Page 1

ac Meter

Protocol Document

WET Labs, Inc.

P.O. Box 518

Philomath, OR 97370

541 929-5650

fax: 541 929-5277

www.wetlabs.com

Page 2

Page 3

Table of Contents

Acknowledgements ............................................................................ 1

1.

Introduction ............................................................................... 1

2.

Background and Evolution ........................................................ 3

2.1 ac-9 ................................................................................................................. 3

2.1.1 Interference Filters ...........................................................................................3

2.1.2 Absorption Detector .........................................................................................3

2.1.3 Internal Optics ..................................................................................................3

2.1.4 Windows ..........................................................................................................3

2.1.5 Flow Tubes.......................................................................................................3

2.1.6 Improved Referencing .....................................................................................3

2.1.7 Electronics........................................................................................................3

2.1.8 Mechanical .......................................................................................................3

2.2 ac-s .................................................................................................................... 4

3.

Operation .................................................................................. 5

3.1 Orientation ...................................................................................................... 5

3.2 Testing ............................................................................................................ 6

3.3 Mounting ......................................................................................................... 8

3.4 Plumbing and Tubing ...................................................................................... 9

3.5 Attaching Prefilter to Remove the Particulate Fraction .................................. 10

3.6 Deployment .................................................................................................. 10

3.6.1 Moorings ........................................................................................................10

3.6.2 Towed Bodies ................................................................................................12

Ship Underway and General Benchtop Operation ......................................................13

3.6.4 Profiling .........................................................................................................13

4.

Calibration ............................................................................. 15

4.1 WET Labs Calibration Procedures ................................................................ 15

4.1.1 Factory Pre-calibration Procedures ................................................................15

4.1.2 Factory Temperature Calibration ...................................................................15

4.1.3 Factory Water Calibration..............................................................................16

4.1.4 Factory Air Calibration ..................................................................................17

4.2 Air Tracking Procedures ............................................................................... 18

4.2.1 When to Use Air Tracking ............................................................................18

4.2.2 Air Tracking Protocol ...................................................................................19

4.3 Field Water Calibration Procedures .............................................................. 20

4.3.1 When to use Field Water Calibrations ...........................................................20

ac meter Protocol (acprot) Revision N 21 May 2008 i

Page 4

4.3.2 Field Clean Water Production System ...........................................................20

4.3.3 Field Water Calibration Protocol ...................................................................22

5.

Data Processing ..................................................................... 26

5.1 Basic WETVIEW Calculations ...................................................................... 26

5.2 Merging ........................................................................................................ 27

5.3 Time Lag Correction ..................................................................................... 27

5.4 Water Temperature and Salinity Corrections ................................................ 28

5.6 Reflective Tube Scattering Correction .......................................................... 30

5.7 Attenuation Acceptance Angle Correction ..................................................... 31

5.8 Other Processing Notes ................................................................................. 32

5.8.1 Considering Spatial Variability......................................................................32

5.8.2 ac-s Mid-spectrum Discontinuities ................................................................32

5.8.3 Outliers ...........................................................................................................32

5.9 Directly Derived Products ............................................................................. 32

5.9.1 Computing Total Absorption and Attenuation from Measurements .............32

5.10 Reality Checks ............................................................................................... 39

6.

References ............................................................................. 41

Appendix 1. Device Files ................................................................. 42

Appendix 2. Sample Matlab Routines: ............................................. 46

ii ac meter Protocol (acprot) Revision N 21 May 2008

Page 5

ac meter Protocol (acprot) Revision N 21 May 2008 iii

Page 6

Page 7

Acknowledgements

While virtually everyone who has sought meaningful and consistent results has contributed to

this evolution of the ac-9 protocol, several scientists provided pioneering efforts, and direct input

on this document. They include Scott Pegau, Percy Donaghay, Mike Twardowski, Scott

Freeman, and Alan Weidemann.

1. Introduction

The ac-9 was originally developed under Naval Research Laboratory sponsorship. Primary

development occurred over a 6-month time span culminating in delivery in September 1993.

Since initial delivery, approximately 180 more units have been used in applications ranging from

tow-yos to long-term moorings. In 2004 a follow-on hyperspectral absorption and attenuation

device, the ac-s, was also introduced. While the manuals for these devices cover basic operation

and processing of the raw signals into engineering units, certain protocols for usage and data

processing have been developed over the years, largely by the scientific community, to provide

the highest possible accuracy in absorption and attenuation data and directly derived products.

As a supplement to the ac-9 and ac-s user manuals, this document details these protocols.

Protocols for ac-9 and ac-s use are broken down into three primary sections. We first discuss

basic operation and deployment issues. Second, we discuss the ac-9 laboratory and field

calibration. Third, we delineate the steps for processing and correction of the data obtained by

the instrument. These three sections are prefaced by an overview of the various engineering

improvements that have occurred over the past few years. A final section provides a concise

summary of the data processing steps as well as a reality check table for determination of data

quality.

This protocol is intended as a hands-on guide for data collection and processing of data from the

ac-9 and/or ac-s. For more general discussions of meter applications or measurement theory you

may wish to consult the references contained in the back of the document.

One should remember that ac-9 and ac-s usage and data processing techniques are subject to

continual evolution. This document attempts to summarize the state of the art in commonly

applied techniques as they stand today. Even as the document is being written, researchers

continue to explore and refine new possibilities in applications, calibration, and processing.

Similarly, engineers at WET Labs continue to strive to improve instrument capabilities,

reliability and ease of use. We urge researchers to stay in touch through our web site

(http://www.wetlabs.com) or by calling us. Likewise, if you have any suggestions or additions to

this protocol document please let us know.

ac meter Protocol (acprot) Revision N 21 May 2008 1

2 ac meter Protocol (acprot) Revision N 21 May 2008

Page 8

Page 9

2. Background and Evolution

2.1 ac-9

The ac-9 has gone through several major design modifications in the last several years to

improve the overall stability and reliability of the instrument. Described below are some of the

more significant changes that have been successfully implemented.

2.1.1 Interference Filters

The ac-9 uses nine band-pass filters to spectrally discriminate the light from a tungsten lamp.

These nine filters are mounted on a filter wheel located in the transmitter pressure housing.

2.1.2 Absorption Detector

The absorption detectors have gone through numerous modifications in effort to improve

long-term reliability, stability, and ease of manufacture.

2.1.3 Internal Optics

Optical mounts for all the lenses and filters were improved to provide better stability and

easier meter assembly.

2.1.4 Windows

Pressure window apertures were increased to eliminate possible partial beam occlusions.

2.1.5 Flow Tubes

The flow tubes and sleeves went through several stages of modifications. Most recently inlet

and outlet nozzle diameters have been increased to provide improved flushing.

2.1.6 Improved Referencing

The ac-9 employs a reference detector within the transmitter optics. This detector measures

the output energy from the source that in turn provides a normalized output from the meter.

With the original filters and optics, throughput in the blue region of the spectrum was not

sufficient to allow one-to-one referencing. We thus integrated values of all three blue

wavelengths and used the single value as a reference for the blue wavelengths. With the

increased throughput provided by the new filters, we have returned to a one-to-one

referencing scheme throughout the spectrum.

2.1.7 Electronics

In 1995 new electronics were developed for the meter. The new board set allowed more

efficient manufacturing and characterization, more flexibility in interfacing, and improved

resistance to shock and vibration.

2.1.8 Mechanical

ac-9 design employs a one-piece yoke, or “unistrut” manufactured from one solid piece of

metal that effectively ties the ac meter into virtually one rigid optical assembly. This

improves long-term stability as well as short-term variability due to mounting stresses. Older

ac-9’s that use three independent stainless steel rods can be upgraded to the unistrut design.

Please contact the factory for information.

ac meter Protocol (acprot) Revision N 21 May 2008 3

Page 10

2.2 ac-s

Based on the 9-wavelength absorption and attenuation meter ac-9 (Moore et al, 1992), the

ac-s offers almost an order of magnitude increase in spectral resolution of in-situ absorption

and beam attenuation coefficients. The ac-s features the same flow-through system as the ac9, same size, and excellent stability. The ac-s employs a 25-cm pathlength for effective

measurement in the cleanest natural waters. The light source employs a linear variable filter

imaged with a collimated beam from a tungsten lamp. The absorption side has a reflecting

tube and a large area detector, whereas the attenuation side has a non-reflective tube and a

collimated detector. The instrument provides an 80+ wavelength output from approximately

400–730 nm with approximately 4 nm steps. Individual filter steps have a FWHM that range

between about 10 to 18 nm. Because of the inherent similarities between the ac-s and the ac9, all procedures described in this document regarding the ac-9 generally pertain to the ac-s

as well, except where noted.

