Page 1

Technical Information

Locking System 1402 "One-Timer"

1.

Product Description

1.1

Main Features

1.2

General Information

.................................................................................

......................................................................................

...............................................................................

2

2

2

2.

Assembly Instructions

2.1

Important Hints for Fitters

2.2

Assembly Exploded View

2.3

Fitting Dimensions and Tightening Torques

2.4

Setting direction of rotation

3.

Operating Instructions for users

3.1

Inportant Hints for Users

3.2

Personal code setting and locking

3.3

Open the lock

4.

Operation Instructions for Administrators

4.1

Important Hints for Administrators

4.2

QUICK-RESET / Emergency Opening

5.

Ordering Information

5.1

Important Basic Information

5.2

Ordering Matrix Cam

5.3

Ordering Matrix Lock / Service Key

............................................................................

......................................................................

....................................................................

..............................................

........................................................................

..............................................................

.......................................................................

.............................................................

............................... ..........................................................

.................................................

............................................................

........................................................

..............................................................................

....................................................................

.................................................................................

..............................................................

3

3

3

4

5

6

6

6

6

7

7

7

8

8

9

10

Revision: 23.10.2018 / Technical changes reserved / All data without warranty / (c) W&F-LOCKS OHG 2017

Page 2

1. Product Description 1402 "One-Timer"

1.1 Main Features

- Combination lock with 10.000 freely programmable user-codes

- Service cylinder with 200 different key numbers for emergency opening and resetting

- QUICK-RESET

- ANTI-SPY

1

for an efficient administration

2

-technology to protect the personal user-codes

- Automatic code-scrambling for even more safety and comfort

- Lock movement R / L settable

- Locking mechanism made of solid zinc die-cast

- Housing made of fibreglass-reinforced and easy to clean special plastic

- Retrofittable for most doors with standard fixing holes 16x19mm

- Lock fixing by nut (SW22)

- Cam fixing by screw (TX25)

- Comprehensive range of cams available with 2 and 3mm thickness

- Ideally suited for 1-point and 3-point cams

1

Innovative function to restore to factory setting within seconds without time-consuming

codefinding

2

Innovative lock-system wherewith the readout and misuse of personal user-codes is no

longer possible

For more informationen visit:

wf-locks.com

1.2 General Information

- Please read carefully these instructions before fitting and first use

- Do not expose lock to enviromental influences like water, moist, dust etc.

- Lock operable within a temperature range from 0- 50°C (32°F to 120°F)

