Page 1

OPERATORS

MANUAL

Single

·

GASOL:IN.E

3

OBP

•

·•·

Phase I 60Hz

G.ENERATORS

.

MG.

· · ·

Fresh·Waterand

..

Ra·w

Fresh·Water

Water

Cooled

and

Cooled

Model

50Hz

Models

J'~'WESTERBEKE

. PUBLICATION NO. 48009

REVISION 7

APRIL2018

•

WESTERB£KE

JI

150

JOHN

.

""!f:Td...,

.,4;,.,};J Member National

CORPORATION•

HANCOCK

ROAD,

MYLES

TAUNTON,

lltlarinc

·].

STANDISH

MA

INDUSTRIAL

02780-7310

Manufacturers

U.S.A.

Associati<m

PARK

··--·

Page 2

CALIFORNIA

PROPOSITION

65

WARNING

Exhaust

colorless

unconsciousness

exposure

•Dizziness

•Nausea

•Headache

•

IF

·,

GET

seek

until

gasses

gas.

can

Weakness

YOU

OR

OUT

INTO

medical

It

has

Marine

exhaust

are

known

to

cause

and

other

contain

Carbon

and

Include:

and

Sleepiness

ANYONE

been

ELSE

THE

FRESH

attention.

inspected

diesel

and

and

some

of

to

the

State

cancer,

reproductive

AwARNING:

Carbon

Monoxide

death.

Symptoms

. •

·•Muscular

•Vomiting

•Inability

EXPERIENCE

AIR

IMMEDIATELY.

Shut

down

and

gBSC)line

its

birth

engine

constituents

of

California

defects,

harm.

Monoxide,

is

poisonous

of

Throbbing

to

ANY

the

unit

repaired.

an

odorless

and

can

Carbon

Twitching

OF

in

Temples

Think

THESE

If

symptoms

and

do

Monoxide

Coherently

and

cause

SYMPTOMS,

persist,

not

restart

This

WARNING

WES'fERBEKE

bulkhead

WE81ERBEKE·alsa

CARBON

/Milg/sleeplng

.

Tlley

are

·

obtainable

DECAL

and

should

neat

iour

MONOXIDE

quartets

lnexpenstve

at

your

Is

provided

be

fixed

engine

recommends

or

generator.

DETECTORS

of

your

and

easily

local

marine

by

to

a

installing

in

the

vessel

•

store.

Page 3

Gasoline

with

an ETHANOL

content

higher

· and

than

may

10°/o (E10)

void

warranty.

is

not

allowed

TM

Engines & Generators

Page 4

page

Page 5

SAFETY

INSTRUCTIONS

'INTRODUCTION

Read this safety manual carefully.

caused

by

failure to follow fundamental rules

precautions.

take the necessary precautions

personnel,

As

the.dwner

and

advisories

is

in

·

stanilalUB;

in

the

potential

mfiitdemit1ce·ai:tivilies.

to

theQWf18ffoperatm:

,

PREVENT

A

while

power.

111

Do

enclosures and

B Shut off electrical

equipment

• Use insulated mats

equipment

• Make sure your clothing

(particularly

•

Remove

electrical equipment

PREVENT

A

exhaust

hot!

• Monitor engine antifreeze coolant

coolant

location

when

A

Ill In case of

before touching the engine or checking

Know

when dangerous conditions exist

and

your

machin"J_. . __

or

ope(&loF,

provided

alignment

followfng

however,

and

8(iual

witfl

tbe'lftTlerican

satef;y

pages.

risks

ELECTRIC

WARNING:

eagiae

Lethal

not operate this

Do

is

m11aiag,

voltage

covers

,power

shoes)

wristwatch

BURNS-

WARNING:

system

recovery

the

WARNING:

Do

components. A running

tank

on

the

water jacketed exhaust

engine

is

Steam

an

engine

to

protect yourself, your

always

for

The

and

00.selW

your

convenience.

Boat

riSl(s

are

not

responsibility

for

compliance

other

condilions

SHOCK

not.taudl

is

machinery

whenever

when

and

HOT

not·tout:h

COLD.

overheat,

Ai:

or

when

jJresellt

without

in

place.

before

working

and

skin are

handling electrical equipment

all jewelry

ENGINE

hot

and

periodically

can

cause

allow

Most

accidents

and

..

. _ _ _ _

the

following.Bafety

This

safety

and

Yacht

limited

electrical

connBctrid

at

accessing

Council

to

the

for

the

ldentiticatioo

with

all

safely

belong

th~

connections!

electrical

on electrical

dry,

when

working

engine

parts

exclushlely

canDet:tions

to

electrical

not

engine

level

at the plastic

at

the

manifold,

injury

or

death!

the

engine

the

coolant.

are

and

rules

lnfonnation

(

ABYC)

infomlation

of

~Hes,

sho,.,,

damp

on

or

gets

very

filler

cap

but

only

to

cool

PREVENT

I A

•

Prevent

sparks

pump,

vapors.

removing

•

Do

Backfire

• Do not smoke or pennit

the

engine/generator clean

chances

II

Be

PREVENT

. A

injury

•

•Follow

hatches

after fueling. Check

running the

before

ii

All

when

ventilated

and

-

•

Do

•

Shut

the

spill.

sources

servicing.

the

1111

Do

Ill

Be

II

Be certain

free

II

Make

properly maintained. Be familiar

Extinguishers rated

for

BURNS -FIRE

WAlllllNG:

:Bash

to

or

Use a

not operate with the air cleaner/silencer

fuel

aware

Flm

IBll

"""""*'

fires. Do not smoke or pennit

occur near the

other potential sources of

suitable

the

fuel

can cause

system.

of

Keep

fire'.

Wipe

- diesel fuel

container

line,

severe

the

up

carburetor,

carburetor,

injury or

flames

compartment

and

all

will

BURNS -EXPLOSION

WARNING:

or

death!

re-fueling safety

starting your

fuel

handling and storing fuels. Store

out of the reach of

not

fill

..

'·

off

fu~

DO Nor

fuel

not alter or

sure

all

of

leaks.

sure a fire extinguisher is installed

all

applications encountered in

clOsed

blower.

vapors

area

the

the

fuel

system.

of

fire

Ensure

system.

fuel

fuel

Explosions

instructi.OllS.

when

fueling.

below

Run

the

engine.

are

highly

explosive.

away

from spark-producing

children.

fuel

tank(s)

while

service

Tuke care in

allow

near

modify

supplies

line

valve

any

smolmig,

the

fuel

proper ventilation

the

fuel

have a positive

fittings

ABC

by the

ar

tlmllll

flames

fuel

line,

filter,

spilled

fuel

or fuel

to

catch

all

fuel

or

fuel

filters.

removeid.

death.

or

sparks

to

occur

and

the

free

of

debris

to

miniurire

spilled

fuel and

burn.

from

fas/

Open and ventilate

for fumes/vapor before

blow~

for

· ·

Use

the

engine

at

the

engine

catc~

open

system or

exists

system.

are

adequately

with

NFPA

Uiis

engine

rapotS

t:an

Keep

the

four

minutes

extreme

fuel

in a

equipment·

is

running.

when

any

fuel

:flames,

engine

when

when

shutoff

tightened

nearby

its proper

are

appropriate

environment.

vessel's

that

valve.

or

fuel

when

near

the

oil.

tJllllSB

cabin

care

well-

servicing

might

or other

servicing

and

and is

use.

Engines & Generators

i

Page 6

SAFETY

INSTRUCTIONS

ACCIDENTAL

A

WARNING:

or

death!

• Disconnect the battery cables before servicing the engine/

generator. Remove the negative lead first and reconnect

it last.

• Make certain all personnel are clear

starting.

• Make certain all covers, guards, and hatches are reinstalled before starting the engine.

BATTERY

A

WARNING:

or

death!

