Page 1

OPERATORS

MANUAL

WESTERBEKE

MARINE

DIESEL

55A

PUBLICATION 041562

2nd Edition

ENGINE

FOUR

I February 1997

l~

----

'WESTERBEKE

WESTERBEKE CORPORATION

~

MYLES STANDISH INDUSTRIAL

WEBSITE:

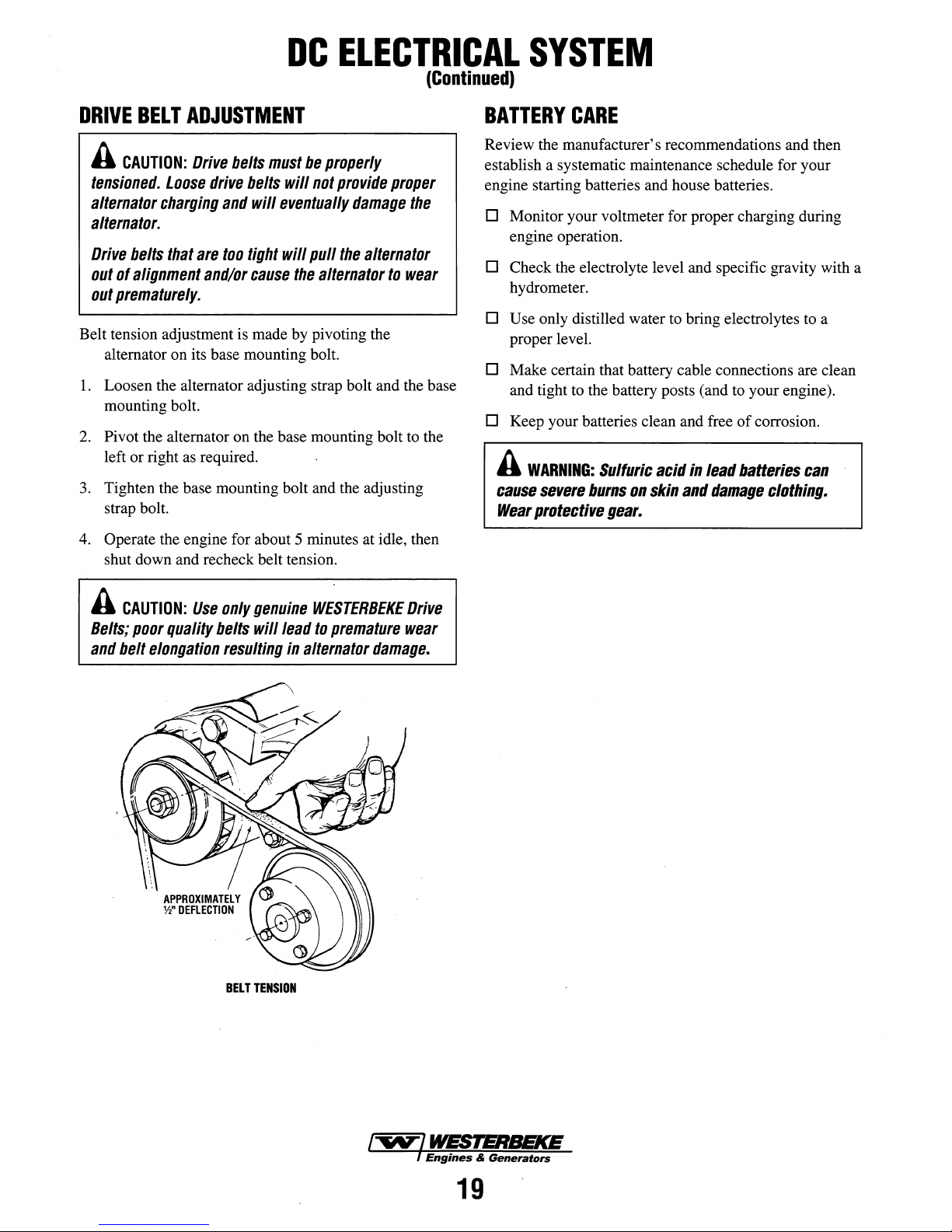

AlMMA

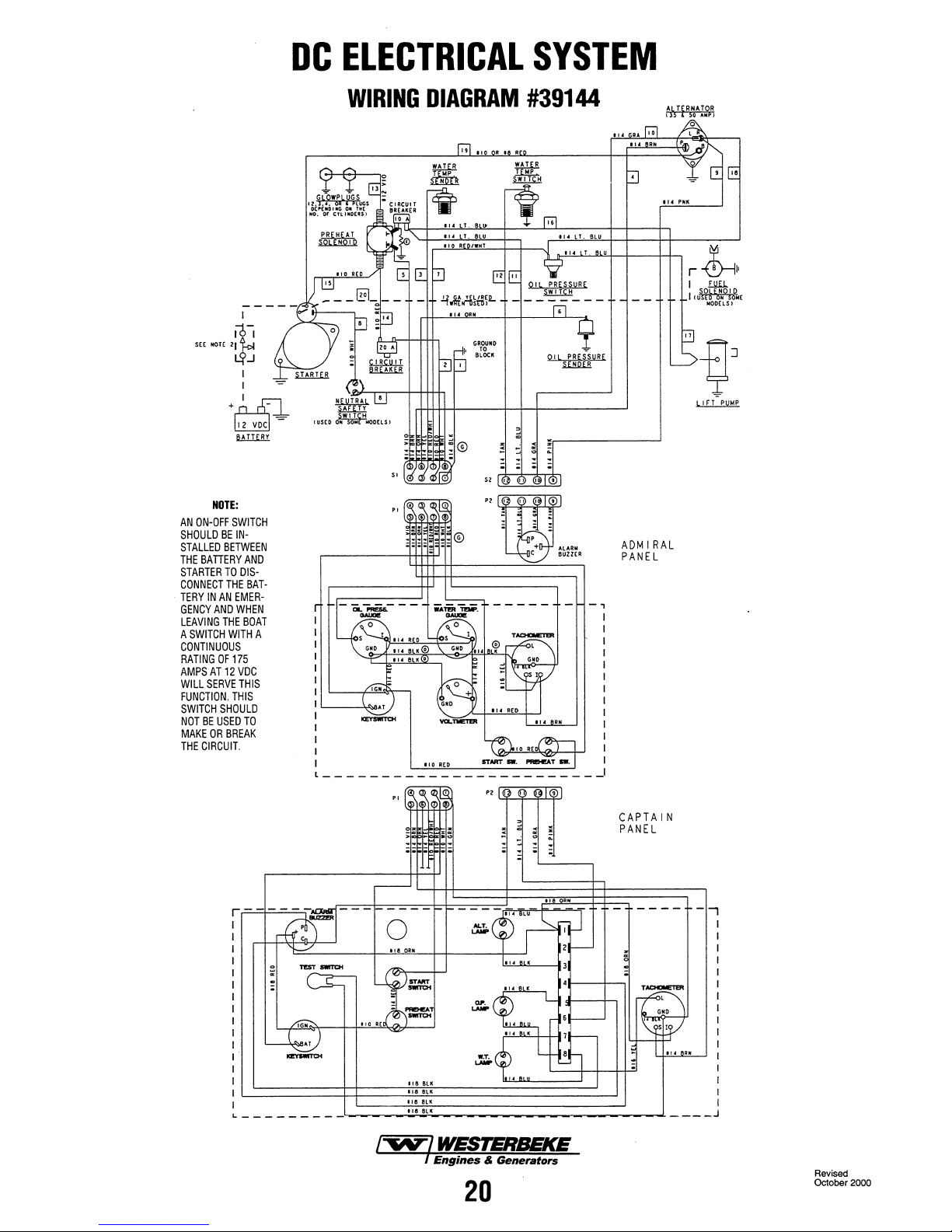

""'''''''''''-

www.WESTERBEKE.COM

Member

National

Marine

·150

JOHN

PARK·

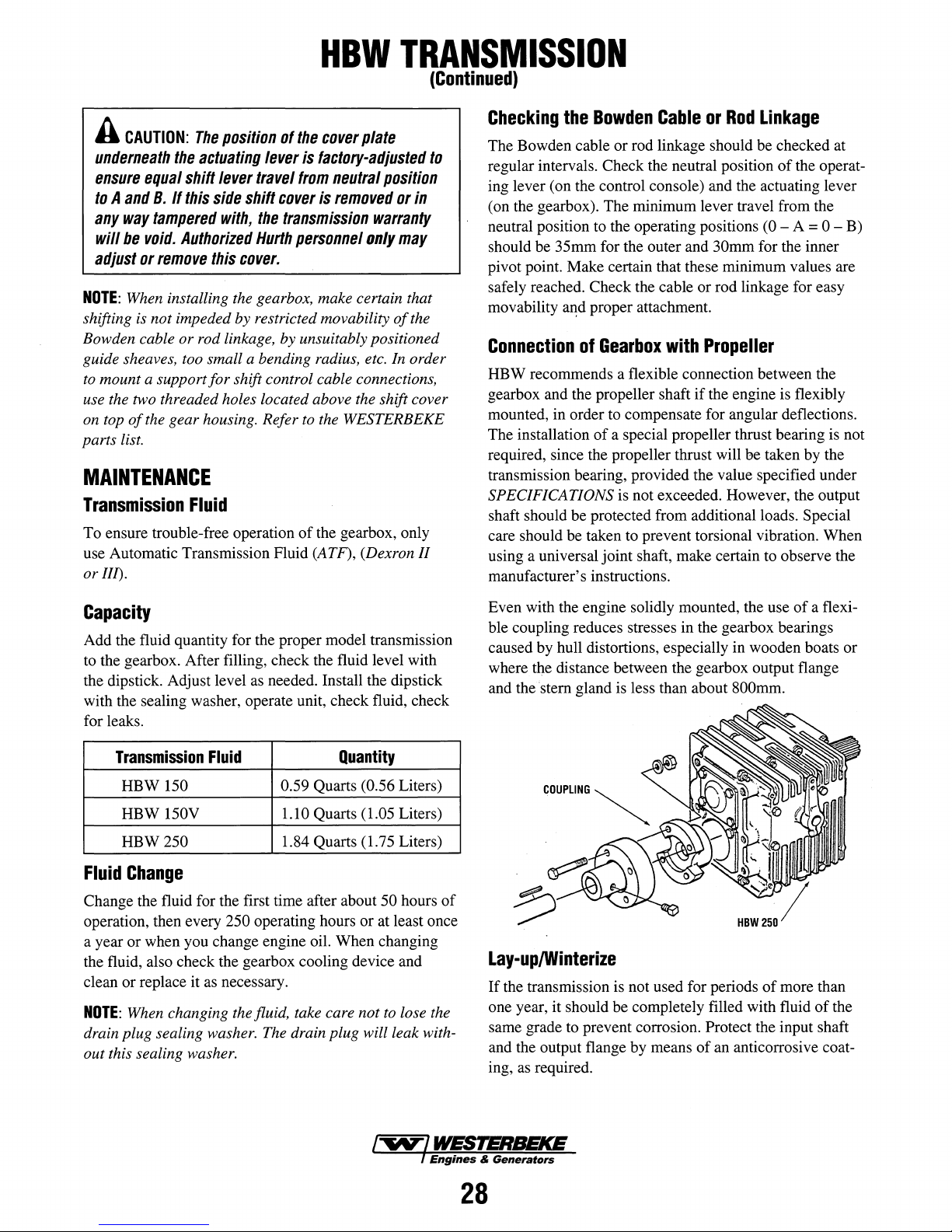

Manufacturers

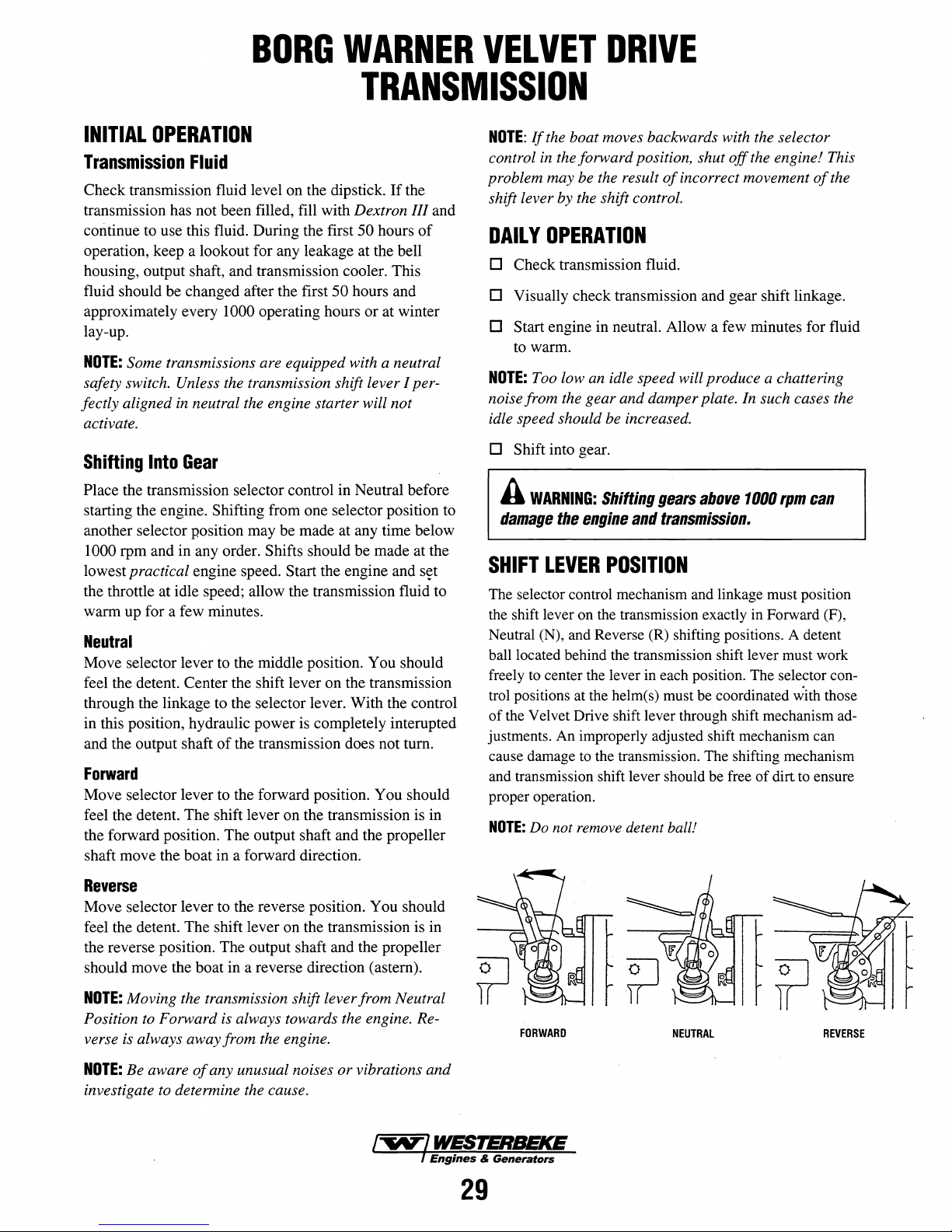

HANCOCK ROAD

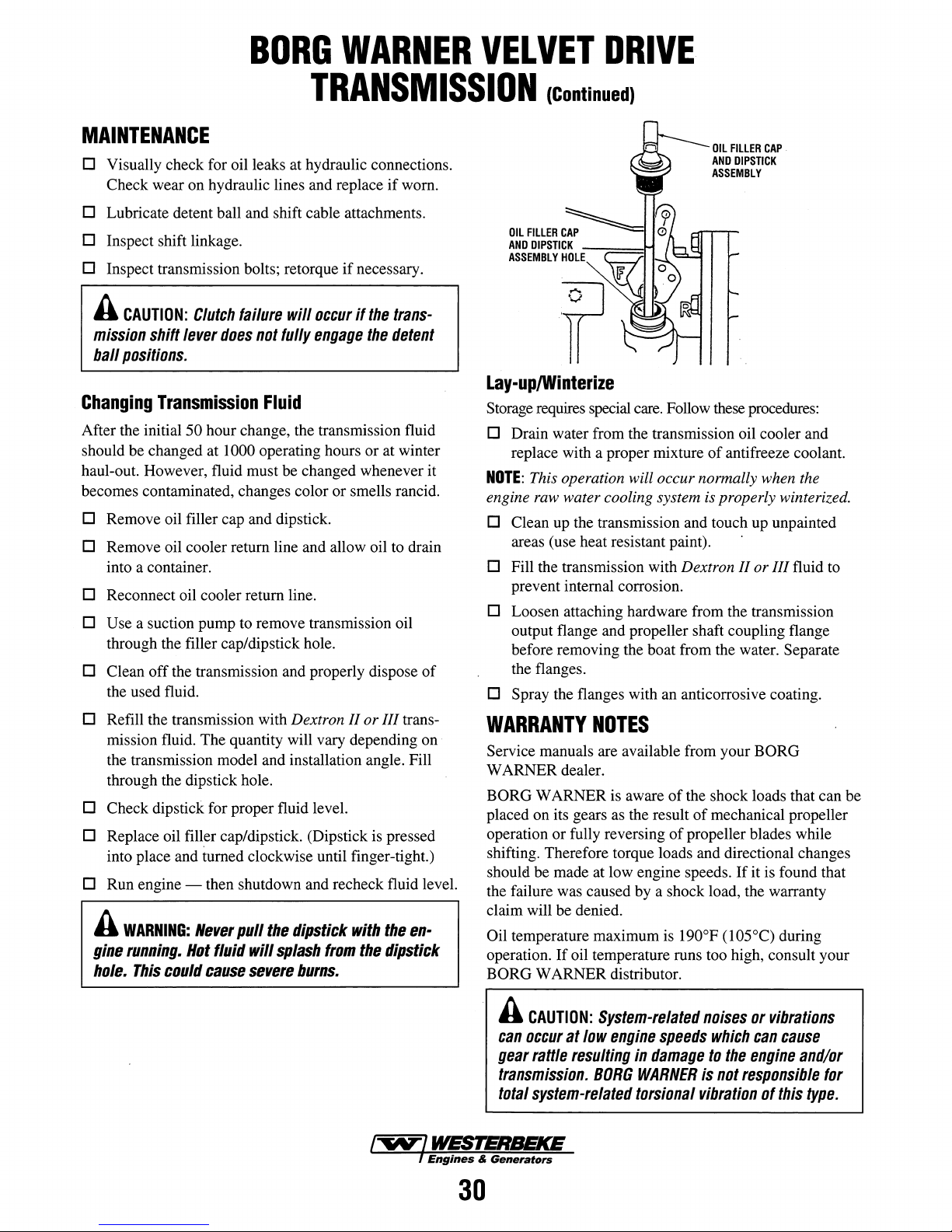

TAUNTON, MA 02780

Association

Page 2

CALIFORNIA

Proposition

65

Warning

Diesel engine exhaust and some

of

its

constituents are known

the State

of

California

to

to

cause

cancer, birth defects, and other

reproductive harm.

I~I

I

WESJ"ERBEKE

Engines & Generators

Page 3

SAFETY

INSTRUCTIONS

INTRODUCTION

Read this safety manual carefully. Most accidents are caused

by

failure

Know when dangerous conditions exist

necessary precautions to protect yourself,

and

The foUowing safety instructions are

the American

PREVENT

A

while

power.

• Do not operate this machinery without electrical

• Shut off electrical power before accessing electrical

• Use insulated mats whenever working on electrical

• Make sure your clothing and skin are dry, not damp

• Remove wristwatch and all jewelry when working on

• Do not connect utility shore power to vessel's

• Electrical shock results from handling a charged capacitor.

PREVENT

A

exhaust

very

• Always check the engine coolant level at the coolant

A

• In case

to

foUow fundamental rules

your

machinery.

Boat

and

Yacht Council (ABYC) standards.

ELECTRIC

WARNING:

engine

is

Lethal

voltage

enclosures and covers in place.

equipment.

equipment.

(particularly shoes) when handling electrical equipment.

electrical equipment.

circuits, except through a ship-to-shore double throw

transfer switch. Damage to vessel's

result

if

this procedure is not followed.

Discharge capacitor by shorting terminals together.

BURNS -HOT

WARNING:

system

SHOCK

Do

not

touch

running,

or

is

present

when

ENGINE

Do

not

touch

components. A running

and

in

AC

electrical

connected

at

these

AC

hot

engine

precautions.

and

take the

your

personne~

compliance with

connections

to

shore

connections!

AC

generator may

parts

or

engine

gets

hot!

recovery tank.

WARNING:

of

