West Penn CN-TM53-25812, CN-TM53-807, CN-UM52-807 Specsheet

MINI INDEX

Te ch n ic a l R e fe re n ce S ec t io n

Understanding National Electrical Code (NEC)…………………

Conduit Capacity …………………………………………………

Fiber Optic Termination Techniques………………………………

Category Cable Termination Techniques………………………

Coaxial Cable Termination Techniques …………………………

Terminal Block Termination Techniques ………………………

Coax Connector Cross Reference ..…………………………

Network Cable Connector Cross Reference ..………………

Audio Cable Connector Cross Reference ..…………………………

Shipping Policy and Warranty Info ..…………………………

Cable Index .……………………………………………………

Cable Accessories index ..…………………………………

Panel Reference Guide..…………………………………

252-253

254-255

256

257

258-259

260

261-263

264

265

266-267

268-270

271-275

276

800-245-4964 • www.westpenn-wpw.com

Technical Reference

WEST PENN WIRE

CABLE WITH CONFIDENCE

The know how. Understanding cable design, coaxial design and fiber optic

design is pages away. You can also find the recommended connectors, tools and

much more technical information that will help you understand cable design and

implementation. We want to make your installation free from problems. If you are

looking for more information on termination techniques, connector selection, or

other technical data, see our web-sites. www.westpenn-wpw.com and

www.westpenn-training.com.

251

Technical Reference

800-245-4964 • www.westpenn-wpw.com

WEST PENN WIRE

CABLE WITH CONFIDENCE

Understanding the National Electrical Code

The National Electrical Code (NEC) is a set of guidelines written to govern

the installation of wiring and equipment in commercial buildings and residential areas. These guidelines were developed to ensure the safety of

humans as well as property against fires and electrical hazards.

Understanding the National Electrical Code is important from the cable

manufacturer engineer and distributor, to the designer and installer.

Anyone involved in specifying cable to installation of cable should be

aware of the basics of the code.

In 1987, the National Electrical Code introduced some major changes that

had a major impact on the wire and cable industry. The code now has listing requirements for communication and power-limited circuit cable.

These requirements developed fire resistance levels for cable. The code

covers initiation of fire by electronic cable as well as flame spread characteristics of the cable.

Code Organization

The NEC code book is made up of nine chapters, with each chapter divided into separate articles pertaining to specific subjects. There are about

five articles that pertain to communication and power-limited cable. Each

article describes wire and cable construction, material use, cable markings, installation environments and applications.