• Do not smoke or allow an open flame near the battery

being serviced. Lead acid batteries emit hydrogen, a

highly explosive gas, which can be ignited by electrical

arcing or

equipment in the vicinity to prevent electrical arcing during servicing.

• Never connect the negative(-) battery cable to the posi-

tive(+) connection terminal

not test the battery condition by shorting the terminals

together. Sparks could ignite battery gases or fuel vapors.

Ventilate any compartment containing batteries to prevent

accumulation

disturb the battery charger connections while the battery

is being charged.

• Avoid contacting the terminals with tools, etc., to prevent

bums or sparks that could cause an explosion. Remove

wristwatch, rings, and any other jewelry before handling

the battery.

• Always tum the battery charger off before disconnecting

the battery connections. Remove the negative lead first

and reconnect it last when disconnecting the battery.

BATTERY

STARTING

Accidental

starting

can

cause

of

the engine before

EXPLOSION

Battery

by

lit tobacco products. Shut off all electrical

of

explosion

explosive gases. To avoid sparks, do not

can

cause

of

the starter solenoid. Do

ACID

injury

injury

TOXIC

• Ensure that the exhaust system is adequate to expel gases

EXHAUST

A

WARNING:

discharged from the engine. Check the exhaust system

regularly for leaks and make sure the exhaust manifolds

are securely attached and no warping exists.

attention to the manifold, water injection elbow, and

exhaust pipe nipple.

• Be sure the unit and its surroundings are well ventilated.

• In addition to routine inspection

install a carbon monoxide detector. Consult your boat

builder

• For additional information refer to ABYC T-22 (educa-

A

odorless

nausea

• Do not use copper tubing in diesel exhaust systems. Diesel

• Do not install exhaust outlet where exhaust can be drawn

• Although diesel engine exhaust gases are not

AVOID

or

tional information on Carbon Monoxide).

WARNING:

gas.

or

death!

fumes can rapidly destroy copper tubing in exhaust systems. Exhaust sulfur causes rapid deterioration

tubing resulting in exhaust/water leakage.

through portholes, vents, or air conditioners.

exhaust discharge outlet

enter the exhaust discharge outlet and close or restrict the

flow

of

exhaust. Avoid overloading the craft.

exhaust fumes from gasoline engines, carbon monoxide

gas is present in diesel exhaust fumes. Some

toms or signs

are:

Vomiting Muscular twitching

Dizziness Intense headache

Throbbing in temples Weakness and sleepiness

MOVING

GASES

Carbon

dealer for installation

Inhalation

of

monoxide

Carbon

monoxide

produces

is

carbon monoxide inhalation or poisoning

(CO}

is a deadly

of

the exhaust system,

of

approved detectors.

(CO}

is

an

flu-like

near the waterline, water could

symptoms,

PARTS

gas!

Pay close

invisible

of

copper

If

the engine

as

toxic as

of

the symp-

A

WARNING:

severe

injury

• When servicing the battery or checking the electrolyte

level, wear rubber gloves, a rubber apron, and eye protection. Batteries contain sulfuric acid which is destructive.

If

it comes in contact with your skin, wash it off at once

with water. Acid may splash on the skin or into the eyes

inadvertently when removing electrolyte caps.

Sulfuric

or

death!

acid

in

batteries

can

cause

Engines & Generators

A

WARNING:

or

death!

• Do not service the engine while it is running.

tion arises in which it

operating adjustments, use extreme care to avoid touching moving parts and hot exhaust system components.

Rotating

is

parts

can

cause

absolutely necessary to make

ii

injury

If

a situa-

Page 7

SAFETY

•

Do

not wear loose clothing or jewelry

equipment; tie back long hair and avoid wearing loose

jackets, shirts, sleeves, rings, necklaces

be caught in moving parts.

could

• Make sure all attaching hardware

Keep

protective shields and guards in their respective

all

check

is

NOISE

times.

fluid

levels or the drive belt's tension

operating.

the

drive shaft and the transmission coupling

is

running; hair

these

rotating parts.

High

noise

levels

places at

•

Do

not

the engine

• Stay clear of

when the engine

be caught in

HAZARDOUS

A

WAR~ING:

loss!

• Never operate

• Do not run

removed.

• Do

not

open.

A

WARNING:

mentally

an

an

engine with

run engines

Do

or

physically

engine without

the

air intake (silencer)

for

long periods

not

work

on

incapacitated

when

servicing

or

bracelets that

is

properly tightened.

and

clothing

can

cause

its

muffler

machinery

by

installed.

with

their enclosures

when

fatigue!

hearing

can

INSTRUCTIONS

while

easily

you

ABYC,

INSTALLING

Read the following

for safety codes and standards. Follow their

tions

ABYC (American Boat and

"Safety Standards for Small Craft"

Order

NFPA

"Fire Protection Standard for Motor Craft''

Order

USCG

"USCG 33CFR183"

Order

are

NFPA

when

installing your engine.

from:

ABYC

3069

Solomon's Island

Edgewater,

(National Fire Protection Association)

from:

NFPA

11

Tracy

Avon

Industrial Park

Avon,

MA 02322

(United States Coast Guard)

from:

U.S.

Government Printing

Washington,

AND

DIESEL

ABYC,

MD

21037

Drive

D.C.

USCG

PUBLICATIONS

ENGINES

NFPA

and

Yacht

Council)

Rd.

Office

20404

USCG

recommenda-

FOR

publications

OPERATORS

Many

of the preceding safety tips and warnings

in

your Operators Manual along with other cautions

notes

to

carefully, maintain

procedures.

GASOLINE

Preparations

begin with a thorough examination of the American Boat and

Yacht

Council's

a combination of sources including the

Sections of the

H-2

Ventilation

H-24 Gasoline Fuel Systems

P-1

Exhaust Systems

P-4

Inboard Engines

E-9

DC

All

installations must comply with the Federal Code of

Regulations

MANUAL

are

repeated

and

highlight critical information. Read your manual

your

equipment, and

ENGINE

to

Electrical Systems

(FCR).

AND

GENERATOR

install a gasoline engine or generator should

(ABYC)

ABYC

standards. These standards

standards of particular interest

follow

all

safety

INSTALLATIONS

are

USCG

and

the

NFPA.

are:

from

Engines & Generators

iii

Page 8

INSTALLATION

When installing WESTERBEKE engines and generators it is important that strict

attention be paid to the following information:

CODES

Strict federal regulations, ABYC guidelines, and safety codes must be complied with

when installing engines and generators in a marine environment.

AND

REGULATIONS

SIPHON-BREAK

For installations where the exhaust manifold/water injected.exhaust elbow

or will be below the vessel's waterline, provisions must be made to install a siphon-

to

break in the raw water supply hose

minimum

of

20" above the vessel's waterline. Failure

the exhaust manifold/water injected exhaust

water

line

of

the

vessel

will

result

of

the

flooding

If

you have any doubt about the position

to the vessel's waterline under the vessel's various operating conditions,

vessel.

the exhaust elbow. This hose must be looped a

to

use

a siphon-break when

elbow

is

in

near or

raw

water

damage

of

the water-injected exhaust elbow relative

below

to

the engine and possible

siphon-break.

NOTE:

A siphon-break requires periodic inspection

operation. Failure to properly maintain a siphon-break can result in catastrophic

engine damage. Consult the siphon-break manufacturer

EXHAUST

The exhaust system's hose MUST be ce1tified for marine use. Conugated Mmine

Exhaust Hose

and turns without the need of additiinal fitting and clamps to accomplish these bends

and turns .In this regard, a single length

system

under any sea conditions and at any angle

SYSTEM

is

MUST

reconunended. The use

be

designed to prevent the entry

of

of

corrugated exhaust hose can be used. The

of

and

cleaning to ensure proper

for

proper maintenance.

this type

of

hose allows for extreme bends

of

water into the exhaust system

vessels heal.

is

close to

the loaded

install a

AVAILABLE

YOUR

DEALER

SIPHON-BREAK

LOOP

PART

FROM

WESTERBEKE

FOR

NO.