before touching the engine or checking the coolant.

Steam

can

cause

injury

or

death!

an engine overheat, allow the engine to cool

PREVENT

A

• Prevent flash fires. Do not smoke

sparks to occur near the carburetor, fuel line, filter, fuel

pump,

vapors.

removing the fuel line, carburetor,

• Do not operate with a Coast Guard Approved flame

arrester removed. Backfire can cause severe injury

death.

• Do not operate with the air cleaner/silencer removed.

Backfire can cause severe injury

• Do not smoke

fuel system. Keep the compartment and the engine/gener-

ator clean and free

fire. Wipe up all spilled fuel and engine oil.

• Be aware - diesel fuel will bum.

PREVENT

A

injury

• Follow re-fueling safety instructions. Keep the vessel's

hatches closed when fueling.

after fueling. Check below for fumes/vapor before running

the blower. Run the blower for four minutes before start-

ing your engine.

• All fuel vapors are highly explosive. Use extreme care when

handling and storing fuels.

area away from spark-producing equipment and out

reach

• Do not fill the fuel tank(s) while the engine is running.

• Shut off the fuel service valve at the engine when servicing

the fuel system. Take care in catching any fuel that might

spill.

sources

Ensure proper ventilation exists when servicing the fuel

system.

• Do not alter

• Be sure all fuel supplies have a positive shutoff valve.

• Be certain fuel line fittings are adequately tightened and

free

• Make sure a fire extinguisher is installed nearby and is

properly maintained. Be familiar with its proper use.

Extinguishers rated

for all applications encountered in this environment.

BURNS -FIRE

WARNING:

or

Use a suitable container to catch all fuel when

Fire

can

cause

other potential sources

or

permit flames

of

debris to minimize the chances

injury or

or

of

or

or

death!

permit flames

spilled fuel

or

fuel filters.

death.

sparks to occur near the

BURNS -EXPLOSION

WARNING:

or

death!

of

children.

DO

of

of

leaks.

Explosions

NOT

allow any smoking, open flames,

fire near the fuel system or engine when servicing.

or

modify the fuel system.

ABC

from

fuel

vapors

Open and ventilate cabin

Store fuel in a well-ventilated

by the NFPA are appropriate

or

can

or

fuel

or

of

cause

of

or

other

the

Engines & Generators

Page 4

SAFETY

INSTRUCTIONS

ACCIDENTAL

A

WARNING:

or

death!

