Western Electric 6071 B Instructions For Use Manual

RADIO

Western

AMPLIFIER

INSTRUCTIONS

Electric

FREQUENCY

No.

Cu'eljr-rva

FOR

B

6071

USE

Printed in

U.S.A.

Instruction Bulletin No.

728

The equipment

described

in

this Bulletin

was

designed and

developed

for the

Wes/47r71

Electric

Company

by.

BELL TELEPHONE

LABORATORIES

RADIO FREQUENCY

AMPLIFIER

No. 607

1 B

CONTENTS

Page

Page

INTRODUCTION

1 Installation of

Amplifier

Tubes....

12

Power

Requirements (Table)

1 Bias Voltages

and

Plate

Current

(Table)

13

GENERAL

DESCRIPTION 2

Amplifier Input

Circuit 2

TUNING

ADJUSTMENTS

13

Amplifier Tubes

2

Preliminary

13

Amplifier

Output

Circuit 2

Amplifier

Input

Circuit

13

Harmonic

Suppression and Antenna

Neutralizing

and

Amplifier

Output

Coupling

2

Tuning

14

Monitoring

Circuit 2

Coupling

Circuit

Tuning

14

Power

Circuits

2

Adjustment

of

Output

Transformer

Power

Control and Protection Cir-

Turns

15

cuits

3

Antenna

Tuning

15

Formula

for Coupling

Capacity

15

INSTALLATION

3

Final

Tuning

Operations

16

General

3

Typical

Meter

Readings

(Table)

16

Ground

System 4

Summary

of

Adjustments

16

Antenna

5

Formula

for Antenna

Current

17

Power

and Control

Connections... 5

Operation

at

Reduced

Power

17

Radio Frequency

Input

Connections 5

Formula

for

Efficiency

(Foot-

Audio

Frequency

Connections

5

note)

17

Transformer

Connections

6

Miscellaneous

Installation

Notes.. .

Change

of Transmitter

Nameplates

6

6

MODULATION

At Normal

Power

18

18

At

Reduced

Power

19

PRELIMINARY

ADJUSTMENTS

OF

POWER

CIRCUITS

Power

Supply

Circuits

Fuse

Ratings

(Table)

Preheat

Rectifier

Tubes

Delay

Relay

Grid Bias

Load

Resistances

6

6

7

7

7

9

MONITORING

Monitoring

Levels

Maximum

Monitoring

Levels

(Table)

Monitoring

Circuit

Impedance

19

19

19

19

Door

Switch and Filament

Relays..

9

Plate

Rectifier

Contactor,

Surge and

OPERATING

PROCEDURE

20

Filter

Resistance

Relays

9

Starting

the

Equipment

20

Grid

Bias Marginal

Relay

9

Stopping

the

Equipment

20

Overload

Relay

10

Overload

Relay

Reset

20

Normal

and

Overload

Current

Operating

Use

of

Meters

20

(Table)

10

Operating

Use of

Load

Resistance.

21

General

12

Definition

of "Resistance

Intro-

duced"

(Footnote)

21

PRELIMINARY

ADJUSTMENTS

OF

RADIO

FREQUENCY

CIR-

CONNECTION

TO OTHER

EQUIP-

CUITS

12 MENT

22

General

12 Connection

to

Transmitter

Other

Adjustment

of Antenna

Impedance 12 Than

No. 12B

22

Value

of

Antenna

Condenser Connection

to Amplifier

of

Higher

(Table) 12

Power

22

I

MAINTENANCE

General

Care

of the

Cabinet

Cleaning

Variable

Air

Condensers

Relays

and Magnetic

Contactors

23

Vacuum

Tubes

23

Vacuum

Tube

Sockets

24

Repair

of Thermocouples

24

Additional

Routine

24

CONTENTS

(Continued)

Page

Page

22

APPARATUS

INFORMATION

27

22

23

23

LOCATION

OF TROUBLE

25

General

25

Power

Control

Circuit

25

Fuses

25

Reduced

or

No

Radiation

26

Distortion

26

Noise

27

II

SPARE

PARTS

27

General

List

of Spare Parts for

the

6071B Amplifier

27

Special List

of Spare

Parts for the

1000

Watt Equipment

28

Special List

of

Spare

Parts

for the

500

Watt Equipment

28

Special List

of Spare Parts for

the

250

Watt

Equipment

28

ENGINEERING

SERVICE AND

IN-

FORMATION

FOR

ORDERING

REPLACEMENTS

29

RADIO

FREQUENCY

AMPLIFIER

No.