WITH

1"

HOSE

044010

STAINLESS

A

detailed

engines

.is

also

Website:

Marine

and

generators

available

www.westerbeke.com

Installation

is

supplied

in

pdf

format

Manual

on

covering

with

every

our

website

Engines & Generators

iv

gasoline

unit

sold.

to

download

and

This

diesel

manual

Page 9

TABLE

Parts

Identification

Parts

Identification

Introduction

Installation

Rigging and Lifting ...................................................... 6

Location and Mounting ................................................ 6

Raw

Raw Water

Fuel,

Fresh Water Cooled Models ......................................... 8

Control

Remote

......................................................................

........................................................................

Water Discharge ................................................... 7

Engine

Panels • Starting/Stopping

Panel ............................................................... 9

Preparations

Pre-start Inspection ..................................................... 10

Fresh Water Cooled Models ....................................... 10

Safety

Shutdown

Overspeed Switch .......................................................

Main Circuit Breaker ..................................................

Fuses ...........................................................................

Exhaust Temperature Switch ......................................

Low

Oil Switch ..........................................................

High

Exhaust Temperature Switch .............................

Maintenance

Engine

Fuel

Cooling

Lubricating

Changing the Oil Filter .............................................. 14

System

Changing the Fuel Filter ............................................ 15

Fuel

.....................................................................

Pump

System

Water

Pump

Water Intake Strainer .................................................. 16

Changing the Impeller ................................................ 16

BCG

.................................................

BPMG

..............................................

Supply Hose .............................................. 7

Oil

and

Engine

Coolant..

..........................

Procedure

for

Initial

Start-Up

Switches

Schedule

................................................................. 15

..................................................

Oil

...................................................

.................................

...........................................

...............................................................

................................................................ 16

OF

2

.4

...........

10

11

11

11

11

11

11

11

12

14

15

16

CONTENTS

3

6

8

9

Cooling

Raw

Cooling

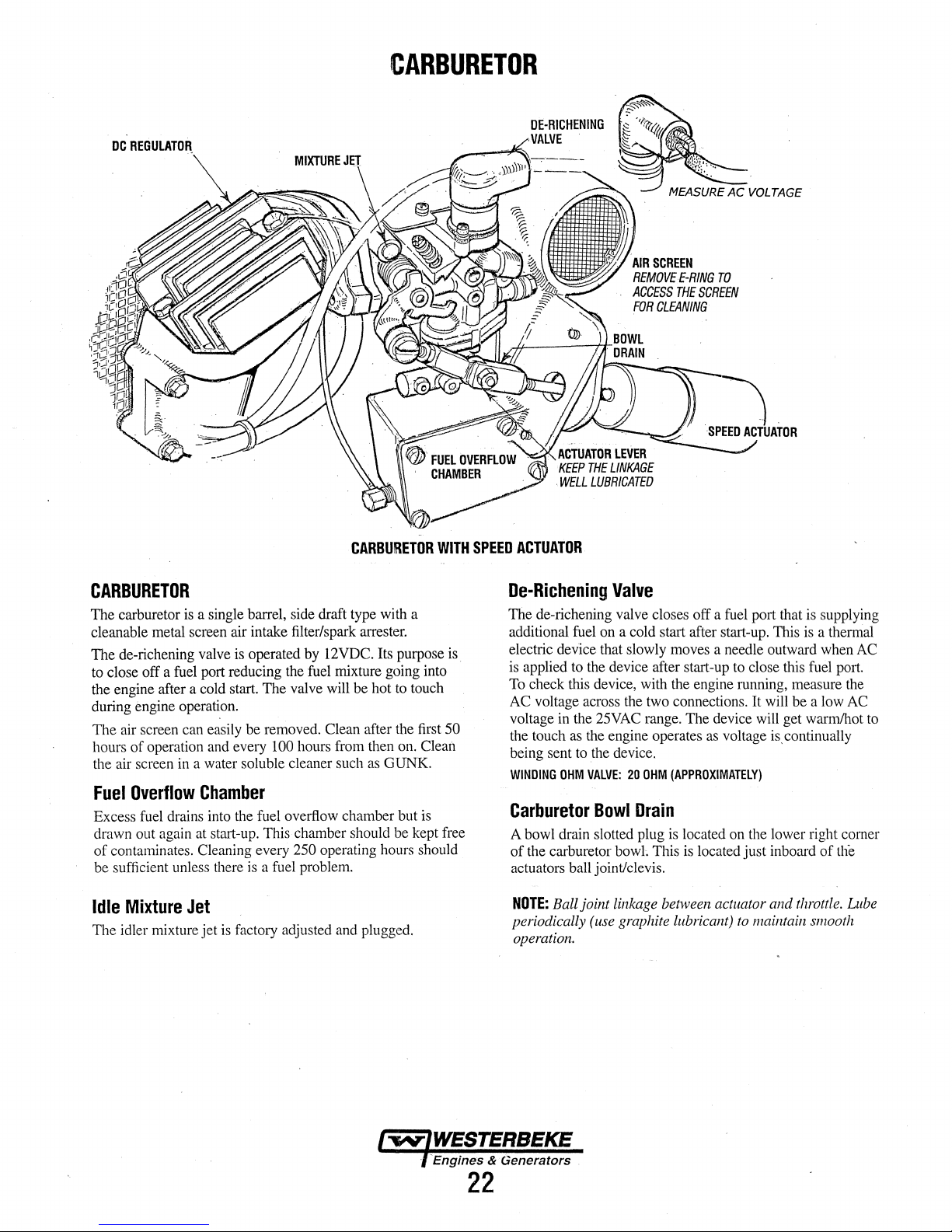

Carburetor

DC

Shore

Electronic

Engine

Troubleshooting

Wiring

Generator

BCG/BPMG

BCG

lay-Up

Flushing

Generator

Metric

Suggested

*Models manufactured with heat exchangers for cooling with fresh

water/coolant

fresh cooling via WESTERBEKE'S FRESH WATER COOLING

System

Water

Re-Assembly .............................................................. 19

System

Thermostat. .................................................................

Heat Exchanger .........................................................

Circuit/Battery

Power

Adjustments

Adjusting the Drive

Oil Pressure ................................................................ 25

Engine Compression Test ........................................... 26

Water

Pump

Ignition Timing ........................................................... 26

Spark Plug .................................................................. 27

Thermostat [Raw Water Cooled Model] .................... 27

Valve Clearance .......................................................... 28

Replacing the Timing

Diagram

Information

Internal

and

The

Conversions

[Fresh

Water

Cooled

Modelst

Pumps

[Overhaul)

........................................

...............................................................

........................................................................

..........................................................

Transfer

Governor

Switch

.......................................

.......................................................

.......................................................

Belt

............................................ 25

Belt ........................................................ 26

Belt

.........................................

Guide

...................................................

...............................................................

...................................................

Troubleshooting

Wiring

Diagram

Recommissioning

Cooling

Specifications

.........................................

.......................................

......................................

System

.......................................

.............................................

........................................................

Spare

Parts

.................................................

or

raw water cooled models that have been converted to .

.............

KIT.