• Disconnect the battery cables before servicing the engine/

generator. Remove the negative lead first and reconnect

it

last.

• Make certain all personnel are clear

starting.

• Make certain all covers, guards, and hatches are re-

installed before starting the engine.

BATTERY

A

WARNING:

or

death!

• Do not smoke or allow an open flame near the battery

being serviced. Lead acid batteries emit hydrogen, a

highly explosive gas, which can be ignited by electrical

arcing or by lit tobacco products. Shut off all electrical

equipment in the vicinity to prevent electrical arcing during

servicing.

• Never connect the negative

tive

(+) connection terminal

test the battery condition by shorting the terminals

together. Sparks could ignite battery gases

Ventilate any compartment containing batteries to prevent

accumulation

disturb the battery charger connections while the battery

being charged.

• Avoid contacting the terminals with tools, etc., to prevent

bums or sparks that could cause an explosion. Remove

wristwatch, rings, and any other jewelry before handling

the battery.

• Always tum the battery charger

the battery connections. Remove the negative lead first

and reconnect

BATTERY

A

WARNING:

severe

STARTING

Accidental

EXPLOSION

Battery

of

explosive gases. To avoid sparks, do not

it

last when servicing the battery.

ACID

Sulphuric

injury

or

death!

starting

explosion

(-)

of

acid

can

cause

of

the engine before

can

cause

battery cable to the posithe starter solenoid. Do not

or

off

before disconnecting

in

batteries

injury

injury

fuel vapors.

can

cause

TOXIC

• Ensure that the exhaust system

• Be sure the unit and its surroundings are well ventilated.

• In addition to routine inspection

• For additional information refer to ABYC T-22 (educa-

• Do not use copper tubing in diesel exhaust systems. Diesel

• Do not install exhaust outlet where exhaust can be drawn

is

• Although diesel engine exhaust gases are not as toxic as

AVOID

EXHAUST

A

WARNING:

discharged from the engine. Check the exhaust system

regularly for leaks and make sure the exhaust manifolds

are securely attached and no warping exists.

attention to the manifold, water injection elbow, and

exhaust pipe nipple. .

install a carbon monoxide detector. Consult your boat

or

builder

tional information on Carbon Monoxide).

A

WARNING:

odorless

nausea

gas.

or

death!

fumes can rapidly destroy copper tubing in exhaust systems. Exhaust sulfur causes rapid deterioration

tubing resulting in exhaust/water leakage.

through portholes, vents,

exhaust discharge outlet is near the waterline, water could

enter the exhaust discharge outlet and close or restrict the

of

flow

exhaust fumes from gasoline engines, carbon monoxide

gas is present

toms or signs

are:

exhaust. Avoid overloading the craft.

Vomiting

Dizziness

Throbbing

Muscular twitching

Intense headache

Weakness and sleepiness

MOVING

GASES

Carbon

dealer for installation

Carbon

Inhalation

in

diesel exhaust fumes. Some

of

carbon monoxide inhalation

in

produces

temples

monoxide

monoxide

or

air conditioners. If the engine

PARTS

(CO)

is a deadly

is

adequate to expel gases

Pay close

of

the exhaust system,

of

approved detectors.

(CO)

is

an

invisible

flu-like

symptoms,

of

copper

of

the symp-

or

poisoning

gas!

• When servicing the battery or checking the electrolyte

level, wear rubber gloves, a rubber apron, and eye protection. Batteries contain sulfuric acid which is destructive.

it comes in contact with your skin, wash it off at once

with water. Acid may splash on the skin

inadvertently when removing electrolyte caps.

or

into the eyes

A

WARNING:

If

Engines & Generators

or

death!

• Do not service the engine/generator while

situation arises

ii

Rotating

in

which it is absolutely necessary to make

parts

can

cause

it

injury

is running.

If

a

Page 5

SAFETY

INSTRUCTIONS

operating adjustments, use extreme care to avoid touching

moving parts and hot exhaust system components.

• Do not wear loose clothing

equipment; avoid wearing loose jackets, shirts, sleeves,

or

rings, necklaces

moving parts.

• Make sure all attaching hardware is properly tightened.

Keep protective shields and guards in their respective

places at all times.

• Do not check fluid levels or the drive belts' tension while

the engine/generator is operating.

• Stay clear

when the engine is running; hair and clothing can easily

be caught in these rotating parts.

of

HAZARDOUS

A

WARNING:

bracelets that could be caught

the drive shaft and the transmission coupling

NOISE

High

or

jewelry when servicing

noise

levels

can

cause

in

hearing

loss!

• Never operate a generator without its muffler installed.

• Do not run an engine with the air intake (silencer)

removed.

• Do not run engines

their enclosures open.

or

generators for long periods with

ABYC,

INSTALLING

NFPA

AND

GASOLINE

USCG

PUBLICATIONS

AND

DIESEL

FOR

ENGINES

AND

GENERATORS

Read the following ABYC, NFPA and USCG publications

for safety codes and standards. Follow their recommendations when installing your WESTERBEKE engine/generator.

ABYC

"Safety Standards for Small Craft"

Order

(American Boat and Yacht Council)

From:

ABYC

15 East 26th

New York, NY 10010

NFPA

(National Fire Protection Association)

"Fire Protection Standard for Motor Craft"

Order

From:

NFPA

1 Batterymarch Park

P.O. Box 9101

Quincy,

USCG

(United States Coast Guard)

"USCG 33CFR183"

From:

Order

U.S. Government Printing Office

Washington, D.C. 20404

~treet

MA

02269-9101

A

WARNING:

are

mentally

OPERATORS

Many

of

the preceding safety tips and warnings are repeated

in your Operators Manual along with other cautions and

notes to highlight critical information. Read your manual

carefully, maintain your equipment, and follow all safety

procedures.

GASOLINE

00

or

physically

MANUAL

ENGINE

AND

not

work

on

machinery

incapaCitated

GENERATOR

by

fatigue!

when

you

INSTALLATIONS

Preparations to install a gasoline engine or generator should

begin with a thorough examination

Yacht Council's (ABYC) standards. These standards are from

a combination

Sections

H-2 Ventilation

H-24 Gasoline fuel systems

P-l

Exhaust systems

P-4 Inboard engines

E-9

DC

All installations must comply with the Federal Code

Regulations (FCR).

of

sources including the USCG and the NFPA.

of

the ABYC standards

Electrical systems

of

the American Boat and

of

particular interest are:

of

Engines & Generators

iii

Page 6

INSTALLATION

When installing WESTERBEKE engines and generators it is important that strict

attention be paid to the following information:

CODES

Strict federal regulations, ABYC guidelines, and safety codes must be complied with

when installing engines and generators in a marine environment.

AND

REGULATIONS

SIPHON-BREAK

For installations where the exhaust manifold/water injected exhaust elbow

or below the vessel's waterline, provisions must be made to install a siphon-break

the raw water supply hose to the exhaust elbow. This hose must be looped a minimum

of

18"

above the vessel's waterline. Failure to use a siphon-break when the exhaust

manifold injection port is

damage to the engine

EXHAUST

The exhaust hose must be certified for marine use. The system must be designed to

prevent water from entering the exhaust under any sea conditions and at any angle

of

the vessels hull.

SYSTEM

A

detailed

diesel,

dealer.

40

engines

at

or below the load waterline will result in raw water

and

possible flooding

page

Marine

and

generators,

Installation

of

is

available

the boat.

Manual

from

covering

your

WESTERBEKE

gasoline

is

close to

and

in

Engines & Generators

iv

Page 7

TABLE

OF

CONTENTS

Introduction

Warranty

Product Software ................................................... 2 Fuel Filters ........................................................... 16

Notes, Cautions and Wamings .............................. 2 Fuel Water Separator ........................................... 16

Serial Number Location ........................................ 3 Fuel Injection Pump Control ............................... 16

Understanding the Diesel Engine .......................... 3 Priming (Bleeding) the Fuel

Ordering Parts ........................................................ 3 Air Cleaner ..........................................................

Control

Admirals Panel ...................................................... 4 Charging Voltage .................................................

Captains Panel ....................................................... 5 Alternator Drive Belt Adjustment .......................

Diesel Fuel,

Diesel FueL ............................................................ 6 DC Wiring Diagrams ........................................... 20

Engine

Engine Coolant ...................................................... 6

Preparations

Prestart Inspection ................................................. 7 Adjusting Valve Clearances ................................ 23

Starting/Stopping

Break-In

The

Daily

Check List. ...........................................................

Start Your Engine ................................................

Maintenance

Engine

Changing the Coolant ..........................................

Thermostat ...........................................................

Raw

Water

Raw Water Cooling Circuit.. ............................... 14

Raw Water Pump ................................................. 1 4

Zinc Anode ........................................................... 14

Raw Water Pump Belt Adjustment ..................... 14

.............................................................. 2

Procedures

Panels

Coolant

.......................................................... 4

Engine

Oil .............................................................. 6

For

Procedure

Routine

Schedule ...........................................

System .................................................

.............................................. 2

Oil

and

Engine

Initial

Start-Up

Procedure

................................................. 9 Compression Test ................................................ 26

..........................................

.......................................................

Coolant.. ........ 6 Battery Care .........................................................

........................... 7

.................................. 8 Timing Belt Inspection and Replacement... ......... 24

'"

Engine

Fuel

DC

Water

Engine

..... 10 Fuel Injection Nozzle Test... ................................ 26

10

10

11

13

13

13

14

HBW

Borg

Engine

Lay-up

WESTERBEKE

Standard

WESTERBEKE

WESTERBEKE

Oil

Change

System ............................................................. 16

Electrical System .............................................

Heater

Water Heater Installations ................................... 22

Adjustments

Transmission

Warner

Troubleshooting .........................................

Troubleshooting Water Temperature and

Oil Pressure Gauges ............................................ 32

and

Recommissioning ............................... 33

Hardware

.................................................

System ....................

