Page 1

W.E.ST.

Technical Documentation

POS-124-A-PDP

POS-124-I-PDP

Two axes positioning and synchronisation control module with

integrated profibus interface and SSI sensor interface

Elektronik GmbH

Page 2

W.E.ST.

1 General Information ............................................................................................................................................. 4

1.1 Order number .............................................................................................................................................. 4

1.2 Scope of supply ........................................................................................................................................... 4

1.3 Accessories ................................................................................................................................................. 4

1.4 Symbols used .............................................................................................................................................. 5

1.5 Using this documentation ............................................................................................................................ 5

1.6 Legal notice ................................................................................................................................................. 5

1.7 Safety instructions ....................................................................................................................................... 6

2 Characteristics ..................................................................................................................................................... 7

2.1 Device description ....................................................................................................................................... 8

3 Use and application ............................................................................................................................................. 9

3.1 Installation instructions ................................................................................................................................ 9

3.2 Typical system structure ............................................................................................................................ 10

3.3 Method of operation ................................................................................................................................... 10

3.4 Commissioning .......................................................................................................................................... 12

4 Technical description ......................................................................................................................................... 13

4.1 Input and output signals ............................................................................................................................. 13

4.2 LED definitions ........................................................................................................................................... 14

4.3 Circuit diagram ........................................................................................................................................... 15

4.4 Typical cabling ........................................................................................................................................... 16

4.5 Connection examples ................................................................................................................................ 16

4.6 Technical data ........................................................................................................................................... 17

5 Parameters ........................................................................................................................................................ 18

5.1 Parameter overview ................................................................................................................................... 18

5.2 Parameter description ................................................................................................................................ 20

5.2.1

LG (Changing the language for the help texts) ................................................................................. 20

5.2.2

PDPADR (Profibus adress) ............................................................................................................... 20

5.2.3

MODE (Switching between parameter groups) ................................................................................. 20

5.2.4

SENS (Module monitoring) ............................................................................................................... 21

5.2.5

STROKE1 /STROKE2 (Full stroke) ................................................................................................... 21

5.2.6

VRAMP1 /VRAMP2 (Ramp time for external speed demand) .......................................................... 21

5.2.7

VMODE1 / VMODE2 (Switching over the control mode)................................................................... 22

5.2.8

VMAX1 / VMAX2 (Maximum speed in NC Mode) ............................................................................. 22

5.2.9

POL1 / POL2 (Output polarity) .......................................................................................................... 23

5.2.10 EOUT1 / EOUT2 (Output signal in case of error) .............................................................................. 23

5.2.11 INPX (Sensor type define) ................................................................................................................ 24

5.2.12 SSI:OFFSET (Sensor offset) ............................................................................................................. 24

5.2.13 SSI:POL (Direction of the sensor signal) ........................................................................................... 24

5.2.14 SSI:RES (Signal resolution) .............................................................................................................. 25

5.2.15 SSI:BITS (Number of bits) ................................................................................................................. 25

5.2.16 SSI:CODE (Signal coding) ................................................................................................................ 25

5.2.17 AIN (Analogue input scaling) ............................................................................................................. 26

5.2.18 A1 / A2 (Acceleration time) ............................................................................................................... 27

5.2.19 D1 / D2 (Deceleration / braking distance) ......................................................................................... 27

5.2.20 V01 / V02 (Loop gain setting) ............................................................................................................. 28

5.2.21 CTRL1 / CTRL2 (Deceleration function characteristic) ..................................................................... 29

5.2.22 GL: P (gain of the synchronization in SDD mode) ............................................................................. 30

5.2.23 GL: V0 (gain of the synchronization in NC mode) ............................................................................. 30

5.2.24 GL:T1 (Time constant of the synchronisation control) ....................................................................... 30

5.2.25 GL:E (Window for the synchronization error) .................................................................................... 30

Elektronik GmbH

CONTENTS

Page 2 of 45 POS-124-*-PDP-1121 13.02.2013

Page 3

W.E.ST.

