Westerbeke 63B FOUR, 71B FOUR, 108C SIX, 82B FOUR, 108B SIX Operators Manual And Installation Manual

...Page 1

OPERATOR'S MANUAL

AND

INSTALLATION GUIDE

WESTERBEKE

63(B)&(C)

FOUR

108(B) & (C) SIX

MARINE DIESEL

Publication #038922

- 71B

ENGINES

Edition

November 1994

FOUR

Three

- 82B

FOUR

-

Page 2

Page 3

OPERATOR'S

MANUAL

AND

INSTALLATION

GUIDE

WESTERBEKE

63(B)&(C)

FOUR

- 71B

FOUR

- 82B

FOUR

-

108(B) & (C)

SIX

MARINE

DIESEL

ENGINES

Publication #038922

Edition

Three

November 1994

Page 4

Page 5

SAFETY PRECAUTIONS

The

following symbols appear

in

this manual to call

attention

to

and emphasize conditions potentially

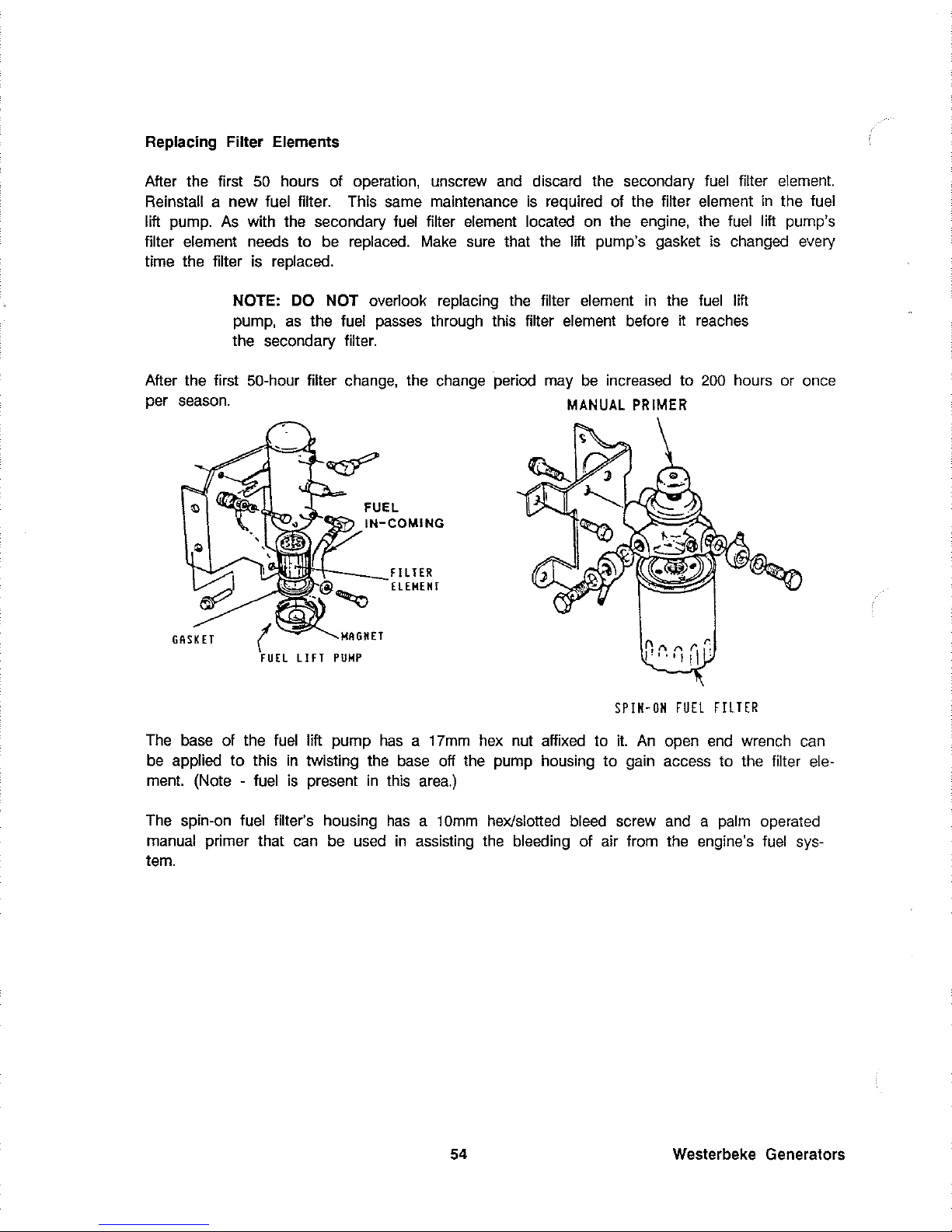

dangerous to the operator.

II

WARNING

II

The

above symbol is

used

in

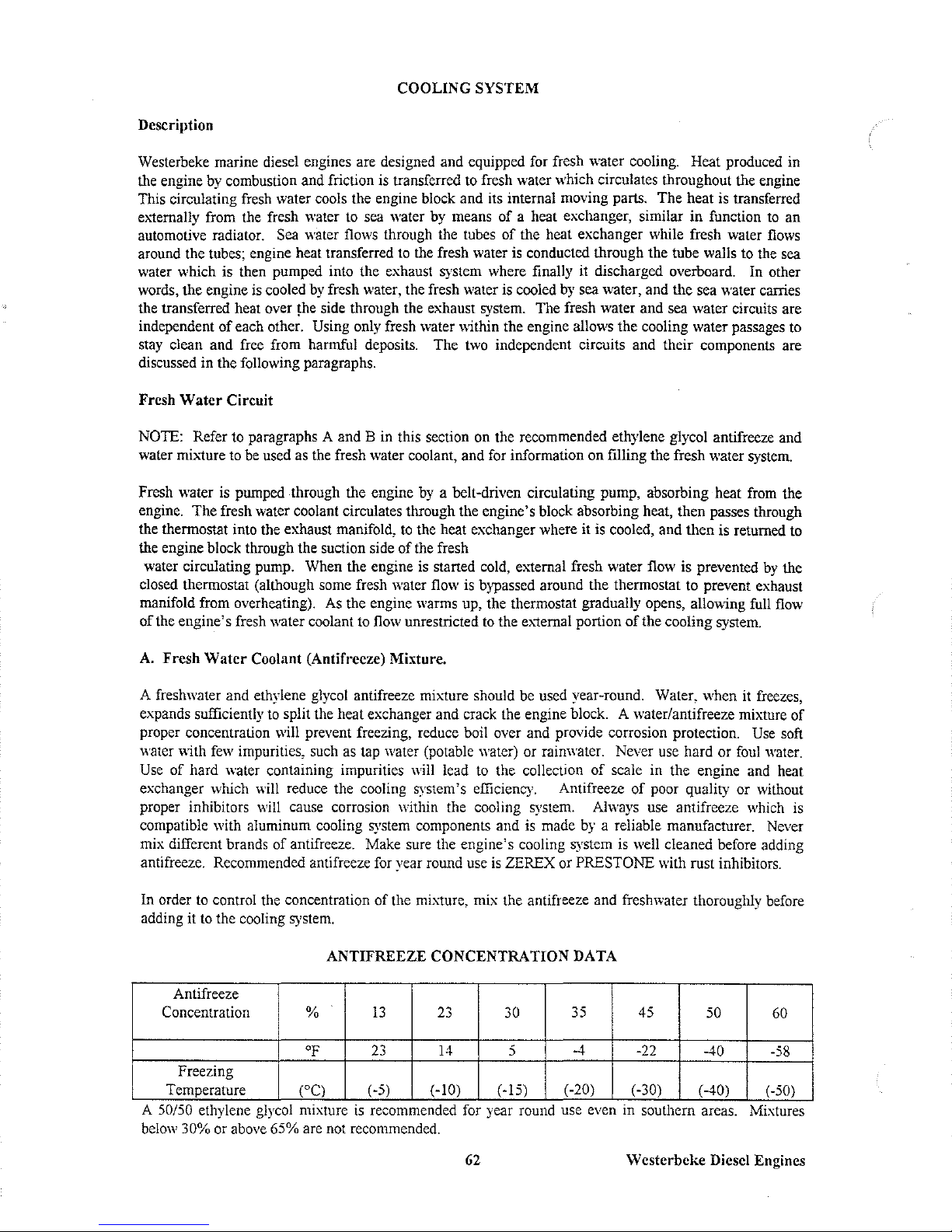

the manual to warn of

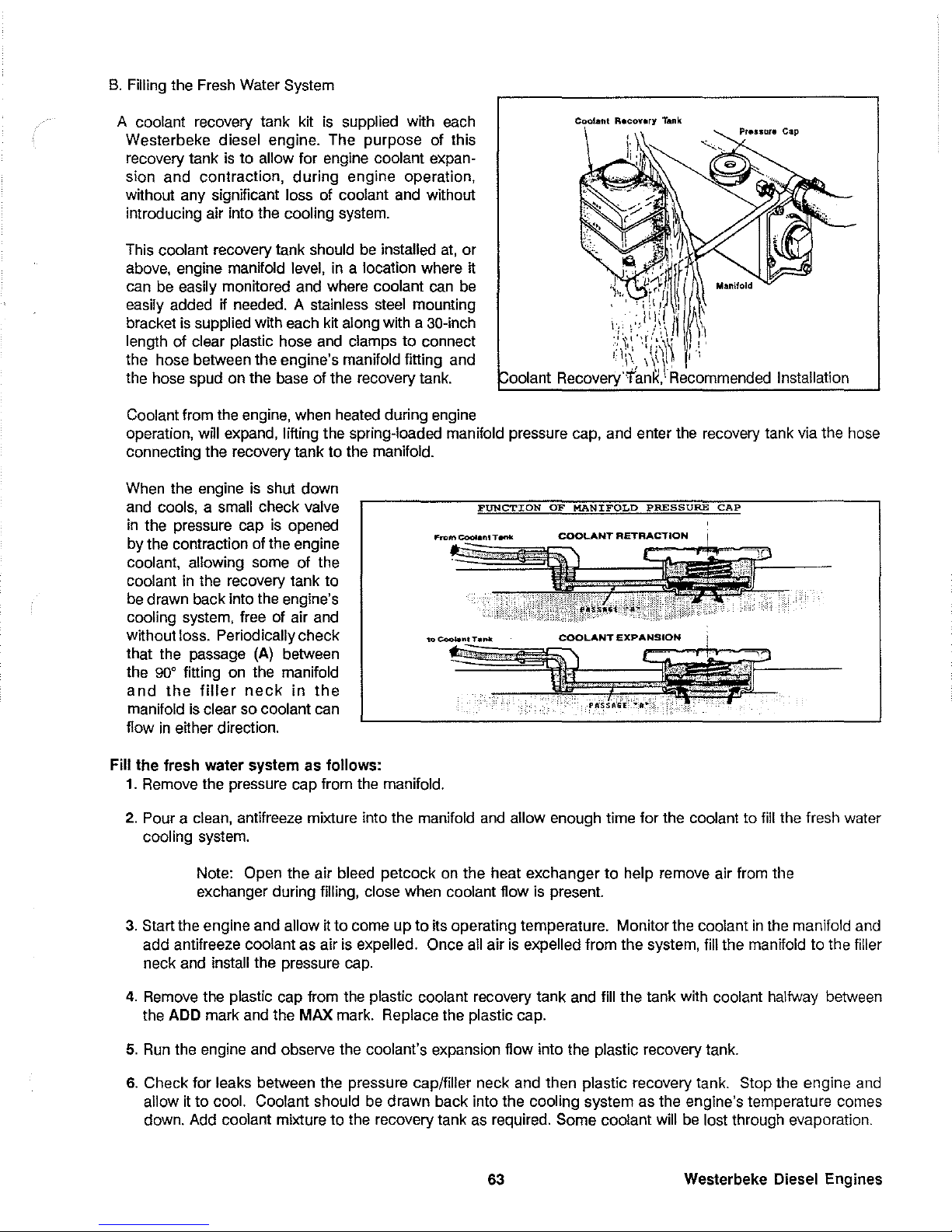

possible serious personal injury or loss of life.

I CAUTION I

The

above symbol is used

in

the manual

to

caution

personnel of possible damage to equipment.

Read

the manual carefully and thoroughly before at-

tempting

to

operate

the

equipment.

Know when

dangerous conditions

can

exist and take necessary

precautions to protect

personnel and equipment.

Fuels, exhaust gases, batteries, electrical equipment,

and

moving and hot parts are potential hazards that

could result

in

serious personal injury or death. Follow

recommended procedures carefully.

Always operate bilge blowers for at least five minutes

before starting a

gasoline-fueled engine; ensure no

gasoline fumes are present before starting.

• Prevent Electric Shock

Shut off

electric power before accessing electrical

equipment.

Use

insulated mats whenever working

on

electrical

equipment.

Make

sure your clothing is dry, not damp (particular-

ly

shoes), and keep your skin surfaces dry when

handling electrical equipment.

Remove wristwatch and

jewelry when working

on

electrical equipment.

Do

not connect utility shore power to vessel's

AC

circuits, except through a ship-to-shore double-

throw transfer switch. Damage to vessel's

AC

gen-

erator may

result if this

is

not done.