4 ac meter Protocol (acprot) Revision N 21 May 2008

Page 11

ac

-9

3. Operation

3.1 Orientation

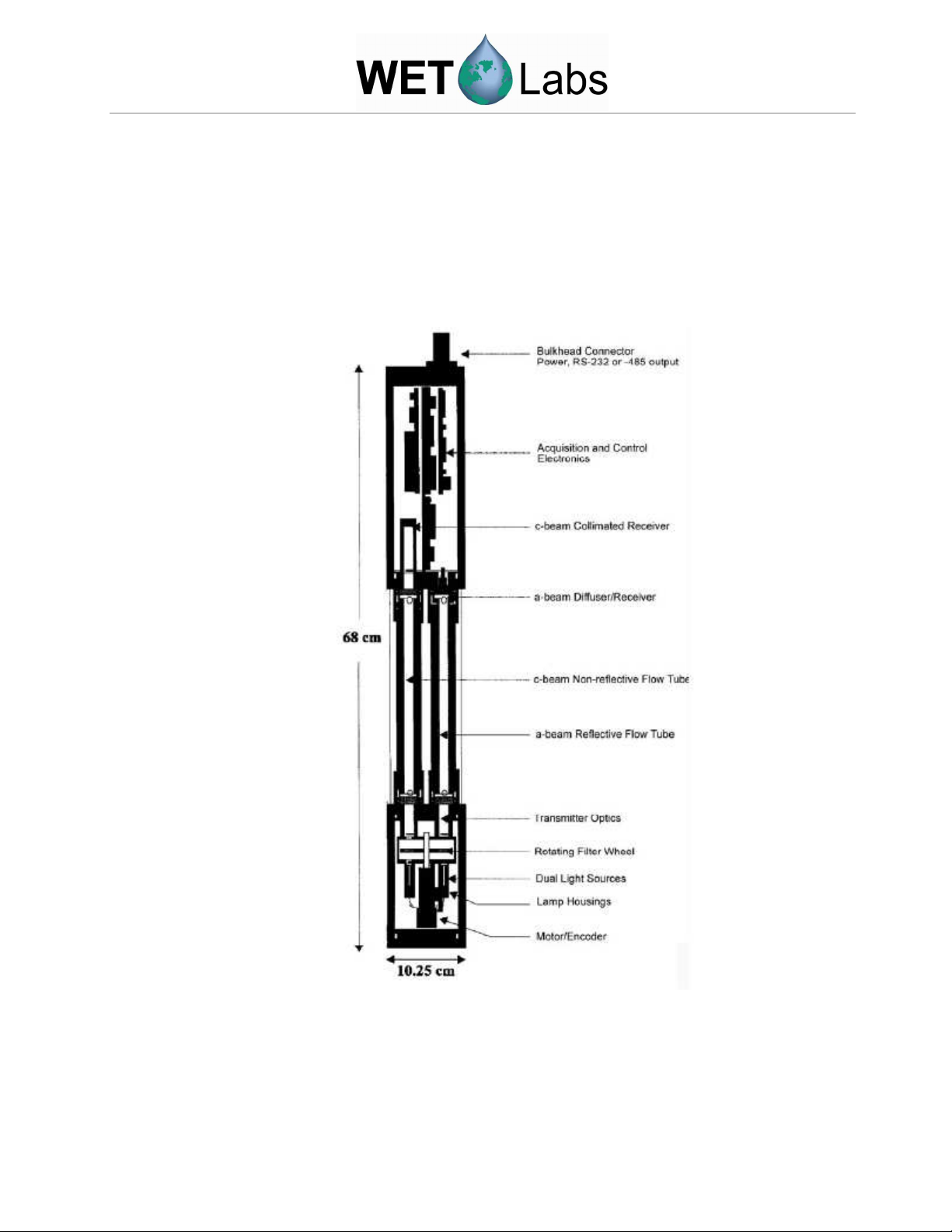

Before testing your instrument, familiarize yourself with the ac-9 and the ac-s (Figure 1).

Figure 1. Description of ac-9 components, many of which are shared with the ac-s.

ac meter Protocol (acprot) Revision N 21 May 2008 5

Page 12

Both instruments consist of two pressure cans separated by a unistrut. The bottom pressure can

houses the transmitter optics and filter wheel. The top can contains the receiver optics and the

control electronics. Two removable plastic flow assemblies reside within the area separating the

two cans. These two assemblies define the flow volumes for the absorbance and transmittance

measurements.

Remove the black plastic flow tubes by sliding the flow tube sleeves towards the middle of the

flow tube. The flow tube will lift out, exposing the transmitter and detector windows on the

lower and upper flanges respectively. Be careful not to scratch the windows. The attenuation

tube is different than the absorption tube. Its flow chamber is black plastic and the two sleeves

on the tube are identical. This tube installs on the “c” side of the instrument (the side with the

identical looking windows). The “c” tube has no “up or down” orientation. The absorption flow

assembly is lined with a reflective quartz tube and one of the two sleeves is flat on top (the lip

present on all the other sleeves is missing). This tube installs on the “a” side of the instrument

that can be identified by the “a” detector that is on the upper flange and is the only window that

is clearly different from the other three (has a white diffuser where the other windows are

clear). The flow tube sleeve without the lip fits over the absorption window with diffuser, so

there IS an “up and down” orientation to the “a” tube.

You may want to mark the flow assemblies and their orientation with tape or marking pen

before using the instrument at sea so that there is no confusion when reinstalling the tubes after

cleaning your optics. Incorrect installation of the flow tubes will result in incorrect optical

measurements and water leaking around the sleeves because of improper o-ring seals (the

absorption window with detector has a different o-ring than the rest of the windows).

When re-installing the sleeves of the flow tubes, line up the white nylon set screws with the

grooves in the flow tubes. This will ensure that the water flow will not be blocked by the “tabs”

on the ends of the flow tubes.

The flow tube for the “c” channel may be considered optional as long as the detector is not

exposed to very intense ambient light (e.g., direct sunlight). This allows for the possibility of a

free path attenuation measurement when the flow tube is absent. Stray light is normally not a

concern with the “c” channel because of the collimating optics in the detector assembly. The

flow tube for the “a” channel is always required.

3.2 Testing

Before deploying the ac-9 or ac-s in the field you will want to test the unit to familiarize

yourself with the hardware and software, and to verify basic operation. Assuming that you are

using the factory-supplied software (WETView) to perform these tests, you will require the

following:

1. A clean, solid lab table or workbench;

2. The ac-9 or ac-s with test cable (or sea cable);

3. A power supply (the ac-9 and ac-s require 10–18 VDC);

4. A computer with WETView software installed for data acquisition.

6 ac meter Protocol (acprot) Revision N 21 May 2008

Page 13

•

•

•

•

•

•

Installing WETView is very simple. You will need a 400 MHz or better PC running the

Windows 2000 or higher operating system with at least 10 Mb free hard disk space.

Create a directory or folder to copy the necessary files needed to install WETView onto your

machine. Copy the entire contents of the two disks you received with your ac-9 into this

directory on your computer. You should have the following files in your directory:

WETVIEW.001

WETVIEW.002

SETUP.EXE

WETPROCE.EXE

AC9XXXX.DEV

AIRXXXXX.CAL

One of the files copied is SETUP.EXE; run this program and follow the online instructions to

complete WETView installation.

Connect the factory supplied test cable to COMM port in your computer (or USB port via a serial to

USB converter). Connect the power leads to the power supply. The black lead is typically the V+

lead. Before connecting the cable to the instrument, use a multi-meter to check the input power.

Connect the ground probe to pin 1 on the pigtail connector (the centrally located pin). Connect the

hot probe to pin 4 (the pin directly opposite from pin 1). You should measure somewhere between

10–18 volts across these two pins. No other pins should have any voltage on them. Turn the power

supply off. Connect the pigtail to the instrument. Push the connector straight on to avoid damaging

the pins. Apply power to the instrument and allow it to warming up for about 30 s.

