Westerbeke 10.0 KW-60Hz SBEG, 11.6KW-50 Hz SBEG, 12.5 KW-60Hz SBEG, 10.0 KW-5, 14.0 KW-60Hz SBEG Operator's Manual

...Page 1

~£

"

.....

It

/I

~

"':.

} .

~

OPERATORS

8.0KW . 60Hz

10.0KW • 60Hz

12.5KW·

14.0KW·

60Hz

60Hz

.--.;;"

o q

~I.D"'"

i

MANUAL

SBEG

SBEG

SBEG

SBEG

/6.4KW •

/ 8.0KW·

/10.0KW •

/11.6KW •

4-

'"

'"

50

50

50

50

Hz

Hz

Hz

Hz

SBEG

SBEG

SBEG

SBEG

MARINE

PUBLICATION

,

u)

ra-Low

G E

NO.

Carbon

49735

FOURTH

Monoxide

GENERATORS

EDITION FEBRUARY 2009

Emissio

s

Page 2

Gasoline with an ETHANOL content

higher than 10% (E10) is not allowed

and may void warranty.

Engines & Generators

Page 3

CALIFORNIA

WARNING

Exhaust

gasoline

its

the

cancer,

reproductive

Exhaust

colorless

gas

from

engines

constituents)

State

of

California

birth

defects,

harm.

gasses

gas.

contain

Carbon

unconsciousness

exposure

•

Dizziness

can

include:

.Nausea.

•

Headache

•

Weakness

IF

YOU

GET

OUT

seek

until

and

OR

ANYONE

INTO

medical

it

has

been

Sleepiness

THE

attention.

inspected

PROPOSITION

diesel

(and

are

known

and

some

to

cause

and

other

65

of

to

AWARNING:

Monoxide

and

death.

ELSE

FRESH

Carbon

Monoxide,

is

poisonous

Symptoms

•

Throbbing

•

Muscular

•

Vomiting

• Inability

EXPERIENCE

AIR

IMMEDIATELY.

Shut

down

and

ANY

the

repaired.

an

of

Carbon

in

Twitching

to

Think

OF

If

unit

and

odorless

and

can

cause

Monoxide

Temple.s

Coherently

THESE

SYMPTOMS,

symptoms

do

not

and

persist,

restart

A

WARNING

should

be

generator.

WESTERBEKE

MONOXIDE

of

your

obtainable

DECAL

fixed

to a bulkhead

also

recommends

DETECTORS

vessel.

at

your

Theyare

is

provided

in

local

marine

by

WESTERBEKE

near

your

engine

instafling

the

living/sleeping

inexpensive

and

easily

CARBON

store.

Engines & Generators

and

or

quarters

WARNING

GaooraIors

Pn:xb;e

CARBON

RBgIJat~ReqtNed

MONOXIDE

Page 4

SAFETY

INSTRUCTIONS

INTRODUCTION

Read this safety manual

caused

precautions.

take

personne~

The

by

failure

the

necessary

and your

following

Know

safety

the American Boat and

PREVENT

A

while

power.

• Do not operate this machinery without electrical

enclosures

• Shut off electrical power before accessing electrical

equipment.

• Use insulated mats whenever working on electrical

equipment.

• Make sure your clothing and skin are dry,

(particularly shoes) when handling electrical equipment.

• Remove wristwatch and

electrical equipment.

•

Do

circuits, except through a ship-to-shore double

transfer switch. Damage

result if this procedure is not followed.

• Electrical shock results from handling a charged capadtor.

PREVENT

A

exhaust

very

• Always check the engine coolant level at the coolant

recovery

A

•

In

~fore

ELECTRIC

WARNING:

engine

not connect utility shore power

Discharge capacitor by shorting terminals together.

Is

Lethal

and

voltage

BURNS -HOT

WARNING:

system

hot!

tank.

WARNING:

case

of

an engine overheat, allow the engine

touching the engine or checking the coolant.

carefuay.

to

follow

funtlamental

when

dangerous

precautions

Most

accidents

rules

conditions

to

protect yourself, your

machinery.

instructions

Yacht

are

Council

in

complkmce

(ABYC)

SHOCK

Do

not

touch

AC

electrical

running,

covers

or

when

connected

is

present

in

at

these

place.

all

jewelry when working on

to

vessels

to

vessels

AC

ENGINE

Do

not

touch

hot

engine

components. A running

Steam

can

cause

injury

are

and

exist and

with

stantlards.

connections

to

shore

connections!

not

damp

AC

throw

generator

parts

engine

or

may

or

gets

death!

to

cool

PREVENT

A

• Prevent

sparks

pump, or other potential sources

vapors. Use a suitable container

removing the

• Do

arrester

death.

•

Do

Backfire

• Do

the

engine/generator clean and free

chances

• Be aware - diesel fuel will bum.

PREVENT

A

injury

• Follow re-fueling safety instructions.

hatches closed when fueling.

after fueling. Check below for fumes/vapor before

running the blower. Run the blower for four minutes

before starting your engine.

•

All

when

ventilated area away from spark-producing equipment

and out of the reach

•

Do

• Shut off

the

spill.

sources

ing.

fuel

• Do

• Be sure

• Be certain fuel line fittings are adequately tightened

free of leaks.

• Make sure a

properly maintained. Be familiar with

Extinguishers rated ABC

for

BURNS -FIRE

WARNING:

to

not

operate with a Coast Guard Approved

removed.

not operate with the air cleaner/silencer removed.

not

smoke

fuel

system. Keep the compartment and

Fire

can

cause

flash

fires.

Do

not smoke or pennit

occur near the carburetor,

fuel

line, carburetor, or

can

of

cause

fire.

Backfire

or

pennit

Wipe

severe

injury

flames

up

all spilled

can

injury

or

fuel

of

spilled fuel or

to

catch

fuel

cause

severe

or

death.

or

sparks

of

debris

fuel

death!

flames

line,

filter,

all

fuel when

filters.

flame

injury

to

occur

the

to

minimize the

and

engine

BURNS -EXPLOSION

WARNING:

or

death!

fuel

handling and storing fuels. Store

not

fill

fuel

DO NOT allow any smoking, open

of

Ensure

system.

not

alter or modify the fuel system.

all

applications

Explosions

vapors

are

highly explosive.

the fuel tank(s) while the engine is running.

the

fuel

service

system.

all

Take

fire

near

the

proper

ventilation

fuel supplies have a positive shutoff

fire

extinguisher is installed nearby and

encountered

from

fuel

Open and ventilate cabin

of

children.

valve

at

the engine

care in catching

fuel

system

exists

by

the

NFPA

in

vapors

Keep

Use

extreme care

fuel

any

or

engine

when

its

are

this

environment.

can

the vessels

in a well-

when

fuel that might

flames,

when

servicing

proper

appropriate

cause

valve.

use.

servicing

or other

servic-

or

fuel

fuel

or

near

oil.

the

and

is

Engines & Generators

Page 5

SAFETY

INSTRUCTIONS

ACCIDENTAL

A

WARNING:

STARTING

Accidental

starting

can

cause

injury

ordeathl

• Disconnect

generator.

it

last.

•

Make

starting.

