Page 1

IL 33-DAH-1

Digitrip Retrofit System for

Westinghouse DA-75 Breakers

Table of Contents

SAFETY PRECAUTIONS................................................................................................................1

Kit Components List.........................................................................................................................2

Step 1: General Breaker Preparation............................................................................................3

Step 2: Removing the Original Electromechanical Trip Units........................................................3

Step 3: Preparing the Sensors......................................................................................................4

Step 4: Installing the Sensors........................................................................................................4

Step 5: Installing the Trip Unit Mounting Platform..........................................................................5

Step 6: Preparing the Trip Unit Assembly......................................................................................6

Step 7: Installing the Trip Unit........................................................................................................6

Step 8: Installing the Trip Finger....................................................................................................7

Step 9: Installing the Reset Arm Assembly...................................................................................7

Step 10: Installing the DTA Assembly.............................................................................................8

Step 11: Installing the 2-Point Terminal Block.................................................................................9

Step 12: Installing the Breaker Mounted CPT.................................................................................9

Step 13: Final Connection of the Harnesses and Wiring...............................................................11

Step 14: Installing the Auxiliary Switch..........................................................................................14

Step 15: Testing the Breaker.........................................................................................................15

Step 16: Mounting the Cell Harness.............................................................................................15

Step 17: Installing the Retrofitted Breaker in the Cell....................................................................16

Kit Parts List...................................................................................................................................17

Torque Values for General Mounting..............................................................................................21

Torque Values for Copper BUS Connectors...................................................................................21

INDEX............................................................................................................................................25

Page 2

Digitrip Retrofit System for Westinghouse DA-75 Breakers

SAFETY PRECAUTIONS

WARNING

POWER CIRCUIT BREAKERS ARE EQUIPPED

WITH HIGH SPEED, HIGH ENERGY OPERATING

MECHANISMS. THE BREAKERS AND THEIR

ENCLOSURES ARE DESIGNED WITH SEVERAL

BUILT-IN INTERLOCKS AND SAFETY

FEATURES INTENDED TO PROVIDE SAFE AND

PROPER OPERATING SEQUENCES. TO PROVIDE MAXIMUM PROTECTION FOR PERSONNEL ASSOCIATED WITH THE INSTALLATION,

OPERATION, AND MAINTENANCE OF THESE

BREAKERS, THE FOLLOWING PRACTICES

MUST BE FOLLOWED. FAILURE TO FOLLOW

THESE PRACTICES MAY RESULT IN DEATH,

PERSONAL INJURY, OR PROPERTY DAMAGE.

• Only qualified persons, as defined in the National

Electric Code, who are familiar with the installation and maintenance of power circuit breakers

and their associated switchgear assemblies

should perform any work associated with these

breakers.

IL 33-DAH-1

• Completely read and understand all instructions

before attempting any installation, operation,

maintenance, or modification of these breakers.

• Always turn off and lock out the power source

feeding the breaker prior to attempting any

installation, maintenance, or modification of

the breaker. Do not use the circuit breaker as

the sole means for isolating a high voltage

circuit. Follow all lockout and tagging rules

of the National Electric Code and all other

applicable codes, regulations, and work rules.

• Do not work on a closed breaker or a breaker

with the closing springs charged. Trip (open) the

breaker and be sure the stored energy springs

are discharged before performing any work. The

breaker may trip open or the charging springs

may discharge, causing crushing or cutting

injuries.

• For drawout breakers, trip (open), and then

remove the breaker to a well-lit work area before

beginning work.

• Do not perform any maintenance: including

breaker charging, closing, tripping, or any other

function which could cause significant movement

of the breaker while it is on the extension rails.

Doing so may cause the breaker to slip from the

rails and fall, potentially causing severe personal

injury to those in the vicinity.

• Do not leave the breaker in an intermediate

position in the switchgear cell. Always leave it

in the connected, disconnected, or (optional)

test position. Failure to do so could lead to

improper positioning of the breaker and

flashover, causing death, serious personal

injury, and / or property damage.

• Do not defeat any safety interlock. Such

interlocks are intended to protect personnel

and equipment from damage due to flashover

and exposed contacts. Defeating an interlock

could lead to death, severe personal injury,

and / or property damage.

Effective December, 1998

Page 3

Page 2

IL 33-DAH-1

Cutler-Hammer Digitrip Retrofit Kits are available in

a number of configurations that provide a wide

which level of Retrofit Kit is to be installed and

which components are included with the Kit.

range of features. The Digitrip System starts with

the 510 Basic Kit which offers true RMS sensing,

overcurrent protection, and self-testing features.

Advanced Digitrip Retrofit Kits feature zone

interlocking, digital alphanumeric displays, remote

alarm signals, IMPACC communications, energy

The instructions contained in this manual cover the

installation of all levels of Retrofit Kit. If the Kit you

are installing does not contain a certain component,

skip the instructions for that component and

proceed to the next.

monitoring capabilities, power factors, and

harmonic content measurements.

Throughout the Retrofit process, refer to the Torque

Tables at the back of this manual for specific

The following table provides a quick reference of

torque values.

the components supplied with each level of Retrofit

Kit. Before beginning the Retrofit process, take a

minute to review the information contained in the

table. It is important that the Retrofitter understand

If you have any questions concerning the Retrofit

Kit and / or the Retrofit process, contact

Cutler-Hammer at 1-800-937-5487.

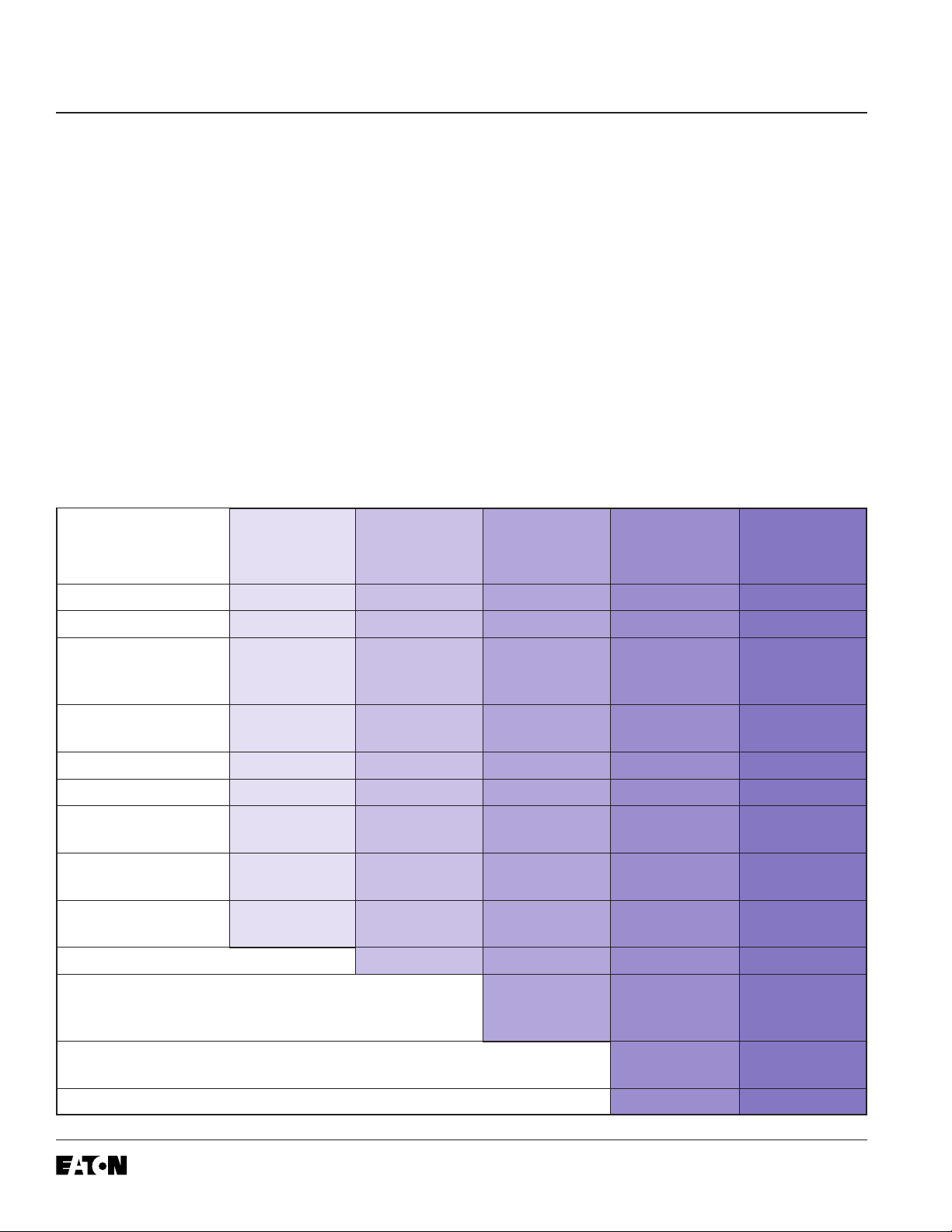

510 with

Components 510 Basic Zone 610 810 910

Interlock

Trip Unit

Rating Plug

Auxiliary Current

Transformer

(CT) Module

Auxiliary

CT Harness

Sensors

Sensor Harness

Direct Trip

Actuator (DTA)

