Page 1

Owners Manual for

Worr Game Products

252 Granite Street

Corona, CA 92879

Tech: 909.520.9911 • Fax: 909.520.9699

www.worr.com

Page 2

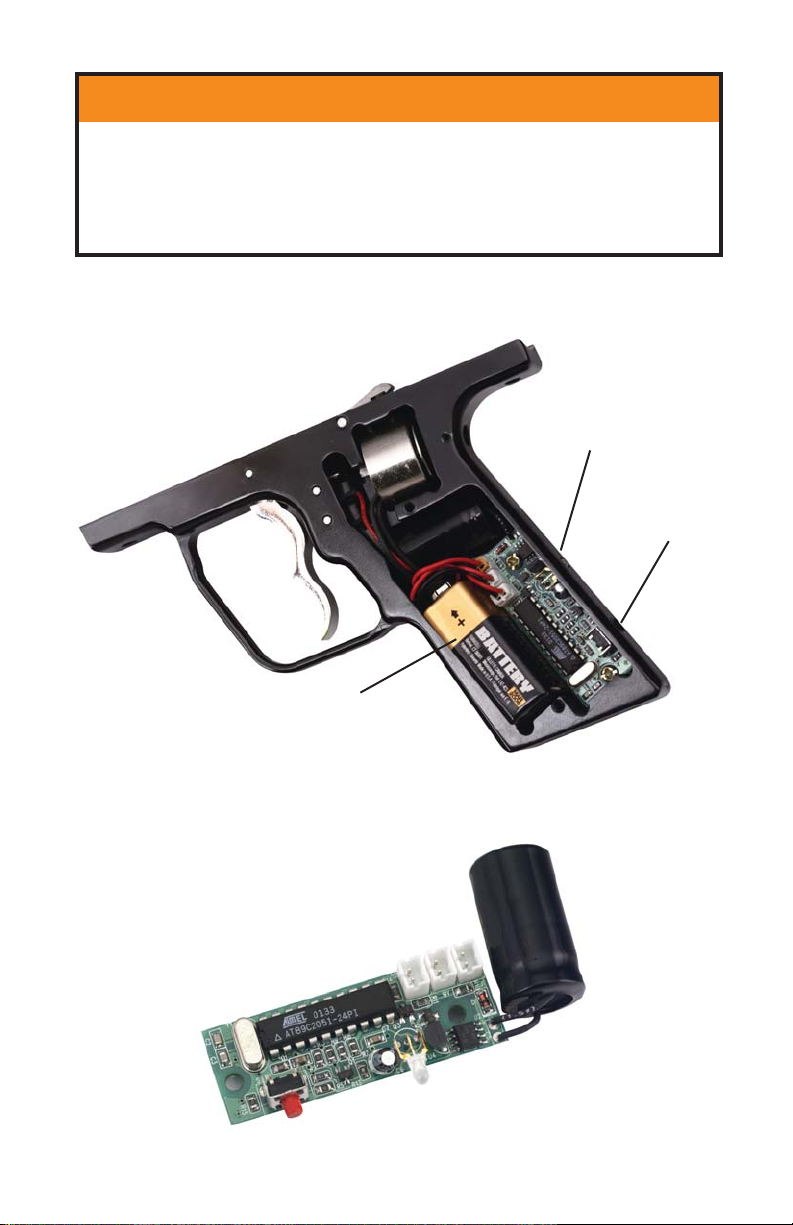

WARNING

•Protect all Electronic Components from moisture and water at all times.

•Always disconnect the battery when marker is not in use.

•Use only 9volt battery in marker.

•Do not use rechargeable batteries in your E-Ranger.

•Using rechargeable batteries voids your warranty.

L.E.D. light

on/off button

9v battery

Electric Grip frame and circuit

board for E-Ranger.

Page 3

RANGER SERIES MARKERS

Thank you for purchasing a Ranger Series marker. Ranger Series are

considered to be the "ultimate" in semi automatic markers, featuring the

most sophisticated internal components in the industry. All Ranger Series

come with the Dura valve system, perhaps the world's most advanced

valve system. Often considered upgrade items by other manufacturers,

all Ranger Series come standard with the following components: A true

.45 grip frame, custom barrel, external velocity adjuster, and an anti-double feed system.

