Page 1

'

OPERATORS

MARINE

SINGLE

·

8.0

.DIESEL

•

60Hz_.6.0.

-t £ R

"

((,

}

~·

0 . q

litp"''

AND

THREE

II

~

_,.

"'

..,

MANUAL

GENERATORS

PHASE

·50Hz

BJD

.

·

:10.0

11

..

0 • 60Hz_8.·8

.

1·2

..

5 ·

. PUBLICATION

• 60Hz_7.5.•

·50Hz

60Hz_...

~ ~

..

~

-,>,.,,

. 9.4 ·

NO:

36146 l

Rt:V.

~

50Hz

50Hz

5 - JULY 2018

~.-

BtD·

BTD

.

BTO.{Al

~,~~-·TEBBE/fe

-·

. . . .

.Af.W

-··-

.

;j

..

Wf4STERSEKE

MYLES

STANDISH

WEBSITE:

WWW.WESTERBEKE.COM

CORPOIMTfON • 150

INDUSTRIAL

PAIJK • TAUNTON

JOHN

HANCOCK

MA

ROAD

02780

Page 2

..

CALIFORNIA

PROPOSITION

·65

WARNING

Marine

exhaust

are

knovin

to

cause

and

other

Exhaust

colorless

unconsclousnll$$

exposure

•Dizziness

•

•Headache

•

gasses

gas.

can

Nausea

Weakness

and

contain

Carbon

and

Include:

Sleep/nBS$

diesel

and

gasoUn(t

and

some

of

to

the

State

cancer,

birth

reproductive

A

wARNING

Carbon

Monoxide

dealfl~

Symptoms

•

•

•·

•lfllfbility

engine

Its

constituents

of

California

defects,

harm.

Monoxide,

Is

poisonous

of

Throbbing

Muscular

Vomiting

to

an

odorless

and

Carbon.Monoxlde

In

Temples

'fiNitcbing

Think

and

can

cause

Coherently

IF

YOU

OR

ANJ'ONE

(JET

OUT

INTO

seek

medical

until

it

bas

A

WARNING

should

generator.

WESTERBEKE

MONOXIDE

are

Inexpensive

hardware·

DECAL

be

fixed

to a bulkhead

also

DETECTORS

and

store.

ELSE

THE

FRESH

'

attention.

been

inspected

Is

provided

recommends

near

the

easily

obtainable

EXPERIENC~JINY

AIR

IMM.

'EDIA.

Shut

down

and

repaired.

by

WESTERB£KE

near

your

engine

installing

engine

room.

at

OF

TELY.If

tile unit

CARBON

your

and

and

or

They

local

THESE

SYMPTOMS,

symptoms

dq

not

restart

persist,

Page 3

SAFETY

INSTRUCTIONS

INTRODUCTION

Read

this

safety manual carefully.

caused

by failure

precautions.

take

the

necessary

personne4

PREVENT

A.WARIINS:

11/lite

engine

,_,.I.Biflal

•

Do

not

enclosures

•

Shut

off electrical power before accessing electrical

equipment '

•

Use

insulated mats whenever working

equipment

•

Make

sure

(particularly shoes)

•

Remove

electrical equipment.

PREVENT

A

WARNING:

exbaust

system

to

follow

/UUJW

when

dangerous

precautions

and

your

machinery.

ELECTRIC

i$mllllillg,

SHOCK

•

lllltiDul:b

rmttagels

operate

this

machi:nety

and

CO'VetS

your clothing and

when~

wristwatch and

BURNS-

HOT

Dllllllt,.

t:llllfiDIIIIII A fllllllillg

fut«/limental

iw

,_,at

in place;

hot!

• 'Monitor engine antifreeze

coolant recovery tank and periodicaJly at

on the

water

location

when

the engine

I

AwAIIIIIIIII:

• In

case

of

an engme overheat,

before touching the engine. or checldng the coolant·

jacketed

is

COLD.

___

Most

eonditions

to

protect)ourseff,

AC

elllt:ttit:al

whtilt

t:IJii1iel:tl1t

without electrical

skin

are

an

jewehy

ENG.

bOI

engine

coolant

level at the

exhaUst

.,.,_

allOw

accidents

rules

t11ese

t:tHaJt:tltiDsl.

on

electrical

dry,

electrical equipment.

when

parts

fiii!J/De

the

manifold, hilt only

tb.e

erigine

are

and

exist

and

your

t:III8Cfi1Rls

ttJ

$htJte

not

damp

working on

Ill

gets

very

plastic

filler cap

to

cool

PREVENT

• Prevent

sparks

pump,

vapors.

removing

•

Do

Backfire can cause severe injuty or death.

•

Do

the

engine/generator clean

chances of

• Be aware-diesel fuel

·

PREVENT

A

I

_ ill/lilt

• Follow re·fuclmg safety instructions. Keep the vessel's

batches

after fueling. Check below for fumes/vapor before

running

prior

vessel

•

All

when

ventilated

and out

•

Do

• Shut off the fuel service valve at

the fuel system.

spill. DO

sources

servicing.

the fuel system. ·

•

Do

•

Be

• Be certain fuel·line fittings

• Make

BURNS-

flash

to

occur

or other potential sources of spilled fuel or

Use a suitable container

tb.e

not operate

not

smoke

fuel system.

fire.

BURNS-

WAIIIIIIIG:

or

tlealb!

closed

tb.e

blower.

to starting, following the

builder.

fuel

vapors

handling

area

of

tb.e

not fill the fuel tank(s) while the engine is running.

NOf

of

fire

Ensure

not alter or modify the fuel

sure

an

fuel

free ofleaks. ·

sure

a

fire

properly maintained. Be familiar with its

Extinguishers

for

an

applications encountered in this

FIRE

fires.

Do

not smoke or permit

near

tb.e

carburetor,

fuel line, carburetor,

With

the air

cleaner/sUencer

or

permit

flames

Keep

the compartment

and

free

Wipe

up

an

spilled

Will

burn.

EXPLOSION

--.

when

are

highly

and

away

reach

'Thke

allow any smoking,

near

the

proper

supplies

extinguisher

rated

from

fueling.

Run

~g

from

of

ABC by the

Open

the

engine

rec()1TIJ'Tleililatiin

explosive.

fuels. Store fuel in a well-

spark-prQducing

children. ·

care in·catcbing

fuel

system

ventilation

sys•

have a

are

is

:ftam.es

fuel

line,

filter,

to

catch

all fuel

oi:

fuel

filters.

removed.

or

sparks

to

occur

and

the

of

debris to mininri1.e

fuel

and

engine

fuel

vapiiiS.

t:a11

and ventilate cabin

compartment blower

Use extreme care

equipment

the

engine when servicing

any

fuel that might

open

flames,

or

engine

when

exists

when

posi~ve

adequately tightened

installed

NFPA

shutoff

nea.tby

proper

are

appropriate

environment.

or

fuel

fuel

when

near

cause

of the

or

··

serVicing

valve.

and

use.

the

oiL

other

and

is

·

1-w'IWEBTERBEKE

l Engines & Generators

i

•'

.

Page 4

SAFETY

INSTRUCTIONS

ACCIDENTAL

A

WARNING:

or

death!

