Westermo SDW-550 E-mark, SDW-541-MM-ST2, SDW-550B, SDW-532-MM-SC2-SM-SC15, SDW-541-MM-SC2 User Manual

...Page 1

©

Westermo Teleindustri AB

SDW-500

SERIES

User Guide

6644-2214

Industrial Ethernet

5-port Switch

www.westermo.com

Page 2

2

6644-2214

Legal information

The contents of this document are provided “as is”. Except as required by applicable

law, no warranties of any kind, either express or implied, including, but not limited to,

the implied warranties of merchantability and fitness for a particular purpose, are made

in relation to the accuracy and reliability or contents of this document. Westermo

reserves the right to revise this document or withdraw it at any time without prior

notice.

Under no circumstances shall Westermo be responsible for any loss of data or income

or any special, incidental, and consequential or indirect damages howsoever caused.

More information about Westermo can be found at the following Internet address:

http://www.westermo.com

Software tools

Related software tools are available in the folder software tools under

technical support on the Westermo website.

Page 3

3

6644-2214

Safety

Before installation:

Read this manual completely and gather all information on the unit. Make sure

that you understand it fully. Check that your application does not exceed the safe

operating specifications for this unit.

This unit should only be installed by qualified personnel.

This unit should be built-in to an apparatus cabinet, or similar, where access is

restricted to service personnel only.

The power supply wiring must be sufficiently fused, and if necessary it must be

possible to disconnect manually from the power supply. Ensure compliance to

national installation regulations.

This unit uses convection cooling.To avoid obstructing the air flow around the unit,

follow the spacing recommendations (see Installation section).

Before mounting, using or removing this unit:

Prevent access to hazardous voltage by disconnecting the unit from power supply.

Warning! Do not open connected unit. Hazardous voltage may occur within this

unit when connected to power supply.

Class 1 Laser Product

Do not look directly into fibre optical fibre port or any connected fibre although

this unit is designed to meet the Class 1 Laser regulations.

Care recommendations

Follow the care recommendations below to maintain full operation of unit and to fulfil

the warranty obligations.

This unit must not be operating with removed covers or lids.

Do not attempt to disassemble the unit. There are no user serviceable parts inside.

Do not drop, knock or shake the unit, rough handling above the specification may cause

damage to internal circuit boards.

Do not use harsh chemicals, cleaning solvents or strong detergents to clean the unit.

Do not paint the unit. Paint can clog the unit and prevent proper operation.

Do not expose the unit to any kind of liquids (rain, beverages, etc). The unit is not

waterproof. Keep the unit within the specified humidity levels.

Do not use or store the unit in dusty, dirty areas, connectors as well as other mechanical

part may be damaged.

If the unit is not working properly, contact the place of purchase, nearest Westermo

distributor office or Westermo Tech support.

Fibre connectors are supplied with plugs to avoid contamination inside the optical port.

As long as no optical fibre is mounted on the connector, e.g. for storage, service or

transportation, should the plug be applied.

!

!

!

Page 4

4

6644-2214

Note. Fibre Optic Handling

Fibre optic equipment needs special treatment. It is very sensitive to dust and dirt. If

the fibre will be disconnected from the modem the protective hood on the transmitter/

receiver must be connected. The protective hood must be kept on during transportation.

The fibre optic cable must also be handle the same way.

If this recommendation not will be followed it can jeopardise the warranty.

Cleaning of the optical connectors

In the event of contamination, the optical connectors should be cleaned by the use of

forced nitrogen and some kind of cleaning stick.

Recommended cleaning fluids:

• Methyl-, ethyl-, isopropyl- or isobutyl-alcohol

• Hexane

• Naphtha

Maintenance

No maintenance is required, as long as the unit is used as intended within the specified

conditions.

