Page 1

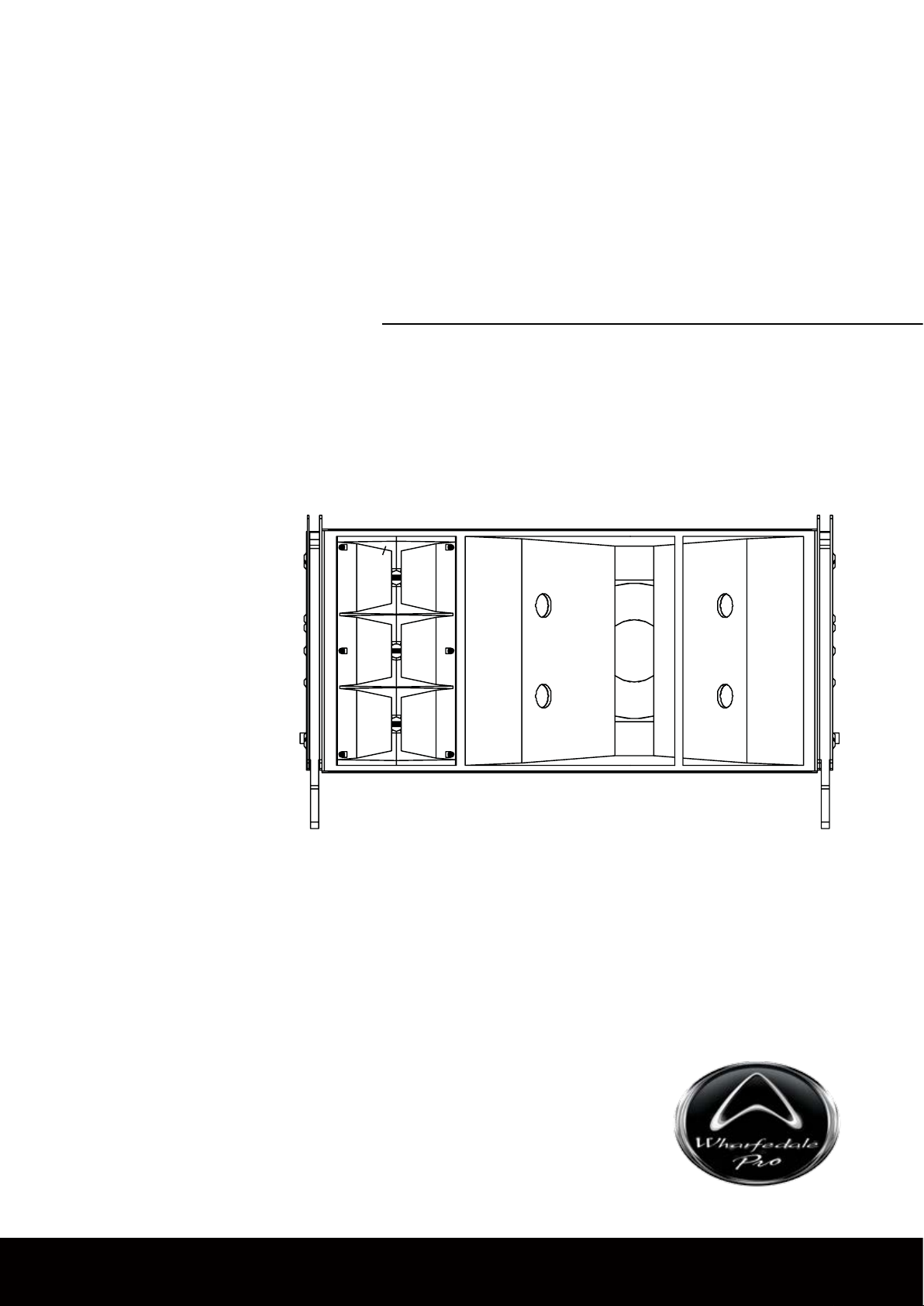

WLA-12

OPERATING MANUAL AND USER GUIDE

www.wharfedalepro.com

Page 2

OPERATING MANUAL AND USER GUIDE

Important Warnings And Safety Instructions

• Read these instructions

• Follow these instructions

• Keep these instructions for future reference

• Heed all warnings

• Do not use this system near water or moisture

• Clean only with a dry cloth

• Install in accordance with these Wharfedale Pro operating instructions

• Follow the manufacturers operating instructions for all peripheral devices such

as ampliers and processors

• Do not install near heat sources such as radiators, heat registers, stoves or

any other apparatus that produces heat (For example lighting systems and

ampliers)