• Make certain

re-installed before starting

BATTERY

A

WARNING:

the

battery cables before servicing

Remove

certain

the

all

personnel are clear of

all

covers, guards,

EXPLOSION

Battery

negative lead

and

the

engine.

explosion

can

first

and

reconnect

the

engine before

hatches are

cause

injury

the

engine/

ordeathl

• Do not smoke or

being serviced. Lead acid batteries emit hydrogen, a

highly explosive

arcing or by lit tobacco products.

equipment

during servicing.

• Never connect the negative (-) battery cable

positive (+) connection terminal of

Do

not test the battery condition by shorting

together.

Ventilate

accumulation of explosive

disturb the battery charger connections while

is

•

Avoid

burns or sparks that could cause

wristwatch,

the

• Always turn the battery charger off before disconnecting

the

and

BATTERY

A

selfllfll

Sparks could ignite battery gases or

any

being charged.

contacting

battery.

battery connections. Remove

reconnect it last when disconnecting

ACID

WARNING:

Injury

allow

an

open

flarue

near

gas,

which can

in

the

vicinity

compartment containing batteries

the

terminals with tools, etc.,

rings,

and any

Sulfuric

or

deathl

acid

be

ignited

Shut off all electrical

to

prevent electrical arcing

the

starter solenoid.

gases.

To

avoid sparks,

an

explosion. Remove

other jewelry before handling

the

negative lead

in

batteries

the

by

the

can

battery

electrical

to

the

the

terminals

fuel

vapors.

to

prevent

the

battery

to

prevent

battery.

cause

do

first

not

TOXIC

• Ensure that

• Be

•

• For additional information refer

•

•

• Although diesel engine exhaust gases are not

AVOID

EXHAUST

A

WARNING:

discharged

regularly

manifolds/water-injected

sure

the

Run

blowers

Do

not

run

equipped

detector that complies

boat

builder or dealer for installation of approved

detectors.

(educational information

A

WARNING:

odorless

nausea

gas.

or

deathl

Do

not

use

fumes

can

systems.

copper tubing resulting

Do

not install exhaust outlet where exhaust

through portholes,

exhaust discharge outlet

the

enter

flow

of exhaust.

exhaust

gas

symptoms

poisoning

Vomiting

Dizziness

Headache

Nausea

is

present

fumes

MOVING

GASES

Carbon

the

from

for

leaks

unit

when

the

generator set or engine unless

with

a functioning marine carbon monoxide

Carbon

Inhalation

copper tubing

rapidly destroy copper

Exhaust sulfur causes rapid deterioration of

exhaust discharge outlet

from

in

or

signs

are:

Inability

Throbbing

Muscular twitching

Weakness

monoxide

exhaust system

the

engine. Check

and

make

and

its

surroundings are

running

with

is

sure

elbow

is

the

generator

ABYCA-24. Consult your

to

on

Carbon Monoxide).

monoxide

produces

in

diesel

tubing

in

exhaust/water leakage.

vents,

or

air

conditioners.

is

near

the

and

Avoid

overloading

gasoline engines, carbon monoxide

diesel exhaust

of

carbon

fumes.

monoxide

to

think coherently

in

temples

and

sleepiness

PARTS

(CO)

is a deadly

adequate

the

the

securely

ABYC

(CO)

Uu-like

exhaust

waterline, water could

the

to

exhaust system

exhaust

attached.

well

set

T-22

is

an

symptoms,

systems.

in

exhaust

close

or restrict

craft.

Some of

inhalation

gasl

expel

gases

ventilated.

or

engine.

the

boat

invisible

Diesel

can

be

drawn

If

the

engine

as

toxic

the

or

is

the

as

• When servicing the battery or checking

level, wear rubber gloves, a rubber apron,

protection. Batteries contain sulfuric acid

destructive.

off at once

the

into

caps.

If

it

comes

in

with

water.

Acid

eyes inadvertently

contact

with

may

splash

when

removing electrolyte

the

and

which

your

on

electrolyte

eye

is

skin,

wash

the

skin

or

A

WARNING:

ordeathl

it

Engines & Generators

• Do

not

situation

make

operating

touching moving pafts

components.

ii

service

arises

Rotating

the

in

adjustments,

engine

which

parts

it

and

can

while

it

is

is

absolutely

use

extreme

hot

exhaust system

cause

injury

running. If a

necessary

care

to

to

avoid

Page 6

SAFETY

•

Do

not wear loose clothing or jewelry

and

or

parts.

levels

and

guards

the

and

equipment; tie back long hair

jackets, shirts, sleeves, rings, necklaces or bracelets that

could be caught

• Make sure all attaching hardware

Keep

protective shields

places at all times.

•

Do

not check

the

engine

• Stay clear of

the

when

be

caught

HAZARDOUS

A

WARNING:

in

fluid

is

operating.

the

drive shaft

engine

is

in

these rotating

NOISE

High

moving parts.

levels

running; hair

noise

loss!

• Never operate

• Do not run

removed.

•

Do

not run engines for

open.

A

WARNING:

mentally

or

an

engine without

an

engine with

Do

not

physically

incapacitated

the

air intake (silencer)

long

periods with their enclosures

wade

on

when

servicing

avoid wearing loose

is

properly tightened.

in

their respective

drive belts tension

the

transmission coupling

and

clothing can easily

can

cause

hearing

its

muffler installed.

machinery

by

fatigue!

when

INSTRUCTIONS

while

you

ABYC,

INSTALLING

Read

for

recommendations

ABYC (American Boat

"Safety Standards

Order

NFPA (National Fire Protection Association)

"Fire Protection Standard for Motor Craft"

Order

USCG

"USCG 33CFR183"

Order

are

NFPA

the

following ABYC,

safety codes

from:

ABYC

3069

Solomon's Island

Edgewater,

from:

NFPA

II Tracy Drive

Avon

Industrial

Avon,

MA

(United States Coast

from:

U.S.

Government Printing

Washington,

AND

USCG

DIESEL

MD

02322

D.C.

ENGINES

NFPA

and

standards. Follow their

when

installing

and

Yacht

for

Small Craft"

Rd.

21037

Park

Guard)

20404

PUBLICATIONS

and

USCG

your

engine.

Council)

Office

FOR

publications

OPERATORS

Many

of

in

your Operators Manual along with other cautions

notes

to highlight critical information. Read your manual

carefully, maintain your equipment,

procedures.

GASOLINE

Preparations to install

thorough examination of the American Boat

Council's (ABYC) standards. These standards

combination of sources including

Sections of

H-2

P-1

P-4lnboard

E-9

All

installations must comply with

Regulations

MANUAL

the

preceding safety

ENGINE

the

Ventilation

Exhaust Systems

DC

Electrical Systems

(FCR).

AND

ABYC standards of particular interest

Engines

tips

and

and

GENERATOR

an

engine should begin

the

USCG

the

warnings are repeated

Federal Code of

follow all safety

INSTALLATIONS

and

with

are

and

and

a

Yacht

a

the

NFPA.

are:

"""

WESTERBEKE

Engines & Generators

iii

Page 7

CARBON

MONOXIDE

"CO"

ISAFE-CO

GENERATORS

IMPORTANT

DESCRIPTION

Carbon monoxide "CO"

is

a colorless, tasteless, odorless, lighter than air poisonous

gas

that can kill you without

one of the major safety risks associated with boating.

threat that must not

Westerbeke Safe-CO generators are designed

of

normal levels

99%.

