Westerbeke 8.0KW BTDAR, 12.5KW BTDBR, 10.0KW BTDAR, 15.0KW BTDCR, 14.0KW BTDCR Operator's Manual

OPERATORS

.

MOBILE

I

.....

.

8.0KW

...GENERATORS

. .

..

BIOAR

and

. - -

r

-"

•

MANUAL

INDUSTRIAL

.

,.

10.0KW

BIOAR

12.5KW

BIOBR·

14.0

REVISION 2

WESTERBEKE

MYLES

WEBSITE:

..

...,~~

NMMA

CORPORATION

STANDISH

Member

INDUSTRIAL

WWW.WESTERBEKE.COM

National

--

·15.0KW

CR

'150

JOHN

Marine

PARK'

TAUNTON

Manufacturers

HANCOCK

ROAD

MA

02780

Association

BIOCR

A

WARNING

Exhaust

colorless

unconsciousness

exposure

-Dizziness

-Nausea

-Headache

IF

GET

seek

until

~W·

, "

,

'G!lneratots

gasses

Weakness

YOU

OR

OUT

medical

it

has

~!"!A!!'ii!!R~'

Prod~

Regular

1Fj=~~~

contain

gas.

Carbon

can

include:

and

ANYONE

INTO

THE

attention.

been

"!!N~I!'!N~G~

QARSON

~n!9nance

Carbon

Monoxide

and

death.

Sleepiness

ELSE

EXPERIENCE

FRESH

AIR

Shut

inspected

MONOXIDE

Required

and

A

WESTERBEKE

bulkhead

WESTERBEKE

CARBON

\,

,inexpensi~e

local

'j

i

Monoxide,

is

poisonous

Symptoms

-

Throbbing

-

Muscular

-

Vomiting

-Inability

IMMEDIATELY.

down

repaired.

WARNING

maflne

an

of

Carbon

in

TWitching

to

Think

ANY

OF

It

the

unit

and

DECAL

and

near

your

also

MONOXIDE

and

easily

or

hardware

odorless

and

can

Monoxide

Temples

Coherently

THESE

SYMPTOMS,

symptoms

do

not

is

provided

should

be

engine

recommends

DETECTORS.

obtainable

and

cause

persist,

restart

by

fixed

or

generator.

store.

to

a

installing

They

are

at

your

CALIFORNIA

PROPOSITION

Marine

exhaust

are

known

to

cause

and

diesel

and

some

to

the

cancer,

other

reproductive

65

and

of

State

gasoline

its

birth

WARNING

engine

constituents

of

California

defects,

Jtarm.

INTRODUCTION

Read

this

safety manual

caused

by

failure

precautions.

take the

necessary

personnel, and your

The

following

the

American

to

follow

Know

when

precautions

machinery.

safety instructions

Boat

and

carefully.

fundamental

dangerous

to

Yacht

Council

Most

conditions

protect

are

in

(ABYC)

SAFETY

accUIents

rules

yourself,

compliance

are

and

exist and

your

with

standards.

INSTRUCTIONS

•

Do

not operate with

Backfire can cause severe injury

•

Do

not

smoke

fuel

the

engine/generator clean

chances of

• Be

PREVENT

system.

fire.

aware

- diesel fuel will burn.

BURNS -EXPLOSION

the

or permit

Keep the compartment

Wipe

air cleaner/silencer

or

death.

flames

or sparks to

and

free of debris

up

all spilled fuel

removed.

occur

and

the

to

minimize the

and

engine

near

oil.

PREVENT

A

while

these

•

Do

enclosures and

• Shut off electrical

equipment.

• Use insulated

equipment.

•

Make

(particularly

•

Remove

electrical equipment.

• Electrical shock results from handling a charged

capacitor.

together.

PREVENT

A

exhaust

very

•

Always

recovery tank.

A

•

In

before touching

PREVENT

ELECTRIC

WARNING:

engine

connections!

not

operate

sure

00

is

running.

this

covers

mats

your

clothing

shoes)

wristwatch

Discharge capacitor

BURNS -HOT

WARNING:

system

hot!

WARNING:

case of

00

components. A running

check

the

Steam

an

engine overheat, allow the engine to cool

the

BURNS -FIRE

SHOCK

not

touch

AC

electrical

Lethal

voltage

machinery without electrical

in

place.

power

before accessing electrical

whenever working

and skin

when

handling electrical equipment.

and

all jewelry

by

are

shorting

connections

is

present

on

electrical

dry,

not damp

when

working

terminals

ENGINE

not

touch

hot

engine

parts

engine

engine coolant level

can

cause

engine

or

checking

injury

at

the coolant

or

death!

the

coolant.

at

or

gets

on

A

WARNING:

injury

or

death!

•

All

fuel

when

handling and storing

well-ventilated area

equipment and out of the reach of children.

•

Do

not

• Shut off

the fuel

spill.

DO

sources

servicing.

the

fuel

•

Do

not alter or modify

• Be sure

• Be certain fuel line fittings

free

oflealrs.

• Make

sure a fire

properly maintained. Be faruiliar with its proper use.

Extinguishers rated

for all applications encountered in this environment.

ACCIDENTAL

A

WARNING:

or

death!

•

To

prevent accidental starting

generator,

• Disconnect the battery

generator.

it last.

•

Make

certain all personnel

starting.

• Make certain all covers, guards,

re-installed before starting

Explosions

vapors

are

highly

fill

the fuel tank(s) while the engine

the

fuel

service

system.

of

system.

all

Take

NOT

allow

fire

near

the

Ensure

proper

fuel supplies have a positive shutoff

extinguisher

from

fuel

explosive.

fuels.

Store

away

from spark-producing

valve

at

the

care in catching

any

smoking, open

fuel

system

or

ventilation

the

fuel

system.

are

adequately tightened and

is

installed

ABC

by

the

NFPA

vapors

Use

engine

any

engine

exists

STARTING

Accidental

remove the 8

Remove the negative lead

starting

when

amp

fuse from

cables

before servicing

are

the

can

servicing

clear of

and

engine.

first

hatches

extreme

fuel

fuel

flames,

when

nearby

are

cause

the

and

the

can

cause

care

in

a

is

running.

when

servicing

that

might

or other

when

servicing

valve.

and

appropriate

injury

the

control

panel.

the

engine/

reconnect

engine

before

are

is

A

WARNING:

• Prevent

sparks to occur near

pump,

vapors.

removing the

flash

or other potential sources of spilled fuel or fuel

Use a suitable container to catch

Fire

fires.

fuel

can

cause

Do

not

the

carburetor,

line,

carburetor, or

injury

smoke or permit

fuel

fuel

or

death!

line,

all

filters.

flames

filter,

fuel

when

-..v

or

fuel

WESTERBEKE

Engines & Generators

SAFETY

INSTRUCTIONS

BATTERY

A

or

•

Do

being

highly

arcing

equipment

during

•

Never

positive (+) connection terminal of

Do

together.

Ventilate

accumulation of explosive

disturb

is

•

Avoid

bums

wristwatch,

the

•

Always

BATTERY

A

severe

•

A

EXPLOSION

WARNING:

death!

not

smoke or

serviced. Lead acid batteries emit

explosive

or

servicing.

connect the negative (-) battery

not

being charged.

contacting

or

battery.

the

battery connections. Remove the negative lead

and

reconnect it last

Battery

by

lit tobacco products. Shut off all electrical

in the

test the battery condition by

Sparks could

any

compartment containing batteries to prevent

the

battery

sparks that could cause

rings, and

tum

the

explosion

allow

an

open

gas,

which

can be ignited

vicinity

battery charger off before disconnecting

to

ignite

gases.

charger

the

connections while

terminals with

any

other jewelry before handling

when

disconnecting

prevent

battery gases

ACID

WARNING:

injury

When

servicing the battery or checking

level,

wear rubber

protection. Batteries contain sulfuric acid

destructive.

off

at

once with

into

the

caps.

WARNING:

Sulfuric

or

death!