11

Disconnect the battery cables before servicing the engine/

generator. Remove

it

last.

11

Make certain all personnel are clear of the engine before

starting.

11

Make certain all

re-installed before starting the engine.

BAmRY

A

WARNING:

or

death!

11

Do not smoke

being serviced. Lead acid batteries emit

highly explosive

arcing or by lit tobacco products.

equipment

dming servicing.

11

Never connect the negative

positive ( +) connection terminal of the starter

Do

not test the battery condition by shorting the tenmnals

together.

Ventilate any compartment containing batteries

accumulation

disturb the battery charger connections while the battery

is being charged.

11

Avoid

burns or

wristwatch, rings,

the battery.

11

Always turn the battery charger off before disconnecting

the battery connections. Remove the negative lead

and reconnect

BATTERY

A

WARNING:

severe

11

When servicing the battery

level wear rubber gloves, a rubber apron,

pron;;ction.

destructive.

it off

into

the

caps.

STARTING

Accidental

the

covers,

starting

negative lead first and reconnect

guards,

can

and

hatches are

cause

injury

EXPLOSION

Battery

or

in the vicinity to prevent electrical arcing

Sparks could ignite battery gases or fuel vapors.

of

contacting

sparks that could cause

it

explosion

allow

an open

gas,

which can be ignited

explosive gases.

the

tenninals with tools, etc.,

and any

last when servicing the battery.

can

cause

injury

flame

near the battery

hydrogcm,

by

Shut off all electrical

(-)

battery

cable to the

solenoi~

To

avoid sparks, do not

an

explosion. Remove

other jewelry before handling

electrical

to

ACID

Sulfuric

injury

or

death!

Batteries contain

If

it

at

once with

eyes inadvertently when removing electrolyte

acid

in

batteries

or

checking the electrolyte

sulfuri~

comes in contact

water.

Acid

may

can

cause

and eye

acid

wbic~

With

your skin, wash

splash on the skin or

to

a

prevent

prevent

first

is

TOXIC

11

11

11

11

. A

11

II

11

AVOID

11

EXHAUST

A

WARNING:

Ensure that the exhaust system is adequate to expel

discharged from the engine. Check

regularly for leaks and

water-injected elbow

Be sure the unit and its surroundings are well ventilated.

Run

blowers when running the generator set

Do not

run

equipped with a functioning marine carbon monoxide

detector that complies with ABYC A-24. Consult your

boat builder or dealer for installation of approved

detectors.

For additional information, refer to ABYC 1H-22

(educational information on Carbon Monoxide).

WARNING:

odorless

nausea

gas.

or

death!

Do

not use copper tubing in diesel exhaust systems.

Diesel fumes

systems.

copper tubing resulting in exhaust/water leakage. .

Do

not install exhaust outlet where

through portholes, vents, or

exhaust discharge outlet is near the waterline, water could

enter the exhaust discharge outlet and close or restrict the

flow

of

exhaust:

Although diesel engine

exhaust fumes from gasoline engines, carbon monoxide

gas

is

present in diesel exhaust fumes. Some

symptoms or signs of carbon monoxide inhalation or

poisoning

Vomiting

Dizziness

Headache

Nausea Weakness and sleepiness

MOVING

A

WARNING:

or

death!

Do not service the engine while

situation arises

make operating adjustments,

touching moving parts and hot exhaust system

components.

GASES

Carbon

the generator set or engine unless

Inhalation

can rapidly

Exhaust sulfur causes rapid deterioration

are:

monoxide

make

is

securely attached. ·

carbon

monoxide

produces

destroy

Avoid

overloading the craft.

exhaust

Inability to

Throbbing

. Muscular twitching

(CD)

the

sure

the

(CD)

flu-like

copper

emanst

air

conditioners.

gases

think

in temples

is a deadly

exhaust system

exhaust manifold/

or

engine.

the

is

an

invisible

symptoms,

tubing

in

can be

If

the

are not as toxic

of

the

coherently

PARTS

Rotating

in which it is absolutely necessary to

parts

use

can

cause

it

is running.

extreme care

injury

If

to

boat

a

gas!

ga8es

is

exhaust

of

<kawn

engine

as

avoid

Engines & Generators

ii

Page 5

• Do

not

wear loose clotbing or

equipment;

rings,

moving

• Make sure all

Keep

places

• Do not check

the

engine

•

Stay

when

be

~ught

HAZARDOUS

A

WARNI.

I

.

IIISS!

• ·

Never

• Do not run an

removed.

A

WARNING:

IIIINifally

OPERATORS

Many

of

in

your Operators

notes to highlight critical information.

carefiill.y,

procedures.

avoid

wearing

necklaces

parts. ' ..

protective

at

clear

the engine

or bracelets that

attaching

shields

all

times.

fluid

levels

is operating.

of

the

drive

shaft and the transmission

is

running;

in these rotating parts.

NOISE

NG:

lligb

lltlise

operate

111

phpit:aiJy

an

engine without

engine

with the air intake (silencer)

liD""' wmi'llll

i11capat;/tatBII

MANUAL

the

preceding

maintain

safety tips

Manuai

your

equipment,

jewe]ry

loose

hardware is properly

and

guards

or the

drive

hair and clothing can easily

levels t:all t:allSB

mat:hillett

and

along with

SAFETY

when servicing

jackets~

and

shirts,

could

be caught in

in

their respective

belt's tension

.

itS

nmffler

installed.

..

by

fatigue/

warnings

other

cautions

Read

your

follow all safety

sleeves,

tightened.

hearbig

are~

manual

INSTRUCTIONS

while

coupling

,

atB

and

ABYC,

INSTALUNG

Read

for

tions

ABYC

"Safety Standards

Order

A_BYC

'613

Annapolis.

(410)

www.abycinc.org.

NFPA

''Fire Protection Standard for Motor Craft"

Order

NFPA

lB~Park:

P.O.

·

Quincy,

USCG (United States

"CFR

Code

Order

U.S.

WashingtoJt.

NFPA

the

following

safety

Codes

when

installing your

(American Boat

from;

ThirdDtreet, Suite

MD 21403

990-4460

(National FJie

From:

Box

9101

MA

33

AND

of

Federal

From:

Government Printing Office

AND

.USCG

MARINE

and

()2269.:.9101

CFR46"

Regtilations

D.C. 20404

ENGINES

ABYC,

standards.

and

for Small Craft"

10

Protection

Coast

PUBUCADO.

AID

GENERATORS

NFPA

and

USCG

Follow

UNIVERSAL

Yacht

Guard)

their

engine

Council)

Association)

FOR

publications

recommenda-

ENGINE

Preparations

ough examination

(ABYC)

sources including the USCG

Sections

All

Regulations (FCR).

