Page 1

OPERATOR'S MANUAL

&

INSTALLATION GUIDE

WESTERBEKE

KW

BTDA 15.0

BTDA 12.0

- 60 Hertz

KW

- 50 Hertz

,~

MARINE

GENERATOR SET

Publication #038663

August 1990

DIESEL

Edition One

WESJ'ERBEKE

WESTERBEKECORPQRATJON

AVON INDUSTRIAL PARK,

AVON,,vA

02322.

T£L.:(5"")588-77oo

Page 2

Page 3

SAFETY PRECAUTIONS

The following symbols appear

to

attention

dangerous to the operator.

and emphasize conditions potentially

in

this manual to call

nWARNINGjI

The above symbol

possible serious personal injury or loss of

The above symbol

personnel of possible damage to equipment.

Read

the manual carefully and thoroughly before attempting

dangerous conditions can exist and take necessary

precautions to protect personnel and equipment.

Fuels, exhaust gases, batteries, electrical equipment,

and moving and hot parts

could

recommended procedures carefully.

Always operate bilge blowers for at least five minutes

before starting a gasoline-fueled engine; ensure no

gasoline fumes are present before starting.

• prevent Electric Shock

to

resutt in serious personal injury or death. Follow

Shut off electric power before accessing electrical

equipment.

Use

insulated mats whenever working on electrical

equipment.

is

used in the manual to warn of

life.

ICAUTIONI

is

used in the manual to caution

operate the equipment. Know when

are

potential hazards that

•

Use

Extreme Care When Handling Engine

(A

constant danger

Do not fill fuel tank(s) while the engine

Do

not smoke or use

or the fuel tank.

•

Do

Not Atter or Modify the

Be

sure all fuel supplies have a positive shut-off

valve.

Be

certain fuel line fittings are adequately tightened

and free of leaks.

Make sure a fire extinguisher

is

properly maintained.

use. Extinguishers rated

propriate for

environment.

• Use Extreme Care When Servicing Batteries

Wear rubber gloves, a rubber apron, and eye

protection when servicing batteries.

Lead acid batteries emit hydrogen, a

plosive gas, which can be ignited by electrical

cing or by a lighted cigarette, cigar, or pipe.

smoke or allow

serviced.

vicinity to prevent electrical arcing during servicing.

Shut off all electrical equipment

of

explosion

an

open flame near the engine

Fuel

Be

ABC

all

applications encountered

an

open flame near the battery being

or

fire exists)

is

running.

System

is

installed nearby and

familiar with its proper

by the NFPA

highly-ex-

Fuel

are ap-

in

Do

in

this

ar-

not

the

is

Make sure your clothing

ly

shoes), and keep your skin surfaces dry when

handling electrical equipment.

Remove wristwatch and jewelry when working on

electrical equipment.

Do

not connect utility shore power to vessel's

Circuits, except through a ship-to-shore doublethrow transfer switch. Damage to vessel's

erator may resutt H this

Be

extremely careful when working on electrical

components. High voltage can cause injury or

death.

• Exhaust Gases

Ensure that the exhaust system is adequate to expel

gases discharged from the engine.

system regularly for leaks and make sure the

haust manifolds

ing exists.

Be

sure the unit and its surroundings

tilated.

Are

are

dry, not damp (particular-

AC

is

not done.

Toxic

Check exhaust

securely attached and no warp-

are

well-ven-

AC

gen-

ex-

• Ayoid

MOYing

Do

not service the unit while the unit is running;

situation arises

to make operating adjustments, use extreme care

to avoid moving parts and hot exhaust system

ponents.

Do

not wear loose clothing or jewelry when servicing

equipment; avoid wearing loose jackets, shirts or

sleeves, rings, necklaces, or bracelets that might

caught in moving parts.

Make sure

tightened. Keep protective shields and guards in

their respective place

Do

not check fluid levels or the drive-belt's tension

while the unit

Do

not work on the equipment when mentally or

physically incapacitated by fatigue.

parts

in

which it is absolutely necessary

all attaching hardware is properly

at

all

times.

is

operating.

if

com-

be

a

15.0KWBTDA

1

Westerbeke Generators

Page 4

FOREWORD

Thank you for selecting a Westerbeke marine product for your use.

We

at Westerbeke

are

pleased to have you as a customer.

Read this manual carefully and observe all of the safety precautions indicated. Operating

procedures, periodic preventive maintenance procedures, installation checks, system descriptions

and minor adjustment procedures are included so you can operate your equipment safely and

properly, maintain the equipment at a high level of efficiency, and expect dependable performance

and long service life in return.

Product Software Disclaimer

all

Product software of

kind; such as brochures, drawings, technical data, operator's and

workshop manuals, parts lists and parts price lists, and other information, instructions and

specifications provided from

and; accordingly,

is

Sources

provided

Westerbeke cannot be responsible

or

representations with respect thereto, Including the accuracy, timeliness

In

thereof, and will

connection with,

no event be liable for any type of damages

or

arising out of, the furnishing or use

other than Westerbeke,

to

Westerbeke customers only as a courtesy and service.

for

the

content

of

is

not wtthin Westerbeke's control

such software, makes no warranties

or

completeness

or

Injury Incurred

of

such software.

For example, components and subassemblies incorporated in Westerbeke's products and supplied

as

by others (such

engine blocks, fuel systems and components, transmissions, electrical

components, pumps and other products) are generally supported by their manufacturers with

their own software, and Westerbeke must depend on such software for the design of Westerbeke's

own product software.

by

changes made

Westerbeke's suppliers, of which Westerbeke rarely has notice in advance,

Such software may

be

outdated and no longer accurate. Routine

are frequently not reflected in the supplier's software until after such changes take place.

In

Westerbeke customers should also keep in mind the time span between printings of Westerbeke

product software and the unavoidable existence of earlier, non-current, Westerbeke software

editions in the field. Additionally, most Westerbeke products include customer-requested special

features that frequently do not include complete documentation.

In

summation, product software provided with Westerbeke products, whether from Westerbeke

or other suppliers, must not and cannot be relied upon exclusively as the definitive authority

on the respective product.

It not only makes good sense but

representatives of Westerbeke or the supplier

and currency of the product software being

Westerbeke Generators 2

is

imperative that appropriate

in

question be consulted to determine the accuracy

consulted by the customer.

15.0KWBTDA

Page 5

Warranty Procedures

Should your unit require special attention, contact your Westerbeke dealer for assistance. The

Westerbeke Service Organization

is

trained to provide the support necessary to ensure long-term

dependable performance.

If,

within

received a Customer Identification Card (figure

60

days of submitting the Warranty Registration Form for your unit, you have not

1.2)

registering your warranty, please contact

the factory in writing with model information, including the unit's serial number and commission

date.

tno:

IEST£RBEKE

AVOM

nON,

Mall

CORPORHIOII

INDU$TlUAL

IIA

02122

To:

PARk

CUSTOMER IDENTIFICATION

.~

loIaph

Str

..

U 12234

III

'lbA

1nll9

t

Alolu.

140

.... 1 IS

hpi

....

Unit

1.0.