Mounting Brackets

and Hardware

External Plug 1 Connector 2 Connector 4 Connector 4 Connector

Harness Harness Harness Harness Harness

Cell Harness

Breaker Mounted

Control Power

Transformer (CPT)

Potential Transf ormer

(PT) Module

Auxiliary Switch

Effective December, 1998

Page 4

IL 33-DAH-1

Page 3

Step 1: General Breaker Preparation

Before attempting to remove the Breaker from

the cell or perform any Retrofit Operation, be sure

to read and understand the Safety Precautions

section of this manual. In addition, be sure to read

and understand the

Instructions for the Application

of Digitrip RMS Retrofit Kits on Power Circuit

Breakers

(Retrofit Application Data - Publication

AD 33-855-1), supplied with the Digitrip Retrofit Kit.

WARNING

DO NOT ATTEMPT TO INSTALL OR PERFORM

MAINTENANCE ON EQUIPMENT WHILE IT IS

ENERGIZED. SEVERE PERSONAL INJURY OR

DEATH CAN RESULT FROM CONTACT WITH

ENERGIZED EQUIPMENT. VERIFY THAT NO

VOLTAGE IS PRESENT BEFORE PROCEEDING.

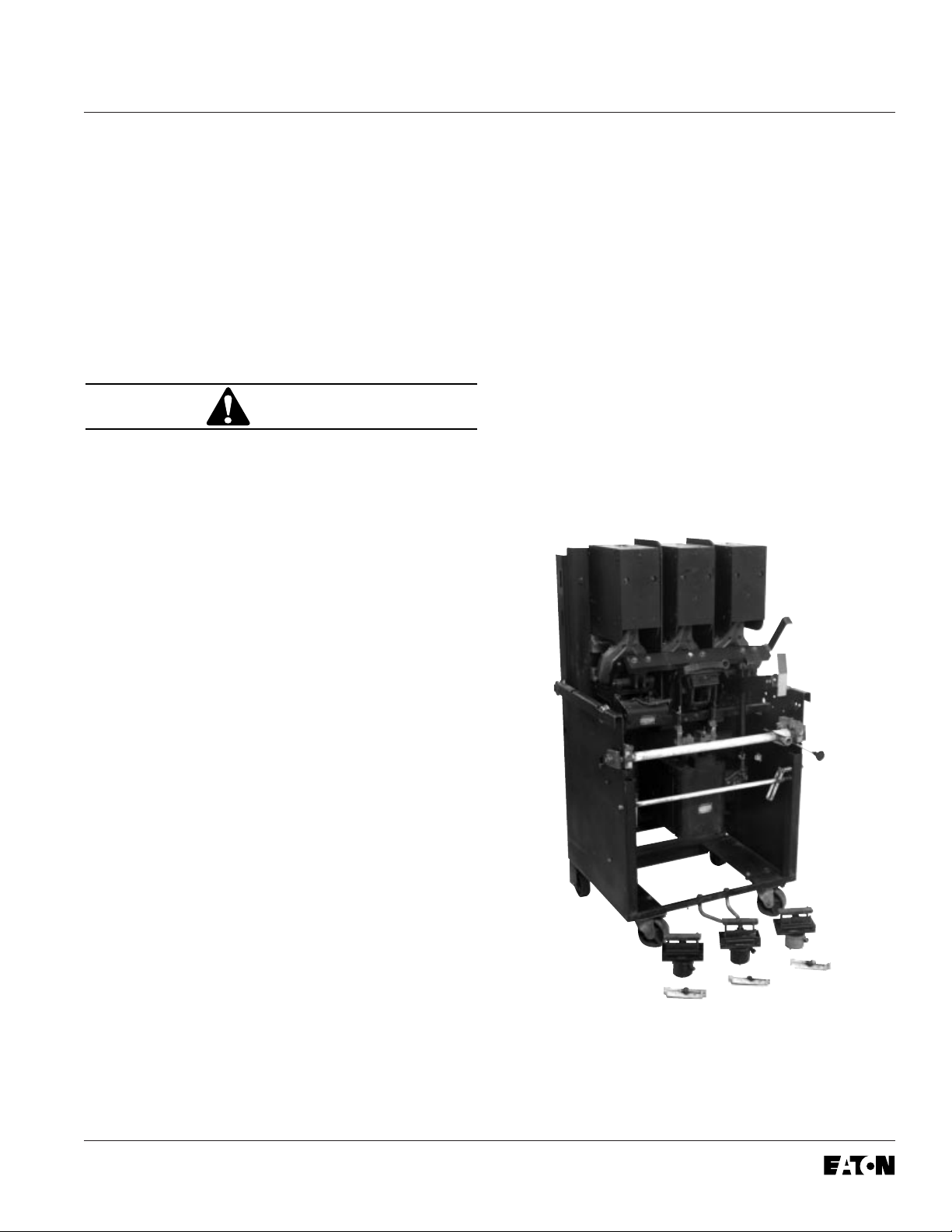

A. Trip the Breaker and remove it from the Cell.

Move the Breaker to a clean, well-lit work

bench.

To begin the Retrofit Process, refer to the

components list at the end of this manual. Lay

out the components and hardware according

to the steps outlined. The components and

hardware will be used to complete each step

in the Retrofit Process.

Step 2: Removing the Original

Electromechanical T rip Units

Follow the Westinghouse DA-75 Instruction Manual,

originally supplied with the Breaker, to perform the

following procedure.

A. Remove and scrap the original

Electromechanical Trip units and all

associated hardware.

NOTE: It is the responsibility of the

Retrofitter to insure that the Breaker and

all original components are in good

condition. Visually inspect all Breaker

components for signs of damage or wear.

If any signs of damage or wear are

detected for components not included in the

Retrofit Kit, secure the necessary

replacement parts before beginning the

Retrofit Process.

The force necessary to trip the Breaker

should not exceed seven (7) lbs.

