Page 1

OPERATOR'S MANUAL

WESTERBEKE

BTG - 9

KW

Marine Gasoline

Generator Set

Publication # 36710

Edition One

June 1987

jr~

'WESTERBEKE

j

WESTERBEKE

•

150

JOHN HANCOCK

CORPORATION • MYLES

ROAD,

TAUNTON,

STANDISH

MA

02780-7319

INDUSTRIAL

U.S.A.

PARK

Page 2

Gasoline with an ETHANOL content

higher than 10% (E10) is not allowed

and may void warranty.

Engines & Generators

Page 3

The

following

manual

emphasize

dangerous

equipment.

Read

before

ment.

can

to

Fuels,

electrical

parts

result

death.

carefully.

Always

least

oasoline-fueled

line

•

•

to

call

conditions

to

WARNING

CAUTION

the

attempting

exist

protect

are

five

fumes

Prevent

Shut

accessing

Use

on

electrical

Make

(particularly

surfaces

cal

Remove

working

Dc

not

to

through a ship-to-shore

transfer

AC

generator

Be

extremely

electrical

can

Exhaust

Ensure

adequate

from

system

sure

attached

Be

sure

ings

This

manual

manual

Know

when

and

personnel

exhaust

equipment,

potential

in

serious

Follow

operate

minutes

are

Electric

off

electrical

insulated

sure

dry

equipment.

wristwatch

on

connect

vessel's

switch.

cause

injury

~

that

to

the

regularly

exhaust

and

the

are

well-ventilated.

symbols

attention

potentially

the

operator

This

sy~bol

manual

serlOUS

loss

sonnel

to

take

clothing

components.

to

of

symbol

of

equipment.

carefully

to

dangerous

necessary

and

gases,

hazards

personal

recommended

bilge

enoine;

present

~

electric

mats

equipment.

shoes;,

when

electrical

utility

AC

may

resul~.

careful

or

~

!£tiE

the

exhaust

expel

engine.

for

manifolds

no

warping

unit

appear

warn

personal

life.

to

possible

operate

equIpment.

and

moving

blowers

before

ensure

before

equ1pment.

whenever

is

handling

and

equ1pment.

circuits,

Damaoe

when

death.

gases

Check

leaks

and

SAFETY PRECAUTIONS

in

this

to

and

or

to

the

is

used

in

of

is

used

caution

and

thoroughly

the

condi t ions

precautions

batteries,

that

injury

procedures

starting

starting.

power

dry,

and

keep

jewelry

shore

double-throw

to

workinc

High

.

system

discharged

are

exists.

its

surround-

the

possible

inJury

and

securely

or

in

the

per-

damage

equlp-

and

hot

could

or

for

at

no

not

electri-

vessel's

exhaust

a

oaso-

before

working

damp

sk1n

when

power

except

on

vol~age

is

make

Use

•

Enoine

expros

Do

running.

Do

the

Keep

the

Be

positive

Be

adequately

leaks.

Make

installed

maintained.

proper

ABC

all

environment.

Use

•

'b"atterles.

Wear

and

batteries.

Leac

c

be

c

Dc

near

off

vicinity

arcing

Avoid

•

Do

make

hot

Do

ry

loose

rings,

might

Make

properly

tive

all

Do

belt

t1ng.

Do

tally

fatigue.

Extreme

Fuel.

ioner

not

fill

not

smoke

eng1ne

combustible

uni

t.

sure

certain

sure

use.

by

the

applications

Extreme

rubber

eye

acid

hiohlv-explosive

1clniced

11ghted

not

smoke

batten'

all

electr

dur1ng

~

not

operating

care

exhaust

not

when

be

sure

shields

times

not

tension

not

or

service

wear

servicing

jackets,

necklaces,

.•

check

work

running;

treme

Care

(A

fire

fuel

or

or

the

all

fuel

shutoff

fuel

tightened

a

fire

nearby

Be

NFPA

Care

gloves,

protection

batteries

b\'

cig~rette,

or

beino

ical

to

servicing.

Parts.

if

absolutely

to

avoid

system

loos~

caught

all

attaching

tightened

and

fluid

while

on

physically

When

c'onstant

exists.)

tank

use

open

fuel

tank.

materials

supplies

valve.

line

and

extinouisher

and

familiar

Extinguishers

ar e appropr

encountered

When

Servicing

a

rubber

when

emit

oas,

electrical

cigar,

allo'"

an

serviced.

equipment

prevent

unit

while

adjustments,

moving

components.

clothing

equipment;

shirts

or

bracelets

in

moving

and

guards

levels

unit

equipment

incapacitated

Handllne

danger

with

flame

away

fittinos

free

ii

properly

with

iate

serv1cing

hvdrooen,

wh-ich -

arC1nc

or

open

electrical

unit

necessary

use

parts

or

or

sleeves,

parts.

hardware

keep

protec-

in

place

or

is

when

engine

have

rated

in

apron,

pipe.

flame

in

jewel-

avoid

driveopera-

men-

near

from

are

its

for

this

can

or

Snut

the

exand

that

at

by

of

of

is

is

to

is

a

Page 4

IMPORTANT

Product

technical

and

instruct

than

accordingly,

courtesy

THE

software

data,

parts

price

ions

Westerbeke,

and

CONTENT

and

is

service.

REPRESENTATIONS

TIMELINESS

LIABLE

CONNECTION

SUCH

For

SOFTWARE.

example,

Westerbeke's

blocks,

cal

components,

ported

Westerbeke

Westerbeke's

may

by

be

Wester

notice

supplier's

OR

FOR

WITH,

fuel

by

their

m'ust

outdated

beke'

in

advance,

software

ANY

components

products

systems

own

PRODUCT

of

SOFTWARE

all

kinds,

operator's

lists

speci

is

fica t ions

not

provided

WESTERBEKE

OF

SUCH

WITH

SOFTWARE,

RESPECT THERETO, INCLUDING

COMPLETENESS

TYPE

OR

OF

ARISING

and

and

and

pumps

and

manufacturers

depend

on

product

and

no

longer

s

supplier

s,

are

until

DISCLAIMER

such

and

workshop

(and

other

prov

within

to

Westerbeke

THEREOF,

DAMAGES

OUT

OF,

sub-assemblies

supplied

components,

other

products)

with

such

software

software.

accurate.

of

wh

frequently

after

such

as

brochur

manuals,

related

ided

from

Westerbeke's

customers

CANNOT

MAKES

AND

OR

THE

by

BE

NO

WILL

INJURY

FURNISHING

others

transmissions,

are

their

for

Such

software,

Routine

ich

Wester

not

changes

es,

parts

information),

source

control

RESPONSIBLE

WARRANTIES

THE

IN

NO

INCURRED

incorporated

(such

generally

own

software,

the

changes

beke

rarely

reflected

take

place.

dr

awing

lists

s

other

and,

only

as

FOR

ACCURACY,

EVENT

OR

USE

into

as

engine

electri-

sup-

and

design

however,

made

has

in

the

s,

a

OR

BE

IN

OF

of

Westerbeke

between

unavoidable

software

Westerbeke

fea

tur

es

tation.

In

summation,

ducts,

and

whether

cannot

authority

sense,

but

Westerbeke

mine

the

consulted

customers

pr

intings

existence

ed

i t

products

that

be

on

the

is

or

accuracy

by

the

of

ions

fr

equen

product

from

Westerbeke

relied

respective

imperative

the

supplier

and

customer.

should

Westerbeke

of

in

the

include

tly

do

software

upon

that

in

currency

also

earlier,

field.

customer-requested

not

provided

or

exclusively

product.

appropriate

question

of

keep

product

non-current

include

other

the

in

mind

software,

Addi t ionally,

complete

with

Westerbeke

suppliers,

as

It

not

only

representatives

be

consulted

product

the

Westerbeke

the

definitive

makes

software

time

and

special

documen-

must

to

deter-

being

span

the

most

pro-

not

good

of

Page 5

FOREWORD

Thank

at

Read

you

Westerbeke

this

throughout.

procedures,

ment

procedures

equipment

of

efficiency,

in

return.

Should

dealer

to

your

for

provide

performance.

If,

your

below)

writing

within

unit,

registering

with

commission

for

selecting

are

manual

Operating

installation

safely

and

unit

assistance.

the

60

days

you

have

Model

date.

pleased

carefully

are

and

included

properly,

expect

require

support

of

not

your

information,

a

Westerbeke

to

have

and

procedures,

checks,

dependable

special

The

Westerbeke

necessary

submitting

received

warranty,

you

observe

system

herein

maintain

attention,

the

a

including

marine

as

a

customer.

all

safety

periodic

descriptions

so

that

the

performance

Service

to

ensure

Warranty

Customer

please

the

product

precautions

preventive

you

equipment

and

contact

Organization

long-term

Registration

Identification

contact

unit

serial

for

and

can

at

long

your

the

your

use.

included

maintenance

minor

operate

a

high

service

Westerbeke

is

dependable

Form

Card

factory

number

We

adjust-

your

level

life

trained

for

(see

in

and

from: J.H. Westerbeke Corp.

Avon

Industrial

Avon, MA 02322

Park

•

r'~jr

CUSTOMER IDENTIFICATION

Mail

To:

~

Adam

85

Smith

Maple

Alden,

ModeJ_

B'TG

Expires

WESTERBEKE

AV(JfoINOUS'kll"L

rutx

I>A/iiI,

~/"'''''.'~A¥

lel',~~"3~_"CA&1

AV(h

10.1,1.023.'1.

•

Street

IN

12234

9KW

7/7/88

Ser.#1234C706

'I.

