th at ships with the console) summarizes the console’s

physical connections, software, and Surface controls.

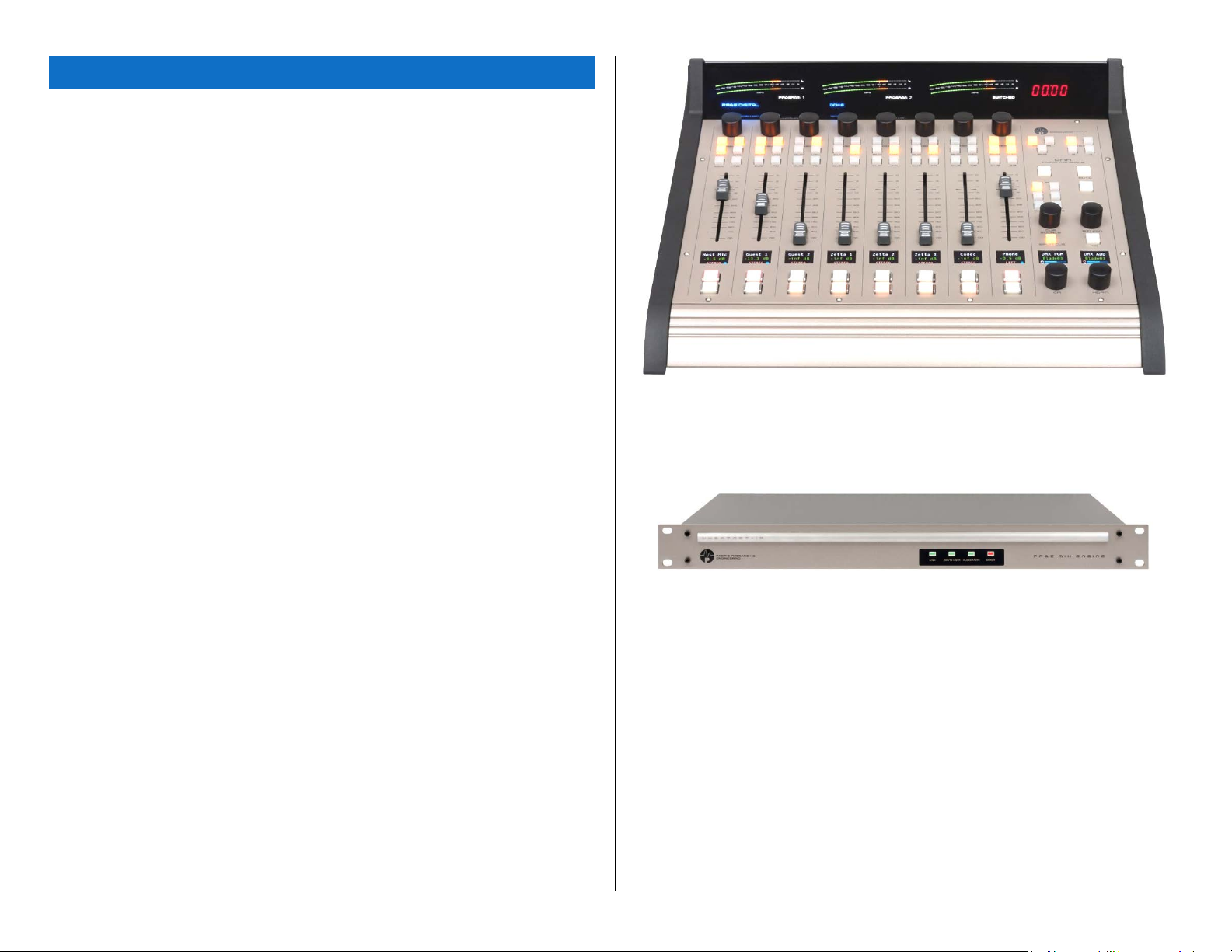

The DMX console has these main components:

● DMX-8 or DMX-16 Surface – This part is commonly referred to as

the “console” s ince it sits on the countertop and ha s all of the board

operator controls. Figure 1-1 shows the DMX-8 Surface. The DMX

Surface has these features:

● Fader Channels – There are eight fader channels on the DMX-8

and sixteen on the DMX-16. Each fader channel has eight push

buttons with LE D illumination (channel on, channel off, cue on/off,

talkback (TB), and four PGM bus assigns), a color Organic Light

Emitting Diode (OLED) display to show channel status, a 100 mm

fader, and a rotary Channel Encoder to select the channel’s source.

The Channel Encoders also allow access to these Advanced Channel Features: audio mode, panning, and EQ & Dynamics settings,

any of which can be locked out for daily operations.

● Monitor Controls – The console supports a Control R oom and an

associated Studio with: CR monitor, CR headphone, Cue, and

Studio Monitor lev el controls; C R and Studio monitor sou rc e

selectors; timer controls; and four console Event buttons.

● Meter Bridge – There are three stereo LED meters showing PGM

1, PGM 2, and a Switched signal (PGM 3, PGM 4, EXT, and CUE, if

enabled). An On Air “Hot Mic” indicator and a four digit timer are

also included in the D M X meter bridge.

● Headphone outpu t – A board operator headphone amp is included in the DMX Surface with a ¼” TRS jack on the right side of the

chassis, in-line with the OLED displays.

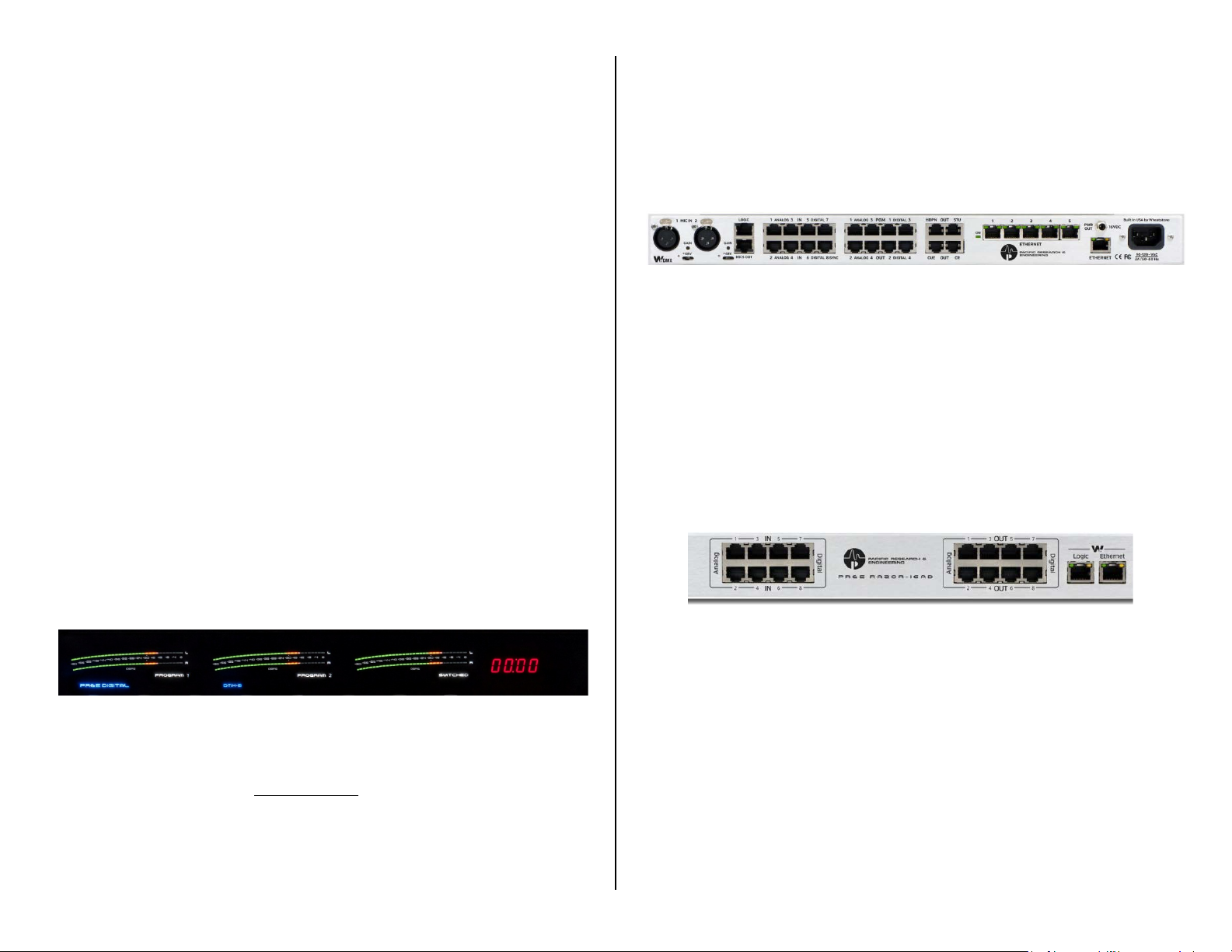

Figure 1-1 DMX-8 Surface

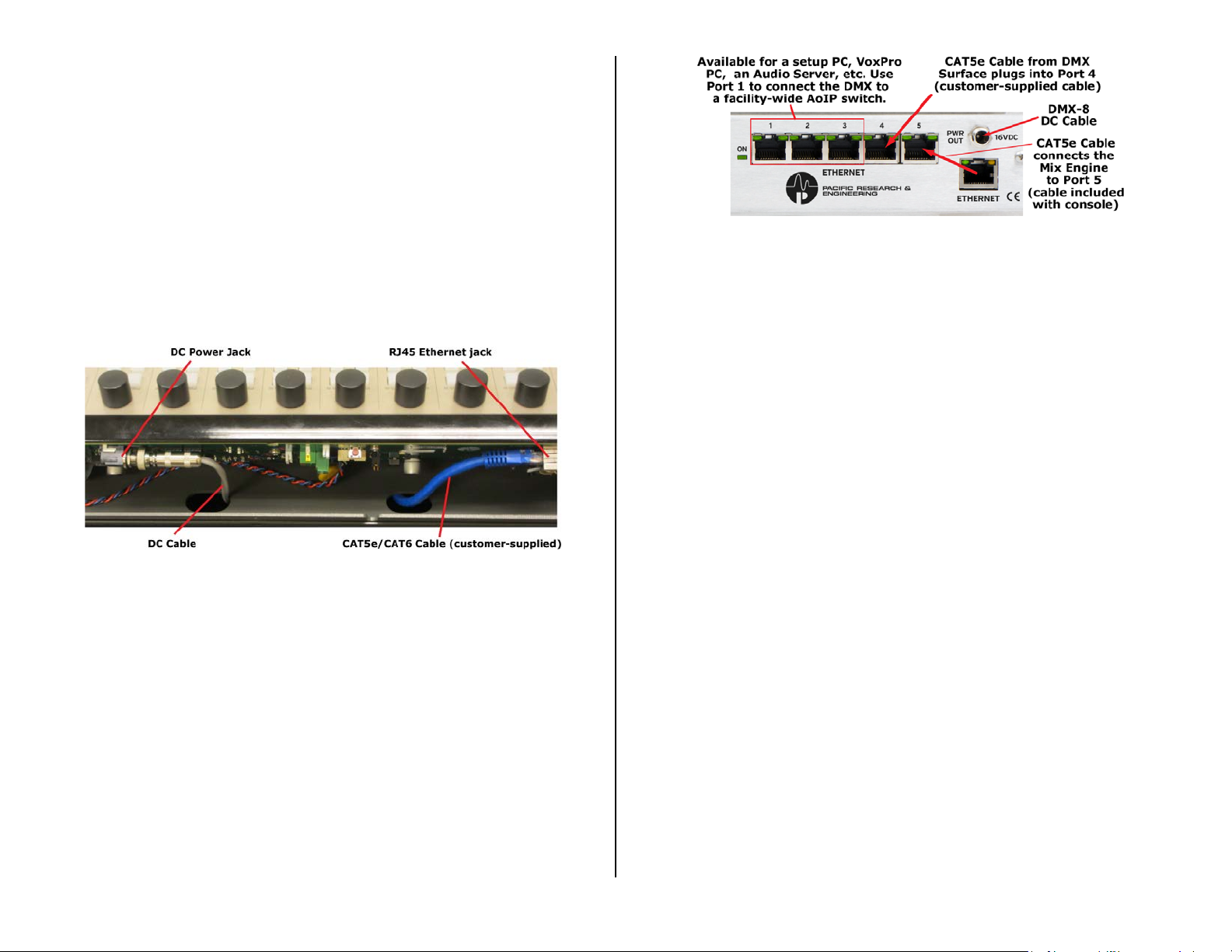

● PR&E Mix Engine – The 1RU Mix Engine (Figure 1-2) has the audio,

logic, and netw ork connections for the DMX console along with the

DSP, signal mixing, and AoIP (Audio over IP) interface functions.

Figure 1-2 PR&E Mix Engine, front panel

The PR&E Mix Engine has these main features:

● 5-port Gigabit Ethe r net switch to network the Surface and Engine,

along with three other Ethernet devic es , like an admin PC; audio

playback server; VoxPro PC; Razor I/O Interface; or a main AoIP

gigabit switch to network multiple DMX studios together

● Two low-noise mic preamps, with female XLR inputs, each with

switchable phantom power and input gain trim pot

● Eight stereo/dual mono inputs (four analog and four AES)

● Four stereo program outputs (analog and AES on each output)

● Four stereo analog outputs for Control Room, Studio, Cue, and an

operator headphone outp ut for an outboa rd amp

● One 6-port GPIO logic connector

5

● DC power source for the DMX-8 Surface (the DMX-16 Surface has

Figure 1-3 Surface Controls

DMX and EMX consoles a nd Razor I/O Interfaces are not

a separate in-line DC supply)

● Installation Kit – The DMX ships with a USB thumb drive with PDF

documentation files and the PR&E software application installers for

the three software apps used for console configuration . Note that PR&E

Navigator is a licensed application, so a site license (gratis) is required

to continue using it beyond a n initial evaluation period.

