Westermo SDW-541-F1G-T4G, SDW-550-T5G User Manual

©

Westermo Teleindustri AB

www.westermo.com

User Guide

6644-2240

Industrial Ethernet

5-port Switch

SDW-500

SERIES

SDW-541-F1G-T4G

SDW-550-T5G

2

6644-2240

Legal information

The contents of this document are provided “as is”. Except as required by applicable

law, no warranties of any kind, either express or implied, including, but not limited to,

the implied warranties of merchantability and fitness for a particular purpose, are made

in relation to the accuracy and reliability or contents of this document. Westermo

reserves the right to revise this document or withdraw it at any time without prior

notice.

Under no circumstances shall Westermo be responsible for any loss of data or income

or any special, incidental, and consequential or indirect damages howsoever caused.

More information about Westermo can be found at the following Internet address:

http://www.westermo.com

3

6644-2240

Safety

Before installation:

Read this manual completely and gather all information on the unit. Make sure

that you understand it fully. Check that your application does not exceed the safe

operating specifications for this unit.

This unit should only be installed by qualified personnel.

This unit should be built-in to an apparatus cabinet, or similar, where access is

restricted to service personnel only.

The power supply wiring must be sufficiently fused, and if necessary it must be

possible to disconnect manually from the power supply. Ensure compliance

to national installation regulations.

This unit uses convection cooling.To avoid obstructing the air flow around the

unit, follow the spacing recommendations (see Installation section).

Before mounting, using or removing this unit:

Prevent access to hazardous voltage by disconnecting the unit from power supply.

Warning! Do not open connected unit. Hazardous voltage may occur within this

unit when connected to power supply.

Class 1 Laser Product

Do not look directly into fibre optical fibre port or any connected fibre although

this unit is designed to meet the Class 1 Laser regulations.

Care recommendations

Follow the care recommendations below to maintain full operation of unit and to fulfil

the warranty obligations.

This unit must not be operating with removed covers or lids.

Do not attempt to disassemble the unit. There are no user serviceable parts inside.

Do not drop, knock or shake the unit, rough handling above the specification may cause

damage to internal circuit boards.

Do not use harsh chemicals, cleaning solvents or strong detergents to clean the unit.

Do not paint the unit. Paint can clog the unit and prevent proper operation.

Do not expose the unit to any kind of liquids (rain, beverages, etc). The unit is not

waterproof. Keep the unit within the specified humidity levels.

Do not use or store the unit in dusty, dirty areas, connectors as well as other mechanical

part may be damaged.

If the unit is not working properly, contact the place of purchase, nearest Westermo

distributor office or Westermo Tech support.

Fibre connectors are supplied with plugs to avoid contamination inside the optical port.

As long as no optical fibre is mounted on the connector, e.g. for storage, service or

transportation, should the plug be applied.

!

!

!

4

6644-2240

Note. Fibre Optic Handling

Fibre optic equipment needs special treatment. It is very sensitive to dust and dirt. If

the fibre will be disconnected from the modem the protective hood on the transmitter/

receiver must be connected. The protective hood must be kept on during transportation.

The fibre optic cable must also be handle the same way.

If this recommendation is not, it jeopardises the warranty.

Cleaning of the optical connectors

In the event of contamination, the optical connectors should be cleaned by the use of

forced nitrogen and some kind of cleaning stick.

Recommended cleaning fluids:

• Methyl-, ethyl-, isopropyl- or isobutyl-alcohol

• Hexane

• Naphtha

Maintenance

No maintenance is required, as long as the unit is used as intended within the specified

conditions.

SPECIAL CONDITION FOR SAFE USE

Ambient temperature:

This unit is designed for use in extreme ambient temperature conditions according to

the following: –40 ºC to +74 ºC (–40 ºF to +165 ºF)

