Westell AWC‐TMAV‐850‐FB Installation Manual

R

030‐300302 Rev A, December 2013

Equipment Issue 1

‐ Installation Guide ‐

Westell AWC‐TMAV‐850‐FB Tower Mounted Amplifier

Section AWC‐TMV‐850‐301

1. GENERAL

1.1 Document Purpose

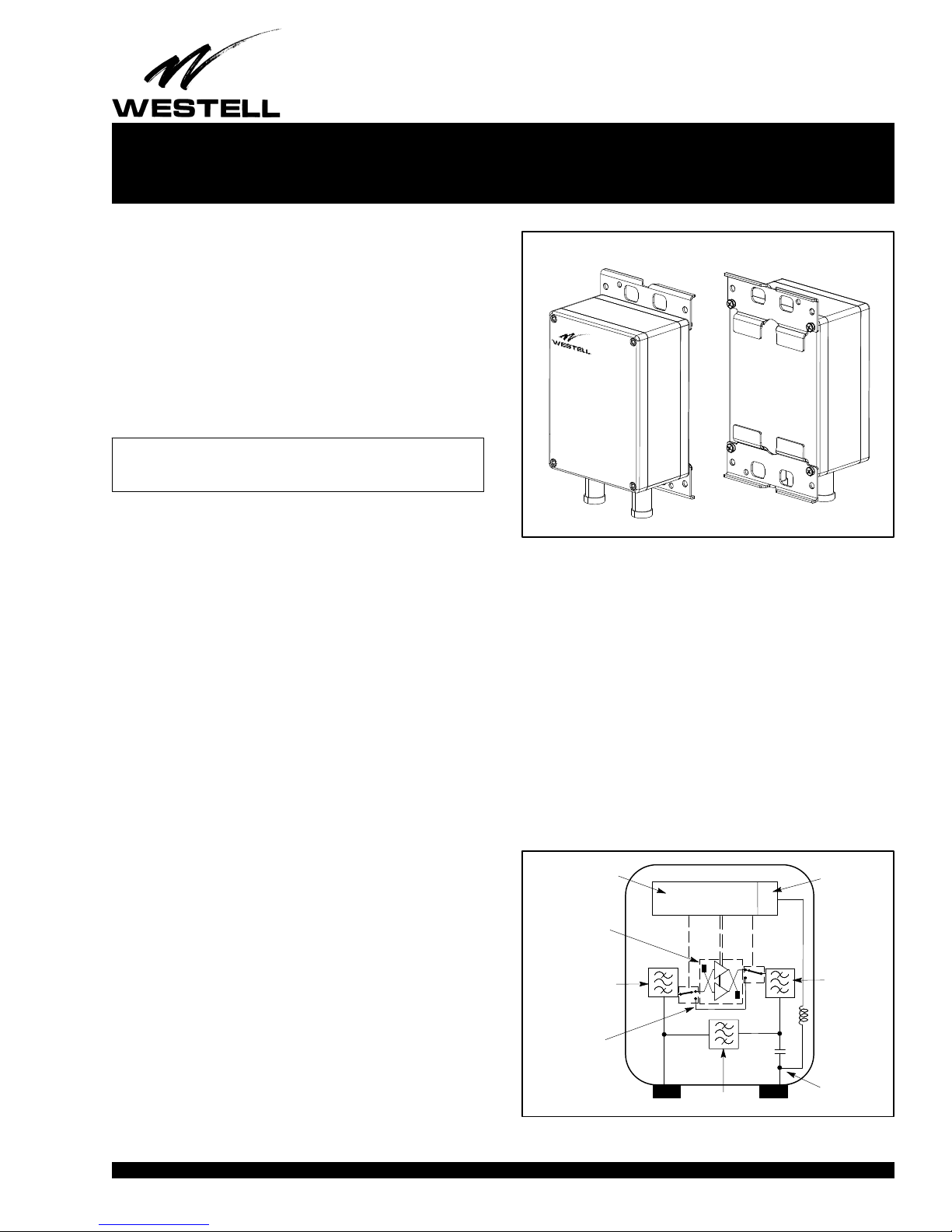

This document provides installation and specification information

on Westell's AWC‐TMAV‐850‐FB 850 MHz Full Band Tower

Mounted Amplifier (TMA). A Westell AWC‐TMAV‐850‐FB

TMA is shown in Figure 1. See Table 1 for ordering information.

1.2 Document Status

Whenever this document is updated, the reason will be stated in

this paragraph.

‐ NOTE ‐

Hereafter, the AWC‐TMAV‐850‐FB Tower Mounted Amplifier may

be referred to as the “TMA.”

1.3 Product Purpose & Description

Westell's TMA's are costeffective tools to extend cell site cover

age and improve cell site capacity by conditioning and

amplifying the user‐endpoint uplink signal in an LTE radio ac

cess network. Westell's TMAs can be used in any application

which requires improved receiver sensitivity of the BTS/eN

odeB.