If

it

eyes inadvertently

Carbon

gloves,

comes

water.

acid

in

Acid

monoxide

in

a rubber

contact

may

when

can

cause

injury

flame

near

the

battery

hydrogen,

by

electrical

electrical

the

shorting

To

avoid sparks,

tools,

an

explosion.

batteries

apron,

with

splash

removing electrolyte

(CO)

arcing

cable

to

the

starter solenoid.

the

terminals

or

fuel

the

battery

etc.,

to prevent

Remove

the

battery.

can

cause

the

electrolyte

and

eye

which

is

your

skin,

on

the

skin or

is a deadly

a

vapors.

do

not

first

wash

gas!

A

WARNING:

odorless

nausea

•

•

• Although diesel engine exhaust

AVOID

A

or

•

• Do not wear loose clothing

it

• Make

•

gas.

or

Do

not

use copper tubing in

fumes

can

systems.

copper tubing resulting in exhaust/water

Do

not

install exhaust outlet

through vents,

exhaust

gas

is

present in diesel exhaust

symptoms

poisoning

Vomiting

Dizziness

Throbbing

MOVING

WARNING:

death!

Do

not

situation

make

operating adjustments,

touching

components.

eqnipment;

jackets, shirts, sleeves, rings, necklaces

could be caught in moving

sure

Keep

protective shields and

places

at

Do

not

the engine

HAZARDOUS

Carbon

Inhalation

monoxide

produces

flu-like

(CO)

is

an

invisible

symptoms,

death!

diesel

exhaust

rapidly

destroy

copper

tubing

Exhaust sulfur causes rapid deterioration of

where

or

air conditioners.

gases

fumes

from gasoline engines, carbon

fumes.

or

signs of carbon monoxide inhalation

are:

Muscular twitching

Intense headache

in

temples

Weakness

systems.

in exhaust

leakage.

exhaust can

are

not

as

monoxide

Some of

and sleepiness

be

toxic

the

PARTS

RotaUng

service

the

arises

in

moving

tie

back long hair

all

attaching hardware

all

times.

check

fluid

is

operating.

NOISE

parts

can

cause

injury

engine while it

which it

parts and hot exhaust system

levels

or

is

running.

is

absolutely necessary

use

extreme care

or

jewelry

and

parts.

guards

the

when

avoid

wearing

or

bracelets that

is

properly

in their respective

drive belts tension while

.

servicing

If

a

to

tightened.

Diesel

drawn

as

or

to

avoid

loose

• Ensure that the exhaust system

the

discharged from

regularly for leaks

are

securely

attention

• Be

sure

•

In

addition to routine inspection of

install a carbon monoxide detector. Consult your dealer

for installation of

attached

to

the manifold

the

unit

engine.

and

and

and

its

approved

make

is

adequate

Check the exhaust system

sure the exhaust

no

warping

and

exhaust.

surroundings

detectors.

to

expel gases

manifolds

exists.

Pay

are

well

ventilated.

the

exhaust system,

...v'

A

loss!

close

• Never operate

•

•

A

mentally

WESTERBEKE

Engines & Generators

ii

WARNING:

Do

not run

removed.

Do

not

run engines for long periods with their enclosures

open.

WARNING:

or

High

noise

levels

can

cause

an

engine without its muffler installed.

an

engine with the air intake (silencer)

00

not

work

on

machinery

physically

incapacitated

by

tatigue!

hearing

when

you

are

TABLE

Parts

Identification

Introduction

Warranty Procedures ........................................

Serial

Diesel

Generator

Description

Description

Remote Panel .................................................... 6 Description .... : ............................................ : ....

Preparations

Prestart Inspection ............................................ 7

Generator Voltage ............................................. 7

......................................................... 3 Engine

Number Location .................................. .4

Fuel,

Engine

Control

for

Starting/Stopping

Safety Shutdown Switches ............................... 9

Generator

The

Daily

Break-in

Operation

Maintenance

Cooling

Changing Coolant ........................................... 14

Thermostat ........ : .............................................

Fuel

Fuel FilterIWater Separator ............................ 16

Fuel Injection

Fuel Lift Pump ................................................ 16

Engine

Remote

Oil

DC

Starter

Glow

Generator

Generator

Remote

Generator

Generator

System

System

Fuel Lift Pump Filter. .................................... .16

Fuel Filter ....................................................... 16

Engine Fuel Filter .............

.......................................................

Lubricating

Engine Oil Change ......................................... 17

Oil

Filter

Pressure

Testing Oil Pressure ........................................ 19

.......................................................

Electrical

Alternator Troubleshooting ............................ 20

12 Volt DC Control Circuit ............................ 21

Battery Care .................................................... 21

Motor

Troubleshooting .......................................... : ...

Service ............................................................ 23

Plugs .........................................................

Wiring

Wiring

Instrument

Wiring

WiringSchematic

.............................................

Oil,

and

Coolant

Panels

of

Switches .................................... 6

of

Gauges· ...................................... 6

Initial

Procedure

....................................

Start-Up

...............................

Procedure

.........................

.................

.........................

..........................................

Schedule

....................................

..................................................

Pump ...................................... .16

: ............................. 16

OiL

.................................... 17

................................... : ...........

System

....

.....................................

.....................................................

Diagram

Schematic ~ ..

Panel

Diagram

#44744

.....................

~.~

............

................................

#044927

..................

...........................

OF

CONTENTS

2

Engine

.3

5

6

Valve Clearance Adjustment .......................... 30

Testing Engine Compression ..........................

Fuel Injectors .................................................

Drive Belt Adjustment. ...................................

Control

Electronic

7

Controller Adjustment ....................................

Inspect and Adjust ..........................................