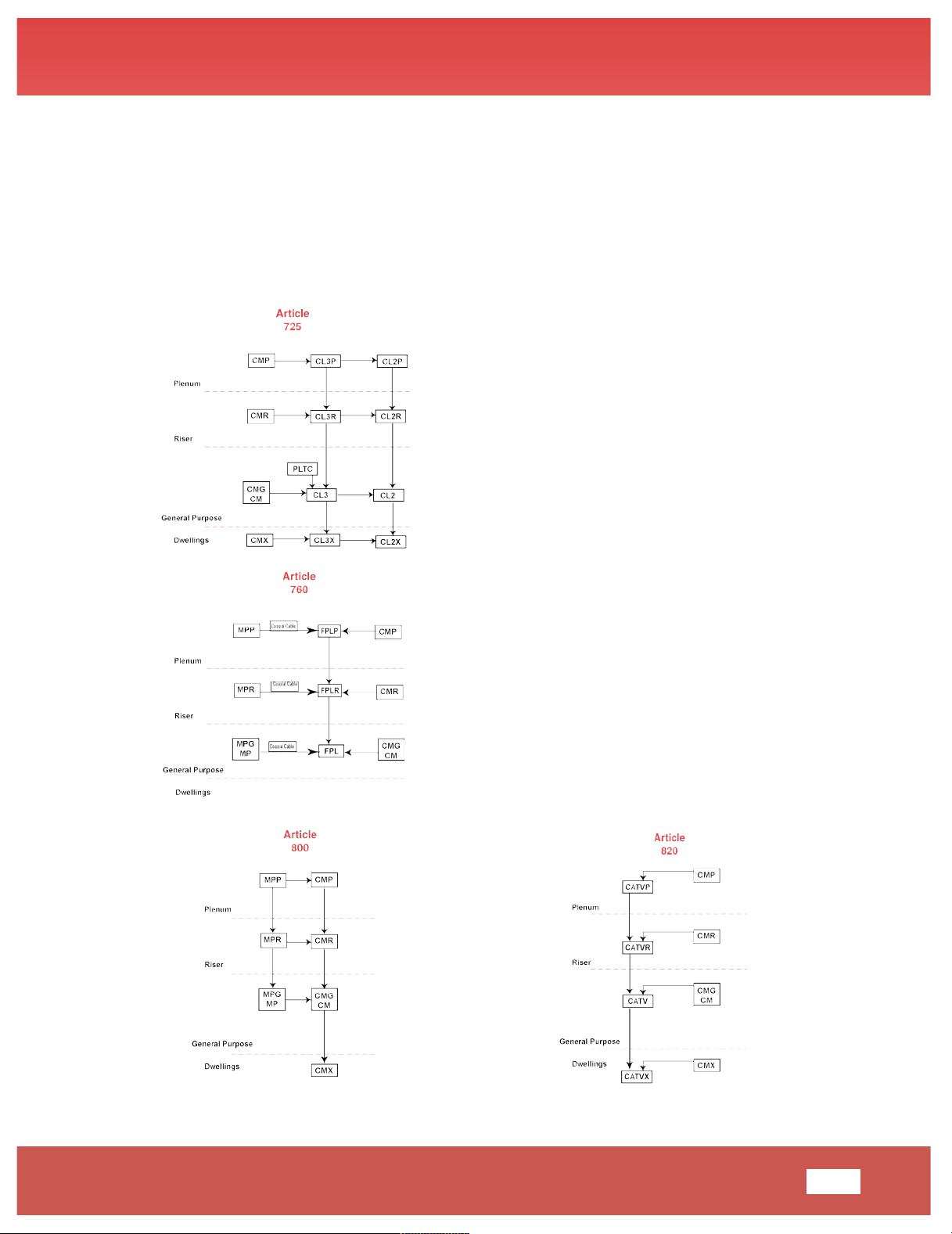

Article Categories

There are four articles that cover communication, power-limited and

CATV wiring. There is another category that deals strictly with optical

fiber. The following is a list of those articles and the applications or systems they cover:

Article 725 - Class 1, Class 2, Class 3, Remote-control, Signaling and

Power-Limited circuits

Article 760 - Fire Protective Signaling Systems

Article 770 - Fiber Optic Systems

Article 800 - Communication Circuits

Article 820 - Community Antenna Television

Article Overviews

The NEC code can be somewhat confusing to the novice who has not

studied the code in depth. In most cases, within an article, a listing will

allow for a higher listed cable to be substituted for lower listed cable. Or

some listings from one article may be substituted for another article listing with possible restrictions. This section will briefly cover the basis of

the code to try to make things clearer for you. You should consult the NEC

book for exact specifications, wording, and accuracy of the code. This is

not in any way an exact excerpt from the code.

Article 725

Article 725 covers Class 1, Class 2, and Class 3 remote control and signaling cables as well as power-limited tray cable. Power-limited tray cable

can be used as a Class 3 or Class 2 cable. Cable listed multi-purpose, communications, or power-limited fire protective can be used for Class 2 and

Class 3 applications. A Class 3 listed cable can be used as a Class 2 cable.

Article 760

Article 760 covers power-limited fire protective cable. Cable listed as

power-limited fire protective cable can also be used as Class 2 and Class 3

cable. Cable listed as communications and Class 3 can be used as powerlimited fire protective cable with restrictions to conductor material and

type, gauge size and number of conductors.

Article 770

Article 770 covers fiber optic cable. This article covers three general types:

non-conductive, conductive, and composite. Non-conductive type refers

to cable containing no metallic members and no other electrically conductive materials. Conductive type refers to cable containing non-current

carrying conductive members such as metallic strength members, etc.

Composite type refers to cable containing optical fibers and current carrying electrical conductors. Composite types are classified according to the

type of electrical circuit that the metallic conductor is designed for.

Article 800

Article 800 covers multi-purpose and communication cable. Multi-purpose cable is the highest listing for a cable and can be used for communication, Class 2, Class 3, and power-limited fire protective cable.

Communication cable can be used for Class 2 and Class 3 cable and also

as a power-limited fire protective cable with restrictions.

Article 820

Article 820 covers community antenna television and RF cable. CATV

cable may be substituted with multi-purpose or communication listed

coaxial cable.

Designation and Environmental Areas

Not only does listing by circuit types have to be adhered to, but installation in various environments have to also be considered. The NEC has

designated four categories for various environments. These will be listed

from the highest to the lowest listing. A higher listing can be used as a

substitute for a lower listing.

Plenum - This listing is suitable for use in ducts, plenums, and other space

used for environmental air without conduit and has adequate fire-resistant and low-smoke producing characteristics. It can also be used for

applications below.

Riser - This listing is suitable for use in a vertical run, in a shaft or from

floor to floor, and has fire-resistant characteristics capable of preventing

the carrying of fire from floor to floor. It can also be used for applications

below.

General Purpose - This listing is suitable for general-purpose use, with the

exception of risers, ducts, plenums, and other space used for environmental air, and is resistant to the spread of fire. It can also be used for all applications below.

Restricted Applications - This listing is for limited use and is suitable for

use in dwellings and for use in raceways and is flame retardant. Restricted

use is limited to non-concealed spaces of 10 feet or less, fully enclosed in

conduit or raceway, or cable with diameters less than .25" for a residential

dwelling.

