Westerbeke 6.0KW -50Hz EDT, 9.4KW-50Hz, 9.2KW -50Hz EDT, 12.5KW-60Hz, 12.6KW-60Hz Service Manual

...Page 1

,(Eft/l

"

(y

~

.':1:;'

~

o

~LD'I'f

SERVICE

MANUAL

~

4i

,q

-10

'"

&It

8.0KW-60Hz . 6.0KW-50Hz

10.0KW-60Hz·

..

11.5KW-SOHz

·7.5KW-50Hz·EDT

9~2KW·50Hz

12.5KW-60Hz9.4KW-50Hz

EDT

EDT

EDT

12.6KW-60Hz

15.0KW-60Hz

. -

Single

and

10.4KW-50Hz

12.0KW-50Hz

. -

Three

Phase

EDT

EDT

:\D~NEt-D1ESEL-GENERATORS

PUBLICATION NO.54600

REVISIONl

JANUARY 2010

~

WESTERBEKE

WESTERBEKE

MYLES

WEBSITE:

....

..,.~~

NMMA

--

CORPORATION • 150

STANDISH

Member

INDUSTRIAL

www.WESTERBEKE.COM

National

Marine

JOHN

PARK·

Manufacturers

HANCOCK

TAUNTON

ROAD

MA

02780

Association

I]

Page 2

A

WARNING

Exhaust

colorless

unconsciousness

exposure

-Dizziness

-Nausea

-Headache

IF

GET

seek

until

WARNING

Generators

gasses

Weakness

YDU

DR

OUT

medical

it

has

Produce

Regular

Maintenance

rry~~~;.~

contain

gas.

Carbon

can

include:

IIIId

ANYONE

INTO

THE

attention.

been

CARBON

Required

Carbon

Monoxide

and

death.

Sleepiness

ELSE

FRESH

Inspected

MONOXIDE

Monoxide,

is

poisonous

Symptoms

-

-

-

-Inability

EXPERIENCE

AIR

IMMEDIATELY.

Shut

down

and

repaired.

A

WARNING

WESTERBEKE

bulkhead

WESTERBEKE

CARBON

living/sleeping

They

obtainable

of

Throbbing

Muscular1lvitching

Vomiting

ANY

the

unit

DECAL

near

MONOXIDE

are

inexpensive

at

an

odorless

and

Carbon

in

Temples

to

Think

OF

THESE

If

symptoms

and

do

is

provided

and

should

your

engine

also

recommends

DETECTORS

quarters

and

your

local

and

can

cause

Monoxide

Coherently

SYMPTOMS,

persist,

not

restart

by

be

fixed

to

or

generator.

installing

in

of

your

vessel.

easily

marine

store.

a

the

CALIFORNIA

PROPOSITION

Marine

exhaust

are

known

to

cause

and

diesel

and

some

to

the

cancer,

other

reproductive

65

and

of

State

WARNING

gasoline

its

birth

engine

constituents

of

California

defects,

harm.

Page 3

SAFETY

INSTRUCTIONS

INTRODUCTION

Read this safety

caused

by

tions.

Know

necessary precautions

and your machinery.

The following

American Boat and

PREVENT

A

WARNING:

while

engine

power.

•

Do

not

enclosures

• Shut off electrical

equipment.

•

Use

insulated

equipment.

•

Make

(particularly

•

Remove

electrical equipment.

•

Do

not

circuits, except through a ship-to-shore double

transfer

result if

• Electrical shock

tor.

Discharge

PREVENT

A

WARNING:

exhaust

very

hot!

•

Always

recovery

A

WARNING:

•

In

case

before

lfUmual

failure

when dangerous conditions exist and

safety

ELECTRIC

is

Lethal

voltage

operate

and.

sure

your

shoes)

wristwatch

connect utility

switch.

this

procedure

BURNS -HOT

system

check the engine coolant

tank.

of

an

touching

carefully.

to

follow fundamental rules and precau-

to

protect yourself, your

instructions

Yacht

Council (ABYC)

Most accidents

are

in compliance

SHOCK

00

not

touch

AC

electrical

running,

this

covers

mats

capacitor

Is

machinery

in

power

whenever

clothing

when

and

shore

Damage

results

Of

when

connected

pfesent

is

at

these

without electrical

place.

before

accessing

working

and

skin

are

handling

all

to

not

from

by

electrical

jewelry when

power

to

vessel's

shorting terminals

AC

followed.

handling a charged capad-

ENGINE

00

not

touch

hot

engine

components. A running

level

Steam

can

cause

injury

engine

overheat,

the engine

allow

or

checking the

the

are

take

personne~

with

standards.

connections

to

shore

connections!

electrical

on

electrical

dry,

not

damp

equipment.

working

vessel's

AC

generator

together.

parts

engIne

at

the

coolant

Of

death!

engine

coolant.

throw

may

Of

gets

to

the

on

cool

the

PREVENT

A

. • Prevent

sparks

pump,

vapors.

removing

•

Do

arrester

death.

•

Do

Backfire

•

Do

the

engine/generator

chances

•

Be

PREVENT

A

injury

• Follow re-fueling

hatches closed

after fueling.

•

•

•

•

•

•

• Make sure a

BURNS -FIRE

WARNING:

flash

fires.

to

occur

or

other

Use a

the

not

operate

removed.

not operate

can

cause

not

smoke

fuel

system.

of

fire.

aware -

diesel

BURNS -EXPLOSION

WARNING:

Of

death!

ning

the

blower.

starting

All

when

tilated area

out of

Do

Shut

the

spill.

Do

your

fuel

vapors

handling

away

the

reach of children.

not

fill

the

off

the

fuel

fuel

system.

DO

NOT

sources

ing.

fuel

Be

Be

of

fire

Ensure proper ventilation

system.

not alter or

sure

all

fuel

certain

fuel

free ofleaks.

properly

Extinguishers

for

maintained.

all

applications

Fire

can

Do

not

near

the

potential

suitable

fuel

container

line,

with

a Coast

Backfire

with

the

severe

or

pennit

Keep

the compartment

clean

Wipe

up

fuel

carburetor,

and

Explosions

safety

when

fueling.

Check

below

Run

the

engine.

are

highly

and

storing

from

spark-producing equipment

fuel

tank(s)

service

Take

care

allow

any

near

the

fuel

modify

supplies

line

fittings

fire

extinguisher

Be familiar

rated

ABC

encountered

cause

injury

smoke

or

carburetor,

sources

air

flames

will

instructions.

valve

the

of spilled

to

or

Guard

can

cause

cleaner/silencer

injury

or

or

sparks

free

of

all

spilled

bum.

;fom

fuel

Open

for

fumes/vapor

blower

for

explosive.

fuels.

Store

while

the

.t

the

in

catching

smoking,

system

exists

fuel

system.

have a

positive

are

adequately

is

installed

with

by

the

NFPA

in

Of

death!

pennit

fuel

line,

fuel

catch

all

fuel

filters.

Approved

severe

death.

to

and

debris

to

fuel

and

vapors

Keep

and

ventilate

four

minutes

Use

extreme

fuel

engine

engine

any

open

fiames,

or

engine

when

shutoff

nearby

its

proper

are

this

environment.

flames

or

filter,

fuel

or

fuel

fuel when

flame

injury

or

removed.

occur

near

the

ruiniruize

engine

oil.

can

cause

the vessel's

cabin

before

run-

before

care

in a well-ven-

and

is

running.

when

servicing

fuel that

servicing

tightened

appropriate

when

ruight

or

other

servic-

valve.

and

use.

the

and

the

is

Engines

& Generators

i

Page 4

SAFETY

INSTRUCTIONS

ACCIDENTAL

A

WARNING:

or

death!

• Disconnect the battery

generator.

last.

it

•

Make

starting.

•

Make

re-installed before starting

BATTERY

A

WARNING:

or

death!

