Page 1

-(£ft.It

" ·_j

~

}

i.

0

~

_,.

"'

"' '

'q

_ll1.o"-'.

OPERATORS

7

.0

BCG

GASOLINI··

and

· 5.0

7

.0

BGG•5\ll-z

•GEi-TORS

MANUAL

BCGA

.

•

60Hz

. ·

~

SINGLE

PUBLICATiON

.

.REVISIQN

OCTOBER

PHASE

Nb~

oa~ii~o:

3

201e

·

..

,·

'WESIERBEKE .

....

,.tr:

........

A/J'N.

~

WESTERBEKECORPORATTON•

150

JOHN

FAX

1·508-884-9688

HANCOCK

ROAD.•

~WEBSITE:

MYLES

TAUNTON

STANDISH

MA

WWW.WESTE'RBEKE.COM_

INDUSTRIAL

027S0-7319

•TEL. 1·508-823-7677

PARK

Page 2

AWARNING:

Exhaust

colorless

unconsciousness

exposure

•Dizziness

•Nausea

•Headache

•

IF

GET

seBk

until

·

.

W

. . . .

Genaratora

Regular

gasses

gas.

carbon

can

include:

Weakness

YOU

OUT

A.

Produl:e:

IWIWE!!!@!!!1\E

--ras.,,,,.&~

and

OR

ANYONE

INTO

medical

it

h~

been

RN

CARBON

Maintenance

THE

attention.

·1

Required ·

contain

Carbon

Monoxide

and

death.

Sleepiness

ELSE

EXPERIENCE

FRESH

AIR

Shut

Inspected

NG

MONOXIDE.

·Monoxide,

is-poisonaas

Sy,;,ptomB:ot

•

Throbbing

•Muscular

•Vomiting

•Inability

IMMEDIATELY. N sympto111$

down

and

repaired.

A

WARNING

WESTERBEKE

bulkhead

WESTERBEKE

CARBON

living/sleeping

They

are

obtainable

an

odorless

and

Carbon

in

Temples

Twitching

to

Think

ANY

OF

THESE

the

unit

and

DECAL

is

and

should

near

your

engine

also

recommendslnstalllng

MONOXIDE

Inexpensive

at

DETECTORS

quarters

your

local

can

Monoxide

Coherently

SYMPTOMS,

do

not

provided

be

of

and

easily

marine

aµd

cause

persist,

restart

by

fixed

or

generator.

In

your

vessel.

store.

to

the

a

CALIFORNIA

PROPOSITION

Marine

exhaust

are

known

to

cause

and

diesel

and

some

to

the

cancer,

other

reproductive

and

of

State

65

gasoline

birth

WARNING

engine

its

constituents

of

California

defects,

harm.

Page 3

Page 4

SAFETY

INSTRUCTIONS

INTRODUCTION

/lead

this

safety

caused

by

failure

precautions.

take

the

necessary

personnel,

As

the

ownttr

safety

rules·

This

safety

Bt>ataiul

·

riaks

page

and

Yacht

are

not

I.:

The

ac~

maintenance

exclusively

manual

Know

·and

your

or

operator,

and

advisories

infonntJt!on

Cou'tleil

lifnited.

respofisibiliiy./or

risks

for

activities,

fiJ)he·

carefully.

to

follow

fundamental

when

dangerous

precautions

to

machinery.

always

provided/or 1our

iS

in

alignment

(Al'fYCJstandtitds;

to

the

i'4forlitdtion•

the

identifictitiOn•of

compliance

ll1id

owllertopetator.

with all

tither

Most

accidents

conditions

protect

observe

with theAmerkan

in

stifety · tzdvisories,

codons

PREVENTELECTRIC'SHOCK

"ii

WARNING:·

while

engine

·power.

•

• Shut

•

•

• Remove wristwatch and all jewelry

Lethal

Do

not operate this machinery without electrical

enclosures

off electrical power before accessing electrical

equipment.

Use

insulated mats whenever working on electrical

equipment. ·

Make

sure your clothing

(particula:rly

electtfoal equipment.

PREVENT·BOflNS

.

i\wAflltNG:

·

mam

veryhotl

• Monitor engine antifreeze

sysftml

coolant recovery

location

when

the engine

Do

alittouch

is

running,

voltage

and

covers in place.

shoes) when·handling electrical

-

DiJ

hot

clllllpanllnts~

· · ·

tank and periodically

on

the

water jacketed exhaust manifold; but only

is

COLD.

AC

sllt:trlaal

or

when

con1111ctt1d

.Is

present

HOT:·ENGINI!

tOut:~.hOt

at

tllese

and

skin

are

When

~

'iltJ~nS.Patts

1l

ian11lng

.·

coolan,t

level at the plastic

are

rules

and

exist

yourself,

the

your

following

.convenience.

however

the

following

potenti.al

belOng

aonneations

to

sllore

aonnections!

dry, not damp

equiptnent.

working

...

·

or

engine

gets

at

the filler cap

and

safety.

on

PREVENT

A

• Prevent

funtp,

·

II ·

•

.·Do

• Be

PREVENT

A

Injury

• Follow re-fueling safety instructions.

hatches closed when fueling.

• All

•

Do

• Shut off the

• Do not alter or modify the fuel

•

Be

•

• Make sure a

BURNS -FIRE

WARNING:

sparks

to

or

vapors.

Use a suitable container

remo\Ting

I>o

not opetate with the air cleaner/silencer

Bae~ can cause severe injury or

not smoke or permit

the

fuelsysteni. Keep the compartment

engine/generator clean and free of debris to minimize

chances of

aware

BURNS-

WARNING:

or

tleath!

after fueling. Check below for fumes/vapor before

running

before starting your engine.

fuel

vapors

when

handling

well-ventilated area away from spark-producing

equipment

not

fill

servicing

thannight spill.

flames,

or other

engine

when

when servicing

sure all fuel supplies have a positive shutoff

Be certain fuel line fittings are adequately tightened

free

of

leaks.

properly maintained. Be familiar

Extinguishers rated ABC

for all applications encountered in

Fire

can

cause

injury

flash

fires.

Do not smoke or permit

occur near the carburetor,

other potential sources of spilled

the

fuel

line, carburetor, or

flames

fire.

Wipe

up all spilled

- diesel fuel

will

to

or sparks

burn.

fuel

catch

fuel

death.

fuel

EXPLOSION

the

and

the

the

blower.

fuel

fuel

fuel

servicing.

fire

ExplOSions

are

highly

and

out

of

tank(s) while

service

system.

DO

sources

the

extinguisher

from

fuel

vapors

Keep

Open

and

Run the blower

explosive.

storing

fuels.

the reach

valve

Take

NOT

allow

of

fire

Ensure proper ventilation

fuel system.

by

for

Use

Store

of

children.

the

engine

at

the

engine

care

in catching

any smoking,

near

the

system.

is

iii.stalled

with

the

NFPA

this

or

death!

line,

fuel

all

filters.

to

and

and

·the

ventilate

four minutes

extreme

fuel

is

when

fuel

system

nearby

its

proper

are appropriate

environment.

flames

or

filter,

fuel

or

fuel

fuel

when'

~moved.

occur

near

the .

the

engine

oil.

can

cause

vessel's

cabin

care

in a ·

flllllli?g.

any

fuel

open

or

exists

valve.

·

and

and

is

use.

ln

case

of

an

•

before touching

engine overheat, allow the engine

the

engine or checking

the

to

coolant.

cool

·

Englhf1/1"Jt

Generators

i

Page 5

SAFETY

INSTRUCTIONS

ACCIDENTAL

A

WARNING:

or

death!

a Disconnect

generator.

last.

it

a

Make

starting.

a

Make

installed before starting the engine.

BAmRY

A

WARNING:

or

death!

a

Do

not

being

highly explosive

arcing

equipment

ing

servicing. . _

•

Never

tive

not

test the battery condition

together.

Ventilate

accumulation of explosive gases.

disturb

is

being charged.

•

Avoid

burns

wristwatch,

the

battery.

•

Always

the

battery connections. Remove the negative lead

and

STARTING

Remove

certain

certain

Accidental

the

battery cables before servicing

all

personnel are clear

all

covers, guards, and hatches

starting

the negative lead first

EXPLOSION

Battsry

smoke or allow

serviced. Lead acid batteries emit hydrogen, a

or

by

lit tobacco products. Shut off

in

the

connect the negative(-) battery cable

( +) connection terminal

Sparks could ignite battery gases

any

compartment containing batteries

the

battery charger connections while

contacting the terminals with tools, etc.,

or

sparks

rings,

turn the battery charger off before disconnecting

reconnect it last when disconnecting the

sxplaslon

an

gas,

which can be ignited

vicinity

that could cause an explosion. Remove

to

and any

can

open

flame

prevent electrical

of

the starter solenoid.

by

shorting the terminals

To

other jewelry before handling

BAmRYACID

A

WARNING:

sevsrs

Injury

•

When

servicing the battery or checking the electrolyte

level,

wear rubber gloves, a rubber apron,

tion.

Batteries contain sulfuric acid which

If

it comes

with

water.

inadvertently

Sulfuric

or

death/

in

contact with your skin, wash it off at once

Acid may splash

when

acid

In

batteries

·

on

the skin

removing electrolyte caps.

can

cause

Injury

the

and

reconnect

of

the engine before

are

causs

Injury

near the battery

by

elect?cal

all

electrical

arcing

to

the

or

fuel

to

avoid sparks,

the

to

battery.

can

cause

and

eye protec-

is

destructive.

or

into the eyes

engine/

re-

dur-

posi-

Do

vapors.

prevent

do

battery

prevent

first

not

TOXIC

a Ensure

a

a

• For additional information refer

•

a

a

EXHAUST

A

WARNING:

that

discharged from

regularly

are

securely

attention

exhaust pipe

Be

sure

the

In

addition

install a

builder

or

tional

infonnation

A

WARNING:

odorlsss

nausea

Do

not

use

fumes

can

tems.

Exhaust sulfur causes rapid deterioration of

tubing resulting in exhaust/water leakage.

Do

not

install exhaust outlet where exhaust

through

exhaust discharge outlet

enter

the

flow

of

exhaust.

Although

exhaust

gas

is

present in diesel exhaust

toms

or

are:

Vomiting

Dizziness

Throbbing

Muscular twitching

Intense headache

Weakness

AVOID

a

MOVING

A

WARNING:

or

death!

Do

not

service the engine while it

tion

arises

operating adjustments,

ing

moving parts

GASES

Carbon

monoxide

the

exhaust system is adequate

the

engine. Check

for

leaks

and

make sure

attached

to

the manifold, water injection

nipple.

unit

to

carbon

dealer

gas.

or

dsatbl

copper tubing in

rapidly

portholes, vents,

exhaust

diesel engine exhaust

fumes

signs of carbon monoxide inhalation or

in

and sleepiness

and

no

warping

and

its surroundings are

routine inspection of

monoxide

for

Inhalation

destroy

discharge

Avoid

from gasoline engines, carbon

temples

detector.

installation

on

Carbon Monoxide).

carbon

of

to

monoxld1

pradllCIJS

diesel

copper

or

air conditioners.

is

near

the

outlet

overloading the

gases

fumes.

PARTS

in

which it

Rotating

parts

can

is

absolutely

use

extreme care

and

hot exhaust system

(CO}

Is

the

the

exhaust

exists.

the

Consult

approved

ABYC

(CO}

flu-like

exhaust

tubing

waterline,

and

close

are

Some

causs

is

running.

necessary

a

deadly

to

expel

exhaust

manifolds

Pay

elbow,

well

ventilated.

exhaust

your

detectors.

T-22

Is

an

symptoms,

systems.

in

exhaust

can

If

water

or

restrict

craft.

not

as

monoxide

of

Injury

If

to

to

avoid

components.

gas!

gases

system

close

and

system,

boat

(educa-

Invisible

Diesel

sys-

copper

be

drawn

the

engine

could

the

toxic

as

the

symp-

poisoning

a

situa-

make

touch-

lwlWESTERBEKE

f

Engines & Generators

ii

Page 6

m

Do

not

wear

loose

clothing

equipment;

jackets,

could

II

Make

Keep

places

Ill

Do

not check

the

engine

!Ill

Do

not

the

exhaust

generator

death

HAIARIOUS,NOISE

'>':":<•···.-."'"'·-.f:.o•.-

'~~WiRNlNG:

tie

shirts,

be

caught

sure

all

protective

at

all

times.

fluid

is

operating.

allow-any

discharge

is

operating.

can

occur.