DMX-8 consoles include a n IEC AC power cord for the Mix Engine and a

DC cable for the Surface. DMX-16 consoles include an in-line DC supply for the Surface and two IEC AC power cords for the Mix Engine and

in-line supply. All consoles include a s hort CAT5e cable to con nect the

Mix Engine to its built-in Ethernet switch.

DMX OVERVIEW

The DMX console is a compact, self-contained, Audio over Internet

Protocol (AoIP) radio broadcast and production c onsole that uses the

WheatNet-IP (WNIP) AoIP netw or king convention. Designed for 24 / 7

operation, the console has two main hardware components: a 1RU rack

mount PR&E Mix Engine, which has all of the console’s audio and logic

connections plus a 5-port Gigabit Ethernet Switch; and a tabletop board

operator controller, called the Surface (which most users refer to as the

“console”). Both Surface and Mix Engine are fully FCC and CE certified.

The DMX console ships with a default configu r a tion so it can be powered

up and used straight out of the box. These default settings are quickly

changed, to configure the console for use in an on-air studio, production

room, newsroom, or other application, using the Windows PC apps that are

included with the console. Their use is c ov er ed in deta il in Chapter 3.

Razor I/O Interfaces (1RU, FCC and CE certified) are available to add

audio and logic I/O to any DMX console. Razors use RJ45 connectors for

audio (eight inputs a nd eight outputs ). They come in three I/O sty les: all

analog I/O with two mic preamps (Razor 16A); all AES I/O (Razor 16D);

or half analog and half-AES (Razor 16AD). Each Razor also has a 6-port

GPIO logic connector. Each Razor connects to a port on the Mix Engine’s

Gigabit Ethernet s witch using a single CAT5e or CAT6 cable of up to 330

feet (100 meters).

interoperable with a WNIP network because they lack

the Intellige n t Networking capabilities built into every

WNIP Blade. However, audio can be st reamed between

the PRE-IP devices and the WNIP devices when WNIP

Navigator is licensed for “cross-networking.” For details,

contact Wheatstone technical su pport, prior to

networking a WNI P a nd PRE-IP system toge th er, to

ensure that the two systems are running the code

required to support cross-network audio streaming.

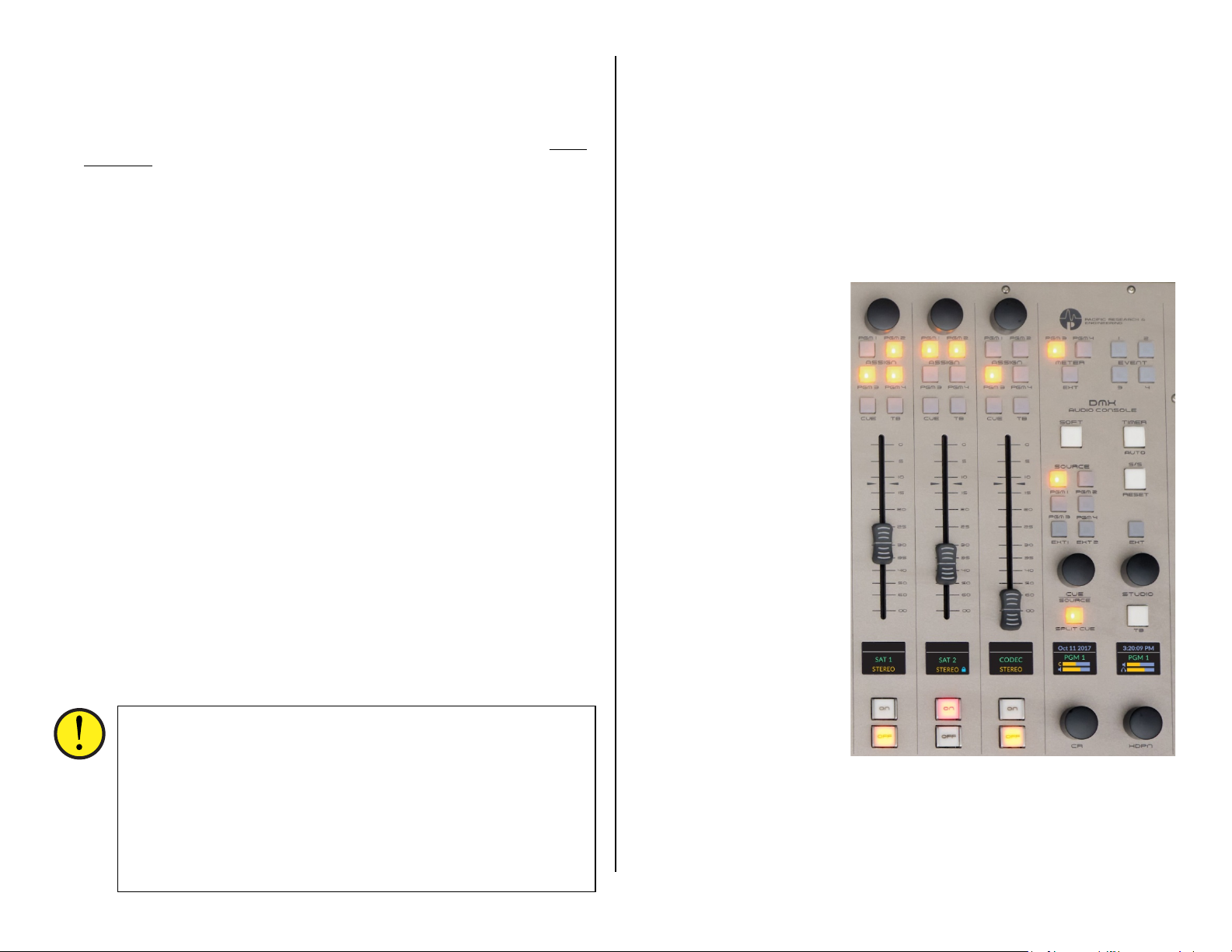

DMX Surface

The Surface’s eight or sixteen audio c ontrol channel strips are called

Fader Channels (three channels are shown in Figure 1-3along with the

monitor controls). Each fader channel has a large-knob rotary encoder to

allow the board operator to select the audio source for each fader channel.

The channel display, located just below each channel’s fader, shows the

name of the audio source currently “dialed up” on that channel along with

other source or channel status information. Rotating the encoder, while

the channel is off, switches the channel display to list alternate sources

that are visible on that channel. One source name is highlighted. Pressing

once or “clickin g” the rotary encoder “takes” that highligh ted s ource,

connecting it to that fader channel.

The fader channel’s

audio is assigned to any

combination of Program

buses using the four

assignment buttons just

below the channel

encoder.

Each fader channel has

a 100 mm fader for bus

level control, plus

illuminated Channel Off,

Channel On, Cue, and

Talkback (TB) buttons. All

of the fader channel

controls are iden tified in

Figure 4-2 on page 46.

At the right end of the

Surface are the Monitor

Controls. Each control and

display is identif ied in

Figure 4-4 on page 49.

The left column (CR) has

the Control Room con trols.

Three buttons at the top

select which source (PGM

3, PGM 4, or External) is

feeding the Switched

Meter. A large userdefined Soft button (no

default setting) is just above the six Control Room mon itor s ource select

buttons (PGM 1 – PGM 4, EXT 1, and EXT 2) which control which source

feeds the Control Room monitor s and board operator headphone output. A

Spilt Cue button sets how cue audio is fed to the hea dphones (if cue is set

to feed the headphones during console configuration).

6

The right column (STUDIO) has four Event buttons; two large Timer

control buttons; a studio monitor sou r c e s elector (EXT); and a large Talk

to Studio button (TB).

The CUE/SOURCE, CR, STUDIO, and HDPN controls are rotary encoders

used primarily to c ontrol the level of the four dedicated monitor outputs on

the Mix Engine. The two Monitor OLED displays show the current levels for

those four outputs and their status (a red X over a bar graph icon indicates

that output is muted).

The CUE/SOURCE and STUDIO encoders are also used to select and take

“wild sources” for the CR and Studio, and are used to assign sources to the

various EXT buttons.

The Surface controls are all on a sin g le field-replaceable Control Panel

that connects to an internal network interface board us in g one (DMX-8) or

two (DMX-16) plug-in ribbon cables. This allows for rapid field

replacement, with m inimal interruption to operations , in case of spills or

other damage to the Surface controls since the program audio is flowing

through the Mix Engine rather than through the Surface (except for the

audio to the side panel-mounted headphone jack).

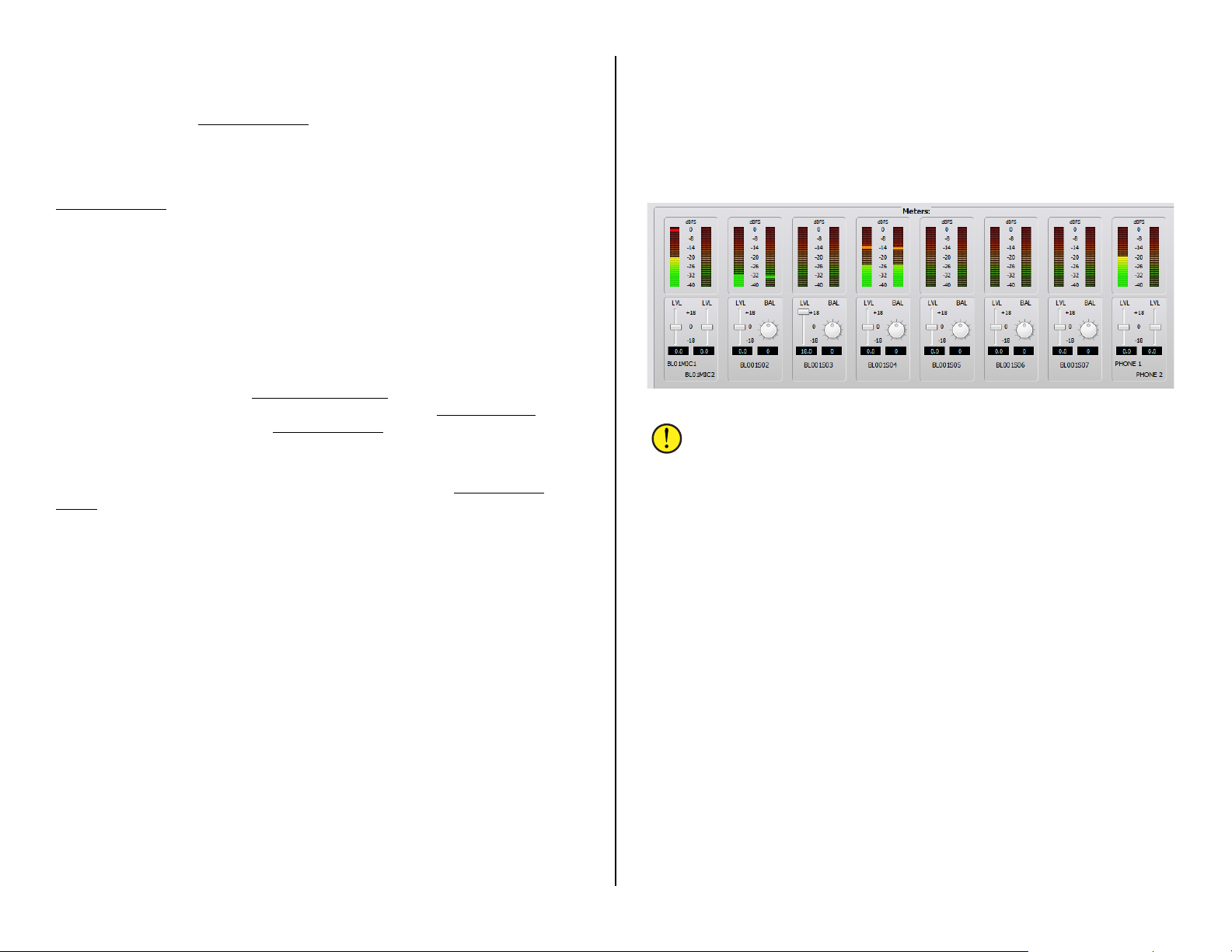

Meter Bridge

The integrated direct-view Meter Bridge (Figure 1-4) sits above and

behind the control panel. It has three stereo level meters, a Timer, and an

On Air indicator. The left meter displays the Program 1 bus levels. The

middle meter displays the Program 2 bus levels . The right meter is

switchable between showing the other two program buses ( PGM 3 or PGM

4) or an External signal (EXT) like an off-air tuner signal. The switched

meter can also be set to auto-switch to show cue levels while cu e is active.

The meters normally show both the average and peak levels, but

software settin g s allow them to be changed to show only the average level

or only the peak levels for special functions.

powering); Signal Processing with EQ and dynamics (applied on a fader

channel basis); eight routable audi o inputs (four analog and four AES);

four Program audio o u tputs (four analog and four AES outputting the

same set of signals); four dedi c a ted analog output s (to feed powered

Control Room and Studio monitors, powered cue speakers, and an

outboard board operat or headphone amp); six GPIO logic contact s

(each independently set to fun c tion as a logic inpu t or logic output) and an

Ethernet jack to connect the Engine to the built-in Gigabit switch.