Linear

8

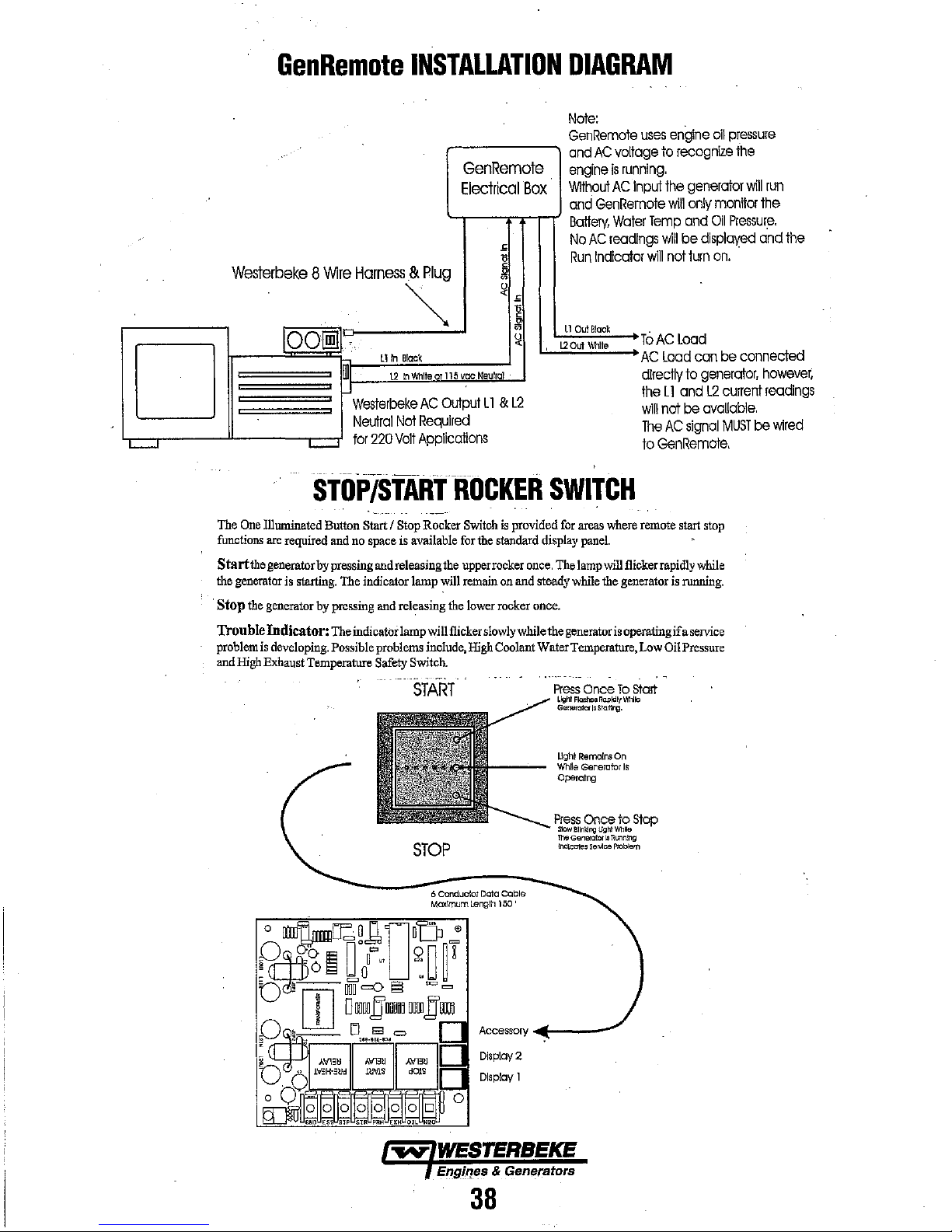

GenRemote

GenRemote

.10

.11

.12

14

15

16

GenRemote

GenRemote

Stop/Start Rocker Switch ..............................

GenRe

.

Generator

mote

Power

BT

Generator

BT

Generator

BT

Generator

Generator

BT

Generator

BT

Generator

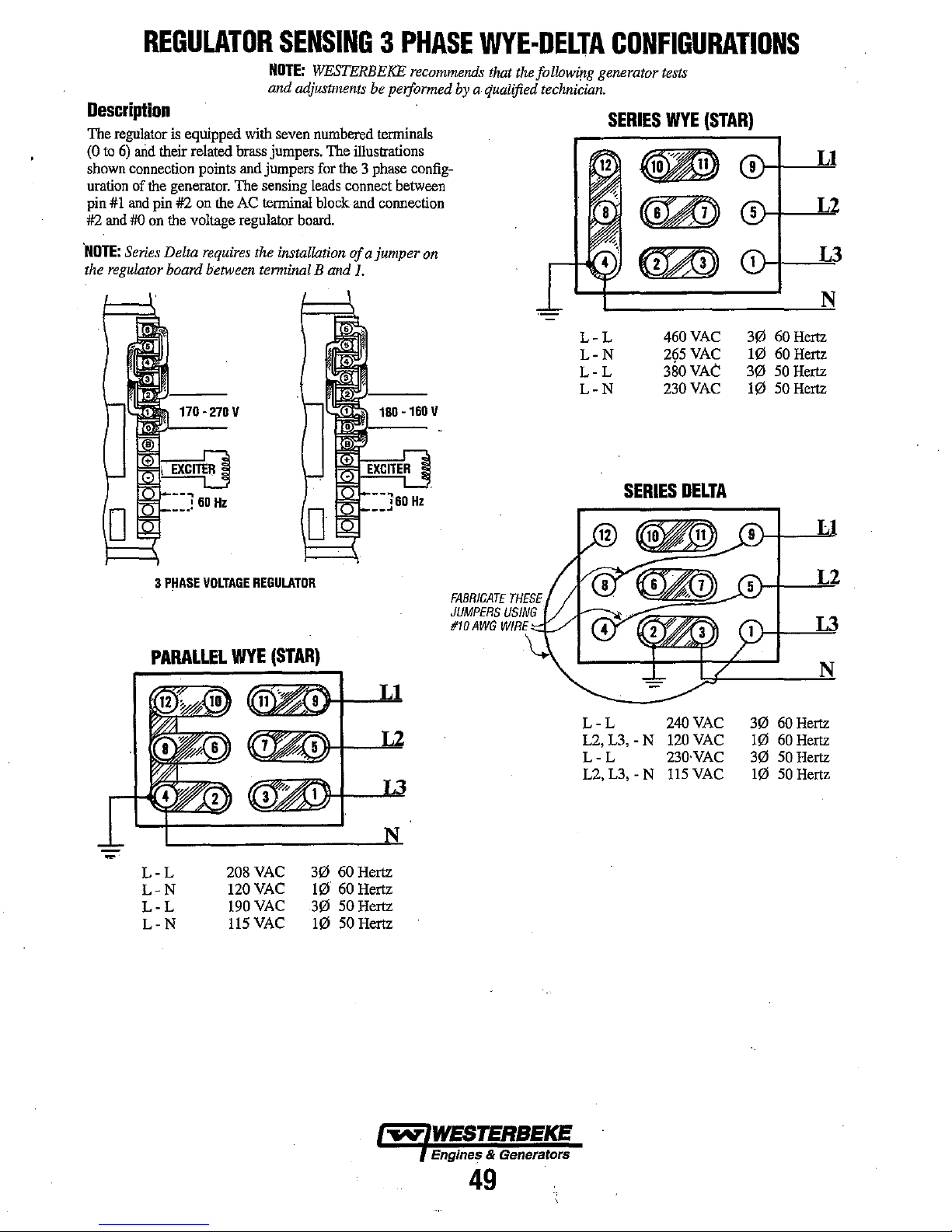

Regulator

BT

18

19

Generator

Specifications

Specifications

20

Generator

Generator

Generator

22

22

Generator

Engine

Standard

24

25

25A

26

Sealants and Lubricants .................................. 56

.

Metric

Suggested

27

27

A

Troubleshooting

Adjustme·nts

Panel

Troubleshooting

Governor

Actuator

Troubleshooting

Calibration

Control

Wiring

Installation

Specifications

[Chart] ........................

....... : ...................................

[Chart] ............. 32

Adjustments

.....................

[Chart] ..........

.....................................

Station

Diagram

.............................

.............................

Oiagram

.....................

..............................

litformation .......................................

Take

Off

Systems

...................................

....................................................