• Use only accessories specied or supplied by Wharfedale Pro

• Do not use shielded microphone/instrument cables to connect ampliers and

speakers, use only approved speaker cables with proper connectors

• Use caution with placement and operation of this speaker system, permanent

hearing damage can be caused by prolonged exposure to excessive sound

ressure levels

p

• Refer all servicing to qualified professionals. Servicing is required when the

loudspeaker has been damaged in any way, such as impact damage, liquid

ingress or foreign object damage. In addition the loudspeaker should be

referred to qualied service personnel if there is any kind of malfunction.

Rigging, suspending and mounting should only be attempted by

experienced qualied professionals. Incorrect usage can result in

damage to equipment and property, injury and even death. Under

no circumstances should you attempt to rig, suspend or mount

these speakers unless you are fully qualied and certied to do

so by relevant local, state and national authorities. If you are not

properly qualied or do not know of pertinent regulations consult

qualified personnel for advice. Consult a structural engineer

before suspending a speaker system and ensure that the total

weight of your system can be held by the truss or mounting

surface.

Inspect all mounting hardware before your line array is own. If there is any

damage or distortion to any mounting hardware do not fly the array until

any damaged hardware is repaired or replaced. Only use Wharfedale Pro

supplied Quick Release Pins, contact your Wharfedale Pro Distributor if any

Quick Release Pins are lost or damaged.

1

Page 3

Contents

WLA Series

Important Warnings And Safety Instructions ...................................................1

Introduction ..........................................................................................................3

Features................................................................................................................4

Splay Angles ........................................................................................................5

Level Tapering .....................................................................................................5

Air Absorption .....................................................................................................6

Full Range Mode ..................................................................................................8

Bi-Amp Mode .......................................................................................................9

Parallel Wiring ....................................................................................................10

WLA-12 Fly Frame ............................................................................................. 11

WLA-12 Dolly .....................................................................................................13

Installation ..........................................................................................................14

Dimensional Drawings - WLA-12 .....................................................................18

Dimensional Drawings - WLA-12 Fly Frame ...................................................19

Dimensional Drawings - WLA-12 Dolly ............................................................20

Example Arrays .................................................................................................21

Specication ......................................................................................................22

Warranty..............................................................................................................22

2

Page 4

OPERATING MANUAL AND USER GUIDE

Introduction

The Wharfedale Pro WLA-12 is a mid format line array system with exceptional

output, frequency response, di rectivity and throw capabili ty. High tech

transducers

size ratio.

The

WLA-12 achieves ultra high sensitivity with its fully horn-loaded architecture.

A horn-loaded 12” LF is combined with three horn-loaded titanium compression

drivers for the HF, generating huge SPL with maximum efciency. The ultra high

sensitivity

of power ampliers, ensuring that your system can generate a huge SPL.

and enclosure design techniques give the WLA-12 a perfect power to

of the WLA Series creates punishing level from even the most modest

Physically

natural intelligibility, clarity and precision without the need for expensive speaker

management. A rear panel bypass setting allows you to use an external active

crossover network or speaker management system to ne tune the system.

hino Rock™, our proprietary ultra tough textured composite finish is used

R

to ensure that the WLA-12 can withstand life on the road, even in the most

demanding touring applications.

A versatile captive, hidden rigging system allows for fast setup with the widest

range of splay angles, while keeping the toughened steel brackets hidden

within the chassis. Inter element splay angles from 0° to 12.5° are possible, a

guarantee

aligned transducers and an internal passive crossover network deliver

that a WLA-12 system can meet the needs of your venue.