Be

extremely careful when working

on

electrical

components. High voltage can cause injury or

death.

• Exhaust Gases Are Toxic

Ensure that the exhaust system is adequate to

expel

gases discharged from the engine. Check exhaust

system

regularly for leaks and make sure the ex-

haust

manifolds are securely attached and no warp-

ing exists.

Be

sure

the unit and its surroundings are well-ven-

tilated.

• Use Extreme Care When Handling Engine

Fuel

(A constant danger

01

explosion

or

fire exists)

Do

not fill fuel tank(s) while the engine

is

running.

Do

not smoke or

use

an open flame near the engine

or the

fuel tank.

•

Do

Not Alter or Modjfy the

Fuel

System

Be

sure all fuel supplies have a positive shut-off

valve.

Be

certain fuel line fittings are adequately tightened

and free of

leaks.

Make sure a fire extinguisher is installed nearby and

is properly maintained.

Be

familiar with its proper

use.

Extinguishers rated

ABC

by the NFPA

are

ap-

propriate for

all applications encountered

in

this

environment.

• Use Extreme Care When Servicing Batteries

Wear rubber

gloves, a rubber apron, and eye

protection when servicing batteries.

Lead acid batteries emit hydrogen, a

highly-ex-

plosive

gas, which can be ignited by electrical ar-

cing or by a

lighted cigarette, cigar, or pipe.

Do

not

smoke or allow an open flame near the battery being

serviced. Shut off

all electrical equipment

in

the

vicinity to prevent

electrical arcing during servicing.

• Avoid Moving Parts

Do not service the unit while the unit

is

running;

if

a

situation arises

in

which it

is

absolutely necessary

to

make operating adjustments,

use

extreme care

to avoid moving parts and hot exhaust system components.

Do not wear

loose clothing or jewelry when servicing

eqUipment; avoid wearing loose jackets, shirts or

sleeves, rings, necklaces, or bracelets that might be

caught in moving parts.

Make sure

all

attaching

hardware is properly

tightened. Keep protective shields and guards

in

their respective place

at

all times.

Do

not check fluid levels or the drive-belt's tension

while the unit

is

operating.

Do not work

on

the equipment when mentally or

physically incapacitated by fatigue.

Page 6

Page 7

FOREWORD

Thank you for selecting a

Westerbeke

marine

product for your

use.

We

at

Westerbeke

are

pleased

to

have

you

as

a customer.

Read

this

manual

carefully

and

observe

all

of the safety precautions indicated. Operating

procedures, periodic preventive maintenance procedures, installation

checks,

system

descriptions

and

minor adjustment procedures

are

included

so

you

can

operate your equipment

safely

and

properly, maintain the equipment

at

a high

level

of efficiency,

and

expect dependable performance

and long service

life

in

return.

Product Software Disclaimer

Product software of

all

kind; such

as

brochures, drawings, technical

data,

operator's

and

workshop

manuals,

parts lists

and

parts price

lists,

and

other information, instructions

and

specifications provided from sources other than

Westerbeke,

is

not within Westerbeke's control

and;

accordingly,

is

provided to Westerbeke customers only

as

a courtesy

and

service.

Westerbeke cannot be responsible for the content of such software, makes no warranties

or representations with respect thereto, including the accuracy, timeliness or completeness

thereof, and will in no event be liable for any type of damages

or

injury incurred in

connection with, or arising out of, the furnishing or use

of

such software.

For

example,

components

and

subassemblies incorporated

in

Westerbeke's prodUcts

and

supplied

by others (such

as

engine blocks,

fuel

systems

and

components, transmissions, electrical

components, pumps

and

other products)

are

generally supported

by

their manufacturers with

their

own

software,

and

Westerbeke must depend

on

such

software for

the

design of Westerbeke's

own product software.

Such software may

be

outdated and no longer accurate. Routine

changes made by Westerbeke's suppliers, of which Westerbeke

rarely

has

notice

in

advance,

are

frequently not reflected

in

the

supplier's software until after

such

changes take

place.

Westerbeke customers should

also

keep

in

mind

the time

span

between

printings of Westerbeke

product software

and

the unavoidable existence

of

earlier,

non-current,

Westerbeke

software

editions

in

the field. Additionally, most

Westerbeke

products include customer-requested special

features that frequently do not include complete documentation.

In

summation, product software provided with

Westerbeke

products, whether from Westerbeke

or other suppliers, must not

and

cannot

be

relied

upon exclusively

as

the definitive authority

on

the respective product. It not only

makes

good

sense

but

is

imperative that appropriate

representatives of Westerbeke or the supplier

in

question

be

consulted to determine the accuracy

and

currency of the product software being consulted by the customer.

1

Westerbeke Diesel Engines

Page 8

Warranty Procedures

Should your

unit

require special attention, contact your Westerbeke dealer for assistance.

The

Westerbeke Service Organization

is

trained to provide the support necessary to

ensure

long-term

dependable performance.

If,

within

60

days

of

submitting the Warranty Registration Form for your unit, you

have

not

received a Customer

Identification

Card,

shown

below,

registering your warranty,

please

contact

the factory

in

writing with model information, including the unit's

serial

number

and

commission

date.

Unit 1.0. Plates

"""" .["IRBE!.!

COR'ORllI0~

I'O~

1~1M1~IJL

PllII<

uo~

....

ona

'---(~'ff:-

Mall To:

CUSTOMER IDENTIFICATION

••••

~.;.h

II

Mopl. ~ .....

Udo

•.

U 12134

10,,,

..

"llI!1

s..

.•

""._"

Customer Identification

Card

For future service, repair or warranty

reference,

Westerbeke suggests that you

fill

in

the blank

spaces

in

the diagram below with the information from your machine.

-

o 0

•

MODEL

SPEC AVON MA USA

SER.NO..

Unit 1.0. Plates

Westerbeke Diesel Engines

2

Page 9

Section

FOREWORD

GENERAL

INFORMATION

MODEL

PHOTOS

TABLE

OF

CONTENTS

63B

FOUR

GENERAL

SPECIFICATIONS

63B

FOUR

SYSTEM

SPECIFICATIONS

71B

FOUR

GENERAL

SPECIFICATIONS

71B

FOUR

SYSTEM

SPECIFICATIONS

82B

FOUR

GENERAL

SPECIFICATIONS

82B

FOUR

SYSTEM

SPECIFICATIONS

108B

SIX

GENERAL

SPECIFICATIONS

108B SIX

SYSTEM

SPECIFICATIONS

INSTALLATIONS & INSTALLATION

CHECKS

EXHAUST

SYSTEM

RAW

WATER

INTAKE

SYSTEM

OPERATIONS -CAPTAIN'S

PANEL

-

ADMIRAL'S

PANEL

PREPARATIONS

FOR

STARTING

STARTING

PROCEDURE

STOPPING

PROCEDURE

ENGINE

BREAK-IN

PROCEDURES

FUEL

SYSTEM

DC

CONTROL

CIRCUIT

WIRING

DIAGRAM:

