Page 1

TD-36

DIN-rail Tele and Leased Line modem

TD-36 485

DIN-rail Tele and Leased Line modem

with I/O and RS-485

www.westermo.com

©

Westermo Teleindustri AB

User Guide

6618-2202

TD-36

Page 2

Page 3

3

6618-2202

Legal information

The contents of this document are provided “as is”. Except as required by applicable

law, no warranties of any kind, either express or implied, including, but not limited to,

the implied warranties of merchantability and fitness for a particular purpose, are made

in relation to the accuracy and reliability or contents of this document. Westermo

reserves the right to revise this document or withdraw it at any time without prior

notice.

Under no circumstances shall Westermo be responsible for any loss of data or income

or any special, incidental, and consequential or indirect damages howsoever caused.

More information about Westermo can be found at the following Internet address:

http://www.westermo.com

Page 4

4

6618-2202

Safety

Before installation:

This modem is for restricted access area use only.

Read this manual completely and gather all information on the unit. Make sure

that you understand it fully. Check that your application does not exceed the safe

operating specifications for this unit.

This unit should only be installed by qualified personnel.

This unit should be built-in to an apparatus cabinet, or similar, where access is

restricted to service personnel only.

The power supply wiring must be sufficiently fused, and if necessary it must be

possible to disconnect manually from the power supply. Ensure compliance to

national installation regulations.

Maximum 20 A branch circuit protection required.

The product is intended to work with IT power system.

This unit uses convection cooling. To avoid obstructing the airflow around the unit,

follow the spacing recommendations (see Cooling section).

Before mounting, using or removing this unit:

Prevent access to hazardous voltage by disconnecting the unit from power supply.

Warning! Do not open connected unit. Hazardous voltage may occur within this

unit when connected to power supply or TNV circuits.

Care recommendations

Follow the care recommendations below to maintain full operation of unit and to fulfil

the warranty obligations.

This unit must not be operating with removed covers or lids.

Do not attempt to disassemble the unit. There are no user serviceable parts inside.

Do not drop, knock or shake the unit, rough handling above the specification may cause

damage to internal circuit boards.

Do not use harsh chemicals, cleaning solvents or strong detergents to clean the unit.

Do not paint the unit. Paint can clog the unit and prevent proper operation.

Do not expose the unit to any kind of liquids (rain, beverages, etc). The unit is not waterproof. Keep the unit within the specified humidity levels.

Do not use or store the unit in dusty, dirty areas, connectors as well as other mechanical

part may be damaged.

If the unit is not working properly, contact the place of purchase, nearest Westermo

distributor office or Westermo Tech support.

Maintenance

No maintenance is required, as long as the unit is used as intended within the specified

conditions.

Page 5

5

6618-2202

According to:

TIA-968-A and CS-03 Part 1, issue 9

This equipment complies with Part 68 of the FCC rules and the requirements adopted by the ACTA.

On the left side of this equipment is a label that contains, among other information, a product

identifier in the format US:AAAEQ##TXXXX. If requested, this number must be provided to the

telephone company.

A plug and jack used to connect this equipment to the premises wiring and telephone network must

comply with the applicable FCC Part 68 rules and requirements adopted by the ACTA. A compliant

telephone cord and modular plug is provided with this product. It is designed to be connected to a

compatible modular jack that is also compliant. See installation instructions for details.

Caution-to reduce the risk of fire, use only No.26 AWG or lager telecommunication cable.

The USOC jack required RJ11-C, and the REN is used to determine the number of devices that

may be connected to a telephone line. Excessive RENs on a telephone line may result in the

devices not ringing in response to an incoming call. In most but not all areas, the sum of RENs

should not exceed five (5.0). To be certain of the number of devices that may be connected to a

line, as determined by the total RENs, contact the local telephone company. For products approved

after July 23, 2001, the REN for this product is part of the product identifier that has the format

US:AAAEQ##TXXXX. The digits represented by ## are the REN without a decimal point

(e.g., 03 is a REN of 0.3). For earlier products, the REN is separately shown on the label.

If this equipment TD-36/485 causes harm to the telephone network, the telephone company will

notify you in advance that temporary discontinuance of service may be required. But if advance

notice isn't practical, the telephone company will notify the customer as soon as possible. Also, you

will be advised of your right to file a complaint with the FCC if you believe it is necessary.

The telephone company may make changes in its facilities, equipment, operations or procedures that

could affect the operation of the equipment. If this happens the telephone company will provide

advance notice in order for you to make necessary modifications to maintain uninterrupted service.

Agency approvals and standards compliance

Type Approval / Compliance

EMC EN 61000-6-2, Immunity industrial environm

EN 55024, Immunity IT equipment

EN 61000-6-3, Emission residential environments

FCC part 15 Class B

EN 50121-4, Railway signalling and telecommunications apparatus

IEC 62236-4, Railway signalling and telecommunications apparatus

Safety EN 60950-1 and UL 60950-1, IT equipment

PSTN CS 03 Part 1, issue 9

FCC part 68, TIA-968-A

ETSI TS103 021-1, ETSI TS103 021-2, ETSI TS103 021-3

AS/ACIF S002, AS/ACIF S006

Page 6

6

6618-2202

If trouble is experienced with this equipment TD-36/485, for repair or warranty information, please

contact Westermo Data Communication,Inc. 11200 Westheimer,Suit 900. Houston,TX,,77042.

Phone number: 713-240-0367. If the equipment is causing harm to the telephone network, the

telephone company may request that you disconnect the equipment until the problem is resolved.

There are no repairs the customer/user can perform inside the modem.

In the event of equipment malfunction, all repairs should be performed by our Company or an

authorized agent. It is the responsibility of users requiring service to report the need for service to

our Company or to one of our authorized agents. Service can be facilitated through our office at:

Westermo Data Communication Inc

11200 Westheimer Suit 900

Houston,TX, 77042

TEL:713-240-0367

Connection to party line service is subject to state tariffs. Contact the state public utility commission,

public service commission or corporation commission for information.

If your home has specially wired alarm equipment connected to the telephone line, ensure the installation of this TD-36/485 does not disable your alarm equipment. If you have questions about what will

disable alarm equipment, consult your telephone company or a qualified installer.

Electrical Safety Advisory:

Parties responsible for equipment requiring AC power should consider including an advisory notice

in their customer information suggesting the customer use a surge arrestor. Telephone companies

report that electrical surges, typically lightning transients, are very destructive to customer terminal

equipment connected to AC power sources. This has been identified as a major nationwide problem.

Page 7

7

6618-2202

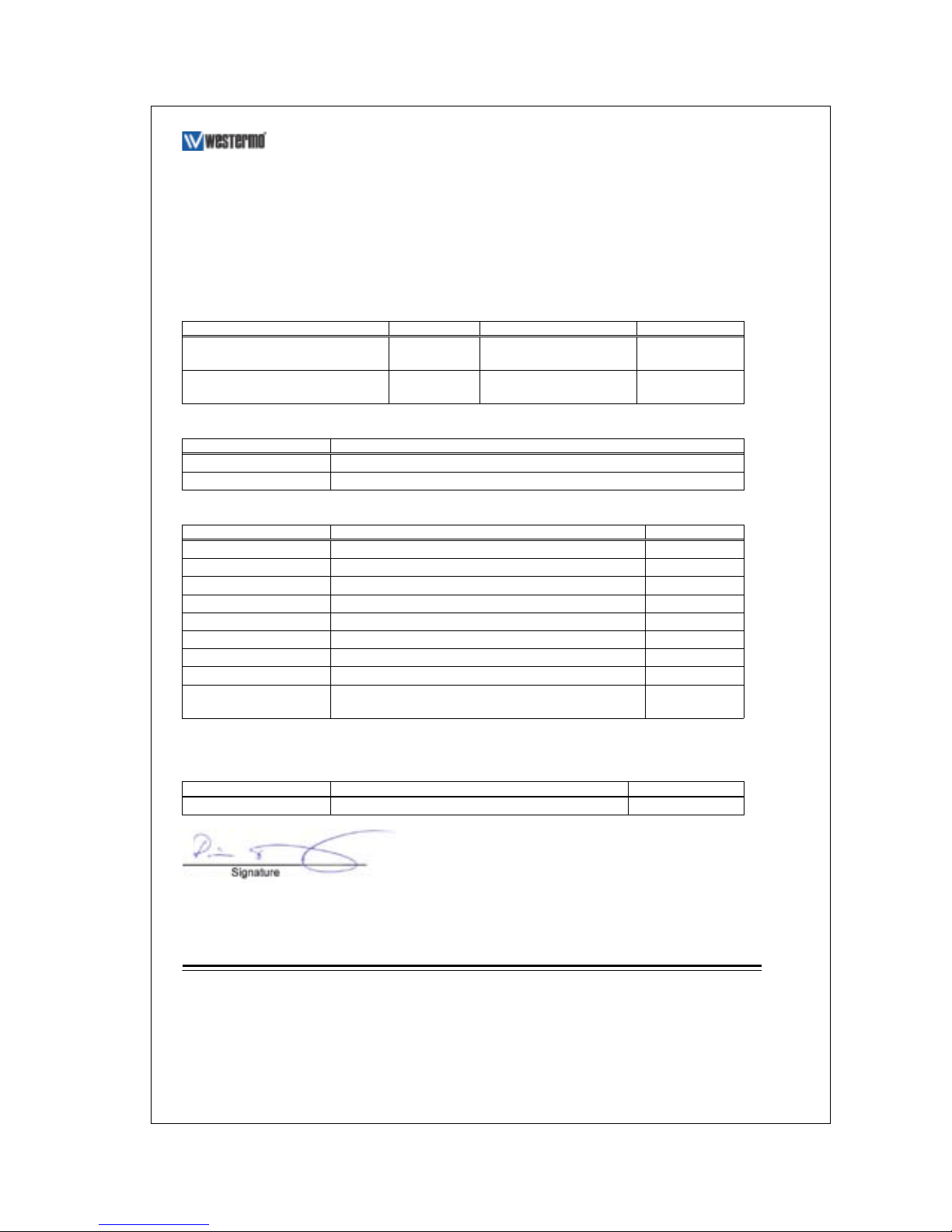

Declaration of Conformity

Westermo Teleindustri AB

Declaration of conformity

Org.nr/

Postadress/Postal addr ess

Tel.

Telefax

Postgiro

Bankgiro

Corp. identity number Registered office

S-640 40 Stora Sundby 016-428000 016-428001 52 72 79-4 5671-5550 556361-2604 Eskilstuna

Sweden Int+46 16428000 Int+46 16428001

The manufacturer

Westermo Teleindustri AB

SE-640 40 Stora Sundby, Sweden

Herewith declares that the product(s)

Type of product Model Art no Installation manual

DIN-rail Tele and Leased Line

modem

TD-36

3618-0101

6618-2201

DIN-rail Tele and Leased Line

modem with I/O and RS-485

TD-36 485

3618-0001

6618-2201

is in conformity with the following EC directive(s).