·

.>··

back

sleeves,

in

moving

attaching

shields

levels

swimming

.

··

•

Hi{l/l:noise-levels

long

rings,

hardware

and

opening

Carbon

or

jewelry when servicing

hair

and

avoid wearing foose

necklaces or bracelets that

parts.

is

properly tightened.

guards

in their respective

or

the

drive belt's

or

activity around

for

the generator while

Monoxide poisoning or

can

caus.e

fiip!

II

Never

II

Do

not

flame

II

Do

not

open

(when

A

WARNING:

mentally

operate

arrester

an

run

the

engine

removed.

run

engines

installed).

/lo

or

phY,ically

engine

without

with

for long periods with their enclosures

not

work

incapacitated

its muffler installed.

the

air intake

on

machinery

by

SAFETY

tension

while

or

near

the

hearing

cSilencer)

when

fatigue!

or

.

you

are

INSTRUCTIONS

ABYC,

INSTALLING

Read

for

qonswben installing your engine.

ABYC

"Standards and Technical Information Reports

Craft"

Order

Order

Order

NFPA

AND

USCG

ENGINES

the following ABYC, NFPA

safety codes and standards.

{American Boat and Yacht Council)

from:

ABYC

613

Third Street, Suite 10

A.Juiapolis,

www.abyci:nc.org

NFPA - No.302 (National Fire Protection

"Pleasure and Commercial

from:

National Fire Protection Association

Batfofy Mart:h Park

Qumcy,

U~'¢GJDtiite,d

"reglifatedfons are under titles CFR33

Code

from:

U.S.

Washington,

MD

21403 ·

MAOi269

States Coast

of

Regulations"

Government Printing Office

D.C.

20404

PUBLICATIONS

AND

GENERATORS

and

USCG

Follo:w

Motc>rCraft"

their

Gil!!-fd)

recornmenda-

Association)

and

CFR.46

FOR

publications

for

Small

of

the

OPERATORS

Many

of the

in

your

notes

to

carefully,

procedures.

GASOLINE

Preparations

begin

with a

Yacht

Council's

a combination of sources

Sections

H-2

Ventilatio[).

·

H-24

Gasoline Fuer

P-1

Installation of

for

P-4

Marine

Blb\C

All

installations

Regulations

www.abycinc.org

MANUAL

preceding

Operators

highlight

maintain

ENGINE

to

install

thorough

(ABYC)

of

the

ABYC

for

Propulsion

Inboard

and

DC

(FCR).

Manual

critical

your

AND

a gasoline engine

Boats

Systems

Exhaust

and

Engines

Electrical

must

comply

safety

tips

and

warnings are repeated

along

with other cautions and

infonnation.

equipment,

GENERATOR

examination

standards. These standards are from

lnc~uding

standards

using

Systems

Auxiliary Engines

and

Systems

with

Reiid,

yo1fr

arid

follow

ail

· ·

INSTALLATIONS

or

generator should

of

the American Boat and

the USCG and

of

particular interest are:

Gasoline

Transmissions

on

Boats

the Federal Code

manual

safety

the

of

NFPA.

·Engines & Generators

iii

Page 7

When

installing

attention

WESTERBEKE

be

paid

to

the

following

INSTALLATION

engines

information:

and

generators it

is

important that strict

CODES

Strict federal regulations,

when

AND

REGULATIONS

ABYC

installing engines and

guidelines,

generators

and

safety

in a marine

codes

must

environment.

SIPHON-BREAK

For installations where the exhaust manifold/water injected exhaust

or

will

be

below

the vessel's

break

in

the

raw

water supply

minimum

the exhaust manifold injection port

raw

If

you

to

siphon-break.

NOTE:

operation.

engine

EXHAUST

The exhaust system's hose

Exhaust Hose

and

and

system

under

of 20"

above

water damage

have

the vessel's waterline under

A

siphon-break

Failure

damage.

to

any

doubt about the position of the

to

Consult

SYSTEM

is

recommended.

turns

without

turns .In

MUST

any

the

this

regard, a single

be designed

sea conditions

waterline,

the

vessel's

the engine

requires

properly

the

siphon-break

MUST

need

of

to

and

at

provisions

hose

to

the

exhaust

waterline.

is at or below the load waterline will result in

and

possible flooding

the

vessel's various operating conditions, install a

periodic

inspection

maintain a siphon-break

manufacturer

be

certified

The

use

of this type of hose

additiinal

prevent

fitting

length

of corrugated exhaust hose

the

entry of

any

angle

Failure

water-injected

for

and

of

vessels

must

be

made

to

elbow.

This

hose

to

use a siphon-break wheli -

of

the

boat.

exhaust

and

cleaning

can

to

result

for proper

marine

use.

Corrugated

allows

clamps

to

accomplish

water

into

the

exhaust system

heal.

be

complied

elbow

is

install a

must

ensure

in

siphon-

be

looped a

elbow

proper

catastrophic

maintenance.

Marine

for

extreme

these

can

be

used.

with

close

to

relative

bends

bends

The

AVAIL.&,QLE

YOUR

DEALER

SIPHON-BREAK

LOOP

FROM.

WESTERBEKE

WITH

STAINLESS

A

detailed

engines

to

download

Marine

and

generators,

from

Installation

is

supplied

our

website

Engines & Generators

Manual

at

covering

with

each

gasoline

unH. A pdf

www.westerbeke.com.

iv

and

diesel,

Is

available

Page 8

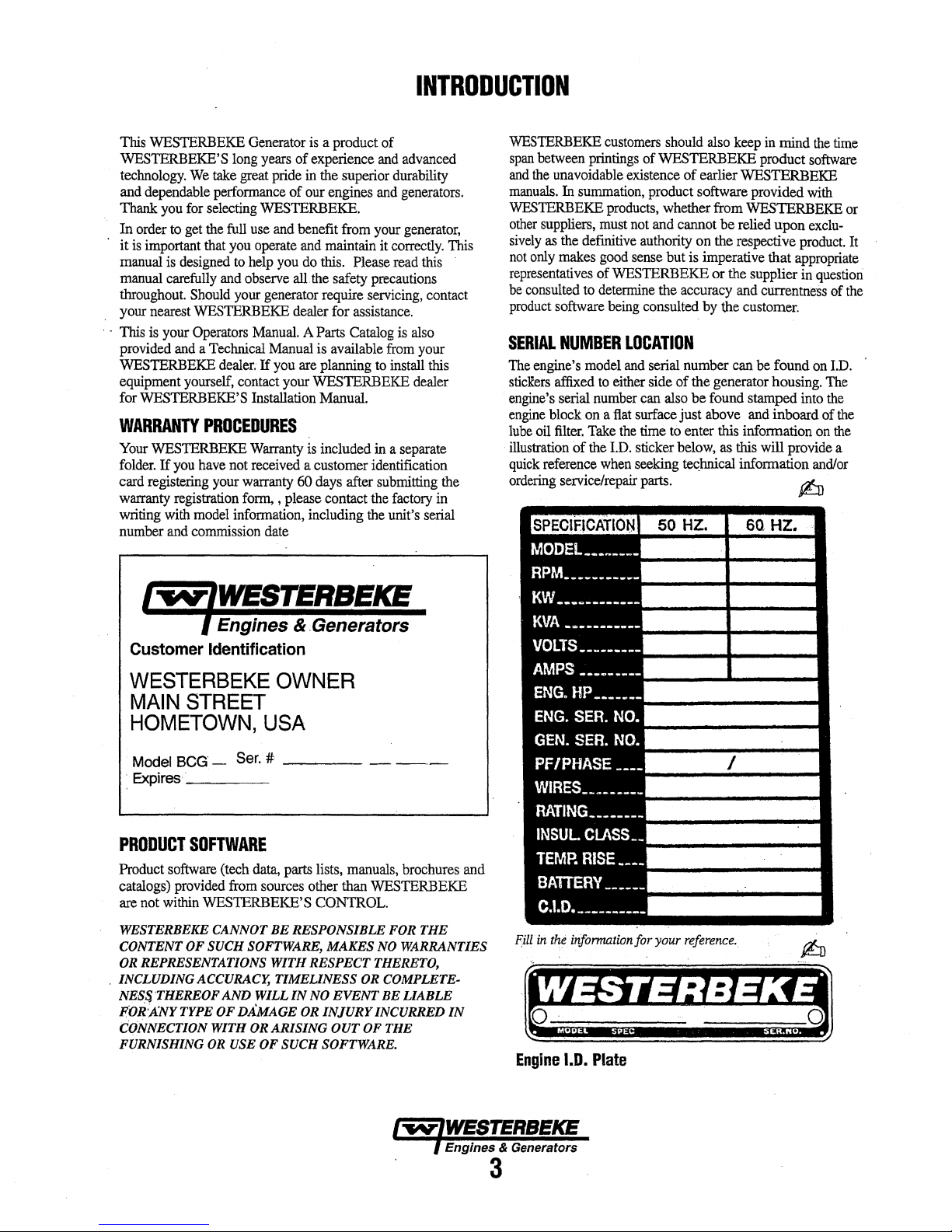

TABLE

Parts

Identification

Introduction

Warranly Procedures ............................................... .3

Serial Number Location ........................................... 3

Fuel,

Engine

Preparations

Control

Operating

Operating

Break-In

Safety

Maintenance

Cooling

Raw

Raw

Changing Coolant ..................................................

Drive

Thern1ostat

lleat Exchanger ......................................................

Fuel

Syslem

Fuel

Gasoline/Water Filter .............................................

Carburetor Filter Screen .........................................

Carburetor ..............................................................

Engine

Oil Change .............................................................

Remote Oil Filter ...................................................

Starter

Testing ....................................................................

Battery

Testing ....................................................................

Engine

Engine

Speed/Hertz Adjustment ........................................

Governor Maintenance ........................................... 28

Spark Plugs ................. : ..........................................

Choke Solenoid ......................................................

Valve

Ignition tirning .......................................................

Torquing Cylinder

Wiring

Wiring

Wiring

Generator

\Viring Diagram .....................................................

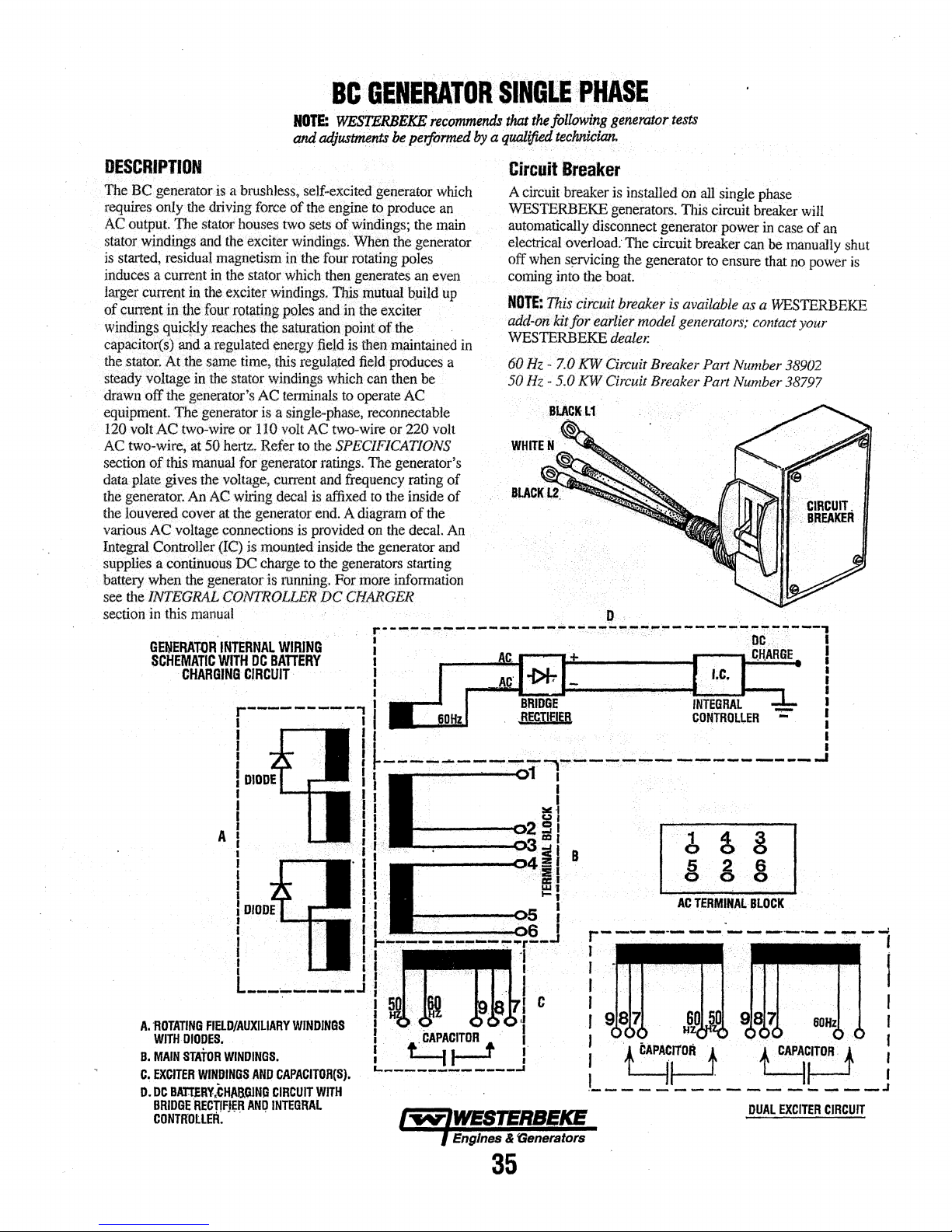

Circuit Breaker .......................................................