#36467

#36844

#39144

COOLING

SYSTEM

LUBRICATION

SYSTEM

TRANSMISSIONS

HBW & HSW -HURTH

BORG

WARNER

WALTER

V-DRIVE

ENGINE

TROUBLESHOOTING

MAINTENANCE & ADJUSTMENTS

LAY-UP & RECOMMISSIONINGIWINTERIZING

TABLE

OF

STANDARD

HARDWARE

TORQUE

SPECIFICATIONS

SPARE

PARTS

Page

1

4

6

14

15

17

18

20

21

23

24

27

34

38

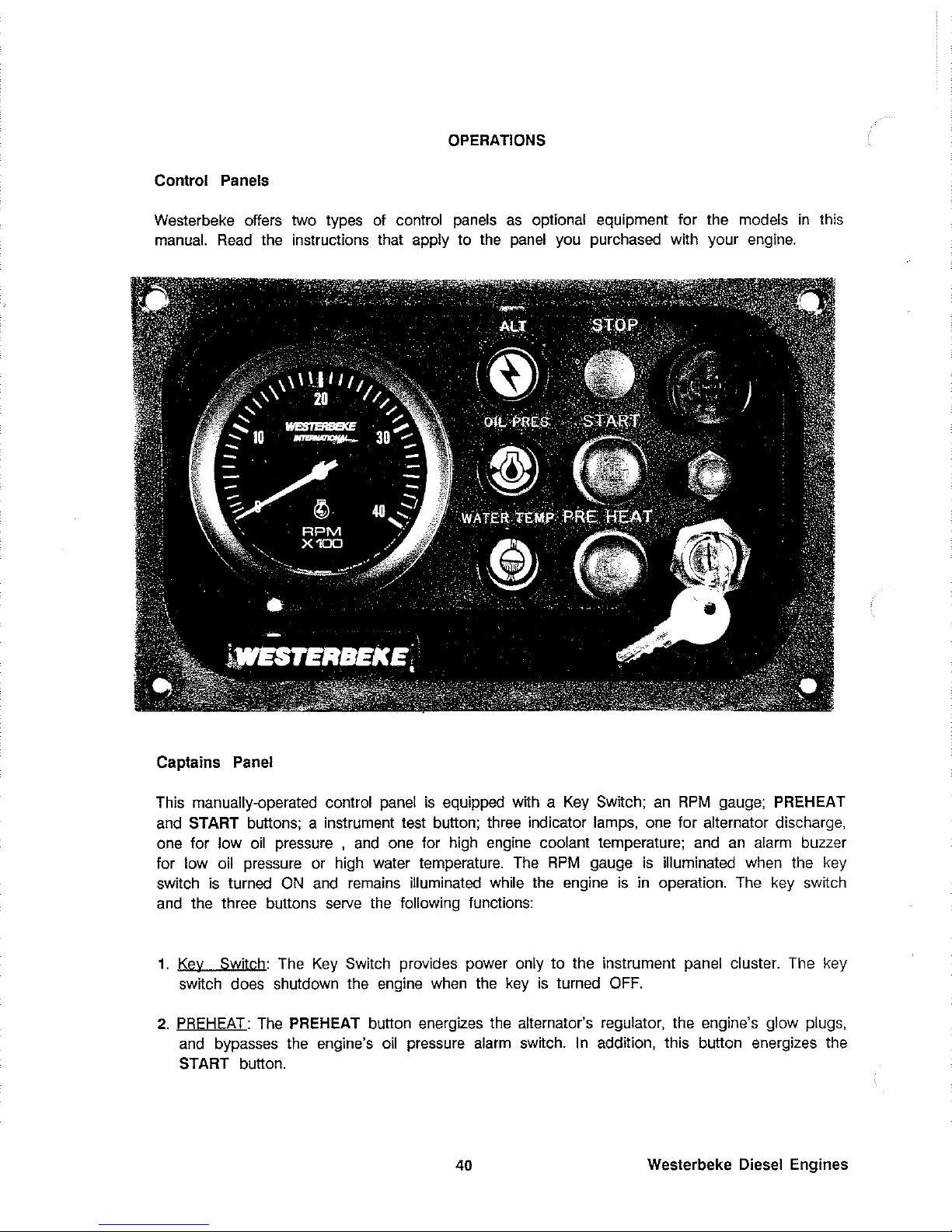

40

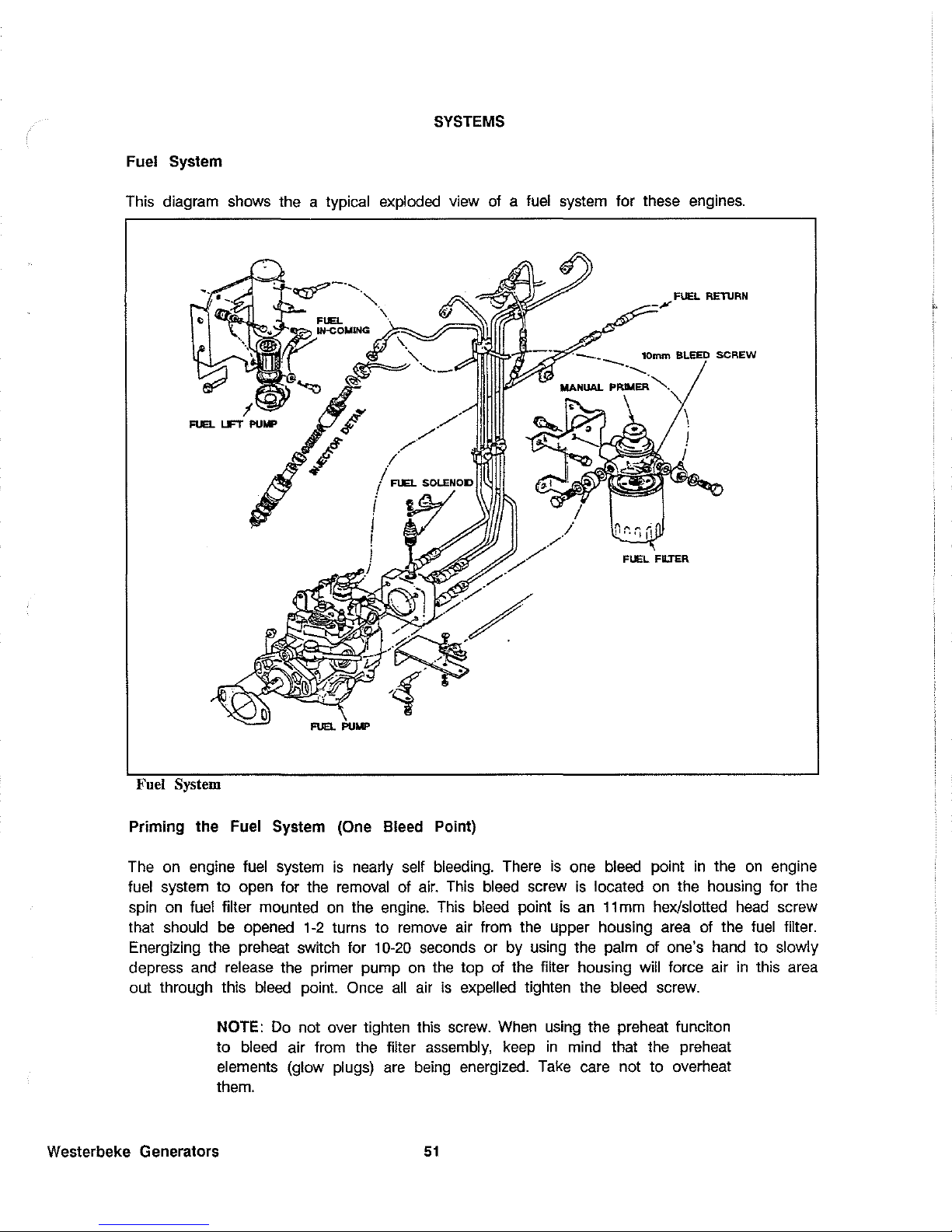

42

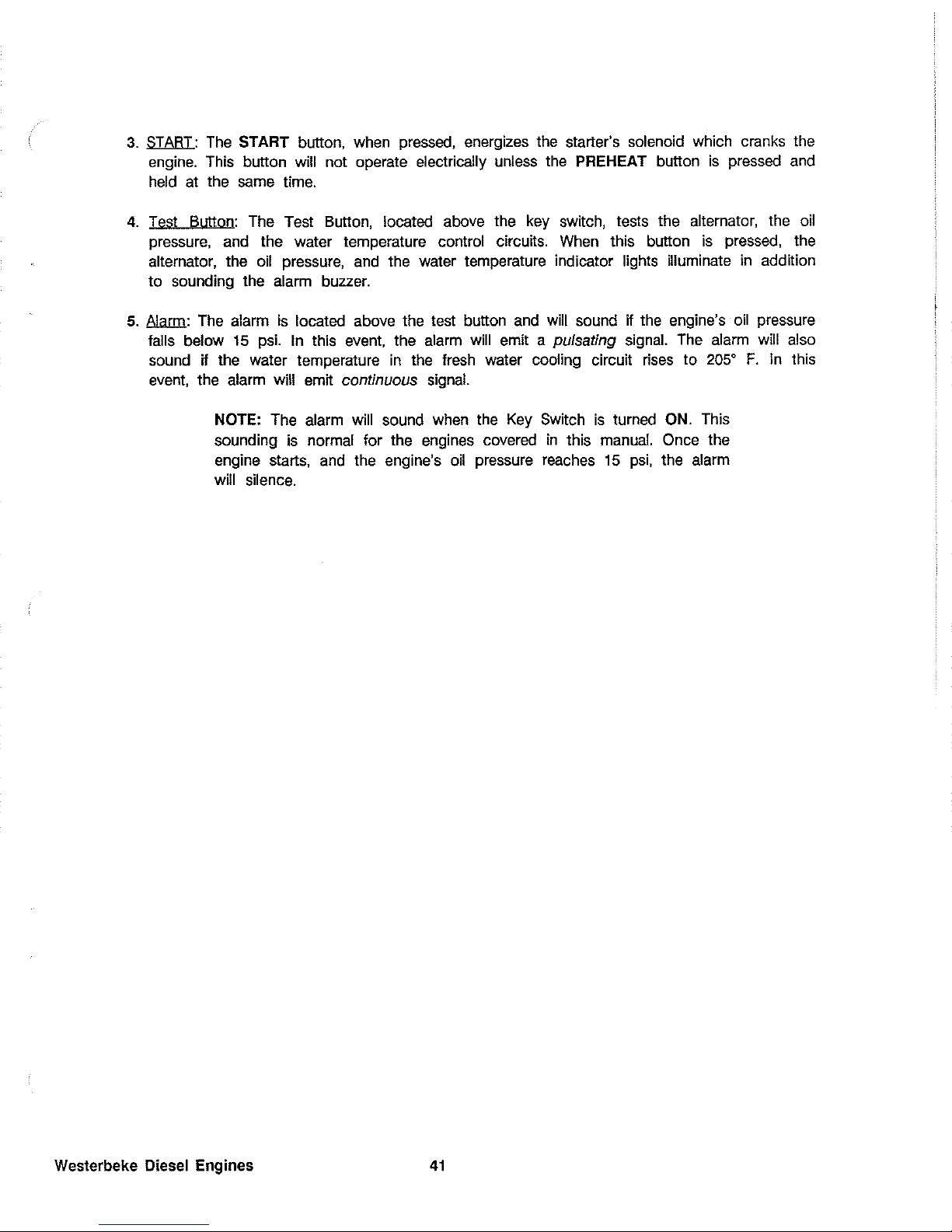

45

46

49

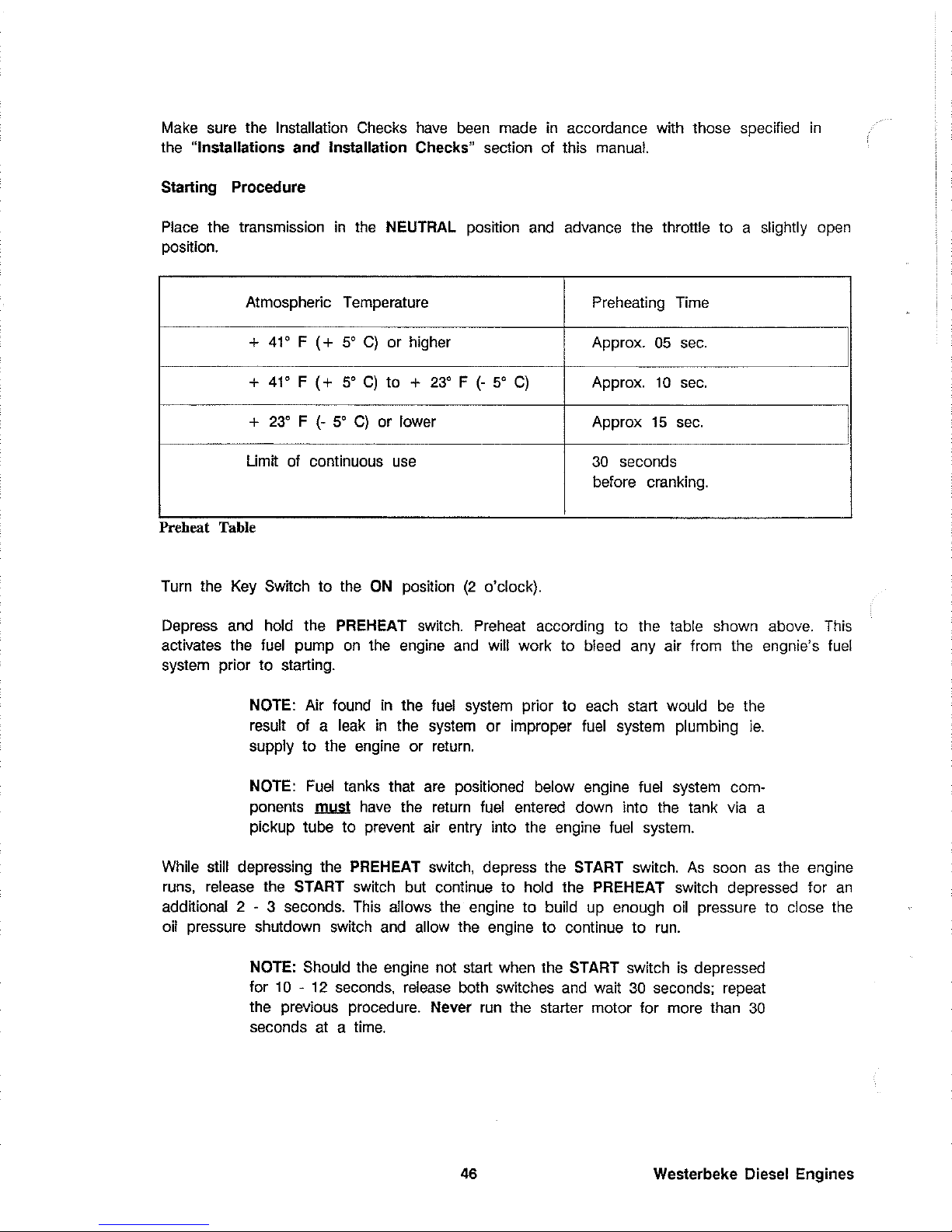

50

51

56

58

60

62

68

70

70

79

85

90

92

97

100

101

102

Page 10

GENERAL INFORMATION

Introduction

This

manual

contains the equipment operating procedures

as

well

as

additional information

needed

to help the operator

keep

the marine equipment

in

proper working order. Study

and

follow the instructions carefully. A planned maintenance program

is

included

in

this

manual.

Adhering to the program will result

in

better equipment performance

and

longer equipment

life.

Proper diagnosis of a problem

is

the most important step to satisfactory repair; therefore, a

troubleshooting table

is

included.

Understanding the Diesel Engine

The

diesel

engine closely resembles the gasoline engine

since

the mechanism

is

essentially

the

same.

The cylinders

are

arranged

above

a closed crankcase; the crankshaft

is

of the

same

general

type

as

that of a gasoline

engine;

and

the diesel

engine

has

the

same

type of

valves,

camshaft,

pistons, connecting

rods,

and

lubricating

system.

Therefore,

to a great

extent,

a diesel engine requires the

same

preventitive maintenance

as

a

gasoline

engine.

The

most important factors are proper ventilation

and

proper maintenance

of

the

fuel

lubricating

and

cooling

systems.

Replacement of

fuel

and

lubricating filter

elements

at

the time periods specified

is a must,

and

frequent checking for contamination (that

is,

water,

sediment,

or

algae)

in

the

fuel

system

is

also

essential.

Another important factor

is

the

use

of

the

same

brand

of

high detergent diesel lubricating

oil

designed specifically for

diesel

engines.

Be

careful

not to put gasoline

in

the diesel

fuel

tank(s). Gasoline does not

have

the

same

lubricating qualities

as

diesel

fuel;

consequently, gasoline

in

the

fuel

lines will damage components

in

the

fuel

injection pump

and

fuel

injectors.

The

diesel engine does differ from the gasoline

engine;

however,

in

its handling

and

firing

of

fuel.

The

carburetor

and

ignition systems

are

done away with

and

it their place

are

two

components

- the

fuel

injection pump

and

the

fuel

injectors.

Protecting Your Investment

The

five

most important steps to insure long engine

life

are:

1.

Proper installation.

In

particular, the use of

an

anti-siphon break to preclude

raw

water intrusion into the engine

via

the exhaust elbow

is

essential.

2.

Avoid Overcranking. This

can

fill the engine with

raw

water .

3.

Change the lubricating

oil.

4.

Maintain the cooling system.

5.

Winterizing your Westerbeke product.

Ordering Parts

Whenever

replacement parts

are

needed,

always provide the generator model number designation

(Le.

63B

FOUR),

engine

serial

number,

and

generator

serial

number

as

they appear

on

the

data

plates

located

on

the exhaust manifold

and

on

the generator

end.

You

!111.§1.

provide

us

with this information

so

we

may properly identify your generator

set.

In

addition, include a

complete part description

and

part number for

each

part

needed

(see

the separately furnished

Parts

List).

Also,

be

sure

to insist upon Westerbeke factory packaged parts

because

"will fit"

or generic parts

are

frequently not

made

to the

same

specifications

as

original

eqUipment.

Westerbeke Diesel Engines 4

Page 11

General Information (continued)

Note that component locations

in

the

manual

are

referenced

from the front

of

the engine which

is

the pulley/drive belt

end.

(The

flywheel/generator

end

is

the

rear

end.)

Left

and

right

sides

are

deteremined

by

the engine; imagine straddling the engine

and

facing

in

the

same

direciton

as

the front of the engine: the left side

is

at your

left,

the right

side

is

at your

right.

Westerbeke generator

sets

are

thoroughly checked

and

given a

final

run

under various load

conditions before leaving the factory. Test running the generator

ensures

dependable operation,

long service I

ite,

and

a satisfied

owner.

Care at the factory during assembly

and

thorough testing

have

resulted

in

a Westerbeke diesel

engine-driven generator capable of

many

thousands

of

hours of dependable

service.

However,

what the manufacturer cannot

control

is

the manner or location

the

generator

is

installed

in

the

vessel

or the manner

in

which the unit

is

operated

and

serviced

in

the

field.