.......................................................... 22

.............. , ................................ 23

................................................ 27

Velvet Drive

55A

55A

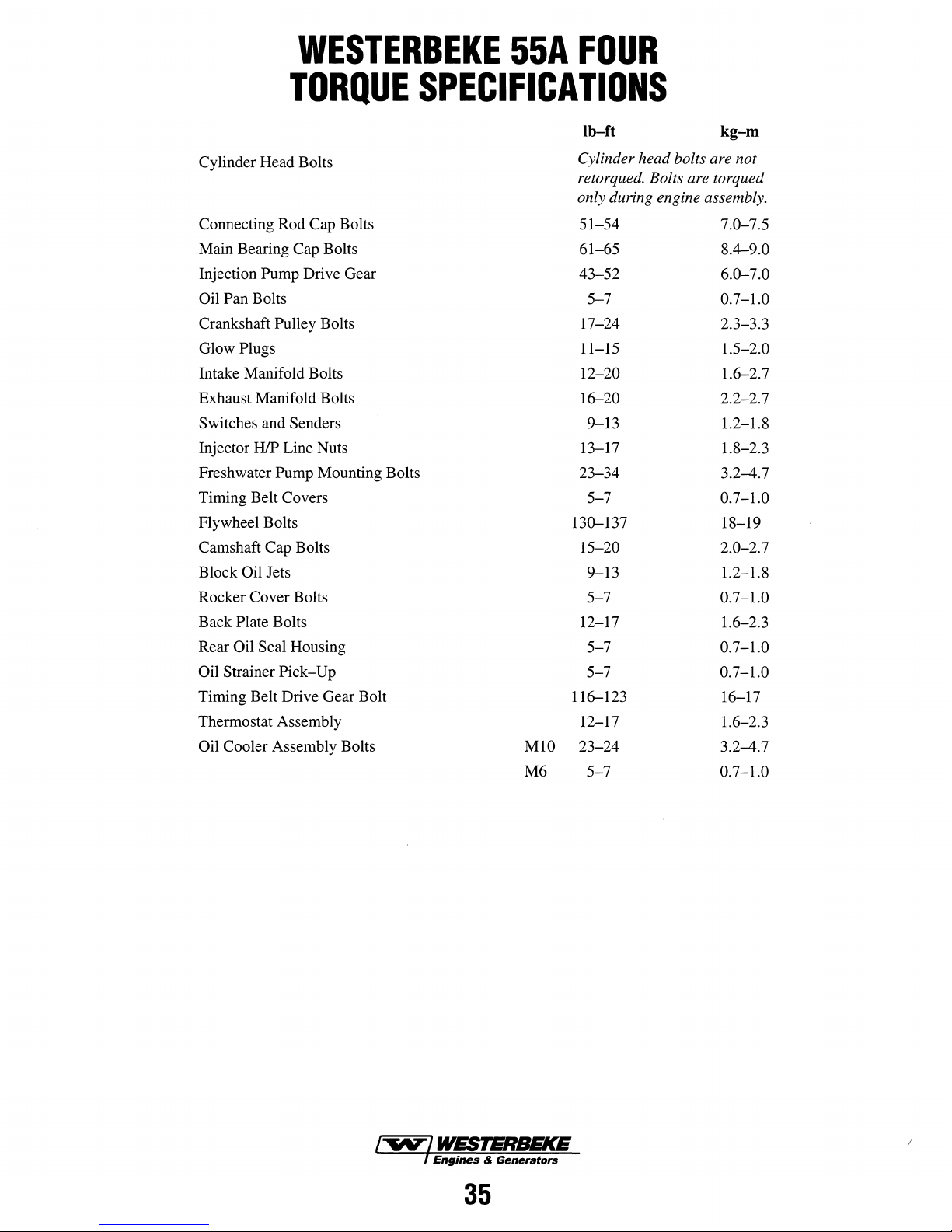

55A

Transmission

Torque

Torques

FOUR

FOUR

............ 29

Specifications ........ 35

................................ 36

Specifications ......... 37

Parts

Identification38

15

17

17

18

18

19

19

31

WESTERBEKE

WESTERBEKE CORPORATION' AVON INDUSTRIAL PARK

AVON, MA

02322'

TEL: (508)'588-7700·' FAX: (508) 559-9323

1

Page 8

INTRODUCTION

This WESTERBEKE Marine Diesel Engine is a product

of

WESTERBEKE' S long years

vanced technology. We take great pride in the superior

durability and dependable performance

and generators. Thank you for selecting WESTERBEKE.

In order to get the full use and benefit from your

engine, it is important that you operate and maintain it

correctly. This manual is designed to help you do this.

Please read this manual carefully and observe all the

safety precautions throughout.

quire servicing, contact your nearest WESTERBEKE

dealer for assistance.

This is your operators manual. A

also provided and a Technical Manual is available from

your WESTERBEKE dealer. Also,

to

install this equipment, contact your WESTERBEKE

dealer for

WARRANTY

Your WESTERBEKE Warranty is included in a

separate folder.

identification card registering your warranty

submitting the warranty registration form, please contact

the factory in writing with model information, including

the unit's serial number and commission date.

WESTERBEKE'S installation manual.

PROCEDURES

If

you have not received a customer

of

experience and ad-

of

our engines

Should your engine re-

Parts Catalog is

if

you are planning

60 days after

PRODUCT

Product software (tech data, parts lists, manuals,

brochures and catalogs) provided from sources other than

WESTERBEKE are not within

CONTROL.

WESTERBEKE

THE CONTENT

WARRANTIES OR REPRESENTATIONS WITH

RESPECT

TIMELINESS

WILL

IN

DAMAGE

WITH

USE

OF

WESTERBEKE customers should also keep in mind

the time span between printings

product software and the unavoidable existence

WESTERBEKE manuals. In summation, product software provided with WESTERBEKE products, whether

from WESTERBEKE or other suppliers, must not and

cannot be relied upon exclusively

authority on the respective product.

good sense but is imperative that appropriate representatives of WESTERBEKE or the supplier in question be

consulted to determine the accuracy and currentness

the product software being consulted by the customer.

SOFTWARE

WESTERBEKE'S

CANNOT

OF

THERETO, INCLUDING ACCURACY,

OR COMPLETENESS THEREOF

NO

EVENT

OR

INJURY

OR ARISING

SUCH SOFTWARE.

BE

SUCH

OUT

SOFTWARE,

BE

LIABLE FOR

INCURRED

OF

RESPONSIBLE FOR

ANY

IN

CONNECTION

THE FURNISHING OR

of

WESTERBEKE

as

the definitive

It

not only makes

MAKES

TYPE

of

NO

AND

OF

earlier

of

TYPICAL

Customer Identification

WESTERBEKE OWNER

MAIN

STREET

HOMETOWN, USA

Model 55A Four Ser. #U53890-48

Expires

CUSTOMER

WESTERBEKE

AVON,

7/20/97

MA

02322·

IDENTIFICATION

CORPORATION·

TEL:

(508)

AVON

558·7700·

INDUSTRIAL

FAX:

CARD

(508)

559-9323

PARK

NOTES,

As this manual takes you through the operating procedures, maintenance schedules, and troubleshooting

your marine engine, critical information will be highlighted by

explanation follows:

NOTE:

A

observed,

your

A

followed,

CAUTIONS

NOTES, CAUTIONS, and WARNINGS. An

An

operating procedure essential to note.

CAUTION:

Procedures,

can

result

AND

in

the

WARNINGS

which

if

not

strictly

damage

or

destruction

engine.

WARNING:

Procedures,

can

result in

which

personal

if

injury

not

or

properly

loss

of

of

life.

of

I"VVI

I

WESTERBEKE

Engines & Generators

2

Page 9

INTRODUCTION

(Continued)

SERIAL

An identification nameplate that displays the engine

model number and engine serial number is mounted

the side

this information on the blank decal provided below. This

will provide a quick reference when seeking technical information and/or ordering parts.

UNDERSTANDING

The diesel engine closely resembles the gasoline

engine, since the mechanism is essentially the same.

The cylinders are arranged above a closed crankcase;

the crankshaft is

gasoline engine, and the diesel engine has the same

types

lubricating system.

To a great extent, a diesel engine requires the same

preventive maintenance as a gasoline engine. Most

important are proper ventilation and proper maintenance

of

the fuel, lubricating and cooling systems. Replacement

of

fuel and lubricating filter elements at the time periods

specified and frequent checking for contamination

(water, sediment, etc.) in the fuel system are essential.

Also important is the consistant use

detergent diesel lubrication oil designed specifically for

diesel engines.

The diesel engine does differ from the gasoline engine,

however, in its method

carburetor and ignition systems are done away

with and in their place is a single component - the fuel

injection pump - which performs the function

NUMBER

of

the engine manifold. Take the time to enter

of

valves, camshaft, pistons, connecting rods and

LOCATION

THE

DIESEL

of

the same general type as that

of

handling and firing

ENGINE

of

a brand

of

of

of

on

of

a

high

fuel. The

both.

ORDERING

Whenever replacement parts are needed, always pro-

vide the engine model number and engine serial number

as they appear on the silver and black identification

nameplate located

with this information so we can identify your engine. In

addition, include a complete part description and part

number for each part needed (see the separately furnished

Parts Catalog). Also insist upon WESTERBEKE pack-

aged parts because will

not made to the same specifications as original equipment.

NOTE:

Component locations in this manual are refer-

enced from the front

drive belt end. Left and right sides are determined as

follows: imagine straddling the engine, facing in the

same direction as the front

is at your left, the right side is

PROTECTING

Care at the factory during assembly and thorough testing

have resulted in a WESTERBEKE diesel engine capable

of

many thousands

ever the manufacturer cannot control how

engine is installed in the vessel or the manner in which

the unit is operated and serviced in the field. This is up

to the buyer/owner-operator.

NOTE:

Six important steps to ensure long engine life:

o Proper engine installation

o

An

cludes an anti-siphon break to prevent water from

entering the engine.

o Changing the engine oil

erating hours.

o Proper maintenance

according to the maintenance schedule in this

manual.

PARTS

on

the manifold. You must provide us

fit

or

generic parts are frequently

of

the engine which is the pulley/

of

the engine: the left side

at

your right.

YOUR

efficient well-designed exhaust system that in-

INVESTMENT

of

hours

of

dependable service. How-

and

and

of

all engine components

or

where the

alignment.

oil filters every 200 op-

I~I

I

o

Use

clean, filtered diesel fueL

o Winterize

Recommissioning" section in this manual.

WSJERBEKE

Engines

& Generators

3

your

engine according to the "Lay-up

and

Page 10

CONTROL

PANELS

WESTERBEKE offers two optional

the instruction page that applies to the panel you

panels-

select

pur-

chased.

ADMIRALS

This manually-operated control panel is equipped with a

KEY

SWITCH and

TIME

meter which measures the

in

hours and in

WATER

temperature in degrees Fahrenheit, an OIL

gauge which measures the engine's oil pressure in

pounds per square inch, and a

AGE

gauge which measures the system's voltage. All

gauges are illuminated when the key switch is turned

and remain illuminated while the engine is in operation.

The

panel also contains two rubber-booted push buttons,

one for

PREHEAT

PANEL

RPM

gauge with an ELAPSED

1110

hours. The panel also includes a

TEMPERATURE

and one for START.

WATER

GRADUATED

ILLUMINATED

TURNED

TEMPERATURE

engine's

running time

gauge which indicates water

PRESSURE

DC

control circuit VOLT-

ON

TEMPERATURE

IN

ON.

THE

DEGREES

WHILE

THE

ENGINE'S

IS

170°·190°

GAUGE:

THIS

FAHRENHEIT

KEY

SWITCH

NORMAL

F

GAUGE

AND

IS

OPERATING

You will notice that when the engine is shut down with

the Key Switch turned

OFF, the water temperature gauge

will continue to register the last temperature reading indicated by the gauge before electrical power was turned

OFF. The oil pressure gauge will also hold its reading.

The temperature gauge will once again register the engine's

true temperature when electrical power is restored

to the gauge

A separate alarm buzzer with harness is supplied with

every Admiral

Panel.

The

installer is responsible for

electrically connecting the buzzer to the four-pin connection on the

engine's

electrical harness.

The

installer

is also responsible for installing the buzzer in a location

where it will be dry and where it will be audible to the

operator should it sound while the engine is running.

The

buzzer will sound when the ignition key is turned

ON

and should silence when the engine has started and

the

IS

engine's

IS

oil pressure rises above

OIL

PRESSURE

ATED

ILLUMINATED

TURNED

OIL

PRESSURE

IN

POUNDS

ON.

GAUGE:

WHILE

THE

RANGES

15

psi.

THIS

PER

SQUARE

THE

KEY

ENGINE'S

BETWEEN

GAUGE

SWITCH

NORMAL

IS

INCH

(PSI)

OPERATING

30-60

GRADU-

AND

IS

PSI.

IS

RPM

GAUGE:

TERS

PER

ENGINE

RECALIBRATED

ACCURACY

THE

PANEL.

HOUR

TERS

AND

AS A GUIDE

MAINTENANCE

SCHEDULE.

PREHEAT

THE

PUMP,

PUMP,

PASSES

SURE

BUTTON

START

THE

ENGINE.