Wiring Diagram (60Hz) ......................................... 36

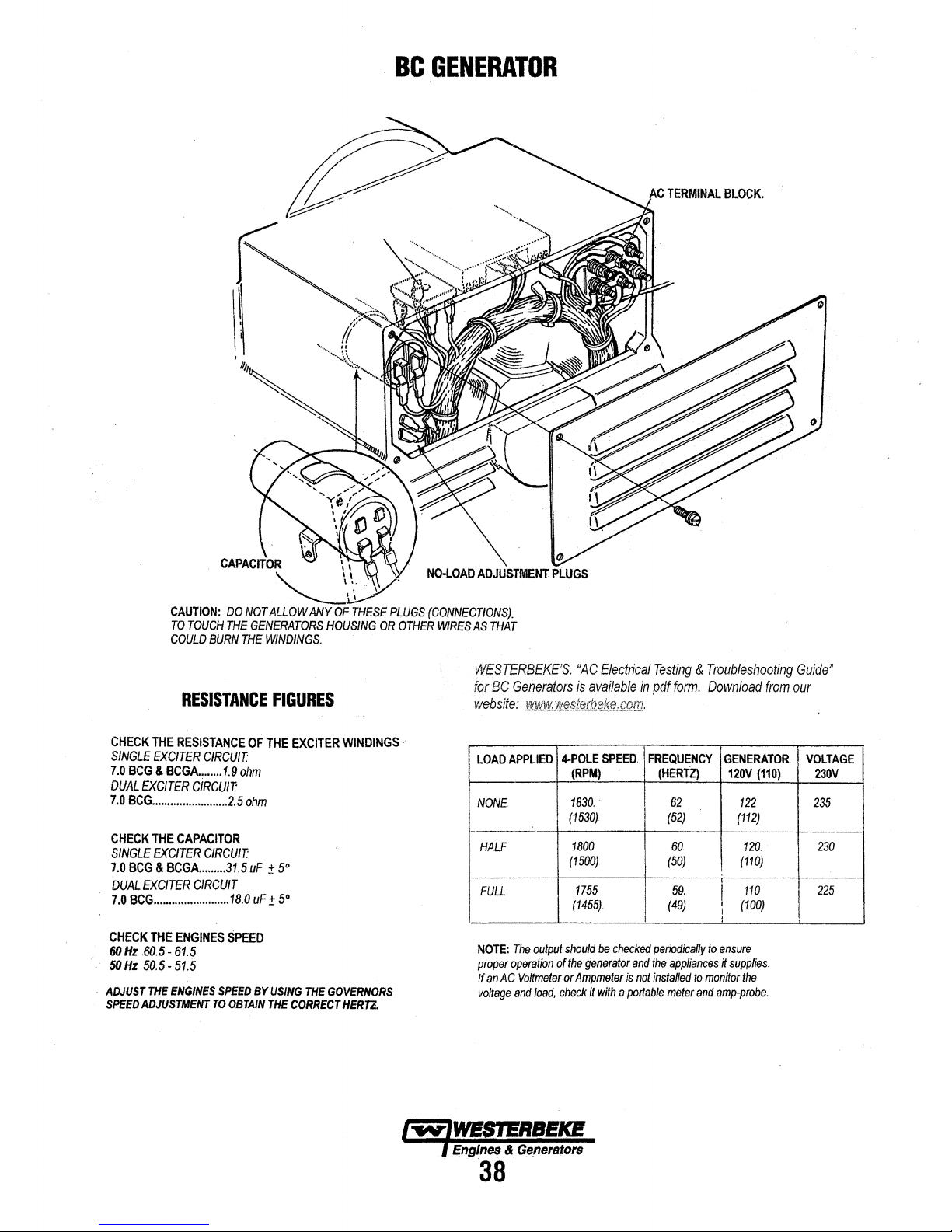

No-Load Adjustmem .............................................. 37

Generator Resistance Values .................................. 38

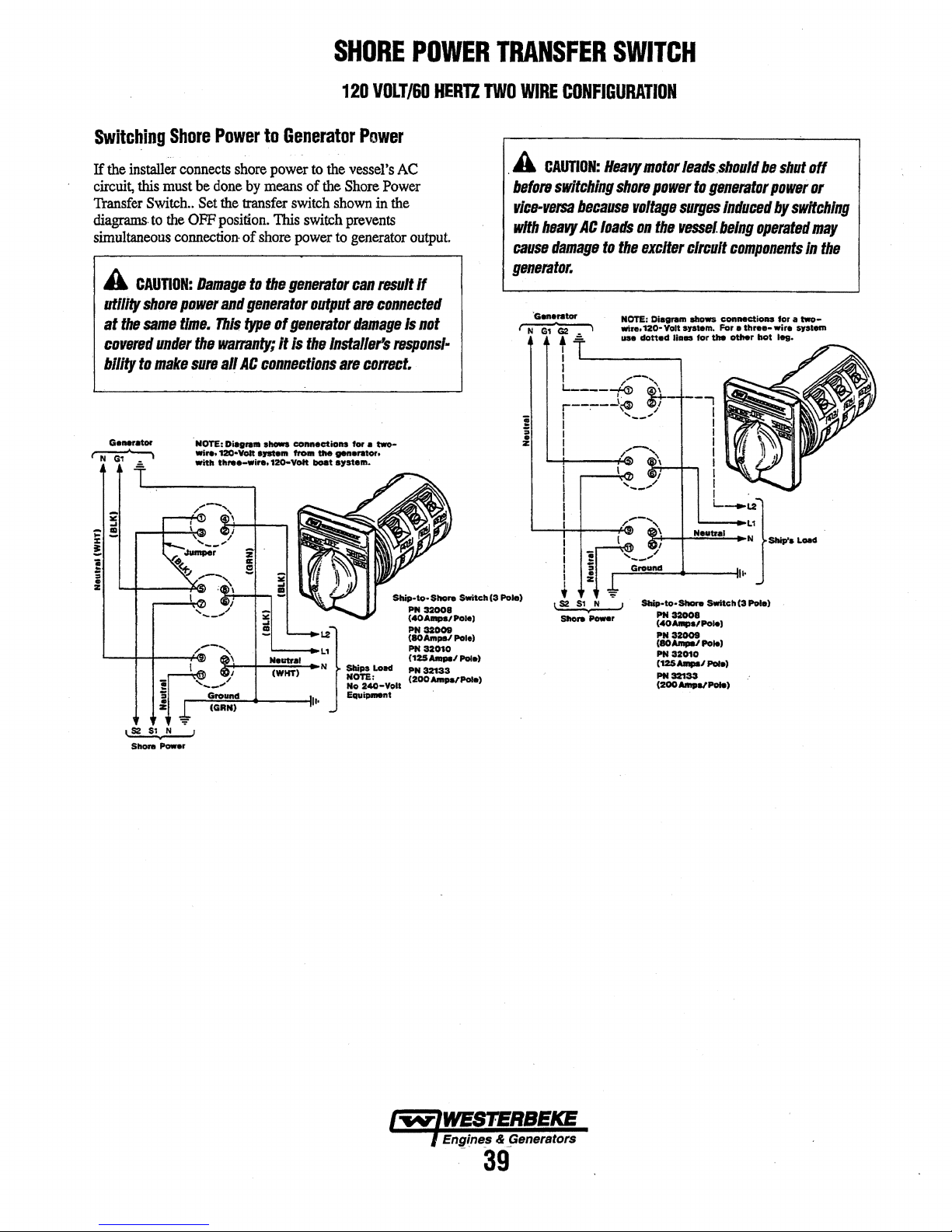

Shore Power Transfer Switch ................................ 39

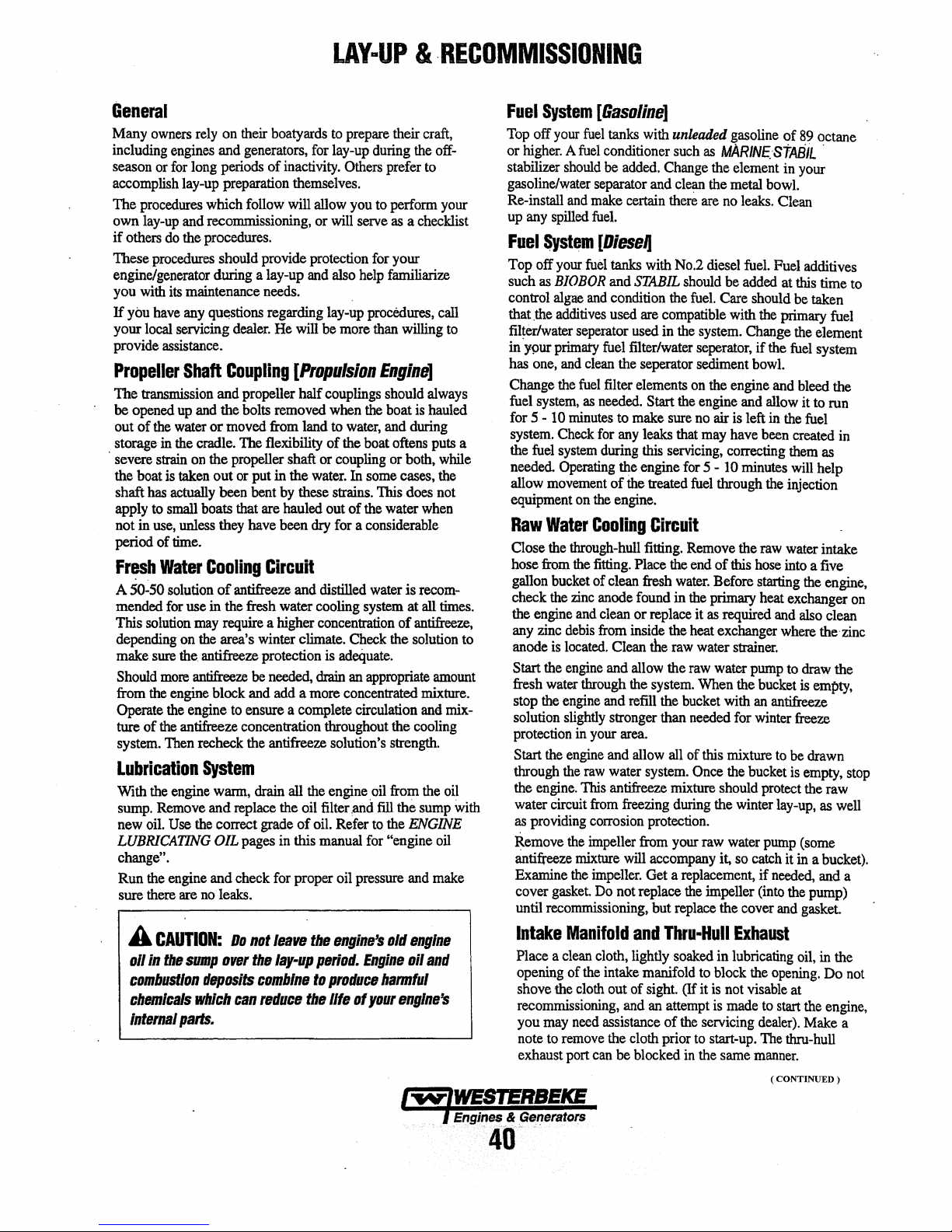

Lay-Up

....................................................................