SPECIAL NOTES FOR COMMUNICATION CABLES:

* MULTI-CONDUCTOR CABLES WITH 24-16AWG CONDUCTORS CAN BE

RATED UL AND C(UL).

* MULTI-CONDUCTOR CABLES WITH 14-8AWG CONDUCTORS ARE

UL LISTED ONLY

* 10-8AWG SPEAKER CABLES ARE CL2 ONLY AND MUST INDICATE

AUDIO USE ONLY

252

Technical Reference

800-245-4964 • www.westpenn-wpw.com

WEST PENN WIRE

CABLE WITH CONFIDENCE

National Electrical Code

Substitution Chart

The following chart explains the NEC cable hierarchy and will give you a

"picture" view of how this all fits together. The chart starts with the higher

listed cable at the top descending to the lower listed cable. Following the

arrows will allow you to find what listing can be substituted for others.

Also note restrictions in which case you will have to review the NEC code

in order to see if your cable is applicable.

Final Considerations

The National Electrical Code is widely accepted as the suggested regulations governing the proper installation of wire and cable in the United

States. The code is revised every three years to keep safety in the forefront

in wire and cable manufacturing and installation. Even though the code is

generally accepted, each state, county, city and municipality has the

option to adopt all of the code, part of the code, or develop one of its

own. The local inspectors have final authority of your installation.

Therefore, the NEC is a good reference when questions arise about the

proper techniques for a particular installation, but local authorities should

be contacted for verification.

When choosing cable for your installation there are four guidelines to follow to keep problems to a minimum:

1. The application and environment determines

which type of cable you can use and what

rating it should have. Make sure the cable

you’re installing meets the proper ratings for

your application.

2. If you will be substituting a cable with

another, you must have a cable that is rated

higher than what the code calls for. Check with your

local inspector as to what is allowed in your local area.

3. The NEC code is a general guideline that can

be adopted in whole or in part. Your local state, county,

city, or municipal approved code is what you must fol

low. Contact your local authorities for verification of the

code in your area.

4. The local inspector or fire marshal has the final authority

to approve or disapprove any installation of cable based

on the National Electric Code or on the local code.

If you remember these four guidelines, you should have fewer complications and headaches when installing cable in your area. Remember to

always work closely with your local authorities.