That

part

is

up to the buyer/owner-operator.

5 Westerbeke Diesel Engines

Page 12

::;;

"

~

ci-

"

~

"

t::l

fi'

i:E.

i":l

'"

.0

s·

"

~

'"

70'

Exhaust

Elbow

Zinc

Anode

Domestic

Water

Heater

(Return)--

__

Instrument

Panel

Connection

___

Transmission

Shift

Lever

Fresh

Water

Coolant

Fill

Optional

DC

Charging

Alternator

Domestic

Water

Heater

Connection

(To)

63

B FOUR

Lube

Oil

Drain

Hose

Adjustable

Engine

Isolator

Page 13

-..j

~

;;

~

?i

\:)

;S"

~

l'l

"

""

S"

il

Optional

Refrigeration

Compressor

\

Top

Engine

Fuel

Injection

Pump

Alarm

Oil

Pressure

Sender

Oil

Fill

Preheat

Solenoid

Lube

Oil

Dipstick

Starter

with

Solenoid

inc

Anode

Domestic

Water

Heater

(Return)

Instrument

Panel

Connection

/

,

Battery

Ground

Connection

Transmission

Cooler

Adjustable

Engine

Isolator

Lube

Oil

Cooler

Transmission

Drain

Page 14

~

t>

~

ci-

t>

,...

'"

~

[

trI

"

'!S.

"

'"

~

00

Domestic

Water

Heater

Connection

Fuel

Manual

Primer

Preheat

Solenoid

________

Zinc

Anode

Domestic

Water

Heater

(Return)-

Heat

Exchanger

Marine

Transmission

(To)

Fresh

Water

Fill

Cap

71 B FOUR

Optional

Refrigeration

Compressor

Optional

DC

Alternator

Page 15

'-0

::::

"

~

;:).

"

~

c

;;.

~

i"j

"

".9.

"

"

~

Optional

Refrigeration

Compressor

Fuel

Lift

Pump

Lube

Oil

Drain

Hose

Oil

Pressu

re

Switch

Lube

Oil

Cooler

Air

Intake

Silencer

Fuel

Manual

Primer

Lube

Oil

Dipstick

/

/

Fuel

Filter

inc

Anode

Domestic

Water

Heater

(Return)

Starter

with

Solenoid

Pressure

Sender

Lube

Oil

Filter

Page 16

~

~

ci-

"

?:

I:;

[

M

::l

OQ

S·

~

-

o

Exchanger

Air

Bleed

Petcock

70°

Exhaust

Elb

Domestic

Water

Heater

(Return)

Instrument

Panel

Connection

Transmission

Shift

Lever

Domestic

Water

Fresh

Water

Unit

I.

D.

Plate

DC

Charging

Alternator

Raw

Water

Pump

Lube

Oil

Drain

Hose

(To)

Adjustable

Engine

Isolator

Starter

with

Solenoid

82

B FOUR

Page 17

-

-

~

~

"

d-

"

:r.-

"

l:'

;;0

~

t'l

=

1J,S.

=

&l

Fuel

Lift

Pump

Fuel

Injection

Pump

Top

Engine

Oil

Fill

Adjustable

Engine

Isolator

f

Oil

Pressure

Sender

Preheat

Solenoid

Lube

Oil

Filter

Secondary

Fuel

Filter

Zinc

Anode

Domestic

Water

Heater

(Return)

Fresh

Water

Block

Drain

Plug

Transmission

Cooler

Transmission

Drain

• F

Page 18

~

~

do

"

~

o

[

l'1

"

..

5"

I;;

-

IV

Domestic

Water

Heater

(To)

90'

Exhaust

Elbow

Exchanger

Air

Bleed

Petcock

Transmission

Cooler

Transmission

Dipstick

Transmission

Vent

Transmission

Drain

Plug

Fresh

Water

Fill

Cap

Starter

with

Solenoid

108 B

SIX

Top

Engine

Oil

Fill

Cap

Lu

DC

Charging

Alternator

Oil

Drain

Hose

Page 19

~

w

::::;

~

'"

;:).

'"

:>:'

"

I:;)

;;.

~

1'1

"

".9.

1:

'"

Top

Engine

Oil

Fill

Cap

Water

Temperature

Alarm

Switch

Water

Temperature

Sender

Fresh

Water

Circulating

Pump

Adjustable

Engine

Isolator

Lube

Oil

r

Secondary

Fuel

Filter

Oil

Pressure

Sender

Fuel

Lift

Pump

20

A

DC

Circuit

Breaker

Zinc

Anode

Domestic

Water

Heater

(Return)

Instrument

Panel

Connection

il

Pressure

Alarm

Switch

Page 20

63(B) & (C)

Four

Marine

Diesel

Engine

General

Specifications

Engine Type

Governor

Valve Mechanism

Combustion Chamber

Bore

& Stroke

Piston Displacement

Firing

Order

Direction

of

Rotation

Maximum Torque (at

2900 rpm)

Compression Ratio

Compression

Pressure

Valve Seat Angle

Valve Clearance

(engine cold)

Dimensions

Inclination

Dry Weight

Engine

Speed

Fuel Consumption

Westerbeke Diesel Engines

Diesel, four-cycle, fresh water-cooled, vertical, in-line

(63

hp at 3600 rpm maximum)

Integral

of

the injection pump, mechanical flyweight type.

Overhead

Swirl chamber type

3.50 x 3.51 inches (88.9 x 89.9 mm)

134.8 cubic inches (2.21 liters)

1-3-4-2

Clockwise, when viewed from the front

93

Ib-ft (10.92 kg-m)

21:1

427 psi

(30.0 kg/cm') at 200 rpm

Intake

45° Exhaust 45°

Intake 0.12 inches (OJ mm)

Exhaust

0.012 inches (0.3 mm)

Height: 25.30 inches (642.6 mm)

Width: 21.19 inches (538.2 mm)

Length: 38.75 inches (984.3 mm)

Continuous

14° Temporary 25° (not to exceed 30 min.)

611

lbs

(192 kgs)

Idle speed:

750 - 1000 rpm

Cruising speed:

2500 - 3000 rpm

1.2

US

gph (4.5 Iph) running

at

2500 rpm (approximate)

when the propeller allows 3600 rpm at full open throttle

while underway

in

forward gear.

14

Page 21

63(B) & (C)

Four

Marine

Diesel Engine

General

Specifications

(Continued)

Fuel

System

Fuel

Injection

Pump

Injection Timing

Nozzle

Injection

Pressure

LiftPump

Fuel Filter (on engine)

Air Cleaner

Air Flow (engine combustion)

(engine cooling)

Cooling

System

General

Operating Temperature

Fresh Water

Pump

Sea

Water Pump

No.2

diesel oil (cetane rating

of

45

or higher)

Diesel KIKI Mechanical Governed

OOTDC

Throttle type

1920 psi (135 kg/cm

2

)

12

volt plunger type

Spin-on (replaceable)

Metal screen type-cleaner

140 cfm (3.9 cmm) at 3600 rpm

250 cfm (7.0 cmm)

Fresh water-cooled block, thermostatically-controlled

with

sea water exchanger system.

170 -

1900 F (77 - 88

0

C)

Centrifugal type, metal impeller, belt-driven

Positive displacement, rubber impeller, gear-driven

Sea Water Flow,

at

3600 rpm 12.0 gpm (45.4 Ipm) approximate

(measured before discharging into

exhaust elbow)

System Capacity (fresh water)

Lubrication

System

General

Oil Filter

Sump Capacity

Operating

Oil Pressure

Oil

Grade

10

U.S. qts. (9.9 liters)

Pressure feed, rotor type, driven

by

spiral gears from

camshaft

Full flow, paper element, spin-on type

5.3

U.S. qts. (5.0 liters) not including filter

30 - 60 psi (2.1 - 4.2

kg/cnl)

at maximum engine rpm and

at normal operating temperature.

API specification CC or

CD

15

Westerbeke Diesel Engines

Page 22

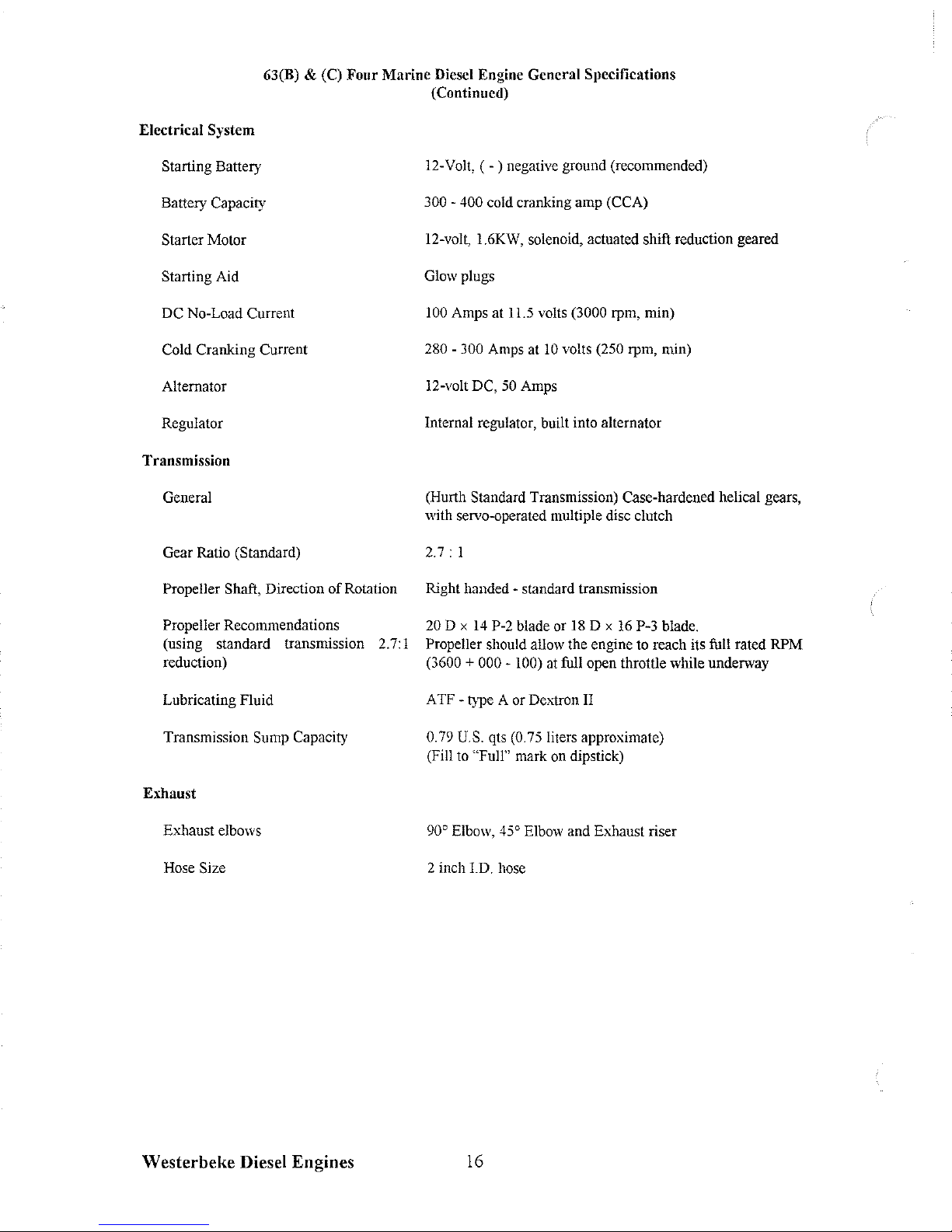

63(B) & (C) Four Marine Diesel Engine General Specifications

(Continued)

Electrical

System

Starting Battery

Battery Capacity

Starter Motor

Starting Aid

DC No-Load Current

Cold Cranking Current

Alternator

Regulator

Transmission

General

Gear Ratio

(Standard)

Propeller Shaft,

Direction

of

Rotation

Propeller Recommendations

(using standard transmission 2.7:1

reduction)

Lubricating Fluid

Transmission

Sump Capacity

Exhaust

Exhaust elbows

Hose

Size

Westerbeke Diesel Engines

12-

Volt, ( - ) negative ground (recommended)

300 - 400 cold cranking amp (CCA)

12-volt, 1.6KW, solenoid, actuated shift reduction geared

Glow plugs

100

Amps at

U.S

volts (3000 rpm, min)

280 - 300 Amps at

10

volts (250 rpm, min)

12-volt DC,

50

Amps

Internal regulator, built into alternator

(Hurth

Standard Transmission) Case-hardened helical gears,

with servo-operated multiple disc clutch

2.7:

I

Right handed - standard transmission

20 D x

14

P-2 blade or

18

D x

16

P-3 blade.