Oil

and

for

Initial

Panels

................................................................

Instructions

Instructions

Procedure

Shutdown

Schedule

System

.............................................................

Water

Pump ...................

Water

Intake Strainer .....................................

Belt

Adjustment ...........................................

............................................................. l 7

...................................................................

Lift

Pun1p

Lubrication

Motor

.......... ~ .....................................................

Charging

Troubleshooting

Adjustments

Adjustment ................................................... 30

Diagram

(Engine)

Schematic

Diagrams

Information

and

Recommissioning

OF

CONTENTS

........................................................

Engine

(Daily

SWitcbes

.......................................................

Oil

Circuit...

Coolant

Start-Up

....................................................

(Remote

Operation)

.............................

....................................

Paneis)

........................

..........................

...........................................

.................................................

.,

..............................

.................................................. 20

............................................

................................................

......................................................

Head

........................................

...............................................

(Engine)

(Panels)

...........................................

.............................................

..................................................

....................................

1 o

11

12

14

15

15

16

16

17

18

t8

18

18

19

20

21

22

22

24

25

26

28

28

29

29

30

30

31

32

33

34

35

35

..40

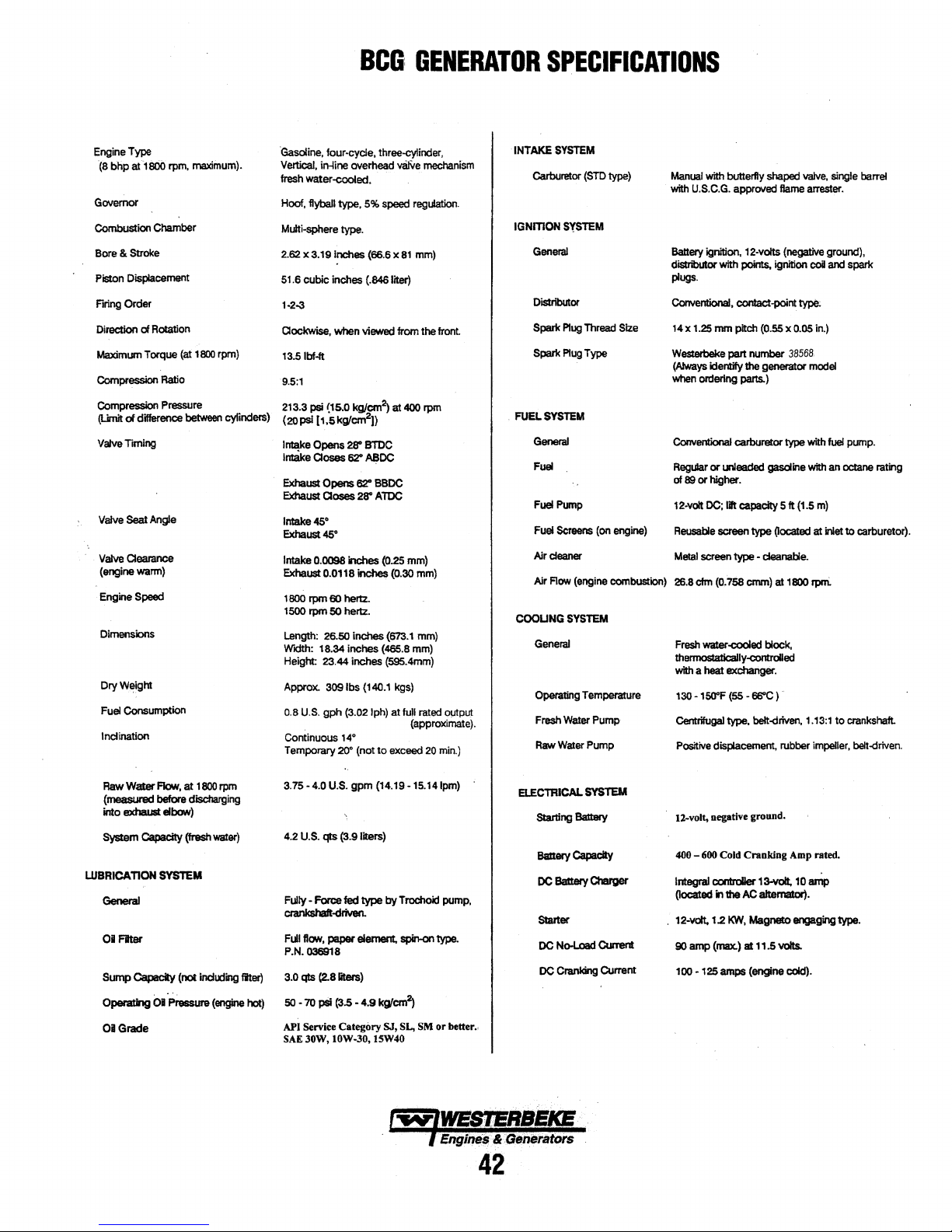

Specifications ............................................................... 42

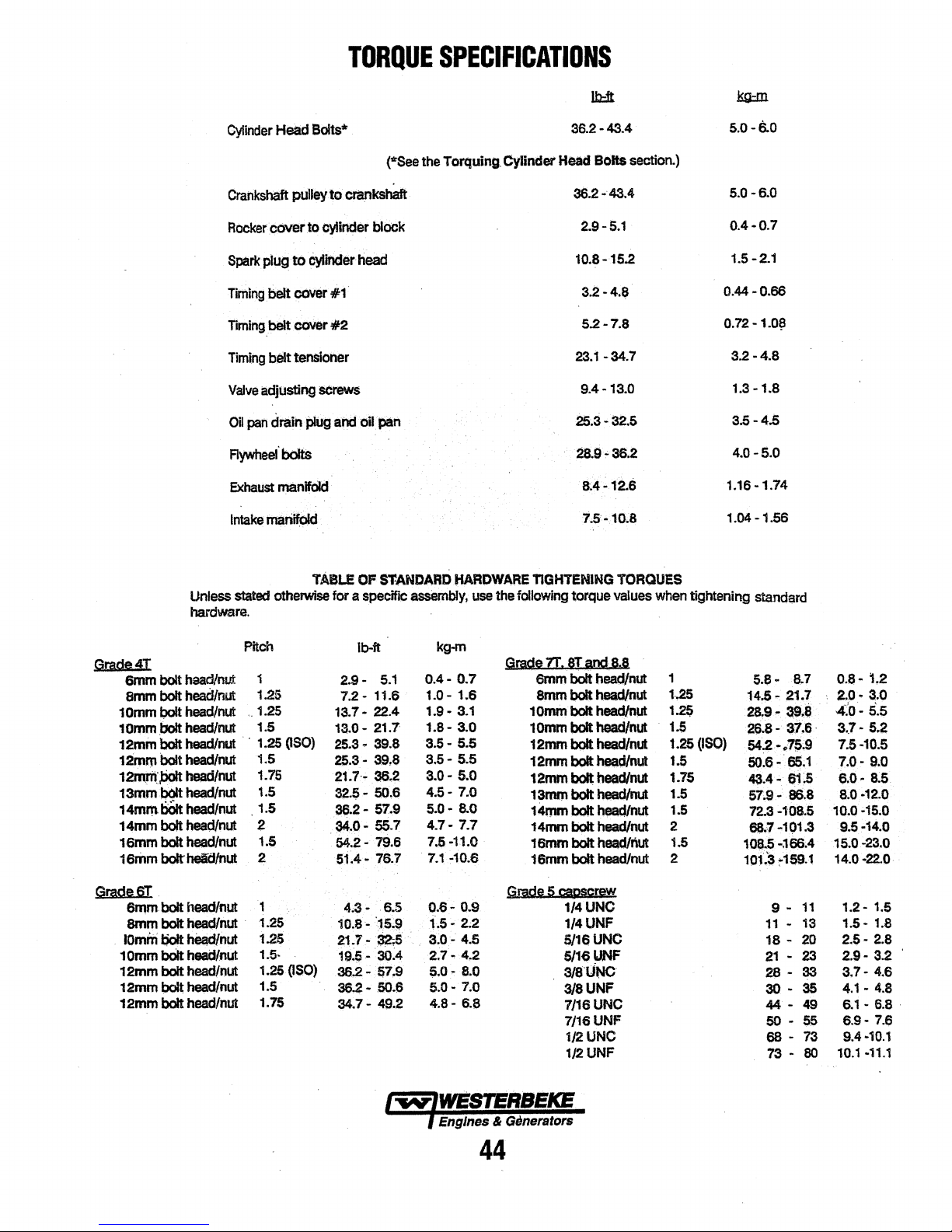

Torque

Suggested

Specifications ...................................................

Spares

..........................................................

44

.45

2

3

5

6

7

8

9

Page 9

20AmpDC

Circuit Breaker

Lube Oil

Dipstick

PARTS

Fresh Water Coolant

Model Data Tag

FUI

IDENTIFICATION

Lube

OH

Fill

Exhaust Temperature Switch

Distributor

45° Exhaust Elbow

Oil Pressure

Switch

...

Heat Exchanger .

Control Panel

8A

&15AFUSES~

--~

/

Air

lntak~

DC Battery Ground

Connection

REAR

Starter with Solenoid

Flame Arrester

FRONT

AC

Connections---

Outlet

Gasdenser

Lube Oil Drain Hose

lwiWESTERBEKE

Engines & Generators

2

i--~-Water

Switch

Sea Water Pump

Zinc Anode

Temperature

Page 10

INTRODUCTION

This

WESTERBEKE

WESTERBEKE'S

technology.

and dependable perfonnance of our engines

Thank

In order

it

is

manual

manual carefully

throughout.

your nearest

· ·

This

provided

WESTERBEKE

equipment

for WESTERBEKE'

We

you

for

to

get

important that

is

designed

Should

WESTERBEKE

is

your

Operators

and

a Technical Manual

yourself,

WARRANTY

Your

WESTERBEKE

folder.

If

you

have

card registering

warranty registration

writing

with

model

and

number

commission

Generator

long

years

take

great

selecting WESTERBEKE.

the

full

use

you

operate

to

help

and

observe all.the safety precautions

your

Manual.

dealer.

If

contact your WESTERBEKE dealer

S Installation Manual.

is

a product of

of experience

pride

in

the superior durability

and

benefit from your

and

maintain it

you

do

this.

generator require servicing, contact

dealer for assistance.

A Parts Catalog

is

you

are

planning

PROCEDURES

Warranty

not

received a customer identification

your

warranty

form, , please contact the factory in

information, including

date

60

is

days

included

and

advanced

and

generators.

generator,

correctly.

Please read

is

also

available

from

to

install

in

a separate

after submitting the

the

unit's serial

this

your

this

This

WESTERBEKE

span

between printings of WESTERBEKE product

and

the

unavoidable existence of earlier WESTERBEKE

manuals.

WESTERBEKE

other

suppliers, must

sively

as

not

only

makes

representatives

be

consulted

product

software

SERIAL

The

engine's

sticRers

affixed

engine's serial

engine

block

lube

oil

filter.

illustration

quick

reference

ordering

SPECIFICATION

MODEL

RPM __________

KW

___

customers

In

summation,

products, whether from WESTERBEKE or

the

definitive authority

good

ofWESTERBEKE or the supplier in

to

determine

being

NUMBER

model

to

either side of the generator housing.

number

on a flat

Take

of

the

I.D.

when

service/repair parts.

should

also

keep

product software provided

not

and cannot be relied upon

on

the respective

sense but is imperative that

the accuracy

consulted

and

by

the customer.

