Page 1

TECHNICAL

SPECIFICATIONS

FG6RL Series

High Efficiency / Direct Vent or Non Direct Vent

Condensing Downflow Gas Furnace

Induced Draft - 92.1 AFUE Input 40,000 - 120,000 Btuh

The high efficiency downflow gas furnace may be installed

free standing in a utility room, or enclosed in an alcove or

closet. The extended flush jacket provides a pleasing

“appliance appearance.” Design certified by the Canadian

Standards Association (CSA). The product is truly designed

with the contractor and the consumer in mind.

FEATURES & BENEFITS

• Best warranty in the business -

– A lifetime warranty on the heat exchanger

– 8 Year Limited Parts and 5 Year Quality Pledge

• 100% fired and tested - All units and each component

(both mechanical and electrical) are tested on the

manufacturing line.

• Best packaging in the industry - Unique design assures

product will arrive to the homeowner dent free.

• Clean and quiet operation - Due to the unique design of

in-shot burners, location of inducer, return air vents, and

use of insulation.

• Fixed 30 second blower delay at burner start-up assures

a warm duct temperature at furnace start-up. Adjustable

blower off settings (60, 120, 160 and 180 seconds).

• Fixed 30 second post purge increases life of heat

exchanger.

• SmartLite

ignitors in furnaces using hot surface ignition technology.

Programmed to learn the heat-up characteristics of the

ignitor, then adapt the ignition time to the characteristics

of the furnace so the ignitor is energized appropriately.

• Dependable, hot surface ignitor - Innovative application

of an appliance type ignitor with a 20 year history of

reliability, assures no callbacks because of handling.

• Color coded wire harness - Designed to fit the

components, all with quick-connect fittings for ease of

service and replacement.

• Tubular primary heat exchanger - Heavy gauge

aluminized steel heat exchanger assures a long life.

• Stainless steel secondary heat exchanger assures long

life.

• 90-second fixed cooling cycle blower-off delay (TDR)

increases cooling performance when matched with a

NORDYNE coil.

TM

Control Board — Provides extended life to

• Approved for direct vent furnace, category IV venting

system – May be vertically or horizontally vented using

either a one-pipe or two-pipe system for maximum flexibility

in installation.

• Fully insulated blower cabinet for quiet operation.

• Multi-speed direct drive blower - Designed to give a

wide range of cooling capacities. 40VA transformer included.

• LP convertible - Simple burner orifice and regulator spring

change for ease of convertibility.

• Diagnostic light flashes identify limit failure, pressure

switch failure and improper ground and polarization -

for easy troubleshooting.

• Incorporates integrated control board with connections

for electronic air cleaner, humidifier and twinning.

• Factory installed drain system for reliable performance.

• Door design enhances furnace appearance and uses

screw fasteners for great fit and accessibility.

• 3 amp fuse protection against high and low voltage shorts;

protects transformer and control board.

• Low voltage terminal board for easy field wiring.

• Components and Controls - Designing quality into our

products means selecting manufacturers that have a

reputation for delivering high quality, dependable products.