Run the WETView software by clicking on the icon in WINDOWS. When the interface is

displayed, you will need to provide a device file name (DEV file). Click on the <O> button in

the center top of the screen or choose “Open Device File” from the File Menu at the top left of

the screen. Browse to the folder containing the DEV file. The program will ask you to choose

the proper COMM port. Select COMM1 through COMM8 as appropriate. At this point, the

software will do some handshaking with the instrument and the “Start Logging” Button (or the

F1 key) can be used to start data collection. After 5–10 seconds, tabular data should be

displayed on the right side of the screen. A real time graph will begin to develop, using the

graph parameters set at the time. Please refer to the manual for the full details of running the

WETView software. After a short time, click on the F2 button. Data collection will stop and

you will be prompted for a file name to apply to the data if you should want to archive it. Press

ESC if you do not want to save the data. To quit the program, choose QUIT from the File menu,

not the (non-functioning) close button in the upper right of the program window. At this point

you have successfully completed a bench test of the instrument.

ac meter Protocol (acprot) Revision N 21 May 2008 7

Page 14

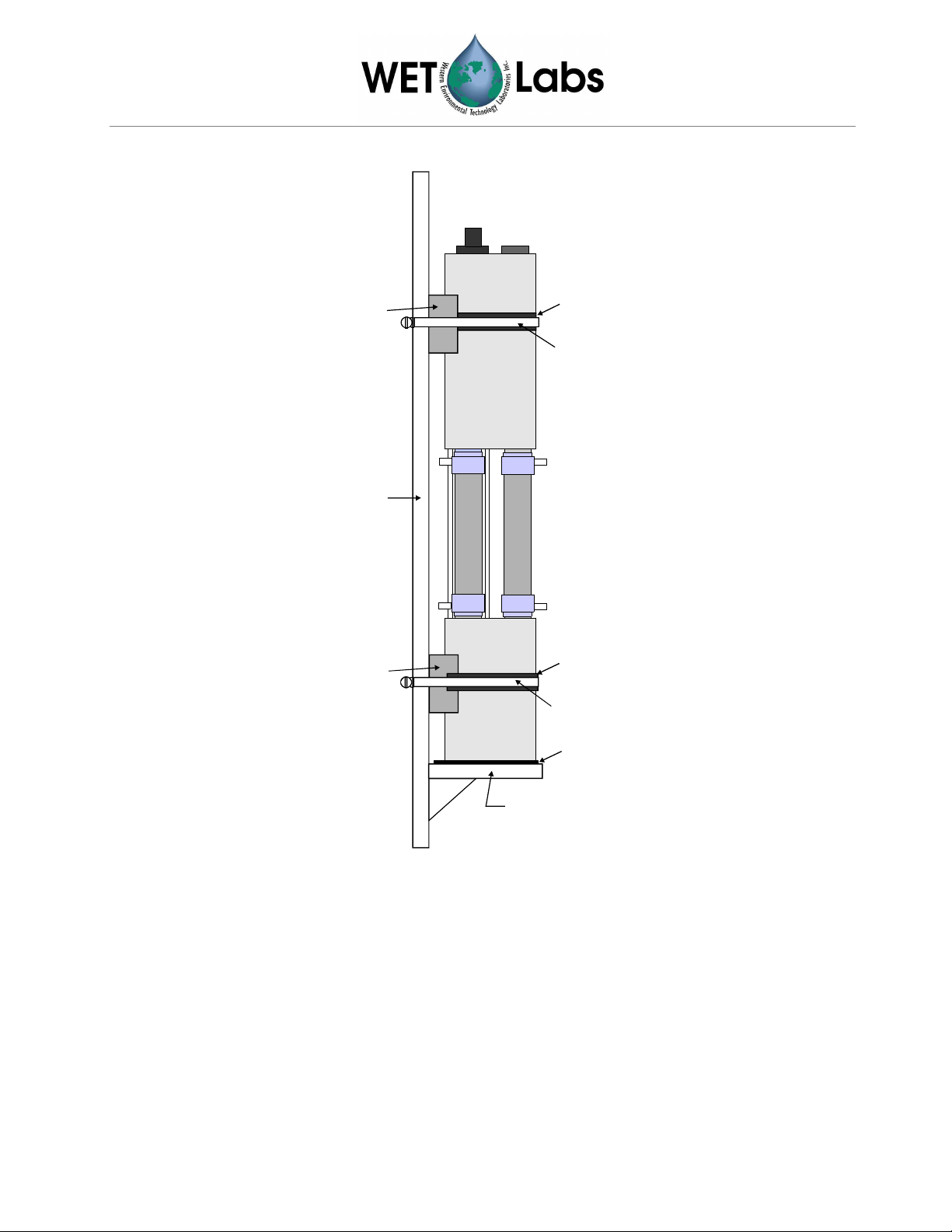

3.3 Mounting

shouldbejustsnugtoavaoidapplyinganytorquetotheac-9.

Delrinor

PVCSaddle

Lowering Cage

Mounting Bar

Delrinor

PVCSaddle

Rubber

Sheet

Stainless

Hose Clamp

ac-9

Rubber

Sheet

Stainless

Hose Clamp

Rubber

Sheet

Steel Ledge

or Step

Note:Tightenupper hoseclamptightly. Lowerhoseclamp

Figure 2. Deployment cage mounting suggestion for ac-9 and ac-s.

The ac-9 and ac-s contains two optical paths that are sensitive to lateral and torsional stresses.

To ensure that the unit functions properly, it is important to minimize stresses when mounting

the unit to a frame. If possible, the ac device should be mounted vertical. These sensors can be

used in other orientations, but for the most accurate results field water calibrations should be

carried out when in the preferred deployment orientation to account for drifts associated with

small changes in the alignment of the optical paths. In the vertical orientation, it is preferable to

rest the bottom of the ac device on the cage framework and attach both the upper and lower

housings to the vertical framework of the cage (Figure 2). The housing attachments do not need

to be any tighter than required to hold the ac device to the cage as the main support is the

8 ac meter Protocol (acprot) Revision N 21 May 2008

Page 15

bottom rest. If the ac device is to be mounted horizontally, it is critical to support both housings.

If the ac device is mounted horizontally and supported by only one housing, more substantial

deformation of the optical path will occur that may cause the unit to provide inaccurate

readings.

3.4 Plumbing and Tubing

It is important to ensure good flow through the ac meter flow tubes. The flow rate through the

instrument should be kept above 1 liter/min to resolve environmental changes over fine spatial

and temporal scales. This can be achieved by maximizing the tubing size and using a pump

such as the Sea-Bird Electronics SBE-5 running at a minimum 3000 rpm. The ac meter flow

tube sleeve nozzles are ½ in. to improve performance by potentially increasing the flow rate and

flushing through the flow assemblies, and to easily mate with the pump.

The detector for the absorption channels is very sensitive to external light, and the attenuation

detector can be affected when exposed to intense ambient light, so it best to eliminate the

leakage of any external light into the flow cells. This is accomplished by ensuring that all tubing

attaching to the flow cell sleeves is completely opaque or covered with opaque black tape. Note

that some electrical black tape is not completely opaque and can produce errors in absorption

readings at the surface.

Tygon tubing and other varieties may contain plasticizers that could possibly affect the optical

measurements if exposed to the sample for a significant amount of time. For short lengths of

tubing in typical applications using continuous flow, the type of tubing has not proved to be a

concern, as long as it is clean, laboratory grade. When using Tygon tubing, it is best to use a

thick-wall tube to prevent kinks in the tubing or collapse of the tubing due to possible pressure

differentials when pumping. Other types of tubing are available and include Teflon, Teflonlined Tygon, and expensive grades of tubing without plasticizers. Many of the types of tubing

are rigid and care must be taken to prevent kinks from forming.

The plumbing should be installed in a manner that ensures bubbles cannot be trapped anywhere

in the system. A typical plumbing set-up is described. The upper and lower flow tube nozzles

are used for the outflows and inflows, respectively. Opaque tubing is attached to the intake

nozzles and dropped to the bottom of a deployment cage. The pump for the ac device should be

placed above the upper set of nozzles of the flow tubes. A “Y” fitting is used to merge the

outflows from the two flow cells into one flow that can be connected to the pump. On the

outflow from the pump a bubble degasser is typically installed. This device is an inverted “Y”

housing a Teflon insert with a small hole through the center that allows bubbles to escape the

system. It is required that the pump pull the water through the tubes rather than push it through.