3

Page 5

Features

WLA Series

High Sensitivity, Full Horn Loaded Design

400W/800W/1600W Power Handling

12” Horn Loaded LF Driver

3” LF Voice Coil

3x 1” Exit HF Compression Drivers

1.8” Pure Titanium HF Diaphragms With Rare Earth Magnets

Physically Aligned Transducers

Internal Passive Crossover Network

External Crossover Bypass Switching

Front Hinged Rigging System

Captive Rigging Hardware with Tethered Quick Release Pins

Comprehensive Adjustable Splay Angles

Tethered Quick Release Pins (Each Rated To 2000Kg)

Rhino Rock™ Textured Composite Finish

Trapezoid Baltic Birch Plywood Enclosure

2x Parallel Speakon Inputs

4

Page 6

OPERATING MANUAL AND USER GUIDE

Splay Angles

The WLA can be configured with several different splay angles. The splay

angles determine the amount of overlap between individual units. This is used

o determine the amount of summation, or “throw”, for separate sections of the

t

array. As the splay angle between boxes increases the summation decreases but

spectral variance due to interactions between elements is also decreased.

For many venues a good compromise between throw and spectral variance

can be reached by varying the splay angle across the length of the array. By

varying the angular separation along the length of the array a balance can be

m

et for the required coverage. Smaller splay angles provide higher summation

to cover more distant seating and bleachers. Larger splay angles provide lower

summation

can provide even coverage over long distances.

with reduced spectral variance for closer seating. Used correctly this

Each group of loudspeakers with a different splay angle will require a separate

channel of amplification and different EQ settings. This is due to the different

summation effects caused by differing splay angles.

Level Tapering

Tapering the level of enclosures has a beam steering effect which can be used in

conjunction with angular separation between elements. The beam will be steered

away from the “on-axis” center line of the array toward the cabs being driven at

the highest level. The extent of the beam steering effect depends on the length of

the array and the level difference between the top and bottom of the array. This

echnique allows you to further tailor the vertical coverage to differently shaped

t

venues, reducing the level variance between the front and rear of the venue.

Ideally the level of each enclosure is tapered gradually (e.g. 0.5dB or 1dB

per element). This means you will require an amplifier channel per element in

passive mode, or two amplier channels per element in bi-amp mode. Groups of

elements can be tapered in pairs or more, although a more gradual taper will give

you

smoother vertical pattern control.

