OWNER'S MANUAL INDEX

Machine Serial Number:

Date Shipped:

Band Saw Machine Tool MODEL F-1620-A CNC

Contents of this binder:

X Material Safety Data Sheets

X Machine Operation and Maintenance Manual ........................ 900427

X Safety Manual ................................................ 900401

X Band Saw Blade Selection and Application Manual .................... 900409

X Drive Gear Reduction Bulletin, Cone Drive ............................ FL-1

X Barfeed Layout ........................................ Drawing 447140

X Machine Layout ........................................ Drawing 446817

X Metering Valve Assembly................................. Drawing 010370

X Drive Assembly ........................................ Drawing 448170

X Blade Tension Assembly ................................. Drawing 446915

X Guide Assembly 1¼" Blade ............................... Drawing 446807

Blade Brush Assembly ................................... Drawing 610805

X

Hydraulic Chip Conveyor Layout (Option) ................... Drawing 447350

X

System Hydraulics Diagram (Basic Machine).................. Drawing 019632

X System Electrical Diagram ................................ Drawing 020452

Barfeed Holddown Layout (Option) ........................ Drawing 1014700

Saw Vise Holddown (Option) .............................. Drawing 447118

X

Door Safety Interlock Key

Operation VCD

X

I INTRODUCTION

Efficient performance of any machine tool is

the right combination of:

1) Machine, matched to the work load.

2) Tooling, matched to the work piece.

3) Operator, trained and conscientious.

W. F. Wells provides the machine tool.

Consult a reliable blade supplier for the

proper tooling, matched to the work piece.

Operators must not use this machine without

first reading through the manuals in this

binder. The time it takes will be more than

made up in man hours and machine

down-time saved.

This manual, together with other manuals in

this binder, explains installation, operation

and maintenance of W. F. Wells Model

F-1620-A CNC automatic band saw machine

tool. The purpose is to thoroughly familiarize

operators with proper procedures to get the

best performance and dependability from the

machine tool.

As soon as any machine arrives on the

receiving dock, give it a thorough visual

inspection to assure no damage occurred

during transport.

Normally, if the machine crating is in good

condition the machine is in good condition.

If the shipping crate shows damage or signs

of repair, note it on the waybill. Uncrate and

inspect the machine while the driver is still at

the dock, or refuse it.

II INSTALLATION

Give careful consideration to the machine

installation site.

The plant engineer must establish work flow

to and from the machine. The machine must

be level and anchored for proper, efficient,

trouble free operation.

The operator must have room to perform his

job safely. The work area must be

uncluttered and well-lighted. Maintain

temperature in the machine area at a level to

provide maximum operator comfort. If it is

not, machine operators will compensate in

clothing or move about, creating a condition

of hazard.

A. Site Preparation.

See the contents page for the machine floor

layout print, with recommended anchoring

procedure.

Establish machine location in relation to

material handling work flow to the machine

and related production functions.

Recommended anchoring procedure is

anchor bolts set in concrete and the machine

set over the anchor bolts, through holes in

the machine base.

1. Establish the intersection of the

machine blade line of travel to the stationary

vise line according to the plant engineer's

layout and prepare the foundation.

2. If adequate foundation exists, lay

out anchor bolt locations with 12" long cross

lines and drill anchor bolt holes into the

concrete 6-8" deep and 4-6" in diameter.

See the contents page for optional

equipment and prepare anchoring the entire

assembly as one unit.

3. Place the recommended bolt and

sleeve assembly in the hole with bolt threads

centered on the cross lines and extending

above the floor line sufficient to receive the

machine base. Fill around the assembly with

grout or concrete. The shoulder of the

sleeve must be at the floor line, allowing for

later bolt to hole alignment. Allow concrete to

cure fifteen days before machine installation.

B. Machine Assembly.

1. Place steel plate on the foundation

in screw jack locations.

Turn screw jacks on the four outside corners

of the machine base down for leveling. Turn

the center jacks up, out of the way.

4

2. Set the sawing unit frame over the

anchor bolts in the foundation, screw jacks

on the steel plate.

Vise Cylinders

The saw and barfeed cylinders have been

removed for shipping. The following

information is for both cylinders.

Attach the cylinder to the machine

using four 3/8-16 x 1" hex head screws. The

cylinders should be marked “saw bed” or

“barfeed” respectively. The saw vise cylinder

has the emergency stop bracket bolted to it.

To attach the coupling to the end of

the cylinder rod. Raise the saw head.

Slide the vise assembly to the end of the

bed. Tighten the cylinder rod to the coupling

using a 7/8" wrench on the cylinder rod flats

and a 1½” wrench (or Channel Locks) on the

coupling.

See maintenance section IV, page 12.

2. Electric hook-up. See maintenance

section IV, page 21, and motor rotation

direction after hook-up.

D. Leveling and Anchoring.

This machine must be level for precision sawing. Unauthorized moving or

bumping the machine alters the setup,

causing inaccurate sawing. Level the ma

chine. Flat material, laid across the optional

infeed conveyor, barfeed carriage and

machine bed up to the blade line must be flat

with no gaps between the material and the

machine. A machine not being level is a

major cause of getting crooked cuts.

See part "A," site preparation, for proper

foundation.

Use steel plate under each leveling screw

jack to prevent the jacks from drilling into

concrete during years of use.

Connect the hydraulic hoses to the

cylinder.

Emergency Stop Cable

The emergency stop cable is an

added safety feature. It is designed to

protect the operator, or any body who comes

close to the machine, from being pinched or

crushed by the moving barfeed.

Run the red cable though the two

pulleys on the back of the machine and

connect it to the bracket on the end of the

saw vise cylinder.

Remove any slack and tighten the cable.

Pull the cable to make sure it is working.

Push the reset button on the cable switch to

reactivate the feature.

C. Pre-operation Check-out.

Do not attempt to operate this machine

before completing the pre-operation

check-out.

1. Remove support blocks in the saw

bed to assure an accurate level reading.

2. Spread the guide arms and open

the vise jaws.

Place an accurate machine level on the saw

bed between the vise jaws. Lower the high

end of the saw bed. Use only the outside

four corner screw jacks for leveling.

3. Use a straightedge, with level on

top, along the infeed table roller surface and

saw bed. Bring the table to level with the

saw bed.

4. Run the level out over the infeed

table. Bring the table to level with the saw

bed.

5. Check all level readings. Turn

screw jacks between the outside four corner

jacks fully down on steel plate for even

weight distribution.

1. Check fluid levels and filters.

6. Tighten all screw jack lock nuts and

5

check all level readings.

7. Tighten nuts on the anchor bolts

through the saw frame.

7. Keep hands away from the blade

after it is installed.

B. Operator Controls.

8. Dam around each screw jack and

pour grout up to the base of the machine to

prevent shifting.

III SAFETY and OPERATION

Few safety devices benefit the careless

worker. Safety is an attitude either accepted

or rejected by the operator.

A. Safety.

For the operator who abides by his local

shop safety practices add the following,

applying to this machine.

1. Lock or tag out the electric disconnect during routine maintenance.

2. Replace guards and safety devices

removed during maintenance, before returning the machine to service.

3. A qualified assistant operator need

not be at the controls of this machine when

the regular operator is not. Authorize other

workers in the area to shut down the

machine with the Emergency Stop control in

the event of conditions of hazard.

CNC SAW OPERATION

The following is a quick start guide to begin

cutting material within minutes after applying

machine power. This machine is designed

using state of the art technology for high

quality cut parts. The color touch screen

offers simple operation with operator

prompts and diagnostics directing new and

experienced operators like no other sawing

machine. Most screens have help pages

associated with them for new operators that

provide the necessary information to operate

the machine without the written manual. The

attached manual provides advanced help

and documentation to assist the touch

screen prompts and help pages. All faults

and prompts are logged with time and date

stamps to trace machine operation history.