The key consideration is that the plumbing configuration provides a clear path for bubbles to

escape the system when the sensor is deployed. If small bubbles are lodged in the flow cells, the

optical measurements will have errors. If bubbles become lodged in the pump, the pump will

stall and not work.

Separate intake tubes for the “a” and “c” sides of the instrument are recommended over using

“Y” or “T” fittings to separate the flow from a single intake tube. This is because evidence from

laboratory measurements indicates that a “Y” fitting may partition some particles preferentially

into one arm of the “Y” (Twardowski et al. 1999).

ac meter Protocol (acprot) Revision N 21 May 2008 9

Page 16

In profiling applications where the sensor package may experience abrupt changes in rates of

descent and/or ascent, it is recommended that the inlet and outlet pressures of the flow system

be balanced. This is achieved by assuring that the entrance point and exit point of the tubing are

positioned at the same depth, i.e., a tube is installed that runs from the outflow leaving the pump

to the bottom of the cage where the sample intake tube is positioned (taking care not to orient

them too close together).

3.5 Attaching Prefilter to Remove the Particulate Fraction

An ac-9 or ac-s can be used to measure absorption by the dissolved fraction of water only. The

dissolved material responsible for this absorption is collectively known as colored dissolved

organic material (CDOM), “yellow matter,” or Gelbstoff. A capsule filter, typically with 0.2 µm

pore size, is attached in-line to either the “a” or “c” flow tube (or both) intake, so that particles

are removed prior to measurement. It is best to carefully cut the outer capsule of the filter off

with a saw (careful not to cut the filter pleats) to expose more filter surface area to the water.

Because CDOM is primarily composed of hydrophobic humic material, it is essential that the

capsule filter have a hydrophilic membrane. Otherwise, the filter may remove important

hydrophobic dissolved material.

Because scattering from the material present in the <0.2 µm fraction from natural waters

typically is negligible, attaching the filter to the intake of either the “a” or “c” side should yield

the same results. This is actually an excellent test to determine if your meter is operating as

expected. When deploying multiple ac devices, occasionally attaching prefilters to all the

meters is also an effective means of cross-calibrating the sensors.

To measure both the dissolved and particulate fractions of water independently, a dual ac-9 or

ac-s configuration may be assembled where one device has a prefilter (measures the dissolved

fraction only) and the other device does not (measures the dissolved + particulate fractions).

One ac device may be used to obtain the same set of data if successive casts are made, some

with the prefilter and some without. Extra care must be given to purging the system of air when

a filter is used, and there are other considerations to take into account, such as smearing of the

data because of longer (and variable as the filter captures more and more particles) time lags

(the time required for a sample to transit from the intake, through the filter, into the flow tube,

and undergo measurement). Using a high-speed pump (e.g., 4000-RPM SBE-5) is

recommended to minimize this effect. Even with a high-speed pump, however, time lags are

typically greater than 10 seconds (see section 5.3).

3.6 Deployment

The ac-9 and ac-s may be used in a variety of deployment modes. While emphasis and protocol

development has focused primarily upon profiling applications, the meter has also been used in

moored, lab flow-through, autonomous underwater vehicle, and towed applications. Each of

these modes requires some consideration in how best to optimize results from the meter. Below,

some of the most important issues are addressed with the primary modes of deployment.

3.6.1 Moorings

3.6.1.1 Anti-fouling—One of the most problematic aspects of a moored deployment of any

optical device is accumulation of biological growth on the optical surfaces. The enclosed

flow path of the ac-9 helps to retard biological fouling of the meter’s windows and the

10 ac meter Protocol (acprot) Revision N 21 May 2008

Page 17

reflecting tube. Additional protection against biofouling may be provided by using copper

tubing on the inflow and outflow tubing of the flow tubes. The inhibitive effect is provided

by the slow dissolution of copper into the water between sampling events. Research has

shown that the use of copper tubing on the inflow and outflow tubing on an ac meter can

extend the measurement duration up to 60 days on coastal moorings (Manov, et al., 2004).

3.6.1.2 Warm-up—It is normally best to characterize and use the ac-9 or ac-s after a 5- to 10minute warm-up from initially powering the meter. Moored deployments, however, typically

require sampling within thirty seconds after turning the unit on to conserve power. In order

to assure accuracy in the field, multiple samples should be collected with a clean dry system

in the lab, using the sample interval that is to be employed in the mooring. For best results,

the testing should occur at temperatures close to those to be found in the water. Once

multiple files have been collected, measurements in optically clean water (see Calibration,

section 4) may be made and compared to baseline zero values expected when applying the

device file (.dev) provided by the factory. Any offsets, which may or may not have a

temporal dependence while the instrument warms up, can later be applied to field

measurements as a correction.

3.6.1.3 Ground loops—The housing of the ac-9 and ac-s operates at ground potential,

effectively tying the instrument common to the seawater. Under normal circumstances this

should create no problems. However, depending upon other instrumentation attached to the

mooring, inadvertent current leakage paths, and ill-considered power schemes, there lies

potential for ground loops. In moored deployments, where packages can potentially be left

unattended for months, the ground loops can drain batteries, result in noisy measurements,

and damage instruments. While there is no set method for the determination and elimination

of ground loops the following steps provide general guidelines:

• Create a systems grounding diagram. Consider the seawater as a ground plane.

• Note all terminations to the seawater.

• Measure voltages across these terminations to determine possible voltage potentials.

Also check voltages across the instruments to the cage.

• If possible, immerse the package in salt water, and repeat the previous step

• A 2–3 day test deployment with instruments in the water could provide important

information on expected versus realized battery voltage decay.

• Mitigating a suspected ground loop is highly system specific. If you suspect a loop you

may wish to consult the factory for advice.

3.6.1.4 Plumbing—The inability to pre-purge moored deployments in near surface waters

makes it vitally important to properly plumb your system. If the tubing and meter orientation

do not facilitate rapid flushing of bubbles, air could easily become entrapped within the flow

assemblies. Also, in areas where the meter may be sampling large amounts of re-suspended

particulates, good flushing is critical to prevent sediment build-up within the meter. If

possible, pumping speeds may be set to higher speeds (4000–4500 RPM for the SBE-5) and

the incorporation of the larger nozzle diameter lock sleeves is recommended.

3.6.1.5 Calibration—Field calibrations immediately before and after mooring deployments

are essential to allow tracking of any drift due to fouling or possible instrument changes (see

section 4). The calibration should be performed as soon as possible after removal of the

ac meter Protocol (acprot) Revision N 21 May 2008 11

Page 18

mooring from the water and after stored data is uploaded. Conducting a field water

calibration before cleaning the meter allows drift assessment in the “as-is” condition, which

will include drift due to both fouling and instrument changes. A second calibration after the

meter has been thoroughly cleaned will allow the user to track instrument specific drift. The

effects of fouling may be obtained by taking the difference between these two calibrations. In

situations where optically clean water is not available, obtaining an air tracking file after the

meter has been cleaned and dried will at least provide an indication of the meter stability

through the period of performance.

3.6.1.6 Power consumption and battery life—To assure that a viable data set is collected

during the entire period of deployment one must assure that they provide enough energy

capacity (batteries) to effectively operate throughout the duration. The ac-9 or ac-s with

pump will consume approximately 1 amp at 12 volts DC. Assuming a nominal on-time of

one minute for each sample, the instrument will use about 1/60 of an amp-hour during each

cycling. In addition, one must consider the power consumed by the data logger tied to the

instrument in both its “on” and “off” states. Batteries typically provide a rated capacity in

amp-hours, but this can mean different things for different types of batteries. For instance a

twelve volt, D-cell alkaline battery pack is rated around 12–14 amp hours, but due to the

near-linear decay rate of the batteries and the fact that this rating implies the amount of

energy that the battery might provide until it is at 50 percent voltage, the usable capacity is

only about 1/3 of the rated capacity. You must also take into account de-rating of the

capacity due to lower water temperatures. Near-zero degree Celsius temperatures could

reduce usable lifetimes by 30 percent. In generally, it is wise to provide ample over-capacity

in your power system. All things considered, the price of batteries is usually cheap compared

to the price of lost data.

3.6.2 Towed Bodies

3.6.2.1 Mounting—In mounting to a towed unit you must consider both the stability of the

device and the flight characteristics of the entire towed unit. While the latter consideration is

out of scope for this discussion, the former topic is straightforward. The mounting should

firmly secure the meter towards both ends, without applying excessive torque on the unit.