AND

GENERATOR

to

install

standards.

of

the

ABYC

H-32Ventilati.on

H-33

Diesel

P-1

Instal1atiion

and

Auxilliary

P-4

Marine

E-ll

AC & DC

TA Batteries

installations

must comply with the Federal Code of

an

engine.should begin with a

of

the American Boat and

These

standards

standards of particular interest

for boats

Fuel

Systems

of

Exhaust

Engines

Inboard

Elec1rlcal

and

Battery

Engines

INSTALLAnONS

Yacht

Council's

are

a combination of

and

the NFPA

using

diesel fuel

Systems

and

Systems on Boats

Chargers

for

Propulsion

Transmissions

thor-

are:

j...,.,.IWESTERBEKE

f Engines & Generators

iii

Page 6

When

iilstalling

attention·

WEST.BRBEKE

be

paid

to

the

following

INSTALLATION

engines

information:

and

generators

· ·

it

is

important

that

strict

CODES

· S~

when

AND·-ULATIONS

federal

reguiations,

installing

engines

ABYC

and

SIPHON-BREAK

For

installations

or

-Will

be

break

in

minimum

the

ex1uzust

raw

water damage

If

you

have

to

the

vessel's

rtphon..bretilc.

NO'I'E:

A.

operation.

engine

dimiilge~'

EXHAUST-SYSTEM

The

exhaust'

Exhaust~

and-~

and

toms.

system

MU$'1'·

under

any

where

the~

beloW

die

·v-essers

the

raw

water

supply

of

20''

abo'Ve

the

manifr!ld injection port

to

tk;e

~anti

~y

doubt

about

waterline

· · · · ·

sq,hoti-b~k

Failure_

CiJMiift

under

reqili.rns

tp_properly_

the

...

system's

without

In

tbis

sea

hase

is

recommended..

the

need

~~

a

single

be

designed·to

conditions·

aixl

.

guid8nnes,

generators

manifold/water

waterlirie,

hose

to

the

vessel's

water~

is

pQssibk

the

position

the

~·s

Periofl!.c

mabitain

sijihmi-break

MUS'J;

be

certified

The

use

of

additional

lengtb

prevent

at

-any

the

angle

and

sa.fety

codes

in a

marine

environment.'

inject.Cd

proViSiOnS

exhaust

lit

or

of the

flwJection

a

siphon-break

manufacturer

of

fitting

of

.entry

iniist

~

elbow.

This

Failare to

below

jl.ooding.

water

various

use a Biphon-bretilc

the 'to¢

of

the

..

injected

operating

and

cleaning

can

for

for

marine

use.

this

tYPe

of

hose

and.

clamps to

corrugated~

of

waterlnto the

of

vessels

heel.

ml¥Jt

be

cornpU~

exhaust

maae

waterline

'io

hose

elb9w

is

'llisfiill a

must

be

will

resrilt in

!Joat.

exhaust

conditi~

result

proper

Conugated

allows for

accomplish

hose

elbow

inBtall

to

ensure

p10per

in

catastrophic

riuiintenance.

Marine

eXtreme

these beMs .

can

be

used

exhaust

system

with

close

to

'SipliOii-

looped

when

~ve

a

bends

The

a

AVAILAB~FROM

:aWES'IEM.EKE

SIPHON-BJ:iEAK

LOOP'

WITH

STAiNLESS

A

detailed

engines

to

download

Marlne.lnstallatiiJD

and

Manual

generators,

frail

oar

wibsite

Is

supplied

at

v.ritb

\VViW.westerbeke.com.

IW'IWESTERBEKE

l Engines & Generators

iv

covering

each

gBSQiine

unit A pdf

and

diesel,

is

available

·

Page 7

TABLE

Parts

Identification

Introduction

Diesel

Generator

Preparations

Safety

.........................................................

Fuel,

Engine

Control

for

Shutdown

Starting/Stopping

Generator

Break-In

Maintenance

Cooling

Air

Fuel

Engine

DC

Starter

Engine

Valve

System

Raw Water

Intake Strainer .............................................

Heat Exchanger .......................................... .14

Thermostat ...................................................

Zinc Anode .................................................. 16

Intake

Fuel Filters ...................................................

Fuel Lift Pump .............................................

Silencer

System

.......................................................

Lubricating

Oil Change ................................................... 19

Oil Pressure ................................................. 19

Electrical

Alternator .....................................................

Motor

Testing .................. , ...................................... 22

Disassembly ................................................. 23

Adjustments

Glow Plugs .................................................. 24

Injector ......................................................... 24

Throttle Control/Generator Frequency ........ 25

Drive Belt Adjustment.. ............................... 25

Clearance

11.0 BTD and 12.5 BTD(A) ........................ 26

8.0 and 10.0

............................................

Oil

and

.Panels

Initial

Switches

Procedure

Procedure

Schedule

Engine

....................................

Start-Up

and

...............................

......................................

Coolant.

.........................

Sensors

.............

.........................

..................................................

Pumps .......................................

............................................

Oil

.......................................

System

.........................................

.....................................................

...........................................

and

Timing

BTD

........................................ 27

.............................

OF

CONTENTS

.2

3

......

5 10.0 Kw

6 11.0 Kw

7 12.5 Kw BTD(A) ......................................... 34

8

9

.1

o

11

13

14

14

15

16

17

17

18

19

20

20

22

24

26

Specifications

8.0 Kw

BT

Generator 6 and

Voltage Regulator ........................................ 38

BT

Troubleshooting Chart ........................... 38

Internal

Resistance Values ........................................ 39

Generator

No

Load .......................................................

Full Load .....................................................

Generator Frequency ..................................

6 Stud

Internal

Resistance Values ....................................... .42

Internal

3

Phase,

AC

Voltage

Shore

w ..

Power

o·

1nng

#34651 - 8

#36412#36412#36412

#36412

#41479-

#41479

#43853#43853

#43944#43944

Remote

Power

Lay-Up

Take

and

Suggested

.......................................................

BTD

................................................ 28

BTD

.............................................. 30

BTD

.............................................. 32

12

Stud

..............................

Wiring

Wiring

Wiring

sagrams

Oil

Schematic

Voltage

AC

Adjustment

Connections ..............................

Schematic

(12

Stud)

...............

........................

(&Stud)

.................

Diagram

12

Wire,

Connections

Reconnectable

Transfer

Switch

...................

BE 3 Phase

................

...........................

...................................................

BT

.............................................

No Relays ..................................... 47

Schematic No Relays ................... 48

-Two

- Schematic Two Relays ................. 50

- Schematic .....................................

-Schematic

-

Fill

Recommissioning

Spare

Relays .................................. .49

BTD

and BTD(A) .......................

BTD and BTDA ........................... 53

..................................... 54

BTDA Diagram ............................ 55

BTDA

Schematic ......................... 56

...................................................

Off

System

.....................................

...........................

Parts

......................................

.

37

.39

.40

40

40

.41

.41

.42

.43

44

.45

.

46

.51

52

57

58

59

61

Engines & Generators

1

Page 8

·

PARTS

IDE.NTIFIC.ATIO

N.

/ALL

MODELS

The Control Panel faces aft on some of these models

_with the .emergency Stop

Swi~ch

on the back .

CONTRO

L

PANEL

.