LOCATION

and

serial number can

can

also

be found stamped

surface just above and inboard of

the

time

to

enter this information

sticker

below,

as

this

seeking

te~hnical

50 HZ.

___

~----

_

G

_______

_

in

mind

appropriate

currentness of

be

found

will provide a

information

$:JJ

60,

HZ.

the

time

software

with

exclu-

product.

question

on

I.D.

The

into

the

the

on

the

and/or

It

the

Engines & .Generators

Customer

WESTERBEKE

MAIN

HOMETOWN,

Model BCG -

.

Expires·_----·

PRODUCT

Product software (tech

catalogs)

are

not

WESTERBEKE CANNOT

CONTENT OF SUCH SOFTWARE, MAKES NO WARRANTIES

OR REPRESENTATIONS

.

INCLUDING ACCURACY,

NESS THEREOF

POR'ANYTYPE OF DA0MAGE OR

CONNECTION WITH OR

FURNISHING

Identification

OWNER

STREET

USA

Ser.

#

----

SOFTWARE

data,

parts lists, manuals, brochures and

provided

within

from

sources other than WESTERBEKE

WESTERBEKE'S CONTROL.

BE

RESPONSIBLE FOR THE

WITH

TIMELINESS

AND

WILL

IN

ARISING

OR

USE OF SUCH SOFTWARE.

-

---

RESPECT THERETO,

OR COMPLETE-

NO

EVENT

INJURY

OUT OF THE

BE

LIABLE

INCURRED

IN

·

KVA

-~---------

VOLTS

AMPS

________

___

ENG.

HP----~-

ENG.

SER.

GEN.

SER.

PF/PHASE----

WIRES

________

RATING

INSUL

TEMP.

CLASS

RISE----

_______

BATIERY

C.1.D.

----------

Fill

in

the

informa.tionfor

Engine

l.D.

G

____

NO.

NO.

------

Plate

_

_

.•

_

_

your

I

reference.

Engines & Generators

3

Page 11

.

ORDERING

Whenever

generator

include a

needed

part

Also

will fit

specifications

NOTES,

As

this

maintenance

generator,,

CAUTIONS,

NOTE:

A

observed,

PARTS

replacement

and

engine

complete

(see

insist

upon

or

generic

as

CAUTIONS

manual

schedules,

critical

and

An

operating

CAUTION:

can

engine.

A

WARNING:

fa/lawed,

NOTE:

by

WESTERBEKE.

the

SPARES

Certain

WESTERBEKE

SUGGESTED

as

proper

way.

spares

on-board

NOTE:

manual).

the

about

can

A

carbon

engine

room.

AND

spares

fuel

WESTERBEKE

and

accessories

inventory

Also

available

These

drive

engine.

these

kits.

parts

are

needed,

model

and

serial

part

description

the

separately

WESTERBEKE

parts

are

frequently

original

equipment.

AND

takes

you

through

and

information

WARNINGS.

procedure

Procedures,

result

in

the

Ptocedures,

result

in

personal

monoxide

Affix

warning

this

decal

and

furnished

packaged

WARNINGS

the operating

troubleshooting of your

will

be

An explanation

essential

which

damage

which

injury

decal

in a visable

ACCESSORIES

will

be

needed

to

support and

generator or engine

SPARE

and oil

of

are

provide

Visit

our

PARTS).

filters

will

brochure

the

basic

can

provide

proper

Spare

Parts

service

website:

Often

be

difficult

you

to

assist

WESTERBEKE

Kits

spares

www.westerbeke.com

INTRODUCTION

always

provide

numbers.

part number for each

not

highlighted

to

if

not

or

If

has

when

even

with a suggested

(last

In

addition,

Parts

Catalog).

parts

because

made

to

the

same

procedures,

by

NOTES,

follows:

note.

strictly

destruction

not

prapedy

ar

lass

been

location

maintain

cruising

simple

to

you

page

needed

of

of

life.

provided

in

(see

items

obtain

along

in preparing

parts.

in

this

in

maintaining

to

the

your

your

such

learn

an

the

PROTECTING

Care

at

the

have

resulted

many

thousands

manufacturer

installed

operated

buyer/owner

NOTE:

Six

•

Proper

• An

efficient

anti-siphon

engine.

•

Changing

hours.

•

Proper

components

this

•

Use

•

Winterize

RECOMMISSIONING

UNDERSTANmNG

The

gasoline

ways

similar

are

vertical

overhead camshaft

a solid-state distributor

camshaft-driven.

lubrication

which

is

generator's

maintenance

The

most

proper ventilation, maintenance of the

system,

YOUR

factory

during

in a

WESTERBEKE

of hours of

cannot control

in

the

vessel

and

serviced in

operator.

important

engine

maintenance

manual.

clean,

steps

and

well-designed

break

to

the

engine

according

filtered

your

engine

THE

engine

driving

to

a gasoline

in-line,

system,

thermostatically

important

cooling

engine

that

system

and

which

The engine

and a fresh

requires

is

required of a

factors

INVESTMENT

assembly

generator

dependable

how

or

or

the

manner

the

field.

this

to

ensure

long

generator

prevent

oil

of

unleaded

according

exhaust

and

all

engine

to

the

section

fuel

installation.

water

oil

filters

maintenance

in

GASOLINE

an

AC

generator

automobile

the

engine's

is

chain-driven.

which

is

horizontally

incorporates a pressure

water-cooled

controlled.

the

same

gasoline

to

the

generator's

and

the

generator

and

thorough

capable

service.

where

the

in

which

is

up

to

generator

system

thaJ

from

entering

every

and

generator

schedule

to

the

JAY-UP

this

manual.

ENGINE

engine.

cylinder

head

The

mounted

engine

To a large

preventative

automobile

fuel

system,

back-end.

testing

However

generator

the

unit

the

life:

includes

the

I

00

operating

AND

is

in

many

The

cylinders

has

engine

type

block

degree,

longevity

ignition

of

the

is

is

an

in

an

utilizes

and

the

engine.

are

CARBON

WESTERBEKE recommends mounting a carbon

detector in

even

The presence

from

elbow/e:xhaust

If

carbon monoxide is present, ventilate the area

air

MONOXIDE

the

vessels living quarters. Carbon monoxide,

in

small amounts,

of

carbon monoxide indicates

the engine or generator or

hose.

and

correct

the

DETECTOR

is

problem immediately!

deadly.

from

the

an

exhaust

exhaust

monoxide

with

.

leak

clean

Engines & Generators

4

Page 12

FUEL,

ENGINE

OIL

AND

ENGINE

COOLANT

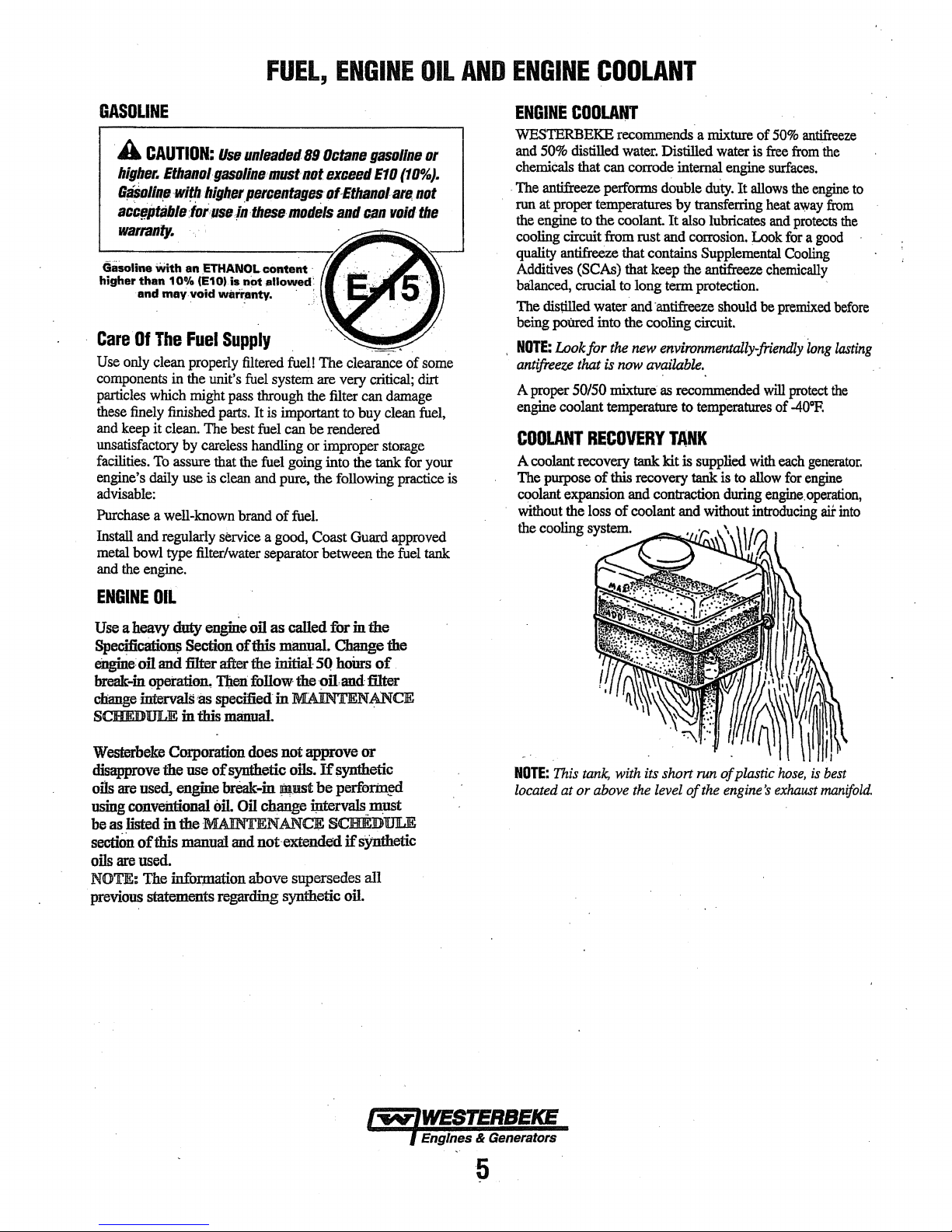

GASOLINE

·A

CAUTION:

higher.

Etbana/

BefSDll°'e

a~/e;far.·use.!R·tbesemo*/s

warranty.

Gaisoline With an

highar

than

108/e

and

mllY

Care

Of

The

Use

only

clean properly filtered

components

particles

these

and

keep

unsatisfactory by careless handling or improper

facilities.

engine's daily use is clean

advisable:

Purchase

Install

metal

and

the

in

which might

finely

finished

it

clean.

To

a well-known

and

regularly service a

bowl

type

engine.

Ilse

unleaded

gasa/lne'must

·wif~

hillher.1111rce11tages

89

Octaae

not

exceed

of·Ethaaol

and

ETHANOL

lE10) is

void

Fuel

the

unit's

The best

assure that the

filter/water separator between the

content

nOt

warr~nty.

·

•llowed'

. :

Supply

fuel!

The

fuel

system are very critical; dirt

pass

through the filter

parts.

It is important to buy clean

fuel

can be rendered

fuel

going into the tank

and

pure, the following practice

brand

of

fuel.

good,

Coast Guard

gasal/ae

E10

caa

cl~~

can

(100/o).

are,

not

void

the

of

damage

storage

for

approved

fuel

or

some

fuel,

your

tank

.

,

is

ENGINE

WESTERBEKE

and

chemicals

The

run at proper temperatures

the engine to the coolant

cooling

quality

Additives

balanced,

The distilled water

being polired into the cooling circuit.

NOTE:

antifre~

A

engine

COOLANT

A coolant recovery tank kit is supplied

The

coolant

without the loss of coolant

the

COOLANT

recommends a mixture of

50%

distilled

antifreeze performs double

circuit from rust and

antifreeze that contains

crucial to long term

Look for

proper

SO/SO

coolant

pmpose of this recovery tank

expansion

cooling

water.

Distilled

that can corrode internal engine

by

It

(SCAs)

that

that keep

and

·antifreeze should

tlie

new

environmentally-friendly

is

now

available.

mixture

temperature

RECOVERY

system.

as

and

contraction

recommended

TANK

and

water

du~.

transferring

also

lubricates

corrosion.

