Westinghouse WH1000i, WH2000iXLT Owner's Manual

California

Proposition 65 Warning

The engine exhaust from this product

contains chemicals known to the state of

California to cause cancer, birth defects

or other reproductive harm.

Proposition 65 Warning

Certain components in this product and its

related accessories contain chemicals

known to the state of California to cause

cancer, birth defects or other reproductive

harm. Wash hands after handling.

California

DISCLAIMERS:

All information, illustrations and specifications in this manual are based on the latest information available at

the time of publishing. The illustrations used in this manual are intended as representative reference views only.

Moreover, because of our continuous product improvement policy, we may modify information, illustrations and/or

specifications to explain and/or exemplify a product, service or maintenance improvement. We reserve the right to

make any change at any time without notice. Some images may vary depending upon which model is shown.

ALL RIGHTS RESERVED:

No part of this publication may be reproduced or used in any form by any means – graphic, electronic or

mechanical, including photocopying, recording, taping or information storage and retrieval systems – without the

written permission of Westpro Power Systems, LLC.

2

CONGRATULATIONS ON OWNING A WESTINGHOUSE

INVERTER

!

DANGER

This manual contains important instructions for operating this inverter. For your safety and the

!

For Your Records:

Date of Purchase: Inverter Model Number:

Purchased from Store/Dealer: Inverter Serial Number:

Purchase Receipt: (retain your purchase receipt to ensure trouble-free warranty coverage)

Product Registration

To ensure trouble-free warranty coverage, it is important you register your Westinghouse inverter. You can register

your inverter by either:

1. Filling in the product registration form below and mailing to:

2. Registering your product online at www.westpropower.com

To register your inverter you will need to locate the model number

and serial number. The serial number tag is located toward the

bottom of the inverter housing on the opposite side of the muffler.

safety of others, be sure to read this manual thoroughly before operating the inverter. Failure to

properly follow all instructions and precautions can cause you and others to be seriously hurt

or killed.

Product Registration

Westpro Power Systems, LLC

W237 N2889 Woodgate Road, Unit B

Pewaukee, WI 53072

Model Number

Product Registration Form

PERSONAL INFORMATION INVERTER INFORMATION

First Name: Model Number:

Last Name: Serial Number:

Street Address: Date Purchased:

Street Address: Purchased From:

City, State, ZIP:

Country:

Phone Number:

E-Mail:

TABLE OF CONTENTS

CONGRATULATIONS ON OWNING A WESTINGHOUSE INVERTER ..............................................................3

For Your Records: .........................................................................................................................................3

Product Registration .....................................................................................................................................3

Product Registration Form ............................................................................................................................3

SAFETY ....................................................................................................................................................................7

SAFETY DEFINITIONS ......................................................................................................................................7

SAFETY SYMBOL DEFINITIONS ......................................................................................................................7

GENERAL SAFETY RULES ...............................................................................................................................8

SAFETY LABELS AND DECALS – WH1000i ................................................................................................... 10

SAFETY LABELS AND DECALS – WH2000i SERIES .....................................................................................12

SAFETY LABELS AND DECALS – WH2000iXLT .............................................................................................14

UNPACKING ...........................................................................................................................................................16

UNPACKING THE INVERTER ..........................................................................................................................16

Components: ..............................................................................................................................................16

FEATURES .............................................................................................................................................................17

GENERAL INVERTER FEATURES – WH1000i ...............................................................................................17

CONTROL PANEL FEATURES – WH1000i ......................................................................................................18

GENERAL INVERTER FEATURES – WH2000i SERIES .................................................................................19

CONTROL PANEL FEATURES – WH2000i SERIES ........................................................................................20

GENERAL INVERTER FEATURES – WH2000iXLT .........................................................................................21

CONTROL PANEL FEATURES – WH2000iXLT ................................................................................................22

OPERATION ...........................................................................................................................................................23

BEFORE STARTING THE INVERTER..............................................................................................................23

INVERTER PARALLELING OPERATION – WH2000iXLT ONLY ......................................................................24

INITIAL OIL FILL ...............................................................................................................................................25

WH1000i .....................................................................................................................................................25

WH2000i Series ..........................................................................................................................................26

ADDING / CHECKING ENGINE FLUIDS AND FUEL .......................................................................................28

Checking and / or Adding Engine Oil ..........................................................................................................28

Adding Gasoline to the Fuel Tank ...............................................................................................................28

STARTING THE INVERTER .............................................................................................................................29

Using Efficiency Mode ................................................................................................................................30

Resetting the Reset Breaker ......................................................................................................................30

STOPPING THE INVERTER.............................................................................................................................31

Normal Operation .......................................................................................................................................31

During an Emergency .................................................................................................................................31

MAINTENANCE ......................................................................................................................................................32

MAINTENANCE ................................................................................................................................................32

Maintenance Schedule ...............................................................................................................................32

ENGINE OIL MAINTENANCE ..........................................................................................................................33

Engine Oil Specification ..............................................................................................................................33

Checking Engine Oil – WH1000i ................................................................................................................33

Checking Engine Oil – WH2000i Series .....................................................................................................34

Adding Engine Oil – WH1000i ....................................................................................................................34

Adding Engine Oil – WH2000i Series .........................................................................................................35

Changing Engine Oil – WH1000i ................................................................................................................35

Changing Engine Oil – WH2000i Series .....................................................................................................36

AIR FILTER MAINTENANCE ............................................................................................................................36

Cleaning the Air Filter – WH1000i ..............................................................................................................36

Cleaning the Air Filter – WH2000i Series ...................................................................................................37

DRAINING THE FLOAT BOWL .........................................................................................................................38

WH1000i .....................................................................................................................................................38

WH2000i Ser

SPARK PLUG MAINTENANCE ........................................................................................................................39

CLEANING THE SPARK ARRESTOR ..............................................................................................................41

CLEANING THE INVERTER .............................................................................................................................41

ies ..........................................................................................................................................39

5

TABLE OF CONTENTS

STORAGE .........................................................................................................................................................41

SERVICE PARTS ..............................................................................................................................................44

WH1000i Service Parts ..............................................................................................................................44

WH2000i Series Service Parts ...................................................................................................................46

TROUBLESHOOTING ............................................................................................................................................48

TROUBLESHOOTING ......................................................................................................................................48