Neoprene-lined saddle clamps are recommended for this purpose. The clamps should be

securely anchored to the frame. In securing the meter, make sure that adequate clearance is

provided for plumbing and wiring. Because of size constraints, the meter usually must be

mounted near horizontal. As a result, it is imperative that a field water calibration be carried

out with the installed meter in the orientation expected during measurement to ensure the

meter is stable in its new orientation (see Section 4).

3.6.2.2 Plumbing—It is recommended that flow inlets and outlets be oriented so that the

hydrostatic pressure is equivalent, thus avoiding variable flow rates associated with variable

rates of ascent and descent (if applicable). This is most easily established by locating the inlet

and outlet hoses at the same level. Plumbing should be installed to allow the system to

completely purge all air when deployed. Because the meter may be mounted horizontally,

use bubble degassers and tubing to allow bubbles to escape. If possible, sending the package

down to 10 m or deeper before underway towing will help pressurize air out of the system. If

orientation and space constraints do not permit a plumbing configuration that enables air to

fully escape, plumb the meter in a manner that will allow air to escape when positioned in

another orientation. On initial deployment, use a tag line to allow immersion of the towed

12 ac meter Protocol (acprot) Revision N 21 May 2008

Page 19

body in this orientation, allow full degassing and run an instrument and data check if

possible, remove the tag line, and tow.

Ship Underway and General Benchtop Operation

3.6.3.1 Keeping the meter within its specified internal temperature range—If the internal

temperature of the ac-9 or ac-s exceeds about 35 degrees C, the automatic temperature

compensation algorithm will start to break down. In general, temperature characterization

and compensation of the ac-9 are based upon in situ or underwater operation of the meter.

The meter’s internal temperature characteristics depend upon the thermal flux between the

meter and its environment. Since water and air make substantially different ambient

environments, it is recommended that the instrument be immersed in water to assure stable

operation. At very least, the transmitter housing (bottom can) should be submerged in water

that is being actively exchanged so it does not overheat. If possible, the instrument may also

be placed in a cold room and allowed to run for at least 10 to 15 minutes until the internal

temperature stabilizes. For best results, carry out a field water calibration after the instrument

temperature has stabilized for a given set of ambient conditions.

3.6.3.2 Eliminating air from the system—Providing a bubble-free water delivery system for

the unit can usually be accomplished by simply plumbing the unit so that water flows into

the unit from the base and flows out from the upper side of the flow cells (i.e. the water

should always flow upward.). Often, however, shipboard seawater supplies have bubbles,

which requires a degassing system of some kind. The simplest method of degassing pumped

seawater is to send the water to a holding tank and then use gravity to draw the sample for

the ac-9 or ac-s from the bottom of the tank. The larger the tank, the more temporal and

spatial smearing the optical signal will experience. Once you are convinced that the water is

flowing through your unit is bubble-free, check the data stream readouts in WETVIEW to

verify. Bubbles in the water flow typically generate substantial spiking, sometimes negative,

in both “a” and “c” channels. A lodged bubble in a flow tube may not introduce substantial

variance in the signals, but will typically shift baselines. If it appears there is a lodged bubble

in a flow tube that is difficult to remove, try stopping the flow, removing the flow tubes,

drying the inside of the tubes and the ac-9 or ac-s windows with lint-free lens paper,

reassemble and test again.

3.6.4 Profiling

3.6.4.1 Mounting—When profiling, the meter is usually mounted vertically on a cage. The

pump should be located above the ac-9 flow tubes to allow it to pull water up through the

flow tubes. The inlet nozzle tubing should be arranged to sample from undisturbed water

below the package. (See Section 3.3 for detailed instructions on instrument mounting and

Section 3.4 for instructions on plumbing).

3.6.4.2 Pre-purge—Care must be taken to ensure that all bubbles are purged from the system

before beginning to sample. After the meter is appropriately mounted and plumbed (see

Sections 3.3 and 3.4), lowering the package to 10+ meters during the initial 5-minute warmup provides effective purging.

3.6.4.3 Free-fall Descent—To provide the highest quality data with good vertical resolution

when deploying from a ship on a wavy ocean, the deployment package should ideally be a

free-fall type system, with the buoyancy set to allow a slow descent rate. By making the

ac meter Protocol (acprot) Revision N 21 May 2008 13

Page 20

package a free-fall type, it becomes de-coupled from the ship’s motion, allowing better

vertical resolution and preventing hydrostatic surging in the flow system. If a free-fall

descent is not feasible, make sure the intake and outflow of the plumbing for the meter are at

the same depth to ensure a constant flow rate (see section 3.4).

3.6.4.4 Time Constants and Spatial Resolution—The actual descent rate you use should

depends on system capabilities and the desired vertical resolution. In a free-fall mode,

descent rate will be determined by the net buoyancy of the package. A descent rate of ~30

cm/sec will provide ~20 data points in each meter. This is typically considered adequate

resolution for sampling the open ocean, but sampling to 500 m would take almost 30

minutes. In considering spatial resolution, the flushing rate and volume of the flow assembly

are also factors. Each side of the flow assembly encapsulates a ~30 ml volume. This means

that for a 2 liter/min flush rate, the meter will completely exchange volumes about 67 times

in 1 minute. For significantly reduced flow rates, the package descent rate may need to be

reduced to maintain adequate spatial resolution for a specific application.

3.6.4.5 Care of Meter Between Casts—Requirements for cleaning the ac-9 and ac-s between

casts vary depending upon the interval between casts, water conditions, and signs of obvious

fouling from previous casts. Basic guidelines:

• The meter should be cleaned at least once per day. This could occur after the last cast of

the day or before the first cast of the day. It can also correspond with a field calibration.

(See Section 4.3 for field calibration details.)

• The meter should be cleaned if fouling is suspected.

• The meter should be cleaned if the intervals between casts are sufficiently long to allow

drying within the flow assemblies.

• Profiling in very clean waters where signal changes are on the order of 0.01 m

require more frequent cleaning.

• In addition to cleaning optical surfaces, washing down the exterior of the meter

regularly with fresh water reduces possible effects of corrosion.

-1

may

14 ac meter Protocol (acprot) Revision N 21 May 2008

Page 21

4. Calibration

4.1 WET Labs Calibration Procedures

The standard ac-9 and ac-s calibration procedures at WET Labs include a series of

characterization tests to confirm the instrument’s performance is within factory specifications,

temperature calibration, pure water calibration, and an air calibration.

4.1.1 Factory Pre-calibration Procedures

The pre-calibration procedures at the factory confirm that the meter is operating within

specifications before it goes through calibration. First, a 12-hour burn-in period indicates if

there are any immediate problems. The optical throughput of the ac-9 or ac-s is then tested by

recording the output of the signal and reference detectors. Minimum and maximum signal

levels are determined to assure that the appropriate instrument precision and dynamic range

can be obtained for each channel. A mechanical stability test is performed by subjecting the

meter to shaking/vibrations in both the horizontal and vertical positions. The meter is also

subject to a shock test to make certain that the output of the meter is not altered during normal

shipping and handling procedures. A final performance test is performed by collecting data

with the meter on the bench. After a sufficient warm-up period, the raw precision of each

channel should be approximately 0.001 m-1 or less. Precision is determined by taking the

standard deviation of a one-minute air data file, measured in inverse meters at approximately

1 Hz.

4.1.2 Factory Temperature Calibration

During the temperature calibration of the ac-9 and ac-s, the instrument’s temperature

coefficients are determined. The temperature coefficients provide a correction factor for

temperature for each channel of the ac-9 and ac-s. The temperature calibration data is also

used to identify unusual instrument performance issues causing the output of the meter to

change dramatically as a function of temperature.

The WET Labs temperature calibration is performed by placing the meter in a water bath.