.17

.18

20

21

.21

22

23

23

24

25

29

30

32

33

.34

35

36

37

.38

39

~40

Engines & Generators

1

Page 10

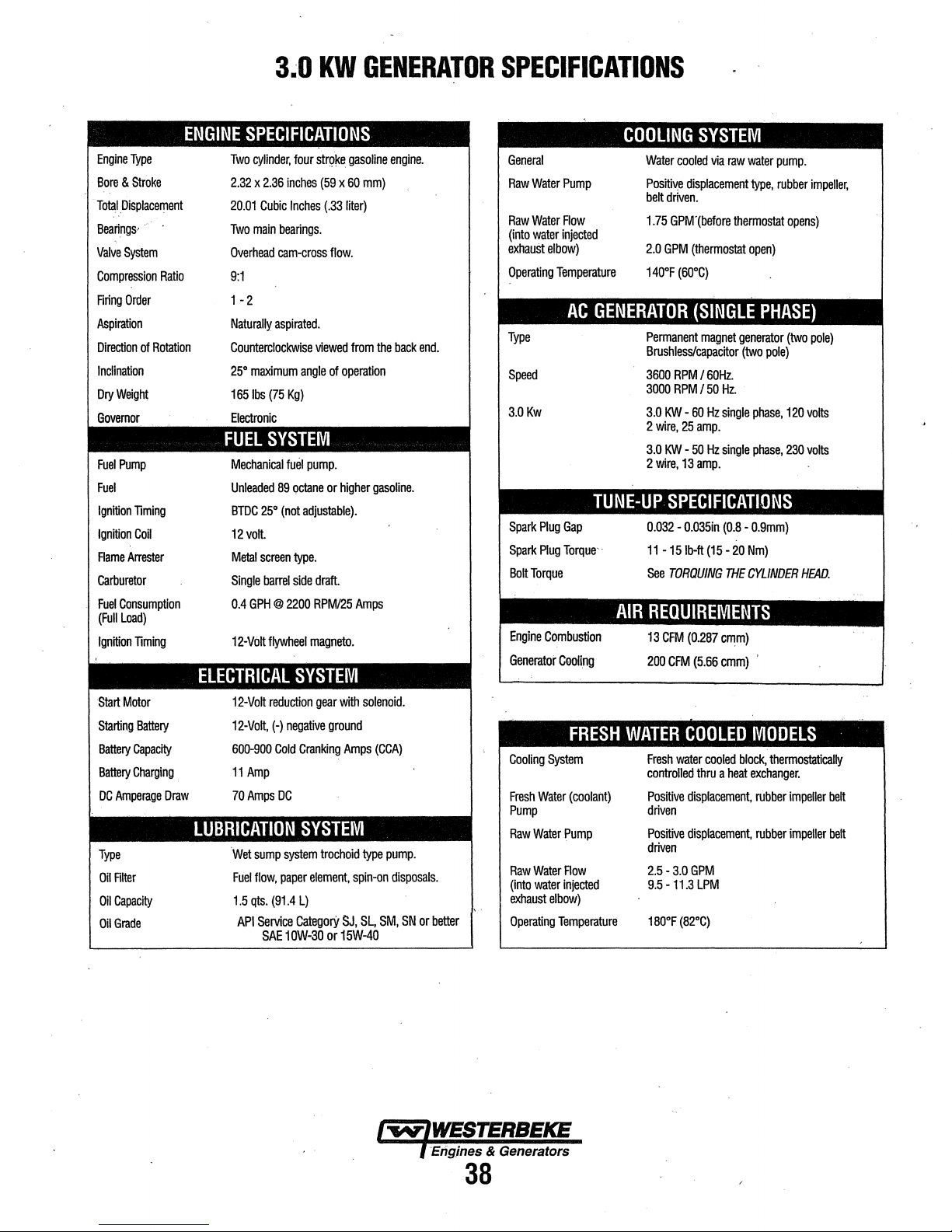

3.0KW

BC1G

GENERATOR

. .

EXHAUST".

HOSE

CONNECTION'

PARTS

10-ENTIFICATION

1_DA

FU$J

GROUNDk°fRAP

IGNITION

CONTROL

MODULE

...--ACTUATOR

LEFT

SIDE

AC

CIRCUIT

BREAKER

ENGINE

SERIAL

·

_Nl,IJA~ER

.

RIGHT

SIDE

COOLANT

SWITCH

DRIP

TEMPERATURE

·

CO~LANT

SERVICE

PAN

PRESSURE

CAP

SIDE

Engines & Generators

2

Page 11

3.0

KW

BPMG

GENERATOR

1IGNITION

CONTROL

,MODULE

GENERATOR

TECHNICAL

DATA

LABEL

ENGINE

MAGNETIC

PICK-UP

SERIAL

NUMBER

PARTS

IDENTIFICATION

IGNITION

COIL

IPHONBREAK

•CONNECTION

SERVICE

SIDE

WATER

INJECTED

EXHAUST

ELBOW

IGNITION

EXHAUST

FUEL

COi

PUMP

ENGINE

SERIAL\;:

NUMBER

FRESHWATER

(COOLANT)

10AFUSE

\

,.....,

......

,

HOUR··

METER'~

--t.._

MODEL

~

GENERATOR

ACTUATOR

LEFT

ARBURETOR

COOLANT

PUMP

SIDE

SERVICE

RAW

WATER

SIDE.·

PUMP

ZINC

ANODE

DRIP·PAN

Engin~t;;

& Generators

3

Page 12

These

high

performance marine engines are products of

WESTERBEKE's long years

technology.

dependable performance of

Thank

In

order

it

is

Th.is

manual carefully

throughout.

your nearest WESTERBEKE dealer for assistance.

This

provided

WESTERBEKE dealer.

equipment, contact your WESTERBEKE dealer for

WESTERBEKE'

WARRANTY

Your

folder.

form

registering your warranty, please contact the factory

writing with model information, including the unit's

serial number

Customer

We

take great pride in

you

for selecting WESTERBEKE.

to

get the

full

important that

manual

is

your operators manual. A parts catalog

and

you

is

designed

and

observe all

Should your engine require servicing, contact

a technical

S installation manual.

PROCEDURES

WESTERBEKE Warranty is included in a separate

If, after 60 days of submitting the

you

have

not received a customer identification card

and

commission

Identification

of

experience and advanced

the

superior durability

our_

engines and generators.

use

and benefit from your generator,

operate and maintain

to

help you

manual_

If

you are planning

do

the

safety precautions

is

available

date.

it

correctly.

this. Please read

is

from

to

install

Warranty

Card

also

INTRODUCTION

your

this

and

this

SERIAL

The

plate located on top

engine's serial number is also stamped on the engine block.

NUMBER

engine's

serial and model number are etched on a

ENGINE

SERIAL

NUMBEK-ll--ftti~roi··

-~a-

~

..

..--~·-~

Registry

in

Take the time to enter this

the nameplate

reference when seeking technical information and/or ordering

parts.

generator's

The

on

a decal on the the generator control panel. Take the

to enter the infonnation on the blank decal below. This will

provide a quick reference when seeking technical information and/or ordering parts.

as

shown above,

serial number and model number is located

LOCATION

of

the unit (flywheel cover). The .

L

g~~

~ation

as

-

on the illustration of

this will provide a quick

name-

time.

lw/WESTERBEKE

Customer Identification

MR.

WESTERBEKE OWNER

MAIN STREET

HOMETOWN,

Model

Expires

PRODUCT

Product

brochures

WESTERBEKE are not within WESTERBEKE's control.

WESTERBEKE CANNOT

CONTENT

RANTIES

THERETO, INCLUDING ACCURACY, TIMEUNESS OR

COMPLETENESS THEREOF

BE

INCURRED

OF

WESTERBEKE customers should

span between printings of WESTERBEKE product software

and

product software. The product software provided

WESTERBEKE products, whether

other suppliers, must not and cannot be relied upon exclu-

sively

software, (technical data, parts lists, manuals,

UABLE

THE FURNISHING OR USE

the

unavoidable existence of earlier WESTERBEKE

as

the definitive authority

USA

Ser.#

SOFTWARE

and

catalogs), provided

OF

SUCH

SOFTWARE, MAKES

OR REPRESENTATIONS WITH RESPECT

FOR

ANY

TYPE

IN

CONNECTION WITH

from

sources other

BE

RESPONSIBLE FOR THE

NO

AND

WILL

IN

NO

OF

DAMAGE OR INJURY

OR

ARISING

OF

SUCH

SOFTWARE.

keep

in

mind

from

WESTERBEKE

on

the respective product.