No Short name

89/336/EEG Electromagnetic Compatibility (EMC)

73/23/EEG Low Voltage Directive - LVD

References of standards applied for this EC declaration of conformity.

No Title Issue

EN 61000-6-2 Immunity for industrial environments 2 (2001)

EN 55024 Information technology equipment – Immunity 1 (1998)

EN 61000-6-3 Emission standard for industrial environments 1 (2001)

EN 60950 Safety of information technology equipment 6 (2000)

EN 50121-4 Railway signalling and telecommunications apparatus

IEC 62236-4 Railway signalling and telecommunications apparatus

UL 60950-1 Safety – Part 1: General Requirements 1 (2007-07-07)

CSA C22.2 60950-1-03 Safety – Part 1: General Requirements 1 (2006-07)

FCC Part 68 Terminal Equipment to Telephone Network according

to TIA-968-A and CS-03 Part 1, Issue 9

(2006-11-03)

The last two digits of the year in which the CE marking was affixed: 06

Herewith declares that product(s) listed above is in conformity with

No Title Issue

FCC part 15 Radio frequency devices

Pierre Öberg

Technical Manager

26 of May 2008

Page 8

8

6618-2202

Type tests and environmental conditions

Electromagnetic Compatibility

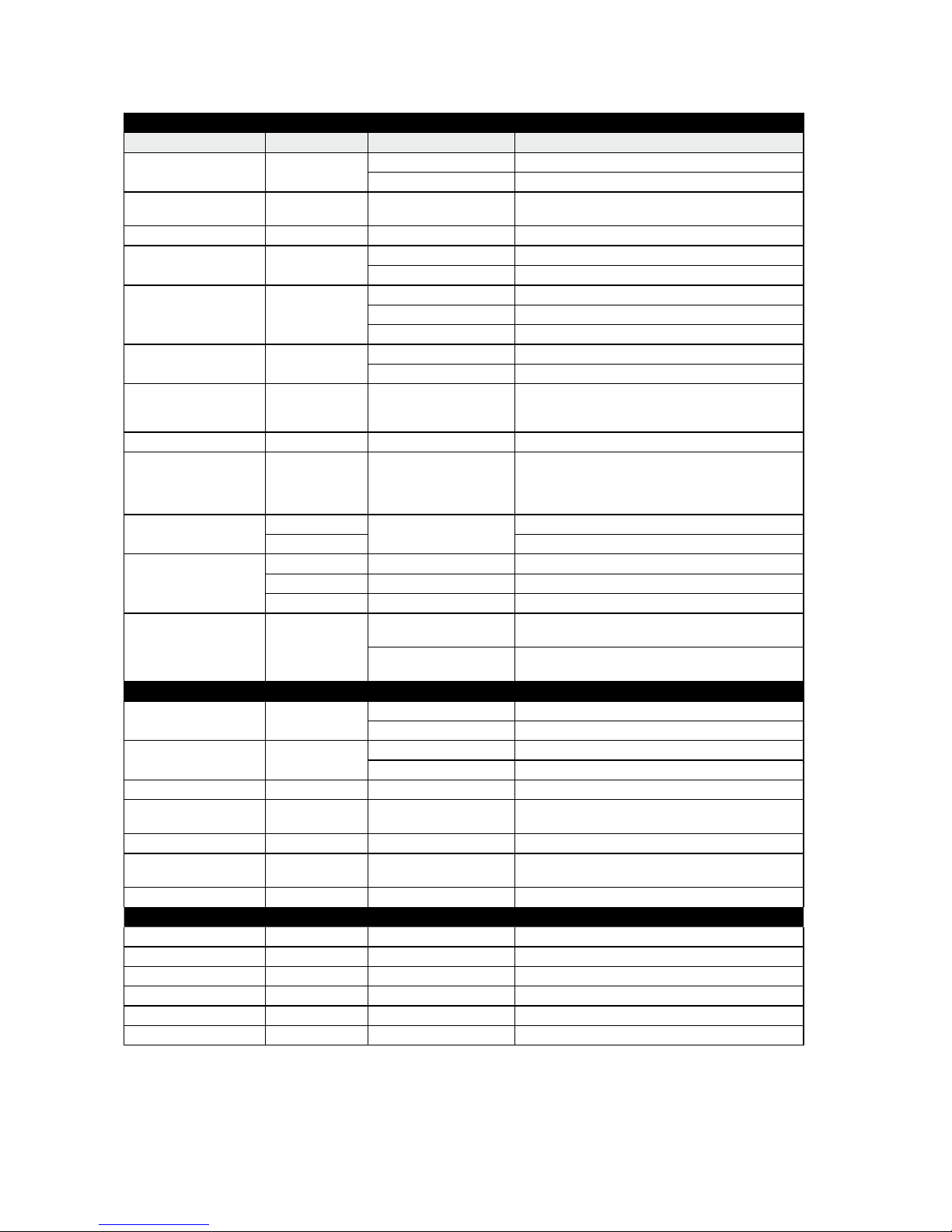

Phenomena Test Description Test levels

ESD EN 61000-4-2 Enclosure contact ± 6 kV

Enclosure air ± 8 kV

RF field AM

modulated

IEC 61000-4-3 Enclosure 10 V/m 80% AM (1 kHz), 80 – 1000 MHz

20 V/m 80% AM (1 kHz), 80 – 2000 MHz

RF field 900 MHz ENV 50204 Enclosure 20 V/m pulse modulated 200 Hz, 900 ± 5 MHz

Fast transient EN 61000-4-4 Signal ports ± 2 kV

Power ports ± 2 kV

Surge EN 61000-4-5 Signal ports unbalanced ± 2 kV line to earth, ± 2 kV line to line

Signal ports balanced ± 2 kV line to earth, ± 1 kV line to line

Power ports ± 2 kV line to earth, ± 2 kV line to line

RF conducted EN 61000-4-6 Signal ports 10 V 80% AM (1 kHz), 0.15 – 80 MHz

Power ports 10 V 80% AM (1 kHz), 0.15 – 80 MHz

Voltage dips and interruption

EN 61000-4-11 AC power ports 10 & 5 000 ms, interruption

10 & 500 ms, 30% reduction

100 & 1 000 ms, 60% reduction

Mains freq. 50 Hz EN 61000-4-16 Signal ports 100 V 50 Hz line to earth

Voltage dips and

interruption

EN 61000-4-29 DC power ports 10 & 100 ms, interruption

10 ms, 30% reduction

10 ms, 60% reduction

+20% above & –20% below rated voltage

Radiated emission EN 55022 Enclosure Class A

FCC part 15 Class A

Conducted emission EN 55022 AC power ports Class B

FCC part 15 AC power ports Class B

EN 55022 DC power ports Class B

Dielectric strength EN 60950 Signal port to other

isolated ports

2 kVrms 50 Hz 1 min

Power port to other

isolated ports

3 kVrms 50 Hz 1 min

2 kVrms 50 Hz 1 min (@ rated power <60 V)

Environmental

Temperature Operating –25 to +70°C

Storage & Transport –40 to +70°C

Humidity Operating 5 to 95% relative humidity non condensing

Storage & Transport 5 to 95% relative humidity non condensing

Altitude Operating 2 000 m / 70 kPa

Reliability prediction

(MTBF)

MIL-HDBK-

217F

Operating

Service life Operating 10 year

Vibration IEC 60068-2-6 Operating 7.5 mm, 5 – 8 Hz

2 g, 8 – 500 Hz

Shock IEC 60068-2-27 Operating 15 g, 11 ms

Packaging

Enclosure UL 94 PC / ABS Flammability class V-1

Dimension W x H x D 55 x 100 x 132 mm

Weight 0.36 kg

Degree of protection IEC 529 Enclosure IP 20

Cooling Convection

Mounting Horizontal on 35 mm DIN-rail

Page 9

9

6618-2202

Description

The TD-36 (485) is designed to function reliably within industrial environments and in

areas of high level interference.

The TD-36 (485) is a V.34 modem meaning that it can support bidirectional data rates of

up to 33.6 kbit/s on the PSTN or leased line side. Fast connect ensures that leased lines

can re-establish connections in the range of 5 seconds.

The modem is equipped with transient protection on the line side and a “watchdog”

that monitors and automatically resets the modem in the event of a fault. These functions together with remote configuration make the modem perfect for installation at

unmanned sites and prevent the need of costly service trips.

The modem also has password protection, dial-back security and caller ID answering to

ensure that only authorised users can communicate with the modem and any connected

equipment.

The TD-36 (485) also has a single digital input and output relay. The input and output can

be used to trigger, or be triggered by a number of different user defined events. Both the

digital input and output are galvanically isolated from the rest of the modem.

For ease of setup the modem is supported by the Westermo TD-tool configuration software but also has DIP switches to assist configuration. Drivers for Windows setup are

also supplied.

… Extended temperature range –25°C to +70°C

… Data rate up to 33.6 kbit/s with Fast Connect

… Terminal rate up to 115.2 kbit/s

… 2-wire Leased Line (also 4-wire Leased Line on TD-36 485)

… V23 HDX with multidrop (also FDX on TD-36 485)

… DTR and incoming data dialling

… DIP-switch configuration

… Watchdog

… Secure call back and access

… Industrial environment transient protection on all interfaces

… Up to 11 bits

… Tri-Galvanic isolation (interface/line/supply)

… Caller ID presentation and answering

… Remote configuration

… RS-422 / RS-485 interface (only in TD-36 485)

… Digital I/O (only in TD-36 485)

… Dial backup for PSTN and Leased Line (only in TD-36 485)

Page 10

10

6618-2202

Generic I/O

The generic I/O gives the following functionality:

1. Establishing a data connection to a predefined target number

When the input is pulsed, the modem establishes a data connection to the stored

predefined number. After a time (specified in the modem) without data exchange,

the connection is released by an inactivity timer.

2. Sending an SMS Message to a predefined targetnumber

When the input is pulsed, the modem will send an SMS to a predefined number.

The SMS Messages can handle at least 160 characters. TAP and UCP protocols are

supported.

3. Sending a Text Message to a predefined targetnumber

When the input is triggered, the modem will establish a connection to the stored

modem number and transfer a predefined text message. This is not an SMS message.

4. Using the remote digital output

When the input is triggered, the modem will establish a connection to the stored

number of a remote TD-36 and send out a command, that pulses the remote output

according to a predefined sequence.

5. Executing an AT-Command string

Pre-programmed AT command strings stored in the modem can be executed.

These can (for example) be used for switching DTE communication parameters for

online and offline modes by using two entries.

6. Transparent I/O

When the input is triggered, the modem will establish a connection to the stored

number of a remote TD-36 and send out a command, and after a connection is

established, the I/O is bi-directional.

Page 11

11

6618-2202

Digital Output

The digital output gives the following functionality:

1. Output Contact

The modem has a change over relay output (SPDT-contact). This output can be

controlled by a remote modem through Transparent I/O and Output service in the

Generic I/O function. The output can also be programmed to follow the local DCD

or DTR signals.

