Page 1

Spectral Absorption

and Attenuation Meter

ac-s

User’s Guide

WET Labs, Inc.

P.O. Box 518

Philomath, OR 97370

541 929-5650

www.wetlabs.com

ac-s User’s Guide (ac-s) Revision H 21 May 2008

Page 2

Page 3

Attention!

Return Policy for Instruments with Anti-fouling Treatment

WET Labs cannot accept instruments for servicing or repair that

are treated with anti-fouling compound(s). This includes but is not

limited to tri-butyl tin (TBT), marine anti-fouling paint, ablative

coatings, etc.

Please ensure any anti-fouling treatment has been removed prior to

returning instruments to WET Labs for service or repair.

ac-s User’s Guide (ac-s) Revision H 21 May 2008

Page 4

Page 5

ac-s Warranty

This unit is guaranteed against defects in materials and workmanship for one year from

the original date of purchase. Warranty is void if the factory determines the unit was

subjected to abuse or neglect beyond the normal wear and tear of field deployment, or in

the event the pressure housing has been opened by the customer.

To return the instrument, contact WET Labs for a Return Merchandise Authorization

(RMA) and ship in the original container. WET Labs is not responsible for damage to

instruments during the return shipment to the factory. WET Labs will supply all

replacement parts and labor and pay for return via 3rd day air shipping in honoring this

warranty.

Shipping Requirements for Warranty and Out-of-warranty Instruments

1. Please retain the original shipping material. We design the shipping container to

meet stringent shipping and insurance requirements, and to keep your meter

functional.

2. To avoid additional repackaging charges, use the original box (or WET Labs-

approved container) with its custom-cut packing foam and anti-static bag to return

the instrument.

• If using alternative container, use at least 2 in. of foam (NOT bubble wrap or

Styrofoam “peanuts”) to fully surround the instrument.

• Minimum repacking charge for ac meters: $240.00.

3. Clearly mark the RMA number on the outside of your shipping container and on

all packing lists.

4. Return instruments using 3rd day air shipping or better: do not ship via ground.

ac-s User’s Guide (ac-s) Revision H 21 May 2008

Page 6

Page 7

Table of Contents

1. Instrument Setup and Testing ......................................................................... 1

1.1

Installing WETView ................................................................................................ 1

1.2

Bench Testing .......................................................................................................... 2

1.3

Air Tracking ............................................................................................................. 3

1.4

Cleaning ................................................................................................................... 3

1.5

System Requirements............................................................................................... 5

2. Operation ........................................................................................................... 6

2.1

Basic Power On........................................................................................................ 6

2.2

Mounting and Deploying the Meter ......................................................................... 6

2.3

Data Collection ........................................................................................................ 9

2.4

Care and Maintenance............................................................................................ 10

3. Data Processing .............................................................................................. 11

3.1

Analog Acquisition ................................................................................................ 11

3.2

Analog-to-Digital Conversion ............................................................................... 11

3.3

Digital Processing and Data Output ....................................................................... 11

3.4

Data Format ........................................................................................................... 11

3.5

Post Processing ...................................................................................................... 11

3.6

Temperature-dependent Absorption Correction .................................................... 14

3.7

Scattering Correction ............................................................................................. 15

4. Calibration and Characterization ................................................................... 16

4.1

Temperature Correction ......................................................................................... 16

4.2

Precision ................................................................................................................. 16

4.3

Absolute Calibration .............................................................................................. 17

4.4

Linearity and Dynamic Range ............................................................................... 17

4.5

Air Calibration and Tracking ................................................................................. 17

5. Specifications ................................................................................................. 20

5.1

Connectors ............................................................................................................. 20

5.2

Power Requirements .............................................................................................. 22

6. Technical Reference ....................................................................................... 23

6.1

Mechanical ............................................................................................................. 23

6.2

Optics ..................................................................................................................... 23

6.3

Electronics.............................................................................................................. 26

6.4

Signal Processing ................................................................................................... 26

Appendix A: Data Record Format ...................................................................... 28

Primary Processing ............................................................................................................. 29

Appendix B: Pressure Sensor Use and Care.................................................... 33

Appendix C: Common Mode A/C Induced Noise ............................................. 34

ac-s User’s Guide (ac-s) Revision H 21 May 2008 i

Page 8

Page 9

1. Instrument Setup and Testing

This section provides an introduction to the ac-s and describes how to set up and perform air

tracking and bench testing prior to deploying the ac-s.

The ac-s is delivered in a sturdy wooden shipping container with the following components:

• ac-s, with one absorption flow tube and one attenuation flow tube

• four flow sleeves

• four protective black plastic caps

• dummy plug with lock collar

• this manual

• WETView User’s Guide

• additional reference: ac-9 Protocol Document

• WETView software and instrument-specific calibration information

• Ten-foot test cable

• double “Y” de-bubbler tubing

• stainless steel intake screens

Familiarize yourself with the ac-s: remove the black plastic flow tubes by grasping the

flow tube sleeves and sliding them away from the ends of the flow tube (toward the

middle of the flow tube). You only have to slide the collars about ½ in. to unlock the flow

tube from its fixed position. The flow tube will lift out, exposing the transmitter and

detector windows on the lower and upper flanges respectively. Observe the flow tubes.

The attenuation tube is different from the absorption tube. Its flow chamber is plastic and

the two sleeves on the tube are identical. This tube installs on the “c” side of the

instrument (the side with the identical looking windows). The “c” tube has no “up or

down” orientation. The absorption tube is lined with a quartz tube and one of the two

sleeves is flat on top (the lip present on all the other sleeves is missing). This tube installs

on the “a” side of the instrument, which can be identified by the “a” detector on the upper

flange and is the only window, which is clearly different from the other three. The flat

flow tube sleeve goes on this detector.

You may want to mark the tubes and their orientation with tape or marking pen before

using the instrument at sea so there is no confusion upon reinstalling the tubes after

cleaning the optics. Reinstall the flow tubes before bench testing your instrument. If you

have removed the plastic caps from the stainless nozzles, replace them at this time.

1.1 Installing WETView

WETView displays data produced by WET Labs ac meters. It runs on PC-compatible

computers with at least 16 Mb of memory and 3 Mb free hard disk space running

Windows-95 or later operating system.

1. Insert the WETView CD in the host computer.

2. Double-click on the SETUP.EXE icon. Setup will guide you through the rest of the

installation process.

ac-s User’s Guide (ac-s) Revision H 21 May 2008 1

Page 10

When installed, the following files should be on the hard disk: WETVIEW.EXE,

WETVIEW.UIR, ACSXXX.DEV, AIRXXYYY.CAL. The .DEV and .CAL files are the

calibration files for your particular instrument. They are not installed by setup and will

need to be copied to the hard drive manually.

Caution

If you have old device files from previous calibrations, you should rename them or

archive them in a different directory so that they will not be overwritten.

1.2 Bench Testing

The following items are needed to bench test the ac-s:

• A clean, solid lab table or work bench

• The ac-s with 10-foot test cable (or sea cable)

• A 10–35 volt power supply (the ac-s requires 10–35 VDC)

• A PC with WETView installed.

1. Connect the test cable to COMM1–COMM4 of the computer. Connect the power

leads to the power supply. The black lead is the V+ lead. Before connecting the cable

to the instrument, use a multimeter to check the input power.

2. Connect the ground probe to pin 1 on the pigtail connector (the center pin as you are

looking into the connector). Connect the hot probe to pin 4 (Figure 4). You should

measure the power supply voltage across these two pins.

3. Turn the power supply off.

4. Connect the pigtail to the instrument. Push the connector straight on to avoid

damaging the pins. Apply power to the instrument and allow it to begin warming up.

5. Run WETView. When the interface is displayed, you will need to provide a .DEV file

name. Click on the <O> button in the center top of the screen or choose “Open

Device File” from the File Menu at the top left of the screen. The program will ask

you to choose the proper COMM port. Select COMM1 through COMM4 as

appropriate. Note that WETView supports COMM1 through COMM4 only.

6. Click on the center button or <F1> to start displaying data. After 5–10 seconds,

tabular data should be displayed on the right side of the screen. A real time graph will

begin to develop, depending on the graph parameters set at the time. Refer to the

WETView User’s Guide for details of running the WETView software.

7. After a short time, again click on the center button that will stop the data collection

and ask for a file name to apply to the data if you should want to archive it. Press ESC

if you do not want to save the data. To quit the program, choose QUIT from the File

menu. At this point you have successfully completed a bench test of the instrument.

2 ac-s User’s Guide (ac-s) Revision H 21 May 2008

Page 11

1.3 Air Tracking

WET Labs provides an air calibration (.CAL) file similar to the device (.DEV) file and

can be applied in WETView in the same manner. The DEV file provides the clean water

offsets so that when measuring clean, fresh water, the instrument’s output should be very

nearly 0.0 for all channels. The .CAL file provides the offsets that provide 0.0 values

when the instrument is clean and dry and measuring air values. This is a useful tracking

tool for catching instrument drift, filter aging and improper cleaning.