Effective December, 1998

Page 5

Page 4

IL 33-DAH-1

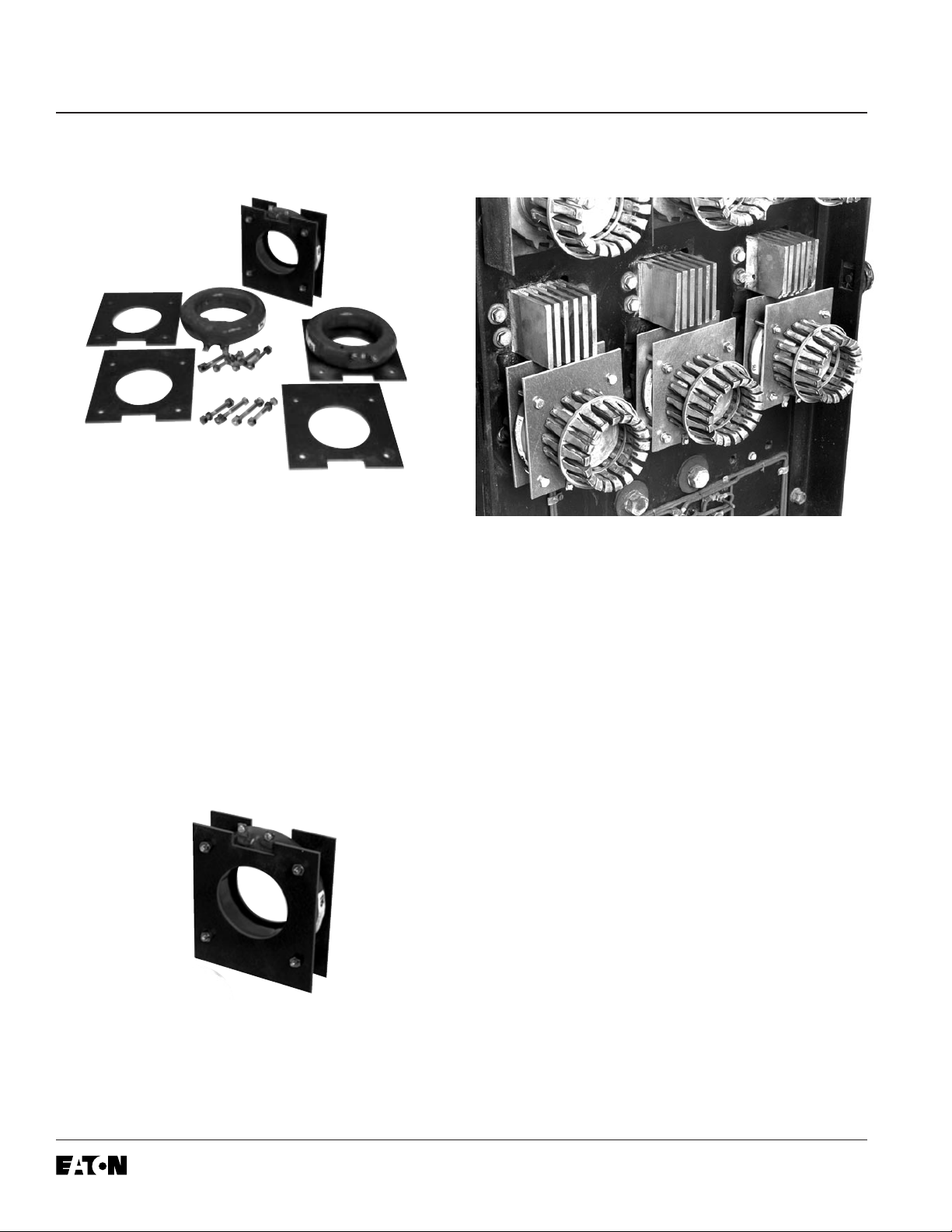

Step 3: Preparing the Sensors

A. Place each Sensor between two Glass Poly

Insulation Plates. The connector stabs should

be positioned towards the cutouts in the

Insulation Plates as shown.

B. Secure the Glass Poly Plates on either side of

the Sensors using the (12) .250-20 × 2.00"

bolts, (24) flat washers, and (12) elastic stop

nuts supplied. Note that the bolts must be

installed so that the bolt heads will be against

the back of the Breaker and the stop nuts away

from the Breaker (same side as the screw

heads of the Sensor terminals). Do not over

tighten the bolts.

Step 4: Installing the Sensors

A. Remove and save the center bolts securing the

bottom Finger Clusters to the Breaker Stabs.

Remove the Finger Clusters.

B. Install a Sensor Assembly over each Breaker

Stab, with the Sensor terminals pointing

downward and the bolt heads outward as

shown.

C. Reinstall the Finger Clusters and secure them

using the original hardware.

Effective December, 1998

Page 6

IL 33-DAH-1

(4)

Page 5

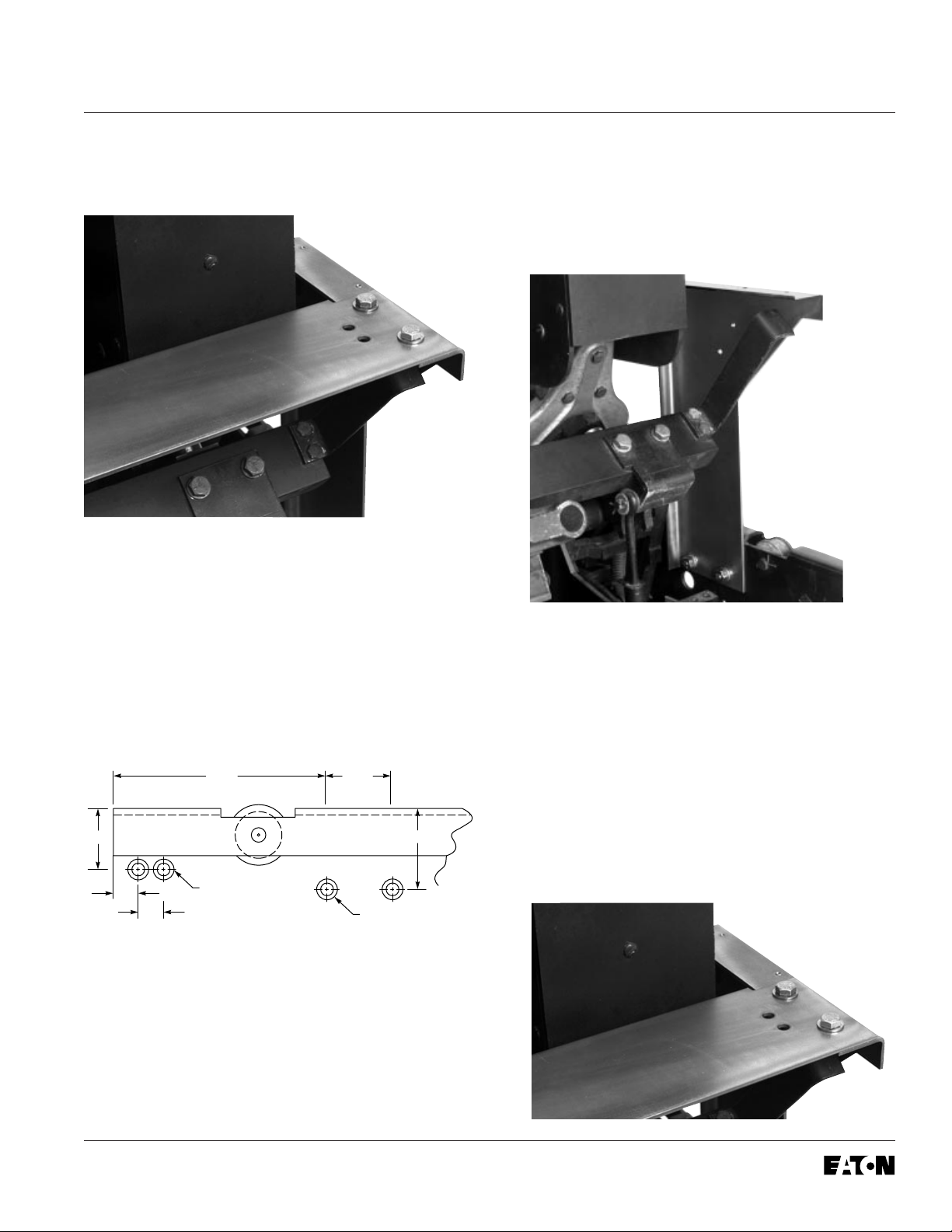

Step 5: Installing the Trip Unit Mounting

Platform

A. Using Drilling Plan “A”, drill and counter sink

two .375" holes in both the left and right

Breaker side plates.

B.

Mount the right and left Trip Unit Support Brackets

to the Breaker side plates as shown, using the

(4) .312-18 × .750" flat head screws, (4) flat

washers, (4) lock washers, and (4) nuts

supplied.

Do not tighten them completely at this time.

NOTE: The holes for mounting the DTA

(see Step 10) should also be drilled and

countersunk in the right Breaker Frame

at this time.

Drilling Plan “A”

6.50" 2.00"

1.81"

Drill 0.375" Dia. and

0.75"

0.75"

Countersink to 0.578"

Head Size (2)

Right Side Only

Drill 0.375" Dia. and

Countersink to 0.578"

Head Size

2.38"

NOTE: For ease of assembly, the 2-Point

Terminal Block (Step 11-A) can be mounted

to the inside of the right Trip Unit Support

Bracket at this time.