Plate

For

future

repair or warranty

erence,

service,

ref-

Westerbeke

suggests that you fill

the blank spaces in figure

1.3

with the infor-

mation

from

your

machine.

figure 1.2: Customer Indentification

in

•

figure 1.3: Unit I.D. Plate

Card

15.0KW BTDA

3

Westerbeke Generators

Page 6

Table

Of

Contents

Section

SAFTEY PRECAUTIONS

FOREWORD

PRODUCT SOFlWARE DISCLAIMER

WARRANTY PROCEDURES

GENERAL INFORMATION

PROTECTING YOUR INVESTMENT

15.0

BTDA GENERAL SPECIFICATIONS

15.0

BTDA SYSTEM SPECIFICATIONS

INSTALLATION CHECKS

EXHAUST SYSTEM

RAW WATER INTAKE SYSTEM

COOLING SYSTEM

-

14

Page

1

2

2

3

11

12

13

• 16

18

23

27

28

ENGINE CONTROL

REMOTE

REMOTE PANEL

WIRING DIAGRAM # 36474

PREPARATIONS FOR STARTING

STARTING

STOPPING PROCEDURE

FUEL

LUBRICATION SYSTEM

DC CONTROL CIRCUIT

WIRING DIAGRAM #36411

COOLING SYSTEM (FRESH WATER/RAW WATER)

BT

OPTIONAL VOLTAGE REGULATOR

OPERATION

PROCEDURE

SYSTEM

GENERATOR

PANEL

29

30

31

34

35

38

40

45

47

51

56

62

Weslerbeke Generators

4

15.0KW BTDA

Page 7

Table

Of

Contents

(continued)

Section

SHORE POWER CONNECTIONS

3 PHASE BT GENERATOR

3

PHASE VOLTAGE REGULATOR

ENGINE TROUBLESHOOTING

GENERATOR TROUBLESHOOTING

PERIODIC MAINTENANCE

TABLE

TIGHTENING TORQUES

LAY-UP

SPARE PARTS

OF

STANDARD HARDWARE

AND RECOMMISSIONING/WINTERIZING

-

AND ADJUSTMENTS

Page

64

68

69

74

77

78

64

86

90

1S.0KW BTDA

S

Westerbeke Generators

Page 8

RIGHT SIDE OF GENERATOR

AC

Water

Exhaust

Injected

Elbow

Exhaust

Manifold

Fresh

Water

Fill

Cap

Lube

Oil

Fill

Cap

Water

\

Temperature

Sender

DC

Charging

Alternator

Belt

Guard

Westerbeke Generators

6

15.0KW

BTDA

Page 9

LEFT SIDE

OF

GENERATOR

Water

Fuel

Fuel

Raw

Fuel Pressure Gauge

Temperature

Switch

Filter

Water

Pu

Oil

Pressure

___

~.

Sender

Lube

Oil

.------~

Oil Pressure Switch

Dipstick

..

---

Lube

Preheat

Oil

Solenoid

Filter

Starter

Control Panel

Generator

C

Battery

Ground

with

Solenoid

Switch

Data

Plate

Connection

15.0KW BTDA

7

Westerbeke Generators

Page 10

(This

page intentionally left blank)

15.1

Westerbeke Generators

8

15.0KW

BTDA

Page 11

(This page intentionally left blank)

15.0KW

BTDA

9

Westerbeke Generators

Page 12

(This page intentionally left blank)

Westerbeke Generators

10

15.0KW

BTDA

Page 13

15.0KW BTDA MARINE DIESEL GENERATOR SET GENERAL INFORMATION

Introduction

This manual contains equipment operating procedures and information to help the operator

maintain the marine equipment

carefully. A planned maintenance program

will

resuH

in

better equipment performance and longer equipment

problem

is

the most important step to satisfactory repair; therefore, a troubleshooting table

in

proper working order. Study and follow the instructions

is

included in this manual. Adhering to the program

me.

Proper diagnosis of a

is

included.

Service And Parts Manuals

For in-depth maintenance and repair, the service manual for the

15.0KW

BTDA

can be purchased

from your local dealer.

Product Description

The diesel engine closely resembles the gasoline engine since the mechanism is essentially

the same. The cylinders

are

arranged above a closed crankcase; the crankshaft

is

of the same

general type as that of a gasoline engine; and the diesel engine has the same type of valves,

camshaft, pistons, connecting rods, and lubricating system.

Therefore, to a great extent, a diesel engine requires the same preventive maintenance

gasoline engine. The most important factors

are

proper ventilation and proper maintenance of

as

the fuel, lubricating and cooling systems. Replacement of fuel and lubricating filter elements at

is

the time periods specified

manatory, and frequent checking for contamination (that

sediment, or algae) in the fuel system

is

also essential. Another important factor

is,

is

the use

water,

of the same brand of high detergent diesel lubricating oil designed specifically for diesel engines.

Be

careful not to put gasoline in the diesel fuel tank(s). Gasoline does not have the same

lubricating qualities

as

diesel fuel; consequently, gasoline in the fuel lines will damage components

in the fuel injection pump and fuel injectors.

The diesel engine differs from the gasoline engine; however, in that the functions of the

carburetor and ignition system

are

performed by the fuel injection pump and the fuel injectors.

Ignition results from a higher compression ratio which eliminates the need for spark plugs, but

neccitates the use of a heavier block.

a

15.0KW BTDA

11

Westerbeke Generators

Page 14

Protecting Your Investment

The five most important steps to insure

1.

Proper Installation.

In

particular, the use of

intrusion into the engine via the exhaust

2.

Avoid overcranking. This

3.

Change the lubricating

4.

Maintain the cooling system.

5.

Winterizing your Westerbeke product.

can

fill the engine with

oil.

long engine

elbow

Ine

are:

an

anti siphon break to preclude

is

essential.

raw

water.

raw

water

Ordering Parts

Whenever you require

(I.e.

15.0

~

BTDA)

the data

plates located on the exhaust manifold and on the generator end.

us with this information so

replacement parts, always provide the generator model number designation

, engine serial number, and generator serial number as they appear on

You

~

provide

we

may

properly identify your generator set.

In

addition, include a

complete part description and part number for each part needed (see the separately furnished

Parts List).

or generic parts

Also,

be

sure to insist upon Westerbeke factory packaged parts because "will fit"

are

frequently not made to the same specifications as original equipment.

Note that component

is

the pulley/drive

are determined by the engine; imagine

as the front of the engine: the

Westerbeke generator sets

locations in the manual are referenced from the front of the engine which

bett

end.

(The

flywheel/generator end

is

the rear end.) Left and right sides

straddling the engine and facing in the same direction

left side

are

thoroughly checked and given a final run under various load

is

at your

left,

the right side at your right.

conditions before leaving the factory. Test running the generator ensures dependable operation,

long service

Care at the factory during

life,

and a satisfied owner.

assembly and thorough testing has resulted in a Westerbeke diesel

engine-driven generator capable of many thousands of hours of dependable service. However,

the manufacturer cannot

in

which the unit

is

operated and serviced

control the installation of the generator in the vessel or the manner

in

the field. That part

is

up to the buyer/owner-operator.

Westerbeke Generators

12

15.0KW BTDA

Page 15

15.0 KW BTDA General Specifications

Engine Type

Governor

Combustion Chamber

Bore

& Stroke

Piston Displacement

Firing

Order

Direction of Rotation

Maximum Torque

(at

Compression Ratio

Compression Pressure

lim~

Valve

Timing

1800

rpm)

Diesel,

four·cycle, four-cylinder, fresh water-cooled,

vertical in-line overhead valve mechanism

(30

hp

at

1800 rpm maximum).

Mechanical type (integral of the injection pump)

Swirl type

3.50 x 3.50 inches (88.9 x

134.8 cubic inches (2.209

89

mm)

I~ers)

1-3-4-2

Clockwise, when viewed from the front

148

Ib-It

(20.46 kg-m)

21:1

2

47'

)

at 200 rpm

2

)

BTDC

ABDC

427 psi

384

(30

kg/cm

psi (27.0 kg/cm

Intake Opens 17"

Intake Closes

Valve

Seat Angle

Valve

Clearance

(engine cold)

Engine

Speed

Dimensions

Weight

Fuel

Consumption

Inclination

Exhaust

Exhaust Closes

Intake

Exhaust

Intake 0.012 inches

Exhaust 0.012 inches (0.3

1800 rpm

1500 rpm

Opens 51'

45'

30'

60

Hertz

50

Hertz

13'

BBDC

ATDC

(0.3

mm)

mm)

Height: 25.74 inches (653.8

Width: 21.19 inches (538.2

mm)

Length: 39.63 inches (1006.6

765

Ibs

(347

kgs)

1.8

gph (6.81Iph) at full rated output

(approximate)

15'

Continuous

Temporary 20'

(not to exceed 20 min.)

mm)

mm)

15.0KW

BTDA

13 Westerbeke Generators

Page 16

15.0 KW

BTDA

Fuel System

General

Fuel

Fuel

Injection Pump

Fuel Injection Timing

System Specifications

Open flow,

No.