Propeller should allow the engine to reach its full rated RPM

(3600

+ 000 - 100) at full open throttle while underway

A TF - type A or

DeA1ron

II

0.79

U.S. qts (0.75 liters approximate)

(Fill to

"Full" mark on dipstick)

90'

Elbow,

45'

Elbow and Exhaust riser

2 inch I.D. hose

16

Page 23

71

B Four Marine Diesel Engine General Specifications

Engine Type

Governor

Valve

Mechanism

Combustion Chamber

Bore &

Stroke

Piston Displacement

Firing Order

Direction of Rotation

Maximum Torque

(at

2200

rpm)

Compression

Ratio

Compression

Pressure

Valve

Seat

Angle

Valve

Clearance

(engine cold)

Dimensions

Inclination

Dry Weight

Engine

Speed

Fuel

Consumption

Westerbeke

Diesel Engines

Diesel,

four-cycle, four-cylinder, fresh water-cooled,

vertical,

in-line

(71

hp at

3600

rpm

maximum)

Intergral

of

the injection pump, mechanical

flyweight type

Overhead

Swirl

chamber type

3.50 x 4.0

inches

(88.9 x 101.6

mm)

154.0

cubic inches

(2.5

liters)

1-3-4-2

Clockwise, when

viewed

from the front

118

Ib-ft

(16.31

kg-m)

21:1

427

psi

(30

kgJcm

2

)

at

200

rpm

Intake 45', Exhaust 30'

Intake

0.012

inches

(0.3

mm)

Exhaust

0.012

inches

(0.3

mm)

Height:

26.9

inches

(684.2

mm)

Width:

22.2

inches

(563.6

mm)

Length:

39.5

inches

(1003.3

mm)

Continuous 14', Temporary 25'

(not to

exceed

30

min.)

652

Ibs

(295.9

kgs)

Idle

speed:

750 -1000

rpm

Cruising

speed:

2500 -3000

rpm

1.4

U.S.

gph

(5.2

Iph)

running at

2500

rpm

(approximate) when the propeller allows

3600

rpm

at

full

open throttle while underway

in

forward

gear.

17

Page 24

718 Four Marine Diesel Engine System Specifications

Fuel System

Fuel

Injection Pump

Injection Timing

Injectors

Injection

Pressure

Lift Pump

Fuel

Filter

(on

engine)

Air

Cleaner

Air Flow (engine combustion)

Cooling System

General

Operating Temperature

Fresh

Water Pump

Sea

Water Pump

Sea

Water

Flow,

at

3600

rpm

(measured before discharging

into exhaust

elbow)

System

Capacity (fresh water)

Lubrication

System

General

Oil

Filter

Sump Capacity

Operating

Oil

Pressure

No.

2 diesel

oil

(cetane rating of

45

or

higher)

Diesel

KiKi

mechanical governed

0°

TOC

Throttle type

1920

psi

(135

kg/cm

2

)

12

volt - plunger type

Spin-on type (replaceable)

Metal

screen type - cleanable

160.4

cfm

(4.5

cmm) at

3600

rpm

Fresh

water cooled block, thermostatically-controlled

with

sea

water exchanger system

170 -190° F (77 -88°

C)

Centrifugal type,

metal

impeller, belt-driven

Positive displacement, rubber impeller, gear-driven

10

gpm

(37.8

Ipm)

approximate

11.5

U.S.

qts

(10.9

liters)

Pressure

feed,

rotor type, driven

by

sprial gears

from camshaft

Full

flow, paper element, spin-on type

6.3

U.S.

qts

(6.0

liters) not including filter

30 -60

psi

(2.1 -4.2

kg/cm

2

)

at maixmum engine

rpm

and at normal operating temperature

Oil

Grade

API

specification

CC

or

CD

18

Westerbeke Diesel Engines

Page 25

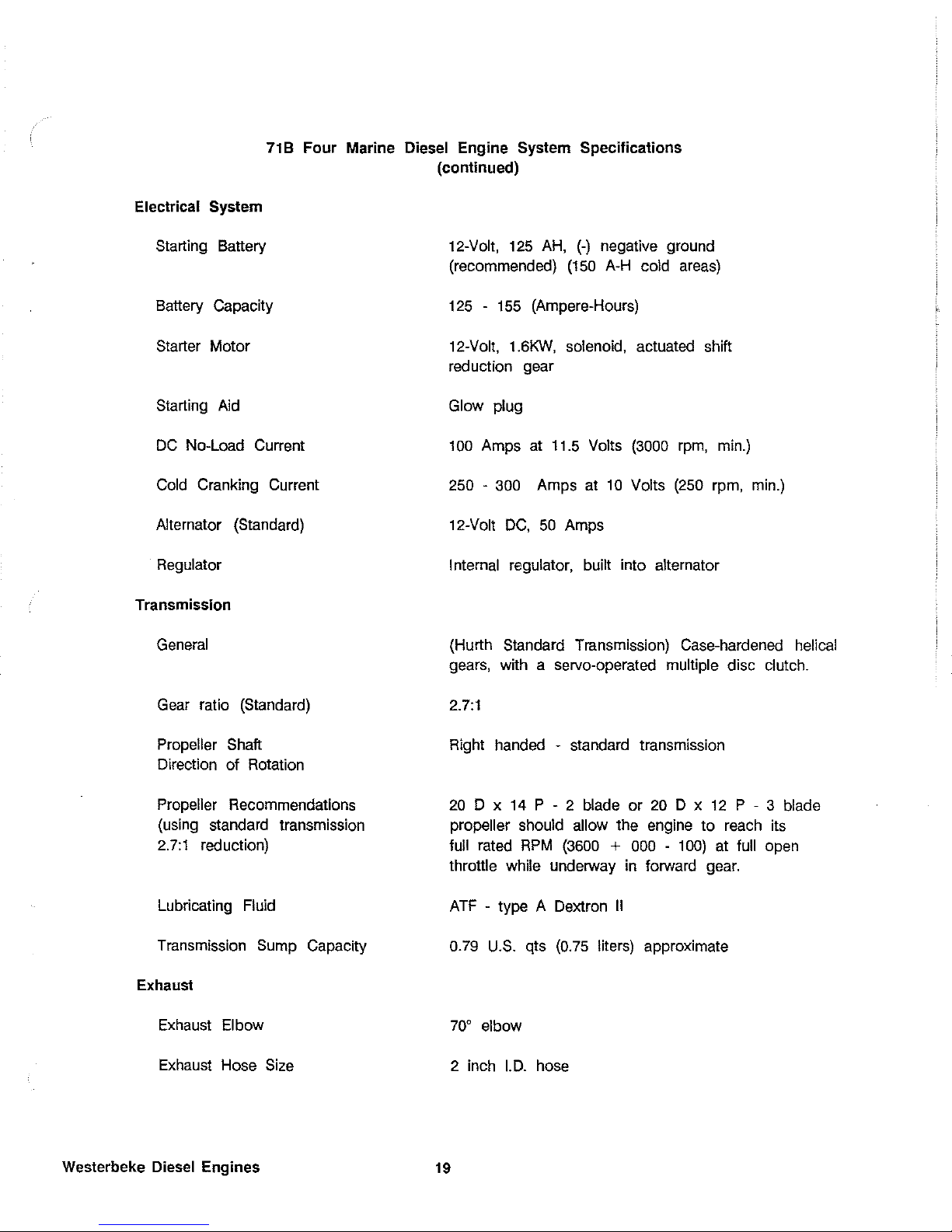

71

B Four Marine Diesel Engine System Specifications

(continued)

Electrical System

Starting

Battery

Battery Capacity

Starter Motor

Starting

Aid

DC

No-Load Current

Cold

Cranking Current

Alternator (Standard)

Regulator

Transmission

General

Gear

ratio (Standard)

Propeller Shaft

Direction of Rotation

Propeller Recommendations

(using

standard transmission

2.7:1

reduction)

Lubricating

Fluid

Transmission

Sump

Capacity

Exhaust

Exhaust

EI

bow

Exhaust

Hose

Size

Westerbeke Diesel Engines

12-Volt,

125

AH,

(-)

negative ground

(recommended)

(150

A-H

cold

areas)

125 -155

(Ampere-Hours)

12-Volt,

1.6KW,

solenoid, actuated shift

red

uction gear

Glow plug

100

Amps at

11.5

Volts

(3000

rpm,

min.)

250 -300

Amps at

10

Volts

(250

rpm,

min.)

12-Volt

DC,

50

Amps

I nternal regulator, built into alternator

(Hurth Standard Transmission) Case-hardened helical

gears, with a servo-operated multiple disc clutch.

2.7:1

Right handed - standard transmission

20

D x

14

P - 2 blade or

20

D x

12

P - 3 blade

propeller should allow

the engine to

reach

its

full rated

RPM

(3600 + 000 -100)

at

full

open

throttle while underway

in

forward

gear.

A

TF

- type A Dextron

II

0.79

U.S.

qts

(0.75

liters) approximate

70' elbow

2 inch

I.

D.

hose

19

Page 26

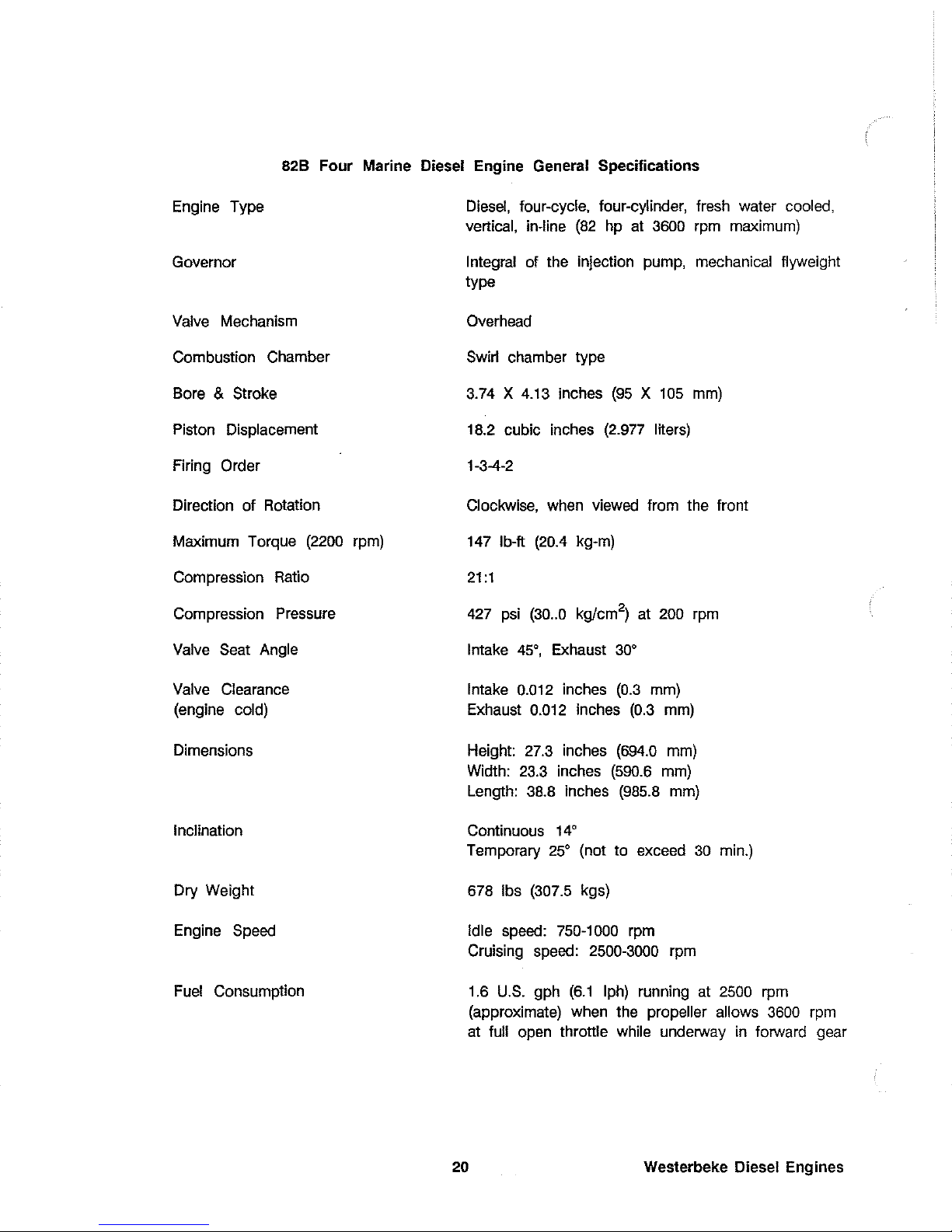

82B

Four Marine

Diesel

Engine

General

Specifications

Engine Type

Governor

Valve

Mechanism

Combustion Chamber

Bore

& Stroke

Piston Displacement

Firing

Order

Direction of Rotation

Maximum Torque

(2200

rpm)

Compression

Ratio

Compression Pressure

Valve

Seat

Angle

Valve

Clearance

(engine cold)

Dimensions

Inclination

Diesel,

four-cycle, four-cylinder, fresh water cooled,

vertical, in-line

(82

hp at

3600

rpm

maximum)

Integral

of

the injection pump, mechanical flyweight

type

Overhead

Swirl chamber type

3.74 X 4.13

inches

(95 X 105

mm)

18.2

cubic inches

(2.977

liters)

1-3-4-2

Clockwise,

when

viewed

from the front

147

Ib-ft

(20.4

kg-m)

21

:1

427

psi

(30

..