Understanding the National Electrical Code

253

800-245-4964 • www.westpenn-wpw.com

Technical Reference

WEST PENN WIRE

CABLE WITH CONFIDENCE

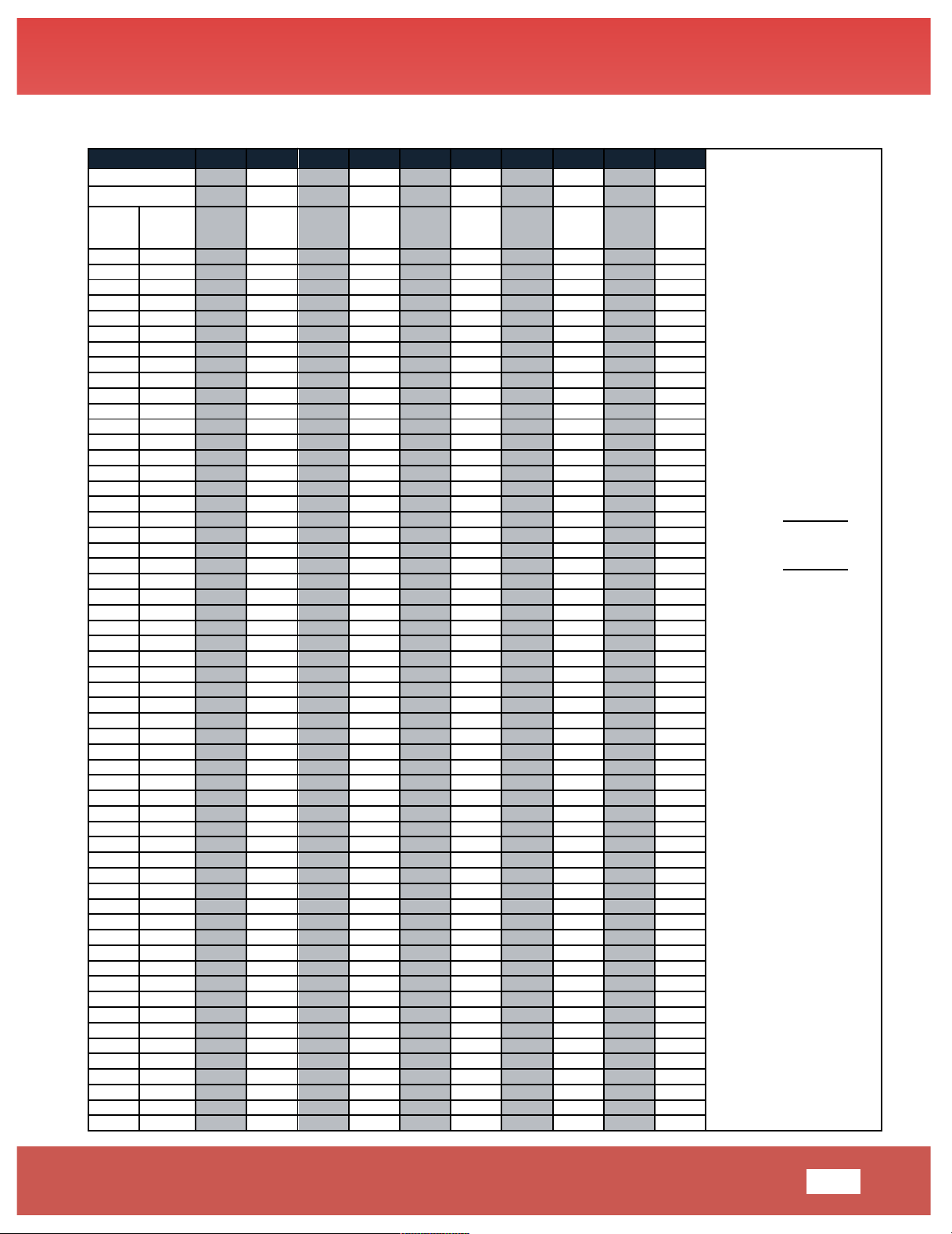

Calculating Conduit Capacity

One Cable Type in Conduit

The following information is to provide you with a quick and easy reference

for conduit fill requirements. This information is to be used as a general

guideline. Each installation has different restrictions for installation environments and/or local codes to follow.

The Conduit Capacity Chart provided on the following page is for applications when only one type of cable is to be used in a conduit. For example, if

you know the diameter of the cable you will be installing, use the cable O.D.

column, and find the exact or next largest diameter cable O.D.. Follow this

row over to the number of cables you need to install in a conduit. Then follow this column to the top of the chart and read the conduit size required

for the number of cables you need to install.

Multiple Types of Cable in One Conduit

If you will be mixing various cable diameters in a conduit, then this overall

chart does not apply. You will have to use the following guidelines to calculate the conduit fill requirements.

To determine the conduit size required for a particular installation of cable

follow these steps:

1. Square the O.D. of each cable and total the results.

2. Multiply the total by .7854*. This is the total area of

the cables in square inches.

3. From the Permissible Area row on the Conduit

Capacity Chart shown on the following page, select

the conduit size with an area equal to or greater -

than the total area you calculated.

* See Important Notes and

Installation Suggestions

** Permissible Area to be occupied (sq. in.) is

based on the NEC standard of 40% fill, which applies

to three or more non-lead covered cable installed in the

same conduit.

Important Notes and

Installation Suggestions

• A single cable is permitted to occupy 53% and two cables

are limited to 31% conduit fill. For a single cable use .5927 in step 2, for two

cables use 1.1034, and three or more cables use .7854.

• This chart is based on the maximum number of cable per mitted in con-

duit under the National Electrical Code, and is calculated on the area of the

cable with 40% of the

conduit filled. For conduit runs of 50 to 100 feet, the installed number

should be reduced by 15%, or use the next larger size conduit. If more than

two 90 degree bends are to be used in the conduit run, or if the run is to be

over 100 feet in length, insert a pull box.

• An anti-friction agent is recommended in pulling

operations.

*CAUTION: Select an anti-friction agent which is suitable for the cable

jacket material. The electronic characteristics of unjacketed cable may

change due to the application of anti-friction agents.

*

COLD ENVIRONMENT PRECAUTION: Due to the nature of PVC

compounds to become non-pliable when stored or handled in

ambient temperatures of 32 degrees F or less, we recommend the

following:

"Prior to installation, condition the cable for at least 24 hours at

room temperature to provide the best flex properties for ease of

installation."

• Permissible area chart does not apply to metallic and nonmetallic surface raceways; consult the NEC for recommendations.

THE NATIONAL ELECTRICAL CODE FORBIDS

THE INSTALLATION OF COMMUNICATION CABLE

IN THE SAME CONDUIT AS POWER CABLE.