More to follow in the operation manual.

1.) After wiring the machine, leveling,

connecting the vise cylinders, and turning

on the disconnect, the machine is ready to

operate.

2.) Push the hydraulic start. The machine

hydraulics will start. Be sure the E-stop is

pulled out and the stop cable is reset.

4. Do not allow casual climbing or

leaning on the machine. Slippery coolant

covered surfaces are not detected until too

late to prevent the slip.

5. Wear heavy protective gloves

during blade change for positive control of

the blade.

Guard against all other body

contact with

the blade. Never wear gloves while

operating this or any machine tool.

6. Always wear eye protection

when operating this equipment.

6

3.) The home carriage screen will appear

after the hydraulics start. Move the carriage

forward until the “home OK” appears.

4.) Put the blade on the machine and then

tension it.

5.) The machine is now ready to make a

manual cut or an automatic cut. The

operator prompts and help screens will guide

from this point as well as the following

detailed instructions.

Note: The pages after page 20 in this

manual show each touch screen and contain

the help screen for each as well. The

operator should look at each screen and

read the help instructions before operation.

The green dot on the blade tension dial is

reference for proper blade tension.

The needle must always be at the green dot

during sawing to maintain blade tension.

See page 17 to adjust blade tension to blade

manufacturer specifications.

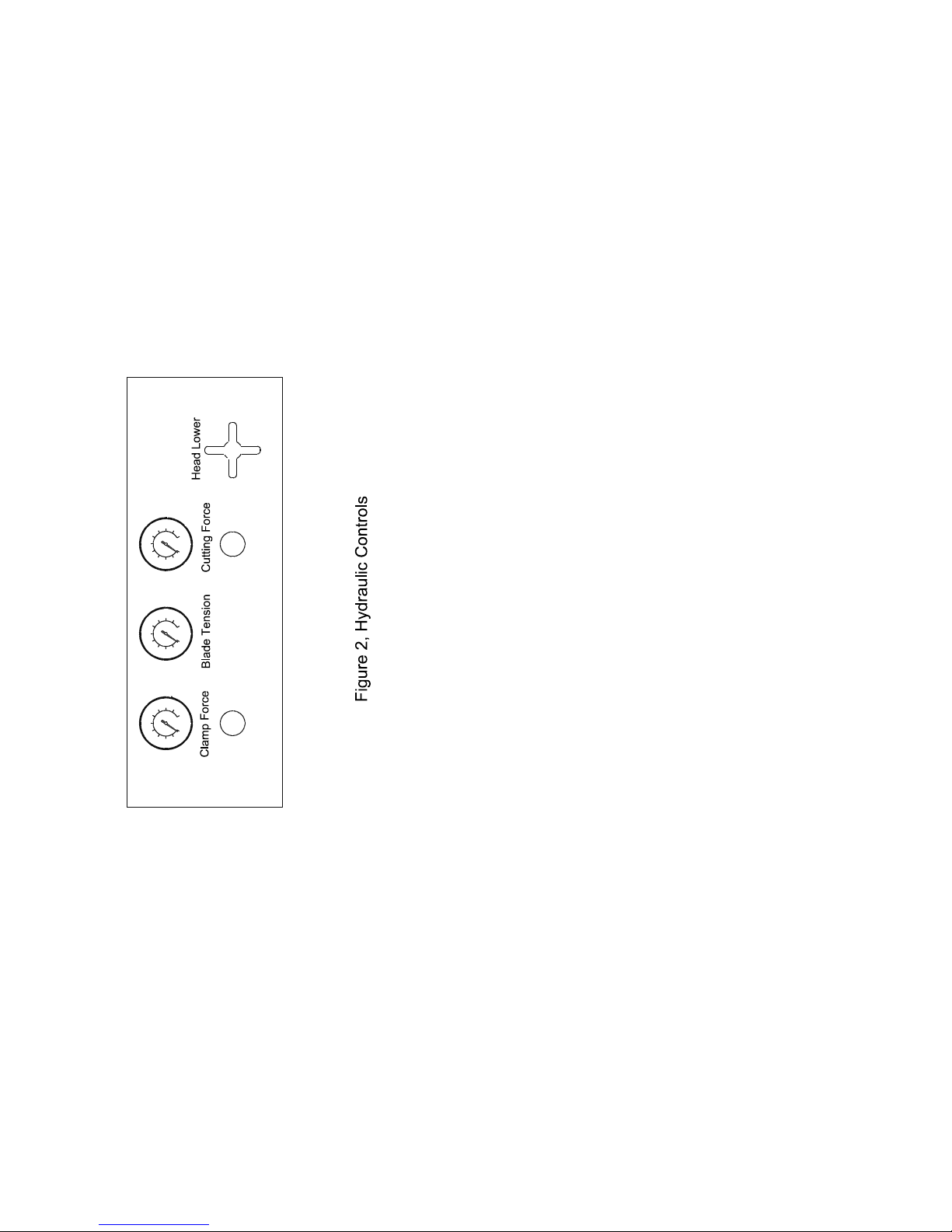

Cutting force dial is reference for blade force

important factor.

For fast, smooth sawing and lower cost per

cut, request a reliable blade supplier make

test cuts on the machine and the work piece

with his recommended blades.

Normally a thin section of work requires a

light sawing force and a wide section greater

force.

However, as the blade guides spread wider

for bigger stock, a longer distance between

the guides, the blade loses some of its

rigidity, or blade beam strength.

On wide stock use a lighter sawing force and

use only new blades which require less force

to make a satisfactory cut. Applying more

sawing force to penetrate a wide work piece

causes blade run out--a crooked cut in the

work piece.

As blades dull sawing wide work, replace

them with a sharp blade.

Set dulled blades aside for sawing smaller

work where the short span between the

guides provides greater saw blade beam

strength, rigidity, and makes cuts within

tolerance. Follow blade manufacturer

instructions for breaking in a new blade.

For more details on sawing force, see Blade

Selection Manual 900409 in this binder.

against the work piece.

Turn the sawing force control right or left to

increase or decrease sawing force on the

work piece.

Two metering valves, one in each guide arm

just above the blade, monitor the sawing

force.

Carefully determine sawing force. It is a very

Saw head approach feed control adjusts saw

head feed down to the work piece.

This control valve fully closed, the saw head

will not move.

The control fully open, the saw head will

come down at it's top speed. At the point the

blade contacts the work piece and begins

sawing, the dual hydraulic sawing force

system takes over.

Guide Arm Positioning.

When positioning the blade guide arm make

certain the area under both arms is clear of

obstruction.

The right guide arm and vise jaw stay at the

right side of the saw bed, next to the drive

wheel.

The left guide arm and vise jaw adjust to

work piece size.

7

For maximum safety and for support of the

blade while sawing, move the left guide arm

close to, but not touching the left vise jaw.

Allow a half inch extra space to open the

vise jaw.

To move the guide arm, loosen the hand

lever above the guide arm, releasing the

clamp. Slide the arm to place and tighten

the hand lever.

C. Operating Sequence.

Do not operate this machine before studying

manuals in this binder.

Follow the sequence closely, so it is

automatic as you become familiar with the

machine.

Blade installation procedure is in the maintenance section under mechanical

adjustments.

1. Move the blade guide arm far left.

2. Set all controls to Off, Stop and Manu-

al.

3. Switch on the electric disconnect.

4. Start the hydraulic pump.

5. Raise the saw head.

6. Tension the saw blade.

7. Adjust the machine to the work per

part "B", clearance for blade and guide arm,

number of pieces, length and any optional

equipment.