WAR-

EVENT

the

time

with

than

OUT

or

SPECIFICATION

MODEL---~----

RPNI

__________

KW

___________

.:·_:,__,·

KVA

-----------

VOLTS

AMPS

ENG.

ENG.

GEN.

PF/PHASE

WIRES

RATING

INSUL

TEMP.

BATTERY;,;

C.1.0.

Fill

in

________

---~----

HP-------

SER.

NO.

SER.

NO.

----

________

_______

CLASS

RISE

----

____

----------

the

information

_

_

_

..

_

__

_

for

50 HZ.

your

own

reference.

60 HZ.

I

$:JJ

4.

Page 13

INTRODUCTION

ORDERING

Whenever replacement parts

generator and engine model and serial numbers. In addition,

include a complete part description and part number for each

part needed (see

Also

insist upon WESTERBEKE packaged parts because

will

fit

specifications

NOTES,

As

this

maintenance schedules, and troubleshooting of your

generator,

NOTES,

follows:

NOTE:

A

observed,

the

A

followed,

NOTE:

WESTERBEKE.

by

e1J.gine

SPARES

Certain

your WESTERBEKE generator or engine

SUGGESTED

as

proper fuel and oil

the

way.

spares

on-board inventory of

PARTS

are

needed,

the

separately furnished

or generic parts are frequently not

as

original equipment.

CAUTIONS

manual takes

critical information will be highlighted

CAUTIONS,

An operating

CAUTION:

can

engine

or·generatar.

WARNING:

can

A carbon monoxide warning decal has

room.

AND

spare parts will

WESTERBEKE will provide

and

accessories brochure to assist

AND

WARNINGS

you

through the operating procedures,

and

WARNINGS.

procedure

Procedures,

result

in

the

damage

essential

which

Procedures,

result

In

personal

Affix

this

decal

ACCESSORIES

be

needed

SPARE

PARTS).

filters

the

Often even simple items

can be difficult

proper WESTERBEKE parts.

or

which

injury

in

a visible

to

support

you

always

Parts

made

An explanation

to

if

not

destruction

if

or

you

provide

Catalog).

to

by

note.

strictly

not

properly

loss

of

been

location

and

maintafu

when

cruising (see

to

obtain

with

a suggested

in preparing

the

same

of

·,

life.

provided

in

alort.g

the

the

s:Uch

an

PROTECTING

Care at the factory during assembly

have

resulted in a WESTERBEKE generator capable of

many

thousands of

manufacturer cannot control

installed

operated

buyer/owner-operator.

NOTE:

Seven

•

Proper

•

An

efficient

an

anti-siphon break

YOUR

INVESTMENT

hours

of dependable service. However

how

in

the vessel or the manner in

and

serviced in

important

the

steps

field.

to

engine and generator

well-designed

to

prevent

exhaust

and

thorough testing

or where the generator

which

the

unit

This

is

up

to

the

ensure

long

generator

installation.

system

that

water

from entering

engine.

•

Chang;.ng

ing

•

Proper

nents

the

hours.

maintenance

according

engine

oil and oil filters

of

all engine and generator

to

the maintenance

every

schedule

100

in this

manual.

•

Use

clean,

filtered unleaded fuel.

,.

•

Winterize

Recommissioning"

•

Raw

system

manual.

UNDERSTANDING

TQe

gasoline engine driving

ways

are

in-line, and the engine's cylinder head

camshaft which

pressure

block.

To

a large degree,

preventive maintenance that is required of a gasoline

automobile

generator's longevity

the

fuel system, ignition system, and cooling

your engine according

section

Water

Cooled

according

Model

to

THE

similar to a gasoline automobile

is belt-driven. The engine incorporates a

type

lubrication system, and a water-cooled

the

generator's engine requires

engine.

The

are

in this manual.

- Flush the engine

the procedures found in this

GASOLINE

an

AC generator

most important factors

proper ventilation, maintenance of

to

the "Lay-up and

cooling

GENERATOR

is

in

many

engine.

The cylinders

has

an

overhead

the

to

the

system.

the

is

is

life:

includes

the

operat-

compo-

engine

same

Engines &

5

CARBON

WESTERBEKE recommends mounting a carbon

detector in

even

The presence

from

elbow/exhaust

entering your

If

carbon monoxide

air

Generate>.rs

MONOXIDE

the

vessels

living quarters. Carbon monoxide,

in

small amounts, is deadly.

of

carbon monoxide indicated

the

engine or generator or

hose,

or

boat.

is

present, ventilate

and

correct

the

problem immediately!

DETECTOR

from

the

the

fumes

from a nearby

an

exhaust

the

area

exhaust

monoxide

leak

vessel

are

with

clean

Page 14

RIGGING

The

wire

AND

engine/generator

rope

or

chain

engine/generators

erator

by

means

eyes

have

been

designed

slings

are

not

necessary.

NOTE:

and

competent

Rigging

work

in

LIFTING

is

fitted

slings

capable

weight

to

of

tackle

attached

to

carry

is

best

done

handling

mo.chin(!ry.

INSTALLATION

with~lifting

of

the

eyes

the

by

eyes~

supporting

and

lift

to

these

full

weight:

someone

Attach

the

the

engine/gen-

slings.

The

auxiliary

experienced

lifting

SIDE

VIEW

LOCATION

A

solid,

proper

allow

ing.

Locate

away

Refer

information

AND

level

mounting

operation

adequate

from

to

space

the

generator

bilge

WESTERBEKE'S

on

iflStalling a Marine

MOUNTING

platform

of

your

generator.

on

all

sides

away

from

splash

and

vapors.

installation

is

very

important

Select a location

for

ventilation

living

quarters,

manual

for

Generator

USE

THE

PAN

TO

AS

THE

THE

LOCATING

HOLES

for

the

that

will

and

servicand

detailed

in a boat.

A

TEMPLATE-FOR

PROPER

PLYWOOD

MOUNTING

BASE

AC

CONNECTIOM

-RAW

WATER

INLET

0.51n

t,D,

HOSE

DIMENSIONAL

For dimensional

Westerbeke

current

website

drawings

(2.7mml

DRAWINGS

drawings.

www.westerbeke.com

with

dimensions.

View

WATER

OllTI.ET

HOSES

D.5in

the drawings

for

(2.7mm)

on

the

ANo

DISCHARGE

l.D.

the

most

.

314n

PLYWOOD-BOLTED/FIBERGLASSED

.

IN

PLACE

BATTERY

TO

REFER

DIAGRAM

ATTACHMENTS

STARTER

TO

MOTOR

THE

WIRING

IN

THIS

MANUAL

..

(·)NEGATIVE

LEAD

(+)POSmVE

LEAD

Engines & Generators

6

Page 15

INSTALLATION

RAW

WATER

DISCHARGE

The raw water cooled 3.0KW Generator is cooled

internally

by

a continuous flow

of

raw water.

The fresh water cooled model is cooled internally by fresh

water (coolant). This coolant is cooled

of

raw water (via the heat exchanger).

by

a continuous flow

Both model generators use the engine cooling raw water to

cool the exhaust system as it is discharged overboard. A raw

water supply hose delivers the raw water from the engine to

the water injected exhaust elbow.

RAW

WATER

The raw

the engines cooling system to the inlet connection

water injected exhaust elbow must

SUPPLY

water

supply hose from the discharge connection on

HOSE

be

looped a minimum

of

the

of

12 inches (30cm) above the vessels loaded water line.

