CS12-553-401

User Manual

Important Safety Information

Antennas used for the purpose of radiating signals indoors are limited to a maximum gain of 3 dBi. The

outdoor antenna used for the purpose of communicating to the wireless infrastructure is limited to 3dBi

gain, or any combination of gain and loss that equates to 3dB at input. Each antenna must be positioned

to observe minimum separation requirements from all users and bystanders. The following guidelines

should be used when considering separation distances.

INDOOR antennas must be placed such that, under normal conditions, personnel cannot come within

20 cm (~8.0 in.) from any inside antenna. Adhering to this minimum separation will ensure that the

employee or bystander cannot exceed RF exposures beyond the maximum permissible limit as defined

by section 1.1310 i.e. limits for General Population/Uncontrolled Exposure.

OUTDOOR antenna must be positioned such that, under normal conditions, personnel cannot approach

closer than 120 cm. (~4 ft.). A non- directional antenna having a maximum gain of 3 dBi is used,

precautions should be taken to prevent personnel from routinely passing closer than specified.

Cellular Specialties, Inc. grants to the purchaser a fully paid license, at no additional

charge, to copy or otherwise reproduce all or portions of the product documentation. Such

reproduction shall be for the purchasers use only.

Table Of Contents

Section 1

Hardware Configuration

System Level Block Diagram..................................................................4

Block Diagram of the Major Components...............................................5

Module Face Plate Configuration ...........................................................6

Module Label Locations ........................................................................7

Section 2

Installation

Physical Installation into the Train........................................................8

Required RF and Power Cabling ....................................................9-10

Power Up and Check Out Procedures ...............................................11

Section 3

Hardware Operations

Location and Offset Values for Test Points.........................................11

Indicator Lights ................................................................................12

Troubleshooting ...............................................................................13

Warranty and Repair Procedures ................................................14-18

Section 4

Software Operations

Software Operation Overview .........................................................19-45

Software Behavior Under Normal Conditions ...................................46-47

Terms Used in This Manual...................................................................................48

Index ................................................................................................................49

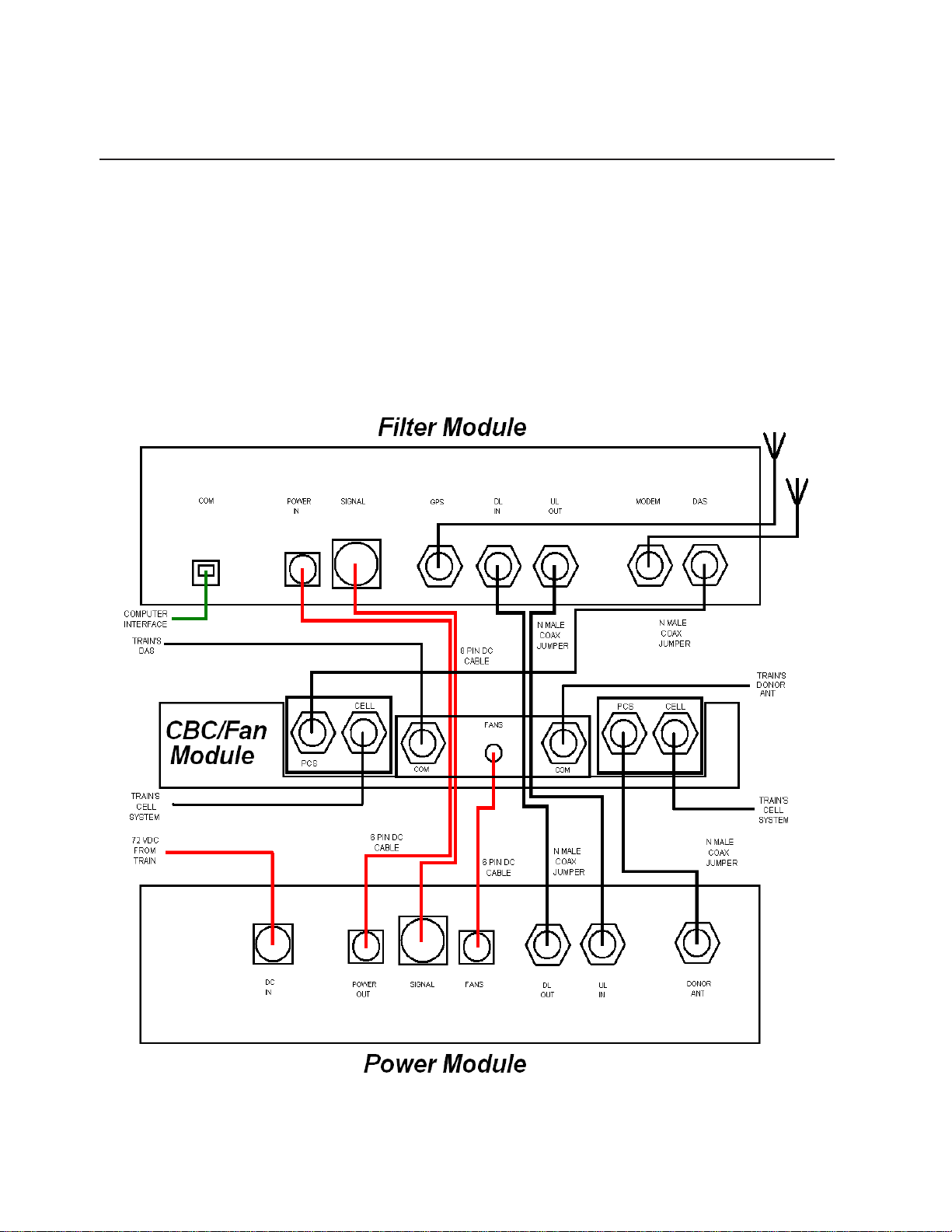

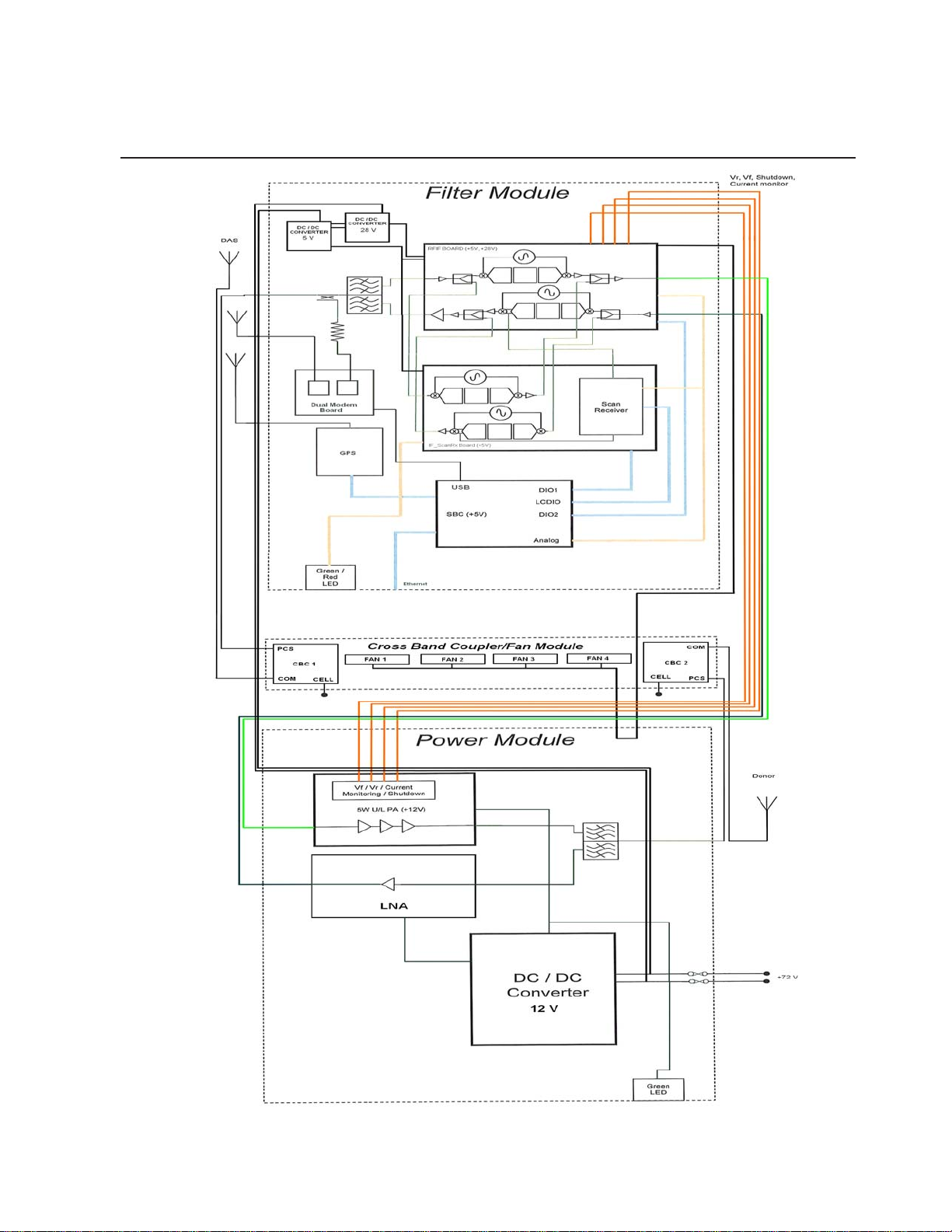

Hardware Configuration

This CSI repeater system is comprised of three modules and the cable assemblies

that interconnect them.

The Filter Module provides frequency selection and filtering. It also houses the

system computer. The Power Module provides amplification and power distribution. The

CBC/Fan Module (Cross Band Coupler/Fan Module) is the interface between the train’s

existing Cellular repeater system and this PCS repeater.