2 diesel oil (cetane rating of 45 or higher)

Distributor Type

0"

TDC

sen

priming·

(VE)

Diesel

(Top Dead Center)

one bleed point

KiKi

Nozzle

Fuel

Filter PN#024363

cleaner

Air

Air Flow (engine combustion)

Cooling System

General

Operating Temperature

Fresh Water Pump

Raw

Water Pump

Raw

Water

Flow,

at

1800 rpm

(measured before discharging

into exhaust

System Capacity

elbow)

(fresh water)

Throttle

type

Spin-on (Replaceable)

screen type - cleanable

Metal

cfm

(1.9

70.0

cmm)

Fresh water-cooled block, thermostatically-controlled

wtth heat exchanger.

170 - 190" F (77 - 88'

C)

Centrifugal type, metal impeller, bett-driven

Positive displacement, rubber impeller, gear-driven.

6.0 gpm (22.7

10.0 qts

Ipm)

(Itters)

Lubrication

General

Oil

Filter PN# 035828

Sump Capacity (not including filter)

Operating

Oil

Grade

Westerbeke Generators

System

Oil

Pressure (engine hot)

Pressure fed system

Full

flow,

paper element, spin-on type

5.3

U.S.

qts

(5.0

50 -65

API

psi

service

(3.5

CC -CD

14

Itters)

plus filter/cooler assembly

- 4.57 kg/cm

2

)

15.0KWBTDA

Page 17

15.0

KW

BTDA System Specifications (continued)

Electrical System

Starting Battery

Battery Capacity

DC

Charging Alternator

12·Vott,

125

51

(-)

negative ground

ampere·Hours

Amp rated, belt·driven

Starter

Starting Aid

DC

No·Load Current

DC

Cranking Current

AC

Generator

General

12·Volt,

reduction

Glow plugs, sheathed type

± 2 % of rated Amps

280

Amps (engine cold)

Brushless, four·pole, revolving field.

Pre·lubricated, single·bearing

design.

Reconnectable, single·phase transformer

regulation (optional solid·state voltage regulation).

Voltage120

220 Votts •

or 120/240 Volts •

50

Hertz.

60

Hertz

Voltage regulation: ±5% no load to full load.

Frequency regulation:

±3

Hertz

(5%)

no load

to full load.

Rating (Volts

AC)

15.0KW BTDA

60

Hertz (1800

50

Hertz

Generator Cooling

(60

Hertz) at 1800 rpm

(1500

rpm)

rpm)

Air

Requirements

NOTE: Increase air supply

Engine Combustion Air Requirements

(60

Hertz),

at

1800

rpm

120 Volts125 Amps

120/240 Volts125/62.5 Amps

220 Volts60 Amps

225

• 250 cfm (6.37 • 7.08

15%

for

50

Hertz operation (1500 rpm).

70

cfm

(1.89

cmm)

15

cmm)

Westerbeke Generators

Page 18

15.0

KW

BTDA System Specifications (continued)

Tune-up Specifications

Injector Pressure

Engine Timing

Governor

Generator Compartment

Ambient Temperature

NOTE:

generator compartment ambient temperature below 104°

Forced ventilation should be provided

1920 +

Static timed - drop valve method

0.180 ± .005 inches

0°

1 mm of cam lift using measuring device for

injection pump.

Hydraulic mechanical type in the injection pump

104° F (40"

T.O.C.

71

- 0 psi

or

#1 cylinder.

C)

Maximum

as

(135

+ 5 - 0 kg/cm2)

BTDC

needed to maintain

F.

Westerbeke Generators

16

15.0KW BTDA

Page 19

General

the boats on which Westerbeke generators are installed vary in design, installation

Since

procedures will vary according to your boat's specific design. The intent of this section

not to advise boatyards or installers

However, the owner/operator must

on

procedures already well-developed and well-understood.

realize there are details of the installation which require

is

periodic checks to ensure the best operating conditions for the equipment and safe operating

conditions for the

in

the vessel

personnel

are

of prime importance.

Factors in the installation that must

on

board. Proper location and installation of the diesel generator

be

considered

are:

(1)

ventilation; to aid in cooling the

generator end, to provide air for engine combustion and to remove heat produced by the

(2)

the

AC

e)(haust

expel exhausl

and

engine while operating,

and to quiet the exhaust and to

electrical connections; both

supply of properly filtered fuel to the fuel pump

system; to properly discharge

gas,

(3)

the cooling water supply,

DC,

and

(5)

a fuel system that will provide

on

the engine.

~AOTIONI

raw

cooling water

an

unrestricted

(4)

the

Fill The Engine With

For safety reasons, the generator's engine

oil

for shipment. Before leaving the factory, however, each generator

is

thoroughly tested

set

things, provides

all

WITh

oil in

internal parts with a coating of

011

Before Starting

is

not filled with lubricating

ITS

engine. This testing, among other

oil.

This oil acts

as

a preservative, providing reliable protection against corrosion for at least

one year ~ the generator

is

properly stored.

Do

not overfill.

Inspection of Equipment

is

The generator

equipment

shipped from the factory securely mounted and properly crated. Accessory

is

shipped

in

a separate small

box,

usually packed wtthin the generator's crate.

Before accepting shipment of the generator set from the transportation company, the crate

should

you

delivery receipt.

sure that the proper notation

are your protection against

be

opened and the contents inspected for concealed damage.

If

damage

is

noted,

should require the delivery agent sign "Received in damaged condition" on the proper

Also,

check the contents of the shipment against the packing list and make

is

made ~ any discrepancies exist. These noted discrepancies

loss

or

damage. Claims concerning loss or damage must

be

made to the carrier, not to Westerbeke Corporation.

15.0KW BTDA

17

Westerbeke Generators

Page 20

Generator Mounting - Location

complete generator

The

un~

is

mounted on lightweight rails by means of four flexible isolatro

mouints that help prevent the transfer of vibration from the generator to the

generator mounting

several 1/2 inch boh holes so bohs can

be

employed to properly

rail

ahs

secure the generator to its mounting platform.

rails.

Eachj

figure 3.3:

The mounting location

water and water from above cannot splash or drip

engine and generator

repairs

to provide fresh

~nerator

Mounting

/llJ.lS1

be

/llJ.lS1

be

dry, above low-lying vapor

accessible for minor servicing and repairs. Access for major

should be given consideration

cooling air for the generator end, for engine combustion needs, and to remove

as

on

the generator or drive engine.

well.

The generator set

areas,

and

/llJ.lS1

in

heat produced by the engine while operating. The generator set needs fresh

location

generator

be strong enough to support the generator during

in

the vessel ~ is

area.

The platform on which the generator and its mounting rails are located

installed. Hot generator discharge air

all

angles of vessel operation.

/llJ.lS1

1/2-

MOUNTING

HOLES

an

area where bilge

The

drive

be properly ventilated

cool air

be removed from the

in

whatever

/llJ.lS1

15.0KW BTDA

18

Westerbeke Generators

Page 21

Generator Mounting - Rigging and Lifting

The generator

is

fitted with lifting eyes. Rope or chain slings capable of supporting the generator's

weight should be attached to the eyes and the generator lifted by means of tackle attached

to these slings. The lifting eyes have been designed to carry the full weight of the generator;

therefore, auxiliary slings are not required or desired.

ICAUTION!

Sling Lifting Angle Must Not Exceed 10 Degrees

Slings must not be so short as to place signfficant stress

eyes.

Strain placed on the generator's lifting eyes by the lifting sling must not be in

excess

of

10

degrees from !he vertical plain.