ELECTRICALLY

IS

PRESSED

REGIS-

REVOLUTIONS

MINUTE

OF

THE

AND

CAN

FOR

FROM

REAR

OF

THE

METER:

REGIS-

ELAPSED

BE

FOR

BUTTON:

THE

FUEL

AND

THE

THE

ENGINE'S

ALARM

SWITCH.

ENERGIZES

BUTTON:

THIS

BUTTON

AND

TIME,

SOLENOID

UNLESS

SHOULD

ALTERNATOR'S

STARTER'S

BE

USED

THE

WHEN

PRESSED,

EXCITER,

SOLENOID

ENGINE'S

PROTECTIVE

IN

THE

START

WHEN

PRESSED,

WILL

THE

HELD

AT

ENERGIZES

THE

FUEL

ON

THE

INJECTION

GLOW

PLUGS.

OIL

ADDITION,

BUTTON.

ENERGIZES

WHICH

CRANKS

NOT

OPERATE

PREHEAT

THE

SAME

LIFT

IT

BY-

PRES-

THIS

THE

BUTTON

TIME.

/

AUTOMATIC

/

HIGH

WATER

BEEN

SUPPLIED

FRESH

WATER

WILL

CLOSE

TINUOUS

LOW

OIL

SWITCH

SWITCH

ENGINE'S

CLOSE

SOUNDING

EMIT A PULSATING

ALARM

TEMPERATURE

WITH

COOLANT

SOUNDING

SIGNAL.

PRESSURE

IS

LOCATED

MONITORS

OIL

PRESSURE

THE

SIGNAL.

SYSTEM

ALARM:

THE

INSTRUMENT

REACHES

THE

ALARM

ALARM: A LOW

OFF

THE

ENGINE'S

THE

ENGINE'S

FALL

TO 5 -10

ALARM.

IN

AN

ALARM

PANEL.

210° F (98°C),

WHICH

WILL

OIL

PRESSURE

OIL

GALLERY.

OIL

PRESSURE.

PSI,

THIS

THE

EVENT,

KEY

POWER

INSTRUMENT

CLUSTER.

SWITCH

ENGINE

THE

DC

INDICATES

THE

CHARGED.

SHOW

BUZZER

IF

THE

THIS

SWITCH

EMIT A CON-

ALARM

THIS

SHOULD

SWITCH

THE

ALARM

SWITCH:

PROVIDES

ONLY

TO

PANEL

THE

KEY

SHUTS

THE

DOWN

WHEN

KEY

IS

TURNED

VOLTMETER:

THE

13V

THE

WILL

WILL

AMOUNT

IS

SHOULD

TO

14V.

BATTERY

HAS

ENGINE'S

THE

OFF.

BEING

l-vvl

WESJERBEKE

I

Engines & Generators

4

Page 11

CONTROL

PANELS

(Continued)

CAPTAINS

PANEL

This manually-operated control panel is equipped with

a KEY SWITCH; an RPM gauge;

PREHEAT and

START buttons; an INSTRUMENT TEST button; three

indicator lamps, one for

one for low OIL

RPM

GAUGE:

OF

FOR

PANEL.

REGISTERS

THE

ACCURACY

'MINUTE

BRATED

THE

PRESSURE, and one for high ENGINE

ENGINE

AND

FROM

ALTERNATOR DISCHARGE,

REVOLUTIONS

CAN

THE

BE

RECALI-

REAR

PER

OF

COOLANT TEMPERATURE; and an alarm buzzer

for low OIL

PRESSURE or high WATER TEMPERA-

TURE. The RPM gauge is illuminated when the key

switch is turned

ON and remains illuminated while the

engine is in operation.

ALARM:

THE

ALARM

WILL

SOUND

IF

THE

ENGINE'S

OIL

FALLS

BELOW

IN

THIS

THE

THIS

SOUNDING

OIL

15

SIGNAL.

IN

EVENT,

ALARM

PRESSURE

PULSATING

TEMPERATURE

205°F.

NOTE:

ON.

ENGINE'S

PSI.

IN

THIS

THE

ALARM

THE

FRESHWATER

THE

ALARM

WILL

SOUND

IS

NORMAL.

REACHES

EVENT,

THE

ALARM

WILL

ALSO

COOLING

WILL

EMIT A CONTINUOUS

WHEN

THE

ONCE

THE

15

PSI,

KEY

ENGINE

THE

WILL

SOUND

CIRCUIT

SWITCH

ALARM

/

PRESSURE

EMIT

A

IF

THE

WATER

RISES

TO

SIGNAL.

IS

TURNED

STARTS

AND

WILL

SILENCE.

TEST

BUTTON:

PRESSED,

ALTERNATOR,

WATER

WHEN

ALTERNATOR,

WATER

TO

ALARM

TESTS

PRESSURE,

TEMPERATURE

CONTROL

CIRCUITS.

PRESSED,

PRESSURE,

TEMPERATURE

INDICATOR

LUMINATE

SOUNDING

BUZZER.

THE

WHEN

THE

THE

AND

THE

THE

THE

AND

THE

LIGHTS

IN

ADDITION

THE

OIL

OIL

IL-

START

BUTTON:

THE

STARTER'S

ENGINE.

UNLESS

HELD

AT

IT

WILL

THE

PREHEAT

THE

WHEN

SOLENOID

NOT

SAME

TIME,

PRESSED,

WHICH

OPERATE

BUTTON

,....,.,

ENERGIZES

CRANKS

ELECTRICALLY

IS

THE

PRESSED

AND

WESJERBEKE

I

Engines & Generators

PREHEAT

BUTTON:

THE

ALTERNATOR'S

PUMP,

THE

AND

THE

IN

START

FUEL

ADDITION,

BUTTON.

PUMP,

PASSES

SWITCH,

THE

WHEN

REGULATOR,

SOLENOID

THE

ENGINE'S

ENGINE'S

PRESSED,

ON

GLOW

OIL

PRESSURE

THIS

BUTTON

KEY

POWER

STRUMENT

,

THE

ENGINE

KEY

ENERGIZES

THE

FUEL

THE

INJECTION

PLUGS.

ALARM

ENERGIZES

SWITCH:

ONLY

PANEL

KEY

SWITCH

DOWN

IS

TURNED

LIFT

IT

BY-

PROVIDES

TO

THE

IN-

CLUSTER.

SHUTS

WHEN

THE

OFF,

THE

5

Page 12

DIESEL

FUEL,

ENGINE

OIL

AND

DIESEL

Use fuel that meets the requirements

of

Class 2-D (ASTM), and has a cetane rating

or

better. .

Care

Use only clean diesel fuel! The clearance

nents in your fuel injection pump is very critical; invisible dirt particles which might pass through the filter can

damage these finely finished parts.

clean fuel, and keep it clean. The best fuel can

dered unsatisfactory by careless handling

storage facilities.

tank for your engine's daily use is clean and pure, the

following practice is advisable:

Purchase a well-known brand

Install and regularly service a good, visual-type filterl

water separator between the fuel tank and the engine.

Raycor 500

a filter.

ENGINE

Use a heavy duty engine oil with an API classification

CF or CG4 or better. Change the engine oil after an

initial 50 hours

of

operation thereafter. For recommended oil viscosity,

see the following chart:

Of

The

FUEL

Fuel

FG

or

OIL

of

or

Supply

It

is important to buy

To

assure that the fuel going into the

of

fuel.

900 FG is a good example

break-in operation, and every 200 hours

ENGINE

specification

of

#45

of

the compo-

be

ren-

or

improper

of

such

COOLANT

ENGINE

The use

mended for year-round use. Use antifreeze that is compatible with aluminium components, and never mix

different brands

this can

nents.

NOTE:

lasting antifreeze that is now available.

Antifreeze mixtures will protect against an unexpected

freeze and they are beneficial to the engine's cooling

system. They retard rust and add to the life

lating pump seal.

Antifreeze

Freezing

COOLANT

A coolant recovery tank kit is supplied with each

WESTERBEKE diesel engine. The purpose

covery tank is to allow for engine coolant expansion

of

and contraction during engine operation, without the loss

of

coolant and without introducing air into the cooling

system.

COOLANT

of

an antifreeze mixture

of

antifreeze. Do not use straight water,

be

detrimental to the cooling system compo-

Lookfor

Temperature

the new environmentally-friendly long

ANTIFREEZE

concentration

23%

14°F

(-5°C)

RECOVERY

of

50/50 is recom-

PROTECTION

35%

-4°F

(-20°C)

TANK

-40°F

(-40°C)

50%

of

the circu-

of

this re-

60%

-58°F

(-50°C)

Operating

Above

41°-68°F

Below

A

CAUTION:

of

engine

oil

additives;

in

the

mixture

your

engine.

Temperature

68°F

(20°C)

5-20°C)

41°F

(5°C)

00

not

to

mix.

additives

of

to

produce

allow

Each

brand

different

properties

two

or

contains

brands

Oil

Viscosity

SAE

30

SAE

20

SAE

more

could

harmful

or

10W-30

or

10W-30

10W-30

brands

its

own

react

to

COOLANT

RECOVERY

TANK

6

Page 13

PREPARATIONS

FOR

INITIAL

START-UP

PREST

Before starting your engine for the first time

prolonged layoff - check the following items.

ART

INSPECTION

or

after a

o Check the engine oil level; add oil to maintain the

level at the high mark on the dipstick.

o Check the fuel supply and examine the fuel

filter/separator bowls for contaminants.

o Check the transmission fluid level.

NOTE:

Refer to the specifications pages in this manual

fuel, oil, and transmission types and quantities.

OIL

DIPSTICK

FULL

LDW----~1l!J

for

o Check the DC electrical system. Inspect wire

connections and battery cable connections.

o Visually examine the unit. Look for loose or missing

parts, disconnected wires, unattached hoses, and

check threaded connections.

o Check the coolant level in the plastic recovery tank

and at the manifold.

NOTE:

If

the engine has not yet been filled with coolant,

refer to the

"Engine Coolant" section

COOLANT

RECOVERY

TANK

of

this manual.

MANIFOLD

PRESSURE

CAP

l-vvl

WESJERBEKE

I Engines & Generators

7

Page 14

STARTING/STOPPING

PROCEDURE

STARTING

Place the transmission in neutral and advance the throttle

control to slightly open.

A

CAUTION:

in

neutral.

damage

vessels

Tum

the

PREHEAT:

panel lights, gauges and meters, and fuel solenoid will be

activated. The

accordance with the following chart:

PROCEDURE

Make

certain

Starting

to

your

in

transmission,

nearby.

KEY

SWITCH to the

Depress the PREHEAT switch.

PREHEAT

the

transmission

gear

could

result

your

ON

position (2

switch should be depressed in

in

boat,

The

is

serious

and

0'

clock)

voltmeter,

Temperature/Preheat

Atmospheric

+41

+41

°F(

+23°F(-5°C)

Limit

START:

press the

noid. Upon engine firing, release the

not release the PREHEAT switch until the oil pressure

reaches

ture and low oil pressure protective circuits do not

vate, the engine will remain energized and continue

to run.

While still depressing the PREHEAT switch, de-

Temperature

°F(

+5°C)

or

higher

+5°C)

to

23°F

(-5°C)

or

lower

of

continuous

START

15

psi. Then as long as the high water tempera-

use

switch. This will engage the start sole-

Preheating

Approx.

Approx.

Approx.

30

seconds

START

10

seconds

15

seconds

20

seconds

before

switch.

Time

cranking

Do

acti-

A

CAUTION:

the

engine

system

cause

raw

water

filling

the

water

can

exhaust

vent

this

supply

through-hull

muffler,

engine

water

cranking.

entry

owner/operator

Once the engine starts, check instruments for proper oil

pressure and battery charging voltage.