C. Mount the Trip Unit Mounting Platform to the

Support Brackets using the (4) .312-18 × .750"

bolts, (8) flat washers, (4) lock washers, and (4)

nuts supplied. Tighten the hardware connecting

the Mounting Platform to the Support Brackets,

and then the Support Brackets to the Breaker

side plates. Assure that the Mounting Platform

and Support Brackets are square with the Breaker.

Effective December, 1998

Page 7

Page 6

IL 33-DAH-1

Step 6: Preparing the Trip Unit Assembly

A.

For Kits Supplied with a PT Module Only.

the PT Module to the Glass Poly Insulation

Barrier as shown, using the (2) .138-32 × .500"

screws, (4) flat washers, (2) lock washers, and

(2) nuts supplied.

D. Mount the Trip Unit Mounting Brackets to the

sides of the Aux. CT Module, using the (4)

.190-32 × .375" screws, (4) lock washers, and

(4) flat washers supplied, so they “pinch” the

Trip Unit in place.

Mount

E. Remove the Trip Unit cover and install the

Rating Plug. Replace the cover.

F. Install the Digitrip Nameplate on the top of the

Trip Unit.

B. Secure the Glass Poly Insulation Barrier to

the back of the Aux. CT Module using the (2)

.190-32 × .375" screws, (2) lock washers, and

(2) flat washers supplied.

C. Install the Trip Unit on the top of the Aux. CT

Module using the (2) brass spacers, (2)

.190-32 × 4.00" screws, (2) lock washers, and

(2) flat washers supplied as shown. Note that

the brass spacers are placed between the

bottom of the Trip Unit and the top of the Aux.

CT Module.

G. Connect the Aux. CT Harness to the Trip Unit

and Aux. CT Module.

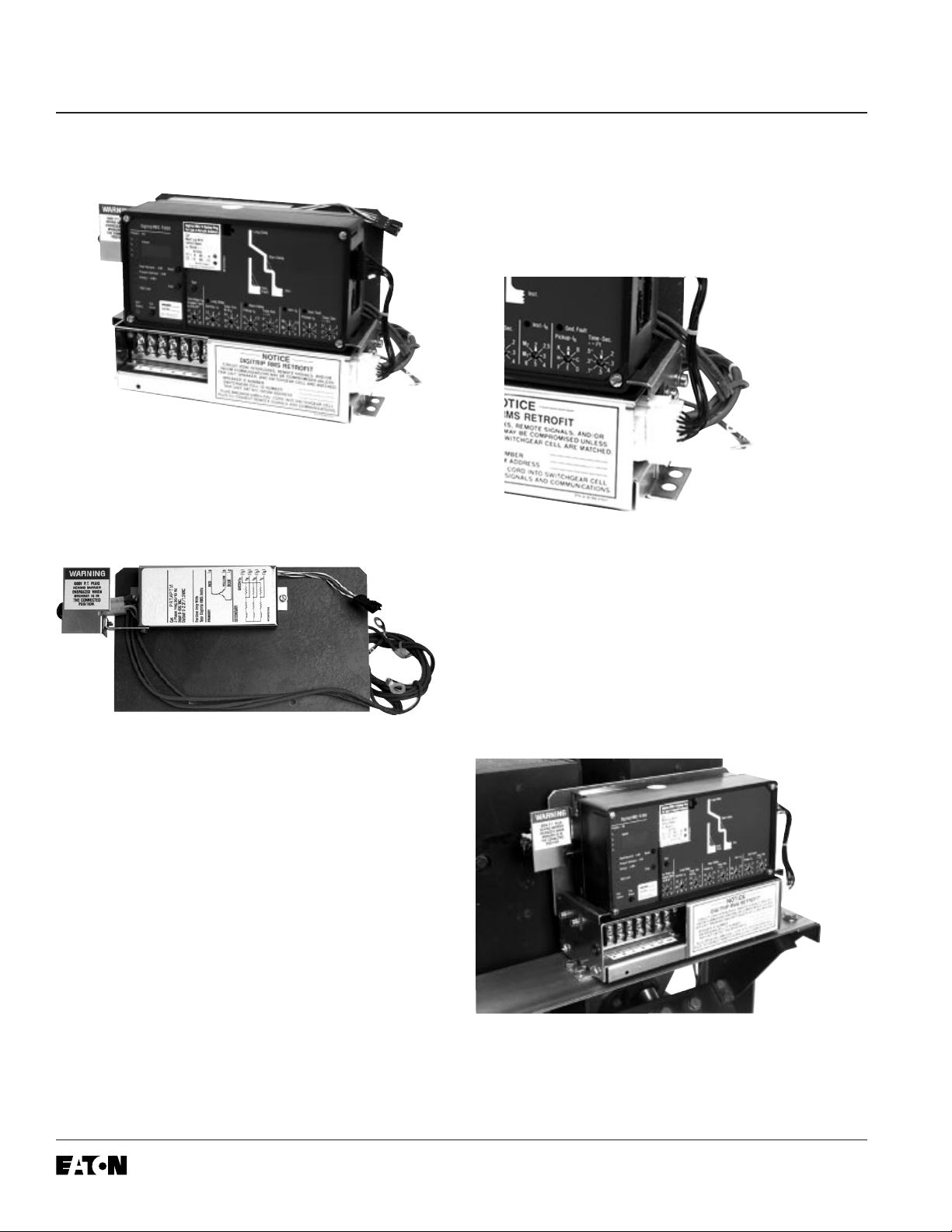

Step 7: Installing the Trip Unit

A. Mount the Trip Unit / Aux. CT Module Assembly

to the Trip Unit Mounting Platform as shown,

using the (4) .250-20 × .750" bolts, (8) flat

washers, (4) lock washers, and (4) nuts supplied.

