Page 1

DH-4 Data Handler

User’s Guide

The user’s guide is an evolving document. If you find sections that are unclear, or missing

information, please let us know. Check our website periodically for updates.

WET Labs, Inc.

PO Box 518

Philomath, OR 97370

(541) 929-5650

wetlabs@wetlabs.com

DH-4 Revision E5 19 June 2006

Page 2

Page 3

Attention!

Return Policy for Instruments with Anti-fouling Treatment

WET Labs cannot accept instruments for servicing or repair that are treated with anti-fouling

compound(s). This includes but is not limited to tri-butyl tin (TBT), marine anti-fouling paint, ablative

coatings, etc.

Please ensure any anti-fouling treatment has been removed prior to returning instruments to

WET Labs for service or repair.

DH-4 Revision E5 19 June 2006

Page 4

Page 5

DH-4 Warranty

This unit is guaranteed against defects in materials and workmanship for one year from

the original date of purchase. Warranty is void if the factory determines the unit was

subjected to abuse or neglect beyond the normal wear and tear of field deployment, or

in the event the pressure housing has been opened by the customer.

To return the instrument, contact WET Labs for a Return Merchandise Authorization

(RMA) and ship in the original container. WET Labs is not responsible for damage to

instruments during the return shipment to the factory. WET Labs will supply all

replacement parts and labor and pay for return via 3rd day air shipping in honoring this

warranty.

Shipping Requirements for Warranty and Out-of-warranty Instruments

1. Please retain the original shipping material. We design the shipping container to meet

stringent shipping and insurance requirements, and to keep your meter functional.

2. To avoid additional repackaging charges, use the original box (or WET Labs-approved

container) with its custom-cut packing foam and anti-static bag to return the instrument.

• If using alternative container, use at least 2 in. of foam (NOT bubble wrap or

Styrofoam “peanuts”) to fully surround the instrument.

• Minimum repacking charge for ac meters: $50.00.

3. Clearly mark the RMA number on the outside of your shipping container and on all

packing lists.

4. Return instruments using 3rd day air shipping or better: do not ship via ground.

DH-4 Revision E5 19 June 2006

Page 6

Page 7

Table of Contents

1. Getting Started....................................................................................................... 1

1.1

Install Host Program ....................................................................................... 1

1.2

Verify Electrical Functionality .......................................................................... 1

1.3

Verify System Operation ................................................................................. 2

2. Setting Operational Modes ................................................................................... 7

2.1

Profiling Mode ................................................................................................. 8

2.2

Moored Mode ................................................................................................ 13

2.3

Real-time Mode ............................................................................................ 19

3. Reference: Status Displays................................................................................. 25

3.1

Setup Status ................................................................................................. 25

3.2

Host Status ................................................................................................... 25

3.3

Logger Port Setup ......................................................................................... 25

3.4

Logger Status ............................................................................................... 26

4. Reference: Pull-down Menus .............................................................................. 29

4.1

Files .............................................................................................................. 29

4.2

Modes ........................................................................................................... 29

4.3

Commands ................................................................................................... 29

4.4

Logger_Port .................................................................................................. 32

5. Reference: Window Tabs .................................................................................... 35

5.1

Port Setup ..................................................................................................... 35

5.2

Logger Control .............................................................................................. 41

5.3

Data Status ................................................................................................... 47

5.4

Upload Logger Data ...................................................................................... 48

5.5

Real Time Data ............................................................................................. 50

5.6

Recording: OFF/ON ...................................................................................... 51

5.7

PC-Logger .................................................................................................... 52

6. Hardware .............................................................................................................. 55

6.1

Specifications ................................................................................................ 55

6.2

Standard DH-4 Connector Configuration ....................................................... 56

6.3

Standard Data Format .................................................................................. 58

6.4

Maintenance ................................................................................................. 58

Appendix A: Configuration Worksheets ............................................................... 59

Sample Worksheet .................................................................................................... 59

Blank Custom Configuration Worksheet .................................................................... 62

Appendix B: Real-Time Data Format ................................................................... 64

Appendix C: File Handling .................................................................................... 65

DH-4 Revision E5 19 June 2006 i

Page 8

Page 9

1. Getting Started

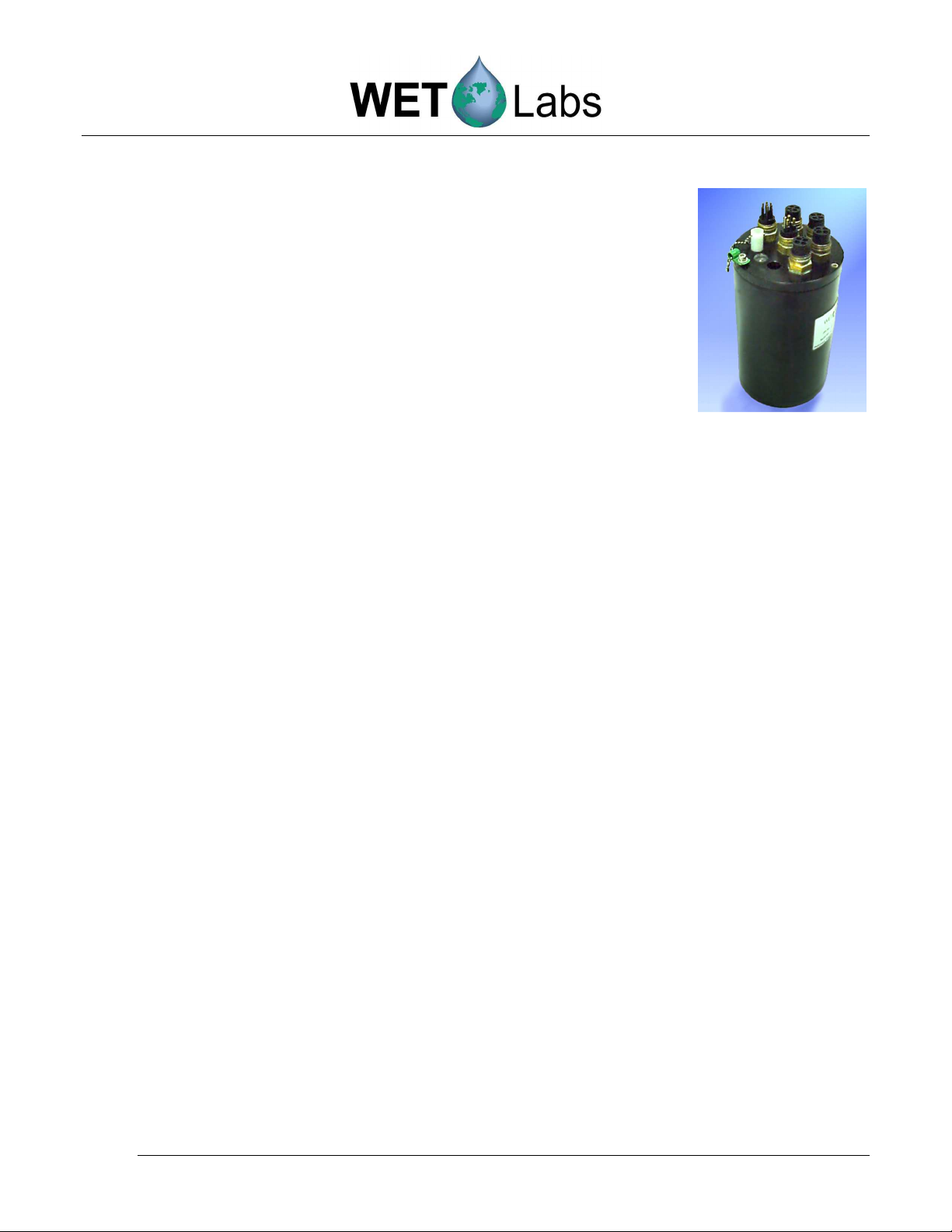

The Data Handler (DH-4) and its associated software,

WET Labs Host, controls four, six or eight input-output

ports for a variety of serial or analog instruments,

providing for the simultaneous collection, time stamping,

storage and merging of data streams from all of the ports.

Depending on the capabilities of the host computer, output

from one to all of the instruments can be viewed in real

time through the host software.

The DH-4 (data logger) is delivered with the following components:

• Test cable

• Dummy plugs with lock collar for each bulkhead connector

• This user’s guide

• Custom Configuration Sheet

• WET Labs Host software on CD

• WET Labs File Archive Processing (WAP) software on CD

• WAP User’s Guide

1.1 Install Host Program

Insert the WET Labs Host software CD into the host computer and copy the contents to a

desired location on the host computer. The WAP software may also be installed at this time.

Refer to the WAP User’s Guide for details on using this data processing software.

1.2 Verify Electrical Functionality

We recommend following the steps below to verify the system’s electrical functionality

when you first receive your DH-4. You will need the following items:

• A clean, solid lab table or work bench.

• A multimeter.

• The DH-4.

• Test cable (includes terminations for an RS-232 connection into a host computer,

power leads that connect to a power supply, and a connector to the DH-4).

• Any meter(s) that will be used with the DH-4.

• A 12–15 volt power supply.

• A computer with WL Host installed.

1.2.1 Check Test Cable Voltage:

1. Connect the power leads to a 12–15 volt power supply (safe operating range).

The black lead is the V+ lead. Use a multimeter to check the input power

before connecting the cable to the instrument.

DH-4 Revision E5 19 June 2006 1

Page 10

•

2. With the power supply turned on, touch the multimeter ground probe to socket 1

on the test cable connector. Connect the “hot” probe to pin 4 (the pin directly

opposite from pin 1). You should measure 12–15 volts across these two pins.

3. Turn the power supply off.

1.3 Verify System Operation

1. If necessary, attach the test cable power leads to a stable power source that supplies

12–15 VDC. Make sure the polarity is correct before switching on the power supply.

2. Connect the RS-232 connector to the desired serial port of the host PC.

Note that if your instrument is sending data in the RS-485 format, an RS-485 to RS232 converter is required to allow proper operation.

WARNING!

Power input on this unit is diode-protected from reverse polarity power-up, but this is not

100 percent insurance against damaging the meter, nor will it protect it from over-voltage.

3. Plug the submerged (wet) end of the test cable into the DH-4.

Applying electrical grade silicone spray or an equivalent to the rubber base of the

instrument bulkhead connector makes the plug insertion easier and provides greater

assurance of a good seal. Do NOT use stopcock greases or products like WD-40.

These will cause de-lamination of the rubber from the metal surface of the bulkhead

connector. Use a connector lock ring if one is available.

Tips

Refer to the Custom Configuration Sheet that ships with your DH-4 for a

summary of factory configuration settings.

•

The Configuration Sheet in Appendix A refers to the example setup used in

this manual.

4. Ensure the DH-4 is connected to the host computer and power supply as above.

5. Connect any additional meter(s) to the DH-4. It may help to refer to the Custom

Configuration Sheet that ships with each DH-4: when possible, configurations

settings specific to your system are set at the factory and documented on the Custom

Configuration Sheet.

6. Start WET Labs Host program.

7. Turn on power to the DH-4.

2 DH-4 Revision E5 19 June 2006

Page 11

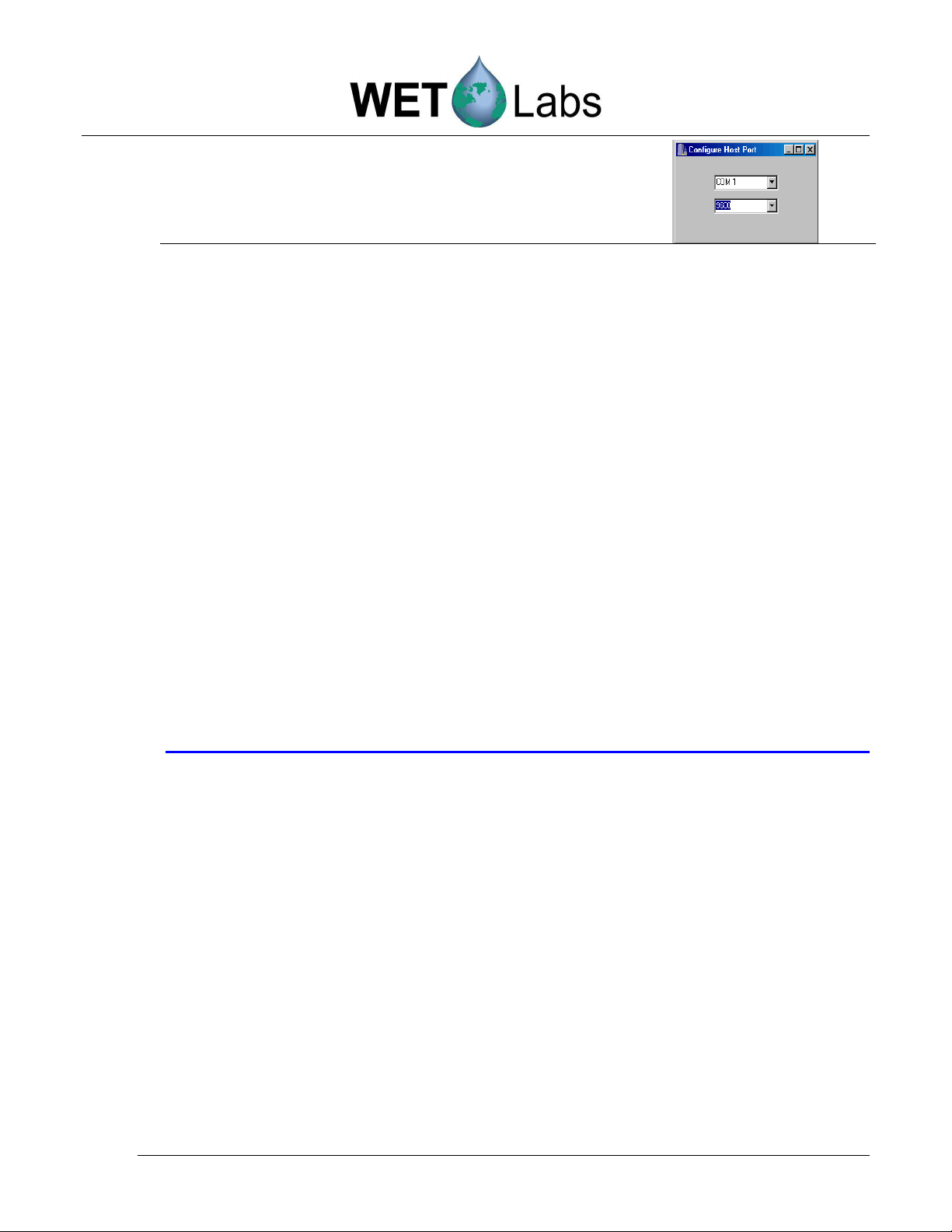

8. The first time WET Labs host is started, the

program screen will be mostly empty, with only a

Configure Host Port window appearing.