8. Open the vises.

9. Switch the machine mode to manual.

and select "Off" on their respective switches.

If an outboard vise or a holddown is used,

and the trim-cut material is too short to

clamp, leave the outboard selectors in the

"Off" position until the Auto cycle pushes the

stock out from under the holddown. Then

select "Clamp".

12. Start the saw blade and adjust blade

speed for the work piece.

13. Adjust sawing force and close the

feed control valve.

14. Press the saw head feed control and

open the approach feed control valve slightly

to feed the blade into the work piece slowly.

15. Monitor the chips, thin and curled.

Adjust the sawing force.

16. Switch the barfeed control from

Manual to Auto while making the first trim

cut. The machine can be placed in Auto

mode operation from a stand still by:

A) Selecting "Auto" on the mode switch.

B) Clamping the saw vise.

C) Starting the blade.

D) Pushing "Cutting Head Lower". The ma-

chine will now cycle automatically.

10. Move the work piece under the blade

for a trim cut.

11. Adjust clamping force for the work

piece and clamp the vise jaws. If there are

selectors for optional holddowns or for an

outboard vise, select "Clamp" on the selector

switch to enable them for automatic operation. If any of the outboard vises or

holddowns are not being used, manually

move them to a position as to not interfere

with the automatic operation of the machine,

8

17. The machine will automatically saw

and feed a pre-set number of pieces, or, the

out of stock limit switch senses the end of

stock passing through the barfeed. One or

the other will shut down the machine.

If the 2 or 3 stroke option is used, a short

delay will be noticed while the carriage vise

is clamping. This allows time for the out of

stock limit to be made.

If the counter, or limit switch are not used

and manual shut down is necessary, turn the

mode selector to "Manual". This locks out all

cycles except the saw head. The saw will

complete the cut, return to the raised

position and the system will shut down, just

as the machine functions with a manual cut.

18. Open the vise jaws and move the

work as necessary.

weld. Automatic blade welders will get out of

adjustment, or an inexperienced welder

operator may improperly anneal the weld.

If this is not the problem, see the maintenance section on sawing force and blade

wheel alignment.

19. Shut down the machine with the

Emergency Stop control.

D. Trouble Shooting.

Common band sawing problems listed

here give instructions for correcting the

problem.

Consider a problem carefully.

Get at the underlying cause of a problem

rather than remedy a series of side effects.

1. Scale on the work piece.

Hot-rolled steel will have a degree of mill

scale. On low carbon steel the scale does

not affect sawing rates, but the scale dulls

the saw blade teeth. Remove scale from the

sawing area.

2. Hard surfaces.

Torch cutting and improper grinding some

steel creates a case-hardened shell a few

thousandths of an inch thick. Sawing

through it will dull saw blade teeth. Saw and

change blades as they dull is the only solution, until the hardened area saws through.

3. Crooked sawing.

If a new blade saws crooked, or begins to

saw straight but after several cuts starts to

saw crooked and results are worse with each

cut, see the above paragraphs, the blade

selection manual and the maintenance

section on sawing force.

A machine not being level is a major cause

of getting crooked cuts. See leveling and

anchoring section, page 4, for more

information.

4. Broken blades.

Check to see if blades are breaking at the

5. Stripped teeth.

This is usually caused by improper sawing

force and blade speed.

See the blade selection manual, and the

maintenance section for a sawing force

check.

6. Poor blade life.

Blade speed too fast for the work piece is

the usual cause of poor blade life. See paragraphs 1 and 2 in this section.

7. Erratic saw head feed.

Uncontrollable saw head feed into the work

piece can be:

a) Defective blade welding, defective weld

grinding, blade teeth points stripped or

wrong blade for the work piece.

b) Lubrication, section IV.

c) Leveling and anchoring, sec. II.

d) Blade guide clearance, blade linkage or

metering valve. See maintenance section IV.

e) If erratic feed is still a problem, look for

brass frame thrust screw excessive wear.

Brass marks front and back of the left post

the saw head rides on, or brass dust at the

base of the post means the machine is not

level, or thrust screws are too tight against

the post.

1) Loosen lock nuts holding the thrust

screws, front and back of the left post frame.

Remove the thrust screws.

2) File the post contour from the face of the

9

thrust screws.

3) Turn the rear screw in first, bringing it up

to the column. Push gently on the frame to

feel contact with the post.

4) Hold the frame with the rear screw

against the post. Turn the front screw to the

post, lightly, then back it off cTH turn. c

TH

turn is the required .008 clearance between

the post and screws in the frame.

5) Tighten the lock nuts and check the saw

head for smooth feed.

8. Saw head stall.

If the blade comes to the work piece and

starts the cut but seems to float without

sawing, check the following malfunctions.

a) Make sure the blade is sharp, and the

proper blade for the work piece. Too much

sawing force applied to a small tooth blade

on a wide work piece fills saw tooth gullets

before the blade clears the work piece to

empty the gullets.

Chips locked in the tooth gullet, still in the

blade kerf, force teeth tips up away from the

cut, causing the blade to float through the

kerf. Change the blade to one with fewer

teeth and larger gullets, or use less sawing

force to form smaller chips, at the risk of

heating the blade to the point of hardening

the work piece.

will not move, or come down only slowly.

See the maintenance section for a blade

guide inspection.

e) Silt will by-pass a plugged hydraulic fluid

filter and accumulate in the metering valve.

Check the hydraulic fluid reservoir for a

milky-white color. Water or coolant in the

fluid will contaminate the entire system.

See hydraulic fluid level and sawing force in

the maintenance section.

9. Saw blade stall.

If the blade jams in the cut it is either the

wrong blade for the work piece, too much

sawing force for the blade or blade tension is

improper.

Correct the sawing practice.

Wait five minutes and press the motor starter

reset control. If the blade stalls with the

motor running, shut the machine down. Free

the blade from the kerf and tension the blade

properly. Rotate the work piece a few

degrees so the blade will not hang up in the

same kerf.

10. All system stall.

The hydraulic pump motor is thermal overload protected to shut down the system if the

motor overheats. Let the motor cool five

minutes and press the reset control. Also

see electric maintenance section "D."

b) Monitor the sawing force.

Use only 30 to 50 pounds of sawing force

and use the proper blade for the work piece.

c) Look for a hydraulic line kink from the

blade guides back to the control console,

limiting hydraulic fluid flow from the metering

valve to the control valve.

d) Look for dirt lodged in the blade guides,

preventing the metering valve from functioning. Keep the guides clean. Dirt and chips

blocking the metering valve linkage forces

the metering valve closed and the saw head

10

11. Saw head drift.

It is normal for the saw head to drift down

while sitting idle for a time.

Remove all work from the vise jaws, tools

and other material from the work bed at the

end of each shift.

Unauthorized machine use or drift down, the

blade coming into contact with material left in

its path, may destroy the blade and the

material.

IV MAINTENANCE

To assure smooth running machinery and

save hours of downtime and repair costs

follow inspection, adjustment, lubrication and

maintenance outlined here.

Check that all machine cycles function

through completion, not partly blocked.

A. Lubrication.

The lubrication chart in the back of this

manual depends on shop conditions and machine use.

1. Fluid levels and filters.

Routinely check fluid levels and filters. Lock

or tag out the electric disconnect switch.

a) Hydraulic fluid.

Check the fluid level with the saw head lowered and the machine turned off. Fluid showing in the screen, ½" to 1" from the top of the

top is proper level. Bring the fluid level up to

the this level with Mobil DTE-24.

Low fluid level allows air to enter the pump,

causing dieseling, cavitation and a ruined

pump.