Effective December, 1998

Page 8

IL 33-DAH-1

Page 7

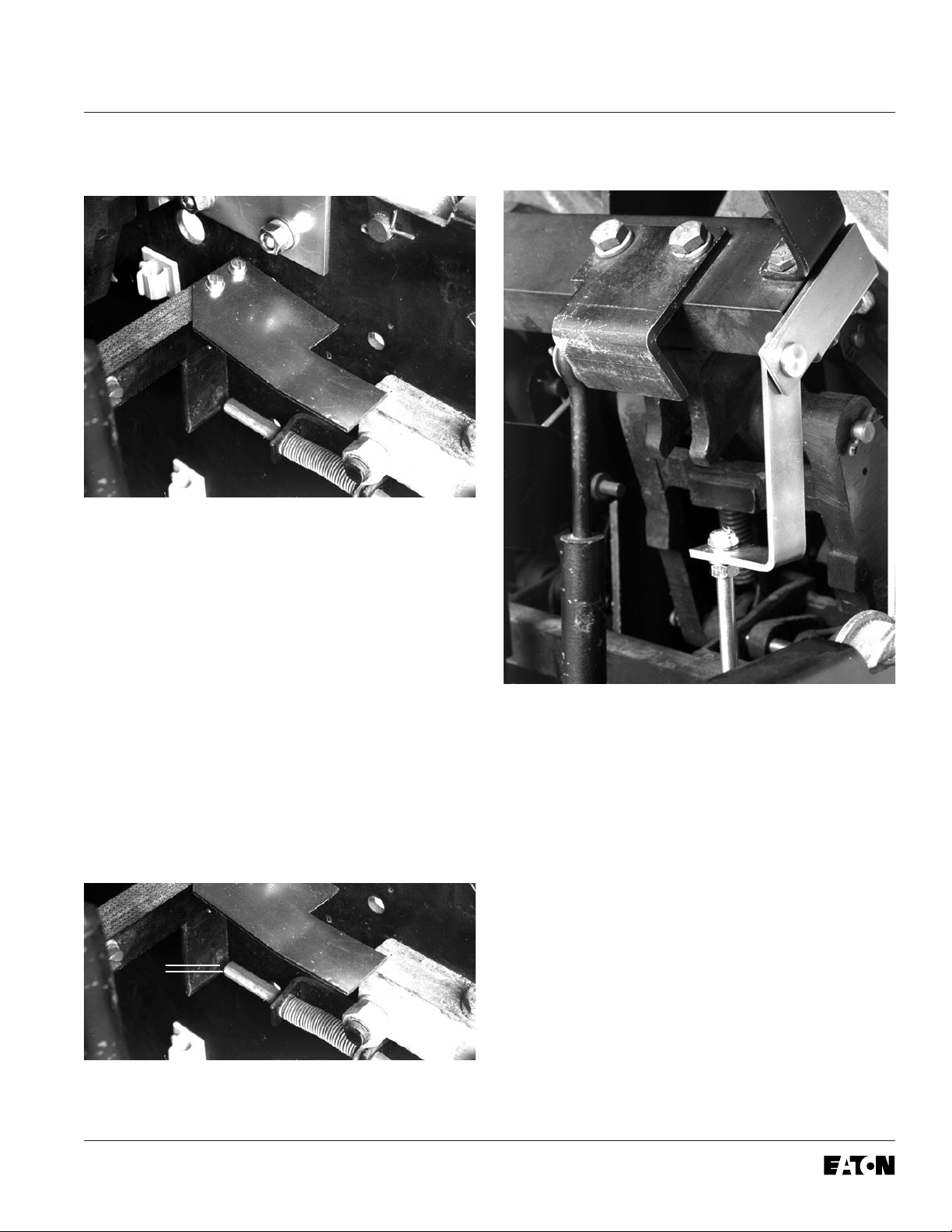

Step 8: Installing the Trip Finger

A. Note the position of the original Trip Finger and

associated “gap” between the Trip Finger and

manual Trip Shaft. Remove the original Trip

Finger and scrap the mounting hardware.

Step 9: Installing the Reset Arm Assembly

B. Mount the new Trip Finger on the top of the

Cross Bar (with the curve upward and the notch

to the right) as shown, and the original Trip

Finger back on the bottom of the Cross Bar.

Secure using the (2) .190-32 × 1.75" bolts,

(4) flat washers, (2) lock washers, and

(2) nuts supplied.

C. Verify that the original Trip Finger has been

reinstalled in its initial position by checking the

gap (noted in Step 8-A) between the original

Trip Finger and manual Trip Shaft.

GAP

A. Remove the original Interlock Arm. Scrap the

original bolts, washers, and nuts.

B. Mount the Reset Arm Assembly to the bottom

of the Cross Bar and the original Interlock Arm

to the top of the Cross Bar in its original

position, using the (2) .190-32 × 1.75" bolts, (4)

flat washers, (2) lock washers, and (2) nuts

supplied. The Reset Arm Assembly should be

positioned so that the Reset Arm is hanging

downward as shown.

Effective December, 1998

Page 9

Page 8

IL 33-DAH-1

Step 10: Installing the DTA Assembly

B. Remove the two nuts, flat washers, and spring

from the Reset Assembly, being careful that the

brass spacer does not slide off the all-thread.

C. Position the DTA Assembly behind the DTA

Mounting Bracket, with the Reset Assembly

Shaft going through the slot in the DTA Reset

Arm. Mount the DTA Assembly to the DTA

Mounting Bracket, as shown, using the (4)

.164-32 × .312" pan / lock screws and (4) flat

washers provided.

D. With the DTA in the latched position and the

DTA Release Arm lifted up over the brass

sleeve, reinstall the large flat washer, spring,

small flat washer, and (1) nut onto the Reset

Assembly Arm. Snug the nut against the brass

sleeve.

®

E. Apply Loc-Tite

242 to the threads at the base

of the installed nut. Install the second nut and

tighten the nuts against each other.

A. Mount the DTA Mounting Bracket to the right

Breaker side panel, as shown, using the holes

drilled in Step 5 A and the (2) .312-18 × .750"

screws, (2) flat washers, (2) lock washers, and

(2) nuts provided.

F. Connect a 24 VDC power supply to the DTA

terminals; positive to positive and negative to

negative. Close the Breaker manually. Energize

the DTA to trip the Breaker; de-energize when

the Breaker trips. Make certain that the DTA

resets. If the Breaker fails to properly trip or

reset, it may be necessary to shorten the brass

spacer on the Reset Assembly Shaft. Make the

necessary adjustments until the trips and resets

are sure and positive each time.

Effective December, 1998

Page 10

IL 33-DAH-1

Page 9

Step 11: Installing the 2-Point Terminal Block

For Kits Supplied with a Breaker Mounted

CPT Only.

Step 12: Installing the Breaker Mounted CPT

A. Mount the 2-Point Terminal Block to the

pre-drilled holes in the right Trip Unit Support

Bracket as shown, using the (2) .138-32 × .750"

screws, (4) flat washers, (2) lock washers, and

(2) nuts supplied.

B. Route the DTA wires from the DTA Assembly to

the 2-Point Terminal Block. After assuring the

wires are clear of any moving components

within the Breaker, connect the DTA wires to

the 2-Point Terminal Block.

A. Align the holes in the Breaker Mounted CPT

with the predrilled holes on the left side of the

Trip Unit Mounting Platform. Secure the CPT to

the Trip Unit Mounting Platform using the (4)

.190-32 × .500" screws, (8) flat washers, (4)

lock washers, and (4) nuts supplied. Note that

the X1 and X2 terminals face the front of the

Breaker.

B. Insert the black plug of the CPT Harness into

the receptacle in the Trip Unit.

Effective December, 1998

Page 11

Page 10

IL 33-DAH-1

C. Route the CPT Harness between the Trip Unit

and the Insulation Barrier to the CPT. Strip .250"

of insulation and attach a .138" ring terminal to

each wire of the CPT Harness. Connect the

CPT Harness wires to the X1 and X2 terminals

of the CPT.

D. Position the fuses on the High Voltage (HV)

Wires in an accessible location. Route the HV

Wires between the Trip Unit and Insulation

Barrier to the Breaker Mounted CPT, then cut

the Load Side of each HV Wire to an

appropriate length. Strip .250" from the Load

Side HV Wires and attach a .138" ring terminal

to each. Attach the HV Wires to the CPT

terminals to achieve the required voltage (see

the following table). The HV Wires will be

connected to the Phase Frames later in the

Retrofit process.

Voltage Required CPT Terminals Used

600 Volt Circuit H1 & H2

E. Attach the Glass Poly Insulation Plate to the top

of the CPT, as shown, using the screws and

lock washers supplied with the CPT kit.

F. Attach the appropriate warning label for the

Breaker to the left of the CPT on the Trip Unit

Mounting Platform.

Voltage Required CPT Terminals Used

480 Volt Circuit H1 & H4

240 Volt Circuit H1 & H3

208 Volt Circuit H1 & H2

Effective December, 1998

Page 12

IL 33-DAH-1

Page 11

Step 13: Final Connection of the

Harnesses and Wiring

A. Feed the Sensor Harness through the hole in

the left side of the Aux. CT Module. Connect the

Sensor Harness to the proper terminals on the

Aux. CT Module. Refer to Section 12 of the

Retrofit Application Data, supplied with the

Retrofit Kit, for detailed wiring specifications.

B. Route the Sensor Harness between the Glass

Poly Insulation Barrier and the back of the Trip

Unit, then down along the right Trip Unit

Mounting Bracket and through the hole in the

Breaker Back Plate as shown. Secure the

Sensor Harness as shown using the wire

clamps and (6) .138-20 × .500" thread cutting

screws supplied.

Connect the green ground wire from the Sensor

Harness (with the ring terminal) to the screw in

the left side of the Aux. CT Module.

C. Route the Sensor Harness to the bottom of the

Sensors. Connect the ring terminals of the

Sensor Harness to the Sensors. Refer to

Section 12 of the Retrofit Application Data,

supplied with the Retrofit Kit, for detailed wiring

specifications.

Depending on the Sensors supplied with the

Retrofit Kit, the following convention applies.

Sensor Style No.

4A35613H01 X1-X2 = 3000 A

Effective December, 1998

Page 13

Page 12

D.

For Kits Supplied with a PT Module Only.

Refer to Section 7-3, Power Flow Convention of

the Retrofit Application Data, supplied with the

Retrofit Kit for additional wiring information and

to verify the Phase Convention used on this

Breaker Application.

Route the PT Wires between the Glass Poly

Insulation Barrier and the back of the Trip Unit,

then down along the right Trip Unit Mounting

Bracket to the area where the original

Electromechanical Trip devices were removed

(Step 2).