9. Input the COM port and the baud rate (default 9600). The red backgrounds will turn

white. Close the window. Both time indicators on the left of the window (Host

Status and Logger Status) will increment, indicating the DH-4 and PC are

communicating.

10. Go to the Modes pull-down menu and select Profile Logging.

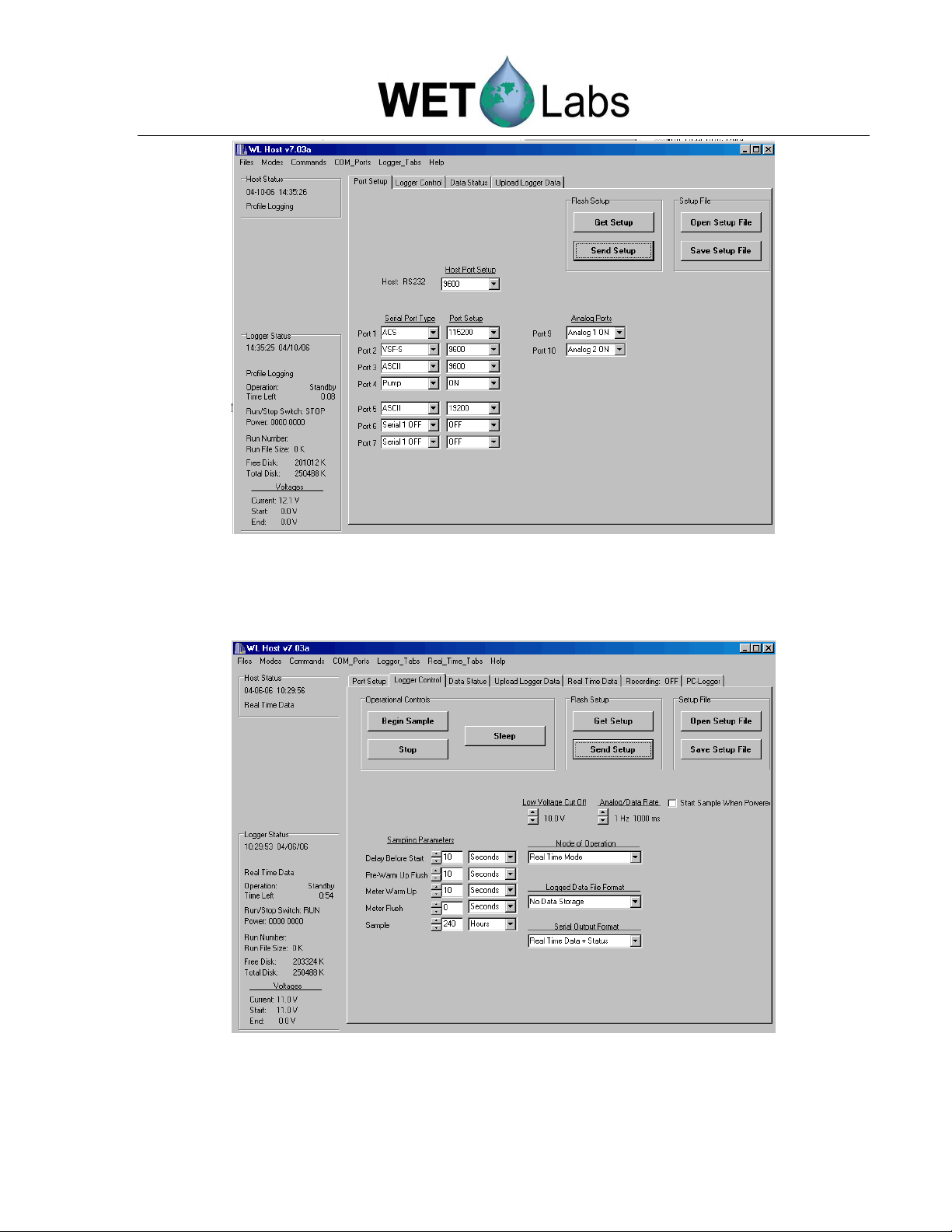

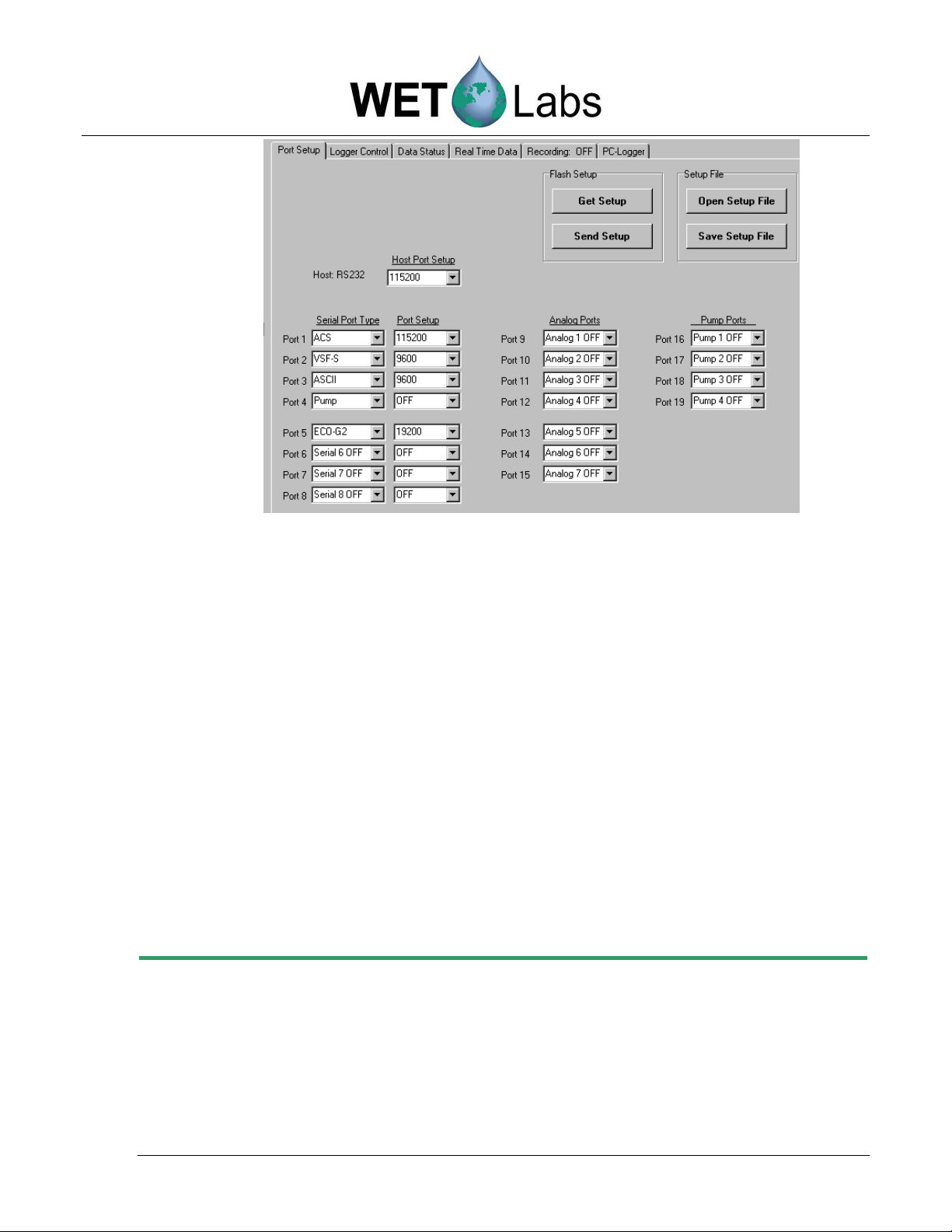

11. Go to the now-visible

Port Setup

tab and press

Get Setup

to load the logger’s settings

into the Host program.

12. Review the Serial Port Type, associated Port Setup baud rate, Analog Ports, and

Pump Ports settings. These settings can also be found on the Custom Configuration

Sheet that ships with your data logger. See Reference section 5.1 for details about

Port Setup options.

Note

For purposes of illustration in this user’s guide, WET Labs Host software runs the following:

Host Port: DH-4

Port 1: ac-s

Port 2: ECO VSFS, Volume Scattering Function Meter with Bio-wiper™

Port 3: CTD

Port 4: Pump

Port 5: ECO FLNTUS, fluorometer-turbidity sensor with Bio-wiper™

DH-4 Revision E5 19 June 2006 3

Page 12

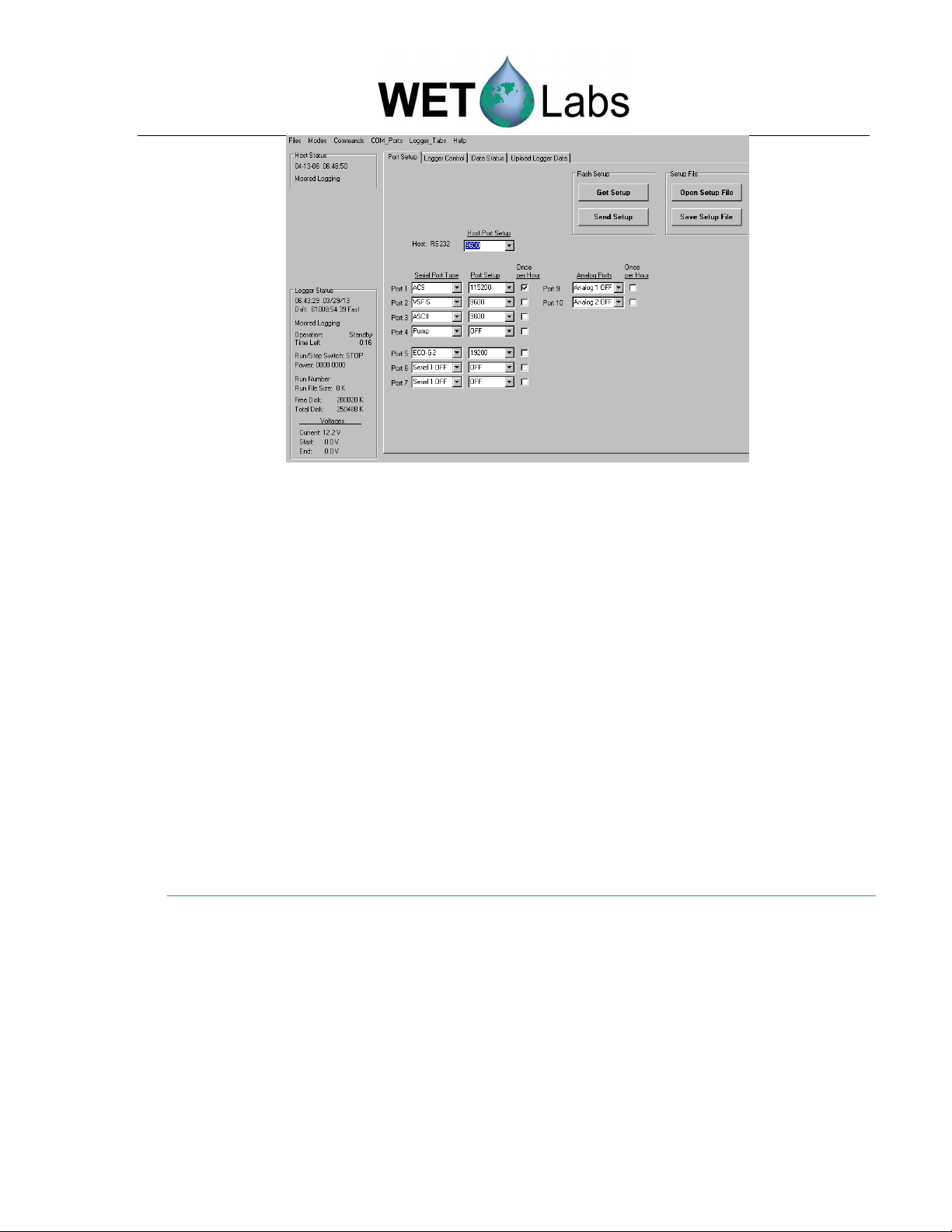

Port Setup tab settings

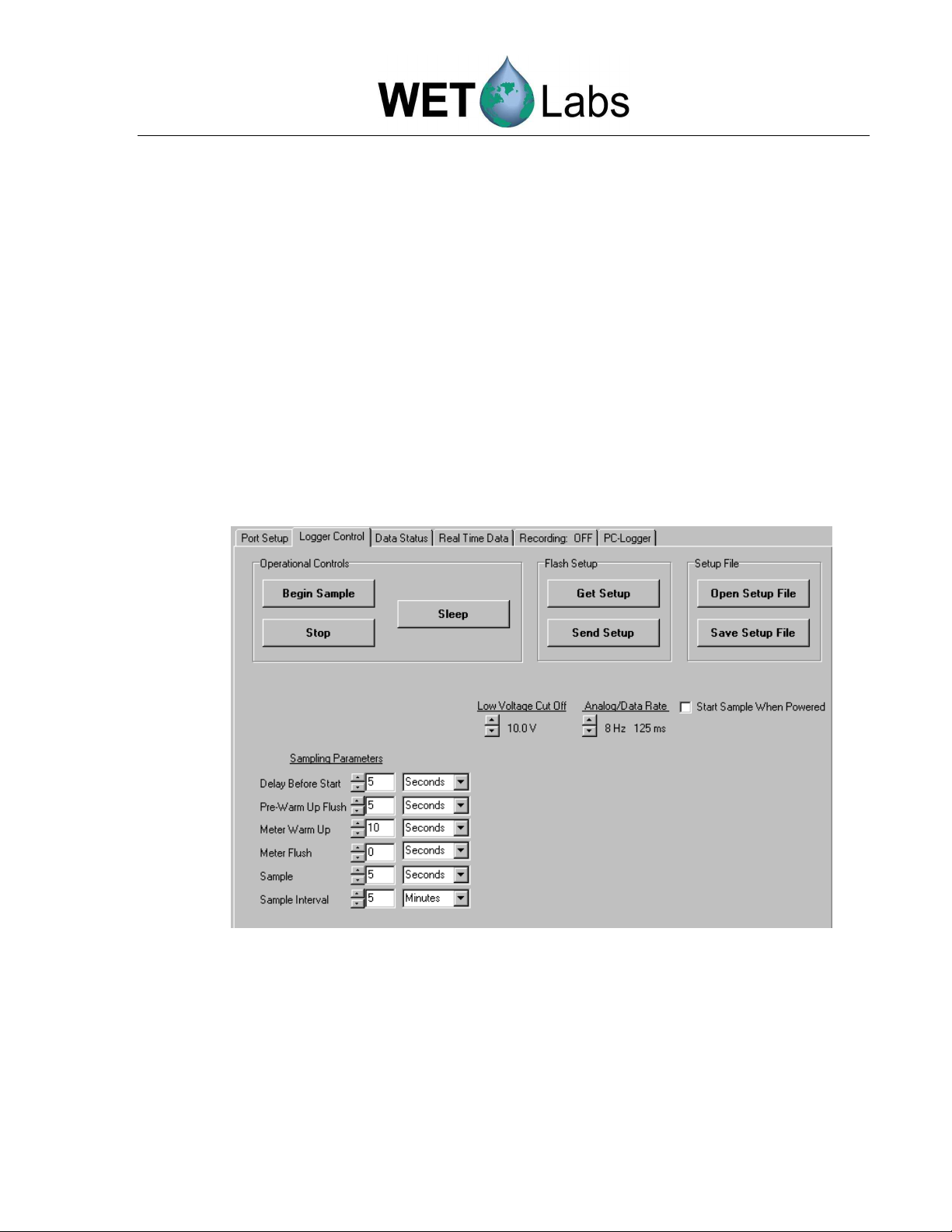

13. Select the Logger

Setup

tab to view the factory-set logger control settings. Refer

to section 5.2 for details on Logger Control configuration options.

Logger Control tab settings

14. To save these settings on the host computer: Select the Save Setup Files button

and in the resulting window, name the setup and click OK. This will allow you to

retrieve the factory settings in the future.

4 DH-4 Revision E5 19 June 2006

Page 13

•

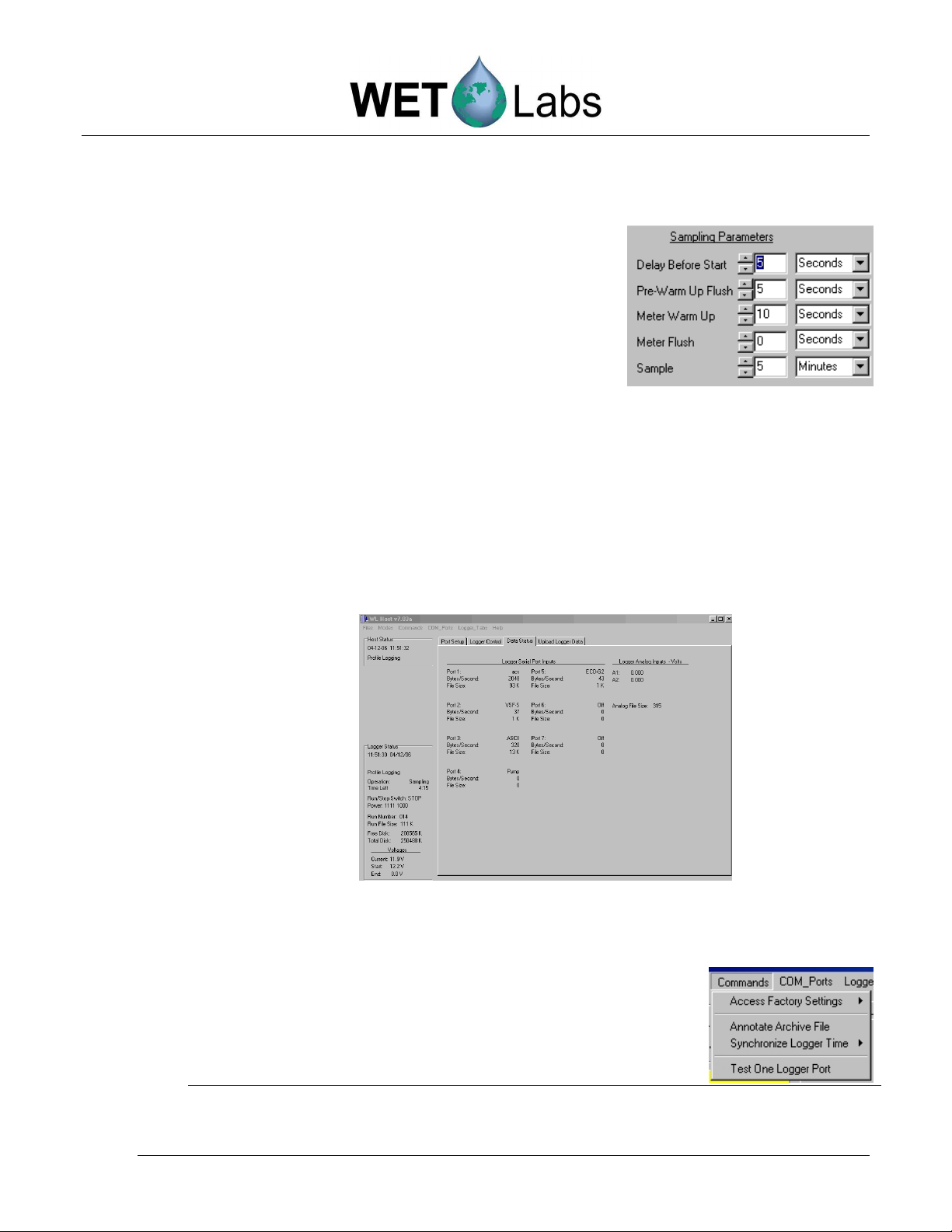

15. There are two options to verify that the meters connected to DH-4 are functional

and communicating. Option 1 allows checking multiple meters. Option 2 tests

one meter at a time, but also provides baud rate information.

Option 1: test multiple meters

In the Logger Control tab select Begin

Sample. Sampling begins with the program

cycling through the preset sampling

parameters. For example, there will be 5

seconds for Delay Before Start and Pre-

Warm Up Flush, and 10 for Meter WarmUp before the system begins active sampling

for 5 minutes.

Select the Data Status tab. The status of each port is displayed. Depending on

the operation the data logger is performing, either the Bytes/Second and/or the

File Size will increment. While the logger is performing a pre-sampling warmup or flush operation, only the bytes/second will increase. When sampling

begins, the file size will increment as well.

Return to the Logger Control tab and select Stop.

• Option 2: test a single meter

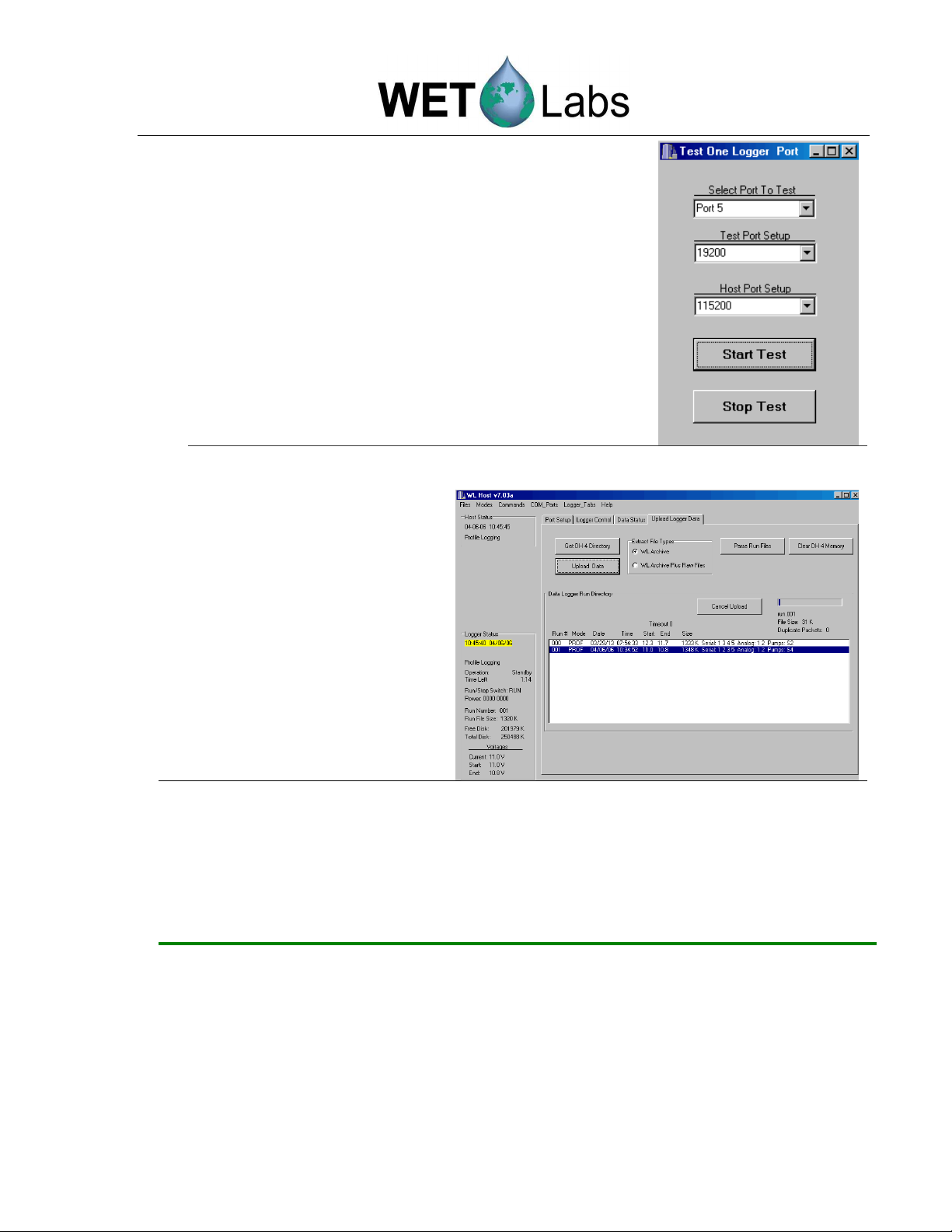

Select Commands/Test One Logger Port

DH-4 Revision E5 19 June 2006 5

Page 14

a. Select the data port (and thus instrument) you

wish to test.

b. Select the instrument’s baud rate.

c. Select the host computer’s baud rate.

d. Select Start Test. The Real_Time Data window

appears, showing scrolling data.

e. Select Stop Test when communication is

verified.

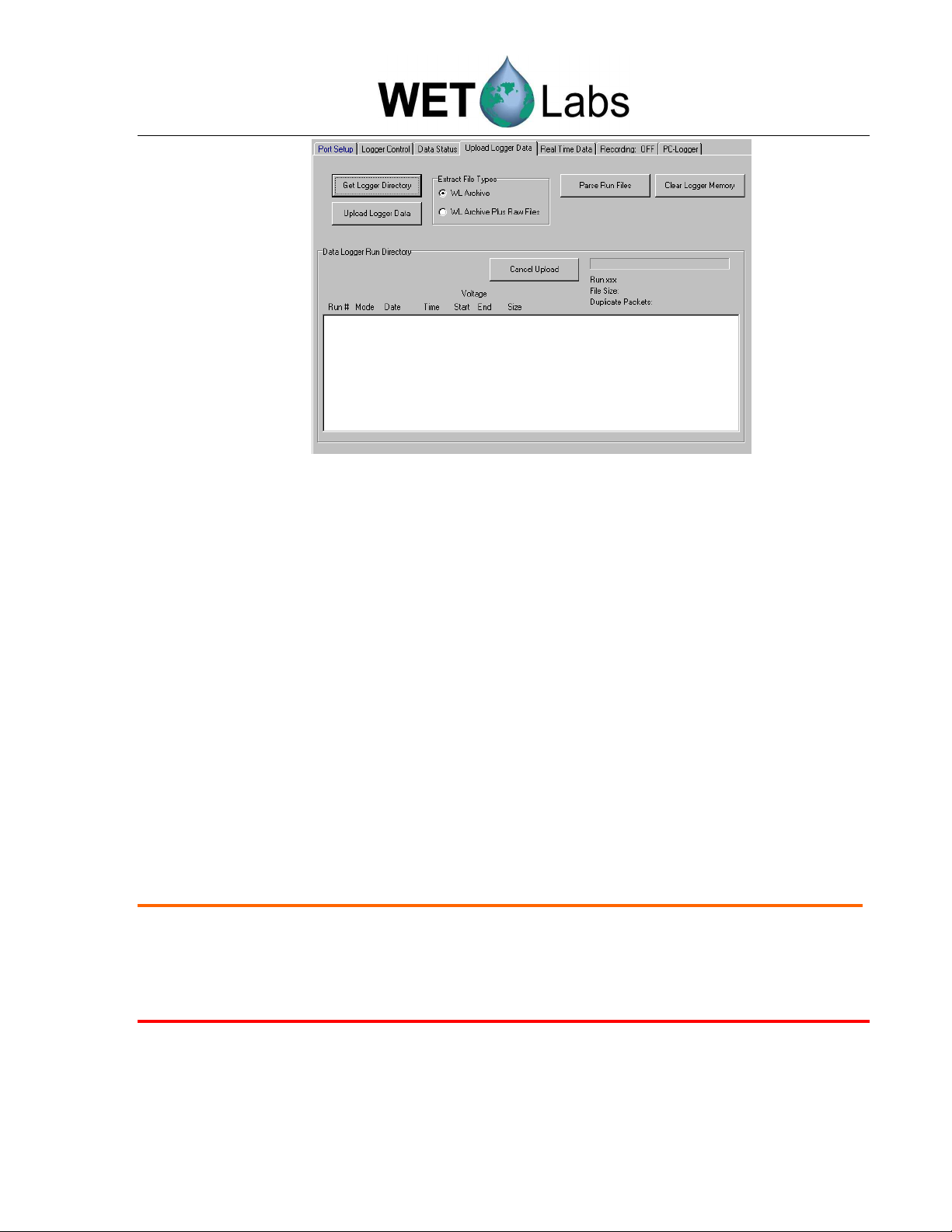

16. To upload and save the test

run from above, select the

Upload Logger Data tab,

then Get DH-4 Directory.