Several standards

parts per million

CO

"ppm" and hours of exposure:

Regulator

EPA

ACGIH

EPA

NIOSH

OSHA

ACGIH

NIOSH

NIOSH

(IDLH)

1200

ppm

is

the

so-called

IMMEDIATELY

A city

in

concentration

Paris

DANGEROUS

California characterizes the effect

this

per

Million

25

100

200

Even though the generator normally produces very low levels

CO,

an

of

extremely dangerous. For this reason it

tant

is

it

tor sounds, do not tum

You

detector on, tum off all engines

boat leaving ports and hatches open,

help.

As

to dilution in the open

exhaust outlet, the higher the concentration

exhaust leak of untreated exhaust would be

to

install a

always turned on and functioning properly. If this detec-

can not taste, smell, or otherwise detect

soon

as

CO leaves

CO

is

a component

any

be

underestimated.

in the engine exhaust by approximately

for

CO

have been published, expressed in

CO

ppm

9 8

25

35

35

50

125

200

1200

IDLH

concentration

TO

LIFE

way:

warning.

Exposure

AND

of

engine exhaust.

CO

poisoning is

to

reduce

Hours

8

1

8

8

0.5

0.0

0.0

-

HEALTH.

of

CO

Responses

Pennissible exposure level, no

apparent

No

Allowable for several hours.

Shonld not be exposed above

this level for any period

time. A possible mild frontal

headache in two

detector near the generator and

it

off,

assuming it

the

exhaust outlet,

air.

The closer a person is

toxic symptoms.

poisoning for long period.

to three hours.

is

extremely impor-

to

is

a false signal.

CO.

Leave

and

generators, evacuate the

and

seek professional

the

level

is

subject

to

the

of

CO.

It

is

a

of

be sure

the

INFORMATION

In a closed space, such

It

or underneath a stern swim platform, concentrations

potentially rise

exhaust system due

gas.

Therefore, one should never rely on dilution of

exhaust

Westerbeke

reduction

engine's air/fuel ration coupled with after treatment

special catalyst.

model

because each engine is different. Also, certain

system components are commonized across several engine

models being adequate for some and extra-adequate for

others, thus producing different

models.

The fuel system which accomplishes the required precise

air/fuel ratio control

components: purchased sub-assemblies, machined castings,

sensors, electronics

of

CO

reduction,

these components can and will cause variability of

output.

CO

concentration also varies with load. Usually, but not

always, the worst case

load.

to

the undiluted level emanating from

to

provide a margin

Safe-CO generators achieve

of

typical

CO emissions are not the same for every

any

INSPECTION

The catalyst is critical

intrusion into the exhaust system will likely quickly

compromise the proper operation

Westerbeke's exhaust system installation instructions dated

on

or after February 2004 must be adhered

NOTE:

Water intrusion

ered under warranty. neither Westerbeke

product warranty

mandated by various regulating authorities such as

and CARB.

Maintenance

flow

the

fuel filters and air filters (if any).

Inspection

critically important. The exhaust elbow

loosening

surface of the catalyst. Any visual irregularity

flush,

intrusion. The cause

addressed. If there

be

elbow gasket, and exhaust elbow, check for

CO

a

of

the

honeycomb appearance

replaced. Upon careful reassembly

while the engine

CO

analyzer.

rwr the emissions specific warranty

of

any

fuel

to

the engine

of

the

catalyst at the prescribed intervals

metal clamp

is

as

the engine compartment, the boat,

will

to

a lack of fresh air

of

safety.

CO

by

precise control control of

CO levels for different

is

comprised

and

others. Because

variability

CO concentration occurs at maximum

to

optimizing CO levels. Any water

is

in

not a product defect and is not cov-

to

dilute the exhaust

an

approximate 99%

of

many different

of

the

extreme level

the functioning of

of

the catalyst.

to.

the

the

in

fuel

the

s nonnal

EPA

components affecting the

is

critically important, such

to

provide a view

is

most likely a result of water

of

the irregularity must be identified and

irregularity,

is

running. This must be performed with

the

catalyst and gasket must

of

flow

is

removed

of

the output

of

the normal

the

catalyst, exhaust

the

presence of

of air or

is

by

the

a

any

CO

as

~

WESTERBEKE

Engines & Generators

iv

Page 8

CARBON

MONOXIDE

"CO"

ISAFE-CO

GENERATORS

IMPORTANT

Catalyst perfonnance will degrade over time. As the

CO

generator accumulates operating hours,

will increase.

bours

Verification

seasonally

Verification involves actual sampling

appropriate

There are two locations where exhaust gas can be sampled.

but

Dry,

in

hole

measurements. Measurements at this location may not be

practical in

temperature limits

temperatures involved or the possibility

The

other location is the boat's exhaust outlet, which

contains entrained cooling water (except

systems).

location and it is critical that the probe not ingest water.

Probe-type analyzers have an air pump drawing a gas sample

through the probe. As a result, they tend to ingest water when

it is present.

opening pointed in the direction

out

of

the flow. Position the analyzer

the tubing leading to the probe running continuously downhill. Observe the usually translucent tubing between the

probe and the analyzer and be sure no water is being

ingested.

repaired

The

catalyst

of

engine

hot, exhaust can

the exhaust elbow intended for back pressure

If

or

operation.

of

satisfactory

or

each

1,000

CO

analyzer.

all instances due to the high exhaust temperature,

of

Only analyzers with probes should be used at this

Be

sure to aim the probe downwards with the

any water is ingested into the analyzer, it must be

replaced and recalibrated.

must

be

CO

levels

hours

(which

be

sampled at the plugged tapped

the analyzer, safety concerns over

of

the water flow and

concentrations

replaced

of

as

every

must

be

done

ever

occurs

exhaust gas with an

of

high levels

dry stack exhaust

high

as

possible with

2,000

first),

of

just

CO.

INFORMATION

Whenever taking the time to verify proper CO concentration

from the exhaust with a

opportunity to use the analyzer to

looking for

connection

exhaust manifold to the water injected exhaust elbow, and all

subsequent downstream exhaust components and hoses.

Remember, exhaust gas that has not yet passed through the

catalyst is raw, untreated exhaust and is very high in

content.

Analyzers usually require periodic calibration. Follow the

instructions that come with the analyzer very carefully

regarding calibration.

The

Extech, TIP, Testo,

Zellwgwer Analytics, Industrial Scientific Corp, GFG,

Teledyne and others. Westerbeke recommends analyzers with

a probe connected to the analyzer by a length

tubing. They are slightly more expensive than those with the

sensor built into

to sample the exhaust coming out

CO from exhaust leaks. Pay close attention to the

of

the cylinder head to the exhaust manifold, the

following are manufacturers that offer CO analyzers:

one

CO analyzer, always take the

"sniff'

around the engine

TSI, Bacharach, Auke, Monoxor, Fyrite,

of

transparent

end

of

the analyzer, but they allow you

of

the boat's exhaust outlet.

CO

TPI,

CO

When measuring

CO

ambient

upwind

level at the exhaust will be influenced upwards by the

ambient level.

level by also measuring

of

the exhaust outlet, especially

at the exhaust outlet be aware

CO

away from and

in

marinas. the

EXHAUST

MANIFOLD

of

ADJUSTABLE

CLAMP

INSTALLING A NEW

CATALYST

the

CO

~

WESTERBEKE

Engines & Generators

v

Page 9

EMISSIONS

This genset meets

Emissions Standards

California users of this genset should

unauthorized modifications or replacement of

air

intake, or speed control system components that affect

engine emissions are prohibited. Unauthorized modification,

removal or replacement of

Federal Emissions Compliance Period: The Federal

Emissions

indicates

has

Catagory C=

Compliance Period referred

the

been shown to meet Federal Emissions requirements.