Dirty hydraulic fluid is usually because the

reservoir filler cap is not in place.

Dirty hydraulic fluid causes valves to stick

and orifices to plug. Machine adjustments to

improve poor sawing will constantly change.

If hydraulic fluid inspection reveals dirt, or is

milky-white with water or coolant, contamination is in all lines and cylinders. Break primary connections and blow out the lines. Drain

and rinse the reservoir twice with fuel oil.

Swab out the reservoir and fill it with clean

fluid. Change the hydraulic fluid filter cartridge.

Activate all cycles several minutes to flush

out the machine.

Repeat the process five times, or until there

is no dirt or discoloration in the hydraulic

fluid.

Change the filter cartridge again.

Install a chain and lock on the reservoir filler

neck and cap.

Hydraulic fluid temperature over 130° is a

malfunction.

Check the fluid level.

Check the fluid for proper viscosity.

b) Hydraulic fluid filter.

Original equipment hydraulic fluid filter

cartridge (part number 911231) furnished

with this machine is a spin-on type with a

classification of three micron, absolute,

filtering .003 contamination out of the

system.

Replacing the filter cartridge with a rating

greater than three micron, ten micron for

instance is a popular filter, will downgrade the system and life expectancy of

the machine.

Change the filter cartridge once a year

(2,000 hours) for a trouble-free operation.

Locate the filter cartridge mounted inside the

lower front panel of the operators console.

Unscrew and discard the contaminated filter

and gasket. Check the gasket on the new

filter cartridge for damage. Wipe a thin film

of fresh fluid on threads and gasket of the

new cartridge and turn it on the filter system,

hand tight only. Make certain the cartridge

bottoms out on the filter system head.

c) Gear case oil.

See the contents page for the drive gear

reducer bulletin.

NOTE: Drain the blade drive reducer case

after the first 80 hour run-in period.

Flush the case with a light flushing oil. Filter

the old oil, or replace it with fresh oil.

Each 2,000 hours of operation drain the

reducer cases, flush, and fill with fresh oil.

Check gear case fluid levels at the sight

glass on the front of the case or pipe plug at

the side of the gear case, or oil standing in

the filler elbow. With the machine shut down

oil must be visible in the filler elbow, or seep

out the loosened pipe plug.

Add fresh oil as necessary to bring the level

up.

W. F. Wells and Cone Drive-Textron use and

recommend using only Mobil SHC-634

11

synthetic oil.

It is normal for gear reducers to operate at

housing temperatures up to 200 degrees.

Keep finned areas on the case clean to allow

maximum heat dissipation.

Keep breather plugs on top of the cases

clear of dirt to avoid gear case oil

contamination.

B. Coolant Fluids and Pump.

Caution: During machine set up and trial

running fill the coolant tray. Coolant fluid is a

heat sink for the pump and it must not be

operated unless the coolant tank is full of

coolant. Routinely clean the coolant tray and

pump screens. A blocked screen will stall

the pump. A damaged screen allows chips

to block or enter the pump chamber, ruining

the pump within minutes.

This machine has a 15 gallon coolant tray

capacity.

Consider coolant type and machine use

before filling the tray. Some fluids

deteriorate more rapidly than others. The

work piece and the blade determine

coolant/lubricant type.

There are coolant fluids and there are cutting

fluids.

Faster blade speeds require efficient coolant

to prevent saw blade overheating.

Increased tool surface speed makes the

cutting edge run hot. Without proper coolant

blade metal temperature passes critical at a

given point. Blade teeth soften and dull.

1. Straight cutting oil.

Slow blade speeds for hard metals and saw

blades that remove a large chip from the

work piece require more coolant/lubricant.

At these slow speeds high lubricity straight

cutting oil is popular.

Do not use straight cutting oil in this machine

unless factory labels clearly show machine

equipment includes oversize coolant pump,

lines and nozzles.

2. Water soluble oils.

Water soluble oils offer good cooling as well

as good lubrication.

Use one part oil to fifteen parts water for

most steels.

Use one-to-one water and soluble oil for tool

steel sawing.

This machine can use this fluid.

3. Synthetic oils.

Synthetic oils, without chemical solution, are

similar to water soluble oil capability and

dependability and used in the same manner.

Use one part oil to fifteen parts water for

aluminum sawing. A drawback to some

synthetic oils is animal fat in the formula

which deteriorates in time, and at high

temperatures, causing a breakdown of the

fats, creating an unpleasant odor.

This machine can use this fluid.

4. Chemical solutions.

Some cooling/cutting fluid used in high

speed aluminum machining and freemachining alloys contain chemical wetting

agents.

The application is useful but side effects are

harmful to the work piece and the machine.

Do not use chemical coolant in this machine

unless factory labels clearly show machine

equipment includes corrosion resistant

pump, hoses, seals and paint.

C. Mechanical.

1. Blade installation.

WARNING: Do not install a blade on this

machine before completing the pre-operation

check-out.

See the Saw Blade Selection and

Application manual to select the proper

blade for the work piece.

For maximum feed, speed and blade life,

request a reliable blade supplier conduct test

sawing with his recommended blades on the

machine and the work piece.

a) Start the hydraulic pump and release

12

blade tension.

b) Raise the saw head so the guide arms

clear the vise jaws.

c) Lock or tag out the electric

disconnect switch. Always disconnect

power before touching the blade or

opening the wheel covers.

d) Open the blade wheel guard doors.

Blade wheels rotate counterclockwise as

seen from the operator's console, drawing

blade teeth through the work piece from left

to right against the stationary vise. Wear

heavy gloves for positive control of the

blade. Hold the blade in front of the wheels

with teeth pointing to the back of the

machine. Teeth on the lower blade loop must

angle right, toward the drive wheel.

If teeth on the lower loop point to the back of

the machine but angle left, toward the

tension wheel, the band is inside out.

Reverse it.

For safety, clear personnel from the area.

Loop the band over a handy guard post or

trash barrel. Twist the band, as far around

the circumference as necessary, until the

band snaps over.

e) Again, hold the blade in front of the

wheels with teeth pointing to the back of the

machine. Teeth on the lower loop must angle

right, toward the drive wheel.

f) Place the top of the loop over the frame

posts, into the blade guard channel, and

onto the wheels.

Pull the back of the band up next to the

wheel flanges.

g) Start the machine and jog the tension

control just enough to take up slack in the

band. Shut down the machine.

This machine is equipped with door interlock

safety switches. The blade cannot be started

with the blade guard doors open.

h) Open the blade guides with the thumb

lever cap screws in the face of the guides.

One guide at a time, grasp the blade firmly

each side of the guide, twist the teeth down

and bring the back edge of the blade up

between the guide blocks.

i) Tighten the thumb lever cap screws in

the guides, check that the back of the blade

is next to the wheel flange.

j) Close the blade guard doors.

Start the machine and run the blade 30

seconds.

k) Shut down the machine.

Check that the back of the blade is close to,

but not scrubbing on the wheel flanges.

.010" to .030" clearance is ideal. Check

blade tension before each saw cut.

2. Blade wheel alignment.

Wheel alignment is not part of a routine

machine setup for a sawing operation.

Factory-aligned, inspected and tested

wheels, blade and guides require no

maintenance.

The usual cause of misalignment is

experimenting or bumping the wheels or

guides with the work piece or material

handling equipment.

Routinely check the wheel flanges for wear.

Be alert to audible and visual changes in

machine operation. A high-pitched metal-tometal scrubbing sound coming from the

wheel guard doors is the back of the blade

scrubbing on the wheel flange. The blade

will wear the flange from the wheel before

the blade breaks.

When checking wheel alignment use only a

new blade, known to be straight. A used

blade may have developed a camber,

making results of an adjustment useless.