•

Do

not smoke or

being

highly explosive

arcing

equipment

during

• Never connect

positive (+) connection

Do

not test the battery

together.

Ventilate

accumulation of explosive

disturb

being

is

•

Avoid

bums

wristwatch,

the

battery.

•

Always

the

battery

and

reconnect it last

BATTERY

A

WARNING:

severe

STARTING

Accidental

Remove

certain

certain

all

personnel

all

covers,

the

EXPLOSION

Batteryexplosion

allow

serviced.

Or

servicing.

the

contacting the

or

Lead

gas,

by lit

tobacco

in

the

vicinity

the

negative

Sparks could ignite battery

any compartment contaiuing batteries

battery

charger

charged.

sparks that could

rings,

and

turn

the battery

connections.

ACID

Sulfuric

injury

or

death!

starting

cables

negative

are

guards,

the

an

open

acid

batteries emit

which

products.

to

prevent

(-) battery cable

terminal

condition

gases.

connections

terminals

cause

any

other

charger

Remove

when

disconnecting

acid

can

cause

injury

before

servicing

lead

fust and reconnect

clear

of

and

hatches

engine.

can

cause

flame

near

can

be

ignited

Shut off

electrical

of the starter

by

shorting the

gases

To

avoid

with

Iools,

an

explosion.

jewelry before handling

off before disconnecting

the negative lead

in

batteries

the engine/

the

engine

are

injury

the

hydrogen,

by

electrical

all

electrical

arcing

to

solenoid.

or

fuel

sparks,

while

the battery

etc.,

the

battery.

can

cause

battery

the

10

Remove

before

a

terminals

vapors.

to

prevent

do

not

prevent

first

TOXIC

• Ensure that the

•

•

• For additional

•

•

EXHAUST

A

WARNING:

discharged

regularly

manifolds/water-injected

Be

sure the unit and

Run

Do

not

equipped

detector that

boat builder or

detectors.

(educational information

A

WARNING:

odorless

nausea

Do

fumes

systems.

copper tubing

Do

through portholes,

exhaust discharge outlet

enter

flow

• Although

exhaust

gas

symptoms

poisoning

Vomiting

Dizziness

Headache

Nausea

AVOID

from

for

leaks

blowers

or

not

not install exhaust outlet

the

of exhaust.

is present in

when

run

the

with a functiOning

complies

information

gas.

Inhalation

death!

use

copper

can

rapidly

Exhaust sulfur

resulting

exhaust

diesel

fumes

or

signs

are:

MOVING

GASES

Carbon

monoxide

exhaust

generator

dealer

Carbon

system

the

engine.

and

make

elbow

its

surroundings

running

set

with

for installation of approved

monoxide

produces

(CO)

is

adequate

Check

sure

the

is

securely

the

generator

or

engine

marine

ABYCA-24.

refer

to

on

Carbon

(CO)

flu·like

.

tubing

in

diesel

destroy

discharge

Avoid

engine

from

diesel

Inability

Throbbing

Muscular twitching

Weakness

copper

causes

rapid deterioration of

in

exhaust/water leakage.

where

vents,

or air conditioners.

is

near the

outlet

overloading

exhaust

gasoline

exhaust

of carbon

to think coherently

engines,

monoxide

in

temples

and

sleepiness

gases

fumes.

tubing

and

PARTS

is a deadly

the exhaust system

exhaust

are

well ventilated.

set

unless

carbon

Consult your

ABYC

Monoxide).

is

an

to

expel gases

attached.

or

engine.

the boat

monoxide

T-22

invisible

gas!

symptoms,

exhaust

systems.

in

exhaust

exhaust

waterline,

close

or

the

craft.

are

not

carbon

Some

inhalation or

Diesel

can

be drawn

If

the engine

water could

restrict the

as

toxic

monoxide

of

the

is

as

•

When

servicing

level,

wear

protection. Batteries contain sulfuric

destructive.

at

once

off

into

the eyes inadvertently

caps.

the

rubber

If

it

comes

with

water.

battery

or

checking

gloves,

a rubber apron,

in contact with your

Acid

may

when

acid

splash

removing electrolyte

the

electrolyte

and

which

skin,

on

the skin or

eye

is

wash

it

...v'

WESTERBEKE

Engines & Generators

ii

A

WARNING:

or

death!

•

Do

not service the

situation

make operating

touching

components .

Rot~ting

arises

in which it

adjustments,

moving

engine

parts

parts

can

while

it

is

absolutely

use

extreme

and

hot exhaust system

cause

is

running.

injury

If

a

necessary

care

to

to

avoid

Page 5

•

Do

not

wear

loose

equipment;'tie

jackets.

could

•

Make

Keep

places

•

Do

the

•

Stay

when

be

HAZARDOUS

A

shirts,

be

caught

sure

all

attaching

protective

at

all

times.

not

check

fluid

engine

is

operating.

clear of

caught

the

the

engine

in

these

NOISE

WARNING:

loss!

•

Never

operate

•

Do

not

run

an

removed.

•

Do

not

run

engines

open.

A

WARNING:

mentally

or

physically

clothing

back

long

sleeves,

an

engine

in

moving

shields

levels

drive

is

running;

rotating

High

engine

for

Do

not

rings,

shaft

noise

with

long

work

incapacitated

or

jewelry

hair

and

necklaces

parts.

hardware

and

guards

or

the

and

hair

parts.

levels

without

the

air

periods

on

SAFETY

when

avoid

wearing

or

bracelets

is

properly

in

their respective

drive

belts

tension

the

transmission

and

clothing

can

cause

its

muffler

intake

(silencer)

with

their

machinery

by

fatigue!

'when

servicing

loose

that

tightened.

while

coupling

can

easily

hearing

installed.

enclosures

you

INSTRUCTI'ONS

ABYC,

INSTALLING

Read

for

recommendations

ABYC

"Safety

Order

NFPA

are

NFPA

the

safety

(American

Staudards

from:

ABYC

3069

Edgewater,

(National

"Fire

Protection

Order

from:

NFPA

11

Tracy

Avon

Avon,

USCG

(United

"USCG

Order

from:

U.S.

Washington,

AND

USCG

DIESEL

following

codes

Solomon's

Industrial Park

MA

33CFR183"

Government

and

MD

Standard

Drive

02322

States

D.C.

ABYC,

standards.

when

Boat

for

Island

21037

Fire

Small

Protection

Printing

20404

PUBLICATIONS

ENGINES

NFPA

and

USCG

Follow

their

installing your

and

Yacht

Craft"

Rd.

for

Motor

Coast

Guard)

Office

engine.

Council)

Association)

Craft"

FOR

publications

OPERATORS

Many

of

in

your

notes

to

carefully,

procedures.

GASOLINE

Preparations

thorough

Council's

combination

Sections

H-2

P-l Exhaust

P-4

E-9

All

installations

Regulations

MANUAL

the

preceding

Operators

highlight

maintain

ENGINE

to

install

examination

(ABYC)

of

sources

of

the

ABYC

Ventilation

Inboard

DC

Electtical

(FCR).

Manual

critical

must

safety

along

information.

your

equipment,

AND

an

engine

of

the

standards.

including

standards

Systems

Engines

Systems

comply

tips

and

warnings

with

other

cautions

Read

your

and

follow all

GENERATOR

should

American

These standards are a

the

of particular interest

with

INSTALLATIONS

begin

with

Boat and Yacht'

USCG

and

the

Federal

are

manual

sarety

the

Code

repeated

and

a

NFPA.

are:

of

~

WESTERBEKE

Engines & Generators

iii

Page 6

TABLE

OF

CONTENTS

Installation

Parts

Introduction·

Serial

Engine

Testing

Engine.Disassembly

Engine

Assembly

Thermostat

Actuator

Heat

Exchanger

hijection

Injection

Governor

Fuel

Injectors

Glow

Starter

Raw

Water

Valve

Air

Intake

Testing

Drive

........... ~ .................................................. 2 Oil

Ide

rr

Ica

rD'

Ion

rawlngs

n I

.............................................................