Figure 1-5 PR&E Mix Engine, rear panel

Input and Output Connectors

All audio, logic, and network connections on the Engine and on the

optional Razor I/O Interface (Figure 1-6)—other than microph one preamp

inputs which have female XLR connectors, use RJ45 connectors and

category wiring (CAT5, C AT 5e, or CAT6). Figure 2-4 on page 12 has wiring

pin outs for the RJ45 connectors used to connect analog audio, digital

audio, and logic to/f rom the DMX console.

Analog and AES wiring conforms to th e StudioHub+ con vention with two

balanced analog, or one AES/EBU (AES3) signal, per RJ45 jack.

The RJ45 Logic jack has six GPIO logic ports plus a +5V and a GND

connection which use the WheatNet-IP (WNIP) logic jack wiring format.

Figure 1-6 Razor 16AD Interface, rear panel RJ45 Connector Detail

Figure 1-4 DMX Meter Bridge

The four-digit Timer is controlled manually, using the Monitor section

S/S button (Timer Sta r t/ Stop control), or a utomatically , when the Auto

Timer button is lit and an au d io s ource, set for T imer R es et (assigned to

specific audio signals in the Surface Setup

app) is turned on.

PR&E Mix Engine

All audio and logic connections are made on the rear of the Mix Engine

(Figure 1-5). This 1RU device has a 5-port Gigabit switch; two highquality low-noise Mic Preamps (with gain control and 48-volt phantom

DMX SPECIFICATIONS

Test Conditions:

FSD = Full Scale Digital, 0 dB FSD equivalent to +24 dBu analog

0 dBu corresponds to 0.775 v olts R M S—regardless of the circuit

impedance, as measured using a 600 ohm circuit.

Noise specs measured using a 22 Hz – 20 kHz bandwidth. A 30k Hz

bandwidth increases the noise measurement by 1.7 dB.

Wheatstone / PR&E reserves the righ t to c hange the following

specifications without notice or obligation.

7

Mic Preamp

Source Impedance: 150 – 600 Ω, balanced

Nominal Input Level: -50 dBu

Input Rang e: -70 to -31 dBu (using trim control to reach nominal level)

Equivale nt Input Noise: -131 dBu

Logic GPIO

Six per RJ45 connector: Connection assignments made using PR&E

Navigator

Logic Inputs: Current-limited using internal pull-up. Supports +5 to +12

voltage logic. For a log ic low, input volta ge m ust fall below +2 .5 volts.

Logic Output: +5 to +24 VDC logic, 50 m A nominal, 100 mA max

(logic input or o utput; the type of log ic c ommand)

Analog I/O (Inputs & Outputs: +4 dBu, balanced)

Input Impedance: >10 k Ω, bridging

Optimal Source Impe dance: <1 k Ω

Analog In > Analog Out Frequen cy Response:

+0.0, -0.25 dB, 20 Hz to 20 kHz @ +4 dBu

Analog In > Analog Out THD & Noise:

<0.0025%, 20 Hz-20 kHz @ + 4 dBu

Nominal / Maximum Input Level: +4 dBu / +24 dBu

(±18 dB of level gain/trim control available in the PR&E IP Navigator)

Output Source Impedance: <10 Ω balanced

Output Load Impedance: 600 Ω optimal

Nominal / Maximum Output Level: +4 dBu / +24 dBu

(±18 dB of output leve l gain/trim contr ol in the PR&E IP Navigator)

A > D Conversion: 24-bit resolution

D > A Conve rsion: 24-bit, advanced Delta-Sigma

Digital I/O (AES/EBU Inputs & Outputs)

Reference Level: -20 dB FSD (equivalent to analog +4 dBu)

Nominal / Maximum Input or O utput Level: -20 dB FSD / 0 dB FSD

(±18 dB of level gain/ tr im control available in the PR&E IP Navigator)

Digital In > Digital Out Frequency Response:

±0.0 dB, 20 Hz to 20 kHz @ -20 dB FSD

Digital Input > Analog Output THD & Noise:

<0.00017%, 20 Hz-20 kHz @ -20 dB F SD

Signal Format: AES-3, S/PDIF (inputs only)

Digital I/O (continued)

AES-3 Input Compliance: 24-bit (uses SRC to support incoming s a m p le

rates of 32 – 96 kHz, 16- to 24-bit resolutions)

AES-3 Output Compliance: 24-bit

Output Sample Rate: 44.1 or 48 kHz

Processing Resolution: 24-bit

Surface Dimensions

DMX-08: 4.25" x 17.625" x 17" (H, W, D)

DMX-16: 4.25" x 29.625" x 17" (H, W, D)

DMX-16 Engine Dimensions

A 1RU rack-mounted device:

1.75" x 19.0" x 13.25" (H, W, D)

Razor I/O Interface Dimensions

A 1RU rack-mounted device:

1.75" x 19.0" x 9.25" (H, W, D)

Power Supply

Type: Internal switc hing supply on the Razor and the DMX-16 Engine,

which also powers the DMX-8 control surface; the DMX-16 Surface uses

a separate in-line switching DC power supply

AC input: Detachable IEC cord

AC input: 90-240 VAC, 50/60 Hz

Output: +16 VDC @ 1 amp (PWR OUT jack on DMX Engine)

Output: +16 VDC @ 2.67 amps (Surface in-line supply)

Power Requirements

DMX-16 Engine: <27 watts at 120 VAC / 60 Hz

DMX-08 Surface: <10 watts at 120 VAC / 60 Hz

DMX-16 Surface: <20 watts at 120 VAC / 60 Hz

Razor: <15 watts at 120 VAC / 60 Hz

Environment

Ambient Temperature: Less than 40°C

Cooling: Convection c ooled, no fans

8

WARRANTY STATEMENT

LIMITED WARRANTY BY WHEATSTONE CORPORATION

1. All equipment sold and shipped to final destinations w i thin the USA and its

possessions warranted for one (1) full year from the date of purchase against

defects in material and workmanship. All equipment sold and shipped to final

destinations outside the U.S.A. and its possessions warranted f or one (1) f ull

year from the date of purchase ag ainst defects in material and workmanshi p.

All repairs to maintain the unit at original specification will be made at no

charge to the original purchaser, except for shipping and insurance costs to be

prepaid by the owner to the factory in the event the unit cannot be serviced by

an authorized Wheatstone Corporation dealer.

2. This Warranty is subject to the following restrictions and conditions:

a) The owner must h ave filled out the en closed Warranty Card and returned

it to Wheatstone Corpor ation; or at the time of servi cing the owner must

provide proof of purchase from an authorized Wheatstone Corporation distributor or de aler.

b) This Warranty is valid for the original purchaser on the unit. Parts used for

replacement are warranted for the remainder of the original warranty period. Repair or replacement is in the discretion of Wheatstone Corporation

and is the exclu sive remedy hereunder.

c) This Warranty DOES NOT apply to damage or defects resulting from abuse,

careless use, misuse, improper installation, electrical spikes or surges, or

alteration, repair, or service of the unit or equipment by anyone other than

Wheatstone Corporation or its authorized dealer.

d) This Warranty is void if the serial number has been removed, altered or

defaced.

e) This Wa r ranty DOES N O T cover lo ss or damage, direct or in direct, arising

out of the use or inab il it y to use this unit or for s hi pping or transportation

to any dealer.

f) Wheatstone Corporation reserves the right to modify or change any unit in

whole or in part at any time prior to return delivery in order to incorporate

electronic or mechanical impro ve me nts d ee med appr opriate by the

Wheatstone Corp o r ation but without incurring any responsibility for modifications or changes of any unit previously delivered or to supply any new

equipment in accordance with any earlier specifications.

g) THERE ARE NO OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTO-

RY, INCLUDING ANY WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. IF FOR ANY REASON, ANY IMPLIED OR

STATUTORY WARRANTY CANNOT BE DISCLAIMED, THEY ARE LIMITED TO

THIRTY (30) DAYS FROM THE DATE OF PURCHASE. WHEATSTONE

COPORATION IS NOT RESPONSIBLE FOR ELECTRICAL DAMAGE, LOSS OF

USE, INCONVEN IENCE, DAMAGE TO O T HER PROPERTY, OR ANY OTHER INCIDENTAL OR CONSEQUENTIAL, WHETHER DIRECT OR INDIRECT, AND

WHETHER ARISING IN CONTRACT, TORT, OR OTHERWISE. NO REPRESENTATIVES, DEALERS, OR WHEATSTONE PERSONNEL ARE AUT HORIZED

TO MAKE ANY WARRANTIES, REPRESENTATIONS, OR GUARANTIESS OTHER THAN THOSE EXPRESSLY STATED HEREIN.

9

2 – DMX HARDWARE INSTALLATION

ach DMX Surface is 17” (43.2 cm) deep and 4 1/4" (11 cm)

tall. The DMX-8 Surface is 17 5/8" (45 cm) wide. The DMX16 Surface is 29 5/8” (75.3 cm) wide.

The PR&E Mix Engine (1RU) mounts within the studio

cabinetry below the Surface location. Install a 1RU blank panel, or mount

the Mix Engine at the top of the rack, to ensure adequate ventilation . All

DMX components are convection cooled so the y can be mounted into any

studio, includin g ones with active m ic r op hones, witho ut adding any

environmental noises. When locating the Surface and Engine, avoid close

proximity to device s which generate electromagnetic fields, such as large

power transform er s, motors, and audio amps using switching supplies.

LOCATING THE DMX COMPONENTS

The DMX Surface is designed to set on top of the studio furn iture

countertop with the fron t of its palm rest sitting between six and twelve

inches (15 to 30 cm) from the edge of the countertop (Figure 2-1). This

“setback space” allows keyboards and mice, a VoxPro controller, copy, log

sheets, etc. to be plac ed in front of the console.

The PR&E Mix Engin e (1 RU) is rack mounted in a 19” rack below the

countertop. It’ s typically loc ated near the top of a r a ck close to the DMX

Surface. The r e are no controls on the front panel, but there are four sta tus

LEDs on the front to indicate Engine status. The Engine’s rear panel must

be easily accessible since that’s where the audio, logic, and network

connections for the DMX cons ole a re m a de. We recommend adding a 1R U

blank or vent panel above the Mix En gin e to ensure adequate ventilation .

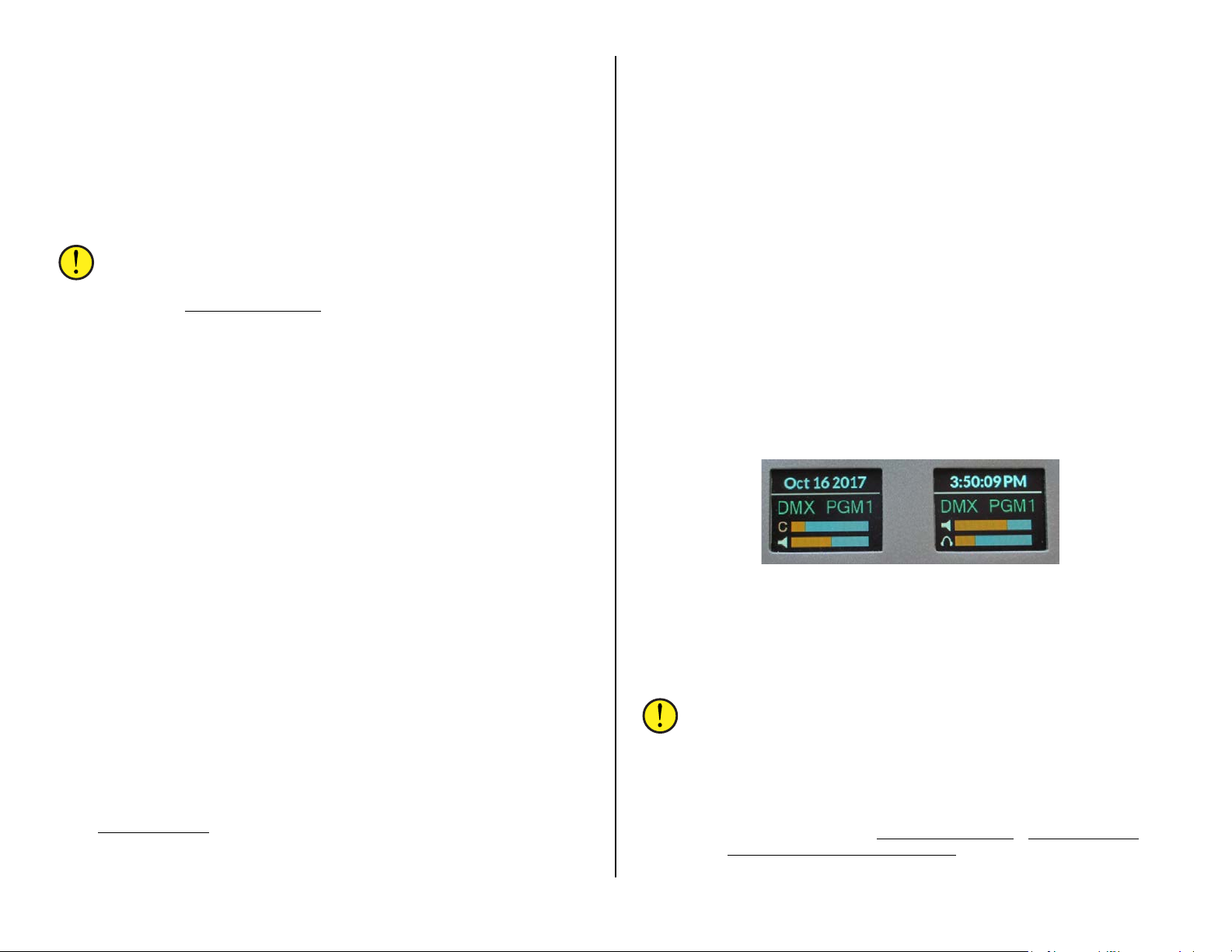

With a DMX-8 Surface, a 16-foot locking DC cable (included) connects

the Surface to the PWR OUT jack on the ba ck of the Mix Engine. This

constrains where the Mix Engine ca n physically be located s ince the DC

cable must not be under strain w hen connected between the Su r f ace a nd

Mix Engine.