OIL Fi

ll

AC

CONNECTION

OUTLET

DRIVE

BEl

COVER

REA

R

THERMOSTA

Ti

ASSEMBLY

RAW

WATER

PUMP

FRONT

RIGHT

SIDE

MANIFOLD

PRESSURE

CAP

COOLANT

FILL

,_

,-~ _

OIL

SUMP

2

AIR

INTAKE

SILENCER

-

DC

ALTERNAT

OR

FUEL-RUN

SOLENOID

OIL

PRESSURE

SWITCH

OIL

DRAIN

HOSE

FRONT

GENERATOR

EMERGENCY

STOP

SWITCH

ART

SOLENOID

Page 9

This

WESTERBEKE

WESTERBEKE's

technology.

dependable

Thank

In

order

is

important

manual

manual

throughout.

your

This

is

an

Manual

ordered

Dealer

We

performance

you

for

to

get

that

is

designed

carefully

Should

nearest

WESTERBEK;E

is

your

operators

Installation

is

available

in

book

WARRANTY

Your

WESTERBEKE

product

documentation

Registration

Corporation

register

Customer

registering.

your

date

Customer

Card

or

your

products

Identification

If

'you

product

available.

model

Identification

Diesel

Generator

long

years

of

take

great

pride

of our

engines

selecting

the

WESTERBEKE.

full

use

and

benefit from your

you

operate

and

to

help

you

do

and

observe

your

Manual

in

fonn

from a WESTERBEKEIUNIVERSAL

generator

manual.

and

Parts

pdf form

all

dealer for

Along

on

is

experience

in

the

superior durability

and

maintain

this.

Please~

the

safety

require

assistance.

wi~

Information. A Serv1ce

our

website

PROCEDURES

go

Warranty

you

can

to

our

warranty

do

not,

number,

package.

card

Statement

There is a

fill

out

and

mail

website:~.westerbeke.com

on

line.

You

in

the

mail

within

please

contact

the

serial

number

Card

I.....,.IWESTERSEKE

J Engines & Generators

Customer

MR.

MAIN

HOMETOWN,

Model

Expires

NOTES,

As

maintenance

engine,

CAUTIONS,

NOTE:

A

observed,

your

Identification

GENERATOR

STREET

______

USA

_____

CAUTIONS

this

manual

An

takes

schedules,

critical.infonnation

and

operating

CAUTION:

can

result

engine.

OWNER

_

_

AND

WARNIN~S

you

through

and

troubleshooting

will

WARNINGS.

procedure

Procedures,

In

the

essential

damage

Serial#

the

operating

be

highlighted

An

explanation

which

or

____

to

if

not strictly

destruction

INTRODUCTION

a product of

and

advanced

generators.

generator

it

correctly.

re8.d

this

precautions

servicing,

this

is

included

Warranty

to

should

factory

and

of

note.

contact

manual,

or

can

Westerbeke

rece1ve

60

days

and

in

service

procedures,

your

marine

by

NOTES,

follows:

of

This

.there

be

in

~d

of

have

_

and

the

·

it

.

a

PRODUCT

Pioduct

brochures

WESTERBEKE

WESTERBEKE

CONTENT

WARRANTIES

THEREJ'O,

COMPLETENESS

BE

UABLE

iNCURRED

.

OF

THE

WESTERBEKE

time

software

WESTERBEKE

provided

WESTERl3EKE

be

relied

the

respective

but

is

WESTER.BEKE

to

determine

product

SOFTWARE

software,

FURNISHING

span

between

and

with

upon·

imperative

software being consulted

(tech

and

catalogs),

are not

CANNOT

OF

SUCH

OR

REPRESENTATIONS

INCLUDING

THEREOF

FOR

ANY

IN

CONNECTION

customers

printings of

the

l.inavoidable

manuals.

WESTERBEKE

or other suppliers,

exclusfvely

product.

the

It

that appropriate

or

the

accuracy

data,

provided

within

SOFIWARE,

TYPE

OR

not qnly

supplier

paltS,

lists,

manuals,

from

sources

WESTERBEKE's

BE

RESPONSIBLE

MAKES

WITH

ACCURACY;

AND

OF

USE

should

WESTERBEKE

existence

In

summation,

products, whether

as

the

and currentness of

TIMEliNESS

WIU

IN

DAMAGE

WITH

OR

ARISING

OF

SUCH

also

keep

of

earlier

product

must

not

definitive

makes

representatives

in

questi,on

by

good

the

customer.

authority

other

than

control.

FOR

THE

NO

RESPECI'

NO

EVENT

OR

INJURY

OUT

SOFIWARE.

in

mind

the

product

·

software

from

and

cannot

on

sense

of .

be

consulted

the

. ·

OR

.

PROTECTING.Y~UR.INVESTMENT

Care

at

'f:4e

factory

during assembly and

have

resiuted

maiJy

manufiicturer

install~·

operaftd

buyer/owner.:.Operator.

NOTE:

•

Proper

• An efficient

ananf:t.siphon

engine.

w

Changing

mainte~UZ'nce

•

Proper

n.eitts

manuaL

a

Use

•·

Wmterize

Recommis~rtin~'

in a WESTERBEKE

thousands of hours of dependable

cannot

control how or where the

in the vessel

'and

serviced

SiX

imp~'(tant

engine

or

in

steps

and

generator

·

the mannerin

the

well-designt!fd

breafc

to prevent waterfrom

· .

the

engine oil and

sclledule.

maintettillibe

i:Zecording

to

of

the

· · ·

cledli;:filter{!d

your engine

#2 dieaelfnet.

ticcoramg

section

field.

to

ensure

ex1uiust

oil

all

engine and

m.ai:tttenance

in

~orough

generat9r

This

long

instDllaiion

capable

~ervice;

which

is

up

to

generator

and.

systt!fm

fi1ters1

(lCcording

generator

schedule

to

the

~'LD.y·tzp

this

manual.

testing

However

generator

the

unit

the

life:

alignment.

that

includes

entering

in

this

atul

of

the

is

is

the

..

io

tlie

colf!.PO•

A

WARNING:

followed,

can

result

Procedures,

in

personal

which

injury

if

not

or

loss

properly

of

life.

Engines & Generators

3

Page 10

INTRODUCTION

SERIAL

The

nameplate

a

eJiliaust

The

the

the

~tion

NUMBER

engine's

engine's serial number

engine

side

below

model

mounted

manifold.

block

oil

flU

opening. Take time

on

the

LOCATION

and

serial number are lqcated. on

on

the side ofthe water jacketed

is

also found stamped

on

a flat surface just above the

to

enter this infonn-

illustrated nameplate.

in

NOTE:

A

carbon

monoxide

by

WESTSRBEKE.

engine

room.

UNDERSTANDING

The

diesel

engine closely resembles

since

the

mechanism

are

arranged

the

same

diesel

cbnnecting

Therefore,

same

most important factors

maintenance

Replacement

time

periods

contanlination (that is,

system

of

the

designed

The diesel engine does differ fromthe gasoline

however,

carburetor

their

place

which

above a closed

general

type

engine

has

the

rods

and lubricating

to

a great extent, a diesel engine

preventive

is

same

performs

maintenance

of

the

of fuel and lubricating

specifi~d

also

essential.

brand

of

specifically

in

its

methodof.han.~g

and

ignition systems

is

a single component-

the

warning

Affix

this

decal

THE

DIESEL

is

essentially the same

crankcase; the crankshaft

as

that of a gasoline

same

types

of valves,

system.

as

a gasoline

are

proper ventilation

fuel,

·lubricating

is a

must,

and frequent

water,

sediment, etc.) in

Another important

high

detergent

for

diesel

engines.

ttre

function of

both.

decal

has

in a visible

ENGINE

the

gasoline

..

