Page 1

OPERATORS

. -

-

8~:5;!Kw.

..

BTG

·,

50Hz

MANUAL

·6.8Kw

BTG

50Hz

8.5Kw

12.5Kw

15.0Kw

MARINE

BTGA

BTG

BTG

GASOLINE

~,.._.

rWESTERBEKE

J

J

MYLES

WEBSITE:

am.,_.

NAIHA

......

6,0Hz

60Hz

6.8Kw

10.0Kw

60Hz . 12.0Kw

GENERATORS

PUBLICATION

REVISIONS

-MARCH2018

WESTERBEKE

STANDISH

WWW.WESTERBEKE.COM

Member

CORPORATION

INDUSTRIAL

Ntditmal

.

#035909

•150JOHN

PARK • TAUNTON

Marine

MllnufacturersAssoclaJion

HANCOCK

MA

02TBo

BTGA

BTG

BTG

ROAD

50Hz

50Hz

50Hz

Page 2

CALIFORNIA

PROPOSITION

WARNING

Exhaust

gasoline

its

the

cancer,

reproductive

Exhaust

colorless

unconsciousness

exposure

•Dizziness

gas

from

engines

constituents)

state

of

California

birth

defects,

harm.

gasses

gas.

can

contain

carbon

and

include:

•NaiiSea.

•Headache

•

Weakness

IF

YOU

SET

seek

until

OR

ANYONE

OUT

INTO

medical

it

bas

and

Sleepiness

THE

attention.

been

inspected

65

diesel

and

(and

some

of

are

known

to

to

cause

and

other

A

WARNING:

Carbon

Monoxide

death.

ELSE

FRESH

Monoxide,

is

poisonoiiS

SympfDms

•

•

•

•Inability

EXPERIENCE

AIR

IMMEDIAmY.

Shut

down

and

repaired.

of

Throbbing

Muscular

Vomiting

ANY

the

unit

an

odorless

and

Carbon

in

Temples

Twitching

to

Think

OF

THESE

If

symptiJ!US

and

do

and

can

cause

Monoxide

Coherently

SYMPTOMS,

persist,

not

restart

A

WARNING

should

be

generator.

WESTERBEKE

MONOXIDE

of

your

vessel.

obtainable

DECAL

is

provided

fixed

to a bulkhead

also

recommends

DETECTORS

They

at

your

in

are

local

by

WESTERBEKE

near

your

installing

the

living/sleeping

inexpensive

marine

store.

engine

CARBON

and

easily

and

or

quarters

Page 3

Gasoline

with

an ETHANOL

content

higher

· and

than

may

10°/o (E10)

void

warranty.

is

not

allowed

AJ~

~

•WESTERBEKE™

Engines &

Generators

Page 4

Blank

page

Page 5

SAFETY

INSTRUCTIONS

'INTRODUCTION

Read

this

safety

manuol

caused by foilure

precautions.

. toke the

perso~eJ.~

As

the.dftmer

and

advisories

Is

in

·

stimdatd8;

in

the

potential

l'1lfiln1enarlce

to

the

:PREVENT

A

wblle

power.l.etha/

1111

Do not operate

enclosures and

111

Shut off electrical

equipment

111

Use ilisulated mats whenever working on electrical

equipment

111

Make

(particularly shoes) when

Ill

Remove wristwatch and all

electrlca1

PREVENT

A

exhallst

Know

necessary

your

or

ope(8toF,

provided

af1g11menfwitft

hovrevel;

followilg

E!rKI

ar;:tual

pages.

aCiMlies.

QWRef/operator.

ELECTRIC

WARNING:

engine

is

voltage

sure your clothing and skin are dry, not damp

equipment

BURNS-

WARNING:

system

hot!

111

Monitor engine antifreeze coolant level at the plastic

coolant recovery

location on the water jacketed exhaust manifold, but only

when the engine

A

WARNING:

1111

In case

before touching

of

an

engine overheat, allow the engine

carefully.

to

follow

fundamental

when

dangerous

precautions

machinBr!:

always~

for

your

the~

safety

riSks

The

responsNlyforthe

risks

for

comp(tanCe

and

other

Most

accidents

rules

conditions

to

protect

_

..

_ _

the

and

Yacht

limited

with

following

all

belong

c:onvenience.

Boat

are

not

conditions

SHOCK

Do

not.

trlllt:h

Ai:

electrical

ruDlling,

tbis

covers

components. A tullning

or

when

oolmecteil

is

present

machinery without electrical

in

,power

HOT

Do

llot-tDut:h

tank and periodically

is

COLD.

Steam

can

the

engine or checking the coolant.

at

th~

place.

before accessing electrical

handling electrical equipment

jewelry

when working on

ENGINE

hot

engl11e

cause

injury

and

exist

yourself,

,safe#¥

1his

safely

Cormcil

to

the

lnfonnation

ldenfilication

safety~~

eXClusiVely·

CtJIIIIectitms

tD

shore

titJDllections!

parts

or

engine

gets

at

the filler cap

or

death!

are

and

your

roles

information

(

ABYC)

of

very

to

cool

PREVENT

I A

111

Prevent

sparks to

pump, or other potential

vapors.

removing the fuel

111

Do not operate with the

Backfire can

Ill

Do

the fuel system.

engine/generator clean and free of

chan~

1111

Be

PREVENT

. A

injury

1111

•Follow

hatches closed when fueling. Open

after fueling.

running

before

111

All

when

ventilated area away from spark-producing equipment

and

-

Ill Do not fill the fuel tank(s) while the engine is running.

111

Shut'·off

the

spill. DO NOT allow any

SQl.n"ceS

servicing.

the fuel system.

Ill Do not alter

Ill

Be sure all fuel supplies have a positive shutoff

Ill

Be certain fuel line fittings are adequately tightened

free

1111

Make sure a fire extinguisher is installed nearby and is

properly maintained. Be

Extinguishers rated ABC by

for all applications encountered

BURNS-

WAJIIIIIIG:

:6ash

fires. Do not smoke or permit

occur near the carburetor, fuel line,

Use a suitable container to

cause

not smoke or permit flames or sparks to occur near

of

fire;

aware-

diesel fuel

BURNS-

WARNING:

or

death!

n>-fueling

Check

the

blower. Run

starting

fuel

vapors

handling and storing fuels. Store fuel in a well-

out

of

the reach

the

fuel

fue~

system.

of

fire near

Ensure proper ventilation

or

of leaks.

FIRE

F/rB

..........

line, carburetor, or fuel filters.

air

severe injury or death.

Keep

the

Wipe

up all spilled fuel and engine oil.

will

/tljtlry

Dr-

sources

of

spilled

catch

cleaner/silemcer

compamnent and the

debris

burn.

EXPLOSION

ExploslollS

safety

your engine. · ·

are

highly

service valve at the engine

Thke care

the

modify the fuel system.

from

fuel

'llllfJOI'S

instructi.OJ:!S.

below for fumes/vapor before

the

blow~

explosive.

of

children.

in

ca~b4J.g

smoKing,

fuel

system or

familiar with its

the

Keep the vessel's

and

for

Use

any fuel that

open

engine

exists

NFPA

in

~

flames

filter,

fuel

or fuel

all fuel when

removed.

to minimize

t:a11

t:aiiSII

ventilate

four minutes

extreme

are

environment

cabin

care

when

servicing

flames, or other

when

when servicing

valve.

proper

use.

apptopriate

or

fuel

the

might

and

Engines & Generators

i

Page 6

SAFETY

INSTRUCTIONS

ACCIDENTAL

A

WARNING:

or

death!

•

Thm

unit's

engine.

•

Make

starting.

•

Make

re-installed before starting the engine.

BAnERY

A

WARNING:

or

death!

• Do not smoke or

being serviced. Lead

highly explosive

arcing

equipment in the

during

• Never connect

positive ( +) connection terminal of the starter solenoi?.

Do

not

together.

Ventilate

accumulation of explosive

disturb the battery charger connections

is

being charged.

•

Avoid

burns or sparks that could cause

wristwatch, rings,

the

battery.

•

Always

the

battery connections

and

BATTERY

A

WARNING:

severe

• When servicing

level,

protection. Batteries contain sulfuric

destructive.

it off at once

into the

caps.

STARTING

Accidental

OFF

the

DC

breaker on the control panel or

battery

selector

certain all personnel

certain

all

covers,

switch

guards,

starting

to

are

can

OFF

before

clear of the engine before

and hatches

EXPLOSION

Battery

or

by

lit tobacco products. Shut off

servicing.

the

test the battery condition by shorting

Sparks could ignite battery

any

compartment containing batteries

contacting

turn

the

reconnect it last

explosion

allow

an

acid

gas,

which can be ignited

vicinity

battery charger off before disconnecting

to

negative(-) battery cable

the

terminals with

and

any

..