- For cleaning use damp cloth and common houshold detergent

- Don't use aggressive or chemical products

- When cleaning avoid that water or detergend enters the lock

- 2 -

Page 3

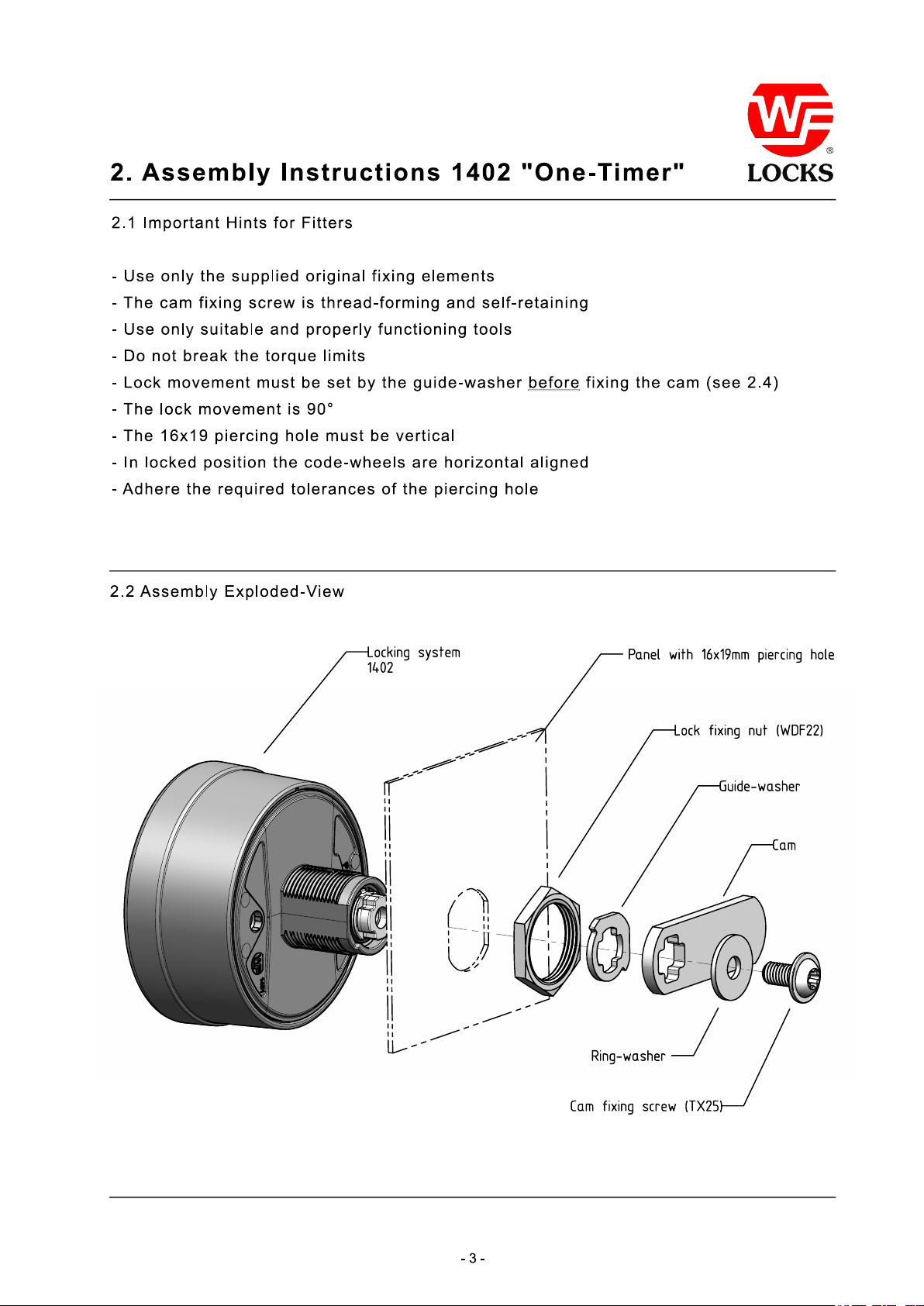

2. Assembly Instructions 1402 "One-Timer"

2.1 Important Hints for Fitters

- Use only the supplied original fixing elements

- The cam fixing screw is thread-forming and self-retaining

- Use only suitable and properly functioning tools

- Do not break the torque limits

- Lock movement must be set by the guide-washer

- The lock movement is 90°

- The 16x19 piercing hole must be vertical

- In locked position the code-wheels are horizontal aligned

- Adhere the required tolerances of the piercing hole

2.2 Assembly Exploded-View

Locking

system

1402

before

fixing the cam (see 2.4)

with

Panel

16x19mm

Lock

fixing

nut

Guide-washer

piercing

(WDF22)

hole

- 3 -

Ring-washer

Cam

fixing

screw

Cam

(TX25)

Page 4

2. Assembly Instructions 1402 "One-Timer"

2.3 Fitting Dimensions and Tightening Torques

Cam

fixing

screw

M:

max.

6Nm

(TX25)

12mm

max.

thickness

Panel

30

60

Lock

M:

max.

20,5

fixing

8Nm

nut

(WAF22)

Piercing

hole

+0,2

16

0

15,5

5

min.

If

locking

allow

- 4 -

into a slot

clearance

32

Recommended

from

centre

to

edge

new

of

piercing

(for

distance

of

piercing

door

+0,2

0

19

holes)

Page 5

2. Assembly Instructions 1402 "One-Timer"

2.4 Setting direction of rotation

Orientation guide washer

in

locked-position

90°

Direction of rotation to unlock

R

90°

"R" for right-hinged doors

90°

L

90°

"L" for left-hinged doors

- 5 -

Page 6

3. Operation Instructions for Users

1402 "One-Timer"

3.1 Important hints for users

- In opened position with vertically aligned numbers the lock is in coding mode

- In vertical position displayed or selected code is automatically stored and scrambled

when closing.