The

engine;

camshaft,

requires

engine.

and

arid

cooling

filter

elements at

factor

diesel

lubrication

and

firing

done

away

the

fuel

injection

been

provided

position

engine,

cylinders

and

the

The

proper

systems.

checking

the

fuel

is

the

engine,

of

fuel.

with

and

pump

in

the

is

of

the

pistons,

the

for

use

oil

The

in

-

An

identification

displays

CARBON

WES1ERBEKE

detector

even

The

from

elbow/exhaust

entering

If

air

the

engine

MONOXIDE

in

the

vessels

in small amounts,

presence

the

carbon

and

engine·

your

monoxide

correct

of

hose,

boat.

the

plate

on

the

model

and

DETECTOR

recommends

living

is

carbon

monoxide

or

generator

or

the

is

present,

problem

top

of the engine

serial

number.

mounting

quarters.

deadly.

or

fumes

immediately!

Carbon

indicates

from

the

from

.

ventilate the

a carbon

an

exhaust

a nearby

area

air

intake

also

monoxide

mono:xide,

exhaust leak

vessel

are

with

clean

ORDERING

Whenever

provide

and

generator serial number

black

provide

your

description

separately furnished Parts

WESTERBEKE

parts

original

SPARES

Certain spares

WESTERBEKE

dealer

See

the

Generator

INSTALLATION

The

Westerbeke

supplied

PARTS

replacement/service parts

the

generator

name

plate located

us

with

generator set.

and

are

frequently

equipment.

AND

will

assist you in preparing

SPARE

Accessories,

. . .

model

this

information so

In

addition,

part number for each part

packaged parts because will

not made

ACCESSORIES

will

be

needed

generator.

PARTS

page in this

MANUAL

Installation

with

this

unit.

see the

number,

as

they

appear on

on

the generator

we

include a complete

List).

Also insist

to

the

same

to

support

Your

local WES'IERBEKE

an

manual.

ACCESSORIES

Manual

are

needed,

engine serial

rnay

and

inventory of spare

publication

always

number,

the

silver

end.

You

must

properly

part

needed

(see

upon

fit

or

generic

specifications

maintain

For

Engine

brochure.

#043268

GENERATOR

10

and

identify

the

as

your

parts.

and

is

DECAL

Engines&. Generators

4

Page 11

DIESEL

FUEL,

ENGINE

OIL

AND

ENGINE

COOLANT

DIESEL

Use a diesel

SAE J 313

dies~!

Care

Use

in

dirt

secondary

is

fuel

improper

the

following

Purchase a well-known

combat

mended

'Klee~1

diesel

Install

fiHeriwater

The

such

ENGINE

Use a good brand of engine oil, with

and

manual. Change the engine oil and oil

hours of engine break-in operation and

of

Westerbeke Corporation does not

the use of synthetic

break-in

change intervals must

SCHEDULE

if

NOTE:

statements regarding synthetic

FUEL

fuel

that

meets

the

requirements

and

fuel

Of

The

only

clean

your

engines

particles

important

can

be

storage

tank

for

practice

BACTERIAL

such

+

Cetane

fuel

and

Raycor

filters. A 10

has a Cetane

according

Fuel

diesel

fuel

which

filters

can

to

buy

rendered

facilities.

your

engine's

as

Bio-Bor

Boost

when

an

regularly

separator

500

MA

micron

injection

might

clean

is

Ultra

service a good,

rating of

to

ASTM

0975.

Supply

fuel!

The

clearance

pump

pass

through

damage

unsatisfactory

advisable:

between

or

fuel,

To

daily

brand

growth

and

to

help

Low

230

filter

these

and

assure

use

of

fuel.

on

an

additive

restore

Sulfur

the

RMAM

element

the

OIL

SAE

as

stated in the

operation thereafter.

must be performed using conventional

section

synthetic oil is

The

infonnation above supersedes all previous

SPECIFICATIONS

oil.

If

synthetic oil

be

as

of

this manual and not

used.

listed

oil.

#45

is

finely

keep

by

that

is

clean

The

fuel

diesel

visual-type

fuel

are

approve

in

of

No.

2-D

or

higher

grade

of

the

components

very

critical;

invisible

the

primary

machined

it

clean.

careless

the

use

tank

such

lubricity

tank

and

.good

is

recommended.

an

API

filter

then

is

used,

the

MAINTENANCE

and

parts.

The

best

handling

fuel

going

and

pure,

the

of

additives

is

recqm-

as

Diesel

back

intO

is

being

used.

fuel

the

engine.

examples

classification

section of this

after the initial 50

every

100

or

disapprove of

engine

oil.

Oil

to

be extended

of

It

or

into

to

the

of

hours

ENGINE

WESTERBEKE

and

chemicals

The

run

engine

circuit

antifreeze

(SCAs)

to

The

being

NOTE:

antifreeze

PURCHASING

Select a brand

Antifreeze

additive

cylinder

brands.

engines.

mixture

needed.

MAINTENANCE

COOLANT

50%

distilled

that

antifreeze

at

proper

to

the

from

that

that

long

term

distilled

poured

Look

that

speci11~d

to

protect

walls.

that

offer

Select

will

Change

recommends a mixture

water.

Distilled

can

corrode

performs

temperatures

coolant,

rust

contains

keep

protection.

water

into

for

the

is

double

and

and

corrosion.

Supplemental

the

antifreeze

and

antifreeze

the

cooling

new

environmentally-friendly

1ww

available.

ANTIFREEZE

of

antifreeze

for

diesel

against

Prestone

the

always

·and

antifreeze

pre-mixed

be

added

the

antifreeze

SCHEDULE

MAINTENANCE

Change

number

protect

COOLANT

TI1e

contraction

without

provided

water

operating

the

engine

of

operating

and

lubricate

RECOVERY

coolant

recovery

of

the

introducing

with

fresh

coolant

conversion

the

engine.

coolant

hours

the

allows

engines

air

into

water

engine

kit

water

internal

duty.

by

transferring

lubricates

Look

chemically

should

circuit.

specified

engines

cavitation

Zerex

specifically

variety

to

the

mixture

in

every

five

as

the

chemical

have a limited

TANK

for

the

coolant

the

system.

cooled

models

and

must

of

50%

is

free

engine

surfaces.