,~",~

wfsrc~p

~

,'()(

~

Page 6

Title

TABLE

OF

CONTENTS

GENERAL

GENERAL

SYSTEM

TUNE-UP

INSTALLATION

BT

GENERATOR

OPERATION

SERVICE

ENGINE

DC

CIRCUIT DESCRIPTION

GENERAL

AND

..••••••••.•••••.••••••.••••..

SPECIFICATIONS

SPECIFICATIONS

SPECIFICATIONS

••••••••.••••••••.•••••

.•••••••••••.•••••••••••

•.••••.•••.•..••••.••.•..•.

AND

MAINTENANCE

ADJUSTMENT

•••••••••••••••.•••

INFORMATION

CARE

OF

THE

GENERATOR

ENGINE TROUBLESHOOTING

•••••••••••••••

••••.•••.••.••.

••••••••••..••

.•••.••••••••

•••••••••••.•.

••••...•.

••.•••••••.••.

1

3

4

6

7

18

25

28

32

36

38

40

TIGHTENING

TORQUES

••••••.••••••••.••

42

Page 7

Introduction

GENERAL

This

information

working

planned

the

equipment

step

manual

rna

prog

ram

to

satisfactory

to

order.

in

tenance

life.

contains

assist

Study

will

Proper

result

included.

Understanding

The

to

a

points

gasoline

an

belt-driven,

and

camshaft-driven,

automobile

and

the

Gasoline

engine

engine.

overhead

condenser

thermostatically-controlled

changer

To a great

~equires

would

factors

tilation

system,

system.

extent,

the

give

the

contributing

and

and

the

same

preventive

gasoline

maintenance

generator

the

the

prog r am

repair;

driving

type

a

the

gasoline

to

equipment

operator

and

follow

is

in

better

diagnosis

consequently,

Powered

the

The

cylinders

camshaft.

distributor

pressure

water-cooled

maintenance

engine

the

of

long

the

end.

to

included

equipment

of

Generator

AC

generator

type

engine

in

his

life

fuel

operating

maintain

the

instructions

in

a

problem

are

The

engine

which

lubrication

engine

used

that

automobile.

of

system,

procedures

the

equipment

th

is

manual;

per

formance

is

the

a

troubleshooting

is

in

many

vertical

utilizes

is

horizontally-mounted

block

to

drive

any

responsible

The

the

unit

ignition

carefully.

most

and

system,

the

most

are

system,

as

in

adher

and

important

ways

in-line,

a

with

AC

generator

important

proper

well

proper

ing

longer

table

similar

with

breaker

and

an

ex-

operator

ven-

cooling

as

A

to

is

a

Order

When

tory

serial

of

in

Note

front

ing

contacting

about

number

the

exhaust

order

that

of

Parts

your

to

identify

component

the

flywheel/generator

right

eng

the

Westerbeke

a

This

satisfied

Care

resulted

many

turer

That

ine

left

final

thousands

part

sides

and

side

run

is

done

at

in

cannot

facing

engines

owner.

the

is

your

Westerbeke

Westerbeke

as

they

manifold/coolant

your

locations

engine

or

are

determined

in

is

at

your

and

under

to

various

ensure

A

record

factory

a

Westerbeke

of

hours

control

up

to

the

dealer,

unit,

appear

on

unit.

in

which

is

transmission

by

the

same

left,

dir

the

generator

load

conditions

dependable

of

this

during

assembly,

gasoline

of

dependable

the

treatment

owner/operator.

always

the

nameplate

tank).

the

manual

the

pulley/drive

end

the

engine;

ection

right

sets

are

operation,

test

engine-driven

service.

the

parts

provide

This

is

the

as

side

thoroughly

before

is

maintained

and

unit

distributor,

the

(located

information

are

referenced

rear

imagine

the

at

front

your

leaving

long

thorough

generator

However,

receives

model

on

belt

end.)

straddling

of

right.

checked

service,

at

the

testing,

in

or

number

the

is

necessary

end.

the

and

the

factory.

capable

the

the

the

fac-

surface

from

(The

Left

eng

ine:

given

factory.

and

have

manufac-

field.

and

the

and

the

a

of

1

Page 8

BTG 9 KW

Gasoline

Generator

2

Set

Page 9

GENERAL

MARINE

SPECIFICATIONS

BTG 9 KW

GASOLINE

GENERATOR

SET

Engine

Type

Combustion

Valve

Bor

Piston

Firing

Mechanism

e &

Stroke

Displacement

Order

Direction

Compression

Compression

Valve

Timing

Chamber

of

Rotation

Ratio

Pressure

Gasoline,

in-line

Multi-sphere

Overhead

2.99

60.6

x

2.87

cubic

1-2-3

Clockwise,

9.5:1

177.8

Intake

Intake

Exhaust

Exhaust

psi

Opens

Closes

Opens

Closes

4-cycle,

type

camshaft,

inches

inches

when

(12.5

19·

51·

51·

19·

3-cylinder,

belt-driven

(76 X 73

(0.993

viewed

kg/cm2),

BTDC

ABDC

BBDC

ATDC

liter)

from

at

mm)

the

350

vertical,

front

rpm

Valve

Valve

(eng

Eng

Seat

Clearance

ine

ine

Speed

Dimensions

Weight

Sea

Water

(measured

from

Fuel

heat

Consumption

Angle

warm)

Flow,

at

discharge

exchanger)

at

1800

rpm

Intake

Exhaust

Intake

Exhaust

1800

rpm

governor)

Height:

Width:

Length:

386

lb

4.5

-

1.5

gph

output

45·

45·

0.0079

0.0079

(belt-driven

23.38

18.69

28.25

(175.0

5.0

(5.68

kg)

gpm

lph)

(approximate)

inch

inch

inches

inches

inches

(17.03

(0.20

(0.20

mechanical

(593.85

(474.73

(717.55

-

18.92

at

full

mm)

rom)

rom)

rom)

mm)

lpm)

rated

3

Page 10

SYSTEMS

SPECIFICATIONS

FUEL

SYSTEM

Fuel

Carburetor

Governor

Lift

Air

pump

Cleaner

COOLING

General

Operating

Fresh

Water

SYSTEM

temperature

Pump

Unleaded

(minimum

Down-draft,

Mechanical

12-Volt

lift

Metal

Fresh

or

leaded

octane

single-barrel

type,

electric;

capacity

screen

water-cooled

6

type

89)

ft

gasoline

belt-driven

-

block,

thermostatically-controlled

with

130-lS0·F

Centrifugal

impeller,

sea

water

(55·

exchanger

-

type,

belt-driven

66·C)

metal

(1.8

m)

cleanable

system

Sea

Water

Sea

Water

(measured

Pump

Flow,

at

exchanger)

System

(fresh

Capacity

water)

LUBRICATION

General

Oil

Filter

Sump

(filter

Oil

(engine

Capacity

not

Pressure,

hot)

at

discharge

SYSTEM

included)

at

1800

1800

rpm

from

rpm

heat

positive

impeller,

4.75

5.7

-

qts

5.0

Pressure

chain-driven

Full

flow,

type.

3.0

qts

50 -70

(2.841

psi

displacement

belt-driven

gpm

(5.39

type

(17.98

liters)

with

through

paper

liters)

(3.5

-

rubber

-

trochoid

balance

element,

4.9

18.92

spin-on

kg/cm

Ipm)

pump,

shafts

2

)

Oil

Grade

API

4

spec

SD

or

SE

Page 11

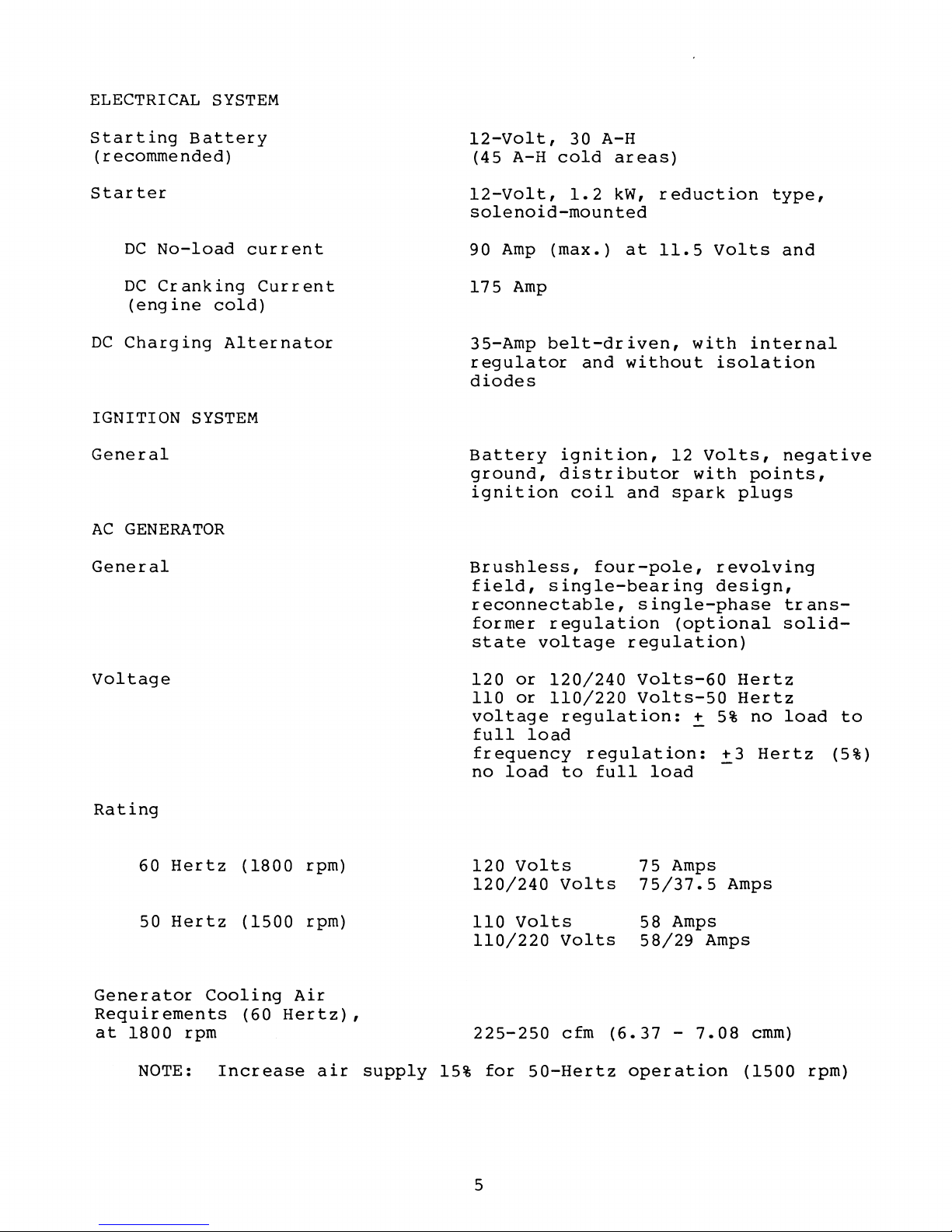

ELECTRICAL

SYSTEM

Starting

Battery

(recommended)