Section 1

System Level Block Diagram

-4-

Hardware Configuration

Section 1

Block Diagram of the Major Components

- 5 -

Hardware Configuration

Section 1

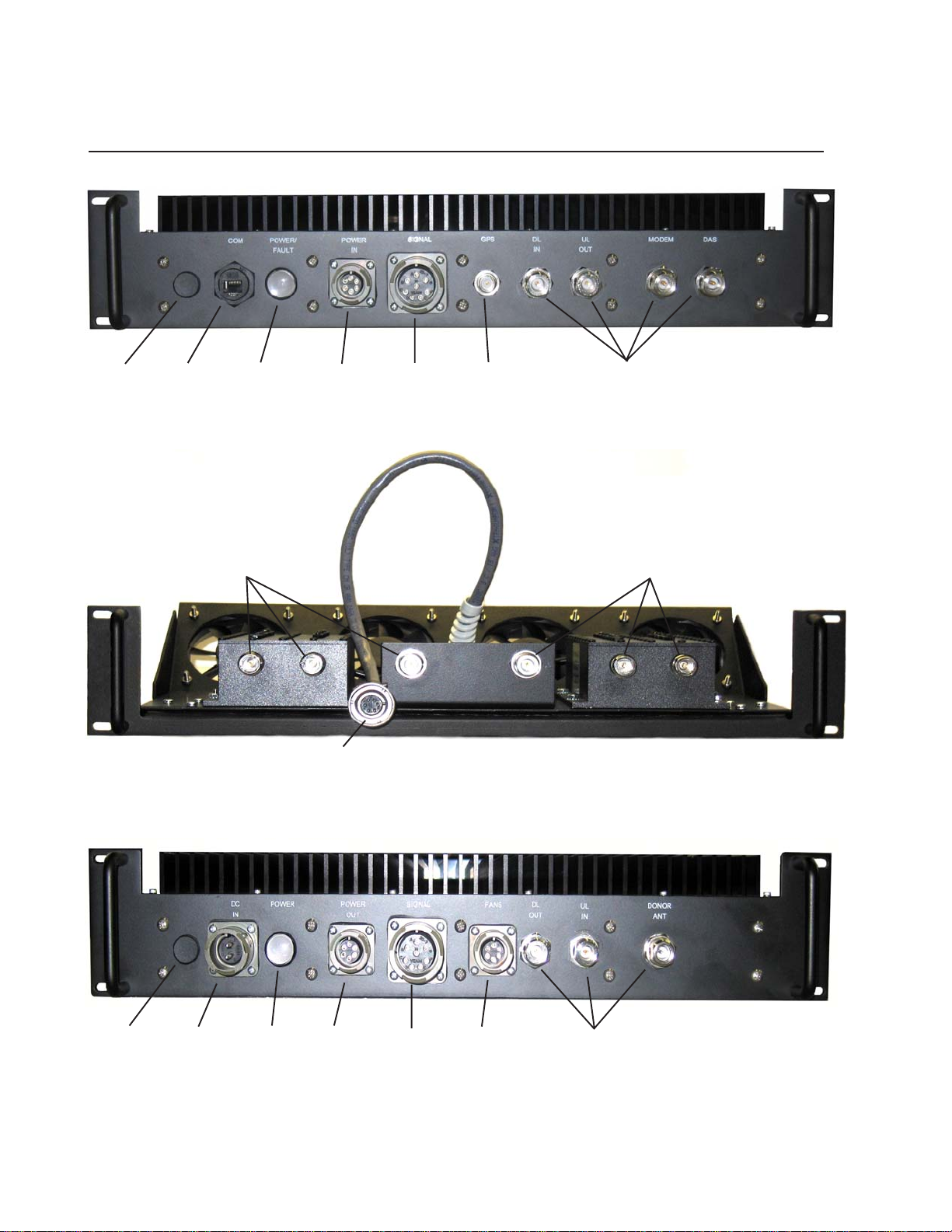

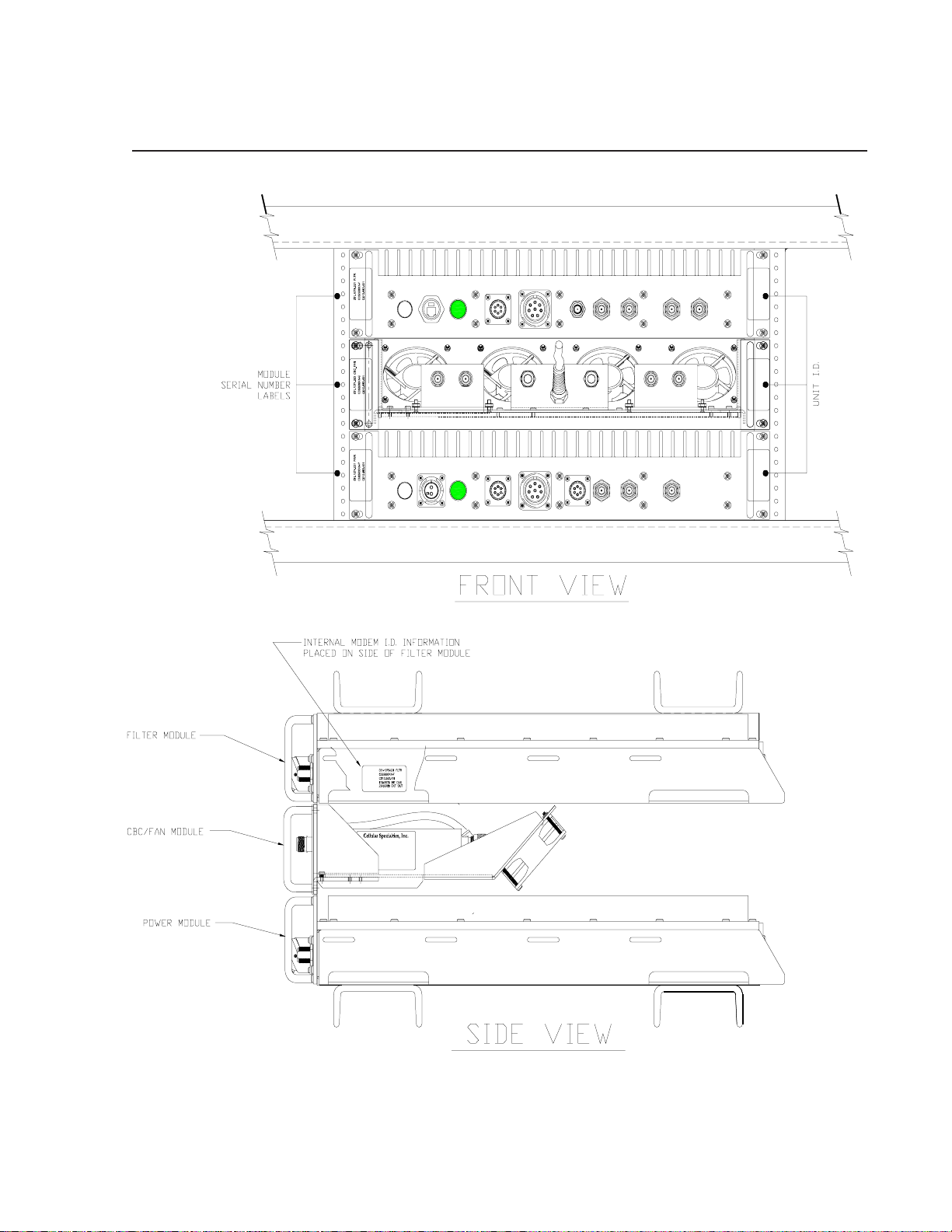

Filter Module

One Way

Vent

CONN

RJ45

FAULT LED

FEMALE

RF CONN

POWER/

CONN

N TYPE

CONN

6 PIN DC

CONN

6 PIN DC

8 PIN DC

CONN

TNC RF

CBC/Fan Module

N TYPE

FEMALE

RF CONN

One Way

Vent

CONN

2 PIN DC

LED

POWER

CONN

6 PIN DC

CONN

Module Face Plate Configuration

Power Module

8 PIN DC

CONN

6 PIN DC

-6 -

N TYPE

FEMALE

RF CONN

Hardware Configuration

Section 1

Model #:

Model #: Model #:

Serial #:

Serial #:

Serial #:

POWER/

COM

www.cellularspecialties.comwww.cellularspecialties.com

Item #:

POWER

FAULT

IN

A

G

A

F

E

B

H

B

F C

C

D

E D

DLGPSSIGNAL

OUTIN

DASMODEMUL

1

A

1

Item #:

Item #:

www.cellularspecialties.com

FHS-632-8 FHS-632-8

DC

POWER

IN

A

VEAM

16-11

0

B

COMMON COMMON

POWER

SIGNAL FANS

OUT

G

A

F

B

F

E

C

D

DL

A

B

H

C

DE

OUT

A

F

B

E

C

D

DONOR

UL

ANT

IN

B

1

C

Model #:

Serial #:

Item #:

ESN #:

www.cellularspecialties.com

Module Label Locations

- 7-

Installation

Section 2

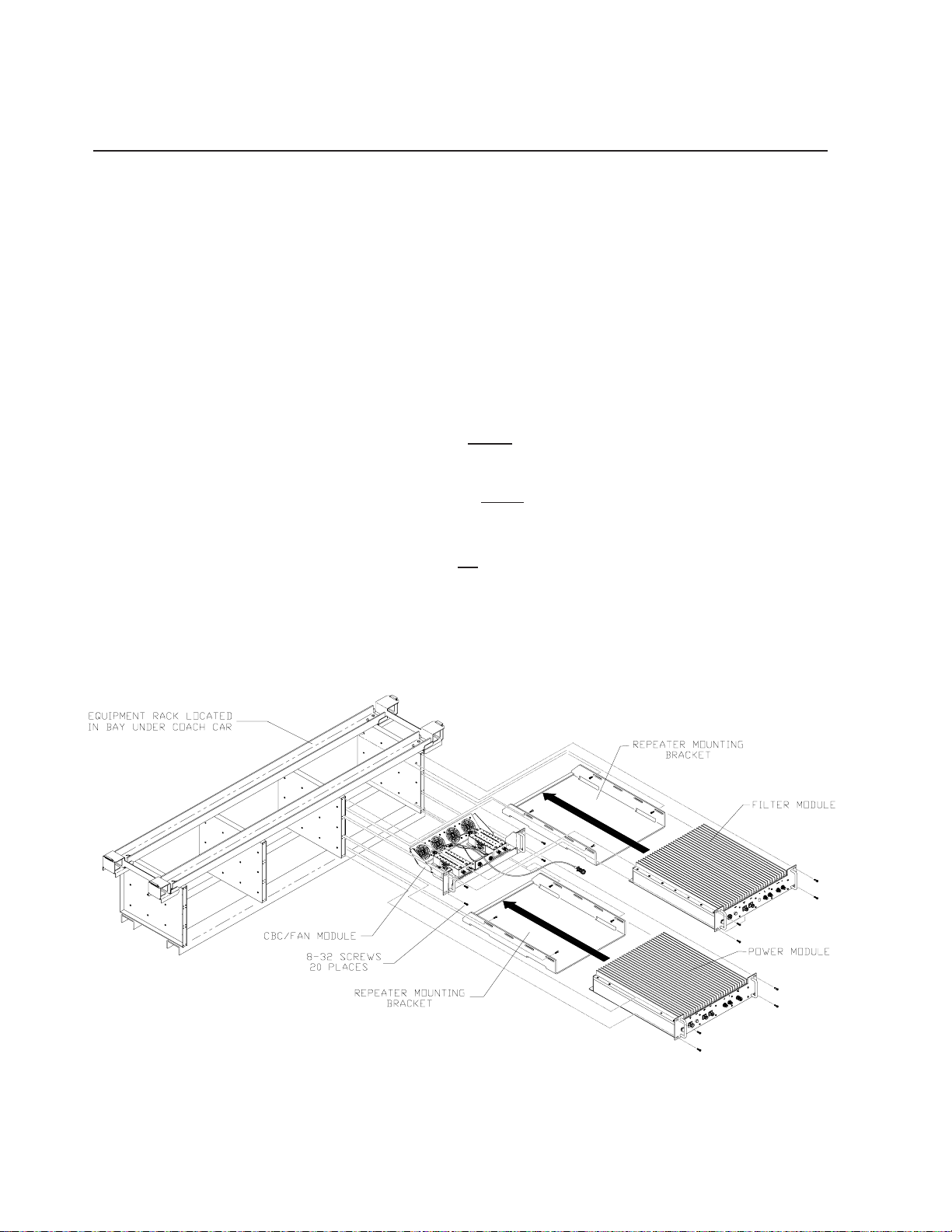

1. Unpack each of the three boxes that make up the CSI repeater system for the

Acela train. The first box contains the Filter Module and associated components.

The second box contains the Power Module and associated components.

Lastly, the third box contains the CBC/Fan Module and associated components.

2. After unpacking, the major components should include one Filter Module, one

Power Module, one CBC/Fan Module and two Repeater Mounting Brackets.

The minor components are 20 #8-32 Phillips Head Machine Screws and cabling for

interconnection of the modules, which will be detailed on the next page. If any parts

are discovered to be missing contact Cellular Specialties, Inc. at 1-877-844-4274 to

arrange for replacements to be sent.

3. Install the Repeater Mounting Brackets, one in the rack’s bottom slot and one

in the rack’s top slot using 4 #8-32 Phillips Head Machine Screws for each.

4. Install the Power Module in the rack’s

4 #8-32 Phillips Head Machine Screws.

5. Install the CBC/Fan Module in the rack’s

4 #8-32 Phillips Head Machine Screws.

6. Install the Filter Module in the rack’s top slot as shown and secure with

4 #8-32 Phillips Head Machine Screws.

bottom slot as shown and secure with

middle slot as shown and secure with

Physical Installation Into The Train

- 8 -

Section 2

Installation

1. With each of the three modules in place, DC and RF cables can be installed. Locate the DC cable with a 6 pin

bayonet type connector at each end (DC1) and connect one end from the POWER IN port on the Filter Module to the

POWER OUT port of the Power Module. Twist each connector clockwise until locked.

2. Locate the DC cable with an 8 pin bayonet type connector at each end (DC2) and connect one end from the

SIGNAL port on the Filter Module to the SIGNAL port of the Power Module. Twist each connector clockwise until

locked.

3. Connect the DC pigtail (DC3) from the CBC/Fan Module to the port labeled FANS on the Power Module. Twist the

connector clockwise until locked.

4. Locate two 1’ N male to N male coax jumpers (RF2 & RF3). One is installed from the DL IN port on the Filter Module

to the DL OUT port on the Power Module. The other jumper connects between the UL OUT port on the Filter Module

to the UL IN port on the POWER Module.

connectors as damage to the jumper and/or equipment may occur.

5. The next N male to N male coax jumper (RF4) is installed from the DAS port on the Filter Module to the PCS port on

the right side cross band coupler in the CBC/Fan Module. The final coax jumper (RF1) is connected from the port

labelled DONOR ANT on the Power Module to the PCS port on the left side cross band coupler in the CBC/Fan Module.

Note: hand tighten only. Do not use tools to tighten ANY N type

6. Connect the GPS antenna lead to the port on the Filter Module labelled GPS.

7. Connect the Modem antenna to the port on the Filter Module labelled MODEM.

8. Connect the Train’s donor antenna lead to the COM port on the left side cross band coupler in the CBC/Fan Module.

9. Connect the lead from the train’s cellular system donor port to the CELL port on the left side cross band coupler in

the CBC/Fan Module.

10. Connect the lead to the train’s cellular system’s DAS port to the CELL port on the right side cross band coupler in

the CBC/Fan Module.

11. Connect the Train’s DAS antenna lead to the COM port on the right side cross band coupler in the CBC/Fan Module.

12. The final connection is to the train’s 72VDC power supply. Locate the 2 pin power supply cable and plug it into the

2 pin bayonet type connector on the Power Module labelled DC IN. Twist the connector clockwise until locked.

RF and Power Cabling

- 9 -

Section 2

Installation

Note: located on the left side of the Filter Module is a standard RJ45 connector port designed to accept CAT-5E

cable, the connector is labelled COM. This port is used to provide a computer interface. Refer to the diagram

below for a graphical representation of the connections described on the previous page.

CAT-5E with RJ45

Connector to

Provide Computer

Interface with the

Repeater

Train’s 72 Volt

DC Power Cable

With 2 Pin Bayonet

Connector

DC1 - 6 Pin Bayonet

to 6 Pin Bayonet

DC Cable Assem b ly

Coax with N

Connector to

The DAS Side

of the Train’s Cell

Repeater

DC2 - 8 Pin Bayonet

to 8 Pin Bayonet

DC Cable Assem b ly

DC3 - Fan Pigtail with

6 Pin Bayonet

Connector

Coax with N

Connector to

The Train’s DAS

RF2 - 1' N Male to N Male

Coax Jumper

Coax with TN C

Connector from

Train’s GPS

Antenna

Coax with N

Connector from

Train’s Donor

Antenna

RF3 - 1' N Male to N Male

Coax Jumper

Coax with N

Connector from

The Donor Side

of the Train’s Cell

Repeater

RF4 - 1' N Male to N Male

Coax Jumper

Auxiliary Modem

Antenna

RF1 - 1' N male Right Angle

to N male Right Ang le

Coax Jumper

RF and Power Cabling

- 10 -

Section 2

Installation

Power Up

To power up the CSI repeater simply connect the 72 VDC power cable from the train to the DC IN port on the Power Module.

When powered up, the repeater will begin in the Operational Mode, using the “Band Switching Algorithm”. The repeater will not

key until boot up is complete, a GPS location fix is obtained and the unit is within an ” Area Definition”.

Normal Operation

After boot up and a GPS position fix is obtain the repeater will begin operation based on the Area Definitions, “Channel

Power Measurement and Keying Decision” and “Low Isolation Detection and Protection” algorithms. The operational software

will continuously monitor the repeater’s environment and make the necessary adjustments to keep the product operating

within specifications and FCC Type Certification.

System Status

The Software provides real time status data reporting the state of the repeater. This status contains:

Timestamp Modem Band Type Satellite Count

System Up Time Active Filer NoBox Count

Software Version In-band input Searching Count

System Serial Number Measured Output Scan RX Run State

Model Number Composite Input DeKey Limit

Item Number AGC Mode Scan RX Filter ID

Location AGC Attenuation # of Channels

Modem Signal Strength GPS RunState 1 -10 Channel Freq’s & SSI

Modem Registration Status Latitude

Modem Phone Number Longitude RF Alarms: System Alarms:

Modem Current Band Filter ID Over Range Synthesizer Lock

Modem System ID Filter Name Oscillation Voltage

Modem Network ID Location VSWR Temperature

Modem Temperature BTA Out of Band Overdrive Software

Alarms

The Operating Software will monitor the repeater for conditions that are out of normal operation, triggering an alarm

event. The Operating software in conjunction with the Communications Subsystem when so configured will send

alarm messages via E-mail or SMS texting to a User Provisioned account.

Low Signal Hardware

No Signal

Each Alarm has these User Provisioned Capabilities.:

· Disable the System: The Operating software can disable the System (prohibit Keying) until the alarm

condition is cleared if provisioned

· Alarm Filter Conditions: A Filter Condition (such as X number of occurrences per hour) to the alarm to

prevent false or un-useful notifications if provisioned.

· Send an Alarm Message: The Operating Software can send a notification via message E-mail or SMS

through the Communications Subsystem if provisioned.

· Alarm Clear Message: The Operating Software can send an alarm clear message when an alarm

condition clears if provisioned.