2. Remotely controlled

The output can be programmed to follow a remote modem data input. A remote unit

can also set/reset the output as well as transferring a sequence of “set- and resets” of

the output.

3. Follow DCD/Network

The output can be programmable to follow the local DCD or DTR signal.

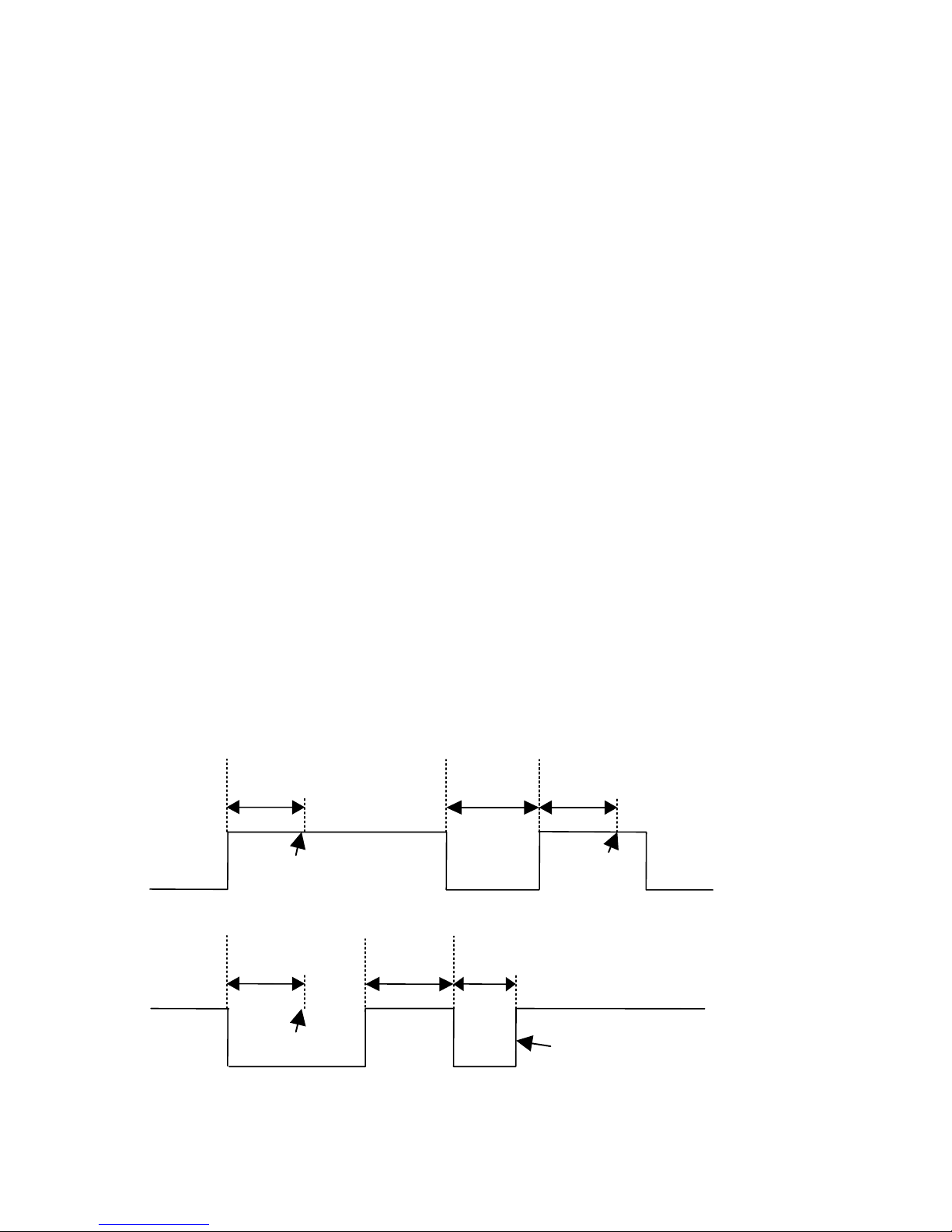

Digital Input

The digital input gives the following functionality:

1. Static input

A static digital level trigged input high or low triggers the Generic I/O. With a level

trigged input only the first entry in the Generic I/O list can be trigged by the I/O input.

The input is trigged when the selected level has been stable for ta ms. A new trig will not

occur until the input has return to the opposite state an back again.

t

a

High level trigged input timing

≥

t

a

Trig

Trig

t

a

Low level trigged input timing

≥

t

a

Trig

No trig due to low

level shorter than t

a

t

a

<t

a

Page 12

12

6618-2202

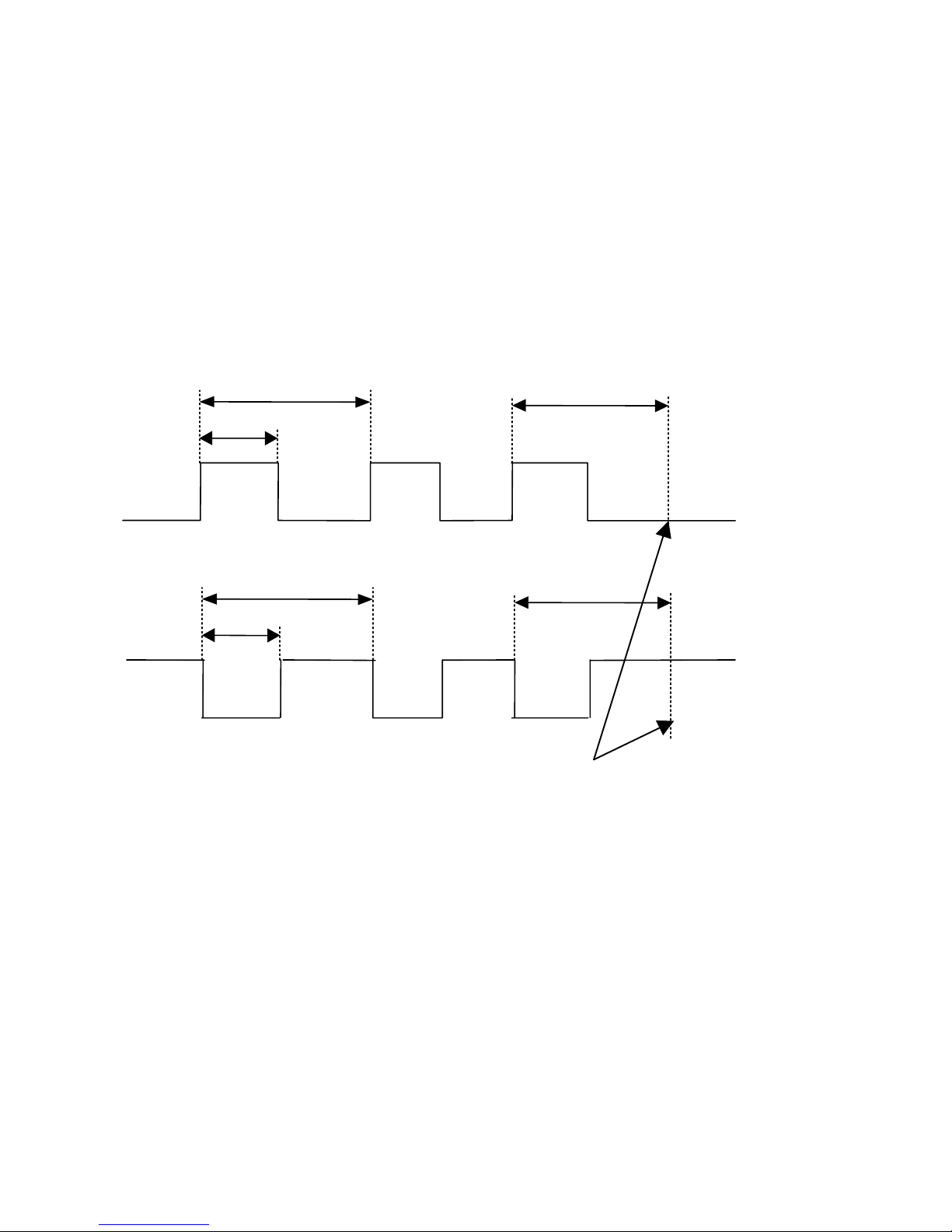

2. Pulsed Input

When input is set to edge trigged pulsed the number of pulses counted selects the entry

to be trigged.

For the pulsing of an input, some timings must be kept.

The input is filtered and pulses shorter than ta is discriminated. The time between pulses

must also be kept shorter than Tp. One other restriction on Tp is that Tp ≥ 2ta.

When time between pulses exceeds Tp the number of pulses are accumulated and an

entry selected by number of pulses counted.

The parameter ta is also used when output pulsing is selected.

The parameters ta and Tp are programmable from 10 ms to 2550 ms.