NOTE:

Never attempt to engage the starter while the

engine is running.

NOTE:

Some unstable running may occur in a cold engine.

Depressing the Preheat switch

will help stabilize the engine

perature reaches 170°-190°F (77°-88°C) and a propeller

load is applied

and

the

preheat

the

DC

alternator will be discernible.

STARTING

Make certain the lubricating oil conforms with the ratings for

the prevailing temperature. Check the table

oil section

The

battery should be fully charged to minimize voltage

drop.

Use a sufficient amount

See TemperaturelPreheat chart on this page.

Prolonged

starting

with

pump

is

pumping

cooling

enter

manifold

from

and

system

the

once

happening

correcting

Engine

is

not a warrantable

should

to

the engine. When the engine is running

switch is depressed, a charging load on

UNDER

of

this manual.

cranking

can

result

raw

water.

during

engine's

the

by

shut-off,

the

damage

exhaust

cause

intervals

in

the

This

may

raw

water

cranking.

cylinders

system

closing

draining

of

resulting

issue;

keep

this

in

mind.

for

10-15 second intervals

RPM

until the operating tem-

COLD

of

CONDITIONS

preheat to aid in starting.

engine

happen

through

by

the

raw

the

the

excessive

the

without

exhaust

be-

the

This

raw

way

of

fills.

Pre-

water

exhaust

from

raw

on

the engine

the

NOTE:

When starting:

A voltage drop will occur

when the preheat switch

is depressed.

Should the engine not start when the

depressed for

wait

30 seconds; repeat the procedure above and preheat

longer.

30

seconds.

10 to 20 seconds, release both switches and

Never

run

the

starter

for

more

START

than

switch is

/"VVI

I Engines & GeneratDrs

STOPPING

To

stop the engine, bring the throttle to an idle position

and place the transmission in neutral. Allow the engine to

idle for a few moments to stabilize temperatures.

the key to the

the instrument panel and engine, de-energizing the fuel

solenoid

it and stopping the engine.

Made certain the key switch is in the

(12 o'clock).

will discharge.

warn the operator

The

is to remove the key from the Key

the engine.

on

best method

WESJERBEKE

8

PROCEDURE

Tum

OFF

position. This opens the DC circuit to

the injection pump, stopping fuel flow from

OFF

position

If

the Key Switch is left ON, the battery

An

engine alarm buzzer is provided to

of

this condition (Key Switch ON).

of

preventing the battery from discharge

Switch after stopping

Page 15

BREAK-IN

PROCEDURE

THE

FIRST

Although your engine has experienced a minimum

hour

of

proper operation

The service life

the engine is operated and serviced during its initial

hours

of

Your new engine requires approximately

tial conditioning operation to break in each moving part

in order to maximize the performance and service life

the engine. Perform this conditioning carefully, keeping

in mind the following:

1. Start the engine according to the Starting Procedure

section in this manual; run the engine at fast idle

while checking that all systems (raw water pump, oil

pressure, battery charging) are functioning.

2. Allow the engine to warm up (preferably by running

at fast idle) until the water temperature gauge moves

into the

3. While using the vessel, run the engine at varying en-

gine speeds for the first

50

HOURS

of

one

test operations to ensure accurate assembly and

of

all systems, break-in time is required.

of

your engine is dependent upon how

50

use.

130° -140°F range.

25

50 hours

hours.

of

ini-

of

4. A void rapid acceleration, especially with a cold

engine.

S.

Use caution not to overload the engine. The presence

of

a gray or black exhaust, and the inability

engine to reach its full rated speed, are signs

overload.

6. During the next 25 hours, the engine may be operated

at varying engine speeds, with short runs at full rated

rpm. A void prolonged idling during this break-in period.

Breaking-in a new engine basically involves seating

the piston rings to the cylinder walls. This cannot be

accomplished by long periods

early running at full rpm. Idle running may glaze the

cylinder walls, resulting in excessive oil consumption

and smoky operation. Excessive speed

loading, especially with a cold engine, may cause scoring

of

the cylinder walls, producing similar results. Operate

the engine in moderation during the

riod. (Don't baby the engine, but do not abuse it.)

NOTE:

See the Transmission section

break-in information on your transmission.

of

running at idle, nor by

or

50-hour break-in pe-

of

this manual

of

the

of

an

heavy over-

for

rVtTl

I

WESJERBEKE

Engi_s

& Generators

9

Page 16

THE

DAILY

ROUTINE

CHECK

Each day before starting your engine, take a few

moments to run this check list:

LIST

o Visually inspect the engine for fuel, oil, or water

leaks.

o Check the oil level (dipstick).

o Check the transmission fluid level.

o Check for loose wires at the alternator.

o Check the starting batteries level (weekly)

o Check drive belts for wear and proper tension

(weekly).

o Log your engine running time. These hours relate to

scheduled maintenance.

o Check fuel supply; always keep fuel tank(s)

possible.

as

full

o Look for clean fuel in the fuel/water separator bowl.

o Check the coolant level in the plastic recovery tank.

START

NOTE:

more detailed instructions.

1.

2. Tum KEY to the

3. Depress

4. While pressing PREHEAT, push START. As engine

5. Hold

NOTE:

the above procedure, and PREHEAT longer.

6. Allow a few minutes for the engine to warm at a

as

YOUR

See Starting/Stopping Procedure in this manual

Put transmission in neutral, throttle advanced.

fires - release START.

PREHEAT until oil pressure reaches

and/or alarm shuts off.

Should engine fail to start, wait 30 seconds, repeat

comfortable rpm (approx.

rpm, shift into gear, and get underway.

ENGINE

ON position

PREHEAT (10

(2

o'clock)

to

15

seconds).

1200 rpm), then reduce the

15

for

psi

NOTE:

Excessive loss

tem leak. Check the entire system.

cooling system pressure tester to pressurize the cooling

system to locate the area

coolant loss, refill the system as outlined

for Initial

Start-Up in this manual.

of

coolant indicates a cooling sys-

If

necessary, use a

of

leakage. In cases

of

excessive

in

Preparations

l-vvl

WESTERBEKE

r

Engines & Generators

10

Page 17

MAINTENANCE

A

WARNING:

Wear

the

tools

for

engine's

NOTE:

Many

and

may require the expert knowledge

Never

attempt

proper

each

DC

safety

equipment

job.

Disconnect

electrical

of

the following maintenance jobs are simple but others are more difficult

equipment.

to

perform

such

the

battery

any

as

of

a service mechanic. A complete service

SCHEDULE

service

goggles

terminals

manual is availablefrom your WESTERBEKE dealer.

while

and

gloves,

when

the

engine

and

servicing

is

running.

use

the

any

of

correct

the

SCHEDULED

Fuel

Fuel/Water

Engine

Transmission

Coolant

Drive

Visual

Throttle

Control

Adjust

Fuel

Starting

(and

Engine

•

Adjust

Lubricate

with"

MAINTENANCE

Supply

Separator

Oil

Level

Level

Belts

Inspection

and

Transmission

Cable

Engine

Filter

Batteries

House

Batteries)

Oil

the

Valve

Panel

Lockeze"

Fluid

Level

of

Engine

Idle

Speed

Clearances

Key

Switch

CHECK

EACH

DAY

0

0

0

0

0

0

0

HOURS

OF

OPERATION

100

50

NOTE:

oil will inhibit the engine's ability to remain cool.

0

250

Please keep engine surface clean. Dirt and

0 0

500

750

1000

1250

0

0

0 0 0

Every

50

0

0

Clean

Initial

operating

off

excessive

engine

hours

corrosion.

oil & filter

check

change

electrolyte

at

50

hrs.,

0 0 0

0 0 0 0 0 0

Diesel

Check

necessary).

Oil

level

on

dipstick.

Fluid

LOW

Check

manifold.

Inspect

and

adjust

Check

wiring

nuts

Check

Lubricate

Adjust

Initial

250

levels

and

then

change

Initial

(Do

At 1 st

EXPLANATION

MAINTENANCE

No.2

octane

rating

for

water

and

dirt

should

indicate

level

should

dipstick

recovery

Add

coolant

proper

tension

if

needed.

fuel,

oil

electrical

loose

fittings,

with

WD-40

(750-1000

at

50

sure

both

every

the

hrs.

then

indicate

tank;

and

connections.

rpm).

hrs,

connections

100

at

50

each

on

at

for

for

and

tight.

for

to

change

hrs.

make

adjustment

not

retorque

100

OF

SCHEDULED

of

45

in

fuel

between

between

if

empty,

if

needed.

('h "

to

Check

belt

water

leaks.

cotter

or

equivalent.

then

change

hours.

hrs.,

then

cylinder

head)

year

cetane

or

better.

(drain/replace

MAX.

and

MAX.

and

check

at

'Is"

depression)

edges

for

wear.

Inspect

Keep

bolts

pins,

etc.

every

are

very

tight.

every

50Q

at

winterizing.

if

LOW

&

hrs.

TransmiSSion

Air

Cleaner

Exhaust

·WESTERBEKE

Fluid

System

recommends

this

service

be

0 0 0 0 0

0 0

0 0 0 0

performed

by

an

authorized

/"VVI

I Engines & GeneratDrs

mechanic.

WESJERBEKE

11

Initial

fluid

hrs.

or

at

winterizing.

Replace

element

Initial

check

Inspect

for

siphon

brake

elbow

for

inside

necessary.

carbon

passages;

change

filter.

at

50

leaks.

operation.

and/or

clean

at

50

Clean

hrs.,

then

Tight

connections

and

hrs.,

then

or

replace

every

Check

the

corrosion

replace

every

250

elements.

250

hrs.

check,

exhaust

buildup

as

on

Page 18

MAINTENANCE

SCHEDULE

(Continued)

SCHEDULED

Engine

Heat

Zinc

Electric

(if

applicable)

Raw

Coolant

*Fuellnjectors

*Starter

*Preheat

MAINTENANCE

Hoses

Exchanger

Anode

Fuel

Lift

Water

Pump

System

Motor

Circuit

Pump

Filter

NOTE:

CHECK

EACH

DAY

Use engine

hour

meter

gauge to log

your

or record your engine hours by running time.

HOURS

OF

OPERATION

50

100

250

D

D D D D D

500

750

1000

1250

D D D D D D D

D D D D D D

D

D D

D

D

D

D D

D D

engine hours

EXPLANATION

Hose

should

spongy.

Check & tighten

Clean

or

replace.

and

clean

out

Initial

filter

every

pump

replace

both

flush,

and

condition

solenoid

and

and

operation

clean

glow

ohms).

change

250

adjust

lubricate.

filter

Remove

wear;

Lubricate

Drain,

appropriate

Check

spray

Check

Remove

Clean

Check

and

(4-6

OF

MAINTENANCE

be

hard & tight.

all

Open

heat

debris.

at

50

hours,

hours.

cover

and

if

needed.

when

and

anti-freeze

and

lubricate.

plugs;

Also

reassembling.

refill

cooling

mix.

injection

(see

Engine

motor

Start.

of

preheat

check

inspect

SCHEDULED

Replace

if

clamps.

then

impeller

pressure

pinion

soft

end

change

gasket.

with

Remove

hose

exchanger

replace

system

opening

Adjustments).

for

corrosion.

motor

solenoid.

resistance

or

cap

for

and

drive.