Alarm Notification Message

The alarm messages consists of the Systems Identification Tag, a summary of the current alarms, and a short

English message describing the alarm condition(s). Below is a list of the alarms that will trigger an alarm message

to be sent.:

Downlink Over Range Downlink High Temperature Scan Receiver Low Uncalibration

Uplink Over Range Downlink Low T emperature Scan Receiver High AGC Disabled

Synthesizer Error Uplink High VSWR No GPS Data Property File Error

DAC Error Uplink Low VSWR No GPS Lock DAS Failure

DC Current High Uplink Filter Load No GPS Fix Watchdog Timer

DC Current Low Uplink Over Current GPS Antenna Cu rr ent Modem Not Responding

Downlink High VSWR Uplink Under Current GPS Fix Filter Not Present User Login

Downlink Low VSWR Oscillation Chassis Overheat Password Changed

Downlink Filter Load Uplink High Temperature Chassis Under Temp CPU Boot

Downlink Over Current Uplink Low Temperature Software Abort Placed in Disabled Condition

Downlink Under Current Fan Failure Software Error In Maintenance Mode

Powerup and System Check Out Procedures

-11 -

Section 3

Hardware Operations

Test Point Locations and Values

The CSI repeater, CS12-553-401, by design, has no external test points. The Power and Filter modules are

sealed with no user serviceable parts inside. The CBC/FAN Module had no user serviceable parts, if fans

are observed to fail the module can be sent back to CSI for evaluation. Testing and configuration is done

exclusively by interfacing the repeater with a laptop or desktop computer and using the Web based GUI or

the TMI. Both user interfaces will provide a complete status of the repeater. In most cases if all other

components of the system prove to be working properly and the repeater is not, the user will need to

return the unit to CSI for inspection and repair. See the Warranty and Repair Procedures in Section 3 of

this manual.

If the covers for the Power and or Filter modules are removed by the user the warranty will be void and

the cost of any needed repair will be the responsibility of the user.

Indicator Lights

This repeater was designed with only two external indicator lights. Both are approximately 3/4”

diameter LEDs. Located on the Filter Module face plate, between the COM and POWER IN ports, the first

LED labeled POWER/FAULT glows red as the repeater is powered up. When the unit completes all of

it’s bootup procedures the LED will change color and glow green to indicate the system is operating

normally. If the LED remains red it’s an indication of a problem and the user will need to check the

system status using the Web based GUI or the TMI.

The second LED is located on the faceplate of the Power Module, between the DC IN and POWER OUT

connector ports. This light is designed only to show that the unit has DC current and will glow green

when the unit is powered.

Troubleshooting

All cables should be checked for shorts and opens.

The rooftop antenna (Donor Antenna), should be checked for damage.

The DAS antennas should be checked for damage.

If cables and antennas are acceptable and the problem persists, check repeater status using the Web

based GUI or the TMI. See Alarm/Action Matrix on the next page.

Should the repeater fail, or if service is lost and the cause can not be determined from the steps above, the user

should contact CSI Technical Support @ 1.877.844.4274. CSI will remotely access the repeater and advise the

respondent of next step(s).

-12-

Hardware Operations

Subsystem Alarm Name Alarm Send Shutdown Disable

Downlink Power Over Range Critical Yes Yes No

Low Signal Routine No No No

No Signal Routine No N o No

Out of Band Signal Routine No No No

Uplink Power Over Range Critical Yes Y es No

Out of Band Signal Routine No No No

Common Hardware Alarms Synthesizer Error Critica l Y es Y es Y es

Dac Error Cr itical Y es Yes Y es

DC Current High Severe Yes Yes No

DC Current Low Severe Yes Yes No

Downlink P A Oscillation Routine No N o No

Input Power High Routine No N o No

High VSWR Severe Yes No No

Low VSWR Severe Yes No No

FilterLoad Critical Yes Yes No

Overcurrent Severe Yes No No

Undercurrent Severe Yes No No

Low Isolation Routine No N o No

High T emperature Severe Yes Yes No

Low T emperature Severe Yes No No

Uplink P A HighVSWR Severe Yes No No

Low VSWR Severe Yes No No

FilterLoad Critical Yes Yes No

Overcurrent Severe Yes No No

Undercurrent Severe Yes No No

Oscillation Routine No No No

Low Isolation Routine No N o No

High T emperature Severe Yes Yes No

Low T emperature Severe Yes No No

Fan Activation Routine No No No

Fan Failure Severe Yes No No

Scanning Receiver Alarms ScanRcvrLow Severe Yes Yes No

ScanRcvrHigh Severe Yes Yes No

GPS Receiver Alarms No GPS Data Criti cal Yes Y es Y es

No GPS Lock Severe Yes No No

No GSP Fix Critical Yes Yes No

Gps Antenna Current Severe Yes No No

Gps Fix Filter Not Present Severe Yes Yes Yes

Software Alarm Types Overheat Severe Yes No No

Undertemp Severe Yes No No

Software Abort Critical Yes Y es ??

Software Error Severe Yes Yes No

Uncalibration Critical Yes Yes Yes

Agc Disabled Cri tical Y es Y es Yes

Property File Error Critical Y es Yes No

Das Failure Crit ical Y es Yes No

Watchdog Timer Critical Yes Yes No

Heartbeat Informational No Yes No

Communications Modem Not Responding Severe Yes No No

Modem Not Connected Routine No No No

Section 3

T ype E-mail Op Mode? Unit?

- 13 -

Hardware Operations

1 Scope

The warranty period for this product shall be 18 months (548 calendar days)

from the date of the Purchaser’s Acceptance, plus any extended maintenance periods as specified in the order. During said period(s), CSI warrants

that each repeater will be free of defects in material and workmanship.

CSI’s sole obligation and the Purchaser’s exclusive remedy for any breach

of warranty is limited to adjustments, repairs, or at the Purchaser’s option,

replacement of a System or parts of a System thereof at no cost to the CSI.

All exchanged Systems or System parts will become the property of the

CSI. Servicing hereunder will be furnished by the CSI’s nearest service

location. CSI shall perform this service at a time agreed to by the Purchaser. This warranty will not apply to a p articular item if:

(a) Adjustment, rep air or replacement is required because of accident,

neglect, misuse, failure of electric power, environmental controls, transport ation or causes other than ordinary use, except that such adjustment, repair,

or replacement is required due to actions caused by or the responsibility of

CSI’s employees or CSI’s authorized agents;

Section 3

(b) The Purchaser fails to operate a System or follow operator-level maintenance procedures in accordance with the CSI’s recommendations;

(c) Any person other than the CSI’ s engineer or an authorized agent of the

CSI modifies, adjusts, or repairs the product or performs any maintenance

service other than routine operator-level maintenance without the CSI’s prior

written consent.

The warranty hereunder does not include:

(a) Any furnished consumable supplies,

(b) Painting or refinishing the product,

(c) Electrical work external to the product,

(d) Installation, maintenance or removal of alterations or attachments to the

product except as provided by the original system design.

CSI’s liability for breach of the above warranty will in no event exceed the

purchase price of the Product(s) that has been paid by the Purchaser.

Warranty and Repair Procedures

-14 -

Hardware Operations

2 Product Hardware Warranty (Non-Software)

(a) CSI represents and warrants to the Purchaser that upon delivery of a repeater to

the Purchaser, all right, title and interest in the unit will pass to the Purchaser free of

all liens, imperfections in title, claims, charges, restrictions, or other encumbrances.

The CSI represents and warrants a repeater’s Hardware (specifically excluding the

Product Software) as furnished shall be new, merchant able, free from defects in

material and workmanship, fit for the ordinary purpose for which the product is used,

shall not infringe on any U.S. Patent, and for the period specified in this document

from the date a repeater is delivered and shall conform to this documents specifications. Should a unit not conform to the foregoing warranties, CSI shall repair or

replace defective or nonconforming product.

(b) During the warranty period, a defective repeater shall be either repaired on-site

by the CSI or returned to the CSI for repair or replacement at no charge or cost to

the Purchaser. The Purchaser shall bear the risk of loss or damage until a unit is

placed in the possession of the carrier. Unless otherwise agreed to by the CSI and

the Purchaser, for a product that is returned to the CSI for rep air , CSI shall complete

repairs and return repaired the product, or ship a replacement product, within three

(3) days of receipt of defective repeater at CSI’s designated repair location. CSI

shall bear the cost of transportation charges for shipment to CSI (FOB origin freight

collect) of the product to be repaired or replaced. For return shipments from CSI to

the Purchaser, CSI shall bear the risk of loss or damage during transit and shall

prepay and bear the cost of transportation charges for shipment of the product that

has been repaired or replaced. If a repeater returned is not defective, CSI shall

promptly advise the Purchaser in writing of the determination and in such cases,

CSI shall return product to the Purchaser at the Purchaser’s expense and risk in its

“as received” condition. If a repeater is returned and is not in warranty, CSI shall

promptly advise the Purchaser in writing of this determination and the charge to

repair the product. In such cases, CSI shall repair the product if so instructed by

the Purchaser in writing and charge the Purchaser for labor, part s, and shipping.

Section 3

(c) During the warranty period, if the Purchaser’s technical personnel attempt to

determine whether or not a CSI repeater is the cause of service interruption and

cannot identify and resolve the problem causing the interruption after communicating

with CSI’s technical personnel via telephone or other suitable means, and the

service interruption still exists, then the Purchaser may request that CSI begin onsite repairs as soon as possible, but in no event later than one (1) business day

plus reasonable travel time after receiving the Purchaser’s request. If the problem is

with CSI’s product, (software or hardware), such on-site repairs by CSI shall be at

no charge to the Purchaser.