Number

Location

Troubleshooting

for

Overhaul..

.............................................

.............................................

Inspection

.................................................

...............................................................

............................................................

........... : ....................................................

.....................................................

Pump

..................................................

Pump

Timing

......................................

.............................................................

.~~

................................................

Plug

Testlng

Motor

Pump

Clearance

.............................................

....................................................

..............................................

...............................................

......... , ................................................

Engine

Belt

CompreSSion

Adjustment

......................................

..............................

.3

4

.......................................

.........................................

..4

5

9

10

16

28

34

.34

35

36

37 A

38

.40

.41

.42

.46

.48

.49

............................

.49

.49

Pressure

Actuator

Service

Alternator

Wiring

#54193 1O-15Kw

#54655 1O-15Kw

#53477 5.5Kw EDCI7.6-15 EDT

#54628 5.5Kw EDCI7.6-15 EDT ..................

#54680 5.5Kw EDCI7.6-15 EDT

#52793 5.5Kw EDCI7.6-15 EDT ..................

Specification

Generator . Information

BT

Generator

Generator

I t

mal

n e

BT

.

Troubleshooting 3 Phase

Voltage

Torque

Special

Remote

Remote

Hardware

Metric

.......................................................

.................... : ............................................

Limits

Chart..

Testing

........................................

.............................................

Diagrams

EDT

3 Phase .....................

EDT

Charts

3 Phase

..........................................

24V

.......................................

Single

FrequencyNoltage

W"

iring

Phase

D'

lagram

...............................

Changes

....................................

.............................

Regulator

Specifications

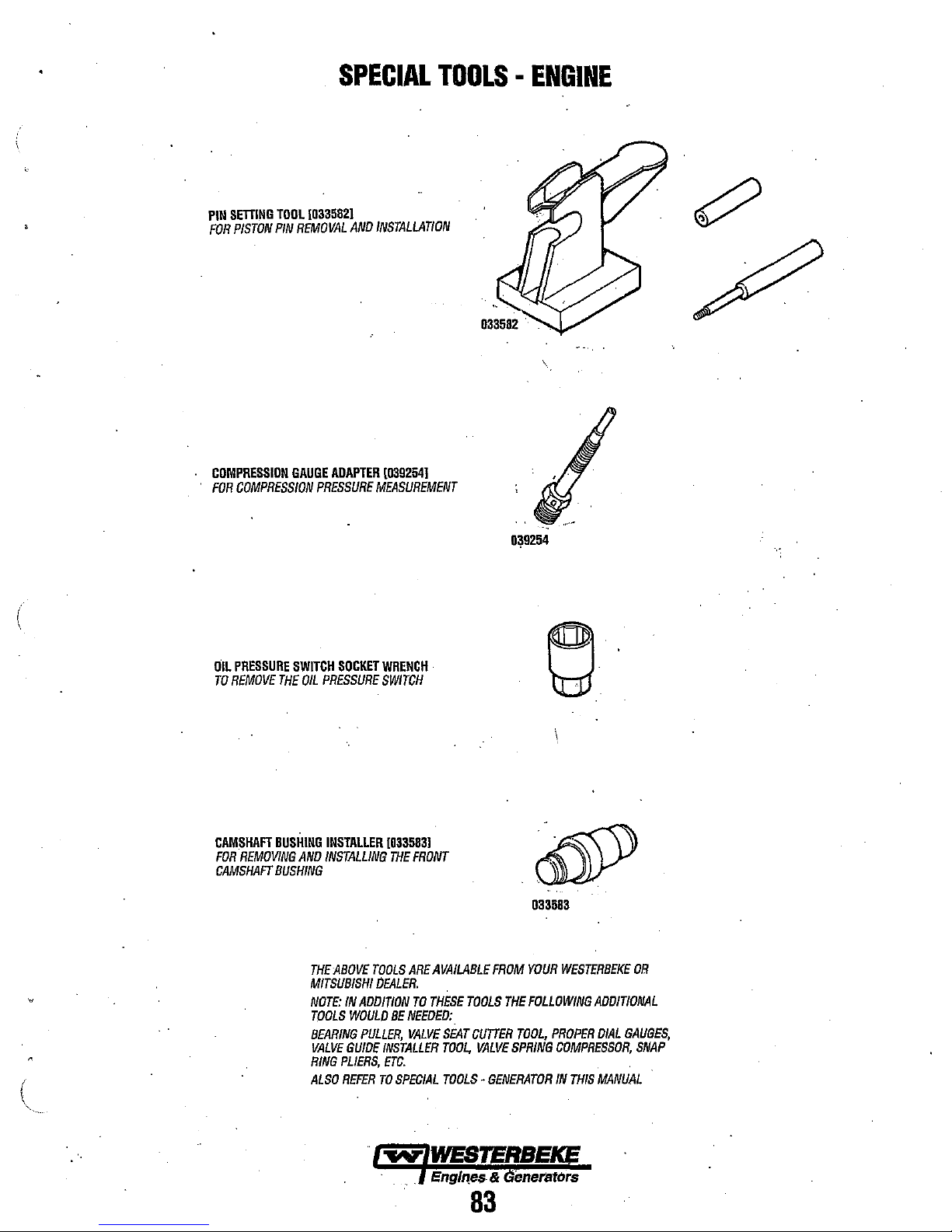

Tools

Oil

Filter

Stop/Start

Chart

Conversion

AdJustments

........................

.......................................

....................................................

..................... : .........................

PaneL

................................

.................................................

Data

...................................

24V

24V

.............

...........

..

, ... : ...

............

50

51

52

54

57

58

59

60

61

62

63

68

70

75

78

79

81

82

83

84

84

85

86

.

~

WESTERBEKE

Engines & Generators

1

Page 7

When

installing

attention

WESTERBEKE

be

paid

to

the

following

INSTALLATION

engines

information:

and

generators

it

is

important

that strict

CODES

Strict

when

AND

federal

regulations,

installing

REGULATIONS

engines

SIPHON-BREAK

For

installations

or

will

be

break

in

the

minimum

the

exhaust

raw

water

If

you

have

to

the

vessel's

siphon-break.

NOTE:

A

operation.

engine

damage.

EXHAUST

The

exhaust

prevent

of

the

water

vessels

where

below

the

vessel's

raw

water

of

20"

above

manifold

damage

any

doubt

waterline

to

siphon-break

Failure

to

Consult

SYSTEM

hose

must

from

entering

hull.

injection

the

about

requires

properly

ABYC

and

generators

the

exhaust

waterline,

supply

the

vessel's

engine

the

under

the

siphon-break

be

certified

the

guidelines,

manifold/water

hose

to

waterline.

port

and

.position

the

vessel's

periodic

in a marine

provisions

the

exhaust

is

at

or

possible

of

the

various

inspection

and

safety

environment.

injected

must

elbow.

Failure

below

the

flooding

water-injected

operating

and

maintain a siphon-break

manufacturer

for

marine

use.

The

exhaust

under

any

sea

codes

mnst

be

exhaust

be

made

This

to

use a siphon-break

load

of

the

elbow

to

install

hose

must

waterline

boat.

exhaust

conditions,

.

cleaning

can

for

system

conditions

to

result

proper

must

ensure

in

catastrophic

maintenance.

be

and

complied

is

close

iI

siphon-

be

looped

when

will

result

elbow

relative

install

proper

designed

at

any

angle

.

with

in

a

to

to

a

AVAILABLE

YOUR

DEALER

FROM

WESTERBEKE

\

}

A

detailed

engine

can

and

be

obtained

Marine

Installation

generators

from

is

suppied

our

website

Manual

~

covering

with

each

unit.

in

pdf

form.