The PT Wires are marked for connection to

Phases 1, 2, and 3 with corresponding

numbers.

NOTE: Before cutting the PT Wires, verify

the Phase Convention used on the Breaker

Application.

IL 33-DAH-1

E.

For Kits Supplied with a Breaker Mounted CPT

Only.

Route the

of the Breaker through the opening in the

Breaker Back Plate and along the rear of the

Breaker to the top Phase Frames.

Note: The power convention of the

Westinghouse DA-75 Series Breakers is

normally

Breaker Phase Frames are on the

of the Breaker and the Bottom Breaker

Stabs are on the

The HV Wires from the CPT MUST BE

ATTACHED to the

it is determined that the power flow for the

Breaker application is opposite the normal

convention, the HV Wires must be attached

to the Bottom Phase Frames. The bolts used

to secure the PT Wires can be used to

connect the HV Wires.

Line Side

Top to Bottom

Load Side.

Line Side

HV Wires to the rear

, meaning the Top

Line Side

of the Breaker. If

Route the PT Wires to a position suitable for

attachment to the proper Breaker Phase

Frames. Move the PT Wire markers to a

position where they will still be attached to the

wires after cutting. Cut the wires to length, strip

each wire .250", and install a .250" ring terminal

to each PT Wire.

Connect each PT Wire to the corresponding

Breaker Phase Frames using the (3)

.250-20 × .500" bolts, (3) lock washers, and

(3) flat washers supplied.

Note: The

than necessary and are cut during the

following steps. Before cutting the wires, be

sure that sufficient length is left so that the

connections can be made to the correct

Finger Clusters or Phase Frames.

For Kits Supplied with a Breaker Mounted CPT

F.

Only.

Using a .234" drill, drill and tap one hole in

the top of the Phase 1 and 2 or Phase 2 and 3

Phase Frames.

G.

For Kits Supplied with a Breaker Mounted CPT

Only.

Cut the HV Wires to the appropriate

length for attachment to the appropriate Phase

Frames. Strip .250" from each HV Wire and

attach a .250" ring terminal. Using the (2)

.250-20 × .500" bolts, (2) flat washers, and (2)

lock washers supplied, connect the HV Wires

to the appropriate Phase Frames.

Line Side

HV Wires are longer

Effective December, 1998

Page 14

IL 33-DAH-1

H. Feed the two wires from the DTA Extension

Harness through the opening in the left side of

the Aux. CT Module. Connect the wire marked

“+” to the “OP” terminal and the unmarked wire

to the “ON” terminal.

I. Route the DTA Extension Harness between the

Glass Poly Insulation Barrier and the back of

the Trip Unit, then down along the right Trip Unit

Support Bracket to the 2-Point Terminal Block.

Connect the wire from the DTA Extension

Harness marked with “+” to the “+” terminal and

the unmarked wire to the other terminal.

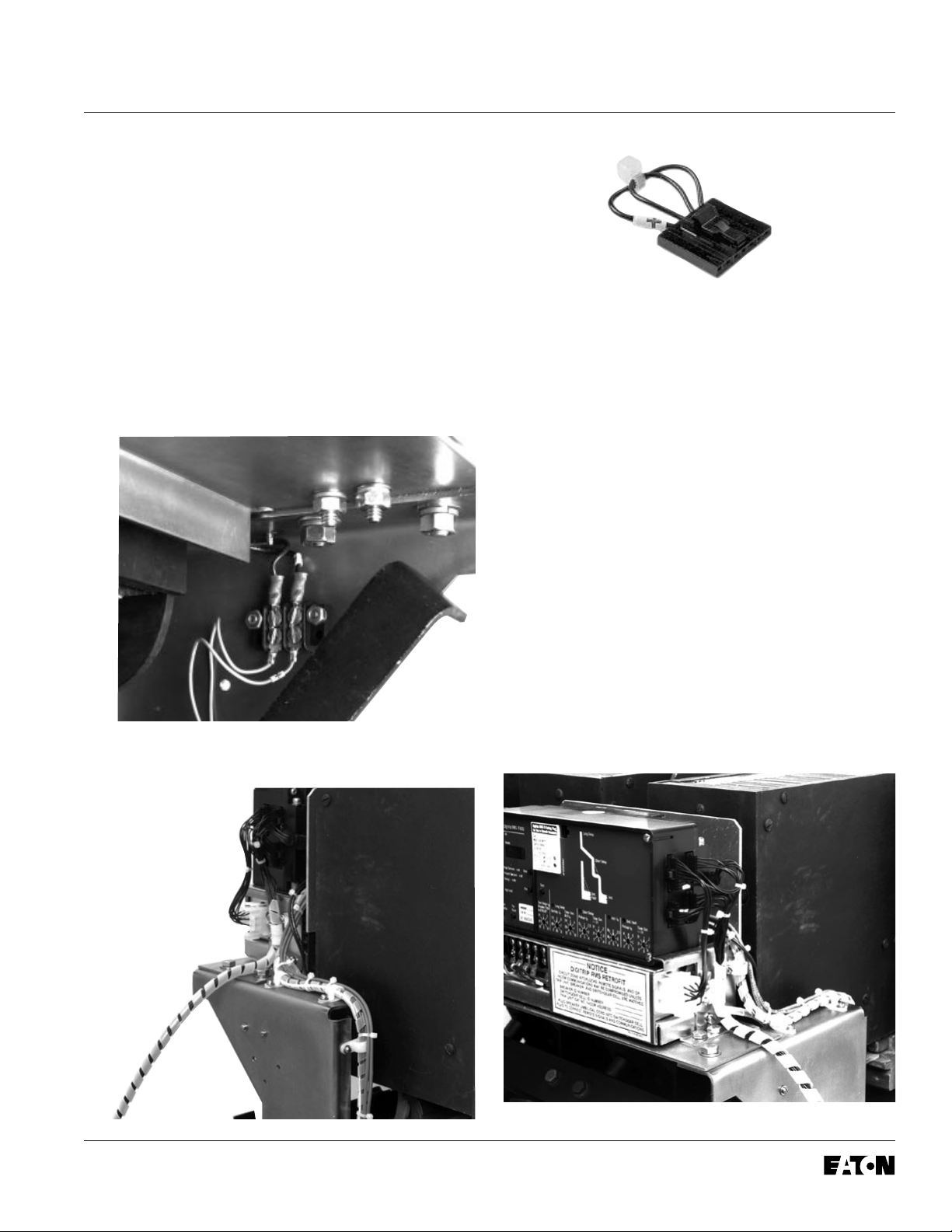

NOTE: For 510 Basic Retrofit Kits, the

External Harness is the plug pictured above.

It is to be plugged into the right side of the

Trip Unit.

For Kits Supplied with a PT Module Only.

K.

Connect the PT Harness to the External

Harness.

L. Use the wire ties, wire clamps, and self

adhesive wire clips provided to dress all wires

and harnesses to keep them away from any

moving parts within the Breaker.

Page 13

J. Connect the External Harness to the Trip Unit.

NOTE: The self adhesive wire clips should

be attached to the right Breaker side panel

to secure the Sensor Harness. The wire

clamps should be attached to the hardware

mounting the Aux. CT Module and the Trip

Unit, as shown, to secure the Sensor

Harness, External Harness, and PT

Extension Harness.

Effective December, 1998

Page 15

Page 14

IL 33-DAH-1

For Kits Supplied with an Aux. Switch Only.

Step 14: Installing the Auxiliary Switch

A. Using diagonals, cut 2.625" off the

Microswitch Arm.

C. Connect the two wires (with ring terminals) from

the External Harness to the Auxiliary Switch.

Connect one wire to the normally “Open”

terminal and the other wire to the “Common”

terminal of the Auxiliary Switch.

D. Making sure the Microswitch arm is behind the

Interlock Bar, mount the Aux. Switch Assembly

to the pre-drilled holes in the right Trip Unit

Mounting Bracket, using the (2) .164-32 × .500"

screws, (4) flat washers, (2) lock washers, and

(2) nuts supplied.

B. Mount the Microswitch to the Auxiliary Switch

Mounting Bracket, as shown, using the (2)

.138-32 × 1.25" screws, (8) flat washers, (4)

lock washers, and (4) nuts supplied.

