Page 1

User Guide

6651-2241

ODW-730-F1

Fibre Optic Modem

Westermo Teleindustri AB

©

Industrial Converter

RS-485 to Fibre Optic Link.

Point to Point applications

www.westermo.com

Page 2

Legal information

The contents of this document are provided “as is”. Except as required by applicable

law, no warranties of any kind, either express or implied, including, but not limited to,

the implied warranties of merchantability and fitness for a particular purpose, are made

in relation to the accuracy and reliability or contents of this document. Westermo

reserves the right to revise this document or withdraw it at any time without prior

notice.

Under no circumstances shall Westermo be responsible for any loss of data or income

or any special, incidental, and consequential or indirect damages howsoever caused.

More information about Westermo can be found at the following Internet address:

http://www.westermo.com

2

6651-2241

Page 3

Safety

Before installation:

!

Read this manual completely and gather all information on the unit. Make sure

that you understand it fully. Check that your application does not exceed the safe

operating specifications for this unit.

This unit should only be installed by qualified personnel.

This unit should be built-in to an apparatus cabinet, or similar, where access is

restricted to service personnel only.

The power supply wiring must be sufficiently fused, and if necessary it must be

possible to disconnect manually from the power supply. Ensure compliance to

national installation regulations.

Branch circuit protection (fuse) is required for this unit with rating not

exceeding 20 A.

Product should be connected to UL Listed power supplies rated 12 – 48 VDC,

min 500 mA or 24 VAC, min 500 mA or reliably grounded DC SELV source*.

This unit uses convection cooling. To avoid obstructing the airflow around the

unit, follow the spacing recommendations (see Cooling section).

!

Before mounting, using or removing this unit:

Prevent access to hazardous voltages by disconnecting the unit from the power

supply.

Warning! Do not open a connected unit. Hazardous voltages may occur within

!

this unit when connected to a power supply.

Class 1 Laser Product

This unit is designed to meet the Class 1 Laser regulations. However, the user is warned

not to look directly into fibre optical fibre port or any connected fibre.

Care recommendations

Follow the care recommendations below to maintain full operation of the unit and to

fulfil the warranty obligations.

This unit must not be operated with covers or lids removed.

Do not attempt to disassemble the unit. There are no user serviceable parts inside.

Do not drop, knock or shake the unit. Rough handling beyond the specification may

cause damage to internal circuit boards.

Do not use harsh chemicals, cleaning solvents or strong detergents to clean the unit.

Do not paint the unit. Paint can clog the unit and prevent proper operation.

Do not expose the unit to any kind of liquids (rain, beverages, etc).

The unit is not waterproof. Keep the unit within the specified humidity levels.

Do not use or store the unit in dusty, dirty areas. Connectors as well as other

mechanical parts may be damaged.

If the unit is not working properly, contact the place of purchase, nearest Westermo

distributor office, or Westermo Tech support.

Fibre connectors are supplied with plugs to avoid contamination inside the optical port.

The plug should be fitted when no optical fibre is inserted in the connector, e.g. during

storage, service or transportation.

* Applicable for ODW-730-F1 only

6651-2241

3

Page 4

Note. Fibre Optic Handling

Fibre optic equipment requires careful handling as the fibre components are very

sensitive to dust and dirt. If the fibre is disconnected from the modem, the protective

plug on the transmitter/receiver must be replaced. The protective plug must be kept on

during transportation. The fibre optic cable must also be protected in the same way.

If this recommendation is not followed, it can jeopardise the warranty.

Cleaning of the optical connectors

In the event of contamination, the optical connectors should be cleaned by using forced

nitrogen and some kind of cleaning stick.

Recommended cleaning fluids:

• Methyl-, ethyl-, isopropyl- or isobutyl-alcohol

• Hexane

• Naphtha

Maintenance

No maintenance is required, as long as the unit is used as intended within the specified

conditions.

Agency approvals and standards compliance

Type Approval / Compliance

EMC EN 61000-6-1, Immunity residential environments

EN 61000-6-2, Immunity industrial environments

EN 61000-6-3, Emission residential environments

EN 61000-6-4, Emission industrial environments

EN 55022, Emission IT equipment, class A

EN 55024, Immunity IT equipment

FCC part 15 Class A

EN 50121-4, Railway signalling and telecommunications apparatus

IEC 62236-4, Railway signalling and telecommunications apparatus

Safety UL/CSA/IEC/EN 60950-1, IT equipment*

EN 60950-1, IT equipment**

ATEX** EN 60079-0 and EN 60079-15

* Applicable for ODW-730-F1 only

** Applicable for ODW-730-F1 Ex only

FCC Part 15.105

Notice:

EN 55022 Notice:

4

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

This is a class A product. In a domestic environment this product may cause radio interference in which case the user may be required to take adequate measures.