It

allows

heat

and

protects

for a good

Cooling

balanced,

be

premixed

for

diesel

contains a special

erosion

'of

are

two

nationally

for

use

in

so that

the

cooling

system

according

this

manual.

years

regardless

additives

expansion

during

engine

This·recovery

and

with

be

installed

antifreeze

from

the

the

engine

away

from

the

cooling

quality

Additives

crucial

before

long

lasting

engines.

the

engine's

known

(fiesel

cO!TeC:t

when

to

the

of

that

life.

and

operation

tank

the

fresh

before

to

the

'

the

is

NOTE:

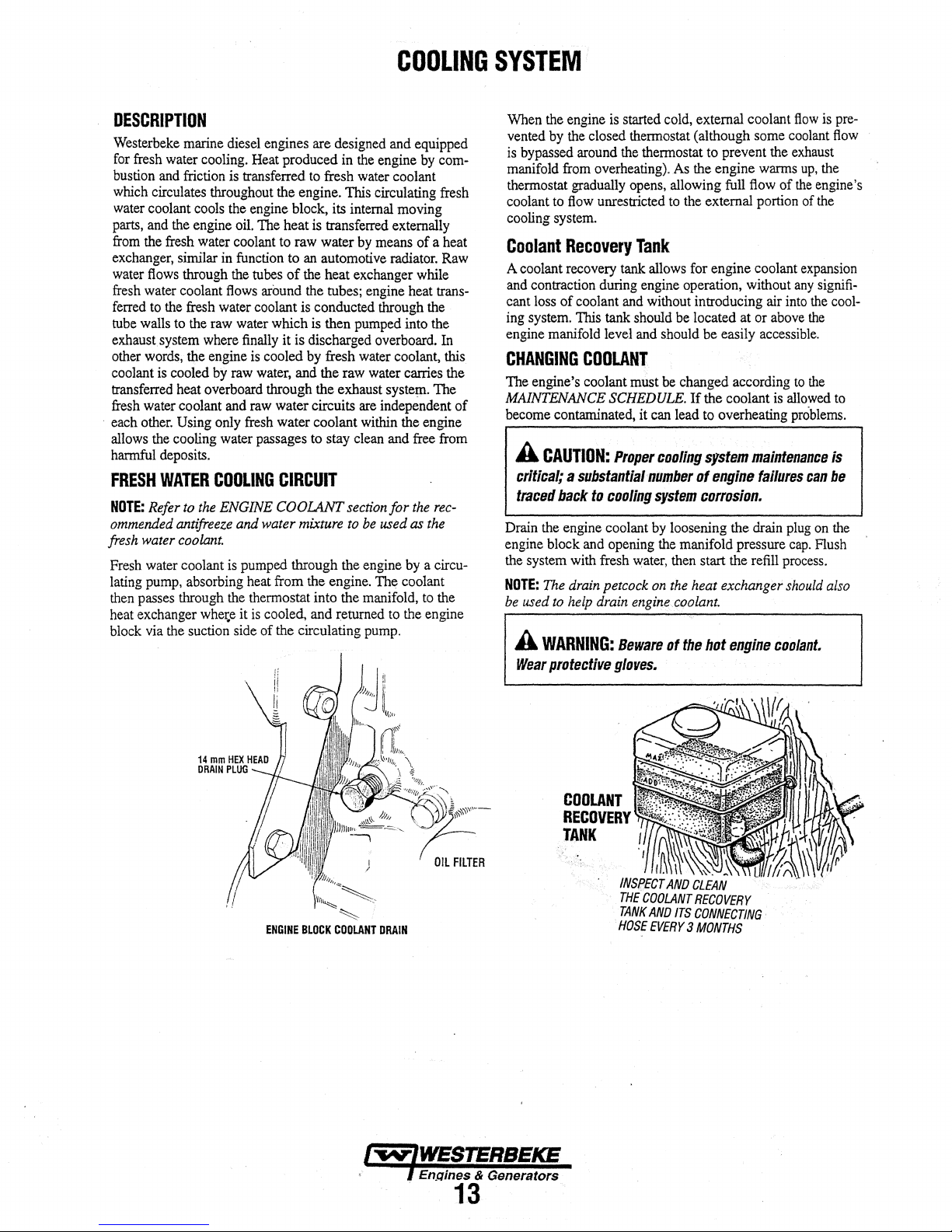

T7lis

located

at

can

be

located

particular

Engines & Generators

5

tank,

with

or

above

the

below

installation

its

sh01t

level

the

level

makes

of

this

run

the

of

of

plastic

engine's

the

engine's

necessary.

hose,

is

manifold,

manifold

best

but

if

it

the

Page 12

GENERATOR

CONTROL

PANELS

DESCRIPTION

Thls

manually

diesel

generators

engine

control

All

three

following

PREHEAT:

preheating

bypassing

turns

on

the

excitation.

When

the

·panel

lights,

activate.

START:

The

energizes

While

the

START

switch

begins

to

PREHEAt

pressure

reaches 5 -

STOPPING:

switch a

switches to the

nates this

engine.

To

stop the engine, simply depress the STOPswitch. The

DC

path

the

relay

should be held depressed until

completely.

NOTE:

When

gauge

and

last

temperature

will

retwn

OF

SWITCHES

controlled

is

panel

switches are momentary contact type

functions:

TI1e

PREHEAT

the

engine

the

engine

fuel

solenoid

PREHEAT

gauges

START

the

starter solenoid and activates the starter

PREHEAT

engages·

fire,

the

switch

The STOP toggle switch is a nonnally closed

DC

path through the three automatic shutdown

K2

DC

path to the

to

the

K2

and

the engine shuts

the

engine

the

oil

and oil press

to

zero

,series

of WES1ERBEKE marine

equipped with toggle switches

and,

optionally, at remote

toggle switch serves two purposes:

for

easy starting and defeating of

oil

pressure switch. The defeat function

..

instrument power

switch

is

depressed,

and

meters

and

fuel solenoid

toggle switch closes the

switch

is

still depressed, depressing

the start solenoid. When.the engine

START

pressure

switch should be released. The .

should

not

be released until

10

psi.

run relay. Opening this switch termi-

K2

run relay shutting

run relay is terminated, de-energizing

down.

The STOP switch

the

generator shuts

is

shut

down,

the water temperature

gauge will continue

we

readings displayed.

once

electrical power

and

the

Kl

is

restored.

panels.

and

alternator

voltmeter,

will

relay that

the

down

to

on

the

serve

..

oil

the

down

register

They

the

the

the

EMERGENCY

stop switch

is

normally closed.

will

open the

panel and shut the engine down.

switch is not toggled

petforming maintenance.

DESCRIPTION

Coolant

Engine coolant (water) temperature should normally

175°

to

Engine

Oil pressure (psi)

load but should

DC

Voltmeter

Indicates the amount

13.5V

STOP:

on

the

DC

circuit

OF

Temperature

195° F (80°

Oil

Pressure

may

range between between 30

to

14.4V.

The EMERGENCY.

side of

the

control

box.

When

depressed, it

to

the

control

As

~he

it

can

be

used

when

GAUGES

to

90°

C).

fluctuate depending

the

battery is being charged should

.

on

to

the

60

psi.

Hourmeter

Registers elapsed time and is used

petform scheduled maintenance.

REMOTE

For remote operation of

switches are

connected

serve the same functions

switch

serves

WIRING

PANEL

used.

The PREHEAT

in

parallel

is

in

series with

the

same function. There

DIAGRAM

with

in

the

the gauge panel's switches

as

the

this

as

a guide for

generator system,

and

START

in

the

gauge panel.

gauge panel's STOP switch

is

a REMOTE

manual.

when

the

same

switches

The

START/STOP

GENERATOR

:J%

~l~

RELEASE

STARTER

::

PREHEAT

•

MUST

PRESS.