The DMX-16 Surface uses an in-line DC supply with captive DC cable and

an IEC AC cord. An isolated AC outlet must be located below the

countertop to allow the six-foot DC cable to plug into the Surface and the

six-foot AC cord to plug in to an AC outlet.

Note: The DMX-16 DC supply (Wheatstone p/n 980064) can

power a DMX-8 Surface if the Surface must be located more than

15 feet from where the Mix Engine is mounted.

The Surface requires a straight-thru category cable (customer-

supplied CAT5e or CAT6 cable) to connect the Surface to Port 4 on the

Mix Engine’s rear panel Ethernet switch.

The DMX Surface is typically just set onto the countertop since its weight

(16 lbs for DMX-8, 26 lbs for DMX-16) and four large rubber feet should

hold it in place. However, if the Surface must be fastened to the

countertop for security reason s , a step-by-step procedure is listed in the

section Fastening the Surface to the Coun tertop, on page 11.

Figure 2-1 DMX-8 Surface, Countertop Positioning

For the cleanest in s tallation, we r ecommend drilling a one to two inch

cable access hole through the countertop below the Surfa ce’s position.

Only the customer-supplied CAT5e/CAT6 cable and the DC power cable

and connector pass through this hole so hole size is not critical. The hole

could be sized to match an available hole grommet or it could be left raw

since it’ll be covered by the Surfac e.

1. Position the Surface on the countertop so that the palm rest is

parallel to the countertop edge and is s e tback the desired amou nt

(typically, between six and twelve inches).

10

2. Use a pencil to mark th e c ountertop at the center of the front edge

of the palm rest (for the DMX-8, this is the center line between

fader channels 5 and 6, as shown in Figure 2-1).

3. Move the Surface out of the way and mark a point 13” beh ind the

palm rest mark, perpendicular to the countertop e dge. This marks

where the one to two inch cable access hole will be drilled.

4. Drill the cable access hole through the c ountertop.

Surface Placement & Cable Connections

Before setting the Surfac e back into position, remove the upper rear

cosmetic cover by removing the black #1 Phillips screws. The top of the

cover fits into a slot in the Meter Bridge top cover, so it may h av e to be

pulled down sligh tly to remove it from the slot. When removed, the

network host board, with the DC power jack and RJ45 Ethernet jack,

shown in Figure 2-2, is revealed.

Figure 2-2 Surface rear view (upper rear cover removed)

Route the DC and CAT5e cables up through the countertop hole and

through the two lower chassis access holes (Fig 2-2). Plug and latch the

CAT5e cable into the RJ45 Ethernet connector. Plug the DC cable into the

DC power jack, tightening its housing onto the threaded jack. Reattach

the upper rear cover then set the Surface into position on the countertop.

On a DMX-8 Surface, route both the DC and CAT5e cables to the back of

the Mix Engine (Figure 2-3). Plug the CAT5e cable into Port 4 on the builtin ETHERNET switch. On a DMX-8 Surface plug the DC cable into the

PWR OUT jack, tightening its housing on to the threaded jack .

On a DMX-16 Surface, route the CAT5e cable to the En gin e a nd plug it

into Port 4 on the ETHERNET switch. Plug the in-line DC power supply’s

IEC AC cord into an is ola ted AC outlet.

If not connected a lr eady, connect the shor t blu e CAT5 cable (supplied

with the console) from the ETHERNET jack to Port 5 on the ETHERNET

switch, as shown in Figure 2-3

Figure 2-3 Mix Engine, Rear Panel Partial View,

Ethernet and DC Power Connections

Fastening the Surface to the Countertop

If the Surface must be fastened to the countertop for security reasons,

the two front feet from the chassis must be removed. The Surface’s

control panel (identif ied in Figure 2-1) must also be r em ov ed. Two long #6

screws with oversize washers and lock washers are required. The screw

length must extend through the countertop, from below, and through the

two front feet with j ust enough thread left to fasten to the chassis. These

two screws must not extend over ¼” through the chassis when tight, to

avoid contacting th e c ontrol panel circuit board or ribbon c a ble.

The cable access hole must already have been drilled (per the steps

starting on page 10) and the two Surface cables must have been run

through the hole and plugged into the Surface. The Surface must be

unpowered during this procedure.

1. Unscrew the two front feet. Retain the two #6 s crews, lock

washers, and flat washers for possible future reuse.

2. Remove all of the hex head screws , us in g a 1/ 16” hex driver, from

around the control panel. Lift it up just enough to unplug the

ribbon cable(s): one cable on a DMX-8, tw o cables on a DMX-16.

Set the control pan e l a s ide.

3. Set the Surface into position and m ark the countertop through the

front two feet’s mounting holes using a pencil, the 1/16” hex

driver, or a thin center punc h.

4. Move the Surface aside and drill two 3/16” holes completely

through the cou ntertop.

5. This step requires two people. One person inserts and holds the

two long #6 screws (with lock washers and oversize washers)

through the cou ntertop from below (with the appropriate

screwdriver for the two screws).

A second person sets the two feet onto the screws then aligns the

Surface over the two scr ews , holding it in position while the two

long #6 screws are tightened. Make sure the Surface remains

11

parallel with the countertop edge while tightening the two screws.

Do not overly compres s the two rubber feet and verify the two

screws do not protrude over ¼” through the chassis.

6. Set the back edge of the control panel onto the Surface chassis

and plug in the ribbon cable(s). Set the control panel back down

onto the chassis and reinstall the hex-head screws.

PR&E MIX ENGINE CONNECTIONS

To facilitate wiring the PR&E Mix Engine, create a wire list, listing all

connections to and from peripheral devices. Identify and c r ea te labels for

each end of each audio, logic, and network cable. List these connections in

a master facility wiring logbook to ease ins ta llation, futu r e system wiring

and equipment changes, and sys tem troubleshooting.

Audio cabling to and from the Mix Engine should always be run with the

maximum practic a l d is tance from all AC mains wiring. The Surface’s power

cable only carries DC voltage, so audio wiring can r un parallel to or even

be tie wrapped with this c able without problem.

All line level ana log a udio, AES/EBU , and logic signals are on the Mix

Engine and use RJ45 jacks. Pin out signal lists, and the standard category

wire colors used for the analog and digital audio conn e c tor s and the Logic

connector are shown in Figure 2-4.

Figure 2-4 Audio & Logic RJ45 Pin Outs & Signals

For most applicat ions, either shielded twisted pair (STP) or unsh ield ed

twisted pair (UTP) wiring can be used interchangeably. When crimping

your own CAT5 cables, UTP has an advantage because it’s a lot easier to

crimp than STP w ir ing. To simplify au dio wiring, standard length straightthru CAT5 cables can be used along with RJ45 Au dio Adapters to connect

to peripheral devices.

StudioHub, and other vendors, have a wide variety of RJ45 Audio

Adapters, most of which a re car r ied by W heatstone and PR&E dealers . For

more information about what adapters are available, and about

StudioHub+ wiring practices , refer to the StudioHub adapter w eb pa ge:

http://www.studiohub.com/adapterdonglessplitterscouplers.php

To simplify logic wiring, various GPIO Interfaces for WheatNet-IP Logic

connectors are a vailable from Nota BotYet (

breaks out the six G PIO connections fr om the Mix Engine or Raz or RJ45

Logic jacks to screw terminals so that “old school” hardware-wired

peripherals, like warn ing lights and hot mic LEDs, can easily be c onnected.

When RJ45-to-audio and RJ45-to-logic adapters are used, generic premade straight-thru CAT5 cables, with RJ45 plugs on ea c h end, can be used

to quickly conne c t the Mix Engine an d Razor I/O Interfaces to the audio

and logic connections on peripheral devices.

When wiring directly from an RJ45 ja c k on the Mix Engine or Razor to

individual XLR, TRS, or other audio c onnectors, single-pair UTP (DataMax

5100 or similar) can be used to wire an AES or mono analog con nection.

Dual-pair UTP (DataMax 5200 or similar) can be used for wiring to stereo

connections when a single connec tor (like a D-Sub) is used on the

peripheral device.

When wiring to a stere o a nalog device with two connectors use two

single-pair UTP wires connected to a common RJ45 to clea nly connect the

two audio connector s. Alternately , when breaking out the two wire pairs

from a single CAT5 cable to go to two audio connectors, place shrink

tubing over each wire pair then shrink tube those and the end of the CAT5

jacket to create a reliable, and clean looking, connection.

The exception to the practice of using UTP cable is for the microphone

cables that plug into the f em ale XLR connectors on the Engine, Razor 16A,

and M4IP-USB. These must use s hielded analog wiring specifica lly

designed for low-level balanced signals. Room monitor outputs that

connect to self-powered monitor speakers ma y also need to use shielded

cable, with the shield termin a ted a t th e m on itor speaker end, sin c e there

is no shield conne c tion on the Mix Engine’s RJ45 jacks.

Note: The StudioHub+ wiring convention specifies pin 4 as DC

Ground to support POE (Power over Ethernet). The Mix Engine and

Razor RJ45 connectors do not tie pin 4

ground since neither product supports POE. Thus, a ground

connection can only be made at the peripheral device end. If the

peripheral device has an unbalanced input with a Tip-Sleeve or

RCA connector, an audio balun transformer (balanced:

unbalanced) or a signal matchbox must be used.

All Mix Engine analog line-level inputs and outputs are intended to

connect balanced +4 dBu signals using only the plus (+) and minus (-)

signals from the peripheral s to connect to the + a nd - terminals on the

RJ45 plugs (as listed in Figure 2-4).

Unbalanced device outputs can directly connect to DMX analog inputs

by connecting th e low (-) signal wires (p in 2, ORG, and/or pin 6 , GRN) to

GND on the unbalanced device. Connect the hot wire (the un ba lanced +

signal) to the WHT/ORG and/or WHT/GRN wires (terminals 1 and 3). Since

the unbalanced device will h a ve a very low output level—as compared to a

www.notabotyet.com). Each

(the blue CAT5 wire) to

12

balanced signal, use the PR&E Navigator Device > Sources tab to adjust

the input gain. Any DMX input can be increased by up to +18 dB.

When DMX analog outputs need to connect to unbalanced devices, a

matchbox or an audio balun transformer (balanced:unbalanced) must be

used. You can, alternately, connect the + wires (the WHT/ORG and/or

WHT/GRN wires on terminals 1 a nd 3) to the unbalanced device direc tly ,

but the ground wire from the unbalanced device must be broken out of the

wiring and connected to the Mix En g ine or Razor chassis in order to

connect it to ground. One way to do this would be to connect a small

spade lug and grou nd wire to the Phillips screw on a MIC XLR connector.

Note: On an output, do not ground the two low (-) signals (the

ORG and GRN wires on terminals 2 and 6) at the unbalanced

device in an attempt to connect an unbalanced device directly to a

Mix Engine or Razor output. This can cause phase issues and

crosstalk, and c ould lead to componen t failure since this effectively

shorts an activ e op a m p output to ground.

Ethernet Connections

Ethernet network wiring also uses RJ45 jacks but, because a PRE-IP

network is running at 1000Ba s e-T (1 Gigabit or 1 GB) for the most reliable

network operation only C AT5e or C AT6 cabling should be used.

For a short conn ection, like conne c ting the PR&E Mix Engine to Port 5

on the Etherne t switch (Figure 2-3 on page 11), CAT5 cable can be u s ed

but all longer cable runs must use either CAT5e or CAT6 cabling.

Ports 1, 2, and 3 on the five-port Gigabit Ethernet switch are available

to connect an “a d m in PC” with the PR&E ap plic ations installed on it. This

PC will not need to rem a in connected during normal use u nless PR&E

Navigator is used to control signal connections. Alternately , if a VoxPro or

other audio editor PC is networked with the DMX, the PR&E apps can be

installed on that PC (it would then b e termed the admin PC). The other

two switch ports are available to n etwork a WNIP-compatible media

server, and/or a Razor I/O Interface or an M4IP-USB Blade.

Port 1 can alternately connect the DMX to an AoIP switch to network

the DMX with additional DMX and EMX consoles, Razor I/O Interfaces ,

M4IP-USB Blades, and WNIP-compatible media severs to create a large

PRE-IP network. See Appendix A for details on PRE-IP networ k expansion.

DMX POWER UP

The PR&E Mix Engine, the Razor I/O Interfaces , and M4IP-USB Blades

do not have power switches since all are designed for continuous 24/7

operation. They are designed to work with AC mains supplying 90 - 240

VAC @ 50 or 60 Hz. For the most reliable operation, all DMX c omponents

should only plug into isolated ground circuits (orange outlets in the U SA)

which are on a UPS (Uninterruptible P ower Supply).

When AC power is first applied, it takes a b out 90 seconds for e a ch DMX

device to boot up, c onnect to the PRE -IP netw ork, and be ready for use. If

the DMX-16 Surface is powered up without being connected to its Mix

Engine, or if th e Mix Engine itself is not pow ered, the meter bridge level

displays’ peak LEDs will scan across all meters to visually ind ic ate the

Surface is not communica ting with its Mix Engine. Once the Sur face and

Mix Engine are properly con nected via Ethernet, the meters’ LEDs stop

scanning.