10'

SLING LIFTING

ANGlE

EXCEED

MUST

10'

LIFTING

NOT

on

the generator's lifting

EYE

ENGIME

figure 3.4: Lifting Angle

The general rule in moving generators

and firmly fixed in place. Move the engine a little at a time and see that

ported. Eliminate the possibility of accidents by avoiding haste.

tts

by

crankshaft pulley.

In

certain sttuations

tions other than the horizontal posttion. Certain sttuations exist

is

to see that all equipment used

Do

tt

may

be necessary to lift the engine in posi-

by

is

amply strong

tt

is

firmly sup-

not lift the generator

which the engine must

be lowered endwise through a small hatchway which cannot be made larger. Under these

conditions,

ff

the opening of the hatchway

is

extremely small,

tt

is

possible to reduce, to

some extent, the outside dimensions of the generator by removing external components

such

as

the cooling system's piping, the heat exchanger, certain filters, the mounting rails

and other obstructive equipment. This accessory equipment should be removed by a

competent mechanic and special care should be taken to avoid damage to any exposed parts.

In

addition, be careful to prevent dirt from entering any opening created by the removal of

equipment. Removed parts should be returned to their respective position once the

ator

is

in

tts

In

case

installation

tt

becomes necessary to hoist the generator front -end upwards or generator-end upwards,

area.

Replace gaskets

as

needed for the parts that were removed.

gener-

the attachment of lifting slings must be done carefully to avoid the possibility of damaging the

parts

on

which the weight of the slings may bear. Special rigging work

is

best done by someone

experienced and competent in handling heavy machinery.

Westerbeke Generators

19

15.0KWBTDA

Page 22

Ventilation

is

The ventilation requirements of the generator sets include the following: combustion air

quired for the engine cylinder; cooling air

is

required for the generator end and also for

re-

removing the head produced by the generator's engine during operation; and ventilating air

is

required

the generator

Keep

to

clear the bilges below the generator, as well

is

located, of potentially toxic and flammable diesel vapors.

in

mind that hot air rises, so heated air should be removed from the upper area of the

as

the compartment in which

generator compartment and cool fresh air should be directed to the lower areas of the

compartment. Ventilation should be accomplished with the aid of blowers especially when the

is

vessel

not underway. Refer to the

the airflow requirements of the

System

Fuel

ge,!1erator

"SYSTEM

set.

SPECIFICATIONS" section of this manual for

The generator

aJ.lW.

have

~s

own fuel supply line; in other words,

~

aJ.lW.

have

~s

own fuel

tank pickup tube and primary filter/water separator. Do not tee off another engine's fuel

supply. The fuel system should

installed

in

such a manner

as

to

allow the engine-

be

mounted fuel pump to pump and maintain a positive inlet pressure to the injection pump

all

under

operating conditions,1 1/2 - 2 p.s.i.. The minimum size of the fuel supply line

and fuel return line is 1/4 inch, inside diameter, and there should be a primary fuel filter/

water separator installed between the fuel tank and the fuel pump.

on

stalled

the engine, between the fuel pump and the injection pump; this filter has a

Only one fuel filter

is

replaceable filter element.

The fuel tank's fuel pickup tube should

be

strainers should

incorporated in the fuel pickup tube.

clear and unobstructed.

No

screens or gauze

be

Make sure that the fuel supply and return lines are secruely anchored to prevent chafing

all

and that

system has a positive shut-off valve; know

fittings are sufficiently tightened to prevent leaking. Also, make sure your fuel

ns

locaton and how ~ operates.

NOTE:

in

Do

not use spring-loaded check valves

lieu

of mechanical shut-off valves. This type valve can create fuel

in

the fuel supply line

starvation problems for the engine's fuel system.

Fuel

tanks that

connection at the tank extending down into the tank

are

located below the engine's fuel system level must have their fuel return

in

the same manner as the pickup tube;

otherwise, air will replace fuel Siphoning out of the engine's fuel system through the return.

in-

Make sure the fuel tank filler

awash. The fuel tank's vent should be routed so

Be

sure there

Be

familiar with its use.

applications

Westerbeke Generators

is

properly sealed to prevent water entry should it become

as

to prevent water enter

is

a fire extinguisher installed near the unit and that it

An

in

this environment.

extinguisher

w~h

the

NFPA

rating of

20

ABC

as

well.

is

properly maintained.

is

appropriate for

15.0KW BTDA

all

Page 23

011

Drain Hose

An

oil sump drain hose is installed on the engine wtth the discharge end secured by a

bracket at the front of the engine.

cap and the discharge end of the hose from the support bracket and lowering the hose

into a container. The hose cap

tended. or have a pup added, for easier removal of the old

Oil

fttting

may

is

1/4 inch

be

drained from this hose by removing the

NPT

(National Pipe Tap) and can

oil,

if desired.

be

ex-

Connecting Pressure Sensing Devices

Oil

pressure sensing devices, such

engine's oil gallery wtth the use of extended nipples or tees. The reason

continued engine vibration

If

these fittings fail during engine operation, lubricating oil will be lost and internal engine

damage will

When additional sensing devices such

function on engine

the oil gallery using an appropriated grade of lubricating oil hose. Any fittings used to con-

nect the hose to the gallery

be

not

Electrical System

The electrical system should

down with clamps or plastic ties and that

enough to prevent chafing from vibration.

are tight and that they are made to the appropriate terminals.

DC

Electrical Connections

resutt.

oil pressure, these devices

used for this application.

causes fatigue of the ftttings used to

mug

be

checked to make sure all wiring harnesses are properly tied

to

011

Gallerlos

as

senders and swttches, must not be connected to

is

simply that

make

such a connection.

as

swttched or sensors need to

mug

be bulkhead-mounted and connected to

be of steel or malleable iron composttion. Brass must

all

wiring harnesses

Check to make sure

are

all

be

installed that

spaced at intervals close

engine harness connections

an

A common ground for the negative

of the generator, next to the starter,

tery ground should be connected

Connect the battery's positive

tion.

15.0KWBTDA

(+) connection to the starter solenoid tagged for this connec·

To

avoid

an

overcharging condition, and a possible equipment failure

do not disconnect the

(-)

DC

terminal connection

in

the form of a threaded grounding stud.

at

this stud.

is

found at the bellhousing

fAOTIONI

DC

battery source while the engine

21

The

bat-

is

running.

Westerbeke Generators

Page 24

Generator

Make sure that the

correct and in acordance with the specific

this

leads

(AC

Output)

AC

output connections within the generator's

AC

Load Connections diagram found later in

manual.

are

(See

the "BT

protected against chafing as they exit the generator housing

GENERATOR"

section of this manual.) Make sure the

AC

terminal block

IWARNiNGI

Do not smoke or allow an open flame near batteries. Lead acid batteries emit

hydrogen, a

Batteries

highly-explosive

gas.

are

AC

Make sure the positive

the starting solenoid. The negative

ground stud tagged at the rear of the engine

(+) battery connection

(-)

is

connected to the battery connection of

battery connection should be connected to the

block.

!WARNiNGJ

Protect Yourself When Servicing The Battery

When servicing the battery of checking the

rubber apron, and eye protection. Battery acid may

eyes inadvertently when removing the

Check the battery's electrolyte level and specific gravity to ensure maximum engine

starting efficiency. Make sure the battery's terminals

electorlyte

electrolyte caps.

level,

wear rubber gloves, a

splash on the skin or into the

are

clean and tight.

