West Marine 7865645 Instruction Manual

FRANÇAIS

Water Pressure Pump

2.4

Instruction Manual

Manuel d’instruction • Manual de instrucción

2

Recreational Craft Directive 94/25/EEC

ISO 8849: 1990/Electrical operated bilge pumps

ISO 8846: 1990/Electrical devices - Protection against ignition of surrounding flammable gases

ISO 10133: 1994/Electrical systems - Extra low-voltage DC installations

Electromagnetic Compatibility Directive 89/336/EEC

EN55014: 1993/Radio Disturbance

Made in the USA

English 3

Français 7

Español 11

Contents • Contenu • Contenido

3

Model 7865645 Water Pressure Pump 2.4

12V DC five chamber positive displacement diaphragm pump.

Typical applications

This pump is the ideal choice for pressurizing water

in a closed system such as that found in a boat or

in a recreational vehicle.

It can easily build the pressure required for a

pressurized water supply system.

Features

• Quiet operation

• Smooth flowing

• Self priming

• Integrated pressure switch turns pump on and off

automatically when tap is opened and closed

• Dry running without damage

• Low power consumption

• Quick disconnect fittings

Working principle

As the pump runs, pressure builds until reaching

2.8 bar/41 psi. At this point, the integrated pressure

switch automatically shuts the pump off.

The pump is equipped with positively checking

outlet valves which ensure that the pressure is

maintained after the pump shuts off.

When water is demanded (at the faucet, shower,

etc.) the pressure decreases. After a moderate

drop in pressure, the integrated pressure switch

automatically turns the pump back on.

Due to it’s durable construction and thoughtful design, the pump will provide many years of service.

Important! The pressure setting of this pump is

made at the factory. Warranty invalidated by

pressure switch interference.

Specifications

Body: Polypropylene

Valve housing: Polyamide

Valves: EPDM

Diaphragm: Santoprene

Connection: ISO228/1-G

3/8" NPT, 1/2" (13mm)

hose and 1/2" NPT,

3/4" (19mm) hose

Liquid temperature: Max. +120°F (+50°C)

Fasteners: Stainless steel

Max. suction lift: 6.5 ft (2m)

Cut in pressure: 1.7 Bar/25 psi

Cut-off pressure: 2.8 Bar/41 psi

Duty cycle: Intermittent,

max 20 min

Motor: 87W, 12V DC

with built in

thermal protection

Weight: 3.5 lb (1.6kg)

The motor and switch are ignition protected

according to ISO 8846 (Small craft – Electrical

devices – Protection against ignition of surrounding

flammable gases).

Pressure and capacity data

Based on water at 68°F (+20°C) and at full voltage

of the motor.

Amperage

Pressure Flow draw

Bar kPa Psi L/min GPM 12V

0 0 0 9.4 2.4 2.5A

0.4 40 5.8 8.8 2.3 3.3A

0.8 80 11.6 8.1 2.1 4.0A

1.2 120 17.4 7.3 1.9 4.6A

1.6 160 23.2 6.7 1.8 5.2A

2.0 200 29 5.8 1.5 5.8A

2.4 240 34.8 4.9 1.3 6.4A

2.8 280 40.6 4.1 1.1 6.9A

Fuse required: 10A

ENGLISH

4

Installation

Locate the pump in a dry location.

1. If the pump is mounted vertically, the motor shall

face up.

2. Mark screw positions and drill pilot holes

(see drilling template page 16).

3. Mount the pump using stainless steel screws

taking care not to over compress the vibration

dampening rubber feet.

4. Reinforced, high-pressure flexible tubing is

recommended. If rigid pipe is used, a length

(minimum 9"/225 mm) of flexible tubing shall be

installed between the pump and the rigid pipe.

This will address noise and/or damage caused by

vibration transmitted to rigid pipe.

5. Use stainless steel hose clamps to secure tubing

to quick disconnect fittings and other hose barbs

in the system.

NOTE: The strainer must be installed in line before

the pump intake, to prevent debris from entering

pump and interfering with proper functioning

of valves.

Electrical installation

1. The pump must be installed according to SS-EN

ISO 10133 (Small craft – Electrical system –

Extra low voltage DC installation for continous

current). Note: The fuse must be ignition

protected.

2. The motor is equipped with built in thermal

protection to prevent the motor from overheating.

The protection is automatically restored when the

motor is cooled.

3. If the pump is connected with separate earth

lead, this should be yellow/green and connected

to the motor base.

4. See the wiring table for correct installation.

Negative wire must be black. Choose wire size in

accordance with total wire length.

5. The wire connections must be sealed with a

marine sealant.

NOTE: Before installation with electrical control

systems, check that equipment to be used is of

sufficient rated capacity to accept amperage draw

of motor. Low voltage will cause motor to overheat.

Maintenance

The system shall be periodically sanitized using

the following procedure:

1. Fill the tank with a solution of household bleach

and potable watern .03 oz. (1ml) bleach to

32 oz. (1 L) water.

2. Open all faucets and run until water flowing

smells of bleach.

3. Close all faucets.

4. Drain solution from tank.

5. Refill tank with potable water.

6. Open all faucets and run until bleach has

been purged.

Max wire

Wire size length* in m

18 GA (1.0 mm2) 11.9

16 GA (1.5 mm2) 17.9

14 GA (2.5 mm2) 29.8

* The wire length is the total distance from the

battery to the pump and back to the battery.

It is recommended to use a relay with a light

wire from main cable to switch to shorten the

main leaders.

Wiring dimensions

(based on 10% voltage drop)

Other electrical devices, e.g. switch, circuit breaker,

must be installed between the pump and the

positive (+) lead on the battery (on the red wire).