1.4 Product Mounting Location

The TMA is typically installed on a cell tower, close to the an

tenna. See Paragraph 3.4 for mounting steps and Figure 6 for

dimensions.

1.5 Product Features

Features of the TMA are shown in the following list.

S Advanced, balanced LNA design with variable gain capability

S Low noise figure, return loss, and bypass insertion loss

S Compact size

Front View

Rear View

Figure 1. Tower Mounted Amplifier (TMA) Unit

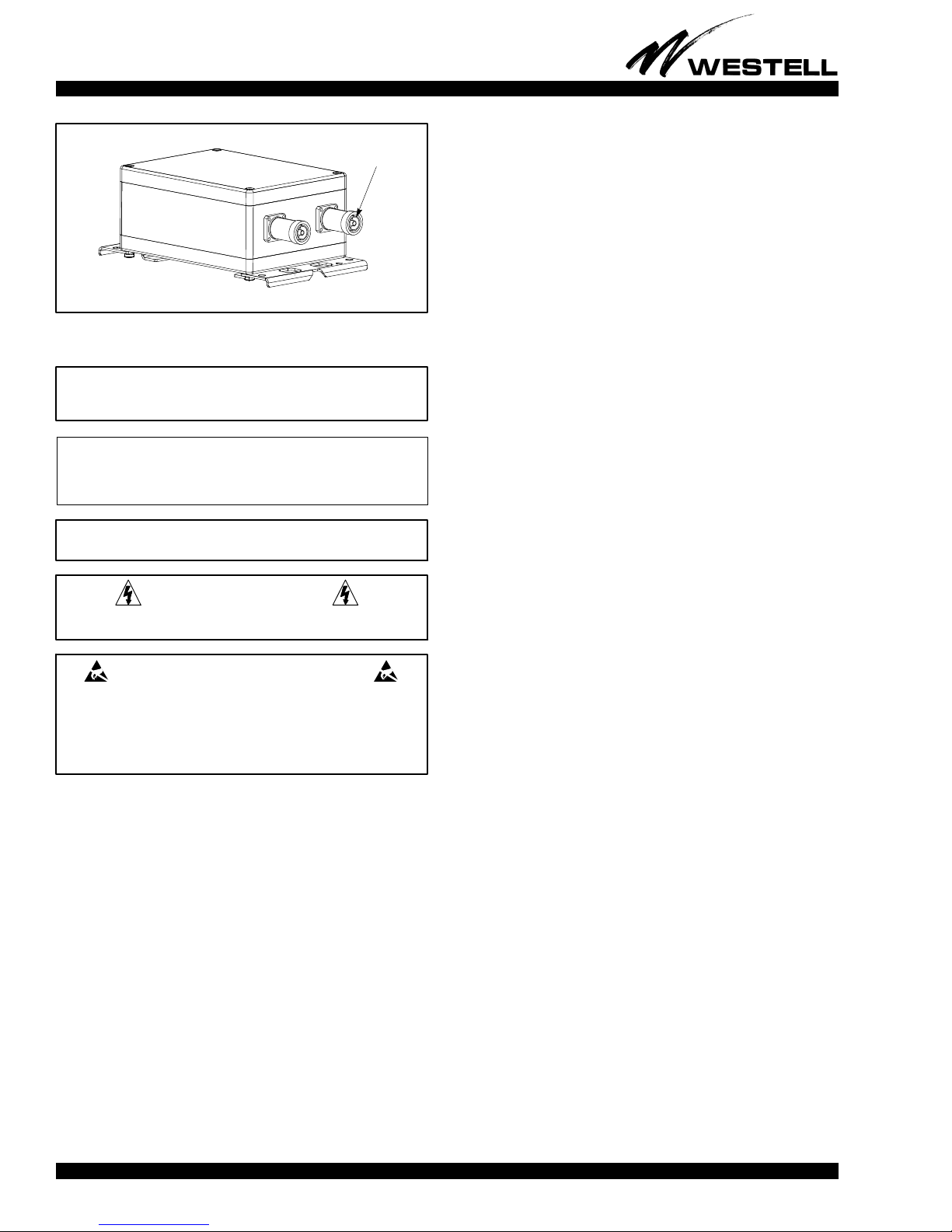

2.2 PreLNA Rx BPF

This is the preLNA (Low Noise Amplifier) band pass filter.

This filter conditions the uplink signal from the antenna before

the LNA.

2.3 Balanced Low Noise Amplifier

This is the amplifier of the TMA and includes the bypass cir

cuitry.

2.4 PostLNA Rx BPF

This is the postLNA band pass filter. This filter conditions the

uplink signal to the eNodeB.

2.5 Tx BPF

This is the transmit band pass filter. This filter conditions the du

plexed downlink signal from the eNodeB to the antenna.