Page 5

5

6644-2214

Agency approvals and standards compliance

Type Approval / Compliance

EMC EN 61000-6-2, Immunity industrial environments

EN 61000-6-31, Emission residential environments

EN 61000-6-42, Emission industrial environments

E-Mark, Road Vehicles, 10R-04 7216

3

Safety EN/IEC 60950-1, IT Equipment

UL 60950-1, IT Equipment 1st Edition

4

Marine DNV GL rules for classification – Ships and offshore units

5

Note 1 _ Applicable only for 3644-x001

2 _ Applicable only for 3644-0019, 3644-002x and 3644-003x

3

_ Applicable only for 3644-6001

4

– Applicable only for 3644-0001

5

– Applicable only for 3644-0001, 3644-0022 , 3644-0023, 3644-0025,

3644-0032, 3644-0033, 3644-0035

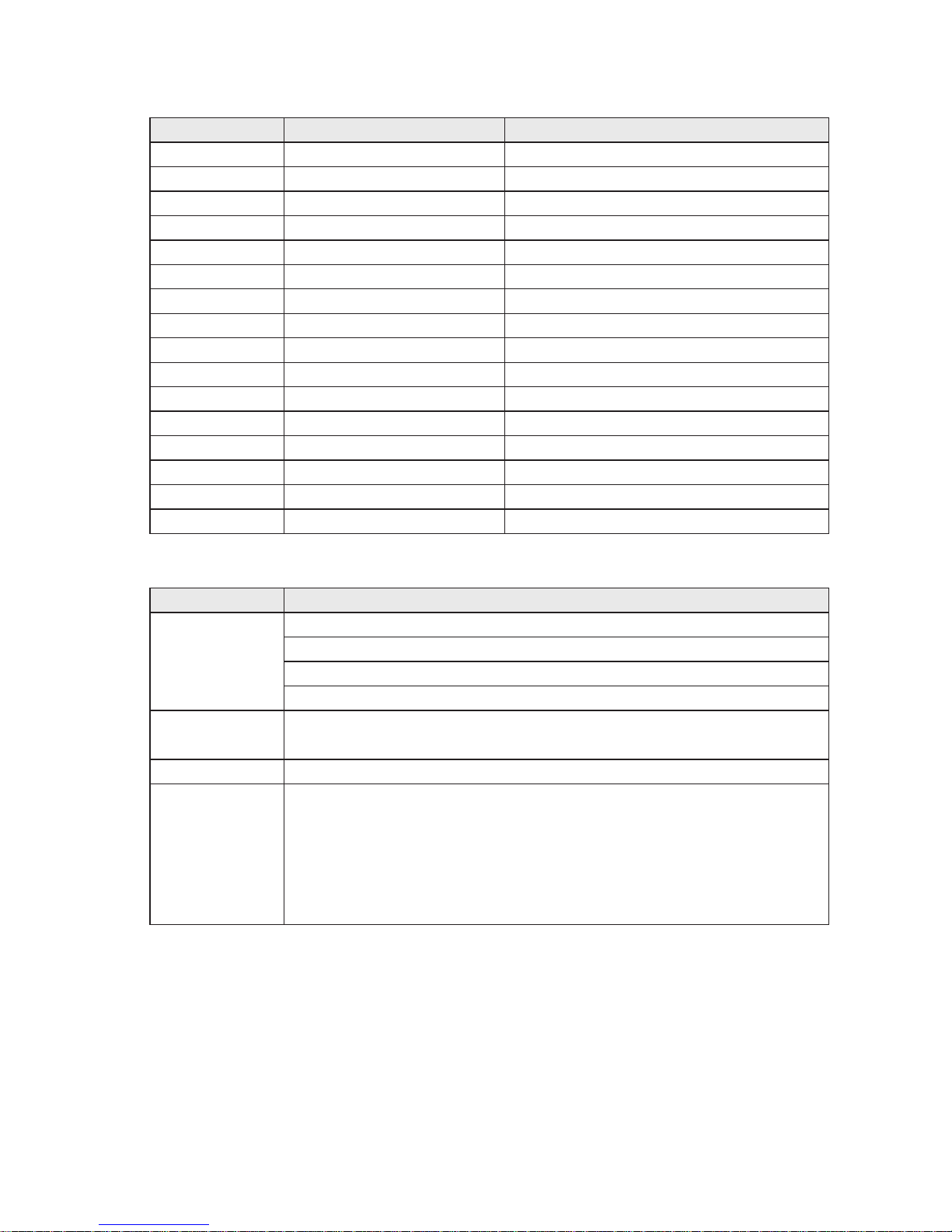

Article number, model and description

Article Model Description

3644-0001 SDW-550 10/100Base-T/TX: 5 ports

3644-6001 SDW-550 E-mark 10/100Base-T/TX: 5 ports

3644-0015 SDW-550B 10/100Base-T/TX: 5 ports

3644-0019 SDW-532-MM-SC2-SM-SC15 10/100Base-T/TX: 3 ports 100Base-FX: 2 port

3644-0020 SDW-541-MM-SC2 10/100Base-T/TX: 4 ports 100Base-FX: 1 port

3644-0021 SDW-541-MM-ST2 10/100Base-T/TX: 4 ports 100Base-FX: 1 port