When you install WETView, the latest air .CAL file should be transferred to your

WETVIEW directory. The name of the file takes the form AIRXXYYY.CAL where XX

is the calibration number; YYY is the instrument serial number.

When a .DEV file is opened in WETView, it will display *.DEV in the dialog box, which

will list all the .DEV files on the default drive. If you change the *.DEV to *.CAL, the

available .CAL files will be displayed. Select the latest .CAL file and start collecting

data. Make sure the black plastic caps are installed on the flow tube nozzles so no

ambient light can enter the flow tubes. If the instrument is clean and dry, the values

displayed in WETView should be very close to 0.0 (within 0.005–0.01). If the values are

within this range, the instrument is clean and ready to deploy. If the values are outside

this range, the first step is to re-clean the instrument and then reapply the .CAL file

offsets.

1.4 Cleaning

1. Remove flow tubes and all O-rings. Remove the sleeves from the flow tubes. Wash

the windows with a mild detergent diluted with distilled, reverse osmosis-filtered

(RO) or de-ionized (DI) water and rinse the flow tubes. Use Kimwipes or other lintfree tissues to wash the windows. Rinse the meter off completely with water to ensure

no soap residue is left inside the flow tubes or on the windows.

2. Dry the meter. Place the instrument in a protected area where it can dry completely.

Using a small heater to blow warm air over the meter may help speed the process.

Using dry nitrogen to blow-dry the meter and remove water from the small grooves

around the windows will also help speed the process. It is suggested that the

instrument be left overnight to dry out completely. Reassemble the meter. Carefully

replace O-rings and slide collars back on to the flow tubes. Replace O-rings around

the windows.

3. Clean windows using a Kimwipe or lens paper. Place a couple of drops of methanol

or ethanol on the Kimwipe. With firm pressure, gently wipe the windows with

methanol. This should remove any visible streaks on the windows. If necessary,

follow with a dry wipe in one direction across the window face. Blow off any lint or

dust with a dry air source.

4. Clean the flow tubes by putting a few drops of methanol on a Kimwipe and, using a

wooden dowel rod, carefully slide the Kimwipe through the flow tube. Repeat this

ac-s User’s Guide (ac-s) Revision H 21 May 2008 3

Page 12

procedure with both flow tubes. Examine each flow tube when you are through to

ensure there are no streaks or small pieces of lint left on the inside of the flow tube.

5. Dry the windows. Since small amounts of moisture can affect the air readings, it is

important to ensure the meter is completely dry. Using nitrogen to blow dry the

windows immediately before replacing the flow tubes works very effectively. This

will remove any water or methanol trapped in the small grooves around the window.

6. Replace the flow tubes. Carefully slide the flow tubes into place without sliding dirt

across the windows. Slide the sleeves up around the windows and over the O-rings,

making certain they are firmly in place and aligned correctly. Use small black caps, or

black electrical tape, over each of the nozzles on the flow tube to provide a dark

environment and to keep the meter clean and free of moisture while obtaining data.

7. Turn the meter on and allow it to warm up for at least 15 minutes. When the meter is

stable you should be able to collect 10 minutes worth of data and the values should

not vary more than 0.005 m-1 over the 10-minute time period.

8. Collect data. Record a one- to two-minute file and save data. Repeat steps 4–6 until

you can collect three data files, cleaning the windows after each file, such that the

average values for each channel vary by no more than 0.005 m-1.

The meter is calibrated over a specific range of internal temperatures (refer to your

calibration sheet). If the meter’s internal temperature is higher than the maximum

calibration range, it may be operating out of spec. Setting the meter in a shallow pan of

water (immerse most of the lower can) can help keep the instrument cool. This process

should be repeated until the air values are within specification. This may take three or

more iterations but is very important to be done carefully before taking your instrument

to sea. The air calibration procedure should be done again at the end of a cruise or data

collection period to track the instrument’s performance over time.

Note

The ac-s time averages its dark offsets. If the flow tubes are removed, incoming light

corrupts the dark readings. Following flow tube replacement while the meter is still

running, either wait three minutes for the dark offsets to stabilize, or cycle the power to

the instrument, resetting the dark offsets.

4 ac-s User’s Guide (ac-s) Revision H 21 May 2008

Page 13

1.5 System Requirements

This section explains the basic system components necessary to operate the ac-s. Note

that components will vary depending on whether the ac-s is used for profiling, on a

mooring, or underway flow.

Instrument

The ac-s and its flow tube assembly form the basic optical sensor.

Pump

The flow-through system will typically require an ancillary pump to assure proper

operation. Pump requirements depend upon desired flow rates, required depth of

operation, power availability, and existing hardware.

Cabling

The ac-s requires a minimum of four conductors for power and RS-485 output. (Three

conductors for RS-232 output).

Power Supply

The ac-s requires a 10–35 VDC supply, capable of providing a minimum of 10 watts

continuous output. Additional wattage will be required to also drive a pump from the

same supply. If a longer cable is used, power losses must be accounted for in determining

the power supply voltage and power requirements.

Serial Communications

Data from the ac-s is transmitted via both RS-232 and RS-485 depending on which

sockets are connected to the instrument’s bulkhead connector. Regardless of the mode of

transmission you use, you must have a serial interface on your computer or data logger

capable of accepting data from the instrument at a rate of 115,200 baud. If you have an

instrument with RS-485 output and are using a computer with standard RS-232

communication ports or USB ports, optional protocol converters can be readily obtained.

Host/Data Logger

The ac-s can be interfaced to any computer or data logger capable of supporting a

115,200 baud rate serial interface. If you plan to use our WETView software acquisition

package you will need a computer running Windows 95 or newer.

Software

The WETView host software package interfaces directly to the ac-s via your computer

serial port. WETView allows real-time graphical visualization of the data in any of

several ways such as a function of time, depth, or wavelength. WETView automatically

applies calibration constants, temperature corrections and generates a tab-delimited

ASCII text file that can be imported into programs such as Excel or MatLab for postprocessing or manipulation.

ac-s User’s Guide (ac-s) Revision H 21 May 2008 5

Page 14

2. Operation

2.1 Basic Power On

1. Check cable wiring. Make sure the “+” lead of the test cable is connected to the “+”

terminal of your power supply. Make sure the “–” lead of the test cable is connected

to the “–” terminal of your power supply. Verify that your power supply is providing

between 10 and 35 VDC, and is rated for at least 2 amps.

WARNING!

Power input on this unit is diode-protected from reverse polarity power-up, but

this is not 100 percent insurance against damaging the meter, nor will it

protect it from over-voltage.

2. Cable connections. The surface (dry) end of the cable should have terminations for

an RS-232 connection into the computer and leads that connect to a power supply.

Attach the power leads to a stable power source that supplies 10–35 VDC to the ac-s.

Make sure the polarity is correct before switching on the power supply. Connect the

RS-232 connector to the desired serial port of the data collection computer. If your

instrument is sending data in the RS-485 format, an RS-485–to–RS-232 or RS-485–

to–USB converter is required to allow proper operation. Plug the submerged (wet)

end of the cable into the ac-s. Applying a small amount of silicone grease or

equivalent to the base of the instrument bulkhead makes the plug insertion easier and

provides greater assurance of a good seal. Use a connector lock ring if one is

available.

3. Turn on power supply. To verify basic operation when not hooked directly to a

computer, remove one of the flow tubes and, in a darkened environment, place a

white piece of paper into the beam path. You should be able to see the beam image on

the piece of paper. You should be able to hear a faint whirring of the filter wheel

motor if you place your ear directly against the lower can. If you neither hear the

motor nor see the beam, the unit is not working. In this case, check your connections

and your power supply. If the instrument still does not run, you may want to seek

technical assistance from the factory.

4. For optimum stability allow the instrument to warm up for 3–5 minutes before

collecting data. While this is not an absolute requirement, the instrument’s electrooptics are subject to an initial stabilization period.

2.2 Mounting and Deploying the Meter

ac-s operation is optimized for a vertical to forty-five degrees off-vertical orientation with

the bulkhead connector facing upward (Figure 1). If your application requires a

horizontal mounting, take care to provide proper pump priming and to avoid trapping air

bubbles in the flow tubes. This can be accomplished by taking the system to a depth of 20

6 ac-s User’s Guide (ac-s) Revision H 21 May 2008

Page 15

meters and allowing the required in-water warm up period to occur at depth. This helps

the pump to prime properly and compresses small air bubbles, allowing them to be

expelled from the ac-s.

In addition, operating the instrument in the horizontal position could potentially cause

small variations in the meter’s response due to the different orientation of the filter

wheel’s rotational plane. Therefore, we recommend that both air and water calibrations

be done in the orientation in which the meter will be deployed to obtain the best results.