Select a Run # to upload,

then select Upload Logger

Data. Choose a location to

store the data. The upload

status bar indicates file size

and status of upload progress.

17. Select Clear DH-4 Memory to erase the data from the DH-4.

18. Exit the program by selecting Exit under the File menu.

Tip:

6 DH-4 Revision E5 19 June 2006

We highly recommend you experiment with changing and retrieving settings to get

a feel for the flexibility of the host software before deploying your system.

Page 15

2. Setting Operational Modes

WET Labs Host can operate in several modes. Which you choose, of course, depends on

your application. This section describes setup for the three most frequently used modes of

operation:

1. Profile Logging Mode—typically used to assess a column of water, with the logger and

other instruments moving vertically through the column.

2. Moored Logging Mode—typically used for stationary deployments. WET Labs host

provides settings options for low power, or “sleep” intervals, as well as flushing options.

Data is stored at the logger.

3. Real Time Output—similar to profiling, but no data is stored to the logger; it is sent

directly to a host PC. Selecting the appropriate settings to save data in WET Labs Host

are critical in this mode.

Less frequently used, and requiring an advanced understanding of WET Labs Host software:

• Analog Output—Transmits ASCII data from analog meters in real time.

• Advanced Logging/Output—Used only for custom instrument configurations, or

when a combination of modes is required.

DH-4 Revision E5 19 June 2006 7

Page 16

2.1 Profiling Mode

This subsection details the steps and selections to execute a profile for the example system

listed below:

•

Host Port: DH-4

•

Port 1: ac-s

•

Port 2: ECO VSFS, Volume Scattering Function Meter with Bio-wiper™

•

Port 3: CTD

•

Port 4: Pump

•

Port 5: ECO FLNTUS, fluorometer-turbidity sensor with Bio-wiper™

When possible, configuration settings specific to your system are set at the factory. The

Custom Configuration Sheet that ships with your DH-4 represents a hard-copy summary of

the DH-4’s flash settings as they appear in the host program’s setup windows.

2.1.1 Changing or Verifying Configuration Settings

Supply power to the DH-4. Start the host program. Select COM port and baud rate

(default: 9600). Select Profile Logging from the Modes menu.

Port Setup tab:

1. Load configuration settings using one of the options below:

• To retrieve the DH-4’s current configuration, select Get Setup.

• To load configuration settings saved to the host PC, select Open Setup

File, select the desired file, then select Send Setup to send those settings

to the DH-4.

• To load factory default settings, go to the Commands pull-down menu, then

Access Factory Settings > Load Default Flash Setup. These are also

available on the Custom Configuration Sheet that ships with your DH-4.

2. If necessary, change the settings under the Serial Port Type, Port Setup,

and Analog Port options. Note that Setup Not Current will appear on a

yellow banner on the status portion of the host program window if any

settings are changed.

8 DH-4 Revision E5 19 June 2006

Page 17

Tip

Sample Port Setup tab settings for profiling mode

Logger Control tab:

1. Check the Low Voltage Cut Off setting. Set to the highest value of the

minimum voltage requirement for all the meters being used. For example, if

you’re deploying an ac-9 (min. requirement 10.0 V), and an ECO fluorometer

(min. requirement 7.5 V), set the Low Voltage Cut Off to 10.0 V.

2. Check Analog/Data Rate setting. Set to the fastest meter’s data rate. For

example, if you’re deploying an ac-s (8 Hz), ac-9 (6 Hz), and an ECO

fluorometer (1 Hz), set the Sample Rate to 8 Hz.

If the logger is being used with meters whose total output is more than 1024 bytes of

data per sample, set the Analog/Data Rate higher than the meter data rate to prevent

data loss. For example, if the total output is 2500 bytes/second, set the logger to at

least 3 Hz.

Set the rate of data acquisition to the fastest

meter’s data rate.

ac-s meters:

ac-9 meters:

ECO meters:

Analog meters:

4 or 8 Hz

6 Hz

1 Hz

1 Hz

DH-4 Revision E5 19 June 2006 9

Page 18

If your system uses analog meters:

Each analog bulkhead on the DH-4 can optionally support two analog channels.

Therefore, each analog bulkhead has two analog definitions in the DH-4 host

program. (Analog 1 and Analog 2 correlate with analog bulkhead 1, Analog 3 and

Analog 4 correlates to analog bulkhead 2, etc.)

To use both channels on a given bulkhead, there must be a Y cable that originates

from the DH-4 bulkhead and terminates at each of the supported instruments. If a

Y cable is not available, each analog port will only support one analog device at

the odd numbered Analog ID (Analog Bulkhead 1 = Analog 1, Analog Bulkhead

2 = Analog 3, etc.)

3. When the desired settings are input: Select Send Setup to send the configuration

settings to the DH-4’s flash memory. To save the configuration settings to the host

computer, select Save Setup File.

4. To begin sampling, select the Begin Sample button.

Sample Logger Control tab settings for profiling mode

10 DH-4 Revision E5 19 June 2006

Page 19

2.1.2 Tracking Incoming Data

Select the Data Status tab to display the current data status of all meters. Refer to

Reference section 5.3 for details of what each status line represents.

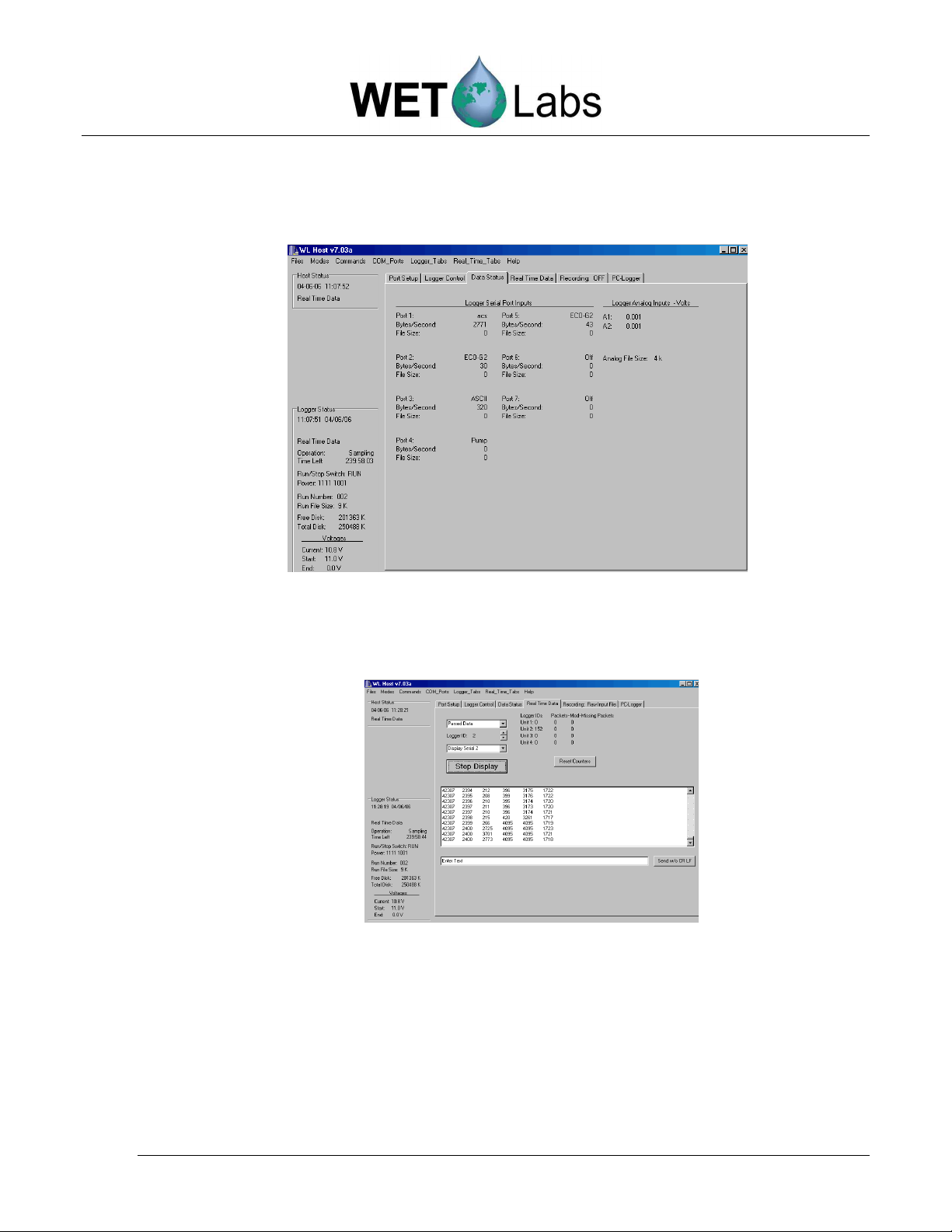

Viewing Data Status tab, profiling mode

To stop the sample, press Stop at the Logger Control tab.

2.1.3 Uploading Data

1. Go to the Port Setup tab and press Get Setup to ensure the most recent flash

settings are loaded.

2. Under the Logger Port Setup combo box, choose the fastest data rate that the host

cable and COM port can support. Three-meter cables can run at 115,200 baud.

3. Press Send Setup to send the baud rate change to the data logger. The logger will

change to the meter’s baud rate and the host program will follow suit. There will be a

brief pause as the logger and PC change their baud rates.

Occasionally, the logger and PC will lose track of each other while the baud rate

change is occurring. This will be indicated by a red background for baud rate. Press

Send Setup again. It may be necessary to toggle power to the data logger if resending the command doesn’t synchronize baud rates.

DH-4 Revision E5 19 June 2006 11

Page 20

Upload Logger Data in profiling mode

4. At the Upload Logger Data tab, select Get DH-4 Directory to retrieve all the DH-4

file information.

5. Select one or more of the runs that appear in the Data Logger Run Directory. In the

example above run 001 will be uploaded.

6. Select WL Archive from the combo box. This will create a data file that combines the

data from the selected files.

7. Select the runs to be uploaded, then select Upload Data to upload them. The status

section will update while uploading is occurring.

8. Selecting Cancel Upload will stop data upload. If multiple runs have been selected,

you will be prompted to cancel all uploads or individual run uploads.

2.1.4 Clearing DH-4 Memory

Caution!

Once “Clear DH-4 Memory” is pressed, the data is not retrievable.

WARNING!

Turning off the data logger while memory clearing is in progress

corrupted data logger file system.

To clear the DH-4 memory, select the Clear DH-4 Memory button in the Upload

Logger Data tab (above).

12 DH-4 Revision E5 19 June 2006

WILL

result in a

Page 21

2.2 Moored Mode

This subsection details the steps and selections to execute a moored operation for the

example system listed below:

• Host Port: DH-4

• Port 1: ac-s

• Port 2: ECO VSFS, Volume Scattering Function Meter with Bio-wiper™

• Port 3: CTD

• Port 4: Pump

• Port 5: ECO FLNTUS, fluorometer-turbidity sensor with Bio-wiper™

When possible, configuration settings specific to your system are set at the factory. The

Custom Configuration Sheet that ships with your DH-4 represents a hard-copy summary of

the DH-4’s flash settings as they appear in the host program setup windows.

2.2.1 Moored Logging Configuration Settings

Supply power to the DH-4; start the WET Labs Host program. Select COM port and baud

rate (default: 9600). Select Moored Logging from the Modes menu.

Port Setup tab:

1. Load configuration settings using one of the options below:

• To retrieve the DH-4’s current configuration, select Get Setup.

• To load configuration settings saved to the host PC, select Open Setup

File, select the desired file, then select Send Setup to send those settings

to the DH-4.

• To load factory default settings, go to the Commands pull-down menu,

then Access Factory Settings > Load Default Flash Setup. Note that

these are also available on the Custom Configuration Sheet that ships with

your DH-4.

2. If necessary, change the settings under the Serial Port Type, Port Setup, Analog

Port options. Note that Setup Not Current will appear on a yellow banner on the

status portion of the host program window if any settings are changed.

3. Check the Once Per Hour checkbox to allow instruments with a high current

draw to run only during the first sample period after the beginning (“top”) of

the hour. This allows you to obtain several samples per hour from instruments

with lower current draws without the power penalty of instruments with a high

current draw.