3644-0022 SDW-541-SM-LC15 10/100Base-T/TX: 4 ports 100Base-FX: 1 port

3644-0023 SDW-541-MM-LC2 10/100Base-T/TX: 4 ports 100Base-FX: 1 port

3644-0024 SDW-541-SM-SC15 10/100Base-T/TX: 4 ports 100Base-FX: 1 port

3644-0025 SDW-541-SM-LC40 10/100Base-T/TX: 4 ports 100Base-FX: 1 port

3644-0030 SDW-532-MM-SC2 10/100Base-T/TX: 3 ports 100Base-FX: 2 port

3644-0031 SDW-532-MM-ST2 10/100Base-T/TX: 3 ports 100Base-FX: 2 port

3644-0032 SDW-532-SM-LC15 10/100Base-T/TX: 3 ports 100Base-FX: 2 port

3644-0033 SDW-532-MM-LC2 10/100Base-T/TX: 3 ports 100Base-FX: 2 port

3644-0034 SDW-532-SM-SC15 10/100Base-T/TX: 3 ports 100Base-FX: 2 port

3644-0035 SDW-532-SM-LC40 10/100Base-T/TX: 3 ports 100Base-FX: 2 port

Corrosive

environment

Notice:

This product has been successfully tested in a corrosion test according to

IEC 60068-2-60, method 3. This means that the product meets the requirements

to be placed in an environment classified as ISA-S71.04 class G3.

Note! If the product is placed in a corrosive environment, it is important that all

unused connector sockets are protected with a suitable plug in order to avoid

corrosion attacks on the gold plated pins in connectors.