6651-2241

Page 5

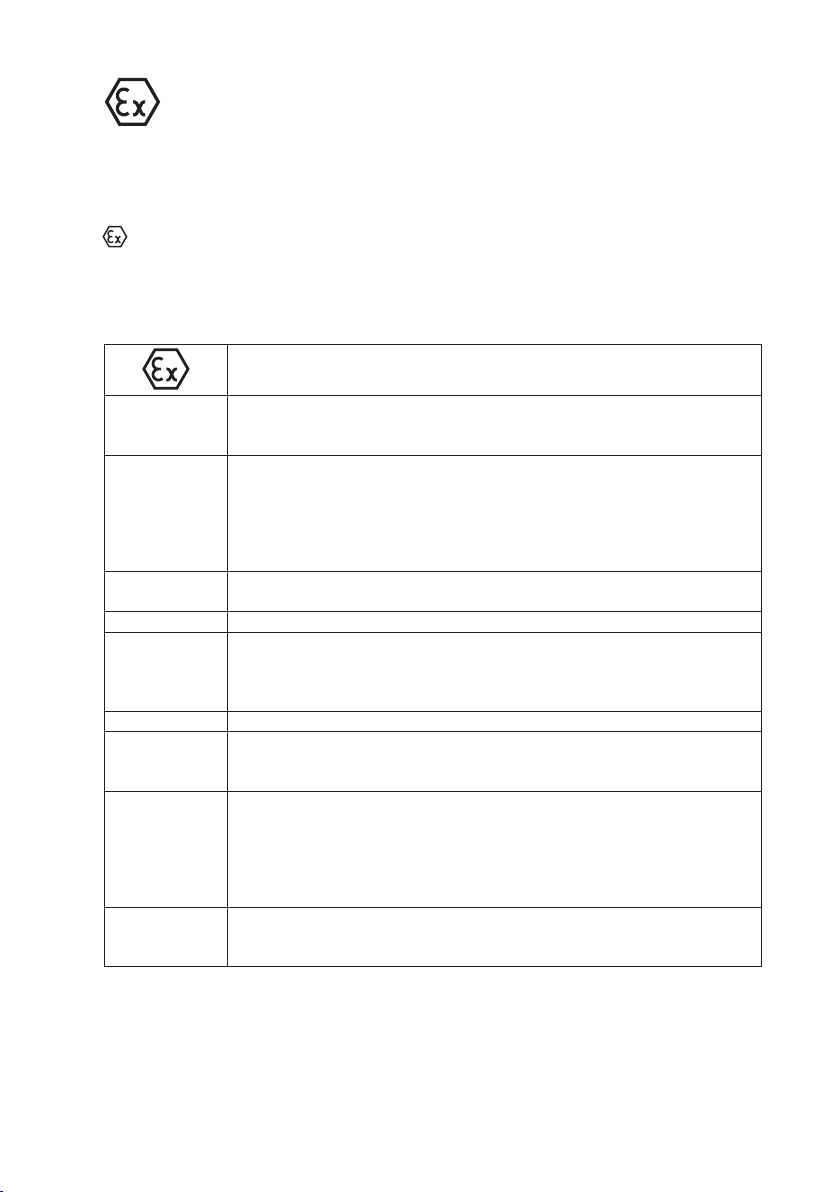

ATEX Information (Applicable for ODW-730-F1 EX only)

General

This unit is intended for use in Zone 2 hazardous location only.

Marking

II 3 G

Ex nA IIC T4 Gc

SPECIAL CONDITION

WARNING – DO NOT SEPARATE WHEN ENERGIZED

Indicate that this unit complies with relevant European standards that are

harmonised with the 94/9/EC Directive (ATEX).

II

3

G

Ex Indicates that this unit is in conformity with relevant European Ex standard(s).

nA

IIC Gas group, a typical gas i hydrogen.

T4

Gc

SPECIAL

CONDITION

Equipment group II.

This unit can be installed in all places with an explosive gas atmosphere other

than mines susceptible to firedamp

Equipment category 3.

A category is the classification according to the required level of protection.

This unit ensures the requisite level of protection during normal operation and

is intended for use in areas in which explosive atmosphere caused by gases,

vapours, mists, or dust mixtures are unlikely to occure or, if they do occure, are

likely to do so only infrequently and for a short periode only.

Indicates protection concerning explosive atmospheres caused by gases,

vapours or mists (G).

Type of protection used.