DH-4 Revision E5 19 June 2006 13

Page 22

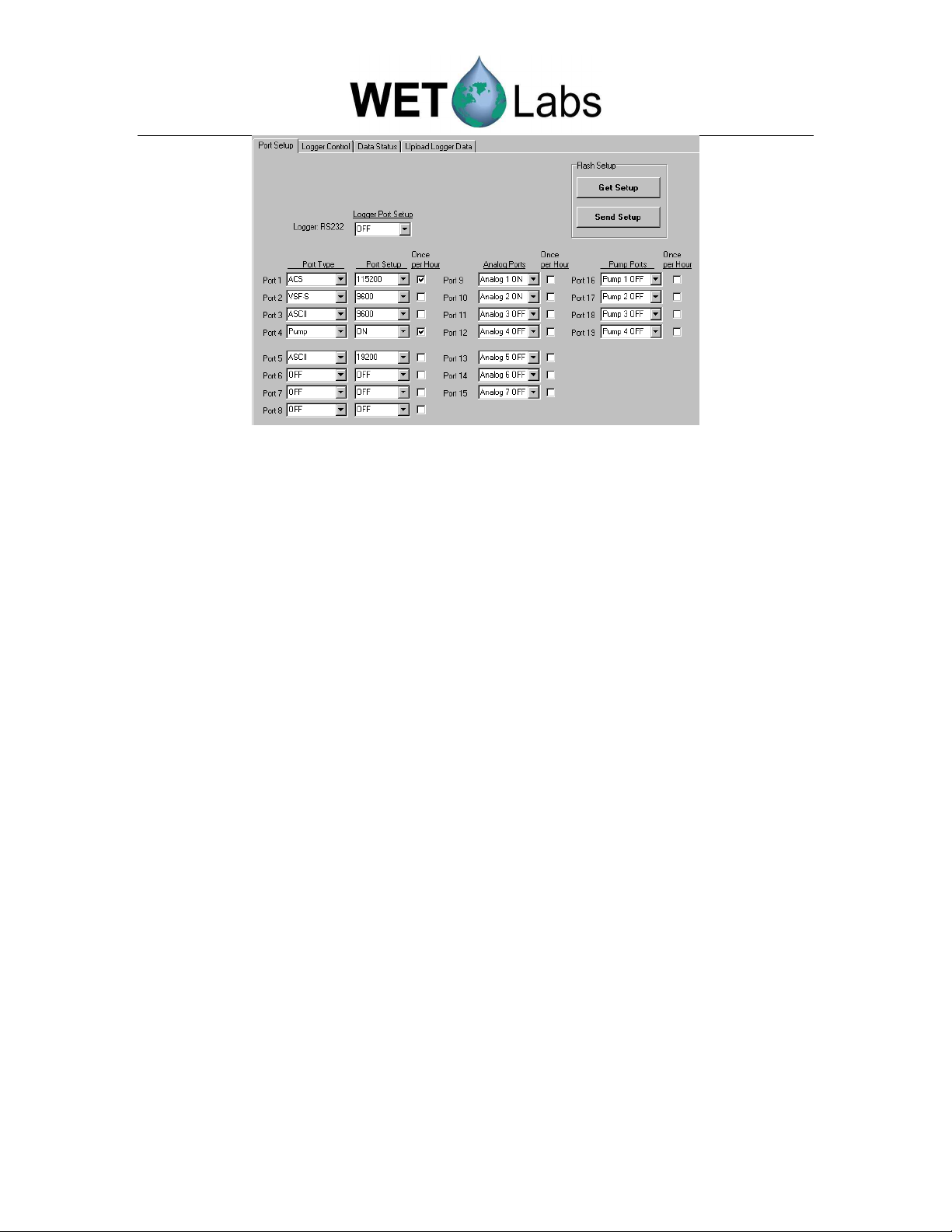

Sample Port Setup settings for moored mode

Logger Control tab:

1. Check the Low Voltage Cut Off setting. Set to the highest value of the

minimum voltage requirement for all the meters being used. For example, if

you’re deploying an ac-9 (min. requirement 10.0 V), and an ECO fluorometer

(min. requirement 7.5 V), set the Low Voltage Cut Off to 10.0 V.

2. Check Analog/Data Rate setting. Set to the fastest meter’s data rate. For

example, if you’re deploying an ac-s (4 or 8 Hz), ac-9 (6 Hz), and an ECO

fluorometer (1 Hz), set the Sample Rate to 8 Hz.

If the logger is being used with meters whose total output is more than 1024

bytes of data per sample, set the Analog/Data Rate higher than the meter data

rate to prevent data loss. For example, if the total output is 2500 bytes/second,

set the logger to at least 3 Hz.

Tip

Set the rate of data acquisition to the fastest

meter’s data rate.

ac-s meters:

ac-9 meters:

ECO meters:

Analog meters:

If your system uses analog meters:

Each analog bulkhead on the DH-4 can optionally support two analog channels.

Therefore, each analog bulkhead has two analog definitions in the DH-4 host

program. (Analog 1 and Analog 2 correlate with analog bulkhead 1, Analog 3 and

Analog 4 correlates to analog bulkhead 2, etc.)

To use both channels on a given bulkhead, there must be a Y cable that originates

from the DH-4 bulkhead and terminates at each of the supported instruments. If a

Y cable is not available, each analog port will only support one analog device at

the odd numbered Analog ID (Analog Bulkhead 1 = Analog 1, Analog Bulkhead

2 = Analog 3, etc.)

4 or 8 Hz

6 Hz

1 Hz

1 Hz

14 DH-4 Revision E5 19 June 2006

Page 23

3. Commands drop down menu:

Synchronize the DH-4 and

host PC clocks. Select

Synchronize Logger Time

then

Synchronize Time Now

,

.

Note

Turning on “Automatic Time Sync” will prevent you from seeing the DH-4 clock drift and should

not be used for moored applications.

4. When the desired settings are input: Select Send Setup to send the configuration

settings to the DH-4’s flash memory. To save the configuration settings to the host

computer, select Save Setup File.

5. To begin sampling, select the Begin Sample button.

Sample Logger Control settings for moored mode

DH-4 Revision E5 19 June 2006 15

Page 24

2.2.2 Tracking Incoming Data

Select the Data Status tab to display the current data status of all meters. See Reference

section 5.3 for details of what each status line represents.

Viewing Data Status tab in moored mode

To stop the sample, press Stop at the Logger Control tab.

2.2.3 Uploading Data

1. Go to the Port Setup tab and press Get Setup to ensure the most recent flash

settings have been loaded from the data logger.

2. Under the Logger Port Setup combo box, choose the fastest data rate that the host

cable and COM port can support. Three-meter cables can run at 115,200 baud.

3. Press Send Setup to send the baud rate change to the data logger. The logger will

change to the meter’s baud rate and the host program will follow suit. There will brief

pause as the logger and PC change their baud rates.

Occasionally, the logger and PC will lose track of each other while the baud rate

change is occurring. This will be indicated by a red background for baud rate. Press

Send Setup again. It may be necessary to toggle power to the data logger if re-sending

the command doesn’t synchronize baud rates.

4. At the Upload Logger Data tab press Get DH-4 Directory to retrieve all the DH-4

file information.

5. Select one or more of the runs that appear in the Data Logger Run Directory. In the

example below, runs 002 and 003 will be uploaded.

6. Select WL Archive from the combo box. This will create a data file that combines the

data from the selected files.

16 DH-4 Revision E5 19 June 2006

Page 25

7. Select the runs to be uploaded, then select Upload Data to upload them. The status

section will update while uploading is occurring.

8. Selecting Cancel Upload will stop data upload. If multiple runs have been selected,

you will be prompted to cancel all uploads or individual run uploads.

Sample Upload Data in moored mode

2.2.4 Clearing DH-4 Memory

Caution!

Once “Clear DH-4 Memory” is pressed, the data is not retrievable.

WARNING!

Turning off the DH-4 while memory clearing is in progress

WILL

To clear the DH-4 memory, select the Clear DH-4 Memory button in the Upload

Logger Data tab (above).

corrupt its file system.

DH-4 Revision E5 19 June 2006 17

Page 26

18 DH-4 Revision E5 19 June 2006

Page 27

2.3 Real-time Mode

Because data is not saved by either an individual instrument or the DH-4 in this mode, it is

critical to set up WET Labs Host software so that all data is sent to the host PC.

This subsection details the steps and selections to execute a real-time operation for the

example system listed below:

• Host Port: DH-4

• Port 1: ac-s

• Port 2: ECO VSFS, Volume Scattering Function Meter with Bio-wiper™

• Port 3: CTD

• Port 4: Pump

• Port 5: ECO FLNTUS, fluorometer-turbidity sensor with Bio-wiper™

When possible, configuration settings specific to your system are set at the factory. The

Custom Configuration Sheet that ships with your DH-4 represents a hard-copy summary of

the DH-4’s flash settings as they appear in the host program setup windows.

2.3.1 Setting Configurations

1. Supply power to the DH-4; start the WET Labs Host program.

2. Select COM port and baud rate (default is 9600).

3. Select Real Time Data from the Modes menu.

Port Setup tab:

1. Load configuration settings using one of the options below:

• To retrieve the DH-4’s current configuration, select Get Setup.

• To load configuration settings saved to the host PC, select Open Setup

File, select the desired file, then select Send Setup to send those settings

to the DH-4.

• To load factory default settings, go to the Commands pull-down menu,

then Access Factory Settings > Load Default Flash Setup. Note that

these are also available on the Custom Configuration Sheet that ships with

your DH-4.

2. Select Host Port Setup baud rate. Though the default is 9600, data in this mode is

coming through the DH-4 directly to the PC from each instrument. A much faster

data rate, such as 115200, is recommended to prevent a bottleneck or error messages.

3. If necessary, change the settings under the Serial Port Type, Port Setup, and

Analog Port options. Note that Setup Not Current will appear on a yellow banner

on the status portion of the host program window if any settings are changed.

DH-4 Revision E5 19 June 2006 19

Page 28

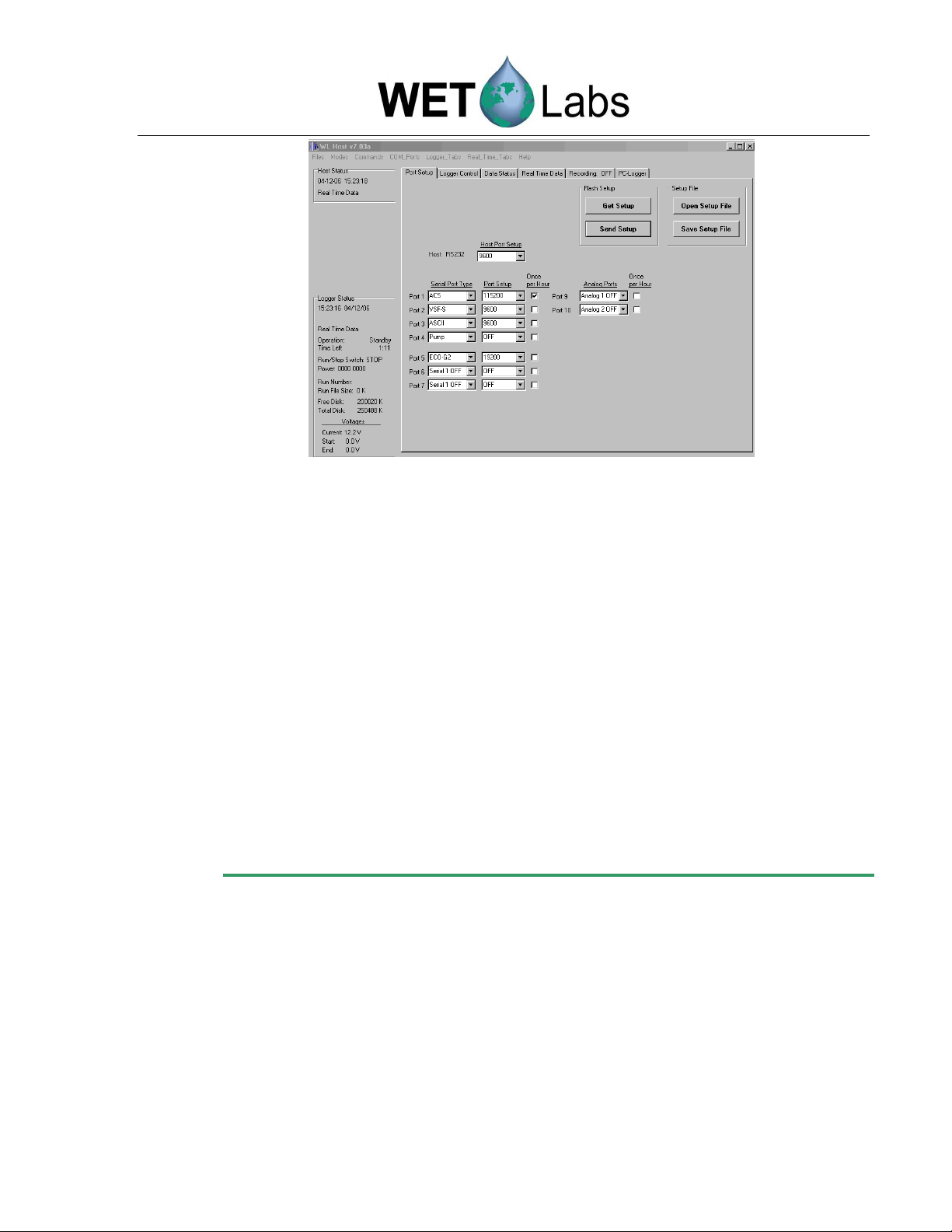

Port Setup for Real Time mode

Logger Control tab:

1. Check the Low Voltage Cut Off setting. Set to the highest value of the minimum

voltage requirement for all the meters being used. For example, if you’re deploying an

ac-9 (min. requirement 10.0 V), and an ECO fluorometer (min. requirement 7.5 V), set

the Low Voltage Cut Off to 10.0 V.

2. Check Analog/Data Rate setting. Set to the fastest meter’s data rate. For example, if

you’re deploying an ac-s (8 Hz), ac-9 (6 Hz), and an ECO fluorometer (1 Hz), set the

Sample Rate to 8 Hz.

If the logger is being used with meters whose total output is more than 1024 bytes of

data per sample, set the Analog/Data Rate higher than the meter data rate to prevent

data loss. For example, if the total output is 2500 bytes/second, set the logger to at

least 3 Hz.

Tip

Set the rate of data acquisition to

the fastest meter’s data rate.

ac-s meters:

ac-9 meters:

ECO meters:

Analog meters:

4 or 8 Hz

6 Hz

1 Hz

1 Hz

If your system uses analog meters:

Each analog bulkhead on the DH-4 can optionally support two analog channels.

Therefore, each analog bulkhead has two analog definitions in the DH-4 host

program. (Analog 1 and Analog 2 correlate with analog bulkhead 1, Analog 3 and

Analog 4 correlates to analog bulkhead 2, etc.)

To use both channels on a given bulkhead, there must be a Y cable that originates

from the DH-4 bulkhead and terminates at each of the supported instruments. If a

Y cable is not available, each analog port will only support one analog device at

the odd numbered Analog ID (Analog Bulkhead 1 = Analog 1, Analog Bulkhead

2 = Analog 3, etc.)