Remove the

when

can

open

flame

batteries emit

prevent electrical

gases.

To

an

explosion. Remove

other jewelry before handling

servicing the

ACID

injury

or

death!

wear rubber

If

it

with

eyes

inadvertently when removing electrolyte

Sulfuric

the

acid

in

batteries

battery or checking the electrolyte

gloves,

comes

water.

a rubber

in

contact with your

Acid

may

apron,

splash

cause

servicing

are

cause

near the battery

hydrogen,

by

all

to

the

gases

or

avoid

sparks,

while

tools,

etc.,

negative

battery.

can

and

acid

which

skin,

on

injury

tum

the

the.

Injury

a

ele~cal

electncal

arcing

the

termmals

fuel

vapors.

to

prevent

do

not

the battery

to

prevent

lead

first

cause

eye

is

wash

the

skin or

TOXIC

• Ensure that the exhaust system

•

•

EXHAUST

A

WARNING:

discharged from

regularly

water-injected

Be

sure

the

Run

blowers when running

Do

not

run the generator set or engine unless the boat

equipped with a functioning marine carbon

detector that complies

boat builder or dealer

detectors.

• For additional information, refer

(educational information

A

WARNING:

odorless

nausea

•

• Do

•

AVOID

A

or

•

gas.

or

Do

not

use

Diesel

fumes

systems.

copper tubing resulting in exhaust/water leakage.

not

install exhaust outlet where exhaust can be

through portholes, vents, or air conditioners.

exhaust discharge outlet

enter

the

flow

of exhaust.

Although

exhaust

gas

is

present in

symptoms

poisoning

Vomiting

Dizziness

Headache

Nausea

MOVING

WARNING:

death!

Do

not

service

situation arises in

make

operating adjustments, use extreme care

touching moving parts

components.

GASES

Carbon

the

for

leaks and

elbow

unit

and

Carbon

Inhalation

monoxide

engine.

make

is

securely

its surroundings

with

for

installation of

on

monoxide

produces

(CO}

Is a deadly

is

adequate to

Check

the

exhaust

sure

the exhaust manifold/

attached.

are

the

generator set or

ABYC

A-24.

to

ABYC

Carbon

Monoxide).

(CD}

is

flu·llke

death!

copper tubing in diesel exhaust

can

rapidly

destroy

Exhaust sulfur causes rapid deterioration of

is

exhaust

fumes

discharge

Avoid

overloading

diesel engine exhaust

from

gasoline

diesel

exhaust

or

signs

of

carbon

are:

Inability

Throbbing in temples

Muscular twitching

Weakness

copper

near the waterline, water

outlet and

engines,

monoXlde

close

the

gases

are

carbon

fume~.

S?me

to

think coherently

and sleepiness

PARTS

Rotating

the

engine

which

parts

can

cause

while

it

is

it

is

absolutely necessary

and

hot exhaust system

running.

gas!

expel

system

well

ventilated.

engine.

monoxide

Consult

approved

an

your

TH-22

invisible

symptoms,

systems.

tubing

in

exhaust

If

the

or restrict

craft.

not

as

toxic

monoxide

of.

the

mhalation

injury

If

a

to

avoid

gases

is

drawn

engine

could

the

as

or

to

Engines & Generators

ii

Page 7

1!11

Do

not

wear

loose

clothing

equipment;

jackets,

could

1:1

Make

Keep

places

19

Do

not

the

engine

!1il

Do

not

the

exhaust

generator

death

4kW:«\RNING:

I(J~!

II

Never

1'1

Do

not

flame

1!11

Do

not

open

A

WARNING:

mentally

tie

shirts,

be

caught

sure

all

protective

at

all

times.

check

is

operating.

allow

any

discharge

is

operating.

can

occur.

operate

run

the

arrester

run

engines

{when

installed).

or

physically

back

sleeves,

in

moving

attaching

shields

fluid

levels

swimming

High

an

engine

engine

removed.

Do

not

or

jewelry when servicing

long

hair

and

rings,

necklaces

parts.

hardware

and

guards

or

the

drive

or

activity

opening

Carbon

noise

with

for long

work

for

Monoxide

levels

without

the

periods

on

air

machinery

incapacitated

SAFETY

avoid

wearing

or bracelets

is

properly tightened.

in

their respective

belt's tension

around or

the

generator

can

cause

its

muffler installed.

intake (silencer)

with their enclosures

by

fatigue!

loose

while

poisoning

hearing

when

you

INSTRUCTIONS

that

while

near

or

or

ABYC,

INSTALLING

Read

for

tions

AB:YC

"Standards

Craft"

Order

the

Order

Order

are

NFPA

the

following ABYC, NFPA and

safety codes

.when

installing your engine.

(American Boat and Yacht

and

from:

ABYC

613 Third Street,

Aprtapolis,

www.abycinc.org

NFPA-

"Pleasure and Commercial Motor Craft"

National Fire Protection Association

Battery Match

Quincy,

USCfl(Uritted

"regulatedions

Code of Regulations"

U.S. Government Printing Office

Washington,

No.302 (National Fire Protection

from:

MA 02269

from:

AND

USCG

PUBLICATIONS

ENGINES

and

Technical Information

MD

Park

are under titles

D.C.

AND

GENERATORS

standards. Follow their

St1ite

10

21403

States Coast Guard)

CFR33

20404

USCG

Council)

Reports

and

FOR

publications

recommenda-

for

Small

Association)

CFR46

of

the

OPERATORS

Many

of

in

your

notes

to

carefully,

procedures.

GASOLINE

Preparations

begin

with

Yacht

Council's

a

combination

Sections

H-2

Ventilation

·

H-24

Gasoline

P-1

Installation

for

P-4

;M:arine

EllAC

All

installations

Regulations

www.abycinc.org

MANUAL

the

preceding

Operators

highlight

maintain

ENGINE

to

install

a

thorough

(ABYC)

of

of the

ABYC

.for

Fuel'

of

Propulsion

Inboard

and

DC

Electrical

must

(FCR).

critical

sources

safety

tips

and

warnings are repeated

Manual

along

with

other

<;autions

information. Read

your

equipment, and follow

AND

GENERATOR

a gasoline

examination of the American Boat

standards of particular interest

Boats

Systems

Exhaust

and

Auxiliary Engines

Engines

comply

engine

standards. These standards

tnc~uding

using Gasoline

Systems

Systems

the

and

Transmissions

on

with

the

yoU:r

INSTALLATIONS

or generator should

USCG and

Boats

Federal Code of

manual

all

safety

and

are·

the

and

from

NFPA.

are:

Engines

iii

& Generators

Page 8

When

installing

attention be paid to the

WESTERBEKE

INSTALLATION

following

engines

information:

and

generators

it

is

important that strict

CODES

Strict

when

AND

federal

installing

REGULATIONS

regulations,

engines

and

SIPHON-BREAK

For installations

or

will

be below the vessel's

break in the

minimum

the exhaust manifold

raw

water

If

you

have

to

the

vessel's waterline under

siphon-break.

NOTE:

A

siphon-break

operation.

engine

damage.

EXHAUST

The exhaust system's hose

Exhaust

and

and

system

under

Hose

turns

turns.

MUST

any

where

the

raw

water supply hose

of

20"

above

the

injection

damage

Failure

any

doubt about

Consult

to

the

requires

to

properly

SYSTEM

is

recommended.

without

the

Iieed

In

this

regard, a single length of corrugated exhaust hose

be

designed

sea conditions

ABYC

guidelines,

generators

exhaust manifold/water injected exhaust

waterline,

to

vessel's waterline.

port

is

engine

and

the

position of

the

vessel's various operating conditions,

periodic inspection and

maintain a siphon-break

the

siphon-break

MUST

of additional

and

to

prevent

at

The

any

be

use

angle of

and

in

a marine

provisions

the

exhaust

Failure

at or

below

possible

certified for

the

flooding

the

water-injected exhaust elbow relative ·

manufacturer

of

this

type

fitting

and

entry of

vessels

safety

codes

environment.

must

be

elbow.

This

to

use

the load

of

cleaning

can

for proper

marine

use.

of hose

clamps

water

into

heel.

must be complied

made

a siphon-break

waterline

the

result

allows

to

the

elbow

is

close to

to

install a siphon-

hose

must

be looped a

when

wiU

result in

boat.

instaU

to

ensure

proper

in

catastrophic

maintenance.