≥

t

a

≤

T

p

>Tp

≥

t

a

≤

T

p

>Tp

Positive edge trigged input timing

Negativ edge trigged input timing

Number of pulses counted

accumulated here

Page 13

13

6618-2202

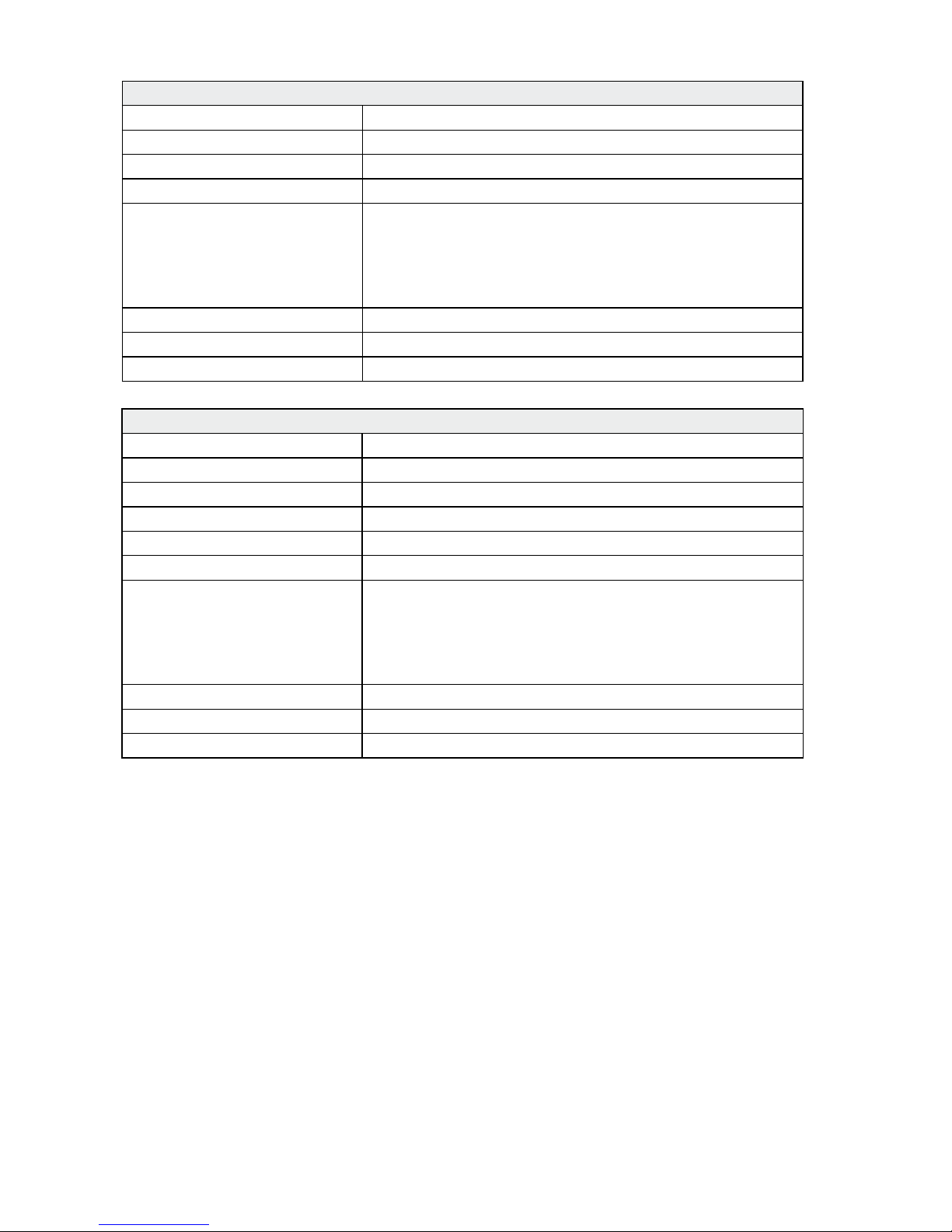

Interface specifications

Power AV

Rated voltage 20 to 250 VDC

24 to 240 VAC

Operating voltage 18 to 300 VDC

22 to 264 VAC

Rated current

125 mA @ 18 VDC

15 mA @ 110 VDC

8 mA @ 250 VDC

120 mA @ 22 VAC

35 mA @ 95 VAC

28 mA @ 240 VAC

Rated frequency DC: –

AC: 48 – 62 Hz

Inrush current I

2

t 0.45 A2s

Startup current* 0.25 A

peak

Polarity Polarity independent

Isolation to All other ports 3 kV

rms 50 Hz 1 min

Connection Detachable screw terminal

Connector size 0.2 – 2.5 mm

2

(AWG 24-12)

Shielded cable Not required

Power LV

Rated voltage 12 to 48 VDC

12 to 27 VAC

Operating voltage 10 to 60 VDC

10 to 30 VAC 48 – 62 Hz

Rated current 150 mA @ 12 VDC

70 mA @ 24 VDC

40 mA @ 48 VDC

150 mA @ 12 VAC

70 mA @ 24 VAC

Rated frequency DC: –

AC: 48 – 62 Hz

Inrush current I

2

t 0.25 A2s

Startup current* 0.30 A

peak

Polarity Polarity independent

Isolation to All other ports 3 kV

rms 50 Hz 1 min

Connection Detachable screw terminal

Connector size 0.2 – 2.5 mm

2

(AWG 24-12)

Shielded cable Not required

* External supply current capability for proper startup

Page 14

14

6618-2202

Public Switched Telephone Network (PSTN)

Electrical specification Public Switched Telephone Network

Data rate 300 bit/s – 33.6 kbit/s

Protocol B103, B212, V21, V22, V22B, V23C, V23 HDX, V32, V32B, V34

Protection Installation Fault Tolerant (up to ±60 V)

Isolation to Power port 3 kV

rms 50 Hz 1 min

Leased Line 2 kV

rms 50 Hz 1 min

RS-232 2 kV

rms 50 Hz 1 min

RS-485 2 kV

rms 50 Hz 1 min

I/O 2 kV

rms 50 Hz 1 min

Connection RJ-11C and Detachable screw terminal

Connector size Detachable screw terminal 0.2 – 2.5 mm

2

(AWG 24 – 12)

Shielded cable Not required

Leased Line (LL)

Electrical specification 2- or 4-wire Leased Line

Data rate 300 bit/s – 33.6 kbit/s

Protocol B103, B212, V21, V22, V22B, V23C, V23 HDX, V32, V32B, V34

Transmission range PSTN 30 dB

Budget Leased Line max 40 dB

Protection Installation Fault Tolerant (up to ± 60 V)

Isolation to Power port 3 kV

rms 50 Hz 1 min

Leased Line 2 kV

rms 50 Hz 1 min

RS-232 2 kV

rms 50 Hz 1 min

RS-485 2 kV

rms 50 Hz 1 min

I/O 2 kV

rms 50 Hz 1 min

Connection Detachable screw terminal

Connector size 0.2 – 2.5 mm

2

(AWG 24 – 12)

Shielded cable Not required

Page 15

15

6618-2202

* Railway installation close to the rails.

For a cable located within 3 m and connected to this port, the use of shielded cable is recommended, this is

to minimise the risk of interference. The cable shield should be properly connected (360°) to an earthing point

within 1 m of this port. This earthing point should have a low impedance connection to the conductive enclosure of the apparatus cabinet, or similar, where the unit is built-in. This conductive enclosure should be connected to the earthing system of an installation and may be directly connected to the protective earth.

RS-422/485

Electrical specification EIA/TIA-485 ITU V.11

2-wire or 4-wire twisted pair

Data rate 300 bit/s – 115.2 kbit/s

Data format 7 or 8 data bits, Odd, even or none parity, 1 or 2 stop bits.

9-12 bit words

Protocol Transparent

Retiming Yes

Turn around time <10 µs (half duplex)

Transmission range ≤ 1200 m, depending on data rate and cable type (EIA RS-485)

Settings 120 W termination and failsafe biasing 680 W

Protection Installation Fault Tolerant (up to ±60 V)

Isolation to Power port 3 kV

rms 50 Hz 1 min

PSTN Line 2 kV

rms 50 Hz 1 min

Leased Line 2 kV

rms 50 Hz 1 min

I/O 1.5 kV

rms 50 Hz 1 min

Galvanic connection to RS-232

Connection Detachable screw terminal

Connector size 0.2 – 2.5 mm

2

(AWG 24 – 12)

Shielded cable Not required*

Miscellaneous Do not connect RS-232 and RS-422/485 simultaneously

RS-232

Electrical specification EIA/TIA-232

Data rate 300 bit/s – 115.2 kbit/s

Data format 7 or 8 data bits, Odd, even or none parity, 1 or 2 stop bits.

9-12 bit words

Protocol Transparent

Retiming Yes

Transmission range Cable length ≤ 15 m

Isolation to Power port 3 kV

rms 50 Hz 1 min

PSTN Line 2 kV

rms 50 Hz 1 min

Leased Line 2 kV

rms 50 Hz 1 min

I/O 1.5 kV

rms 50 Hz 1 min

Galvanic connection to RS-485

Connection 9-pin D-sub female (DCE)

and Detachable screw terminal (DCE )

Connector size Detachable screw terminal 0.2 – 2.5 mm

2

(AWG 24 – 12)

Shielded cable Not required*

Miscellaneous Do not connect RS-232 and RS-422/485 simultaneously

Page 16

16

6618-2202

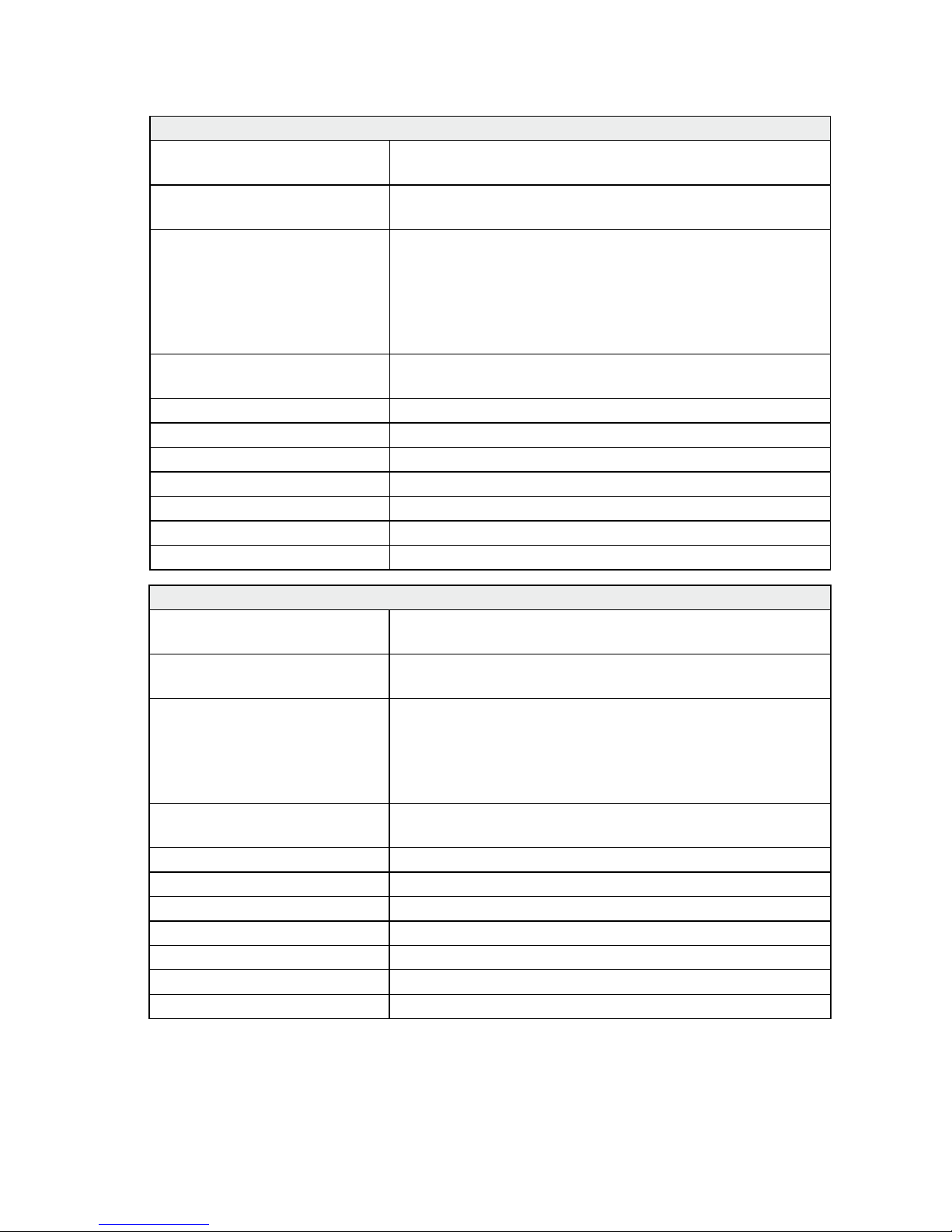

Generic I/O interface Input

Electrical specification Opto isolated input

Input voltage range 0 – 60 VDC

Input current 5 mA @ 60 VDC

Input inactive Uin < 2.5 V

Input active Uin >5.0 V

Transmission range Cable length ≤ 15 m

Connection Detachable screw terminal (DCE )

Connector size 0.2 – 2.5 mm

2

(AWG 24 – 12)

Isolation to Power port 3 kV

rms 50 Hz 1 min

PSTN line 2 kV

rms 50 Hz 1 min

Leased Line 2 kV

rms 50 Hz 1 min

RS-232 2 kV

rms 50 Hz 1 min

RS-485 2 kV

rms 50 Hz 1 min

I/O output 2 kV

rms 50 Hz 1 min

Shielded cable Not required*

Page 17

17

6618-2202

* Railway installation close to the rails.