Initially, the meter’s flow tubes are completely dried, filled with argon gas, and sealed off,

preventing any moisture from reaching the flow path or the windows. The water bath

temperature is cooled from about 35 degrees Celsius down to approximately 5 to 7 degrees

Celsius over a 90-minute period. This water temperature range corresponds to an internal

instrument temperature range of approximately 10–40 degrees Celsius. Data is recorded

during this period. After a complete temperature cycle, the data is examined to determine if

there are any unusual features in the absorption and attenuation values as a function of

internal instrument temperature. If changes over temperature of the meter vary too greatly

(within about 0.01 m-1 overall) or if severe non-linearities are detected, the instrument is

sent back to the production floor for examination and necessary modifications. This process

may include replacement of detectors, lamps, and/or electronics depending on the cause of

the problem. If the instrument looks good after the initial temperature cycle, the

temperature coefficients are calculated and applied to the device file that is ultimately

supplied with the meter.

ac meter Protocol (acprot) Revision N 21 May 2008 15

Page 22

Acquisition software, including versions of WETView 5.0 and higher, employ a correction

algorithm that uses multiple offset values,

∆

, obtained by measuring output differences

Tn

over small temperature increments. Instrument values are collected and averaged every one

to two degrees C through the operational temperature range of the instrument. From these

values we generate a look-up table of temperature compensation offsets [

∆

]. This table is

Tn

contained in each instrument’s device file. Using the table, WETView then applies the

algorithm, [a' = a

raw

-

∆

] for given temperatures in the table. For temperatures that fall

Tn

between table values, the program applies a linear interpolation upon the data for further

correction. By using this scheme, we can thus effectively compensate for any non-linear

changes due to temperature, in the instruments’ output.

For examples and an explanation of device files, refer to Appendix 1.

The internal instrument temperature range, defined for each individual meter, may vary by

a few degrees although typically the range extends from about 10 to 40 degrees Celsius.

The exact temperature range is specified for each meter on the Calibration Sheet that is

supplied for every new calibration. The ac-9 will remain within the factory temperature

specifications over the internal instrument temperature range specified. Operation within

this range is necessary to obtain results within the specifications of the device. For most

accurate results, avoid operating the meter above about 35 degrees C. Typically,

temperature characterizations below 10 degrees C are not required, even in the coldest

waters, because internal heat generated by the lamp and electronics maintain internal

temperatures at or above this level.

For an example and explanation of a Calibration Sheet, refer to Appendix 1.

4.1.3 Factory Water Calibration

The purpose of the WET Labs water calibration is to determine the offset values of

absorption and attenuation that result in a zero reading with optically clean water in the

sample volume of the flow tubes. This is analogous to a blank used in any

spectrophotometer. These water offset values are listed on the Calibration Sheet and

included in the device file for each meter’s new calibration.

Before conducting a water calibration, the ac-9 and ac-s optics are properly cleaned and the

meter is allowed to warm up for at least 15 minutes (see Section 4.2.2 for detailed cleaning

instructions).

WET Labs maintains a custom water purification system that includes a commercial deionization system and filtration system. After primary de-ionization, the water is processed

by a Barnstead purification unit and stored in a 60-liter holding tank that re-circulates

through an ultra-violet chamber and additional purification filters. Water for calibration is

drawn through a final 0.01-micron ultra-filter at the point of delivery. The circulating

holding tank allows the highly reactive de-ionized water to equilibrate with the ambient

conditions and the ultra-violet chamber prevents any biological contamination from

entering the reservoir. The system is continuously monitored and water quality is checked

using a simple scattering detection test prior to each calibration to maintain consistent and

accurate water calibrations.

16 ac meter Protocol (acprot) Revision N 21 May 2008

Page 23

During the water calibration, water from the pure water system is flushed continuously

through both flow tubes of the meter at a rate of approximately 1.5 L/min. Values of

absorption and attenuation are collected using WETView and the results are used to create a

device file. Thus, with optically clean water in the flow tubes, the ac-9 or ac-s should read

zero on all channels when using this device file. In order to confirm that the offsets are

accurate, the cleaning process is repeated until the results are repeatable to within +/- 0.003

m-1. Once the final offsets are collected, they are used to create the final water calibration

values in the factory device file specific to that meter. The offsets are thereafter

automatically applied when running WETView with that device file.

For an example and explanation of a Device File refer to Appendix 1.

The water temperature and the internal instrument temperature are important parameters for

the user to consider when processing data, trying to obtain water calibrations in the field, or

reproducing pure water calibrations in the laboratory. The water temperature is recorded

during the calibration with typical values ranging from less than 5 to 35 degrees Celsius.

When processing data it is important to correct for changes in the absorption of pure water

that occur as a result of temperature fluctuations (see Section 5, Data Processing). These

changes are a physical phenomenon that have nothing to do with the instrument, but require

attention to obtain the most accurate results possible. Knowledge of the water temperature

during calibration is thus a critical parameter because one needs to know the temperature

difference between the water sample and water used for calibration to apply a correction.

Internal instrument temperature is also recorded for each water calibration. It is important

that this value fall within the temperature range specified in the temperature calibration. Both

the water temperature and the internal temperature of the instrument during calibration are

recorded on the Calibration Sheet.

4.1.4 Factory Air Calibration

The purpose of the WET Labs air calibration is to determine the offset values of absorption

and attenuation that result in zero readings with air in the sample volume of the flow tubes.

These air offset values are listed on the Calibration Sheet and included in the air tracking

device file for each meter’s new calibration.

Before conducting an air calibration, the exposed optics are properly cleaned and completely

dried, the flow tubes are filled with argon, and the meter is allowed to warm up for at least

15 minutes (see Section 4.2.2 for detailed cleaning instructions). One of the most critical

aspects of obtaining a good air calibration is that the exposed optics and flow assemblies of

the meter must remain absolutely dry and that the air in the flow tubes be devoid of

humidity.

During the air calibration, the meter’s absorption and attenuation values are collected using

WETView and the values used to create a device file for air. With these offsets applied, the

ac-9 should thus read zero on all channels. To confirm the offsets are accurate, the cleaning

process is repeated until the results are repeatable to within +/- 0.003 m-1.

Once the final air offsets are collected they are used to create a final factory device file for

air tracking. This file is provided with each new meter distribution and is denoted as

AIRXXYYY.CAL, where the XX represents the calibration number and the YYY represents

ac meter Protocol (acprot) Revision N 21 May 2008 17

Page 24

the instrument serial number. This file can subsequently be used in air tracking procedures

(see below).

The air CAL file is similar to the DEV file and can be applied in WETView in the same

manner. The difference in the two files is that the DEV file provides the clean water offsets

so that when measuring clean, fresh water, the instrument’s output should be zero for all

channels if the instrument has not experienced any drift. The CAL file provides the offsets

that provide zero values when the instrument is clean and dry and measuring air values.

Refer to Section 4.2 for more details on using your air tracking files. Remember, when

obtaining air files, it is important to block light entering the flow assemblies by covering the

inlet and outlet nozzles with tape or the black plastic caps provided by the factory.

An important parameter to consider when trying to confirm or reproduce air calibrations is

the internal temperature of the instrument during the air calibration. Because the output of

the ac-9 is only compensated for temperature over the temperature range specified on the

Calibration Sheet, any operation outside of this range may result in offsets in the data. This is

most often a concern with air calibrations because the instrument is operating in air, meaning

a large portion of the heat generated internally by the ac-9 is not rapidly dissipated to the

surrounding environment. The temperature of the instrument during the WET Labs air

calibration is recorded on the Calibration Sheet.

4.2 Air Tracking Procedures

4.2.1 When to Use Air Tracking

Air tracking can be used to monitor offsets in the instrument’s output due to changes in the

optical system caused by shipping or mounting of the instrument to a cage or other

deployment package. Air tracking can also be used to monitor instrument drift over extended

periods of time. Air tracking involves the collection of data with the ac-9 in air using

WETView and the factory air device file. Output collected following the Air Tracking

Protocol are considered the Air Tracking Offsets. These offset values are an indication of

changes in the optical throughput of the instrument since the factory air calibration and may

be used in certain situations to correct data collected using the ac-9 or ac-s.

In practice, it is difficult to carry out air calibrations with the accuracy required for tracking

instrument drift offsets. This is because the absolute cleanliness and complete lack of

moisture on the optics or in the air may be difficult to achieve, especially in the field.

Furthermore, drifts obtained via air tracking have been shown to be slightly different than

drifts obtained via the more accurate water calibration method (see below). One factor

thought to influence this dynamic is the subtle change in the reflectivity and transmissivity of

the optical windows over time due to continual cleaning and other unavoidable window

contact associated with normal usage. Because the reflectivity of the windows is different in

air versus water, this could result in air drifts that do not exactly match drifts in clean water.