Westerbeke Generators

22

15.0KW BTDA

Page 25

Exhaust System

Carbon monoxide is a dangerous

and

monoxide inhalation or poisoning

• Dizziness • Vomiting

• Intense Headache • Muscular Twitching

• Weakness and Sleepiness • Throbbing

Carbon monoxide gas Is deadlyl

is

potentially lethal. Some

tNAANiNGI

gas

that can cause unconsciousness

of

the symptoms or signs of carbon

are

listed below.

in

Temples

The generator should have its own separate exhaust installed so that the entry of

into the engine's exhaust

or while the vessel is under sail or power

rolling or pitching. Special atlention

secure, tight and free

The

raw

water supply through-hull sea cock fittings

scoop types or weed less scoop types must not

of

raw

water through the cooling system filling

When a water lift type exhaust system is used (figure

mounted

downward into the exhaust muffler. Loops

exhaust elbow and the water lift muffler should

as close to the engine as practical.

manHold

of

leaks.

and cylinders is prevented while the engine is

in

~

which case the vessel

be

taken to

be

the

make

~

be

of

used,

as they tend to encourage siphoning

exhaust.

may

experience heeling,

certain the exhaust system is

the flush-hull type. High-speed

3.13.4), the exhaust muffler should be

The

exhaust discharge should always drop

in

the exhaust hose between the water-injected

be

avoided,

as

these

will

trap and hold water.

raw

nOl

water

running,

figure 3.13.4: Water Lift Exhaust System

Westerbeke Generators

23

15.0KWBTDA

Page 26

u.n.",

II"

...

UUI_

IU'"

"I('

UI(

figure 3.13.5: Siphon Break

For installations where the exhaust manHold/water-injected exhaust elbow

below the vessel's water line, provisions

ID~tallatioD

~

be

is

close

to

or

made to install a siphon-break or a vent

in the raw water supply hose to the water-injected exhaust elbow. (figure 3.13.5) This

stops the

flow of

exhaust and

~

be looped above the water line. This siphon-break or vent

the water line during

used,

~

empty of water when the engine

to

prevent siphoning.

Dry

stack-type exhaust systems (figure 3.13.6)

exhaust

manHold

supported and

must be made for discharging the engine's

raw

water that runs through the

engine cylinders when the engine

raw

water cooling system from filling the

is

shut down. This

raw

water supply hose

~

always be above

all angles of vessel operation to prevent siphoning. The vent, when

have its vent hose or tube routed so it can remain above the water line and

is

shut down. This allows air to enter through this vent

must

be attached to the generator engine's

by means of a flexible connector pipe. This system

~

be properly

insulated to prevent water from entering into the engine's cylinders. Provisions

raw

cooling water .

..........

c.

c

....

c.

~

i I

15.0KWBTDA

"Z.C.

....

~~3

-

figure 3.13.6: Dry Stack Exhaust

c_

••••

,

pc.

LJ.C

•••

~E

..

•••

•

c.

_ ..

e.

J

.....

c ,.

....

ue

..

........

"Jrra

.. e

_

f'

.........

•• • S.C

a.c.

""""=="===~~~~~~~!:.=c.

24

~oc..7;;J--

........

_

)

..

e •

•••

Westerbeke Generators

Page 27

Exhaust Elbow Installation

The Westerbeke Corporation offers a 7Z' exhaust elbow

can install on your engine's exhaust

the exhaust

elbow purchased for your generator.

manHold.

Refer to the instruction below when installing

NOTE: Fabricated exhaust elbows or risers attached to the exhaust

manHold

1.

Coat only one side

shall not exceed 8 Ibs when unsupported.

of

the exhaust

gasket with "High Tack" (Manufactured

by Permatex Company, Brooklyn,

N.Y.)

adhesive sealant. Place this coated surface against the exhaust manHold's

ex-

haust port flange (the gasket should

stick to the flange without falling off).

2. Place the clamp over the elbow's

flange.

against the exhaust manHold's flange

Place your exhaust elbow

so

the exhaust manHold's flange rests

snug against the exhaust elbow's flange

with the gasket centered between the

two. Now

slip the exhaust clamp over

both flanges.

as

well

as

an

exhaust riser you

#38374

Elbow

3.14:

3.

A Tighten the clamp just enough

figure

so the exhaust elbow can remain attached to the

B.

The exhaust elbow discharge

~

be

directed downward

Exhaust Elbow Installation

manHold

and still be rotated.

so

the mixture of

water and exhaust gases will flow/fall downward into the exhaust muffler which must be

positioned

hose connected between the exhaust

and possibly allow water to flow back into the engine during starting or

4. Adjust the

is

acquired.

5. Carefully tighten the clamp between 2 to 3

below the exhaust elbow. There should be no loops or rises in the exhaust

elbow by rotating

elbow and the muffler,

it

until the desired alignment with the exhaust piping

Ib-It,

or 24 to 35 Ib-in, or 0.27 to

as

these would trap water

at

shut down.

0.41 kg-m.

r.:;AOTIONj

3 Lb·Ft Torque Umlt

Approach the 3 Ib-It torque limit with caution. The clamp's threads will

H more than 3 Ib-It

break

If

a leak exists, correct it immediately .

is

applied to the clamp.

raw

. Westerbeke Generators

25

15.0KW BTDA

Page 28

Exhaust Back-Pressure

The exhaust discharge hose

and minimal run to prevent excessive exhaust

pressure. Exhaust back-pressure should

before a generator

Excessive back-pressure will affect the engine's

formance which affects generator

To measure

manometer, a pressure gauge, or a water column.

boatyard or marine mechanic should have a manometer

or a pressure gauge.

have a tapped hole in

be

drilled and tapped for a 1/8 inch

dry area of the elbow.

Measure the engine's back-pressure at the exhaust

elbow while the generator

Refer

to the pressure specifications listed below. \

A water column can be made

tube and taping one end of the tube along a

yardstick and fitting the other end of the tube

a 1/8 inch

NPT

is

for

back-pressure, use a mercury

(National

must be of adequate size

back-

be

checked

put into service (figure 3.15.1)

per-

AC

power output.

A

If the generator set does not

~s

exhaust elbow, one

NPT

f~ing

is

under a full-load.

by

taking a clear plastic figure 3.15.1: Exhaust Elbow Connections

Pipe

Tap) pipe fitting.

II!!.&:

in

the

w~h

..

..

"

"

H Exhaust

,n

..

~

~I

-Insulation

Exhaust

Elbow

Mercury

Manometer

Measure the engine's back-pressure in the dry

area of the exhaust elbow while the generator

under a full-load.

NOTE: Dimension A (figure 3.15.5)

cannot exceed 27 inches of water.

Back

pressure,

ment, should not exceed the following specifica-

tions:

2 inches of mercury

27 inches of water in a water column

15.6 ounces psi

1.0

1.11

psi

kg/cm

as

measured by a gauge instru-

2

"--.

is

1/8

NPT Plug

\

15.0KW BTDA

26

Westerbeke Generators

Page 29

Exhaust System Failures

an

When the engine's raw water is fed into

exhaust system so that the full stream of this water

strikes a surface, errosion takes place. This errosion may cause premature failures. The proper

design of either a water jacketed or water injected

raw

requires that the

not directly strike a surface.

be

as

low

as

possible, which can be achieved

water inlet be posttioned so that the entering stream of

In

addition, the veloctty of the entering

"wet" exhaust system to prevent this problem

raw

water does

raw

water stream should

by

having inlet fittings as big in diameter

as

possible.

is

The best protection against carbon monoxide poisoning

a daily inspection of the complete

exhaust system. Check for leaks -around manifolds, gaskets, and welds. Make sure exhaust

lines are not heating surrounding areas excessively.

If

situation immediately.

you notice a change

shut down the unit immediately and

in

the sound or appearance of the exhaust system,

have

the system inspected and repaired at once

excessive heat

is

present, correct the

by

If

qualified mechanic.

Make sure there are no unnecessary objects suspended from any portion of the exhaust lines.

Exhaust risers installed off the exhaust manifold should not exceed 8

Ibs in total weight when

rigidly constructed. Excessive weight could cause deflection or distortion of the manifold resulting

in

damage and/or internal leaks. Inspect insulated portions of the exhaust system to ensure

there

is

no deterioration of the insulation.

a

ICAUtloN)

Do Not Overcrankl

resu~

Prolonged cranking intervals without the engine starting can

raw

filling the exhaust system with

raw

because the

water pump

water cooling system during cranking. This

engine's cylinders by

way

of the exhaust

system fills. Prevent this from happening by closing the

water coolant. This may happen

is

pumping

raw

water through the

raw

water can enter the

manHold

once the exhaust

raw

water supply

through-hull shut-off, drain the exhaust muffler, and correct the cause

for the excessive engine cranking needed to obtain a start. Engine

raw

water entry

this in mind.