5

Page 7

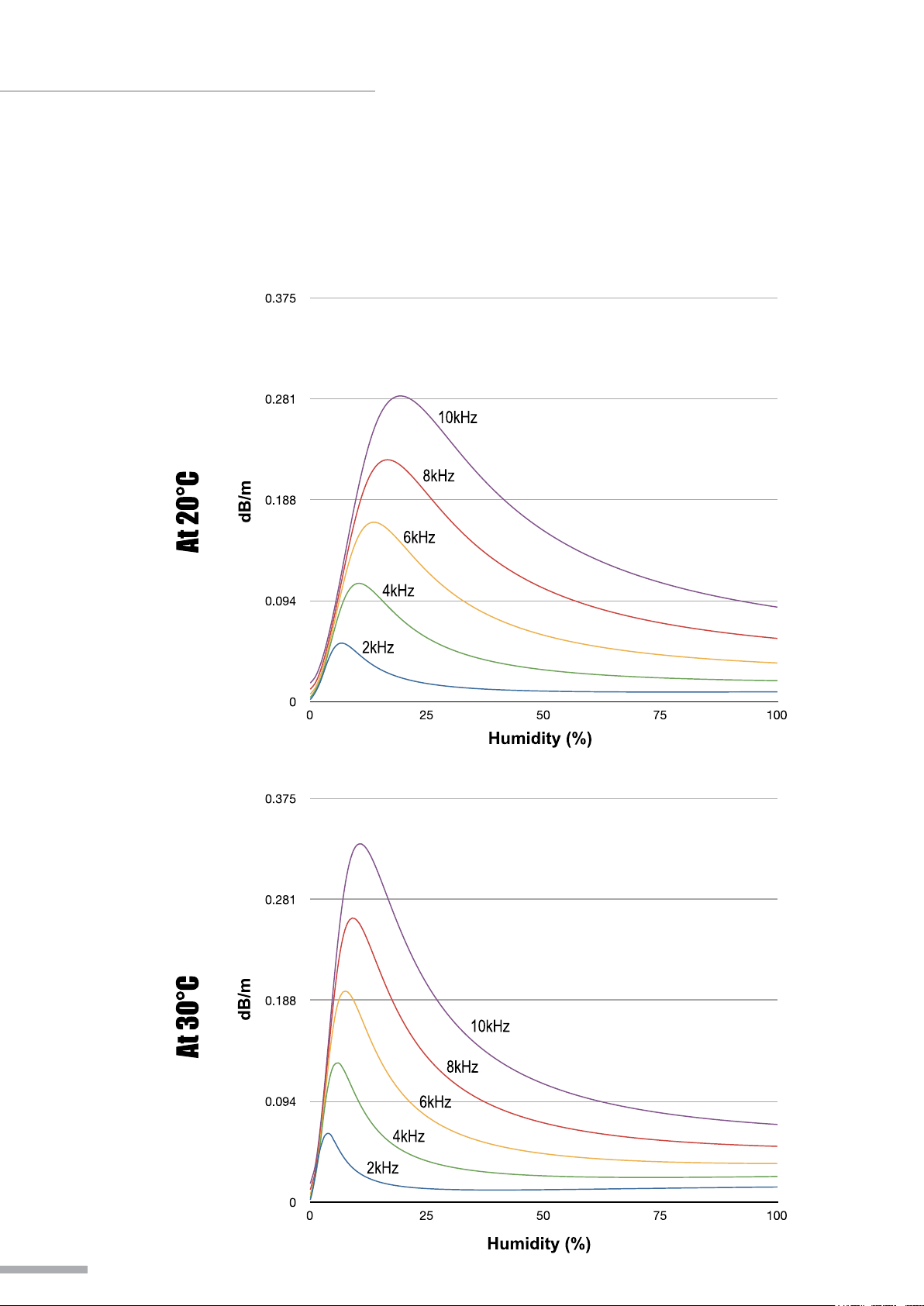

Air Absorption

The high frequency performance of the medium and long throw sections of

the line array will be limited by air absorption. As the distance from the source

increases, the mid and high frequencies will be reduced. The amount of

absorption at a given frequency is a function of pressure, temperature, and

relative humidity. By far the most important factor is the relative humidity,

although temperature does have a signicant effect.

T

of loudspeakers covering the middle to rear of the venue will require equalization

to compensate for this effect. Air absorption is difcult to predict with any great

a

when the audience arrive or the weather changes. It is important that the venue

is monitored during the event as the equalization applied during the design stage

with an empty venue may not be suitable during the event.

WLA Series

o achieve minimal spectral variance across the coverage of the array, the groups

ccuracy, and in any case the relative humidity of the venue is likely to change

As a general guide, boost above 8KHz for a long throw group of loudspeakers,

and

12KHz for a medium throw group of loudspeakers is recommended.

The chart overleaf shows attenuation in dB/m for a given frequency and humidity.

It

is important to note that the effects of air attenuation are linear, unlike the level

attenuation from distance from the inverse square law. For example, at 100m a

source would be 40dB down compared to it’s SPL at 1m. Assuming 50% relative

humidity and 20ºC the level at 10KHz will be an additional 16dB below this

(approximately 56dB down).

6

Page 8

OPERATING MANUAL AND USER GUIDE

Air Absorption

Humidity (%)

7

Page 9

Full Range Mode

WLA Series

8

Page 10

OPERATING MANUAL AND USER GUIDE

Bi-Amp Mode

9

Page 11

Parallel Wiring

WLA Series

10

Page 12

OPERATING MANUAL AND USER GUIDE

WLA-12 Fly Frame

THE WLA-12 AND FLY FRAME IS CERTIFIED TO HOLD A TOTAL

WEIGHT (INCLUDING THIRD PARTY HARDWARE) OF 750KG. 12

ELEMENTS CAN BE FLOWN WITH A SAFETY FACTOR OF 5.7.