Air tracking can be effective as a quick check to make sure the meter is functioning

correctly, however. Use the air tracking device file, AIRXXYYY.CAL, with the WETView

software package. Connect the ac-9 to power and allow it to warm up for at least 15 minutes.

Without removing the flow tubes or cleaning the optics, the absorption and attenuation

18 ac meter Protocol (acprot) Revision N 21 May 2008

Page 25

values should be within +/- 0.01 m-1 of zero. Use the Air Tracking Protocol listed below to

obtain good air readings. Larger offsets may indicate misalignment of the optics during

shipping and handling.

Air tracking data is most easily obtained in the laboratory, where the environment is

consistently clean and dry. Air calibrations can be performed while in the field, however, it

can be difficult to obtain good air calibrations on a ship due to the moist environment.

Readings can be significantly offset by small amounts of moisture or dirt in the flow tube

sample volume, resulting in considerable tracking inaccuracies.

4.2.2 Air Tracking Protocol

4.2.2.1 Soap wash and rinse—Remove flow tubes and all O-rings from the windows. Remove

the collars from the flow tubes. Remove the O-rings on the flow tubes themselves. Use a mild

detergent solution to gently wash all of the windows and rinse the flow tubes. Use lint-free

wipes or lens paper to wash the windows. Rinse off the meter completely with water to ensure

no soap residue is left inside the flow tubes or on the windows.

4.2.2.2 Dry the meter—Place the instrument in a protected area where it can dry out

completely. Using a small heater to blow warm air over the meter may help speed up the

process. Using dry nitrogen or argon to blow dry the meter and remove water from the small

grooves around the windows will also help speed up the process. It is suggested that the

instrument be left over night to dry out completely. Reassemble the meter. Carefully replace Orings and slide the sleeves back on the flow tubes. Replace O-rings around the windows.

4.2.2.3 Solvent Cleaning—Use lint-free wipes or lens paper. Clean the windows with reagentgrade methanol or ethanol. (When using ethanol make sure to use protective gloves. Dilute

solutions of at least 50% alcohol can also be prepared.) This process should remove any

residual oils or organic material on the windows. Repeat this two to three times. Using a small

flashlight or laser pointer to carefully examine the windows is also helpful.

4.2.2.4 The flow tubes should also be cleaned—Place a few drops of methanol on a lint-free

wipe and, using a wooden or plastic dowel rod, carefully slide the lint-free wipe through the

flow tube. Repeat this procedure with both flow tubes. Examine each flow tube when you are

through, to make certain that there are no streaks or small pieces of wipe on the inside of the

flow tube.

4.2.2.5 Dry the windows—Since small amounts of moisture can affect the air readings, it is

important to ensure that the meter is completely dry. Using nitrogen to blow dry the windows

immediately before replacing the flow tubes works very effectively. This will remove any

water or methanol trapped in the small grooves around the window.

ac meter Protocol (acprot) Revision N 21 May 2008 19

Page 26

4.2.2.6 Replace the flow tubes—Carefully slide the flow tubes into place, avoiding direct

contact between the window surfaces and the ends of the flow tube. Slide the collars up around

the windows and over the O-rings, making certain they are firmly in place and aligned

correctly. Use small black caps, or black electrical tape, over each of the nozzles on the flow

tubes to provide a dark environment and to keep the meter clean and free of moisture while

obtaining data.

4.2.2.7 Allow meter to warm up—If your meter is not yet powered, turn the meter’s power on

and allow the meter to warm up for at least 15 minutes. When the meter is stable you should be

able to collect 10 minutes worth of data and the values should not vary more than 0.005 m-1

over the 10-minute time period.

4.2.2.8 Collect data—Use WETView and the air CAL file to record a one to two minute file

and save the data. Repeat steps 4.2.2.4 through 4.2.2.6 until you can collect three data files,

cleaning after each file, such that the average values for each channel vary by no more than

0.005 m-1.

4.3 Field Water Calibration Procedures

4.3.1 When to use Field Water Calibrations

Maximum accuracy of measurements is obtained by performing water calibrations of the ac9 and ac-s in the field. Field water calibrations can remove the effects of instrument drift

associated with changing optical components and small misalignments of the optical system

caused by shipping or mounting of the instrument on a cage or other deployment package.

Field calibrations allow the operator to track instrument drift over time and are a highly

recommended exercise to help one obtain the most accurate data possible. This is critical in

clear ocean waters. Historically, drifts have been recorded as high as 0.01 m-1 per month,

particularly in the blue channels of new instruments that are used often.

When a reliable source of optically clean water from a high-end water polishing system is

available, water calibrations are a relatively straightforward exercise in the field. The

concept behind the water calibrations is simple. The idea is to provide the instruments with a

source of clean, bubble-free water that can be used as a reference value, or blank. This is the

same concept used when the factory offset values are determined.

Clean water can be produced in the lab and transported to the ship in acid and base washed

polycarbonate containers, or a portable system can be brought for shipboard use. For shorter

cruises, the former option is usually a good one. However, if you are inclined to produce

your own clean water, we provide a general description of what is required in this document.

4.3.2 Field Clean Water Production System

4.3.2.1 Pre-Filtration Unit—To increase lifetime of the primary filtration unit it’s desirable

to provide pre-filtration of the input water. A 1–5 micron commercial cartridge with possible

addition of a activated charcoal filter work well for this task.

4.3.2.2 Primary Filtration Unit—The primary filtration unit typically consists of a

commercial filtration unit such as the Barnstead E-Pure system or the Milli-Q Q-Pak

treatment system. These units incorporate multiple stage filters to remove particulates, free

20 ac meter Protocol (acprot) Revision N 21 May 2008

Page 27

r

Carbo

y

ions, and organics. For the purposes of optically clean water production, organics and

particulates form the dominant signals, so be certain that cartridges are used in these systems

for organic removal. These systems require an active AC power source, so factor that in

when considering use of the system.

4.3.2.3 Water Storage Unit—Rather than directly coupling the clean water output from the

production unit to the ac-9 or ac-s outlets, it’s advisable to provide an intermediate storage

unit. An acid- and base-washed 20-liter polycarbonate carboy works well for this task. The

advantages of storing the water are two-fold. It allows the clean water to equilibrate with the

ambient temperature and for bubbles to come out of solution or dissolve. This is critical

since most water polishing systems that do not have tank reservoirs produce water with

microscopic bubbles. Water should sit for at least 4 hours before performing a calibration.

4.2.3.4 Water Delivery System—A field water delivery system is straightforward to set up

and operate as shown in Figure 6. A cap with barb fittings is used to allow for the connection

of tubing to pressurize the polycarbonate carboy and to allow water flow to the instruments.

The carboy is pressurized to no more than 10 psi using a clean air source such as an oil-free

air pump or a tank of nitrogen gas. Note that only very slight positive pressure within the

system is required and care should be taken to avoid over-pressurizing the system and

possibly creating a dangerous situation. The air tube inside the carboy should be short to

prevent creating bubbles when pressurizing the carboy. A tube for the water should extend

nearly to the bottom of the carboy. The tubing from the carboy is connected to one of the

bottom nozzles of the ac-9 or ac-s flow tubes. All tubing must be completely opaque to avoid

light leaks. This can be achieved by wrapping black tape around the tubing. A short piece of

tubing with a valve is connected to the top nozzle on the flow tube. The valve serves two

purposes. It allows the operator to stop the water flow, conserving the calibration water. It

also provides required backpressure, which helps to keep gases in solution preventing the

formation of micro-bubbles. Typically, the valve is used to restrict flow to a trickle. After the

flow of water has been initiated, gently rocking the meter can dislodge any trapped bubbles

before the flow is restricted with the valve.

ac-9inCage

Approx

Outlet Valve

10PSI

Teflon

Tubing

Clean Water

CleanAi

Source

ac meter Protocol (acprot) Revision N 21 May 2008 21

Page 28

Figure 6. A simple schematic of a field water-calibration delivery system.

Maintaining a viable clean water production system requires some care and common sense.

Most filtration packs perform de-ionization of the water. Using a mineral-rich water source

may quickly foul the filter cartridge. Storing the unit between uses may require special

handling of the filters. Many systems provide a resistivity gauge that indicates the ion purity

of the water. This is useful in determining whether your filters are fouled but is not a reliable

indicator of optical clarity.