Figure 1. ac-s mounting positions

Specific mounting instructions will depend upon implementation of the sensor. To assure

long term instrument integrity and optimum operation, observe the following basic

procedures:

1. Do not make direct contact between the ac-s pressure housing and a metal frame

or hose clamp. The ac-s is available in one of two pressure-housing materials.

Aluminum is used for full ocean depth rated units and an acetal copolymer plastic is

used for the standard units rated to 500 meters. The aluminum housing is hard

anodized with a special plastic impregnation to assure minimum corrosion damage

and to provide electrical isolation from the aluminum housing and its surrounding

environment. However, metal-to-metal contact with the housing can damage this

coating and result in possible corrosion of the pressure case. We recommend a

neoprene spacer between the unit and its frame or clamp. At the very least, any

contact area should be taped carefully to assure mechanical and electrical isolation.

2. Do not apply torsional stress to the instrument housing. The optical path is

encased in a rigid housing, but is still subject to distortion if the unit is subjected to

undue stress. The instrument has a delicate optical path that is subject to

misalignment if stress is applied unevenly to the upper and lower cans. Make sure the

unit is mounted on at least two points and that neither point is a stress point.

ac-s User’s Guide (ac-s) Revision H 21 May 2008 7

Page 16

3. Make sure you have provided for an unobstructed upward flow through the flow

chambers and the pump (Figure 2).

Figure 2. Proper connection of ac-s flow tube

The following suggestions will help you obtain the highest quality data from your ac-s:

• The instrument is extremely sensitive and should be handled carefully.

• A sturdy shipping/transport container should be used to transport your instrument to

the field. The instruments are sturdy, but the optics can be jarred out of alignment

when subjected to shock.

• The data will be adversely influenced by bubbles, dirt or grease in the flow path or

misalignment of the flow tubes. Make sure that the flow tubes, pump tubing and

screens are free of dirt and grease. Clean with ethanol or warm soapy water. Rinse

with clean tap or distilled water. Do not allow water to dry on the windows as this

will leave a residue that may be hard to remove.

• Secure the ac-s to a sturdy cage or lowering frame that will protect the instrument from

striking the deck, ship’s side, or sea bed. Use a dielectric isolator (rubber sheeting or

thick tape) to isolate the instrument’s aluminum case from the steel cage.

• When clamping the instrument to the cage, make certain no torsional stresses are

applied. Even slight wracking of the instrument can alter the beam alignment. This

will severely degrade the data quality, especially on the ‘c’ side, which requires an

extremely tight alignment tolerance.

• Once every couple of days, take a data file in air to track any instrument drift. The

instrument must be very clean and completely dry to achieve an accurate air

8 ac-s User’s Guide (ac-s) Revision H 21 May 2008

Page 17

calibration measurement. Using compressed dry nitrogen or oil-free dry air to blow

the instrument’s flow tubes and windows dry will speed the drying process.

• Upon deployment, the instrument should be lowered to just below the water’s surface.

Turn on the instrument and pump and check to ensure that the pump has primed and

is operating properly. Lower the package to a depth of 10–20 meters. Run the

instrument for 3–5 minutes to allow the motor controller to stabilize, the flow tubes to

clear and the instrument to begin to equilibrate with the water temperature.

• After the warm up period, raise the package to just below the surface and begin data

collection. The initial depth will be dependent on the natural surface conditions and

the amount of bubbles that the ship itself is generating. Steadily lower the cage

through the water column.

• The upcast can proceed immediately after the downcast. It is your choice whether to

open a new data file for the upcast or include the down and upcast data in a single file.

• Once the cage is back to the just below the surface, stop the data collection and turn

off the pump. Carefully bring the cage on deck and lash it down. Give the cage and

instrument a fresh water wash down after every cast. If this is not practical, wash the

instrument at the end of each data collection day. Holding a hose (at low pressure)

over the pump discharge port will flush the tubing and the flow tubes. Rinse the

flanges and connectors. If leaving the instrument on deck for more than a few

minutes, cover the cage with a tarp to avoid over-heating the instrument due to solar

insolation. At the end of each data collection day, remove the tubes and carefully

clean and dry both the flow tubes and windows. Failure to flush the instrument with

fresh water may cause corrosion damage over time.

2.3 Data Collection

WET Labs offers several output configuration options to provide flexible interfacing to

different systems. These various output protocols are discussed at length in the Data

Processing Section of the manual. Unless supplied with a custom output protocol the

instrument powers up in a free run mode. This means that when turned on the unit

automatically begins acquiring data and outputting that data in its appropriate format.

Typically the instrument comes supplied with RS-485 and RS-232 output operating at

115,200 baud.

RS-485: For longer cable lengths and maximum data integrity, RS-485 protocol is the

preferred method of data transfer. Data is transmitted from the instrument in a binary

format. To view this data, you must have a program capable of reading binary data. If

you are using our WETView software package, the binary read is done automatically. If

you do not plan to use WETView or a WET Labs data logger, consult the Data

Processing section of this manual for a detailed description of the binary data format.

ac-s User’s Guide (ac-s) Revision H 21 May 2008 9

Page 18

RS-232: Operating across an RS-232 cable, you can obtain binary data from the

instrument. If you are using WETView, read the operational instructions contained in the

software manual.

2.4 Care and Maintenance

Built for field deployment, the ac-s requires minimal maintenance. However, following

these simple recommendations will assure optimum data integrity as well as longer

instrument life.

After a field deployment of the ac-s you should clean the instrument prior to storage.

Refer to Section 1.4 for detailed cleaning procedures. The following steps will help

prolong the life of the instrument:

1. Rinse the pressure housing. If a dummy plug for the connector is available, install it

on the main bulkhead connector before flushing the instrument. Begin with a

thorough rinsing of the unit and its flow tubes with fresh water. After rinsing, toweldry the pressure housing and remove the flow tubes.

WARNING!

Do not use acetone on the windows. It will damage the window holders.

2. Wash the windows. The windows should be cleaned with dilute soapy water,

followed by ethyl alcohol, and should receive a final rinse with distilled or reverse

osmosis-filtered water. This will remove any fingerprint oil, grease or other

contaminants from the windows. Use lint free lens cleaning paper to avoid scratching

the windows or detectors.

3. Wash the flow tubes. To clean the absorption path’s reflective tube, carefully plunge

an alcohol-soaked tissue through the tube and rinse thoroughly with distilled water.

Whenever plunging a tissue through the tube, use a wooden or plastic dowel to

prevent scratching the sides of the tube. After rinsing, dry the tube either by blowing

dry nitrogen through it or by plunging a soft tissue. The attenuation path flow tube is

virtually maintenance free, except for occasional cleaning. Follow the same basic

procedures supplied for cleaning the absorption path tube. Remove the flow tube

sleeves when drying the flow tubes.

4. Store the meter. Store and transport the ac-s in a shock-protected environment.

Typically, units are shipped in a sturdy wooden crate. Using the crate will assure that

you can safely transport the instrument, providing it is handled in a reasonably careful

fashion.

10 ac-s User’s Guide (ac-s) Revision H 21 May 2008

Page 19

3. Data Processing

Data from the ac-s is acquired and processed through the following steps.

3.1 Analog Acquisition

Optical radiation at the reference and signal channels is continuously monitored by

operational amplifiers operating in a current to voltage configuration. The amplifiers are

configured for a gain of approximately 107 for the reference channels and approximately

2 * 106 for the signal channels.

3.2 Analog-to-Digital Conversion

The A/D used in the ac-s supports six input channels that are triggered pair wise. Four

channels are dedicated to the attenuation beam reference and signal channels and the

absorption beam reference and signal channels. Another channel is dedicated to the

output of the optional pressure sensor amplifier. The sixth channel is preceded by an 8

channel analog mux, and is used to sample ancillary analog signals including the internal

and external temperatures via thermistors within the unit. During a single filter wheel

rotation, the A/D concurrently samples all 4 signal and reference detectors for both

beams. Ancillary signals are sampled during the “dark” periods when the beams are not

passing through the filters.

3.3 Digital Processing and Data Output

The CPU takes multiple samples of both signal and reference channels, accumulates them

through the sampling period, and then averages the values at the end of the sampling

period. Once averaged, light and dark values are collected for each channel. The CPU

takes the difference of these values to derive its output value. Once signal data is

accumulated over a given filter wheel rotation its output is transmitted through the RS232/RS-485 port. For a more detailed explanation, see Section 6.4, Signal Processing.

3.4 Data Format

The ac-s outputs data in binary format. If you will not be collecting the data using

WETView, your collection system will need to be able to handle binary data. Beware that

some serial port terminal programs such as HyperTerminal are not capable of capturing

true binary data streams. HyperTerminal, for example, fails to capture ASCII NULL

characters (hex 00). WETView is capable of processing collected binary files in addition

to serial data. If you prefer to use your own software to process the ac-s output data,

please refer to Appendix A for a description of the ac-s data packet formatting.