WESTERBEKE

Eng/ntis & Generators

2

gasoline

and

Additional

diesel

copies

www.westerbeke.com.

Page 8

PARTS

IDENTIFICATIO'N/GENERATORS

CONTROL

•

I

OIL

LEFT

SIDE

FRONT

RAW

WATER

PANEL

CONNECTION

-"or'nu

EXHAUST.

TEMPERATURE

r~t-t-:'--''-EXH,AUST

EXHAUST

MANIFOLD

~~~-:-7"----STA,RTSOLENOID

-STAIITER

..

BREAK

COOLING

TO

ELBOW

MOTOR

AIR

TO

AIR

INTAKE

REAR

PANEL,

BACK-ENQ,

,BHEAKEH

REAR

'

' '

PREHEAT

SOLIENOID'----'"

MANIFOLD

PRESSURE

~:-:--=--=--=-

""

'K\1Jk-'--~----",

SENDDR

CAP

_-_-_-_-_- _-_-

"'----

DIPSTICK

PRESSURE

..:.-~II':.F_IL_L

IN-LINE

~~BLEED

THERMOSTAT

ASSEMBLY

AIR

INTAKE

SILENCER & FILTER

INJECTION

PUMP

SUMP

FUEL

FILTER

FRONT

PETCDCK

Ol~

FILL

DRAIN

HOSE

Engines & Generators

3

Page 9

I:ustomer

lilentificationCard

)

\

J

A,<I,di~lqnal.aetaue4

.vldM.ijtQtli\lr·~ections

.

li!,~erl!!llt,.~1tt11'!l(ltot,

\\QQti11lrl1!llllP$,e,I¢;

ihfun1l\ltionllliti'.pedfic~ti(jnsareptti~

of·tiii$jfu\ntiJ!!,·.roY~ijtj~the·

st~rter·i1l()t()r,

\)!l&in'f.aqj

.

us

e

l!l1

nts,

.

Page 10

The

following

problems

these

problems,

problems.'This

these

the

need

ing

ENGINE

troubleshooting chart

relating

to

engine

service, the probable

and the recommendations to overcome

chart

may

for

an

engine overhaul.

be

describes

of

assistance

certain

causes

in

determin-

TROUBLESHOOTING

NOTE:

The

of

.

ampere

mounted

engine's electrical

manual

on

reset circuit

the

same

bracket.

system

breaker.

is protected

The

preheat solenoid

by a 20-

is

PROBLEM

HARD

STARTING

LOW

CRANKING

1.

Engine

011

viscosity

2.

Run-down

3.

Worn

4.

Battery

5.

Defective

6.

Defective

DEFECTIVE

1.

Air

2.

Clogged

3.

Low

4.

Inadequate

5.

Injection

6.

Injection

MAIN

1.

Low

a.

b.

c.

d.

e.

g.

2.

Burnt

3.

Faulty

4. Incorrect

5.

Governor

battery.

battery.

terminals

starter.

main

INJECTION

trapped

fuel

injection

pump

too

ENGINE

compression.

Incorrect

Inadequate

Valve

stem

Broken

Compression

t .

Piston

Worn

piston

glow

glow

governor

spring

PROBABLE

SPEED

too

high.

loosely

connected.

drive

section.

SYSTEM

in

fuel

passage.

filter.

pressure.

spray.

delivering

early.

TROUBLES

valve

clearance.

contact

of

seized.

valve

spring.

leaks

through

ring

seized.

ring

and

plug.

plug

operation.

lever

out

of

POSITION

CAUSE

insufficient

valve

seat.

cylinder

cylinder.

posnion.

fuel.

head

gasket.

1.

Replace

2.

Recharge

3.

Replace

4.

Clean

5.

Repair

6.

Check

1.

Bleed

2.

Clean

3.

Adjust

4.

Clean

5.

Repair

6.

Adjust

a.

b.

c.

d.

e.

t

g.

2.

Replace

3.

Correct

4.

Set

lever

5.

Correct

VERIFICATION/REMEDY

engine

oil

with

less

viscous

battery.

battery.

terminals

clutch

air

or

or

Adjust

Lap

Replace

Replace

Replace

Replace

Overhaul

or

replace

for

from

fuel

replace

Injection

replace

or

replace

injection

valve

valve.

valve

valve

gasket.

piston

engine.

glow

plug.

lead

wire

to

starting

spring

and

correct

cables.

starter.

disengagement.

system.

filter.

pressure.

nozzle,

injection

pump.

timing.

clearance.

and

valve

guide.

spring.

and

piston

ring.

connection.

position.

011.

lOW

LOW

OUTPUT

COMPRESSION

INJECTION

1.

Incorrect

2.

Insufficient

3.

Low

injection

INSUFFICIENT

1.

Airtrapped

2.

Clogged

3.

Contaminated

INSUFFICIENT

1.

Clogged

SYSTEM

injection

filter.

air

OUT

timing.

injection.

pressure.

FUEL

in

fuel

system.

fuel

tank.

INTAKE

cleaner.

OF

ADJUSTMENT

AIR

Engines & Generators

5

See

HARD

STARTING

.

1.

Adjust

injection

timing.

2.

Repair

or

replace

3.

Check

1.

Check

2.

Clean

3.

1.

Clean

Clean

injection

and

retighten

or

repiace

tank.

or

repiace

injection

nozzle

filter.

air

pump.

and

adjust

pressure.

connector.

~ieaner.

(continued)

Page 11

PROBLEM

LOW

OUTPUT

(cont.)

ENGINE

PROBABLE

OVERHEATING

1.

Low

coolant

level.

2.

Loose

V-belt.

3.

Incorrect

4.

Low

injection

engine

all

timing.

level.

TROUBLESHOOTING

.,

CAUSE·

1.

2.

3.

6.

VERIFICATION/REMEDY

Add

coolant.

Adjust

or

replace

Adjust

injection

Add

engine

oil.

)

V-belt.

timing.

EXCESSIVE

CONSUMPTION

EXCESSIVE

CONSUMPTION

OIL OIL

FUEL

LEAKAGE

1.

Defective

2.

Broken

3.

Loose

4.

Loose

5.

Loose

6.

Broken

7.

Loose

OIL

1.

Worn

2.

Worn

3.

Incorrectly

4.

Displaced

OIL

1.

D~fective

2;

Worn

ENGINE

1.

Noisy

2.

Smoky

3.

Moving

4.

Poor

5.

Improper

6.

Improper

oil

gear

gear

case

drain

oil

pipe

rocker

rocker

LEVEL

RISING

piston

piston

posit.ioned

or

LEVEL

FALLING

stem

valve

and

BODY

knocking.

exhaust.

parts

compression.

valve

valve

seals.

case

gasket.

attaching

plug.

connector.

cover

gasket.

cover

attaching

ring

..

or

cylinder.

twisted

connecting

seal.

valve

guide.

TROUBLES

nearly

seized

timing.

clearance.

bolts.

piston

or

bolts.

ring

gaps.

rod.

excessively

worn.

1.

Replace

2.

Replace

3.

Retighren

4.

Retighten

5.

Retighten

6.

Replace

7.

Retighten

1.

Replace

2.

Replace

3.

Correct

I

4:

Replace

1.

Replace

4.

Replace a valve

1.

See

KNOCKING.

2.

See

SMOKY

3.

Repair

4.

See

LOW

5.

Adjust.

6.

Adjust.

all

seals.

gasket.

bolts.

plug.

oil

connections.

gasket.

attaching

ring.

piston

ring

connecting

stem

or

replace.

COMPRESSION;

bolts.

and

rebore:cylinder.

gap

positions.

rod.

seal.

and

valve,guide.

EXHAUST.

HARD

)

STARTING.

SMOKY

EXHAUST

INSUFFICIENT

1.

Air

Intake

NOZZLE

1.

Seized

2.

Worn

IMPROPER

FUEL

LEAKS

WHITISH

1.

excessive

2.

Excessive

a.

b.

c.

INTAKE

obstructed.

TRDUBLES

nozzle.

nozzle.

FUEL

OR