6

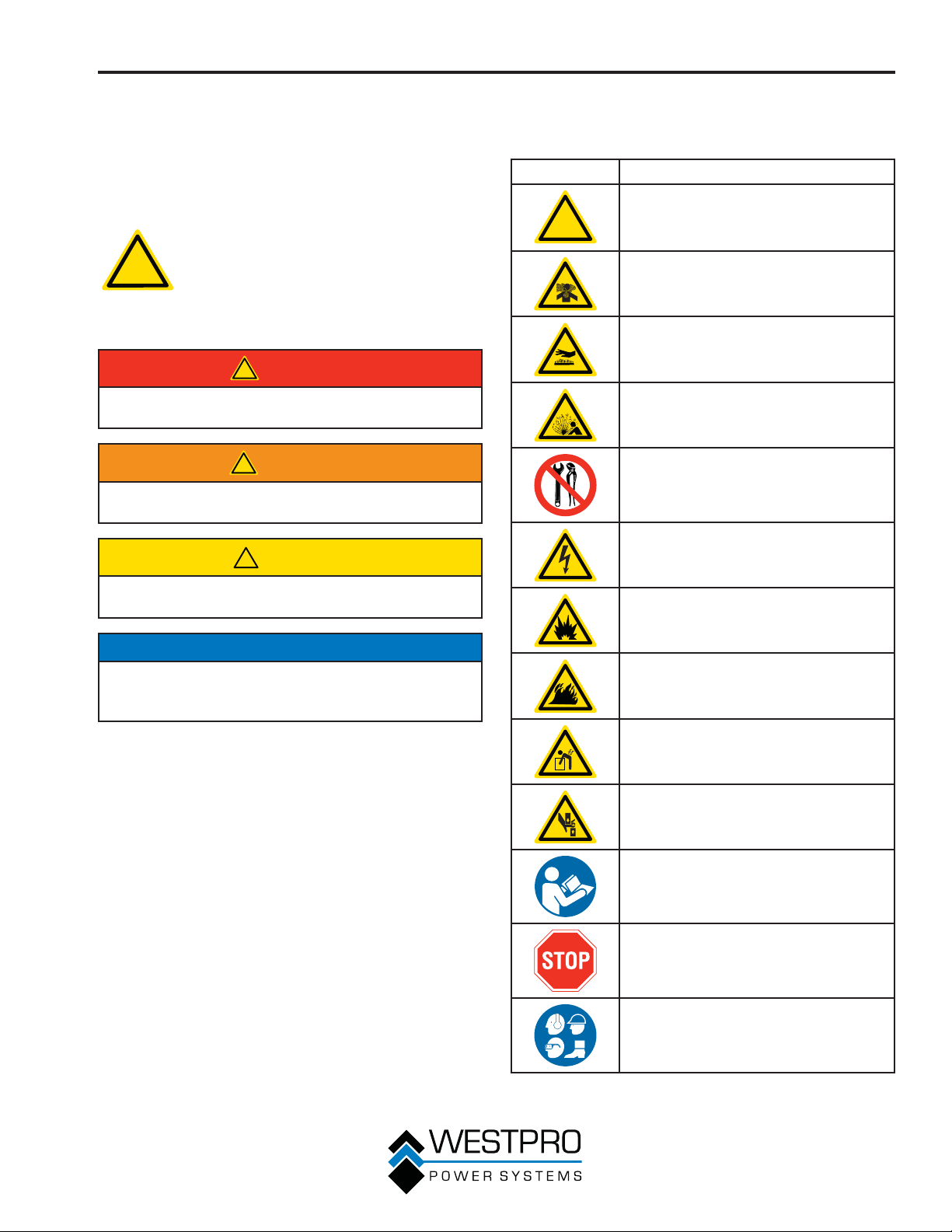

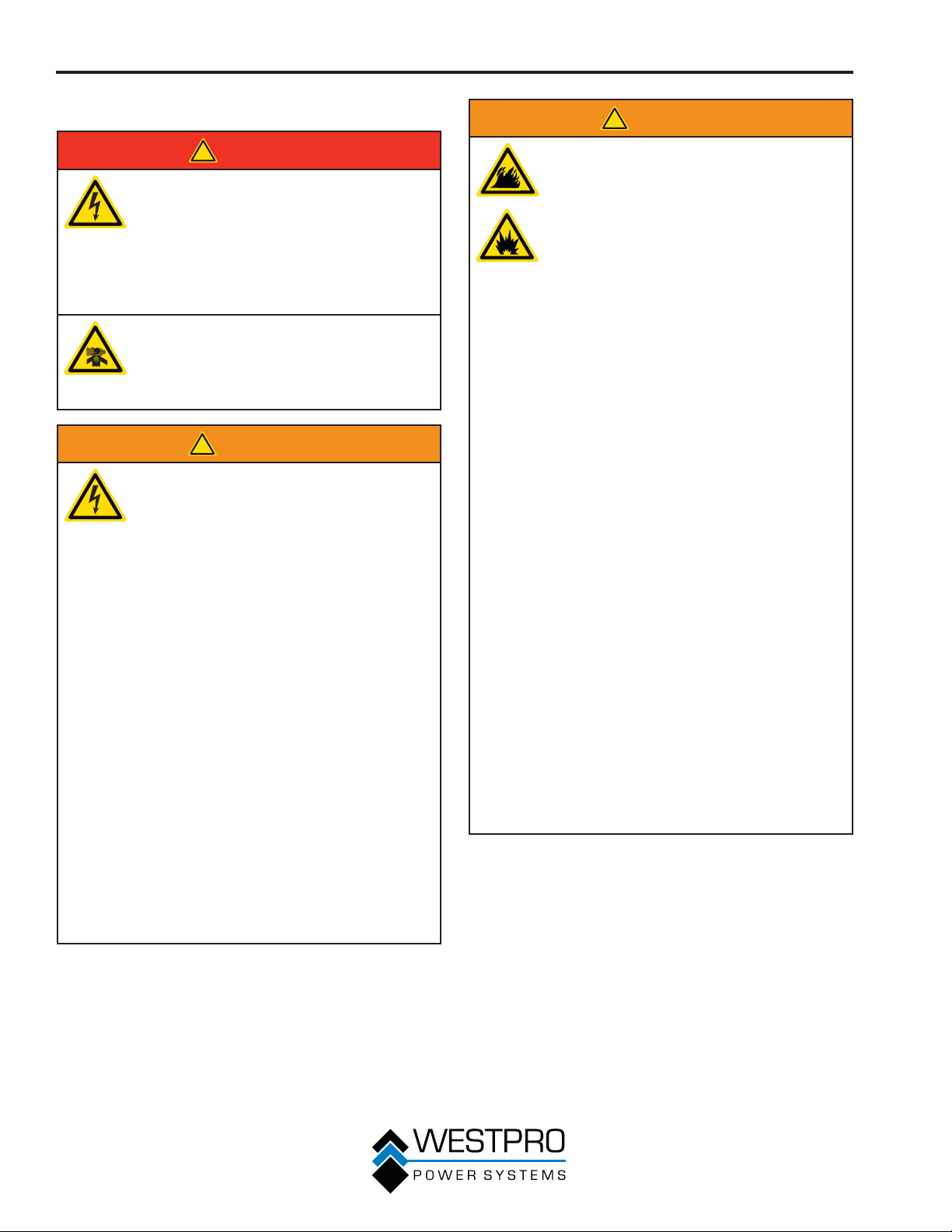

SAFETY

SAFETY DEFINITIONS

The words DANGER, WARNING, CAUTION and

NOTICE are used throughout this manual to highlight

important information. Be certain that the meanings of

these alerts are known to all who work on or near the

equipment.

This safety alert symbol appears

with most safety statements. It

!

Indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

means attention, become alert, your

safety is involved! Please read and

abide by the message that follows

the safety alert symbol.

!

DANGER

!

WARNING

!

CAUTION

SAFETY SYMBOL

DEFINITIONS

Symbol Description

!

Safety Alert Symbol

Asphyxiation Hazard

Burn Hazard

Burst/Pressure Hazard

Don’t leave tools in the area

Electrical Shock Hazard

Explosion Hazard

NOTICE

Indicates a situation which can cause damage to the

inverter, personal property and/or the environment, or

cause the equipment to operate improperly.

OTE:N Indicates a procedure, practice or condition

that should be followed in order for the

inverter to function in the manner intended.

Fire Hazard

Lifting Hazard

Pinch-Point Hazard

Read Manufacturer’s Instructions

Read Safety Messages Before

Proceeding

Wear Personal Protective Equipment

(PPE)

7

SAFETY

GENERAL SAFETY RULES

!

DANGER

Never use the inverter in a location

that is wet or damp. Never expose the

inverter to rain, snow, water spray or

standing water while in use. Protect

the inverter from all hazardous weather

conditions. Moisture or ice can cause a

short circuit or other malfunction in the

electrical circuit.

Never operate the inverter in an

enclosed area. Engine exhaust

contains carbon monoxide. Only

operate the inverter outside and away

from windows, doors and vents.

!

WARNING

Voltage produced by the inverter could

result in death or serious injury.

• Never operate the inverter in rain or a

floodplain unless proper precautions

are taken to avoid being subject to

rain or a flood.

• Never use worn or damaged

extension cords.

• Always have a licensed electrician

connect the inverter to the utility

circuit.

• Never touch an operating inverter if

the inverter is wet or if you have wet

hands.

• Never operate the inverter in highly

conductive areas such as around

metal decking or steel works.

• Always use grounded extension

cords. Always use three-wire or

double-insulated power tools.

• Never touch live terminals or bare

wires while the inverter is operating.

• Be sure the inverter is properly

grounded before operating.

!

WARNING

Gasoline and gasoline vapors are

extremely flammable and explosive

under certain conditions.

• Always refuel the inverter outdoors,

in a well-ventilated area.

• Never remove the fuel cap with the

engine running.

• Never refuel the inverter while the

engine is running. Always turn

engine off and allow the inverter to

cool before refueling.

• Only fill fuel tank with gasoline.

• Keep sparks, open flames or other

form of ignition (such as match,

cigarette, static electric source) away

when refueling.

• Never overfill the fuel tank. Leave

room for fuel to expand. Overfilling

the fuel tank can result in a sudden

overflow of gasoline and result in

spilled gasoline coming in contact

with HOT surfaces. Spilled fuel can

ignite. If fuel is spilled on the inverter,

wipe up any spills immediately.

Dispose of rag properly. Allow area

of spilled fuel to dry before operating

the inverter.

• Wear eye protection while refueling.

• Never use gasoline as a cleaning

agent.

• Store any containers containing

gasoline in a well-ventilated area,

away from any combustibles or

source of ignition.

• Check for fuel leaks after refueling.

Never operate the engine if a fuel leak

is discovered.

8

!

WARNING

Never operate the inverter if powered

items overheat, electrical output drops,

there is sparking, flames or smoke

coming from the inverter, or if the

receptacles are damaged.

Never use the inverter to power

medical support equipment.

!

Always remove any tools or other

service equipment used during

maintenance from the inverter before

operating.

NOTICE

Never modify the inverter.

Never operate the inverter if it vibrates at high levels,

if engine speed changes greatly or if the engine

misfires often.

Always disconnect tools or appliances from the

inverter before starting.