For a cable located within 3 m and connected to this port, the use of shielded cable is recommended, this is

to minimise the risk of interference. The cable shield should be properly connected (360°) to an earthing point

within 1 m of this port. This earthing point should have a low impedance connection to the conductive enclosure of the apparatus cabinet, or similar, where the unit is built-in. This conductive enclosure should be connected to the earthing system of an installation and may be directly connected to the protective earth.

Generic I/O interface Relay Output

Electrical specification One change over contact

Switching voltage Max 40 V AC/DC

Switching current Max 500 mA AC/DC

Electrical endurancee 5 x 10

5

operations at 20 W / 20 VA Resistive load

Transmission range Cable length ≤ 15 m

Connection Detachable screw terminal (DCE )

Connector size 0.2 – 2.5 mm

2

(AWG 24 – 12)

Isolation to Power port 3 kV

rms 50 Hz 1 min

PSTN line 2 kV

rms 50 Hz 1 min

Leased Line 2 kV

rms 50 Hz 1 min

RS-232 1.5 kV

rms 50 Hz 1 min

RS-485 1.5 kV

rms 50 Hz 1 min

I/O input 2 kV

rms 50 Hz 1 min

Shielded cable Not required*

Page 18

18

6618-2202

* Direction relative to this unit.

Leased Line

Position

D-sub

Screw

terminal

Direction* Description

D-sub

description

No. 1 No. 4 Outd Data Carrier Direct (DCD)

No. 2 No. 7 Out Received Data (RD)

No. 3 No. 8 In Transmitted Data (TD)

No. 4 No. 3 In Data Terminal Ready (DTR)

No. 5 No. 1 Not Connected Signal Ground (SG)

No. 6 No. 2 Out Data Set Ready (DSR)

No. 7 No. 6 In Request To Send (RTS)

No. 8 No. 5 Out Clear To Send (CTS)

No. 9 No. 9 Out Ring Indicator (RI)

RS-232 (DCE)

1

2

3

4

5

6

7

8

9

Position Product marking

RJ-11C

Screw

terminal**

Direction* Description RJ-11C Screw terminal

a – Not Connected

b In/Out PSTN Transmit/ Receive

Disconnects from “pin c”

when the modem goes

Off-Hook

c No. 2 In/Out PSTN Transmit/ Receive

d No. 1 In/Out PSTN Transmit/ Receive

e In/Out PSTN Transmit/ Receive

Disconnects from “pin c”

when the modem goes

Off-Hook

f – Not Connected

* Direction relative to this unit. ** The PSTN screw terminals are shared with 2-wire Leased Line.

PSTN

LL2

LL1

Position Direction Description Product marking

No. 1 In/Out 2-wire Receive/ Transmit LL1

No. 2 In/Out 2-wire Receive/ Transmit LL2

Page 19

19

6618-2202

Power

LED Indicators

(for details see page 22)

* Direction relative to this unit.

Position Direction* Description Product marking

No. 1 In AC: Neutral

DC: –Voltage

No. 2 In AC: Line

DC: +Voltage

Page 20

20

6618-2202

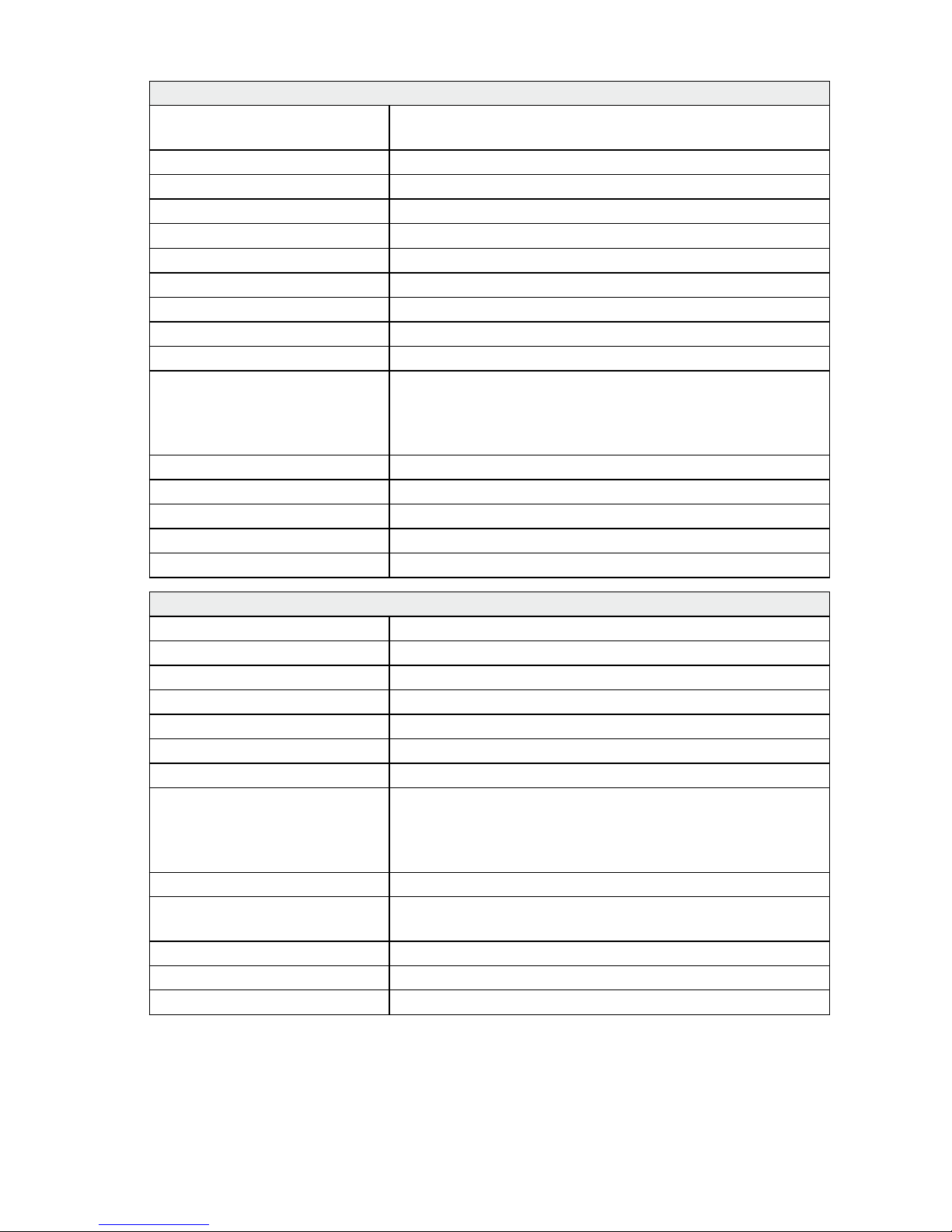

Leased Line

* Direction relative to this unit.

Position

D-sub

Screw

terminal

Direction* Description

D-sub

description

No. 1 No. 4 Outd Data Carrier Direct (DCD)

No. 2 No. 7 Out Received Data (RD)

No. 3 No. 8 In Transmitted Data (TD)

No. 4 No. 3 In Data Terminal Ready (DTR)

No. 5 No. 1 Not Connected Signal Ground (SG)

No. 6 No. 2 Out Data Set Ready (DSR)

No. 7 No. 6 In Request To Send (RTS)

No. 8 No. 5 Out Clear To Send (CTS)

No. 9 No. 9 Out Ring Indicator (RI)

RS-232 (DCE)

1

2

3

4

5

6

7

8

9

Position Product marking

RJ-11C

Screw

terminal**

Direction* Description RJ-11C Screw terminal

a – Not Connected

b In/Out PSTN Transmit/ Receive

Disconnects from “pin c”

when the modem goes

Off-Hook

c No. 2 In/Out PSTN Transmit/ Receive

d No. 1 In/Out PSTN Transmit/ Receive

e In/Out PSTN Transmit/ Receive

Disconnects from “pin c”

when the modem goes

Off-Hook

f – Not Connected

* Direction relative to this unit. ** The PSTN screw terminals are shared with 2-wire Leased Line.

PSTN

LL2

LL1

Position Direction* Description Product marking

No. 1 Out 4-wire Transmit LL1

In/Out 2-wire Receive/ Transmit

No. 2 Out 4-wireTransmit LL2

In/Out 2-wire Receive/ Transmit

No. 3 In 4-wire Receive LL3

In/Out 2-wire Receive/ Transmit at

Leased Line PSTN backup

No. 4 In 4-wire Receive LL4

In/Out 2-wire Receive/ Transmit at

Leased Line PSTN backup

Page 21

21

6618-2202

RS-422/485

Power

I/O Input/Relay Output

LED Indicators

(for details see page 22)

* Direction relative to this unit.

* Direction relative to this unit

Position Direction* Description Product marking

No. 1 In AC: Neutral

DC: –Voltage

No. 2 In AC: Line

DC: +Voltage

Position Direction* Description Product marking

No. 1 In R+ ( A’) Receive RS-422/485 4-wire R+

No. 2 In R– (B’) Receive RS-422/485 4-wire R–

No. 3 Out T+ (A) Transmit RS-422/485 4-wire T/R+

In/Out T+ (A/A’) Transmit/Receive RS-485 2-wire

No. 4 Out T– (B) Transmit RS-422/485 4-wire T/R–

In/Out T+ (A/A’) Transmit/Receive RS-485 2-wire

Position Direction* Description Product marking

No. 1 In Input + +

No. 2 In Input – –

No. 1 In/Out Normal

closed contact

NC

No. 2 In/Out Common

contact

C

No. 3 In/Out Normal

open contact

NO

Page 22

22

6618-2202

LED Indicators

LED Status Description

TD

Transmit data

OFF No data

ON / FLASH The modem receiving data on the DTE interface

RD

Receive data

OFF No data

ON / FLASH The modem transmitting data on the DTE interface

RTS

Request

to send

OFF RTS signal is inactive

ON RTS signal is active

DCD

Data carrier

detect

OFF DCD signal is inactive

ON DCD signal is active, modem has detected a carrier or the signal is

set to always ON

DTR

Data terminal

ready

OFF DTR signal is inactive

ON DTR signal is active

REL

Reliable mode

OFF Reliable mode is OFF, direct or normal mode

ON Reliable mode is ON

FLASH Reliable mode with error correction and compression

LINE OFF The modem is on-hook

ON The modem is off-hook with an established connection

FLASH Line backup interface in use

PWR

Power

OFF The modem has no power

ON The modem is up and running

Only for TD-36 485

I/O IN OFF The I/O input is inactive

ON The I/O input is active

I/O OUT OFF The I/O output is inactive, C and NC connected

ON The I/O output is active, C and NO connected

Page 23

23

6618-2202

DIP-switch settings

Before DIP-switch settings:

Prevent damage to internal electronics from electrostatic discharges (ESD)

by discharging your body to a grounding point (e.g. use of wrist strap).