Starter

DC

No-load

DC

Cranking

(eng

ine

DC

Charging

IGNITION

SYSTEM

General

AC

GENERATOR

General

current

Current

cold)

Alternator

l2-Volt,

(45

A-H

l2-Volt,

30

cold

1.2

A-H

solenoid-mounted

90

Amp

175

35-Amp

regulator

(max.)

Amp

belt-driven,

and

diodes

Battery

ground,

ignition

Brushless,

field,

ignition,

distributor

coil

four-pole,

single-bearing

reconnectable,

former

state

regulation

voltage

areas)

kW,

reduction

at

11.5

without

12

and

spark

single-phase

(optional

regulation)

Volts

with

isolation

Volts,

with

revolving

design,

type,

and

internal

negative

points,

plugs

trans-

solid-

Voltage

Rating

60

Hertz

50

Hertz

Generator

Requirements

at

1800

rpm

NOTE:

(1800

(1500

Cooling

(60

Increase

rpm)

rpm)

Air

Hertz),

air

supply

120

110

voltage

full

frequency

no

120

120/240

110

110/220

225-250

15%

load

for

or

120/240

or

110/220

regulation:

load

to

Volts

Volts

Volts

Volts

cfm

50-Hertz

Volts-60

Volts-50

regulation:

full

load

75

75/37.5

58

58/29

(6.37

operation

+

-

Amps

Amps

Amps

-

7.08

Hertz

Hertz

5%

+3

Amps

no

Hertz

cmm)

(1500

load

rpm)

to

(5%)

5

Page 12

Engine

Requirements,

at

Combustion

1800

rpm

(60

Air

Hertz),

32

cfm

(0.906

cmm)

TUNE-UP

Spark P lug

Contact

Dwell

Condenser

Valve

(warm

Timing,

SPECIFICATIONS

Point

Angle

Clearance

eng

at

Gap

Clearance

Capacity

ine)

1800

rpm

0.028

0.016

58'

-

0.27

Intake

Exhaust

14

•

+

-

.036

-

.020

-

66'

microfarad

0.0079

0.0079

l'

BTDC

inch

inch

inch

inch

(0.7

(0.4

(0.20

(0.20

rom)

0.9

-

mm)

0.5

-

rom)

mm)

6

Page 13

General

INSTALLATION

Proper

are

of

Factor

for

exhaust

exhaust

and

electrical

Factors

and

cussed

location

prime

s

the

access

in

importance.

in

the

generator

system

and

in

expel

the

for

this

and

installation

installation

for

to

properly

exhaust

connections.

location

serv

icing

manual.

proper

gas;

that

and

of

that

must

cooling

discharge

cooling

must

repair

the

be

raw

be

considered

s.

generator

considered

and

engine

cooling

water

These

set

water,

supply;

are

factor

in

the

are

ventilation

combustion

quiet

fuel

proper

s

will

vessel

air;

supply;

support

be

dis-

the

There

properly

Location

The

location

areas,

It

should

and

repairs.

as

well.

fresh

Hot

The

to

generator

platform

support

fastened

are

four

secure

and

be

cooling

to

away

properly

The

on

the

it

1/2-inch

the

generator

should

from

Access

location

air

for

discharge

which

generator

at

all

bolt

be

being

ventilated

for

the

the

angles

holes

such

splashed

major

must

generator

air

must

generator

and

of

to

that

be

vessel

(1/2"

in

its

it

by

and

repairs

properly

be

is

securely

7

Mounting

each

mounting

is

..9!..,y,

bilge

accessible

should

end

and

removed

mounted

operation.

Holes)

generator

platform.

above

water

or

be

ventilated

for

from

should

hold

the

water

for

given

engine

the

mounting

low-lying

from

minor

consideration

to

provide

combustion.

generator

be

strong

mounting

rail

vapor

above.

servicing

the

area.

enough

rails

to

Page 14

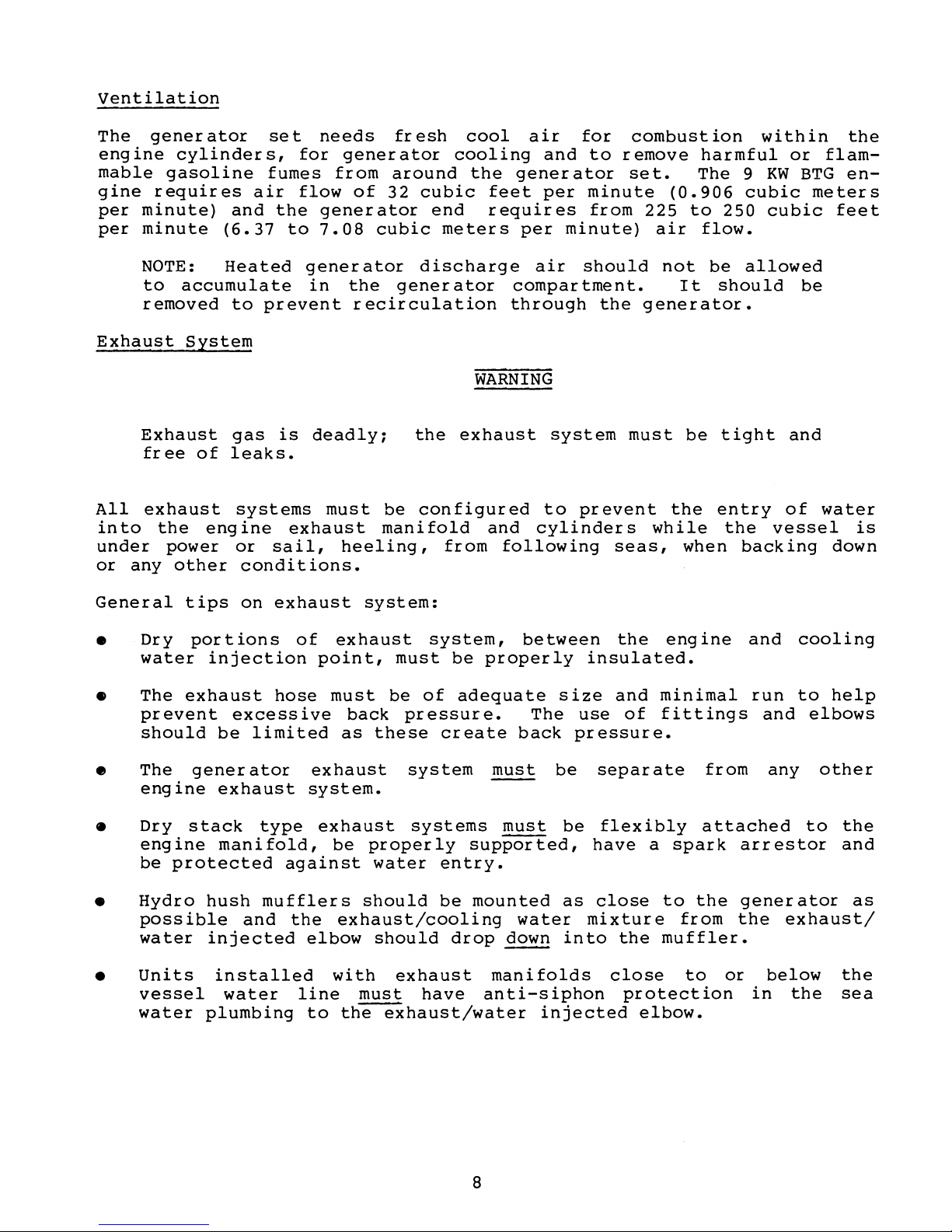

ventilation

The

engine

mable

gine

per

per

Exhaust

All

into

under

or

generator

requires

minute)

minute

NOTE:

to

removed

Exhaust

free

exhaust

any

cylinders,

gasoline

accumulate

System

of

the

engine

power

other

set

fumes

air

and

the

(6.37

Heated

to

gas

leaks.

systems

or

conditions.

to

prevent

is

exhaust

sail,

needs

for

generator

from

flow

generator

of

generator

7.08

in

the

recirculation

deadlY1

must

heeling,

fresh

around

32

cubic

end

cubic

discharge

generator

the

be

configured

manifold

cool

cooling

the

feet

requires

meters

WARNING

exhaust

and

from

air

generator

per

air

compartment.

through

following

for

and

to

per

minute

from

minute)

should

system

to

prevent

cylinders

combustion

remove

set.