When power is fir st applied to the Mix Engine, the rear panel green O n

LED (next to the E thernet switch) ligh ts up first. This is f ollowed by the

green LEDs blinking on active Eth er net switch ports. N ote that the Surfa ce

Ethernet jack only blinks one LED s ince it communicates at 100Base-T.

The Mix Engine and Razor ports wil l have both green LEDs blinking since

they communicate at 1000Base-T. A networked PC will also only blink one

LED when its NIC does not support 1GB speeds.

The front panel LINK LED (Figure 2-5) lights up solid when th e Mix

Engine’s Eth ern e t jack is connected to p ort 5 of the Ethern et s witch. On a

stand-alone DMX, the oth er two front panel green LEDs: ROUTE MSTR

(Route Master) and CLOCK MSTR (Clock Master) also light up solid—after

about 90 seconds, indicating the Mix Engine is ready for use.

When a new DMX is networked with existing EMX and DMX consoles , the

new PR&E Mix Engine may not be designated as a master, thus its ROUTE

MSTR and CLOC K MSTR LEDs could both be off. This simply indicates

there’s other networked Mi x Engines in the PRE-IP network which are se t

as the Route Maste r or Clock Master. W ith multiple Mix Engines, one Mix

Engine is designated as the Rou te M a s ter w hile a second one is designated

as the Clock Master.

Figure 2-5 Engine Front Panel Status LEDs

If the red ERROR LED s hould light, it indica tes an error condit ion has

occurred in the Mix Engine. To r eset this error, first try rebooting the Mix

Engine using PR&E Navigator. If the red LED r ema ins lit, power cycle the

Mix Engine (un plug the AC cord from the Mix Engine, wait five seconds

then plug the AC cord back in) .

If the red Error LED lights u p a gain after it restarts it indicates a serious

fault in the Mix Engine which will require service. Contact Wheatstone

technical support for assistance. See Chapter 5 (page 58) for information

on obtaining service and support for your DMX console.

13

CHECKING OUT THE DMX FEATURES

With the Mix Engine and DMX Surface both powered up and connected

to the built-in Ethernet switch, on a stand-alone DMX all three green LEDs

on the Engine’s front panel (Figure 2-5 on page 13) will be lit. The Surface

should appear as shown in Figure 1-1 on page 5, but without any m ete r

displays since there’s no audio connected to the c onsole yet!

Note: Figure 4-2, on page 46, identifies each fader chann el control

and Figure 4-4, on page 49, identifies each monitor control.

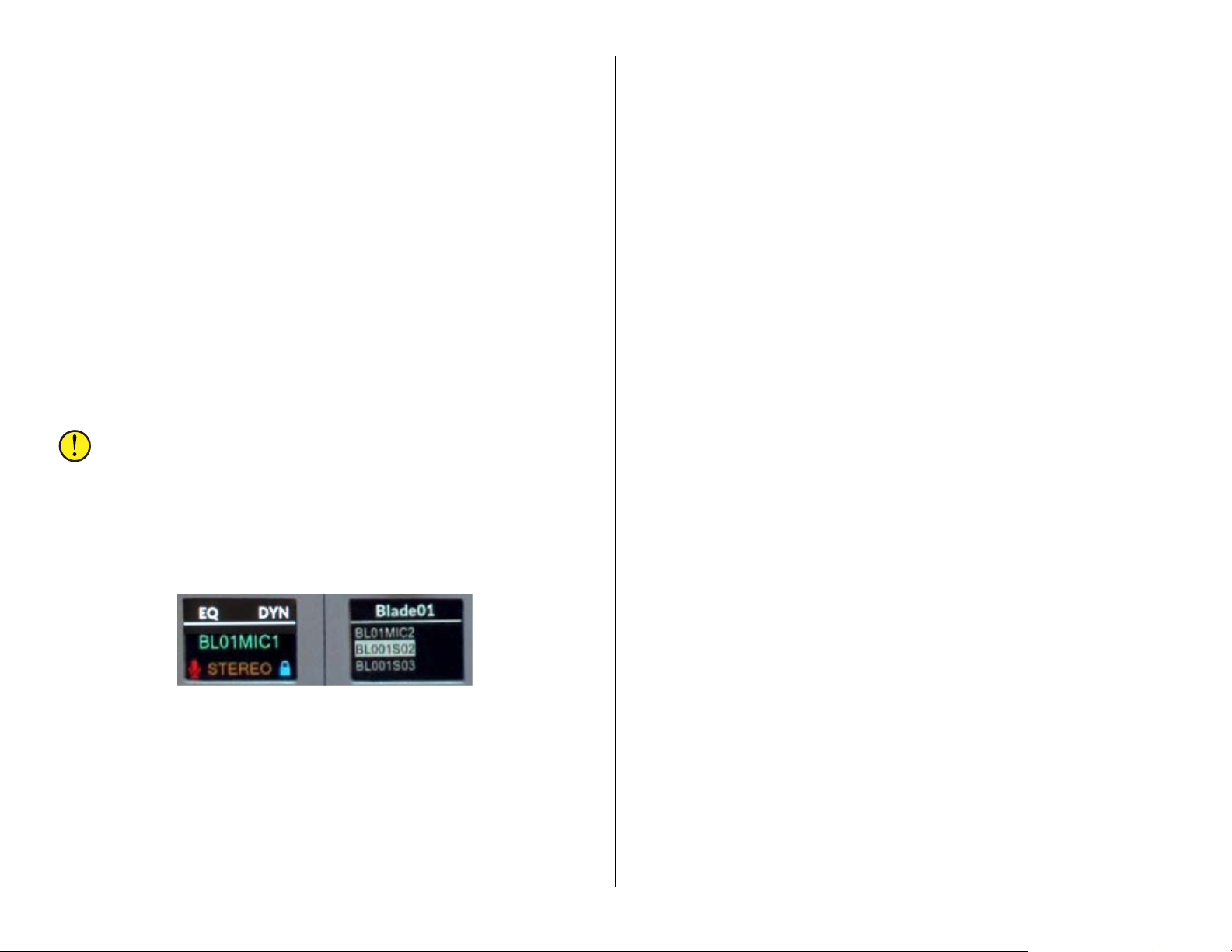

On Fader Channel 3, with the channel turned off, rotate the Channel

Encoder. That channel’s display switches to show a list of source names

with one name h ighlighted (Figure 2-6). The name shown above the white

line (Blade01 in Figure 2-6) lists the name of the system device with that

highlighted source (Blade 01 is the default n a m e for the PR&E Mix Engine).

Rotate the channel 3 encoder until BL001S02 is highlighted as shown in

Figure 2-6. Press on c e on the channel encod er to select that signa l. This is

called “clicking” the encoder–just like clicking a PC m ouse button. The

highlighted signal is now connected to that fader channel and BL001S02 is

shown, in green, in the middle of the channel 3’s display (Figure 2-7).

Note that in the nor m al displays the spac e a bov e the white line is used

to show when cue, equalization, and dynamics are active on that channel.

When cue is active, CUE is shown in the middle of this area. Icons for the

High Pass and/or Low Pass Filters are shown wh en they’re active. EQ (for

Equalization) and DYN (for Dynamics) are shown when they’re active on a

channel. From the factory, mic processing is loaded into channels 1 and 2,

and is turned on, hence the EQ and DYN indications on those two fader

channels.

Figure 2-6 Selecting a Channel Source

Rotate the encoder clockw ise to move the highlighting down the

alphanumeric list of names. Rotate the en c oder c ounter-clockwise (CCW)

to move the highlighting up through the names. The names wrap to

present a continuous list. NoSource, which appears at the top of the list, is

a good way to identify when the names have wrapped around.

Every physical input on the DMX Engine has a signal name of up to eight

characters. The default names all start with BL, for Blade, followed by that

Blade’s ID number (1 is the default ID number for the PR&E Mix Engine).

The default names end with a signal number, like S02, to identify the

physical connection on the Mix Engine and optional Razor I/O Interface.

All DMX inputs are set for stereo—except for Analog Input 1, which is

set as dual mono, with BL01MIC1 and BL01MIC 2 set as its source names.

The remaining Analog inputs are: BL001S02; BL001S03; and BL001S04.

The four AES input s’ default names are BL001S05 thru BL001S08. These

numbers match the jack numbers listed on the Mix Engine’s rear panel.

Analog input 1 is design ed to jumper to MICS OUT so the two mic

preamps can be used without ha ving to change any settings. If the built-in

mic preamps are not used, Analog Input 1 can be reset to a stereo input

using PR&E Navigator

After the Mix Eng ine’s physical input signal names you’ll see the internal

signals within the DMX. Many, if n ot m ost, of these signa ls are typically

not set as “visible” on fader channels, but on a new console all signals are

set as visible to ease installing and configuring the DMX. Setting signal

visibility is cover ed in the Visibilities Page Tab section starting on page 29.

(see page 38, Changing the Signal Type section).

Figure 2-7 Displays for Channels 1, 2, and 3

Below the source name, in oran ge, is the channel’s mode setting. Th e

default setting for every channel is STEREO (mono sign a ls like mics are fed

to both left and right channels by default).

To either side of th e m ode name are icons to indicate source status. On

the right side a lock ic on indicates that source’s LIO status (logic control

status) by color when the channel is turned on. On the left side—if the

channel source is identified as a m ic , there’s a mic icon which turns red

while that channel is turned on.

Advanced Channel Features

Each channel has three Advanced Channel Features: Mode, Pan, and

EQ & Dynamics, which are accessed by “double-clicking” or quickly

pressing twice on the channel encoder. The advanced features are all

unlocked when the DMX ships from the f a c tory.

“Double-click” the channel 3 encoder (tap it twice quick ly). Mode now

appears above the white line. Rotating the encoder, while Mode is shown

in the display, ste ps through the four audio modes (Righ t, Left, Mono, and

Stereo). Make sure STER EO is s hown then double-click the encoder again.

Now Pan is shown above the white line. Rotating the encoder now pa ns

or balances the signal to the left or right of center. Readjust the encoder

so CENTER is shown then double-click the encoder again.

The displays on channels 1 -8 switch to show the EQ & Dynamics

control screens. The initial display screens set whether EQ & Dynamics are

turned on (set I n) or off (set Out) on that channel. Additional screens are

14

displayed to adjus t the EQ & Dynamic s settings. On fader channels 1 and

2, both EQ and Dynamics are set In by default, for “light mic processing,”

since these channels are typically assigned to the Host and Guest mics.

The rest of the fader ch annels do not have any EQ or Dynamics settings

applied. Refer to the Cha pter 4 s ec tion , EQ & Dynamics, starting on page

51, about how to: set EQ and Dynamics in/out; how to adjust their

settings; how to save the EQ & Dynamics settings on any channel; and

how to recall previ ously saved settings to any channel.

For now, double-click the channel encoder again. The eight channels

switch to their normal displays showin g their current source names.

Note: The Mode, Pan, and EQ & Dynamics controls should be

selectively locked out from board operator access pr ior to releasing

the console for daily use. This is done using the Talent Access page

tab in the DMX Surface S e t up

app (page 23).

Connecting Audio

To understand the audio connections and DMX Surface features, connect

a stereo analog audio signal (like a +4 dBu test tone or a CD player) to the

ANALOG 2 IN jack on the Mix Engine (Figure 2-9 on page 16 shows the

Mix Engine jacks) using wiring that follows the StudioHub+ wiring protocol

(Figure 2-4 on page 12). This audio input is named BL001S02, which was

set as the Channel 3 source in the previous section.

Assign channel 3 to PGM 1, PGM 2, PGM 3, and PGM 4 (light up all

four assignment buttons). Set the channel fader so the middle line on the

fader knob aligns with the two arrows at the -12 dB position. This sets that

channel for unity gain through the console.

the CR Out jack. In the left column of the monitor section, select PGM 1

as the monitor source for the Control Room. DMX PGM1 is shown in the

left monitor disp la y (Figure 2-8). Use the CR encoder to adjust the

volume of CR Out. Its relative output level is indicated in the bottom bar

graph, with the sp ea ker icon, in the lef t m onitor display.

Move the test output to the HDPN Out jack. Its output level, and the

DMX Surface’s headphone jack level, is adjusted using the HDPN

encoder. Its level is indicated in the bot tom b a r g r aph in the righ t display

with the headphone icon. It uses the same monitor source as CR Out.

Move the test output to the STU Out jack. Its current monitor source is

shown in the right-hand display. NoSource appears in the right-hand

display from the factory. To set a source for the Studio, press/hold (for

three seconds) the EXT button just above the Studio encoder. The button

blinks and a list of source names appear in the right-hand display. Rotate

the Studio encoder to highlight DMX PGM1 then click th e Studio encoder

to assign that sour ce to the EXT button. The EXT button lights up solid and

DMX PGM1, now set as the Studio monitor source, is shown in the righ t

monitor display.

The Studio encoder is also used to adjust the STU Out volume, when not

selecting monit or s ources. The s tudio monitor level is indicated by the

upper bar graph in the right display with the speaker icon.

Turn Channel 3 on by pressing and releasing the On button directly

below that channel’s display. The button turns red indicating that

BL001S02 is now connected to the assigned Program buses.

If the input is a +4 dBu test tone, then all of the green meter segments

will light, along with the first y ellow segment, which indicates -20 dbFS

(dBFS = deciBels below Full Scale). This is equivalent to 0 VU on an analog

VU meter. The Program 1 and Program 2 meters should show this

level. The Switched meter will also show this level by press in g Meter

PGM 3 or Meter PGM 4 in the monitor s ection of the control s urface.