Warranty and Repair Procedures

- 15 -

Hardware Operations

(d) During the Warranty period, if the service interruption still exists after compliance

with (c) above, and the service interruption is caused by either CSI’s defective repeater(s)

and/or CSI’s product that does not confirm to specification and the CSI has been given a

reasonable time frame, as determined by the Purchaser, to correct the service interruption, the Purchaser may return the product to CSI and receive a credit for the total

purchase price of the Product or a completely new repeater, at the Purchaser’s option,.

(e) Any replacement, rep air, modification, inst allation or other service performed by CSI

shall be warranted, commencing with the date upon which repaired product is returned to

the Purchaser, for the remainder of the unexpired period of the warranty .

(f) The warranties do not extend to a repeater to the extent that such repeater has been

subjected to misuse, neglect, abuse, accident caused by the Purchaser or by a third

party subsequent to the delivery of the unit, and such action is the cause of the damage

or malfunction.

Section 3

3 Product Software Warranty

(a) CSI warrants that the Purchaser shall have quiet enjoyment of the Product Software

and that the Product Software and the Purchaser’s use shall be free from claims of infringement, misuse or misappropriation of any intellectual property right during the term of the

Purchaser license to Use the Software. As to Product Software which the CSI does not

have title, CSI warrants that has rights in the Software sufficient to permit the license of the

Software to and that CSI has full right, power and authority to license the Software and

other rights granted hereunder to V erizon Wireless.

(b) CSI also warrants that the media containing the Software will be free from defects in

material and workmanship and that all related services provided by CSI shall be rendered by

qualified personnel who will perform the tasks assigned consistent with good professional

practice and the state of the art involved.

(c) CSI also warrants that there does not exists an copy protection or similar mechanisms

within the Product Software, which will, either now or in the future, interfere with the operation of the Product. Furthermore, CSI warrants unless requested in writing by the Purchaser

and the Purchaser approves response, or CSI advises the Purchaser in writing that it is

necessary to perform valid duties under this attachment and authorized in writing by the

Purchaser, any Product Sof tware provided to the Purchaser by CSI for Use by the CSI or the

Purchaser shall:

Warranty and Repair Procedures

-16 -

Hardware Operations

· contain no hidden files;

· not replicate, transmit or activate itself without control of an of an authorized

person operating computer equipment on which it resides;

· not alter , damage or erase any data or computer programs without control of an

authorized person operating computer equipment on which it resides;

· cont ain no encrypted imbedded key , node lock, time-out or other function,

whether implemented by electronic, mechanical or other means, which restricts or

may restrict Use or access to any programs or data developed under this Agreement, based on residency on a specific hardware configuration, frequency of

duration of Use, or other limiting criteria (“Illicit Code”).

(d) Where the Product Software is intended to be used in transaction processing or in

the public switched network, CSI represents that nothing in the Product Software

precludes the Purchaser form integrating a network management solution (including

transaction processing and network monitoring) with the Product Software.

Section 3

(e) For the period specified beginning with the effective date of license of the Software, CSI represents and warrants that the Product Software will perform in accordance with specifications. If within one year (365 days) subsequent to the expiration

of the warranty period CSI has not repaired the Product Software to perform in accordance with specification for any exception communicated in writing by the Purchaser

to CSI during the warranty period, the Purchaser may order and CSI shall refund to

the Purchaser the amount paid to it for the nonconforming Product Software.

(f) CSI represents and warrants that if any portion of the Product Software is or

becomes unusable, totally or in any respect, the Supplier will correct errors, defects

and nonconformity and restore the Product Software to conforming condition without

additional charge to the Purchaser.

Warranty and Repair Procedures

- 17 -

Hardware Operations

4 Continuing Availability of Service and Parts

(a) CSI shall, if requested by the Purchaser, provide the Purchaser with

maintenance service, repair service and parts for the Product and Software, for a period of seven (7) years after extended Product and Service

agreements have been discontinued by the Purchaser . If CSI is unable to

supply such services and/or parts or CSI is unable to obtain an alternative

source to provide such services and/or parts for the Purchaser , then the

CSI shall, without obligation or charge to the Purchaser, provide the

Purchaser with drawings or other documents required to either manufacture or buy such parts and the technical information or any other rights

necessary for the Purchaser to manufacture or purchase such parts for

the purpose of supporting the Purchaser’s customer base.

(b) The technical information shall include, by example and not by way of

limitation:

· Manufacturing drawings and specifications of materials and parts

comprising the replacement and repair parts and components;

· Manufacturing drawings and specifications covering special tooling

and operation;

· A det ailed list of all commercially available Continuing A vailability of

Service and Partsble parts and components purchased by CSI on the

open market, disclosing the part number , name and location of the

Company and price lists for the purchase; and

· One complete copy of the source code used in the preparation of any

software licensed or otherwise acquired by the Purchaser from CSI,

provided however, that such source code shall remain the property of

CSI and shall be separately licensed to the Purchaser for use by the

Purchaser to support the Product.

Section 3

(c) In the event that CSI either (i) does not own the source code or (ii)

does not have the rights to disclose such source code, then CSI shall

disclose its licensor or owner of said source code and shall get the rights

on behalf of the Purchaser.

(d) Certain parts of the Product Software is subject to a licensing agreement and is sublicensed to the Purchaser. In the event of the inability to

provide updates or continuing support of the application software at a

reasonable cost, CSI shall assist the Purchaser in locating an alternative

source.

5 Product Returns

Please call 1.877.844.4274 to obtain a Return Material Authorization (RMA)

number for product assessment and repair .

Warranty and Repair Procedures

-18 -

Section 4

Software Operations

Web based GUI Session

Primary access to the repeater is gained using a LAN connection and a web browser program such as Firefox by

Mozilla, or Internet Explorer from Microsoft. The repeater ships in DHCP server mode and by default the IP address will

be 192.168.1.100. *

If connecting directly to the repeater from a laptop or PC with a crossover CAT-5E cable or over a LAN the user types

the IP address of the repeater into the browser address line to connect. When connection is made the user will be

prompted for a user name and password. For the purpose of the GUI session, the

the password is csi1234. This can also be changed as required. Internet access is not required to use the GUI.

If you are connecting using a laptop, verify that your Ethernet port is powered. Some laptops will not allow Ethernet

connection when on battery power. If this is the case with the laptop you are using you will need to plug it in or update

the power settings.)

default user name is webuser and

(Note:

*DHCP is a protocol that allows computers on a network to be automatically configured appropriately for that network.

Networks provide DHCP service by maintaining one or more servers that listen for special broadcasts on the network,

called DHCP requests. These requests are made by computers when they first join a particular network. The DHCP

server replies with configuration information that the requester uses to join the network.

In the case of this repeater, the unit is configured to act as a DHCP server by default. This means that a computer

configured to make a DHCP request on joining a network (most laptops are set up this way) will automatically receive a

configuration from the repeater when it is connected to it via the local network port. This connection is made with either

a crossover cable or an Ethernet switch or hub.

One word of caution: The repeater, if it joins a network already managed by another DHCP server, may cause

disruptions in that network. To avoid any such problems, reconfigure the unit for static or DHCP client mode before

connecting it to such a network. (The local networking config page in the web interface, and the menu interface, can

be used to achieve this.)

General Operation Overview

-19 -

Section 4

Software Operations

System Status:

When login is complete the user is brought to the system status page. The links on the page are activated by clicking on

them.

General Operation Overview

- 20 -

Section 4

Software Operations

Local Network:

If the user selects Local Network from the System Status page, the following screen is displayed and from here network

configuration can be modified as required. The default is set to DHCP Server. It is recommended you check with your IT department for explanation of the options and approval before you connect this repeater to your network or change the options.

General Operation Overview

- 21 -

Section 4

Software Operations

RF Configuration:

From here the user may return to the System Status screen or click on the other options. If the user would like to modify RF

configuration click on the words RF Configuration in the brown navigation box and the screen below is displayed.

To change gain settings the user will select the Uplink only or Uplink and Downlink radio buttons. The user then inputs the

gain value desired. Gain values from 53.5 dB to 85.0 dB may be selected. The repeater will not allow the user to set

values outside this range. By pressing the Change Settings button the gain change is implemented. When a new filter set

is required, it may be selected by clicking Program a Filter in the navigation box.

General Operation Overview

- 22 -

Section 4

Software Operations

Program a Filter:

The user may select the desired filter by pressing the band/sub-band and modulation selection buttons. Undesired bands/subbands if lit will require the user to manually “deselect” them before programming. Pressing the Program button will complete

the selection and load the desired filter. The time required to complete this process will take just a few moments. Note: If the

filter desired is not currently in the unit, additional filters along with instructions on how to load them are available by contacting CSI.

General Operation Overview

- 23 -

Section 4

Software Operations

Remote Network:

Highlight the carrier on whose network the repeater and modem will be configured and click the Change Settings button. Note:

the system will require restart for the change to take effect.

General Operation Overview

- 24 -

Section 4

Software Operations

SNMP Configuration:

To change SNMP settings click SNMP Configuration in the navigation box, the screen below will be displayed. If the user is not

well versed in Simple Network Management Protocol he or she should check with their IT professional for proper setting

requirements.

General Operation Overview

-25 -

Section 4

Software Operations

System Health:

By clicking System Health the current state of the repeater can be reviewed.

***

***The user may clear alarms and the Event Log by clicking the Clear Log button.

General Operation Overview

- 26 -

Section 4

Software Operations

Install & Upload:

Should a software install or upgrade be needed it can be done from the Install & Upload screen shown below. As with the other

screens it can be reached by clicking the words in the navigation box.

General Operation Overview

-27 -

Section 4

Software Operations

Reboot:

If a reboot of the repeater becomes necessary click on the Reboot option in the navigation box and the Reboot page is

displayed.

General Operation Overview

-28 -

Section 4

Software Operations

Alarm Configuration:

In order to review and configure the system’s alarms click on the Alarm Configuration line in the navigation box and page

shown below is displayed.

General Operation Overview

- 29 -

Section 4

Software Operations

Log Configuration:

In order to review and update the system’s log configuration, click on the Log Configuration line in the navigation box and page

shown below is displayed.