Emissions Warranty Information packet, if information

Engine Fuel Requirements

Engine

Engine Ignition

Engine Lubricating Oil Requirements See ENGINE OIL RECOMMENDATIONS.

Engine Adjustments

Engine Emission Contol System

Catalyst See MAINTENANCE SCHEDULE.

Oxygen Sensor

Back Pressure See MAINTENANCE SCHEDULE.

the

requirements of Califomia's Exhaust

as

stated

on

the

nameplate.

be

aware that

fuel,

exhaust,

the

engine label

number of operating hours

250

hrs, B=500 hrs,m A

Valve

Adjustment See MAINTENANCE SCHEDULE.

TimIng

is

prohibited.

to

on

the

for

which

=IOOO.hrs.

EMISSIONS

nameplate

the

engine

CONTROL

The California emissions control warranty statement

factory.

The engine

RECOMMENDATIONS.

See MAINTENANCE SCHEDULE.

ECU.

The

engine

manufacture.

See

MAINTENANCE SCHEDULE.

You

and

gensel.

maintenance

should seek assistance

dealer.

Califorrtia genset users

locating information related

Board

INFORMATION

is

certified

emission

should carefully review operator (Owner) Installation

other

manuals

If

you

are

or

requirements

TABLE

as

this

manual when

to

operate

control

on

system

and

information

unsure that

service

of

your

from

may

for

emissions

the

unleaded gasoline. See FUEL

consists

of

you

receive

the

installation, use,

genset

is

authorized,

an

approved WESTERBEKE

use

the

table below

to

the

California

control.

is

genset

engine

located

is

shipped

design

Air

in

from

and

with

the

your

you

as

an

aid

Resources

same

the

precision

in

-..v'

WESTERBEKE

Engines & Generators

vi

Page 10

INSTALLATION

When installing WESTERBEKE engines and generators it is important that strict

attention be paid to the following information:

CODES

Strict federal regulations, ABYC guidelines, and safety codes must be complied with

when

AND

installing

REGULATIONS

engines

and

generators

in a marine

environment.

SIPHON-BREAK

For installations where the exhaust manifold/water injected exhaust elbow is close to

or

will be below the vessel's waterline, provisions must be made

break in the raw water supply hose to the exhaust elbow. This hose must be looped a

minimum

the exhaust

water

If

you have any doubt about the position

to

the

siphan-break.

NOTE:

operation. Failure to properly maintain a siphon-break can result

engine damage. Consult the siphon-break manufacturer

EXHAUST

The exhaust hose must be certified for marine use. The system must be designed to

prevent water from entering the exhaust under any sea conditions and at any angle

of

of

20" above the vessel's waterline. Failure to use a siphon-break when

manifold injection port is at

tlamage to

vessel's

A siphon-break requires periodic inspection and cleaning to ensure

the

engine

waterline

and

under

possible flooding

the

vessel's

or

below the waterline will result in raw

of

the boat.

of

the water-injected exhaust elbow relative

various

operating

for

SYSTEM

the vessels

hUll.

to

install a siphon-

conditions,

proper maintenance.

install a

proper

in

catastrophic

t··

AVAILABLE

YOUR

WESTERBEKE

DEALER

fROM

Carefullr

WESTERBEKE

Additional

review

the

Engine

manuals

Marine

or

Generator.

are

available

Installation

from

rour

Engines & Generators

manual

provided

WESTERBEKE

vii

with

rour

dealer.

Page 11

TABLE

Parts

Identification

Introduction

Warranty Procedures ......................................... 3

Serial

Fuel,

Preparations

Starting/Stopping

Remote

Break-In

Safety

Maintenance

Fuel

Bleeding the Fuel System ...........................

Cooling

Changing Coolant ........................................... 13

Thermostat ...............................

Raw

Raw

Engine

Oil Change ...................................................... 16

Remote

Engine

Spark Plugs ..................................................... 19

High

Drive Belt Adjusment ..............

Fuel Pressure Test ........................................... 19

Engine Compression Test.. ................

Ignition Timing ...............................................

Timing Belt Inspection and Replacement ......

Engine

Electrical

DC

Battery Care ....................................................

Number

Engine

Panel

Procedure

Shutdown

System

System

Water Pump ........................................... .15

Water Intake Strainer. ............................. 15

Lubricating

Adjustments

Tension Cords ........................................ 19

Troubleshooting

Electrical

OF

CONTENTS

.............................................

................................ , ........................

Location .................................. .4

Oil,

and

for

Initial

Procedure

Engine

Coolanl...

Start-Up

.........................

...............................

..............

......................................................

(Daily

Switches

Schedule

Operation)

.................

..................................

.....................................

.......................................................

..................................................

, ......... , ............ 14

Oil

....................................... 16

Oil Filter. ............................................... 17

...

................. , ......... , ............

, ......... , ............ 19

, ......... ,

Guide

Troubleshooting

System

........................................

.........................

Guide

.....................

10

12

.l2A

13

19

..

20

20

21

.24

26

.28

29

2

3

5

6

7

8

8

9

Wiring

Starter

Generator

BE

Generator

Lay-up

Generator

Shorepower

Metric

Standard

Suggested

Schematic

Motor

Information

Generator

AC

and

Recommissioning

Specifications

Transfer

Conversion

Hardware

Spare

-.,y:

#49167

....................................................

.....................................................

Voltage

...........

and

Parts

....

............................

......................................

Connections

.................

...........................

.................................

Switch

.............................

....................................

Sealants ....................

........................................