PURPLISH

engine

rtse

Poor

piston

Seized

piston

Excessive

AIR

011.

of

oil

Into

combustion

contact.

piston-to-cylinder

.

ring.

clearance.

E,?glnes & Generators

chamber.

1.

Remove

1.

Replace

2.

Replace.

Replace

Find

fuel

1.

Correct

a.

b.

c.

obstruction.

..

with

proper

leaks.

oil

level.

Check.

Replace

Replace

fuel.

or

clean.

or

correct.

(continued)

6

Page 12

PROBLEM

SMOKY

EXHAUST

(cont.)

WHITISH

d.

Worn

e.

Low

I.

Excessive

3.

Injection

4.

Insufficient

ENGINE

PROBABLE

OR

PURPLISH

valve

engine

timing

compression.

stem

and

oil

viscosity.

oil

pressure.

is

too

(cont.)

late.

TROUBLESHOOTING

.

CAUSE

valve

guide.

3.

4.

VERIFICATIONJREMEDY

d.

Replace.

e.

Replace.

I.

Correct.

Adjust.

See

LOW

COMPRESSION;

HARD

.

STARTING.

(

ABNORMAL

OR

NOISE

SOUND

BLACKISH

1.Engine

2.

3.

CRANKSHAFT

1.

2.

3.

CONNECTING

1.

2.

3.

PISTON,

1.

2.

3.

4.

VALVE

1.

2.

3.

4.

OR

body

a.

Poor

compression.

b.

Improper

Insufficient

Improper

Badly

Badly

Melted

Worn

Worn

Bent

Worn

Worn

Piston

Piston

Worn

Excessive

Worn

Worn

fuel.

worn

worn

bearing.

connecting

crankpin.

connecting

PISTON

cylinder.

piston

seized.

seized

MECHANISM

camshaft.

valve

timing

fan

pulley

DARK

troubles.

intake

AND

bearing.

crankshaft.

ROD

pin.

gear.

GRAYISH

valve

clearance.

air

(air

MAIN

AND

rod

big

rod.

PIN,

AND

and

ring

clearance.

bearing.

cleaner

clogged).

BEARING

CONNECTING

end

PISTON

worn

bearing.

RING

or

damaged.

ROD

BEARING

a.

b.

2.

Clean

3.

Replace

1.

Replace

2.

Grind

3.

Replace

1.

Replace

2.

Grind

3.

Correct

1.

Rebore

2.

Replace

3.

Replace

4.

Replace

1.

Replace.

2.

Adjust.

3.

Replace.

4.

Replace.

See

LOW

Adjust.

air

cleaner.

wfth

proper

bearing

crankshaft.

bearing

bearing.

crankshaft.

bend

or

cylinder

piston.

piston

piston

COMPRESSION;

fuel.

and

grind

and

check

replace.

to

oversize

and

rebore

and

rings.

HARD

crankshaft.

lubrication

and

replace

cylinder.

STARTING.

system.

piston.

ROUGH

OPERATION

INJECTION

1.

Uneven

2.

Control

3.

Worn

delivery

4.

Inadequate

GOVERNING

1.

Governor

2.

Fatigued

PUMP

SYSTEM

injection.

rack

malfunctioning.

valve.

Injection

SYSTEM

lever

malfunctioning.

governor

spring.

..,...

nozzle

spray.

WESTERBEKE

EngInes & Generators

7

1.

Adjust

injection

2.

Disassemble,

3.

Replace.

4.

Replace

1.

Check

governor

2.

Replace.

orreplace

check

Injection

shaft

and

correct

nozzle.

and

parts.

Injection

correct

pump.

operation.

(continued)

Page 13

PROBLEM

KNOCKING

ENGINE

KNOCKS

1.

Main

engine

a.

Overheated

b.

Carbon

2.

Too

early'lnjectlon

3.

Too

high

4.

Improper

ENGINE

PROBABLE

WITHOUT

troubles.

cylinder.

deposits

in

Injection

fuel.

cylinder.

timing.

pressure.

TROUBLESHOOTING

CAUSE

MUCH

.'

SMOKE

2.

3.

4.

VERIFICATION/REMEDY

a.

See

OVERHEATING;

b.

Clean.

Correct.

Correct.

Replace

with

proper

fuel.

LOW

OUTPUT.

INTERMITTENT

EXHAUST

OVERHEATING

LOW

SOUND

DlL

PRESSURE

KNOCKING

1.

Poor

2.

Injection

3.

Improper

1.

Fuel

2.

Fuel

3.

Water

1.

V-belt

2.

Damaged

3.

Lack

4.

Low

5.

Knocking.

6.

Moving

7.

Defective

1.

Worn

2.

Relief

3.

Clogged

4.

Diesel

WITH

compression.

pump

a.

Poor

b.

Poor

c.

After-injection

d.

Nozzle

filter

pipe

sucks

mixed

slackening

of

coolant.

oil

level

parts

thermostat.

Bearings.

valve

011

dilution

DARK

malfunctioning

nozzle.

spray.

chattering.

drip.

needle

valve

clogged.

air.

in

fuel

or

slippery

water

pump.

or

poor

seized

malfunction.

cooler.

of

the

SMOKE

seized.

oil

quality.

or

damaged.

011.

•.

with

011.

1.

See

LOW

2.

Adjust/Repair

a.

Clean

b.

Repair

c.

Repair

d.

Replace.

1.

Clean

or

2.

Retighten

3.

Replace

fuel.

1.

Adjust,

replace

2.

Replace.

3.

Add.

4.

Add

or

change.

5.

See

KNOCKING.

6.

Replace.

7.

Replace.

1.

Engine

overhaul

2.

Overhaul

3.

Repair.

4.

Injection

COMPRESSION;

or

replace

or

replace

or

replace

replace.

pipe

jOints

or

clean.

replace

011

pump.

pump

repair.

HARD

nozzle.

nozzle.

nozzle.

or

replace

bearings.

STARTING.

pipe.

)

Engines

8

.&.

Generators

LCD

DISPLAY

FAULTS

(continued)

Page 14

ENGINE

TROUBLESHOOTING

LCD

DISPLAY

FAULTS,

PROBLEM

LCD

DISPLAY

NOT

ILLUMINATE

LOW

OIL

HIGH

COOLANTTEMPERATURE

HIGH

EXHAUSTTEMPERATURE

BATTERY

GENERATOR

overspeed

Underspeed

LED

DISPLAY

TURN

WAITING

DOES

PRESSURE

VOLTAGE

FREQUENCY

(steady

(flashing

EDGES

PINK

FOR

ECU

LED)

LED)

PROBABLE

1.

Check

2.

20

amp

3.

Loose

4; 1

amp

1.

Oil

level

2.

Lack

of

3.

Ground

4.

Faulty

5.

Faulty

1.

Check

2.

Sea

water

3.

Check

4.

Faulty

5.

Ground

6.

Faulty

1.

Check

2.

FaultY

3.

Ground

4.

Faulty

5.

Sea

water

6.

Faulty

1.

Check

2.

Check

3.

Che,ck

4:

Faulty

1.

Check

2.

Check

3.

Amperage

4.

Crank

(underspeed

1.

Compartment

too

high.

1.

ECU

and

2.

Loose

3.

Panel

4.

Blown 8 amp

5.

Terminating

6.

Battery

CAUSE

ballery.

breaker

off.

display

connection.

fuse

blown

(faulty)

low/oil

leak.

oil

pressure

connection.

control

module

oil

pressure

system

pump.

water

temperature

connection.

control

sea

exhaust

Connection.

control

fire

alternator

charge

battery

control

engine

fuel

cycle

LCD

cable

DC

Voltage

sensor.

coolant

pump

sensor.

module

water

flow.

temperature

module

pump.

suppression

drive

voltage.

connections.

module

speed.

supply.

load.

with

no

fault)

ambient

display

connection.

breaker

OFF.

fuse.

ReSistors.

to

•.

(ECU).

level.

drive

belt.