*Engine

Cylinder

and

Valve

Clearance

DC

Alternator

Heat

Exchanger

Transmission

Engine

Transmission

Damper

Plate

Engine

Timing

'WESTERBEKE

recommends

Compression

Oil

Cooler

Belt

this

service

be

performed

by

an

D D

D D D

D

D

D

D

authorized

mechanic.

Incorrect

engine

pressure

Check

ing

Remove;

press u re

Remove;

pressure

Chattering

of

Remove

NOTE:

recommended interval could result

belt failure resulting in major damage to the

engine.

valve

clearance

performance;

and

timing,

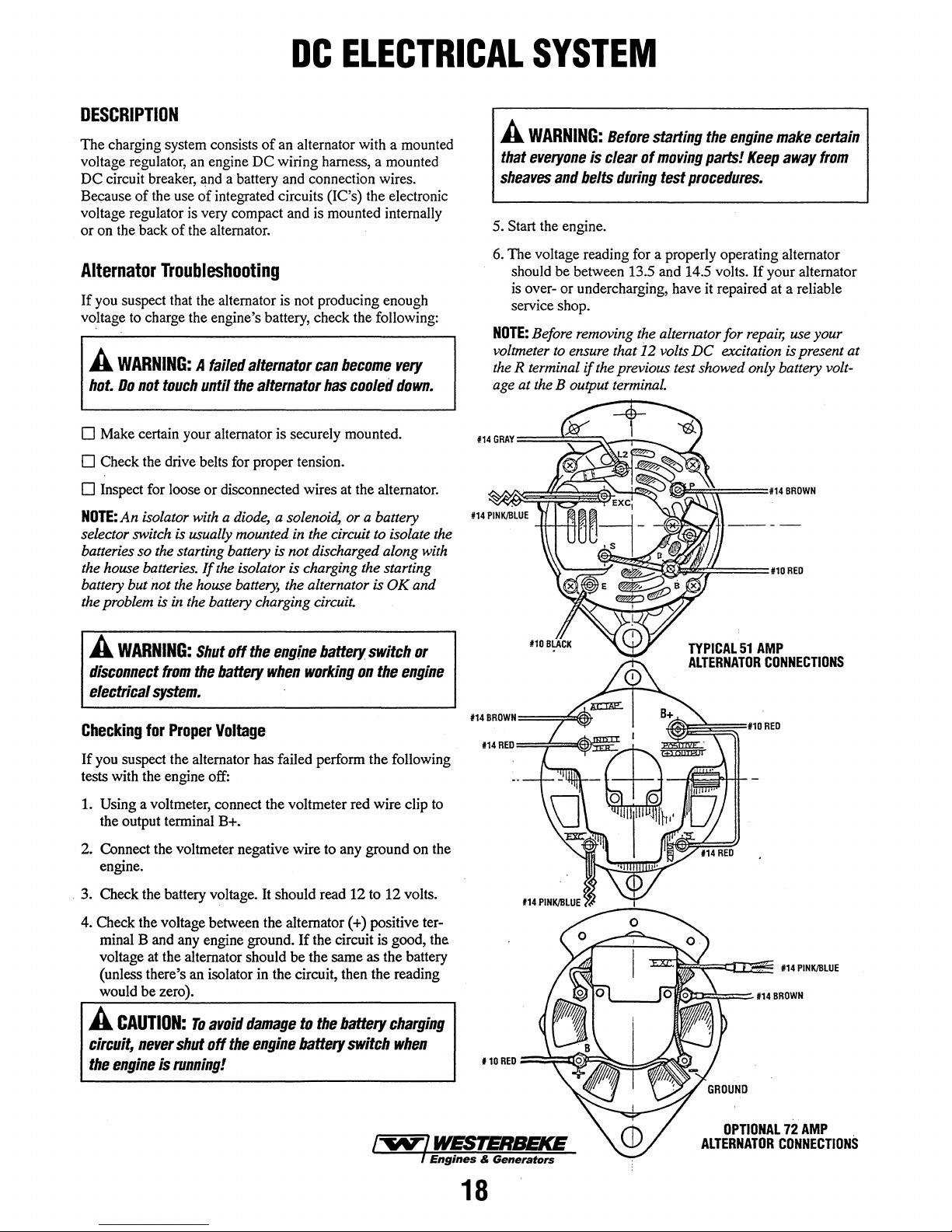

DC

charge

bracket;

tighten

have

professionally

tested.

have

professionally

tested.

at

damper

idle

plate

and

replace.

Failure to replace the timing belt

and

from

electrical

and

wear.

will

check

compression

adjust

alternator.

low

rpms

Remove

result

valve

connections.

cleaned

cleaned

in

clearances.

Check

is

an

indication

and

replace.

in

poor

mount-

and

and

at

timing

the

I~l

I

WSJERBEKE

Engines & Gene",tors

12

Page 19

ENGINE

COOLANT

CHANGING

The engine's coolant must be changed every eight to

twelve months depending on the engine's use.

coolant is allowed to become contaminated, it can lead

to overheating problems.

A coolant recovery tank allows for engine coolant expansion

and

nificant loss

cooling system. This tank should be located at or

engine manifold level, and be easily accessible.

Drain the engine coolant by loosening the drain plug on

the engine block and opening the manifold pressure cap.

Flush the system with fresh water, then start the refill

process.

ual for locations.

NOTE:

The petcock on the heat exchanger can also be

used to drain engine coolant.

THE

COOLANT

If

the

contraction during engine operation, without

of

coolant and without introducing air into the

.\:>?i~:":';';~---

~---

COOLANT

See the Parts Identification photos in this man-

any

sig-

above

COOLANT

RECOVERY

TANK

CAP

COOLANT

RECOVERY

TANK

EXPANSION

the

Start the engine and bring it to operating temperature.

Monitor the coolant in the manifold and add as needed.

Fill the manifold to the filler neck and install the pressure

cap.

Remove the cap on the coolant recovery tank, fill with

coolant to halfway between

the cap.

Run the engine and observe the coolant expansion flow

into the recovery tank.

After checking for leaks, stop the engine and allow

it to cool. Coolant should draw back into the cooling

system as the engine cools down. Add coolant to the

recovery tank

NOTE:

Periodically check the condition

Ensure that the upper and lower rubber seals are in good

condition and check that the vacuum valve opens and

closes tightly. Carry a spare cap.

if

needed. Clean up any spilled coolant.

LOW

and MAX, and replace

of

the pressure cap.

THERMOSTAT

A thermostat, located near the manifold at the front

engine, controls the coolant temperature as it continuously flows through the closed cooling circuit. When

the engine is first started the closed thermostat prevents

coolant from flowing (some coolant is by-passed through

a hole in the thermostat to prevent the exhaust manifold

from overheating). As the engine warms up the thermo-

stat gradually opens. The thermostat is accessible and can

be checked, cleaned, or replaced easily. Carry a spare

thermostat and gasket.

of

the

WATER

TEMPERATURE

ALARM

A

WARNING:

Wear

protective

TO

REFILL

With the enginge running in idle, slowly pour clean

premixed coolant into the manifold.

NOTE:

Open the air bleed petcock on the heat exchanger

to help remove air from the system. When a steady flow

of

coolant appears

water drain plug and continue to fill the system until the

manifold remains full. Close the petcock on the heat

exchanger when antifreeze flows from

Beware

gloves.

WITH

at

of

the

hot

COOLANT

the drain plug opening, close the

engine

it.

coolant.

I~l

I Engines & GeneratDrs

WSJ&lBEKE

13

THERMOSTAT

WATER

TEMPERATURE

SENDER

Page 20

ENGINE

OIL

CHANGE

DRAIN

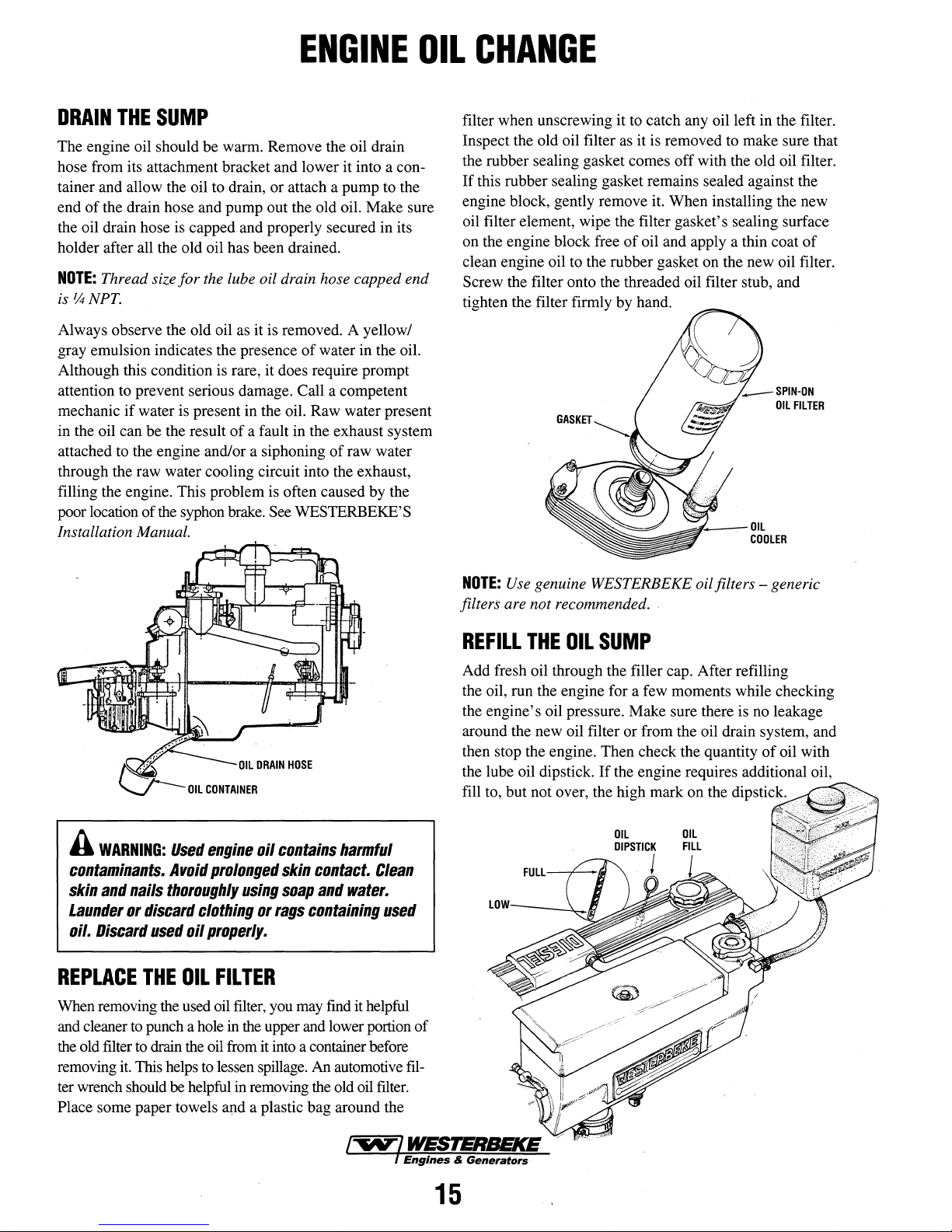

The engine oil should be warm. Remove the oil drain

hose from its attachment bracket and lower it into a container and allow the oil to drain, or attach a pump to the

end

the oil drain hose is capped and properly secured in its

holder after all the old oil has been drained.

NOTE:

is

Always observe the old oil as it is removed. A yellow/

gray emulsion indicates the presence

Although this condition is rare, it does require prompt

attention to prevent serious damage. Call a competent

mechanic

in the oil can be the result

attached to the engine and/or a siphoning

through the raw water cooling circuit into the exhaust,

filling the engine. This problem is often caused by the

poor location

Installation Manual.