SAFETY

9

SAFETY

SAFETY LABELS AND DECALS – WH1000i

5

1

6

3

2

4

10

1

3

5

Figure 1

2

4

6

FRONT

BACK

SAFETY

4

5

3

1

2

6

1

4

2

5

Figure 2

3

6

11

SAFETY

SAFETY LABELS AND DECALS – WH2000i SERIES

6

3

1

5

2

4

1

3

5

2

4

6

FRONT

BACK

12

Figure 3

SAFETY

3

1

4

5

2

1

3

4

2

5

Figure 4

13

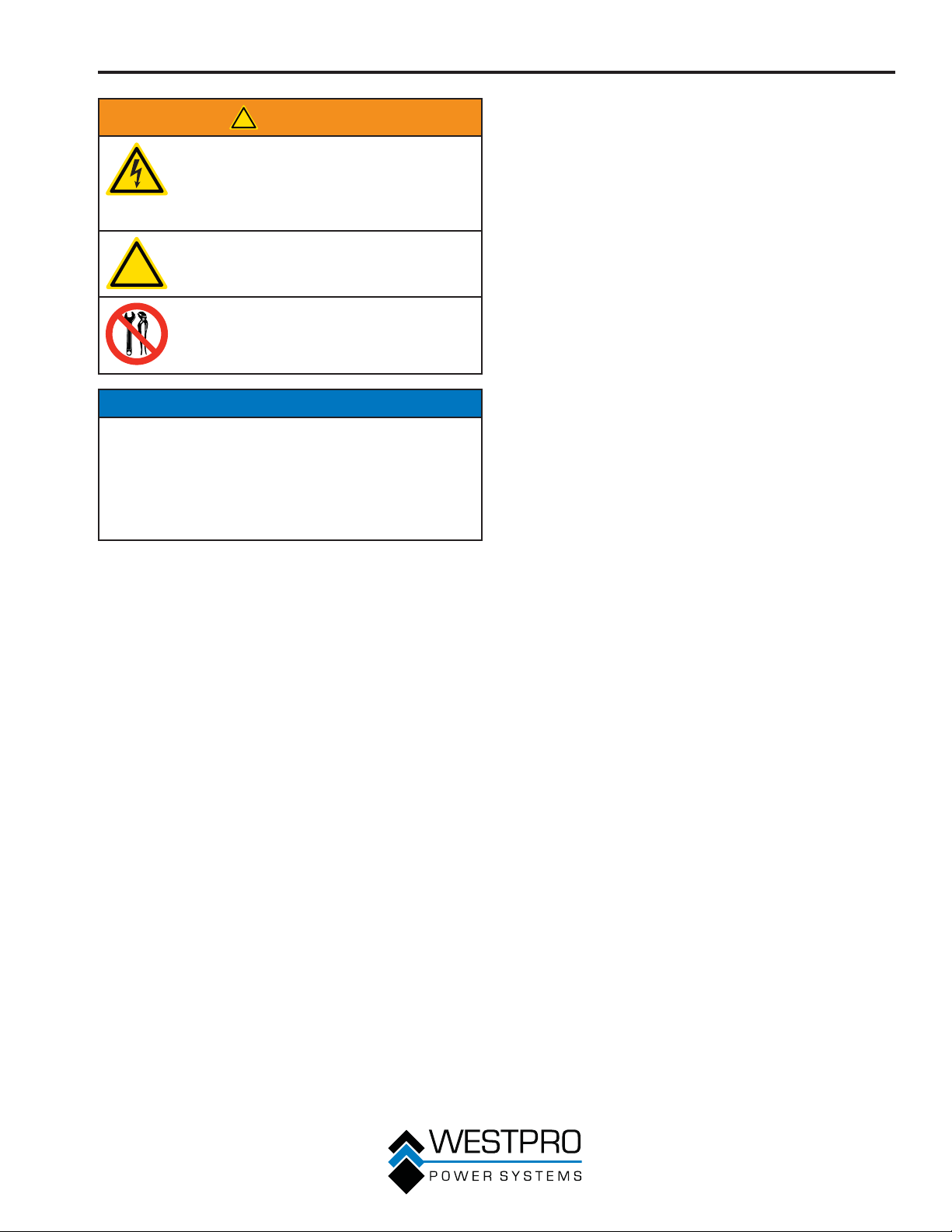

SAFETY

SAFETY LABELS AND DECALS – WH2000iXLT

6

3

1

5

2

7

1

3

5

Figure 5

4

2

4

6

FRONT

7

BACK

14

SAFETY

3

1

4

5

2

1

3

4

2

5

Figure 6

15

UNPACKING

UNPACKING THE INVERTER

!

CAUTION

Always have assistance when lifting

the inverter. The inverter is heavy;

lifting it could cause bodily harm.

Avoid cutting on or near staples to

prevent personal injury.

!

Tools required – box cutter or similar device.

1. Carefully cut the packing tape on top of the carton.

Fold back top flaps to reveal the manual. Remove

2.

the document and save it for reference.

3. Carefully cut two sides of the carton to remove the

inverter.

Components:

Tool Bag (1)

Screwdriver (1)

Bottle of SAE 15W-40 Oil (1)

(2000i only)

Oil Fill Bottle (1)

16

GENERAL INVERTER FEATURES – WH1000i

FEATURES

1

2

3

4

5

7

6

Figure 7

1 - Control Panel: Contains the reset breaker,

outlets and warning lights.

2 - Spark Plug Access Cover: Remove the

cover to service the spark plug.

3 - Recoil Handle: Pull to start the engine.

4 - Engine/Fuel Control Switch: Turns the

engine and the fuel on and off.

17

5 - Fuel Cap and Vent: Open the vent to run the

engine and close the vent when the engine is off.

6 - Engine Service Panel: Remove the panel to

access the engine for maintenance.

7 - Muffler and Spark Arrestor: Avoid contact

until the engine is cooled down. The spark

arrestor prevents sparks from exiting the

muffler. It must be removed for servicing.

FEATURES

CONTROL PANEL FEATURES – WH1000i

1

678

Figure 8 – Control Panel Features

1 - 120-Volt, 20-Amp Duplex Outlet (NEMA

5-20R): The outlet is capable of carrying a

maximum of 20 amps.

2 - Reset Breaker: If the inverter is overloaded,

the reset breaker will trip. The engine will

continue to run, but there will be no output

from the inverter. Unplug the devices and

reduce the load. Push in the reset breaker to

reset it.

3 - Choke Knob: Pull out to the ON position

to start the engine, and push in to the OFF

position once the engine is running.

4 - Efficiency Mode Switch: When turned to the

ON position, the engine will sense the load

needed and run at a slower RPM to save fuel.

2

3

4

5

5 - Ground Terminal: The ground terminal is used

to externally ground the inverter.

6 - Low Oil LED: The red light will come on

and the engine will shut down if the oil level

becomes low. You must add oil to the correct

level before the inverter can be restarted.

7 - Overload LED: The red light will come on if the

inverter is overloaded. Decrease the load before

restoring inverter operations.

8 - Output Ready LED: The light will be green

when the inverter is ready to be used.

18

FEATURES

GENERAL INVERTER FEATURES – WH2000i SERIES

2

1

3

4

9

8

5

6

7

Figure 9

1 - Control Panel: Contains the reset breaker,

outlets and warning lights.

2 - Choke Knob: Pull out to the ON position

to start the engine, and push in to the OFF

position once the engine is running.

3 - Recoil Handle: Pull to start the engine.

4 - Engine/Fuel Control Switch: Turns the

engine and the fuel on and off.

5 - Spark Plug Access Cover: Remove the

cover to service the spark plug.

19

6 - Engine Oil Fill/Drain Plug Service Panel:

Remove the panel to access the engine oil fill/

drain plug for maintenance.

7 - Air Cleaner Access Panel: Remove the panel

to access the air cleaner for maintenance.

8 - Fuel Cap and Vent: Open vent to run the engine,

and close the vent when the engine is off.

9 - Muffler and Spark Arrestor: Avoid contact until

the engine is cooled down. The spark arrestor

prevents sparks from exiting the muffler. It must

be removed for servicing.