In addition to the standard features all Ranger Series markers come

equipped with, the T-Ranger and E-Ranger mar kers come standard with

extra features. The T-Ranger comes standard with a gas through front

grip, Torpedo drop forward with on/off dial.The E-ranger comes standard

with an electronic .45 grip, vertical regulator, two piece barrel, and

Torpedo drop forward with on/off dial.

As a new Ranger consumer, please read this manual in its entirety to

understand safe operation of the paintball marker. Once you have read

the entire manual, please help us, help you, by taking the time to fill out

the warranty registration card and sending it in immediately.

We want our Ranger Series owners to get the most enjoyment out of our

markers and we can better serve your needs if you take the time to fully

understand your marker and submit your warranty card.

Table of Contents

I. Liability Statement

II. Ranger Series Introduction

III. Safety and Handling

IV. Preparing the Ranger for Usage:

Cylinders, Loaders & other Accessories

V. Preparing the Ranger for Field Operation

VI. Cleaning and Maintenance

VII. Field Stripping

---Ranger Schematic

---Parts List

VIII. Transportation and Storing Your Ranger

IX. Ranger-Fine Tuning

X. Troubleshooting

XI. Warranty

3

Page 4

I. Liability

Worr Game Products ships its markers with the user, distributor and sales agent

understanding that Worr Game Products will not accept any responsibility for its

handling and use in public or private. The user accepts this sole liability when

purchasing and using any marker produced/sold by Worr Game Products. Worr

Game Products disclaims any implied warranties or any responsibility for any

errors that may appear in this manual.

Even if all safety rules are adhered to and equipment is worn, Worr Game

Products limits its liability solely and strictly to the replacement of the marker.

, as the user of the marker, you do not accept total liability, Worr Game Products

If

requests that you do not use our paintball markers. You are not to use this marker

unless you accept all liability and release Worr Game Products of all liability

through any use or misuse thereof.

By using the paintball marker you release Worr Game Products of any and all liability associated with its use.

The paintball marker you have chosen is not a toy. It is imperative that it is used

under adult supervision or by adults. When using the marker please adhere to all

local, state and federal laws. Read the entire manual before using this

paintball marker.

II. Ranger Introduction

It is very important that before using the Ranger paintball marker, every individual

that will be using the marker reads this entire manual for proper operation, safety

and handling. The most important understanding of the paintball marker is to

realize that it is NOT a toy, caution should be used at all times. Never point the

marker at anyone that does not have the appropriate head, eye and body protection.

thermore, the marker should never be pointed or fired at anyone, and should

Fur

only be used at a supervised, licensed and insured paintball field.

Paintball is a sport that the entire family can enjoy. However, proper guidelines

should be followed to ensure safety and enjoyment for everyone involved. It is

important that before using the Ranger, you must become knowledgeable of the

marker -- bef

before handling the marker. You should become completely familiar with the

assembly, disassembly and learn to inspect the mar ker for wear, nicks and burs

on all parts. This will ensure proper operation of the marker before heading to

the field. O-rings and cup seals often need replacement. A detail schematic is

included for reference on all parts of the marker and should allow for easy

maintenance. However, if you do not feel comfortable, take the marker to an

authorized dealer with all the proper documentation for a qualified technician to

perform proper maintenance.

ore going to the paintball field to use it. Leave the CO2cylinder off

4

Page 5

We are confident that you will be satisfied with your purchase of the Ranger and

look forward to serving you. Plus we are always looking for ways to improve and

listen to changes consumers want on their markers. So please call us at 800-755-5061

and tell us what you think.

III. Safety and Handling

Always have a barrel “condom” or other barrel blocking device (approved by the

Paintball Products Manufacturers Association) in place and keep the safety ON

when handling your marker. When repair ing or cleaning your marker first remove

barrel and gas cylinder, then depressurize your marker by pointing in safe direction and dry-firing. Always treat the paintball marker as if it were loaded.

When handling the marker, always keep your fingers or any other objects away

from the trigger assembly to avoid accidental discharges. Make sure when

carrying or transporting the mar ker, to keep the muzzle pointed downward.

