Fiber Optics

Cable Construction

Connectors

Splice

Assemblies

Testing

WEST PENN WIRE

CABLE WITH CONFIDENCE

Fiber Optics: Fiber Cables

Fiber Optics

Fiber Optic use started in the early 1970’s. Corning Glass Works developed a ber optic cable

with a loss of 20dB/km, today many ber optics have extremely low loss- .5dB/km for SingleMode.

During the 1980’s telephone companies began to deploy ber throughout their networks. By implementing a ber network, telecom companies could future proof their systems backbone.

Fiber Optics is used in many applications such as: Telecommunication, High bandwidth Data,

Video signaling, long distant CCTV, Communication between re alarm panels, and much more.

Fiber Optics- Advantages

• Maintaining signal integrity in high EMI/RFI applications

• Long distant installations

• Security Issues

• Future Proong

• Greater amount of information carrying capacity (bandwidth)

• Easy installation - light weight, simplied termination

Fiber Optics- Disadvantages

• Expensive overall installation cost

• Can not carry electrical power

WEST PENN WIRE

CABLE WITH CONFIDENCE

Fiber Optics: Fiber Cables

Optical Fibers

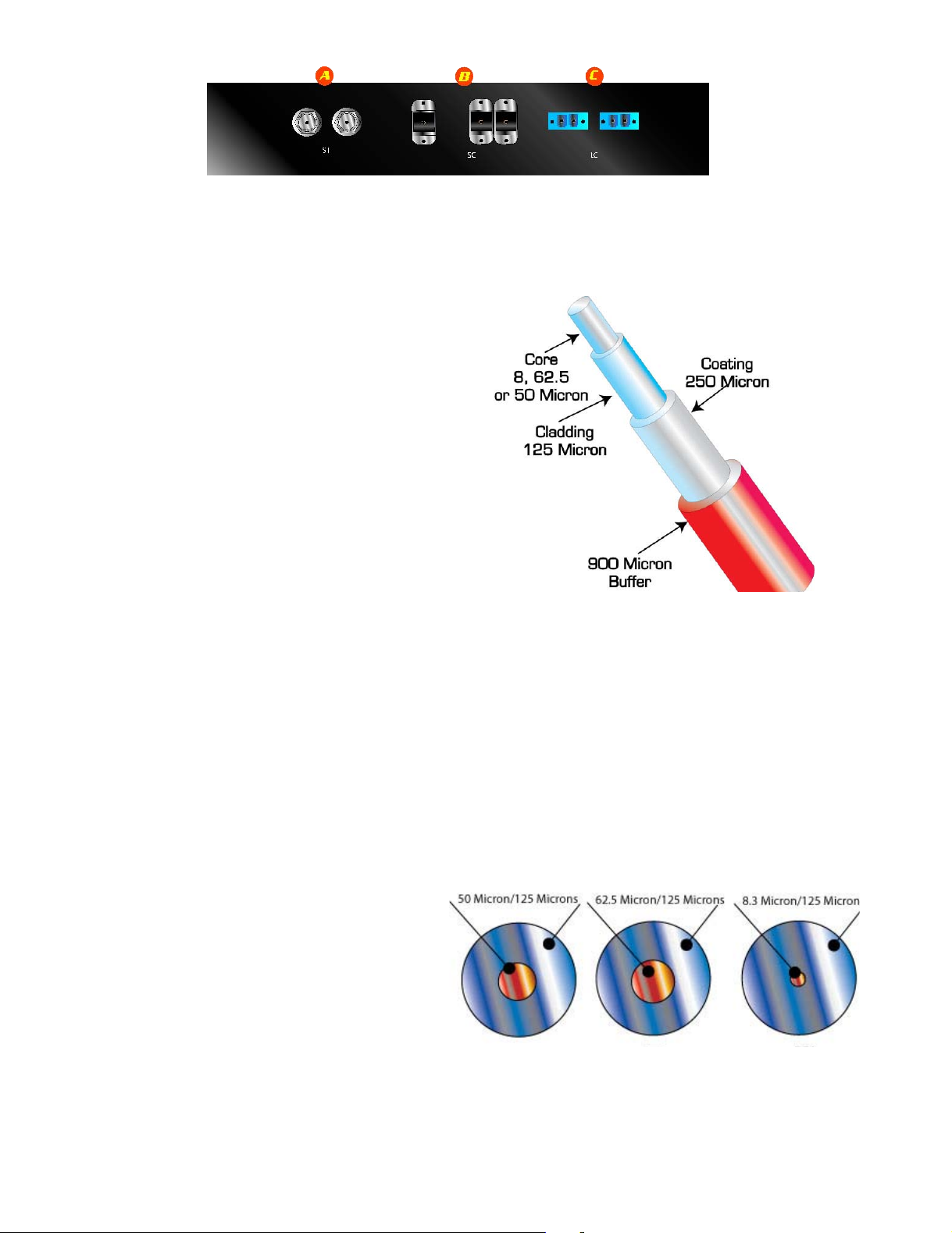

A glass optical Fiber is made of three components:

1. Core - Light Carrier of the optical ber. It is made

from a doped glass(Silica). The silica material of

the core allows the light signals to be carried

efficiently and effectively across the ber.

Sizes of the Core:

• 8µm (8.3 or 9µm) Single Mode

• 50µm - MulitMode

• 62.5µm - MultiMode

µm - microns - 1000microns =1mm

2. Cladding - Surrounds the Cladding, it is also made

from a different type of silica. The glass of the

cladding is made to contain the light within the

core.

Sizes of the Cladding:

• 125µm

3. Plastic Coating - Surrounds the Cladding and acts as a protector for the glass. The coating is

implemented to protect the glass while it is shipped to the Fiber Optic Cable Manufacturers.

The Coating is normally clear (color), but for all Outdoor cables the coating is color coded to

help identify the individual bers. The coating has to be removed to connect the ber to a

connector or splice.

Sizes of the Coating:

• 250µm

Single-Mode Fibers - 8/125µm

Single mode or path of light from

a laser source.

Long Haul installations.

Multi-Mode Fibers- 50/125µm or 62.5/125µm

Multiple modes or paths of light from the

LED source.

Shorter Installation

Both Single-Mode and MultiMode will handle Audio,Video, and Data simultaneously.