This unit is a non-sparking device "nA" which is constructed to minimize the

risk of occurence of arcs or sparks capable of creating an ignition hazard during

conditions of normal operation.

Temperature class T4 (T4 = 135°C).

This unit is classified in accordance with its maximum surface temperature

(external and internal).

Equipment protection level Gc (EPL Gc).

Equipment for explosive gas atmospheres, having a "enhanced" level of protection, which is not a source of ignition in normal operation and which may have

some additional protection to ensure that it remains inactive as an ignition

source in the case of regular expected occurences. EPL Gc are analogous to the

ATEX Categories (Category 3 G = EPL Gc).

This unit has a special condition of use.

The special condition for safe use contains safety related information that is

necesarry for the correct installation and safe use.

6651-2241

5

Page 6

Ratings

Power (12 – 48) VDC; 300 mA

Ambient temperature –40ºC ≤ Ta ≤ +70ºC

Ingress protection (IP) IP21

Maximum surface temperatur 135ºC (temperature class T4)

Safety Control Drawing

Degree of protection IP 21

Ambient temperature –40°C to +70°C

Installation spacing

Direction relative this unit!

FP

Minimum 25 mm above / below

Minimum 10 mm left / right

Position Descripton Input / Output values

1 In & out / Relay contact (NO)

2 In & out / Relay contact (C)

3 In & out / Relay contact (NC)

Galvanically isolated via mechanical relay.

See user manual for proven transient protection.

Position Descripton Input / Output values

1 In+ (EIA RS-485 A) U

2 In / R– (EIA RS-485 B)

3 In/out / T+ (EIA RS-485 A)

4 In/out / T– (EIA RS-485 B)

Uin = 60 VDC max

Iin = 500 mA max

= ± 5 Vpk

max

I

= ± 250 mA

max

Data rate:

300 bit/s to 1.5 Mbit/s

1234

Position Descripton Output values

Rx In / Receive port

Tx Out / Transmit port

Max 0 dBm

Position Descripton Intput values

1 In / Common

2 In / +Voltage A

3 In / +Voltage B

4 In / Common

See section Type tests and environmental conditions in this

user manual for proven transient protection.

6

Uin = (10 – 60) VDC

Iin = 400 mA max

PIn = Max 4 W

6651-2241

Page 7

SPECIAL CONDITION FOR SAFE USE

Ambient temperature:

This unit is designed for use in extreme ambient temperature conditions as follows:

–40 ºC ≤ Ta ≤ +70 ºC

Installation in an apparatus cabinet:

This unit requires installation in an Ex certified apparatus cabinet suitable for the area of use and

providing a degree of protection of at least IP54.

Resistance to impact:

This unit requires installation in an apparatus cabinet where adequate resistance to impact is

provided by the apparatus cabinet. See "Installation in an apparatus cabinet" above for requirements

on the external apparatus cabinet.

Resistance to light:

This unit requires installation in an apparatus cabinet where it is protected from light

(for example daylight or light from luminaires).

See "Installation in an apparatus cabinet" above for requirements on the external apparatus cabinet.

Secureness of plugs:

When this unit is installed in an explosive atmospheres, all connectors must be mechanically secured

to prevent loosening.

Conductor temperature:

When this unit is installed in locations with high ambient temperature, special precautions shall be

taken upon the choice of external conductors and the temperature rating of the conductor(s).

Directive 94/9/EC alongside with other directives:

Directive 2004/108/EC (EMC) applies and to assure a safe performance of this unit under the scope

of Directive 94/9/EC, refer to the electromagnetic immunity level specified under "Type tests and

environmental conditions" in this manual.