Supplemental

the

antifreeze

protection.

to

tempCratures

is

to

during

without

\

50%

antifreeze

is

free

from

surfaces.

It

allows

the

heat

away

and

protects

Look

for

Cooling

chemically

be

premixed

will

protect

of

-40°R

with

each

allow

for

engine.operation,

introducing

\{i

the

engine

from

the

a

good

before

'wng

lasting

the

generator.

engine

aii:

into

to

ENGINE

Use

Specifi~

eilgine:

break-in

change intervals

SCHEDULE in this

Wesrerbeke

disapprove

oils

using

be as

sectiOD.

oils

NOTE: The infor,mation above supersedes all

previous

OIL

a

heavy

duty

enghie

oil as called fbr

Section oftbis manual.

oil

and

filter after the initial

opetatian.

Corporation does

the use

are

used, engine break-in

conventional

listed

in

of

this

are

used.

statements regarding synthetic

TJ:ten

follow the

ti

specified in MAINTENANCE

manual.

of

synthetic oils.

oil.

Oil

change

the

MAINTENANCE SCHEDULE

manuai

and

not-extended

SQ

-0ilan.d

not

approve or

If

~ust

be

iJ:ltervals_

in

the

Change

hoUrs

filter

synthetic

pertbr:in~

must

if

sYnthetic

oil.

of

the

NOTE:

Thi.s

located at or

tank,

with its short

above

the

level

of

run

the

of

plastic

engine's

hose,

exhaust

is

best

manifold.

Page 13

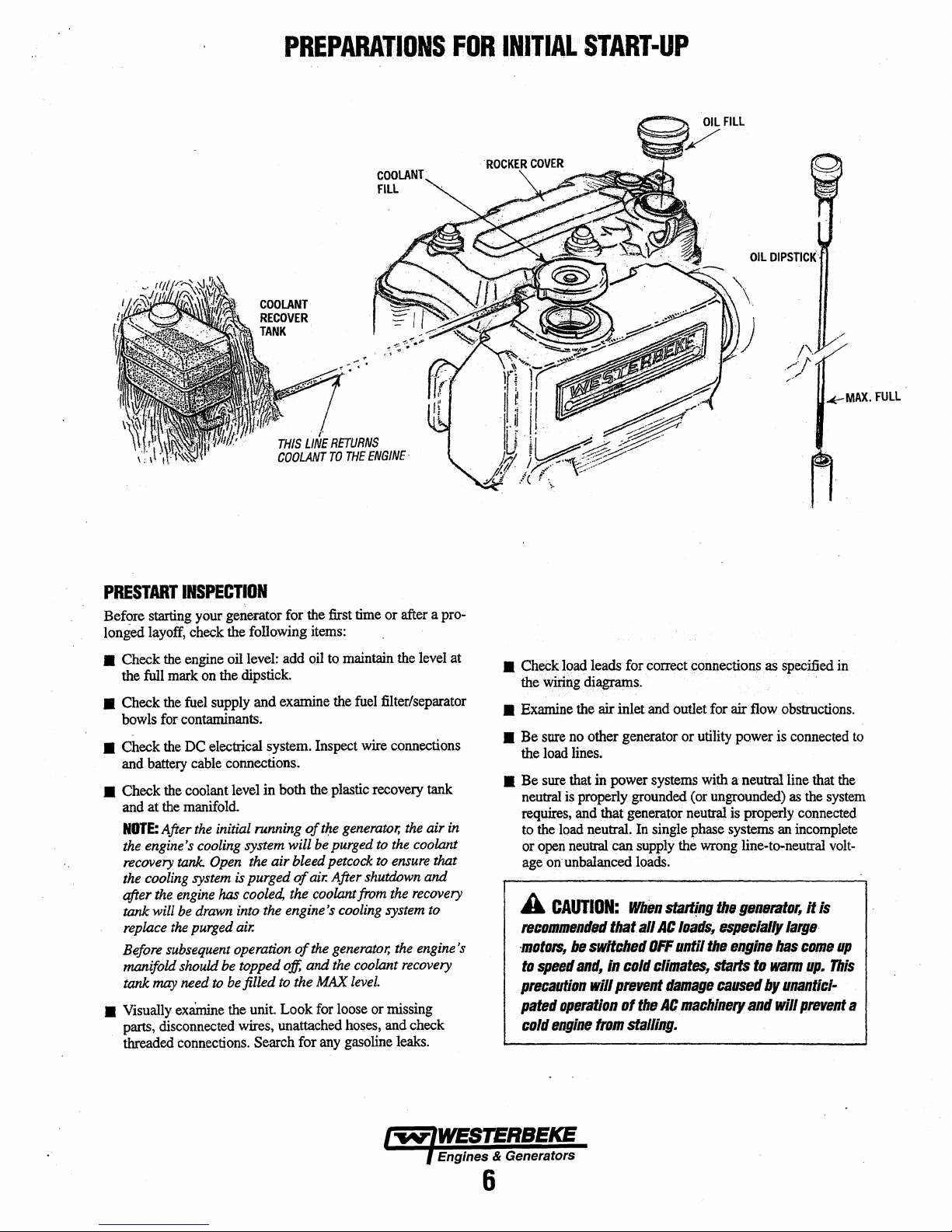

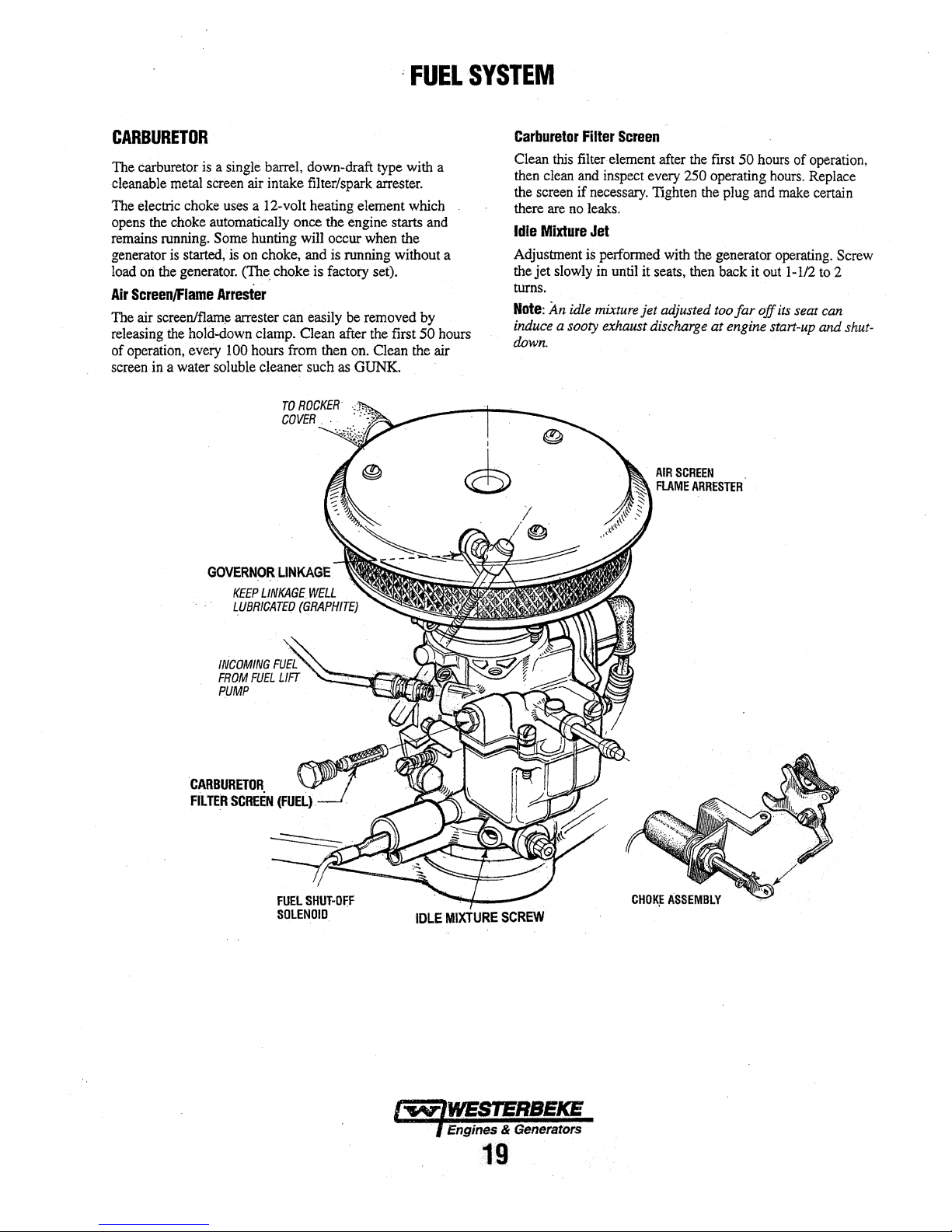

PREPARATIONS

COOLANT·

FILL

FOR

INITIAL

START·UP

OIL

DIPSTICK

4-MAX.FULL

PRESTARTINSPECTION

Bef91'e

starting

layoff,

longed

• Check

the

full

a Check

bowls

a Check

and

battery

a Check

and at

NOTE:

the

engine's

rec<JVery

the

cooling

after

tank

replace

Before

manifold

tank

•

Visually

parts,

threaded

your

check

the

engine

mark

on

the

fuel

supply

for

contaminants.

the

DC

electrical system.

cable

the

coolant

the

manifold.

After

the

cooling

tank.

Open

system

the

engine

will

be

drawn

the

purged

subsequent

should

may

need to

exainine

disconnected

connections.

generator for the

the following

oil

level:

add

the dipstick.

and

examine

connections.

level

in both

initial

running

system

will

the

air bleed

is purged

has

cooled,

into

air.

operation

be topped

be

filled

the

wires, unattached

<Jf

the

the

engine's

of

off,

to

the

unit.

Look

Search for

first

items:

Qil

to

maintain

the

Inspect

the

plastic

of

tlJ.e

generator,

bepurged

petcock

air.

After

coolant

cooling

the

generator,

and

the

MAX

for

loose

any

time

or after a pro-

fuel

filter/separ:ator

wire

recovery

to

to

shutdi:Jwn

from

system

coolant

leveL

or

missing

hoses,

and

gasoline

the

level

connections

tank

the

air

in

the

coolant

ensure

that

and

the

rec<JVery

to

the

engine's

recovery

check

leaks.

at

a

.Che(:kl()ad

the

Wiring

•

Examine

• Be

sore

the

load

a

Be

sure

neutral

isproperly.grounded,.(or.ungrolJJlded)

requires,

to

the

load

or

open

~ge

onunbalanced

A

CAUTION:

teOO/llllltllltltld

·motors,

'"

speff/

precaution

patsd

operation

cold

qine

leads

for

correct

diagrams.

the

air

inlet

~d

no

other generator or

lines. ·

that

in power

and.

that

generat()r

neutral.

neutral

can

In

supply

loads.

If/lien

tbatall M

be

swltdled

anti,

will

tram

In

cold

prtJvent

al the

stalling.

tiff

<;onnections

outlet for air

utility

systems

single

with

neutl'at

phase

the

V'lrong

start!PI!

loar$,_

until•

t:lialates,

damage

AC

machinery

.as

specified

flow

obstructions.

power

is

connected

a neutral line

is

properly

systems

line-to-neutral volt-

ti!•

fP11Jllflllor,

that

as

the

connected

.~

incomplete

n

Is

11$/lf1Dlallylarg11

1111!Ji.n11

b.f!s

t:Oflle

·starts

to

watm

up.

callSfld

by

and

unantlBJ.

will

prevent

in

to

the

system

up

This

a

Engines & Generators

6

Page 14

CONTROL

PANELS

DESCRIPTION

The generator mounted control

ON

switch (black), a START switch(white) and a

switch (red).

The

ON

switch provides power

switch by-passes the protective oil pressure shutdown switch

until the oil pressure reaches 5 -

The

START switch energizes the start solenoid/starter which

cranks the engine. This switch will

switch is depressed and held at the same time.