It is very important to have the proper paintball protection before going to the

paintball field for play. This includes and is not limited to eye, head, throat, and

body protection. All protection used should be designed for the sport of paintball,

e.g.: eye gear designed specifically for paintball usage.

Remember

, the Ranger paintball marker should never be pointed or fired at anyone,

and should only be used at a supervised, licensed and insured paintball field.

IV. Preparing the Ranger for Usage

Cylinders-- The Ranger is designed to use CO

blow back system. You may attach the proper CO

standard American threading on the CO

cylinders or adapters that are designed for the paintball industry. Please purchase

your cylinders and accessories from stores specializing in paintball products and

make sure the cylinders they are selling meet American Industry Standards.

Foreign cylinders with different threading may strip your air connection assembly.

Do not use them. If you have problems screwing a cylinder onto your marker, go

back to the store and consult with knowledgeable staff members. Do not force the

cylinder into the assembly. When purchasing your CO

paintball store employees for the proper procedure in handling and storage of

your cylinder(s).

Make sure to always get your cylinders filled by authorized, skilled and

knowledgeable technicians for the correct fill limits of each cylinder. Do not try to

refill cylinders by yourself. Do not use cylinders that have not been properly maintained

or that are damaged. It is very important that caution be exercised when refilling

or attaching CO2cylinders.

cylinder. The Ranger is designed to use

2

5

for the proper function of the

2

cylinder that uses the industry

2

cylinder, consult with the

2

Page 6

CAUTION: Please be aware that your marker may still be pressurized even

after the removal of the CO2cylinder!

Loaders-- All Rangers come with its own BOSS™loader. However, there are

several loaders on the market that will fit the Ranger. If you want a different loader,

go to a local paintball store and purchase one that fits your needs and will work correctly with the Ranger. They range from simple gravity feed loaders to motorassisted loaders. The choice is yours, but make sure it fits correctly.

Barrels -- All Ranger markers will fit Autococker style threaded barrels.

Regulator -- If your Ranger came equipped with a regulator, you can adjust

pressure by turning the screw on the bottom of the regulator. To raise the pressure,

turn the screw counter clockwise and clockwise to lower.

.45 Grip Frames -- Only use aftermarket .45 Grip Frames approved by

Worr Game Products. Other grip frames may void your warranty.

V. Preparing the Ranger for

Field Operation

CAUTION: Always wear proper eye protection when firing your marker.

As previously noted, you are to treat the marker as if it were loaded at all times.

When handling the mar

any other objects away from the trigger assembly so there are no accidental discharges. There should always be a barrel plug in the muzzle or a barrel blocking

device covering the muzzle of the marker until it is ready to be fired.

ker always have the safety

ON and k

eep your fingers or

Instructions for Ranger and T-Ranger (Skip ahead for E-Ranger instructions)

A) With the muzzle of the Ranger pointed in a safe direction (away from people,

animals or other objects) place the loader onto the Ranger.

B) Pull the bolt back until it is locked into position. Activate Firing Safety Pin.

C) Gently and carefully screw the CO

On the Ranger this would be directly into the air receiver. On the T-Ranger,

turn the on/off knob on the ASA counterclockwise (placing it in the off position).

Gently and carefully screw the CO

Now turn the on/off knob on the ASA clockwise (placing it in the on position).

This will now pressurize the marker.

D) At this point you are ready to fill the loader with .68 caliber paintballs designed

specifically for use with paintball markers. Fill the loader until it reaches its

capacity as designated by loading instructions or MPG requirements.

E) You may now remove the barrel plug or other barrel blocking device, keeping

the muzzle pointed in a safe direction.

cylinder onto the air receiver of the Ranger.

2

cylinder onto the air receiver of the T-Ranger.

2

6

Page 7

F) When you are ready to begin play, aim at target and turn safety off. The Ranger

is now ready to fire. Pulling the trigger will result in a paintball being projected

from the barrel of the marker. Remember, you are to fire the Ranger only if

ALL safety rules are being followed. Do not fire until all safety rules are followed

and proper safety equipment is worn. Please remember, the marker should

never be pointed or fired at anyone, and should only be used at a supervised,

licensed and insured paintball field.

Instructions for E-Ranger

A) With the muzzle of the Ranger pointed in a safe direction (away from people,

animals or other objects) place the loader onto the Ranger.