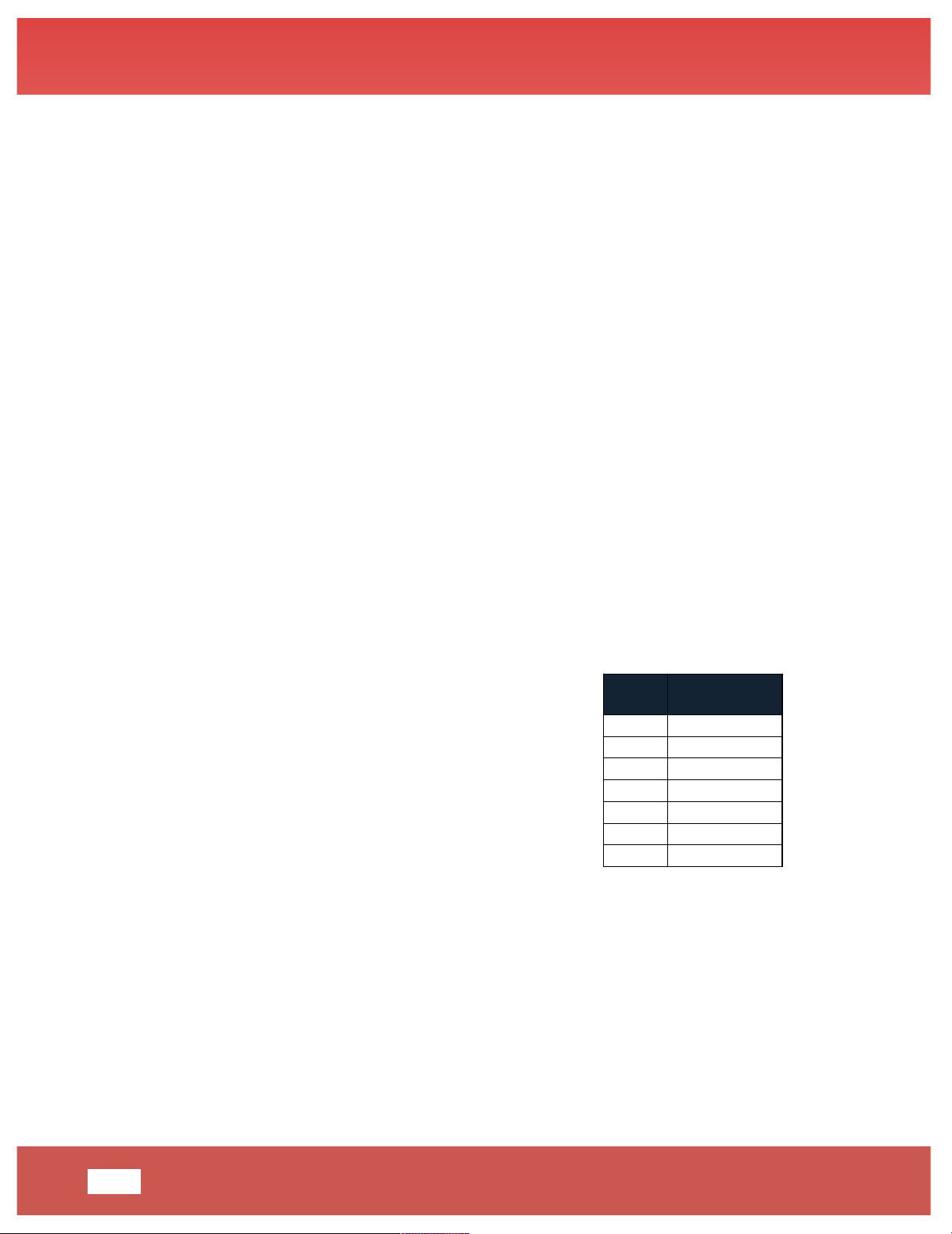

Pulling Tensions

Under the stress of approximately 15,000 lbs./sq. in. annealed copper will

begin to permanently stretch. The table below lists the absolute maximum

recommended pulling tensions for conductor sizes. For multiple conductor

cable, multiply the appropriate value by the total number of conductors.

These pulling tensions must be equally distributed among the

conductors.

THESE LIMITS MUST NEVER BE EXCEEDED

EVEN MOMENTARILY!

DON’T JERK THE CABLE!

The electronic characteristics of a cable may change due to excessive ten-

sion and crushing.

Max. Pulling

Tension

12 AWG

Gauge

77 lbs

14 AWG 48 lbs

24 AWG 4 lbs

22 AWG

20 AWG 12 lbs

18 AWG 19 lbs

16 AWG 30 lbs

7 lbs

254

800-245-4964 • www.westpenn-wpw.com

Technical Reference

WEST PENN WIRE

CABLE WITH CONFIDENCE

Conduit Capacity Chart

Conduit Size 1/2 3/4 1 1 1/4 1 1/2 2 2 1/2 3 3 1/2 4

EXAMPLES:

Example A.

Sample Cable:

227- .260” O.D.

Go down the Cable O.D. inch col-

umn. Find the number equal to

or greater than the cable O.D. Go

across to find the number of

cables in the appropriate conduit

size.

.269”- Closest .275”

13 in a 1

1/2

” Conduit.

Example B.

Three different Cables:

227 - .260” sqd. = .0676

D434 - .411” sqd. = .1689

6350 - .275” sqd. = .0756

+

.3169

x .7854

.2489

On the Permissible Area- equal to

or greater. The

closest area is .034

Use a 1” Conduit

Important Note: This conduit

capacity chart is to be used as a

general guideline. Because local

codes can vary from the NEC.

West Penn Wire cannot be held

responsible for this information

as it pertains to your installation.

Proper conduit fill is the sole

responsibility of the installer and

it is your responsibility to see that

your installation will pass local

codes.