NOTE DIP-switch alterations are only effective after a power on.

S4 S3

S5S2S1

S1 DIP-switch

Selection of DTE speed

S1 DIP-switch

Stored values / Auto detect

ON

1 2 3 4 5 6 7 8

Use stored values

ON

1 2 3 4 5 6 7 8

9600 bit/s

ON

1 2 3 4 5 6 7 8

Auto detect*

ON

1 2 3 4 5 6 7 8

1200 bit/s

ON

1 2 3 4 5 6 7 8

300 bit/s

ON

1 2 3 4 5 6 7 8

600 bit/s

ON

1 2 3 4 5 6 7 8

2400 bit/s

ON

1 2 3 4 5 6 7 8

19.2 kbit/s

ON

1 2 3 4 5 6 7 8

38.4 kbit/s

ON

1 2 3 4 5 6 7 8

57.6 kbit/s

ON

1 2 3 4 5 6 7 8

115.2 kbit/s

ON

1 2 3 4 5 6 7 8

4800 bit/s

* 300 and 600 baud not supported

Page 24

24

6618-2202

S1 DIP-switch

Selection of DTE format

ON

1 2 3 4 5 6 7 8

7E 1S

ON

1 2 3 4 5 6 7 8

7E 2S

ON

1 2 3 4 5 6 7 8

7O 1S

ON

1 2 3 4 5 6 7 8

7O 2S

ON

1 2 3 4 5 6 7 8

8N 1S

ON

1 2 3 4 5 6 7 8

8N 2S

ON

1 2 3 4 5 6 7 8

8E 1S

ON

1 2 3 4 5 6 7 8

8E 2S

ON

1 2 3 4 5 6 7 8

8O 1S

ON

1 2 3 4 5 6 7 8

8O 2S

ON

1 2 3 4 5 6 7 8

Direct mode 8E1 or 8O1. 8O1

in command mode

ON

1 2 3 4 5 6 7 8

Direct mode 8E2 or 8O2. 8N2

in command mode

ON

1 2 3 4 5 6 7 8

Direct mode 7E1 or 7O1. 8N1

in command mode

ON

1 2 3 4 5 6 7 8

Direct mode 7E2 or 7O2.8N2

in command mode

ON

1 2 3 4 5 6 7 8

7N 2S

S2 DIP-switch

Leased Line Mode selection

ON

1 2 3 4 5 6 7 8

Leased Line disable, PSTN enable

ON

1 2 3 4 5 6 7 8

Leased Line answering

ON

1 2 3 4 5 6 7 8

Leased Line calling

S2 DIP-switch

DTE interface selection

ON

1 2 3 4 5 6 7 8

RS-422/485 disabled,

RS-232 enabled

ON

1 2 3 4 5 6 7 8

RS-422/485 enabled,

RS-232 disabled

S2 DIP-switch

RS-422/485

ON

1 2 3 4 5 6 7 8

RS-422/485, 2-wire

ON

1 2 3 4 5 6 7 8

RS-422/485, 4-wire

Page 25

25

6618-2202

S2 DIP-switch

Selection PSTN backup of Leased Line

ON

1 2 3 4 5 6 7 8

Backup of Leased Line disabled

ON

1 2 3 4 5 6 7 8

Backup of Leased Line enabled

S2 DIP-switch

Remote configuration control

ON

1 2 3 4 5 6 7 8

Use stored values

ON

1 2 3 4 5 6 7 8

Remote configuration disabled

S2 DIP-switch

Leased Line 2/4 wire selection

ON

1 2 3 4 5 6 7 8

Leased Line 2-wire

ON

1 2 3 4 5 6 7 8

Leased Line 4-wire

S2 DIP-switch

Selection of answering/calling mode for PSTN backed up Leased Line

ON

1 2 3 4 5 6 7 8

Answering

ON

1 2 3 4 5 6 7 8

Calling

S3 DIP-switch

Line mode setting

ON

1 2 3 4 5 6 7 8

Use stored values

ON

1 2 3 4 5 6 7 8

Reliable mode enabled (AT\N2)

ON

1 2 3 4 5 6 7 8

Buffer mode enabled (AT\N0)

S3 DIP-switch

Blind dialing

ON

1 2 3 4 5 6 7 8

Use stored values

ON

1 2 3 4 5 6 7 8

Enable blind dialing (ATX3)

S3 DIP-switch

Dial abort

ON

1 2 3 4 5 6 7 8

Use stored values

ON

1 2 3 4 5 6 7 8

Dial abort disabled (AT&A1)

ON

1 2 3 4 5 6 7 8

Direct Mode enabled (AT\N1)

Page 26

26

6618-2202

S4 DIP-switch

Auto retrain control

ON

1 2 3 4 5 6 7 8

Use stored values

ON

1 2 3 4 5 6 7 8

Auto retrain disabled (AT%E0)

S4 DIP-switch

Data compression control

ON

1 2 3 4 5 6 7 8

Use stored values

ON

1 2 3 4 5 6 7 8

Data compression disabled

(AT%C0)

S4 DIP-switch

DCD, DTR and DSR control

ON

1 2 3 4 5 6 7 8

Use stored values

ON

1 2 3 4 5 6 7 8

DCD and DSR always on, DTR

ignored (AT&C0&D0&S0)

S4 DIP-switch

Set modem to factory default

ON

1 2 3 4 5 6 7 8

Use stored values

ON

1 2 3 4 5 6 7 8

Restore factory default setting*

* Don’t leave S4:1 in ON position if not intending to restore factory setting at every power on.

S3 DIP-switch

Flow control DTE interface

ON

1 2 3 4 5 6 7 8

Use stored value for AT&Kn

ON

1 2 3 4 5 6 7 8

RTS/CTS flow control enable

(AT&K3)

S3 DIP-switch

PLC parameter setting

ON

1 2 3 4 5 6 7 8

Use stored values

ON

1 2 3 4 5 6 7 8

PLC settings

(ATQ1E0&C1&K0&A1)

S3 DIP-switch

Leased Line termination

ON

1 2 3 4 5 6 7 8

Termination disabled

ON

1 2 3 4 5 6 7 8

Termination of Receiver

in 4-wire mode

ON

1 2 3 4 5 6 7 8

Termination of Transmitter / Receiver

in 2-wire mode and Transmitter in

4-wire mode

ON

1 2 3 4 5 6 7 8

Termination of both Transmitter

and Receiver in 4-wire mode

Page 27

27

6618-2202

S4 DIP-switch

Selection of line speed and modulation

ON

1 2 3 4 5 6 7 8

Use saved parameters defined by

AT+MS

ON

1 2 3 4 5 6 7 8

V.34, 9600

ON

1 2 3 4 5 6 7 8

V.21 300

ON

1 2 3 4 5 6 7 8

V.32bis 14400

ON

1 2 3 4 5 6 7 8

V.23 1200 hdx

ON

1 2 3 4 5 6 7 8

V.34 19200

ON

1 2 3 4 5 6 7 8

V.22 1200

ON

1 2 3 4 5 6 7 8

V.34 24000

ON

1 2 3 4 5 6 7 8

V.22bis 2400

ON

1 2 3 4 5 6 7 8

V.34 28 800

ON

1 2 3 4 5 6 7 8

V.32bis 4800

ON

1 2 3 4 5 6 7 8

V.34 33600

ON

1 2 3 4 5 6 7 8

V.32bis auto

ON

1 2 3 4 5 6 7 8

Automatic line speed

ON

1 2 3 4 5 6 7 8

V.32bis 9600

S5 DIP-switch

RS-422/485 termination

No termination

ON

1 2 3 4

Factory default

ON

1 2 3 4 5 6 7 8

S4

ON

1 2 3 4 5 6 7 8

S3

ON

1 2 3 4 5 6 7 8

S2

ON

1 2 3 4 5 6 7 8

S1

S5

ON

1 2 3 4

Termination of R in 4-wire connection

ON

1 2 3 4

Termination of both T and R in 2-wire

connection

ON

1 2 3 4

Termination of both T and R in 4-wire

connection

ON

1 2 3 4

Page 28

28

6618-2202

S1 DIP-switch

Selection of DTE speed

ON

1 2 3 4 5 6 7 8

1200 bit/s

S2 DIP-switch

Leased line mode selection

ON

1 2 3 4 5 6 7 8

1200 bit/s leased line /mulidrop

S4 DIP-switch

V.23 line modulation

ON

1 2 3 4 5 6 7 8

V.23 1200 HDX/FDX

S1 DIP-switch

Selection of DTE-format

ON

1 2 3 4 5 6 7 8

8E1, 8O1, 8O1

in command mode

ON

1 2 3 4 5 6 7 8

8E2, 8O2, 8N2

in command mode

ON

1 2 3 4 5 6 7 8

7E1, 7O1, 8N1, 8N1

in command mode

ON

1 2 3 4 5 6 7 8

7E2, 7O2, 8N2, 8N2

in command mode

S2 DIP-switch

Leased line 2/4-wire selection

ON

1 2 3 4 5 6 7 8

2-wire leased line

ON

1 2 3 4 5 6 7 8

4-wire leased line

S3 DIP-switch

Carrier active using RTS or incoming data

ON

1 2 3 4 5 6 7 8

Incoming data

ON

1 2 3 4 5 6 7 8

RTS controlled

S4 DIP-switch

Permanent carrier control

ON

1 2 3 4 5 6 7 8

Disabled

ON

1 2 3 4 5 6 7 8

Enabled

V.23 2- / 4-wire HDX- / FDX-leased line settings for TD-36 485

Page 29

29

6618-2202

S3 DIP-switch

V.23 leased line termination*

ON

1 2 3 4 5 6 7 8

Termination disabled

ON

1 2 3 4 5 6 7 8

Termination of transmitter /

receiver in 2-wire mode and

Transmitter in 4-wire mode

ON

1 2 3 4 5 6 7 8

Termination of receiver

in 4-wire mode

ON

1 2 3 4 5 6 7 8

Termination of both transmitter /

receiver in 4-wire mode

* The leased line should be terminated at the end points.

Termination recommandations of Leased lines

and Dial-up connections

In some connections the communication line (Leased Line or PSTN) must be

terminated. The table below shows the right way to activate the termination

for different usages. As a standard, the receiver in multidrop systems at the end

points shall be terminated.