To inspect the wheel flanges or to adjust

either wheel, raise the saw head so the

wheel guard doors clear the control console.

Release blade tension and lock or tag out

the electric disconnect switch.

13

a) a. To adjust the tension wheel, see

the contents page for the tension assembly

print and Figure 3.

(1) Open the tension wheel guard door.

The tension wheel mounts on a sliding plate.

Locate and loosen two lock nuts, under the

wheel spokes, top and bottom of the outside

edge of the slide plate.

(2) A set screw beside each lock nut is a

spacer for the plate.

See "A" Figure 3, above.

The blade is running too close to the wheel

flange, scrubbing, the wheel rim too far from

the frame plate on the outside. Turn both

set screws counterclockwise, equally, ¼ turn

each, drawing the outside rim of the wheel

closer to the frame plate.

NOTE: Do not overcompensate. Turn the

set screws equally ¼ turn only.

(5) Tighten the lock nuts.

Check the clearance as in step (3).

b) To adjust the drive wheel, see the

contents page for the drive assembly print

and Figure 4, below. The drive wheel mounts

on the output shaft of the gear reducer,

bolted to the back of the saw head frame

plate. Adjusting the gear case adjusts the

drive wheel proportionally in the same

direction.

1) In the cabinet at the back of the saw

head behind the drive wheel, locate four hex

head screws on the gear case, locking

threaded spacers and the gear case to the

The blade is running too far away from the

wheel flange, the wheel rim too close to the

frame on the outside. Turn both set screws

clockwise, equally, ¼ turn each, pushing the

outside rim of the wheel away from the

frame plate.

NOTE: Do not overcompensate. Turn the

set screws equally ¼ turn only.

(3) Tighten the lock nuts.

Close the wheel guard doors.

Tension the blade. Start the blade and run

it 30 seconds.

Shut down the machine.

Check that the blade is not still running too

far away from, or scrubbing on the wheel

flange.

(4) See "B" Figure 3, above.

saw head

frame plate. On the side of the gear case

next to the cabinet wall, hold the threaded

spacers and loosen the two hex head lock

screws top and bottom of the gear case, one

or two turns.

14

2) If the blade is running too far from the

wheel flange, the wheel rim low on the

outside, too close to the frame plate, see

"A," Figure 4, below, turn both threaded

spacers, equally, top and bottom of the case

¼ turn counterclockwise, drawing the gear

case closer to the frame plate, pushing the

wheel rim away from the frame plate. NOTE:

Do not over-compensate. Turn

the threaded spacers ¼ turn only.

3) Tighten the hex lock screws.

Tension the blade and run it 30 seconds.

Shut down the machine. Check that the

blade is not still running too far away from, or

scrubbing on the wheel flange. .010" to .030"

clearance is ideal.

4) If the blade is running too close to the

wheel flange, scrubbing, see "B," Figure 4,

below, the wheel rim high on the outside,

turn both spacers clockwise, equally, ¼ turn,

pushing the gear case away from the frame

plate, drawing the outside wheel rim closer

to the frame plate.

5) Tighten the hex lock screws and check

the clearance as in step (3).

3. Blade tension adjustment. Factory-set

blade tension is for size and type blades

used in general purpose sawing.

The blade tension control must be in the

Tension position while sawing.

The dial indicator needle at the operator's

control console must come exactly to the

green dot on the dial.

If the tension indicator needle does not

reach, or passes the green dot, inaccurate

sawing or blade break results.

For maximum feed, speed and blade life

consult a reliable blade supplier for recent

research in tooling.

Request test cuts on the machine and the

work piece with his recommended blade.

Tension the blade to manufacturer specifications with a precision tension gauge

mounted on the blade.

The supplier will install his gauge on the

blade.

Tension the blade.

When the needle on the control console dial

reaches the green dot, the blade supplier will

determine from his gauge whether to

increase or decrease tension for his recommended blade.

To change blade tension, remove the cover

on the lower front of the operator's control

console.

Increase or decrease blade tension with the

double lock knob hydraulic valve, inside left

wall of the cabinet.

With tension adjusted for the choice of

blades, lock the valve.

Move the green dot to the new needle

location on the face of the gauge.

When changing blade types for other work,

tension the new blade to blade manufacturer

specifications.

Before each cut, make sure the tension

needle is at the green dot.

4. Sawing force check.

The dual hydraulic servo-controlled sawing

force system measures work piece

resistance to the blade while sawing,

applying uniformly controlled force to the

blade for accurate sawing regardless of

configuration, size or type of material.

Sawing force range for this machine is 0 to

400 pounds, adjusted at the operator's

control console.

See controls 20 and 21 on page 6.

Too much or too little sawing force results in

uneven sawing or broken blades.

With each blade change, inspect the blade

guides for chips and sludge build up. They

prevent blade guides and metering valve

linkage from working properly, producing

other than the sawing force adjusted at the

control console.

Sludge in the coolant or hydraulic fluid, a

malfunctioning sawing force dial, metering

valve or linkage from the blade to the

metering valve alters the dial reading from

actual force the blade applies to the work

15

piece.

Use preventive maintenance.

Check the sawing force.

a. Tension the blade, spread the guide

arms and vise jaws. Raise the saw head.

Do not start the blade.

b. Close the saw head approach feed

control valve and press the saw head feed

control.

c. Open the saw head approach control

valve just enough to lower the saw head

slowly.

Tap the blade lightly at the guides, seating

the blade in the metering valve linkage.

Sawing force is adjusted by lengthening or

shortening the linkage that runs from the

metering valve to the carbide back-up

slipper. See drawing 010370A.

The metering valves close and the sawing

force/saw head stops applying force on the

saw blade.

To verify that the metering valve is working,

lift the linkage as shown in drawing

010370A. The frame should stop coming

down.

If more than .040" of travel is needed to stop

the frame, adjust the linkage as described in

section 8.

If the tensioned blade only partly returns

when pushed down out of the guides,

without hanging up, continue this check.

Linkage travel must not be less than .030"

and not more than .040".

More than .040" travel, the linkage too short,

will not control the metering valves and may

let saw teeth enter between the blocks, ruining the blade and the blocks.

Less than .030" travel, the linkage too long,

will hold the metering valves closed, hold the

saw head in suspension or come down only

slowly.

Check the linkage travel.

a) Fasten a dial indicator to the guide

arm with the contact point resting on the

back edge of the saw blade.

Set the dial to "0" and place a block of wood

under the blade next to the guide arm.

Use a piece of round stock in the blade tooth

gullet and bring the saw head down on the

block of wood.

When the saw head stops, read the dial indicator. Check both guides.

b) If the blade is not hanging up in the

guides and blade travel at both guides is

.030" to .040", problems with the sawing

force check is not with linkage travel from

the back of the blade to the metering valves.

Go to step 7 for a metering valve check.

5. Metering valve linkage check.

If the sawing force check failed, linkage from

the back of the blade to the metering valves

may be worn or the blade guide blocks may

be pinching the blade.

Be certain the guides are flushed clean and

try forcing the tensioned blade in and out of

the blocks.

Under full tension the blade must only partly

return back up into the guide. If it hangs up,

sticks or slides too freely between the

blocks, go to step 6 for a blade guide check

before continuing here.

16

c) If linkage travel is more than .040" it is

too short to close the metering valves. The

probable cause is a blade track worn in the

backup slipper greater than .030". Go to

step 6, dismantle and inspect the guides and

backup slipper. If the backup slipper is not

worn adjust the linkage during the metering

valve check.

d) If blade travel is less than .030" the

linkage is too long to let the metering valves

control sawing force. The probable cause is

a backup slipper replacement and shims

added to the linkage, or, guide blocks

binding the blade. Go to the next step for a

blade guide inspection.