S Heavy‐duty top and bottom mounting brackets with various

mounting holes to accept mounting bolts/screws and

mounting straps or bands

S Two, female, 7/16 DIN connectors at the bottom of the unit;

one for antenna connection and one for BTS

S Weather rating of IP67 (temperature range of ‐40_ to +65_C)

2FUNCTIONAL DESCRIPTION

The TMA includes the following functional blocks, as shown in

Figure 2.

2.1 Control, Bias & Alarm Electronics

This block includes the control processor, AISG modem, and

lightning protection.

1312I1RA

Control, Bias &

Alarm Electronics

Balanced Low

Noise Amplifier

Pre-LNA Rx BPF

−

RF Bypass

& Switches

Copyright 2013 Westell, Inc. All rights reserved.

Tx BPF

BTSANTENNA

Figure 2. Block Diagram

Lightning

Protection

Post-LNA

Rx BPF

Bias-T

Page 1 of 6

Section AWC‐TMV‐850‐301

When installing:

Verify connectors are free of debris

Mount TMA so connectors face down

Weatherize connections after connecting cables

Remove caps

Figure 3. Bottom View Showing Connectors

Female

7/16 DIN connector

030‐300302 Rev. A

R

cable. For deployments where the eNodeB provides power, a

CIM is not needed as power is injected onto the center pin of the

RF cable leading to the TMA directly by the eNodeB.

3.2 Verifying Functionality Prior to Mounting

Prior to mounting the TMA on the tower, verify proper opera

tion of the unit by following the steps listed in either Paragraph

3.2.1, 3.2.2, or 3.2.3 below, depending on the powering method.

3.2.1 Powered from the PDU using a CIM

When power is from the Power Distribution Unit (PDU, such as

a Westell AWC‐PDU‐6) using a Current Injector Modem (CIM,

such as the Westell AWC‐CIM+R), follow the steps below.

‐ CAUTION ‐

Improper grounding could be service affecting and cause service

interruptions.

‐ INSPECTION NOTE ‐

Visually inspect the product for damages prior to installation. If

damaged in transit, immediately report the damage to the transporta

tion company and to Westell.

‐ CAUTION ‐

Do not apply power until all connections are complete.

‐ CAUTION ‐

Risk of electric shock. Differential voltages of up to 260V can exist

on telecommunications lines.

CAUTION ‐ STATIC‐SENSITIVE

This product contains static‐sensitive components! Proper

electrostatic discharge procedures must be followed to maintain

personal and equipment safety. Do not store units near magnetic,

electromagnetic or electrostatic fields. Always store or ship units in

the original static‐protective packaging from Westell. Use anti‐static

mats when working on units.

3 INSTALLATION

3.1 Determine Power Options

The AWCTMAV850FB is powered by applying DC voltage to

the center pin of the 7/16 DIN connector labeled BTS. There are

several options for providing the power:

1. Connect the connector labeled `ANT' of the CIM to the

connector labeled `BTS' on the TMA. Note that depending

on the model of CIM used, an adapter may be required.

2. Connect the AISG connector of the CIM power cable to the

CIM. Connect the other end of the CIM power cable to PDU.

3. Connect PDU power cable to appropriate power source as

indicated in the PDU installation documentation.

4. Check TMA functionality by observing the LED's on the

PDU. A red LED indicates the TMA is in alarm.

5. If the TMA is in alarm, verify all connections. If all connec

tions are correct, replace TMA.

3.2.2 Powered from a Westell AISG Controller using CIM

When power is from an AISG Controller (such as a Westell

AISG‐RM3 controller or an AISG‐CNTRL‐A controller kit),

follow the steps below.

1. Connect the connector labeled `ANT' of the CIM to the

connector labeled `BTS' on the TMA. Note that depending

on the model of CIM used, an adapter may be required.

2. Using an AISG cable provided with the AISG controller,

connect the cable to the male AISG connector on the CIM.

Connect the other end of the AISG cable to the AISG con

troller.

3. Using the AISG controller software, verify that the TMA is

operational and that no alarms are present.

4. If alarms are present, verify all connections. If all connec

tions are correct, replace TMA.

S eNodeB

S Westell Power Distribution Unit (e.g., AWCPDU6)

S Westell Rack‐Mount AISG Controller A99AISGRM3

S Westell's A99AISGCNTRLA portable AISG controller

kit to power the TMA for running AISG commands

Westell PDU's and AISG controllers supply the DC voltage to

power the TMA via Westell's Current Injector Modem (CIM).

The CIM injects the DC voltage onto the center pin of its 7/16

DIN connector labeled BTS. To power the TMA, the CIM can

be connected to the TMA or can be connected via an RF jumper

2

3.2.3 Powered from an eNodeB without CIM

Verification of the TMA operation when used with an eNodeB

as the power source is beyond the scope of this document. The

basic steps are shown below:

1. Connect the connector labeled `BTS' on the TMA to the

eNodeB.

2. Power up the TMA using the eNodeB command line inter

face.

3. Check for alarms using the eNodeB command line inter

face.

1312I1RA

Loading...

Loading...