1ST.

-

tO

e

·wESTERBEKE.

NOTE:

For

additional information

STARTING/STOPPING PROCEDURE, DC

DIAGRAMS and TROUBLESHOOTING

ty

.

STOP

START

~').

(

,f~~

on

Control

PRESS

2ND

,

.....

,:

Panels.

WIRING

GAUGES.

indicate

generator

show

to

three

are

and

STOP

and

Refer

to:

£Engines

6

& Generators

Page 13

PREPARATIONS

FOR

INITIAL

START-UP

PRESTART

This section of

ration,initial starting, break-in, starting

stopping procedures.

the

conditions indicated

will

set

Before starting your generator set

prolonged layoff, check

0 Check the engine

at

0 Check the

tor bowls·for contaminants.

INSPECTION

the

manual

provides the operator

Follow

and

your

give reliable performance

the

following

oil

level.

the high mark

on

the dipstick.

fuel

supply and examine

(warm

the procedures

WESTERBEKE

and

long

for

the

first

items:

Add oil

to

the

0 Check the DC electrical system. Inspect

and

battery cable connections. Make certain the(+)

tery cable is connected

negative (-) cable is connected

the

coolant

the

manifold.

is

(this location

0 Check

and

at

0 Visually examine

parts, disconnected

threaded connections.

0 Check load

the

wiring diagrams.

leads

0 Examine air inlet

0 Be sure

to

0

Be

the

system requires,

connected

3-phase systems

ply

loads.

no

other generator or utility power

load lines.

sure that

neutral is properly grounded (or

the

in

power systems

to

the

wrong

line-to"neutral voltage

0 Make sure the mounting installation

0 Make sure that

the

to.

the starter

tagged).

level

in

both

the

unit.

Look

wires,

unattached

for

correct connection

and

outlet

and

that the generator

load neutral.

an

incomplete or

generator

solenoid

to

the

the

plastic

for

loose or

for

air

flow

with a neutral

ungrounded)

In

single

open

on

is

is

properly

hoses,

with

or

cold)

as

presented

service

time

maintain

fuel

filter/separa-

wire

connections

and-the

engine

ground

recovery

missing

and

as

specified

obstructions.

is

connected

line

neutral

phase

and

neutral

unbalanced

secure.

grounded.

prepa-

and

for

generator

life.

or

after a

the

level

bat-

stud

tank

check

in

that

as

the

is

properly

some

can

sup-

A

CAUTION:

recommended

be

switched

and,

in

cold

will

prevent

of

the

AC

When

that

all

OFF

until

climates,

damage

machinery

starting

AC

loads,

the

engine

starts

caused

and

will

the

generator,

especially

has

come

to

warm

up.

by

unanticipated

prevent a cold

stalling.

GENERATOR

The speed

however, it is advisable to verify.

60 hertz The engine no-load speed is set

50

hertz The engine no-load speed is set at

The speed of the generator engine

however

adjusted

·VOLTAGE

actual service load or test load

the load

adjusted to suitable

your authorized WESTERBEKE service

VOLTAGE

of

the generator engine is adjusted at the factory,

At rated amperage hertz output may decrease

58.5-

59.0 Hz.

At rated amperage hertz output may decrease

48.5 - 49.0 Hz.

is

adjusted

it

is

advisable

to

optimum

ADJUSTMENT

to

be

used

to

values

in

service.

values

verify.

The voltages

no-load and full-load (refer

in

this manual). If possible,

of

the same power factor

If

the

voltage cannot

and

a fault seems evident,

dealer.

it

large

up

to

This

precaution

operation

engine

at

61.5 - 62

51.5

at

the

are

is

motors,

speed

from

Hz.

to

Hz.

to

factory,

easily

to

apply

as

be

contact

RECAP

DIPSTICK~

GLOW

PLU

CONNECTION

SIDE

Engines & Generators

7

OIL

FILL

CAP

OIL

FILL

CAP

Page 14

SAFETY

SHUTDOWN

SWITCHES

AND

SENSORS

SAFETY

The engine is protected

switches. Should shutdown

without

SHUTDOWN

finding and

correcting

SWITCHES

by

three automatic shutdown

occur,

do

not attempt

the

cause.

Refer

to

to

restart

the

heading "Engine Stops" in the TROUBLESHOOTING

section

The following

switches:

High

An exhaust temperature switchis located on

injected exhaust

The switch's contact open at 260°

The switch's contacts:elose when the temperature lowersto

of

this

manual.

is

a description

Exhaust

If

the

contacts open

DCruncircuitisinterrupted and

approximately

Temperature

elbow.

due

225°F (l07°C).

EXHAU$1

TEMPERAfURE

(HIGH)

of

Its

contacts are normally closed.

to

a high coolant temperature, the

SWITCH

these automatic shutdown

Switch

the

water

the

unit shuts

"270°F(l27°

down.

-127°C).

Low

Oil

Pressure

A

low

oil

pressure switch

gallery adjacent

open when

monitors the engine's oil pressure. Oil pressure closes

contacts. Should the engine's

contacts open interrupting the

down.

the

Switch

is

located off the engine's

to

the oil

filter.

Its contacts

engine is in a static state, this switch's sensor

oil

pressure

DC

run circuit shutting the unit

OIL

PRESSURE

SENDOR

are

fall

to

normally

5-l 0 psi, the

oil

the

Engine

A high engine coolant temperature switch located

thermostat housing.

contacts open

circuit

contact

contacts close when the coolant

195°F (107°C).

Coolant

due

is

interrupted and

open

at

approximately 210°F (99°C). The switch's

Temperature

Its

contacts

to

a high coolant temperature,

the

SWitch

are

norma1ly

unit shuts down.

tem.perature.lowers

closed.

The

THERMOSTAT

ASSEMBLY

on

the

If

the

DC

switch's

to

the

run

Engine

The engine's DC circuitis protected

230 amp DC breaker. Should amperage in excess of 20 amps

by

engine's

Investigate

This

The·

shown

DC

Circuit

draw

through the breaker caused by an issue

DC

circuit, it will open and shut

the

is·

done by pushing the red

wiring

connections

in

the

WIRING

Breaker

issue and then manually reset

b1.1tton

ENGINE

DC

BREAKER

CIRCUIT

to

·these

components

DIAGRAMS

in

b}'~'l

engine mounted

the

in.

.

this

manual.

with

the

unit down.

the

breaker.

are

/"W'JWESTERBEICE

. · E'ngfnes & Generators

' 8

Page 15

STARTING/STOPPING

PROCEDURE

THE

STARTING

Westerbeke

glow

plugs

illustration

der.