225

air

the

generator.

must

while

seas,

The

(0.906

to

not

It

be

the

when

harmful

9

cubic

250

flow.

be

allowed

should

tight

entry

the

backing

within

or

KW

BTG

cubic

be

and

of

vessel

the

flam-

en-

meters

feet

water

is

down

General

•

Dry

water

•

The

prevent

should

•

The

engine

•

Dry

engine

be

•

Hydro

possible

water

units

•

vessel

water

tips

portions

exhaust

gener

stack

protected

on

injection

excessive

be

exhaust

manifold,

hush

injected

installed

water

plumbing

exhaust

hose

limited

ator

type

against

mufflers

and

system:

of

exhaust

point,

must

back

as

exhaust

system.

exhaust

be

should

the

exhaust/cooling

elbow

with

line

to

must

the

system,

must

be

pressure.

these

properly

water

should

exhaust

exhaust/water

be

of

adequate

create

system

systems

entry.

be

drop

have

between

properly

The

back

~

~

supported,

mounted

water

down

manifolds

anti-siphon

injected

insulated.

size

use

pressure.

be

separate

be

flexibly

have

as

close

mixture

into

the

and

close

engine

minimal

of

fittings

a

spark

to

the

muffler.

protection

elbow.

from

attached

the

from

to

and

run

and

any

arrestor

generator

the

or

below

in

cooling

to

help

elbows

other

to

the

and

exhaust/

the

the

sea

as

8

Page 15

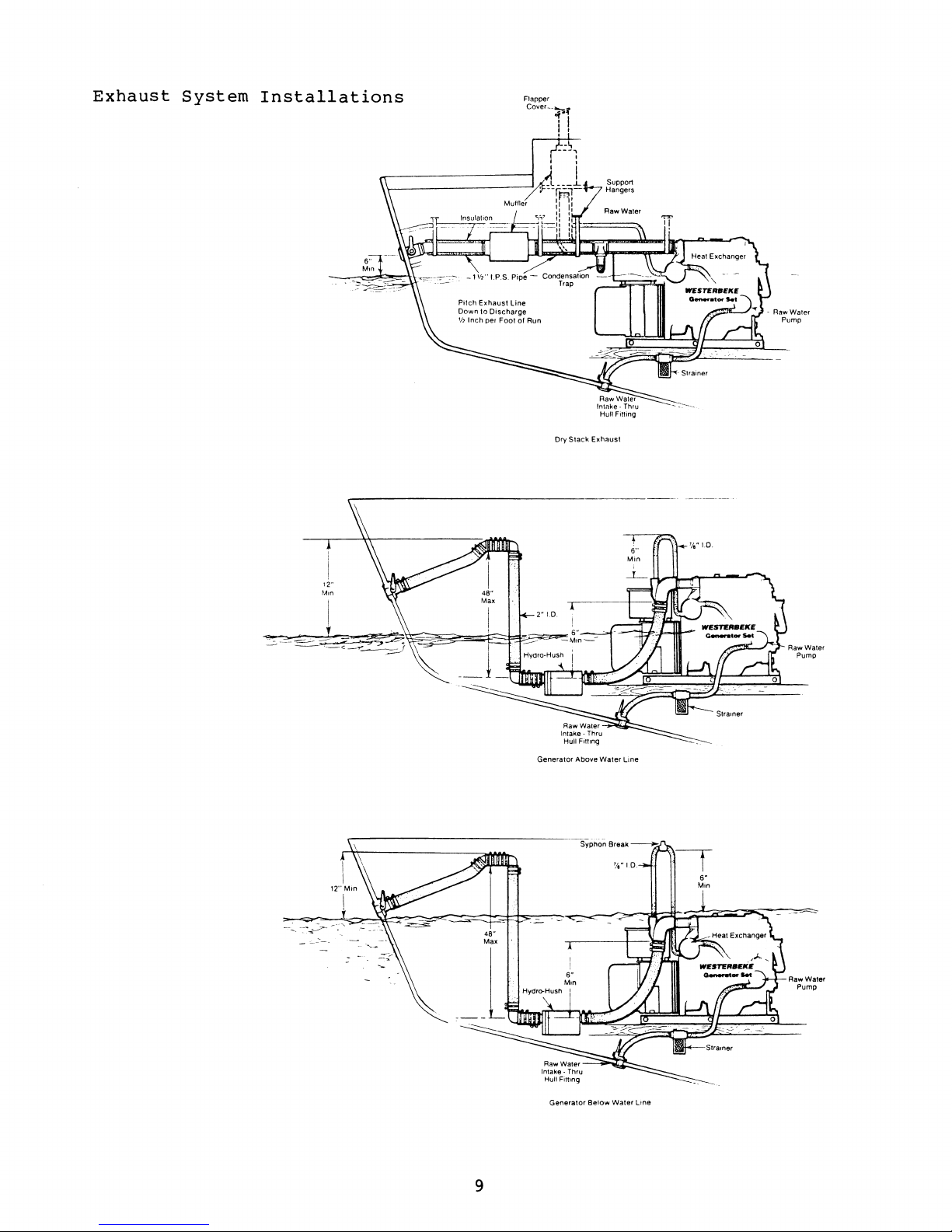

Exhaust

System

Installations

Flapper

Cover_~.f

'1

! I

Dry

Slack

SUPpor1

Hangers

Exhaust

-

RawWaler

Pump

Generator Above Water

Lme

AawWater

Pump

AawWater

Pump

9

Generator

Below

Water

Lme

Page 16

CAUTION

Overcranking

amounts

Exhaust

discharge

cranking.

and

starting

Fuel

System

Gasoline

potential

promptly

The

tank

fuel

and

Anti-Siphon

siphoning

tank

a

when

fitting

connection

designed

then

supply

not

action

there

loosens

and

and

with

of

cooling

gas

pressure

accumulated

Shut

open

and

correct.

leakage

cause

and

ensure

to

teed

off

Protection

that

is

to

the

installed

no

off

thru-hull

once

started.

in

of

the

generator

the

is

permits

a

break

create

connection

to

engine

water

may

water

or

around

fire

the

compartment

supply

the

or

a

protect

pumped

not

during

water

Investigate

WARNING

the

and/or

should

to

term

fuel

applied

to

rupture

leak

to

the

against

start

in

always

generator

explosion.

be

another

continue

in

in

the

engine.

results

to

periods

supply

is

properly

from

engine.

to

the

fuel

line

fuel

the

exhaust

be

until

reason

compartment

its

the

to

flow

supply

between

Fuel

siphoning.

in

sufficient

of

unit

(s)

Repair

ventilated.

own

means

out

systems

excessive

system.

excessive

starts

for

hard

is

leaks

pickup

of

preventing

of

the

line,

the

fuel

----

to

a

in

or

must

the

fuel

when

tank

be

The

illustrations

publication

layouts

NOTE:

shut-off

line

The

fuel

vibration

inches.

A

filter/water

between

water

and/or

The

that

must

from

engine

fuel

water

not

with

is

line

and

Use

the

tank

Fuel

anti-siphon

Anti-siphon

valves

routed

should

chafing.

as

separator

fuel

the

fuel,

failure.

vent

cannot

be

shown

System

must

below

few

connections

tank

should

enter

allowed

on

Compliance

be

routed

The

is

and

both

be

the

the

following

protection.

devices

be

installed

the

top

and

line

recommended

eng

ine,

of

which

routed,

fuel

to

tank

accumulate

Guideline),

or

level

supported

should

in

the

to

are

and

(s)

page

(taken

show

electrically-operated

when

of

be

supply

for

remove

prime

the

through

the

the

fuel

to

supported

line

use

harmful

causes

discharge

in

fuel

prevent

in

the

the

the

from

basic

distribution

tank.

every

as

possible.

fuel

debr

of

fuel

located,

vent.

vent

Coast

fuel

leaks

12 -14

system,

is

system

so

Moisture

Guard

system

fuel

from

and

that

line.

10

Page 17

Basic

Fuel

[UE

~

T AN

System

FUEL

~

TO

Layouts

LINE

ALWAYS

P--DLE!!",V_E_L_-==....:!!:..=.=!",,"=,_

NO

with

ABOVE

....

ANTI·SIPHON

Anti-Siphon

FUEL

TANK

TOP

LEVEL

_=~~=-====:=.~~:.-:-

DEVICE

OPERATED

VALVE

__

OR

NEEDED

Protection

-::-='::=:-:=:-=-=~~-:-d

ELECTRICALLY

ANTI·SIPHON DEVICE

VALVE

FUEL

TANK

TOP

~

ANTI·SIPHON

STOP

GOES BELOW

ANTI·SIPHON DEVICE

0-,.---- OPERATED

FUEL

liNE

BELOW

OR

ELECTRICALLY

AT

FUEL

TANK

WITHDRAWAL

LEVEL

FUEL

VALVE

DEVICE

AT

FUEL

OR

POINT WHERE

TANK

OR

ELECTRICALLY

FUEL

STOP

VALVE

------;p

FUEL

FUEL

TANK

TOP

OPERATED FUEL STOP

FITTING

LINE

BELOW

TOP

LEVEL

ELECTRICALLY

FUEL

DISTRIBUTION

TOP

LEVEL

TANK

TOP

LEVEL

ANTI·SIPHON

J OPERATED

FUEL

TANK

OPERATED

LEVEL

FUEL

LINE

DEVICE

FUEL

OR ELECTR

STOP

VALVE

--I

ICALL

Y

11

Page 18

Fuel

system

alcohols)

in

the

components

blended

component

must

fuels.--pailure

failure

and

be

compatible

possible

to

ensure

injury

with

oxygenate

compatibility

to

the

user.