S3 DIP-switch

Termination recomendations for TD-36 485

ON

1 2 3 4 5 6 7 8

PSTN

ON

1 2 3 4 5 6 7 8

Multidrop

V23 2-wire – endunit

ON

1 2 3 4 5 6 7 8

PSTN

Backup

ON

1 2 3 4 5 6 7 8

Multidrop

V23 2-wire – dropunit

ON

1 2 3 4 5 6 7 8

2-wire

Leased Line

ON

1 2 3 4 5 6 7 8

Multidrop

V23 4-wire – endunit

ON

1 2 3 4 5 6 7 8

4-wire

Leased Line

ON

1 2 3 4 5 6 7 8

Multidrop

V23 4-wire – dropunit

Page 30

30

6618-2202

=Termination

T

D-36 485

Slave unit Slave unit Slave unit

T

D-36 485

Slave unit Slave unit Slave unit

Max 0.3 metre

=Termination

T+

T–

T+T- T+T- AB

R+

R–

T+

T–

R– R+ R+T– T– B’ A’ BAT+T+ R–

2-wire termination

4-wire termination

RS-422/485 general advice

Termination recommendations

The RS-422/485 line must be terminated. In the TD-36 485, the termination is combined

with fail-safe functionality. The termination is used to prevent undefined states when the

bus is in tri-state condition.

… Using 2-wire RS-485 both ends should be terminated.

… Using 4-wire RS-485 both pairs shall be terminated at both ends.

… Using 4-wire RS-422 it’s only necessary to terminate the receivers.

RS-422/485 connection pins can be differently named. For some equipment brands

the T+ corresponds to A, but other brands might use some other naming convention.

If a unit does not work it can help to swap A and B.

Page 31

31

6618-2202

CLICK!

10 mm *

(0.4 inches)

25 mm

25 mm

* Spacing (left/right) recommended for

full operating temperature range

Cooling

This unit uses convection cooling. To avoid

obstructing the airflow around the unit, use the

following spacing rules. Minimum spacing 25 mm

(1.0 inch) above /below and 10 mm (0.4 inches)

left /right the unit. Spacing is recommended for

the use of unit in full operating temperature

range and service life.

Removal

Press down the black support at the back of the unit

using a screwdriver, see figure.

Mounting

This unit should be mounted on 35 mm DIN-rail, which is

horizontally mounted inside an apparatus cabinet, or similar.

Snap on mounting, see figure.

Page 32

32

6618-2202

Windows configuration tool TD-Tool

The TD-Tool is a PC – application program with a graphical interface for easy configuration of the complex functions found on the encolsed CD or at the Westermo website.

Please refer to TD-Tool for a complete description of the functionality of the Windows

program.

AT-Commands

Please refer to the AT Commands Interface Guide found on the enclosed CD or at

the Westermo website for a complete list of all available AT-commands and a detailed

description of the serial AT-command interface.

Configuration

The TD-36 (485) can be configured both from the local DTE interface and remotely over

the PSTN network. Whether the local or remote interface is used the configuration can

be made with AT-commands or with a PC-based application configuration tool. Basic

configurations can also be made with DIP switches locally.Remote configuration

The TD-36 (485) can be configured from a remote modem. To configure a TD-36 (485)

any GSM, ISDN or PSTN modem can be used.

The modem used to configure is referred as the “local modem”.

Please make sure that the remote TD-36 (485) is connected to the PSTN network and is

powered up.

… Connect the local modem to it's media (ISDN, PSTN or GSM)

… Connect the PC's com-port to the DTE interface of the local modem.

… Connect the power supply.

… Start a terminal emulation program (i.e. Windows Hyper-Terminal).

… Configure the local modem data rate and word format.

… Set up a connection to the remote TD-36 (485) to be configured by using the

normal dial command: ATD<No><CR>. When connected send the remote escape

sequence <++++>. The called remote TD-36 (485) will acknowledges by requesting the remote password. Enter the correct password (default: no password, just

return). Next; configure the remote TD-36 (485) using AT-commands. The password for remote configuration is defined with AT*WRCP – Remote configuration

password.

… Configure the parameter on the remote TD-36 (485) from your terminal program

and save the settings with AT&W.

… Hang up the connection using the ATH command.

Page 33

33

6618-2202

Application examples

… TD-36 connected to TD-36 with DTR signal call

Configure the units

Set up the connection – The dialling modem

ATA Enter the answer command when RING comes from the network or set up

ATS0=1 to auto answer on 1 RING signal (or more than 1)

Set up the connection – The answering modem

PSTN

Network

NOTE: If no valid DTR signal can be provided by external application, the modems DSR signal can

be used to trig the transmission. Connect the DSR signal via a relay, or other potential

free contact, to the DTR signal. A 10 kohm pull down resistor should also be connected

between the DTR and a signal that is always low e.g. the DCD.

DTR

DSR

DCD

Relay

External

application

10 kohm

May be required in harsh environments.

AT&F Set the unit to factory default

AT&W Store default settings

AT&Z0=nnn Store the number of the remote modem in the dialling TD-36

AT&S0 Set DSR signal always high (if this signal is used to trig the DTR)

AT&B1 Activates automatic DTR dialling if DTR switches from low (OFF)

to high (ON)

AT&W Save settings

Switch DTR from

OFF to ON

The modem will now dial the phone number stored in the first location of

the telephone number table (AT&Z0=<nnn>)

Page 34

34

6618-2202

… Frequently used settings for PLC-systems

Most PLC-systems and other industrial applications where modems are used require the

same changes to the standard settings.

The most commonly encountered problems concern speed, parity and control signals

from the connected equipment.

Speed and parity are changed with the switches under the cover in block S1. If this action

does not solve the problem the modem’s answering codes and possible echoing of commands might be the source of the difficulty.

Below follows a list of commands that might resolve the problems. The commands may

of course be placed on one single command line if desired.

Configure the TD-36 connected to the PLC

PSTN

Network

Note: S3:5 may be used for this purpose.

AT&F Set the unit to factory default.

ATV0 Gives the answering codes in short format. (digits)

ATQ1 No result codes are sent on the RS-232/V.24 connection.

ATE0 Commands that are sent from the terminal/computer etc.

are not echoed back to the RS-232/V.24 connection.

AT&C1 DCD will follow the carrier on the line.

AT&K0 No handshaking.

AT&A1 Character abort option OFF.

AT&W Store default settings.

Page 35

… Leased Line connection using 2- or 4-wire

Leased Line connections can be set up using 2-wire (or 4-wire in TD-36 485).

When renting a 4-wire line from a telephone company one pair of cables for

transmission and one pair for reception are usually provided.

The maximum transmission distance depends on the attenuation of the line.

The maximum value is theoretically 30 dBm. To have a good error rate it is

recommended to keep the attenuation under 25 dB. When renting lines from a telephone

company a longer transmission distance is normally possible as the signals are probably

transmitted over PCM-lines, i.e.

fibre optic or other media with low attenuation.

To set the modem for leased line applications use the dip switches.

Configure the units

35

6618-2202

Leased Line

To make switch setting active the power must be cycled OFF ≥ ON.

S2:1, 2 ON

S2:2 ON

Leased line calling

Leased line answering

S2:5 OFF Leased line 2-wire

S1 Sets speed and parity for the RS-232 port.

S4 Decides line-speed. Must be set in direct mode applications.

Resistance, attunation and distance for different wires

Tele Cable Area Resistance for

double cable

Attunation Recommended

Max distance

(25 dB)

Max Distance

(30 dB)

Ø 0,5 mm* ≈ 0,2 mm

2

175 W/km 1,1 dB/km 23 km 27 km

Ø 0,6 mm* ≈ 0,3 mm

2

123 W/km 0,9 dB/km 28 km 33 km

Ø 0,7 mm* ≈ 0,4 mm

2

93 W/km 0,8 dB/km 31 km 38 km

Ø 0,8 mm ≈ 0,5 mm

2

73 W/km 0,7 dB/km 36 km 43 km

Ø 0,9 mm ≈ 0,64 mm259 W/km 0,6 dB/km 42 km 50 km

* Frequently used in the local network

Page 36

36

6618-2202

… TD-36 – Secure Call-back

The TD-36 is connected to a PLC which one want to restrict access to. The TD-36 can

support access control through the Secure Callback function. In this example password

and callback to a predefined number is chosen. The modem in the calling end is here

chosen to be a PSTN modem, but can be any of the PSTN, ISDN or GSM modem from

the Westermo product range.

The DTE serial speed between the PLC – TD-36 and TDW-33 – PC is assumed to be

9600 8N1 but can be chosen to fit the actual system requirement.

Configure the TD-36

PSTN

Network

AT&F Set the unit to factory default

AT+IPR=9600 DTE baudrate 9600

AT+ICF=3,4 Character framing 8 data, 1 stop, parity none

ATS0=1 Auto answer after first ring

ATQ1E0&C1&K0&A1 Suitable for PLC communication

AT&W Store default settings

AT*WCB=4 Callback enabled, Password and callback number stored

in one or more positions of wcbtab

AT*WCBTAB=1,”+4670428000”,

”n3Y9kA6otYZu8”

Define callback number 1

When password 1 is entered number +4670428000 will

be called

AT*WCBTIME=10 Define delay time between hangup an callback

The TD-36 will wait 10s after hangup to callback

to allow the analogue modem to hangup

Page 37

37

6618-2202

Configure the TDW-33

Set up the connection

AT&F Set the unit to factory default

AT+IPR=9600 DTE baudrate 9600

AT+ICF=3,4 Character framing 8 data, 1 stop, parity none

ATS0=1 Auto answer after first ring

AT&W Store default settings

The dialling modem

TDW-33

The answering modem TD-36 Comment

ATD0705123456 TD-36 answers the call and requests

to TDW-33

Dial the number to TD-36

CONNECT 9600 TD-36 verifies the password to the

passwords stored and if true compare dissconnects.

Operator/system at

TDW-33 enters

Password: n3Y9kA6otYZu8

NO CARRIER Wait 10 s The connection is broken and TD-

36 waits the programmed 10s for

TDW-33 to disconnect

TD-36 dials +4670428000 The number programmed cor-

responding to the password is

dialled, preferable it’s the number

to the TDW-33

CONNECT 9600 CONNECT 9600 Connection is established

between the PC at TDW-33

and the PLC at TD-36

Page 38

38

6618-2202

… TD-36 – Silent answering on predefined number

The TD-36 is connected to a power meter which is remotely monitored. The TD-36

shares the PSTN line with normal telephones which is preferred not to give a ring signal

when the meter is read.

The TD-36 is configured to answer calls on the Caller ID received, the valid numbers to

answer is programmed into the TD-36. There exists a number of standards for sending

Caller ID check which standard is used by your operator. The TD-36 supports the major

implementations of Caller ID. In this example the DTMF Caller ID version is used.

Note that some implementations doesn’t give the possibility to make a silent answer

since the Caller ID is sent between first and second ring signal.

The modem in the calling end is here chosen to be a PSTN modem, but can be any of

the PSTN, ISDN or GSM modem from Westermo product range.