20 DH-4 Revision E5 19 June 2006

Page 29

5. When the desired settings are input: Select Send Setup to send the configuration

settings to the DH-4’s flash memory. To save the configuration settings to the host

computer, select Save Setup File.

Logger Control for Real Time mode

2.3.2 Saving Files in Real-time

1. Select the Recording: OFF/ON tab.

Recording: OFF/ON

2. Check Record Logger Data and Record PC-Logger boxes. All real time data

being received by the PC via the DH-4 will be recorded.

DH-4 Revision E5 19 June 2006 21

Page 30

3. Choose one of the three record buttons and enter a file name and location.

• Record Archive—Records an archive file until the Stop button is

pressed. To make the file name compatible with the file extraction

program WAP, use a single word file name without any spaces and a 3

digit file extension where the extension runs from 000-999.

This option is recommended for recording data while profiling.

Example:

CruiseOne.001 is acceptable.

CruiseOne.dat is not recommended.

Cruise One.001 is not acceptable.

• 1 Hour Archive Files—Creates a new archive file at the start of each

hour appending a 2 digit year, Julian date, and hour on the end of the file

name. To make the file name compatible with the file extraction program

WAP, use a single file name without any extensions. This option is

recommended for recording data during towed or flow-through operations.

Example: If the user enters the file name CruiseOne at 7:05 pm on

January 17, 2004, the host will create a file named CruiseOne04_17.019.

If the Host is still recording at 8:00 pm, the Host will close the existing file

and create a new file named CruiseOne04_17.020.

• 1 Day Archive Files—Creates a new archive file at the start of each new

day appending a 2 digit year and Julian date to the end of the file name.

This option is recommended for recording data during moored operations.

Example: If the user enters the file name CruiseOne on January 17, 2004,

the Host will create a file named CruiseOne04.017.

4. To begin sampling, select the Begin Sample button at the Logger

Control tab.

22 DH-4 Revision E5 19 June 2006

Page 31

2.3.3 Viewing Data

Select the Data Status tab to display the current status of all serial and analog meters.

Refer to section 5.3 for details of what each status line represents.

Sample Data Status for real-time mode

Incoming data can also be viewed in the Real Time Data tab, though with the exception

of ASCII data, it will appear as gibberish until extracted.

Real Time Data tab (incoming ASCII ECO data shown).

To stop the sample, press Stop at the Recording: OFF/ON tab. The data file will be

saved to the chosen location on the host PC.

DH-4 Revision E5 19 June 2006 23

Page 32

24 DH-4 Revision E5 19 June 2006

Page 33

3. Reference: Status Displays

This section describes the functions of the various buttons, selectable options, and status

indicators of the WET Labs Host Program and is designed to be used primarily as a reference

section. Functionally, the program is divided into tabs for logger setup and data collection, with

additional options available from the pull-down menus at the top of the screen. Note that

depending on the operational mode you’ve chosen, not all tabs will be visible.

The Setup Status banner in the upper left hand corner of the host program indicates whether the

parameters on the Port Setup and Logger Control tabs contain the same values that the logger

is currently using.

3.1 Setup Status

If a yellow Setup is Not Current banner is visible, the host may

not contain the same settings that the logger does. To get the

current logger settings, press the Get Setup button on either the

Port Setup or Logger Control tabs.

If the yellow status banner is not visible, the host and the logger have matching parameters

for the Port Setup and Logger Control settings.

3.2 Host Status

•

Time and Date: Displays the time and date of the host PC

and the data logger. The host program automatically updates

the time if the data logger is in standby mode and Automatic

Time Sync is turned on.

•

Mode: Displays the operating mode of the host: Moored

Logging, Profile Logging, Real Time Output, Analog

Output, Advanced Logging/Output.

•

Communication: Displays the Host COM port being used

and the baud rate. Note that if the COM has a red

background, the Logger is not communicating with the host.

If the baud rate background is red, it is incorrect.

3.3 Logger Port Setup

•

COM port selector: Determines from

which COM port the host computer

can communicate with the Logger.

•

Baud rate selector: Determines at

which baud rate the host and logger

communicate.

DH-4 Revision E5 19 June 2006 25

Page 34

3.4 Logger Status

•

Time and date coming from the DH-4. Can be synchronized

with the host PC.

• Operational mode indicator. Matches the Host Status

operation indicator as long as setup is current.

•

Operation:

Shows the operation the DH-4 is currently

performing:

Stand By—Waiting for a command.

Delay—A delay at the start of a data collection sequence before

the meter warm up.

Pre-flush—System pumps flush meters prior to warm-up. Data is

not stored.

Warm Up—Selected meters are powered to reach a stable

operating temperature. Data is not stored. The auxiliary pump is

not in operation.

Flush—Selected meters are powered, and the auxiliary pump is

powered to flush out the meter passages. Data is not stored.

Sample—The data collection segment of the sample sequence.

All selected meters and pumps will be on. Data will be logged if

logging has been selected. Data will be transmitted if Real Time

Data has been selected.

•

Time Left:

Shows the actual time remaining in each operation described above. During

Standby, this is elapsed time since the standby operation began.

•

Run/Stop Switch:

Optional magnetic actuator switch that controls logic. Note that if

power is applied to the logger it will become fully active regardless of the switch’s

position. Status indicators:

RUN—actuator plug inserted. Logger will begin sampling.

STOP—actuator plug removed. DH-4 will terminate the current sample.

Disabled—DH-4 is ready to receive commands.

•

Power:

debug display.

•

Run File Size:

•

Free Disk:

Indicates which relays 1–8 have been turned on. This is primarily a factory

Indicates the current file size of collected data.

Indicates the amount of flash disk space in Kbytes that is unused. The data

logger can use all but the last 200 Kbytes of this flash disk for data storage.

•

Total Disk:

Indicates the total flash disk size in Kbytes. This shows the used and unused

space. All but the last 200 Kb of the flash disk are available for data storage.

•

Voltage:

Current

Start—

End—

—displays existing voltage and is updated once per second.

displays the voltage at the start of the most recent sample.

displays the voltage when the last sample was ended.

26 DH-4 Revision E5 19 June 2006

Page 35

If the modes under the Host Status and the Logger Status are

not the same, the yellow Setup is Not Current banner will be

visible. Press Send Setup to change the loaded status to the

Host Status. Press Get Setup to retrieve the Logger status.

For example, selecting Send Setup will change logger status

to moored. Selecting Get Setup will change the host to Real

Time.

DH-4 Revision E5 19 June 2006 27

Page 36

28 DH-4 Revision E5 19 June 2006

Page 37

4. Reference: Pull-down Menus

The five pull-down menus in WET Labs Host are shown below.

4.1 Files

Open Host Setup File: Opens a saved WL Host

setup file.

Save Host Setup File: Saves a WL Host program

setup configuration. (Particularly useful for saving

settings for both moored and profiling operation.)

File will be saved in the directory the host program

is installed in.

Exit: Closes the host program, automatically saving

the existing (currently selected) configurations in a

file named last.wlh.

4.2 Modes

Moored Logging: for use with moored applications.

Profile Logging: for use with profiling applications.

Real-time Output: for use when no data will be stored on the

logger, but rather sent directly to a host PC in real time.

Analog Output: use to sample and transmit ASCII data from

a set of analog meters in real time. If any digital/serial meters

are to be used, use Real Time Mode.

Advanced User: Use for deployments where a combination

of moored and profile settings are desired.

PC-Logger: for use when data will be sent to the host PC

instead of the data logger.

4.3 Commands

When Moored or Profile modes are selected, the options at

right are available.

DH-4 Revision E5 19 June 2006 29

Page 38

When Real Time and Advanced User modes are selected,

the options shown at right are available.

When Analog Output mode is selected, the options at right

are available.

4.3.1 Access Factory Settings >

The options under this submenu are primarily used for WET Labs personnel for

troubleshooting or de-bugging and should be disregarded.

•

Reset to Monitor

: Exits the host program and allows the user to access low

level functions.

•

Change Logger ID

: Allows changing the default data logger at port 2 to

another port number.

•

Show Analog Calibration

: View calibration settings for analog

instruments. This window can also be used for troubleshooting with WET

Labs personnel.

•

Show Hardware Configuration

: View hardware configurations for all

instruments.

•

Load Default Flash Setup

: Resets the DH-4 configuration settings to those

shipped from the factory.

•

Write Debug File, Add Pad

: Used by WET Labs personnel for debugging.

4.3.2 Annotate Archive File

This allows you to add notes about a given run. These are

inserted into the archive file as ASCII text in logger ID 1,

Port 9. Enter the text to be stored in the Annotate Here box.

Select Insert Annotation to add user-entered text to the

archive file.

Select Start Water Sample to input the time and date the

water sample started.

Select End Water Sample to input the end time.

Water sample annotations may also be incremented or

decremented by clicking on the up arrows next to Next

Water Sample.

Select Reset Sample Count to return the count to 1.

30 DH-4 Revision E5 19 June 2006

Page 39

Note

4.3.3 Synchronize Logger Time >

Automatic Time Sync will constantly update the

data logger’s time while it’s connected to a host

and not sampling and should be used to keep the

logger and the host PC clocks synchronized.

Synchronize Time Now will synchronize the

data logger to the current host PC time.

Turning on Automatic Time Sync will prevent you from seeing the logger clock drift and

should not be used in Moored Mode.

4.3.4 Test One Logger Port

Allows you to test that a meter is properly connected and

communicating with the host. Serial ports 1–8 or analog ports

may be tested at a user-selected baud rate.

To test a port:

1. Select the data port (and thus instrument) you wish to test.

2. Select the instrument’s baud rate.

3. Select the host computer’s baud rate.

4. Select Start Test. The Real_Time window appears,

showing scrolling data.

5. Select Stop Test when communication is verified.

DH-4 Revision E5 19 June 2006 31

Page 40

4.4 Logger_Port

Show/Hide Logger Port Setup

Displays or minimizes the Logger Port Setup in the status

area of WL Host.

Show Logger Port Statistics

Troubleshooting, debugging screen for factory use.

Auto Baud Rate Detection

If checked, the Host software automatically checks that the

Host PC and DH-4 baud rate match.

32 DH-4 Revision E5 19 June 2006

Page 41

DH-4 Revision E5 19 June 2006 33

Page 42

Page 43

5. Reference: Window Tabs

There are seven tabs associated with all aspects of operating the data logger for various

types of deployments. Note that depending on the operating mode you’ve chosen, not all

tabs will be available.

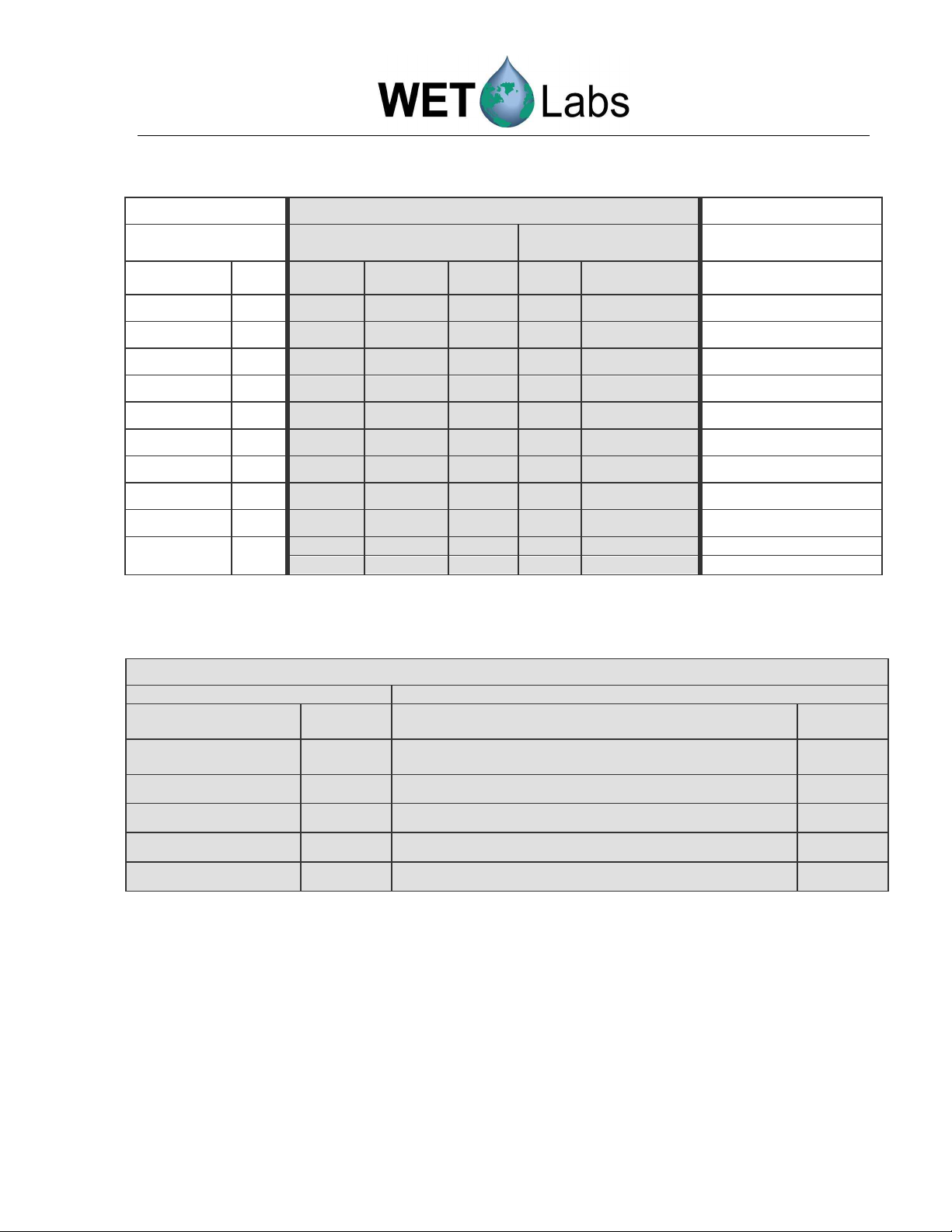

Visible tabs for each operating mode:

Moored Logging

Profile Logging

Real Time Output

Analog Output

Advanced User

5.1 Port Setup

5.1.1 Logger Port Setup

Selectable baud rate for the host port-to-DH-4 connection. Default is 9600.