Only use the Wharfedale Pro WLA-12 with the WLA Flyframe. Ensure that only

rated, certied hardware such as turnbuckles, shackles and chains are used.

Ensure that all truss, structures and ying hardware are capable of suspending

the entire array, plus ying hardware, to a suitable safety factor.

Rigging, suspending and mounting should only be attempted by

experienced qualied professionals. Incorrect usage can result in

damage to equipment and property, injury and even death. Under

no circumstances should you attempt to rig, suspend or mount

these speakers unless you are fully qualied and certied to do

so by relevant local, state and national authorities. If you are not

properly qualied or do not know of pertinent regulations consult

qualified personnel for advice. Consult a structural engineer

before suspending a speaker system and ensure that the total

weight of your system can be held by the truss or mounting

surface.

Inspect all mounting hardware before your line array is own. If there is any

damage or distortion to any mounting hardware do not fly the array until

any damaged hardware is repaired or replaced. Only use Wharfedale Pro

supplied Quick Release Pins, contact your Wharfedale Pro Distributor if any

Quick Release Pins are lost or damaged.

11

Page 13

WLA Series

12

Page 14

OPERATING MANUAL AND USER GUIDE

WLA-12 Dolly

The WLA-12 Dolly should always be used when flying a WLA-12 line array

system. Each WLA-12 Dolly will hold a single WLA-12 element. The WLA-12

Dolly helps to protect the WLA-12 element and aid the connection and flying

process.

13

Page 15

Installation

One Point Hang Procedure - Method 1

1.

Attach a suitably rated shackle to the center spine of the fly frame. Use

washers to ensure the shackle pin is centered on the spine. The connection

point will depend on the splay angles used in your array and can be used to

aim

the array.

2.

Line up all elements face down on dollies.

3.

Attach the front of the elements to each other with quick release pins.

4.

Attach a Pull Back Bar if required.

5.

Connect signal cables to each element. Take care to ensure that cables of a

sufcient length are used for each connection.

6.

7.

8.

9.

10.

11.

the locking hoist hook to the level of the Fly Frame.

Lower

Attach the locking hoist hook to the shackle on the Fly Frame.

Attach the Fly Frame to the top element using quick release pins.

Raise the hoist to a level that tilts the top element. It should be positioned so

that the quick release pins can easily be inserted through the desired Splay

holes.

Angle

Repeat the process of raising the hoist and attaching the Splay Angle Links of

each consecutive element.

Raise the line array to the desired height.

WLA Series

Two Point Hang Procedure - Method 2

Attach suitably rated shackles to front and rear holes on the center spine

1.

of

the Fly Frame. Use washers to ensure shackle pins are centered on the

spine.

Line up all elements face down on dollies.

2.

Attach the front of the elements to each other with quick release pins.

3.

Connect signal cables to the elements. Take care and ensure that cables of

4.

a sufcient length are used for each connection.

Attach

5.

Attach the Fly Frame to the top element using quick release pins.

6.

Raise the hoist to a level that tilts the top element. It should be positioned so

7.

that the quick release pins can easily be inserted through the desired Splay

Angle holes. (note: raise rear hoist rst)

Repeat t

8.

each consecutive element.

Raise the line array to the desired height.

9.

Adjust the hoists to achieve the desired tilt angle of the array.

.

10

locking hoist hooks to the shackles on the Fly Frame.

he process of raising the hoist and attaching the Splay Angle Links of

14

Page 16

OPERATING MANUAL AND USER GUIDE

Method 1 & 2 Diagram

THE WLA-12 AND FLY FRAME

IS CE R TIF I ED TO H OLD A

TOTAL WEIGHT (INCLUDING

THI R D PARTY HARDWARE)

OF 750KG. 12 ELEMENTS CAN

BE FLOWN WITH A SAFETY

FACTOR OF 5.7.

15

Page 17

WLA Series

Two Point Hang (Limited Space) Procedure - Method 3

1.

Attach suitably rated shackles to the front and rear holes on the center spine

of the y frame. Use washers to ensure the shackle pins are centered on the

spine.

2.