(ECU).

switch.

(ECU).

system.

belt.

(ECU).

start

temperature

not

compatible

ECU.

VERIFICATION/REMEOY

1.

Ballery

on.

2.

Turn

breaker

on.

3.

Check

all

cable

connections.

4.

Check/replace.

1.

Check

2.

Test

oil

oil

filter.

3.

Check

4;'

Inspect

5.

Check

1.

Add

coolant.

2.

Inspect

3.

Adjust

4.

Check

5.

Check

6.

Check

1.

Inspect

as

needed.

2.

Test/replace.

3.

Check

4.

,Check

5.

Inspect

6.

BY'pass

1;

Adjusttensionireplace

2.

Check

3.

Check + and·

4.

Check

1.

Check

2.

Inspect

3.

Check + and·

4.

Check

1.

Ventilate

Nola:

display.

1.

Check

2.

Check

3.

Turn

4.

Check/replace

5.

Check

per

resister

6.

Check

unplugged

present.

Determine

oil

level.

add

pressure.

inspect

ground

connection.

all

the

plug

sensor/replace.

Check

Impeller/pump/replace.,

belt

tension.

sensor/replace.

ground

circuit.

plug

connections/replace.

thru

hull

ground

circuit.

plug

connections.

impeller/replace.

system/check.

excitation.

cables

plug

connections/replace.

speed

selling.

filters/replace

cables

cause

for

compartment.

Heat

will

This

will

compatibility

all

cable

ON.

check

fuse.

alilerminating

measured

between

from

ECU

is

cause

oil

and

repair

leaks.

If

OK.

test

oil

pressure

oil

pump.

connections/replace.

for

leaks.

replace

belt.

filling.

hose

and

strainer.

if

worn.

Replace/repair

from

filters.

from

no

start.

often

change

not

effect

with

connections.

DC

vollage

Check

resislors

across

pins

P2-24

ECU.

Power

faulty

.

alternator

ballery

to

Test

fuel

ballery

to

the

c%r

the

operation

Westerlink

across

breaker.

DC

voltage

ara

In

pin

#4

and

P2-25.

turned

sendor.

Correct

engine.

pump

engine.

of

an

of

or

NMEA.

across

place.

and

#5.

P2

ECU

ON.

If

inspect

operation.

LCD

the

engine.

fuseholder

120

ohm

plug

voltage

Is

...

WESTERBEKE

Engines & ,Generators

SA

Page 15

TESTING

FOR

OVERHAUL

HOW

TO

DETERMINE

Cause

Generally,

is

power

fuel

is not necessarily

sometimes

wear.

many

or

inspection

is a

caused

symptoms

of

Low

Compression

the

time

at

which

determlned

and

The

factors.

causes

good

by

various

outpu~

decreased

oil

consumption.

due

to

caused

by

injector

decrease

on

and

means of

by

wom

will

1 Low engine power ontput

in

It

is,

therefore,

the

basis

maintenance.

monitoring

cylinders

occur:

compression

of

2 Increased fuel consumption

3 Increased

4 Hard engine starting

5

Noisy

engine operation

symptoms

These

can result

timing,

tion

also

by

defective electrical

.

alternator,

judge

the

compression pressure

plus increased

obtained

eugine

of

operating

haul, it is important

pressure

which

should be checked

with engine

front end of the

NOTE:

ADJUSTMENT section of

ouly

lacks·

fuel

will take place

regularly.

the measurement of compression pressure is

To

often

also

from

excessive

and

wear

of

starter

and

glow

optimum

properly.

test engine compression see the

engine

caused

oil

consumption.

under

sufficient

compression pressure, incomplete combustion

even

To

to

At

the

because

rpm.

The

engine

crankshaft.

ENGINE

conditions

compression

The

trouble

data

or piston

oil

consumption

appear

plugs

overhaul time

determlne

measure

same

this

OVERHAUl.

an

engine should be

such

as

pressure, and increased

lowered

nozzle

necessary

produced

Oil

engine internal

together.

fuel

and

devices

plugs.

by

compression

if

other parts of the engine

the compression pressure

rpm can be measured

manual.

engine power

with

the

engine iiself, but

wear

pressure

to determlne a cause

by periodic

analysis

warn cylinders and pistons

Satisfactory combustion

the period of engine

the engine compression

time, the engine speed

on

rings,

Symptoms 2 and

mjection, improper injecnozzles.

such

as

Therefore it

by

PERIOD

overhauled

lowered

or

is

a seasonal basis

the following

They

the

the lowered

pressure.

ENGINE

injection

caused

wear.

When

are

battery,

is

desirable

made

at

engine

output

caused

If

is

pump

by

4

is

an

are

over-

at

varies

the

to

OVERHAUL

Compression pressure

engine until piston

Thereafter,

. of these parts.

When

limit, the engine must be overhauled.

The engine requires

blowby evideut, and compression values

below.

290

rpm.

not

exceed

Minimum

for

overhaul.

CONDITIONS

it

decreases

decrease

Engine

of

compression pressure

compression

Tlje

maximum

IO%.

compression

tends

rings

gradually

overhaul

difference

of

to

increase a little in a new

and

valve

seats

with

when

oil

should

be

between

384 psi (27

kglcm')

DISASSEMBLY

1. Before disassembly

defects

which

cleaning.

2. Drain

3.

4.

5. Perform disassembly in a proper order

6.

7.

8.

water,

Clean

or

wash

Do

not remove

disassembly.

Keep

disassembled

necessary.

from

Parts

which

parts

its

reproduced

Pay

parts

necessary,

Carefully check each part or component

faulty

tell

accurately

Take

intrasion of

must

be

they

were

must

be

component,

at

attention

for their positions or directions. Put

to

condition

you

how

during removal or cleaning.

and

cleaning, carefully check

cannot

be

found

after

fuel and

restored

set

assembly.

to

aid

it acted or what

oil

before

disassembly.

the

engine

exterior.

or

disassemble the parts that require

parts

in

order.

Apply

special

care

to

keep

dust

and

dirt.

to

their

respective

removed

aside

so

that

marks

assembly

during

at

disassembly.

separately

the

same

on

assemblies,

..

removal or

in

groups,

combination

was

abnonnal

have