6. Blade guide inspection.

NOTE: Consider this and the next two items

on linkage and metering valve inspection

before making adjustments.

Routinely, when changing blades, check the

guide rollers and backup slipper for dirt and

sludge and proper guide roller clearance.

Normally, guides require adjustment only

after years of wearing in.

If stock or material handling equipment near

the machine bumps the guides they will

break or misalign and require adjustment or

replacement.

Following are three preventive maintenance

checks.

a. Clean, inspect and adjust the guide

rollers.

(1) Guides are factory set .001" wider

than the blade thickness.

.042 blade thickness requires .043 guide

roller clearance.

See the contents page for the blade guide

print.

Guide rollers adjusted too tight or too loose

cause erratic sawing rates, inaccurate cuts

and broken blades.

Release blade tension and lock or tag out

the electric disconnect.

(2) Remove the blade and flush out the

guides.

(3) Check roller clearance with feeler

gauges, or, assemble a new blade on the

machine. Tension the blade.

Look for a tight or loose fit.

Force the tensioned blade down out of the

guide. It must only partly return up into the

guide rollers when released.

(4) Look for blade movement in the sawing area between the guides.

Twist the blade back and forth between the

blade wheel and guide.

(5) If feeler gauges read correct, or if the

tensioned blade only partly returns when

pushed down out of the rollers and there is

no blade movement between the guides

when twisted from outside the guides,

problems with the sawing force check are

not with guide roller clearance.

Go to item 8 on metering valve linkage

check.

(6) If step (5) failed, adjust the guide rollers. Raise the saw head.

Release blade tension. Lock or tag out the

electric disconnect switch.

(7) Release the carbide side inserts so

they can float with the blade during adjustment.

(8) One roller on each guide rigidly

mounts to the casting and is not adjustable. The companion roller adjusts on a

cam shoulder bolt. Loosen the lock nut on

top of the high side of the roller casting,

unlocking the cam bolt. Turn the cam bolt

at the bottom of the roller.

(9) Use feeler gauges to adjust clearance

between the rollers .001" wider than blade

thickness, or go back to step (3).

Caution: Rollers gripping the blade too tight

prevent the metering valve from controlling

sawing force; the blade will snake through

the rollers, inaccurate sawing and blade

break results.

(10) Install and tension a new blade on

the machine. With rollers adjusted, hold the

floating carbide side inserts snug against the

blade and draw them up to the roller casting

with the hex head screws.

Lock them in place against the blade with the

socket set screws at the side of the guide

casting.

17

b. Horizontal guide adjustment.

It is critical when making this check to align

the vise jaws 90° to the saw bed.

(1) Use a combination square with the

head centered. Place the 90° side of the

head into the vise slide in the saw bed and

bring the face of the stationary vise jaw to

square with the combination blade.

Make the same adjustment on the movable

vise jaw.

nut and adjust the plate and blade into

alignment with the blade wheels, square to

the vise jaws.

Use the combination square against the

blade and vise jaws to check the alignment.

See step (1).

c. Vertical blade/guide adjustment.

After a vise jaw adjustment to align the blade

square to the vise jaws, rotate the blade

back square with the saw bed.

(2) With vise jaws aligned square to the

saw bed, move the 90° side of the square

head to the end of the combination blade.

Place the head against the stationary vise

jaw and bring the square blade up against

the saw blade to check for square.

If the blade is square to both vise jaws, go to

step c.

(3) If the saw blade is not 90° to both vise

jaws discover which guide (or both) is out of

alignment. Mount a new blade on the

machine and tension it. On top of the guide

beam, loosen both guide arm clamps. The

tensioned blade will draw the guides into

alignment. Check the blade, square to the

vise jaws. Tighten one guide arm clamp at

a time to see which arm is pulling the

tensioned blade out of square to the vise

jaws.

(4) Determine which guide (or both) to

adjust to align the saw blade to the vise

jaws. Clamp the arm at the guide beam and

see the contents page for the blade guide

print.

(1) Place a dial indicator on the saw bed

near the guide, with the indicator contact

point against the saw blade, directly above

the tooth gullet.

(2) Set the dial to "0.

Open the saw head control valve slightly to

bring the blade down across the dial

indicator contact point slowly.

If the dial indicator reads "0" bottom to top of

the blade at both guides, go on to item 8,

metering valve linkage inspection.

(3) If step (2) failed, adjust any difference

in the dial indicator reading, bottom to top of

the blade, to "0." Locate the adjusting screw

above the guide rollers and the lock nut

behind the guide above the blade.

See the blade guide print. Loosen the lock

nut and turn the adjusting screw to tilt the

roller assembly, bringing the blade to vertical

square with the saw bed. Visually check the

alignment with the combination square.

Check the alignment with the dial indicator

for a "0" reading from bottom to top of the

blade as it passes over the indicator tip.

(5) Loosen the hex screw at the top of

the plate holding the guide assembly to the

arm and the hex nut immediately under it,

unlocking the assembly plate and cam bolt,

allowing the assembly to rotate into

alignment.

(6) Locate the hex head cam bolt on the

opposite side of the plate from the hex lock

18

7. Metering valve inspection.

See the contents page for the blade guide

and metering valve prints.

With each blade change, inspect the blade

guides for chips and sludge build up that prevent metering valves and linkage from working properly.

If the sawing force check failed check the

blade guides and linkage before making this

check.

Particles flaking from walls of hydraulic lines

may have accumulated in the sawing force

system. Check the change date on the hydraulic fluid filter cartridge.

a) Lower the saw head and lock or tag

out the electric disconnect. NOTE: If the saw

head will not come down because of clogged

metering valves, block up under the guide

beam to prevent the saw head from dropping

during the next step.

b) Remove hoses from the metering

valves and hex head screws holding the

valve to the guide arm.

c) Lift the valve body from the guide

block; remove the socket head screws from

the valve cap, shown in foldout 010370.

d) Pull the plunger from inside the valve

body and wash all parts in mineral spirits.

Inspect the seals for embedded particles.

Replace them from 2,000 hour spare parts if

necessary.

e) Cleaning and replacing worn parts

from the blade guide blocks and backup

slippers, up to the metering valves, is a

complete overhaul of the sawing force system, and, properly accomplished, brings

about proper results with the sawing force

check, step 4, page 18.

D. Electrical Maintenance.

WARNING: COMPLETE THE

PRE-OPERATION CHECK-OUT BEFORE

STARTING THIS MACHINE.

During machine installation and trial running,

fill the coolant reservoir. Coolant is a heat

sink for the pump and it must not operate

unless the coolant tank has adequate

coolant. See maintenance section part "B"

on coolant fluids.

A qualified electrician must make electric

hook up and adjustments to this equipment.

See machine voltage, labeled on the electric

cabinet door. See the contents page for the

electric print.

1. After electric hookup check hydraulic

pump rotation.

a) Check hydraulic pump rotation in the

cabinet behind the operator control console.

Rotation must be in the direction of the arrow

on the pump housing. With the hydraulic

pump rotating in the correct direction, the

drive wheel should be rotating counterclockwise; if not, reverse wiring at drive motor.

2. Routinely check limit switch mountings

for dirt and loose fasteners which could

cause a later malfunction.

3. The electric system for this machine

consists of a programmed computer

receiving and coordinating signals from

operator controls and limit switches.

The signals send current to solenoid coils in

valves controlling hydraulic fluid flow to

cylinders maintaining blade tension, moving

the saw head, vise jaws, barfeed, outboard

vise, vertical holddown clamps and powered

roll tables.