Wiring

Single

Voltage

Voltage

Internal

Sensing

Troubleshooting

Specifications

Specifications

Specifications

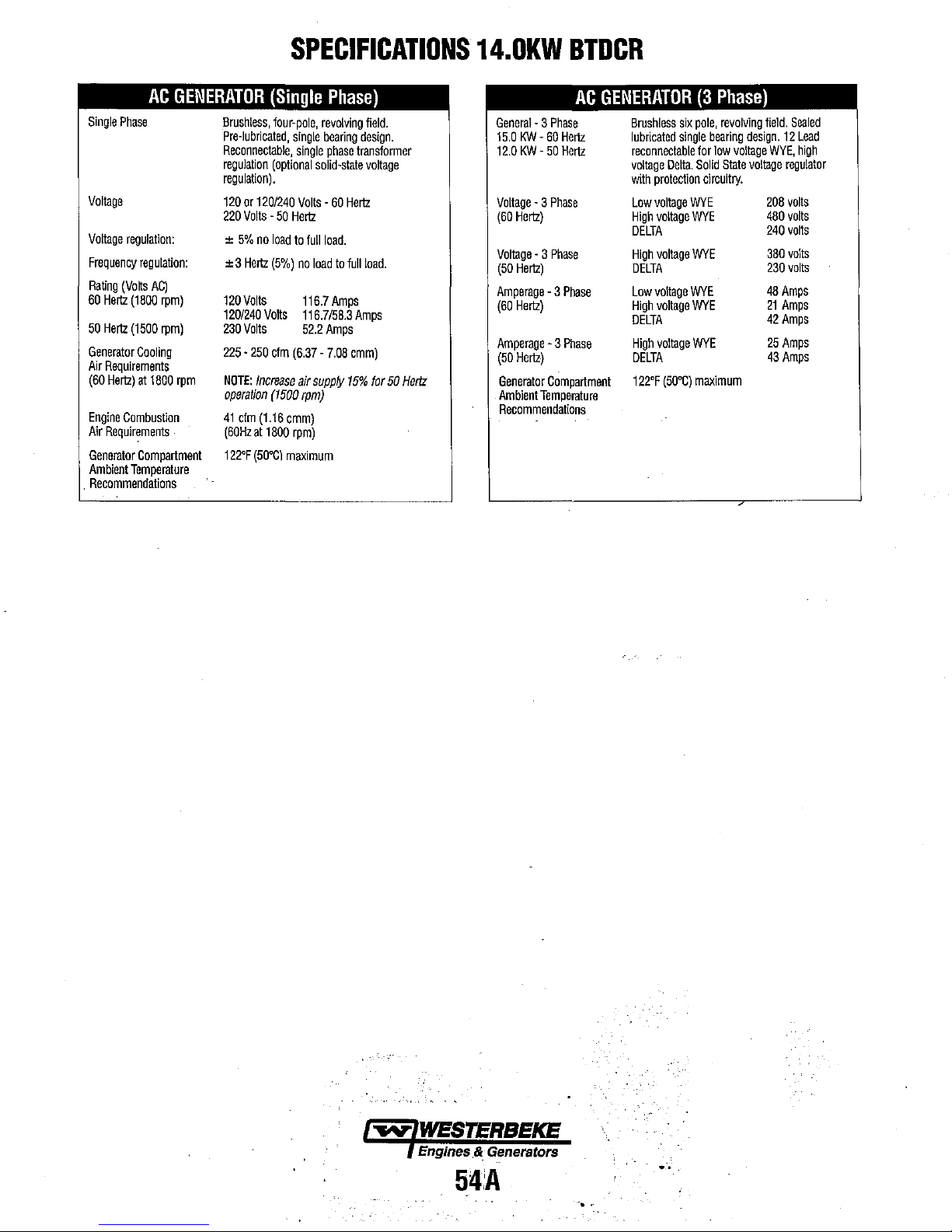

Specifications14,KW

Torque

Hardware

Conversion

Spare

Schematic

......................

Phase ..............................

Adjustment

Regulator..

Wiring

Wye-Delta

1D.DKW/B.DKW

15KW/12.5KW

........................

......

..........................

Configurations

[Chart] ............ 50 .

BTOAR,_

BTOB

R~

1D.DKW/B.oKW

15KW

12.5KW

BTOCR

BTOBR"

BTOC'R _ .....

Specifications

...........................

................................ : .. ; ........

Data

....................................

Parts

.....................................

...............

............

28

30

31

.31

31

33

33

33

33

34

35

36·

.37

38

.38

.39

.41

.42

.43

.44

.45

.48

..

............

.........

..........

........

54A

40

47

49

51

52

53

.54

.54

55

56

57

58

Engines & Generators

1

AIR

INTAKE/AIR

.~SSEMBLY

FILTER

PARTS

IDENTIFICATION

STOP

SWITCH

CHARGING

ALTERNATOR

;REMOTE

PANEL

CONTROL

PANEL

FRONT

OIL

EXHAUST

SUMP

20A

CIRCUIT

REAR

______

OIL

FILL

~

~~l----:;:;J~-

~-i~OOLANT

START

•

LEFT

PRESSURE

,RADIATOR

RIGHT

J---EN'''N.

NUMBER

MOTOR

MOUNT

SIDE

SIDE

SERIAL

PUMP

CAP

BACKEND

PREHEAT

OIL

FILTER.

At

BREAKER

Engines & Generators

2

LIFT

PUMP

DRAIN

HOSE

This

WESTERBEKE

WESTERBEKE's

technology.

dependable

Thank

In

order

is important that

manual

manual

throughout.

your nearest

This

provided and a

WESTERBEKE

equipment contact

WESTERBEKE'S installation

We

perfonnance of

you

for selecting

to

get

is

designed

carefully

Should

WESTERBEKE

is

your

operators

WARRANTY

Your

WESTERBEKE

folder.

If, after

fonn

you

have

registering your

writing

with

model

number

Customer

and

commission

Identification

L~

Diesel

long

years

take

great

pride in

our

WESTERBEKE.

the

full

use

and

you

operate

to

help

you

and

observe

your

generator require

manual. A parts

technical

manual

dealer.

If

your

WESTERBEKE

you

PROCEDURES

Warranty

60

days

of submitting

not

received

warranty,

please contact the factory in

information,

date.

WESTERBEKE

J Engines & Generators

Customer Identification

MR.

GENERATOR

MAIN

STREET

HOMETOWN,

Model15BTDAR

Expires

7120/2008

OWNER

USA

Ser.

INTRODUCTION

Generator

of experience

engines

benefit

and maintain it

do

all

dealer for

are

manual.

a customer identification

Card

#.

is

a product of

and

the

superior durability

and

from

your

this.

Please,

the

safety

precautions

servicing,

assistance.

catalog

is

available

planning

dealer for

is

included

the

Warranty

including

the

advanced

generators.

generator it

correctly.

read

is

also

from

your

to

install

in

a separate

Registry

unit's

and

thIS

this

contact

this

card

serial

PRODUCT

Product software, (tech

brochures

WESTERBEKE

. WESTERBEKE CANNOT BE RESPONSIBLE

CONTENT

WARRANTIES

THERETO,

COMPLETENESS THEREOF AND WILL IN

BE LIABLE

INCURRED IN CONNECTION

OF

THE

WESTERBEKE

time

. software

WESTERBEKE

provided

WESTERBEKE

be relied

the respective product.

but

is

WESTERBEKE

to

determine

product software

NOTES,

As

this

maintenance

engine, critical infonnation

CAUTIONS,

NDTE:

A

observed,

your

SOFTWARE

data,

parts lists,

and

catalogs), provided

are

not within WESTERBEKE's

OF

SUCH

SOFTWARE,

OR

REPRESENTATIONS

INCLUDING ACCURACY, TIMELINESS

FOR

ANY TYPE OF DAMAGE

FURNISHING

span

between printings of

and

the unavoidable existence of earlier

with

WESTERBEKE products, whether

upon

exclusively

imperative that appropriate representatives of

the

CAUTIONS

manual

An

takes

schedules,

and

operating procedure essential

CAUTION:

can

OR

USE

customers should

WESTERBEKE

manuals.

or

or

accuracy

being

WARNINGS.

In summation,

other suppliers, must

as

the

It

not

only

the

supplier in question

and

currentness of

consulted

AND

WARNINGS

you

through

and

troubleshooting

will

Procedures,

result

in

the

damage

engine.

manuals,

from

sources

MAKES

WITH

WIlli

OR

ARISING OUT

OF SUCH

also

keep

product

not

definitive

makes

by

the

be highlighted by

An explanation

which

authority

good

be

the

customer.

operating

to

note.

if

not

or

destruction

other

than

control.

FOR

THE

NO

RESPECT

OR

NO

EVENT

OR

INJURY

SOFTWARE.

in

mind

the

product

software

from

and

cannot

on

sense

consulted

the

procedures,

of

your

marine

NOTES,

follows:

strictly

of

The WESTERBEKE

alphanumeric

date

of

manufacture;A

the

end

of the engine

followed

characters.

decade

the

Beginning in May

represented

2008

by

E=2000s.

decade,

July,

three

Previous

and

2008

HG

number

numbers.

The

the

second

2008,

and

2008

engine

serial

that

can

assist

manufacturing

serial

number.

Today

date

code.

The character indicated

first

number represented

and

third,

the

two

the E the

July.

month

number

one

date

It

consists of a

it consists of

the

characters

of

is

an

in

determining

code

is

two

the

month

of

HE.

H

May

and

the

placed

at

character

the

year

in

that

year.

so

on

HF

Engines & Generators

3

A

WARNING:

followed,

can

Procedures,

result

in

personal

which

injury

if

not

or

properly

loss

of

life.