0 kglcm

2

)

at

200

rpm

Intake 45', Exhaust 30'

Intake

0.012

inches

(0.3

mm)

Exhaust

0.012

inches

(0.3

mm)

Height:

27.3

inches

(694.0

mm)

Width:

23.3

inches

(590.6

mm)

Length:

38.8

inches

(985.8

mm)

Continuous 14'

Temporary 25' (not to exceed

30

min.)

Dry Weight 678

Ibs

(307.5

kgs)

Engine

Speed

Idle

speed:

750-1000

rpm

Cruising

speed:

2500-3000

rpm

Fuel

Consumption

1.6

U.S.

gph

(6.1

Iph)

running at

2500

rpm

(approximate) when the propeller allows

3600

rpm

at

full

open

throttle while underway

in

forward gear

20

Westerbeke

Diesel Engines

Page 27

82B Four Marine Diesel Engine System Specifications

FUEL SYSTEM

Fuel

Injeciton Pump

Injection Timing

ilnjectors

Injection Pressure

Lift Pump

Fuel

Filter (on engine)

Air Cleaner

Air Flow (engine combustion)

(engine cooling)

COOLING SYSTEM

General

Operating Temperature

Fresh Water Pump

Sea

Water Pump

Sea

Water Flow, at

3600

rpm

(measured before discharging

into exhaust elbow)

System Capacity (fresh water)

LUBRICATING SYSTEM

General

Oil

Filter

Sump Capacity

Westerbeke Diesel Engines

No. 2 diesel

oil

(cetane rating of

45

or higher)

Diesel

Kiki

0"

TDC

(Static Timing)

Throttle

1920

psi

(135

kg/cm

2

)

12

Volt plunger tyupe

Spin-on (replaceable)

Metal

screen type - cleanable

189.5

cfm

(5.3

cmm) at

3600

rpm

250 cfm

(7.0

cmm)

Fresh

water-cooled block,

Thermostatically-controlled

with

sea

water exchanger system

170-190" F

(77-88"

C)

Centrifugal type, metal impeller, belt-driven

Positive displacement, rubber impeller, belt-driven

14

gpm

(53

Ipm)

approximate

21

13

U.S.

qts

(12.3

liters)

Pressure

feed,

rotor type, driven by sprial gears from

camshaft

Full

flow, paper element, spin-on type

6.3

U.S.

qts

(6.0

liters) not including filter

Page 28

82B Four Marine Diesel Engine System Specifications

(continued)

Operating

Oil Pressure

Oil Grade

ELECTRICAL SYSTEM

Starting

Battery

Battery Capacity

Starting Aid

Starter Motor

DC

No-Load Current

Cold Cranking Current

Alternator

(Standard)

Regulator

TRANSMISSION

General

Gear Ratio (Standard)

Propeller Shaft

Propeller

Recommendations

(using strandard Transmission

2.0:1

reduction)

Lubricating

Fluid

Transmission Sump Capacity

EXHAUST

Exhaust Elbow

Exhaust Hose Size

30-60

psi (2.1-4.2 kg/cm

2

)

at maximum engine

rpm

and at normal operating temperature

API

Specification

CC

or

CD

12-Volt,

125

A-H,

(-)

negative ground (recommended)

(150

A-H

cold areas)

125-155 (Ampere-Hours)

Glow plugs

12-Volt,

3.0KW,

solenoid, actuated shift, reduction gear

100

Amps at

11.5

volts

(3000

rpm, min.)

250-300 Amps at

10

Volts

(250

rpm, min.)

12-Volt

DC,

51

Amps

Internal regulator, mounted on alternator

(Hurth Standard Transmission) Case-hardened helical

gears, with servo-operated multiple disc clutch

2.04:1

Right handed - standard transmission

20

D X

12

P-2

blade or

20

D X

10

P-3

blade

propeller should allow

the engine to reach its full

rated

RPM

(3600 + 000

- 100) at full open throttle

while underway

in

forward gear

ATF-type A or Dextron

II

0.79

U.S.

qts

(0.75

liters) approximate

700 elbow

2 inch

I.D.

hose

22

Westerbeke

Diesel Engines

Page 29

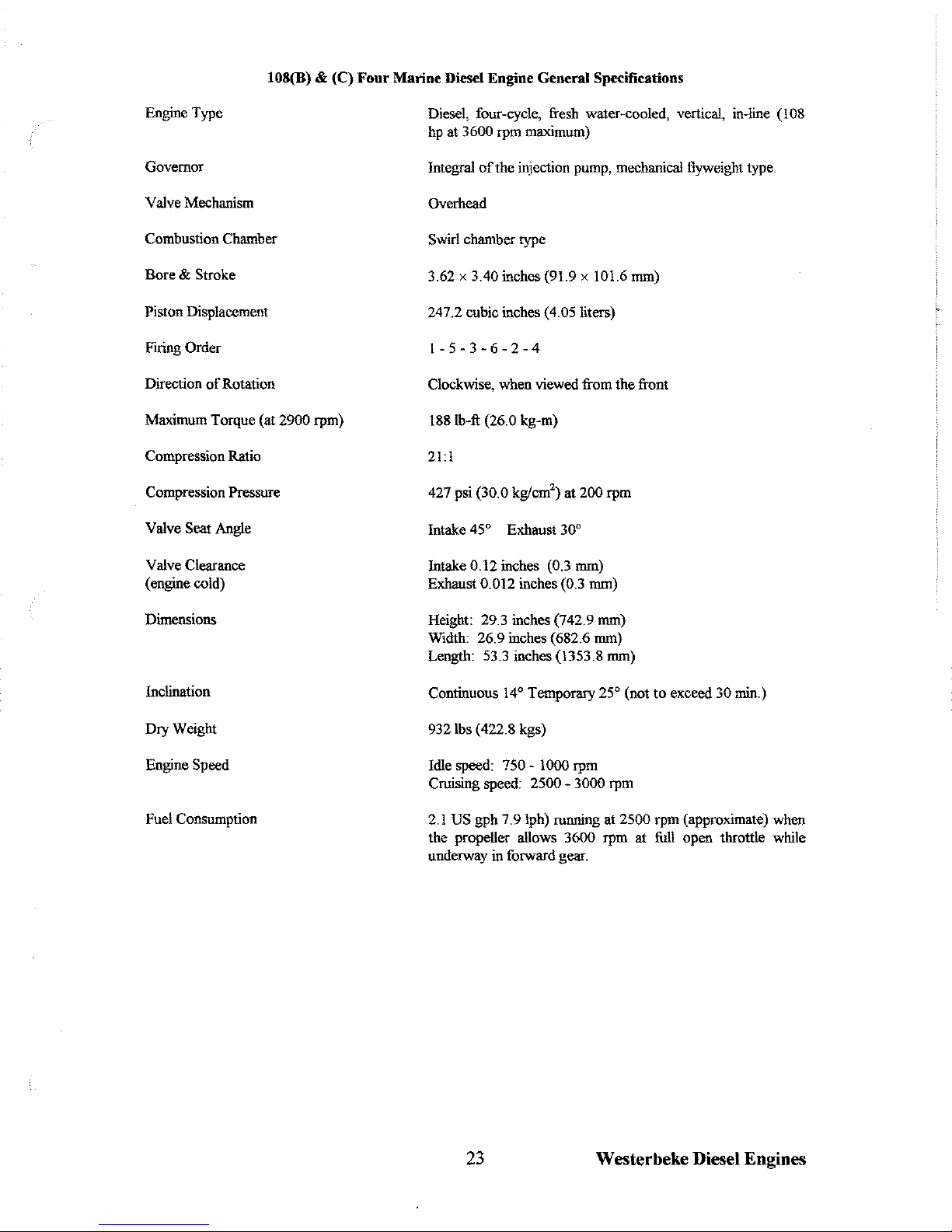

l08(B)

& (C) Four Marine Diesel Engine General Specifications

Engine Type

Governor

Valve Mechanism

Combustion Chamber

Bore

& Stroke

Piston Displacement

Firing Order

Direction

of

Rotation

Maximum Torque (at

2900 rpm)

Compression Ratio

Compression Pressure

Valve Seat Angle

Valve Clearance

(engine cold)

Dimensions

Inclination

Dry Weight

Engine Speed

Fuel Consumption

Diesel, four-cycle, fresh water-cooled, vertical, in-line

(108

hp at 3600 rpm maximum)

Integral

of

the injection pump, mechanical flyweight type.

Overhead

S~rlchambertype

3.62 x 3.40 inches (91.9 x 101.6 mm)

247.2 cubic inches (4.05 liters)

1-5-3-6-2-4

C1oc~se,

when viewed from the front

1881b-ft

(26.0 kg-m)

21:1

427 psi (30.0 kg/em') at 200 rpm

Intake

45° Exhaust 30°

Intake 0.12 inches (0.3 mm)

Exhaust

0.012 inches (0.3 mm)

Height: 29.3 inches (742.9 mm)

Width: 26.9 inches (682.6 mm)

Length: 53.3 inches (1353.8 mm)

Continuous

14° Temporary 25° (not

to

exceed 30 min.)

9321bs (422.8 kgs)

Idle speed:

750 - 1000 rpm

Cruising speed:

2500 - 3000 rpm

2.1

US

gph

7.91ph) running at 2500 rpm (approximate) when

the propeller allows

3600 rpm at full open throttle while

underway

in forward gear.

23

Westerbeke Diesel Engines

Page 30

l08(B)

& (C)

Four

Marine

Diesel Engine General Specifications

(Continued)

Fuel

System

Fuel

Injection Pump

Injection Timing

Nozzle

Injection Pressure

Lift Pump

Fuel Filter (on engine)

Air Cleaner

Air Flow (engine combustion)

(engine cooling)

Cooling

System

General

Operating Temperature

Fresh Water Pump

Sea Water Pump

No.2

diesel oil (cetane rating

of

45

or higher)

Diesel KIKI Mechanical Governed

oomc

Throttle type

1920 psi (135 kg/cm')

12

volt plunger type

Spin-on (replaceable)

Metal screen type-cleaner

257 cfm (7.9 cmm) at 3600 rpm

250 cfm (7.0 cmm)

Fresh water-cooled block, thermostatically-controlled with

sea water exchanger system.

170

- 190° F (77 - 88° C)

Centrifugal type, metal impeller, belt-driven

Positive displacement, rubber impeller, gear-driven

Sea Water Flow, at 3600 rpm 14.0 gpm

(53

lpm) approximate

(measured before discharging into

exhaust elbow)

System Capacity (fresh water)

Lubrication

System

General

Oil Filter

Sump Capacity

Operating

Oil Pressure

Oil Grade

Westerbeke Diesel Engines

16

U.S. qts. (15.1 liters)

Pressure feed, rotor type, driven

by

spiral gears from

camshaft

Full flow, paper element, spin-on type

11.9

U.S. qts. (11.3 liters) not including filter

30 - 60 psi

(2.1

- 4.2 (135 kg/cm') at maximum engine rpm

and at normal operating temperature.

API specification

CC

or

CD

24

Page 31

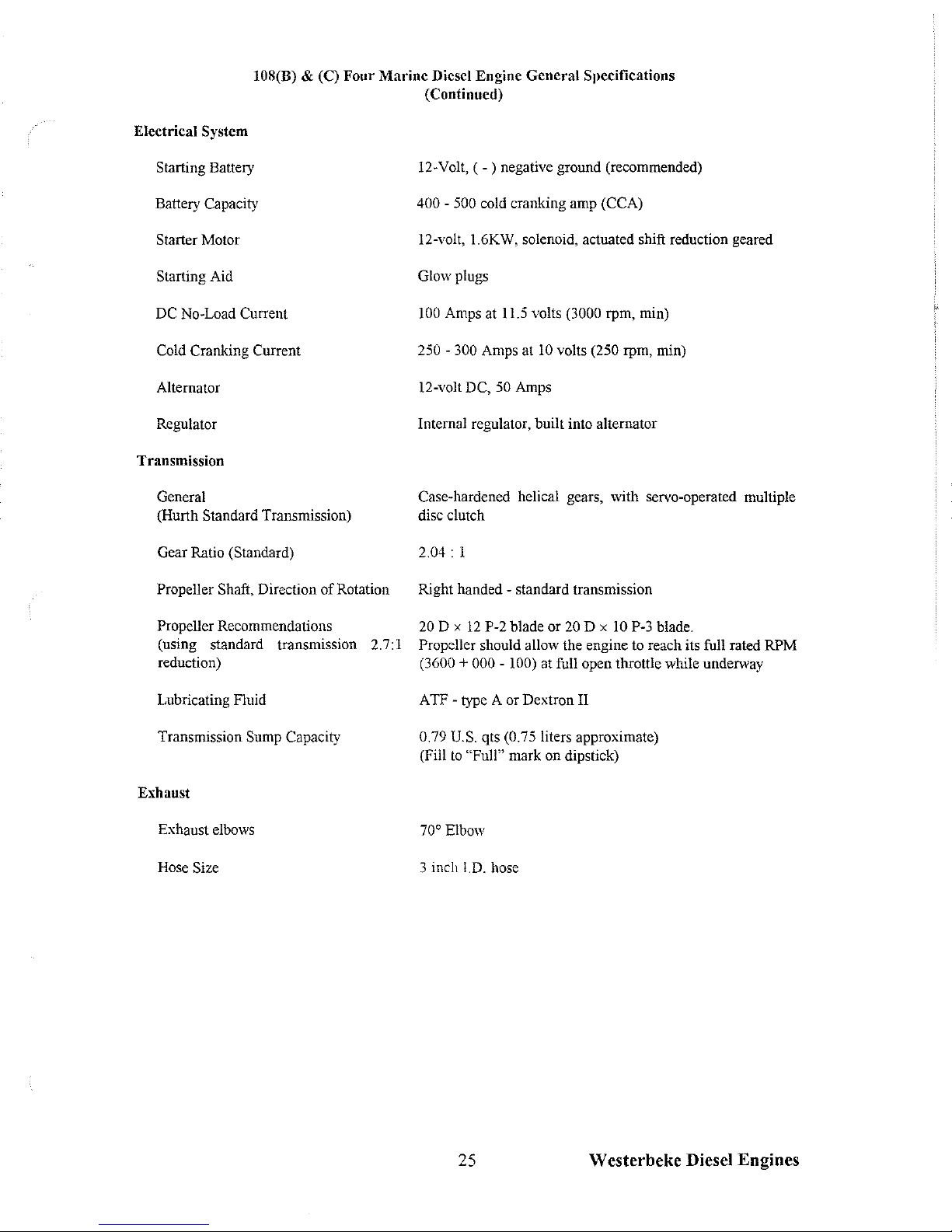

l08(B) & (C)