Connecting an analog test set to each of the four PGM ANALOG outpu ts

will confirm each is putting out +4 dBu. Connecting a digital test set to the

four PGM DIGIT AL outputs (they h av e the same signals as the four analog

jacks) will confirm each is putting out -20 dbFS. The default sources

connected to the PGM outp uts are the PGM 1 to PGM 4 buses, bu t an

alternate source can be connected to any of these four stereo-only outputs

using PR&E Navigator

To check how the four analog monitor outputs (the four OUT jacks) work

connect a test set or a powered mon itor speaker with a balanced input, to

’s Crosspoint grid to change their connection.

Figure 2-8 Monitor Displays Show the Monitor Output Levels

Move the test output to the CUE Out jack. Press Cue on channel 3 (it

lights and CUE is shown in the chann e l display) then use the Cue encoder

to adjust the cue v olume. The upper bar gra ph in the left display, with a C,

indicates the cue output level. Note that e ven though this is a “stereo”

output, the DMX cue system is a mono sum of the input signal.

By following the steps covered in th e Checking Out the DMX

Features section you should now have a good understanding of

how to connect audio into and out of the Mix Engine and how to

use the DMX Surface controls. The rest of this chapter goes over

more specific details about the audio and logic jacks on the Mix

Engine and Razor I/O Interface.

Chapter 3 (beginning on page 20) covers how to install and use

15

the supplied PR&E apps (DMX Surface Setup

the PR&E System Configuration Tool

configure the console for your specific application.

) to name the DMX signals and

, PR&E Navigator, and

PR&E MIX ENGINE SIGNAL NOTES

This section covers the PR&E Mix Engine connections and which PR&E

app is used to configure that signal or c onnection. Figure 2-9 details the

audio and logic jacks on the back of the Mix Engine.

either a logic outpu t (e.g., as an On Tally, Studio In Use tally, Start Pulse,

etc.) or as a logic input (e.g., for Channel On, Channel Off, Cue, etc.).

Each Blade (PR&E Mix Engine, Razor, and M4IP-USB) also has 128 Soft

LIO (SLIO) logic signals th at can be used with WNIP-compatible devices,

like talent stations and media servers, for bi-directional command and

control of the DMX cons ole over Ethern et. SLIO signals are also assigned

using PR&E Navigator

(starting on page 40) for details on assigning both LI O and SLIO logic.

as either an input or an output. See Assigning Logic

Figure 2-9 Mix Engine, rear panel, RJ45 Audio & Logic Jacks

Mic Preamps – There are two microphone preamps in the Mix Engine

with female XLR j a cks. One or two, dynamic or condens er, mics can be

plugged into these low-noise preamps in or d er to boost the mics up to line

level. The two mics are typically assigned to fader channels 1 and 2, which

have factory-set EQ and Dynamics Processing already applied, so having

to use external mic processors is not req uired with the DMX . If additional

mic preamps are needed, each Razor 16A I/O Interface has two mic

preamps and each M4IP-USB Blade has four SQ mic preamps along with

Vorsis mic processing, four USB ports, and local analog and AES outputs

for headphone and studio monitors or recor ding outputs.

Each Mix Engine preamp has an input trim control and a 48-volt

phantom power sw itch. Set the phantom switch on

mics. A yellow LE D lights to show phantom power is active. For dynamic

mics, like an RE-27, set the phantom power s witch to off (LED off).

The trim level, if it needs adjustment, is made after the console is wired

up since it requires the mic to be assigned to a fader chann el so its level

can be seen on th e meters and it can be listened to. Typically, the trim

level is adjusted with the channel fader set to un ity gain. With the talent

speaking at their normal “radio voice level” adjust the trim pot so the top

of their average bar graph signal is around -20 dB FSD or their peaks are

bouncing around -8 dB dBFS on the Program meters. If you want to add

EQ and Dynamics Processing, you would do so after the mic preamp gain

trim is properly adjusted.

MICS OUT – This jack has the line level outputs from both mic preamps:

Mic Preamp 1 is “left” and Mic Preamp 2 is “right.” Connect a short

straight-thru CAT5 cable from MICS OUT to ANALOG IN 1 since that

input is preset for two mono mic signa ls rather than for a stereo signal as

are all other Mix Engine inputs.

LOGIC - The Mix Engine and Razor I/ O Interfaces each have one RJ45

Logic jack for con necting logic to non-IP external devices like a Henry

warning light in ter face or a CD play er . Each Logic jack has six LIO logic

ports (on pins 2–7) plus ground (on pin 1) and +5 volts (on pin 8). Each

logic port is independently a s s ign ed, using PR&E Navigator

to power condenser

, to set it as

ANALOG IN - All analog inpu ts a r e des ign ed for balanced +4 dBu sign a ls,

but unbalanced -10 dBv signals can also be connected—without needing a

match box, since each input has input gain and balance controls in PR&E

Navigator (see Level & Balance Con tr ols on page 39).

Inputs are labeled as ANALOG IN 1-4 on the Mix Engine. They are

assigned these default names: BL01MIC1 (in put 1 left), BL01MIC2 (in put 1

right), BL001S02 (input 2), BL001S03 (input 3), a nd BL001S04 (input 4)

in the DMX signal lists. Inputs 2, 3, an d 4 can also be separated in to two

mono inputs (see Changing the Signal Type on page 38) to allow two

independent mono signals, like a pa ir of phone hybr ids, to c onnect to one

RJ45 jack.

DIGITAL IN – The four digital inputs are designe d for stereo differ ential

AES/EBU (AES3) signals which, in most cases, can alternately have an

unbalanced S/PDIF digital signal connected. These jacks are labeled as

DIGITAL IN 5–8 on the Mix Engine. Their def a ult names are BL001S05 –

BL001S08 in the signal list s . They have the same gain/balance controls in

PR&E Navigator

split into two mono signals for connecting digital phone systems.

Note: Digital In 8 can also be used as a Sync Ref er ence input to

synchronize the DMX to an external sample cloc k signal.

PGM OUTPUTS – There are eight PGM Outputs (f ou r stereo bala nced

analog and four AES/EBU) which, by default, connect to the PGM 1 – PGM

4 buses. In the PR&E Navigator

named CB01PGMA – CB01PGMD. A different source can be conn ec ted to

any of these destinations but note th at these outputs cannot be split for

dual mono out operation and the same signal is appli e d to both the analog

and AES/EBU outputs. If you change the source on any PGM output,

uncheck the DMX S ur fa ce Se tup

(Input/Output on page 23) since that option reconnects the four PGM

buses to the four PGM outputs if the Mix Engine is rebooted or powered.

Note: The four AES/EBU outputs can only connect to balanced

AES/EBU inpu ts. Connecting them to unbalanced S/PDIF inputs will

not work. A signa l tr a nslator is required.

as the analog signals and any AES/EBU input can also be

Crosspoint Gr id these four destinations are

option Use Def a ult Signal Mapping

16

MONITOR OUTPUTS – The default sources connected to the four stereo

analog outputs (CUE, CR, STU, HDPN) are: DMX CUE; DMX CR; DMX Stu;

and DMXHdpn. Normally the four monitor level controls (CUE, CR,

STUDIO, and HDPN) control the levels of these monitor outpu ts (their

default destina tion names are: CB01CUE; CB01CR; CB01STU; and

CB01HDPN in the PR&E Navigator

source is connected the Surface control no lon g er affects that output. If

any alternate source is connected be sure to uncheck Use Default Signal

Mapping in the DMX Surface Setup

CR OUT is normally connected to powered Control Room monitor

speakers, while CUE OUT is normally conn ec te d to one or two powered

cue speakers, so they a r e not often connected to an alternate source. If

there is no associated talk studio, the STU OUT jack could connect to a

hybrid and call recorder, an air skimmer, an internet streamer, or oth er

device. Likewise, the HDPN OUT jack, if it doesn’t need to connect to an

outboard headphone amp, could connect to an alternate source for

another stereo analog line output from the Mix Engine.

Note: The built-in ¼” headphone jack, on the right side of

Surface, is destination DMXH d pn, so it is not affected if the HDPN

OUT jack on the Mix Engine is connected to an alternate source.

Crosspoint grid). But when an alternate

app to maintain tha t new source.

ADDITIONAL DMX FEATURES

This section covers other DMX Surface operational features including

how to use the PGM 4 assignment buttons as Off Line bus select buttons

and how to assign sources to the user-set buttons in the monitor control

section. Other topics covered include: gain trim and balance control on the

inputs and outputs; setting mic and monitor muting; and using Telco

devices with the DMX console.

Callers & Remotes

Callers and remotes are commonly called Telco devices since each has a

From Network audio signal (the audio from the caller or remote) and a To

Network audio sign al (called the mix-minus signal) which is sent back to

the Telco device so the caller / rem ote can hear the board operator or hear

the on-air signal—but always minus their own From Network audio.

The To Network audio s ig nal is typically derived from the Telco channel’ s

bus-minus signal which is manually connected to th e hybrid or codec using

the crosspoint grid in PR&E Navigator

Associated Conn ections (each method is cov er ed in Chapter 3).

When using callers and remotes on the DMX, the PGM 4 bus assign

buttons serve double-duty as Off Line (OL) bus assign buttons. The Off

Line bus is solely used to create the To Network signal for a ph one caller

or remote while they are not on-air (i.e., their channel is turn ed off). When

the board operator and/or producer’s mics are assigned to PGM 4/OL

(which is also typically set for p r e -sw itch and pre-fader operation), the

talent can carry on a hands-free conversation with the calle r or r e mote.

or automatically connected by using

When the caller or r emote goes live, the To Network signal is the busminus of the air s ignal (typically PGM 1) so that the caller/remote hears

everything else going to air, but always min us their own audio.

Selecting a Telco device as the channel source is what triggers the builtin Auto Fold Back feature which automatically toggles the To Networ k

signal between the OL bus ( used when the channel is off) and the on-air

PGM bus (used while their channel is turned on). This feature allows a

caller or remote to go liv e to air without the boa rd operator ha ving to

change any board settings . If the board operator n eeds to talk to the caller

or remote while they’re live, pressing the TB button override s the PGM

bus-minus audio sending their mic to that caller or remote.

When a caller or a remote is assigned to a dedicated f a der c hannel,

setting up their To Network signal is simple: that fader channel’s busminus signal is connected (typically using PR&E Navigator

Grid) to the phone hybrid or codec outpu t from the Mix E ngine or Razor.

When callers (or m or e likely remotes) ar e set visible on mu ltiple fader

channels things g et m ore complicate d s ince their mix-minus signal, which

is derived from the bus-minus signal of the channel the caller or remote is

on, also has to be changed to be from whatever channel they are on .

Fortunately, the PR&E Navigator

“trigger conditi on” to be set up for the s ystem to monitor: like a codec

being dialed up on fader cha nnel 15. When that trig ger condition is

detected the system responds by connecting, in this example, the fader 15

bus-minus signal to that codec’s output.

Typically, an Associated Connection would be setup for each fader that a

codec is visible on so that no matter which channel the code c gets taken

on, the correct bus-minus signal will always be connected back to that

codec. Setting up Associated Conne c tions is covered in the Creating and

Using Associate Connections section on page 41.

Associated Connections feature allows a

’s Crosspoint

Using the Off Line Bus

Because the DMX Surface does not have dedicated Off Line bus

assignment buttons, the PGM 4 bus assign buttons can be setup to

function as Off Line assign buttons using the DMX Surface Setup

the PGM 4 / Off Line Options section on page 26).

When this is done, the board operator mic channel is assigned to the OL

bus (its PGM 4 button is lit). When the caller/remote ch annel is off, and

assigned to cue, the board operator can hear th e caller/r em ote in the cue

speakers (or their headphon es ) and th e c aller/remote can hear the talent

using their mic, to a llow for a hands-free conversation.

If a Host or call screener also need to talk to the caller/remote then their

mic channels would also be assigned to PGM 4. They would then talk to

the caller using their mics an d hear the caller through the c ue speaker.

app (see

17

Telco Device Connections

Each caller/remote device’s From Network signal typically con nects to a

Razor analog or digital input with two devices sharing a common RJ45 jack

input, which is s e t for two mono signals ra ther than one ster e o s ignal.

A Razor mono analog or digital output is then connected to the To

Network input on the caller/remot e de vice. The caller/remote output is

connected, in PR&E Navigator

for the channel that the caller/remote is using. See the note on the next

page regarding mono vs. stereo signals on Razor I/O Interfaces.

’s Crosspoint grid, to the bus-minus signal

Signal Gain & Balance Adjustments

PR&E Navigator has level controls for every ph ysical input an d output on

the Mix Engine and Razor (see Level & Balance Controls on page 39). Up

to 18 dB of gain, or 18 dB of trim, from unity gain (0 dB), can be applied

in real time to the audio. Viewing and adjusting the level controls for the

inputs is done in the Blade > Sources tab for each Blade. The outputs are

viewed and adjusted in the Blade > Destinations tab for each Blade.