Raw Water

damage resulting from this type of

The owner/operator should

keep

Intake System

Make sure the intake system (raw water cooling system)

are

the hull inlet, sea cock and strainer

at

least one size greater than the inlet thread of the sea water pump. The strainer should

be

of the type that may be withdrawn for cleaning while the vessel

be mounted below the water line to ensure

unobstructed. Sea cocks and strainers should be

self-priming. Inspect the

is

IlQ1

a warranted.

is

in

proper order. Check that

is

at

raw

make sure there are no collapsed sections, which would restrict water flow. Make sure

The

there are no air leaks at any of the connections.

as

tioned at the vessel water line or below so

to

sea water strainer should

be

self primed.

in

raw

sea and should

water lines to

be

posi-

Westerbeke Generators

27

15.0KWBTDA

Page 30

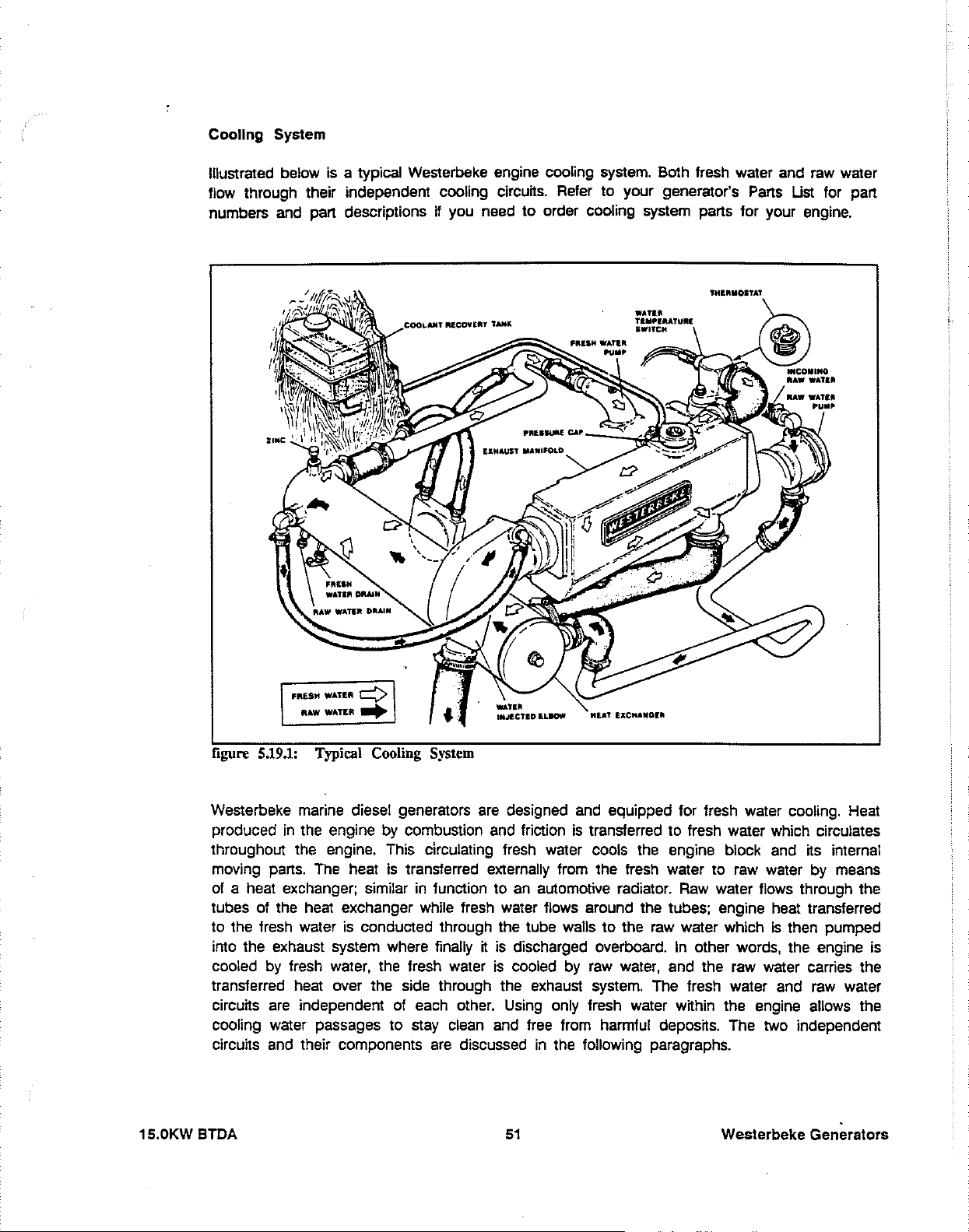

Cooling System

The

generator's engine

water is used

by

a raw water pump and is then injected into the exhaust discharge, carrying

as

the heat exchange's cooling

removed from the engine's fresh water

Raw

water should be supplied to the

using a wire-reinforced hose between the through-hull fitting and the

raw

water should be directed through a visual-type raw water strainer and then delivered to

the pump. Hoses routed from the through-hull

pump should be wire-reinforced to prevent the hose from

operation (suction from the pump

should be mounted

is

fresh water-cooled

cooling

raw

may

collapse a non-reinforced hose).

at

or below the water line to

by

an

engine-mounted heat exchanger.

medium.

Raw

water is pumped into the exchanger

wtth

system.

water pump through a flush-type through-hull fttting

raw

water pump. This

fitting to the strainer and to the raw water

collapsing during the generator's

Raw

water strainers

make

sure the raw water line remains primed

alter shutdown.

!(?AOTlO~

Do

Not Use A Scoop-type Through·hull Fitting

Do not use a scoop-type through-hull fitting

raw water to the generator. Water pressure against this type

while the vessel

is

under

way,

can

push raw water past the raw water

pump's impeller into the generator's exhaust system, filling

as

well.

engine

Flush-type,

and should be located

during

all

angles of boat operation.

clear,

on

the hull so

through-hull fittings

as

a means

of

supplying

tt

are

recommended

as

to be below the waterline

fitting,

and the

tt

the heat

Raw

The use of common-type street elbows

These generally have very restrictive inside diameters. Machined fittings

Coolant Recovery Tank, Recommended

A coolant recovery tank

kh

is supplied

each Westerbeke diesel engine.

of

this recovery tank is to allow for engine

coolant expansion and contraction, during

gine operation, whhout the loss

and

wtthout introducing air into the cooling

The

of

is

not recommended for plumbing the

Installation

whh

purpose

en-

coolant

are

raw

water circutt.

preferred.

system.

be

in

wtth

installed

a loca-

a 30

UN

... , ......

This coolant recovery tank should

at,

or above, engine manifold

tt

can

tion where

where coolant

be easily monhored and

can

be easily added if needed

level,

(figure 3.19). A stainless steel mounting brack-

et

is

supplied

inch length

wtth

each

ktt

along

of

clear plastic hose and clamps

to connect the hose between the engine's

manifold

of

fitting to the hose spud

on

the base

the recovery tank. figure 3.19: Coolant Recovery Tank Installation

"

15.0KW BTDA

28

Westerbeke Generators

Page 31

OPERATIONS

o

PREHEAT

o

~

START

@

~

o o

figure 4.1: Engine Mounted Instrument Panel

Engine Mounted Instrument Panel

The manually-operated series of Westerbeke generators are equipped with toggle switches and

optional remote panels. The Engine Mounted

in

which indicate water temperature

(OIL

PSI).

per square inch

control circuit voltage

and in 1/10 hours. The water temperature,

the

ELAPSED

TIME

meter

This panel

(VOLTS)

is

degrees

and the generator's running time

not illuminated.