- Before closing, remember the code fixed by you or note it down if needed

- Do not select 0-0-0-0 as personal code

- With every opening your personal code is automatically deleted

- In case of lost code contact the administrator

- Leave you locker with opened lock in vertical position

3.2 Personal code setting and locking

1. In

vertical position

set personal code

3.3 Open the lock

2

1

2. Turn lock to the horizontal position

until it clicks into place

(Code is stored and scrambled)

2

1

1. Enter personal Code

2. Turn lock to the vertical position

(Code is deleted)

- 6 -

Page 7

4. Operation Instructions for Administrators

1402 "One-Timer"

4.1 Important hints for Administrators

- With service key you can always open the lock

- With every openeing the code is deleted

- Service key can only be removed in closed position

- Service key is provided with key numbers

- For security reasons please keep the number of service keys at a minimum and keep it

in a safe place

4.2 QUICK-RESET

1

Insert service key into barrel

1.

and turn it 90° to the left

2

2. Open the lock

- 7 -

Page 8

5. Ordering Information 1402 "One-Timer"

5.1 Important Basic Information

Lock, cam and service key will be ordered seperately. A complete order or inquiry

comprises 3 order numbers:

1. Order no. cam

2. Order no. lock

3. Order no. service key

Cam and fixing elements are standardly delivered unmounted. On request the cam

can be premounted as well. The needed specification for that will be done according to

order matrix 5.2.

Important: If you want the cam premounted please make sure that the lock with fixed

cam still fits through the 16x19 pircing hole. That mainly depents on the cam shape and the

panel thickness.

(Bestellmatrix 5.2)

(Bestellmatrix 5.3)

(Bestellmatrix 5.3)

Beispiel: C1402-3-4-20-30-DO

Beispiel: L1402-G-051-R-09-H

Beispiel: S1402-051

The factory-set code is 0-0-0-0.

For security reasons please keep the number of service keys at a minimum.

Service keys and locks are provided with key numbers. For security reasons the key

number of the lock is on the back.

Each order quantity will be delivered keyed to pass. This means that all locks have the

same key number (differ number), with one key opening all.

If you need different key numbers e.g. in order to equip different rooms or permissions

please split the order quantity in different key numbers.

For the service cylinder please chose one of the standard key numbers according the order

matrix 5.3. On request there are additional 200 key numbers available.

For short delivery times please prefer the given standards from the order matrices.

But special designs such as differnt colours or something else can also be requested

at any time.

- 8 -

Page 9

5. Ordering Information 1402 "One-Timer"

5.2 Ordering Matrix Cam

1. Thickness "T"

15,5 T

T = 2mm / 3mm

38

2. Shape

1

3

5

7

2

4

6

8

9

7,9

3

3. Hight of crank "A"

0,3

A

mm

00

03

04

05

06

07

08

10

12

14

16

20

21

25

28

32

34

38

40

44

48

50

64

72

A

0

1,2

1,6

2,0

2,4

2,8

3,2

4,0

4,8

5,6

6,4

7,9

8,3

9,9

11,1

12,7

13,5

15,0

15,9

17,5

19,1

19,9

25,4

28,6

für

-1-2-

-3-5-6-

-3-5-6-

-3-5-6-

-3-5-6-

-3-5-6-

-3-5-6-

-3-5-6-

-3-4-5-6-7-8-

-3-4-5-6-7-8-

-4-7-8-9-

-4-7-8-9-

-3-5-6-

-3-4-5-6-7-8-9-

-4-7-8-9-

-3-4-5-6-7-8-9-

-4-7-8-9-

-4-7-8-9-

-4-7-8-9-

-4-7-8-9-

-4-7-8-9-

-4-7-8-9-

-4-7-8-9-

-4-7-8-9-

Form

0,3

A

4. Lenght "B"

12,5

0,3

R

9

7,5

0,25

5,5

B

0,5

-Lenght "B" made to order

-Step range 1mm

-Lenght before bending max.100mm

9

R

10

A

5. Cam end

DO (Standard)

DX

DB

B

T

20,5

A

Order example cam

:

C1402-

3

-

4

-

20

-

38

-

DO

- 9 -

Page 10

5. Ordering Information 1402 "One-Timer"

5.3 Ordering Matrix Lock / Service Key

Always needed Information

1. Colour

B

(black)

G

(dusty grey

RAL 7073)

(Special colours on request)

2. Service cylinder key no.

033

041

051

(Special key numbers on request)

Only needed if premounting of cam requested (see hint uneder 5.1)

3. Direction of rotation

R

R: right hinged doors

L: left hinged doors

4. Cam position

12

L

09

06

View from front when locked

03

5. Crank direction

(if cranked)

H

V

Order example lock:

(grey lock with premounted cam)

(for cam order see 5.2)

Order example service key

(matching the lock above)

:

L1402-

S1402- 051

G

-

051 -

- 10 -

R

-

09

-

H

Loading...

Loading...