Page 2

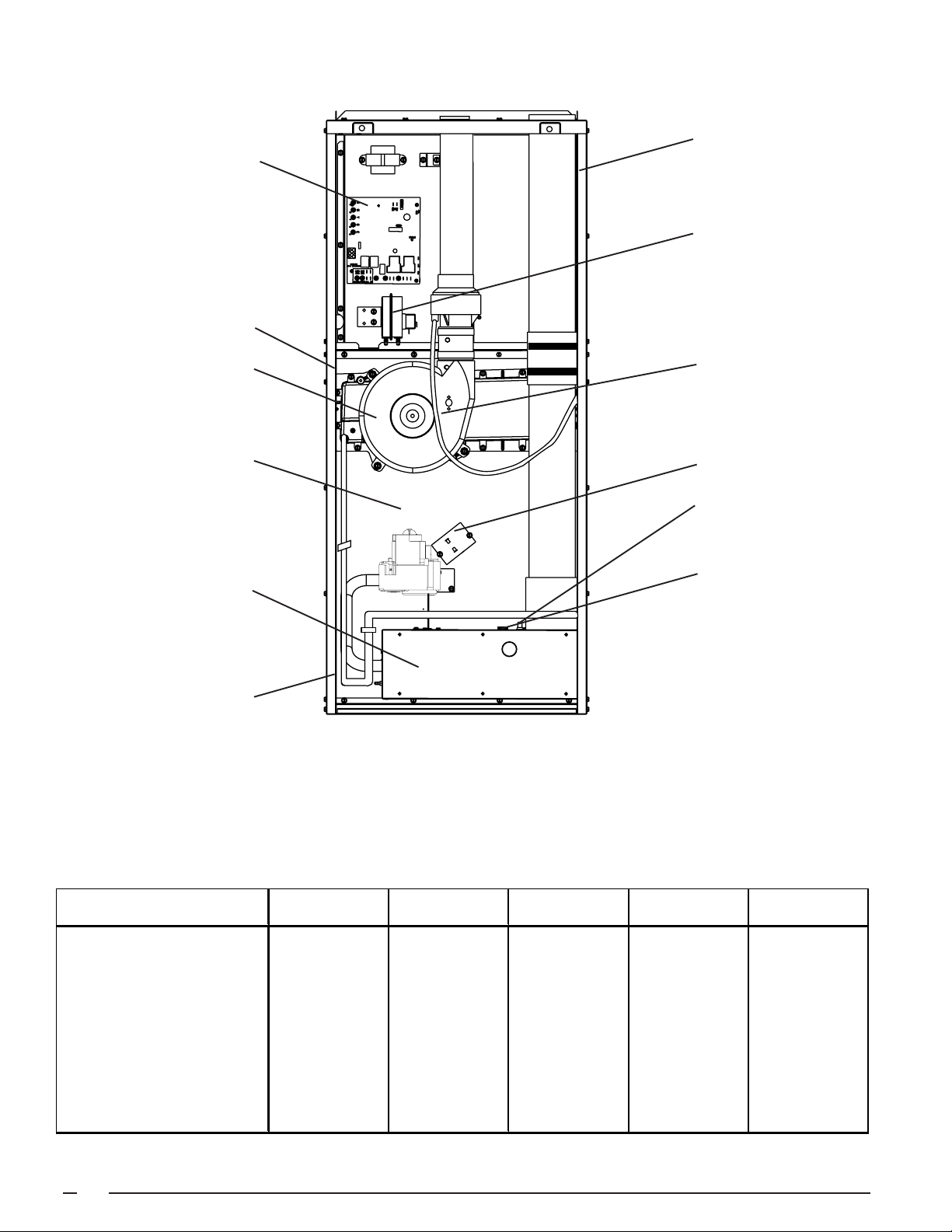

FEATURES

High Efficiency Downflow 90+ Gas Furnace

Solid state integrated control

monitors the burner flame

and limit circuit continuously.

Blower timing has adjustable

OFF settings. Provides

humidifier and electronic air

cleaner connections.

Electrical 2 x 4 junction box can

be moved outside of cabinet

for disconnect.

Vent switch protects against

blocked flue.

Counterflow heat exchanger

orientation and aluminized

steel tubular design, means

improved efficiency and

durability.

Multi-speed PSC motor/

blower provides quiet

airflow, reliable operation

and is installed on a slide-out

track.

Pressure switch assures

proper operation of the

induced draft system.

Induced draft blower

provides quiet and

reliable operation.

Supply air limit.

Remote flame sensor

for proof of flame

carry-over. (Not Shown).

Aluminized steel in-shot

burners, hot surface ignitor

and redundant gas valve

provide safe, reliable ignition

and efficient

combustion.

Factory installed drain

for reliable performance.

Roll-out switch.

STANDARD EQUIPMENT

Direct vent; draft inducer; pressure switch; redundant main gas control; hot-surface ignition; timed ON/OFF blower controls

(TDR); 40VA transformer for air conditioner application; limit controls; direct drive motor; all models can be converted to

use L.P. (propane) gas. Factory approved kits

only

must be used and are available as an optional accessory from your

NORDYNE distributor.