Instrument Panel (figure 4.1) includes two gauges

Fahrenhe~

is

also equipped with two meters which indicate

oil

pressure gauges and

(WATER

OF)

and oil pressure

(ELAPSED

DC

volt meter are illuminated;

TIME)

in

pounds

in

HOURS

DC

15KW BTDA

1.

PREHEAT: The PREHEAT

fuel pump, bypasses the engine's oil pressure

This switch

2.

START: The START

the engine. This switch

and held at the same time.

3.

STOP: Power

switch deactivates the fuel solenoid and shuts off fuel to the engine, causing the engine

to stop.

also energizes the START

is

provided to the fuel solenoid through the

NOTE: When the engine

gauge and the oil pressure gauge will continue to register the last

temperature and oil pressure readings indicated by the gauges before

the electrical power was turned off. The temperature gauge and oil

pressure gauge will return to zero once electrical power

sw~ch

switCh,

will

energizes the engine's glow plugs, activates the electric

sw~ch,

sw~ch.

when pressed, energizes the starter's solenoid which cranks

not operate electrically unless the PREHEAT switch

is

manually shut down, the water temperature

29 Westerbeke Generators

and activates the fuel run solenoid.

STOP

is

switch. Opening this

is

restored.

pressed

Page 32

Remote Control Instrument Panel

The remote

on the engine-mounted Start/Stop panel (page

When starting at a remote location, the green

at approximately

starting of the generator may not be audible from the remote location.

Start/Stop panel (figure 4.2) has three switches that serve the same functions

29).

LED

600

rpm. This indicates when the START

0

GENERATOR

0

RELEASE

STARTER

PREHEAT

PRESS

"'"

1ST

•....

®

!.

-.::

,'.

It has a green

comes on when the generator

sw~ch

"''''-,

..

,--.

®

STOP

START

:

....

- I

®,,~'

. .

,-..,/

.

LED

can

0

2ND

as

light and no guages.

is

running

be released since the

Westerbeke Generators

0

WESTERBEKE

figure 4.2. Remote Control Instrument Panel

30

0

15KWBTDA

Page 33

Instrument Panel Wiring

For

starting and stopping the generator at a remote iocation, three similar switches

The PREHEAT and START switches are connected in parallel with the engine mounted panel's

switches and serve the same functions. The STOP switch is connected in series with the local

panel's STOP switch and serves the same function. The generator may be stopped and started

from either engine mounted or remote positions.

are

used.

Remote

,

'

:

I I

~

__________

L

figure 4.3: Remote Control Insrument Panel Wiring Diagram

Control

r---------------------- --------------

Slop

Switch

114

Rr.d

_

________

19'10

StA

rt.

Switch

#14

P.N.

Panel

Red

21. 91. 3

(Rear

122

Rr.d

Blk

,v14

___________

_

View)

~5

"uuI'

15

~

@--',:..:'''' • ...;G:.;'.::n:.....+-i:::::::::Jc:::::t:::r-______

ii

N

N

..

G

Red

Led

I

j

...

.Ul1p

",l

3 amps

.1

amps

1

"uup

UIl

55

nmp

15

amps

3

amps

__________

52

amp

15

amps

::J

amps

urgt:>

...

rlille

runnina

prt'ht'!tl.-L

9UTI:C

startln£

runnini

surce

Iiltartinl:

running

Oll

!Ottlrl

on

on

Red

Green

Purple

Red

st.nTt

~h!:e_

start

TBl-l

TBI-GND

TR2-2

TBl-2

TBl-4

Figure 4.3 illustrates the

control panel and a remote Start/Stop

Refer to the control circuit wiring diagram #036411 when installing the remote Start/Stop panel.

Refer

used between the engine control panel and the remote Start/Stop

coded

upon distance run and amperage flow through the wire during start.

15KWBTDA

to the

DC

wire sIzIng chart (figure

as

shown to comply with

DC

wifIng connections to

Panel.

4.4)

ABYC

standards and be sure to select the wire size dependent

31 Westerbeke Generators

on page

be

made between the engine mounted

31

when selecting the wire size to

Panel.

Use

the wire color

be

Page 34

A.

::oocleTY

D.C. Wire Sizing Chari

Stranded Conductors For

UT

AUTOmOTIVe

t::nglneers I ype

Ul;

wore

::Olzlng

10% Voltage Drop

wore

l;nan

12

Volt

tI.

Circuits

NaTIOnal

t::leClTlCal

l;ooe

I ype

wore

191<291'9><27

1

j

I 86.7 140

29

2336 13702

130

43.3

17.3

16 14

,

Maximum Length Of Conductor In Feet From Power Source To

210

65 105 165

52 84 132

70

60

46.7

42

28

21

I

1

¥Vire

Size 18

tanding

116X30

ircular

Mill Area

ircuit

Current

nAMPS

1537

I

1.

i 174 260 285

2.

: 87

3.

i 58

4.

143.7

34.7

5.

6.

I

7.

i 24.7 37

8. t 21.7 32.7 52.7 82.7

9.

i 19.3 28.7

10. i 17.3 26

15.

20.

30.

I

40.

j

SO.

I

!

55.

60.

75.

90.

I

10

12

19><23

19><25

5833

9343

330

220 94.6

110

94

73.3 116 186

66

44

33

22

8 6

19><21

49><23

14810 25910

4

I

149><21

37360

i

262

I

210

. 57

175

279

ISO

240

131

210

105 j

70

52.7 83.7

35

26.3

21

300

168 271 28.3 45.3

112 180

56

42 67.3 107

33.7

30.7 49

285

135

211 22.7

90.3 142

54 85.3

77.7

45

71.3

36

57

47.3

2583 4107

16

14 12

19

19

19

6530

142

227

151

71

47.3 75.3 120

40.7 64.7

35.3 56.3

31.7

19

240

113 180

57

143

103 j

89.6

79.6

SO.3

72

30

48

36

24

10

19 19

10380

16510

285

232

190

303

163

260

143

227

127

202

114

182 289

76

121 193 306

57

38

60.7

28.3

45.3

23 36.3

8 6

262SO

Load And

91

96.3

57.7

33

52.3

38.3

4

61

37

41740

I

321

145

230

153 243

115

72

92 148 184

83.3 133

48

76.3

61

51

2 1

I

127 127

66370

Return

182

121 153

97.3 123

81

183690

306

230

167

102

The vottage drop for specific conductor lengths may

Voltage drop

When a

drop

circu~,

at

the electrical device

circuit.

figure 4.4: D.C. Wire

Westerbeke Generators

be

calculated by the formula:

load in amperes

=

conductor length

=

conductor circular

=

in

mil

feet

area

=

lQZ:ixl

CM

X

L.

where:

I

L

CM

including the ground return, uses several different size conductors, the vottage

is

the

sum

of the drops calculated for each size segment of the

..

S,ZlOg

Chart

32

15KW BTDA

Page 35

Description of Starting System

Westerbeke diesel engines use electric starters assisted by glow plugs for both normal and

cold weather starting. The figure below shows a cross-sectional view of one

is

plug

located

When the glow

assists

in

This system

PREHEAT button

in

the combustion chamber so that

plug

is

energized

igniting the

is

fuel.

The

common to Westerbeke Diesels.

must

be

depressed for the time specified in the Preheat Table (figure 4.7.1).

by

resu~

~s

tip

is

in the injector nozzle's spray path.

the PREHEAT button, the plug glows

is

a rapid start with less wear

The

start circuitry

is

Then, while keeping the PREHEAT button engaged, the START button

cylinder. The glow

red

at

the tip and

on

the starter.

designed so that the

is

depressed to crank

the engine.

GLOW

PLUG

15KW BTDA

figure

4.5:

Combustion Chamber

NOTE: The START switch will not energize unless the PREHEAT button

is

depressed.

the cylinder head are activated.

When

depressing the preheat switch, The glow plugs

Use

the preheat intermittently to avoid

overheating the glow plugs.