.30

.31

.33

34

.35

36

.38

39

.40

.41

42

WESTERBEKE

Engines & Generators

1

Page 12

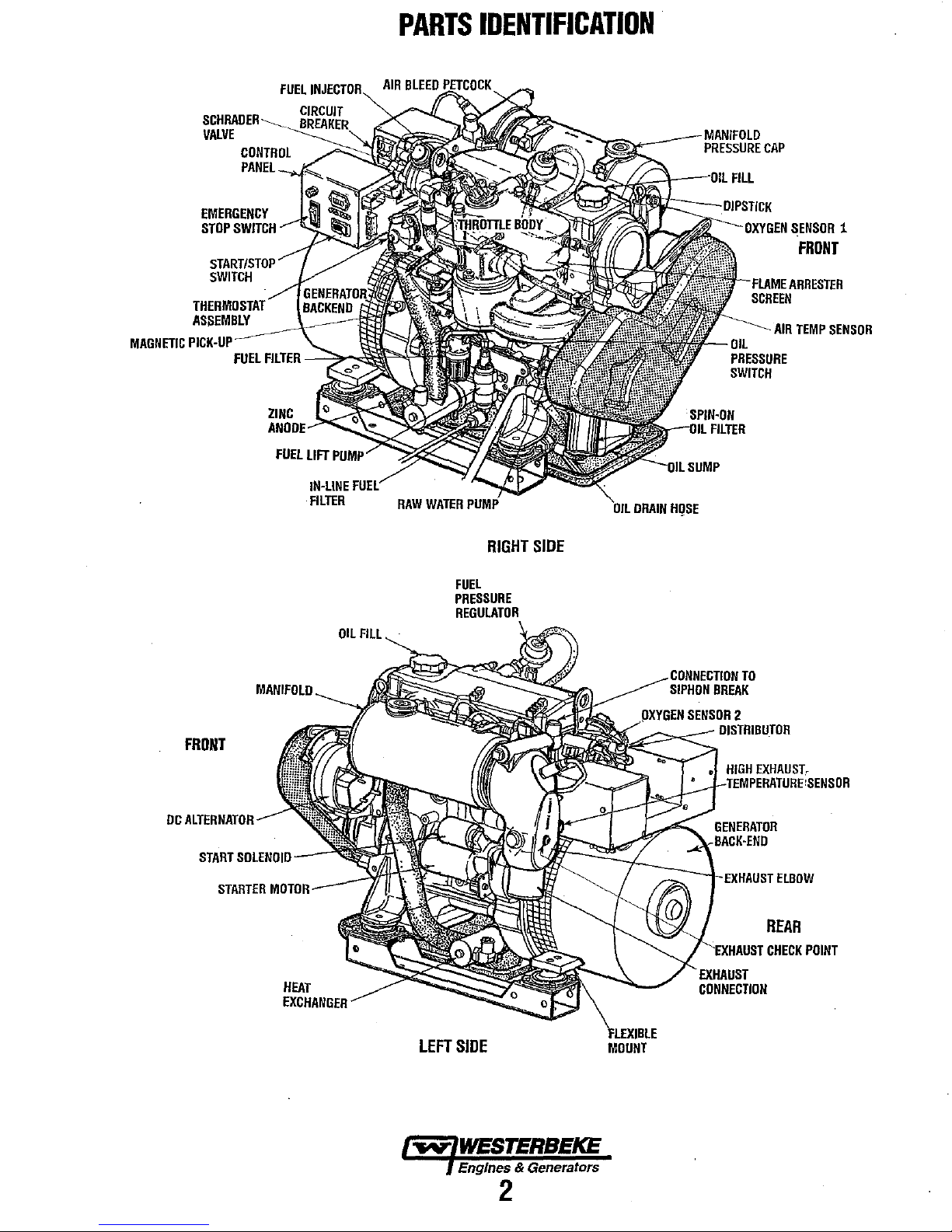

VALVE

CONTROL

PANEL

EMERGENCY

STOP

SWITCH

START/STOP

SWITCH

PARTS

IDENTIFICATION

-----

OX1rGEN

SENSOR

1

FRDNT

MAGNETIC

PICK-UP

FRDNT

ASSEMBLY

FUEL

FILTER

ZINC

ANODE

FUEL

-~~

LIFT

IN-LINE

FILTER

OIL

FUEL

FILL

RIGHT

FUEL

PRESSURE

REGULATOR

SIDE

AIR

TEMP

DRAIN

HgSE

SIPHON

BREAK

SENSOR

,--",:::::o,"<~

2

DISTRIBUTOR

HIGH

EXHAUST.

TEMPERATURE:SENSOR

SENSOR

DC

ALTERNAlroR-----

START

SOLENOID

STARTER

Mn,rnD

HEAT

.--

LEFT

SIDE

~

WESTERBEKE

Engines & Generators

2

MOUNT

GENERATOR

:--t-I'XHIIUST

ELBOW

REAR

'-.E:(HAI~ST

CONNECTION

CHECK

POINT

Page 13

INTRODUCTION

ORDERING

Whenever replacement parts are needed, always provide

generator

include a complete part description

part needed (see the separately furnished Parts Catalog).

insist

or generic parts are frequently not

cations

NOTES,

As

this

maintenance schedules,

tor,

critical information

CAUTIONS,

NOTE:

A

observed,

the

engine

A

followed,

NOTE:

by WESTERBEKE.

the

engine

SPARES

Certain spare parts will

your WESTERBEKE generator or engine

SUGGESTED SPARE PARTS).

as

proper

the

way.

spares

on-board inventory of

PARTS

and

engine

model

and

serial

numbers.

and

part number

upon

WESTERBEKE packaged parts because will fit

made

to

as

original

CAUTIONS

manual

An

operating procedure essemial

CAUTION:

WARNING:

A carbon nwnoxide warning decal has been provided

room.

AND

fuel

WESTERBEKE

and

accessories

equipment.

AND

WARNINGS

takes

you

through

and

will

and

WARNINGS.

Procedures,

can

result

in

the

or

generator.

Procedures,

can

result

in

personal

Affix this decal in a visable location in

the

operating procedures,

troubleshooting of your genera-

be

highlighted

An

explanation

to

which

if

damage

or

which

if

injury

ACCESSORIES

be

and

needed

oil

filter can

will

brochure

the

proper WESTERBEKE

to

Often

be

difficult

provide

to

assist

support

even

you

you

In

addition,

for

the

same specifi-

by

NOTES,

follows:

note.

not

strictly

destruction

not

properly

or

loss

of

life.

and

maintain

when

cruising (see

simple

items

to

obtain

along

with

a suggested

in

preparing

parts.

of

the

each

Also

such

an

PROTECTING

Care

at

the

have resulted

many

thousands of hours of dependable service.

manufacturer

installed

operated

YOUR

INVESTMENT

factory

in

and

during assembly

in

a WESTERBEKE generator capable of

cannol

control

the

vessel

or

the

manner

serviced

in

the

how

field.

or

This

and

where

in

which

is

thorough testing

However

the

generator

the

unit

up

to

the

buyer/owner-operator.

NOTE:

Six important steps

• Proper engine

•

An

efficient well-designed exhaust system that includes

anti·siphon break to prevent water

an

engine.

• Changing the engine oil

inghours.

• Proper maintenance

nents according

manual.

•

Use

clean,jiltered unleaded fuel.

• Wuzterize

Recommissioning" section in this manual.

and

your

ellgille according to the "Lay-up

UNDERSTANDING

The gasoline engine driving

ways

similar

to

a gasoline

are verticle in-line,

overhead camshaft

a solid-state distributor

camshaft-driven. The engine incorporates a pressure

lubrication system,

which

is

thermostatically-controlled.

generator's

that

important factors

ventilation,

cooling system

engine

is

required of a gasoline automobile engine.

which

requires

to

maintenance

and

/0

ensure long generator lite:

generator illStallatWll

from

am!

oil jilters every 100 operat-

of

all engine and generator compo-

to

the maintenance schedule

THE

GASOLINE

an

automobile

and

the

engine's cylinder head

is

chain-driven. The engine utilizes

which

is

and a fresh

the

the

generator

water-cooled engine

the

same

generator's longevity are proper

of

the

fuel

GENERATOR

AC

generator

engine.

horizontally

To

a large

preventive

system,

backend.

mounted

ignition

and

alignment.

entering the

in

is

in

many

The

cylinders

has

degree,

maintenance

The

the

is

is

this

and

an

and

type

block

the

most

system,

~

WESTERBEKE

Engines & Generators

4

Page 14

FUEL,

ENGINE

OIL

AND

ENGINE

COOLANT

GASOLINE

A

CAUTION:

rating

of

89

harm

to

your

Care

Of

The

Use

only clean

your

fuel

injection pump

particles which might pass through

finely

these

and

keep it clean. The best

unsatisfactory

facilities.

engine's daily

advisable:

Purchase a well-known brand of

Install

metal

and

ENGINE

Use

Change

break-in operation,

thereafter.An

for

To

and

regularly service a good, Coast Guard approved

bowl type filter/water separator between

the engine.