FEATURES

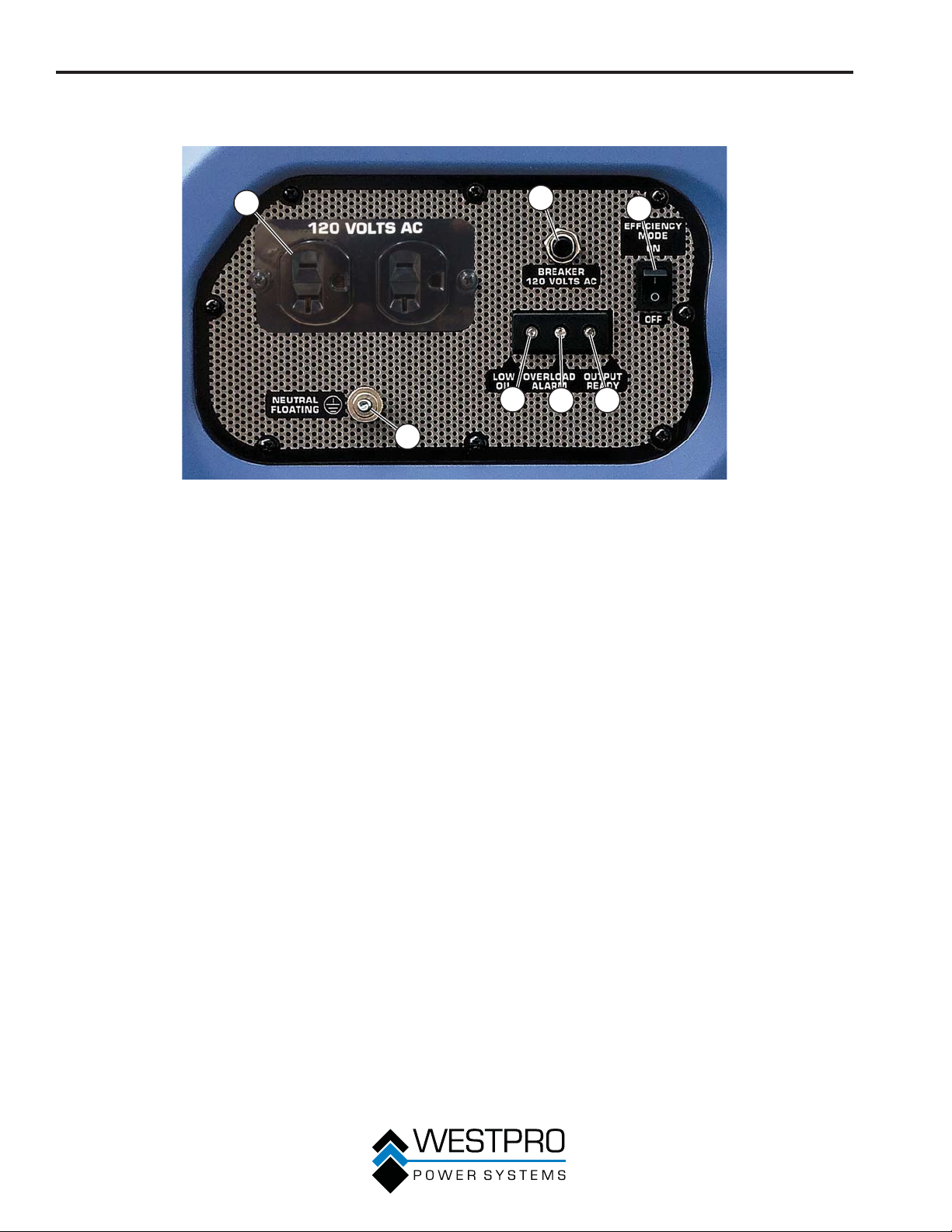

CONTROL PANEL FEATURES – WH2000i SERIES

1

7

Figure 10 – Control Panel Features

1 - 120-Volt, 20-Amp Duplex Outlet (NEMA

5-20R): The outlet is capable of carrying a

maximum of 20 amps.

2 - Reset Breaker: If the inverter is overloaded,

the reset breaker will trip. The engine will

continue to run, but there will be no output

from the inverter. Unplug the devices and

reduce the load. Push in the reset breaker to

reset it.

3 - Efficiency Mode Switch: When turned to the

ON position, the engine will sense the load

needed and run at a slower RPM to save fuel.

2

6

4 - Output Ready LED: The light will be green

5 - Overload LED: The red light will come on if

6 - Low Oil LED: The red light will come on

7 - Ground Terminal: The ground terminal is

5

when the inverter is ready to be used.

the inverter is overloaded. Decrease the load

before restoring inverter operations.

and the engine will shut down if the oil level

becomes low. You must add oil to the correct

level before the inverter can be restarted.

used to externally ground the inverter.

3

4

20

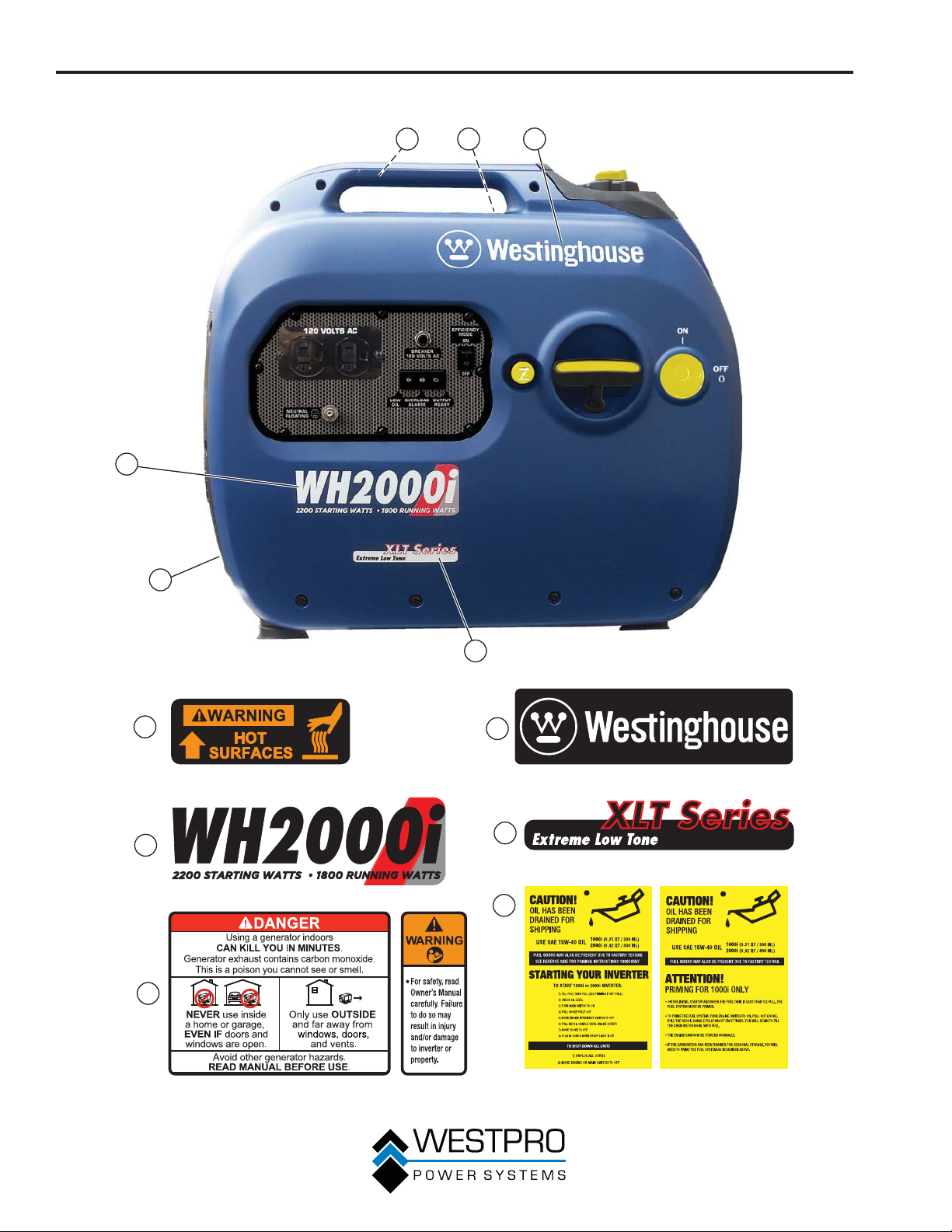

FEATURES

GENERAL INVERTER FEATURES – WH2000iXLT

2

3

1

9

4

8

7

1 - Control Panel: Contains the reset breaker,

outlets and warning lights.

2 - 12-Volt DC Power Socket: Provides 12-volt

DC power up to 8 amps.

3 - Recoil Handle: Pull to start the engine.

4 - Engine/Fuel Control Switch: Turns the

engine and the fuel on and off.

5 - Spark Plug Access Cover: Remove the

cover to service the spark plug.

5

6

Figure 11

6 - Engine Oil Fill/Drain Plug Service Panel:

Remove the panel to access the engine oil fill/

drain plug for maintenance.

7 - Air Cleaner Access Panel: Remove the panel

to access the air cleaner for maintenance.

8 - Fuel Cap and Vent: Open vent to run the engine,

and close the vent when the engine is off.

9 - Muffler and Spark Arrestor: Avoid contact until

the engine is cooled down. The spark arrestor

prevents sparks from exiting the muffler. It must

be removed for servicing.