Four

Marine

Diesel Engine

General

Specifications

(Continued)

Electrical

System

Starting

Battery

Battery Capacity

Starter Motor

Starting Aid

DC No-Load Current

Cold Cranking Current

Alternator

Regulator

Transmission

General

(Hurth

Standard Transmission)

Gear Ratio

(Standard)

Propeller Shaft,

Direction

of

Rotation

Propeller Recommendations

(using standard transmission 2.7:1

reduction)

Lubricating Fluid

Transmission

Sump Capacity

Exhaust

Exhaust elbows

Hose

Size

12-

Volt, ( - ) negative ground (recommended)

400 - 500 cold cranking amp (CCA)

12-volt, 1.6KW, solenoid, actuated shift reduction geared

Glow plugs

100 Amps at

11.5 volts (3000 rpm, min)

250

- 300 Amps at

10

volts (250 rpm, min)

12-volt DC,

50 Amps

Internal regulator, built into alternator

Case-hardened helical gears, with servo-operated multiple

disc clutch

2.04:

I

Right handed

- standard transmission

20 D x

12

P-2 blade or

20

D x 10 P-3 blade.

Propeller should allow the engine to reach its full rated RPM

(3600 + 000 - 100) at full open throttle while underway

A

TF

- type A or Dextron II

0.79

U.S. qts (0.75 liters approximate)

(Fill

to

"Full" mark on dipstick)

70'

Elbow

3 inch

I.D.

hose

25 Westerbeke Diesel Engines

Page 32

NOTES

26

Westerbeke Diesel Engines

Page 33

INSTALLATIONS and INSTALLATION CHECKS

General

Since the boats

in

which Westerbeke engines

are

installed vary

in

design, installation procedures

will vary according to your craft's specific design.

The

intent

of

this section

is

not to advise

boatyards or installers on procedures already well-developed

and

well-understood. However, the

owner/operator must

realize

there

are

details

of

the installation which require periodic checks

to ensure the best operating

condITions

for the equipment

and

safe operating conditions for

the personnel on board. Proper location

and

installation of the diesel engine

in

the

vessel

are

of prime importance.

Factors

in

the installation that must

be

considered

are;

(1)

ventilation, to

aid

in

cooling

and

to

provide air for engine combustion,

(2)

the

exhaust

system,

to properly discharge

raw

cooling

water, to guiet the exhaust

and

to

expel

exhaust

gas,

(3)

the cooling water supply,

(4)

the

fuel supply,

(5)

the electrical connections

and

(6)

the

transmission/propeller connections.

I

CAUTIoN

I

For safety

reasons,

the engine

is

not filled with lubricating

oil

for shipment. Before leav-

ing the factory, however,

each

engine

and

transmission

is

thoroughly tested with oil.

This

testing, among other things, provides

all

internal

parts

with a coating

of

oil.

This

oil

acts

as

a preservative, providing reliable protection against corrosion for at least one year

if

the engine

and

transmission

is

properly stored.

Inspection

of

Equipment

The

engine

is

shipped from the factory securely mounted

and

properly crated. Accessory

equipment

is

shipped

in

a separate

small

box,

usually packed within the engine's crate.

Before accepting shipment

of

the

engine from the transportation company, the crate should

be

opened and

the

contents inspected for concealed

damage.

If

eITher

visible or concealed damage

is

noted, you should require

the

delivery agent

sign

"Received

in

damaged

condITion"

on

the

proper delivery receipt. Also check

the

contents

of

the

shipment against the packing list and

make

sure that the proper notation

is

made

if

any

discrepancies exist.

These

noted discrepancies

are

your protection against loss or

damage.

Claims concerning loss or damage must

be

made

to the

carrier, not to Westerbeke Corporation.

Please

note that the engine's installation angle cannot exceed

14'

from the horiziontal

plane.

Rigging and Lifting

The

engine

is

fitted with lifting

eyes.

Rope

or chain slings capable of supporting the engine's

weight should

be

attached to

the

eyes

and

the engine lifted by means of tackle attached

to

these slings.

The

lifting

eyes

have

been

designed

to

carry the

full

weight of the engine; therefore,

auxiliary

slings

are

not required or desired.

Westerbeke Diesel Engines

27

Page 34

!CAUTION

I

Slings must not

be

so

short

as

to place significant stress on the engine's

lifting

eyes.

Strain placed

on

the engine's lifting

eyes

by

the lifting sling

must not

be

in

excess of

10'

from the vertical

plane.

The

general

rule

in

moving engines

is

to

see

that

all

equipment

used

is

amply strong

and

firmly fixed in

place.

Move

the engine a little at a time

and

see

that it

is

firmly supported.

Eliminate the possibility of accidents by avoiding

haste.

Do not lift the engine by

its

crankshaft

pulley.

In

certain situations

it

may

be

necessary to lift the engine

in

positions other than the horizontal

position. Certain situations exist by which the engine must be lowered endwise through a

small

hatchway which cannot be made larger.

Under these conditions,

if the opening

of

the hatchway

is

extremely

small,

it

is

possible

to reduce,

to

some

extent,

the outside dimen-

10'

sions

of

the engine by removing

external

components such

as

the cooling system's

piping, the heat exchanger, certain filters,

the mounting rails

and

other obstructive

equipment. This

accessory

equipment

should

be

removed

by a competent

mechanic and special care should

be

taken

to avoid damage to any exposed parts.

In

addition, be careful not

to

allow dirt to enter

any

opening created by the

removal

of

equipment. Removed parts should be

returned

to

their respective position once

the engine

is

in

its installation

area.

Replace

gaskets

as

needed for the parts that

were

removed.

ENGINE

SLING

LIFT

ING

ANGLE

MUST

NOT

EXCEED

10'

LIFTING

EYE

In

case

it

becomes necessary to hoist

the

engine front-end upwards or transmission-end upwards,

the attachment

of

lifting slings must

be

done carefullv to avoid the possibility of damaging

the

parts

on

which the weight of the slings

may

bear.

Special rigging work

is

best done

by

someone

experienced

and

competent

in

handling

heavy

machinery.

Engine

Bolts

Bronze or stainless

steel

hanger bolts of appropriate size

are

recommended for

use

through

the engine's flexible mounts.

Less

preferred

are

lag screws because their hold on the wood

is

weakened every time they

are

moved, whereas the hanger bolts stay

in

position.

If

the

nut

on

top

of

the hanger bolt

is

removed to allow the engine to

be

lifted from

its

resting place, the

hanger

bolt itself

remains

in

place

as a stud.

Consequently, the bond between the hanger bolt

and

the wood or fiberglass

is

not

weakened

by the removal of the nut or the engine.

28 Westerbeke Diesel Engines

Page 35

Foundation for the Engine

A good engine

bed

contributes much toward the satisfactory operation

of

the

engine.

The

engine's

bed

must

be

rigidly constructed

and

neither deflect nor twist when

it

is

subjected to

the engine's weight or to the pressures that the boat may experience while operating

in

rough

seas.

The

bed

must keep the engine's alignment within one or two thousandths

of

an

inch

of

this position at

all

times.

The

bed

has

to withstand the forward

push

of

the

propeller

shaft

which pushes against the thrust washer bearing which finally pushes against the engine's bolts

and

bed.

In

fiberglass

hulls,

we

recommend that similar

wooden stringers

as

in

wooden hulls

be

formed

and

fitted, then glassed securely to

the

hull.

This

allows the hanger bolts to

be

installed firmly

in

the wood, thereby reducing

noise

and

transmitted vibration.

The

engine support stringers

must

be

as

wide or wider than the engine mounting

isolator.

Isolator overhang and/or rounded

stringer surfaces are detrimental to the

isolators' ability

to

retain vibration.

Preformed fiberglass engine

beds,

when

used,

should

be

of

sufficient thickness to properly

support the engine and should

be

well-

glassed

to the hull when installed.

GOOD

A

BAD

B

Avoid excessive height,

use

solid

The

temptation to install the engine

on

a pair stringer construction

(A).

of fiberglass angle irons must

be

resisted.

Such

construction will allow engine vibration

to

pass

through to

the

hUll.

Flexible mounts

require a firm foundation against which they must act

if

they

are

to

perform their function.

When

possible, follow

bed

design A

and

avoid

bed

design B (refer

to

the illustration).

Supports

between

the

bed

stringers, and extending from the stringers to the

hull,

may

be

required for proper support

and

to

aid

in

the absorption

of

vibrations.

Propeller Shaft Coupling

The

propeller shaft coupling fitted to the transmission's output flange must transmit not only

the

power of the engine

to

turn

the

propeller shaft and propeller, but must also transmit

the

thrust

of

the engine/transmission either

ahead

or astern.

The

coupling should be carefully machined for a slight forced fit onto the shaft

and

an

accurate

mating surface for

the

coupling to the output flange of the transmission.

For

all

engine models, a propeller half-coupling, bored to shaft

size

for the specific order,

is

supplied.

The

coupling either

has

a keyway with

set

screws or

is

of the clamping type.

29

Westerbeke Diesel Engines

Page 36

The

forward

end

of the propeller shaft

has

a long straight

keyway.

Any burrs should

be

removed

from the shaft's

end.

The

coupling should

be

a light drive fit

on

the shaft

and

the shaft should

not

have

to

be scraped down or filed

in

order

to

get a

fit.

It

is

important that the

key

be

properly fitted both

to

the shaft

and

to

the coupling.

The

key

should

Itt

the side of the keyway

closely, but should not touch the top of the keyway

in

the

hub of the coupling.

If

driving the coupling over the shaft

is

difficult,

the

coupling

can

be

expanded by heating it

in a pail

of boiling

water.

The face

of

the propeller coupling must

be

exactly perpendicular to

the centerline or axis of the

propeller shaft.

Propeller

The

type and

size

of propeller varies with the gear ratio

and

must

be

selected to fit the

application, based upon boat tests. To utilize the

full

power

of

the

engine,

and

to achieve ideal

loading conditions,

use

a propeller which will permit the engine to

reach

its

full

rated

RPM

at

full

throttle while under a normal load and while

it

is

moving the boat forward through the

water.

Alignment

of

the Engine

The

engine must be exactly aligned with the propeller shaft

in

the proper fashion. No matter

what material

is

used

to build a boat the material will

be

found to

be

flexible to some extent;

hence,

the boat's hull will change

its

shape to a greater extent than

is

usually realized when

the boat

is

launched

and

operated

in

the

water.

Therefore, it becomes extremely important to

check the engine's

alignment at frequent intervals and to correct any errors

when

they appear.

Misalignment between the engine

and

the propeller shaft often creates serious problems which

are

often blamed on other areas suspected

of

causing

the

trouble. Misalignment will

cause

excessive bearing

wear,

rapid shaft wear and

will,

in

many

cases,

reduce the life of the boat's

hull

by loosening the hull's fastenings. A bent propeller

shaft

will

have

the exact effect

as

those

just stated; therefore, a perfectly straight

propeller shaft

is

absolutely necessary. One particularly

annoying result of

misalignment

may

be

leakage of transmission

oil

through the transmission's

rear

oil

seal.

If

oil

is

leaking from this

seal,

check

and

make

sure

that the alignment

is

within

the limits prescribed below.

Never attempt a final

alignment with the boat on land.

The

boat should

be

in

the water and

have

had

an opportunity to assume

its

final water form.

The

best time to perform the propeller

shaft/transmission coupling alignment

is

with the

fuel

and

water tanks about half

full

and

all

the

usual

equipment on board,

and

after the

main

mast

has

been

stepped

and

the final rigging

has

been

accomplished.

Take

plenty of time

in

making this alignment

and

do not

be

satisfied with anything less than

perfect results.

Westerbeke Diesel Engines

30

Page 37

The

alignment

is

correct when

the

shaft

can

be

easily slipped backward and forward into

the counterbore,

and

when

a

feeler

gauge

indicates that the flanges come together at

all

points.