6o7113

Introduction

The Western

Electric No.

6071B Amplifier

is

a radio -frequency ampli-

fier

designed

for connection

to

a

Western

Electric

No. 12B

or other Radio

Transmitter

capable

of delivering

100

watts.

It may be operated

at any

frequency

from

550

to 3000 kilocycles

and

will

deliver

250,

500

or

1000

watts

of

completely

modulated

carrier into

a

suitable

antenna. It is com-

posed of

a

No.

71B Amplifier

plus miscellaneous

apparatus such

as

vacuum

tubes,

fuses, etc.,

required for

operation.

The No.

71B Amplifier

consists

of a metal cabinet,

similar to that of

the

No.

12B

Radio Transmitter,

containing

the

radio

-frequency circuits,

complete power

supply

equipment

and all the necessary

control and pro-

tective

circuits.

As the

amplifier is

completely

a -c. operated, no motor -

generators,

batteries

or other

external power

equipment are required.

The amplifier

is

designed

to operate

on

220

-volt, 50-

or 60 -cycle, three-

phase

power

supply.

The following

table gives the total power required

for

operation

at the

three

output ratings

in the

standby

and operating

conditions.

The

power

factor is

90

per cent.

Output

Rating

1000 watts

500 watts

250

watts

Full

Operation

4000 watts

2400

watts

1500

watts

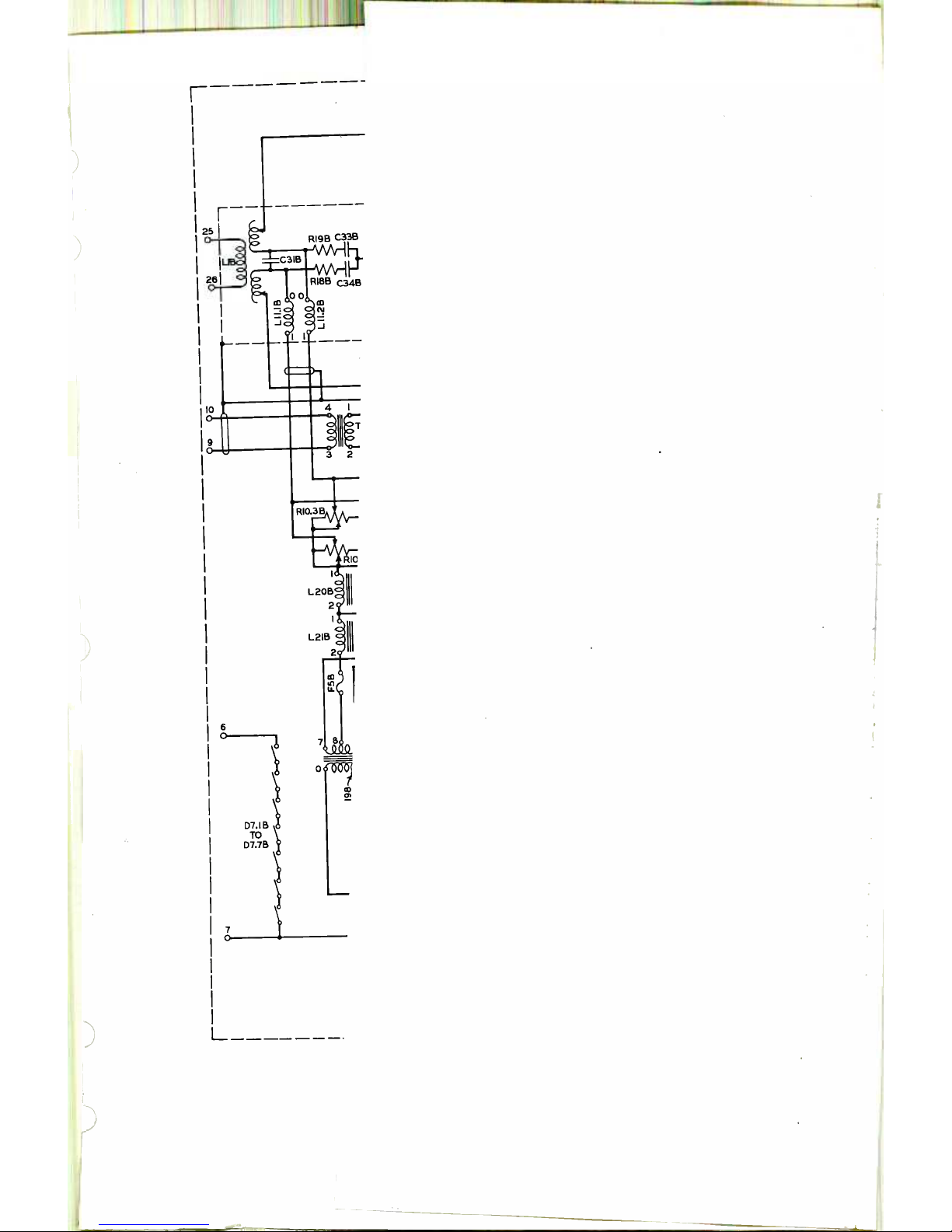

A schematic

diagram

of the

amplifier

circuit is

shown in Figure

1.

The

amplifier

consists

of two

tubes

operating in

a balanced

push-pull

cir-

cuit,

a

circuit

for suppressing

radio

-frequency

harmonics,

and provision

for

efficiently

coupling

the

output

to an

antenna.

Separate rectifiers

pro-

vide

the necessary

direct

current

to the plate

and grid

circuits.

Control

and

protective

circuits

interlock

with

those

of the associated

radio

trans-

mitter

to provide

protection

to the

equipment

and

the operating personnel.

The Nos.

302C,