3.5 Post Processing

Once accumulated by a host computer the data must be post processed to yield

meaningful scientific data.

The primary transfer equation for yielding the attenuation coefficient, c, or the absorption

coefficient, a, for a given wavelength is:

ac-s User’s Guide (ac-s) Revision H 21 May 2008 11

Page 20

(

)

−

-cx (1)

Tr = e

where Tr is the transmittance, c is the attenuation coefficient, and x is the pathlength of

the water volume being measured. The following treatment applies to the absorption case

if c is replaced by a. The pathlength of the ac-s is fixed at 25 cm. In the case of the ac-s

the transmittance is computed by taking the ratio of the signal value to the reference

value:

Tr= (C

) / N (2)

sig/Cref

Substituting equation (2) into equation (1) we get,

(C

sig/Cref

) / N = e

-cx

, (3)

where Csig and Cref are the signal and reference count values from the instrument and N

is an instrument specific calibration constant obtained in the laboratory using clean water.

For more information about how N is derived, see Section 4, Calibration and

Characterization.

We therefore can solve for c (or a) by,

c = - 1/x [ln (C

) - ln (N)] (4)

sig/Cref

or c = - 1/x (ln(C

sig/Cref

)) - (- 1/x (ln(N)) (5)

or c = [(ln(N)/x) - (ln(C

sig/Cref

)/x)] (6)

The ac-s pathlength is a fixed constant (typically at 25 cm) and can be found in the

device file. Now we require the determination of (ln(N)/x) to accurately measure c.

This value is derived for each channel and is supplied with each instrument’s

calibration data sheet as the “Water Offset” value and is referred to as c

in equation

off

(8).

The temperature correction is applied using the temperature from the reference line

and the channels correction table from the either the Calibration Sheet or the Device

File. The approximate correction value is linearly interpolated from the table. First,

the correct temperature bin is determined by finding the two bin temperatures, T0 and

T1, that bracket the current temperature. Then, using the values,

∆

and

∆

Tn

, from the

Tn+1

table, we obtain

TT

0

+∆=∆

( )

−

( )

*

TT

01

∆−∆

(7)

TnTnTnT

+1

where,

∆T = compensation constant

12 ac-s User’s Guide (ac-s) Revision H 21 May 2008

Page 21

-

1

off

off

-

1

-

1

T= current temperature

T0 = first bin temperature

T1 = second bin temperature

∆

= first value

Tn

∆

= second value

Tn+1

This temperature correction is automatically applied by our WETView software. If you

are manually processing the raw data stream, this correction must be applied to arrive at

the temperature-corrected absorption and attenuation coefficients.

WETView reads in the raw binary data and applies an algorithm that

1. Computes uncorrected engineering units (in inverse meters) from the signal and

reference values.

2. Applies a linear temperature correction (for the meter’s internal temperature)

using constants supplied in the instrument’s device file.

3. Applies clean water offsets supplied from the instrument’s device file that provide

a value referenced against clean water.

Combining these steps into one formula:

c(λ) = (c

- 1/x [ln(C

off

sig

/ C

)]) - ∆T (8)

ref

and

a(λ) = (a

- 1/x [ln(A

off

sig

/ A

)]) - ∆T

ref

where

c(λ), a(λ)

c

, a

C

, A

sig

sig

C

, C

ref

ref

x

∆T

is the attenuation coefficient and absorption coefficient, respectively in m

is the water offset value (provided on the Calibration Sheet) in m

is the measured amount of light (power) that reaches the receiver detector from the ac-9

or ac-s data stream in raw digital counts

is the amount of light (power) measured by the reference detector from the ac-9 or ac-s

data stream in raw digital counts

is the sample volume path-length in meters

is the internal temperature compensation correction value in m

derived from Equation

(8).

ac-s User’s Guide (ac-s) Revision H 21 May 2008 13

Page 22

3.6 Temperature-dependent Absorption Correction

Absorption of water shows a temperature dependency that is wavelength-dependent.

While existent throughout the visible portion of the spectrum, at infrared wavelengths the

effect must be taken into account. With regard to the ac-s, the water absorption

temperature effect must be considered to correct the absorption and attenuation at

wavelengths above 700 nm.

Experimental results show that aT*, the water-specific absorption correction due to

temperature at 715 nm is approximately 0.0035 per m-deg. Various researchers (Pegau,

Moore) have derived results ranging from 0.0024 to 0.0035. The corrected 715 nm

absorption is then determined using

a

715T

= a

- [aT* * (Tm - T

715m

)] (8)

cal

where a

is the water temperature corrected absorption at 715 nm, a

715T

715m

is the

measured absorption at 715 nm, Tm is the water temperature at the time of measurement

and T

is the water temperature at time of calibration. T

cal

is recorded at the time of

cal

calibration and is provided with the instrument calibration sheet.

Work is being done to determine the corrections for other wavelengths above 700 nm.

Note

WETView does not perform this water-based absorption temperature correction.

14 ac-s User’s Guide (ac-s) Revision H 21 May 2008

Page 23

3.7 Scattering Correction

The absorption meter uses a reflective tube to collect scattered light. Because of the

reflective tube and detector design, some of the light scattered at angles wider than 41.7

degrees (with respect to the optical axis) is lost. This results in a scattering error for the

absorption meter. This error was empirically determined by measuring apparent a and c

values in the presence of increasing concentrations of a scattering agent (Maalox). The

error in all channels was between 18 and 19 percent throughout most of the a-meter’s

dynamic range. The relationship between a and c remains linear throughout most of a

given wavelength channel’s dynamic range. (>.998) For very high c values (> 12 m-1) we

noticed a slight roll-off in a.

The imperfect reflectivity of the reflecting tube and other imperfections cause scattered

light errors in the absorption meter. The magnitude of these errors must be corrected to

obtain accurate absorption values. There are several alternatives in performing the

scattered light correction. The simplest involves subtracting the temperature-corrected

a

measurment. Assuming that water is the only species present that absorbs light at 715

715

nm, and assuming that the scattering error is spectrally independent, we can use this

wavelength to provide a base for the scattering error correction. This technique is

commonly used in bench-top spectrophotometric measurements. We present one

recommended method developed by Dr. Ron Zaneveld at Oregon State University (SPIE

1992) that has thus far proven to be a robust correction mechanism.

For what follows we assume that pure water absorption and attenuation have been

subtracted.

For a given wavelength (λ) the absorption tube overestimates the absorption coefficient

as it does not measure all of the scattered light. In what follows we will designate the

proportion of the total scattering coefficient that the device does not receive by ka (λ).

If the shape of the scattering function does not change much as a function of wavelength,

we may assume that ka (λ) is not a function of λ.

ac-s User’s Guide (ac-s) Revision H 21 May 2008 15

Page 24

4. Calibration and Characterization

The ac-s is a dual path absorption and attenuation meter whose output values are related to a

specific reference medium that is clean water. The instrument is calibrated to provide a

reading of 0.0 for all channels in clean fresh water. The offset value, determined during our

calibration process, is the number which, when added to the raw instrument output in clean

water, provides zeroes for all wavelengths with the meter at a specific temperature. This

offset value is referred to as N in the preceding sections. This is an important consideration

for users who want to compare data from other transmissometers that do not read 0.0 in clean

water. Therefore, the final output of the WETView software is the absorption and attenuation

with clean water attenuation subtracted.

4.1 Temperature Correction

Beyond confirming basic instrument operation and alignment, temperature corrections

are the first tests performed on the meter. Temperature corrections are requisite to all

other tests. Corrections are performed using WETView. WETView employs a correction

algorithm that uses multiple offset values,

differences over small temperature increments. Instrument values are collected and

averaged every one half to one degree Celsius through the operational temperature range

of the instrument. From these values we generate a table of temperature compensation

offsets [

∆

]. This table is contained in each instrument’s device file. Using the table,

Tn

WETView then applies the algorithm [a’ = a

table. For temperatures that fall between table values, the program applies a linear

interpolation upon the data for further correction. By using this scheme, we can thus

effectively compensate for non-linear changes due to temperature in the instruments’

output. For a description of this algorithm please refer to section 3.5, Post Processing.

∆

values obtained by measuring output

Tn

–

∆

raw

] for given temperatures in the

Tn

4.2 Precision

Precision is determined by running the meter for an interval of time (approximately 20

minutes) and determining the standard deviation of the signal at each wavelength for at

least 100 samples. We perform this measurement in air. With one-second binning of the

signals, nominal performance is approximately 0.010 m-1 for wavelengths below 450 nm,

and approximately 0.002 m-1 for wavelengths 450 and above.

It should be noted that both air value and water value measurements can be difficult to

perform. If running the tests in air, you must insure that the flow tubes, windows and orings are completely clean and dry. Do not allow any ambient light penetration into the

cells. Use a cap or black tape to seal the flow tube nozzle openings.

When operating the instrument in water, use clean water, free of bubbles, and do not

exceed flow rates of 1–2 liters per minute.