B) Remove the two grip screws from the left side of the marker and remove grip.

Hookup a 9 volt battery to proper connector. Do not use rechargeable batteries.

Push the red button for 3 seconds to turn the marker on. A blinking light

indicates the marker is ready to fire. Pull trigger to make sure solenoid is

firing. Replace grip and two grip screws and make sure all wires are under

the cover so that the cover closes correctly.

(Pushing the red button for 5 seconds will turn the marker off. Be sure to

remove the battery from the marker if you are not going to use it for a period

of time to prevent leaking and damage to the marker.)

CAUTION:Your marker can still shoot after being turned off. Be sure to dry

fire in a safe direction to completely deactivate your marker. When

removing battery make sure E-Ranger is off. Otherwise electrical

damage may occur.

C) Pull the bolt back until it is locked into position. Activate Firing Safety Pin

D) Turn the on/off knob on the ASA counterclockwise (placing it in the off position).

Gently and carefully screw the CO

cylinder onto the air receiver of the E-Ranger.

2

Now turn the on/off knob on the ASA clockwise (placing it in the on position).

This will now pressurize the marker.

E) At this point you are ready to fill the loader with .68 caliber paintballs designed

specifically for use with paintball markers. Fill the loader until it reaches its

capacity as designated by loading instructions or MPG requirements.

F) You may now remove the barrel plug or other barrel blocking device, keeping

the muzzle pointed in a safe direction.

G) When you are ready to begin play, aim at a target and turn safety off. The Ranger

is now ready to fire. Pulling the trigger will result in a paintball being projected

from the barrel of the marker. Remember, you are to fire the Ranger only if ALL

safety rules are being followed. Do not fire until all safety rules are followed and

proper safety equipment is worn. Please remember, the marker should never be

pointed or fired at anyone, and should only be used at a supervised, licensed

and insured paintball field.

7

Page 8

VI. Cleaning and Maintenance

BEFORE attempting any disassembly, make sure that the loader and all CO

sources have been disconnected and the marker is NOT pressurized. After playing

with, or storing the marker for any period of time, proper maintenance is necessary

for accurate operation and to maintain peak performance. Make sure the breech

of the marker is clear of any debris or paintballs. Be certain that the barrel plug

is in place and the SAFETY is ON.

Proper maintenance includes cleaning and lubricating the Ranger before playing

or storing the marker. It is imperative that the Ranger be properly lubricated and

kept free of debris and dirt to eliminate any friction that would prevent proper

operation. Use lubricants only if they do not contribute to the deterioration of parts

inside the Ranger, especially O-rings and seals. It is recommended that you use

Teflon or Silicone based lubricants.

You begin cleaning only after the marker has been depressurized. Remove all

CO2 cylinders and remote accessories. Then carefully begin to unscrew the barrel

in a counter-clockwise direction until it is removed. Once it has been taken off it

should be cleaned using soap and water with a squeegee. Then lubricate the

threads with an e

barrel clean as it affects the accuracy of the Ranger. Paintballs have a gelatin

shell that tends to leave residue in the barrel and after use there tends to be a

build up of this gelatin. By cleaning the barrel, you ensure top accuracy, speed

and performance, while limiting the chances of friction-caused ball breakage.

xtremely thin layer of lubricant. It is very important to keep the

VII. Field Stripping

(Be sure to have the schematic drawing available as a reference.)

You begin field stripping only after the marker has been depressurized.

2

A) Make sure that the Ranger is uncocked, by squeezing the trigger, making

sure no foreign objects or paintballs are in the breech.

B) First remove push pin, then unscrew IVG from body. Be careful, it is under

pressure from the main spring. Hold the plug as you unscrew. Next remove the

main spring and spring guide. Then remove the rubber bumper.

Caution: Use only genuine Ranger design bumpers in your marker.

C) By tilting the marker back, the bolt and hammer will now come out.

Note:Watch as the bolt and hammer come out to see how they

join with the connecting pin.

D) It is now possible to clean the upper part of the receiver, including the breech

and power feed tube area. After cleaning the upper frame area with mild

detergent, the bolt and hammer should be lightly lubricated (using Teflon or

silicone based lubricants). Do not o

ver lube.