21

FEATURES

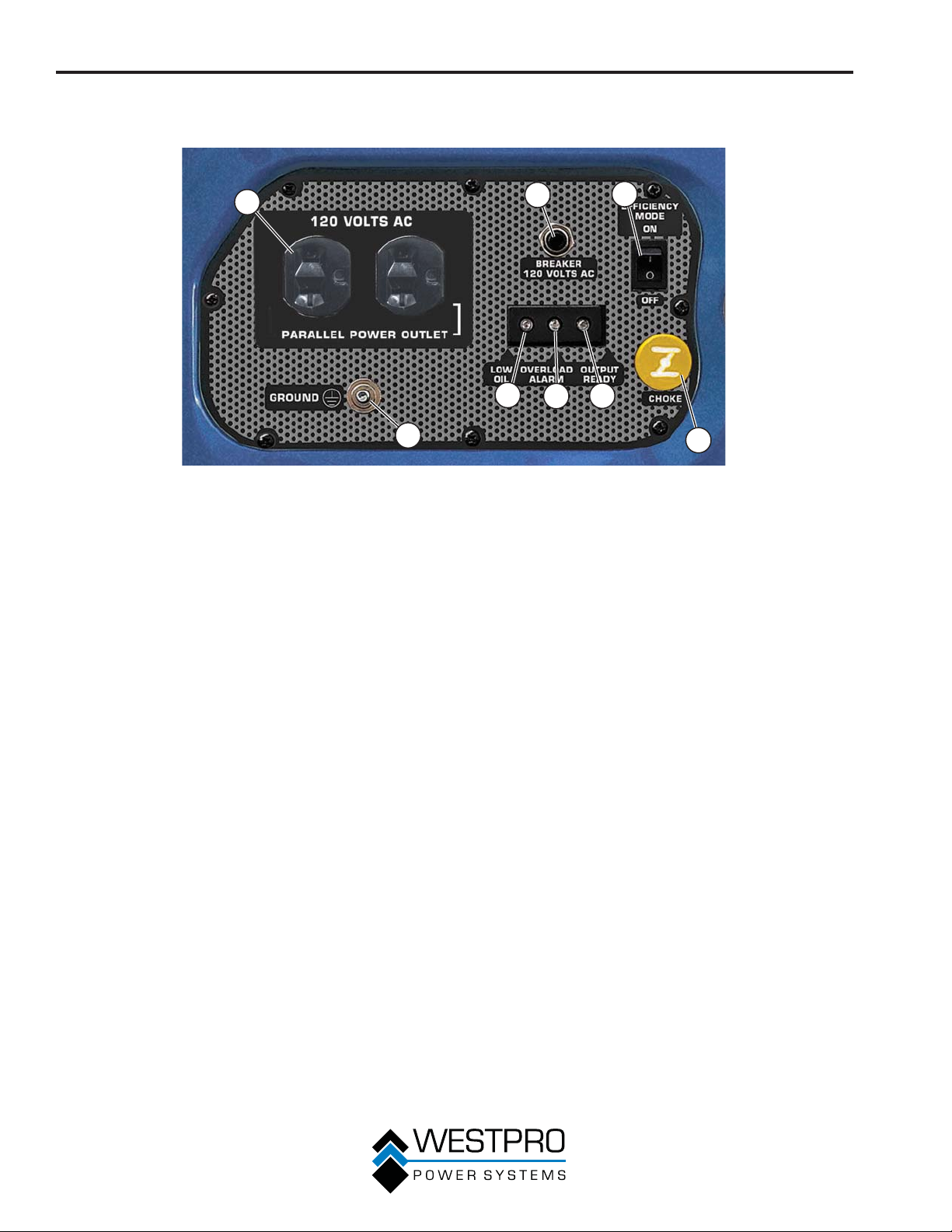

CONTROL PANEL FEATURES – WH2000iXLT

1

8

Figure 12 – Control Panel Features

1 - 120-Volt, 20-Amp Duplex Outlet (NEMA

5-20R): The outlet is capable of carrying a

maximum of 20 amps.

2 - Reset Breaker: If the inverter is overloaded,

the reset breaker will trip. The engine will

continue to run, but there will be no output

from the inverter. Unplug the devices and

reduce the load. Push in the reset breaker to

reset it.

3 - Efficiency Mode Switch: When turned to the

ON position, the engine will sense the load

needed and run at a slower RPM to save fuel.

4 - Choke Knob: Pull out to the ON position

to start the engine, and push in to the OFF

position once the engine is running.

2

7

6

3

5

4

5 - Output Ready LED: The light will be green

when the inverter is ready to be used.

6 - Overload LED: The red light will come on if

the inverter is overloaded. Decrease the load

before restoring inverter operations.

7 - Low Oil LED: The red light will come on

and the engine will shut down if the oil level

becomes low. You must add oil to the correct

level before the inverter can be restarted.

8 - Ground Terminal: The ground terminal is

used to externally ground the inverter.

22

OPERATION

BEFORE STARTING THE

INVERTER

Before starting the inverter, review

Safety on page 7.

Location Selection – Before starting the inverter, avoid

exhaust and location hazards by verifying:

x You have selected a location to operate the inverter

that is outdoors and well ventilated.

x You have selected a location with a level and solid

surface on which to place the inverter.

x You have selected a location that is at least 6 feet

(1.8 m) away from any building, other equipment or

combustible material.

x If the inverter is located close to a building, make

sure it is not located near any windows, doors

and/or vents.

Weather – Never operate your inverter outdoors during

rain, snow or any combination of weather conditions

that could lead to moisture collecting on, in or around

the inverter.

Dry Surface – Always operate the inverter on a dry

surface free of any moisture.

No Connected Loads – Make sure the inverter

has no connected loads before starting it. To ensure

there are no connected loads, unplug any electrical

extension cords that are plugged into the control panel

receptacles.

NOTICE

Starting the inverter with loads already applied to

it could result in damage to any appliance being

powered off the inverter during the brief start-up

period.

Grounding the Inverter – Consult with your local

municipalities for your grounding codes.

!

WARNING

Always operate the inverter on a level

surface. Placing the inverter on nonlevel surfaces can cause the inverter

to tip over, causing fuel and oil to spill.

Spilled fuel can ignite if it comes in

contact with an ignition source such as

a very hot surface.

NOTICE

Only operate the inverter on a solid, level surface.

Operating the inverter on a surface with loose

material such as sand or grass clippings can cause

debris to be ingested by the inverter that could:

• Block cooling vents

• Block air intake system

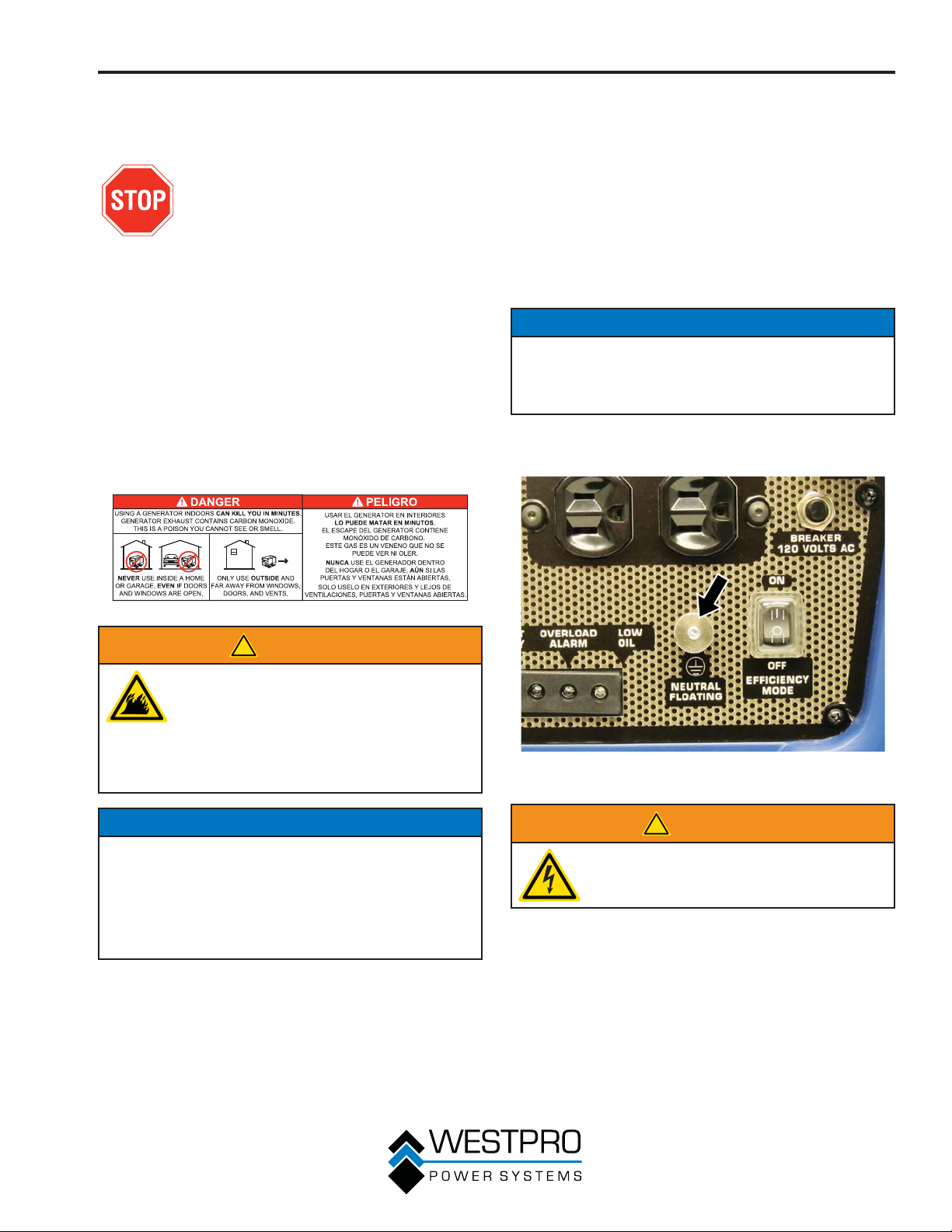

Figure 13 – Ground Terminal on the Control Panel

!

WARNING

Be sure the inverter is properly

connected to earth ground before

operating.