Automatic machine functions start the next

function. A function may look complete but

if a limit switch does not trip, or is faulty, the

computer will not receive the signal. The

solenoid coil cannot activate the valve to

shunt hydraulic fluid to cylinders and hydraulic motors. Usual cause is a burned out

solenoid coil or sticking

E. Parts and Service.

Most-used replacement parts are available

from factory stock with same-day shipment.

Service is available by telephone conference

or a service call to the machine site.

1. Parts.

For 95% insurance against downtime, the

lists show most commonly used parts. Pro-

19

gram them into inventory on a replace-asused basis.

2,000 hours is equal to one eight hour shift

working for one year.

Account for spare parts. Enter them into

inventory with a zero stock level reordering

system to assure availability when the need

arises.

Write additional part numbers assigned for

plant systems compatibility on the lists for

reference.

Shelf life for parts listed is indefinite, only so

long as packaging is intact. Look for packaging opened for inspection, authorized or

otherwise. Repackage parts in suitable

containers and identify them to preserve

usefulness when the need arises.

Except fluids and filters, expect machine life

of those parts planned for replacement to

exceed the hours shown by as much as

three times.

Variables are machine operator and original

equipment manufacturer workmanship reliability.

Nuts, bolts and common parts normally

obtained from hardware or mill supply stores

may not show a part number on the prints,

but will show a part description for local

source replacement.

If a needed part is not identified, provide our

parts department with a detailed description

of the part, where it is on the machine and

what it does in operation. This will be

enough information for our parts department

to identify and supply the part.

2. Service.

Only preventive maintenance is required for

many years, with expendable belts, bulbs,

filters and blade brushes replaced by maintenance personnel. solenoid valve.

Manual machine functions may operate

when automatic sequences will not.

If the machine will not function in the manual

mode, begin checking at the electric source.

Trace through fuses, motor overload and

limit switches to solenoids. If the solenoid

plunger will activate the valve, replace the

burned out coil. If the plunger will not

activate the valve, replace the frozen valve.

See spare parts.

Also, see optional equipment possibilities.

4. A blown fuse in the 115v line, 5a,

under the transformer in the electric cabinet,

is probably caused by dirt or chips inside the

coolant pump. Unplug the coolant pump at

the in-line disconnect. Replace the fuse and

run the machine.

If the fuse holds without the pump, clean all

screens and the coolant pump rotor to determine if the pump can be salvaged.

If the fuse will not hold, look for a short in the

control panel at the operators console.

It is vital to machine life and sawing efficiency that machine operators and maintenance

personnel read and have access to the contents of this binder.

If a sawing or machine malfunction occurs,

try to get at the cause of the problem rather

than remedy a series of side effects.

The index in this manual is topical, offering a

solution to common problems.

If a machine problem cannot be resolved

by in-plant personnel, do not hesitate to call

our service department. A factory-trained

and qualified person will resolve the malfunction on the telephone.

For Parts or Service

Telephone 269-279-5123

Fax 269-279-6337

parts@wfwells.com

www.wfwells.com

For faster service, furnish the machine

model and serial number from the

identification plate on the machine bed.

Note your serial number here:

Model F-1620-A CNC

SEE SPARE PARTS LISTS NEXT PAGE

20

MODEL F-1620-A CNC Recommended Spare Parts List

Group I, 2,000 Hours

Qty Part# Description

1 900091 Blade brush.

2 901023 Blade brush bearing.

1 908965 Blade drive belt.

8 901204 Blade guide rollers, 1¼" blade.

2 292290 Blade backup slipper, carbide

4 292420 Blade guide side inserts, 1¼" blade

1 911231 Hydraulic system filter cartridge.

1 921530 Saw head limit switch assembly.

2 900811 One quart of synthetic gear box oil.

Group II, 5,000 Hours

1 908966 Sprocket, Drive Motor.

1 908967 Bushing, Drive Motor Sprocket.

1 908966 Sprocket, Gear Box.

1 908961 Bushing, Gear Box Sprocket.

1 900085 Lift cylinder leather, 1¼" .

1 900086 Lift cylinder leather, 1 ¾".

1 010370 Metering valve assembly.

Group III, 10,000 Hours

1 445115 Tension wheel assembly w/ bearings, 1¼" blade.

1 309341 Drive wheel, 1¼" blade.

21

The following recommendations are for nominal clean operations.

Consider shop conditions and machine use when wiping oil on exposed areas.

Saw blade and guide lubrication depends on a properly functioning coolant distribution

system. Check the coolant pump screens often to be sure they are clean and in place.

Clean the coolant pan and change or filter the coolant often, depending on coolant type and

machine use.

NOTE: 80 Hour, one-time maintenance.

See maintenance section IV c, page 13 for the first time gear case oil change.

LUBRICATION INSTRUCTIONS MODEL F-1620-A CNC

INTERVAL

(HOURS)

200

2,000

10,000

LOCATION LUBRICANT SPECS

BLADE TENSION WHEEL SLIDE,

UNDER WHEEL. GREASE

CYLINDER RODS.

SAW HEAD POSTS.

BARFEED SCREW.

SAW HEAD POST.

ELECTRIC MOTOR BEARINGS. GREASE

DOOR HINGES & LATCHES.

GUIDE ARM BEAM.

VISE SLIDES.

HYDRAULIC RESERVOIR. HYDRAULIC

TENSION WHEEL BEARINGS

OIL

OIL

FLUID

GREASE NLGI #2

NLGI #2

300 SSU

AT

100

/

NLGI #2

300 SSU

AT

100

/

Mobil DTE

24

REMOVE AXLE NUT, FRONT

BEARING AND ALL OLD GREASE.

DRIVE GEAR REDUCER Mobil SHC 634

OTHER 2,000

HYDRAULIC FLUID FILTER

CARTRIDGE ( part # 911231)

22

REPACK.

ALSO SEE MAINTENANCE SECTION

Synthetic Oil

SEE MAINTENANCE SECTION

Material Safety Data Sheets

W. F. Wells Incorporated supplies the following Material Safety

Data Sheets, furnished us by the original manufacturer of the

product, as a material used in our equipment of manufacture.

Responsibility for accuracy of information therein rests with the

manufacturer of the product.

It is our intent to seek out, use and pass along to our customers

the safest products available, necessary to the operation of our

equipment.

213770 RUST VETO 377

used on all of our band saw machine tools.

The product is applied to unpainted surfaces before shipping the

equipment.

602623 MOBIL DTE 24

of our band saw machine tools.

The product is in hydraulic fluid reservoirs, motors and cylinders

activated with hydraulic fluid.

MOBIL SHC 624 Synthetic OIL

The product is rust-inhibitive fluid,

The product is hydraulic fluid, used in all

The product is gear case

lubricant, used in some of our band saw machine tools. The

product is in the saw blade drive and powered roll table drive gear

reducer cases.

23

24

102830

1 02820

HHCS1 21 31

FW1 2

HHCS58112

SCREW

447200

JAW

WAS H ER

SCREW

FENCE

FENCE

251880

SLIDE

90902 1

COUPLI NG

4471 20

102960

TI POFF

BED

91 0730

HHCS381 61

SCREW

446002

POST

HHCS1 1 477

SCREW

446860

MOUN T

HHCS581 1 3

SCREW

950051

SEAL

HHCS341 05

SCREW

WEA R PLATE

4471 80

CARRI AGE

PI LLOW BLOCK

9031 95

HHCS3816112

SCREW

4471 50

BASE

910038

SEAL

900211

WAS H ER

HHCS1213512

SCREW

1014100

RAI L

104731

SPACER

104800

CYLI NDER

SHCS381 61

SCREW

DP51 61

PI N

447250

44721 0

JAW

90021 7

WAS H ER

HHCS51 61 81

SCREW

ROLLER

447220

JAW

9001 28

SCREW

HHCS58 11 2

447252

WEA R PLATE

JAW

472454

FHS1 4201 2

SCREW

1014730

WEA R STRIP

9002 39

WAS H ER

HHCS341 621 2

SCREW

447251

FHS1 42034

SCREW

WEA R PLATE

A447266

WELD AT ASSEMBLY

W. F. WELLS

F−1620−A CNC LAYOUT

DRAWING #447140

Weld at assy.