The

glow

that

its

tip

glow

plug

glows

red at the

is

a rapid start

This

system

circuitry

depressed

while

button

NOTE:

HEAT

activates

HEAT

START:

the

Upon

release

5 -

low

will

is

keeping

is

depressed

The

switch

the

intermittently

GLOW

While

START

engine

the

10

psi.

oil

pressure

remain

SYSTEM

diesel

generators use electric starters assisted

for

both

below

shows

plug

is

in

the

injector nozzle's

is

energized

tip

with

is

common

designed

for

the

time

the

PREHEAT

START

switch

is

depressed.

glow

plugs

still depressing

switch.

starting,

PREHEAT

Then

as

protective

energized

normal

and cold weather starting. The

a cross-sectional

is

located

in

the

by

the

PREHEAT

and

assists

in

igniting

less

wear

on

the

to

WESTERBEKE diesels.

so

that

the

PREHEAT

specified

to

crank

in

button engaged,

the

engine.

will not

energize

Depressing

in

the

cylinder

to

avoid

overheating

the

PREHEAT

This

will

engage

release the

switch until the oil pressure reaches

long

as

and

START

the

high water temperature

circuits

continue

view

of

combustion chamber

spray

path.

When

button,

the

the

fuel.

starter.

button

the

preheat

the

do

not

to

run.

NOTE:

A

voltage

when

is

depressed.

unless

the

PREHEAT

head

so

the

glow

switch, depress

starter

switch.

activate,

When

drop

the

preheat

chart.

the

the

use

solenoid.

Do

starting:

will

by

one

cylin-

so

the

plug

The

result

The

start

must

be

Then,

START

PRE-

switch

the

PRE-

plugs.

not

and

the

engine

occur

~witch

Failure

Should

depressed

wait

longer.

'A

engine

filling

pump

lng

engine's

the

closing

draining

of

lng

to

Start

the engine

for

10

30

seconds;

Never

run the

CAUTION:

starting

with

raw

Is

pumping

system

during

cylinders

exhaust

the

from

system

the

raw

the

exhaust

e,x~esslvsengine

raw

water

owner/operator

Remote

The

start

gauges.

lights

rpm.

since

A.

B.

Starting

remote

start

panel

except

When

when

the

This

indicates

the

starting of

When

the

start/stop

START

engine

the

START

depressed

up

the

green

engine

After

released,

PREHEAT

supplies

switch is depressed

this

LED

light

switch.

which

series

LED

is

running.

the

generator

the

voltage

starting

PREHEAT

panel

LED

for a few

closes

path

will

switch

not

start

when

to

20

seconds,

repeat

the

procedure

starter

for

Prolonged

can

water.

raw

cranking.

by

water

result

This

water

way

fills.

Prevsnt

supply

cranking

In

may

through

This

of

muff/sr,

cranking.

entry

Is

not a warrantable

should

keep

this

Procedure

panel

is

the

same

that

it

has a green

at a remote

generator is

when

the

the

will

Continue

for

remain

generator's starter

generator

LED

light

brighten

seconds

the

oil

i2V

is

is

operated

to

the

running

the

START

switch

light

will

dim.

to

pressure

B+

brightly

started

START

the

START

release both

above

more

than

Intervals

the

engine

exhaust

happen

the

because

the

raw

raw

water

exhaust

this

from

manifold

through-hull

and

correcting

Engine

in

mind.

as

the

engine-mounted

LEP

light

location,

may

is

depressed

will

and

When

signaling

hold

to

allow

to

the

and

will

first

switch.

the

at

approximately

switch

not

be

illuminate.

the

starter

the

to

release

the

PREHEAT

oil

safety

switch

fuel

run

illuminated

the

START

not

crank

because

switch

is

switches

and

30

and

preheat

seconds.

without

system

the

water

cool·

can

enter

once

happening

shut-off,

the

cause

damage

result·

issue;

and

no

green

LED

600

can

be

released

audible.

at

the

remote

When

cranks

the

engine

starts

the

pressure

that

solenoid.

while

switch

unless

this

switch

to

is

the

the

the

by

the

the

build

in

The

is

the

Once

the

engine starts, check

proper

oil

pressure

light'load

temperature

applying

NOTE:

to

heavy

Some

Depressing

will

help

stabilize

temperature

the

engine.

the

generator

to

come

loads.

unstable

the

PREHEAT

reaches

and

the

up

running

engine

140-

the

engine's

battery charging

and

allow

the

to

140-150°

switch

may

rpm

occur

for

until

(60-66°

10-15

150° F and a load

the

instruments

voltage.

engine's

C) before·

in a cold

second

operating

is

applied

for

Apply

a

operating

engine.

intervals

STOPPING

1.

·

2.

3.

Remote·Stopping.

To

stop

to

Engine., & Generators

the

-circuit.

generator

goes

9

Remove

allow

the

stabilize

Depress

is

coinpletely

Now

release

PROCEDURE

the

AC

electrical load

generator·to run

its

operating temperatures.

the

STOP

stopped.

the

STOP switch.

switch

.

and

Procedure

the

generator, depress the STOP switch

normally

out.

The

closed

B+

STOP

switch must

comes

to a complete stop

path for voltage

for

be

from

three

to

hold it

to

hel'd

open until the

and

the green

the

generator

five

minutes

until

the generator

which

the engine's run.

LED

and

to

opens

light

Page 16

GENERATOR

BREAK·IN

PROCEDURE

DESCRIPTION

Although

hour

assembly

operated

life

ated

Breaking-in a new

piston

and

scored,

the

Your

conditioning

to

Perform

following:

Start

section.

water

AFTER

Once

tion

between

A

generator

your

of test

operations

procedures

properly, a break-in

of

your

engine

and

serviced

rings

to

smoky

operation

which

break-in

maximize

new

this

the

engine

Run

pump,

period.

engine

operation

the

conditioning

the

oil

START-UP

the

generator

and

then

encourage

20%

and

CAUTION:

by

engine

is

during

engine

the

cylinder

is

caused

requires

performance

according

engine

pressure,

has

60%

Do

running

has

experienced a minbnum

at

the

factory

to

were

followed

dependent

its

initial

basically

walls.

indicate

by

overloading

approximately

to

break

carefully,

to

while

battery

been

a fast

of

full-load

not

attempt

time

is

upon

hours

Excessive

that

the

in

each

and

service

the

STARTING

checking

charging)

started,

warm-up.

for

to

and

required.

how

involves

cylinder

keeping

check

the

break-in

without a load.

make

sure

that

the

The

the

engine

of

use.

seating

oil

consumption

walls

the

generator

50

hours

moving

that

part

life

of

the

in

mind

PROCEDURE

all

systems

are

functioning.

for

proper

Run

the

first

10

your

of

one

accurate

engine

service

is

the

are

during

of

initial

in

order

engine.

the

(raw

opera-

generator

hours.

oper-

CHECK

0

0

0

0

To

the

cuit

NOTE:

draw

draw

GENERATOR

GENERATOR

Once

be

engine's

A

junction

GENERATOR

THE

Monitor

Check

for

Check

for

vibration

Confirm

When

the

When

the

When

the

protect

against

generator's

breaker

8e

aware

required

can

be 3 to 5 times

the

generator

adjustments

break-in

no-load

voltage

with

FOLLOWING

the

control

leaks

abnonnal

and

blow-back

exhaust

engine

engine

engine

unintentional

output

that

is

of

for

starting

INFORMATION

ADJUSTMENTS

required

period

adjustment

the

engine's

INFORMATION

panel

gauges.

of

fuel