303C.

and

304C Radio

Transmitting

Equipments

(250,

500,

and

1000

watt

output,

respectively)

each

consist

of a

No.

12B

Radio

Transmitter

and

a

No.

71B

Amplifier with

their

necessary

accessories.

These

equipments

are

supplied with

tubes,

tube

sockets, condensers,

etc.

for

the power

output

requested.

They may

be

operated

at reduced

power

by

simple

adjustments.

The power

rating

may

be changed

by

the substi-

tution

of the

proper

tubes,

tube sockets

and

other components.

[1]

GENERAL

DESCRIPTION

Amplifier

Input

Circuit

The radio

-frequency

input

voltage

is

obtained

from

the tuned. input

transformer

(L1B)

coupled

to the

output

of

the associated

radio

trans-

mitter.

The input

energy is

dissipated

in

resistances

(R1B and

R2B)

which

are

in

tapped

sections

to permit

adjustment

to the value required

to produce

the

necessary

radio

-frequency

grid voltage

across

the tuned

circuit.

Amplifier

Tubes

The

amplifier

employs

two

radiation -cooled

vacuum

tubes

(V1B and

V2B)

operating

as class

"B" in

a

balanced push-pull

circuit, the tubes

being

biased

to approximate

cut-off.

Amplifier

Output

Circuit

The

plates of

the

tubes

operate into

a

tuned output transformer

con-

taining

a thermoammeter

(M5B)

to facilitate

tuning and neutralizing.

Harmonic

Suppression

and

Antenna

Coupling

Harmonic

suppression

and

antenna

coupling is

accomplished

by the

network

consisting

of L3B,

C11B, C12B and L4B which

couples the

trans-

mitter

to

the antenna

and suppresses

the

radio

-frequency

harmonics.

Meters

(M6B

and

M7B) necessary

to

facilitate

tuning

are provided

in

this circuit.

A resistance

(R8B)

of 100

ohms

is included,

which

may be

connected

by means

of a

link

(D14B)

to serve

as a

load

for

testing at

times when

it is

not permissible

or

desirable

to energize

the

antenna.