been broken

the

progress

reaches

consumption is high,

are

30

kglcm',

disassembly

using

the

components

This

components

cleaning.

of

the

at

minimum or

427 psi at

cylinders

is

an

indication

proper tools .

oil

when

fuel

system

means

each

marked

or

set

on

marks,

fore

any

The part

about

wear

repair

must

for

and

no

parts

from

that

can

be

and

if

sign of

it

more

in.

all

for

will

)

ASSEMBLY

1.

Wash

all

parts,

except

for oil seals, O-rings, rubber

etc.,

with cleaning solvent and dry

2.

Always

you

job.

3.

Use

of oil, grease or sealant

4.

Be

torques

5.

Ant

a-rings must be installed.

use

tools

nnderstand

only good

sure

are

time the engine

how

quality

to

use a torque

specified.

that

are

in good condition and be

to

use

lubricants. Be sure

to

parts

wrench

is

assembled,

them

them before perfonning

as

specified

to

tighten parts for

new

with pressure

to

apply·a coat

..

gaskets and

-.,.y:

OVERHAUL

sheets,

air.

sure

any

which

When rebuilding

and

inspected.

and

the

altemator termlnal

wire brush. Make certain the

wiring connections that connect

Turn

the rotor pulley

Depending

brushes

send it

For additional information

ALTERNATOR

may

to

WESTERBEKE

Engines & Generators

9

CONDITIONS

the

engine,

The housing can be wiped off

on

when

the

need replacing.

a service

shop

TROUBLESHOOTING

the alternator

studs

studs

by

hand.

It should tum

alternator

If

for testing and

on

alternators refer

should

to

the alternator

are

the

was

should

with

be

cleaned

tight

and

wiring

smoothly.

last

serviced.

is

overhaul.

in

this

be cleaned

a solvent

with a

clean the

harness.

at

all

to

the

manual.

the

suspect,

Page 16

ENGINE

DISASSEMBLY

(

GENERATOR

Disconnect

wiring

battery

NOTE:

Separate the exhaust

disconnect the fuel

Drain the engine

Carefully support and then

from

Additional generator information

GENERATOR

PROPULSION

Switch off the batteries and disconnect the battery

from

Drain or pump out

from

Unplug the instrument panel

ttansmission

Detach the

the

engine.

NOTE:

BLOCK

COOLANT

DRAIN

NOTE:

A

coolant

hose

may

boss

plug.

be

in.

lieu

Remove

If

the transmission is not being rebuilt it should

inspected. Flush out

replace the coolant hoses. Inspect

linkage and the propeller shaft

the

For

ttansmission

WES1ERBEKE dealer or

center:.

the

AC

wiring

and

unplug

the engine's

harness

cables

Label

the

from

any

engine.

section

at

the generator control panel.

the engine

lines,

hoses

hose

supply

oil

and

See

SPECIAL

of

at

an<j

the

this

and

tape

or

cables

the

water

return

lines.

coolant

from

unbolt

the generator backend

TOOLS

will

be

manual.

injected

ENGINE

the

engine and

t1Je

engine and engine

ojl'

Label

any

PLUG

on

this

of

the

the

hosa·

transmission

transmission service and maintenance reter

tape

over

the

terminals.

all

the engine oil and drain

hoses.

wiring

harness. Drain

fluid

and the transmission oil cooler

cooler hoses

lines,

and

manual.

and

unbolt

hoses

or

cables

and

pressure test the oil cooler

and

coupling.

cbange the transmission

To

rebuild a transmission contact your

an

authorized transmission service

lubricate the

DC

Remove

over the

as you

in this

the transmission

tis

the

engine.

found

you

Clean

DAMPER

BOLTS

terminals.

separate

elboW

manual.

in the

cables

the

coolant

the

hoses,

separate

be

visually

and

gear

and

repaint

fluid.

to

your

PLATE

.

the

them.

and

from

them.

.

sbift

ENGINE

Take

•

•

• Arrange parts in the order

• Mount the engine on a suitable engine

With

following

l.Remove the transmission damper plate

2.

3. Remove the engine heat exchanger.

4.

5.

6.

7. Remove the engine monnted raw water

S.

9.

COOlANT

lO.Remove the

1l.Reinove

l2.Unbolt the elbows and remove the exhaust manifold

l3.Remove the fuel injection pump. Disconnect the

NOTE:

and

l4.Remove the fuel injection nozzle

NOTE:

·

gasket

DISASSEMBLY

the

following

Oean

the

dirt

and

Be

careful not to

label parts as needed to insure proper

reassembly.

disassembly.

the

lrljnsmission

step

engine flywheel.

Remove

hose

connections

one

end

Remove the bell housing

preheat solenoid monnting braeket.

Remove the engine back plate.

Remove the start motor, drive belt and

Label the wires

complete with its adapter mounting plate. See

WAT.l?R

With the hoses disconnected, remove the thermostat

housing

sender in

Remove the coolant circulatblg pump. Refer

engine block.

its entirety.

injection

PU\IlP

and

Put plugs or

nozzle

injection

gaskets

Remove

scraper.

precautions:

exterior of the engine of

oil.

damage

Keep parts clean. .

separated

by

step

the

engine oil cooler and

from

of

each

hose

and

PUMP

for

and

housing gasket,

place.

CmCULATING

air

intake silencer and the intake manifold.

the oil

61ter

pipes

and

nozzles,

caps

connectors.

nozzles

from

with a wrench.

the

cylinder

the

gaskets

Discard

the disassembled parts.

of

from

procedure

connected

cables.

parts breakdown.

the

oil

and

to

cooler

leaving

PUMP

and the mounting bracket from the

fuel

leak-off pipe

on

the

openings

Golf

tees

work

head.

from

the

the

gaskets.

any

deposits of

disassembly.

the engine,

disassemble the

uil

to

If

to

the

the circuit breaker!

Mark

mating

stand

hoses. Note

the engine.

possible, leave

part being

begin

from

the

alternator.

pnmp,

and

for

engine.

the

removed.

RAW

the

temperature

to

ASSEMBLY.

from

the fuel

of

the

injection

well

as

plugs.

..

Loosen the

Remove

the

fuel

nozzles

.

cylinder

head

with