16 ac-s User’s Guide (ac-s) Revision H 21 May 2008

Page 25

4.3 Absolute Calibration

Absolute calibration of any underwater optical absorption or attenuation sensor is

difficult as there are no absolute standards that can readily be used. The most obvious

choice for a calibration medium, pure water, is difficult to obtain, is unstable once it is

made, and its absolute optical properties are not well known. Nevertheless, pure water is

the baseline for all oceanic property measurements. At WET Labs, we produce our

calibration water with a custom de-ionization and filtration system. After de-ionization,

the water is processed by a series of filters and held in a 60-liter reservoir that recirculates through an ultraviolet chamber and additional filters. Water for calibration is

drawn through a final 0.01-micron ultrafilter before being used. This system allows the

highly reactive de-ionized water to equilibrate, and the ultra-violet chamber prevents any

biological contamination from entering the reservoir.

A qualitative but surprisingly accurate test of water purity can readily be obtained using a

beaker and a small laser in a darkened room. By shining the laser through the water and

viewing slightly off axis to the impinging beam, one can readily detect scatterers in the

water. Try this first with some tap water. It will show you what to look for. Be very

careful to not look directly into the beam, and do not try this test with a high power laser.

The pointing lasers used in lectures work very well for this task. If you see more than one

or two large scatterers in the beam path, your water is unsuitable for a clean water

calibration. WET Labs and researchers from several institutions are presently developing

methods for effective field calibration and in-situ calibration techniques. We provide tech

notes on these methods as they are developed and validated.

4.4 Linearity and Dynamic Range

To determine linearity of the absorption and attenuation detection systems we first vary

scattering agent concentrations and plotted apparent “a” and “c.” Typically linearity in

“c” throughout the dynamic range is extremely high with a regression coefficient of

0.9999. Linearity in “a” exceeds 0.998. Although this test doesn’t truly measure “a,” it

does give a good indication of response.

4.5 Air Calibration and Tracking

During the factory calibration, clean water values are obtained and used to correct the

meter’s output. We then thoroughly dry the meter and record air values. We supply these

values with the calibration page shipped with each meter. These air values represent the

effective measurement of air for a calibrated instrument. This means that if the instrument

user cleans the windows and flow tubes and makes an air measurement and that if the air

measurement matches the factory supplied air values, then resulting clean water

measurements should provide zero values. Equally important—if the air values taken in

the field differ from factory air values, then that difference may be applied as a correction

factor to the original water calibration values contained in the DEV file:

a’

clean

= a

clean

+ (a’

air

– a

) (1)

air

where:

ac-s User’s Guide (ac-s) Revision H 21 May 2008 17

Page 26

a

a’

a

a’

is the clean water offset value supplied with the ac meter

clean

is the corrected clean water offset

clean

is the factory supplied air value

air

is the field obtained air values

air

Alternatively, the offset air value difference can be applied directly to the data as a postprocessing step. Obtaining air values in the field is a much more straightforward process

than obtaining clean water values. This is a powerful technique that can track and

compensate for instrument drift and filter aging. Care must be taken when implementing

this technique since a drop of water or smudge on the windows will result in a reading

quite different from the factory air values. This difference might be interpreted as

instrument drift. By iterating this process several times (re-cleaning the instrument and

obtaining a new set of air values), you will gain experience in differentiating true

instrument drift from smudged optics.

Caution

Back up the factory DEV file before making any modifications to it.

Effective air calibration requires:

1. The instrument’s optical path is clean and dry.

2. The instrument’s optical path is completely shielded from ambient light.

To perform air tracking we recommend the following basic procedures.

1. Remove flow tubes and clean and dry completely. Remove the sleeves from the flow

tubes to assure there is no trapped moisture. Allow the flow tubes to sit in a dry

environment with good air flow.

2. Clean and completely dry the optical windows of the instrument. If the optics have

not been cleaned for some time, clean with a mild solution of detergent and distilled

water, rinse, and wipe dry. Follow with a single wipe across each window with an

ethanol-soaked lens tissue (or other low water content alcohol-type solvent) and then

a single wipe with a dry tissue. If the windows are already fairly clean, simply use the

ethanol wipe procedure. You may wish to apply a stream of pressurized air or

nitrogen around the windows to force moisture from the window mount.

WARNING

Beware of using standard air compressor air. It can blow oil all over the optics.

3. Allow the unit to sit open for an hour or two to assure that it dries.

4. Reassemble and insert flow tubes.

5. Turn on meter and allow it to warm up about 5 minutes.

18 ac-s User’s Guide (ac-s) Revision H 21 May 2008

Page 27

6. Block ambient light from the flow tube entrances and obtain values using WET View

or your own custom program. Record and save about 5 minutes worth of data.

Examine your data in a spreadsheet. At one second binning (2 samples) the data

should maintain a standard deviation of 0.002 m-1 or less above 450 nm. If you have a

substantial slope to the data over the acquisition period your meter may have some

residual moisture in the flow tubes or on the windows. If the optical path isn’t getting

dry, use a small flow of dry nitrogen through the tubes while sampling.

7. Remove flow tube and re-clean the windows. The single wipe technique with ethanol

will work fine at this point.

8. Repeat steps 4–6 until mean values stabilize over three cycles. Use these values as air

calibration values.

ac-s User’s Guide (ac-s) Revision H 21 May 2008 19

Page 28

Mechanical Parameters

Electrical Parameters

Environmental Parameters

Optical Parameters

≥

-

1

-

1

-

1

-

1

-

1

-

1

5.

Specifications

Size 31 x 4.1 in diameter (79 x 10.4 cm diameter)

Weight (in air) 13 lbs (5.9 kg)

(in water) 2.5 lbs (1.1 kg)

Input 10–35 VDC

Current draw 0.83 Amps @ 12 V nominal

Serial output RS-232, -422, or -485

Connector MCBH6M

Sample rate 4 scans/sec., nominal

Temperature range 0–30 deg C

Rated depth 500 m

Pressure sensor optional

Spectral range 400–730 nm

Band pass 15 nm/channel

Pathlength 25 cm (10 cm available)

Beam cross-section 8 mm dia. (nominal)

Linearity

99% R2

Output wavelengths 80–90

Resolution 4 nm

Precision (450–750nm)

Precision (400–449 nm)

Accuracy

+/-0.001 m

+/-0.0005 m

+/-0.005 m

+/-0.003 m

+/- 0.01 m

Dynamic range 0.001–10 m

typ., 0.003 max @ 4 Hz

typ., 0.0015 max @ 1 Hz

typ., 0.0012 max @ 4 Hz

typ., 0.006 max @ 1 Hz

5.1 Connectors

The ac-s has two bulkhead connectors mounted on the top flange. The power and data

connector has six pins and connects to the sea or test cable. It provides input power to the

instrument and data output in RS-232 and RS-485 formats. A second connector with

three sockets provides power to the pump (Figure 3). Pin or socket numbers are molded

into the rubber bodies of the plugs (Figure 4 and Figure 5).

20 ac-s User’s Guide (ac-s) Revision H 21 May 2008

Page 29

Sea/Test Cable Connector Pin or Socket Function

Figure 3. Top Flange Connectors

Figure 4. Sea/Test Cable Connector Pin and Socket Arrangements

1 Common

2 RS-232 Receive

3 RS-485 +

4 Voltage in +10 to +35 VDC

5 RS-232 Send to Host

6 RS 485 -

Voltage supplied to the instrument is internally jumpered to provide power output to the

pump port connector. Power is applied to the pump connector whenever the meter is

powered.

ac-s User’s Guide (ac-s) Revision H 21 May 2008 21

Page 30

Pump Power Cable Connector Pin or Socket Function

WARNING

If the meter is deployed without a plug in the pump connector socket, the

socket contacts will suffer rapid corrosion. Eventually, the corrosion could

travel through the connector, causing the meter to flood.

Always put a pump plug or dummy plug in this socket!

Pin and socket assignments for the pump power connector are shown below.

Figure 5. Pump Cable Connector Pin and Socket Assignments

1 Common

2 Power Output (10–35 VDC)

3 N/C

5.2 Power Requirements

Voltage input: 10–35 VDC

Power requirements: (may differ by +/- 10 percent)

Lamp 1 2.5 watts

Lamp 2 2.5 watts

CPU board 0.3 watts

A/D board 0.5 watts

Motor and controller 0.6 watts

Other electronics 0.5 watts

DC/DC converters 2.1 watts

TOTAL 9.0 Watts

22 ac-s User’s Guide (ac-s) Revision H 21 May 2008

Page 31

6. Technical Reference

Figure 10 shows a diagram of the ac-s. The unit consists of two pressure housings separated

by an aluminum “unistrut” frame. The “bottom” pressure cylinder houses the light sources,

filter wheel, motor controller and transmitter optics. The “top” can houses the receiver optics

and the control and acquisition electronics for the unit. The absorption and attenuation beam

paths and flow tube assemblies are between the receiver and transmitter housings. Power and

communications in and out of the unit are provided via the 6-pin bulkhead connector at the

end of the receiver housing.