General Operation Overview

- 30 -

Section 4

Software Operations

Text Menu Interface:

A Text Menu Interface (TMI) is provided as an alternate means of access and control of the repeater. To use the TMI, also known as

the console interface, connect a CAT -5E cable to the RJ45 connector port labeled COM and a computer making use of a standard

terminal emulation program.

Many terminal emulation programs will work if properly configured. In the following description, “TeraTerm” is used to establish the

TMI session. This program is readily available via the Internet and is free from Ayera Technologies at:

http://www.ayera.com/teraterm/

TeraTerm Pro Web works on Windows 95/98, 2000, XP. Here is the latest TeraTerm Pro Web release:

When the program is started, the following screen is displayed.

Version 3.1.3, October 8, 2002. ttpro313.zip

In the box labeled Host type the repeaters IP address and click OK. The user will then be prompted for a user name and

password. The default user name is “user” and the password “csi1234”. After entering the password and pressing return

the TMI main menu will appear.

General Operation Overview

- 31 -

Software Operations

Section 4

Upon logging the user is presented with a summary of the initialization status. The data represents a top level list of the major

components that must be operating properly in order to have a function system. The display will “block” until a particular

component is finished being initialized.

Status DNLINK UPLINK

============================================

Configuration OK OK

Attenuator 1 OK OK

Attenuator 2 OK OK

Attenuator 3 OK OK

DAC 1 OK OK

DAC 2 OK OK

PLL 1 OK OK

PLL 2 OK OK

DPD 1 OK OK

DPD 2 OK OK

FAN CTRL1 OK OK

FAN CTRL2 OK OK

FPGA 1 OK OK

FPGA 2 OK OK

PRECOMP 1 OK OK

PRECOMP 2 OK OK

GPS OK OK

SCAN RCVR OK OK

Link Initialization Complete

Once the initialization sequence is complete, the user is presented a top level menu used to access all of the systems

operating parameters. The top level menu is organized into three main sections, settable parameters, status parameters, and

system functions.

=========

Main Menu

=========

(1) Set Parameters - Disabled

(2) Get Parameters

(3) System Commands

(x) Exit

->

The “Set Parameters” menu is password protected (user definable) in order to prevent erroneous configurations being made

by non-qualified users. The user will be prompted to enter the correct login and password on a per-session basis. Once the

user has entered the correct values, subsequent access is not inhibited.

=========================

Set Parameters - Disabled

=========================

(1) Maintenance Mode Login

(r) Return to previous menu

->

General Operation Overview

- 32 -

Software Operations

Section 4

——————

Enter Username:csi

Enter Password:csi1234

Maintenance Mode Enabled

========

Main Menu

=========

(1) Set Parameters

(2) Get Parameters

(3) System Commands

(x) Exit

->

==============

Set Parameters

==============

(1) Link Configuration

The “Link Configuration” menu is a collection of menu options that control the RF operating characteristics of a live system.

==================

Link Configuration

==================

(1) Adjust Gain

The “Adjust Gain” option allows the user to control the total gain of the system. Valid gain settings range from 55 dB to 85

db. If the user selects to configure the downlink gain, the uplink gain will automatically be set to the same value. In order

to override this condition, the user will have to select the uplink option and adjust the gain to the desired value.

—————

Links:

(1) downlink

(2) uplink

(r) Return to previous menu

Link?

—————

User Gain:

Setting 85.00 dB

User Gain? 85.0

Auto Setting Uplink Gain to 85.00 dB

To override, set Uplink gain separately

(2) Select Active Filter

The “Select Active filter” option allows the user to toggle between the filters loaded in the RFIF and IF board for test

purposes. Please note that in order for this to work properly, the GPS task needs to be disabled otherwise the filter

selection will be overridden by the current location of the system.

General Operation Overview

- 33 -

Software Operations

Section 4

————————

FILTER settings:

(1) select IF board filter

(2) select RFIF board filter

(3) disable both RFIF and IF board filter

(r) Return to previous menu

FILTER settings?

(3) Filter Programming

The “Filter Programming” option allows the user to select and program one of the loaded filters on the system. The user

will be prompted to select which board the filter will be loaded on, RFIF or IF. Please note that in order for this to work

properly, the GPS task needs to be disabled otherwise the filter selection will be overridden by the current location of the

system.

——————

File names:

(1) pcR0A0D0B0E0F0C0-0

(2) pcR0A0D0B0E0F0C0-Wide

(3) pcR1F0C3C4-0

(4) pcR2E0C3-0

(5) pcR3F0-0

(6) pcR4F0C0-0

(7) pcR5E0F0-0

(8) pcR6D0C3C4-0

(9) pcR7F0C3-0

(r) Return to previous menu

Enter file number?

(4) Power Amplifier Output Control

The “Power Amplifier Output Control” option allows the user to control the state of the power amplifier, ON or OFF. The

setting overrides all other PA control tasks and is persistent across reboots. Care must be taken to insure the user is

aware of the state of this setting so as to eliminate false keyed/de-keyed states.

————————

PA Output Enable:

(1) off

(2) on

(r) Return to previous menu

PA Output Enable?

(r) Return to previous menu

->

(2) Alarm Configuration

The “Alarm Configuration” menu is a collection of menu options that control the alarming operating characteristics of a live

system.

General Operation Overview

- 34 -

Software Operations

Section 4

===================

Alarm Configuration

===================

(1) Alarm Masking

The “Alarm Masking” option provide the user an ability to mask or unmask individual alarms based on the known

operating characteristics of the environment that the unit is place in. Certain alarms will occur that do not directly

affect the proper operation of the system and can therefore be masked. All alarms are still registered with the

system regardless of the alarm state, user notification only takes placed on unmasked alarms.

=============

Alarm Masking

=============

(1) Show Alarm Configuration

(Displays the current mask state of all the alarms.)

(2) All Alarms

(Sets all alarms to a given mask state (ON/OFF)).

(3) Link Alarms

(Sets specific alarms of a particular link to a given mask state (ON/OFF)).

(4) HW/SW Alarm Configuration

(Sets specific alarms of a specific sub-system to a given mask state (ON/OFF)).

(5) Miscellaneous Alarms

(Sets specific miscellaneous alarms to a given mask state (ON/OFF)).

(r) Return to previous menu

->

(2) Alarm Notification

The “Alarm Notification” option provides the user the ability to configure the system to externally notify service

personnel of alarm event s.

==================

Alarm Notification

==================

(1) Alarm Origin Tag

The “Alarm Origin Tag” option provides user access to two settable parameters that are used to

distinguish which system is reporting the alarm. The user should develop a relative scheme of naming

individual units so that they can be easily identified by service personnel. The two parameters are

included as part of the alarm information that is sent.

================

Alarm Origin Tag

================

(1) Host Name

(2) Location

(r) Return to previous menu

General Operation Overview

- 35 -

Software Operations

(2) E-mail Alarm Configuration

==========================

E-mail Alarm Configuration

==========================

The “E-mail Alarm Configuration” option configures the e-mail alarm notification sub-system.

(1) Show E-mail Config

(Displays the current configuration of the e-mail subsystem.)

(2) Enable/Disable msmtp

(Controls the state of the e-mail sub-system, the user must first enable msmtp in order for any e-mail

alarms to be sent.)

(3) Set Recipient Address

(This option allows the user to configure up to five destination e-mail addresses that will receive

system alarm events. It is best to leverage the management and configuration options of a destination

mail server in order to setup a mail group of service personnel that will receive the alarms.)

Section 4

(4) Heart Beat Email Configuration

(The system is capable of being configured to send out a heartbeat e-mail on a periodic basis. This

function can be used to monitor the operational state of the system.)

(5) Send Test Email

(Provided that the e-mail sub-system is enabled and that there are configured destination addresses,

this option will generate a test e-mail for diagnostic purposes.)

(6) E-mail Client Configuration

(This menu item provide access to user configurable options that setup the e-mail client (DSP system)

for use with an authenticated e-mail server and account.)

(r) Return to previous menu

->

(3) SMS Message Configuration

The “SMS Message Configuration” option configures the SMS (Short Messaging Service) l alarm notification

sub-system. This option can be used to send alarm notifications to a user’s cell phone as text messages.

(r) Return to previous menu

->

- 36 -

Software Operations

Section 4

(3) Watchdog Timer Configuration

The “Watchdog Timer Configuration” option configures a hardware based watchdog timer. Once enable, the DSP

software will periodically write to the watchdog timer thus preventing an unscheduled reboot. Certain alarms can

be configured to inhibit this periodic write which in turn will reboot the system when they occur.

============================

Watchdog Timer Configuration

============================

(1) ON

(2) OFF

(3) Reset Reboot Counter

(r) Return to previous menu

->

(r) Return to previous menu

->

(3) Networking Configuration

The “Networking Configuration” menu contains three configuration menus. The “Local Network Configuration” provides access to

the network connection that is made to the system via the Ethernet port located on the front panel of the unit. The “Remote

Network Configuration” is used to configure the wireless modem(s) that are attached to the USB port of the SBC (single board

computer) that controls the unit. The “SNMP Configuration” option is not used or supported in this version of product.

========================

Networking Configuration

========================

(1) Local Network Configuration

The “Local Networking Configuration” menu allows the user to configure the Ethernet port to operate in one of

three modes once enabled. If the unit is configured to have a static IP address, then the user must know what the

characteristics of the network are that the unit will be connected to. In DHCP client mode, the unit will broadcast a

request for an IP address from a properly configured DHCP server on the network. In DHCP server mode (default)

the unit will assign itself an IP address of 192.168.1.100 and it will also listen for DHCP IP address requests. If the

user connects a device (laptop) directly to the Ethernet port (cabling requirements may differ) the unit will issue an

IP address of 192.168.1.90. The unit is currently capable of issuing one client address. This is done to limit

cataclysmic events should the unit be connected to a network that already has a DHCP server.