(butanes,

will

result

The

pump

use

is

discouraged.

on

debris

ing

pressure

Cooling

The

generator

exchanger.

pumped

the

exhaust

engine

The

and

it

sea

sea

through

ting.

brought

water

the

strainer

pump.

thru-hull

and

be

to

wire-reinforced

collapse

water

tion.

pump

Sea

mounted

so

as

to

of

the

under

System

into

fresh

water

water

This

through

fitting

the

from

water

at

be

check

eng

ine

their

for

engine

Sea

water

the

exchanger

discharge,

water

pump

should

a

flush-type

sea

and

Hoses

sea

the

during

or

below

always

valves

Check

to

seats,

check

valves

is

system.

is

be

water

a

visual-type

then

routed

to

water

suction

generator

strainers

the

self-primed.

in

place

valves

draw

defeating

fresh

is

used

by

carrying

belt-driven

supplied

hull

should

delivered

from

the

strainer

pump,

to

of

should

water

of

may

fuel

will

through

contribute

water-cooled

as

the

a

sea

with

to

fit-

be

sea

to

the

should

prevent

the

sea

opera-

be

line

the

tax

their

exchange

water

it

Longest Span

solenoid-type

the

ability

them.

purpose.

to

by

an

pump

the

Belt Tension

3/8-1/2 Inch

Deflection

and

heat

at

shut-off

of

the

Also,

Too

vapor

lock

engine-mounted

cooling

medium

then

removed

fuel

they

high

shutdowns.

injected

valves

can

a

crack-

and

from

lift

trap

heat

is

into

the

Do

not

hull

supply

fitting

to

pressure

fitting,

underway,

the

sea

water

the

generator

Flush-type,

be

located

angles

The

of

use

plumbing

restrictive

use

the

while

can

boat

of

the

CAUTION

a

scoop-type

for

generator.

against

the

push

pump

impeller

exhaust

clear,

on

the

operation.

common-type

sea

inside

the

this

vessel

water

thru-hull

hull

water

diameter.

thru-

sea

water

Water

and

system,

so

as

street

circuit.

type

is

past

in

to

fittings

to

12

filling

be

below

elbows

These

Machined

it

are

the

is

fittings

and

the

engine

recommended

waterline

not

recommended

generally

are

as

and

during

have

preferred.

well.

should

all

a

very

for

Page 19

Automatic

Shutdown

High

An

open

Exhaust

exhaust

the

perature,

switch

22S·F

High

A

high

stat

the

ture

19S·F

Low

A

low

opens

(107·C).

Water

water

housing

generator

reach

(approximate).

Oil

oil

gallery

maintaining

shut

the

Exhaust

Temperature

temperature

ignition

indicating

at

260

Temperature

temperature

to

sense

should

approximately

Pressure

Shutdown

pressure

and

is

the

closed

electr

generator

Back-Pressure

switch

circuit

a

-

270·F

the

shutdown

down

Shutdown

should

lack

of

(127

Shutdown

switch

fresh

water

engine

20S·

Switch

when

ical

when

eng

run

engine

is

proper

Switch

is

fresh

F

switch

ine

located

(96·C)

circuit.

Switch

the

sea

-

l32·C)

(normally

located

coolant

water

+

-

(normally

is

oil

pressure

oil

(normally

on

the

switch

water

and

in

temperature

coolant

S·.

open)

located

This

pressure

exhaust

sense

coolant

resets

closed)

the

This

reaches

switch

drops

closed)

excessive

at

area

of

operating

switch

in

the

to

elbow

and

flow.

approximately

the

thermo-

and

shut

tempera-

resets

engine

10

-

IS

will

open

10 -IS

will

tem-

This

down

at

oil

psi,

and

psi.

Exhaust

prior

vice.

cessive

back-pressure

to

(Refer

back-pressure

performance

Measure

elbow

back-pressure

with

Back-pressure

over

39

at

1-1/2

3

inches

4·

C},

psi

inches

Excessive

by

small

muffler,

pockets

exhaust

Oil

Drain

An

oil

end

drained

the

or

system.

sump

secured

from

hose

tainer.

pump

added,

putting

to

the

and

generator

generator

(manometer)

of

mercury

of

water

22

ounces

(967

kg/m2).

back-pressure

diameter

sharp

high

bends,

volume

drain

by

a

this

from

The

the

hose

for

should

a

generator

illustration.)

will

power

at

under

(0.104

column

per

square

can

exhaust

fittings,

of

hose

is

bracket

hose

by

suppor t br

cap

fitting

easier

be

into

affect

output.

the

full

should

kg/cm2),

(0.099)

be

hose,

water

installed

at

the

removing

acket

is

checked

ser-

Ex-

engine

exhaust

load.

not

kg/cm

inch

caused

small

water

in

the

on

front

the

and

1/4-NPT

removal

be

2

or

the

of

cap

lower

engine

the

and

ing

and

of

engine.

the

the

can

oil,

Mercury

Manometer

with

the

discharge

hose

be

extended,

if

/,Exhaust

\

discharge

Oil

in

to

desired.

Exhaust

Elbow

may

end

a

con-

or

be

of

a

13

Page 20

DC

Electrical

Connections

A common

generator,

stud.

Connect

for

this

To

failure,

engine

Grounding

The

Guard

connected

engine

prevents

and

Optional

tor

generator

regulation

smaller

must

ground

next

It

is

recommended

battery

connection.

avoid

do

is

between

grounded

accidental

electrical

be

the

Remote

for

to

positive

an

overcharg

not

running.

set

must

33CFR-183

the

starter

same

Start/Stop

negative

the

starter,

that

(+)

ing

disconnect

be

grounded

generator

motor

passage

conductors

size

as

(-)

the

to

CAUTION

which

circuit.

of

the

Panel

DC

is

in

the

battery

the

condition,

the

DC

to

specifies

set

cranking

largest

and

and

common

Instrument

found

form

starter

battery

comply

the

This

current

to

battery

at

of

ground

solenoid

and

poss

with

that

vessel's

conductor

the

the

bellhousing

a

threaded

be

connected

ible

source

United

a common

through

engines.

cable.

Panel

terminal

equipment

while

States

conductor

main

(common

propulsion

fuel

This

of

the

grounding

here.

tagged

the

Coast

be

ground)

systems

conduc-

An

optional

switches

will

is

engine

connected

panel.

start/stop

galley.

An

an

engine

can

panel

tored

*

sizes

glow

depressed

optional

engine

be

and

and

35698

for

remote

and

starts

(Refer

operating

wired

and * 36397

a

when

to

(a

to

the

panel

instrument

oil

pressure

to

mounted

the

switches

specific

the

start/stop

green

ON

engage

signal

terminal

to

wir

can

hourmeter

the

terminal

at

for

wire

be

the

RUN

indicator

switch

the

to

ing

diagrams

mounted

panel

gauge,

and

location

operated.

proper

lengths.)

panel

is

starter,

release

blocks

is

water

start/stop

blocks

connection

is

available,

light.

depressed,

and

the

START

in

the

*

35706

in

areas

available

temperature

in

where

(Refer

on

This

dim

then

generator-mounted

and * 36397.)

such

control

the

the

to

poin

when

glow

switch).

as

which

gauge,

switches.

generator-mounted

instruments

the

DC

ts

and

which

RUN

indicator

the

br

ight

This

the

wheel

is

supplied

DC

wir

ing

recommended

are

START

when

panel

This

house

voltmeter,

This

can

be

schematics

mounted

light

switch

the

is

control

remote

or

with

panel

control

moni-

wir

e

14

Page 21

I-'

\J1

OPTIONAL

R,MOn

STAhT

PANIL(RtJ\R

VI'W)

PN

33703

,-

--

-----

- - -

---

---

--

----

-----------1

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I w

I 0..

I

0:

l-

V>

0:

::l

0..

i

D

W

0:

L_

MINIMLJ~1

WIBE

GALJCES

[)

,~

STOP

'>TAR!

'IlRtU/W/PUf,

snllP,

""IG

lit.O

~

[il

-\

tilfHO

IN/PIJH

"TR

IPC

<r

~

n.

~

k.W

Be

?I'·'

,

a

l£

,.J

I-

G.SKWBC

119K~.JBT

<;1::1:.

D~,'G.354Y:lH.SEE

l.A/C

36397

0:

'"

.1

'12

HL!wlR,O

-

16

PURPL

I:

STRIPE

;1

1

.~

"'2

R£O/W/PUf,ru

...

TO

T2·1

,

19A/-IP STARTiNG

T4-1

I

6 AMP

RUNNING

I

1

0

T4

_

2

I

l-----.:J..±J:~npLt:__________..

TO

T2-2

:

£'

AMP

I

I

0

~

I

I

T4-3

,

I

I

I

IQ

G

I

14-4

I

,

,

I

€}-

___

~~~BLACK

__

•

TO

T2-5

T~-5

I 2

AMP

I

,

,

I

-----------------------~

121\t-If'

STARTI'!!>

Rl2

,(El/\

...

JI~F.r

~ThlPl

..

TO

1 I 2

l~

AMP

!::>TA.RTIt~G

L.------.:

b

ANP

rtUt<.,

~I

~;;G:------------------;;·c-J=

2HrH'-;J7T.\"J/npC-;U"'''-;SC;T'''k-;'I-;-E~''

TO

T

1-1

Ii

TO

T B I 2

II

TOTB32

II

TO

TH

3 5

TO

TB3

3

TO

TBI

I

WIRE

LENGTH

FROrol

GENERATOR TO

PANEUFTI

WIRE

r=)~~

~~~~0~()'o~~-I{~~~{t~'-~40t-~/iI50-~6S

-

GAUGE

---

--

----

----

----------

IAWGI

14

12

12

10

10

9 8

,""

..

mulw

E

SfEPBEI(.