INTRODUCTION

SERIAL

The

are

time

plate

when

Parts.~~~~~~~~~~,.~~~

The

engine block just above the injection

serial

flat

NUMBER

engine

and generator

located

on

to

enter

shown

below,

seeking

MOOEL

--

RPM

___________

KVV

____________

KVA

___________

VOLTS

AMPS

ENG,

ENG.

GEN.

PF/PHASE

VVIRES

RATING

INSUL

TEMP.

BATIERY

C.I.O.

engine

serial

number

surface

on

LOCATION

serial

numbers

a decal

this

techuical information and/or

_________

_________

HP

SER.

SER.

________

RISE

_________

is

on

information

as

this

________

______

_

NO.

NO.

___

_

_

_______

CiJ\SS

_

__

__ __

____

__

number

staroped

the left

side

the

generator

on

the illustration of the

will

provide a

_

_

_

_

_

_

_

can

also be

found

pump.

into the generator housing

of the

generator.

and

model

housing.

quick

ordering

staroped

The

numbers

Take

the

narDe-

reference

repair

..

into the

generator

on

the

NOTE:

A carbon monoxide warning decal has been provided

by

WESTERBEKE. Affix this decal

engine

room.

UNDERSTANDING

The diesel

since the

are

the

diesel

conoecting

Therefore,

same

most important

maintenance of the

Replacement of fuel and lubricating filter

time periods

contamination (that

tem

the

designed specifically for

The diesel

however,

carburetor

component function of

engine

mechanism

arranged

SarDe

general

engine

rods

to

preventive

is

also

essential. Another important factor

SarDe

brand of high detergent diesel lubrication

engine

in

its method of handling and

and

both.

ORDERING

Whenever replacement

generator

serial

plate located

this

set.

number for

Parts List). Insist upon WESTERBEKE

because

the

model

number

information so

In

addition,

each

will fit

SarDe

specifications

THE

DIESEL

closely resembles the

is

essentially the

above

a closed crankcase;the

type

as

that of a gasoline

has

the

SarDe

type

and lubricating

a great extent, a

maintepance

factors

are

proper ventilation

fuel,

lubricating and

specified

the

is a

is

water,

does

differ

iguition

systems

fuel injection

must,

diesel

PARTS

parts

number,

as

they

on

the generator

include a

part needed

or

appear

we

may

generic

as

engine

complete

parts

original equipment.

in

a visible position in the

ENGINE

gasoline

SarDe.

crankshaft

of

valves,

camshaft,

system.

diesel

engine

as a gasoline

cooliog

elements

and

frequent

sediment,

from

pump -which

are

on

end.

properly

(see

etc.)

engines.

the

gasoline

firing

are

replaced

needed,

serial

the

are

always

number,

silver

and

You

must

identify

part description and part

the

separately

packaged

frequently

engine,

The

cylioders

engine,

requires

engine.

and

proper

systems.

checking

in

the

fuel

is

the

engine,

of

fuel.

by a single

performs

provide

and

black

provide

your

furuished

not

made

is

of

and

the

pistons,

the

The

at

the

for

sys-

use of

oil

The

the

the

generator

narDe-

us

with

generator

parts

to

An

identification plate

the

engine

model

ENGINE

SERIAL

NUMBER

and

on

the engine

serial

mauifold

number.

also

displays

GENERATOR

10

DECAL

--'GEIIERIITOR

'NUMBER

Engines & Generators

SPARES

Certain

WESTERBEKE

will assist

See

accessories,

INSTALLATION

Publication #43400 provides detailed information

installing generators and a

Also

www.westerbeke.com

SERIAL

the

the

AND

spares

you

SPARE

see

manual

ACCESSORIES

will

be needed

engine.

in

preparing

PARTS page in

WESTERBEKE'S ACCESSORIES brochure.

Your

an

to

local

support

WESTERBEKE

inventory of

this

manual.

MANUAL

copy

is

supplied

is available

to

download

from

our

in a pdf

4

and

spare

For

with

website

format.

maintain

parts.

engine

for

each

at

your

dealer

unit.

DIESEL

FUEL,

ENGINE

OIL

AND

ENGINE

COOLANT

DIESEL

Use fuel that meets the requirements or specification of Class

2-D

Care

Use only clean diesel

in your

particles

these

and keep it clean. The best

unsatisfactory by careless handling or improper storage

facilities.

engine's daily use is clean

advisable:

Purchase a well-known brand

ENGINE

Use a heavy duty diesel oil with an API classification

CF, CG-4, CH-4 or CI-4. Change the engine oil and filter

after an initial

the

MAINTENANCE SCHEDULE in this manual. Westerbeke

Corporation does not approve or disapprove of the use

synthetic oils.

be

must be

section in this manual and not

are used.

NOTE:

ments regarding synthetic

For recommended oil viscosity see the following chart· ,

FUEL

(ASTM),

finely

and has a cetane rating

Of

The

Fuel

fuel

injection pump

which

might pass through the filter can damage

finished parts.

To

assure that the

Supply

fuel!

The clearance

is

very critical; invisible dirt

It

is important

fuel

fuel

and

of

#45

or

better.

of

the components

to

buy

clean fuel,

can be rendered

going into the tank for your

pure, the following practice

of

fuel.

OIL

of

50 hours

oil

and

filter change intervals as specified in the

If

performed using conventional oil. Oil change intervals

as

listed in the MAINTENANCE SCHEDULE

The

information above supersedes all previous state-

Operating

Above

68'F

41'-68'F

Below

41'F

of

break-in operation. Then follow

synthetic

Temperature

(5-20'C)

oils

oil.

(20'C)

(5'C)

are

used, engine break-in must

to

be extended

Oil

SAE

30,

SAE

20,

SAE

10W-30

Viscosity

10W-30

10W-30

or

if

synthetic oils

or

15W-40

or

15W-40

15W-40

of

is

ENGINE

WESTERBEKE recommends a mixture of

and

chemicals that can corrode internal engine surfaces.

The antifreeze performs double

run at proper temperatures by transferring heat away

the engine

cooling circuit from rust and corrosion. Look for a

quality antifreeze that contains Supplemental Cooling

Additives

anced, crucial

The distilled water and antifreeze should be premixed before

being poured into the cooling circuit.

NOTE:

antifreeze that is now available.

Antifreeze mixtures will protect against an unexpected freeze

and they

retard rust and

Antifreeze

Freezing

COOLANT

A coolant recovery tank kit is supplied with each

WESTERBEKE diesel engine. The purpose of this recovery

tank is

during engine operation, without the loss of coolant

without introducing air into the cooling system. This

provided

NOTE:

located at

can

particular

COOLANT

50%

antifreeze

50% distilled water. Distilled water is free from the

duty.

It

allows the engine

from

to

the coolant, and lubricates and protects

(SCAs) that keep the antifreeze chemically

to

long term protection.

Look

for

the new enviromnentallY1riendly long lasting

are

beneficial to the engine's cooling system. They

add

to the life

ANTIFREEZE

concentration

Temperature

RECOVERY

to

allow for engine coolant expansion and contraction

and

must be installed before operating the engine.

7his tank, with its short run

or

above the level

be

located below the level

~nstallation

of

the circulating pump

PROTECTION

23%

14'F

(-5'C)

30%

8'F

(-13'C)

TANK

of

plastic hose,

of

the

engine~

of

the engine ~ manifold

makes this necessary.

35%

-4'F

(-20'C)

manifold, but it

the

good

-40'F

(-40'C)

and

is

best

bal-

seal.

50%

kit

if

to

is

the

A

CAUTION:

engine

oil

additives

to

OIL

The engine's oil pressure, during operation,

by

the oil pressure gauge on the instrument panel. During

normal operation, the oil pressure will range between

60 psi.

NOTE:

reading upwards

have an oil pressure reading as low as

These readings will vary depending upon the temperature

the engine, the load placed on the engine, and the

of

produce

PRESSURE

A newly started, cold engine can have an oil pressure

00

to

mix.