On

installations where the water injected exhaust is close to

or

below the vessels loaded water line, provisions must be

made to install a syphon break in the raw water supply hose.

of

The function

flow after the engine is shutdown. This flow,

will fill the exhaust system

The raw water supply hose must

the syphon break is to stop the raw water

if

not stopped,

a?d

possibly the engine

be

looped well above the

as

well.

loaded water line to allow the syphon break to function

during all attitudes

of

vessel operation to prevent syphoning

when the generator is not operating.

When the generators location is above the loaded waterline

of

the vessel during all attitudes

of

vessel operation, it is still

advisable to loop the raw water discharge hose at least 6

inches or more above the generator and then down to the

inlet connection on the water injected exhaust elbow.

NOTE:

Always use quality hose with

good

wall integrity

wire reinforced hose so it will maintain its shape when

looped

and

also provide proper mechanical support

hose.

#053499

SIPHON

BREAK

AVAILABLE

YOUR

D~R-

/-

/

//~·I::

i ' ' I I I I : ;

I

~,_

I . I I I I

I I I I

FROM

WESTERBEKE

~

...

"··

·i;j}i:

..... ~ ....

~

.

... , ...

,,.,,:....

:!."

... ,,,..,,.,.,,..

,....-<-

.--~

,...

).,....................

~

WATER

INJECTED

EXHAUST

RAW

WATER

SUPPLY

HOSE

/~////'

- I I I I

,,,,...

,,.,......

'\

'\

\ I f I I

-·

""''

\ I

\.

I I I

I I I I I

I I l J I i

: I I ! ! I

I I : i '

I I 1

I 1

' :

·1

WHEN A SIPHON

IS

NOT

,,,,

..

- - '

//

....

~-"'

I I

,'

1

REQUIRED

"\

\\\\

I I

I I

1:

for

BREAK

or

the

~<er>~--'RAW

HEAT

EXCHANGER

WATER

;DRAIN

OIL

DRAIN

EXHAUST

HOSE

SYSTEM

EXHAUST

OVERBOARD

Engines & Generators

7

Page 16

FUEL,

ENGINE

OIL

AND

ENGINE

COOLANT

GASOLINE

, : A

Care

Use only clean

your fuel injection pump is very ctitical; invisible dirt

particles which might pass through the filter can damage

these

and keep it clean. The best fuel

unsatisfactory by careless handling or improper storage

facilities.

engine's daily use

advisable:

_ Purchase a well-known brand of

Install and regularly service a

CAUTION:~-----------'-----.

Use unleaded

must not exceed

ages of Ethanol are not acceptable for use in these

,

_and

can

Of

finely

metal bowl type filter/water separator between the

and the engine.

ENGINE

Use a good brand

and SAE as stated in the

manual.Change the engine oil and oil

hours

Of

of operation thereafter. Westerbeke Corporation does not approve or disapprove

the use

of

break-in must

change intervals must

SCHEDULE-'section

if

synthetic

NOTE:

The

statements regarding synthetic

89

Octane gasoline or

ElO

void

the

The

Fuel

fuel!

finished parts.

To

assure that the

is

(10%).

warrenty.

Supply

The clearance of

It

is important to buy clean

fuel

clean and pure,

good,

higher.

Ethanol gasoline

Gasoline with higher percent-

models

the

components in

can

be rendered

going into the

the

fuel.

Coast Guard approved

tank

for your

following practice

fuel

OIL

of

engine oil, with

SPECIFICATIONS section

engine break-in operation and then every 100 hours

synthetic oil;

be

oil

is

itiformation above supersedes all previous

If

synthetic oil

performed using

be

as listed in the

of

used.

this manual and not

· -

an

filter

Conventional

oil.

API classification

after

the

initial

is

used, engine .

oil. Oil

MAINTENANCE

to

be extended

fuel,

tank

of

this

of

is

50

ENGINE

WESTERBEKE

and

chemicals

The

run

engine

circuit

antifreeze

(SCAs)

to

The

being

NOTE:

antifreeze

50%

antifreeze

at

proper

to

from

that

long

term

distilled

poured

Look

distilled

COOLANT

that

temperatures

the

coolant,

rust

that

keep

protection.

water

into

for

that

.

recommends a mixture

water.

can

corrode

perfonns

and

and

corrosion.

contains

the

antifreeze

and

the

cooling circuit

the

new

is

110W

available.

MAINTENANCE

Change

number

ptotect

COOLANT

The

_

contraction

and

coolant

without

provided

water

coolant

operating

the

engine coolant

of

operating

lubricate

RECOVERY

recovery

of

the

engines coolant

introducing

with

the

air into

fresh

water

conversion

engine.

hours

the

allows

of

50%

Distilled

double

Supplemental

antifreeze

environmentally-friendly

engine

water

internal

duty.

by

transferring

lubricates

Look

chemically

should

every

five

as

the

chemical

have a limited

is

engine

It

allows

and

protects

for a good

Cooling

be

years

free

surfaces.

heat

balanced,

premixed

regardless

additives

TANK

for

the

expansion

during

engine

the

cooled

kit

and

system.

models

must

This

and

be

installed

recovery

with

antifreeze

from

the

the

engine

away

from

the

cooling

quality

Additives

crucial

before

long

lasting

of the

that

life.

and

operation

tank is

the

fresh

before

to

the

NOTE:

Be very careful not

of

t~ie

oil sump will result in erratic operation

white-smokeyloil laden exhaust

starting or no start andfouled spark plugs.

Reference Service Bulletin

to

overfill the oil

discharge,

#256.

sump.

Overfilling

of

the

engine,

possible hard

NOTE:

T11is

located

at

or

can

be

located

particular

Engines & Generators

installation

8

tank,

above

with

below

its

the

the

short

level

level

makes

of

this

run

the

of

of

plastic

hose,

engine's

the

necessary.

manifold,

engine's manifold

1.s

best

but

if

it

the

Page 17

CONTROL

DESCRIPTION

The control panel provides

stop/start rocker switch

The plug-in connections

go:vemor

of

The ignition control

mounted on the

A

before

caused

and

sensor

th~

control panel along

CAUTION:

starting.

by

unanticipated

will

prevent a cold

STARTING

The

engitw

has a 12

To

Start: Press the rocker

release. The engine

the

switch

will

show a RED

running.

Apply

a light load to

warm

up

to operating

loads.

NOTE:

Some

unstable

condition.

and

A

periods

otherwise

severe

This

the

generator loads

CAUTION:

of

time

carbon

'damage

and a hourmeter.

and

remote

module

top

of

the

All

AC

This

precaution

VDC

will

the

temperature

running

should

smooth

Never

without

build·up

to

the

for

loads

crank

generator

are

operate

engine.

the

operator with a

the

engine wiring

panel

with a 10

with

it's plug-in

panel.

must

operation

engine

from

electric

switch

and

light

to

may occur

out as

applied.

the

an

amperage

may

PANEL·

simple

harness,

are

located

amp

be

will

o~

starter:

to

the

start electronically

indicate

and

before

engine

occur

fuse.

wiring

switched

prevent

AC

machinery

starting

·

start

the

allow

applying

in

a cold engine .

the

engine

for

load

being

which

on

the

damage

position

engine

the

engine

warms

Ion~

can

side

is

off

and

and

is

heavy

applied,

cause

START/STOP

to

A

up

start

will

This

cranking

This

starting

with

PROCEDURE

WARNING:

switch

disengage

will

occur

with

is

ta

prevent

which

water

has

no

and

Should

the

been

depressed, a crank

the

starter

and

after

approximately

start.

prplonged

can

result

in

backing

into

engine

fail

stop

the

15

cranking

the

exhaust

the

engine.

START/STOP

SWITCH

!