WEST PENN WIRE

CABLE WITH CONFIDENCE

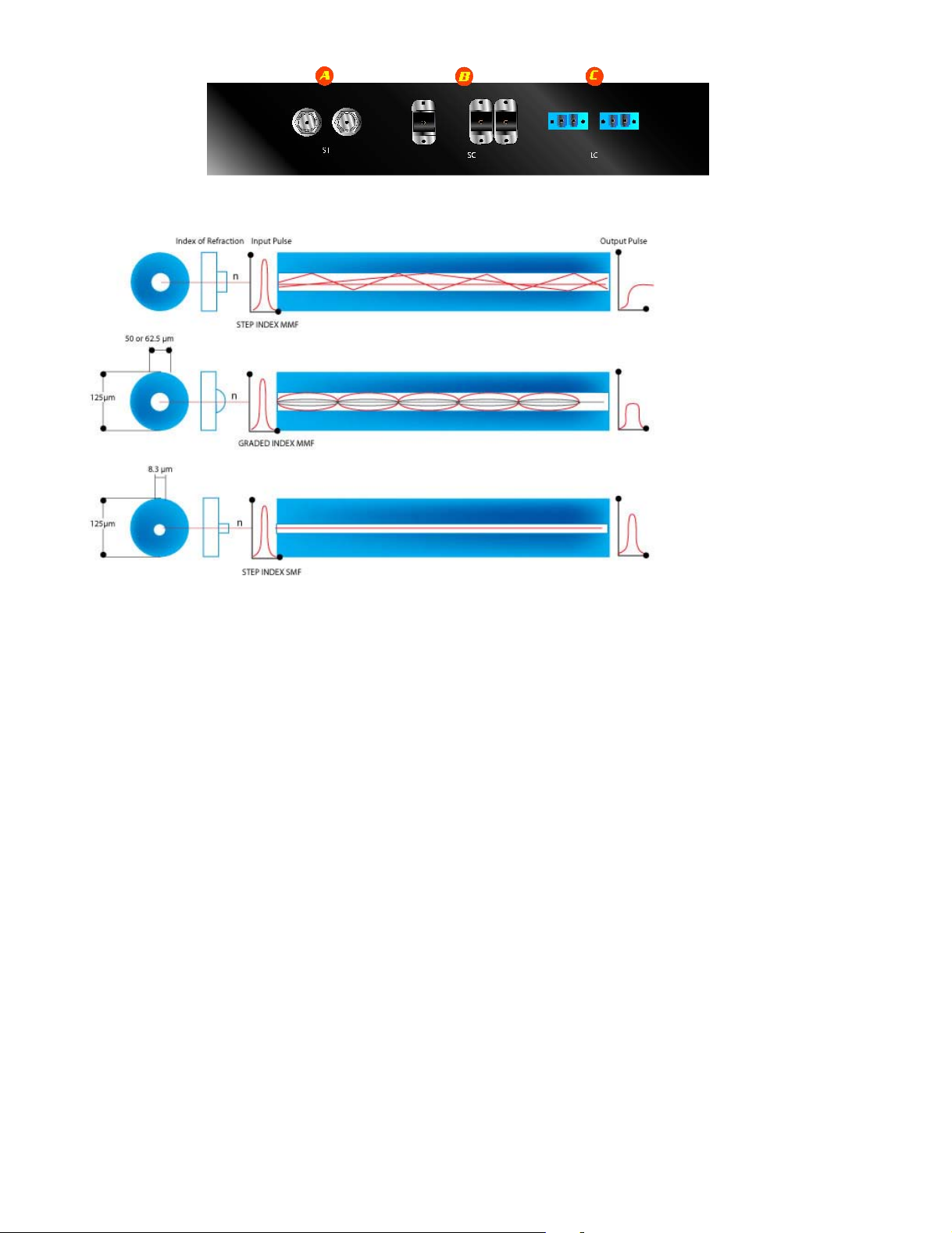

Fiber Optic Dispersion:

Single-Mode Fiber Cables

The Single-Mode core is 10th the size of a human hair. This ber type uses a LASER to transmit

the signals. The ber is designed as a step index, meaning that the core has only one refractive

index to carry the light signal. There is some dispersion over long distances. Chromatic dispersion is caused by the intense LASER ltering into the cladding causing pulse overlap and distorted signals.

Multi-Mode Fiber Cables

The Multi-Mode core is larger and can gather more light. This ber uses an LED or VCSEL to transmit the light signals. A Multi-Mode core has a broader aperture over SingleMode bers. A MultiMode ber also has dispersions over longer distances. This dispersion is called Modal dispersion.

A Mulit-mode core is set up with multiple rings with different refractive index characteristics.

These rings allow the light to be traveled over longer distances without loss of continuity of light,

but these signals can become compromised if the distance is increased too much.

Refractive Index:

Air = 1 Meaning Light travels 186,000miles/second

Normal Glass = 1.5

Cladding = 1.46 Doped to contain the light

Core = 1.48 SingleMode - 1.47 to 1.48 different layers Mulit-Mode

WEST PENN WIRE

CABLE WITH CONFIDENCE

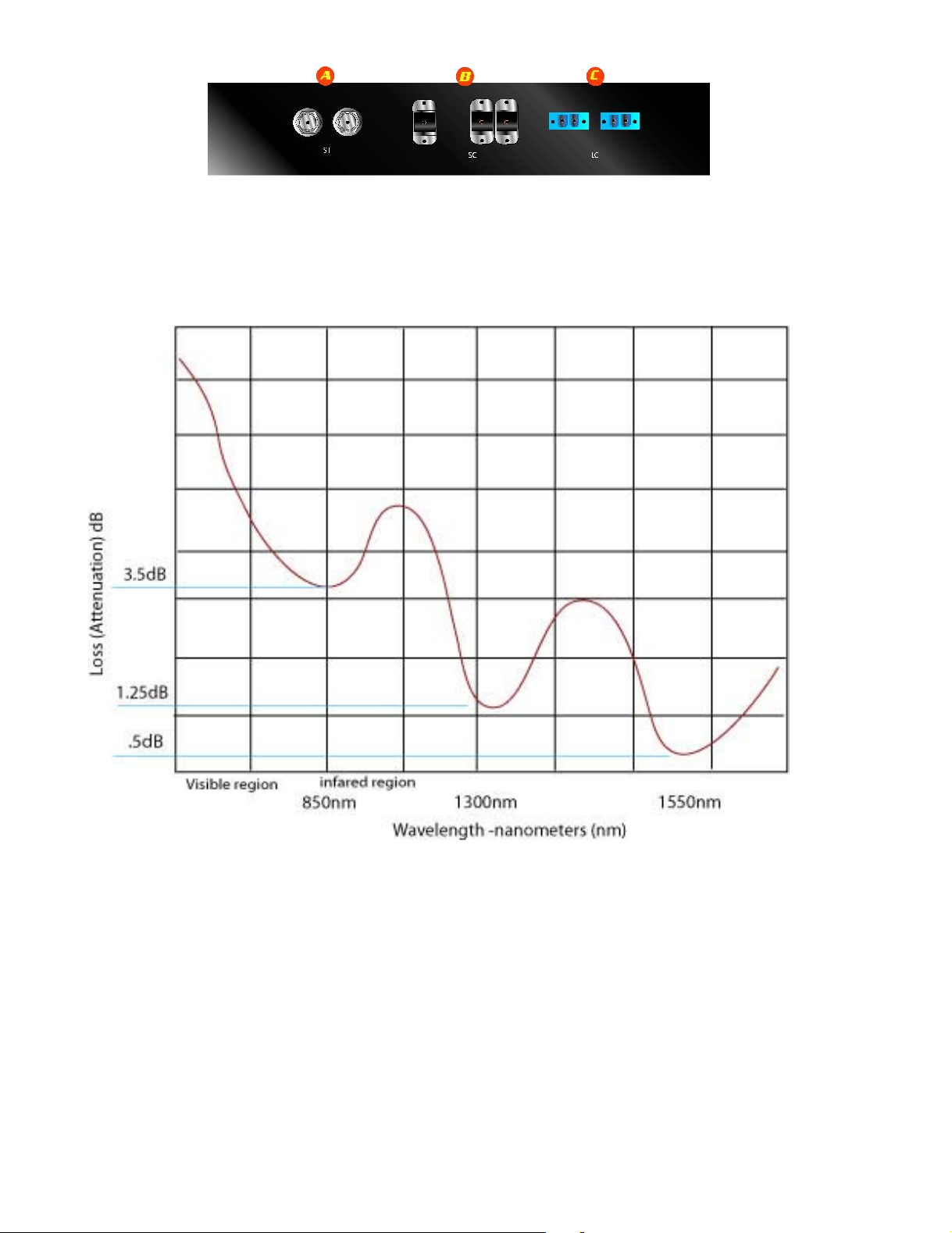

Operating Wavelengths:

There are Primarily three windows of opportunity to transmit light effectively and effectively

through an optical ber. These specic wavelenths are in the infared region.

Visible light starts with Blue - approx. 400nm to Red 700nm. nm=nanometers.

850nm - 3-4dB of loss/km. The least expensive transmitting device. Found on lower speed,

shorter distant applications such as CCTV, Fire Alarm communication devices. ( LED)

Used with Mulit-Mode bers

1300nm (1310nm) - 1-1.5dB of loss/km. The second window of opportunity. Used for higher

speed, longer distant Multi-mode applications. 1310nm is used for Single-Mode shorter distant

applications. LED or VCSEL.

1550nm - .5dB of loss/km. This is the second window of opportunity for SingleMode transmission. This wavelength is used for extremely long distant high bandwidth applications.

WEST PENN WIRE

CABLE WITH CONFIDENCE

Fiber Optic Cable Types

Indoor Fiber Optic Cables

Indoor ber optic cables are designed to

either limit smoke vertically (Riser), or

limit smoke and ame vertically and

horizontally (Plenum). The cables are

constructed with 900µm buffer over the 250µm

coating to help facilitate a connector

Indoor/Outdoor Fiber Optic Cables

Indoor/Outdoor ber optic cables are designed together limit smoke vertically (Riser), or limit smoke

and ame vertically and

horizontally (Plenum). The cables are

constructed with 900µm buffer to

help facilitate a connector. They also provide

water-blocking material.

Outdoor Fiber Optic Cables

Outdoor ber cables are designed to withstand the

environmental elements. They are constructed

with 250µm buffers that ride loosely within a tube

that is lled with waterblocking gel. The Jacket is PE. A PE jacket can not

be brought indoors because of the ame and

smoke it produces when ame is set to it. A outdoor cable has a limit of 50ft. entering a building to

be terminated or spliced to a Indoor rated cable.

Direct Burial Outdoor cables include a armored

sheath for direct burial protection. A connector can

not be placed directly on an outdoor ber because

of the 250µm buffer. A fan-out kit, or splice with a

pre-connected pigtail must be used.

Fan out Kits:

FI-1100 - 6 Fiber Kit

FI-1100

WEST PENN WIRE

CABLE WITH CONFIDENCE

Loading...

Loading...