DlL

a heavy duty engine

the

this

engine

Only

use

unleaded

or

higher.

engine

Fuel

fuel!

finished

by

assure that

use

engine oil

oil

viscosity of

in

Leaded

and

fuel

violate

Supply

The clearance of

is

very

critical; invisible dirt

parts.

It

is

important

fuel

can

careless handling or improper storage

the

fuel

going into

is

clean

and

pure,

fuel.

oil

with

and

filter

after

and

every

100

SAE

all

conditions.

fuel

with

will

cause

your

warranty.

the

components

the

filter

to

be

rendered

the

the

following practice

an

API

classification of

an

initial

hours

of operation

15W-40

is

an

octane

serious

in

can

damage

buy

clean

fuel,

tank

for

your

the

fuel

tank

50

hours

recommended

of

SJ.

is

ENGINE

WESTERBEKE recommends a mixture of 50% antifreeze

50%

that

The

to

the

cooling circuit

antifreeze that contains supplemental cooling additives

that keep

lenn

The water

poured

NOTE:

antifreeze thot is now available.

A proper 50/50 mixture

engine coolant

COOLANT

A coolant recovery tank kit

The

coolant

without

the

COOLANT

distilled

can

antifreeze performs double

run

engine

protection.

purpose of this recovery tank

cooling system.

water.

Distilled water

corrode internal engine surfaces.

at

proper temperatures

to

the

coolant.

from

the

antifreeze chemically balanced, crucial

and

antifreeze should

into

the

cooling circuit.

Use the new environmentallyfriendly, long lasting,

to

temperatures of -40'P

RECOVERY

expansion

the

loss

of

rust

as

and

contraction

coolimt

It

also lubricates

and

recommended

TANK

is

and

is

free

from

duty.

It

allows

by

transferring heat away

and

corrosion.

supplied with each

without introducing

Use

a good quality

be

premixed before

will

is

to

allow

during

engine

protect

for engine

the

protects

the

chemicals

engine

from

the

(SCAs)

to

long

being

the

generator.

operation,

air

into

and

A

CAUTION:

engine

oil

additives

to

produce

00

to

mix.

Each

of

different

properties

not

allow

brand

brands

harmful

two

or

more

contains

could

react

to

your

brands

its

own

in

the

engine.

of

additives;

mixture

~

WESTERBEKE

Engines & Generators

5

Page 15

PREPARATIONS

PRESTARTINSPECTION

Before starting your generator

longed layoff,

• Check the engine

the

full

• Check the

bowls

• Check the

and battery cable connections.

• Check the coolant

and at

NOTE:

the engine:r cooling system will be purged

recovery tank. Open the

the cooling system is purged

after the engine

tank will be drawn into the engine:r cooling system

replace the purged

Before subsequent operation

manifold shauld be topped off,

tank may need to be filled to the

check the following

oil

mark

on

the

fuel

supply

for

contamimmts.

DC

electrical system. Inspect

level

the

manifold.

After the initial running

has

air.

for

the

first

time

items:

level:

add

oil

to

maintain

dipstick.

and

examine

in

both

air

cooled, the coolant from the recovery

the

fuel

wire

the plastic recovery tank

of

the generator, the air in

to

bleed petcock to ensure that

of

air.

After shutdown

of

the generator, the engine's

and

the coolant recovery

MAX

level.

FOR

or

after a pro-

the

level

at

filter/separator

connections

the coolant

GJUi

to

OIL

FILL

INITIAL

•

Visually

parts,

threaded

•

Check

the

• Examine the air

•

Be

the

•

Be

neutral

requires,

to

the

or

open

voltage

•

Make

A

recommended

motors,

up

to

This

unanticipated

prevent a cold

START-UP

examine

disconnected

connections. Search

load

leads

wiring

diagrams.

sure

no

other generator

load

lines.

sure

that

in

is

properly

and

that generator

load

neutral.

neutral

on

unbalanced

certain

the

CAUTION:

be

switched

speed

and,

precaution

operation

the

unit.

wires,

for

correct connections

inlet

and

outlet for

power systems

grounded

In single phase

can

supply

loads.

raw

water

When

starting

that

all

AC

loads,

OFF

until

in

cold

climates,

will

prevent

of

engine

from

Look

for

unattached

for

any

or

utility

with a neutral

(or

ungrounded)

neutral

systems

the

wrong

thru-hull

the

especially

the

engine

starts

damage

the

AC

machinery

stalling.

loose

or

missing

hoses,

and

gasoline

as

specified

air

flow

obstructions.

power

is

connected

line

as

is

properly

an

line-to-neutral

is

open.

generator,

large

has

come

to

warm

caused

by

and

check

leaks.

in

that

the

the

system

connected

incomplete

it

is

up.

will

to

AIR

BLEED

PETCOCK

Engines & Generators

6

Page 16

.

STARTING/STOPPING

PRO

GENERATOR

CONTROL

PANEL

AC

CIRCUIT

IrITii~~~

BREAKER

----+.Ii

HOURMETER

BA

FUSE---_W

EMERGENCY"

","_L

,

"00

5

'

START/STOP

o

SWITCH

--"""'

__

-""

p

m

Starting

Simply press

the

START switch

and

the

generator will start.

A green light will glow indicating the generator

is

running.

Stopping

To

stop-depress

the

STOP side of

the

start

switch,

the

green

light will

go

out

and

the

generator

is

stopped.

Failure

to

Start

The start cycle

will

automatically tenninate if

the

unit

fails

to

start after 12-14 seconds of cranking.

Wait

20

seconds,

then

repeat the start.

If

the

unit again

fails

to

start, investigate

the

cause.

Sometimes after servicing

the

fuel

system or changing

the

fuel

filter,

air can accumulate in

the

fuel

line or

the

throttle

body and prevent starting.

The

Schrader

valves

on

the

throttle body

and

the

fuel

cell

are

used

to

remove trapped

air.

This air

is

mixed

with

fuel

and

under high pressure. Follow

the

BLEEDING THE FUEL

SYSTEM instructions in

this

manual.

•

START----'STOP

o

REMOTE

CONTROL

PANEL

ECU

CONINECTIONS

~-~.-£'---EN["NE

HARNESS

CONNECTION

FIREBOY,

CO

DETECTOR

AND/OR

AUXILIARY

STOP

CONNECTION

REMOTE

START/STOP

PANEL

The

components on

the

panel

are:

1.

A three position start/stop rocker

switch.

2.

A green

LED

run indicator light on the rocker

switch.

3. A four position LED fault shut down display board.

The start/stop rocker switch functions

the

sarne

as

the

start/stop rocker switch

on

the generator's control

panel

as

previously explained.

The start/stop rocker switch indicator light on the rocker

switch

will

illuminate when the start circuit

is

energized.

It

will

go

dim

as

the engine cranks and will brighten

as

the

engine sttuts

to

indicate the generator is running.

The

LED

fault

shut down display board has four separate

LED

lights

to

display

to

the operator the cause of

the

generators

automatic shut

down.

The four

LED

displays

are:

low

oil

pressure, high engine operating temperature, high exhaust

temperature

and

engine over-speedlunder-speed

(flashes).

Should

the

generator shut down

from

one

of these

faults,

the

fault

LED

will remain illuminated.

To

reset

the

LED,

the

stop

switch

must

be

momentarily depressed.