E CCrlF'OPATICJN

~:~'.~'.~'=

---A-VQ!L-~!:!lA;,""Ot:···

JU

-

,''-- NTS -:;:;;;:;;..-;;-;;------

___

________

__

.L

.........

'"''

WIRING

DIAG

R<MOTE START

~_

h·~:~'~J~~~-:~-l~~~O

6

IL--

__

_

::0

CD

8

rt

CD

rn

rt

IlJ

1"1

rt

'i:I

IlJ

;J

CD

I-'

::E;

.....

1"1

.....

;J

lO

o

.....

IlJ

lO

1"1

IlJ

S

::tI=

W

VI

-...J

o

0'1

Page 22

I-'

m

!!.!!ill:!&.

~

r-·~-,§'\

-IOvIiN

~

BATTERY

~~

T~~,~.

bIlTO~ItD

;t·.,

..

BlOO'

I

)1/

STARTER

~

.-

f.I'KU,T

b~[A"ER

,-----~

G;'ttn-o

,

I"NIT,ON

COIL

·'.Pvll./"'HT

~TII.

j[:~

~~~~,

<

fr(~-,·-j

, :

Ol~

PAt:.,S I

')

:.-

:."l1,Tl-llilUTOR

~

~[.!.j~E~

__

J

4----,

i

*'\T-EA~

OPTIONI\L

BALLAST

RESI!:>TOQ

I TEMP I

ir'Of:j

OPTIONAL

"141'l'1I

r

~f1

,.

(Hlll<E;(l,\f,.flJ

"'L~_JJ

,.

~lJL[N<JlO

(,

&.hH)

'rE.

~,J

t L

; .

'U'"

~~~~'Hl~S

il

~:

~

I I 1

.....

~~,

"."

--+t-+-~-I-~~-"

~~~~~ST 1 ~--_---,

~

LI+--+_

fOR

(J)"N(CTlON!>

TO

"'040T[

~r"'lIr

..... U

A(MOl( , ..

!>TIlUHlNr

P'II'Iu.!>,'j,1:t

UII-.moG"

}!iIOto ~ .¥.I,,'J8

·'4P,,1I.

T8-3

TB-2

""1"

~

• ....

61.

"'';'(lllltDSII-,P,

·,,,p"i;

~

"~

IItU/~u~

~'~,P!

r+-

r--

..

E~J

:ll)

I~

l,Ci]

HI,",OVE

THI';,

JIJMl-'lR

'WHE'"

II

.

"-

il~~'~'

L-_-"'..::"":~'''';~'''''"-''''''''"'"'-'

+-HI---+------~-+~.Lr)l

I 2 1 B I

.'4

R(OI~'1,J1<

'.T~I~1

.

_-'

'"",,

~:ttJ

?~,"':,~';'lU

~~

~_j

11

~_

.

L

·'4~,

[)

~ll~DC

:n''''.11

~w

:(:(8

. :

~t!!=:MA!l£

[)t"t>RA~

_________

~l~~;

~~{-.--------

t '

----'Cf)';{--·-----~

""I~/'

"

! ,

flU,,"

t .... ,

....

I"."I-;;::::;:;C;o TI''''''"'

.... L ......

'

~

N·

;;;

.-1;:;-""1

"'

......

,.ri

't':

:.'"~

:

";

'"V-I\" --..

-I----.bP.

,",v---":\:

----.0.)1

r

x.

____

_

@--@

+·-e'~"~

':>TOl>

!oW.

FU",-[

l

15A

S8

HC.U~Ml1ER

STMH

SW

ru';o[

I

"

UU

SWITCH

~i

-]

"~!J:~~.

--~-

-0;:~-

tot.UA;T

II(!.I!.TOJI

1 S

COOL

~ ~1~l~I~L~!~

~"~l4':~l

:~'-"'"-

12

~~-:v~:;--·-i

0-

t-~:=-=

, I

~RII

• I

Pl.ur.~

lfJ-

r

t-··

-~--L

__

J

TI"'i~

-""-

'<~E:-----

fI:!l~l!.""

';:H-----

I.

WESHkuEKE"

GASULINE MARINE

GENEH.ATUR~

AS SHIPf.'ELJ

HUlM

HIE

FA(;TUky

AND

!:xClUStvE

OF

OPTIONAL

Ht-MOlt

IN~TRlJMEIH

(JH

ClJNTHOI

PANELS

l)JMI'lY

WITH us. COAST

GUARD

..

B(;F1-I183,

ACl:ES::iOHY

INSTkUMI:::Nl

ANO

WNTROl

PANHS

DvNUT

NECESSAlmy

SO

COMPLY

AND

"'~E

INHNOtD

TO

BE

INSTALLED

A~OVE

DECto;

ANO'lsm

AHD

FROM

GA::.OllN[

SuuRCES"IN

ACCuHuANCE

WITH

33CfR

183.41014

IT IS THE

I~ESPUNSlbILiTY

Uf

THE BOAT

MANUFACTuHl:n

TO

ItlSUH[

THAT

THE

INSTALLATION

Of

TIU:.~E

GENrf(ATOr~S,ANO

OPTIONAIl.Y,

TliEIU

REMOTI:. INSTHUMl:.NT

lit;

CONTROL

PANEl.S

CQMPL Y

WITH

3.KFH

HB.

c..THIS PROOUCT IS PH.Un.CTEU

BY

A MANUAL

H[StT

Clr~ClIIT

BlUAKlR

lOCATED

Nt:AH

HIE

SlARTER

ANO

AS

ClOSE.

,),~

PQS-::'IBI E

TO

TItl

SUUHCt

OF

CURr~lNT.

[){C[~SIVE

CuRk£fH

URAIN

ArlYWIiER[

IN

THE

INSrHlJ~llNT

PilNEL

,WI~ING

OR

cN&INl

Will

CAU::.E

THE

B~lAKEH

TO

11~1P.

INTHIS

lV[NT

Ttit. I:.N(,INE

WilL

StlLJT

LoOWN

BECAUSE THE

OPENI:.U

8RlAKEH

Will

j)lScONtH:CI

THI:.

fUE.l

SUPPL.Y.

lHl:REFUHE

THE

BUILDfR

laWNER

MUST

BE

SURE

IHAl

fin.

INSTHU"",ENT

t'ANEL

,WIRING

ANU ENGtNE

ARE

INsrALU:D

TO

PRt.VI:.NT

CuNTACl

BrTwUN

£1

FCIHICAl

UEvlCES

AND

SALT

WATER.

3.AN

ON

Off

SWITCH

MUST

BE

IWiTAl1

t:D

TO UISC;ONNI (;1

HIE

STARIEH

FROM

THE

I:JATT£RY

IN

AN

fMEH(.[NCY

ANU WHEN

HAVIN(3

ltit

&OAT.

TWHVI:

VOLT STARTI:.HS

TYl-llCAllY

UfoIAW

~OO

TO

j(){J

At-IFJS

WHEN

CflMIKIN(.,. 1 liE

DUI-lA1IOt4

Of

INDI

....

IUUAL

CRANt(INll

{.;Y(,LES

SHOUlD

NOT

EXCI:.E:D

jO

~rCONDS. A ~WlrCIi

WITtI

A C(,NTiNUlJS

kATIN

...

OF

I7~AMP~

AT

12VULTS

Wilt

NOIIMALLY

~U-/

....

E:.

1HtS

HJNClIUN,BIJT

A

~WITCH

MUST

NOT

~E

USED

TO

'MAI\E" THE

CIHCUIT.

4.SENDER::i

AHE

SUPl'lIE:.O WITH

OPliONAl

INSTIHJME:NT

j'ANH.

[

~1

..

~P.\\'·~"!l"l'''~

__

..

__

INTS

"~WIR'NG

O,.GJ:::k:;,J.

---_ ..

~~J~~1Jif..

Ci<J!iRill

________________

u_~___

IO.~~

36397

g

~

.....

M

.....

::s

U)

0

.....

III

I.C

M

~

=tI=

W

m

W

\0

-....J

Page 23

......

-...J

9KW

BT

SEE

DWG.36397

TO

T81-

2

TO

TB3-2

TO

T82-1

TO

T82-2

TO

T83-S

TO

T81-1

TO

T63-3

'r

It P[I(>i 0

9KW

fe"oIl"'loIAL _ .Jl}

,.. ,

PI

()PClAie-

'>

GAGe

t..JIllill!oIC,

..lJ

REMOTE

INSTRUI'IENT

PANEL

(REAR

VIE,,j)

ASS'Y

PN

33/02

r

--

- -

--

-

-----

---

- - -

--

- -

-----------

-------------1

I

I

I

I

I

I

I

I

I

4KW

BC

I

REo/W/PURPLf

STRIPE

r--

In.

~

STOP

r-$

~

ot-

L---

START

~

~2REo

I

Lj"1/w/PUR

ON

STRIPE

"12 Yi:L

'wi

n

EoSTRIPE

6.!)KW

BC

I

.12REo/W/PURPLE

SEE

0\'/6.

3!)<;39 STRIPE

. 'tZREO/W/PUR

T4-1

'12REO/w/pUR

"mlPe

I

TO

T2-1 19AMP

STAR

6 AMP

RUN

"16

PURPLE

OIL

PRtSSuRE

~

-16

Bl

ACK

'16

PURPL

E

~

I

"14PURPLE

T4-2

il6PURPLE

---f.----+--+----1

TO

T2-2

2AMP

'16

BL

ACK

,----

I

~16LT.BLUE

I

"14LT.&LUE

T4)/

TO

T2-3

~

'"

u

«

--'

II' T4-4 I

~I

TOT2-4.

I

14

TAN

EIEI

.'16TAN

TO

T2-5'

:

"14BLACK

I

s

T4-

e

,t/

"16BLACK

I 2AMP

I

I

TO

TI-I'

:'12 puR/wiRED 19AMP STARTING

STRIPE 6

AMP

RUNNING

TO

T1-2.

1"12

vEL/wiRED

12

AMP STARTiNG

STRIPE

I

H

&

T3-2

~

8

D·I

~

I~

--'

IL---..J

HOURS

"IG

PURPLE

r 0

-~

.~

VOLTS

+

w

--'

a.

<r

::>

a.

<D

.-

L

__

_

---

-.---

----

-

--------------------

-

___ ------

___

--1

WESTERElEKE

CORPORATION

MINIMUM

WIRE

GAUGES

- -

WIRE

LENGTH

FROM

GENERATOR

TO

PANEL

(FTl

AVON

MA

02322

A.-

~~~~E

':!"