Elektronik GmbH

5.2.26 HAND1 / HAND2 (Manual speed) ..................................................................................................... 31

5.2.27 MIN / MIN2 (Overlap compensation) ................................................................................................. 32

5.2.28 MAX1 / MAX2 (Limitation) ................................................................................................................. 32

5.2.29 TRIGGER (Response threshold for the MIN parameter) ................................................................... 32

5.2.30 OFFSET1 / OFFSET2 (Zero correction) ............................................................................................ 33

5.2.31 INPOS:S1 / INPOS:S2 (In position window) ...................................................................................... 33

5.2.32 INPOS:D1 / INPOS:D2 (following error window) ............................................................................... 33

5.2.33 PROCESS DATA (Monitoring) .......................................................................................................... 34

6 Appendix ............................................................................................................................................................ 35

6.1 Failure monitoring ...................................................................................................................................... 35

6.2 Troubleshooting ......................................................................................................................................... 35

6.3 Description of the command structure ........................................................................................................ 37

7 Profibus DP interface ......................................................................................................................................... 38

7.1 Profibus functions....................................................................................................................................... 38

7.2 Installation .................................................................................................................................................. 38

7.3 GSD Configuration File .............................................................................................................................. 38

7.4 Description Profibus DP interface .............................................................................................................. 39

7.5 Commands via PROFIBUS ........................................................................................................................ 40

7.5.1

Command map .................................................................................................................................. 40

7.5.2

Definition of the control bits: .............................................................................................................. 41

7.6 DATA send to PROFIBUS ......................................................................................................................... 42

7.6.1

Feedback map ................................................................................................................................... 42

7.6.2

Definition of the status bits: ............................................................................................................... 43

8 Notes.................................................................................................................................................................. 44

Page 3 of 45 POS-124-*-PDP-1121 13.02.2013

Page 4

W.E.ST.

Elektronik GmbH

1 General Information

1.1 Order number

POS-124-A-PDP-11211 triple stage module with digital SSI-interface with analogue ±10 V

differential output, housing width 67,5 mm

POS-124-I-PDP-1121 triple stage module with digital SSI-interface with analogue 4… 20 mA

output, housing width 67,5 mm

Alternative products:

POS-124-A-PDP-S1-1121 double stage module without digital SSI-interface with analogue ±10 V

differential output, 45 mm housing width

POS-124-I-PDP-S1-1121 double stage module without digital SSI-interface with analogue

4… 20 mA output, 45 mm housing width

1.2 Scope of supply

The scope of supply includes the module including the terminal blocks which are a part of the housing.

The Profibus plug, interface cables and further parts which may be required should be ordered separately. This documentation can be downloaded as a PDF file from www.w-e-st.de.

1.3 Accessories

RS232-SO - Programming cable with RS232 interface

USB-SO - Programming cable with USB interface

WPC-300 - Start-Up-Tool (download: www.w-e-st.de/produkte/software)

PDP-Plug - Profibus connector with switchable terminating resistors

1

The number of the version consists of the hardware-version (first two digits) and the software-version (second two

digits). Because of the development of the products these numbers can vary. They are not strictly necessary for the

order. We will always deliver the newest version.

Page 4 of 45 POS-124-*-PDP-1121 13.02.2013

Page 5

W.E.ST.