I.D. Inches .622 .824 1.049 1.380 1.610 2.067 2.469 3.068 3.548 4.026

Permissible Area* 0.12 0.21 0.34 0.60 0.82 1.34 1.92 2.95 3.96 5.09

Cable O.D

Inch

Cable Area

sq. Inch

.100 .00785 15 27 44 76 103 171 298 450 588 751

.125 .01227 10 17 28 48 66 109 191 288 376 481

.150 .01767 7 12 19 34 46 76 132 200 261 334

.175 .02405 5 9 14 25 34 56 97 147 192 245

.200 .03142 4 6 11 19 26 42 74 112 147 188

.225 .03976 3 5 8 15 20 33 59 89 116 148

.250 .04909 2 4 7 12 16 27 47 72 94 120

.275 .0594 1 3 6 10 13 22 39 59 77 99

.300 .07069 1 3 5 8 11 19 33 50 65 83

.325 .08296 1 2 4 7 10 16 28 42 55 71

.350 .09621 1 1 3 6 8 14 24 36 48 61

.375 .011045 1 1 3 5 7 12 21 32 42 53

.400 .012566 1 1 2 4 6 10 18 28 36 47

.425 .14186 1 1 2 4 5 9 16 25 32 41

.450 .15904 1 1 1 3 5 8 14 22 29 37

.475 .17721 1 1 1 3 4 7 13 20 26 33

.500 .19635 1 1 1 3 4 7 12 18 23 30

.525 .21648 0 1 1 2 3 6 11 16 21 27

.550 .23758 0 1 1 2 3 5 10 15 19 25

.575 .25967 0 1 1 1 3 5 9 13 17 22

.600 .28274 0 1 1 1 3 4 8 12 16 21

.625 .3068 0 1 1 1 2 4 7 11 15 19

.650 .33183 0 1 1 1 2 4 7 10 14 17

.675 .35785 0 0 1 1 1 3 6 10 13 16

.700 .38484 0 0 1 1 1 3 6 9 12 15

.725 .41282 0 0 1 1 1 3 5 8 11 14

.750 .44179 0 0 1 1 1 3 5 8 10 13

.775 .47173 0 0 1 1 1 3 5 7 9 12

.800 .50265 0 0 1 1 1 2 4 7 9 11

.825 .53456 0 0 1 1 1 2 4 6 8 11

.850 .56745 0 0 1 1 1 2 4 6 8 10

.875 .60132 0 0 0 1 1 1 4 6 7 10

.900 .63617 0 0 0 1 1 1 3 5 7 9

.925 .67201 0 0 0 1 1 1 3 5 7 9

.950 .70882 0 0 0 1 1 1 3 5 6 8

.975 .74662 0 0 0 1 1 1 3 4 6 8

1.00 .7854 0 0 0 1 1 1 3 4 6 7

1.025 0.825 0 0 0 0 0 1 3 4 6 7

1.05 0.866 0 0 0 0 0 1 2 3 4 5

1.075 0.908 0 0 0 0 0 1 2 3 4 5

1.100 0.950 0 0 0 0 0 1 2 3 4 5

1.125 0.994 0 0 0 0 0 1 1 2 3 5

1.150 1.039 0 0 0 0 0 1 1 2 3 4

1.175 1.084 0 0 0 0 0 1 1 2 3 4

1.20 1.131 0 0 0 0 0 1 1 2 3 4

1.225 1.179 0 0 0 0 0 1 1 2 3 4

1.250 1.227 0 0 0 0 0 1 1 2 3 4

1.275 1.277 0 0 0 0 0 1 1 2 3 3

1.300 1.327 0 0 0 0 0 1 1 2 3 3

1.325 1.379 0 0 0 0 0 0 1 2 3 3

1.350 1.431 0 0 0 0 0 0 1 2 2 3

1.375 1.485 0 0 0 0 0 0 1 1 2 3

1.400 1.539 0 0 0 0 0 0 1 1 2 3

1.425 1.595 0 0 0 0 0 0 1 1 2 3

1.450 1.651 0 0 0 0 0 0 1 1 2 3

1.475 1.709 0 0 0 0 0 0 1 1 2 2

1.500 1.767 0 0 0 0 0 0 1 1 2 2

255

800-245-4964 • www.westpenn-wpw.com

Technical Reference

WEST PENN WIRE

CABLE WITH CONFIDENCE

ST Connectors - Straight Tip

These connectors are normally used in the Security Industry.

They would be used for connecting Fire Alarm Control

Panels - RS-485, Access Control Panels, CCTV Distribution.

ST connectors are similarly designed to match a BNC

Connector.

Kits Offered: Optimax - FI-3635

Brilliance - FI-4270

LC Connectors - Lucent Connector

These connector type is normally found in the broadcast

environment, and data networking.

They are SFF - Small Form Factor Connectors. SFF connectors are smaller in size for environments where space is a

premium.

Kits Offered: Brilliance FI-4270

Optimax FI-3635

SC Connectors - Square Connector

These connector type is normally found in the data networking environment.