Each

different

properties

of

60 psi (4.2 kg/cm". A warmed engine can

not

allow

brand

brands

harmful

two

or

contains

could

react

to

your

more

brands

of

its

own

additives;

in

the

mixture

engine.

is

indicated

30

25 psi (1.8 kg/cm".

RPM~.

and

of

Engines & Generators

5

GENERATOR

CONTROL

PANELS

DESCRIPTION

This

manualJy

diesel

generators

engine control panel and,

All

three

following

PREHEAT:

preheating

engine oil pressure switch. The PREHEAT function closes

K2

relay.

the

pull coil. .

When

the

panel lights,

solenoid.

START:

The

energizes

While the

START

begins to

PREHEAT

pressure reaches 5 -

STOP:

providing power

opens

flow

To

STOP switch

noid

The

stops rotating

NOTE:

gauge and

last temperature and oil

will

switch engages the start solenoid. When the engine

The

the

of

fuel

stop

the

is

opened,

STOP

When

return

OF

SWITCHES

controlJed series of WES1ERBEKE marine

is

equipped

switches

functions:

The

the

PREHEAT

the

PREHEAT

fire,

STOP

power circuit

switch should

the

to

are

PREHEAT

engine for

as

well

as

switch

gauges

and meters

START

switch should

engine, depress

toggle

starter solenoid

switch

the

START

10

toggle switch

to

the

to

the

engine and

is

depressed,

and the

the

engine is shut

oil pressure

zero once-electrical power

with

toggle switches on

optionally,

momentary contact type

toggle serves two

easy

supplies

is

switch

and

is

switch should be released. The

not

be

psi.

K2

relay.

to

the

the

the

fuel

flow

be

depressed until

gauge

pressure

at

remote

purposes:

starting

fuel

shuts

power feed

and

bypassing

current to

depressed,

and

closes

activates the

still depressed, depressing the

released until

is

a normally closed switch

Opening of

solenoid, stopping the

STOP switch.

to

down,

will continue

readings

the

fuel solenoid

the

voltmeter,

the hold coil

the

KI relay that

starter.

the

this

down the

the engine

the water temperature

engine.

When

to

the

is

the

displayed.

is

restored.

the

panels.

and

serve the

the

of

the fuel

oil

switch

the

fuel

sole-

stopped.

generator

to

register

They

the

EMERGENCY

stop

switch

is

normally

will

open

panel

switch

performing

DESCRIPTION

Coolant

Engine coolant

175'

to

Engine

Oil

pressure

load but should range between between 30

DC

Voltmeter

Indicates

l3V

to

STOP:

on

the

closed.

the

DC circuit to the

and shut

is

the

not

toggled it

maintenance.

OF

Temperature

(water)

195' F (80'

Oil

Pressure

(psi)

may

the

amount

14V.

The

EMERGENCY

side

of

the

control

When

depressed, it

control

engine

down.

As

can

be used

GAUGES

temperature should

to

90' C).

fluctuate depending

the

battery

is

box,

the

when

being

charged

Hourmeter

Registers elapsed time

perform scheduled maintenance.

REMOTE

For

switches

connected

serve

switch

serves

WIRING

remote

are

the

same

is

in

the

PANEL

operation

used.

in

parallel with the

series

same

DIAGRAM

of

The

functions

with

function.

in

and

is

used

the

generator

PREHEAT

gauge

as

in

the

the

gauge

There

is

this

manual.

as

a guide

system,

and

START

panel's

gauge

panei.

panel's

a REM01E

GENERATOR

RELEASE

STARTER

PREHEAT

MUST

~

PRESS

Cf!))

1ST e

WESTERBEKE

NOTE:

For

additional infonnation on Control

STARTING/STOPPING

DIAGRAMS

and TROUBLESHOOTING

PROCEDURE,

f'li

STOP

START

I~~

\,fIiJ

'

normally

on

the

to

60

for

the

switches

switches

The

STOP

switch

START/STOP

PRESS

2

NO

Panels.

DC

WIRING

GAUGES.

indicate

generator

psi.

should

when

to

same

and

STOP

and

Refer

show

three

are

to:

Engines & Generators

6

PREPARATIONS

PRESTARTINSPECTION

This section of

ration, initial starting, break-in, starting (warm

stopping procedures. Follow the procedures

the conditions indicated

set

will

Before starting your generator set

.prolonged layoff, check the following items:

o Check the engine oil level.

at

the

o Check the

tor bowls

o Check the

and

tery

negative (-) cable

(this location

o Check the coolant level

and

o Visually examine the

parts,

threaded

o Check load leads

the wiring diagrams.

o Examine air inlet and outlet

o Be sure

to load lines.

o Be sure that

the neutral

system requires,

connected

3-phase

ply the

loads.

o Make sure the mounting installation is secure.

o Make sure that

the

manual provides the operator

and

your WESTERBEKE generator

give reliable performance

high

mark

on

the dipstick.

fuel

supply

and

for

contaminants.

DC

electrical

battery cable connections. Make

cable

is

connected

is

connected

is

tagged).

at

the

manifold.

unit.

disconnected

connections.

no

other generator or utility power

is

to

systemS

wrong

wires,

for

correct connection

in

power systems with a neutral line that

properly grounded (or ungrounded)

and

that the generator neutral

the load neutral.

an

incomplete

line-to-neutral voltage on unbalanced

the

generator

and

for

the first time

Add

oil

examine the

system.

to

in

Inspect

the

starter solenoid

to

both

the plastic recovery tank

Look for loose

unattached

for

air

In

single phase

or

is

properly grounded.

long service

the engine ground stud

open neutral

as

to

maintain

fuel

wire

certain

hoses,

as

flow

obstructions.

or

with

prepa-

or

cold)

and

presented for

life.

or

after a

the

level

filter/separa-

connections

the (+)

bat-

and

the

missing

and

check

specified in

is

connected

as

the

is

properly

and

some

can

sup-

FOR

INITIAL

GENERATOR

The

however,

60

50Hz

The

however

adjusted

VOLTAGE

actual

load

to

authorized WESTERBEKE service

START-UP

A

CAUTION:

recommended

be

switched

and,

in

will

preven{damage

of

the

stalling.

speed of

Hz

speed of

to

suitable

OFF

cold

climates,

AC

machinery

VOLTAGE

the

it

is

advisable

The

At

rated

48.6 -59.0

The

rated

48.5 -49.0

the

it

is

advisable

to

optimum

ADJUSTMENTin this manual).

service

be used

values

or

in

When

starting

that

all

AC

loads,

until

the

engine

starts

to

caused

and

generator engine

engine

amperage hertz output

engine

amperage

generator engine

values

test

load

service.

arid

fault

by

will

prevent a cold

to

verify.

no-load speed

Hz.

no-load

Hz.

to

speed

hertz output

verify.

no-load

of the

same

If

the voltage cannot be

seems

the

generator,

especially

has

come

warm

up.

unanticipated

it

large

up

tii

This

precaution

operation

is

motors,

speed

engine

is

adjusted

is

adjusted

The

voltages

and

evident, contact your

dealer.

at

the

is

set

at

61.5 -

may

decrease

is

set

at

61.5

may

decrease

at

the

are

full

load

If

possible,

power factor

Hz.

easily

(refer

as

adjusted

from

factory,

62

Hz.

to

At

to

factory,

to

apply

the

DIPSTICK

~

Oil

lEVEL

GLOW

PLUG

CONNECTION

\l\>

~PPROXIMATELY

ONE

QUART

SIDE

Oil

CAP

Y

-.rN'"

WESTERBEKE

Engines & Generators

7

Oil

Fill

CAP

STARTING/STOPPING

THE

STARTING

Westerbeke

glow

plugs

illustration below

cylinder.

ber

tbe

glows

is

This

circuitry

depressed for tbe

while

button is depressed

NOTE:

PREHEAT switch

switch activates

the

plugs.