"t

:~~'~i;l}fi:

"i"

35698

(AWGI

~

(D

5

rt

(D

H

::;l

Ul

rt

1"'1

C

:3

(D

::;l

rt

to

III

::;l

(D

......

~

.....

1"'1

.....

::;l

I.C

t:1

.....

III

I.C

1"'1

~

=It:

W

l.n

0'1

\0

(Xl

Page 24

BT

GENERATOR

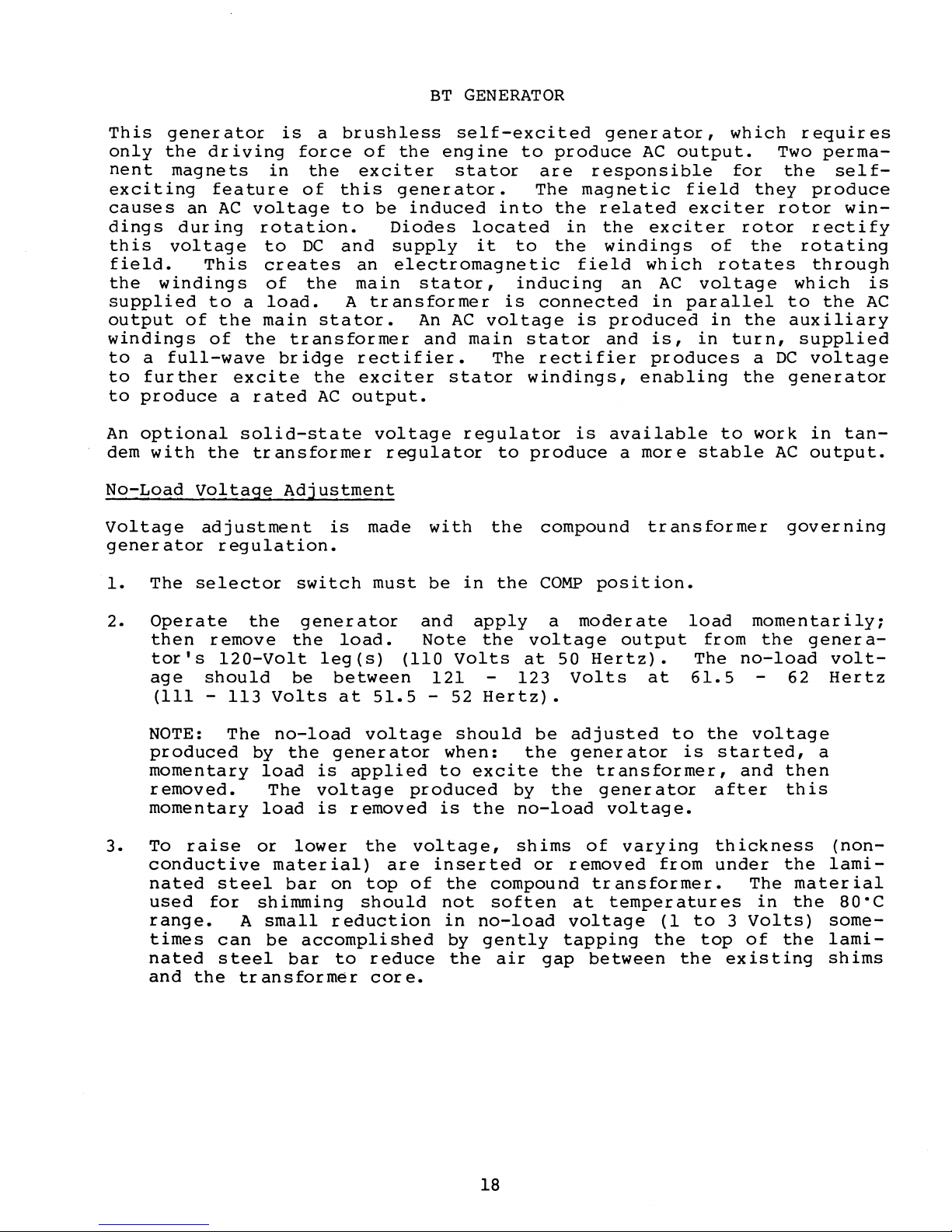

This

only

nent

generator

the

magnets

exciting

causes

dings

this

voltage

field.

the

windings

supplied

output

windings

to

a

full-wave

to

further

to

produce

An

optional

dem

with

No-Load

Voltage

generator

1.

The

driving

feature

an

AC

during

This

to

of

the

of

excite

a

the

Voltage

adjustment

regulation.

selector

is

a

force

in

the

of

voltage

rotation.

to

DC

creates

of

the

a

load.

main

the

transformer

bridge

the

rated

AC

solid-state

transformer

Adjustment

switch

brushless

of

exciter

this

to

and

an

main

A

stator.

rectifier.

exciter

output.

is

self-excited

the

engine

stator

generator.

be

induced

Diodes

supply

electromagnetic

stator,

transformer

An

AC

and

stator

voltage

regulator

regulator

made

must

with

be

in

into

located

it

is

voltage

main

The

to

the

the

to

produce

are

The

the

in

to

the

field

inducing

connected

is

stator

rectifier

windings,

is

produce

compound

COMP

generator,

AC

responsible

magnetic

related

the

exciter

windings

which

an

in

produced

and

is,

produces

enabling

available

a

more

tr

position.

output.

field

exciter

of

rotates

AC

voltage

parallel

in

in

to

stable

ansformer

which

for

they

rotor

the

the

turn,

a

the

work

requires

Two

perma-

the

self-

produce

rotor

rectify

rotating

through

which

to

the

auxiliary

supplied

DC

voltage

generator

in

AC

output.

governing

win-

is

AC

tan-

2.

NOTE:

momentary

momentary

3.

To

conductive

nated

range.

nated

and

Operate

then

tor's

age

(Ill

remove

120-Volt

should

-

produced

removed.

raise

steel

used

times

for

can

steel

the

the

generator

the

be

113

Volts

The

no-load

by

the

load

The

load

or

lower

material)

bar

shimming

A

small

be

accomplished

bar

transformer

load.

leg

(s)

between

at

voltage

generator

is

applied

voltage

is

removed

the

on

top

should

reduction

to

reduce

core.

(110

51.5

are

and

apply

Note

Volts

121

-

52

should

when:

to

excite

produced

is

the

voltage,

inserted

of

the

not

in

by

the

the

voltage

at

123

Hertz).

be

the

by

no-load

shims

or

compound

soften

no-load

gently

air

gap

a

moderate

50

Hertz).

Volts

adjusted

generator

the

transformer,

the

generator

of

removed

transformer.

at

voltage

tapping

between

load

output

The

at

61.5

to

is

voltage.

varying

from

temperatures

(1

to

the

top

the

momentarily;

from

no-load

the

voltage

started,

and

after

thickness

under

The

in

3

Volts)

of

existing

the

62

then

this

the

the

genera-

volt-

Hertz

a

(non-

lami-

material

the

80·C

somelamishims

18

Page 25

Greer,

'fl.....

N~

2 A

Blue

Terminal

1201240V

YelloV'.

o

a=n

0 7 9

60

80

~

3 0

100

L·

BloCK

COf"\nections

60hz

Blacio\

o-L,

Blue

I Selector

~

~

VOltage AaJustmen:

+--+---Transtormer

Compound

Under

age

and

forces

operation

output.