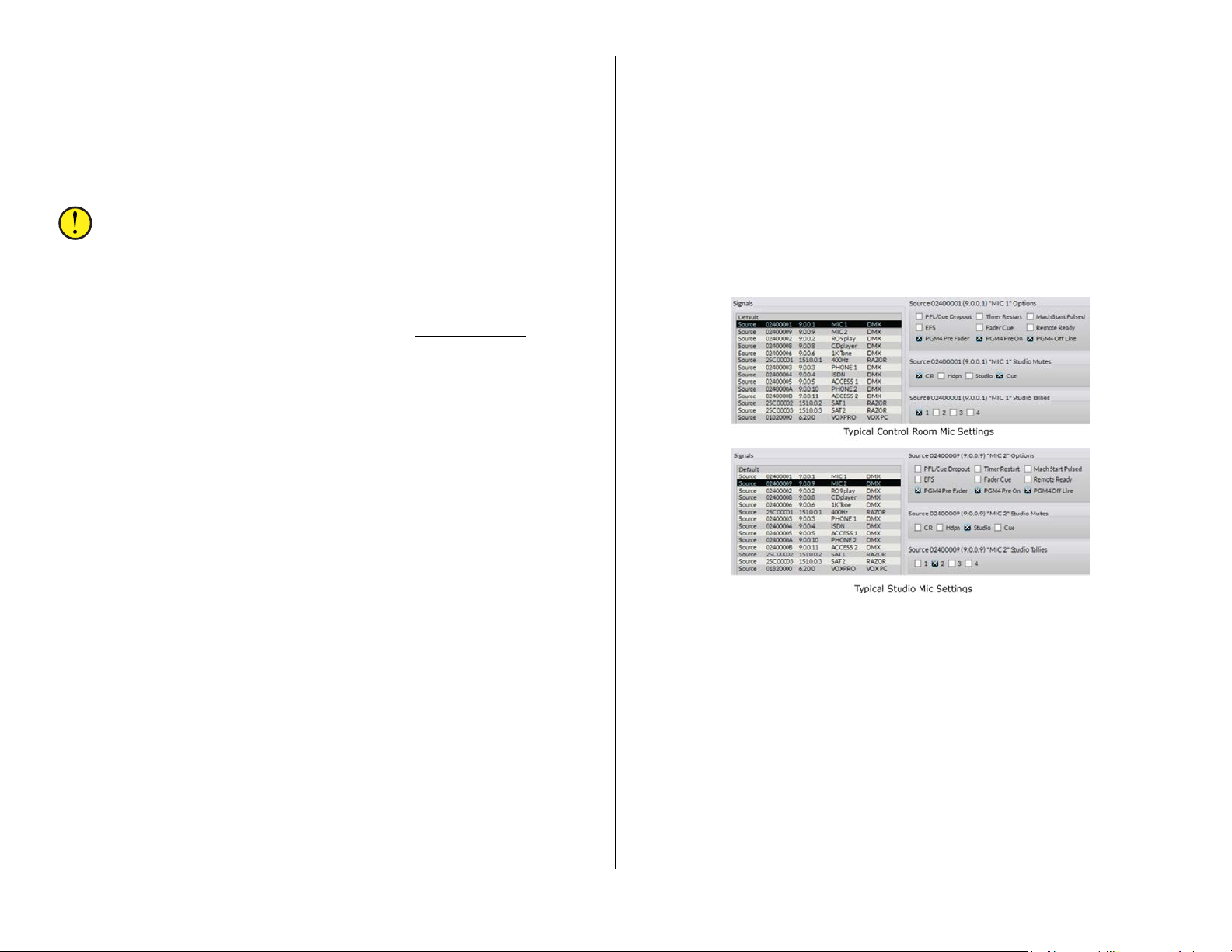

Monitor Muting & Hot Mic Logic

Although any signal can be set to mute th e monitor outpu ts , typically

only mics are set to mute outputs. For Control Room mics you’ll want to

mute the CR and CU E outputs, unless C ue only feeds the studio, in which

case the Studio mics would be s et to m ute the STU and CUE outputs.

These settings are made usin g the DMX Surface Setup

tab (details on using the VDips Page Ta b is on page 25).

app’s VDips page

Setting Monitor & Meter Button Sourc es

The DMX Surface’s monitor section, at the right end of the S urface, has

two columns of controls (see Figure 4-4, page 49). The lef t c olumn (CR)

has the meter and Control Room monitor controls ; the right column

(Studio) has the Events, Timer, and Studio monitor controls. There are

also four user-set source selectors (Meter EXT, CR EXT 1 and EXT 2, and

Studio EXT) plus a user-set Soft button which can be assigned for a

number of different functions, from simple (being set as a talk-to-producer

button or as a remote door lock/unlock button) to complex (taking a salvo

to setup certain channels for a specific function like voice tra cking).

To assign a source to the Meter EXT, or to the CR Monitor EXT 1 or

EXT 2 buttons, press/hold that button for thr ee s econds (until the b utton

begins to blink). The left monitor dis play switches t o s how the source

names available to be assigned to th a t button. Highlight the desired n a m e

using the Cue/Source en c oder a nd then click the encoder to ass ign the

highlighted sourc e to that button.

Two sources can be assigned to the Studi o E XT button: one is selected

when lit and the other is selected when it’s unlit. Press/hold the unlit EXT

button, until it bl inks, to set the unlit button source . Press/hold the lit EXT

button, until it bl inks, to set the li t button source. I n e a c h case the right

monitor display switches to show the available source names that can be

assigned. Use the Studio encoder to highlight a sou r ce name then click the

Studio encoder to a s sign that source.

You can also select a s tudio monitor “ on-the-fly” source by press/holding

the studio encoder, for about three second s , until the list of visible source

names appears in the right-hand monitor display. Highlighted the desired

source then click the Studio encoder. The selec ted source is th e n shown in

red in the right monitor display.

The list of source names that can be assigned to the EXT buttons is set

using the DMX Surface Setup

app’s Visibilities page t a b (page 29).

Saving and Taking Events

The four Event buttons (Event 1 – Event 4) are used to both save and

take console events. A console “Sa ve Event” saves the current settings for

all fader channels (including the Advanced Channel Feature settings) along

with the monitor panel sources and user-set button settings. Typica lly,

engineering sav es the four events a nd then locks out the s ave function

from further us e s o that board operators c an only take eve nts.

To save an Event after the console is se tup for a specific s how or

daypart: press/hold the Event button you want to update. After about

three seconds the button begins blinking. Continue holding the button for

another couple seconds, until the button is lit solid, which indicates the

current status of every Surface control is now saved to that Event number.

Note the event number, an d its console fun c tion or day part, and relay

that information to the board operators.

To take an Event press/hold an Event button until it begins to blink th e n

release the button. Tapping the blinking button then takes that event,

updating the DMX Surface settings. That Event button then is lit solid to

indicate it’s currently active.

Once the desired Events are saved use th e DMX Surface Setup app’s

Talent Access page tab (page 23) to lock out the board operat ors from

overwriting the saved eve nts by unchecking Allow Save Events.

Programming the Soft Button

The Soft button in the CR column in monitor controls can be assigned to:

take a salvo (to make multiple system con nections simu lta neously); make

a momentary connection (useful for talking to an external destination); be

an indicator, to show the hotline phone is ringing; or control a logic output

with button illumin ation (like a Dump button for a profanity delay unit with

the LED functioning as a safe indicator).

How the Soft button functions: as a tally only; as a toggle switch; or as

a momentary switch, is sent in the Buttons pa g e ta b in the DMX Surface

Setup app (page 28). What the button controls, and how the button’s LED

is controlled, is se t in the PR&E Navigator

starts on page 40).

18

app (the Assigning Logic section

RAZOR I/O INTERFACE NOTES

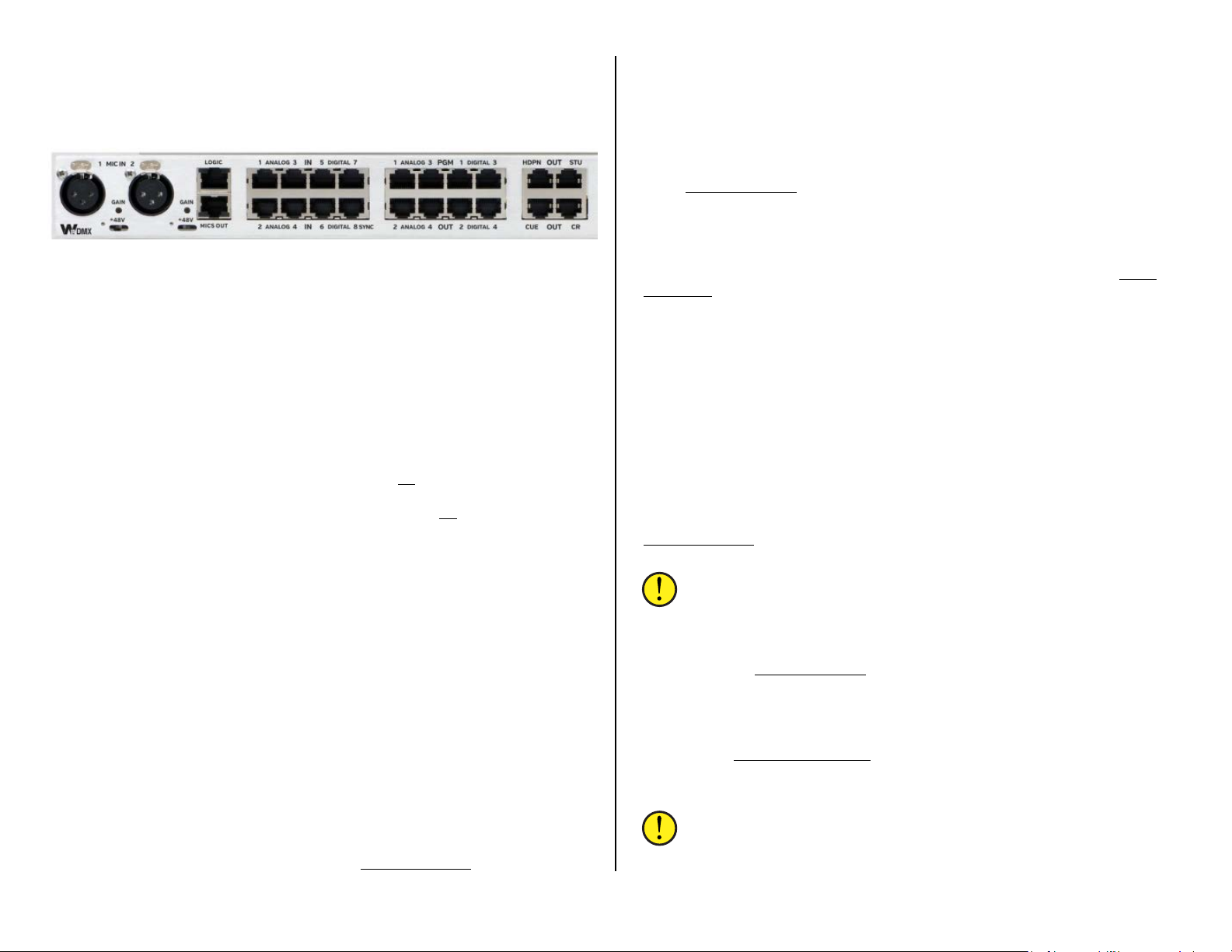

Each Razor has eighteen RJ45 connectors: eigh t have the audio in puts;

eight have the audio outputs; one h a s the Logic LIO; and one (Ethernet)

connects the Ra zor to a PR&E Mix Engin e Ethernet switch port or to a

facility AoIP s witch in a larger PRE-IP network.

On a Razor 16A, sixteen RJ45 connectors are used for the analog inputs

and outputs, each carrying two analog signals (stereo or dual mono). The

Razor 16A also ha s two built-in mic prea m ps, like the PR&E Mix Engine, so

it also has two fema le XLR Mic Inputs and one Mics Out RJ45 jack, which

is connected to an Analog Input usin g a short CAT5 patch cor d . That input

would then need to be split into two mono inp uts from its default stereo

setting using the PR&E Navigator

for details on splitting a stereo input or output into dual mono signals) .

On the Razor 16D, the sixteen RJ45 inputs and outputs each carry one

stereo AES/EB U signal. Any input or output can also be spli t into two mono

signals in PR&E Navigator (page 38, Changing Signal Type).

On the Razor 16AD (rear p anel shown in Figure 2-10) the first four

RJ45 jacks (IN 1–4) are stereo analog inputs. The remain ing four RJ45 IN

jacks (IN 5–8) have four stereo AES/EBU inputs. T he first four RJ45 O U T

jacks have the analog outputs (OUT 1–4) while the last four RJ45 jacks

(OUT 5–8) have the stereo AES/EBU signals.

(see Changing Signal Type on page 38

screen shows the levels for that Razor’s inputs. A second screen shows the

eight stereo output levels. The othe r two screens show tec hnical details for

that Razor like its system name, IP address, MAC address, and version of

code that’s run ning on that Razor.

Figure 2-10 Razor 16AD rear panel connections

Note: The Razor’s Ethernet A oIP jack has eight paired incoming

and eight paired outgoing audio streams. When a Razor input or

output is split into tw o mono signals , each mono signal consumes

one of the eight aud io s tr eams going into or out of the Razor . This

means that if f our stereo inputs or outputs are split in to eig ht

mono signals, and all of those mono sign a ls are connected in PR&E

Navigator, the remaining four stereo inputs or outputs cannot be

used simultaneously because all eight audio streams would already

be consumed by the eight mono sign a ls .

LOGIC - The RJ45 Logic connector is used to connect hard-wired logic to

external devices like warning light interfaces an d tallies. Each Logic

connector is wired per Figur e 2-4 on page 12. The logic conn ec tion s a r e

configured using PR&E Navigator

assigned logic function (see Assigning Logic on page 40).