SC connectors are similarly designed to match a RJ45 modular plug.

Kits Offered: Brilliance FI-4270

Optimax FI-3635

FI-4270

FI-3635

256

800-245-4964 • www.westpenn-wpw.com

Technical Reference

WEST PENN WIRE

CABLE WITH CONFIDENCE

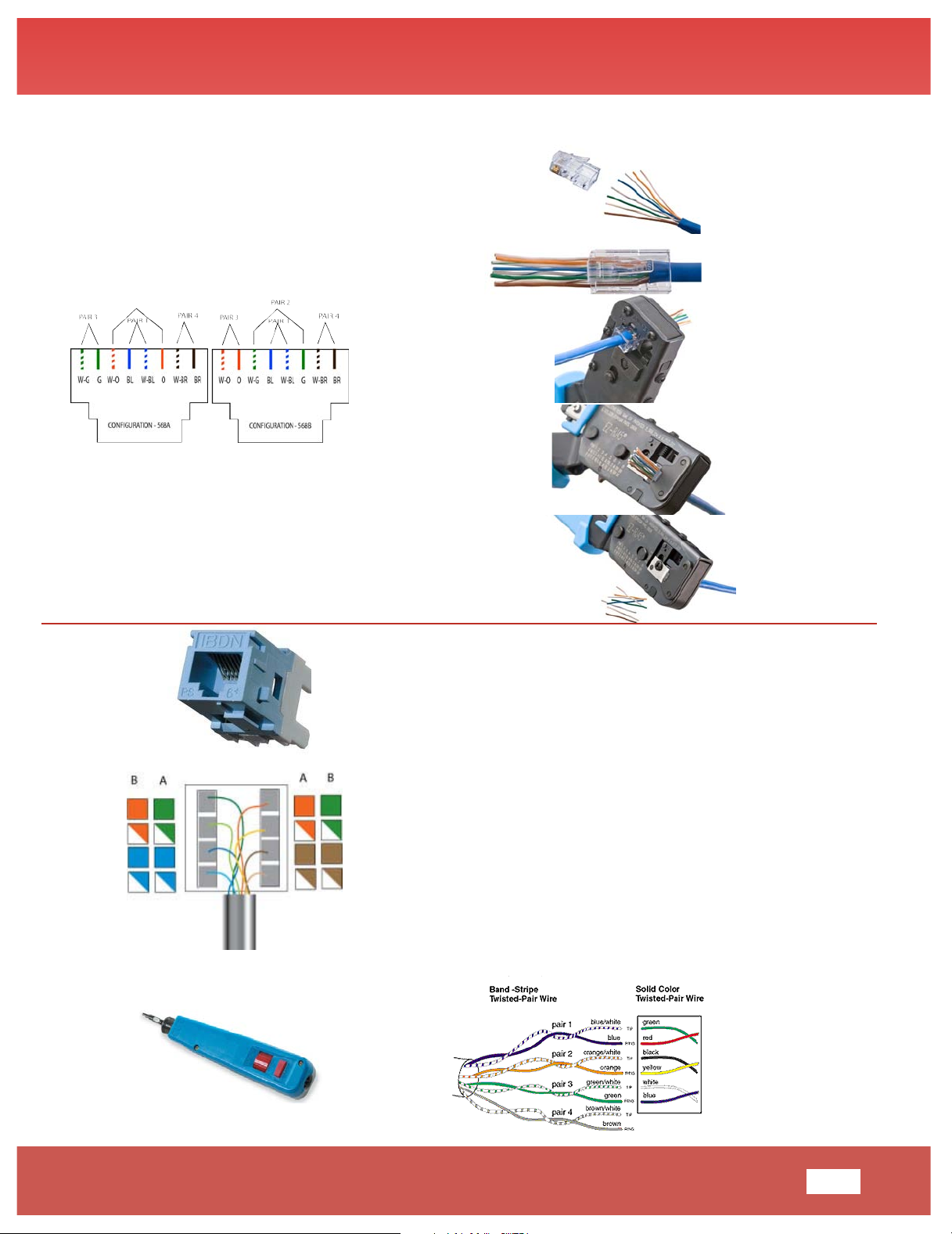

Plug Termination:

1. Strip off 2.00” of jacket

2. Straighten and align wires to T568B or T568A - Trim Pairs

3. Insert wires into connector body

4. Pull tight to ensure jacket is .250” inside connector body

5. Verify wire location and orientation

6. Insert 32-EZP connector into crimp tool- TL-EZRJ45

7. Verify connector is completely seated and cable is fully inserted

8. Squeeze handle of TL-EZRJ45

9. Remove excess wires

10. Check jacket strain relief

11. Check that contacts are all engaged

12. Check that contact dividers are not damaged

13. Check to see if both ends of the cable have been terminated

IDC

All Jacks have IDC- Insulation Displacement Connections.

These connections are made with a punch down tool.

The Punch down tool displaces the insulation while the individual

cable is being pressed between two metal clips.