Standards and date of compliance

EN 60079-0 and EN 60079-15

2010-12-17

6651-2241

7

Page 8

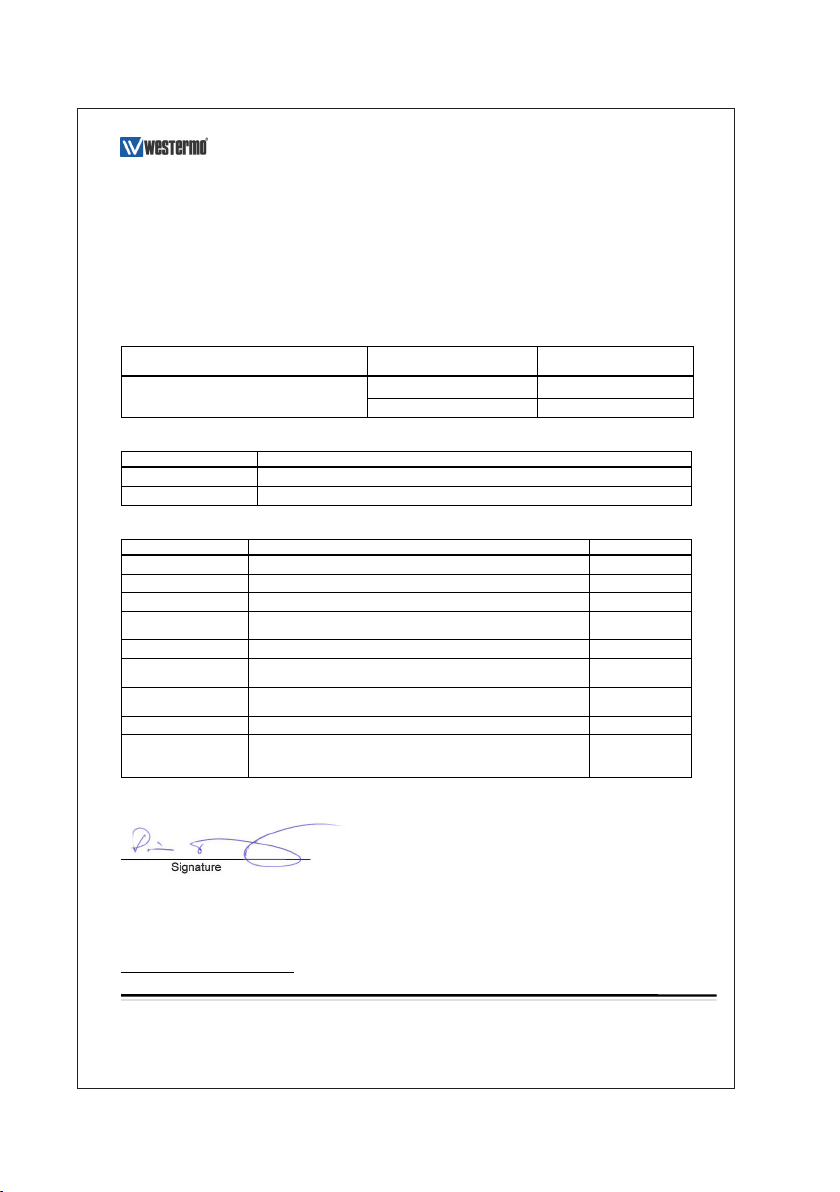

Declaration of Conformity

Org.nr/

Registered office

Westermo Teleindustri AB

Declaration of conformity

The manufacturer Westermo Teleindustri AB

Herewith declares that the product(s)

Type of product Model Art no

Industrial fiberoptic repeaters/media

converters

is in conformity with the following EC directive(s).

No Short name

2004/108/EC Electromagnetic Compatibility (EMC)

94/9/EC1 Equipment Explosive Atmospheres (ATEX)

References of standards applied for this EC declaration of conformity.

No Title Issue

EN 61000-6-1 Electromagnetic compatibility – Immunity residential environments 2007

EN 61000-6-2 Electromagnetic compatibility – Immunity industrial environments 2005

EN 61000-6-3 Electromagnetic compatibility – Emission residential environments 2007

EN 61000-6-4 Electromagnetic compatibility – Emission for industrial

EN 55022 Information technology equipment - Emission 2006 + A1:2007

EN 55024 Information technology equipment - Immunity 1998 + A1:2001 +

EN 50121-4 Railway applications – Electromagnetic compatibility – Emission

EN 60079-0 Explosive atmospheres – Equipment – General requirements 2009

EN 60079-15 Electrical apparatus for explosive gas atmospheres –

The last two digits of the year in which the CE marking was affixed: 11

SE-640 40 Stora Sundby, Sweden

ODW-700 series 3651-07xx

ODW-700EX series 3651-37xx

environments

and immunity of the signalling and telecommunications apparatus

Construction, test and marking of type of protection “n” electrical

apparatus

2007

A2:2003

2006

2005

Pierre Öberg

Technical Manager

15th June 2011

1

Applicable for ODW-700EX series only.

Postadress/Postal address

S-640 40 Stora Sundby 016-428000 016-428001 52 72 79-4 5671-5550 556361-2604 Eskilstuna

Sweden Int+46 16428000 Int+46 16428001

8

Tel.