23

OPERATION

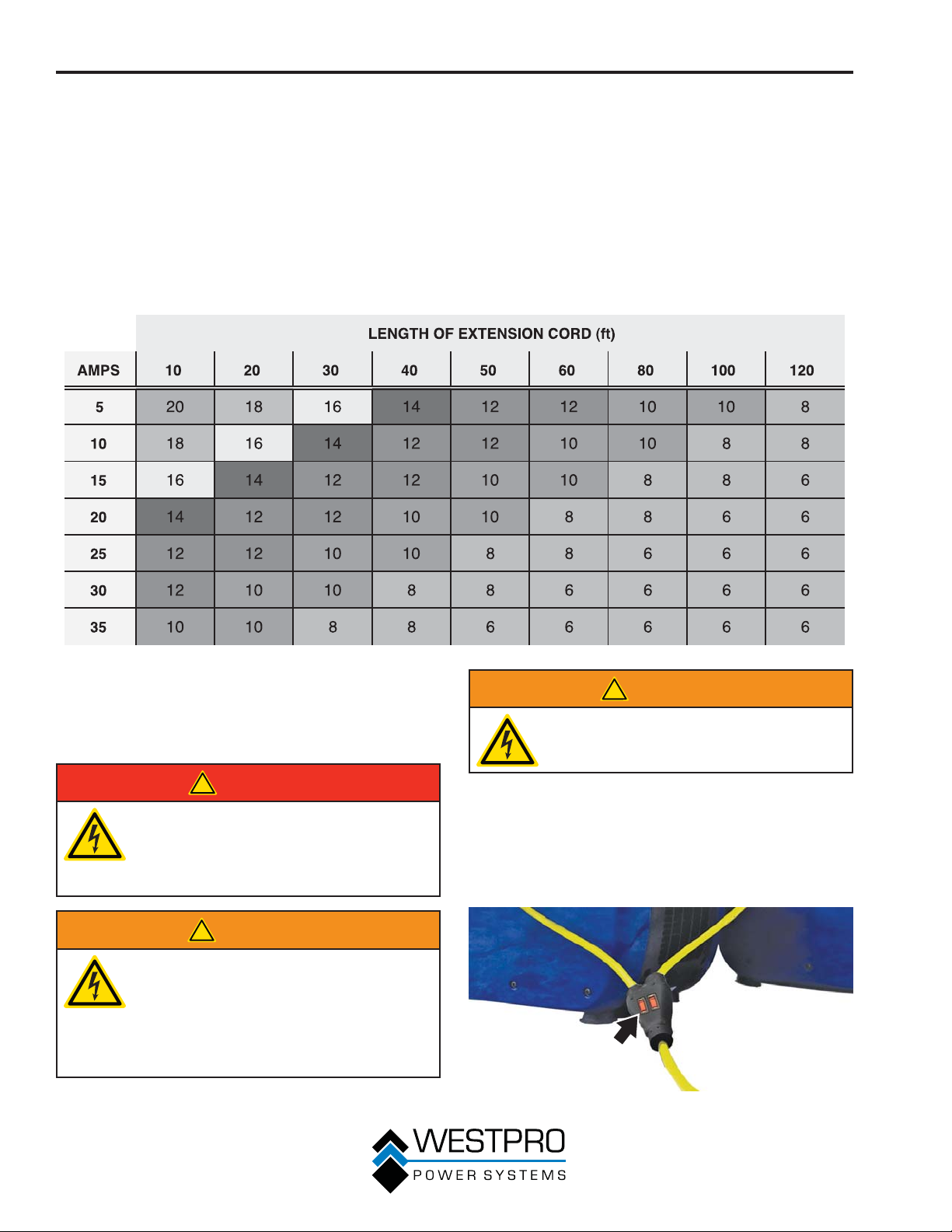

Using Extension Cords – Westpro Power Systems

assumes no responsibility for the content within this

table. The use of this table is the responsibility of the

user only. This table is intended for reference only. The

results produced by using this table are not guaranteed

to be correct or applicable in all situations as the type

and construction of cords are highly variable. Always

check with local regulations and a licensed electrician

prior to installing or connecting an electrical appliance.

Extension Cord Wire Gauge Size

INVERTER PARALLELING

OPERATION – WH2000iXLT

ONLY

!

DANGER

Never connect the paralleling cord to

the inverters with the inverters running.

The inverters must not be running and

both the paralleling cord switches must

be off when connecting the cords.

!

WARNING

Do not attempt to parallel the

Westinghouse inverter with any other

manufacturers’ inverters. Do not use

the paralleling cord for any application

other than inverter paralleling. Do not

use this cord on other manufacturers’

inverters.

!

WARNING

Always ensure that both ends of the

paralleling cord are switched off before

connecting the inverters.

1. Using only the Westinghouse paralleling cord (Part

No. 260041) with both cord switches set to OFF

(O), connect one male plug to one inverter and

connect the remaining plug into the other inverter.

Either of the receptacles on the inverters can be

used (see Figure 15).

Figure 14 – Paralleling Cord ON/OFF Switches

24

OPERATION

2. Start one of the inverters and wait until the ready

light is on.

3. Turn both cord switches to ON (I).

4. Start the remaining inverter; wait until the ready

light is on before connecting the load.

5. When power is present, a light will illuminate in the

three-prong plug that is plugged into the inverter.

Figure 15 – Paralleling Cord Connected

6. To stop the inverters, unplug all connected loads,

turn both cord switches to OFF (O) and unplug the

cord on each inverter.

7. If during operation the inverters’ output is stopped

due to overloading, reduce the connected load by

unplugging appliances, and then push the reset

button and restart the inverter. When the ready light

is on, the load can be reconnected.

WH1000i

1. Loosen the screw and remove the engine service

panel to access the oil fill/drain plug (see Figure 16).

Figure 16 – WH1000i Engine Service Panel

2. Clean area around oil fill/drain plug and remove

plug (see Figure 17).

INITIAL OIL FILL

NOTICE

Engine oil must be added when the inverter is on

a flat, level surface, or an inaccurate reading may

result. Do not overfill. If the engine is overfilled with

oil, it can cause serious engine damage.

Figure 17 – Oil Fill/Drain Plug

OTE:N The oil capacity for the 1000i is 300 ml.

25

OPERATION

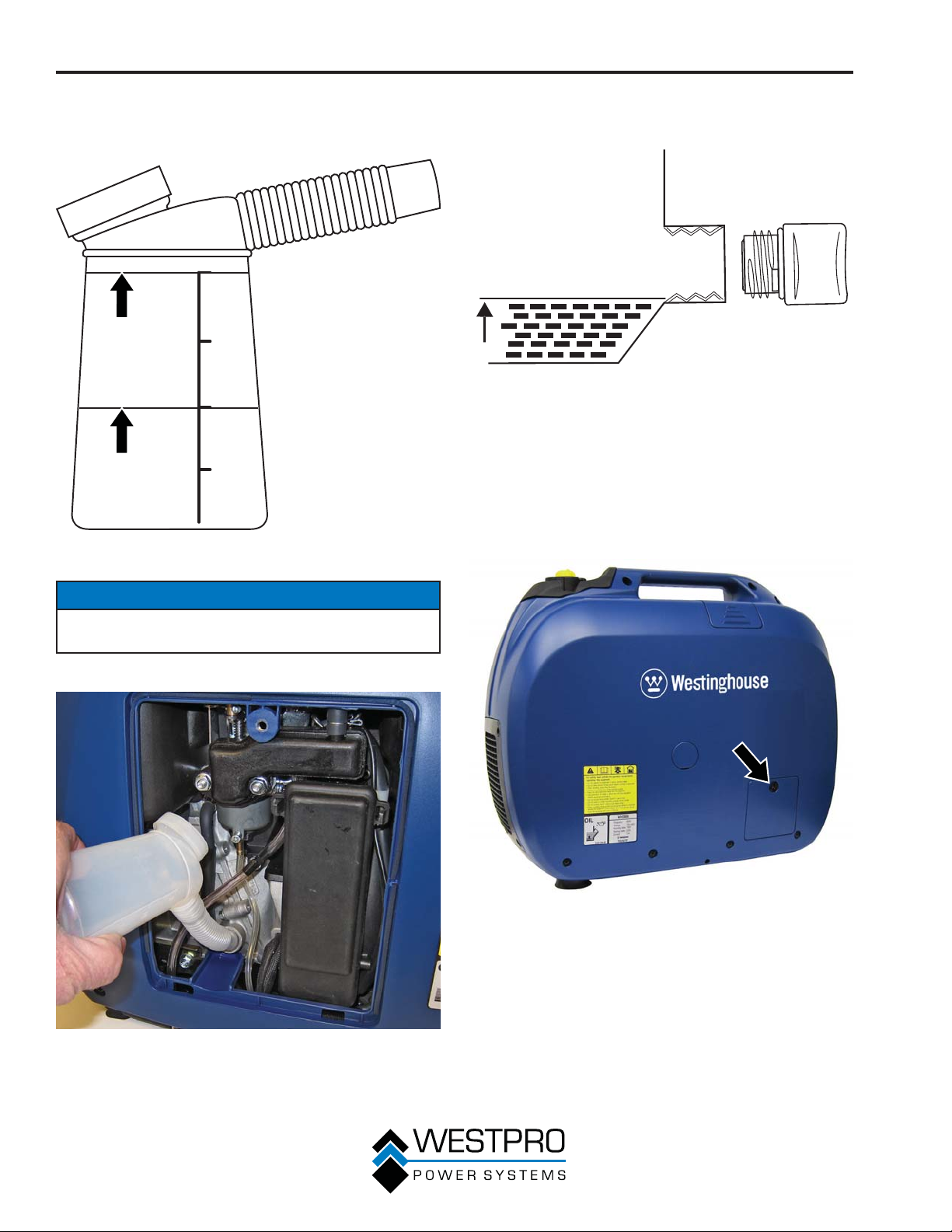

3. Using the supplied oil fill container and oil, fill the

container to the 2.0 mark on the container. Do not

overfill (see Figure 18).