The

STOP switch will twn

switch must

The

panel also has two fuses to protect the

•·A

Stow-blo

•An 8 Amp

any

REMOTE

An

optional remote start/stop panel is available for

controlling the generator from a remote location.

This panel has the same ON, START, and STOP functions

previously described. Also included is a green LED light

which glows once the engine/generator has reached

rpm's. The purpose

release the

engine/generator

be

depressed until the stop sequence

15Amp

Fuse

Fuse

to

protect

optional

remote.

~a'!_efs.

START/STOP

of

the LED is to alert the operator to

START switch. It is also an .'ndication that the

is

running.

panelis

to

the start circuit.

10

psi.

not

off

the engine/generator.

to

protect

the

start

the

engine

operating

PANEL

(OPTIONAL)

equipped with

operate unless the

DC

circuit:

circuit.

circuff

15

RECORDING

FOR

8

an

STOP

nus

nus

is

complete.

ancf

AMP

FUSE

HOURMETER

MAINTENANCE

AMP

FUSE

600

on

HOURS

REMOTE

An optional remote instrument panel is available which

includes a water temperature gauge, oil pressure gauge,

DC charging voltmeter, operating hourmeter

switches.

REMOTE

The remote instrument panel has two sending

installed on the engine block, a water temperature sender and

an

oil pressure gauge sender. Plugged ports for each are

located on the engine.

installed in the thennostat housing and the oil pressure sender

is adjacent to the oil pressure switch.

on the threads

each sender are tied

wiring harness).

The blue wire is for the oil pressure sender and the

is for the water temperature sender.

between terminal board connections

removed. Refer to the REMOTE INSTRUMENT WIRING

DIAGRAM

NOTE:

installers responsibility to comply with the

standards

INSTRUMENT

INSTRUMENT

of

both senders. Electrical connections for

in this manual.

When

installing the optional remote panels, it is

33

CFR

part 183.

PANEL

PANEL

The

water temperature sender is

off

next to the senders location ( in

(OPTIONAL}

INSTALLATION

Use sealing compound

If

there is a jumper

T-1

•.

·

and

U.S.

aQd

start/stop

units

to

tan wire

T-2,

it should

Coast Guard

be

the

be

the

Engines & Generators

7

Page 15

OPERATING

INSTRUCTIONS

STARTING

A

for a minimum

WJntilatlng

fumes

1.

Depress

this

2.

Depress

· starts,

the

NOTE:

the

oil

pressure

maintain

3.

Release

·A

when

caused

and

Once

ator

and

ature

lf

an

gauges

NOTE:

This

and

when

111EGENERATOR

WARNING:

from

primes

release

ON

switch a

Keeping

pressure

to

the

CAUTION:

starting.

by

will

prevent a cold

The

engine

allow

(130°-150°

optional

for

nonnal readings. · · · ·

Soin~·unstable

condition

the

..

Ventilate

of

five

blowers

the

generator

the

ON

switch

carburetor.

the

START (white),

the START switch. Continue

few

the

ON

shutdown circuit allowing the oil

rise

enough

ignition circuit

the

ON

switch.

AllAC

This

precaution

unanticipated

is

running

the engine

Fl

55°-56°C)

instrument panel

should smooth our

generator

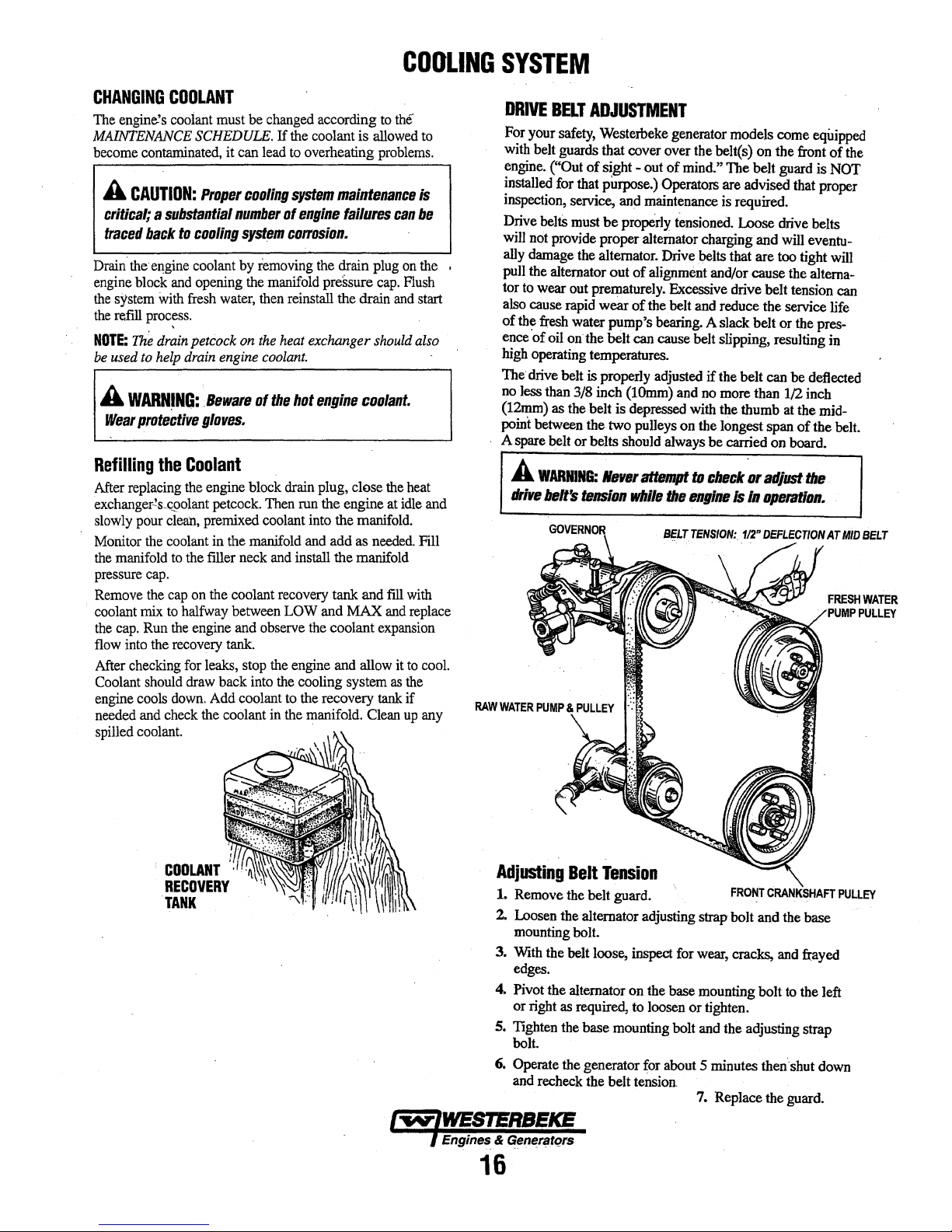

the

generator

mlnut•

remove

seconds

switch depressed by-passes

to

loads

running

prior

any

explosive

comjlarlment

and

hold

Continu.e

when

longer.

close

the

mast

will

operation

engine

ttom.sttllllag.

apply

to

wartn

before applying

is

installed, tnonitorthe.·

may

(l$,th.e

loads

a~

appJit4

A

compatfment

to

starting.

gasoline

and

it

down

(5-15

to

depress

the

geneyator

. ·

switch

an.ti

be

swllched

pre"6nt

of

AC

machinery

-"-

a ligbtJoad

up

ti:>

qperating temper-

the

The

bilges~

•.

sec~nds),

ON.

to

.engage

exhaust

pump

c11olin!J

entettll.e

manifold

frorll

throug/Fhull

cogecting

Engine

warrantable

in

mind.

STOPPING

1.

Remove

generatorto

its

off

damage

.·1

operating temperature).

.

2.

Depress

~.

When

NOTE:

the stop

to

the gener-

heavy

·.

loads.

panel.

CAUTION:

engine

with,

is

pumping

system

happening

damagetesultlngfrom

the

In

an

switch,

Prolonged

starting

raw

water.

raw

during

engine's

once

the

the

emergency,

cylinders

the

exhaust

byt:Joslng

Shutoff,

the

cause

issue:

the

THE

GENERATOR

AC

loads

run

for

an

STOP (red)

generator stops, release the STOP

remove

t;ra11klng

can

result

In

fllllngthe

This

may

water

through

cranking.

draining

of

the

This

by

way

system

the

raw

the

excessive

raw

(Jwner/operator

·

from

the

added 3

the 8

to

S minutes

switch.

if

the

generator will not stop

amp

ju.se

Intervals

happen

tile

miff

of

the

fills.

Prevent

water

exhaust

engine

water

should

generator

in

engine

because

raw

water.

waler

exhaust

supply

muffler,

entry

and

(this

the

control

occ1'tNiJacd!(:l,~ng:i11.e.

e~gtne

'warms'

up

without

the

can

this

and

cranking.

is

not

a

keep

this

allow

the

stabilizes

switch.

using

·

.·Engines

& Generators

8

Page 16

OPERATING

ABNORMAL

An

abnormal stop

and

comes to a stop

may

cause damage

unsafe operating condition. The fault stop conditions

1.

Overspeed condition!.

2.

High

3. Low oil pressure.

4. High exhaust temperature.

Should a fault condition occur, the engine will shut

and

the green LED light

indicating that a fault

should

OVERSPEED

In the case of

must be reset before re-starting

the

Stop switch mtarily

sequence.

If

the overspeed switch itself

depressing

T-1

coil connection

end of

only

as a test.

successful, replace

Do

not

switch.

STOP

is

one

in

which

the

generator

as

a result of

to

the

engine temperature.

on

has

be

located (see ENGINE TROUBLESHOOTING).

an

operating fault which

engine, the generator, or create

the remote panel will

occurred. Once detected,

ceases

SHUTDOWN

an

overspeed shutdown, the overspeed circuit

the

generator. Simply

then

the

the

T-1

run

the generator

STOP

from

wire

with

Re-start

the

proceed with

is

switch

will

the

overspeed switch

electrical

the

generator,

faulty

overspeed switch.

with

faulty

not reset

tape.

out replacing

the

and

re-setting it

the

By-pass

if

this by-pass

the

normal

circuit,

and

this

overspeed

go

tape

is

to

are:

down,

off

the

fault

depress

start

by

lift

the

circuit

INSTRUCTIONS

NOTE:

Overspeed switches draw a small amount

run

an

the

amperage (25 milliamps) at all times once the generator

connected to its starting battery. This amounts

mately 18 amp-hours

concerned with this slight amperage draw during normal

. seasonal operation.

unused for many months, it

amp ignition fuse from

tum

off

the

generator's starting battery

A

CAUTION:

shutdown

tampering

would

injury

and

REMOTE

The remote startpanel

operate the same

except that they have

remote location (where

be

audible). The green

generator is running

switch should be released. For the remote start/stop sequence

refer to

always

with

cause

should

cause

the

PANELS

STARTING

in

a month. It is not necessary

However,

It

is

be

installed

the

overspeed

it

to

malfunction,

the

generator's

generator

as

the generator mounted control panel

green

LED

at

about

THE

if the generator set

is

best to either

the

controlpanel

very

important

and

functioning.

shutdown

could

belt-driven

to

run

away.

and

the remote instrumentpanel

LED lights for starting

the

sound

of

the

lights indicate

600

rpms.

GENERATOR

remove

on

the

switch..

that

the

module,

be a cause

governor

generator.may not

when

That is

on

the

of

to

approxi-

to

be

is

to

be

the

8

generator or

overspeed

Any

which

of

fail

at

a

the

when

the

start

previous page.

is

A

the

Refer

manual.

to

WARNING:

overspeed

the CONTROL

switch

Do

not

operate

by-passed.

PANEL

the

generator

WIRING DIAGRAM

with

in

this

Engines & Generators

g

Page 17

BREAK•IN

BREAK·INPROCEDURE

After

the.generator

and

then

encourage a fast

20%

to

60%

A

CAUTION:

tor

by

running

After

the

first

can

be

increased

vary

the

foad.

Avoid

.

