Page 1

WET Labs, Inc.

Battery Pack

BPA50

User’s Guide

PO Box 518

Philomath, OR 97370

(541) 929-5650

www.wetlabs.com

Battery Pack 50 User’s Guide (BPA50) Revision A 20 December 2007

Page 2

Battery Pack 50 Warranty

The battery pressure housing is guaranteed against defects in materials and workmanship for

one year from the original date of purchase. Warranty is void if the factory determines the

unit was subjected to abuse or neglect beyond the normal wear and tear of field deployment.

To return the instrument, contact WET Labs for a Return Merchandise Authorization (RMA)

and ship in the original container. WET Labs is not responsible for damage to instruments

during the return shipment to the factory. WET Labs will supply all replacement parts and

labor and pay for return via 3rd day air shipping in honoring this warranty.

Return Policy for Instruments with Anti-fouling Treatment

WET Labs cannot accept instruments for servicing or repair that are treated with antifouling compound(s). This includes but is not limited to tri-butyl tin (TBT), marine antifouling paint, ablative coatings, etc.

Please ensure any anti-fouling treatment has been removed prior to returning instruments to

WET Labs for service or repair.

We recommend our Anti-fouling Paint Kit for optimum bio-fouling protection. It includes

Ecominder® anti-fouling paint, tape, brush, and detailed instructions. Ecominder® is

specially formulated as a safe, effective alternative to traditional copper-based anti-fouling

paints. Simply wrap your instrument package with the supplied tape, then paint the tape

with Ecominder®. After deployment, remove the anti-fouling paint by simply peeling off the

tape. Each kit contains more than enough material for two deployments.

Shipping Requirements for Returning Instruments

1. Please retain the original shipping material. The shipping container meets stringent

shipping and insurance requirements.

2. To avoid additional repackaging charges, use the original box (or WET Labs-approved

container) with its custom-cut packing foam and anti-static bag to return the instrument.

•

If using alternative container, use at least 2 in. of foam or bubble-wrap to fully

surround the instrument

3. Clearly mark the RMA number on the outside of your shipping container and on all

packing lists.

4. Return instruments using 3rd day air shipping or better: do not ship via ground.

Battery Pack 50 User’s Guide (BPA50) Revision A 20 December 2007

Page 3

1. Description

The BPA50 is a non-rechargeable battery pack that provides a maximum of 50 Amp hours (Ah)

using alkaline batteries. It has a single bulkhead connector, pressure relief plug and end flange

handle.

The battery pack contains a self-resetting polyswitch circuit breaker to protect connected

instruments and the batteries from a possible short. This circuit breaker senses high current

draw: when its threshold of 3 amps is met or a short circuit condition exists, it instantly

opens the circuit. This state is retained until the fault condition is removed, at which time

the breaker resets and closes the circuit.

2. Specifications

Dimensions:

Weight in air:

Weight in water:

Rated depth:

Voltage output:

Battery type:

Number of cells:

Total capacity:

Circuit protection

Housing:

* The battery core manufacturer’s specifications are for 78 Ah. Note that actual

performance depends on rate of discharge, temperature, and the minimum voltage

requirements of your instrument(s). WET Labs recommends the more conservative

50 AH specification.

56.4 x 10.2 cm

8.63 kg

2.87 kg

200 m

15 VDC nominal (16V peak)

Alkaline

40

50 Ah*

3 Amp polyswitch

PVC with acetal end flange

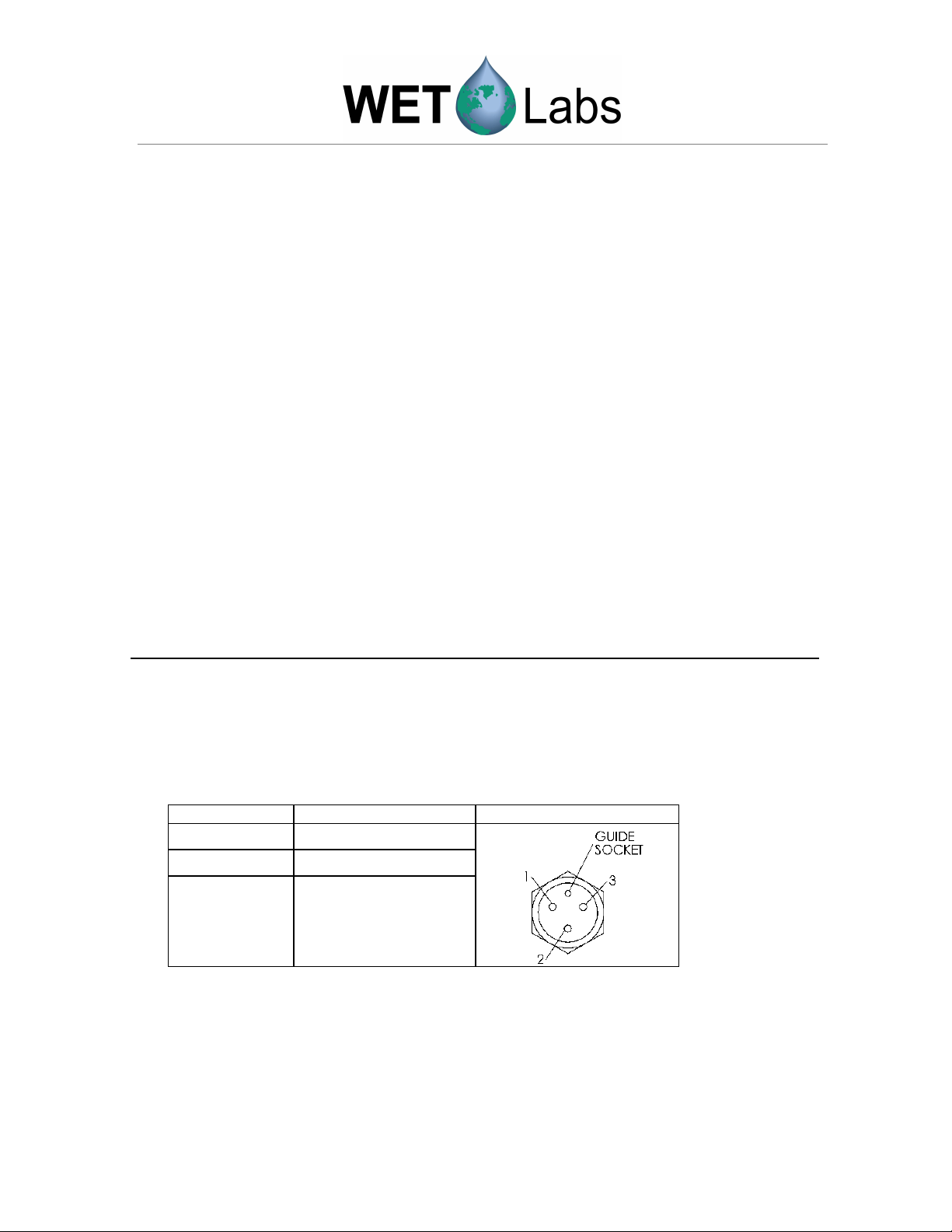

2.1 Connector

Socket Function Diagram

1

2

3 N/C

Battery Pack 50 User’s Guide (BPA50) Revision A 20 December 2007 1

+

Page 4

3. BPA50 Use

The BPA50 provides operational time that is partially dependent upon temperature.

Typical amp hours (AH):

• 4–6 deg C: 28–30 AH

• 10–14 deg C: 44–48 AH

• 16 + deg C: 50 AH or better

Note that if powering instruments that “sleep,” thus using an intermittent current draw,

the BPA50 will last longer.

WARNING!

MAKE SURE THE PRESSURE RELIEF PLUG IS FULLY SEATED

BEFORE DEPLOYMENT.

When connecting the battery pack to a piece of equipment, make sure the polarity is

correct before connecting the battery to the equipment. Also verify that the battery pack’s

output voltage is correct to use with the specific instrument/equipment.

Under normal circumstances, alkaline batteries will not leak and therefore need not be

stored upright.

To order a replacement battery core, contact WET Labs and refer to part number FAA-

000934.

3.1 Checking Functionality

If equipment connected to the battery pack fails to operate, check that it’s properly

connected and turned on.

If it appears the battery pack is not functioning, disconnect equipment and check the

voltage at the battery pack.

•

If it’s below 12 V, the battery core is near exhaustion and a replacement should be

ordered.

•

If it’s 0 V, remove the end flange and check wiring continuity. Refer to the

instructions for replacing the battery core important details about removing and

replacing the end flange.

Revision History

Revision Date Revision Description Originator

A 12/20/07 New document (DCR 554) A. Derr, M. Everett, H. Van Zee

2 Battery Pack 50 User’s Guide (BPA50) Revision A 20 December 2007

Loading...

Loading...