6.1 Mechanical

The ac-s is housed in two robust pressure housings made from acetal copolymer,

separated by an anodized aluminum unistrut frame.

The flow tube assemblies are integral to the optical behavior of the ac-s. They are optical

components that help produce a very precise measurement, and thus they need to be dealt

with accordingly. Before using, inspect both tubes and make sure they are free of stains

and dust. The reflective flow tube for the absorption measurement operates using the

principle of internal reflection. To maintain its reflective properties, it requires a thin air

gap between the outer wall of the quartz tube and the inner wall of the surrounding

sleeve. The reflective tube should be periodically checked for leaks. To determine if the

tube is maintaining its reflective properties, immerse it in water and point towards a fairly

light background. The inside of the tube should appear uniformly bright. If the tube has

leaked, call the factory for repair instructions or tube replacement.

6.2 Optics

The ac-s performs concurrent measurements of the water’s attenuation and absorption

characteristics by incorporating a dual path optical configuration in a single instrument.

Each path contains its own source, optics, and detectors appropriate to the given

measurement. The two paths share a common filter wheel, control and acquisition

electronics. For purposes of description, we refer to the beam performing the attenuation

measurement as the c beam (Figure 7) and the beam used to make the absorption

measurement as the a beam (Figure 8).

ac-s User’s Guide (ac-s) Revision H 21 May 2008 23

Page 32

10

1

7

2

8

3

9

4

10

5

11

6

6.2.1 Filter Wheel

The filter wheel holds two sections of a Linear Variable Filter (LVF), centered 180

degrees from each other on the filter wheel (Figure 6). The two filter sections are cut

from a single LVF such that a portion of the spectrum around 550 nm is covered by both

filters. This overlap is to allow for merging of the data from both filter sections. Each

filter covers approximately a 72 degree section of the beam path across the filter wheel.

The filter wheel rotates at a tightly controlled 8.0 rps, such that the shorter wavelength of

each filter section is traversed before the longer wavelength.

Figure 6. ac-s filter wheel

6.2.2 c Beam Optics

6

1

3

4

2

2

5

7

8

9

8

11

10

2

Lamp

1 mm aperture

Lenses

IR Filter

Filter wheel

Beam splitter

Reference detector

6 mm quartz pressure window

Flow tube

Singlet lens

Signal detector

Figure 7. Schematic Representation of c beam optics

24 ac-s User’s Guide (ac-s) Revision H 21 May 2008

Page 33

1

6

2

7

3

8

4

9

5

10

Light from a DC incandescent source passes through a 1 mm aperture. The light is

then focused through a filter section, onto a 1 mm aperture, creating a narrow band

spectral output. The light then passes through a collimating lens and then through a

beam splitter, creating a primary beam and a reflected beam. The reflected beam

intensity is measured by a reference detector. Using a ratiometric scheme with the

reference and signal detectors, we compensate for long-term lamp drift. The primary

beam then passes through a pressure window into the sample water volume.

A black flow tube encloses the c beam water path. Scattered light that hits the

blackened surface of the flow tube is absorbed and therefore does not contribute to

the measurement of transmitted intensity. Light radiated through the flow path is

therefore subject to both scattering and absorptive losses by the water.

Once through the water path, the light passes through another pressure window and

then is re-focused through a lens upon a receiver detector. A 1 mm aperture is placed

directly in front of the detector, creating a 0.75-degree acceptance angle in water.

6.2.3 a Beam Optics

6

1

3

4

2

10

2

5

7

8

9

10

Lamp

1 mm aperture

6 mm aperture

38 mm singlet lens

Interference filter

Beam splitter

Reference detector

6 mm quartz pressure window

Reflective flow tube

Diffuser/Signal detector

Figure 8. Schematic Representation of a beam optics

The a-beam and c-beam optics are similar. The a-beam light is 45 degrees out of

phase from that of the c beam. Beam splitter optics and aperturing of the beam are

identical with the c beam source optics.

The a beam sample water volume is enclosed by a reflective flow tube. Light passing

through the tube is both absorbed by the water itself and by various pigments

contained in particulate matter within the sample volume. Forward scattered light is

reflected back into the water volume by the reflective tube. The light is then collected

by a diffused large area detector at the far end of the flow tube.

ac-s User’s Guide (ac-s) Revision H 21 May 2008 25

Page 34

The flow tube uses the internal reflection principle in reflecting light back into the

water volume. A clear quartz tube is employed. The outer perimeter of the tube is

enclosed by a thin annular volume of air. Using the Fresnel Equation, one can see that

with an index of refraction of 1.33 in water and index of refraction of 1 in air, the

total internal reflection is achieved to 41.7 degrees with respect to the optical axis.

6.3 Electronics

The main electronic components of the ac-s consist of a power and i/o (input/output)

board, a microprocessor board, an A/D board, an amplifier board, a motor controller

board, a dc motor with an integrated position encoder, two incandescent lamps and four

photodiode detectors.

6.4 Signal Processing

The purpose of the ac-s signal processing circuitry is to take a raw optical signal and

make it into a physically meaningful measurement ready for output. Signals from the

absorption path and attenuation path detectors go through several levels of analog and

digital processing before they are registered as output from the unit. To understand the

exact nature of the ac-s signal processing, it is first necessary to better understand the

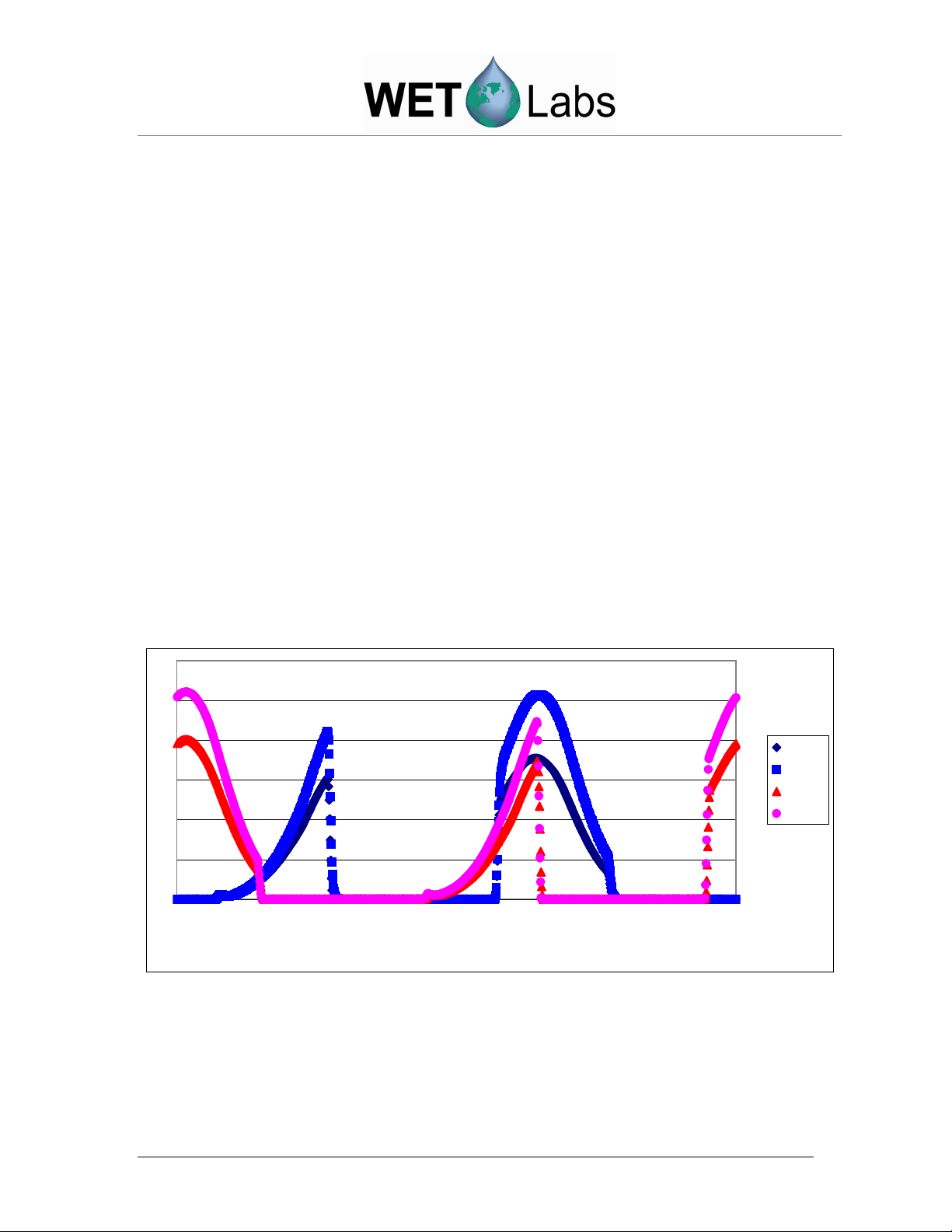

primary data sampling. Figure 9 is a timing representation of the ac-s detector signals

through a single filter wheel rotation. It shows how each of the two filter sections are

brought in line with the optical path once per revolution.