Page 6

6

6644-2214

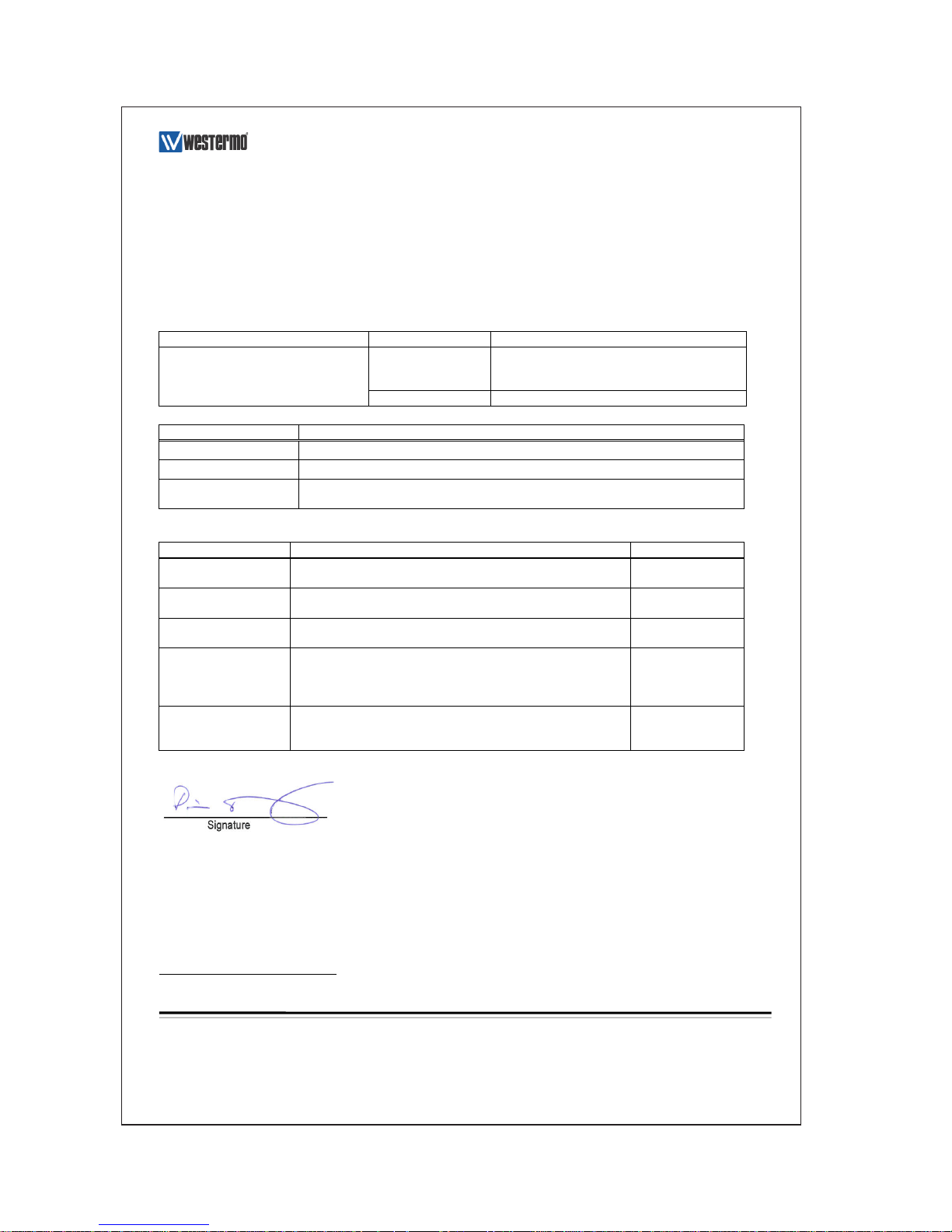

Declaration of Conformity

Westermo Teleindustri AB

Declaration of Conformity

Org.nr/

Postadress/Postal address

Tel.

Telefax

Postgiro

Bankgiro

Corp. identity number

Registered office

S-640 40 Stora Sundby

016-428000

016-428001

52 72 79-4

5671-5550

556361-2604

Eskilstuna

Sweden

Int+46 16428000

Int+46 16428001

The manufacturer

Westermo Teleindustri AB

SE-640 40 Stora Sundby, Sweden

Herewith declares that the product(s)

Type of product

Model

Art no

Industrial Ethernet switch

SDW-500 series

3644-0001, -0002, -0005, -0015, -0019, -0020,-

0021, -0022, -0023, -0024, -0025, -0030,-0031, -

0032, -0033, -0034, -0035

SDW-550 E-mark

3644-6001

is in conformity with the following EU directive(s).

No

Short name

2014/30/EU

Electromagnetic Compatibility (EMC)

2014/35/EU

Low Voltage Directive (LVD)

2011/65/EU

Restriction of the use of certain hazardous substances in electrical and electronic

equipment (RoHS)

References of standards applied for this EU declaration of conformity.

No

Title

Issue

EN 61000-6-2

Electromagnetic compatibility – Immunity for industrial

environments

2005

EN 61000-6-3

1

Electromagnetic compatibility – Emission for residential

environments

2007

EN 61000-6-4

2

Electromagnetic compatibility – Emission for industrial

environments

2007

EN 60950-1

Information technology equipment -- Safety -- General

requirements

2006

+A11:2009

+A1: 2010

+A12:2011

EN 50581

Technical documentation for the assessment of electrical and

electronic products with respect to the restriction of hazardous

substances

2012

The last two digits of the year in which the CE marking was affixed:

16

Pierre Öberg

Technical Manager

21stMarch 2016

1

Applicable for 3644-000x and 3644-6001

2

Applicable for 3644-0019, 3644-002x and 3644-003x.