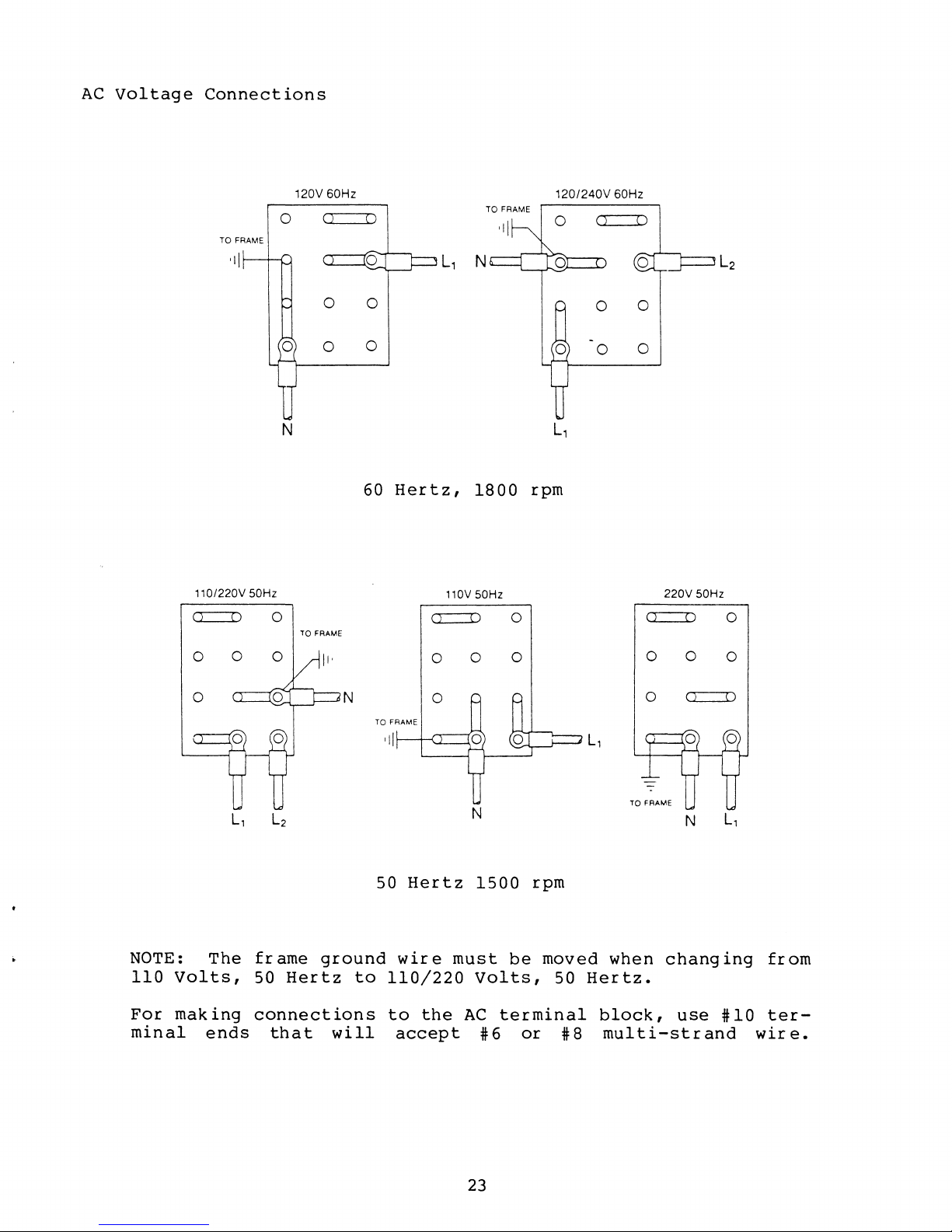

4.

To

bolts

transformer.

load

lower

Illustration shows terminals

connected for

60

transformer regulation

no

by

the

created

remove

from

voltage

the

Hertz on compound

120/240

circumstances

increasing

transformer

within

may

the

close

laminated

the

compound

The

and,

no-load

volt

attempt

the

gap

core

the

steel

addition

conversely,

voltage.

CAUTION

to

between

without

the

air

transformer

gap

bar,

transformer

of

shim

the

Opllonal

Voltage

Regulator

Blue

& White ' I

Wh

G &

reen

Yellow & White ~ C-Black

increase

the

the

use

and

reduce

remove

and

thickness

removal

t

Regulator

Plug

'C":'-Blue

- "

..

,1

Ite

/ Yellow & Black

~

~~

- I Red & White

the

no-load

laminated

of

shims.

dur

ing

no-load

the

lift

two

the

will

of

shim

& White

& White

steel

Magnetic

generator

voltage

upper

bar

raise

thickness

volt-

bar

securing

from

the

the

no-

will

Varying

load

shim

voltage

thickness

by

4

by

.001

to 6 Volts.

inch

19

(0.025

mm)

will

change

the

no-

Page 26

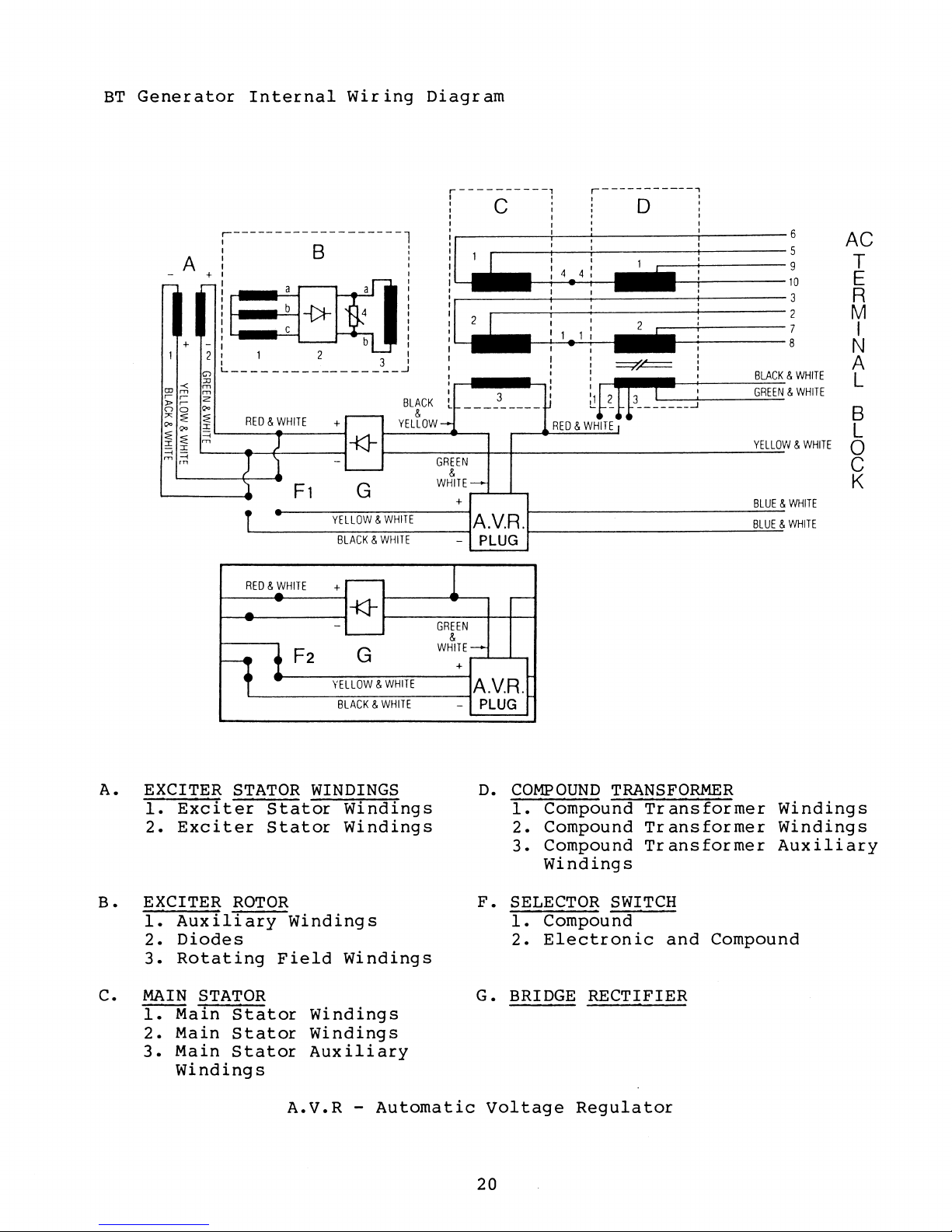

BT

Generator

Internal

Wiring

Diagram

A

+

1-

1

-

+

1

2

~

:JJ

m

m

"';;;

, ,

;z

:»,

Qo

00

~

""~

QoQo

I

::::;

~~

m

~I

--<

-

m--<

'"

,-------------------1

B !

_a

-{)t-

a

4

1==:

-

1

L

_________________

RED & WHITE

)

-

)

'1

1

t

RED & !HITE

...

!

1

F1

F2

b

2

+r--

-

'---

*

3 I

G

YELLOW & WHITE

BLACK & WHITE

+-

-

-

*

G

YELLOW & WHITE

BLACK & WHITE

yELLOW

I

I

I

I

I

I

I

I

I

I

I

I

J

BLACK

&

r----------,

: C I : 0 :

I

I "

I I I 6

I

l~

I

I

I

I

I

I

L

.....

GREEN

&

WHITE-

3 I

_________

+

A.V.R.

-

PLUG

1

GREEN

&

WHITE-

+

~

r-----------,

I'

I

I

i

11

i

I • I

I

I

I

I

I

0

RED & WHITE

...

I

I

=TF=

I

~f~

tI3--L---J

I

.

i

I

I

I

I

I

BLACK

GREEN

YELLO

BLUE

BLUE

A.V.R.

-

PLUG

&

WHITE

&

WHITE

W &

WHITE

&

WHITE

&

WHITE

AC

T

E

R

M

I

N

A

L

B

L

o

C

K

A.

EXCITER STATOR WINDINGS

1.

B.

C.

Exciter

2.

Exciter

EXCITER

1.

Auxiliary

2.

Diodes

3.

Rotating

MAIN

1.

2.

3.

STATOR

Main

Main

Main

Stator

Stator

ROTOR

Field

Stator

Stator

Stator

Windings

Windings

Windings

Auxiliary

Windings

A.V.R

Windings

Windings

Windings

-

Automatic

D.

COMPOUND

1.

Compound

2.

Compound

3.

Compound

Windings

F.

SELECTOR SWITCH

1.

Compound

2.

Electronic

G.

BRIDGE

Voltage

RECTIFIER

Regulator

20

TRANSFORMER

Transformer

Transformer

Transformer

and

Compound

Windings

Windings

Auxiliary

Page 27

Optional

An

optional

for

use

switch

with

vol

the

tage

Installation

1.

The

case.

to

mount

2.

Connect

lator

voltage

solid-state

with

is

moved

standard

output.

regulator

Use

the

board.

the

the

Regulator

9

KW

to

the

compound

is

(2)

M4

regulator

6-prong

voltage

BTG

generator.

ELEC

mounted

x

0.7-mm

generator

regulator

position,

transformer

using

screws,

board.

plug

When

regulator

existing

15

to

(board

installed,

the