2 places.

Assembly with

Loctite 242

(Blue)

B447430

S

SHCHW2R4C1E02

A447215

104803

50" stroke

Was 102800

12−17−4

95005 0

900212

was

2−16−5

was

2−16−5

taper pin

25

26

A

S

S

Y

.

T

O

O

L

C

A

P

B01 0293

750

75

1.1 60

1.

2

3

.3

PRESSURE

1/8−27 NPT

TO TANK

NOTE:

1) CLEAN ALL PAR

GREASE P ACK & ASSEMBLE.

STORE I N COVERED CONTAI NER.

2) USE ASSEMBLY TOOL #01 0356.

3) THI VALVE MUST BE USED

WI TH #91 1 447 CONTROL V ALVE

4) BLEED AI R FROM PORT #1

WH EN I N S TA L L I N G TH I S V AL V E

5) "SINAMIC" VALVES REQUIRE THIS

VALVE BE CONVERTED TO

01 0372 VALVE ASSEMBLY.

TS THROUGHLY−

S

REMOVE 01 0790 AND 91 2303

9/10/91.

1

Me t e r i n g V a l v e

date

scale

title

material

sym. revision

initial

date

rev.

size

drawing number

W. F. Wells

drawn by

010370

none

HHCS1420212

HHCS103212

A010356

A010292

904114

904113

C010294

904113

905044

905044

A010296

A292370

A292380

1/2

5/8

3/4

2

3

27

COVER

41 0 − 3000

RPM

RPM

BELT

CONE DRI VE

40/ 1 RATI O

Gearbox

SHAFT NUMBER 3093 91

900 091

BRUSH ONLY

61 080

COMPLETE

BRUSH

ASSY.

447050

GUAR D

9051 31

GARL OCK

SEAL

446001

POST

9031 22

BUSHI NG

309391

30925

309341

446890

WHEEL

SCREW

SHAFT

COVER

.01 0

.030

9000 20

LI NCOLN

5000

5

908 965

908 96

Bus hi ng

908966

Sprocket

908966

Sprocket

908 96

Bus hi ng

931 933

Mo t o r Bas e

HHCS142012

HHCS1213314

309350

HOLLOW

BOLT

5

HHCS38161

1750 RPM 184 T FRAME

7.5 HP (SAW DUTY)

931 3

1

7

35

LW14 (LOCK WASHER)

LW38 (LOCK WASHER)

HHCS38161

LW38 (LOCK WASHER)

448175

10.25 − 75

900851ASSY

W. F. Wells

Three Rivers, MI

www.wfwells.com

A. C. Drive Assembly F−16−2 & F−1620 A CNC

Drawing number 448170

HHCS38161

440460

440470

440450

1/4−20

RHS

LOCK WAS HE R

HEX NUT

446920

DOOR

900226

Washer

901 2 2

BEARI NG

906743

SNAP RI NG

1

−20 X 6

4

HHS & HN

91 01 49

3" BORE

X

STROKE3"

BLADE

TRAVEL

447040

BLADE

GUAR D

4

HJN3410

440482

SPACER

91 6031

44051 5

WH EE L

1/4−20

RHS

HEX NUT

440540

HI NGE

B/ M 44 115

WH E EL ASSY. WI T H

WH E EL , BEARI NGS

& SPACER.

5

28

5/1 6 CUT WA SH E R

1 OR 2 PER STUD

AS NEEDED FOR

BLADE ADJU STMENT.

900226 washer was 3/4 cut washer 04−02−03

RELEASE

TENSI ON

29

SSS38162

HN3816

292440

292470

WAS H ER

901204

BEARI NG

447040

292395

447020

440905

44081 0

440390

410710

WAS H ER

900215

WAS H E R

292430

292390

292360

HN1213

447050

BLADE GUARD

Note: Use dial indicator to align

295181

292290

440910

HN1220

382140

912673

010296

010370

SEE MET ERI N G

VALVE DRAWI NG.

A292375

Scre w

911500

Coolant Valve

Coo lant Bl ock

Carb i de Back up

Gui d e

Back i ng

447030

Gui d e Arm

Stud

Hand le

Wa s h e r

NOTE:

.0 0

.0 0 34

MOVE MENT MU ST

CLOSE CONTROL

VALVE TO STOP

CUTTI NG HEAD

DESCENT.

Rod

Backi ng

Gui d e Arm

292360

Gui d e

Ca Bol tm

Cam B olt

292420

Insert

Coolant Ho se

010537

Nut

292270

Adj ust i ng

Screw

292410

292270

Adj ust i ng

Screw

HN1213

HHCS14201

Install with

antiseize.

SSS142038

SSS103214

912924

912922

a448191

912111

382153

ASSEMBLY

ew

A292375

Scr

F−16−2 Guard

A292376

Spacer

900216

hex nut

washer

HN1213

SAE12

SAE12

washer

7

Guard

44505

F−1620−HA CNC

and F−16−3

spacer

blade vertical to within .003 TIR.

900215

30

B61 08 4

1/2−13 HN

A255360

9000 91

A61 08 1 5

610805

BLADE BRUSH ASSEMBLY

901 023

950009

5

W. F. Wells

3−29−96

material

title

drawn by

scale

date

size

drawing number

revisionsym.

initial

date

rev.

32

Section BB

Saw

Frame

Saw

Bed

B447355

HHCS1213212

HN1213

900202

Wheel

HHCS12133

FW12

Saw

Base

C107140

Tank

HHCS12131

HN1213

A

A

B

B

Section AA

931902

Coolant Pump

C107970

Conveyor

911029

Motor

447350

F−1620−A CNC

Chip Conveyor

Coolant

15 Gal

A107125

107170

B104855

HHCS381634

107160

screen

34

35

A105211

HHCS34102

A451 421

A451 422 8"

4"

A451 423 1 2"

A111780

HHCS12134

−1 X

HHS

5

8

14

HEX NUT

WAS H E R

B1052 50

B105266

A1014978

A1014979

HHCS12134

SAE WASHER

1

2

−13 X 4

HHS

SAE WASHERS

HEX NU T

1

2

A105265

91 051 1

MI L WAUK EE L H− 1 2

2" BORE X 1 6" STROKE

13/8ROD.

1"−14 FEMALE END

447118

F−1620−A CNC

BARFEED HOLDDOWN

A1014714 PAD

A1014715 PAD

A1014716 PAD

ATTACHED WITH 1/4−20 X 3/8 BUTTON HEAD SCREWS

W. F. Wells

title

scale

date

size

drawing number

revisionsym.

initial

date

rev.

37

B1 0 5320

2" BORE X 1 6" STROKE

91 0 1 52

A1 05266

A1 0531 0

A451 421

A451 422

A1 01 471 4 4"

A1 01 47 1 5

WE AR S TR I P S

8"

A1 05265

HHCS341 02

HHCS1 21 371 2

A1 01 47 40

A1 0533 0

date

scale

title

material

sym. revision

initial

date

rev.

size

drawing number

W. F. Wells

drawn by

1014700

Saw Vise Holddown

F−1620−A CNC

A1 01 47 1 6 12"

A451 423

Loading...

Loading...