Monitoring

Circuit

An audio

output

transformer

(T4B)

connected in

the high

voltage

return

lead provides

ample audio

power

for monitoring purposes.

Power

Circuits

The filaments

of all tubes

operate

on alternating

current. The

filament

transformer primary

voltage

is measured

by a voltmeter (M1B)

and is

maintained

at 200 volts

by

adjustment

of

the

variable

auto -transformer

(T6B).

Grid bias voltage

is

supplied

by a

single full -wave mercury

vapor

rectifier

tube (V9B)

.

The output

of this rectifier

is passed through

a

two

-

section filter

and dissipated

in

an

adjustable resistance

(R10B).

Plate

power for

the amplifier

tubes is

supplied

by a

three-phase

full -

wave

mercury

vapor

rectifier

employing six

tubes (V3B

to

V8B, incl.) .

The

output

of this

rectifier is filtered

by

a

single -section

filter.

[2]

6

O

D7.IB

TO

D7.7B

\ÿ

d

7

O

L-------

r

Power

Control

and

Protection

Circuits

The power

control

circuits consist

of

a combination

of relays

arranged

to energize

the

various power

circuits

of

the amplifier

in

the

correct

sequence

and to provide

the necessary

delay

before

applying

plate

voltage

to

the

rectifier tubes.

The

amplifier

is completely

energized

automatically

by the

operation

of

the

"Master

Control"

switch

located on

the

No. 12B

Radio Transmitter,

if the

"Main Power

Disconnect"

(D1B)

and the

"Filaments" (D3B) switches

are

closed,

and

when the "High

Voltage"

switches

on both the transmitter

and

amplifier

units

are

"On."

For semi-

automatic

starting, the

"High

Voltage"

switches

are left

in the

"Off"

position

when the

"Master Control"

switch

is closed.

After

the

control

circuits

have functioned,

the

starting operation

may

be completed

by

closing the "High

Voltage"

switches.

(See

"Control

Circuit Sequence

Chart,"

Figure 2).

The

protection circuits

(of the

No. 71B

Amplifier)

consist of

the

fol-

lowing relays and

fuses to protect the

equipment

and personnel.

The

door switch

relay (S3B)

removes bias

and plate

voltages

whenever

a

door

switch

(D7B)

is

operated

either

in the

No. 12B Radio

Transmitter

or the

No.

71B

Amplifier.

The grid

bias marginal relay

(S5B) removes the

plate voltage

when

the bias

voltage is below

a proper

value and prevents application

of the

plate voltage when

the

bias

voltage is low.

The overload

relay (S6B) removes the plate

voltage

when an overload

beyond

the

safe capacity of the

rectifier occurs.

The current

demanded

by modulation

peaks and supplied

by

the

filter condenser

does not pass

through this

relay and

cause

unnecessary operation.

The

surge

relay (S7B) and

the

filter resistance

relay (S8B)

are pro-

vided to short out a

resistance, used to limit the condenser

charging cur-

rent,

after the condenser has assumed

its full charge. It

is necessary to

limit

this charging current to prevent excessive

loads

on the

rectifier tubes

and false operation of the overload relay.

Fuses

are provided in the 220

-volt

a -c. circuits and in the

rectifier out-

put circuits as

additional protection

to the

apparatus against circuit

defects.

INSTALLATION

General

The installation

of the

No.

71B Amplifier in conjunction with the

No.

12B Radio

Transmitter, being a

typical

case, is herein dealt with in detail.

Installation in

conjunction with a transmitter other than

the

No.

12B

should

be

facilitated

by these

instructions.

The

No.

302C, 303C,

or 304C Radio

Transmitting

Equipments should

be installed

in accordance with

the installation

drawings

furnished.

The

[3]

transmitter

and amplifier

units

should be

installed in a

light,

well ven-

tilated room and so situated

as to

provide easy access

to the

antenna

and

ground

connections.