4.3.3 Field Water Calibration Protocol

4.3.3.1 Obtaining a Calibration

1. Make sure that the meter is clean (See Section 4.2.2 for cleaning techniques) and that it

has warmed up for at least 5 minutes. Check the internal temperature to ensure that the

unit is operating within the temperature range provided on the calibration sheet.

2. Once the water delivery system is connected to either side of the flow assembly,

pressurize the carboy to no greater than 10 psi and open the outlet valve to purge air out

of the system. Typically you can directly observe the bubbles as they are pushed out of

the meter. Rocking the meter back and forth gently aids purging.

3. Once the meter is purged, use the valve to set the flow rate to approximately 100

mL/min. or less. This pressurizes the system while minimizing the amount of water

required for a calibration. If bubbles have been effectively purged from the system,

restricting flow rates will not change baseline values. In fact, this can be used as one

diagnostic to determine if small bubbles are lodged in the flow path.

4. Using WETView or your own data collection software, collect approximately 30

seconds of data into a file. Do not bin your data. This is to ensure that if a small bubble

passes through the system it can be identified and removed from the data stream. Make

sure that the output is stable and is not drifting.

5. Repeat steps 1–4 until readings in all channels are repeatable within ~0.005 m-1. With

care, repeatability on the order of 0.002 m-1 is achievable for most channels, and this

level should be a target if the meter is to be deployed in very clear waters. Repeatability

is the most important aspect of water calibrations because in many cases (e.g., with a

lodged bubble present in the flow cell) anomalous readings may be obtained that

nonetheless appear stable.

When the acquisition is completed, turn the water off and place the tubing on the other flow

tube. Repeat steps 1–5. Calibration may also be performed on the attenuation and absorption

meters simultaneously by installing a “Y” fitting on the intake to split the flow to both flow

cells.

During the calibration, the calibration water temperature should be logged to allow water

temperature corrections to be performed on the data (see Data Processing section). It is a

good practice to always include the date and water temperature in the file name.

22 ac meter Protocol (acprot) Revision N 21 May 2008

Page 29

Figure 7A. A sample of the changes in ac-9 “a” side water calibrations recorded in 1997.

ac meter Protocol (acprot) Revision N 21 May 2008 23

Page 30

7B. A sample of the changes in ac-9 “c” side water calibrations recorded in 1997.

4.3.3.2 Applying Field Calibration Data

To apply the new calibrations, there are two methods that can be used: a new device file can

be created, or the calibration offsets can be applied during post-processing. The latter method

is strongly recommended, because it is much easier to apply changes and keep track of

potential instrumental drift. For instance, if on a long cruise the instrument appears to drift in

a predictable manner, a regression can be applied during post-processing to derive drift

offsets as a function of time. Using different device files for different time periods can be

difficult to keep organized and does not provide for straightforward drift analyses. Drift

analyses versus time help to pinpoint possible inaccurate calibrations that are not consistent

24 ac meter Protocol (acprot) Revision N 21 May 2008

Page 31

with an overall trend (Figs. 7a and 7b). These analyses can also expose calibrations where

perhaps the water temperature was inaccurately recorded, usually evidenced by large

deviations in the near-IR where temperature has a strong effect on pure water absorption (this

is particularly important with the ac-s, where the spectral range is extended to longer

wavelengths). We are aware of many instances where periodically inaccurate calibrations

were applied to good data, resulting in negative values, oddly shaped spectra, and other

peculiarities. If you do choose to make your own device files, use caution—carefully

organize the files, only use calibrations you have absolute confidence in, and inter-compare

with other calibrations. Large deviations are rare, and should be treated as suspect. It is worth

repeating that repeatability in calibrations is essential.

To create a new device file:

1. Average a portion of the data collected during the calibration that does not show

evidence of bubbles or any drift.

2. Open the device file that was used when collecting the calibration data in a

spreadsheet such as Excel.

3. Subtract the average values from step one from the appropriate water offset value in

the device files. The offsets are given in the third column of the device file.

4. Make sure to save the new device file under a new name and as tab delimited text.

Save all old device files for reference.

To apply water calibration during post-processing, see section 5.5 below.

ac meter Protocol (acprot) Revision N 21 May 2008 25

Page 32

•

•

•

•

•

-

1

off

off

-

1

-

1

5. Data Processing

The ac-9 and ac-s acquire signals representing light losses of a light beam propagating through a

fixed path of water. In order to convert these values into meaningful units of absorption and

attenuation, and to correct for instrument and environmental factors associated with the

measurements, several processing steps are recommended. The following sections within this

chapter describe the steps in more detail. The processing steps listed in section 5.1 are listed in

approximate order of implementation; not all are carried out by WETView.

5.1 Basic WETVIEW Calculations

WETView is the basic WET Labs software package used to acquire and carry out basic

processing of data from the ac-9 and ac-s. WETView automatically carries out these basic data

processing steps during acquisition:

Initial Parsing of Binary Data

Ratio of Signal to Reference

-ln (Signal/Reference) / Pathlength

Application of Internal Temperature Coefficients

Application of Clean Water Offsets (contained in device file)

WETView reads in the raw binary data from the meter, then parses the data. The parsed data

contains digitized signal values for signal and reference levels for each channel. WETView then

applies an algorithm that:

1. Computes uncorrected engineering units (in inverse meters) from the signal and reference

values.

2. Applies a linear temperature correction (for the meter’s internal temperature) using

constants supplied in the instrument’s device file.

3. Applies clean water offsets supplied from the instrument’s device file that provide a value

referenced against clean water.

Combining these steps into one formula:

c(λ) = (c

and

where

c(λ), a(λ)

c

, a

C

, A

sig

C

, C

ref

x

∆T

a(λ) = (a

sig

ref

- 1/x [ln(C

off

- 1/x [ln(A

off

is the attenuation coefficient and absorption coefficient, respectively in m

is the water offset value (provided on the Calibration Sheet) in m

sig

sig

/ C

/ A

)]) - ∆T

ref

)]) - ∆T

ref

is the measured amount of light (power) that reaches the receiver detector from the ac-9

or ac-s data stream in raw digital counts

is the amount of light (power) measured by the reference detector from the ac-9 or ac-s

data stream in raw digital counts

is the sample volume pathlength in meters

is the internal temperature compensation correction value in m

derived from equation

below.

26 ac meter Protocol (acprot) Revision N 21 May 2008

Page 33

(

)

−

The temperature correction is applied using the temperature from the reference line and the

channels correction table from the either the Calibration Sheet or the Device File. The approximate

correction value is linearly interpolated from the table. First, the correct temperature bin is

determined by finding the two bin temperatures, T0 and T1, that bracket the current temperature.

Then, using the values,

+∆=∆

( )

∆

and

∆

Tn

TT

0

*

TT

−

01

, from the table, we obtain

Tn+1

( )

∆−∆

TnTnTnT

+1

where,

∆T = compensation constant

T= current temperature

T0 = first bin temperature

T1 = second bin temperature

∆

= first value

Tn

∆

= second value

Tn+1

This temperature correction is automatically applied by our WETView software. If you are

manually processing the raw data stream, this correction must be applied to arrive at the

temperature-corrected absorption and attenuation coefficients.

Note

For a detailed discussion of the WETView processing of the binary data stream, consult the ac-9,

ac-s, and WETView manuals.

For users writing their own code it is important to fully understand the parsing and these initial

processing steps. Examples of code can be found on our web site (http://www.wetlabs.com).

5.2 Merging

Data collected with the ac-9 or ac-s typically must be merged with CTD and other ancillary

measurements to be able to investigate relationships between different parameters, plot data

versus depth or time, and carry out many of the corrections to ac-9 and ac-s data described

below.

5.3 Time Lag Correction

A lag associated with the time it takes for a sample to initially enter the intake and travel

through the flow cell typically requires correction to ensure data is synchronized in space and

time with other measurements on a sensor package. Typically, all the disparate sensors on a

package have unique time records that enable merging in post-processing.

Time lags are a function of overall intake volume and flow rate. Lab experimentation with dyes

has demonstrated that this overall intake volume should include the entire volume of the flow

cell (~30 mL for the 25 cm path). Flowing sample within the flow cell can be considered

relatively well-mixed and not a “plug flow.” Experimentation in the lab and field has

demonstrated that with approximately 12 in. of ½-in. diameter tubing on the intakes of the flow

cells, time lags are approximately 1.2 s when using a SBE-5 3.5K RPM pump.