Telefax

Postgiro

Bankgiro Corp. identity number

6651-2241

Page 9

Type tests and environmental conditions

Electromagnetic Compatibility

Phenomena Test Description Level

ESD EN 61000-4-2 Enclosure contact ± 6 kV

RF field AM modulated IEC 61000-4-3 Enclosure 10 V/m 80% AM (1 kHz), 80 – 800 MHz

RF field 900 MHz ENV 50204 Enclosure 20 V/m pulse modulated 200 Hz, 900 ± 5 MHz

Fast transient EN 61000-4-4 Signal ports ± 2 kV

Surge EN 61000-4-5 Signal ports unbalanced ± 2 kV line to earth, ± 2 kV line to line

RF conducted EN 61000-4-6 Signal ports 10 V 80% AM (1 kHz), 0.15 – 80 MHz

Pulse Magnetic field EN 61000-4-9 Enclosure 300 A/m, 6.4 / 16 µs pulse

Voltage dips

and interruption

Mains freq. 50 Hz EN 61000-4-16 Signal ports 100 V 50 Hz line to earth

Mains freq. 50 Hz SS 436 15 03 Signal ports 250 V 50 Hz line to line

Radiated emission EN 55022 Enclosure Class B

Conducted emission EN 55022 AC power ports Class B

Dielectric strength EN 60950 Signal port to all other

Environmental

Temperature Operating –40 to +70°C

Humidity Operating 5 to 95% relative humidity

Altitude Operating 2 000 m / 70 kPa

Service life Operating 10 year

Vibration IEC 60068-2-6 Operating 7.5 mm, 5 – 8 Hz

Shock IEC 60068-2-27 Operating 15 g, 11 ms

Packaging

Enclosure, ODW-730 F1 UL 94 PC / ABS Flammability class V-1

Enclosure,

ODW-730 F1 EX

Dimension W x H x D 35 x 121 x 119 mm

Weight 0.26 kg

Degree of protection IP 21

Cooling IEC 529 Enclosure Convection

Mounting Horizontal on 35 mm DIN-rail

EN 61000-4-11 AC power ports 10 & 5 000 ms, interruption

FCC part 15 Class A

FCC part 15 AC power ports Class B

EN 55022 DC power ports Class A

Enclosure air ± 8 kV

20 V/m 80% AM (1 kHz), 800 – 1000 MHz

20 V/m 80% AM (1 kHz), 1400 – 2700 MHz

Power ports ± 2 kV

Signal ports balanced ± 2 kV line to earth, ± 1 kV line to line

Power ports ± 2 kV line to earth, ± 2 kV line to line

Power ports 10 V 80% AM (1 kHz), 0.15 – 80 MHz

200 ms, 40% residual voltage

500 ms, 70% residual voltage

isolated ports

Power port to other

isolated ports

Storage & Transport –40 to +70°C

Maximum surface

temperature

Storage & Transport 5 to 95% relative humidity

Cabelec 6141

2 kVrms 50 Hz 1min

3 kVrms 50 Hz 1min

2 kVrms 50 Hz 1min (@ rated power < 60V)

135ºC (temperature class T4)

2 g, 8 – 500 Hz

6651-2241

9

Page 10

Functional description

STATUS

C

LED’s

Switches

CH 1

SFP

Fibre transceiver

TX

RX

I

E

COM

COM

+VA

O

V

P

+VB

POWER

T

RS -485

R

+5V

0V

+5V

0V

O

C

P

NO

NC

nternal

lectronics

ODW-730

O

V

P

/R

-

-

OVP Over Voltage Protection

OCP Over Current Protection

Converter serial interface – optical fibre

ODW-730 is a fibre optic modem that converts between electrical RS-485 and a fibre

optical link.

ODW-730 can also be used to convert from RS-485 to RS-232 by using a ODW-730 in

the same link as ODW-720.

Repeater – optical fibre links

ODW-730 is a fibre optic repeater that repeats received data from one fibre link out to

the other link. This is useful e.g. for long distance communication, where electromagnetic

interference may occur or when isolation of the electrical network is needed. The maximum optical fibre distance depends on selected fibre transceiver and fibre type. Distances

up to 80 km (50 miles) are available.

10

6651-2241

Page 11

Interface specifications

Power

Rated voltage ODW-730-F1: 12 to 48 VDC and 24 VAC

Operating voltage ODW-730-F1: 10 to 60 VDC and 20 to 30 VAC

Rated current 300 mA @ 12 V

Rated frequency ODW-730-F1 DC and 48 to 62 Hz

Inrush current I²t 0.2 A²s

Startup current* 1.0 Apeak

Polarity Reverse polarity protected

Redundant power input Yes

Isolation to RS-485 and Status port

Connection Detachable screw terminal

Connector size 0.75 – 2.5 mm2 (AWG 18 – 13)

Shielded cable Not required

* External supply current capability for proper startup

Status

Port type Signal relay, changeover contacts

Rated voltage Up to 48 VDC

Operating voltage Up to 60 VDC

Contact rating 500 mA @ 48 VDC

Contact resistance < 50 mW

Isolation to RS-485 and Power port

Connection Detachable screw terminal

Connector size 0.2 – 2.5 mm² (AWG 24 – 13)