Corrugated Marine

for

extreme bends

accomplish these

can

be

used.

exhaust system

with

a

bends

The

•.

AVAILABLE

YOUR

WESTERBEKE

'DEALER

:·s/PHON4fREAiWirif

LOOP'

FROM

STAINLESS

A

detailed

engines

to

and

download

Marine

Installation

generators,

from

our

Manual

is

supplied

website

Engines & Generators

with

at

www.westerbeke.com.

iv

covering

each

gasoline

unit. A pdf

and

diesel,

is

available

Page 9

TABLE

Parts

Identification

Introduction

Fuel,

Engine

Control

Operating

Generator

The

Alarms

Maintenance

Fuel

Cooling

Engine

Remote

Carburetor

Engine

Alternator

Engine

Lay-up

Wiring

Generator

BT

12

BT

Voltage

BT

BTGJBTGA

Panels

Dally

Routine

and

System

Fuel Lift Pumps .....................................................

Gasoline/Water Separator ...................................... 12

System

Changing Coolant .................................................. 13

Heat Exchanger ..................................................... 14

Replacing the Thermostat ...................................... 14

Raw Water Intake Strainer .................................... 15

Raw Water Pump ................................................... 15

Lubricating

Changing the Oil Filter .......................................... 16

011

Adjustments

Electric Choke ....................................................... 19

Engine Compression .............................................. 19

Ignition Wires ........................................................ 19

Valve Clearance ..................................................... 20

Pressure ........................................................... 20

Oil

Spark Plugs ............................................................ 21

Drive Belt Adjustment. .......................................... 21

Govemor ................................................................

12

Volt

Troubleshooting

and

Diagrams

Generator

Stud

Internal

Single

Regulator

Generator

BTG

12.5Kw

BTG

15.0Kw

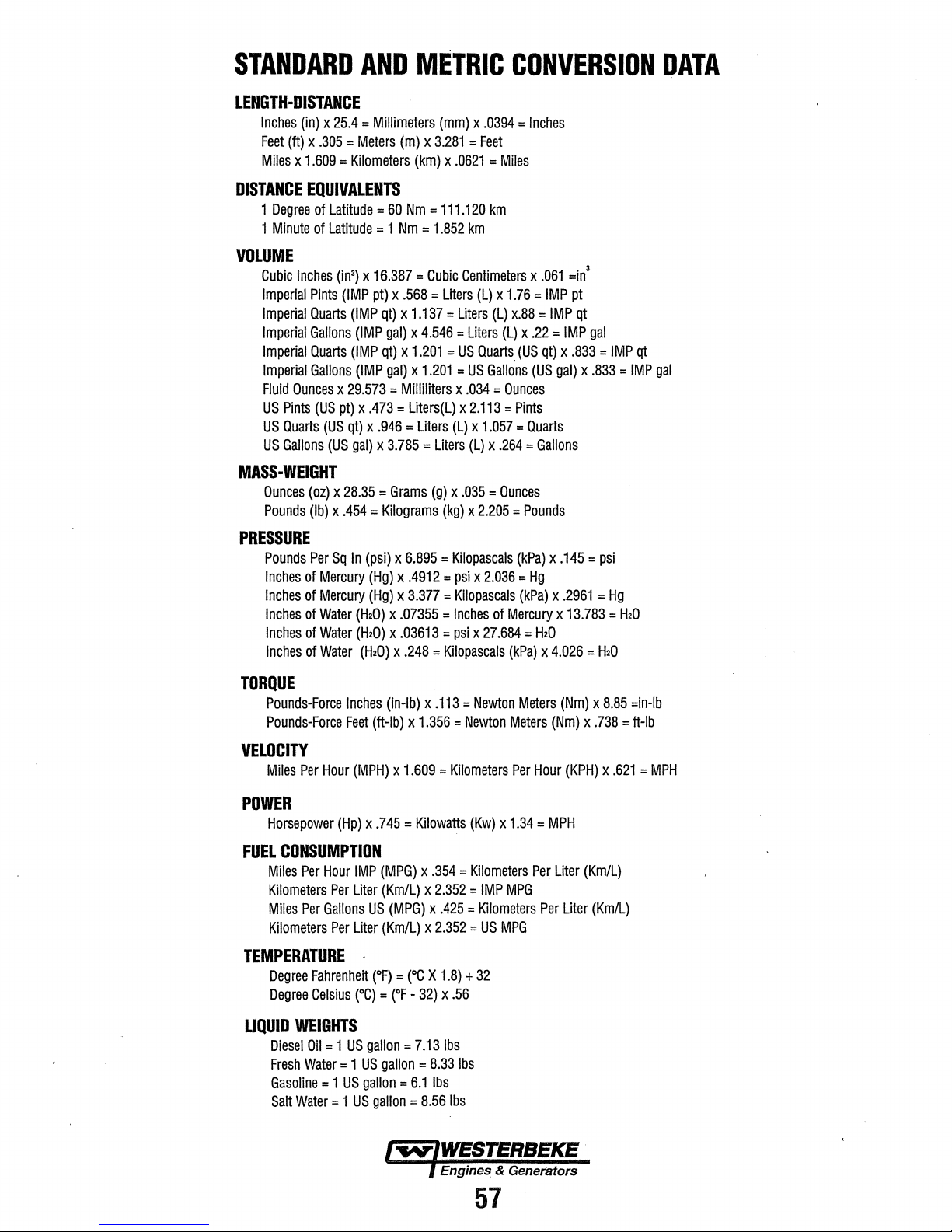

Metric

Conversion

OF

CONTENTS

....................................................

................................................................

011,

and

Engine

Coolant

........................

............................................................

Instructions

Break·ln

................................................

Procedure

...................................

.......................................................

Circuit

Breakers

Schedule

.............................................

......................................

..............................................................

.........................................................

Oil

..............................................

Filter

......................................................

Adjustments

...........................................

..................................................

Testing

DC

....................................................

Circuit .................................................

............................................

Recommissioning

and

Schematics

Information

..............................................

Description

Wiring

Phase

Wiring

Adjustments

Troubleshooting

8.5Kw

Speclfications

Specifications

Speclficatlons

Data

.................................

.......................

.........................................

Schematic

Schematic

.........................

..........................

...............................

............................

..............................

........................................

........................................

..............................................

2

4

s

6

7

8

8

9

10

12

12

13

t6

17

18

19

22

23

23

25

.27

28-3S

36

37

38

39

40

41-50

S1

53

ss

57

Engines & Generators

1

Page 10

J.D.