2.0

1.5

1.0

0.5

Figure 18 – Oil Fill Container

6. Add the 100 ml of oil to the engine. The oil should

now be at the correct level (see Figure 20).

Figure 20 – Engine Oil Correct Level

7. Do not overfill. If oil level is too high, oil will drain out

through the fill plug.

WH2000i Series

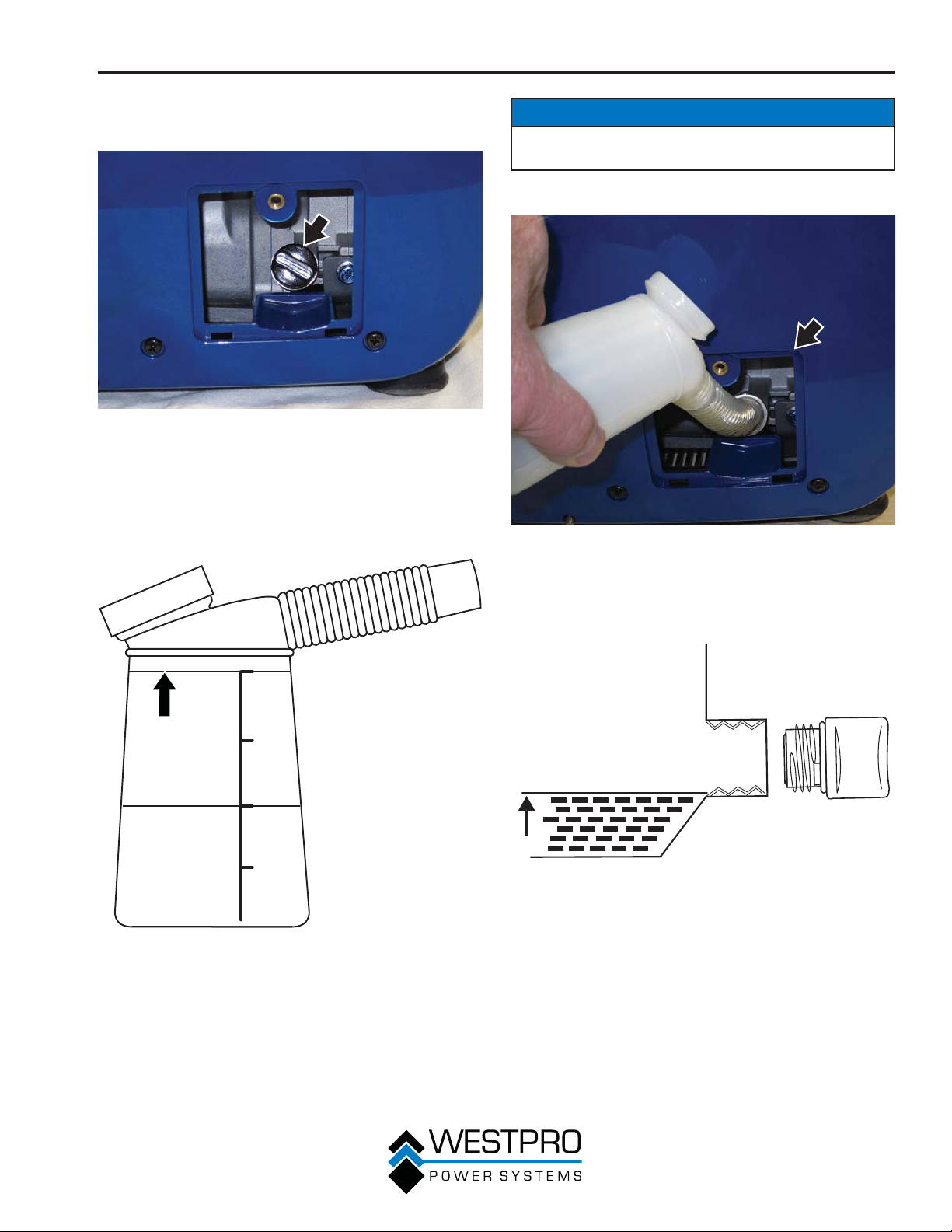

1. Loosen the screw and remove the engine oil fill/

drain plug service panel to access the oil fill/drain

plug (see Figure 21).

NOTICE

Do not tilt the inverter to add oil. It must be filled on a

flat, level surface.

4. Add the 200 ml of oil to the engine (see Figure 19).

Figure 19 – Adding Engine Oil

Figure 21 – WH2000i Engine Service Panel

5. Fill the container with oil again only to the 1.0 mark.

26

OPERATION

2. Clean the area around the oil fill/drain plug and

remove plug (see Figure 22).

Figure 22 – Oil Fill/Drain Plug

OTE:N The oil capacity for the 2000i series is

400 ml.

3. Using the supplied oil fill container and oil, fill the

container to the 2.0 mark on the container. Do not

overfill (see Figure 23).

NOTICE

Do not tilt the inverter to add oil. It must be filled on a

flat, level surface.

4. Add the 200 ml of oil to the engine (see Figure 24).

Figure 24 – Adding Engine Oil

2.0

1.5

1.0

0.5

Figure 23 – Oil Fill Container

5. Fill the container with oil again to the 2.0 mark.

6. Add the 200 ml of oil to the engine. The oil should

now be at the correct level (see Figure 25).

Figure 25 – Engine Oil Correct Level

7. Do not overfill. If oil level is too high, oil will drain out

through the fill plug.

27

OPERATION

ADDING / CHECKING ENGINE

FLUIDS AND FUEL

Before adding/checking engine

fluids and fuel, review Safety on

page 7.

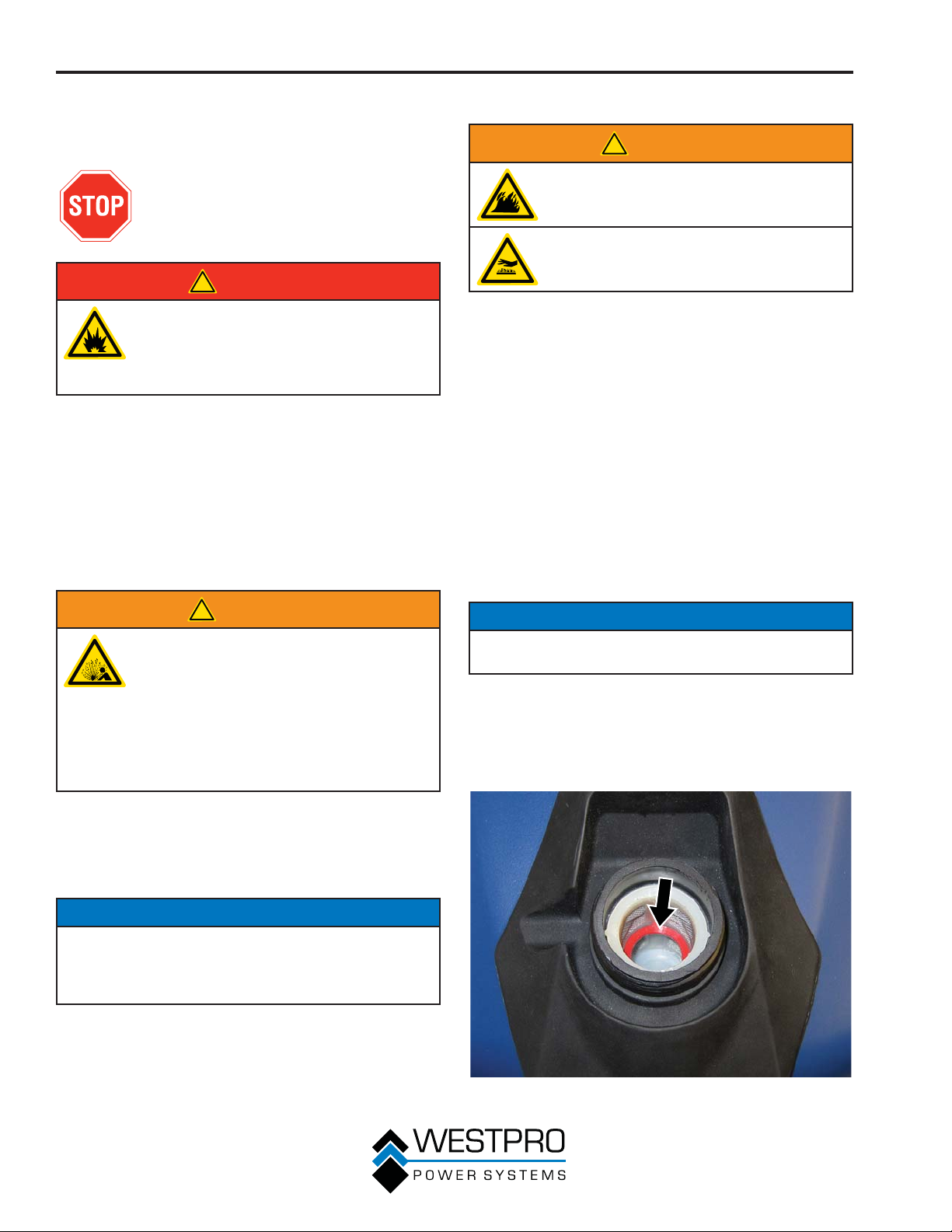

!