Shielded cable Not required

ODW-730-F1 Ex: 12 to 48 VDC

ODW-730-F1 Ex: 10 to 60 VDC

150 mA @ 24 V

75 mA @ 48 V

ODW-730-F1 Ex: DC

Connect the unit using at least 18 AWG (0.75 mm2) wiring

6651-2241

11

Page 12

RS-422/485

Electrical specification EIA RS-485, 2-wire or 4-wire twisted pair

Data rate 300 bit/s – 1.5 Mbit/s

Data format 9 – 12 bits

Protocol Start-bit followed by 8-11 bits

Retiming Yes

Turning time

(2-wire RS-485)

One t

bit

t

= 1 / Baud rate (Baud rate in bit/s)

bit

Transmission range < 1200 m, depending on data rate and cable type (EIA RS-485)

Settings 120 W termination and failsafe biasing 680 W

Protection Installation Fault Tolerant (up to ±60 V)

Isolation to Status and Power port

Connection Detachable screw terminal

Connector size 0.2 – 2.5 mm² (AWG 24 – 13)

Shielded cable Not required

12

6651-2241

Page 13

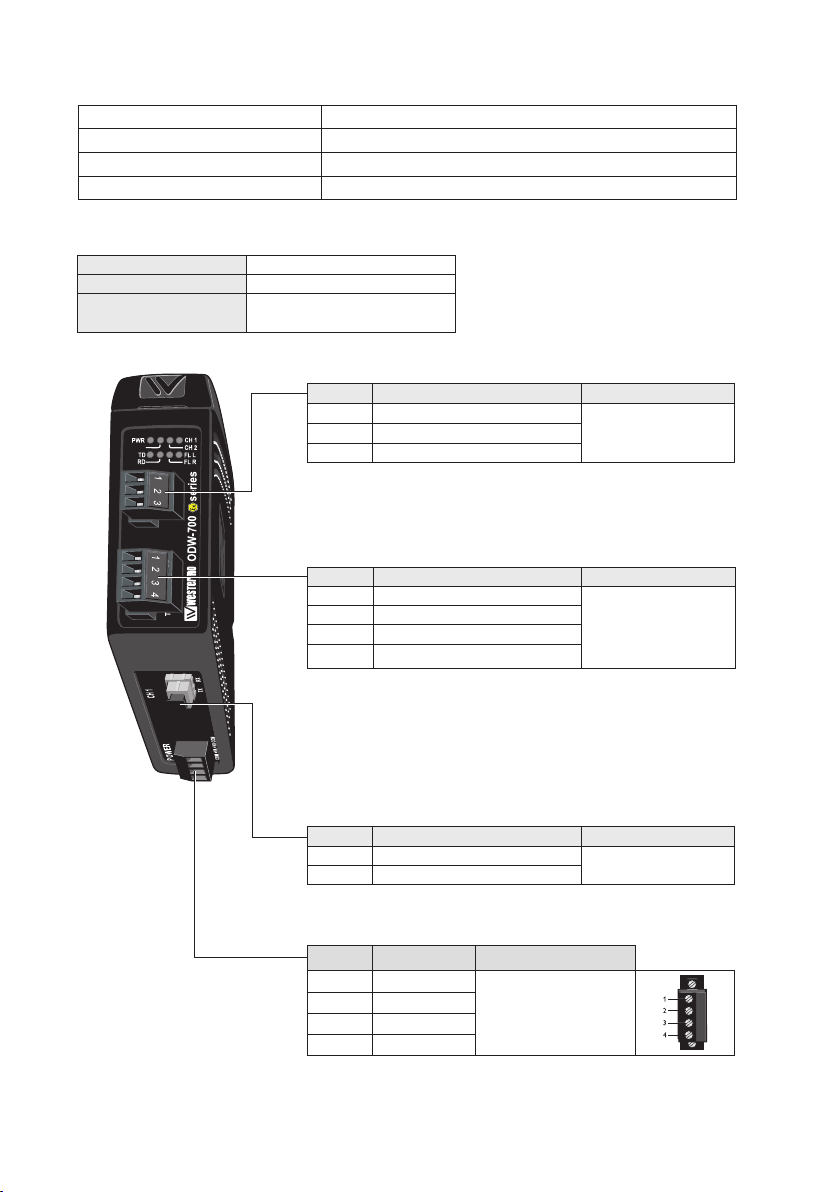

Location of Interface ports, LED’s and DIP-switches

ODW-730-F1

LED Indicators(for details see page 15)