The

so

that its

glow

plug

red at !be

a rapid start witb

system

is

keeping tbe

The

PREHEAT intermittently to avoid overheating

GLOW

SYSTEM

diesel generators use electric starters assisted

for botb normal and cold

shows

a cross-sectional

glow

plug

is located in

tip

is

in tbe injector nozzle's

is

energized

tip

is

common

desigued

time

by

and

assists in igniting

less

wear on tbe

to

WESTERBEKE diesels. The start

so

tbat tbe

specified in

PREHEAT

to

crank tbe engine.

START switch will not energize unless

is

depressed.

the

glow

plugs

weatber

tbe

tbe

PREHEAT

starter.

PREHEAT

tbe

button

engaged,

Depressing

in

the

preheat chatt.

cylinder head

starting.

view

of

one

combustion

spray

patb.

button,

tbe

fuel.

The result

button must be

tbe

START

the

the

PREHEAT

the

The

cham-

When

the

Then,

so

use

glow

by

plug

PROCEDURE

Should

tbe engine not start when tbe

for

10

to

20

depressed

wait

30

seconds;

longer.

Never

Remote

The

start

guages.

lights

rpm.

since

A.

Starting

remote statt panel

panel except tbat it

When

when

tbe generator

This

indicates

tbe starting of

When

tbe

start/stop panel

START

engine

tbe

START

LED

switch

this

light

switch.

depressed for a

which

up

tbe

series

green

LED

is

engine

B.

After

tbe

run

starting

PREHEAT

LED

closes tbe

patb for

will

running.

generator

seconds,

repeat

tbe

procedure

the

starter for more

Procedure

is

tbe

has a green

at

a remote location,

is

runrrlng

when

tbe

tbe

generator

switch

tbe

LED

light will

is

depressed

light

will

will

brighten sigualing

Continue

few

seconds

oil

pressure safety switch that

12V

B+

remain

brightly illuminated while tbe

is

statted and

same

to

released, tbe generator's starter will not crank uuless tbe

PREHEAT

supplies voltage

Once

tbe

proper

light load

temperature

applying

switch

engine statts,

oil pressure

to

tbe generator

to

come

heavy

loads.

is

operated first because tltis switch

to

tbe

START

check

and

battery charging

and

up-to

l40-lS0oP

START

switch is

release botb switches

above

and

preheat

than

30 seconds.

as

tbe

engine-mounted

LED

light and no

tbe

green

at

approximately

START

switch

may

is

depressed

illuminate.

can

be released

not be audible.

at

tbe remote

When tbe

and tbe starter cranks tbe

dim.

When

tbe engine statts

to

release tbe

hold tbe

to

to

allow

tbe fuel

tbe

PREHEAT

oil pressure

run

solenoid. The

START

switch

switch.

tbe engine's insttnments

voltage.

allow

tbe engine's operating

(60-66°C)

Apply a

before

and

LED

600

to

build

is

for

in

is

PREHEAT:

panel

PREHEAT

Depress tbe

lights,

switch

gauges

PREHEAT

and

meters will

shouW

be depressed in accordance

tbe following chatt:

Temperature/Preheat

Almospherlc

+41°F(+5°G)

+41°F(+5°G)

+23°F(-5°G)

Limit

START:

While

tbe

START

Upon

engine

release tbe

15

psi.

Then

oil pressure protective circuits

remain energized

Temperalure

or

higher

to

23°F

or

lower

01

continuous

still

depressing tbe

switch.

This

starting,

PREHEAT

as

long

and

(-5°G)

use

will

release

switch until

as

tbe high

continue

NOTE:

A voltage

when

is

switch.

be

30

PREHEAT

engage

tbe

START

the

water

do

not

to

run.

When

the

depressed.

The volttneter

activated. The

Preheallng

Approx.

Approx.

Approx.

seconds

Time

10

seconds

15

seconds

20

seconds

before

switch,

tbe

starter

solenoid.

switch.

Do

oil pressure

temperature

activate, tbe

starting:

drop

will occur

preheat switch

and

witb

cranking

depress

not

reaches

and

low

engine

will

NOTE:

Some

Depressing

will

help

stabilize

temperature

the

engine.

unstable

the PREHEAT switch for 10-15 second intervals

reaches

the

the

running

engine

140-150°F

may

occur

RPM until

and

in

a cold

the

operating

a load

engine.

is

applied

to

~

WESTERBEKE

Engines & Generators

8

STARTING/STOPPING

PROCEDURE

STARTING

Make

the

prevailiog

OIL

The

drop.

Use a sufficient

sure

the lubricating

section

battery

UNDER

temperatore. Check the table in

in

this

manual.

should

be

amount

Temperature/Preheat

STOPPING

1.

Remove

allow

stabilize

2.

Depress

is

completely

3.

Now

SAFETY

The engine

switches. Should

PROCEDURE

the

AC

electrical

the generator

its operating temperatures.

the

STOP

stopped.

release the

SHUTDOWN

is

protected

shutdown

wilhont finding and

heading ''Engine

section

The following

switches:

of

this

Stops"

manual.

is a description

COLD

CONDITIONS

oil

conforms with

fully

of preheat

chart

to

switch

STOP

charged

elsewhere

run

switch.

to

to

load

from

for three

and hold it

SWITCHES

by

three automatic shutdown

occur,

do

correcting

the

cause.

in

the

TROUBLESHOOTING

of these

the

the

minimize

aid

in

starting.

in

this

section.

the

generator and

to

five

minutes

until

the

not ottempt

Refer

automatic

ratings

ENGINE

voltage

See

to

generator

to

restart

to

the

shutdown

for

the

Remote

To

the

circuit.

generator comes

goes

Low

A

low

engine's

switch's sensor

engine's oil pressure

interrupting the

off

Stopping

stop the

normally closed

the

generator, depress

The STOP switch

to

out.

Oil

Pressure

oil pressure

oil

gallery.

mouitors

DC

engine.

Procedure

the

STOP

B+

path for voltage

must

be

held

a complete stop

Switch

shutdown

Normally open in a

fall

voltage

switch

the

engine's oil

to 5-10 psi,

to

the

K2

switch

to

the engine's

open

until the

and

the

green

is

located off the

static

state,

pressure.

this

switch

relay,

thereby

which

LED light

this

Should

will

open,

shutting

opens

run

the

Coolant

A

housing.

coolant's operating temperatore reach approximately

(99'C), will

relay,

195'F (107'C).

COOLANT

TEMPERATURE

SWITCH

Temperature

high

water temperatore switch i.located

Normal1y

open

and

thereby

shutting

Switch

closed,

this

intermpt the

off the engine.

switch, should the fresh

DC

This

on

the thermostat

voltage

switch resets

to

the

water

21O'F

K2

at

SENSOR

OIL

PRESSURE

OIL

PREilSUFIE-,L

SENOOR

Engine

The generator's

manual reset circuit breaker

draw

wiring

event

relay

source of the

breaker and restart

Circuit

or electrical overload anywhere in

or

the

is terminated. If

.w""""

engine

engine

wiring

generator

problem.

Breaker

is

protected

will

will

shut down

this

should

After

the

generator.

(20

amps

cause

occur,

repairing

by

an

DC).

the

breaker

and

the voltage

the

engine

mounted

Excessive current

the

instrument panel

to

trip.

to

check

and

repair the

fault,

reset the

In

the

this

K2

"'"

WESTERBEKE

Engines & Generators

9

GENERATOR

BREAK-IN

PROCEDURE

DESCRIPTION

Although your engine

hour of test operations

assembly

operated

life of

operated

Breaking-in a

piston

and

scored,

the break-in period.

Your

conditioning operation

to

Perform

following:

Start

section.