Elektronik GmbH

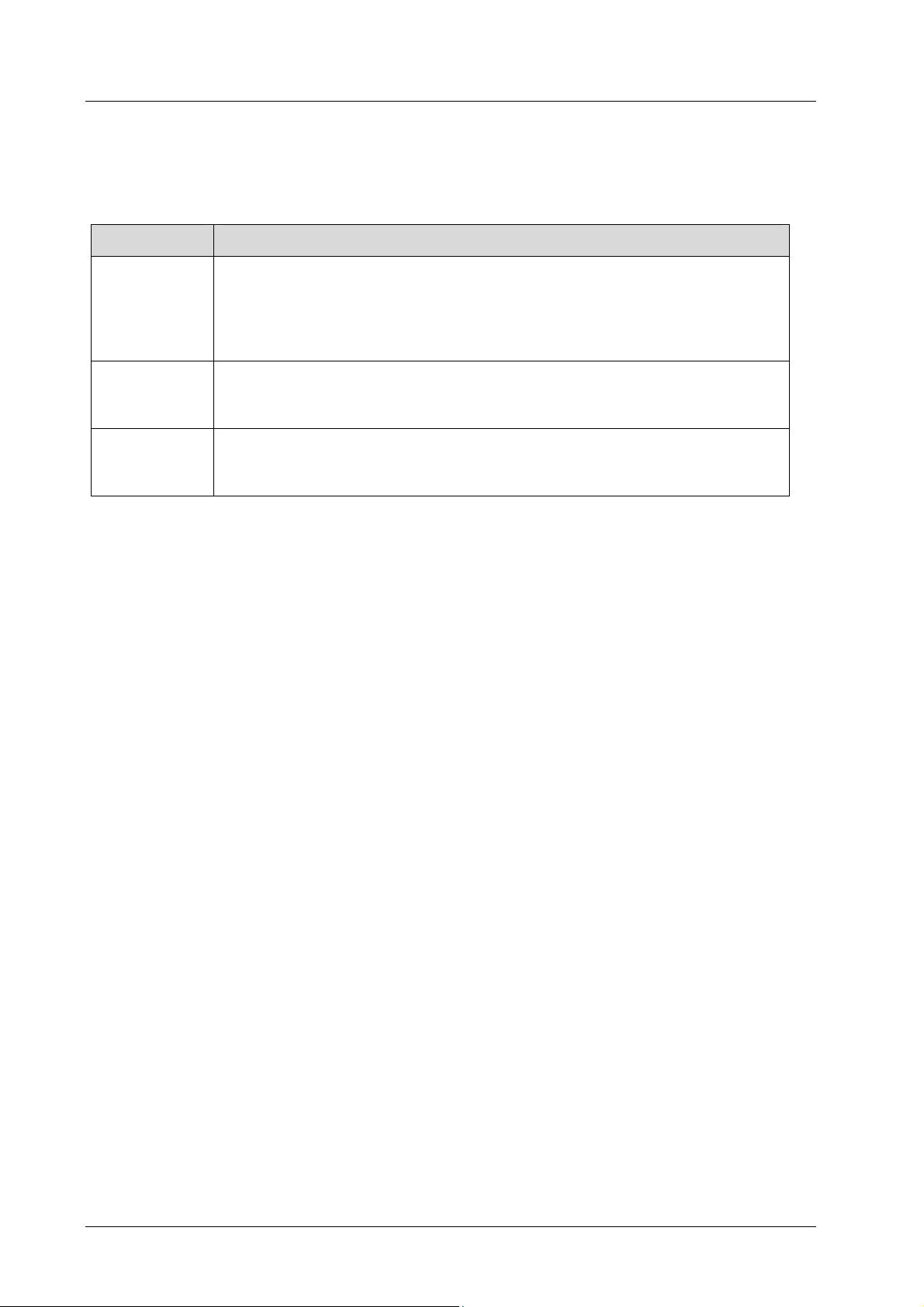

1.4 Symbols used

General information

Safety-related information

1.5 Using this documentation

Structure of the documentation:

The standard product is descibed up to chapter 6. The extensions like POWER STAGE or

SSI-INTERFACE are described in the chapters ADDITIONAL INFORMATION.

1.6 Legal notice

W.E.St.

Gewerbering 31

D-41372 Niederkrüchten

Tel.: +49 (0)2163 577355-0

Fax.: +49 (0)2163 577355 -11

Homepage: www.w-e-st.de or www.west-electronics.com

EMAIL: info@w-e-st.de

Date: 13.02.2013

The data and characteristics described herein serve only to describe the product. The user is required to

evaluate this data and to check suitability for the particular application. General suitability cannot be inferred from this document. We reserve the right to make technical modifications due to further development of the product described in this manual. The technical information and dimensions are non-binding.

No claims may be made based on them.

This document is copyright.

Elektronik GmbH

Page 5 of 45 POS-124-*-PDP-1121 13.02.2013

Page 6

W.E.ST.

Elektronik GmbH

1.7 Safety instructions

Please read this document and the safety instructions carefully. This document will help to define the

product area of application and to put it into operation. Additional documents (WPC-300 for the start-up

software) and knowledge of the application should be taken into account or be available.

General regulations and laws (depending on the country: e.g. accident prevention and environmental protection) must be complied with.

These modules are designed for hydraulic applications in open or closed-loop control circuits. Uncontrolled movements can be caused by device defects (in the hydraulic module

or the components), application errors and electrical faults. Work on the drive or the electronics must only be carried out whilst the equipment is switched off and not under pressure.

This handbook describes the functions and the electrical connections for this electronic

assembly. All technical documents which pertain to the system must be complied with

when commissioning.

This device may only be connected and put into operation by trained specialist staff. The

instruction manual must be read with care. The installation instructions and the commissioning instructions must be followed. Guarantee and liability claims are invalid if the instructions are not complied with and/or in case of incorrect installation or inappropriate

use.

CAUTION!

All electronic modules are manufactured to a high quality. Malfunctions due to the failure

of components cannot, however, be excluded. Despite extensive testing the same also

applies for the software. If these devices are deployed in safety-relevant applications,

suitable external measures must be taken to guarantee the necessary safety. The same

applies for faults which affect safety. No liability can be assumed for possible damage.