8

Page 9

E) To reassemble, take the bolt and hammer and join together using the

connecting pin. Point the Ranger toward the ground and slide the bolt and

hammer in their respective holes until they stop. You will notice that they do

not go in completely. At this point, apply slight pressure to the back of the

hammer and squeeze the trigger. The bolt and hammer should now slide all

the way in.

F) Then install the “Ranger” bumper. Carefully slide the main spring and

spring guide through the bumper. Make sure main spring slides into hammer.

G) Screw in the velocity adjuster plug.

H) Hold securely, and screw IVG into the body of the marker. Be careful not to

crossthread the velocity plug as you screw it back in. The body should

thread in easily by hand. NO

I) After installing the retainer pin back out IVG until it has light pressure against

the pull pin.

TOOLS NEEDED.

VIII. Transporting or Storing Your Ranger

When storing or transporting your Ranger, you should always keep the marker

depressurized. No cylinders or remote accessories should be attached. Because

your marker should never be loaded until you are ready to use it, take the loader

off and keep a barrel plug in the muzzle. Keep the safety on, and try and place

the Ranger in a carrying case to prevent mishandling and keep it clean.

Caution:

Never store your E-Ranger with the battery installed.

General Reminder

Your Ranger is not a toy. It should be used only by adults or with adult supervision.

This marker is not intended for use by non-adults without supervision. Respect other

peoples' property. When using the Ranger, obey all local, state and federal laws.

When entering a paintball field, become aware of their rules and regulations.

Before taking the Ranger on holidays or transporting it through public areas, such

as airports, or bus and trains stations, call ahead for regulatory information

regarding the carrying and transporting of such an item.

9

Page 10

Vertical Feed

Rear Cocking

Bolt

Bolt O-ring

Connecting Pin

Set Screw

Slide Bolt

Low Pressure

Chamber

Low Pressure

Chamber O-rings

45 Grip for the

T-Rang er &

Ranger

Grip O-ring

Gas Through

Grip for the

T-Ranger

2 Piece Barrel

for the E-Ranger

Trigger

Trigger

Spring

Safety Bearing

& Spring

Lock

Washer

Frame

Screw

Grip Cover

Screws

Barrel O-ring

Sear

Safety

Valve

Spring

Cover

Sear

Spring

Grip

C-Clip

1 Piece Barrel

for the T-Ranger

& Ranger

Cup Seal

Guide

Trigger Pin

3/4”

Sear Spring

Aluminum

.45 Grip Frame

Aluminum

Cup Seal

Vertical

Adapter O-ring

Sear

Pins

Pin

Vertical

Adapter

Vertical

Adapter

Retaining

Screw

Regulator

O-ring

Vertical Feed

O-ring

Regulator

Main Body

Washer

Plate Cover

Lock

Frame

Screw

Screws

Retaining

Screw

Trigger

Spring

Plate

Cover

90º Fitting

Gas line

Valve O-ring (PU)

Valve O-ring (NBR)

Dura

Valve

Ball Detent

Trigger

Aluminum

.45 Grip Frame

Drop Forward

Set Screws

Drop

Forward

ASA

Dial

Sear

Sear

Spring

Bumper

Pin 7/8”

Sear Adj.

Trigger Pin 3/4”

Drop Forward

ASA Adapter

Hammer

Retaining

Clip

Valve

Screw

Circuit

Board

Switch Pins

Screws

Main Spring

Connecting Pin

Hammer

O-ring

Sear Pin

Solenoid

Set Screws

Set

Screw

Screw & O-ring

Slide Bolt Rod

Pull Pin

Switch

Solenoid

Capacitor

Plate Cover

& Screws

Circuit

Board

Screws

Velocity

Adjuster

Velocity

Plug

Spring Guide

CAUTION: Before repairing or cleaning your marker, always

remove barrel and propellant source. Then depressurize your marker

by pointing in safe direction and dry-firing.

90º Fitting

Parts in picture may be different from actual product.