NOTE: To provide correct spacing, the

hardware must be installed in the following

order. Insert screws with flat washers

installed through the switch. Install flat

washers, lock washers, and tighten the nuts.

Install another set of flat washers, then the

mounting bracket, flat washers, lock

washers, and nuts.

Effective December, 1998

Page 16

IL 33-DAH-1

Page 15

Step 15: Testing the Breaker

A. Measure the force necessary to trip the

Breaker at the point where the DTA impacts the

Trip Finger. The force necessary to trip the

Breaker MUST NOT EXCEED SEVEN (7) lbs.

B. The Retrofit must be tested using primary

injection. Refer to Section 8 of the

Instructions

for the Application of Digitrip RMS Retrofit Kits

on Power Circuit Breakers

(Publication

AD 33-855-1, June, 1997), supplied with the

Retrofit Kit, for detailed testing procedures and

specifications. For test information specific to

the Trip Unit, refer to the IL publication supplied

with the Retrofit Kit (see the Pick List for the

IL number).

C. While Section 8 of the

Instructions for the

Application of Digitrip RMS Retrofit Kits on

Power Circuit Breakers

provides the information

necessary for testing the Breaker, please keep

the following notes in mind when reviewing

other sections of the publication.

CAUTION:

When all testing is complete, the Trip

Unit must be reset. Failure to do so may cause

the battery in the Rating plug to run down.

Notes:

1. Publication AD-33-855 was created

specifically for the “hundred” series (500,

600, 700, etc.) Retrofit Kits. Therefore certain

sections and figures do not apply to the

“ten” series (510, 610, 810, etc.) Retrofit Kits.

Specifically, these are Sections 13 and 14, as

well as Figures 3-2, 3-3, and 3-4.

3.

For 810 and 910 Kits Only.

Without any

power applied to the system (neither the 120

volt power supply nor the Aux. Power

Module connected), plug the External

Harness into the Cell Harness and check the

impedance between COM 1 and COM 2. The

impedance should be between one (1) and

three (3) ohms. If the impedance is not

within this range, trace the wiring and

examine each connection to assure its

integrity.

Confirm that the IMPACC communication

wiring is correct by following the procedures

detailed in Section 7.4 of the Instructions for

the Application of Digitrip RMS Retrofit Kits

on Power Circuit Breakers. Note that for 810

and 910 Kits, the impedance between COM 1

and COM 2 should be between one (1) and

three (3) ohms.

When testing is complete, disconnect the

External Harness from the Cell Harness.

Final External Harness connection will be

performed in Step 16.

For Kits Supplied with a Cell Harness Only.

Step 16: Mounting the Cell Harness

A. The Cell Harness is to be mounted in the

Breaker Cell. The connector end is to be

mounted on the right front side of the Cell, in a

location suitable for connection with the

External Harness. The Terminal Blocks can be

mounted anywhere space is available in the

Cell as long as connection to the External

Harness can be made.

For All Kits Other Than 510 Basic.

2.

If testing

the Breaker with Short Delay or Ground

Fault functions, be sure to either plug in the

Cell Harness Assembly or use the Zone

Interlock Shorting Plug. Failure to do so may

result in shorter than expected trip times.

Effective December, 1998

B. Route the Cell Harness wiring to keep it away

from any moving parts within the Cell Housing.

Page 17

Page 16

IL 33-DAH-1

Step 17: Installing the Retrofitted Breaker

in the Cell

WARNING

Do not leave the Breaker in an intermediate

position in the switchgear cell. Always leave

it in the CONNECTED, DISCONNECTED, or

(Optional) TEST position. Failure to do so could

lead to improper positioning of the Breaker and

flashover, causing death, serious personal

injury, and / or property damage.

WARNING

It is solely the responsibility of the Retrofitter to

make the necessary modifications to the original Racking Mechanism, or to manufacture a

Racking Bar Adapter, to insure safe racking of

the Breaker into the Cell. If the Retrofitter opts

to modify the original Racking Mechanism, the

Racking Bar Receptacle must be removed from

the Racking Mechanism, moved to a location

where the Racking Bar will not contact the DTA

during racking, and welded to the Racking

Mechanism.

NOTE: It is the responsibility of the Retrofitter

to insure proper Breaker / Cell fit. When racking

the Breaker into the Connected position, the

Retrofitter MUST FOLLOW BOTH the

manufacturer’s instructions and the customer’s

safety standards and procedures for racking a

Breaker into the Connected position.

A. With the Breaker in the Open position and the

springs discharged, slowly rack the Breaker into

the Connected position, making sure there is no

interference or binding. The Breaker should rack

smoothly and without mechanical interference

between any Breaker and Cell parts. The

Retrofitter will feel some resistance when the

primary fingers connect onto the stabs of the

Cell. This is normal.

However, if any unusual resistance is detected

that could be abnormal interference between

the Breaker and Cell parts, stop immediately

and move the Breaker out of the Connected

position. Examine what is causing the

interference and correct the situation.

If the Retrofitter opts to manufacture a Racking

Bar Adapter for use with the original Racking

Mechanism configuration, the drawing and

photo below should be used as a basis.

Breaker Racking Pivot

Adapter

Effective December, 1998

Page 18

IL 33-DAH-1

Digitrip Retrofit Kit Installation Components for the Westinghouse DA-75 Breakers

Step Description Style No. Qty. Comment

Step 3 Sensors 3000/5000 4A35613H01 3

Sensor Mounting Parts 4A35618G04 1

Glass Poly Mounting Plates 6

.250 - 20 × 2.00 Lng. Hex Bolt 12

.250 Flat Washer Stl. 24

.250 - 20 Elastic Stop Nut 12

Step 5 Trip Unit Mounting Platform Parts 4A35618G05 1

Trip Unit Support Bracket R. H. 1

Trip Unit Support Bracket L. H. 1

Trip Unit Mounting Platform 1

.312 - 18 × .750 Lng. Screw Flat 4

.312 - 18 × .750 Lng. Hex Bolt 4

.312 Flat Washer Stl. 12

.312 Lock Washer Stl. 8

.312 - 18 Nut Hex Stl. 8

Page 17

Step 6 Trip Unit 1 See Pick List

Rating Plug 1 See Pick List

Aux. CT Module 6502C78G__ 1

Aux. CT Harness 6502C84G01 1

Trip Unit Assembly Parts 4A35618G07 1

Mounting Bracket L. H. 1

Mounting Bracket R. H. 1

Barrier 1

Digitrip Nameplate 1

Spacer Brass 2

.190 - 32 × 4.00 Lng. Screw Fil. 2

.190 - 32 × .375 Lng. Screw Fil. 6

.190 Flat Washer Stl. 8

.190 Lock Washer Stl. 8

PT Module Kit 6502C82G01 1

.138-32 × .500 Lng. Screw 2

.138 Flat Washer 4 Comm. Only

.138 Lock Washer 2

.138-32 Nut Hex Stl. 2

Ring Terminals (.190, .250, .312, .375, .500), 3 Each Size 5

Effective December, 1998

Page 19

Page 18

IL 33-DAH-1

Digitrip Retrofit Kit Installation Components for the Westinghouse DA-75 Breakers (Continued)

Step Description Style No. Qty. Comment

Step 7 Trip Unit Assembly (From Step 6)

Trip Unit Mounting Hardware 4A35618G08 1

.250 - 20 × .750 Lng. Hex Bolt 4

.250 Flat Washer Stl. 8

.250 Lock Washer Stl. 4

.250 - 20 Nut Hex Stl. 4

Step 8 Breaker Trip Finger Parts 4A35618G09 1

Trip Finger 1

.190-32 × 1.75 Lng. Screw Fil. 2

.190 Flat Washer Stl. 4

.190 Lock Washer Stl. 2

.190 - 32 Nut Hex Stl. 2

Step 9 Breaker Reset Parts 4A35618G10 1

Reset Assembly 1

.250 - 20 × 1.75 Lng. Hex Bolt 2

.250 Flat Washer Stl. 4

.250 Lock Washer Stl. 2

.250 - 20 Nut Hex Stl. 2

Step 10 DTA Assembly Parts 4A35618G11 1

High Force Trip Actuator 4A35618G33 1

DTA Mounting Hardware 4A35618G12 1

Mounting Bracket 1

.312 - 18 × .750 Lng. Screw Flat 2

.312 Flat Washer Stl. 2

.312 Lock Washer Stl. 2

.312 - 18 Nut Hex Stl. 2

.164 - 32 × .312 Lng. Screw Pan Lock 4

.164 Flat Washer Stl. 4

Loc-Tite® 242 1

Step 11 Terminal Block Parts 4A35618G13 1

2-Point Terminal Block 1

.138 - 32 × .750 Lng. Screw Fil. 2

.138 Flat Washer Stl. 4

.138 Lock Washer Stl. 2

.138 - 32 Nut Hex Stl. 2

Effective December, 1998

Page 20

IL 33-DAH-1

Digitrip Retrofit Kit Installation Components for the Westinghouse DA-75 Breakers (Continued)