Further instructions

• The module may only be operated in compliance with the national EMC regulations. It

is the user’s responsibility to adhere to these regulations.

• The device is only intended for use in the commercial sector.

• When not in use the module must be protected from the effects of the weather, con-

tamination and mechanical damage.

• The module may not be used in an explosive environment.

• To ensure adequate cooling the ventilation slots must not be covered.

• The device must be disposed of in accordance with national statutory provisions.

Page 6 of 45 POS-124-*-PDP-1121 13.02.2013

Page 7

W.E.ST.

Elektronik GmbH

2 Characteristics

This electronic module has been developed for controlling hydraulic positioning drives.

Both axes are controlled complete autonomous via the Profibus. Optionally an interconnection to a two

axes synchronised system is intended.

The differential outputs are covered for activation of constant valves with integrated or external

electronics (differential input). Intended is this module for the connection of analogue way sensors 0...10V

or 4...20mA (scalable) or digital SSI sensor interfaces.

The internal control signals operating states and error conditions via Profibus to the higher-level control.

The operation is signaled by a switch output.

Typical applications: Positioning control or synchronization control with hydraulic axes.

Features

• Two independent positioning axes

• Can be combined for synchronization controls

• Command position parameter, actual value response, on loop control byte and status byte via

fieldbus Profibus DP

• Principle of stroke-dependent deceleration for the shortest positioning time or NC profile gen-

erator for constant speed

• Analogue or digital (SSI) actual value registration for both axes

• Superimposed synchronization controller as PT1 actuator

• Usable with zero lapped control valves

• Fault diagnosis and extended function checking

• Simplified parameterization with WPC-300 software version 3.2

Page 7 of 45 POS-124-*-PDP-1121 13.02.2013

Page 8

W.E.ST.