DANGER

Filling the fuel tank with gasoline

while the inverter is running can cause

gasoline to leak and come in contact

with hot surfaces that can ignite the

gasoline.

Before starting the inverter, always check the level of:

x Engine oil

x Gasoline in the fuel tank

Once the inverter is started and the engine gets warm,

it is not safe to add gasoline to the fuel tank or engine

oil to the engine while the engine is running or the

engine and muffler are hot.

Checking and / or Adding Engine Oil

Adding Gasoline to the Fuel Tank

!

WARNING

Never refuel the inverter while the

engine is running.

Always turn the engine off and allow

the inverter to cool before refueling.

Required Gasoline – Only use gasoline that meets the

following requirements:

x Unleaded gasoline only

x Gasoline with maximum 10% ethanol added

x Gasoline with an 87 octane rating or higher

Filling the Fuel Tank – Follow the steps below to fill the

fuel tank:

1. Shut off the inverter.

2. Allow the inverter to cool down so all surface areas

of the muffler and engine are cool to the touch.

3. Move the inverter to a flat surface.

4. Clean area around the fuel cap.

5. Remove the fuel cap by rotating counterclockwise.

!

WARNING

Internal pressure can build in the

engine crankcase while the engine

is running. Removing the oil fill plug/

dipstick while the engine is hot can

cause extremely hot oil to spray out

of the crankcase and can severely

burn skin. Allow engine oil to cool for

several minutes before removing the oil

fill plug/dipstick.

The unit as shipped does not contain oil in the

engine. You must add engine oil before starting the

inverter for the first time. See Engine Oil Maintenance

on page 33 for instructions on checking engine oil

level and the procedure for adding engine oil.

NOTICE

The inverter does not contain engine oil as shipped.

Attempting to start the engine without adding

engine oil will permanently damage internal engine

components.

NOTICE

Do not overfill the fuel tank. Spilled fuel will damage

some plastic parts.

6. Slowly add gasoline into the fuel tank. Be very

careful not to overfill the tank. The gasoline level

should NOT be higher than the red ring (see Figure

26).

7. Install the fuel cap by rotating clockwise.

28

Figure 26 – Maximum Gasoline Fill Level

OPERATION

!

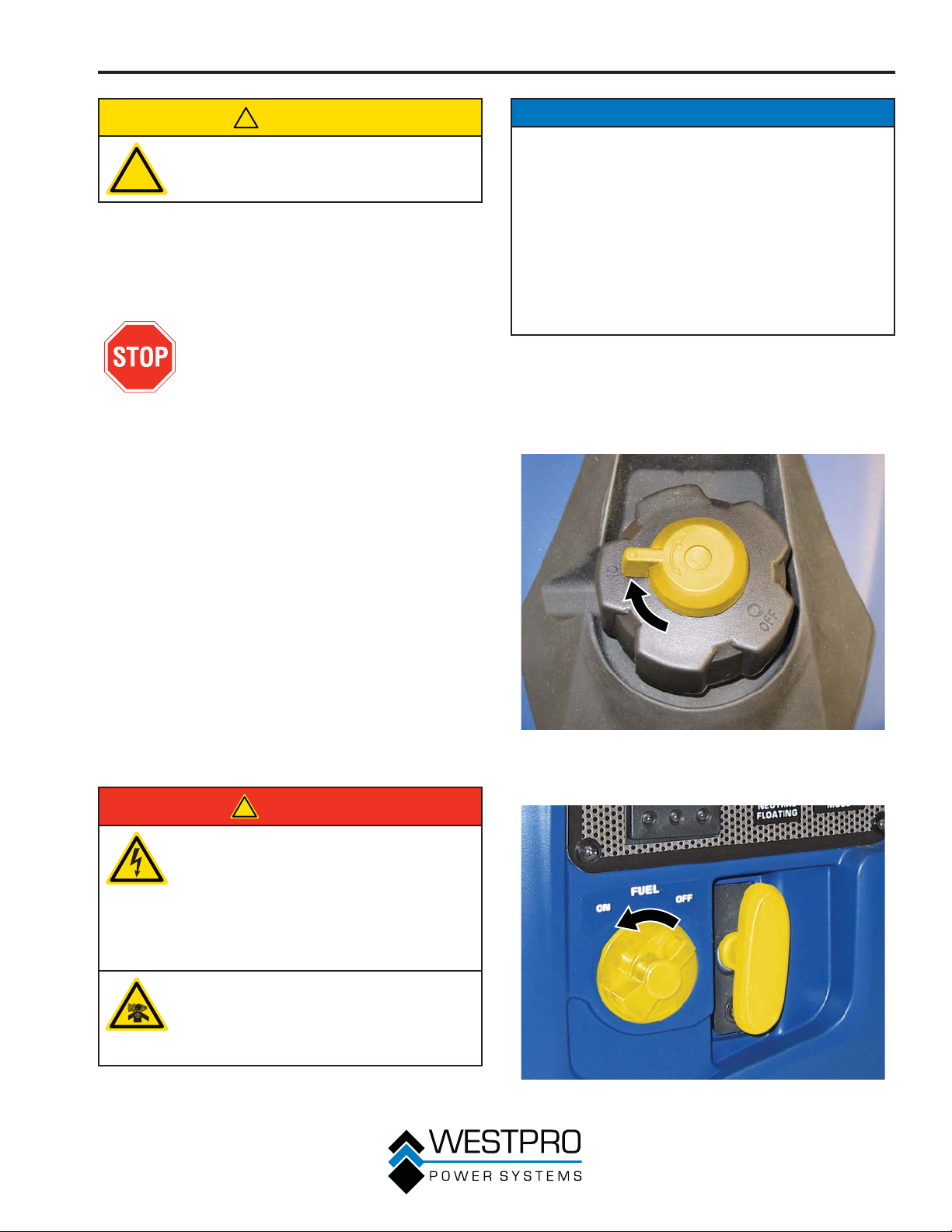

CAUTION

Avoid prolonged skin contact with

!

gasoline. Avoid prolonged breathing of

gasoline vapors.

STARTING THE INVERTER

For proper starting and operation of the inverter,

make sure you review the inverter features and their

descriptions starting on page 17.

Before starting the inverter, review

Safety on page 7.

OTE:N For the WH1000i, upon initial start-up or

when out of fuel, fill the inverter to the full

level. If there is only a half tank of fuel, the

fuel system will need to be primed. To prime

the fuel system, turn the engine/fuel control

switch to the ON position and pull the recoil

handle 5 to 6 times

Before attempting to start the inverter, verify the

following:

x The engine is filled with engine oil (see Checking

Engine Oil – WH1000i on page 33).

x The inverter is situated in a proper location (see

Location Selection on page 23).

x The inverter is on a dry surface (see Weather and

Dry Surface on page 23).

x All loads are disconnected from the inverter (see No

Connected Loads on page 23).

x The inverter is properly grounded (see Grounding

the Inverter on page 23).

!

DANGER

Never use the inverter in a location

that is wet or damp. Never expose the

inverter to rain, snow, water spray or

standing water while in use. Protect

the inverter from all hazardous weather

conditions. Moisture or ice can cause a

short circuit or other malfunction in the

electrical circuit.

Never operate the inverter in an

enclosed area. Engine exhaust

contains carbon monoxide. Only

operate the inverter outside and away

from windows, doors and vents.

NOTICE

The engine is equipped with a low oil shutdown

switch. If the oil level becomes low, the engine will

shut down and will not start until the oil is filled to the

proper level.

Be sure the engine has the proper oil level before

using. Failure to verify that the engine has the proper

oil level could result in engine damage.

Disconnect all loads from the inverter before starting.

Failure to verify all loads are disconnected prior to

starting the inverter could result in damage to the

connected appliances.

OTE:N There are key areas that need to be

addressed when starting the inverter. These

key areas are highlighted in yellow.

1. Turn the fuel tank vent to the ON position (see

Figure 27).

Figure 27 – Fuel Tank Vent

2. Turn the engine/fuel control switch to the ON

position (see Figure 28).

Figure 28 – Engine/Fuel Control Switch (WH1000i

Shown)

29

Loading...

Loading...