oil

fuel

injection

or

the

in

pump

and

a

DAMPER

.

PLATE

'"

Engines & Generators

10

Page 17

15.

Remove

a.

b.

c.

16.

Remove

a.

b.

17.

Fuel injection pump

a.

b.

18.

Remove

NOTE:

in11tallation.

19.

Remov~

blOCk

20.

Remo~e

a.

b.

governor

Remove

Remove

disconnect

Remove

Remove

Remove

Remove

Remove

disconnect

the

the

the

governor weight.

the

the

the

the

the fuel injection pump.

Keep a record

..

the pressure relief valve from

.•

ii'·····

, :

, '

. .

th~r;;~ker

Remove

and

Remove

the

remove

the

assembly.

tie

rod

cover.

spring

from

the

tie

rod

from

governor

sliding

sliding

tie

spring

the

..

,"

.

\

'UNDER

. .

•

'.

bolts

the

valve

assembly.

sleeve.

sleeve

removaL

rod

cover.

from

tie

rod

from

of

the

LOCATEiiJusr'

THE

FUEL

PUMP

DN

THE

ENGINE

BLGCK.'

..

-. ; .

shaft assembly.' ',' .

that

hold

rocker

shaft

caps.

the

tie rod

t\1e

fuel

shaft

the

tie rod

the

fuel

thickness

.

."

.

'

the

rocker stays

assembly.

ENGINE

with

pliers

injection

and

governor

with

pliers

fujection

of

the

shims

. .

.

to

pomp.

weigbts.

to

pomp.

for

in

position

DISASSEMBLY

23.

Remove the cyfuider head assembly. Lift

head

straight

NOTE:

be

separated

Siile1WrtiOI:!

.

ORDER

up

with a hoist.

if

the

gasket

is

from

the

of

the

cylinder head

OF

DISASSEMBLY

seized and

cylinder

the

cylinder hedd

block,

tap

with

a plastic

the

cylinder

around

hammer.

cannot

the

)

thick

"'iIIISASSEMIBLlIIG

•

ROCKER

21.

Disassemble the rocker shaft assembly. Put

tion

on

each

rocker

arm

as

to its location

shaft.

22.

Remov~

head

.

NiltE:

the

before

the .cylinder head bolt. Loosen the

bolts

in

two

or three

it

~ny

p~ris

cylinder head bolts for

loosening

them.

07

$3

.5

.12

steps

in the sequence

on

the

g,iinde~

tightness

G9

.10"

.14

.13

head

1118

SHAFT

are

with a

THE

ASSEMBLY

identifica-

on

the rocker

cylinder

shown.

faUlty,

torque

.

check

wrench

)

"

CYLINDER

HEAD

BOLT

LOOSENING

SEQUENCE

".3'tYEINDER

.

11

Page 18

(

VALVE

SPRING

REMOVAL

•

24:

Removethe valve

a.

Compress the

, remove

b.

Remove

NOTE:

be

cylinder

25.

Remove the valve stem

NOTE:

",

26.

Remove the flywheei.

a.

wrench

b.

in

c.

Install a

Remove the remaining bolts .

.

d.

the

the

The

valves,

set aside separately

./lumber,

Do

not

Have

someone hold the crankshaft pulley

to

Remove one of the bolts'that

position.

safety

in

the

flywheel

Hold the

crankshaft.

facilitate

'

and

valve

valve

retainer,

retainers,

for correct

reuse

prevent

bar (MI2 x

from

flywheel

Joggling

removal.

,

valve spring.'

spring with a valve lifter

lock.

spring and

in'

groups,

se31s

the

valve

the

flywheel

which the bolt

by

hand and withdraw it

the

valve.

springs and valve

each

tagged for

installation.

with

pliers.

stem

seals.

froin

rotating.

hold

the

1.25)

into the

was

flywheel

back and

,

ORDER

OF

ENGINE

lock.!

with

flywheel

threaded

removed.

from

forth

DISASSEMBLY

and

must '

a

hole

the

to

DISASSEMBLY

27.

Remove

position.

removing

28.

Remove

the oil seal case

ey

the

Pull the

it.

the

linder

blC)ck

A

CAUTION:

rear plate.The rear plate

plate

as

straight

oil seal case. Remove the bolts that hold

in

position.

with a

Do

Remove

screwdriver.

not

caUSB

seal.

29.

Remove

cylinder

NOTE:

is

, 30. Remove the crankshaft pulley.

the

tappet.

block

with a valve

The

tappets

removed

REMOVING

CRANKSHAFT

B. Install two

,holes

, "between

prevent it

b.

Remove

before

THE

PULLEY

safety

in the

rear

the

safety

from

the crankshaft

Remove

will

fall

the

tappets

bars

end

of

bars

rotating.

the

push

into

are

(MI2 x

tile

.crankshaft.

to

hold the crankshaft

pulley.

is

as

possible when

the case from

damage

tappets

rod.

the

'oil

pa~

removed.

1.25)

doweled in

to

the

oil

from

the

'

if

the

camshaft

BAR

into the

threaded

Put a bar

the

to

A

WARNING:

heallY

gloves

to

When

avoid

removing

hand

injury.

the

flywheel,

wear

A

WARNING:

,pulley,

slips

be

oft

the

When

pmpared

crankshaff

rBmoving

to

stop

to

the

the

Job

prevent

crankshaff

in

case

the

injury.

bar

'

,

12

Page 19

ENGINE

DISASSEMBLY

TIMING

ORDER

OF

GEARS

DISASSEMBLY

·12

FUEL

.

'PUMP

'REMOVE

AS

NUMBERS

.

SUGGESTED

DISASSEMBLY.

iNJECTION"

CAMSHAFT

12

THRU

AN

ASSEMBLY

INDICATE

ORDER

a

14

.

THE

,

OF

.

IDLER

GEAlf

.

REMOVE 9 THRU

AS

AN

ASSEMBLY

.14

INJECTION

PUMP

CAM~I:IAFT

11

1.;J~r.'nINu.

CAMSHAFT'

\

/

Q

t:RANKSHIIFT

PULLEY

7TIMING

'....v'

GEAR

CASE'

WSTERBEKE

Englnes-& Generators

i

13

Page 20

31.

Remove

hold

32.

Timing gear backlash measurement.

lash

ment.

the timing gear case.

the

timing

A

WARNING:

timing

gear

case.

plate

along

with

of

each

gear

gear

and

case

The

Do

the

keep

in position

front

plate

not

attempt

timing

a record

if

the

Remove

and

Is

to

gear

case

fOr

backlash

ENGINE

the

bolts

that

remove

bolted

remove

by

Measure

correct measure.

exceeds

the

Inside

the

this

tapping.

the

back·

the

limit.

DISASSEMBLY

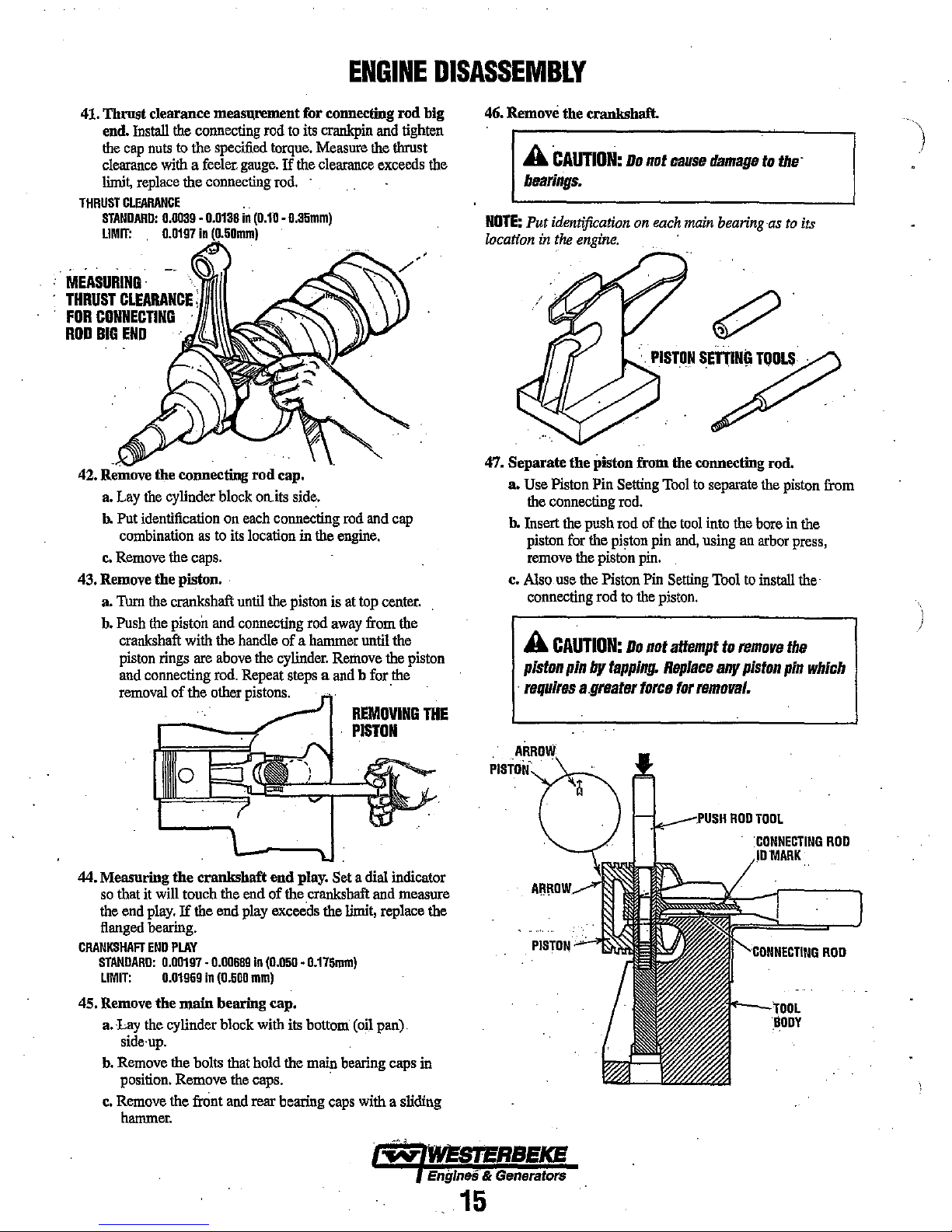

37.

Remove the oil pump.

case.

pump

to

the

cylinder block

38.

Remove

front

hammer

39.

Remove the oil pan.

a.

b.

tIie

plate in

to

separate

Turn

the

engine

Tap

the

bottom comers

hammer

A

pan

the

oil

to

CAUTION:

by

Inserting a screwdriver

011

pan

pan

can

front plate.

position,

remove

and

be

the

upside

the

Do

the

the

result.

Remove

and

Remove

Tap

the

gasket.

down.

of

the

oil

pan.

not

attempt

cylinder