5

6644-2240

Type Approval / Compliance

EMC

EN 50121-4, Railway applications – Electromagnetic compatibility – Emission

and immunity of the signalling and telecommunications apparatus

EN 61000-6-1, Immunity residential environments

EN 61000-6-2, Immunity industrial environments

EN 61000-6-4, Emission industrial environments

Safety

EN/IEC/UL 60950-1, IT-equipment

Marine

DNV GL rules for classification – Ships and offshore units

Environmental

NEMA TS 2-2003

DNV GL rules for classification

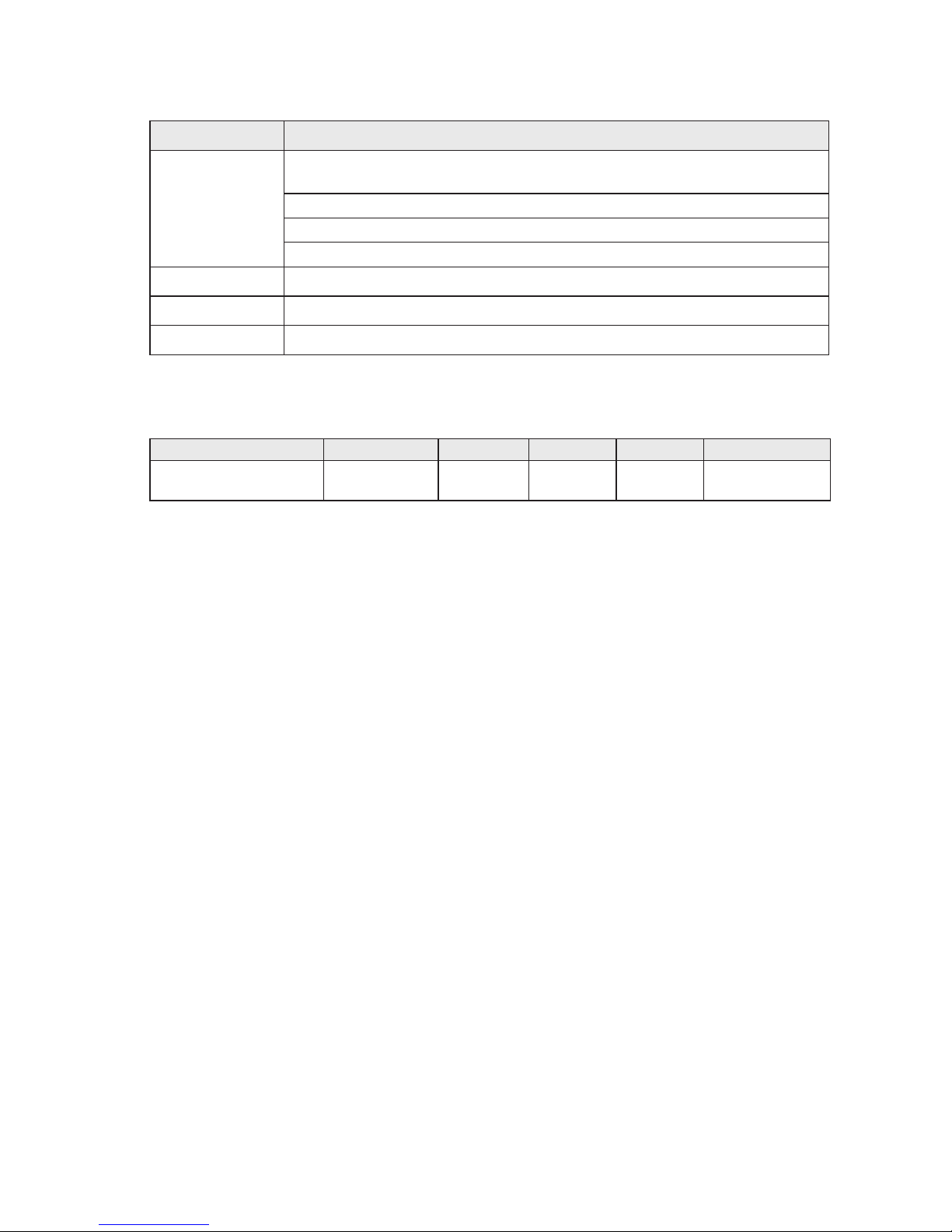

Type Temperature Humidity Vibration EMC Enclosure

SDW-541-F1G-T4G

SDW-550-T5G

D B B B A/IP21

Corrosive

environment

Notice:

This product has been successfully tested in a corrosion test according to

IEC 60068-2-60, method 3. This means that the product meets the requirements

to be placed in an environment classified as ISA-S71.04 class G3 and G4.

Note! If the product is placed in a corrosive environment, it is important that all

unused connector sockets are protected with a suitable plug in order to avoid

corrosion attacks on the gold plated pins in connectors.