RAW

WATER

FRONT

PLATE

PUMP

STARTER

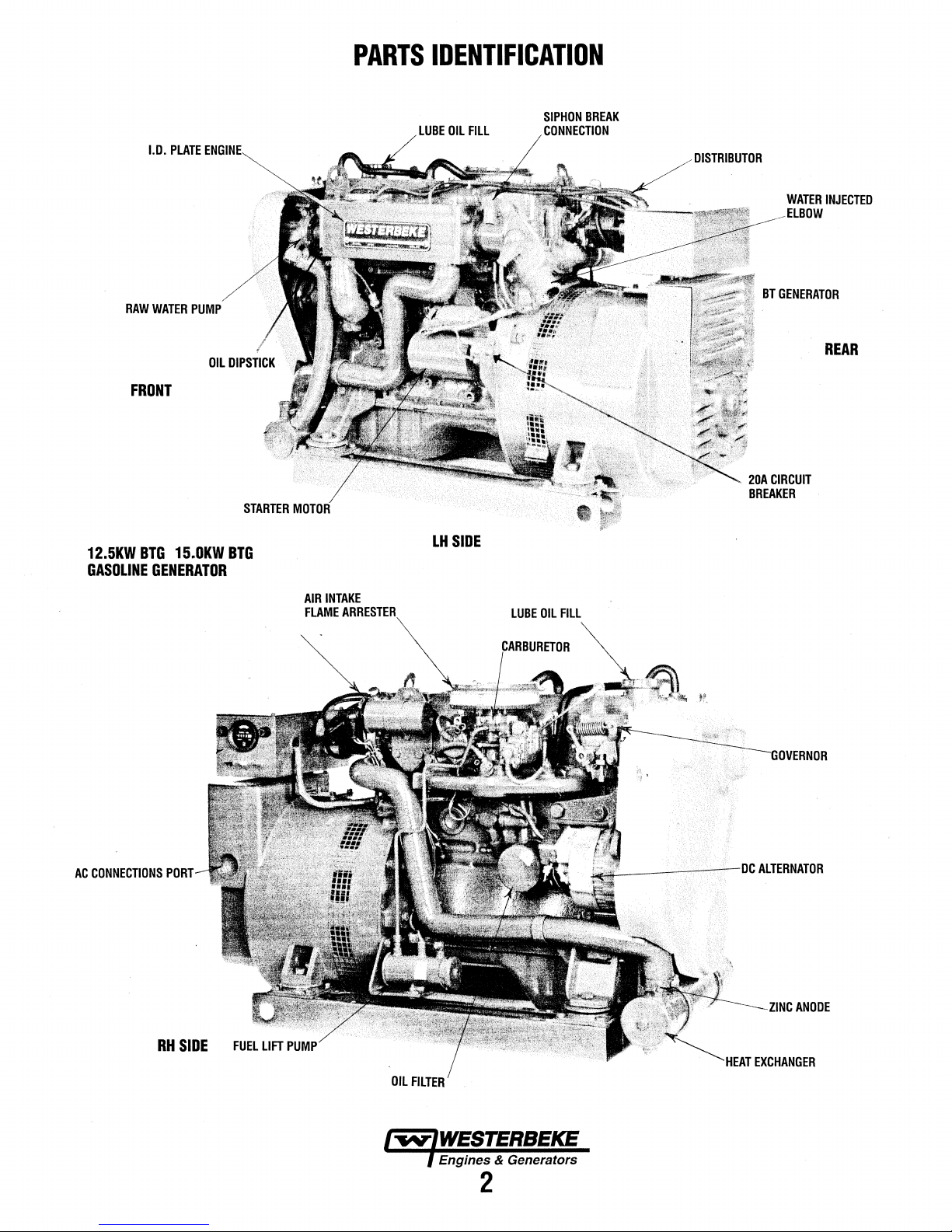

PARTS

IDENTIFICATION

LUBE

OIL

FILL

SIPHON

BREAK

CONNECTION

DISTRIBUTOR

BT

20A

CIRCUIT

BREAKER

WATER

INJECTED

ELBOW

GENERATOR

REAR

12.5KW

BTG

GASOLINE

AC

CONNECTIONS

15.0KW

BTG

GENERATOR

PORT

AIR

INTAKE

FLAME

LH

SIDE

LUBE

OIL

FILL

RH

SIDE

OIL

FILTER

Engines & Generators

2

HEAT

EXCHANGER

ANODE

Page 11

FRONT

HEAT

EXCHANGER

PARTS

OIL

DIPSTICK

IDENTIFICATION

SIPHON

BREAK

CONNECTION

WATER

INJECTED

DISTRIBUTOR

GENERATOR

COMPONENTS

.20A

CIRCUIT

BREAKER

REAR

AC

CONNECTIONS

PORT

STARTER

MOTOR

LH

SIDE

AIR

INTAKE

FLAME

ARRESTER

8,5KWBTG

GASOLINE

OIL

GENERATOR

FILL

ANODE

FUEL

LIFT

PUMP

LUBE

OIL

DRAIN

RHSIDE

Page 12

INTRODUCTION

ORDERING

Whenever

generator

include a complete

part

needed

insist

or

generic

cations

NOTES,

As

this

maintenance

tor,

critical

CAUTIONS,

NOTE:

A

observed,

tile

A

followed,

NOTE:

.

by

WESfERBEKE.

the

engine

SPARES

Certain

your

SUGGESTED

as

proper

the

way.

spares

on-board

PARTS

replacement

and

engine

(see

upon

WESTERBEKE

parts

are

as

original equipment

CAUTIONS

manual

An

takes

schedules,

information

and

operating

CAUTION:

can

engine

01

WARNING:

can

A carbon

room.

AND

spare parts will be

WESTERBEKE

SPARE

fuel

and

WESTERBEKE

and

accessories

inventory of

parts

are

needed,

model

and

serial

part

description

the

separately

frequently

AND

you

through

and

will be

WARNINGS.

procedure

Prot:edures,

teSUif

in

the

generator.

Procedures,

result

in

personal

monoxide

Affix

this

and

furnished

packaged

not

made

WARNINGS

the

troubleshooting

highlighted

An

explanation

essential

which

damage

·

which

injury

warning

decal

decal

in a visable

ACCESSORIES

needed

to

generator

PARTS).

oil

filter

the

brochure

or

Often

can

be

difficult

will

provide

to

proper

WESTERBEKE

engine

assist

always

numbers.

part

number

Parts

Catalog).

parts

because

to

the

same

operating

of your

by

NOTES,

to

note.

U

not

strictly

01

destruction

if

not

01loss

has

support

and

when

even

simple

to

obtain

you

with a suggested

you

in

provide

In

addition,

for

each

will

specifi-

procedures,

genera-

follows:

of

properly

of

life.

been

provided

location

maintain

cruising

items

along

preparing

parts.

the

Also

fit

in

(see

such

an

PROTECnNG

Care

at

the

have

resulted

many

thousands

manufacturer

installed

operated

buyer/owner-operator.

NOTE:

Six

•

Proper

• An

ejJicient

an anti-siphon break to prevent water from entering the

engine.

•

Changing

ing hours.

Proper

•

nents according

manuol.

•

Use

clean,

•

Winterize

Recommissioning" section in this manual.

UNDERSTANDING

The

gasoline

ways

similar

are

verticle

overhead

a

solid-state

camshaft-driven.

lubrication

which

is

generator's

that is

required

important

ventilation,

cooling

CARBON MONOXIDE DETECTOR

YOUR

factory

in a

cannot

in

the

vessel

and

serviced

important

engine

weU-designed

the engine oil

maintenance

filtered

your engine according

engine

to a gasoline

in-line,

GamShaft

distributor

system,

thennostatically-controlled.

engine

factors

maintenance

system

INVESTMENT

during

assembly

WES1ERBEKE

of hours of

and

to

and

which

The

and a fresh

requires

of a

to

and

dependable

control

how

or

the

manner

in

the

field.

steps

to

ensure

generator installation

exhaust system that

and

oil

of

all engine

the maintenance schedule in

unleaiJed

THE

driving

the

which

engine

gasoline

the

the

fueL

GASOLINE

an

AC

automobile

engine's

is

chain-driven.

is

horizontally

incorporates

water-cooled

the

same

automobile

generator's

of

the

fuel

generator

and

thorough

generator

or

where

in

This

long

filters every 100

capable

service.

the

generator

which

the

is

up

to

generator

and

and

generator

to

the "Lay-up and

GENERATOR

generator

cylinder

preventive

longevity

system,

backend.

engine.

The

a

To

a large

engine.

is

The

head

mounted

pressure

engine

are

ignition

testing

However

unit

the

olignment.

includes

in

many

cylinders

has

engine

degree,

maintenance

The

proper

of

the

is

is

life:

operat-

compo•

this

an

utilizes

and

type

block

the

most

system,

WESTERBEKE

monoxide

quarters. Carbon

ean

be

deadly.

The presence

exhaust

system,

or

If

Ventilate

locate the

Engines & Generators

leak

from

from

a neighboring

the dectector

4

highly

recommends

detector in the vessels living and sleeping

monoxide even in small amounts,

of

carbon

monoxide

from

the

main

engfu.e

the

the

area,

source

exhaust

signals

of

discharge location on the

vessel.

the presence

move

into a fresh air location and

the

carbon

mounting a carbon

indicates a possible

or generator, it's

of

carbon

monoxide

and arrest it.

monoxide.

exhaust

vessel

Page 13

FUEL,

ENGINE

OIL

AND

ENGINE

COOLANT

GASOLINE

A

CAUTION:

rating

of

harm

to

your

Care

Of

The

Use

only

clean fuel! The clearance of the

your

fuel

iqjection pump is very critical; invisible dirt

particles which might pass through the

these

finely

and

keep

it clean. The best fuel

unsatisfactory

facilities.

engine's

advisable:

Purchase a

Install

metal bowl type filter/water separator

and

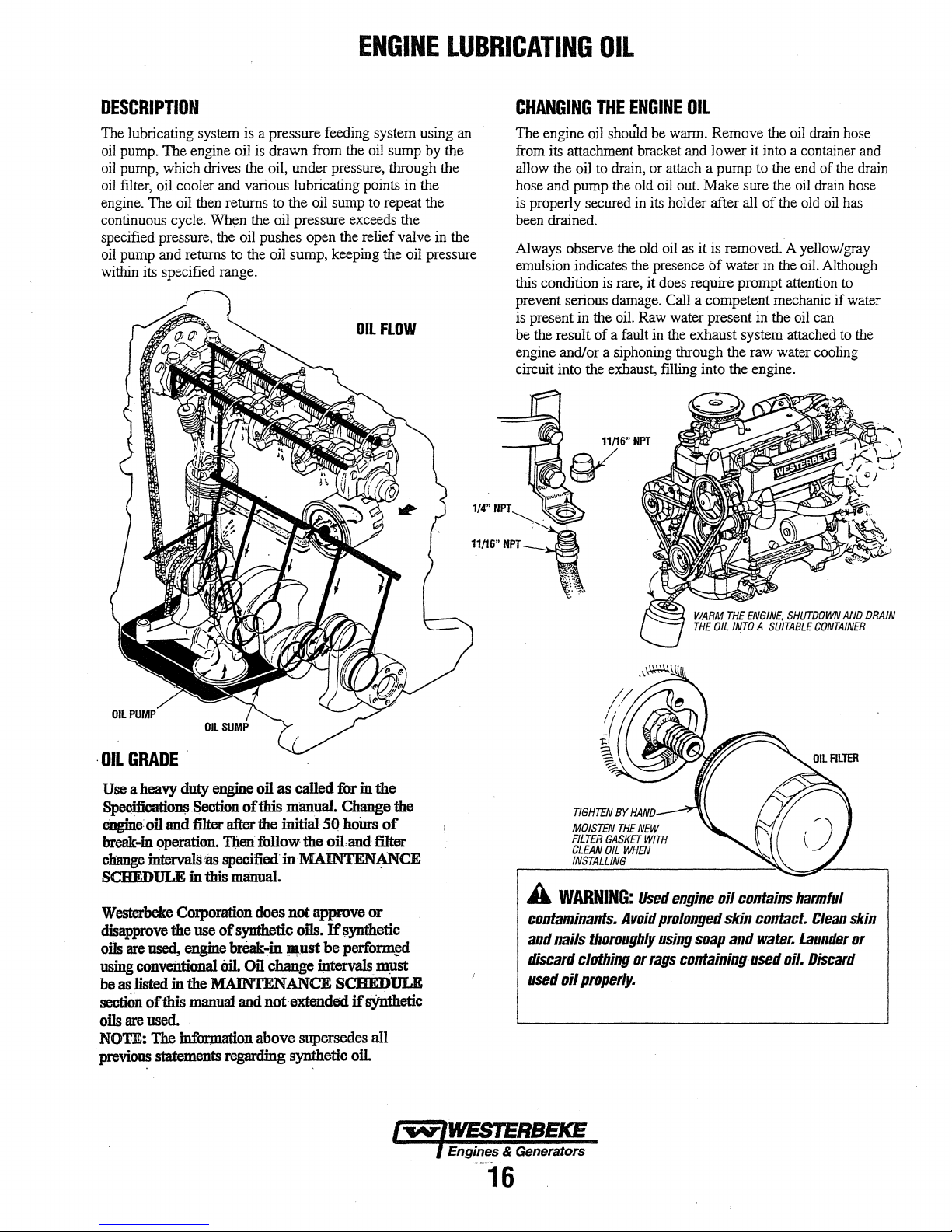

ENGINE

Use a heavy duty

Specificati~

eilgine

break~in

change

SCHEDULE in this

To

daily

and

tile

engine.

OIL

on

and filter after the

operation.

intervalS

Only

use

unleaded

89

or

higher.

engine

Fuel

finished

by

assure that the fuel going into the

use

well~known

regularly service a

Section

'as

Leaded

and

fuel

violate

your

Supply

parts. It is important

can

be

careless handling or improper

is

clean

and

pure,

the

brand

of

fuel.

good,

Coast

engine

on

as

called for in the

of

this manual.

initial-

50 hours

Then

follow the olland filter

specified in MAINTENANCE

manual.

fuel

with

will

cause

warranty.

components

fllter

can damage

to

buy

rendered

following

Guard

between

~the

of

an

octane

serious

clean

storage

tank

for your

practice

approved

the

fuel

in

fuel,

tank

is

ENGINE

WESTERBEKB

50%

that

The

to

the

cooling circuit

antifreeze that

that

term

The

poured into

NOTE:

ontij'ree~

A proper

engine coolant to temperatures

COOLANT

A coolant

The

coolant

without

the

COOLANT

recommends a mixture

distilled

can

antifreeze perfonns double

run at proper temperatures by transferring heat

engine

keep

protection.

water and antifreeze should

purpose

cooling

water.

corrode

Use

internal

to

the

coolant. It also

from

contains

the

antifreeze

the

cooling

the

new

that is now

50/50

mixture

environmentally-friendly~

RECOVERY

recovery

expansion

the

tank

of

this

and contraction

loss

of coolant and

system.

Distilled water is

engine

surfaces.

duty.

lubricates

rust and

corrosion.

supplemental

chemically

circuit

available.

as

recommended

of

be

TANK

kit

is

supplied with

recovery

tank

without

of

free

It

allows

Use a

cooling

balanced,

premixed

will protect

-40"F

is

to

allow

during

engine

introducing air

50%

antifreeze

from

the

chemicals

the

engine

away

and

protects

good

quality

additives

crucial

before

long

lasting~

each

generator.

for

engine

operation,

from

the

{SCAs)

to

long

being

the

into

and

Westerbeke

disapprove the use

oils

are

using conveirtional

be

as listed in the MAINTENANCE SCHEDULE

section

oils

are

NOTE: The

previous statements regarding synthetic on.

Corporation does not approve

of

synthetic oils.

used, engine break-in ... ust

oil.

on

change

of

this

manua1

used.

information above supersedes all

and

not

extended

or

If

~thetic

be

perfor.tn!'d

~tervals

__

must

if

sYnthetic

Engines & Generators

5

Page 14

CONTROL

PANELS

DESCRIPTION

The

generator mounted control_panelis equipped

ON switch

switch (red).

The ON switch provides power to the start circuit

switch by-passes

until the oil pressure reaches

The

cranks

switch

The

switch must

The panel also has two

• A 15 amp slow bluw fuse protects

•An

any optional

REMOTE

An optional remote start/stop panel is available

controlling the generator from a remote location.

This panel

previously described. Also included is a green

which glows once the engine/generator

rpm's. The purpose

release the START switch. It is also

engine/generator

(black),

START switch energizes the start solenoid/starter which

the

engine.

is

depressed and held at the

STOP

switch

8 amp fuse protects the

START/STOP

has

a START switch(white)

the

protective

This

switch

will

turn off the engine/generator,

be

depressed until the stop sequence

fuses

rembte

start/stop

the same ON, START, and STOP

of

the LED is

is running. ·

oil

pressure

5 - I 0 psi.

will

not operate

same

to protect

engine

or

instrument

PANR

to

time.

the

the

start

operating

(OPTIONAL)

has

alert the

an

indication that the

and

a

shutdown

unless

DC

circUit:

circuit.

circuit

panel.

for

LED

reached

operator

with

an

STOP

This

switch

the on

.This

is

complete.

·

Ond

functions

light

600

to

..

REMOTE

An

includes

DC charging voltmeter, operating

switches.

INSTRUMENT

optiol)al

remote instrument

a water temperature gauge,

·

REMOTE

The

installed

an

oil pressure

located

installed in the thermostat housing

is

adjace~~

on

the-thi:eads

each

wiring

The

is

for the water temperature

between

removed. Refer

DIAGRAM

NOTE:

installers

standards

INSTRUMENT

remote instrument

on

the engine

gauge

on

the engine.

to the oil pressure switch.

of

sender

are

tied off

harD.ess),

blue wire

iS

tenninal board connections

in this

When

installing

responsibility

33

CFR

both

PANEL

PANEL

panel

block,

sender.

The

water temperature sender is

senders.

next

(OPTIONAL)

panel

is

available

oil

pressure

hourmeter,

and

INSTALLAnON

has two sending units to

a water

Plugged ports for each

to

temperature

and

the oil pressure sender

Use

sealing

Electrical connections

the senders location ( in

· · · . . .

.'for

the

oil

to.

the.

manual.

part

j»:essure

sender.

REMOTE

the

optional

to

comply

183.

sender

and.

If

there

is a jumper

T-1

and

T-2,

INSTRUMENT

rembte

panels,

with

the

U.S.

which

gauge,

start/stop

be

sender

are

compound

for

the tan

it

should

WIRING

it

is

Coast

Guard

and

the

wire

be

the

. Engines & Generators

6

Page 15

OPERATING

INSTRUCTIONS

PRESTART

Before starting your generator for the first time

longed layoff, check the following items:

a Check the engine oil level:

the full mark on the dipstick.