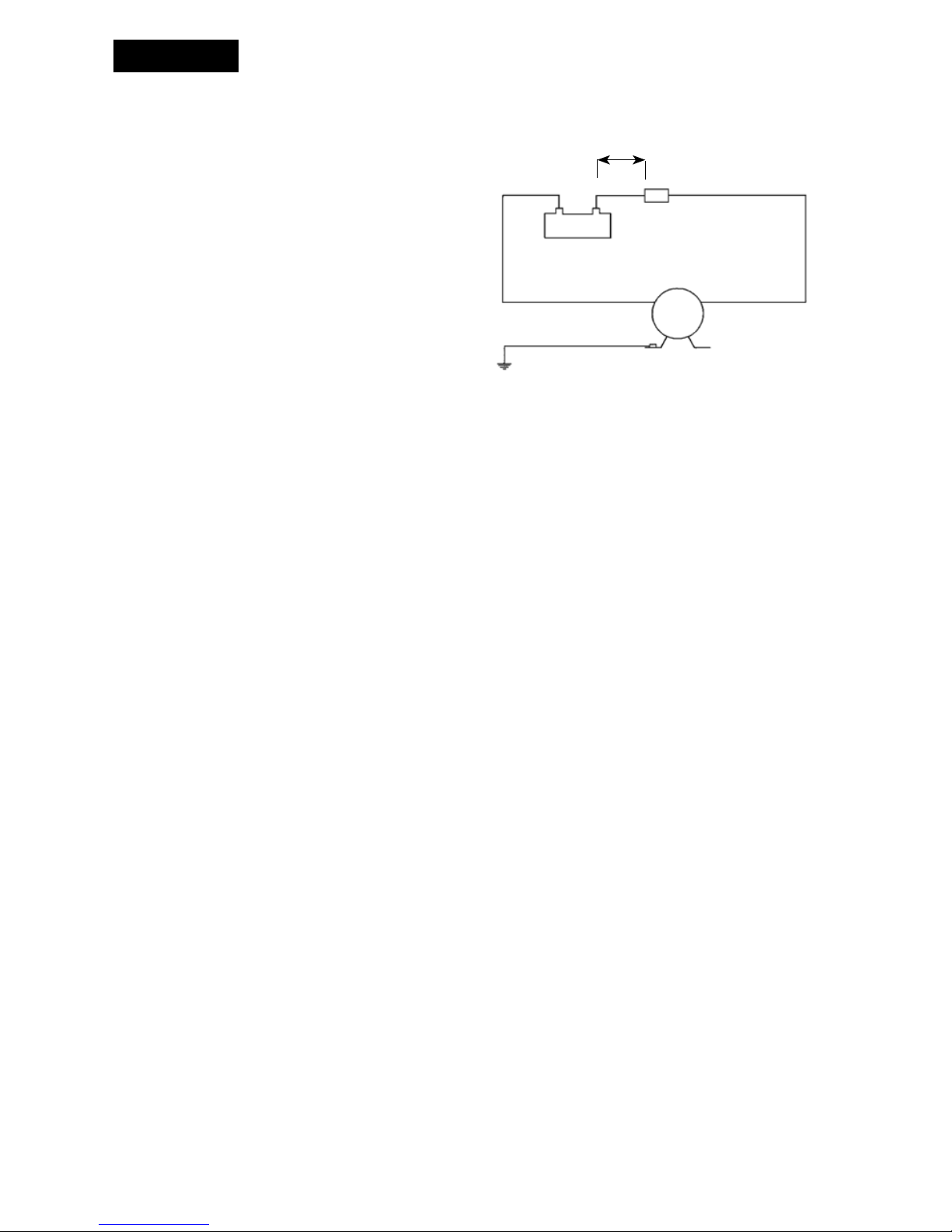

Wiring table

Pump

Terminal

fuse

Max 8" (0.2m)

Red

Black

Green/yellow

+

–

ENGLISH

5

There’s nothing more important to us than customer satisfaction.

If you have any questions or your purchase does not meet your

expectations, please do one of the following:

• Contact your local West Marine store

• Call

1-800-BOATING

• Contact us at www.westmarine.com

Start-up procedure

After pump installation, the system can be started

by using the following procedure:

• Fill water tank

• Open one tap

• Turn on pump

• Close tap once water begins flowing

• Open each additional tap until all air has

been purged from system

• Pump will shut off after taps are closed

and pressure builds to the set point of the

pressure switch

Self-priming

Pump is self-priming up to 6 ft (2m). Intake lines

must be air-tight to ensure self-priming.

Dry running

Pump will not be damaged by shorter period

of dry running. It will, however, unnecessarily

reduce your battery power.

CAUTION: Do not use pump for any liquids other

than fresh water and sea water.

Temperature

Max liquid temperature: +120°F (+50°C)

Max ambient temperature: +140°F (+60°C)

Winterizing

If water is not drained from the system during

freezing temperatures, damage is likely to be

sustained in the plumbing and in the pump. To

prevent damage follow the instructions below:

1. Drain water storage tank.

2. Open all taps.

3. Run pump until remaining water is expelled.

4. Disconnect inlet and outlet tubes.

5. Run pump briefly to confirm that

water has been expelled.

6. Taps shall remain open and pump fittings shall

remain disconnected until temperatures are

above freezing.

Never start a frozen pump. Even if it is drained

it might contain a small amount of frozen water

that locks the rotor.

Accessory

Model 7923667 Universal Strainer

ENGLISH

Loading...

Loading...