Page 11

Ranger Series Parts List

1 Piece Barrel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0201

2 Piece Barrel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0201E

2 Piece Barrel O-ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0201Ea

Main Body (Ranger & T-Ranger) . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0202

Main Body (E-Ranger) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0202E

Vertical Feed (Ranger & T-Ranger) . . . . . . . . . . . . . . . . . . . . . . . . .RG-0203

Vertical Feed (E-Ranger) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0203E

Vertical Feed O-ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0203a

Low Pressure Chamber (black) . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0204

Low Pressure Chamber (chrome) . . . . . . . . . . . . . . . . . . . . . . . . .RG-0204E

Low Pressure Chamber O-ring . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0204a

Aluminum .45 Grip Frame (Ranger & T-Ranger) . . . . . . . . . . . . . . .RG-0205

Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0214

Trigger Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0214s

Trigger Assembly Insert . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0214a

Trigger Assembly Spring . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0214b

Trigger Assembly Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0214c

Sear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0215

Sear Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0216

Aluminum .45 Grip Frame (E-Ranger) . . . . . . . . . . . . . . . . . . . . . .RG-0205E

Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0205E1

Trigger Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0205E2

Sear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0205E3

Sear Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0205E4

Sear Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0205E5

Sear Adj. Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0205E6

Set Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0205E7

Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0205E8

Switch Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0205E9

Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0205E10

Solenoid Set Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0205E11

Circuit Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0205E12

Circuit Board Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0205E13

Plate Cover (L) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0205E14

Plate Cover (R) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0205E15

Vertical Adapter (Ranger & T-Ranger) . . . . . . . . . . . . . . . . . . . . . .RG-0206

Vertical Adapter (E-Ranger) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0206E

Vertical Adapter O-ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0207

Valve Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0208

Cup Seal Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0209

Aluminum Cup Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0210

Valve O-ring (valve side - PU) . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0211PU

Valve O-ring (hammer side - NBR) . . . . . . . . . . . . . . . . . . . . . . . . .RG-0219NB

Dura Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0212

Vertical Adapter Retaining Screw . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0213

Bumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0217

Main Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0218

12

Page 12

Ranger Series Parts List

Spring Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0219

Velocity Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0221

Velocity Adjuster Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0222

Velocity Adjuster Screw O-ring . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0222a

Pull Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0223

Retaining Clip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0223A

Safety Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0224

Safety Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0225

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0226

Safety C-Clip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0226c

Trigger Pin 3/4” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0228

Sear Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0229

Sear Spring Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0230

Rear Cocking Bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0231

Slide Bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0231S

Slide Bolt Rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0231R

Bolt O-ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0232

Connecting Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0233

Hammer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0234

Hammer O-ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0235

Connecting Pin Set Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0236

Ball Detent (black) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0237

Ball Detent (chrome) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0237c

Valve Pin 7/8” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0240

Gas line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0241

90º Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0242

Retaining Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0243

Lock Washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0244

Frame Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0245

Grip Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0246

Grip Cover Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0247

Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0249

Regulator O-ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0249a

Drop Forward (chrome) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0250c

Drop Forward (black) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0250b

Drop Forward Set Screw (for ASA) . . . . . . . . . . . . . . . . . . . . . . . . .RG-0250a

Drop Forward Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0250x

ASA Adapter (black) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0251b

ASA Adapter (chrome) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0251c

ASA Adapter Dial (black) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0251d

ASA Adapter Dial (chrome) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0251e

Gas Through Grip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0252

Gas Through Grip O-ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG-0252a

13

Page 13

IX. Ranger - Fine Tuning

Velocity Adjustment- Varying the Speed of the Paintball:With the Ranger pointed

in the downward direction, rotate the velocity screw clockwise. This increases the

mainspring tension and increases the velocity. Turning the velocity screw counterclockwise decreases the pressure on the mainspring and decreases the momentum gained by the hammer. Thus, there is a decrease of gas flow, causing a

decrease of velocity. Once the velocity is set, take the small allen wrench supplied

and lock the velocity into place by turning the set screw clockwise.

When adjusting the velocity, be sure to have the marker chronographed at the

field where you intend to play and make necessary adjustments. Different fields

have different velocity requirements. Please consult range officer when to going

to play.

X. Troubleshooting

CAUTION: Before repairing or cleaning your marker, always remove barrel

and propellant source. Then depressurize your marker by

pointing in safe direction and dry-firing.