INSPECTION

add

or

after a pro-

oil to maintain the level at

a Check the fuel supply and examine the fuel filter/separator

bowls for contaminants.

a Check the

and battery cable connections.

DC

electrical system. Inspect wire connections

a Check the coolant level in both the plastic recovery tank

and at the manifold.

NOTE:

After the

the

engine's cooling

recovery

the

cooling system

after

the

tank will be

replace

Before subsequent

manifold should

tank

the purged

may

tank.

engine

drawn

need

initial

Open

has

be

to

be

running

system

will

the

air bleed petcock

is

purged

of

cooled,

into

air.

operation

topped

the

filled

the

engine's

off,

to

of

the

generator,

be

purged

air.

After shutdown and

coolant

of

the

and

the

cooling

generator,

the

MAX

level.

from

coolant

to

the

to

ensure

the

system

the

the

air

coolant

that

recovery

to

engine's

recovery

.

in

a Check load leads for correct connections as specified in

the wiring diagrams.

a Examine the air inlet and outlet for air flow obstructions.

a Be sure no other generator or utility power

the load lines.

is

connected to

a Be sure that in power systems with a neutral line that the

neutral is properly grounded (or ungrounded) as the system

requires, and that generator neutral is properly connected

to the load neutral.

or open neutral can supply the wrong line-to-neutral volt-

age on unbalanced loads.

A

CAUTION:

recommended

motors,

to

speed

be

switched

and,

precaution

pated

operation

cold

engine

In single phase systems

When

starting

that all

In

will

from

AC

OFF

cold

climates,

prevent

of

the

stalling.

until

damage

AC

the

loads,

especially

the

engine

starts

caused

machinery

an

incomplete

generator,

large

has

to

warm

by

unanticl·

and

will

it

Is

come

up

up.

This

prevent

a

STARTING

A

for a

·

ventilating

fumes

1. Depress

this

2. Depress

starts,

the

NOTE:

the

oil pressure shutdown circuit allowing

pressure to rise enough

maintain the ignition circuit

3.

Release

Once

ator

ature

If

an

gauges for

NOTE:

This condition should smooth out

and when the generator loads are applied

THE

GENERATOR

WARNING:

minimum

from

the

primes

the

release

ON

switch

Keeping

the

The

engine

and

allow

(130°-150°

optional instrument panel is installed, monitor the

normal

Some unstable running may occur

Ventilate

of

five

blowers

the

generator

ON

switch and hold it down (5-15 seconds),

carburetor. Continue to depress ON.

START (white), when the generator

the

START

a few seconds longer.

the

ON

ON

switch.

is running apply a light load to the gener-

the engine

F/

55°-56°C) before applying heavy loads.

readings.

the

generator

minutes

remove

prior

any

explosive

compartment

switch. Continue to engage

switch,

depressed by-passes

to

close the switch and

to

warm up to operating temper-

as

to

starting.

the engine warms

compartment

The

gasoline

and

bilges.

the

oil

in

a cold

engine.

up

A

CAUTION:

the

engine

exhaust

pump

cooling

enter

with

is

pumping

system

the

manifold

from

happening

through~hull

co«ecting

Engine

damage

wa«antable

in

mind.

STOPPING

1. Remove the

generator to run for an added 3 to 5 minutes (this stabilizes

its

qperating temperature).

2.

Depress the

When the generator stops, release the

3.

NOTE:

In

an

the stop

panel.

switch,

Prolonged

starting

raw

can

water.

raw

during

enginets

once

the

cylinders

the

exhaust

by

closing

shutoff~

cause

draining

of

resulting

Issue:

the

THE

GENERATOR

AC

loads from the generator and allow the

STOP

(red) switch.

emergency,

remove

cranking

result

This

water

through

cranking.

by

system

the

the

excessive

from

in

may

way

raw

the

raw

intervals

filling

happen

the

This

of

fills.

water

exhaust

water

owner/operator

if

the

generator will not

the 8 amp

fuse

the

because

raw

raw

water

the

exhaust

Prevent

supply

muffler,

engine

entry

should

STOP

in

the

without

engine

water

can

this

cranking.

Is

not

keep

switch.

stop

control

the

and·

a

this

using

Engines & Generators

7

Page 16

DESCRIPTION

Although your engine

test

hour of

assembly procedures

operated properly, a break-in

life of

operated and serviced

Breaking-in a

piston

and

scored,

break

Your

conditioning operation

to

maximize the perlormance

Perlorm

following:

Start the engine according

section. Run the engine

water

reach

AFTER

Once the generator

tion

between

operations

your

engine

new

rings

to

smoky

operation

which

is

-in

period.

new

engine requires approximately 50 hours of initial

this

conditioning

pump,

oil pressure, battery

its

full

rated speed

START-UP

and

then encourage a

20% and

has

at

were

is

dependent

during

engine basically

the cylinder

indicate

caused

by

to

while

has

been

60%

of

experienced a minimum of one

the

followed

break

carefully,

are

fast

GENERATOR

factory

to

make

sure accurate

and

that the engine

time

is

required. The service

upon

how

the engine

its

initial hours of

involves

walls.

Excessive oil consumption

that

the cylinder walls are

overloading

in

each

and

service life

keeping

to

the

STARTING

checking that all systems

charging)·

signs

of

an

started,

check for proper opera-

warm-up.

full

load for

the

use.

seating the

the

engine during

moving part

of

the engine.

in

mind the

PROCEDURE

are

functioning.

overload.

Run

the generator

first

10

in

hours.

BREAK·IN

is

the

order

PROCEDURE

the

After

load

can

periodically

Avoid

overload

smoky

exhaust

Monitor

it within the generators'

1800

rpm

control of the generators

drawn

current

NOTE:

Be

current

amperage

amperage.

GENERATOR

Once

the generator

(raw

governor adjustments

the engine's break-in

(see

period

ENGINE

also

be required in conjunction

ment

(see

first

10

hours of

be increased

vary

the

current being

to

produce

aware

drawn

draw

See

to

the

load.

at all

times.

with

reduced output

rating.

60

from

the

generator.

of

motor

required for

can be 3

GENERATOR

ADJUSTMENTS

has

been

required

period

ENGINE

ADJUSTMENTS. A

GENERATOR

SPEED

the

generators

the

full-load

An

overload

drawn

Since

hertz,

or

engine

break

starting

starting

to 5 times

INFORMATION

placed

for

(first

(HERIZ)ADJUSTMENTunder

no-load

with

INFORMATION).

operation,

rated

output,

is

signaled

voltage

from

at

loads

motors.

normal

engine speed (hertz) during

50

and

frequency.

the

generator

the

generator operates

1500

to

produce

-in

is

governed

and

the

high

This

starting

running

in

in

operation,

hours)

voltage

the

engine's speed adjust-

there

or

after

adjustment

the

then

this

by

a

and

50

hertz,

by

the

manual.

may

this

keep

at

be

may

THE

CHECK

Follow

• Check that all generator circuit breakers (power panel)

•

•

• Check the oil

• Check the coolant

• Check your

• Check the starting

• Check the drive belt

CHECK WITH

• Check for abnormal noise

•

LIST

this

checklist each

the off position before

Record

the hourmeter

to the maintenance

Visually

blow-back sounds.

Confirm

When

When the engine

When

inspect the engine

exhaust

the

engine

the engine

level

fuel

THE

schedule).

(dipstick).

level

supply.

batteries

ENGINE

smoke:

is

cold

is

is

day

before starting your

starting.

reading

for

warm -almost

overloaded -some

in

your log (engine hours

for

fuel,

oil,

in

the

coolant recovery tank.

(weekly).

wear

and

proper tension

RUNNING.

such

as

knocking, vibration

-White

Smoke.

Smokeless.

or water leaks.

Black

DAILY

generator.

(weekly).

Smoke.

are

relate

an:tf

ROUTINE

NOTE:

Some unstable

This

condition should

is

reached and loads

in

A

CAUTION:

periods

generator.

of

time

running

abate

are

Do

not

without

may

as

normal

applied.

operate

.a

load

occur in a cold

operating

the

generator

being

placed

engine.

temperature

for

long

on

the

8

Page 17

ALARMS

AND

CIRCUIT

BREAKER

SAFETY

The engine

switches.

without

~ng

TROUBLESHOOTING

The

switches:

High

An exhaust temperatllre switch is located on the exhaust

elbow.

the

sensor indicate an excessive exhaust temperature

quate.supply

This

resets

HIGH

SHUTDOWN

is

protected

Should a shutdown

SWITCHES

by

three

occur,

finding and correcting the cause.