SPECIFICATIONS

FG6RL MODEL NUMBERS: -040C-12A -060C-12A -080C-16B -100C-16B -120C-20C

Input-Btuh (a) 40,000 60,000 80,000 100,000 120,000

Heating Capacity - Btuh 36,000 56,000 74,000 93,000 112,000

AFUE 90+ 92.1 92.1 92.1 92.1

Blower D x W 10 x 6 10 x 6 10 x 10 10 x 10 11 x 10

Motor H.P. -Speed -Type 1/3 - 3 - PSC 1/3 - 3 - PSC 1/2 - 4 -PSC 1/2 - 4 -PSC 3/4 - 4 -PSC

Motor FLA 7.0 7.0 9.0 9.0 11.1

Maximum Ext. SP - In. W.C. 0.5 0.5 0.5 0.5 0.5

Temperature Rise Range - °F 35 - 65 40 - 70 45 - 75 50 - 80 45 - 75

Note: All models are 115V, 60 Hz. Gas Connections are 1/2" N.P.T. AFUE = Annual Fuel Utilization Efficiency

(a) Ratings to 2,000 ft. Over 2,000 ft. reduce 4% for each 1,000 ft. above sea level.

2

Page 3

DIMENSIONS

3/4"

3/4"

43"

1"

Combustion Air Inlet

24 1/2"

Exhaust Vent

22 1/2"

24 7/8"

7/8" Dia. Electric

21 7/8"

1 1/2" x 3 1/2" Dia.

Opening for

Gas Connection

21 1/4"

27 7/8"

Connection

8"

Condensate

Drain Outlet

15 1/2"

Exhaust Vent

2" Dia.

3/4"

21 1/2"

‡

A

‡

B

C

L

D

Bottom Supply

Air Opening

Combustion

‡

C

3/4"

2 1/2"

21 1/2"

Condensate

Drain Outlet

Vent

(3" for 80/100

2" for 40/60)

19 3/4"

24 7/8"

7/8" Dia. Electric

Connection

21 7/8"

1 1/2" x 2 1/2"

Knockout For

Gas Connection

10 1/4"

19 3/4"

Bottom Opening

3/4"

18 3/4"

or 13 1/4"

9 1/4"

16 3/4"

or 11 1/4"

19 3/4"

or 14 1/4"

28 3/8"

1 9/16"

Downflow Sub-base

2"

19 5/8"

1 inch thick fiberglass 3 lb density

3"

MODEL

NUMBER

FG6RL-

Furnace Input

(Btu/ Hr)

A

(in.)

Dimensions

B

(in.)

C

(in.)

D

(in.)

Shipping

Weights

(lbs)

040C-12A 40, 000 14 1/4 12 3/4 4 5/8 11 3/4 135

060C-12A 60, 000 14 1/4 12 3/4 4 5/8 11 3/4 135

080C-16B 80, 000 19 3/4 18 1/4 10 17 1/4 174

100C-16B 100,000 19 3/4 18 1/4 10 17 1/4 185

120C-20C 120,000 22 1/2 21 12 1/2 21 1/8 209

Allow 36" minimum clearance for service.

BLOWER PERFORMANCE

Model Heating External Static Pressure (Inches Water Column)

Number Input Motor Motor 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

*RL-

040C-12 40,000 Medium 1/3 1140 - 1090 - 1060 - 1030 - 980 35 950 36 910 37 870 39

060C-12 60,000 Medium 1/3 1120 45 1070 48 1040 49 1010 50 960 53 930 55 890 57 850 60

080C-16 80,000 Med-High 1/2 1435 47 1395 49 1350 50 1300 52 1255 54 1200 56 1150 59 1090 62

100C-16 100,000 Med-High** 1/2 1475 57 1435 59 1385 61 1335 63 1290 66 1240 68 1190 71 1130 75

120C-20 120,000 Med-High** 3/4 1924 52 1883 53 1836 55 1781 56 1728 58 1675 60 1613 62 1538 65

(Btuh) Speed HP CFM Rise CFM Rise CFM Rise CFM Rise CFM Rise CFM Rise CFM Rise CFM Rise

High* 1280 - 1210 - 1180 - 1140 - 1090 - 1070 - 1030 - 990 -

Low** 875 39 835 41 820 41 805 42 780 43 770 44 760 45 750 45

High* 1260 40 1190 43 1155 44 1120 45 1075 47 1030 49 980 52 940 54

Low** 855 59 815 62 800 64 780 65 760 67 730 70 710 - 690 High* 1635 - 1585 - 1525 - 1460 46 1400 48 1330 51 1260 54 1180 57