This remote panel is a plug-in accessory and

is

available with a

15'

to

100' wiring harness .

~

WESTERBEKE

Engines & Generators

7

Page 17

BREAK-IN

PROCEDURE/DAILY

OPERATION

BREAK-IN

After the generator has been started, check for proper

operation and then encourage a fast wann-up. Run the

generator between

hours.

A

genllfBtor

After the first 10 hours

can be increased to the full-load rated output; then

cally vary the load.

Avoid overload at all times. An overload is signaled by a

smoky exhaust with reduced output voltage and frequency.

Monitor the current being drawn from the generator and keep

withinthe

it

at

1800 rpm to produce 60 hertz, control

engine break-in is governed by the current drawn from the

generator.

To protect against unintentional overloading

'.

the generator's output leads should be routed thmugh a

circuit breaker

generator.

NOTE:

current drawn required/or starting motors.

amperage drawn

amperage. See GENERATOR INFORMATION in this

manual.

PROCEDURE

20%

to

60%

of

full load for the first 10

CAUTION:

Be

aware

Do

not

attempt

by

running

generators' rating. Since the generator operates

thitt is rated at the rated output

without a load.

of

afmotor

can

be 3

the generators' operation, the load

starting loads and the high

to

to

break·in

of

5 times nonnal

the generator's

of

This

your

periodi-

the generator,

of

the

starting

running

NOTE:

Some unstable running may occur in a cold engine.

This

condition slwuld abate as nonnal operating temperature

is reached and loads are applied.

A

CAUTION:

periods

of

00

not

time

without a load

operate

the

generator

being

placed

for

on

long

the

generator.

STOPPING

Remove the major

Allow the generator to run for a few minutes to stabilize the

operating temperature and press the

CONTROL PANELS).

NOTE:

the maintenance schedule

GENERATOR

Once the generator has been placed in operation, there may

be governor adjustments required for engine speed (hertz)

during the engine's break-in period (first

this period (see

under ENGINE ADJUSTMENTS. A no-load voltage

adjustment may also be required in conjunction with the

engine's speed adjustment (see

INFORMATION).

A

THE

GENERATOR

AC

loads from the generator one at a time.

STOP switch down, (see

After the first

50

hours

for

of

generator operation check

the

50

hour service check.

ADJUSTMENTS

50

ENGINE SPEED (HER1Z) ADJUSTMENT

GENERATlOR

WARNING: . VENTILATION

hours) or after

CHECK

Follow this checklist each day before starting your generator.

• Record the hourmeter reading

• Visually inspect the engine for fuel, oil, or water leaks.

• Check the oil level (dipstick).

• Check the coolant level in the coolant recovery tank.

• Check your fuel supply.

• Check the starting batteries (weekly).

• Check the drive belt for wear and proper tension (weekly).

• Check for abnormal noise such as knocking, vibration and

•

LIST

in

your log (engine hours

relate to the maintenance schedule).

blow-back sounds.

Confmn

When the engine is cold - White

When the engine is

When the engine is overloaded - some Black

exhaust smoke:

wann

Smoke.

- almost Smokeless.

Smoke.

Gasoline vapors can explode. Before starting the engine,

operate the blower for at least four minutes and check both

the engine compartment and the bilge for gasoline vapors.

Run the blower below cruising speed.

Engines & Generators

8

Page 18

SAFETY

SHUTDOWN

SWITCHES

DESCRIPTION

The engine/generator is protected by switches and sensors

that send signals

to

the ECU that it interprets as a fault and

automatically shuts down the generator drive engine. When

an automatic shutdown occurs, one of the control panel fault

LED lights will illuminate indicating what fault caused the

engme to shutdown.

TIlls LED will stay illuminated.

To

correct the fault, refer

to

ENGINE TROUBLESHOOTING

in

this manual. Do

not

attempt

to restart

the

generator

before correctiog

the

fault.

WDISPlAY

PCBOARD

(INTERIOR

VIEW)

~I

CONTROL

PANEL

INDICATOR

LIGHTS

PRESSURE

FUSE

Four

LED

fault ligbts are located on the generator control

panel

and

the

remote start/stop panels. Should a problem

occur during generator operation the individual light will

indicate

Where

the problem

is

and at the same time shut the

generator down. The light

wjll continue

to

glow after the

generator shuts down.

Should this occur, refer

to

ENGINE

TROUBLESHOOTING in this manual.

OIL

GALLERY

OIL

PRESSURE

SENSOR

An oil pressure sensor (located just below the oil filter) sends

a

DC

Voltage to the ECU that it interprets

as

oil pressure.

Should

this

voltage faIl below a certain level, the ECU will

shut

the

generator down and illuminate the low oil pressure

LED.

Should

this occur, refer

to

ENGINE

TROUBLESHOOTING

in this manual.

EXHAUST

TEMPERATURE

SWITCH

A temperature switch is mounted on the exhaust elbow

to

monitor

the

temperature

of

the exhaust coolant and gasses.

Should

the

switch sense an excessive exhaust temperature,

the

ECU

will

shut the generator down and

the

exhaust

temperature LED will illuminate on the control panel.

Should

this

occur, refer

to

ENGINE TROUBLESHOOTING

in

this

manual.

COOLANT

SENSOR

THERMOSTAT

ASSEMBLY

COOLANT

TEMPERATURE

SENSOR

A coolant temperature sensor is located on the thennostat

housing

to

monitor the engines fresh water coolant. Should

the

coolant temperature reach

21O"F,

the ECU will shut the

generator down and the engine temperature LED will

illuminate.

Should this occur, refer

to

ENGINE

TROUBLESHOOTING in this manual.

OVERSPEED

SWITCH

An

overspeed high RPM shutdown sensor

in

the ECU will

shut the engine down if the engine

RPM"S exceed

the

set

limit and the LED will remain

lit.

If

an

underspeed problem

occurs, the engine

will

shutdown

and

the LED will remain

flashing.

DC

CIRCUIT

BREAKER

The generators engine

is

protected

by

a panel mounted man-

ual

reset circuit breaker (20 amp).

An

electrical overload

in

the

engine's wiring hamess or the instrument panel

will

trip

this

breaker

and

shutdown the engine/generator. If this should

occur, inspect and repair the problem. then reset the breaker

and

sestart

the

engine/generator.

Engin~s.

& Generators

9

Page 19

A

WARNING:

running.

use

serviCing

Wear

the

co"ect

any

I

SAFE

I Maintenance items that are very imponant to the proper operation

CD "Safe

MAINTENANCE

Never

the

tools

of

proper

the

engine's

CO"

attempt

for

generators.

safety

each

DC

to

perform

equipment

job.

Disconnect

electrical

SCHEDULE

any

such

equipment.

service

as

goggles

the

battery

while

and

terminals

the

engine

gloves,

when

is

and

of

SCHEDULED

MAINTENANCE

Fuel

Supply

Fuel/Water

Engine

Oil

Coolant

Level

Drive

Belts

Visual

Inspection

Sparts

Plugs

Starling

(and

Engine

Generalor

Fuel

Air

Exhausl

Engine

Raw

Heal

Cootanl

Fuel

Inlel

Banerles

House

011

un

Pump

Screen

Syslem

Hoses

Waler

Exchanger

Syslem

Filler

Fuel

Filler

Separator

Level

of

Engine

I~EI

Baneries)

FcHI

Pump

CHECK

EACH

DAY

0

0

0

0

0

weekly

0

0

weekly

HOURS

OF

OPERATION

100

50

NOTE:

will

inhibit

0

0 0

0

250

500

Keep

engine

the

surface

engine's

0

0

0

0 0

abifity

0 0 0 0 0 0

0

0

0

0

0 0 0

0 0 0 0

0 0 0

0 0

0

0

0 0

0 0

0

0

0

0

750

1000 1250

clean.