At

least three

feet

of

clearance

should be

allowed on

all sides and top

of the

units. If

forced ventilation

of the transmitter

room

is

employed,

care

should be exercised

in

arranging

this ventilation

so that dust

and dirt are

not blown or

drawn into the

equipment.

Two

hardwood bases should

be prepared

for the units

in accordance

with

the

installation

drawing,

and if practicable,

all

ground leads,

power

and

audio conduits should

be in place

before the equipment

is set up.

The

No.

12B

Radio Transmitter should

be

placed

on one of

the

hardwood bases

and

the

back and two

sides of the unit

should

be removed

by removing

the

screws

which fasten them to the frame.

The

right side of

the transmitter

unit is removed

permanently and side guide

pins at the

top of the

trans-

mitter frame

should be removed to permit

the proper

alignment

of the

transmitter

and amplifier units.

Before

the

No.

71B Amplifier is

set in

place on

its hardwood

base,

remove the

knock-outs in

the junction

box

in

the

No. 12B Radio Trans-

mitter. This

junction

box

is

located in

the

lower

front right-hand

corner

of

the

transmitter unit (see view "C

-C"

on

installation

drawing

ESX-

601752).

Remove the back

and

the

right side

from the

amplifier

unit

by

removing the screws

which fasten

them to the

frame. The

left side

of the

unit

should

not

be removed.

When the

amplifier

unit

is in place

and care-

fully aligned

with the transmitter unit, a

11/2 inch Chase

nipple

and

lock -

nut

should

join the

junction

box

in

the

transmitter

unit to the

amplifier

unit.

Ground System

A

typical

interior ground system

layout is

shown

on the

installation

drawing

(ESR-601783). All

metal

structures

such

as building

frame,

water and

steam

pipes,

conduits,

roofs and stacks should

be bonded

to the

interior

ground

system. All

ground

connections

should be as

short and

direct as possible

and all joints

should

be soldered or

welded. Where

in-

stallations are made in

tall

buildings

the

information given

on

ESR-601783

and

associated

drawings may not apply

entirely,

in

which case

additional

engineering information should be requested.

The

main

ground

terminal of the transmitter unit

is

located at the

extreme

lower

right-hand corner in front

of

the

junction box.

It

consists

of

a cadmium

plated

copper strip

43/4

inches

long which is

fastened to the

main transmitter frame

by means of two bolts

located at the

ends of the

strip.

The main ground terminal

of

the amplifier unit

is located at the

extreme

lower

left-hand

corner of the cabinet

in front of the terminal

strip. It

is similar in construction

to that of

the transmitter

unit and

is

fastened

to the

main

frame

of the amplifier

by means of bolts.

The

ground

connection for each

unit should consist of a 4

inch by 1/64 inch

copper

strip, one

end of

which

should be

soldered

to the removable

strip

which is

then

bolted to the ground

terminal. The other end

is soldered to

the main

ground

system.

It is suggested

that

the

lugs

which

are

bolted

to

the

[4]

ground

terminal

in

the

transmitter

unit

be temporarily

removed

while

soldering

the ground

strip.

All

ground

connections

should

be

as short

and

direct

as possible.

Antenna

The

No. 71B

Amplifier

can

be operated

with

an

antenna

of

any

resist-

ance

and

reactance,

but

where

antennas

of

less

than

12 or

more

than

90

ohms

are

encountered,

additional

engineering

information

should

be

requested.

The

antenna

lead-in

from

the

grounding

switch

is connected

to terminal

27

located

on top

of the

amplifier

unit.

Copper

tubing

is recom-

mended

for this

purpose.

Power

and

Control

Connections

A

1 -inch conduit

should

be

installed

from

the

service

entrance

to

the

junction

box

in

the

transmitter

unit

and

three

No. 8

B&S gauge

BRC

wires

should

be pulled

through

from

the

220 -volt,

3 -phase,

50-

or

60 -cycle

power

supply.

These

wires

connect

to

terminals

1,

2

and

3

of the

amplifier

terminal

block.

Connect

terminals

2 and 3

of the

amplifier

to terminals

1

and

2, respectively,

of the

transmitter

terminal

block.

Using

No.