Med-Low** 1230 55 1200 56 1165 58 1130 60 1090 62 1050 65 1000 68 960 71

Low 1050 - 1035 - 1010 - 980 - 950 - 910 - 870 - 820 -

High* 1600 53 1555 54 1500 56 1445 59 1380 61 1310 65 1240 68 1160 73

Med-Low 1320 - 1290 - 1250 - 1215 - 1170 - 1120 - 1070 - 1020 -

Low 1150 - 1130 - 1110 - 1075 - 1040 - 1000 - 950 - 890 -

High* 2085 48 2034 49 1965 51 1909 52 1842 54 1779 56 1714 58 1631 61

Med-Low 1718 58 1671 60 1629 61 1612 63 1567 64 1510 66 1464 68 1412 72

Low 1501 66 1497 69 1461 66 1428 70 1397 72 1364 73 1316 - 1266 -

** Factory Set Cooling Speed

** Factory Set Heating Speed

- Not Recommended

NOTES: 1. Airflow rates of 1800 CFM or more require two return air connections. Data is for operation with filter(s).

2. Temperature rises in the table are approximate. Actual temperature rises may vary.

3. Temperature rises and airflows for external static pressures greater than 0.5 are for reference only.

These conditions are not recommended.

3

Page 4

MODEL IDENTIFICATION CODE

B

Cabinet Width

Approx. CFM

Airflow

@ 0.5" WC

12 = 1200

16 = 1600

A = 14 1/4

B = 19 3/4

C = 22 1/2

Gas

Design Series

Residential

L =Downflow,

Condensing

FG 6 R

100

Heating Input - Btuh

040 = 40,000

060 = 60,000

080 = 80,000

100 = 100,000

120 = 120,000

C 16L

C = U.S. / Canada

VENTING

All models are approved for vertical non direct (1 pipe) and direct (2 pipe) venting applications. See Vent Table below

for specified sizes and allowable lengths.

VENT TABLE

APPLICATION SIN GLE PIPE LENGTH (ft.) DIREC T VENT, DUAL PIPE LENGTH (ft.)

with 1 long radius elbow** with 1 long radius elbow on each pipe**

PVC,CPVC or ABS Outlet Outlet Inlet/Outlet Inlet/Outlet Inlet/Outlet

SCH. 40 Pipe Size 2" 3" 2" 2" 3" 2" 3" 3"

Models 040

80 150 404050509090

Models 060 & 080 60 150 30 30 35 35 90 90

Models 100 & 120 30 150 15 15 25 25 90 90

ACCESSORY VENT KITS

Kit Order Number

U.S. LP Conversion Kit

(0 to 10,000 f t.)

Canadian LP Gas Conversion Kit

(0 to 4,500 f t.)

Fossil Fuel Kit 914762

Downflow Sub-Base A Cabinet 902974

B Cabinet 902677

C Cabinet 904108

Variable Speed Blower Kit

For "A" Cabinets

Variable Speed Blower Kit

For "B" & "C" Cabinet s

904090A

904091A

904231

904075

Kit

Description

Horizontal

Exterior Vent

Mounting Kit

Neutralizer Kit

(all models)

2" PVC 3" PVC 4" PVC

9023730 9023750 9023760

* NOTE:

1. Subtract 2.5 ft. for each

additional 2" elbow and 3.5 ft.

for each additional 3" elbow.

2. Two 45 degree elbows are

equivalent to one 90° elbow.

3. One short radius elbow is

equivalent to 2 long radius

elbows.

4. Do not include termination

elbows in calculation of vent

length.

5. This table is applicable for

elevations from sea level

to 2000 ft. For higher

elevations decrease vent pipe

lengths by 8% per 1000 ft. of

altitude.

6. Only the above pipe materials

are approved for use with FG6

Condensing Furnaces.

9023770

O'Fallon, MO

Westinghouse products are manufactured and distributed by NORDYNE.

213B-0506 (Replaces 213B-0504)

Before purchasing this appliance, read important energy cost

and efficiency information available from your retailer.

Specifications and illustrations subject to change without notice

and without incurring obligations. Printed in U.S.A. (05/06)

Loading...

Loading...