Page 7

7

6644-2214

Environmental conditions

Isolation between interfaces

Power Interface to all other 2.8 kV DC 2.0 kV RMS @ 50 Hz and 60 s duration

TX signal Interface to all other 2.1 kV DC 1.5 kV RMS @ 50 Hz and 60 s duration

TX shield Interface to all other 1.5 kV DC 1.0 kV RMS @ 50 Hz and 60 s duration

Environmental

Temperature, operating –25 to +70°C (SDW-550),

–25 to +65°C (SDW-541)

–25 to +60°C (SDW-532)

Temperature, storage and transportation –25 to +70°C

Relative humidity, operating 5 to 95% (non-condensing)

Relative humidity,

storage and transportation

5 to 95% (condensation allowed outside packaging)

Altitude, operating 2000 m/70 kPa

Mechanical

Dimension (W x H x D) 35 x 121 x 119 mm

Weight 0.2 kg

Mounting DIN-rail

Degree of protection IP21

Configuration

Auto configured (auto-negotiation) or manually setting of speed and duplex of individual TX port,

by DIP-switches.

Port mirror function is possible to set with DIP-switch. With the port mirror function active the

switch will copy all outgoing traffic to port 1. This can be used to monitor all traffic going out

from the switch. Packets may be discarded if the total throughput exceeds the port speed of port

1.

Fibre optic power budget

Model Multimode

MM-xx2

Singlemode

SM-SC15

Singlemode

SM-LC15

Singlemode

SM-LC40

Transmitted wavelength 1310 nm 1310 nm 1310 nm 1310 nm

Min. output power, transmitter –19 dBm –15 dBm –15 dBm –5 dBm

Max. output power, transmitter –12 dBm –8 dBm -8 dBm 0 dBm

Input sensitivity, receiver –31 dBm –34 dBm –31 dBm –34 dBm

Min. power budget 12 dBm 19 dBm 16 dBm 29 dBm

Max. power budget 19 dBm 26 dBm 23 dBm 34 dBm

Recommended fibre cable and

core / cladding diameter

50/125

62.5/125

9/125

10/125

9/125

10/125

9/125

10/125

Attenuation in connectors / splices

Type Normal attenuation

Connector 0.2 - 0.4 dBm

Fusion splice 0.1 dBm

Mechanical splice 0.2 dBm

Page 8

8

6644-2214

Description

The SDW-550 is an Industrial Ethernet 5-port switch.

All ports support auto-negotiation, but DIP-switches also allow speed and duplex

configuration of any individual TX port. It is also possible to set up one port to monitor

traffic to/from the switch.

The SDW-550 has been designed to meet high industrial specifications, providing very

high dependability in harsh environmental conditions.

Features:

… TX shields individually isolated

… Wide DC power range 12 – 48 VDC

… Wide temperature range

… Automatic MDI/MDI-X crossover

… LED indicators for Power, Speed, Duplex, Link and Traffic

… Port monitoring

… 35 mm DIN rail mounting

… Enable or disable of flow control

Example of applications are:

… 5-port switch

… Ethernet isolator, for STP networks

Page 9

9

6644-2214

Interface specifications

Power SDW-500 series

Rated voltage 12 –48 VDC, polarity protected

Operating voltage 9.6 – 57.6 VDC

Rated current @12 VDC power input

SDW-550 320 mA

SDW-541-MM-SC2 450 mA

SDW-541-MM-ST2 450 mA

SDW-541-SM-LC15 450 mA

SDW-541-SM-SC15 350 mA

SDW-541-SM-LC40 350 mA

SDW-541-MM-LC2 350 mA

SDW-532-MM-SC2 600 mA

SDW-532-MM-ST2 600 mA

SDW-532-SM-LC15 450 mA

SDW-532-SM-SC15 450 mA

SDW-532-SM-LC40 450 mA

SDW-532-MM-LC2 450 mA

SDW-532-MM-SC2-SM-SC15 450 mA

Rated frequency DC

Connection Detachable screw terminal

Connector size 0.2 – 2.5 mm² (AWG 24-12)

Ethernet TX

Electrical specification IEEE std 802.3. 2000 edition

Data rate 10 Mbit/s or 100 Mbit/s, manual or auto

Duplex Full or half, manual or auto

Connection SC, ST or LC

Circuit type Optical

Transmission range 100 m

Ethernet FX

Electrical specification IEEE std 802.3. 2000 edition

Data rate 10 Mbit/s or 100 Mbit/s, manual or auto

Duplex Full or half, manual or auto

Connection SC, ST or LC

Circuit type Optical

Transmission range 100 m

Page 10

10

6644-2214

Connections

Power connection

Network

Fibre connection

or RJ-45 connection

Network

RJ-45 connection

LED indicators

Available models:

… SDW-550 10/100Base-T/TX: 5 ports

… SDW-541 10/100Base-T/TX: 4 ports 100Base-FX: 1 port

… SDW-532 10/100Base-T/TX: 3 ports 100Base-FX: 2 ports

NOTE! SDW-532-MM-SC2-SM-SC15

Port 4: SC Single mode 15 km connector

Port 5: SC Multi mode 2 km connector

Page 11

11

6644-2214

Power

The SDW-500 series supports redundant power connection.

The positive input are +VA and +VB, the negative input

for both supplies are COM.

The power is drawn from

the input with the highest

voltage.

FX SC Multi- or single mode (optional)

Ethernet FX connection.

1300 nm multi- or singlemode fibre tranceiver with SC-connector.

The dust protection plug shall be mounted when no fibre is connected.

TX

Ethernet TX connection (RJ-45 connector), automatic MDI/MDI-X crossover.

CAT 5 cable is recommended.

Unshielded (UTP) or shielded (STP) connector might be used.

8

7

6

5

4

3

2

1

FX LC Multi- or single mode (optional)

Ethernet FX connection.

1300 nm singlemode fibre transceiver with LC-connector.

The dust protection plug shall be mounted when no fibre is connected.

FX ST Multi mode (optional)

Ethernet FX connection.

1300 nm multi mode fibre tranceiver with ST-connector.

The dust protection plugs shall be mounted when no fibre is connected.

12 3

3-pos screw terminal

Description Power

1 COM 0 V

2 +VA A: 9.6 – 57.6 VDC

3 +VB B: 9.6 – 57.6 VDC

Contact Signal Name Direction Description/Remark

1 TD+ In/Out Transmitted/Received data

2 TD– In/Out Transmitted/Received data

3 RD+ In/Out Transmitted/Received data

4 – – –

5 – – –

6 RD– In/Out Transmitted/Received data

7 – – –

8 – – –

Shield – – HF-connected

Page 12

12

6644-2214

LED indicators

At power on the PWR flashes during initialising.

Indicators (LED) Power (PWR)

Link (LINK) of every port

Speed (SPD) and duplex (DPX) of TX ports

LED Status Indication of

PWR ON Internal power, initialising OK

Slow flash Initialisation progressing

Fast flash Initialisation error

LINK OFF No Ethernet link

ON Good Ethernet link

Flash Ethernet data is transmitted or received, traffic indication

SPD OFF 10 Mbit/s

(TX only) ON 100 Mbit/s

DPX OFF Half duplex

(TX only) ON Full duplex

Page 13

13

6644-2214

DIP switch settings SDW-550

DIP-switches are accessible under the lid on top of the unit. DIP-switches are used to

configure the unit.

Warning!

Prevent damage to internal electronics from electrostatic discharges (ESD) by

discharging your body to a grounding point (e.g. use of wrist strap), before the lid

on top/front of the unit is removed.

Warning! Do not open connected equipment.

Prevent access to hazardous voltages by disconnecting the unit from AC/DC mains

supply and all other electrical connections.

!

!

NOTE

When configuration via DIP-switches, the settings of DIP-switches configure the unit only

after a reboot (power off/on).

To be observe when the DIP-switches will be configured

… Speed and duplex setting only valid when auto-negotiation is disabled.

… When monitoring selected all outgoing packets from the switch is also copied to the

port 1.

… Speed and duplex switch settings are ignored for FX ports.

… If auto-negotiation and auto MDI/MDI-X disabled all TX ports support MDI-X

configuration.