FX(Fibre)

(for details

see page 12–13)

DIP-switches accessible under lid

(for details see page 16–17)

Status

screw terminal

Position Description Product

1 Contact with C when fibre optical

links are in operation

2 Common C

3 Open (no contact with C)

when fibre optical links are

not in operation

marking

NO

NC

RS-422/485

screw terminal

Position Direction* Description Product

1 In R+ (EIA RS-485 A’) R+

2 In R– (EIA RS-485 B’) R–

3 In/Out T+ (EIA RS-485 A) T/R+

4 In/Out T– (EIA RS-485 B) T/R–

marking

* Direction relative this unit

6651-2241

Power

screw terminal

Position Direction* Description Product

marking

1 In Common voltage COM

2 In Voltage A +VA

3 In Voltage B +VB

4 In Common voltage COM

13

Page 14

LED indicators

LED Status Description

PWR

Power

FP Not used

CH 2 Not used

CH 1

Channel 1 link status

TD Flash Data received on the electrical interface

RD Flash Data received on the optical interface

FL R

Failure link remote

FL L

Failure link local

* Only valid if used togheter with ODW-720-F1 units in a multidrop network.

Note: During power up, all LED’s will turn on for about 1 second.

ON Power is on.

OFF Power is off.

ON Fiber link to other unit has been estab-

lished at CH 1.

Flashing Optical power detected but link to other

unit has not been established at CH 1.

OFF No optical power detected and no link

to other unit has been established at

CH 1.

and transmitted out on the optical interface.

OFF No data received on the electrical inter-

face.

and transmitted out on the electrical

interface.

OFF No data received on the optical interface.

ON Remote fibre link failure.

A fibre link is out of operation at any

other unit than this one*.

Flashing Hardware error or invalid configuration.

ON Local fibre link failure.

A fibre link is out of operation at this

unit.

Flashing Hardware error or invalid configuration.

14

6651-2241

Page 15

!

DIP-switch settings

Before DIP-switch settings:

Prevent damage to internal electronics from electrostatic discharges (ESD) by

discharging your body to a grounding point (e.g. use of wrist strap)

Note: Disconnect power before DIP-switch settings.

S2S1

S3

S1 DIP-switch, asynchronous mode speed selection

ON

1 2 3 4 5 6 7 8

300 bit/s

ON

1 2 3 4 5 6 7 8

57.6 kbit/s

ON

1 2 3 4 5 6 7 8

1.0 Mbit/s

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

1200 bit/s

2400 bit/s

4800 bit/s

9600 bit/s

19.2 kbit/s

38.4 kbit/s

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

115.2 kbit/s

125 kbit/s

187.5 kbit/s

230.4 kbit/s

250 kbit/s

500 kbit/s

Supervision table when selecting data format

Start bit … … … … … … … …

7 bit … … … …

8 bit … … … …

Parity … … … …

1 stop bit … … … …

2 stop bit … … … …

Number of bit 9 10 10 10 11 11 11 12

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

1.5 Mbit/s

9 bits data

format

10 bits data

format

11 bits data

format

12 bits data

format

S:1:8 always OFF

for point-to-point

applications

6651-2241

15

Page 16

S1 DIP-switch, synchronous mode time frame selection

ON

1 2 3 4 5 6 7 8

1.6 ms

ON

1 2 3 4 5 6 7 8

13 µs

ON

1 2 3 4 5 6 7 8

2 µs

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

S2 DIP-switch

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

S3 DIP-switch

ON

No termination and fail-safe

1 2 3 4

ON

Termination with fail-safe (4-wire)

1 2 3 4

416 µs

208 µs

104 µs

52 µs

26 µs

RS-485

2-wire

RS-485

4-wire

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

8.6 µs

4.3 µs

4 µs

2.6 µs

2.1 µs

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

1 µs

500 ns

300 ns

S:1:8 always OFF

for point-to-point

applications

S2:2 and S2:4 – S2:8 always OFF

S2:3 always ON for point-to-point

applications

Termination with fail-safe (2-wire)

Factory default

ON

1 2 3 4 5 6 7 8

16

S1

ON

1 2 3 4 5 6 7 8

S2

6651-2241

Page 17

Start up guide, point-to-point application

Follow the steps below to get the unit up and running in a simple application.

Master Slave

POWER CH 1

COM +VA +VB COM

POWER CH 1

COM +VA +VB COMTX RX TX RX

… Make sure that DIP-switches S1:8 and S2:2 – S2:8 are set to factory default positions.

(I.e. S1:8 OFF, S2:2 OFF, S2:3 ON and S":4 – S2:8 OFF).