———————————

CAUTION: Network reconfiguration may cause local and remote access interruptions.

———————————

===========================

Local Network Configuration

===========================

(1) enable

(2) disable

(3) set default static IP (192.168.1.100)

(4) set labview calibration IP (192.168.1.69)

(r) Return to previous menu

->

- 37 -

Software Operations

(2) Remote Network Configuration

The “Remote Networking Configuration” menu allows the user to configure the modem connected to the

internal USB port of the SBC. This version of software is preconfigured to enable the default modem type

installed in the unit and no user selection is necessary.

============================

Remote Network Configuration

============================

(1) enable modem

(2) disable modem

(3) Set Modem HeartBeat IpAddress

(r) Return to previous menu

->

(3) SNMP Configuration

The “SNMP Configuration” menu is not supported for this revision of the product.

==================

SNMP Configuration

==================

(1) enable SNMP

(2) disable SNMP

(r) Return to previous menu

Section 4

============================

SNMP Configuration Parameter

============================

(1) Show SNMP Config

(2) List NMS IP Addresses

(3) Clear NMS IP Addresses

(4) Create NMS IP Address List

(5) Heartbeat Control

(6) Heartbeat Frequency

(7) Trap Control

(8) Restart SNMP Daemon

(9) Send Test Trap/Inform

(r) Return to previous menu

->

(r) Return to previous menu

(4) Log File Configuration

The system is capable of storing its log files persistently on a periodic basis so that post mortem analysis can take place. The log

files will be placed in the “/log” directory on the compact flash. The service personnel can then use off the shelf applications to

extract the information to their laptop for review.

- 38 -

Software Operations

Section 4

======================

Log File Configuration

======================

(1) Display Log Rotate Settings

(Displays the current settings of the log file rotation parameters.)

(2) Change Log Rotation Period

(This option allows the user to control the frequency of the log rotation task which will persistently store the log

files based on size.)

(3) Change Minimum Log Size

(If a running log file exceeds this size (in bytes) the log file will be copied to the persistent storage location.)

(4) Change Number of Logs Rotated

(This parameter determines the number of log files of each type to maintain in persistent storage. Once the

maximum number is reached, older files are discarded keeping only the most recent files.)

(5) Configure Log to File

(This option allows the user to write the current system status information to the appropriate log file on a periodic

basis.)

(r) Return to previous menu

->

(5) GPS Configuration

The GPS sub-system is an integral part of the control of the DSP based system. During normal operating mode, the GPS

receiver controls the selection of filters and the key state of the unit. The unit must first receive a valid GPS string from the

satellites before the unit will perform properly. The following menu allows the user to examine and configure the GPS

operating parameters of the unit.

=================

GPS Configuration

=================

(1) Set GPS Mode

The GPS mode menu controls the operational state of the GPS receiver. The system is designed to run with a

GPS emulator connected to COM3 (internal) for use s a test/debug mode. Additional menu items can be used to

assist in the diagnosis of GPS related issues.

============

Set GPS Mode

============

(1) Enable GPS Receiver (default enabled)

(2) Enable GPS Emulator (default disabled)

(3) Disable GPS Receiver (default enabled)

(4) Enable/Disable Amplifier (default enabled)

(5) Set No Box Shutdown Mode (default enabled)

(6) Set No Satellites Shutdown Mode (default enabled)

(r) Return to previous menu

->

- 39 -

Software Operations

(2) Set Time Interval

=================

Set Time Interval

=================

(1) Set Test Delay

(A user selected period used to delay (inhibit) the running of the GPS task.)

(2) Set GPS Receive Update Interval

(This parameter determines interval at which the GPS task acquires the GPS Receiver data. It can be in

seconds and microseconds. The default is 1 sec.)

(3) Set Program Filter Interval

(The interval the GPS task programs the Filter. This is one of the parameters for programming the filter. The

default value is 18 sec. Other parameters for filter programming are distance travelled after one filter is

programmed. Except during the initial programming period when both filter are programmed.)

(4) Set No Data Timeout Interval

(The interval the GPS task can be without receiving any data from GPS Receiver. After which an alarm is sent

and the PA is turned OFF. The default value is 25sec.)

(5) Set Polling Interval

(The interval for which the GPS task remains disabled after the PA is turned OFF. The default is 50 sec.)

(6) Set Emulator Update Interval

(The interval the GPS task reads the GPS Emulator data from the test port. The default is 15 sec.)

(r) Return to previous menu

->

Section 4

(3) Set Programming Distance

========================

Set Programming Distance

========================

(1) Set Distance To Program Filter

(The distance the train may travel after programming one filter at which the next filter is programmed. The

Default is quarter mile (0.25 miles)).

(2) Set Maximum Distance To Program Filter

(The maximum distance the train can travel before programming the next filter. Default is 5 miles.)

(r) Return to previous menu

->

(4) Set Maximum Count

=================

Set Maximum Count

=================

(1) Set Maximum No Box Count

(The maximum count for No Box (no fix data) before an alarm is sent and the PA is turned OFF. Default is 1500 ~

25mins)

(2) Set Maximum No Satellite Count

(The maximum count for not enough satellites (minimum is 3) before an alarm is sent and the PA is turned OFF.

Default is 1800 ~ 30mins)

(r) Return to previous menu

->

- 40 -

Software Operations

(4) Set Test Location

Used to select the location of the test filter set used for troubleshooting purposes.

=================

Set Test Location

=================

(1) Set Default Test Location

(2) Set Box For Test Location

(r) Return to previous menu

->

(6) Read GPS Parameters

Displays the current GPS configuration settings.

======================================================

GPS Parameters

======================================================

Run State Enabled

Debug Msg Level 0

PA Control Mode Enabled

LookUp Table Size 10

Test Delay 0

GpsRx Update Interval 1 secs:0 usecs

Program Filter Interval 18 secs

NoData Timeout Interval 25 secs

Polling Interval 50 secs

Emulator Update Interval 15 secs

Max NoBox Count 1500

Max No Satellites Count 1800

NoBox Shutdown Mode Enabled

No Satellites Shutdown Mo Enabled

======================================================

Section 4

(7) Set Debug Message Level

User selectable debug level, messages are sent to the “/var/log/dr610_2.log” file.

(0) Display No Msg

(1) Display Info Msg

(2) Display Debug Msg

(3) Display More Debug Msg

Enter GPS Debug Msg Level (0)->

(r) Return to previous menu

->

- 41 -

Software Operations

Section 4

(6) Scan Receiver Configuration

The scan receiver hardware is used to monitor the power levels of a set of frequencies for a given filter set. If

the scanned power level is above the maximum threshold value, the task will de-key the unit until such a condition

no longer exists.

===========================

Scan Receiver Configuration

===========================

(1) Scan Receiver Operation

(This option is used to control the state of the scan receiver task (ON/OFF)).

(2) Read Scan Receiver Parameters

(Displays the current configuration settings of the scan receiver task.)

(3) Channel Sample Count

(The number of samples per channel to acquire in order to compute an average power value.)

(4) Key/De-key Threshold

(The maximum power level in dBm which will cause the scan receiver task to de-key the PA.)

(5) PA Recovery Time

(The period of time in seconds that the unit will remain in a de-keyed state following an oscillation

induced de-key.)

(6) De-key Sample Count

(The number of power readings to sample in order to compute the rolling average of the current

scanned channels.)

(7) Short/Fast Key Sample Count

(The number of power readings to sample in order to compute the short/fast average of the current

scanned channels. (See product specification document))

(8) Long/Slow Key Sample Count

(The number of power readings to sample in order to compute the long/slow average of the current

scanned channels. (See product specification document))

(9) Fast/Slow Key Delta Value

(The value in dBm that determines if a fast or slow key decision is made.)

(r) Return to previous menu

(r) Return to previous menu

->

==============

Get Parameters

==============

The “Get Parameters” menu is available to all users in order to view system status information and diagnose

alarm information.

(1) Link Status

The “Link Status” option displays the current state of the system parameters. Information on this page is used

to diagnose the health of the system.

- 42 -

Software Operations

=============================================================================

Timestamp: 2008:11:18 - 20:51:07 UTC

=============================================================================

Uptime : 4 days 5 hours 31 minutes

=============================================================================

Power (dBm) DNLINK UPLINK

=============================================================================

IN-BAND INPUT < -85.00 < -85.00

COMPOSITE INPUT < -70.00 < -70.00

MEASURED OUTPUT < 0.00 < 0.00

CALIBRATED OUTPUT 26.26 35.80

MAXIMUM OUTPUT 26.26 37.00

VSWR —— ——

=============================================================================

AGC (dB)

=============================================================================

MODE ON

ATTENUATION 0.0 0.0

=============================================================================

Status

=============================================================================

VOLTAGE ERR ERR

TEMPERATURE ERR ERR

SOFTWARE ERR ERR

HARDWARE ERR ERR

OSCILLATION ERR ERR

OVERRANGE ERR ERR

CALIBRATION OK OK

=============================================================================

DC Current

=============================================================================

RFIF 0.84

IF 3.43

=============================================================================

Temperature (Celsius)

=============================================================================

RFIF 38.00

IF 46.75

=============================================================================

Power Amplifier

=============================================================================

STATUS OFF

AMPERAGE 0.00 0.13

TEMPERATURE —— 29.99

=============================================================================

Fan Configuration

=============================================================================

STATE OFF OFF

STATUS OK OK

=============================================================================

System Configuration

=============================================================================

GAIN (dB) 85.00 85.00

IF FILTER * pcR0A0D0B0E0F0C0-Wide pcR0A0D0B0E0F0C0-Wide

RFIF FILTER No Filter No Filter

=============================================================================

Section 4

- 43 -

Software Operations

Section 4

(2) System Events

The “System Events” option displays the current list of system alarms. Alarm statistics are maintained in the “Show Counts” option.