A Ref

A Sig

C Ref

C Sig

0 512 1024 1536 2048

Encoder Step

Figure 9. Signal timing for one filter wheel revolution

Each trace represents the optical signal from a detector as the filter wheel spins through

its cycle in relation to the motor encoder position (1 to 2048). During the filter wheel

rotation, the signals output from each detector are continuously monitored and amplified

through analog current-to-voltage amplifier circuitry. The current-to-voltage amplifier

serves as the primary gain stage for each signal. Typical gains for the channels are set at

26 ac-s User’s Guide (ac-s) Revision H 21 May 2008

Page 35

2M for the signal detectors and 10M for the reference detectors. After the primary gain

stage, the signal is passed through three more analog stages for level shifting, voltage

inversion (except the A signal), and buffering. At this point, the signal is ready for

digitization.

The CPU monitors the motor encoder output to determine when the start of the “blue”

filter section is about to pass through the attenuation beam path (encoder step 900 in

Figure 9). At that point, the CPU starts concurrent sampling of all four signal channels.

Throughout the first sample window (encoder steps 900-1640 in Figure 9), the CPU

collects 60 A/D samples at 140 ksamples/sec for each channel. The CPU then waits for

the next encoder edge before collecting the next burst of 60 samples. This resynchronization is necessary to reduce the effects of rotational jitter on the sampled data.

The sampling continues until slightly past the point where the absorption beam has

finished traversing the filter section (encoder step 1640, above). The CPU then waits for

the approach of the “red” filter section, and repeats the sampling process again. Due to

the positioning of the beams and the filters, timing-wise, the c-beam intersects one filter

section for about 1/8 revolution before the a-beam intersects the other filter. This

staggering of the filters relative to the beams is the reason for the phase differences

between the a and c signal traces seen in Figure 9.

Once the signals have been sampled through one full revolution of the filter wheel, the

CPU averages the bursts of 60 A/D samples to a single mean value for each burst. From

within the sample buffers, dark reference values are also obtained and averaged for each

signal. The dark values are then also time averaged with previous dark values to further

reduce noise in the dark measurement. Once averaged, the dark values are then subtracted

from the raw light values in order to create a given datum point:

Csig = Csig

Cref = Cref

Asig = Asig

Aref = Aref

light

light

light

light

– Csig

– Cref

– Asig

– Aref

dark

dark

dark

dark

The CPU collects and buffers one revolution of raw signal data and then outputs 86

signal and reference values for both the attenuation and absorption channels in

wavelength order starting at approx 400 nm, along with internal and external temperature,

and rotational and timing data. Please bear in mind that although the data is all output at

once, the sampling occurs sequentially, such that the first c-beam output wavelength is

sampled one half revolution (6.25 ms) before the 44th output wavelength. From one

output wavelength to the next, the time delay is approximately 488 us. Also keep in mind

that the a-beam data has the same time delay between output spectrum halves, with the

additional condition that the “red” filter is sampled prior to the “blue” filter. That means

that the 44th output point was actually sampled 6.25 ms before the first output point. Due

to the amount of time required to send the data, and requirements on the CPU during

sampling, the next data sample is not captured until a full even number of revolutions

have passed following completion of the data averaging and output. Currently this is

every 4 revolutions, or twice per second.

ac-s User’s Guide (ac-s) Revision H 21 May 2008 27

Page 36

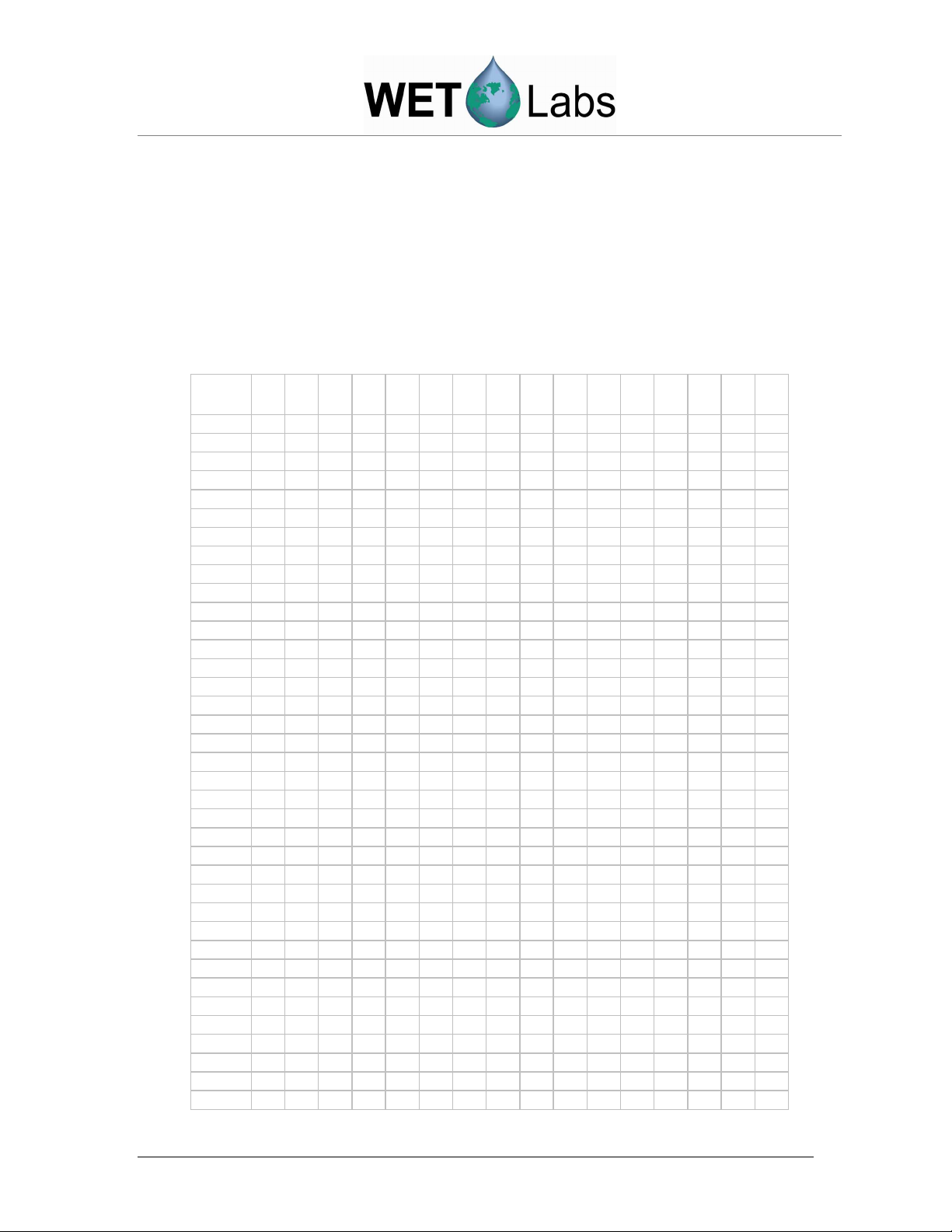

Appendix A: Data Record Format

The ac-s outputs its data as binary records. If you use a terminal emulator program to connect

to the ac-s, the incoming data will appear as seemingly random characters. Table 4 shows a

sample hexadecimal snapshot of binary data collected from an ac-s. The leftmost column and

header rows in are for reference only, and do not appear in the output data. Table 5 shows the

breakout of each field within the data record. Note: You should ensure that your data

collection program is capable of reading a binary bit stream.