… Configure both ODW-730-F1 units for the correct speed and data format using DIP-

switches S1:1 – S1:7.

… Select RS-485 2- or 4-wire mode using DIP-switch S2:1 (OFF = 2-wire, ON = 4-wire).

… Enable the RS-485 termination / fail safe if required using DIP-switches S3:1 – S3:4

(S3:1 asnd S3:2 = 4-wire termination, S3:3 and S3:4 = 2-wire connection.)

… Connect the fibre link between the ODW-730-F1.

… Connect the power supply to both ODW-730-F1.

… After a few seconds the fibre link should be in operation, indicated by an active CH1

LED.

… Connect the serial cables from PLC master and slave to respective ODW-730-F1.

… Frames from PLC master that are correctly received in the ODW-730-F1 will be

indicated by flashing TD LED.

… Frames that are received via the fibre link will be transmitted to the PLC slave

and indicated by flashing RD LED.

… Replies from slave to master will be transferred and indicated in the opposite way.

… The point-to-point application is up and running.

6651-2241

17

Page 18

RS-485 termination at system level

ODW-730 Series

ODW-730 Series

The system should be installed in according to the RS-485 specification. A system should

always form a bus structure where the termination is at the end points of the bus.

See diagrams for details of how this is done with RS-485 2-wire and 4-wire.

R+

R–

T+

T–

R– R+ R+T– T– R– R+ T– T+T+T+ R–

=Termination

T/R+

T/R–

=Termination

Slave unit Slave unit Slave unit

Max 0.3 metre

T/R+T/R– T/R+T/R– T/R+T/R–

Slave unit Slave unit Slave unit

N.B. R+/R–, T+/T– definitions are not standard, it can help to shift + and – if the unit

does not work.

18

6651-2241

Page 19

About the interfaces

Power terminal

The power terminal has two independent inputs, +VA and +VB, allowing redundancy

should either fail. The ODW-730 power supply is galvanically isolated from all other

internal electronics.

Optical fibre interfaces

ODW-730 uses Small From Factor Pluggable (SFP) transceivers that are in compliance

with the Multi-Sourcing Agreement (MSA). This means that a wide range of different fibre

tranceivers and connectors can be used.

RS-485 interface

A 4 position detachable screw terminal that can handle full duplex data rates up to

1.5 Mbit/s and can be set to either 2- or 4-wire RS-485 system.

When 4-wire RS-485 is selected, the terminals T/R+ and T/R– will always be set to

transmit and terminals R+ and R– will always receive data.

Manchester coded protocol can be tranferred with Synchroous mode.

Status port

The status port connects to an internal relay wich may be used to trigger an external

alarm if a fault condition occurs. During normal operation pins 1 and 2 are in contact

with each other, and pins 2 and 3 are isolated. During an optical link failure, or power

failure, pins 1 and 2 are isolated, and pins 2 and 3 are in contact with each other.

6651-2241

19

Page 20

Mounting

CLICK!

This unit should be mounted on 35 mm DIN-rail, which is

horizontally mounted inside an apparatus cabinet, or similar.

Snap on mounting, see figure.

Cooling

This unit uses convection cooling. To avoid obstructing the airflow around the unit, use the following spacing rules. Minimum

spacing 25 mm (1.0 inch) above /below and 10 mm (0.4 inches)

left /right the unit. Spacing is recommended for the use of unit

in full operating temperature range and service life.

10 mm *

(0.4 inches)

25 mm

* Spacing (left/right) recommended for

full operating temperature range

Removal

Press down the black support at the top of the unit. See figure.

20

25 mm

6651-2241

Page 21

6651-2241

21

Page 22

22

6651-2241

Page 23

6651-2241

23

Page 24

Westermo • SE-640 40 Stora Sundby, Sweden

Tel +46 16 42 80 00 Fax +46 16 42 80 01

Sales Units

Westermo Data Communications

E-mail: info@westermo.com

www.westermo.com

China

sales.cn@westermo.com

www.cn.westermo.com

France

infos@westermo.fr

www.westermo.fr

Germany

info@westermo.de

www.westermo.de

For complete contact information, please visit our website at www.westermo.com/contact

REV. G 6651-2241 2014-10 Westermo Teleindustri AB, Sweden – A Beijer Electronics Group Company

North America

info@westermo.com

www.westermo.com

Singapore

sales@westermo.com.sg

www.westermo.com

Sweden

info.sverige@westermo.se

www.westermo.se

or scan the QR code with your mobile phone.

United Kingdom

sales@westermo.co.uk

www.westermo.co.uk

Other Offices

Loading...

Loading...