33

Westerbeke Generators

in

Page 36

Preparation For Starting

stilPS

Take the

described below

shutdown or layup.

in

starting your engine for the first time or after a prolonged

Fill your engine with

may have

ing).

oil

with

and

an

affect on the dipstick read-

Select readily available lubricating

an

API

specification of

an

SAE

number suitable for the

oil

up to or near the

CC

or

CD

upper

lim~

on the dipstick (the installation angle

temperature in your operating area. For

the quantity of oil needed in your engine,

refer to the

tion of this

"System Specification: sec-

manual.

Upper Limit

(Normal

Fill the fuel tank with a good grade of

No.

2 diesel fuel and prime the fuel

Limit

system up to the engine. When returning

fuel

is

free of

is

bled and the engine

Each

un~

air,

the engine's fuel system

is

ready to start.

is

supplied with a coolant recovery

k~

(#24977)

as

standard equipment which must

be installed and the following applies:

A.

Remove the pressure cap from the engine's exhaust manifold and slowly fill the engine's

cooling system with a mixture of water and antnreeze suitable for your temperature zone.

Operate the engine and observe the

the base of the filler neck.

F),

make sure there

Once the engine reaches

is

no problem

coolant level in the

w~h

coolant flow through the manifold. Top off the

manUold.

~s

operating temperature (170 -

Maintain this level to

cooling system and install the pressure cap.

190'

B.

Make sure the plastic recovery tank

28), in a location where

be

mounted at manifold level or above. For installations that require

tank can be mounted

C.

Add coolant to the plastic coolant recovery tank once you have topped off the exhaust

manffold fold right to the filler neck top.

NOTE: This

should

pressurize the system and inspect for the cause.

and air expelled, fill the

recovery tank daily and add

the

Make sure the Installation Checks

"Installations and Installation Checks" section of this manual.

Westerbeke Generators

be

manifold

is

properly mounted near the unit (figure 3.19, page

~

can

be

monitored and filled easily. The recovery tank should

below the exhaust manffold's

is

a closed type cooling system and little or no coolant

lost from the system.

If

excessive coolant

level.

W~h

is

lost, artifically

the manifold filled

coolant recovery tank han full. Monitor this

coolant as needed. Periodically check that

is

full when cold.

have

been made

34 15KWBTDA

in

accordance with those specified

it,

the plastic recovery

in

the

Page 37

Starting Procedure

1.

Depress and hold the preheat switch. Preheat according to the following chart:

Atmospheric Temperature

5°

41° F

+

F (+

41°

+

23° F (-5°

+

Lim~

of continuous use 30 seconds

figure 4.7.1: Preheat Table

2.

While still depressing the

runs,

engine

an

for

release the

additional 2 - 3 seconds. This allows the engine to build up enough oil pressure

(+

5°

C)

C)

,?)

START

to close the oil pressure shutdown

NOTE: Should the engine not start when the START

10 - 12 seconds,

for

the previous procedure. Never

seconds

at

a time.

Preheating Time

or higher Approx. 10 sec.

to + 23° F

(-

5°

C)

Approx. 20

sec.

or lower Approx 30 sec.

before cranking.

PREHEAT

sw~ch,

depress the START switch.

switch but continue to hold the PREHEAT

release

sw~ch

both

and allow the engine to continue to

sw~ch

sw~ches

run

the starter motor for more than 30

and wait 30 seconds; repeat

is

depressed

As

soon

sw~ch

depressed

run.

as

the

Once the engine starts, allow ~ to

engine's instruments are checked for proper

attempt to engage the starter while the engine

15KWBTDA

3. Check

all

the instruments on the panel for proper operation and make sure

discharges with the exhaust discharge once the engine starts.

run

for a few minutes to warm up and stabilize while the

oil

pressure and battery charging voltage. Never

is

running.

NOTE:

condition should smooth out

the

Some unstable running

130 - 150° F (55 -

56°

may

occur

in

a cold engine, but this

as

the operating temperature moves into

C)

range.

35

raw

water

Westerbeke Generators

Page 38

Proper glow plug function

vo~meter

by a

drop (figure 4.7.7) when

the PREHEAT switch

drop will be

vo~age

defective

slight but discernible.

drop is noted,

glow plugs or a

is

indicated

is

depressed. This

tt

may

indicate

fau~

preheat

If

circutt (check for loose connections).

no

figure 4.7.7: Voltage Drop From

I

CAUTION

Prolonged cranking can damage

I

the

englnel

Prolonged cranking intervals wtthout the engine starting can

wtth

raw

filling the engine mounted exhaust system

may happen because the

raw

the

water cooling system during cranking. This

the engine's cylinders by

raw

water pump

way

of the exhaust manffold once the exhaust

system fills. Prevent this from happening by

is

pumping

closing the raw water supply

water coolant. This

raw

raw

through-hull shut-off, drain the exhaust muffler, and correct the cause

for the excessive engine cranking needed to obtain a start. Engine

raw

water entry is not a warrantable

Remote

Starting Procedure

The remote

damage resulting from this type of

issue; the owner/operator

should keep this in mind.

Start/Stop panel (figure 4.2) has three switches that serve the same functions

on the engine-mounted Start/Stop panel (figure 4.1). it has a green

LED

When starting at a remote location, the green

600

rpm.

at approximately

starting of the generator may not be

This indicates when the START switch

audible from the remote location.

comes on when the generator is running

Glow

Plug

resu~

in

water through

water can enter

LED

light and no gauges.

can

be released since the

as

A.

When the preheat switch

illuminate. When the start

light will dim. When the engine starts the

START switch. Continue to hold the PREHEAT depressed for a

pressure to build up and close the oil pressure safety switch that will be in the series

path for

B. After the generator is started and the starter switch is released, the generator's starter will

not crank

supplies voltage

Westerbeke Generators

is

depressed

swttch

12V

B + to the fuel run solenoid

is

at

the remote Start/Stop panel the

LED

light will

depressed and the starter cranks the engine this

LED

light will brighten signaling to release the

few

seconds to allow

until someone again operates the PREHEAT swttch first because this switch

10

the START swttch.

36

15KW

LED

oil

BTDA

Page 39

Starting Under Normal Conditions

Follow

the procedure below for normal starting of the generator:

1.

Make sure there

is

sufficient fuel

on

board. Keep fuel tank(s)

as

full as possible. Check

the fuel filters and water separators for the presence of contaminants and/or water. Drain

and

clean them as needed.

2. Check the coolant

NOTE:

cooling system

a

level

in

the plastic recovery tank. Add coolant solution

Excessiv~

loss of coolant from the plastic recovery tank indicates

leak.

as

Check the entire cooling system and pressurize

needed.

the system using a common automotive radiator pressure tester to

3.

Check the

locate the

be refilled

manual.

this

oil

level

leak.

In

cases of excessive coolant loss, the system must

as

outlined under the "Preparation For Starting" section of

in

the engine sump and look for fuel leaks, particularly H signs of such

leaks are found on the bottom of the engine or below the engine.

in

Start the generator

accordance with the "Starting Procedure" instructions

and allow the engine's operating temperature to reach into the 140 -

placing a load

on

it.

in

150·

F range before

this manual

Starting Under Cold Conditions

Under

listed below when operating your engine

Lubricating

ratings for the prevailing atmospheric temperature. Refer

of this

Voltage

minimize voltage drop across the battery terminals.

The

Enough -

whenever the temperature of the intake air

not rise enough. Refer to the preheat chart found in the "Starting Procedure" section of this

manual.

15KWBTDA

extremely cold temperatures, the following conditions can occur. Follow the instructions

in

cold weather.

Oil

Turns

Viscous - Make certain that the lubricating oil used conforms with the

to

the "Lubrication System" section

manual for

Across

Temperature of

an

atmospheric/oil viscosity specification table.

the

Battery Terminal Drops - Make certain that the battery

the

Intake

Air is Low and

the

Compression Temperature does not Rise

is

fully charged to

Allow the glow plugs to operate sufficiently to aid in starting during the preheat period

is

low and when the compression temperature does

37