DH-4 Revision E5 19 June 2006 35

Page 44

5.1.2 Port Type

Refer to the data logger-specific configuration sheet to identify which bulkhead

connector is associated with each serial port for your specific data logger. Except

where noted, all serial ports are powered during the warm up, flush, and sample

segments of a run. Serial ports may be powered during pre-flush if the port is

selected as a pump.

OFF

—The port will not be powered, nor will any data be accepted from this port

during data sampling.

AC9

—Any data is accepted by this port. The port will be turned off if the voltage

drops below 10.0V. Baud rate: 19200.

AC-S

—Any data is accepted by this port. This port will be turned off if the voltage

drops below 9.5 V. This allows a sample to continue while protecting the ac-s from

damage. Baud rate: 115200.

ASCII

—ASCII data that is terminated with <Carriage Return><Line Feed> (CR

LF) will be accepted by this serial port. Baud rates: 600–115200.

Binary

—All data will be accepted by this serial port. The serial port type has no

restrictions on the format of the data that it receives, making it a good initial

selection when setting up new meters. Baud rates: 600–115200.

ECO-G2

—This port will accept <CRLF>-terminated data and recognizes the

“close shuttered shutdown” command used by the 2nd generation ECO meters.

This allows the meter to close its bio-wiper before the DH-4 removes power

during moored deployments. Baud rate: 19200.

GPS

—Accepts NMEA-0183 data format GPRMC. Baud rate: 4800.

Pump

—This port will provide power for pump operation during the flush and

sample segments of the data collection. If pre-flush is selected, this port will be

powered throughout the sample sequence, including pre-flush and warm-up. No

data will be processed from this port.

Remote Host

—This port provides power and data to telemetry equipment. When

the DH-4 is either in standby or sample mode, the DH-4 will power this port and

transmit data out the port.

SBE 37-SM

—The data logger will query the SBE-37SM every 4 seconds, at

which point the SBE’s data will be retrieved. The SBE 37-SM must be logging

data and be “sleeping” between samples. Baud rate: 9600.

VSF-S

—This type will accept ASCII data from the first generation of ECO

meters such as the VSF and DFL. Additionally, at the end of the sample segment

the ECO-G1 “close shutter” command will be sent to the meter. Baud Rate: 9600.

36 DH-4 Revision E5 19 June 2006

Page 45

WL-Test

Wake/Binary

—Used by WET Labs personnel and not available to the user.

—At the warm-up cycle, the logger will send a 500 ms “break”

command to “wake” meters that are self-powered (internal batteries). The logger

reads all data.

5.1.3 Port Setup

Under the Port Setup column, select the required baud rate for use with the

meter selected under the Serial Port Type. All ports setups will have setups of 8

data bits, no parity bits, and 1 stop bit with the exceptions of “4800,7,E,1” and

“9600,7,E,1,” which will have setups of 7 data bits, an even parity bit, and 1 stop

bit.

5.1.4 Once Per Hour (Moored Mode)

This option is used during moored deployments so that instruments with a high

current draw will run only during the first sample period after the beginning

(“top”) of the hour. This allows the user to obtain several samples per hour from

instruments with lower current draws, without the power penalty of the instrument

with high current draw. This checkbox is only available under the Moored

Logging operation mode.

DH-4 Revision E5 19 June 2006 37

Page 46

5.1.5 Analog Ports

The data logger has the capability of accepting data from up to seven analog

instruments depending on the configuration of the data logger (see your

instrument-specific configuration sheet).

Note that each analog bulkhead on the DH-4 has the optional capability of

supporting two analog channels. Therefore, each analog bulkhead has two analog

definitions in the DH-4 host program. (i.e. Analog 1 and Analog 2 correlate with

analog bulkhead 1, Analog 3 and Analog 4 correlates to analog bulkhead 2, etc.).

To use both channels on a given bulkhead, there must be a Y cable that originates

from the DH-4 bulkhead and terminates at each of the supported instruments. If a

Y cable is not available, each analog port will only support one analog device at

the odd numbered Analog ID (i.e. Analog Bulkhead 1 = Analog 1, Analog

Bulkhead 2 = Analog 3, etc.).

Analog port options:

Off

—This port will not be powered, nor will any data be accepted from this port

during sampling.

Analog On

—This port will be powered and will accept an analog input during

the data collection. Unless otherwise noted in the data logger’s User’s Guide, the

input range is 0–5 V.

Pump On

—This port will provide power to a pump during the flush and sample

segments of data collection. This port will not process any data during the run.

5.1.6 Pump Ports

The data logger can accept data from up to four pumps, depending on the

configuration of the data logger. Refer to the Custom Configuration Sheet that

ships with each DH-4 to identify which bulkhead connector is associated with

each pump port for your specific data logger.

Pump port options:

38 DH-4 Revision E5 19 June 2006

Page 47

Off

—This port will not be powered, nor will any data be accepted from this port

during sampling.

Pump On

—This port will provide power to a pump during the flush and sample

segments of data collection. This port will not process any data during the run.

DH-4 Revision E5 19 June 2006 39

Page 48

5.1.7 Flash Setup

Get Setup will retrieve the setup currently stored on

the data logger. All the setup parameters will be filled

in, and the Setup Status Banner will indicate that the

setup is current.

Send Setup will send the currently displayed setup

to the data logger. The logger will read the setup and

echo the setup back to the host program. The host will

then set the status banner to indicate the setup is

current.

It is not necessary to press Send Setup for each setup parameter that is

changed. Change all the setup fields to match the desired data logger setup, and

then press the Send Setup button.

Caution

Pressing the Send Setup button will cause any currently running data collection

operation to terminate.

Save Setup File stores settings on the host PC.

Open Setup File retrieves configuration settings that

have been saved to the host PC using Save Setup

File.

Tip

Get and Send Setup send configuration settings to the DH-4’s flash

memory; Open and Save WL Host Setup File save settings to the host

PC.

To ensure the desired settings are saved, use Save WL Host Setup File to

save settings to the host PC, then open the saved file using the Open WL

Host Setup File. Select Send Setup to copy the file from the PC to the

DH-4.

40 DH-4 Revision E5 19 June 2006

Page 49

(Moored Mode only)

5.2 Logger Control

The Logger Control tab shown below has all of the options available for Advanced

User Mode. Note that not all options apply to all modes of operation.

5.2.1 Operational Controls

Begin Sample

will start the sequence setup currently stored in the data logger.

Note that if you have changed settings, you must press Send Settings to load the

new settings into the logger. Use the Get Setup and Send Setup buttons to

verify the desired setup is in the data logger.

Stop

: Press to halt operations on the data logger and enter a stand-by mode.

Sleep

:

Causes a pop-up menu to

appear with the option to Sleep Until—Sleep until the

specified date and time and then start the sample sequence.

DH-4 Revision E5 19 June 2006 41

Page 50

5.2.2 Flash Setup and Setup File Buttons

Refer to section 5.1.6 for description of these controls.

5.2.3 Low Voltage Cut Off

Sampling will stop if the input voltage to the data logger drops below the

specified voltage. This is selectable from 6.5 to 14.0 volts.

Note that if your system includes an ac meter and you select either ACS or AC9

from the Serial Port Type in the Port Setup tab, the port will automatically turn

off if voltage falls below 9.5.

5.2.4 Analog/Data Rate

Determines the speed at which analog data is transmitted and also selects the time

interval for serial data packets. The selectable range is from 1 to 10 Hz, which

equals sample intervals of 1000–100ms.

Tip

Set the rate of data acquisition to the

fastest meter’s data rate.

ac-s meters:

ac-9 meters:

ECO meters:

Analog meters:

4 or 8 Hz

6 Hz

1 Hz

1 Hz

5.2.5 Start Sample When Powered

When Start Sample When Powered is checked,

The meter will proceed immediately to Delay

Before Sample when power is applied to the data

logger. It is not necessary to select Begin Sample.

When a DH-4 is powered up and Start Sample

When Powered was selected when the DH4 was

turned off, the DH-4 will automatically start the

programmed sample sequence after a four-second

delay.

If the logger is being used with meters that output more than 1024 bytes of data

per sample, set the Analog/Data Rate higher than the meter’s sample rate to

prevent data loss. For example, if a meter outputs 2500 bytes/second and samples

at 1 Hz, set the logger to at least 3 Hz.

5.2.6 Sampling Parameters

Delay Before Start

—An estimate of the amount of time required to remove

the host cable and replace it with a dummy plug, and place the instrument

suite in position for a drop. Enter a time longer than the deployment of the

data logger assembly is expected to take, or the data logger may start the

meter and pump for data collection while the data logger assembly is still on

the deck, or in the air. Selectable in seconds, minutes, hours from 0–60.

42 DH-4 Revision E5 19 June 2006

Page 51

Pre-Warm Up Flush

—Useful for moored applications, where it may be

desirable to set a longer flush cycle prior to meter warm-up.

Meter Warm Up

—The amount of time the selected meters will be powered

prior to meter flush time. This time is used to allow the instruments to

stabilize electronically. During this time period the meter(s) are powered, but

the pumps are not powered, and data from the meters is collected and

displayed, but not stored. A warm-up time of 2–3 minutes is recommended.

Valid warm up times range from 0–10 minutes. The total warm up time for

the meters is the sum of the warm up time and the flush time. Selectable in

seconds, minutes, hours from 0–60.

Meter Flush

—The amount of time desired to flush the selected meters sample

tubes of air bubbles and debris. During this time period, both the selected

meters and the auxiliary pumps are powered, and data is collected but not

stored. A time period of 10–30 seconds is recommended. Selectable flush

times are 0–120 seconds.

Sample

—The length of time required for the data sample profile or periodic

moored sample. During this time period, the data logger will power selected

meters, the auxiliary pumps, and will collect and store data from the meters.

Selectable in seconds, minutes, hours from 0–300.

Sample Interval

(moored mode only)—The interval of time between

samples. Selectable in seconds, minutes, hours.

WET Labs meters have minimal warm up times that the data logger will

adhere to.

All ac-9 and SAFire meters are given a minimum warm up time of 10

seconds. If the sum of the warm up and flush times does not equal or exceed

10 seconds, the warm up time will be increased until 10 seconds is reached.

When a setup is sent to the data logger, it will review the meter types, select

the longest warm up time required, and apply that warm up time to the setup.

This means the user setting may be overridden.

Caution

The data logger does not receive the profile parameters until the Send Setup

button is selected. You must press the Send Setup button to change the data

logger profile parameters or the last saved profile parameters will be used.

Caution

Selecting the Send Setup button will cause the data logger to halt any current

operation.

DH-4 Revision E5 19 June 2006 43

Page 52

5.2.7 Mode of Operation

The data logger has five operating modes that are

accessible from the Advanced User mode

(right).

The last known mode the data logger was using

will be shown under Mode of Operation.

Profile Mode

Profile Mode is used to determine the “profile” of the water column. While

profiling, the data logger will perform one data collection cycle (delay before

start, pre-warm-up flush, warm-up, flush, and sample), and then stand by for

further commands from the host.

Moored Mode

To determine variances in the ocean environment at a single location over a

long period of time, the data logger is placed in moored mode. While

moored, the data logger will perform one data collection cycle (as in the

profile mode), then go into a low power “sleep” for a preprogrammed period

of time. When the period of time has expired, it will perform a second cycle

(starting with warm up), and then return to a low power sleep. This cycle will

be repeated until

•

battery supply is exhausted,

•

onboard data storage is filled, or

•

the data logger is retrieved and power is removed.

Real Time Mode

Real-time data logging is used to sample an area of water while the data logger

and associated instruments are towed. As the name implies, data is not logged, but

sent directly to a host PC. The instruments sample either continuously or

intermittently depending on the preprogrammed setup.

Analog Mode

Selecting Power Analog Ports will power all the analog ports that have

been selected on the Logger Setup tab after a minimum 5-second delay. An

ASCII data stream will be output from the data logger, but the data will not

be recorded.

Run Logger Port #

(Serial #1 through 8)

Selecting one of these options will power only the instrument selected after a

minimum 5-second delay. Data will be output but not recorded. Using these

options will reset the operational setup for the Host.

Polled Moored Mode

44 DH-4 Revision E5 19 June 2006

Page 53

Selecting this mode allows an external controller (PC, other programmable

controller, or WL Host program) to interactively control the DH-4 while

collecting a single data file over an extended period of time. This is useful

when the desired sampling routine is subject to change because of external

influences such as tides, available power, storms, etc.

5.2.8 Logged Data File Format

The data logger has two data collection options that

are available from the Advanced User mode.

If

No Data Storage

is selected, data will be collected, but not stored. This

allows the user to collect data for a length of time that exceeds the on-board

memory capacity. This is useful if collecting data via a sea cable or larger

capacity data logger, such as ac-9 Plus.

If

WL Archive Files

is selected, the data will be collected in 100 ms packets and

stored in the standard WET Labs Archive File format. These files contain timing

information that allows the WET Labs Archive Processing program (WAP) to

merge the data in a time coherent manner. See Appendix B for a description of the

WL Archive file format.

Please note: the timing information in the WET Labs Archive File format

contains a significant amount of overhead that can consume a large amount of the

data logger’s flash disk. This is particularly true of slow baud rate instruments that

have a small record spread out over a larger period of time. For example, while

collecting data from a CTD meter running at 1200 baud, the data logger may end

up adding 20 bytes of overhead to just 10 bytes of data collected over the 100 ms

time interval. The file will contain more timing information than data. The

overhead usage on fast, “burst-mode” instruments is not as significant, as few

hundred bytes of data may be collected in the 100 ms interval. In this case, the

overhead may be reduced to only 10–20 percent of the data file. For more

information on this option, refer to the WET Labs Archive File Processing User’s

Guide.

5.2.9 Logger Output Format

There are several options for data output for the data

logger (right). Under all options, the normal data

logger status will be transmitted until the sample

segment is reached. When the sample segment is

reached the output format and host baud rate may

change according to the output format option

selected.

DH-4 Revision E5 19 June 2006 45

Page 54

46 DH-4 Revision E5 19 June 2006

Page 55

Status

: Shows the overall data logger system operation in a binary format,

suitable for display using the data logger Host program.