Page 14

14

6644-2214

S3 S2

Port 3 settings

ON

1 2 3 4 5 6 7 8

S1

Auto-negotiation and

auto MDI/MDI-X disabled

ON

1 2 3 4 5 6 7 8

S1

Auto-negotiation and

auto MDI/MDI-X enabled

ON

1 2 3 4 5 6 7 8

S1

10 Mbit/s speed selected

ON

1 2 3 4 5 6 7 8

S1

100 Mbit/s speed selected

ON

1 2 3 4 5 6 7 8

S2

Half duplex selected

ON

1 2 3 4 5 6 7 8

S2

Full duplex selected

Port 1 settings

ON

1 2 3 4 5 6 7 8

S1

Auto-negotiation and

auto MDI/MDI-X disabled

ON

1 2 3 4 5 6 7 8

S1

Auto-negotiation and

auto MDI/MDI-X enabled

ON

1 2 3 4 5 6 7 8

S1

10 Mbit/s speed selected

ON

1 2 3 4 5 6 7 8

S1

100 Mbit/s speed selected

ON

1 2 3 4 5 6 7 8

S1

Half duplex selected

ON

1 2 3 4 5 6 7 8

S1

Full duplex selected

Port 2 settings

ON

1 2 3 4 5 6 7 8

S1

Auto-negotiation and

auto MDI/MDI-X disabled

ON

1 2 3 4 5 6 7 8

S1

Auto-negotiation and

auto MDI/MDI-X enabled

ON

1 2 3 4 5 6 7 8

S1

10 Mbit/s speed selected

ON

1 2 3 4 5 6 7 8

S1

100 Mbit/s speed selected

ON

1 2 3 4 5 6 7 8

S1

Half duplex selected

ON

1 2 3 4 5 6 7 8

S1

Full duplex selected

Port 4 settings

ON

1 2 3 4 5 6 7 8

S2

Auto-negotiation and

auto MDI/MDI-X disabled

ON

1 2 3 4 5 6 7 8

S2

Auto-negotiation and

auto MDI/MDI-X enabled

ON

1 2 3 4 5 6 7 8

S2

10 Mbit/s speed selected

ON

1 2 3 4 5 6 7 8

S2

100 Mbit/s speed selected

ON

1 2 3 4 5 6 7 8

S2

Half duplex selected

ON

1 2 3 4 5 6 7 8

S2

Full duplex selected

S1

Page 15

15

6644-2214

Port 5 settings

ON

1 2 3 4 5 6 7 8

S2

Auto-negotiation and

auto MDI/MDI-X disabled

ON

1 2 3 4 5 6 7 8

S2

Auto-negotiation and

auto MDI/MDI-X enabled

ON

1 2 3 4 5 6 7 8

S2

10 Mbit/s speed selected

ON

1 2 3 4 5 6 7 8

S2

100 Mbit/s speed selected

ON

1 2 3 4 5 6 7 8

S2

Half duplex selected

ON

1 2 3 4 5 6 7 8

S2

Full duplex selected

Port mirroring settings

ON

1 2 3 4 5 6 7 8

S2

No monitoring selected

ON

1 2 3 4 5 6 7 8

S2

Monitoring selected

Flow control selected

S3

Flow control selected

S3

No flow control selected

Factory settings

ON

1 2 3 4 5 6 7 8

S1

ON

1 2 3 4 5 6 7 8

S2 S3

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3 4

Page 16

16

6644-2214

DIP switch settings SDW-541 and SDW-532

DIP-switches are accessible under the lid on top of the unit. DIP-switches are used to

configure the unit.

Warning!

Prevent damage to internal electronics from electrostatic discharges (ESD) by

discharging your body to a grounding point (e.g. use of wrist strap), before the lid

on top/front of the unit is removed.

Warning! Do not open connected equipment.

Prevent access to hazardous voltages by disconnecting the unit from AC/DC mains

supply and all other electrical connections.

!

!

NOTE

When configuration via DIP-switches, the settings of DIP-switches configure the unit only

after a reboot (power off/on).

To be observe when the DIP-switches will be configured

… Speed and duplex setting only valid when auto-negotiation is disabled.

… When monitoring selected all outgoing packets from the switch is also copied to the

port 1.

… Speed and duplex switch settings are ignored for FX ports.

… If auto-negotiation and auto MDI/MDI-X disabled all TX ports support MDI-X

configuration.