Configure the TD-36 connected to the power meter

PSTN

Network

AT&F Set the unit to factory default

AT+IPR=9600 DTE baudrate 9600

AT+ICF=3,4 Character framing 8 data, 1 stop, parity none

ATS0=0 No auto answer on Ring signals

ATQ1E0&C1&K0&A1 Suitable for PLC communication

AT&W Save settings

AT*WACCTAB=1,”016428000”

AT*WACCTAB=2,”016480250”

Set the valid A-numbers for automatic answering

AT*WCID=3,3 Set Caller ID to A-number answer with DTMF coded numbers

Page 39

39

6618-2202

… TD-36 485 2-wire half duplex

In this application the TD-36 485 is set to communicate with a number of units with

RS-485 interface.

The communication is 2 wire half duplex at 38.4 kbit/s, 8 data, parity even and 1 stop bit.

To make switch setting active the power must be cycled OFF -> ON.

Te rmination

TD-36 485

1

2

T/R+

T/R-

3

4

PSTN

Network

Configure the TD-36 485

AT&F Set the unit to factory default

AT&W Store default settings

S2:3 ON RS-422/485 enable RS-232 disable

S2:4 OFF Select 2-wire RS-485

S1:4 ON 38.4 kbit/s

S1:7 ON 8 data bits even parity 1 stop bit

S3:8 ON Termination / Failsafe active

Page 40

40

6618-2202

… Remote output and transparent mode

In this application the TD-36 485 I/O is used to send a SMS and then make an transpar-

ent I/O connection. The transparent I/O is in this example set up to an IDW-90 ISDN

modem, but can be any of the Westermo remote product supporting Generic I/O

(IDW-90, TD-36 485 and GDW-12).

The TD-36 485 has a alarm signal connected to it’s I/O input, when this input is activated

by the external alarm contact an SMS defined by Entry 1 in the entry list is sent. When

the SMS is transferred Entry 2 is programmed to be trigged. Entry 2 is programmed to

set up an Transparent I/O connection to an ISDN-modem IDW-90. The status of the

alarm signal will be transferred to the remote IDW-90 and activate an Alarm bell.

At this time the SMS should be available on the operators mobile showing the reason

for the alarm. The operator can acknowledge the alarm, the acknowledge signal will

now be transferred back to the originating TD-36 485 and alarm system. The alarm

system will deactivate the alarm output causing the remote alarm bell to stop sounding.

The Transparent I/O connection will be terminated by a programmed timeout.

Alarm output

SMS Sending

Connection

Alarm Bell

Timeout

Timeout

retrigger

Timeout

retrigger

Timeout

Alarm

system

Alarm

output

I/O

Input

5 − 48 V

Acknowlidge

output

TD-36 485

5

6

7

8

9

IDW-90

Acknowlidge

Button

Alarm

Bell

5 − 48 V

I/O

Input

5

6

7

8

9

PSTN

Network

GSM

Network

ISDN

Network

Page 41

41

6618-2202

Configure the TD-36 485

Configure the IDW-90

Testing by simulating the event

Activate events – The sending modem

To make switch setting active the power must be cycled OFF -> ON.

AT&F Set the unit to factory default

AT&W Store default settings

AT*WIOP=10,50,2,3,0 Set I/O params

Min pulse time = 100 ms (10)

Pulse repetition = 500 ms (150)

Trig type = Pulsed trigged (2)

Pulse trig type = POS, pos edge (3)

Output type = No output (0)

AT*WIOL=1,2,5,0,0,070428000,

Temp. high server room,

+4670500899,1

Define SMS message on entry 1

Entry = 1 (1)

Service = SMS (2)

Retry = NEXT_ALLWAYS (5)

Timeout = 0

Priority = 0 Data 1 = SMS receiver number (070428000)

Data 2 = SMS text (Temp. high server room)

Data 3 = Service center Adress (+4670500899)

Data 4 = SMS protocol UDP (1)

AT*WIOL=2,7,2,60,0,+4616480250 Define Transparent I/O on entry 2

Entry = 2 (2)

Service = TRANS (7)

Retry = RETRY_3 (2)

Timeout = 600s (60)

Priority = 0

Data 1 = Phone number of the remote IDW-90

(+4616480250)

S3:1,3,4 OFF S3:2 ON V.110 configured for GSM

I/O input pulsed with one puls SMS message transferred

and transparent I/O established

AT*WIOT=1 Force sending of SMS-message at entry 1

AT*WIOT=2 Force the transparent I/O connection to be established

Page 42

42

6618-2202

… TD-36 485 sending text message with SMS by usage of Generic I/O

Configure a TD-36 485 to send different SMS depending

on the I/O input pulse train.

AT&F Set the unit to factory default

AT&W Store default settings

AT*WIOP=5,10,2,3,0 Set I/O params

Min pulse time = 50 ms (5)

Max pulse time = 100 ms (10)

Trig type = Pulsed trigged (2)

Pulse trig type = POS, pos edge (3)

Output type = No output (0)

AT*WIOL=2,2,0,0,0,”num1”,”text1”,”

providernum1”,1,”password1”

Entry = 2 (2)

Service = SMS (2)

Retry = NO (0)

Timeout = 0

Priority = 0

Data 1 = SMS receiver number (num1)

Data 2 = SMS text (text1)

Data 3 = SMS provider number (providernum1)

Data 4 = SMS protocol type UDP (1)

Data 5 = Password if required by provider (password1)

AT*WIOL=3,2,0,0,0,”num2”,”text2”,”

providernum2”,1,”password2”

Entry = 3 (3)

Service = SMS (2)

Retry = NO (0)

Timeout = 0

Priority = 0

Data 1 = SMS receiver number (num2)

Data 2 = SMS text (text2)

Data 3 = SMS provider number (providernum2)

Data 4 = SMS protocol UDP (1)

Data 5 = Password if required by provider (password2)

Configure the TD-36 485

5 – 48 V

Trigging SMS no 2

Trigging SMS no 3

GSM

Network

PSTN

Network

Page 43

Testing by simulating the event

Send message

I/O input pulsed with two pulses

SMS message text1 transferred to receiver num1

I/O input pulsed with three

pulses

SMS message text2 transferred to receiver num2

AT*WIOT=2 Force sending of SMS-message at entry 2

AT*WIOT=3 Force sending of SMS-message at entry 3

Page 44

44

6618-2202

Alarm

system

Alarm

output

I/O

Input

5 − 48 V

Acknowlidge

output

TD-36 485

5

6

7

8

9

IDW-90

Acknowledge

Button

Alarm

Bell

5 − 48 V

I/O

Input

5

6

7

8

9

… Remote output and transparent mode

In this application the TD-36 485 I/O is used to send a SMS and then make a transpar-

ent I/O connection. The transparent I/O is in this example set up to an IDW-90 ISDN

modem, but can be any of the Westermo remote products supporting Generic I/O (IDW90 or TD-36 485).

The TD-36 485 has a alarm signal connected to it’s I/O-input, when this input is activated

by the external alarm contact an SMS defined by Entry 1 in the entry list is sent. When

the SMS is transferred Entry 2 is programmed to be trigged. Entry 2 is programmed to

set up a Transparent I/O connection to an ISDN-modem IDW-90. The status of the alarm

signal will be transferred to the remote IDW-90 and activate an Alarm bell. At this time

the SMS should be available on the operators mobile showing the reason for the alarm.

The operator can acknowledge the alarm, the acknowledge signal will now be transferred

back to the originating TD-36 485 and alarm system. The alarm system will deactivate the

alarm output causing the remote alarm bell to stop sounding. The Transparent I/O connection will be terminated by a programmed timeout.

GSM

Network

PSTN

Network

ISDN

Network

Alarm output

SMS Sending

Connection

Alarm Bell

Timeout

Timeout

retrigger

Timeout

retrigger

Timeout

Page 45

45

6618-2202

Configure the TD-36 485

AT&F Set the unit to factory default

AT&W Store default settings

AT*WIOP=10,50,2,3,1 Set I/O params

Min pulse time = 100 ms (10)

Pulse repetition = 500 ms (150)

Trig type = Pulsed trigged (2)

Pulse trig type = POS, pos edge (3)

Output type = output enabled (1)

AT*WIOL=1,2,5,0,0,”0704

28000”, “Temp. high server

room”,”+4670500899”,1, “password”

Define SMS message on entry 1

Entry = 1 (1)

Service = SMS (2)Retry = NEXT_ALLWAYS(5)

Timeout = 0

Priority = 0

Data 1 = SMS receiver number (070428000)

Data 2 = SMS text (Temp. high server room)

Data 3 = Service center Adress (+4670500899)

Data 4 = SMS protocol UDP (1)

AT*WIOL=2,7,2,60,0,+4616480250 Define Transparent I/O on entry 2

Entry = 2 (2)

Service = TRANS (7)

Retry =RETRY_3 (2) ;Do 3 connection attempts

Timeout = 600s (60)

Priority = 0

Data 1 = Phone number of the remote IDW-90

(+4616480250)

Configure the IDW-90

S3:1,3,4 OFF S3:2 ON V.110 configured for GSM

To make switch setting active the power must be cycled OFF -> ON.

Activate events – The sending modem

IO input pulsed with one puls SMS message transferred and transparent IO established

Testing by simulating the event

AT*WIOT=1 Force sending of SMS-message at entry 1

AT*WIOT=2 Force the transparent I/O connection to be established.

Page 46

Page 47

Page 48

REV.D 6618-2202 2010.07 Westermo Teleindustri AB, Sweden

Westermo Teleindustri AB • SE-640 40 Stora Sundby, Sweden

Phone +46 16 42 80 00 Fax +46 16 42 80 01

E-mail: info@westermo.se

Westermo Web site: www.westermo.com

Westermo Teleindustri AB have distributors in several countries, contact us for further information.

Westermo Data Communications AB

Svalgången 1

SE-724 81 Västerås

Phone: +46 (0)21 548 08 00 • Fax: +46 (0)21 35 18 50

info.sverige@westermo.se

Westermo Data Communications Ltd

Talisman Business Centre • Duncan Road

Park Gate, Southampton • SO31 7GA

Phone: +44(0)1489 580-585 • Fax.:+44(0)1489 580586

E-Mail: sales@westermo.co.uk

Westermo Data Communications GmbH

Goethestraße 67, 68753 Waghäusel

Tel.: +49(0)7254-95400-0 • Fax.:+49(0)7254-95400-9

E-Mail: info@westermo.de

Westermo Data Communications S.A.R.L.

9 Chemin de Chilly 91160 CHAMPLAN

Tél : +33 1 69 10 21 00 • Fax : +33 1 69 10 21 01

E-mail : infos@westermo.fr

Westermo Data Communications Pte Ltd

2 Soon Wing Road #08-05

Soon Wing Industrial Building

Singapore 347893

Phone +65 6743 9801 • Fax +65 6745 0670

E-Mail: sales@westermo.com.sg

Subsidiaries

Loading...

Loading...