Real Time Data + Status

Real Time Data

Analog Data:

: Outputs all the real time data.

The host port baud rate will be unchanged and an ASCII record

: Outputs all the real time data and the logger status.

with all the analog measurements will be transmitted.

Output Serial X

(Serial 1–8)

Data

: Outputs the data from the selected port

during

the sample. The host port baud rate will be changed to match the baud rate of the

serial port selected.

Regardless of the output selected, the data from all the instruments selected will

be recorded in the format specified in Logged Data File Format box.

5.3 Data Status

The Data Status tab provides real-time status information about each of the ports as

sampling progresses.

The following information is available for Ports 1–8 under Logger Port Inputs:

1. Port ID#: Port is OFF, or shows the port type selected.

2. Bytes/Second: the number of bytes received in one second. Increments during

pre-sampling and active sampling.

3. File Size: Shows the size of the data file actively being generated by the meter.

This is only correct if the Host is left connected to the data logger during data

collection.

The Logger Analog Inputs—Volts provides a real-time view of analog data being

sent to the data logger. Data is stored as a time-stamped ASCII file in table format.

DH-4 Revision E5 19 June 2006 47

Page 56

Analog File Size: Shows the approximate amount of memory used for analog data.

5.4 Upload Logger Data

The Upload Logger Data tab allows you to extract sampling data from the data

logger or to upload (save) and extract data from the data logger.

Selecting

Get Logger Directory

will retrieve the run directory from

which you may select one or more runs to upload. This can ONLY be

performed with the data logger in standby mode.

Selecting

Upload Logger Data

will result in a window that allows you to

name and save the file to which data will be saved.

Each data logger run directory contains the information listed below.

Run #

Mode

(of operation)

Date

Time

Start/End

Size

Serial

Analog

000 to 999.

Either Prof (Profiling) or MOOR (Moored)

The date the run was started.

The time of day the run was started.

The measured supplied voltage at the start and end of the run.

Total file size including all the data files and file overhead.

The serial port numbers (1–8) of any serial port that was active during the run.

The analog port number (1–7) of any analog port that was active during the run.

48 DH-4 Revision E5 19 June 2006

Page 57

Pumps

The pump port number (1–4) of any pump port that was power during the run.

Extract WL Archive Files

creates a file that combines the data

from the files selected to view together.

Extract WL Archive Plus Raw Files

will create individual files

for each meter, as well as creating the archive file. The

individual files do not contain any timing information.

Cancel Upload

will stop data upload. If multiple runs have been selected,

you will be prompted to cancel all uploads or individual run uploads.

Parse Run Files

extracts already uploaded Run files

(those stored on the host PC).

Clear Logger Memory

will clear the logger’s flash

memory.

WARNING!

Turning off the data logger while memory clearing is in progress

result in a corrupted data logger file system.

Caution!

Once “Clear DH-4 Memory” is pressed, the data is not retrievable.

Once the memory clearing process has started, the status will change to Clearing

Memory with a red background. Data is stored in the data logger using flash

memory. Depending on the amount of data stored, the number of runs recorded,

and the flash memory size, clearing data may take several minutes. The status for

the data logger must return to the Standby state before any further actions are

taken with the data logger. This includes turning the data logger off.

If, after clearing the logger’s memory using the Clear Logger Memory button,

the values for Free Disk and Total Disk are not zero, it will be necessary to clear

the logger’s memory in a terminal program.

1. In WL Host, select Commands/Access to Factory Settings/Reset to

Monitor. The resulting window will ask if you are sure you want to cease

operations and exit to monitor program. Select Yes.

2. Start a terminal program with settings at 9600 baud, 8 data bits, 1 stop bit,

parity, none. Press Enter to display C: prompt.

3. Type “format,” press Enter. The resulting message “Formatting this drive

will erase all its data. Are you sure?” Type “Y.” Type “app” then Enter.

4. Exit the terminal program, restart WL Logger Host and verify Free Disk and

Total Disk are both 0.

WILL

DH-4 Revision E5 19 June 2006 49

Page 58

5.5 Real Time Data

The Real Time Data tab is visible when in Real Time Output, Analog Output, or

Advanced Logging/Output modes.

The top combo box allows selecting

Data, or Raw PC Data

for output in the display area.

Parsed Data, Raw Logger

Display Data

enables the output. Note that after it is selected, the

button changes to Stop Display.

The Packets-Mod-Missing Packets indicates:

• The number of DH-Mux packets received by the

host PC for each Mux Unit ID

• The number of mod errors detected for each Mux

Unit ID

• The number packets lost when the last mod error

was detected.

This provides the user a method of monitoring the

reliability of the Logger data links.

Reset Counters allows you to reset the Packets-ModMissing Packets to zero.

50 DH-4 Revision E5 19 June 2006

Page 59

You can send commands directly to a data logger with or without a line break by

entering them into the box shown below. To send commands directly to a specific

meter, select Test One Logger Port under the Commands menu, then enter the

command text. Entering “break” will stop communication.

5.6 Recording: OFF/ON

Record Status

Recording: Indicates whether data is being saved to an archive file on

the host computer. It does not apply to the logger. Display is OFF or

ON.

Archive File: Filename to which the collected data is being saved.

File Size: Size of file being saved. File size is updated every second.

Record: Indicates that the data is coming from either the data logger or a PC Logger as set up

in the PC Logger tab. The appropriate checkbox must be checked as well. If the two are not

in agreement, a yellow background will appear. If there is no communication, the background

will be red.

Record Logger Data and Record PC Logger: Checking these boxes enables the user to

determine what data is being recorded to the archive file.

If Record Logger Data is checked, all the real time data being received

by the host from the DH-4 on the logger port will be recorded.

If Record PC Logger is checked and one or more Record PC Logger

COM ports have been configured and are receiving data, the COM Port

data will be saved in the archive file and will be given a Mux ID = 1.

DH-4 Revision E5 19 June 2006 51

Page 60

Record Archive allows you to create a file that only contains

the data from check sum verified DH-Mux records.

1 Hour Archive Files allows you to save data in one hour

increments. Data will be time-stamped by the host computer in

one-hour-long files.

1 Day Archive Files allows you to save data in 24-hour

increments. Data will be time-stamped by the host computer in

24-hour-long files.

Record Raw Input: Factory use. Records raw data with no processing whatsoever.

5.7 PC-Logger

Options under this tab allow you to collect real-time data from individual

instruments using the host PC as a “virtual” data logger (depending on the

number of available serial ports it has) while the logger is transmitting real-time

data. The data from both the logger and the host PC are collected in the same

archive file under the Recording tab.

PC Logger ID: This value is hard-coded into the data logger’s or deck box’s

firmware.

Deck Rate: Selectable at 1.0, 2.0, 3.0, 3.6, 6.1, 9.1, and 18.2 Hz.

PC Input (1–6): Allows you to select a COM port and the appropriate baud rate

for non-submerged data loggers.

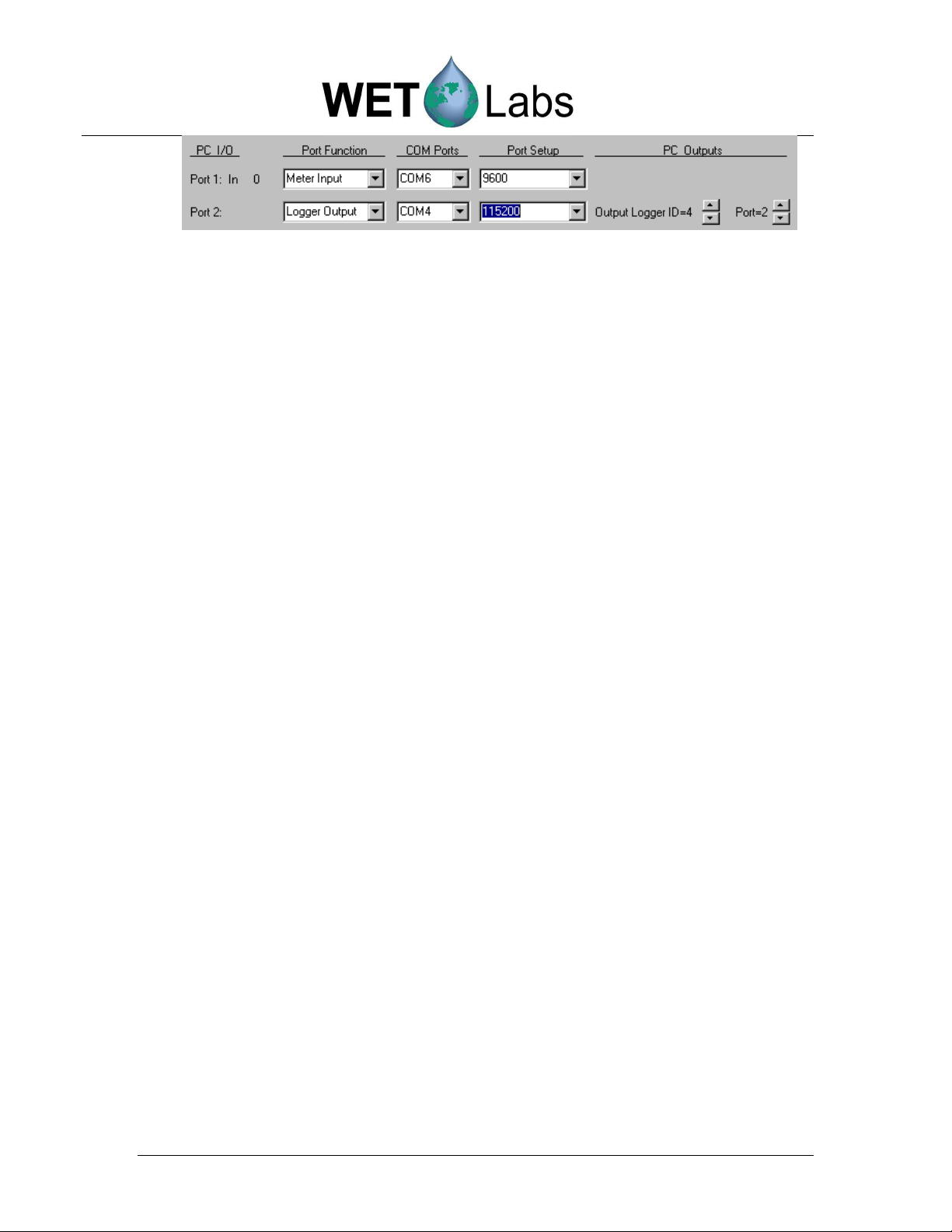

Port Function: Each PC Logger (COM) port can be configured as Meter Input

or Logger Output.

52 DH-4 Revision E5 19 June 2006

Page 61

• If a port is selected as

Meter Input

, the data will save only to the host PC

(“virtual logger”), be given a Logger ID=1, and assigned a Port ID

according to its position on the list of available ports. The user will need

to select an available COM port and the port’s baud rate.

• If a port is selected as

Logger Output

, the user must select the COM port,

the data rate, and the data source. The data source can be any of the input

data streams and is identified by the Logger ID (1=PC Logger, 2=DH-4)

and the Ports 1–8.

DH-4 Revision E5 19 June 2006 53

Page 62

Page 63

6. Hardware

The typical DH-4 has the following external connections:

1. Host port/Power input

2. Serial input

3. Serial input

4. Serial input

5. Serial input

6. Battery input

If your configuration varies from this, refer to the Custom Configuration Sheet at the back of this

manual.

6.1 Specifications

Mechanical

Size 7 x 4.1 (17.8 x 10.4 cm)

Pressure housing acetal co-polymer

Weight 4 lbs (1.8 kg) in air; 0.6 lbs (0.3 kg) in water

Deep unit: 5.7 lb (2.6 kg) in air; 2.3 lbs (1 kg) in water

Rated depth 500 or 5000 m

Temperature range 0–30 deg C

Electrical

Input 7–18 VDC

Current draw 0.6 watts @ 12V nominal

Sleep 70 µAmp (max)

Max power 3 Amp @ input voltage

Sample rate 6 scan/sec., nominal

Host interfaces RS-232, RS-422

Data Handling

Serial data input 1–8 ports, RS-232

Analog input 0–5V

Analog input resolution 12 bit A/D

Baud rates 300–115.2K

Data transfer binary

Memory 64 Mb minimum

DH-4 Revision E5 19 June 2006 55

Page 64

6.2 Standard DH-4 Connector Configuration

Sea/Test Cable Co

nnector Pin Function

Serial Connector Socket Function

Battery Connector Pin Function

DH-4 connectors

1 Ground

2 RS-232 (RX)

3 N/C

4 V +

5 RS-232 (TX)

6 N/C

1 Ground

2 V +

3 RS-232 (RX)

4 RS-232 (TX)

1 Ground

2 V +

3 N/C

56 DH-4 Revision E5 19 June 2006

Page 65

6.2.1 Optional Status LED

An optional LED indicates which of the current operating segments the data logger is in

when the user is either not using the host program for status or the user is not in a

position to view the host program.

Regardless of how the data logger is started, the Status LED will flash according to the

following sequences.

Delay: One second on, four seconds off

Pre-Warm Up Flush: One quick flash (50 ms) per second

Warm Up: Two quick flashes per second

Flush: Continuous quick flashes

Sample: One flash (100 ms) every second

Sleep Status LED is off

6.2.2 Magnetic Switch

Some WET Labs data loggers are equipped with a magnetic switch. This is a

logic/control switch, not a power switch for the data logger. Applying power to the data

logger will cause the data logger to become fully active, regardless of the magnetic

switch’s position.

WET Labs uses two different nomenclatures, providing the same utility, for its data

loggers:

older version

newer version

ON (older) or RUN (newer)—Placing the magnetic actuator in the data logger’s RUN or

ON position tells the data logger that start has been selected. If the other steps identified

in Section 5 have been followed, a data sample will begin.

OFF (older) or actuator removed—Removing the actuator from the ON or RUN position

tells the data logger to terminate the current sample if (and only if) the magnetic switch

was used to initiate the sample. The actuator does not need to be placed in an OFF

position to terminate the sample; simply removing the actuator from the ON or RUN