Page 17

17

6644-2214

Port 3 settings

ON

1 2 3 4 5 6 7 8

S1

Auto-negotiation and

auto MDI/MDI-X disabled

ON

1 2 3 4 5 6 7 8

S1

Auto-negotiation and

auto MDI/MDI-X enabled

ON

1 2 3 4 5 6 7 8

S1

10 Mbit/s speed selected

ON

1 2 3 4 5 6 7 8

S1

100 Mbit/s speed selected

ON

1 2 3 4 5 6 7 8

S2

Half duplex selected

ON

1 2 3 4 5 6 7 8

S2

Full duplex selected

Port 1 settings

ON

1 2 3 4 5 6 7 8

S1

Auto-negotiation and

auto MDI/MDI-X disabled

ON

1 2 3 4 5 6 7 8

S1

Auto-negotiation and

auto MDI/MDI-X enabled

ON

1 2 3 4 5 6 7 8

S1

10 Mbit/s speed selected

ON

1 2 3 4 5 6 7 8

S1

100 Mbit/s speed selected

ON

1 2 3 4 5 6 7 8

S1

Half duplex selected

ON

1 2 3 4 5 6 7 8

S1

Full duplex selected

Port 2 settings

ON

1 2 3 4 5 6 7 8

S1

Auto-negotiation and

auto MDI/MDI-X disabled

ON

1 2 3 4 5 6 7 8

S1

Auto-negotiation and

auto MDI/MDI-X enabled

ON

1 2 3 4 5 6 7 8

S1

10 Mbit/s speed selected

ON

1 2 3 4 5 6 7 8

S1

100 Mbit/s speed selected

ON

1 2 3 4 5 6 7 8

S1

Half duplex selected

ON

1 2 3 4 5 6 7 8

S1

Full duplex selected

S1

S2

Port 4 settings*

S2

Auto-negotiation and auto MDI/

MDI-X disabled

S2

Auto-negotiation and auto MDI/

MDI-X enabled

S2

10 Mbit/s speed selected

S2

100 Mbit/s speed selected

S2

Half duplex selected

S2

Full duplex selected

Port mirroring settings

S2

No monitoring selected

S2

Monitoring selected

Factory settings

ON

1 2 3 4 5 6 7 8

S1 S2

ON

1 2 3 4 5

ON

1 2 3 4 5

ON

1 2 3 4 5

ON

1 2 3 4 5

ON

1 2 3 4 5

ON

1 2 3 4 5

ON

1 2 3 4 5

ON

1 2 3 4 5

ON

1 2 3 4 5

* Setting of port 4 is only possible when using

SDW-541.

These settings are ignored when using SDW-532

Page 18

18

6644-2214

Installation

Mounting / Removal

Before mounting or removing the unit:

Prevent damage to internal electronics from electrostatic discharges (ESD) by

discharging your body to a grounding point (e.g. use of wrist strap).

Prevent access to hazardous voltages by disconnecting the unit from AC/DC mains

supply and all other electrical connections.

Mounting

This unit should be mounted on 35 mm DIN-rail which is

horizontally mounted on a wall or cabinet backplate.

This unit uses convection cooling. To avoid obstructing the airflow

around the unit, use the following spacing rules. Recommended

spacing 25 mm (1.0 inch) above/below and 10 mm (0.4 inches)

left/right the unit.

Snap on mounting, see figure

Removal

Press down the black support at the back of the unit, see figure.

10 mm *

(0.4 inches)

!

25 mm

25 mm

* Spacing (left/right) recommended for

full operating temperature range

CLICK!

Page 19

19

6644-2214

Page 20

REV. G 6644-2214 2017-04 Westermo Teleindustri AB, Sweden

For complete contact information, please visit our website at www.westermo.com/contact or scan the QR code

China

sales.cn@westermo.com

www.cn.westermo.com

France

infos@westermo.fr

www.westermo.fr

Germany

info@westermo.de

www.westermo.de

North America

info@westermo.com

www.westermo.com

Singapore

sales@westermo.com.sg

www.westermo.com

Sweden

info.sverige@westermo.se

www.westermo.se

United Kingdom

sales@westermo.co.uk

www.westermo.co.uk

Other Offices

Sales Units

Westermo Data Communications

Westermo • SE-640 40 Stora Sundby, Sweden

Tel +46 16 42 80 00 Fax +46 16 42 80 01

E-mail: info@westermo.com

www.westermo.com

Loading...

Loading...