Dirt

to

remain

0 0

0

0 0

0

0

0

0 0

0

0

and

cool.

oif

0

0

0

0

Unleaded

Check

necessary).

Oil

dipstick.

Check

Add

Inspect

and

Check

electrical

for

Check

Every

and

excessive

Initial

change

Check

no

Periodically

are

Clean

Initial

Inspecl

Check

buildup

necessary.

Hose

become

Remove

Inspect

Lubricate

Clean

cap

for

Drain,

appropriate

Change

Change

gasoline

for

water

level

should

at

recovery

coolant

for

proper

adjust

if

for

fuel,

connections.

loose

belt

gap,

50

operating

make

sure

corrosion.

engine

both

that

AC

chafing-see

clean

and

at

50

check

for

leaks.

the

exhaust

on

inside

Check

should

spongy.

the

impeller,

impeller

or

replace

and

clean

professional

flush,

every

every

MAINTENANCE

with

and

indicate

tank;

if

needed.

tension

needed.

oil

and

tension.

inspect

connections

oil

and

every

100

connections

GENERATOR

inspect

tight.

hrs.,

then

at

50

hours,

Check

elbow

passages;

that

be

hard & tight.

Check

pump

cover

cam

when

anode.

oul

debris.

cleaning

and

refill

antifreeze

250

operating

250

operating

DESCRIPTION

octane

dirt

in

fuel

between

if

empty,

(3/8'

Check

belt

water

leaks.

Keep

bolts & nuts

for

burning

hours

check

are

filter

change

hours.

are

for

leaks,

every

100

Ihen

anti-siphon

for

carbon

clean

all

connections

and

tighten

and

and

wear

reassembling.

Open

Remove

and

COOling

mix.

hours.

hours.

INFORMATION.

electrical

Replace

inspect

pressure

rating

of

89

(drain/replace

MAX.

and

check

at

manifold.

to

1/2'

deflection)

edges

for

wear.

Inspect

tight.

and

corrosion.

electrolyte

very

tight.

Clean

at

50

hours,

clean

and

secure

connections

hours.

every

250

hours.

valve

operation.

and/or

and

replace

are

tight.

if

hoses

all

hose

for

wear.

plate.

Replace

heat

exchanger

every

1000

testing.

system

with

(continued)

of

higher

filter

if

LOW

on

wiring

and

Check

levels

off

then

with

corrosion

as

clamps.

gasket.

end

hours

Engines & Generators

10

Page 20

MAINTENANCE

NOTE:

Use the engine Murmeter gauge

engine hours by

running

time.

SCHEDULE

to

log your engine hours

or

record your

SCHEDULED

MAINTENANCE

"Starter

Distributor

"Engine

"Engine

"Exhaust

Catalyllc

"Exhaust

Catalyst

Oxygen

CO

Motor

~

Cylinder

CompreSSion

Valve

Clearances

Timing

Elbow

Converter

System

Pressure

.1mI

Sensor

In

Exhaust

and

Belt

~

Back

1"t1f1

CHECK

EACH

DAY

HOURS

OF

100

50

250

500

0

0 0

0 0

0

0

0

OPERATION

750

1000 1250

0

0

0

0

Check

0

and

lubricate.

pinion

Check

cap

and

Incorrect

performance,

timing

Remove

NOTE:

recommended

failure

Test

exhaust

casting

NOTE: A defective

carbon

Remove

inspect.

Perform

developing

above

operating

Remove

inspect

Inspect

Sample

MAINTENANCE

solenoid

drive.

ignition

and

resulting

1.5

and

Clean

timing.

rotor.

valve

clearance

check

adjust

and

replace

Failure

to

replace

interval

in

elbow

is

corroded

monoxide

water

injected

Replace

every

back

pressure

restrictions

PSI

or

41

amperage

water

injected

every

2000

every 1 000

with

CO

analyzer.

valve

major

exhaust

leakage!

DESCRIPTION

motor

for

corrosion.

and

lubricate

Check

condition

will

result

compression

clearances.

every

1000

the

timing

could

result

damage

for

casting

integrity.

or

deteriorated.

elbow

exhaust

2000

that

inches

load.

hours.

hours.

hours.

test

to

ensure

will

of

water

Correct

exhaust

Replace

Replace

elbow

increase

elbow

the

starter

of

in

poor

pressure

hours.

belt

at

in

timing

to

the

engine.

Replace

can

cause

and

system

column

as

needed.

and

as

needed.

every

Remove

motor

distributor

engine

and

the

chain

if

visually

is

not

pressure

at

full

visually

2000

hours.

·WESTERBEKE

recommends

this

service

EXHAUST

be

performed

MANIFOLD

by

an

authorized

ADJUSTABLE

CLAMP

.0~~"

Engines & Generators

mechanic.

11

Page 21

FUEL

SYSTEM

GASOLINE

Use unleaded 89 octane

follow

U.S Coats Guard regulations, close off all hatches and

companionways to prevent fumes from entering the boat, and

ventilate after fueling.

NOTE:

The generator compartment should hnve a gasoline

fume

detector/alarm properly installed

GASOLlNEJWATER

A primary fuel filter

type

must

be

installed between

and the engine to remove water and other

contaminant's from the fuel before they can

be carried to the fuel system on the engine.

Most installers include a type

separator with the installation package as

they are aware

contaminant's

These gasoline filters must have

(not

"see-through") to meet U.S. Coats Guard

requirements. The metal bowls have drain

valves to use when checking for water and

impurities.

of

in

the fuel can cause.

or

higher gasoline. When fueling,

SEPARATOR

of

the water separalting --,-,

th~

of

filter/water

the problems that

metal

and

working.

AND

bowls

WESTERBEKE

i

NUMBER

(49602)

__

PART

~\

ENGINE

Periodically check the fuel counections and the bowl for

leakage. Replace the filter element after the first

then follow the

Changing

1. Shut the fuel supply to the generator off.

2. Ensure there is no pressure in the fuel system by bleeding

S.

6.

7.

INLET

1. Shut off the fuel supply to the generator. Disconnect the

2. Thread

3.

FUEL

FILTER

50 hours

MAINTENANCE SCHEDULE.

Filter

Element

off any existing pressure using a Schrader valve on the

throttle body and fuel cell.

shown on the next page.

Unscrew the fuel bowl from the housing and allow the

bowl to come away from the housing.

Remove and replace the filter element and clean the

bowl.

Inspect both

Press on a new filter and replace the filter bowl.

Open the fuel supply. Inspect for leaks.

FUEL

fuel supply line to the inlet filter and unscrew the filter

from the pump inlet. Take care to catch any fuel that may

be

present.

fuel supply line.

tightening the fuel supply line so

inlet filter.

Tum

generator. Ensure that there are

"0"

rings. Replace

FILTER

on

the replacement inlet filter and connect the

Use care when connecting and

on the fuel supply to the generator and start the

Use a pressure testing kit as

if

necessary.

as

not to distort the

no