MAIN

CIRCUIT

BREAKER

to

start

limit circuit

starting

seconds

without

the

system

once

cycle.

of

engine

filling

the

STOPPING

To

Stop: Press

engine

will

ENOiNE

Abnormal

. An abnonnal

and

comes

cause

damage

operating

the

rocker

switch

to

shutdown

STAR1:

STOP;

and

the

LED

GENERATOR

OPERATION

Depress switch

position.

ite,

I

RUN

LEO

when

START

engine

will remain

engine is running.

Depress switch

posi I ion.

RUN

LEO

Engine

wi

II

light

wil

turn

~STERBEKE

Sn>PJST.ART

Stop

(refer

stop

is

one

to a stop

condition.

to

the

as

engine,

DECAi.

to

SAFETY SHUTDOWN

in

which

the

a result of

· · .

the

generator,

an

stop

to

to

wi

generator

operating

and

release.

will

tum

START

LEO

will

I crank.

on

STOP

11

stop,

orr.

fault

or

create

The

off.

SWITCHES)

ceases

to

run

which

an

unsafe

REMOTE

A

remote

panel

of

the

generator.

plug-in

extension harness. The start/stop

identical.

either

panel.

NOTE:

Holding

depressed

circuit

engaged.

may

Engines & Generators

g

PANEL

is

available that allows for

The

Once

installed,

the

..

keep

start

the start

will

panel

comes

the

(V\Tl

0

button

l

remote

with

either a 15' or 30'

sequence

engine

can

be

operated by

WESTERBEKE"

I

START

?='

~

I

. '

-

-·

·-

STOP

operation

is

0

Page 18

PREPARATIONS

FOR,

INITIAL

START-UP

PRESTART

Before starting

prolonged

•

Make

•,

Check

the

• Check

bowls

• Check

and

• Check

,

wiring

• Examine

• Be sure

load

•

Be

the

system

connected

incomplete

neutral

•

Visually

parts,

threaded

• Check

and

INSPECTION

your

layoff,

certain

the

engine

full

mark

the

fuel

for

contaminant's.

the

DC

battery

cable

load

leads

diagrams.

air

no

other

lines.

sure that

neutral

is

requires,

to

or

voltage

examine

disconnected

connections.

the

coolant

at

the

manifold.

generator

check

the

cooling

oil

on

the

supply

electrical

connections.

for

inlet

anµ

generator

in

power

properly

and

the

load

open

on

unbalanced

the

the

following

level:

dipstick.

and

system.

correct

outlet

systems

grounded

that

neutral.

neutral

unit Look

wires,

Search

level

in

set

for

water

thru-hull

add

oil

exarriine

Inspect

connection

for

air

or

utility

with a neutral

(or

the

generator

In single

can

supply

loads.

for

unattached

for

bott1

the

the

first

time

items:

petcock

to

maintain

the

fuel

wire

as

flow

obstructions.

power

ungrounded)

neutral

phase

the

loose

hoses,

any

gasoline

plastic

or after a

is

open.

the

level

filter/separator

connections

specified

is

wrong

or

and

recovery

in

connected

line

that

as

the

is

properly

systems

line-to-

missing

check

leaks.

tank

the

ati

at

to

NOTE:

After

the

initial running

the

engine's cooling system will be purged

recovery

the

. after the engine has cooled, the coolant from

tank will be drawn into the engine's cooling system

replace

Before subsequent operation

engine's manifold should be topped

recovery

A

recommended

be

and,

wfll

of

tank.

Open

cooling system

the

pflrged

tank_m_ay

CAUTION:

that

switched

in

prevent

the

OFF

cold

climates,

damage

AC

machinery

the air bleed petcock

is

purged

air.

need

When

all

until

caused

and

of

of

air.

of

to

be filled

starting

AC

loads,

the

engine

starts

to

by

will

prevent a cold

the

generator,

to

to

After shutdown and

the

g~erator,

off.

and

to

the

MAX

the

genera.tor,

especially

has

come

warm

up.

This

u11anticipated

stalling.

·.

COOLANT

THERMOSTAT

HOUSING

PRESSURE

~.

TO

COOLANT

t.·

RECOVERY

TANK

the

air

the coolant

ensure

that

the

recovery

to

the

the

coolant

level.

it

is

large

motors,

up

to

speed

precaution

operation

engine

CAP

in

from

SPIN-ON

OILFILTER',

COOLING

BY-PASS

INSPECT

Engines & Generators

WATER

PERIODICALLY

10

COOLANT

SWITCH

TEMPERATURE

Page 19

SAFETY

SHUTDOWN

SWITCHES

SAFETY

This engine is protected by

two

restart

·

the

ENGINE

OVERSPEED PC

The

the engine down "if the engine speed (RPM'S) exceeds the

,operating speed required to run the generator. The overspeed

PC

SHUmOWN

fuseS.

Should a shutdown

without_jUulin,g

heading

Engine

TR.OUBLESHOarING

SWITCHES

three

occur,

and

correcting

Siarts,

runs .and

shutdown switches

do

not

the

cause.

then

shuts

s;ection

of

this

BO~

overspee1:i"PC

board

will reset itself once the engine shuts down. ·

~ard

inside

th~

control panel will shut ·

10AfUSE

OVERSPEED PC BOARD

attempt

Refer

down

manual.

and

to

to

in the

EXHAUST

An exhaust

exhaust elbow sensors an excessive exhaust

(an

inadequate supply

above

system,

water hoses, etc.

exhaust

LOW

Located just

the

engine's oil pressure

5 psi.

angle

TEMPERATURE

temperature

of

240°

F will shut the engine

wat.er

pump,

pump

This

switch will reset itself

cools.

EXHAUST

8.BOW

Oil

SWITCH

to

the

right

This

switch

will

shut the engine

of

operation, dipstick oil level and oil

SWITCH

switch located at the

cooling

of

if

water). A temperature

down.

belt,

seacock,

the oil

:filt.er,

the oil pressure falls

this

down.

will reset itself.

base

temperature

Inspect

water

strainer,

when

switch

to

Check

filter.

of

the

the

cooling

the

~

below

the

The

switch

MAIN

AC

CIRCUIT BOARD

MAIN

CIRCUIT

The

mam

automatically

electrical overload.

Tum

off

the

panel

fuse

precaution.

BREAKER

circuit

breaker

disc;:onnect

AC

breaker and remove the

when servicing the unit

AC

at the control panel

the

AC

power

as

if

there is an

10

a safety

will

amp

FU$ES

A

JOA

fuse

lOca.t.ed

the

DC

el~trical

fuse will blow

An 20A in-line fuse protects the battery .charging circuit

this

fuse

fails,

will

.IJ.~t

be

charging.

on the side

wiring.

and

.the

engine will continue

If

an

shut the engine

of

the control panel protects

.electrical

overload occurs the

down.

to

run but the battery

If

LOW

OIL

PRESSURE

67

OJt

FIL1tH

{);

HIGH

WATER

(Fresh

A high water temperature switch is located at

housing,

coolant's operating

(99°C),

resets itself at l95"F (107°C). ·

will open and shut the engine down.

TEMPERATURE

Water

:Cooled

Normally closed,

·

THERMQSTAT

HOUSING

:Model)

temperature reach

--~==~

this

J

SWltcH

switch, should the

approximately

the

This

SWITCH

-·~

\.