Engine

starts,

runs

and

then

section

of this

following

Exhaust

DC

switch opens at

at

1s

a description of these

Temperature

Normally closed, this switch will

voltage (shutting off

of

raw water

approximately

··~

'

SWitch

the

causes

260-270"F

225'"F

(107°C).

EXHAUST

automatic

shutdown

do not attempt to restart

Refer

to

the

shuts

down

in

the

ENGINE

manual.

autoJIUltic

open

engine) should

high exhaust temperatures).

(127-132°C).

shutdown

and interrupt

the

switch's

(an inade-

This switch

TEMPERATURE.

SWITCH

MOUNTED

EXHAUS(ELBOW

AT

THE

·head-

LOW

OIL

PRESSURE

Allow

oil

pressure

gallery.

sure.

(0.4-

.

Engine

Tlie

manual

draw

wiring

event

breaker

and

fault,

This

switch's sensor

Should

generator's engine is protected

or electrical overload

repair

the

kg/cD).

engine

the

sourc;e

2

Breaker

0.7

Circuit

reset circuit breaker (20

or

the generator will-shut

interrupts

reset the breaker and restart the generator.

ALARM

!llarm

switch

engine's oil pressure

),

this

switch

wiring-

will cause

the

DC

circuiUf

of

the

SWITCH

is

located off

monitors

will

activate a pulsating alann.

amps

anywtrere

the

down

because

problem.

the

the engine's

fall

to

5-10

by

an

engine

DC).

Excessive current

in

the

inst:rum.ent

breaker

this

After repairing

the

shoUld

to

opened

occur,

engine's oil

oil

pres-

psi

'DIL

AlARM

DIL

PRESSURE

mol!Jlted

panel

trip.

•

In

this

check

the

PRESSURE

SWITCH

SWITCH

COOLAIT.TEMPERATURE

A coolant temperature

housing.

coolant's 6peta.ting

210"F

This switch will activate a continuous

(9~C).

switch·

temperature

SWITCH

is

located

reaches

. .

THERMOSTAT

ALARM

SWITCH

on

tbe>thermostat

alarm

aPproximately

ASSEMBLY

if

the

OVEilSPUD

BOARD

High

RPM

Shutdown

An overspeed

generators

engine's speed

correcting the

tarily

DIAGRAMS

NOTE: When troubleshooting a possible faulty

switch. For test purposes to by-pass the switch.

Move

DO NOT purposely by-pass a faulty switch so

to

be

create a potential

engine

depressing the

in this

connection

able

to

operate the generator. This could

SWitch

switch

in

by

grounding

reaches

problem,

stop

manual.

T4

safetY

the

DC

circuit

out

2175

rpm(approximately).

this switch

switch.

onto

hazard.

Refer

TS.

shuts off

the

ignition

can

be reset by

to

the

WIRJNG

TERMINAL

th~

system

if

After

momeq'-

as

the

l"'fAriWESTERBEKE

Engines:& Generators

9

Page 18

A

WARNING:

running.

use

the

correct

servicing

NOTE:

Many

more

difficult and

MAINTENANCE

Never

Wear

any

of

of

the

attempt

the

proper

tools

for

the

engine's

following maintenance jobs

may

require

to

safety

equipment

each

job.

BC

electrical

the

expert knowledge

perform

Disconnect

SCHEDULE

any

service

such

the

equipment.

are

as

goggles

battery

simple

of

a service

while

the

and

terminals

but others

mechanic.

engine

gloves,

are

is

and

when

SCHEDULED

MAINTENANCE

Fuel

Supply

Fuel/Water

Engine

Coolant

Drive

Visual

Spark

Generator

Fuel

Starting

(and

Engine

Re-torque

*Adjust

Clearances

Air

Exhaust

Engine

Inlet

Separator

Oil

Level

Level

Belts

Inspection

Plugs

(if

Filter

(Lift

Batteries

House

Batteries)

Oil

Cylinder

the

Valve

Screen

(Flame

System

Hoses

Fuel

Filter

applicable)

Pump)

of

Engine

Head

Arrester)

CHECK

EACH

DAY

D

D

D

D

D

weekly

D

D

weekly

HOURS

OF

OPERATION

50

100

250

500

750

1000 1250

NOTE:

Please

keep

engine

surface

clean.

and

oil

will

inhibit

the

engine's

ability

to

remain

cool.

D

D

D D

D D

D 0 0 D D D D

D

D D D D D

D

D D D D D D D

D D D

D D D

D

D D D

0 D

D D

D

D D 0 D

D

0 0

Dirt

0

EXPLANATION

Unleaded

higher.

Check

if

Oil

dipstick.

Check

Add

Inspect

and

Check

and

Check

Check

Check

with

(if

Inspect

Every

and

excessive

Initial

change

retorque

Initial

Clean

Initial

for

exhaust

on

Check

spongy.

gasoline

for

water

and

necessary).

level

should

indicate

at

recovery

coolant

if

needed.

for

proper

adjust

if

needed.

for

fuel,

oil

electrical

applicable)

make

leaks.

inside

Hose

Replace every 250 operating hours.

connections.

for

loose

gap;

inspect

that

AC

connections

no

chafing -see

for

for

fuel

50

operating

sure

corrosion.

engine

oil & filter

both

every

at

50

adjustment

at

50

hours,

check

at

Check

elbow

passages;

that

all

should

be

Check

leaks.

connections

hrs.,

50

for

connections

and

OF

SCHEDULED

MAINTENANCE

with

octane

rating

dirt

in

fuel

(drain/replace

between

tank;

if

empty,

tension

(3/8"

to

Check

belt

edges

and

water

leaks.

Keep

bolts & nuts

belt

tension.

for

burning

and

are

clean

GENERATOR

addition

information.

Check

wire

hours

check

electrolyte

are

very

change

at

100

hours.

them

every

500

at

50

hrs.,

then

every

then

every

100

hrs.,

then

every

siphon

brake

operation.

carbon

and/or

clean

andreplace

are

tight.

hard & tight.

tighten

Replace

all

hose

of

FULL

check

1/2"

Inspect

corrosion.

and

INFORMATION

connections.

tight.

50

hours.

hours.

250

corrosion

clamps.

89

or

filter

and

LOW

at

manifold.

deflection)

for

wear.

wiring

tight.

secure

levels

Clean

hrs.,

then

500

hrs.

hrs.

Inspect

Check

buildup

as

necessary.

if

soft

or

on

off

the

continued

Engines & Generatnrs

10

Page 19

NOTE:

Use

engine

hours

MAINTENANCE

the

engine

by

running

hourmeter

time.

gauge

to

SCHEDULE

log

your

engine

hours

or

record

your

SCHEDULED

MAINTENANCE

Heat

Exchanger

Raw

Water

Pump

Coolant

System

*Starter

Distributor

*Engine

*Exhaust

Motor

Cylinder

Compression

Valve

Clearance

Elbow

and

CHECK

EACH

DAY

50

0

0

HOURS

OF

OPERATION

100

250

500

0 0 0 0 0

0

0 0

0 0

0

0

0 0

0

750

1000

1250

0

0

EXPLANATION

MAINTENANCE

Clean

or

replace

anode.

cap

and

clean

out

debris.

for

professional

Remove

for

wear,

Lubricate

Drain,

flush,

appropriate

Check

solenoid

and

lubricate.

pinion

drive.

Check

ignition

distributor

Incorrect

performance.

timing

Test

exhaust

casting

WARNING: A defective

carbon

cleaning

the

pump

replace

both

when

and

antifreeze

and

Clean

timing.

cap

and

valve

clearance

Check

and

adjust

elbow

is

corroded

monoxide

cover

if

needed.

re-assembling.

refill

cooling

motor

and

rotor.

compression

valve

for

or

leakage.

OF

SCHEDULED

Open

heat

exchanger

remove

every 1 000

and

pressure

and

inspect

Also

replace

system

mix.

for

corrosion.

lubricate

Check

will

clearances.

casting

deteriorated.

exhaust

the

condition

result

in

pressure

integrity.

elbow

testing.

the

impeller

the

with

starter

of

poor

Replace

can

end

hours

gasket

Remove

motor

engine

and

if

cause

Carburetor

Screen

*WESTERBEKE

Filter

recommends

this

service

0

be

performed

by

an

0 0 0

0

authorized

mechanic.