(water

AFTER

Once the generator

operation and then encourage a fast

generator between

hours.

procedures

properly,

your

and

rings

smoky

which

new

engine

maximize

this

the

engine

Run

pump,

START-UP

engine

serviced

new

to

operation indicate that the cylinder

is

the

conditioning

the

oil

has

at

were

a break-in time

is

dependent

during

engine

the

cylinder

caused

by

requires

to

performance

according

engine

while

pressure,

has

been started, check

20%

experienced a

the

factory

followed and that

upon

its

initial

basically

walls.

overloading

approximately 50

break in each

and

carefully,

to

the

STARTING

checking that

battery charging)

and

60%

minimum

to

make

is

required.

how

hours

involves

Excessive

the

moving

service

life

keeping

warm-up.

of

full

load for the

of

sure

accurate

the

engine

The service

the

engine

of

use.

seating

the

oil

consumption

walls

are

generator

hours

in

PROCEDURE

all

are

for

during

of initial

part in order

of

the

engine.

mind the

systems

functioning.

proper

Run

the

first

one

is

10

CHECK

D Monitor

D Check for

D Check

D Confirm exhaust

To

the

breaker that

NOTE:

draw required for staning

draw can

GENERAIDR

GENERATOR

Once

be

engine's break-in period

A no-load

conjunction

GENERATOR

THE

FOLLOWING

the

control panel

leaks

of fuel

for

abnormal noise

vibration

When

When

When

protect

generator's output leads

and

blow-back

smoke:

the

engine is cold - White

the

engine is warm - almost Smokeless.

the

engine is overloaded - some

against

unintentional overloading of the

is

rated

at

the

Be

aware

of

motor staning loads and

be 3 to

5 times normal running

INFORMATION

ADJUSTMENTS

the

generator has been placed in operation,

adjustments

required

voltage

adjustment

with

the engine's

INFORMATION in

for

gauges.

and

sounds.

should

rated

motors.

engine

(first

engine oil.

such

as

knocking,

Smoke.

be routed

output of the

This staning

in

this

speed

50 hours)

may

also be

speed

adjustment.

this

Black

the

amperage.

manual.

(hertz)

or

after

required

manual.

friction,

Smoke.

generator,

through

generator.

a circuit

high

current

amperage

See

there

during

this

period.

in

See

may

the

A

CAUTION:

generator

After the first

can

be

periodically vary

by

10

increased

00

running

hours

of

to

the

full-load rated output,

the

load.

not

attempt

to

break-in

without a load.

the

generator's operation, the load

then

your

"""

WESTERBEKE

Engines & Generators

10

THE

DAILY

OPERATION

CHECK

Follow

D

D

D

D

D

D

D

D

D

LIST

this

Record

relate

to

Visually

Check

Check

tanklradiator.

Check

Look

for clean fuel in the fuel/separator transparent

Check

Check

Check

chdck list each

the

hourmeter

the maintenance

inspect

the

oil

level

the coolant level in

your

diesel fuel

for

loose wires

the

starting batteries

drive

belts

reading

the

generator

(dipstick).

for

wear

day

supply.

at

before starting

in

your

schedule.)

for

fuel,

the

coolant recovery

the

alternator.

(weekly).

and proper

your

log

(engine

oil,

or

tension

generator.

hours

water

leaks.

bowl.

(weekly).

START

(See

Allow

operating temperatures' of

applying

generator

Check

temperature,

NOTE:

This

temperature

STOPPING

Remove

time.

stabilize the operating temperature and

switch.

als).

THE

GENERATOR

STARTING

the

the

Some

condition should lessen

A

CAUTION:

.

long

periods

on

the

generator.

Allow

(See

PROCEDURES

engine

to

AC

loads.

to

adjust

to

gauges

for proper

and

DC

unstable running

is

reached and loads

of

time

THE

GENERATOR

the

major

AC

the

generator

STOPPING PROCEDURES

on

warm

up

for 5 to

140°

to

150°F

Apply

loads systematically

each load before applying

oil

pressure,

voltage.

may

occur

as

normal operating

are

Do

not

operate

without a load

loads

from

the generator

to

run

for a

previous

10

minutes

(60°-66°C)

operating

in

applied.

the

generator

being

few

minutes

depress

on

pages).

to

allowing

the

a cold

placed

one

the

previous

reach

before

the

next.

engine.

for

at

a

to

stop

manu-

an

~

WESTERBEKE

Engines & Generators

11

MAINTENANCE

A

WARNING:

running.

use

servicing

NOTE:

difficult and may require the expert knowledge

Wear,theproper

the

correct

Many

Never

attempt

tools

for

any

of

the

engine's

of

the following maintenance jobs are simple but others are more

safety

each

job.

DC

to

perform

equipment

Disconnect

electrical

SCHEDULE

any

service

such

the

equipment.

of

a service mechanic.

as

goggles

battery

while

terminals

the

and

engine

gloves,

is

and

when

SCHEDULED

MAINTENANCE

Fuel

Supply

Fuel/Water

Engine

Coolant

Drive

Visual

Fuel

Sfarting

Engine

Generator

Heat

Fuel

Electronic

(if

applicable)

Exhaust

Engine

Inlet

Separator

Oil

Level

Level

Belts

Inspection

Filler

Batteries

Oil

(and

Exchanger

Filter/Water

Governor

System

Hoses

Fuel

Filter

of

Engine

filter)

Zinc

Anode

Separator

Control

CHECK

EACH

DAY

0

0

0

0

0

weekly

0

0

weekly

HOURS

OF

OPERATION

50

100

NOTE:

Please

and

oil

will

remain

cool,

250

keep

inhibit

the

500

engine

engine's

750

surface

ability

1000

clean.

to

0 0 0 0 0 0

0

0

0

0

0 0

0

0 0 0 0 0

0

0 0

0 0 0

0

0

0

0 0

0 0

0 0

0 0

0 0

0

0

0 0 0 0

0 0

0 0

0

0

0 0

1250

Dirt

0

EXPLANATION

Diesel

No, 2 rating

Check

for

water

if

necessary),

Oil

level

should

dipstick,

Check

at

recovery

Add

coolant

Inspect

for

and

adjust

Check

for

fuel,

and

electrical

Check

for

loose

Initial

change

Every

50

operating

and

make

excessive

Initial

change

Check

with

for

Inspect

exchanger

Inspect

hours

drain

Check

required

as

NOTE:

adjustment

Initial

the

manifold.

and

dilion.

Hose

spongy.

Replace

or

corrosion.

engine

both

that

no

chafing.

additional

zinc

daily,

of

use

separator

and

(hertz)

needed.

These

check

system

other

No

should

Check

initially

as

needed.

MAINTENANCE

of

45

and

dirt

indicate

tank;

if

needed,

proper

tension

if

needed,

Check

oil

and

water

connections,

belt

tension,

at

50

hrs,

hours

sure

connections

oil & filter

every

100

AC

connections

See

GENERATOR

information,

anode,

replace

end

of

zinc

Replace

filter

or

as

found

bowl

as

or

adjust

the

and

the

adjustment

during

or

after

at

50

hrs.,

is

securely

System

is

properly

components

leaks,

be

hard & tight

and

tighten

at

50

hours

OF

SCHEDULED

cetane

or

in

fuel

(drain/replace

between

if

then

change

hours.

anode

then

fastened

are

MAX,

empty,

check

(3/8"

to

bett

edges

leaks,

Keep

bolts & nuts

change

check

electrolyte

are

very

at

are

clean

if

needed,

debris,

element

to

be

needed,

needed,

no·load

speed

regulator

are

not a warrantable

the

unit's

every

to

supported

in

good

Replace

all

hose

and

then

higher,

and

LOW

at

manifold,

1/2"

deflection)

for

wear,

Inspect

wiring

every

250

levels

tight

Clean

50

hrs"

then

and

secure

SECTION

clear

the

every

250

Clean

in

the

board

adjustment

break-in.

250

hrs,

Ensure

the

exhaust

and

serviceable

if

soft

clamps.

once a year

filter

on

tight

hrs,

off

heat

and

panel,

muffler

con-

or

Engines & Generators

12

MAINTENANCE

NOTE:

Use the engine hour meter gauge to log your engine hours

engine hours by running time.

SCHEDULE

or

record your

SCHEDULED

MAINTENANCE

Coolant

System

Air

Intake

Filler