\

thermostat

fresh

water

210"F

switch

10AFUSE

.2DAFUSE

BATTERY

CHARGING

11

Page 20

MAINTENANCE

SCHEDULE

WARNING:

gloves,

and

control

panel,

SCHEDULED

Maintenance

I

DAILY

Coolant

Engine

Fuel/Water

Fuel

Visual

I

INITIAL

Valve

Generator

Engine

Exhaust

Zinc

Fuel

Inlet

Spark

Rame

Water

procedures

CHECK

Level

Oil

Level

Supply

Inspection

50

Clearance

Drive

Oil

System

Anode

Fitter

Fuel

Fitter

Plugs

Arrester

Pump

Never

use

the

or

disconnect

attempt

to

correct.tools

MAINTENANCE

are

all

detailed

BEFO!lE

START-UP

Separator

HOURS

and

of

Engine

OF

BeH

Filter

Screen

(owner

installed)

OPERATION

pertonn

for

the

battery

in

this

any

service

each

job.

terminals.

manual.

while

the

engine

When

servicing/replacing

EXPLANATION

Check

Oil

CAUTION:

}\fter

hours

into

accurate

passages

and/or

Check

hours

Fresh

Check

and

kept

Initial

Measure

Initial

Initial

Check

buildup

Inspect/clean.

Initial

Initial

Check

Initial

Adjust

is

mnning.

at

recovery

level

should

The

sht.it-down,

to

drain

the

sump

dipstick

are

smokey

for

water

or

once a year,

unleaded

for

fuel,

electrical

clean.

adjustment

spring

engine

check

anti-siphon

on

inside

change.

change.

gap

(0.035in

cleaning

belt

tension

Wear

the

DC

components,

OF

SCHEDULED

tank,

if

empty,

indicate

between

oil

sump

on

the

back

before

reading.

well

white

and

gasoline

oil

connections.

length.

oil

and

at

50

of

screen.

this

oil

in

the

the

oil

checking

(Re-starting

oil

laden

dirt

in

fuel.

with

water

Ensure

cold).

Inspect

filter

change

then

operation.

clean

-1/2

engines

an

and

deflection).

into

lubricated).Over-filling

and

(engine

hours,

valve

passages:

(0.8 -0.9mm).

(3/8

proper

safety

equipment

tum

off

the

20

MAINTENANCE

check

at

manifold.

MAX

and

LOW

on

generators

sump.

the

exhaust,

Drain

octane

exhaust

belt

at

every

and

internal

Allow

dipstick.

the

the

hard

filter

rating

leaks.

that

bolts

condition.

50

hours,

250

hours

Check

that

replace

engine

passag~s

at

least a few

An

overnight

engine

is

engines

starting

if

necessary.

of

89

Check

and

nuts

Adjust

then

or

the

as

necessary.

amp

DC

Add

coolant

dipstick.

Do

can

unintentionally

can

hours

period

not a problem

sump

will

and

possibly

Repla~e

or

higher.

for

rust

are

tight.

spring

length

change

both

once a year.

exhaust

elbow

such

circuit

if

needed.

not

linger

and

for

will

as

result

no

filter

or

corrosion.

Surface

as

every

Carefully

for

as

goggles

breaker

overfill!

be

over-mledl

take a number

the

oil

to

settle

provide

an

the

engine's

in

erratic

start.

every

250

Inspect

of

engine

needed.

100

hours.

inspect

carbon

and/or

and

an

the

of

back

even

more

internal

operation,

operating

wiring

should

for

leaks.

corrosion

be

I

EVERY

50

Starting

Fuel

Pump

Zinc

Anode

I

EVERY

Engine

Air

Intake

Timing

Spark

Plugs

lmpeller(s)

NOTE:

OPERATING

Batteries

100

OPERATING

Oil

and

Filter

and

Filter

Bell

Refer

HOURS

OR

MONTHLY

(and

House

Batteries)

HOURS

OR

to

Service Bulletin #276 dated 6

adjustment.

YEARLY

Check

electrolyte

off

corrosion

Inspect

for

NOTE:

Work

difference.

Change

Remove,

Check

for

Inspect

Inspect

May

2015 when performing generator drive belt

Engines & Generators

levels

if

needed.

leaks,

ensure

out

your

Inspect

engine

oil

and

clean

and

wear,

cracks

plug

gap.

AdjusVreplace

impeller(s)

Make

Apply

fuel

own

monthly

filter.

re-install

and

for

condition.

sure

cables

petroleum

and

electrical

schedule,

to

determine

screen

stretching.

as

.needed.

Rep~ce

boats

pack.

12

and

connections

jelly

to

terminals

connections

location,

schedule.

as

needed.

use

are

of

are

for

s/'tore

in

good

corrosion

clean

and

power

order.

Clean

protection.

tight.

can

make

a

Page 21

MAINTENANCE

NOTE:

Use the engine hounneter gauge to log your engine hours

SCHEDULE

or

record

your

engune hours running time.

SCHEDULED

I

EVERY

Valve

Generator

*Exhaust

*Exhaust

Exhaust

*Exhaust

Fuel

Inlet

Generator

Hoses

·~---~~---~--~-~--------

Vibration

Zinc

Generator

MAINTENANCE

250

OPERATING

Clearance

CO

level

Elbow

System

System

Filter

and

Fuel

Filter

Isolators/Engine

Anode

Drive

EXPLANATION

HOURS

OR

YEARLY

Adjust

·-------------------·---~-

·-----------------------------------------~

Back

Pressure

O·Rings

Mounts

·~-----·~~~--~~

Bell

valves.

Wipe

generator

connections

unobstructed.

Sample

Check

exhaust

Always

use a new

carbon

monoxide!

Carefully

carbon

and/or

Perform

pressure

Correct

as

Remove

Remove

Check

that

See

GENERATOR

Engine

hoses

delaminated.

Check

vibration

Remove

Replace

Measure

NOTE:

Refer

and

exhaust

elbow

inspect

corrosion

back

pressure

above

needed.

and

replace

and

replace

AC

connections

should

Check

and

replace

gasket

spring

to

OF

SCHEDULED

clean

of

dust

CO

analyzer.

for

structural

leaks.

build-up

test

psi

or

fuel

inlet

be

firm

and

tighten

zinc

0-rings

inspect

Bulletin

and

wires

NOTE:

Check

to

41

inches

filter

fuel

are

and

brackets

anode.

if

overheated

with

gasket.

for

1.5

INFORMATION.

isolators,

and

length,

Service

MAINTENANCE

engine

exhaust.

or

windings.

integrity.

A

leaking

anti-siphon

on

inside

ensure

of

and

all

sealing

filter.

clean

and

tight.

all

hose

and

Open

needed.

belt

condition.

276

dated

has

Make

Replace

exhaust

valve

passages.

not

developed

water

column

0-rings.

secure.

Replace

if

clamps

as

--------~----~

mounting

-~-~~---~--~----

heat

exchanger

Adjust

May

6,

Remove

certain

if

elbow

elbow

operation.

Clean

restrictions

at

full

Ensure

wires

hoses

become

needed.

brackets.

and

spring

2015.

vent

cover

and

vents

are

clear

is

corroded

or

or

gasket

can

cause

Check

the

exhaust

and

replace

as

that

opera~ing

have

cap(s)

length

amperage

no

chafing.

spongy,

and

clean

as

needed.

will

brittle

inspect

for

and

deteriorated.

exposure

elbow

necessary.

·----

increase

load.

or

out

debris.

"

loose

to

for

I

EVERY

500

OPERATING

R11w

Waler

Pump

I

EVERY

500

OPERATING

Coolant

System

Valve

Clearances

Starter

Dlverter

EVERY

Heat

I

EVERY

•oxygen

•catalyst

----

Motor

Valve

1000

Exchanger

2000

Sensor

·-----

*WESTERBEKE

be

performed

HOURS

HOURS

OPERATING

OPERATING

HOURS

HOURS

recommends

by

an

knowledgeable

OR

OR

OR OR

this

YEARLY

EVERY

EVERY

service

mechanic.

TWO

YEARS

FIVE

YEARS

Remove

the

dual

pumps.

Follow

the

Inspect

and

check

Drain,

thermostat

Incorrect

Check

motor

Replace.

Remove

Remove

Remove

replace

for

leaks

flush

and

and

valve

solenoid

pinion