<lverlo~d

smoky

eXhaust

Monitor

it

at

hertz,

by

To

the

breaker

NOTE:

current drawn

amperage drawn

age. See

the

within

the

1800

rpm

control

the

current

protect

against

generator;s

that

Be aware

GENERATOR

has

been

started,

warm-up.

of

full

load

for

the

first

·Do

not

attempt

without

10

~all

with

currentbeing:d.rawn

genei;a.tors~

to

produce

of

drawn

output

is·

rated·

required

a

/aad~

hours

of

the

generators'

to

the

full-:load

time:;.

¥

l'edoCed:

the

generator's engine

from

unintentional

at·

of

motor starting

can

be 3

output

tating.

60

hertz;

the

leads

should

the

rated output

for

starting

to

5 timesnormalrunning

INFORMATION

rated

··

9yertoa.d

Since

generator.

overloading

check

Run

the

10

hours.

to

break-in

operation,

output;

i~

voltage.

from

i:he

generator

the

generator

or

at

1500

break~in

be

routed

of

the

toads

anti

motors.

in.thisfrtanua.L

PROCEDURE/DAILY

NOTE:

This

for

proper

generator

operation

between

is

reached

condition

A

your

genera-

periods

OPERATION

Some

unstable

should abate

and

loads

CAUTION:

of

time

Do

not

without a load

generator.

the

load

then

periodically

·

.signa}~

and

by

a

frequency~

and

keep

operates

to.produce

cjfi:he

through a circuit

generator.

th~

This starting

is

governed

generator,

high

r:zmper-

50

·

STOPPING

Remove

Allow

the

operating

CONTROL

NOTE:

After

.

the

nuzintelltlnce

.

GENERAToR

Once

be

governor

during

this

period

under

ment

speed

the

the

ENGINE

may

adjustment

.

tHE

GENERATOR

the

major

AC

generator

temperature

PANELS).

the

first

schedule for

ADJUSTMENTS

generator

engine's

(see ENGINE SPEED (HERTZ) ADJUSTMENT

also

has

adjustments

break-in period (first 50

ADJUSTMENTS. A

be

required

(see

running may occur

as

normal operating

are

applied.

operate

the

being

loads

fu:im

the

tb.run

for a

few

and press

SO

hours

beeh

GENERATIOR

of

the

placed

required

in

conjunction

the

STOP

generator operation

50 hour service

in

for

no-load

~n

a cold

temperature

generator

placed

generator

minutes

operation,

engine

INFORMATION).

to

switch

speed

hours)

voltage

with

for

long

on

the

one

stabilize

down,

check.

there

(hertz)

or

the

engine's

engine.

at a time.

the

(see

check

may

after

adjust-

CHECKLIST

Follow

this

checklist

•

R.ecord

the

hounneter reading

relate

to

the

maintenance

•

Visually

II

Check

•

Check

•

Check

•

Check

a

Check

•

Check

blow-by

•

Confirm

When

When

When

inspect

the

the

your

the

the

for

abnormal

sounds.

exhaust

the

engine

the

engine

the

engine

oil

level

coolant

fuel

starting

drive

each

day

before starting

in

schedule).•

the

engine for

(dipstick).

levelin the coolant

supply.

batteries

belts

for

.noise

smoke:

is

cold

is

wann - almost

is

overloaded -

fuel,

(weekly).

wear

and

such

-White

your

oil,

proper

as

knocking,

Smoke.

Smokeless.

some

your

log

(engine

or

water

recovery

tension

vibration

Black

Smoke.

generator.

hotirs

leaks:

tank.

(weekly).

and

Engines & Generators

10

Page 18

SAFETY

SHUTDOWN

SWITCHES

. SAFm

The engine

Should a shutdown

finding

Engine

TROUBLESHOOTING

The following is a

switches:

SHUroOWN

is

protected

occur,

and

correcting

starts,

runs

and

desCription

SWITCHES

by

a variety

do not attempt

the

cause. Refer

then

section

of

shuts dbwn in the

of

this manual. .

of

these automatic shutdown

shutdown switches.

to

restart without

to

the heading

ENGINE

EXHAUST

TEMPERATURE

SWITCH

Exhaust

An

elbow. This switch will open and interrupt the DC voltage tn

the ignition coil (which turns

switch's sensor indicate an excessive exhaust temperature

inadequate supply.of raw water coolant causes high exhaust

temperatures).

(

127° -132"

Temperature

exhaust temperature switch

This switch opens at 260" - 270° F

C)

and resets

Switch

at

approximately

is

located

OFF

on

the

the engine), should the

22."i'F

exh;~ust

(107'' C)

(an

low

Oil

Pressure

A low oil pressure

engine's oil gallery. The switch

pressure. Should the

t11e

switch

will open interrupting the DC voltage

ignition

coil (which turns

Oil

FILTER.

Switch

shutdown

engine's

1.·~¥.-V~

~Ji

switch

oil pressure

OFF

the engine).

LOW

is

located off the

is

kept closed

OIL

PRESSURE

fall

by

engine oil

to

10 -.15

to

the

SWITCH

psi,

r.;:;;

High

RPM

Shutdown

An overspeed shutdown switch shuts

by

grounding out the ignition system should the engine's

speed reach approximately

momentarily depressing the

cause

of

the engine

Engine

Circuit

Breaker

The.

generator's engine is protected

manual reset circuit breaker (20 amps DC). Excessive current

draw

or electrical overload anywhere

wiring or engine wiring will cause

the generator will shut down because

event

breaker interrupts the DC circuit

should occur, check and repair the source of the problem.

After repairing the fault, reset the breaker and restart

generator.

Switch

2175

STOP

overspeed

OFF

the generator set

rpm. Reset the switch b)

switch. (Make sure the

shutdown

to

is

cnrre.cted).

by

an

engine mounted

in

the instrument panel

the breaker

the K2-run

the

to

opened

relay.

trip.

If

the

In

this

this

High

Water

A

high

housing. This switch

to

the

ignition coil (which turns

fresh water coolant's operating temperature reach

approximately 205" F (96" C). ·

This switch resets at 195" F

Temperature

water temperature switch

will

Switch

open and

(!OTC).

is

located on the

inte1rupt

OFF

thcm10st.at

the

DC

voltage

the engine). should

l"flV'iWESTERBEKE

~

the

Engines'&' Generators

11

Page 19

A

WAllNING:

running.

11$8

the

curreot

serrlcin9

NOTE:

Many

more

difficult

MAINTENANCE

Nsver

attetnpt

Wear

tbeprap11raletyeq'1i/1"1ent

t~ols

,,,,

any

of

the

e11gi11e'I

of

the

following

and

may

require

to

perfQrm

,.ch/o/l.111$coanect

DC

BlilctriQal

mamtenance

the

expert

SCHEDULE

any

service

such

the

equipment.

procedures

knowledge

while

as

g11119/e$

battery

are

$imp

of

a

service

terminals

the

engine

and

gloves,

le

but

others

mechanic.

Is

and

when

are

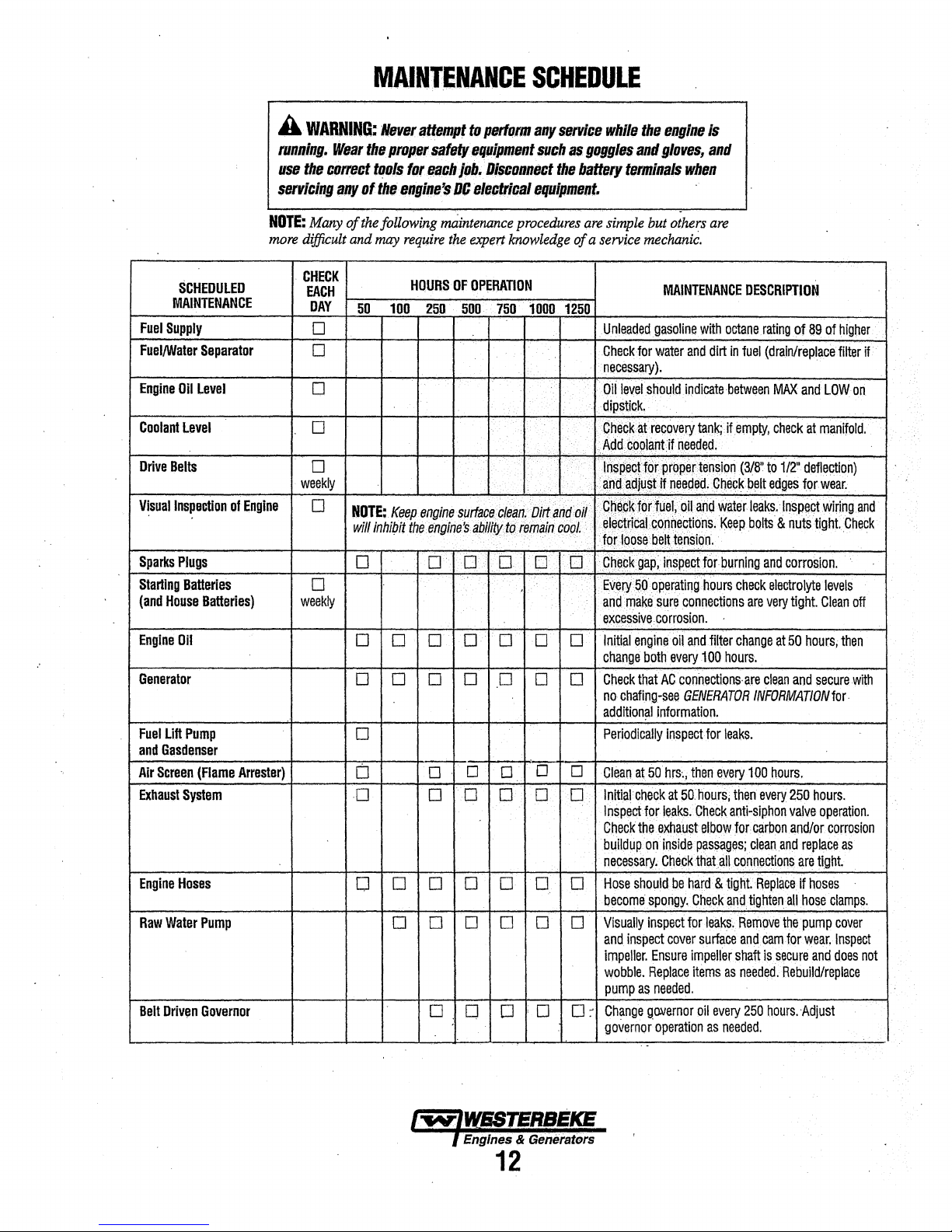

SCHEDULED

MAINTENANCE

Fuel

Supply

Fuel/Water

Engine

Coolant

Drive

V!sual

Sparks

Starting

(and

Engine

Generator

Fuel

and

Air

Exhaust

Engine

Raw

Belt

Separator

Oil

Level

Level

Belts

Inspection

Plugs

Batteries

House

Batteries)

Oil

Lift

Pump

G11sdenser

Screen

(Flame

System

Hoses

Water

Pump

Driven

Governor

of

engine

Arrester)

CHECK

EACH

DAY

0

0

0

0

D

·weekly

0

0

weekly

HOURS

OF

OPERATION

5Q

100

25.0

500

NOTE;.

Keep.

engine

surtace.cle~n·Dirta~r:frJif

wlll

lnhi/Jit

too

engifie'S

ab.lffJYt~iem~in.cgpl.

[j

0

0

0

0 D

·

..

··D··.•

0

. •

I

0

c-

0

D

D

D

0

0

0

D

0 D

D

D

O D 0 0 D 0

D 0 D D

.750

·cc-

.

0 D

·o~

D D

..

0

..

D.

0

1000

D

0

D

0

.·

. i

••

MAINTENANCE

1250

Unleacled

Check

·

necessary).

Oil

clipstick

.

1

crieC:k~recovery

.:Acid#P91ilJJt:if·n.eeded.

· · ·

••·

• ·

··

1

"lli$g~oftorpr~perterlston

. . I

a,ng

•tjbep~:tor

' ·

.•

eleetncat

tor19~sebe~tt!nsiqn.

c'

Eve~

and

ei.<c.essive.

0

Initial

change

D

Check

no

addition~l

Periodically

0

·Clean.

>o

Initial

lnspept

Check

buildup

necessary~

D

Hose

oecome

Visually

and.

impeller.

wobble.

pump

0

~

Change

governor·

gasoline

for

water

and