Step Description Style No. Qty. Comment

Step 12 Breaker Mounted CPT Kit 8259A91G05 1 CPT Only

Ring Terminals (.138, .190, .250, .312, .375, .500) 2 Each Size CPT Only

CPT Mounting Parts 4A35618G20 1 CPT Only

Glass Poly Insulation Plate 1

.190-32 × .500 Lng. Screw Fil. 4

.190 Flat Washer Stl. 8

.190 Lock Washer Stl. 4

.190-32 Nut Hex Stl. 4

.250-20 × .500 Lng. Hex Bolt 2

.250 Flat Washer Stl. 2

.250 Lock Washer Stl. 2

Warning Label (208, 240, 480, & 600 Volt - 1 each) 1

Step 13 Sensor Harness 1

Sensor Harness Parts 4A35618G14 1

Wire Clamp Nylon 6

.138 - 20 × .500 Lng. Screw T. C. 6

.138 Flat Washer Stl. 6

.138 Lock Washer Stl. 6

Wire Clip 4

.250 - 20 × .500 Lng. Hex Bolt 3

.250 Flat Washer Stl. 3 Comm. Only

.250 Lock Washer Stl. 3

.250-20 × .500 Lng. Hex Bolt 2

.250 Flat Washer Stl. 2 From Step 12

.250 Lock Washer Stl. 2

DTA Extension Harness 6503C83G01 1

External Harness 6502C83G0__ 1

External Harness Parts 4A35618G15 1

Wire Clamp Nylon 4

Page 19

Effective December, 1998

Page 21

Page 20

IL 33-DAH-1

Wire Tie Nylon 10

Digitrip Retrofit Kit Installation Components for the Westinghouse DA-75 Breakers (Continued)

Step Description Style No. Qty. Comment

Step 14 Aux. Switch Kit 4A35618G02 1

Microswitch 1

Mounting Bracket 1

.164 - 32 × .500 Lng. Screw Fil. 2

.164 Flat Washer Stl. 4

.164 Lock Washer Stl. 2 Comm. Only

.164 - 32 Nut Hex Stl. 2

.138 - 32 × 1.25 Lng. Screw Fil. 2

.138 Flat Washer Stl. 8

.138 Lock Washer Stl. 4

.138 - 32 Nut Hex Stl. 4

Step 15 Cell Harness 6503C57G__ 1 Except 510 Basics

NOTE: Due to the wide vintage of breakers and the multiple functions of the Retrofit components, some excess

hardware may remain when the Retrofit is complete.

Effective December, 1998

Page 22

IL 33-DAH-1

Page 21

Torque Values for General Mounting

Decimal Standard Torque Torque

Size (in) Size (in-lbs) (ft-lbs)

.112 4-40 10 0.8

.138 6-32 18 1.5

.164 8-32 36 3.0

.190 10-32 46 3.8

.250 1/4-20 100 8.3

.312 5/16-18 206 17.2

.375 3/8-16 356 29.7

.438 7/16-14 572 47.7

.500 1/2-13 856 71.3

Torque Values for Copper BUS Connectors

Decimal Standard Torque Torque

Size (in) Size (in-lbs) (ft-lbs)

.250 1/4-20 60 5

.312 5/16-18 144 12

.375 3/8-16 240 20

.500 1/2-13 600 50

Effective December, 1998

Page 23

Page 22

IL 33-DAH-1

B

C

D

A

E

F

G

A. Sensors

B. Trip Unit

C. Aux. CT Module

D. Rating Plug

E. Direct Trip Actuator (DTA)

F. Aux. Switch

CPT Kit not pictured.

I

K

J

H

L

G. PT Module

H. Sensor Harness

I. DTA Extension Harness

J. Aux. CT Harness

K. External Harness

L. Cell Terminal Block Assembly

Effective December, 1998

Page 24

IL 33-DAH-1

Notes:

Page 23

Effective December, 1998

Page 25

Page 24

IL 33-DAH-1

We wish to thank you f or purchasing the Digitrip Retrofit System. Digitrip Retrofit Kits are designed and manufactured in

America with pride. All the components are engineered to fit the e xisting Circuit Break er with little or no modifications to

the existing Breaker. Howe ver due to the wide variety and vintage of Breakers in use today, an occasional problem may

arise. Please contact us with any questions, comments or concerns.

Phone: 1-800-937-5487 Fax. (724) 779-5899

The instructions for installation, testing, maintenance, or repair herein are provided for the use of the

product in general commercial applications and may not be appropriate for use in nuclear applications. Additional

instructions may be available upon specific request to replace, amend, or supplement these instructions to qualify

them for use with the product in safety-related applications in a nuclear facility.

The information, recommendations, descriptions, and safety notations in this document are based on

Cutler-Hammer’s experience and judgement with respect to retrofitting of power breakers. This information should not

be considered to be all inclusive or covering all contingencies. If further information is required, Cutler-Hammer should

be consulted.

NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WARRANTIES OF FITNESS FOR A PARTICULAR

PURPOSE OR MERCHANTABILITY, OR WARRANTIES ARISING FROM COURSE OF DEALING OR USAGE OF

TRADE, ARE MADE REGARDING THE INFORMATION, RECOMMENDATIONS AND DESCRIPTIONS

CONTAINED HEREIN. In no event will Cutler-Hammer be responsible to the user in contract, in tort (including

negligence), strict liability or otherwise, for any special, indirect, incidental, or consequential damage or loss

whatsoever, including but not limited to damage to or loss of use of equipment, plant or power system, cost of capital,

loss of profits or revenues, cost of replacement power, additional expenses in the use of existing power facilities, or

claims against the user by its customers resulting from the use of the information, recommendations, and descriptions

contained herein.

Cutler-Hammer

130 Commonwealth Drive

Warrendale, PA 15086

Effective December, 1998

Printed in U.S.A. - K

Page 26

IL 33-DAH-1

Page 25

INDEX

Symbols

2-Point Terminal Block 9

510 Basic Retrofit Kits 13

A

Auxiliary Switch 14

B

Breaker Mounted CPT 9

C

Cell Harness 15

CPT Terminals 10

D

Drilling Plan “A” 5

DTA Assembly 8

DTA Extension Harness 13

F

Final Connection of the Harnesses and Wiring 11

G

General Breaker Preparation 3

Glass Poly Insulation Plate 10

H

HV Wires 12

K

Kit Components Table 1

M

Mounting the Cell Harness 15

P

Phase Convention 12

PT Wires 12

R

Racking Bar Adapter 16

Removing the Original Electromechanical Trip Units 3

Reset Arm Assembly 7

Retrofit Kit Installation Components 17

Retrofitted Breaker 16

S

SAFETY PRECAUTIONS 1

Sensor Style No. 11

Sensors 4

T

Testing the Breaker 15

Torque Values for Copper BUS Connectors 21

Torque Values for General Mounting 21

Trip Finger 7

Trip Unit Assembly 6

Trip Unit Mounting Platform 5

I

Installing the 2-Point Terminal Block 9

Installing the Auxiliary Switch 14

Installing the Breaker Mounted CPT 9

Installing the DTA Assembly 8

Installing the Reset Arm Assembly 7

Installing the Retrofitted Breaker in the Cell 16

Installing the Sensors 4

Installing the Trip Finger 7

Installing the Trip Unit 6

Installing the Trip Unit Mounting Platform 5

Effective January, 1998

Loading...

Loading...