============

System Events

=============

(1) List

(2) Show Counts

(3) Clear

(r) Return to previous menu

(3) System Information

The “System Information” option displays the current state of the non-RF parameters.

======================================================

System Info: 2008:11:18 - 20:54:46 UTC

======================================================

Location Software_lab

System Type CSI-DSP85-A

Board Type PCS - Rev. B

Carrier Verizon EVDO

SW Version 02.03.00 RC5

Serial Number CDJ80150-000148

Item Number CS10-369-xxx

Date Built 10/08/2008

Watchdog Timer Enabled

======================================================

Local Area Network:

======================================================

Hostname csi-ringo-prod

Boot Protocol dhcp

IP Address 192.168.1.100

MAC Address

======================================================

Wide Area Network:

======================================================

PPP Enabled YES

Modem Type CDMA

PPP0 Address 166.143.7.196

PPP0 MAC Address 166.143.7.196

PPP1 Address 0.0.0.0

PPP1 MAC Address

======================================================

SNMP Configuration:

======================================================

Enabled YES

Traps/Informs NO

Heartbeat NO

======================================================

MODEM Status Information

======================================================

- 44 -

Software Operations

MODEM #1

RSSI (dBm) -69 (OK)

Registration Sts Modem has registered

Phone Number 9084425314

Current Band Cellular Sleep

System ID 28

Network ID 5

Temperature (C) 36

======================================================

GPS Location Data

======================================================

Run State Enabled

Latitude 42.997005

Longitude -71.468246

Filter ID 1

Filter Name pcR0A0D0B0E0F0C0-Wid

Location Manchester

BTA 500

Satellite Count 3

NoBox Count 0

Searching Count 0

======================================================

Scan Receiver MHz avg dBm

======================================================

Run State Enabled

Dekey Limit -65.00

Filter ID 1

Channels 11

Section 4

Channel-1 1971.25 -110.58

Channel-2 1972.50 -110.38

Channel-3 1973.75 -110.72

Channel-4 1975.00 -110.82

Channel-5 1976.25 -110.00

Channel-6 1977.50 -111.49

Channel-7 1978.75 -111.35

Channel-8 1980.00 -111.06

Channel-9 1981.25 -110.67

Channel-10 1982.50 -110.96

Channel-11 1983.75 -111.01

======================================================

(4) Link Status Loop

The “Link Status Loop” option displays the current state of the system on a periodic basis in the form of a parse able string.

Enter loop delay ->

Display Mode (0 = normal, 1 = BTA changes ->

(r) Return to previous menu

->

- 45 -

Software Operations

The repeater’s operating software have two modes, an Operational mode and a Maintenance mode. These are

described below.

Operational Mode:

Upon power up, the System will begin operation in the Operational Mode. Using a “Band Switching Algorithm” the repeater

will not key until a GPS position fix is obtained and the unit is within an Area Definition.

Once GPS position fix is obtain the repeater will begin operation based on the Area Definitions “Channel Power

Measurement and Keying Decision” and “Low Isolation Detection and Protection” algorithms. The operational software

will continuously monitor the system’s environment and make the necessary adjustments to keep the product operating

with specifications and within the normal operating range of the Product and FCC Type Certification.

System Status

The Operating Software provides real time status data that reports the state of the repeater. This status contains:

Timestamp Modem Band Type Satellite Count

System Up Time Active Filer NoBox Count

Software Version In-band input Searching Count

System Serial Number Measured Output Scan RX Run State

Model Number Composite Input DeKey Limit

Item Number AGC Mode Scan RX Filter ID

Location AGC Attenuation # of Channels

Modem Signal Strength GPS RunState 1 -10 Channel Freq’s & SSI

Modem Registration Status Latitude

Modem Phone Number Longitude RF Alarms: System Alarms:

Modem Current Band Filter ID Over Range Synthesizer Lock

Modem System ID Filter Name Oscillation Voltage

Modem Network ID Location VSWR Temperature

Modem Temperature BTA Out of Band Overdrive Software

Low Signal Hardware

No Signal

Currently System events are stored to a Log File. In future releases, with the exception of the System Serial Number

and System Identifier, The Real Time Status of the Product will be saved to nonvolatile memory for retrieval. The

nonvolatile memory will be able to store 48 hours of Status data, with up to 6 complete status records per minute. The

interval that the status records are saved will be user defined.

The Operating Software will also record to nonvolatile memory and make available to a user in the Maintenance Mode:

- A count and time stamp each time the processor is booted.

- A count and time stamp of each time the operating software is placed into the Maintenance Mode, and the User ID

of the operator that performed the action.

- A count and time stamp each time the Watchdog Timer is activated, and the associated debugging information

available at the time of activation of the Watchdog Timer.

- The count and time stamp of any activation of the “Low Isolation Detection and Protection Algorithm” as defined in

attachment C of this document.

Alarms

The Operating Software has the ability to monitor a System for conditions that are out of normal operation, triggering

an alarm event. The Operating software in conjunction with the Communications Subsystem is capable of sending

alarm messages via E-mail using standard SMTP and POP3 protocols to a User Provisioned e-mail account.

Each Alarm defined has these User Provisioned Capabilities.:

- Disable the System: The Operating software can disable the System (prohibit Keying) until the alarm

condition is cleared.

- Alarm Filter Conditions: A Filter Condition (such as X number of occurrences per hour) to the alarm to

prevent false or un-useful notifications if provisioned.

- Send an Alarm Message: The Operating Software can send a notification via message E-mail through the

Communications Subsystem if provisioned.

- Alarm Clear Message: The Operating Software can send an alarm clear message when an alarm

condition clears if provisioned.

Software Behavior Under Normal Conditions

- 36 -

Software Operations

Maintenance Mode:

The repeater has, in addition to it’s normal “Operational Mode” a “Maintenance Mode”. After system boot up this mode can

be accessed in the TMI only by typing the user name and password of service.

This mode of operation provides all the same menus and features as shown in the software overview on

previous pages except that upon entering the Maintenance Mode, the product will de-key and await instructions

from a connected user. During the Maintenance Mode of operation the Operating Software supports:

- Manual operation of the Key/De-Key function.

- Manual operation of the Area Definition Switching function.

- Manual Setting of the gain setting in both the Uplink and Downlink Directions

- Retrieval of all current User Provisioned Settings from the Product

- Retrieval of the Current Version of software in the Product

- Setting of all User Provisioned Settings

- Retrieval of logged Status data

- Retrieval of boot counts, Maintenance Mode entry counts, Watch Dog timer events with debugging data, and

Low Isolation Detection and Protection events.

- The Ability to Disable and Enable the System.

- A Method to automatically place the System back into operation upon the discontinuance of the Maintenance

session.

- A Method to automatically place the stem back into operation after a User Provisioned time limit of inactivity in

the Maintenance Mode.

- Ability to load Operating Software into the repeater’s processor.

- Ability to perform a “soft” reset of the processor.

Software Behavior Under Normal Conditions

- 37 -

T erms used in this manual

AGC= Automatic Gain Control

CBC= Cross Band Coupler

CSI= Cellular Specialties, Inc.

DAS= Distributed Antenna System

Direct Current

DC =

DHCP= Dynamic Host Configuration Protocol

DL =

Down Link

FCC = Federal Communications Commission

FPGA= Field Programmable Gate Array

GPS =

Global Positioning System

GUI = Graphical User Interface

IP = Internet Protocol

IT = Information Technologies

LAN = Local Area Network

LED= Light Emitting Diode

LNA =

Low Noise Amplifier

PCS = Personal Communications Service

RF= Radio Frequency

SBC= Single board Computer

SNMP= Simple Network Management Protocol

TMI= Text Menu Interface

UL = Up Link

USB = Universal Serial Bus

VSWR = Voltage Standing Wave Ratio

- 38 -

Repeater

Index

Symbols

1, Section 4

A

AGC 8, 9, 4 8

Alarm Configuration 29

Alarm Notification Message 1 1

Alarms 1 1

B

Band Switching Algorithm 11

Block Diagram of the Major

Components 5

C

CBC/Fan Module 4

Circuit Operational Description

20

Continuing A vailability of Service

and Parts 18

CPU 48

Cross Band Coupler/Fan

Module 4

CSI 48

D

DAS 48

DC IN 1 1

default user name 19

DHCP 48

DHCP server mode 19

E

ERP 48

Event Log 26

H

Hardware Configuration 4, 6

Hardware Operations 12

I

Indicator Lights 12

Install & Upload 27

Install Software 27

Installation 8

IP address 19

L

LAN connection 19

LED 48

Local Network 21

Log Configuration 30

M

Maintenance Mode 47

Module Face Plate Configuration 6

Module Label Locations 7

N

Normal Operation 1 1

O

Operational Mode 46

P

password 19

PCS repeater 4

Physical Installation Into The Train 8

POWER IN 9

Power Module 4

POWER OUT 9

Power Up 1 1, 12

Powerup and System Check Out

Procedures 1 1

Primary access 19

Product Hardware Warranty 15

Product Software Warranty 16

Program a Filter 22

R

S

SBC 48

Section 1 4

Section 2 8

Section 3 1 1

Section 4 19

SNMP 48

SNMP Configuration 25

Software Behavior Under Normal

Conditions 46

Software Operations 19

System Alarms 46

System Health 26

System Level Block Diagram 4

System Status 11, 20, 21

system status page 20

T

T eraT erm 31

Terms used in this manual 48

T ext Menu Interface 31

U

USB 48

V

Vent 6

W

Warranty and Repair Procedures

14

warranty period 14

Web based GUI Session 19

F

FAULT LED 6

Filter Module 4

FPGA 48

G

General Operation Overview 19

GPS 1 1

Reboot 28

Remote Network 24

RF 48

RF Alarms 46

RF and Power Cabling 9, 10

RF Configuration 22

- 39 -

D960-1042-001 rev 007

Loading...

Loading...