The metal clips make contact with the conductor.

Terminating RJ45 Jacks

1. Strip cable .750”- 1.00”- Do not damage conductors

2. Fan out the individual Pairs. Do not untwist the

individual pairs more than .500”

3. Place each wire into appropriate IDC slot color code

• Choose between T568A or T568B

4. Punch down the individual wire - Do not punch down

more than twice.

5. Place Protector Hood over the punched down wires

Cross-Compatibility:

Category Cable Termination

257

Color alignment may change depending on the

connector type and manufacturer

TL-110/66

800-245-4964 • www.westpenn-wpw.com

Technical Reference

WEST PENN WIRE

CABLE WITH CONFIDENCE

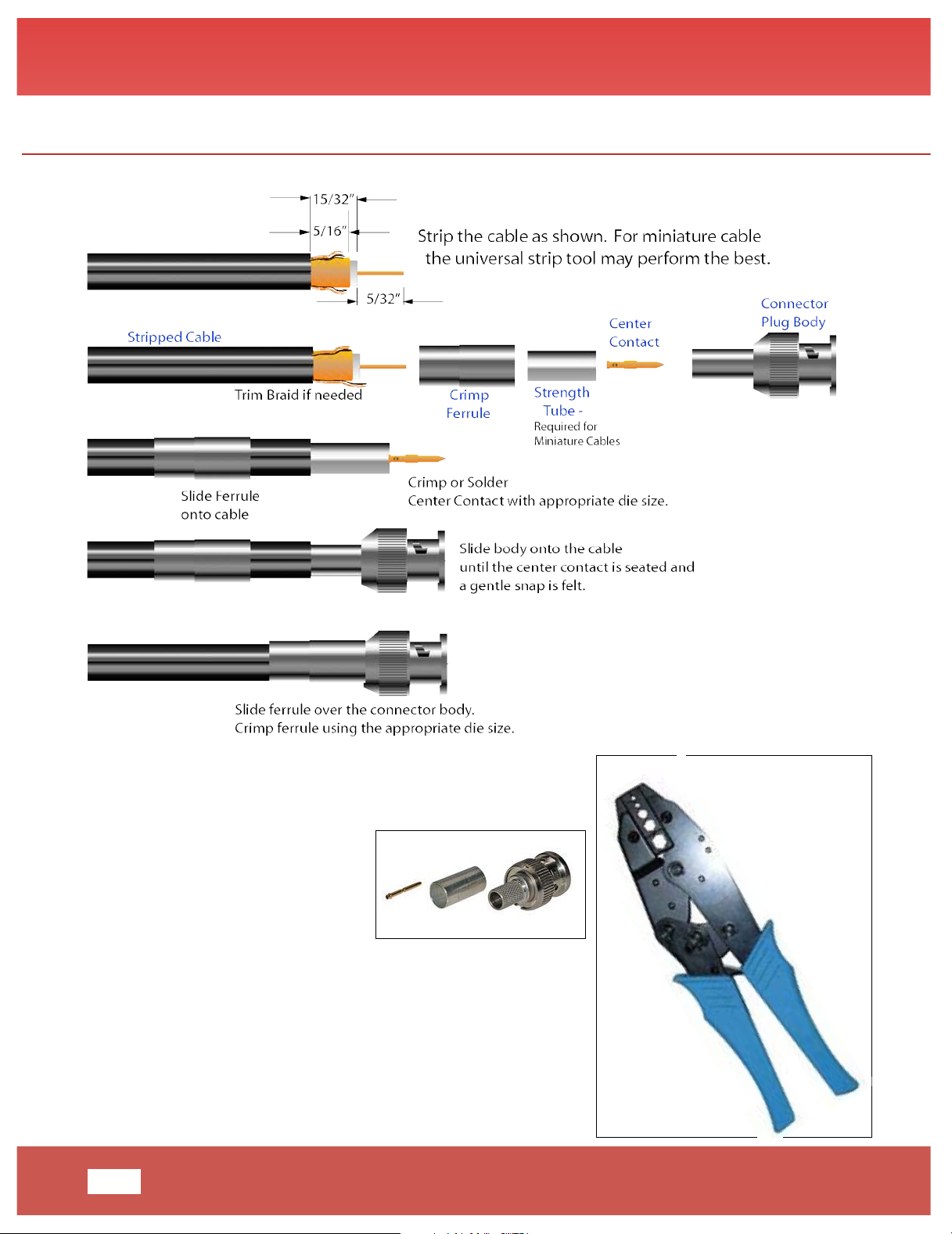

BNC Crimp Connector Termination

Crimp Tool Die Sizes: inches

TL-104: .068, .213, .255

TL-105: .068, .178

TL-803: .065, .068, .178, .213, .255

TL-107: .068, .093, .213, .255, .311

TL-113: .102, .359, .406

TL-115: .068, .100, .324, .384

TL-119: .068, .110, .213, .255, .324

3 Pc. 75 Ohm BNC

258

Loading...

Loading...