The

alignment between the propeller

shaft

coupling

and

the engine's coupling

can

contain

an

error no greater than one thousandth

of

an

inch per inch of the coupling diameter.

For

example,

"\

.993

FEELER

GAGE

"

PROPELLER

\

""

h

~

l

.......

-'

ISTRAIGHT

EOGEI

if your propeller shaft coupling

is

three inches

in

diameter, the maximum error that

can

be

allowed

in

the alignment

is

three thousandths

of

an

inch

(.003).

Engine -Propeller Alignment

In

making the

final

check for alignment, the

engine's

half coupling should

be

held

in

one

position

and

the alignment with the propeller

coupling tested with the propeller coupling

in

each

of four positions

(A),

while rotated

go'

between

each

position.

This

test will also check

whether the propeller's

half-coupling

is

in

exact

alignment on its shaft. Then, keeping the

propeller

coupling

in

one position, the alignment

should

be

checked by rotating the engine's

half-coupling

in

go'

increments, checking dimen-

sion A while

in

each

go'

position until the

half-coupling

has

been

rotated full circle.

The

engine's alignment should

be

rechecked

after the boat

has

been

in

service for

one

to

three weeks

and,

if

necessary, perform the Alignment Testing

alignment again. Usually it will

be

found that

A

SHAFT

the engine

is

no longer

in

alignment.

This

does not

mean

that the work

has

been

done

improperly at first;

rather,

it

means

that the boat

has

taken

some time to take

its

final

shape

and

that the engine's

bed

and

stringers

have

probably absorbed some moisture.

It

may

even

be

necessary to realign the coupling

halves

again at a later time.

Fuel System

The

fuel

system

should

be

installed

in

such a manner

as

to

allow the engine-mounted

fuel

pump to maintain a positive inlet

pressure

to the injection pump under

all

operating conditions.

The

minimum

size

of the

fuel

supply line

and

fuel

return line

is

1/4 inch, inside diameter,

and

there should

be

a primary

fuel

filter installed

between

the fuel tank

and

the

fuel

pump. Only

one

fuel filter

is

installed

on

the

engine,

between

the

fuel

pump

and

the injection pump; this

filter

has

a replaceable filter

element.

The

fuel tank's

fuel

pickup tube should

be

clear and unobstructed. No screens or

gauze

strainers should

be

incorporated

in

the

fuel

pickup tube.

31

Westerbeke Diesel Engines

Page 38

Make

sure that the

fuel

supply

and

return lines are securely anchored to prevent chafing

and

that

all

fittings

are

sufficiently tightened to prevent leaking.

Also,

Make

sure

your

fuel

system

has

a positive shut-off

valve;

know

its

location

and

how it operates.

Ventilation

The

ventilation requirements

of

the engine include the following: combustion air

is

required for

the engine cylinders;

cooling air

is

required for the engine and also for removing the heat

produced during operation;

and

ventilating air

is

required to clear the bilges,

as

well

as

the

compartment

in

which the engine

is

located, of potentially toxic

and

flammable diesel vapors.

Keep

in

mind that hot air

rises,

so

heated

air should

be

removed from the upper

area

of the

engine compartment

and

cool

fresh

air should

be

directed to

the

lower areas

of

the compartment.

Ventilation

should

be

accomplished with the

aid

of blowers especially when the

vessel

is

not

underway.

NOTE:

DO

NOT

use

spring-loaded check

valves

in

the fuel supply line

in

lieu

of

mechani-

cal

shut-off

valves.

This

type

valve

can

create

fuel

starvation problems for the engine's fuel

system.

Fuel

tanks that are located below

the

engine's

fuel

system

level

~

have

their

fuel

return

connection at the tank extending down into

the

tank

in

the

same

manner

as

the pickup tube;

otherwise, air

will

replace fuel siphoning out of the engine's fuel system through the return.

CABIN

COCKPIT

_

___

_

__

-=,14~:.:!CA~x=-.

--=::::"..

HORXZONTAL

PLANE

XNSTRLLATXON

RNGLE

MUST

NOT

EXCEE:D

.1.4'

Please

note that the engine's installation

angle cannot exceed

14'

from the horizontal

Engine Mounting Angle

Make

sure

the

fuel

tank filler

is

property

sealed

to prevent water entry should it become

awash.

The

fuel

tank's vent should

be

routed

so

as

to prevent water entry

as

well.

Be

sure

there

is

a fire extinguisher installed near the unit and that it

is

property maintained.

Be

familiar with its

use.

An

extinguisher with

the

NFPA

rating of

ABC

·is

appropriate for

all

applications

in

this environment.

Westerbeke Diesel Engines

32

Page 39

Oil Drain Hose

An

oil

sump drain hose

is

installed on

the

engine with the discharge

end

secured

by

a bracket

at the front

of

the

engine.

Oil

may

be

drained from this hose by removing the

cap

and

the

discharge

end

of the hose from the support bracket and lowering the hose into a container.The

hose cap fitting

is

1/4 inch

NPT

(National

Pipe

Tap)

and

can

be

extended, or

have

a pump

added, for easier

removal

of the old

oil,

if

desired.

Connecting Pressure

Sensing Devices

to

Oil Galleries

Oil

pressure

sensing

devices, such

as

senders and switches, must not

be

connected to

an

engine's

oil

gallery with the

use

of

extended nipples or

tees.

The

reason

is

simply that continued

engine vibration

causes

fatigue of the fittings

used

to make such a connection. If these fittings

fail

during

engine

operation, lubricating oil will

be

lost

and

internal engine damage

will

result.

When

additional

sensing

devices such

as

switches or sensors

need

to

be

installed that function

on engine oil

pressure,

these devices

~

be

bulkhead-mounted

and

connected to the

oil

gallery using

an

appropriate grade of lubricating oil

hose.

Any fittings

used

to connect

the

hose to the gallery

~

be

of

steel

or malleable iron composition.

Brass

must not

be

used

for this application.

Electrical System

The

electrical

system

should

be

checked

to

make

sure

all

wIring harnesses

are

tied down

properly with clamps or plastic ties, spaced at intervals

close enough to prevent chafing from

vibration. Check to

make

sure

all

the engine's harness connections

are

tight

and

that they

are

made to the appropriate terminals.

I

WARNING

I

Do Not Smoke Near Batteries!

Do

not smoke or allow

an

open flame near the batteries.

Lead

acid

batteries emit hydrogen, a highly-explosive

gas.

Turn off the emergency

switch

in

the battery's positive line.

Make

sure the positive

(+)

battery connection

is

connected to the battery connection

of

the

starting solenoid.

The

negative

(-)

battery connection should

be

connected to the system ground

(engine

block).

I

WARNING

I

Protect Yourself When Servicing The Battery

When

servicing the battery or checking electrolyte

level,

wear rubber

gloves,

a rubber apron,

and

eye

protection. Battery acid may splash

on the skin or into the

eyes

inadvertently when removing electrolyte

caps.

Check

level

and

specific gravity of battery electrolyte to ensure maximum engine starting

efficiency.

Make

sure

terminals

are

clean

and

tight.

33

Westerbeke Diesel Engines

Page 40

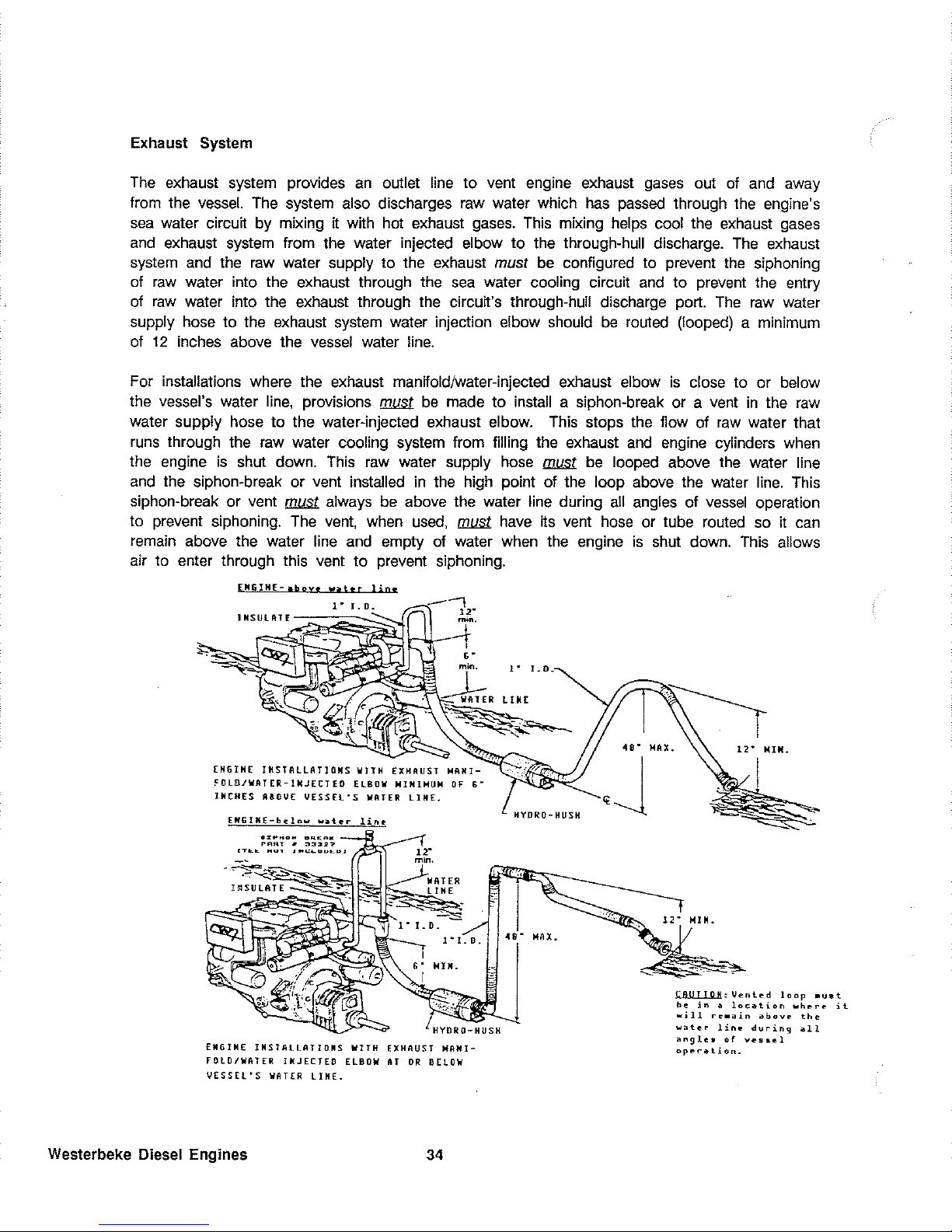

Exhaust System

The

exhaust system provides

an

outlet line to vent engine exhaust

gases

out

of

and

away

from the

vessel.

The

system also discharges

raw

water which

has

passed

through

the

engine's

sea

water circuit

by

mixing

IT

with hot exhaust

gases.

This

mixing helps cool the exhaust

gases

and

exhaust system from the water injected elbow to the through-hull discharge.

The

exhaust

system

and the

raw

water supply to the exhaust must

be

configured to prevent

the

siphoning

of

raw

water into the exhaust through the

sea

water cooling circuit

and

to prevent the entry

of

raw

water into the exhaust through the

circuIT's

through-hull discharge port.

The

raw

water

supply hose to the exhaust system water injection elbow should

be

routed (looped) a minimum

of

12

inches above the

vessel

water line.

For installations where the exhaust manifold/water-injected exhaust elbow

is

close to or below

the vessel's water

line,

provisions

~

be

made to install a siphon-break or a vent

in

the

raw

water supply hose to the water-injected exhaust elbow.

This

stops the flow of

raw

water that

runs

through the

raw

water cooling system from filling the exhaust

and

engine cylinders when

the engine

is

shut down.

This

raw

water supply

hose

~

be

looped above

the

water line

and

the siphon-break or vent installed in the high point of the loop above the water

line.

This

siphon-break or vent

~

always

be

above the water line during

all

angles of

vessel

operation

to prevent siphoning.

The

vent,

when

used,

~

have

ITS

vent

hose

or tube routed so

it

can

remain

above the water line

and

empty of water when the engine

is

shut down.

This

allows

air to enter through this vent to prevent siphoning.

ENGINE-aboy.

wattr

lin«

1"'

I.

D.

INSULATE

ENGINE

INSTALLATIONS

WITH

EXHAUST

~ANI

~OlOJWAT[R-INJ[CTED

ELBOW

~IHIHU~

OF

G-

INCHES

ABOVE

VESSEL'S

WATER

LINE.

EHGI"(-b~low

w~t,r

..

r"HO

......

"'

....

!'flRT " :13327

WATER

LIKE

HYDRO-HUSH

EN61NE INSTALLATIONS

WITH

EXHAUST

MANI-

FOLD/WATER

INJECTED

ELBOW

AT

OR

BELOW

VESSEL'S

WATER

LINE.

Westerbeke Diesel Engines

34

HYDRO-HUSH