If marker auto-triggers or fires and does not re-cock:

1)

A. Check grip frame screws and see if they are loose.

B. Check CO

C. Check hammer O-ring, it may be the wrong size or broken.

D. Make sure the hammer and all bolt and hammer O-rings are lightly lubricated.

E. Look down the back of your Ranger inside of the slide bolt to check if the bolt

rod is bent. If the bolt rod is bent make sure to not crossthread the bolt rod

when reinstalling if needed.

cylinder, it may be low on CO2.

2

Recommendation: Put 2 or 3 drops of lubricant into the bottom line and fire the

marker 20 or 30 times. This will lube the marker from the inside.

2)

Ball Breakage:

A. Check the quality and age of the paintballs when excessive breakage has

occurred.

B. Check the ball detent pin. If detent pin does not protrude into the inside

diameter of the breech, the marker may double feed. This will cause the

marker to chop balls. To correct this problem, replace detent pin. To do

so you must loosen the screws and push the ball detent pin down and

then tighten the screws.

C. Excessively high velocity may also cause paintball breakage.

Air Leaks:

3)

A. If air leaks from the barrel:

i. Replace cup seal.

ii. Replace O-rings on valve

14

Page 14

CAUTION: When handling valve, do not use any abrasive objects or tools

for removal of valve,as this will cause damage to valve and lead to

further gas leakage.

B. If air leaks from the front of the body:

i. Replace O-ring on vertical adapter.

C. If air leaks from bottom line:

i. Replace CO

4)

Velocity Problems:

cylinder O-ring.

2

CAUTION: Before repairing or cleaning your marker,always remove barrel

and propellant source. Then depressurize your marker by

pointing in safe direction and dry-firing.

A. High Velocity:

i.Turn velocity adjuster counter-clockwise. If the velocity screw

has been turned to the point at which it comes out of the velocity

adjuster and velocity is still high, then,

ii. Cut main spring by one or two coils, if problem remains cut

additional coils, one at a time. If you cut two many coils the Ranger

will not function. BE CAREFUL: You are responsible if you cut your

own spring.

B. Low Velocity:

i.Turn velocity adjuster clockwise. If the velocity screw has been

screwed in completely and velocity continues to be low, the main

spring will need to be replaced with a longer or stiffer spring.

C. Inconsistent Velocity:

i. Remove CO

filter.

2

ii. Remove grip frame and tighten valve retaining screw.

5)

Possible E-Ranger Problems:

A. There is no function after attaching the battery:

i. Is the batter y dead? Make sure the battery you are using is good.

ii. Check to see if connectors are fitted. Does it connect to the battery snug.

B. There is juice (battery is good) but the light is not on:

i. Check switch button to see if the on/off is connected correctly.

ii. The program may not be in. Call 1-909-520-9911 and ask for a

technical support representative.

C. Light is on but trigger pull does nothing:

i. Is the mar ker cocked? Pull back on the bolt to cock it.

ii. Is the air tank filled? Refill tank.

iii. Is t here a brok en paintball in the breach? Clean out the marker and barrel.

iv. Check the wires. They may be loose, allowing enough power for the

light to work but not enough to power the marker.

v. Trigger is not hitting the micro switch correctly.

vi.The solenoid and sear may be sticking together. Remove the grip

panel and lubricate with silicon based lubricant as recommended.

15

Page 15

D. Light is on and you hear the solenoid working but the marker will not cock:

E. Regulator Pressure:

i. The height of the sear must be adjusted.

ii. Loosen the sear set screw.

iii. Raise the height of the sear. Turning counterclockwise raises the

height. (Turning clockwise lowers the height)

iv. If the sear is raised too high it will be in too much contact with the

hammer and the marker will not fire.

v. Tighten the sear set screw after adjusting the height of the sear.

The pressure on your regulator should be between 550psi and 800psi.

NEVER exceed 800psi. If it is set too low the marker will not recock. If

the velocity needs to be adjusted lower turn the velocity adjuster screw

counterclockwise. If velocity needs to be increased start at 550 psi and

increase pressure by increments of 10 psi until marker functions properly.

F. You are shooting at a high rate of fire then the marker burps:

G. When you pull the trigger it doesn't feel smooth (or you must pull the trigger

6)

A. Go online at www.worr.com and download our updated troubleshooting guide.

B. Call 1-909-520-9911 for a technical support representative and we will be

NO

Please make sure that when replacing any parts they are supplied by Worr Game

Products. Do NOT replace O-rings that have not been supplied by Worr Game

Products from your dealer. Only Worr Game Products parts for Rangers should

be used. Proper lubrication is also necessary. Use Unique synthetic or K.C.