FRONT PANEL DISPLAY & CONTROL - The Razor has a front panel

OLED display and a rotary encoder (Figure 2-11). The encoder is used to

step through the four scr eens that can be displayed on the Razor. One

as either a logic input or output with an

Figure 2-11 Razor front panel OLED and Encoder

19

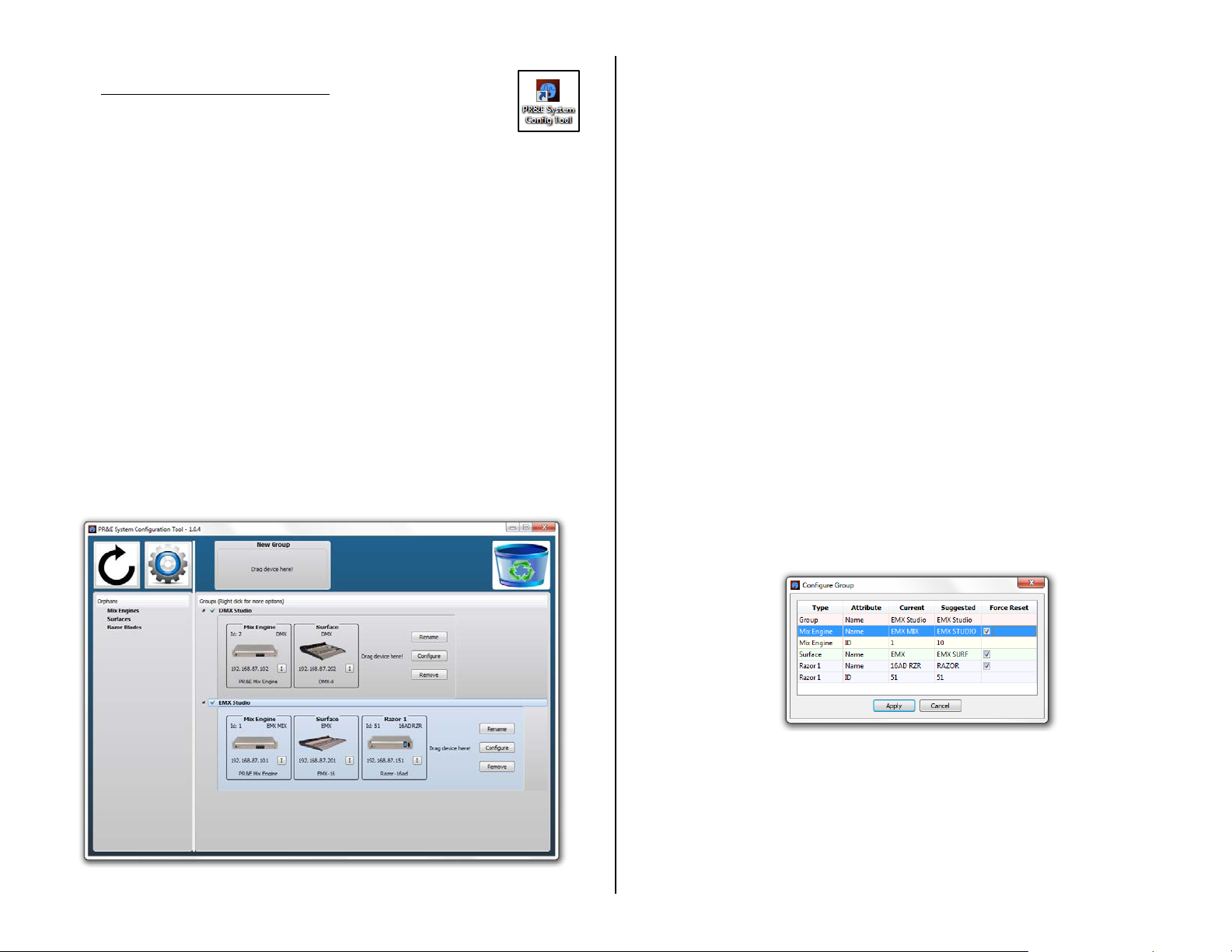

3 – PR&E APPS AND CONSOLE CONFIGURATION

T

he DMX console’s factory-default configuration settings

allow it to be powered u p a nd used straight out of the box.

To set up the console for your specific application the

default configur a tion settings are edited using the software

apps included on a USB flash drive that ships with the console. The apps

can also be downloaded from a Wheatstone file download site (con tact

Wheatstone Tech Support for the links).

The PR&E software apps are installed on an admin PC running Windows

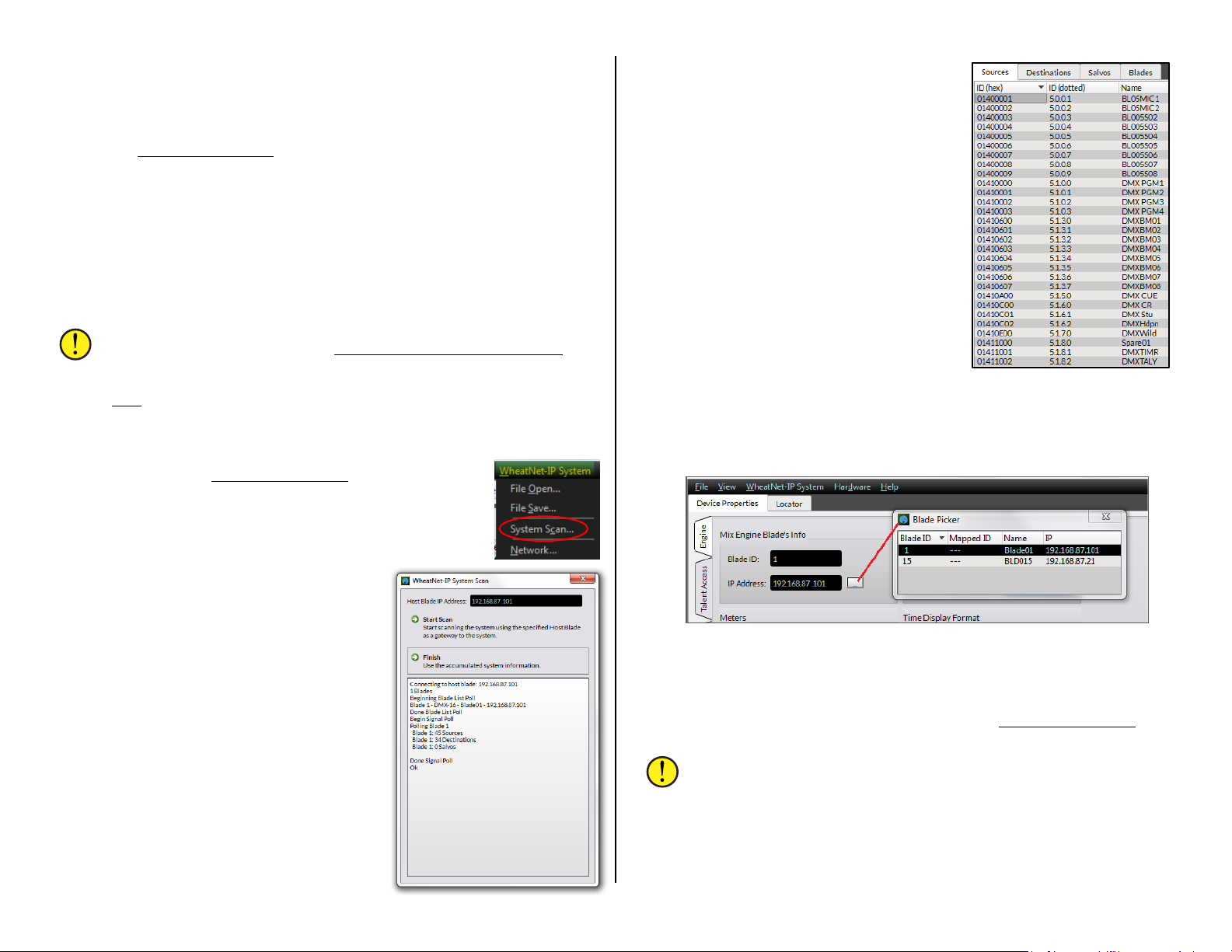

10, 8, 7, or even XP sp3. To communicate with the Mix Engine and DMX

Surface, this admin PC must be set for a fixed IP address in the

192.168.87.0 subnet. Even though the DMX can be changed to use

another Class C subnet, we recommend leaving the DMX set to the default

192.168.87.0 subnet.

Before setting the IP on the NIC connected to the DMX, c onnect the

admin PC to Port 1, 2, or 3 on the Mix Engine’s built-in Ethernet switch

(see Figure 2-3, page 11). T hen set the admin PC to 192.168.87.21 with

a subnet mask of 255.255.255.0. This puts it on the same subnet as the

PR&E Mix Engine (IP address = 192.168.87.101 & name = Blade01) and

the DMX Surface (IP address = 192.168.87.201 & name = Surf01).

set to the recommended settings. If the NIC was incorrectly assigned,

close the DMX Surface Setup

Panel to correct the s e ttings, then restart the DMX Surface Setup

Figure 3-1 DMX Surface Setup, Default View

app then use the adm in PC’s Network Control

app.

To insure each PR&E app is properly installed right-click on the ins ta lle r

icon, or on its file name, and select “Run as Administrator.” Accept the

default installation settings. If a previous ver sion was installed, the

installer automa tically uninsta lls that version prior to in s talling the new

version. A shortcut icon is added to the desktop. In the Sta r t m enu, the

three PR&E apps can be found in the Wheatstone PR&E folder.

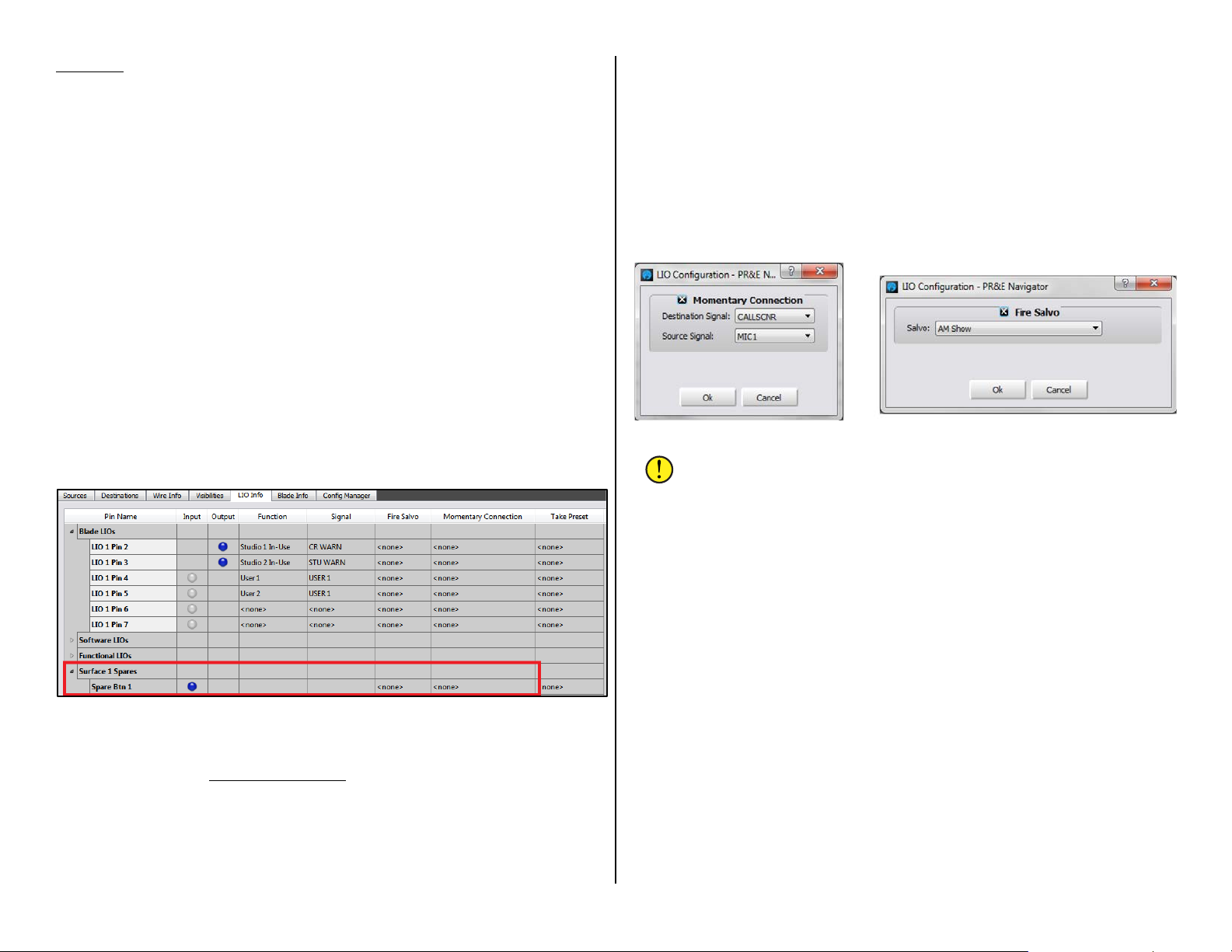

DMX SURFACE SETUP APP

The DMX Surface Setup app is one of the main apps used to

configure the DMX console (the other being PR&E Navigator)

Double-click its desktop icon, shown at right. The app opens

showing the Device Properties tab (Figure 3-1). Click on th e

Locator tab to show it (Figure 3-2). The Locator tab lists every

DMX device connected to the Mix Engine’s Ethernet switch. For a

new DMX console only two dev ices will be shown: the Mix Engine and the

DMX Surface. (Figure 3-2 also shows that the admin PC has the WNIP

audio driver installed to play and record AoIP audio.)