Attach locking hoist hooks to the shackles on the Fly Frame.

3.

Raise the Fly Frame so that the rear connection points are lined up.

4.

Position an element below the Fly Frame and attach the rear of the element

the Fly Frame using quick release pins.

to

5.

Raise the Fly Frame slightly, raise the element and connect the front to the

frame using quick release pins.

6.

Raise the elements again and position another element below it so that the

connection points are lined up.

rear

7.

Now repeat through steps 4-6, before each element is out of reach ensure

that all signal cables have been connected and the length of each one is

adequate.

8.

Raise the line array to the desired height.

9.

Adjust the hoists to achieve the desired tilt angle of the array.

16

Page 18

OPERATING MANUAL AND USER GUIDE

Method 3 Diagram

THE WLA-12 AND FLY FRAME IS CERTIFIED TO HOLD A TOTAL

WEIGHT (INCLUDING THIRD PARTY HARDWARE) OF 750KG. 12

ELEMENTS CAN BE FLOWN WITH A SAFETY FACTOR OF 5.7.

17

Page 19

Dimensional Drawings - WLA-12

WLA Series

�����

������ �

�����

�����

������ �

�����

������ �

������ �

18

Page 20

OPERATING MANUAL AND USER GUIDE

Dimensional Drawings - WLA-12 Fly Frame

THE WLA-12 AND FLY FRAME IS CERTIFIED TO HOLD A TOTAL

WEIGHT (INCLUDING THIRD PARTY HARDWARE) OF 750KG. 12

ELEMENTS CAN BE FLOWN WITH A SAFETY FACTOR OF 5.7.

19

Page 21

Dimensional Drawings - WLA-12 Dolly

WLA Series

20

Page 22

OPERATING MANUAL AND USER GUIDE

Example Arrays

THE WLA-12 AND FLY FRAME IS CERTIFIED TO HOLD A TOTAL

WEIGHT (INCLUDING THIRD PARTY HARDWARE) OF 750KG. 12

ELEMENTS CAN BE FLOWN WITH A SAFETY FACTOR OF 5.7.

21

Page 23

Specication

System Specication

System Type

Frequency Range (-10dB)

Frequency Response (±3dB)

Sensitivity (1w@1m)

Peak SPL

System Impedance

Power Handling

Continuous

Music

Peak

LF Driver

Driver Size

Frame Material

Impedance

Quantity

HF Driver

Driver Size

Frame Material

Impedance

Quantity

Enclosure

Dimensions

(L)

Front (W)

Back (W)

(H)

Enclosure Type

Finish

Finish Colour

Construction Material

Thickness

Grille

Input Connectors

Carton Dimensions

(L)

Front (W)

Back (W)

(H)

Weight

Net Weight

Gross Weight

WLA-12

Range

Full

47Hz-18kHz

65Hz-18kHz

102dB

134dB

8Ω

400w

800w

1600w

305mm / 12"

Al

8Ω

1

45mm / 1.8"

Al

24Ω

3

930mm / 36.6"

483mm / 19.0"

376mm / 14.8"

489mm / 19.2"

Trapezoid

Paint

Black

Plywood

15mm

Black Steel

2 X Parallel Speakon

1025mm / 40.3"

585mm / 23.0"

530mm / 20.9"

580mm / 22.8"

61Kg / 134.2lbs

73Kg / 160.6lbs

WLA Series

WHARFEDALE PRO LIMITED WARRANTY

Wharfedale Pro products are warranted of manufacturing or material defects for a period of one year from

the original date of purchase. In the event of malfunction, contact your authorized Wharfedale Pro dealer or

distributor for information.

*Be aware that warranty details may differ from country to country. Contact your dealers or distributor for

information. These terms do not infringe your statutory rights.

22

Page 24

Wharfedale Professional

IAG House, 13/14 Glebe Road, Huntingdon, Cambridgeshire, PE29 7DL, England

www.wharfedalepro.com

Wharfedale Professional reserves the right to alter or improve specications without notice.

All rights reserved © 2013 Wharfedale Pro. Wharfedale Pro is a member of the IAG Group.

Loading...

Loading...