Clean

at

first

50

hours

and

every

250

hours.

Engines & Generators

11

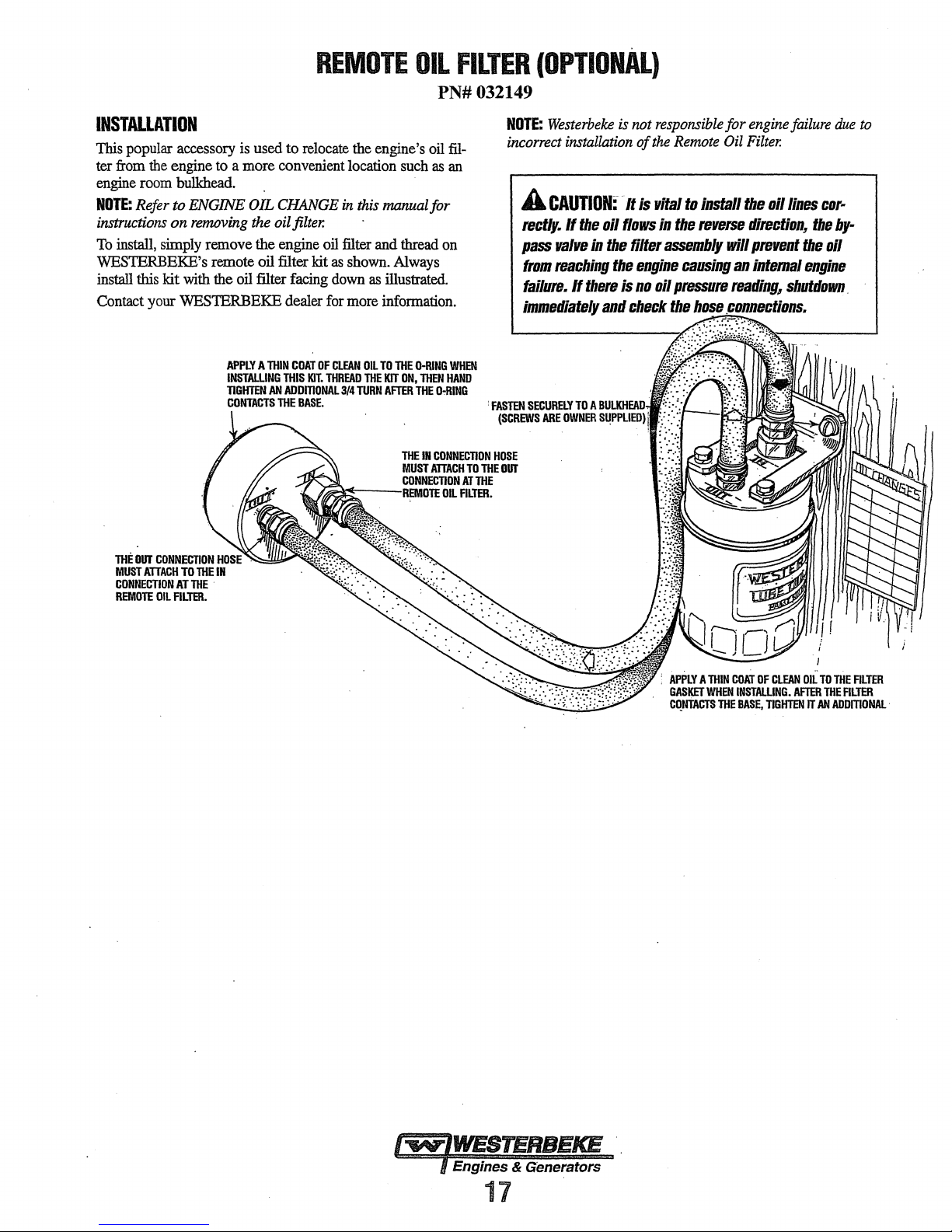

Page 20

GASOUNE

Use

-,.leaded

follow

companionways

ventilate

NOTE:

The

detector/alarm

GASOLINfJWATER

A primary

installed between the

water and other contamirulnts from the

be

carried

Most

instaliers

the installation

that contaminants in the fuel can

These

through'') to meet

bowls have drain valves to use

impurities,

89

.octane

U.S.

Coast

Guard regulations,

to

prevent fumes

after

fueling,

engine

torrtpartment should

properly

SEPARATOR

:fuel

filter of the water separating type must be

fuel·

to

the

fuel

syStem

~lude

~kage

gas

~e filiers must have

0

U;S.

or higher

installed

tank

,on

a type of

as

they

Coa8t

Guard

gasoline.

from

and:

and

the engine to

the

engine.

filter/water~

are

well

cause.

metal

when

FUEL

When

fueling,

clare.

off all

hatcQes

enteij11g

have

working,

AfiJ

bowls

requirements.

checking for water and

a

gasqline

FILTER

fuel

before they

aware

(not

·the

· · ·

of

and

boat,

and·

.

fuine

remove

can

with

the

problems

..

see-

Tbe'metai·

SYSTEM

The

pump

filter

also

clean

off the magnet [the magnet

from

the

fuel].

base hex nut with a

~ggasket

AwARN•G:

CDIIIIBI:fioJJS

Malee

Sllre

fuel

system

.FUR

UFT

should

be cleaned

The

pump base

wrench.

Fuel

is a fire

proper

t:DIRptments.

bazanl

relltilation

PUMP

can

When

leakage

and

every

250

removes

be

removed

reaSsembling,

at the fuel

should

exiSts

WJ.flnerel

operating

metal

by

twisting

rephice

PIIIIIP

be

t:DITBI:ted.

simnt:ing

hoi!rS;

particles

the

the

or its

#14PURPLE

PRESTART

·

BIJ7TON

GASOUNE/WATER

SEPERATOR & RlTER

·C~

The carburetor is a single barrel

by

metalic choke. Refer to

for more information. ·

RJa

UFI'

PUMP

Periodically check the fuel connections

and make sure that no leakage is present and that

are tight and

pump's mounting bolts should be clean and well

the

mo~ting

The start sequence energizes

the

pump operates, it creates

ticking is heard, check for

Also checkthat the ground wire is properly connected

ground.

NOTE: At initial start-up or when re-commissioning the engine,

it maybe necessary to prime the engine's fuel system.

depress and hold the

electric fuel pump which will pump fuel through the engine's

fuel system and

4-6 seconds then proceed to start the engine.

secure.

The DC ground connection at

bolt to ensure proper

ON switch. This will activate the engine's

fill

the carburetor's fuel bowl. Do this for

downdraft

CARBURETOR

to

pump

the

fuel

lift pump

an

audible ticking

12

volts

at

the

type

with

an

electric

ADJUSI'MENTS .

and out of

operation.

pump

the

the

fittings

one

of the

secured

as

the

piston

sound.

If

connections.

to

To

pump

by

in

no

do this

Periodically check

pump

and

make sure that no leakage

fittings

are tight

one of the pump's mounting bolts

secured.l:zy

operations.

the

fuel connections

and

secure. The DC

the mounting bolt to ensure proper

is

ground

should

to

and

present

connection

be clean

out of

and

that

and

pump

the

the

at

well

IW'IWESIERBEKE

f

Engirtf!S

&_Generators

12

Page 21

COOLING

SYSTEM

DESCRIPTION

Westerbeke marine engines are designed and equipped for

fresh water cooling. Heat produced in the engine by

tion and friction

circulates throughout the engine.

coolant cools the engine block,

the engine

fresh water coolant to raw water

exchanger, similar in function

water

flows

fresh water coolant

ferred to the fresh water coolant is conducted through the

tube walls

exhaust system where finally it

other words, the engine is cooled by fresh water coolant, this

coolant is cooled

transferred heat overboard through the exhaust system. The

fresh water coolant and raw water circuits are independent of

each

other.

allows the cooling water passages

. harmful deposits.

FRESH

NOTE:

WATER

Refer to

recommended

fresh

water

Fresh water coolant is pumped through the engine

lating pump, absorbing heat from the engine. The coolant

then passes through the thermostat into the manifold, to the

heat exchanger where it

block via the suction side

engine

is

the

closed thermostat (although some coolant

bypassed around the thermostat to prevent the exhaust

fold from overheating). As the engine warms up, the thermostat gradually opens, allowing

coolant

cooling system.

to

Coolant

A coolant recovery tank allows for engine coolant expansion

and contraction during engine operation, without

cant loss of coolant

ing system. This tank should

engine manifold level and should be easily accessible.

NOTE:

Periodically

sure

cap.

good

condition

closes

tightly.

is