Table 1. Sample ac-s Data Record

row

offset 0 1 2 3 4 5 6 7 8 9 a b c d e f

000: 53 d0 03 01 53 00 00 02 4e 1e 01 ba 21 29 35 ff

010: 00 ff 00 02 d0 05 01 53 00 00 02 4e 1a 01 ba 02

020: a1 7a e4 b9 d7 01 d5 02 b0 00 07 1b 02 01 56 04

030: 05 03 63 04 f4 03 10 04 98 03 da 05 ab 03 ac 05

040: 3b 04 69 06 7c 04 77 05 f5 04 fe 07 67 05 52 06

050: c6 05 ae 08 69 06 4a 07 9f 06 66 09 88 07 3a 08

060: 96 07 33 0a c9 08 47 09 ab 08 1b 0c 32 09 6a 0a

070: dc 09 0e 0d c7 0a a8 0c 2f 0a 2f 0f 84 0c 0f 0d

080: 9a 0b 5c 11 63 0d 9a 0f 23 0c 9d 13 69 0f 3a 10

090: c5 0d f8 15 8d 11 01 12 70 0f 5b 17 c9 12 d8 14

0a0: 32 10 ce 1a 25 14 d2 16 17 12 61 1c b5 16 e8 18

0b0: 20 14 08 1f 85 19 2b 1a 5b 15 e7 22 8e 1b ad 1c

0c0: be 17 d8 25 c7 1e 5d 1f 3d 19 ef 29 33 21 3b 21

0d0: e4 1c 17 2c d5 24 48 24 b4 1e 6f 30 ad 27 7f 27

0e0: 9f 20 de 34 b9 2a f7 2a b6 23 65 38 f3 2e 8e 2d

0f0: e7 26 0b 3d 4e 32 5d 31 29 28 c6 41 d1 36 49 34

100: 84 2b 82 46 63 3a 4f 37 d9 2e 49 4a f4 3e 6a 3b

110: 3b 31 17 4f b2 42 96 3e bc 34 09 54 a0 46 f8 42

120: 6a 37 22 59 d2 4b 90 46 4e 3a 6c 5f 5a 50 7d 4a

130: 75 3d ea 65 44 55 ba 4e f0 41 b3 6b 9a 5b 67 53

140: a2 45 b5 72 35 61 6f 58 73 49 be 78 df 67 9b 5d

150: 41 4d cb 7f 79 6d d1 61 e2 51 ab 85 d7 73 ed 66

160: 64 55 77 8c 10 79 f4 6a be 59 19 92 12 7f cd 6e

170: ef 5c a0 97 d4 85 7d 72 eb 60 01 9d 63 8b 00 76

180: c2 63 41 a2 bd 90 5e 7a 22 67 e0 a7 92 98 2f 7d

190: b7 6a c6 ac 8c 9d 1a 81 13 6d 75 b1 37 a1 cc 84

1a0: 35 70 05 b5 aa a6 4f 87 25 72 54 b9 bf aa 85 89

1b0: cd 74 63 bd 75 ae 5d 8c 20 76 2b c0 b9 b1 d0 8e

1c0: 1e 77 95 c3 6e b4 ce 8f aa 78 9c c5 93 b7 3c 90

1d0: c0 79 3e c7 05 b9 11 91 5e 79 8e c7 e6 ba 63 91

1e0: 9c 79 82 c8 2d bb 23 91 5d 79 13 c7 d9 bb 56 90

1f0: b5 78 5b c7 00 bb 07 8f ac 77 2f c5 83 ba 1e 8e

200: 28 75 c6 c3 76 b8 ab 8c 52 74 0d c0 f8 b6 c8 8a

210: 1e 72 00 bd e6 b4 5c 87 8e 6f ad ba 60 b1 6e 84

220: a9 6d 0a b6 5c ad f9 81 58 6a 07 b1 b7 a9 ee 7d

230: 9c 66 a8 ac 6e a5 37 79 72 62 eb a6 8b 9f e9 74

240: e3 5e ec a0 25 9a 16 70 00 5a c2 99 56 93 db 6a

28 ac-s User’s Guide (ac-s) Revision H 21 May 2008

Page 37

Byte

Num

row

offset 0 1 2 3 4 5 6 7 8 9 a b c d e f

250: ef 56 69 92 46 8d 4f 65 ba 52 0f 8b 15 86 9e 60

260: 82 4d b2 83 db 7f d9 5b 53 49 5e 7c b2 79 16 56

270: 25 45 14 75 86 72 54 51 06 40 e1 6e 75 6b b1 4c

280: 13 3c d0 67 9d 65 3a 47 3a 38 d5 60 f1 5e de 42

290: 89 35 02 5a 82 58 b8 3e 05 31 52 54 47 52 bf 39

2a0: 9c 2d be 4e 3c 4c fc 35 79 2a 70 48 9a 47 85 31

2b0: 8c 27 36 43 35 42 52 2d c8 24 33 3e 15 3d 5c 2a

2c0: 3b 21 5a 39 39 38 a5 26 da 1e 9d 34 98 34 30 23

2d0: b3 1c 1c 30 50 30 03 20 bb 19 bf 2c 49 2c 1c 22

2e0: 44 00 ff 00 ff 00 02 d0 03 01 53 00 00 02 4e 1e

Table 2. Breakout of Data Record Fields for Table 1

Offset

Bytes

Data

00f 4 ff00ff00

013 2 02D0

015 1 05

016 1 01

017 1 53

018 3 000002

01b 2 4e1a

01d 2 01ba

01f 2 02a1

021 2 7ae4

023 2 b9d7

025 2 01d5

027 2 02b0

029 4 00071b02

02d 1 01

02e 1 56

02f 2 0405

031 2 0363

033 2 04f4

035 2 0310

037 2 0498

…

Description

Packet registration

Record length of full packet (not including chksum) = 720

Packet Type 03 and above designates an ac-s meter

reserved

meter type—53 indicates an ac-s

serial number

A reference dark counts

pressure counts

A signal dark counts

raw external temp counts = 22.14° C

raw internal temp counts = 17.91° C

C reference dark counts

C signal dark counts

time in milliseconds since power up (465666 = 7.761 mins)

reserved

Number of output wavelengths = 86 decimal

raw cref1 counts

raw aref1 counts

raw csig1 counts

raw asig1 counts

raw cref2 counts

2d7 2 20bb

2d9 2 19bf

2db 2 2c49

2dd 2 2c1c

2df 2 2244

2e1 1 00

2e2 4 ff00ff00

raw cref86 counts

raw aref86 counts

raw csig86 counts

raw asig86 counts

checksum

pad byte

start of next packet

Primary Processing

ac-s User’s Guide (ac-s) Revision H 21 May 2008 29

Page 38

When receiving binary packets from an ac-s, the first thing to look for is the packet

registration, which is four characters. The characters, in hexidecimal notation, are FF 00

FF 00. After successfully receiving these characters, the 2 byte packet length is the next

item to be received. The packet length indicates the number of bytes sent in the packet,

including the 4 byte packet registration. The packet length excludes the two byte

checksum and the pad byte. The packet length varies from meter to meter depending on

the number of output wavelengths.

The next byte is a packet type identifier used by WETView to distinguish between ac-s

and Histar data packets. It should be 3 or higher for the ac-s.

The next byte is reserved for future use.

The serial number is a standard four-byte long integer. The first byte of the serial number

denotes the instrument type. The remaining three bytes are the binary serial number.

The two bytes following the serial number are the A reference channel dark counts. It is

present mainly for diagnostic purposes.

The next two bytes are the A/D counts from the pressure sensor circuitry. If no pressure

sensor is installed, these two bytes may be ignored. When a pressure sensor is installed,

the depth in meters can be calculated from this number by multiplying the counts by a

meter specific scale factor and then adding a meter specific offset. The depth offset and

scale factor can be found in row 5 of the factory device file provided with the meter. The

offset is the first number in row 5, and the scale factor is the second number in row 5.

The following 2 bytes are the A signal dark counts for diagnostic purposes.

The next two bytes represent the raw external temperature voltage counts from across a

thermistor. The external temp is calculated by a polynomial that converts counts to

degrees C. Calculate the temp using the polynomial:

23

×+××

d + counts c counts b + countsa =y

where a = -7.1023317 E-13, b = 7.09341920 E-8, c = -3.87065673 E-3, and d =

95.8241397

The internal temperature is given as a reading from a thermistor. The manufacturer of the

thermistor provides a function to convert resistance to temperature. The two byte value in

the data packet represents the voltage drop across the resistor. To determine the resistance

of the thermistor, first convert the counts (16 bit unsigned integer) to volts using the

equation:

volts = (5 × counts / 65535)

then convert volts to resistance:

30 ac-s User’s Guide (ac-s) Revision H 21 May 2008

Page 39

resistance = 10,000×volts/(4.516 – volts)

then finally convert resistance (res) to degrees C:

=

temp

1

3

×+×+

))(ln()ln(

rescresba

15.273

−

where a = 0.00093135, b = 0.000221631, and c = 0.000000125741

The following 4 bytes are the C reference and signal dark counts respectively for

diagnostic purposes.

Next is a four byte unsigned integer value representing the time in milliseconds since the

instrument was started up.

Following that is a one byte value that is reserved for future use.

Next is a one byte unsigned integer representing the number of output wavelengths.

Next is the data for the scan. The values are the averaged signal counts (dark count

subtracted) for each detector at each output bin. The counts are 16 bit unsigned values,

transmitted in the order c

ref1

, a

ref1

, c

sig1

, a

sig1, cref2

, …, c

refn

, a

refn

, c

sign

, a

., where n is the

sign

number of output wavelengths. The output wavelengths are in increasing wavelength

order, running from approximately 400 nm to 715 nm or higher.

Following the data, at the end of the packet, a two byte checksum is sent. This checksum

is the unsigned 16 bit sum of all characters sent in the packet, including the identifier (FF

00 FF 00) and up to the last data byte preceding the checksum field.