Agency approvals and standards compliance

6

6644-2240

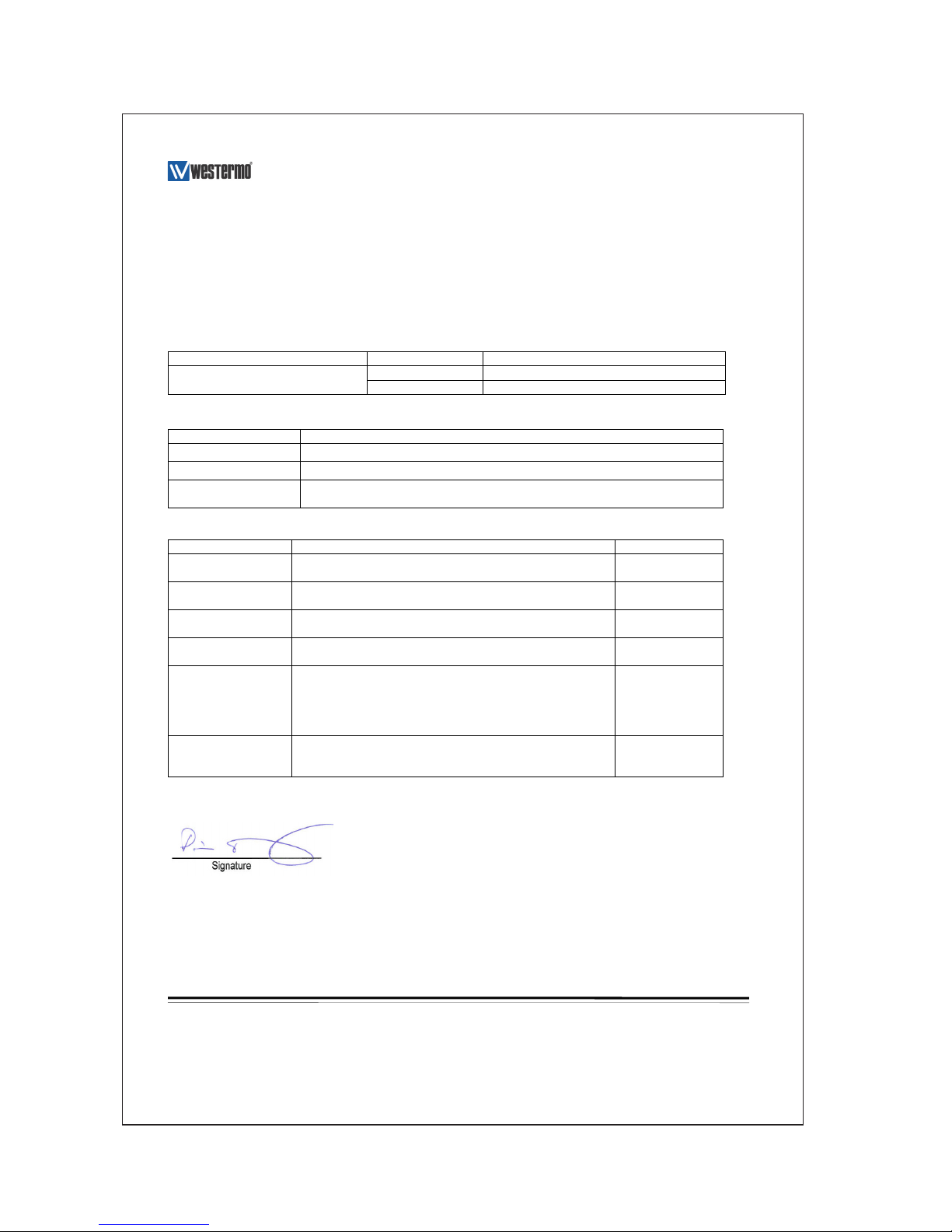

Declaration of Conformity

Westermo Teleindustri AB

Declaration of Conformity

Org.nr/

Postadress/Postal address

Tel.

Telefax

Postgiro

Bankgiro

Corp. identity number Registered office

S-640 40 Stora Sundby 016-428000 016-428001 52 72 79-4 5671-5550 556361-2604 Eskilstuna

Sweden Int+46 16428000 Int+46 16428001

The manufacturer

Westermo Teleindustri AB

SE-640 40 Stora Sundby, Sweden

Herewith declares that the product(s)

Type of product Model Art no

Industrial Ethernet switch SDW-550-T5G 3644-2001

SDW-541-F1G-T4G 3644-2020

is in conformity with the following EU directive(s).

No Short name

2014/30/EU Electromagnetic Compatibility (EMC)

2014/35/EU Low Voltage Directive (LVD)

2011/65/EU Restriction of the use of certain hazardous substances in electrical and electronic

equipment (RoHS)

References of standards applied for this EU declaration of conformity.

No Title Issue

EN 61000-6-1 Electromagnetic compatibility – Immunity for residential

environments

2007

EN 61000-6-2 Electromagnetic compatibility – Immunity for industrial

environments

2005

EN 61000-6-4 Electromagnetic compatibility – Emission for industrial

environments

2007

EN 50121-4 Railway applications – Electromagnetic compatibility – Emission

and immunity of the signalling and telecommunications apparatus

2015

EN 60950-1 Information technology equipment -- Safety -- General

requirements

2006

+A11:2009

+A1: 2010

+A12:2011

+A2: 2013

EN 50581 Technical documentation for the assessment of electrical and

electronic products with respect to the restriction of hazardous

substances

2012

The last two digits of the year in which the CE marking was affixed: 16

Pierre Öberg

Technical Manager

19

th

May 2016

Loading...

Loading...