14 B&S

gauge

BRC

wire connect

terminals

4, 5, 6

and 7

of the

transmitter

unit

to terminals

4, 5, 6 and

7,

respectively,

of the

amplifier

unit.

Radio

-Frequency

Input Connections

In the

No. 12B

Radio

Transmitter

open

link switch

D28A

and

remove

condensers C21A

from their

mounting

posts.

Connect

the

ground

strap

of the

transmitter

to terminal

26

of the

amplifier.

Connect

the

ungrounded

post just

vacated

by condensers

C21A

to terminal

25 of the

amplifier.

When

these

connections

are

complete,

link switch

D2A

may be

used to

connect

resistance

R12A into the

circuit

: that

is,

when this

link

is between

"3"

and

"4"

the resistance

is in circuit,

and

when between

"2" and "3"

the

resistance

is

out

of circuit.

Audio

-Frequency Connections

The

speech

input and

monitoring output

leads

should

be

run in

con-

duit and

brought out

near the terminal

blocks

in the transmitter

unit.

The

speech

input leads connect to

terminals

15 and

16

on

the transmitter

terminal

block and the

monitoring

output

leads connect

to

the

spare

terminals

13 and

14 on

the

transmitter

terminal

block.

Terminals

13 and

14

then

should

be connected to

terminals

9 and

10, respectively,

of the

amplifier

unit. A

No. 19 B&S gauge twisted

pair, rubber

and

lead

covered

cable per

KS -6531 should be

used

for all audio

leads.

Both ends

of the

lead

cable

sheath should

be bonded to the

ground

system

with a

No. 16

B&S

gauge

bare copper

wire

and

all conduits

should

be soldered

or

welded

to the ground

system. In

grounding the

lead cable

sheaths, terminal

10

of the transmitter

unit or

terminal

11 of the amplifier

unit may

be used.

[51

Transformer Connections

The heaviest transformer

(T5B)

is shipped

separately

and

must be

mounted

in its place in

the lower compartment.

Each transformer

ter-

minal

is marked

and

each

wire is

correspondingly

tagged.

Remove the

metal tags or slide them

back upon the

wires

to

avoid a chance

of short

circuiting,

and connect numbered

wires to the

correspondingly

numbered

transformer terminals.

Rectifier transformers (T3B and

T5B) are

equipped

with taps marked

with the primary voltage. The

line voltage should be

measured

at

regular

intervals during an operating

day, the

average

taken, and the

connections

to the transformer

taps made on that marked terminal

which is nearest to

the

average voltage.

Miscellaneous Installation

Notes

When the harmonic suppression coil

is fitted with an

internal

supple-

mentary coil it

is

shipped

with fiber

wedges

to protect

it from breakage.

Remove these

wedges before

energizing

the amplifier.

The equipment

is

shipped

with

condensers,

meters, and

other parts, all

of

which

are

appropriate for

the

frequency,

power

and antenna

impedance

specified in

the

order.

Change

of Transmitter

Nameplates

Certain

apparatus designation nameplates

on the

No.

12B Radio Trans-

mitter are changed

when

the

transmitter is

operated

in conjunction

with

the

No.

71B Amplifier.

The

new

nameplates and mounting screws

are

included

with

the equipment

and can be attached readily

with

a

screw-

driver. The nameplates

to

be substituted

are listed below

:

Original

New

Apparatus

Nameplate

Nameplate

Designation

Designation Designation

M3A

"Antenna

Current"

"Output

Current"

C19A

"Antenna

Tuning"

"Output

Tuning"

The correct

equipment nameplate also will

be

included

and should

be

mounted

in the

designated place in

the center of the front panel of

the

No.

12B

Radio Transmitter.

The

panel is drilled and tapped,

and

the

proper

screws

are provided for

this purpose.

PRELIMINARY

ADJUSTMENTS

OF

POWER

CIRCUITS

Power

Supply

Circuits

Open main

switch D1B

and install fuses

in

accordance

with the follow-

ing

table

which

gives

the

fuse

ratings

in

amperes.

[ 6 ]

Loading...

Loading...