Trouble Free lube.

i. You need to raise the height of the sear.

ii. Loosen the sear set screw

iii.Turn counterclockwise to raise the sear.

i. Tighten the sear set screw after adjusting the height of the sear.

twice to get it to shoot once.

i. The battery may be dead.

ii.The sear may need to be lowered.

iii.The solenoid is stuck. Remove panel and spray the solenoid with WD-40.

Still can't figure it out?

more than happy to answer any questions you might have.

TE: Most common problems are O-ring related or improper cleaning/lube.

16

Page 16

XI. Warranty

Worr Game Products warrants the replacement of any original Ranger part due

to a defect in material and/or workmanship. The warranty period will be effective

for 12 months for parts and labor except the electronic grip frame, on the

E-Ranger, which is 30 days. It becomes effective from the date of purchase and

is valid with a receipt of sale. The warranty card must be filed within 30 days of

purchase to be valid. All warranty repairs will be performed only if the warranty

card is filled out and is on file with Worr Game Products . A photocopy of the sales

receipt must be included with the warranty card. All other services will be charged

for and returned via common mail carrier. Payment may be made in advance, or

shipment will be returned C.O.D., requir ing a $7.50 C.O.D. charge.

Worr Game Products will replace any part determined by Worr Game Products to

be defective, under the terms of this warranty. Any improper operation of the

marker that has been considered a result of, but not limited to, abuse, neglect,

normal wear, improper maintenance or accidental mishaps, or not using original

parts (or par ts not intended for this marker) is not covered by this warranty.

Worr Game Products always reserves the right to judge what will be covered by

warranty.

No other warranties or guarantees, expressed or implied, are made by Worr

Game Products. The sole and exclusive liability of Worr Game Products, or its

authorized dealers, affiliates, or agents pursuant to this warranty will be solely and

limited to repair or replacement of the defective part. Once again, Worr Game

Products always reserves the right to judge what will be covered by warranty.

Other incidental or consequential damages are expressly excluded hereunder.

Worr Game Products, and its authorized dealers, agents, or affiliates will not be

liable under this warranty, nor under any local, state or federal law , or common la w

or otherwise, for any damage or failure, including personal injury, resulting from

misuse, normal use, accidental discharge, alteration or any other possible acts.

Warranty Service is available by calling Worr Game Products for a return authorization number and then sending your marker to:

Worr Game Products

252 Granite St.

Corona, CA 92879

Phone: 800-755-5061

Fax: 909-520-9699

Tech line: 909-520-9911

Email: tech@worr.com

Warranty: You must obtain a return authorization number from Worr

Game Products before sending your marker in for repair.

17

Page 17

Page 18

New Items Summer2002

The Kaner barrel comes in two pieces a back end

and a front end and it has Autococker threads . You

get to pick the front length that creates a 10”, 12”

or 14” barrel and then you pick the back end.The back ends are available with different bore

dimensions including .685, .687, .689, .691, and .693.The one piece back end threads into

any front end from the Kaner barrel series. These barrels produce tight groupings and are

made of aluminum to keep the weight down.

Worr Game Products is pleased to announce the

availability of Worrpaint Paintballs. Made in the

U.S.A. Manufactured solely to Bud Orr’s specifica-

tions. You can be assured nothing but the highest quality paintballs will be produced.

Worrpaint is available in three different grades of paint. Field paint for recreational players,

mid-grade paint for amateur/tournament play and high end paint for the Pro’s.

Competition

Field

Domination

Mid

The Worrgas air system

is the most consistent

high flow air system ever

made for paintball markers. They feature a patent

pending design that blows away the competition. The

result? A tiny very light weight regulator that surpasses

other regs in high flow capabilities.The 3000/4500 psi.

"Worrgas" air systems are available NOW from Worr

Game Products.

Perfection

High

Page 19

Worr Game Products

252 Granite Street

Corona, CA 92879

TECH: 909.520.9911 • FAX: 909.520.9699

www.worr.com

Loading...

Loading...