THE

SUMP

of

the drain hose and pump out the old oil. Make sure

Thread size

1/4

NPT.

if

for

the lube oil drain hose capped end

of

water in the oil.

water is present in the oil. Raw water present

of

a fault in the exhaust system

of

raw water

of

the syphon brake. See WESTERBEKE'S

filter when unscrewing it to catch any oil left in the filter.

Inspect the old oil filter as it is removed to make sure that

the rubber sealing gasket comes

If

this rubber sealing gasket remains sealed against the

engine block, gently remove it. When installing the new

oil filter element, wipe the filter gasket's sealing surface

on the engine block free

clean engine oil to the rubber gasket on the new oil filter.

Screw the filter onto the threaded oil filter stub, and

tighten the filter firmly by hand.

of

off

with the old oil filter.

oil and apply a thin coat

SPIN-ON

OIL

q

__

-OIL

COOLER

of

FILTER

~

~

A

WARNING:

contaminants.

skin

and

nails

Launder

oil.

or

Discard

REPLACE

When removing the used oil filter, you may find it helpful

and cleaner

the old filter to drain the oil from it into a container before

removing

ter wrench should be helpful in removing the old oil filter.

Place some paper towels and a plastic bag around the

to

it.

This helps to lessen spillage. An automotive fil-

OIL

Used

Avoid

thoroughly

discard

used

oil

THE

OIL

punch a hole in the upper and lower portion

OIL

CONTAINER

engine

prolonged

using

clothing

properly.

FILTER

DRAIN

HOSE

oil

contains

skin

soap

or

rags

harmful

contact.

and

Clean

water.

containing

used

NOTE:

Use genuine WESTERBEKE oil filters - generic

filters are not recommended.

REFILL

Add fresh oil through the filler cap. After refilling

the oil, run the engine for a few moments while checking

the engine's oil pressure. Make sure there is no leakage

around the new oil filter or from the oil drain system, and

then stop the engine. Then check the quantity

the lube oil dipstick.

fill to, but not over, the high mark on the dipstick.

of

LOW-

THE

FULL-+--ra

__

OIL

~1frI

SUMP

of

oil with

If

the engine requires additional oil,

!-VVI

r

WESTERBEKE

Engines & Generators

15

Page 21

FUEL

SYSTEM

A

WARNING:

when

servicing

catching

smoking,

the

fuel

lation

exists

FUEL

The fuel injection pump and the fuel injectors are

precisely manufactured and they must receive clean

diesel fuel, free from water and dirt. To ensure this flow

of

filters, a fuel/water separator and the engines spin-on fuel

filter. Visually inspect, clean, and change these filters

according to the maintenance schedule in this manual.

FILTERS

clean fuel, the fuel must pass through at least two fuel

Shut

any

fuel

open

flames

system

when

O-RING----

off

the

fuel

that

when

servicing

the

fuel

system.

may

spill.

or

other

sources

servicing.

the

valve

at

Take

care

DO

NOT

Ensure

fuel

system.

the

tank

in

allow

of

fire

proper

any

near

venti-

FUEL

A primary fuel filter

installed between the fuel tank and the engine to remove

water and other contaminants from the fuel before they

can be carried to the fuel system on the engine.

Most installers include a type

with the installation package

problems that contaminants in the fuel can cause.

A typical fuel filter/water separator is illustrated in this

diagram. This is the Raycor Model

mind that

between the fuel supply tank and engine-mounted fuel

system, any water in the fuel will affect the fuel pump,

engine filter, and injection equipment. The ownerl

operator is responsible for making certain the fuel

reaching the engine's injection equipment is free

impurities. This process is accomplished by installing

and maintaining a proper filtration/separation system.

WATER

if

SEPARATOR

of

the water separating type must be

of

filter/water separator

as

they are aware

500 MA. Keep in

a water separator type filter is not installed

of

the

of

SPIN-ON

FUEL

FILTER-_---JI~~~

1.

Shut fuel supply off.

2.

Loosen the fuel filter, turning counterclockwise with

a filter wrench.

3.

Using a rag, wipe clean the sealing face on the

housing bracket so the new filter can be seated

properly.

4. Lightly oil the sealing O-ring on the

To reinstall, turn the filter assembly counterclockwise

carefully until the O-ring contacts the sealing surface

of

the housing bracket. Turn 2/3 further with the filter

wrench.

5. Turn on the fuel and manually prime the fuel filter

using the priming pump on top

a slow steady pumping action until resistance is felt.

The filter is now primed and the engine is ready

to start.

NOTE:

The cartridge contains fuel. Take care

it

during disassembly. Peiform the "fuel system

bleeding" after replacing the spin-on filter.

new filter.

ofthe

housing. Use

not

to spill

air

FILTER/WATER

L

/SEPARATOR

FUEL

The fuel injection pump is precisely adjusted; most

of

them. When an adjustment is necessary, contact your

WESTERBEKE dealer.

NOTE:

rpm governor adjustment seals.

NOTE:

vide for a satisfactory idle speed with each specific installation.

INJECTION

the adjustments are sealed, so be careful not to break

There is no warranty on engines with broken high

The idle adjustment screw can be readjusted

PUMP

CONTROL

to

pro-

f"VtTf

(Engines

WESJERBEKE

& Generators

16

Page 22

FUEL

SYSTEM

(Continued)

FUEL

If

have an authorized dealer correct these problems. Then

use a diesel fuel biocide to sterilize the fuel (follow the

manufacturer's instructions).

ADDITIVES

fungus or bacteria is causing fuel problems, you should

SPARES

While the likelihood

at sea is slim, the possibility does exist. Therefore, we

recommend that banjo washers, injector seat washers,

and a fuel filter be carried on board at all times. (See the

Spares

spares from your local WESTERBEKE dealer or

distributor.

that cannot be corrected by a simple tightening

fitting, replace the sealing washer with a replacement

found in the engine fuel hardware kit for your model.

PRIMING

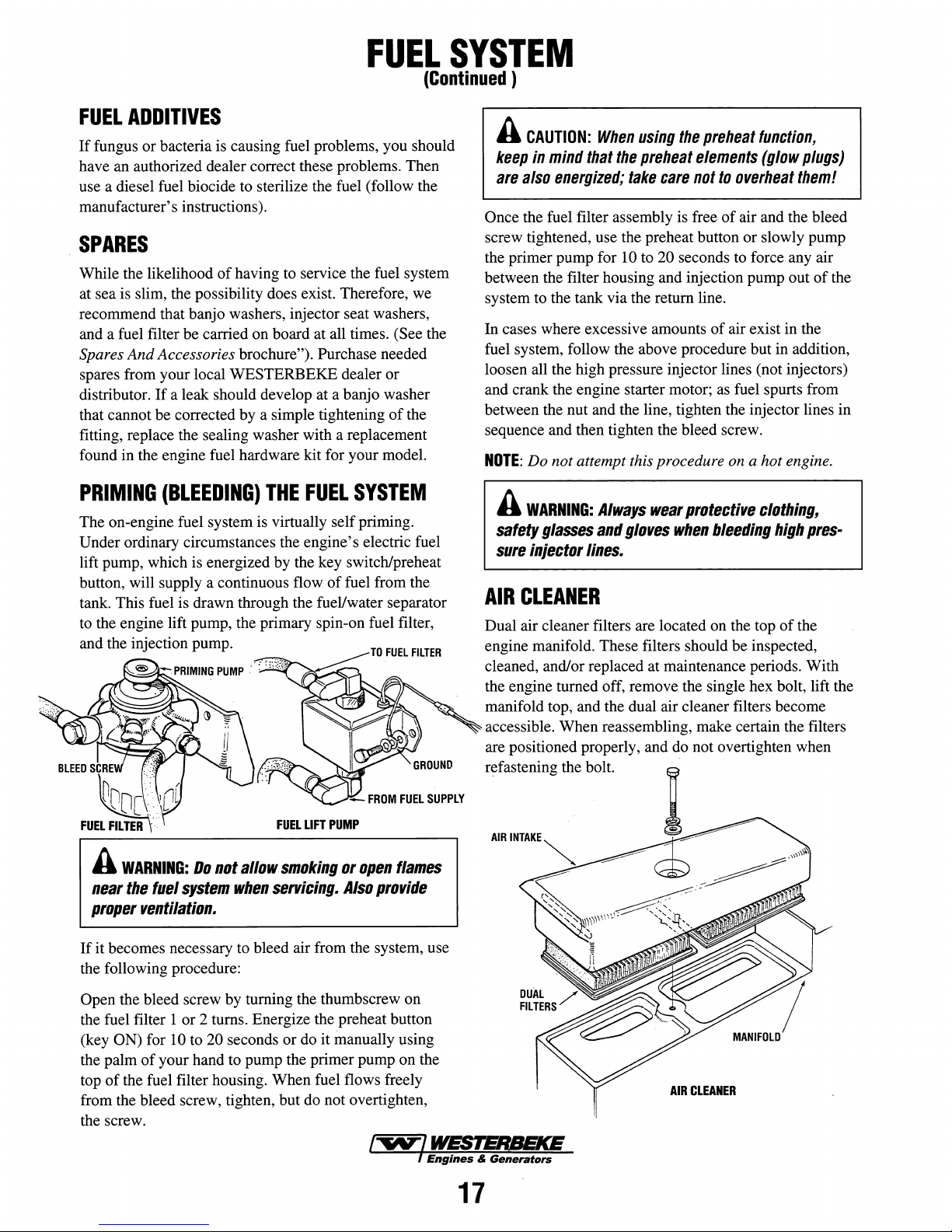

The on-engine fuel system is virtually self priming.

Under ordinary circumstances the engine's electric fuel

lift pump, which is energized by the key switch/preheat

button, will supply a continuous flow

tank. This fuel is drawn through the fuel/water separator

to the engine lift pump, the primary spin-on fuel filter,

and the injection pump.

And

Accessories brochure"). Purchase needed

If

a leak should develop at a banjo washer

(BLEEDING)

of

having to service the fuel system

of

the

THE

FUEL

SYSTEM

of

fuel from the

A

CAUTION:

keep

in

mind

are

also

Once the fuel filter assembly is free

screw tightened, use the preheat button

the primer pump for

between the filter housing and injection pump out

system to the tank via the return line.

In cases where excessive amounts

fuel system, follow the above procedure but in addition,

loosen all the high pressure injector lines (not injectors)

and crank the engine starter motor;

between the nut and the line, tighten the injector lines in

sequence and then tighten the bleed screw.

NOTE:

Do

A

WARNING:

safety

glasses

sure

injector

AIR

CLEANER

Dual air cleaner filters are located on the top

engine manifold. These filters should be inspected,

cleaned, and/or replaced at maintenance periods. With

the engine turned off, remove the single hex bolt, lift the

manifold top, and the dual air cleaner filters become

accessible. When reassembling, make certain the filters

are positioned properly, and do not overtighten when

refastening the bolt.

When

using

the

preheat

that

the

preheat

energized;

not

attempt this procedure on a hot engine.

take

10 to 20 seconds to force any air

Always

and

wear

gloves

elements

care

not

protective

when

of

function,

(glow

to

overheat

of

air and the bleed

or

slowly pump

air exist in the

as

fuel spurts from

clothing,

bleeding

lines.

them!

high

of

the

plugs)

of

the

pres-

FUEL

LIFT

A

WARNING:

near

the

proper

If

the following procedure:

Open the bleed screw by turning the thumbscrew on