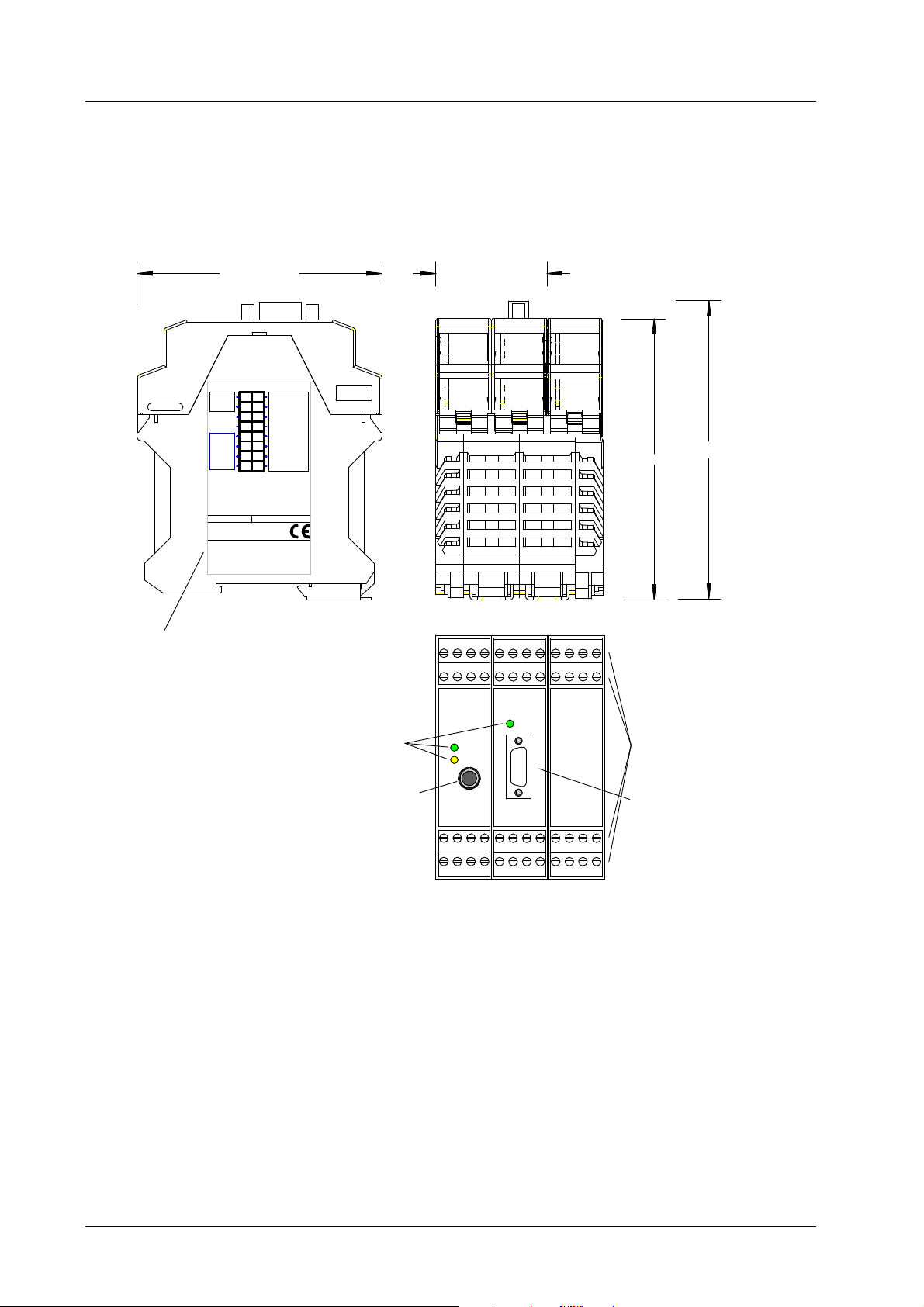

2.1 Device description

Elektronik GmbH

99,0000 mm

D-outputs

Ready

24 V

0 V

Enable

D-inputs

Made in Germany

ID:

V:

W.E. ST.

D-41372 Niederkrüchten

Homepage: http://www.w-e-st.de

1

9

2

10

3

11

4

12

5

13

6

14

15

7

16

8

Add.:Date:

Elektronik

Analogue

GND

GND

Pos. 1

Pos. 2

A

B

Differential

output

Typenschild und Anschlussbelegung

Type plate and terminal pin assignment

LEDs

RS232

Interface

1 2 3 4

5 6 7 8

W.E.ST.

Ready

Status

18 19 2017

22 23 2421

Online

Profibus

9pol SUBD

67,5000 mm

114,0000 mm

34 35 3633

38 39 4037

121,0000 mm

Klemmblöcke (steckbar)

Terminals (removable)

PROFIBUS Buchse

PROFIBUS connector

9 10 11 12

14 15 1613

26 27 2825

30 31 3229

42 43 4441

46 47 4845

Page 8 of 45 POS-124-*-PDP-1121 13.02.2013

Page 9

W.E.ST.

Elektronik GmbH

3 Use and application

3.1 Installation instructions

• This module is designed for installation in a shielded EMC housing (control cabinet). All cables

which lead outside must be screened; complete screening is required. It is also a requirement

that no strong electro-magnetic interference sources are installed nearby when using our control

and regulation modules.

• Typical installation location: 24V control signal area (close to PLC)

The devices must be arranged in the control cabinet so that the power section and the signal section are separate from each other.

Experience shows that the installation space close to the PLC (24 V area) is most suitable. All

digital and analogue inputs and outputs are fitted with filters and surge protection in the device.

• The module should be installed and wired in accordance with the documentation bearing in mind

EMC principles. If other consumers are operated with the same power supply, a star- connected

ground wiring scheme is recommended. The following points must be observed when wiring:

• The signal cables must be laid separately from power cables.

• Analogue signal cables must be shielded.

• All other cables must be screened if there are powerful interference sources (frequen-

cy converters, power contactors) and cable lengths > 3m. Inexpensive SMD ferrites

can be used with high-frequency radiation.

• The screening should be connected to PE (PE terminal) as close to the module as

possible. The local requirements for screening must be taken into account in all cases.

The screening should be connected to at both ends. Equipotential bonding must be

provided where there are differences between the connected electrical components.

• With longer lengths of cable (>10 m) the diameters and screening measures should

be checked by specialists (e.g. for possible interference, noise sources and voltage

drop). Particular care is required with cables of over 40 m in length – the manufacturer

should be consulted if necessary.

• A low-resistance connection between PE and the mounting rail should be provided. Transient in-

terference is transmitted from the module directly to the mounting rail and from there to the local

earth.

• Power should be supplied by a regulated power supply unit (typically a PELV system complying

with IEC364-4-4, secure low voltage). The low internal resistance of regulated power supplies

gives better interference voltage dissipation, which improves the signal quality of high-resolution

sensors in particular. Switched inductances (relays and valve coils connected to the same power

supply) must always be provided with appropriate overvoltage protection directly at the coil.

Page 9 of 45 POS-124-*-PDP-1121 13.02.2013

Page 10

W.E.ST.

Elektronik GmbH

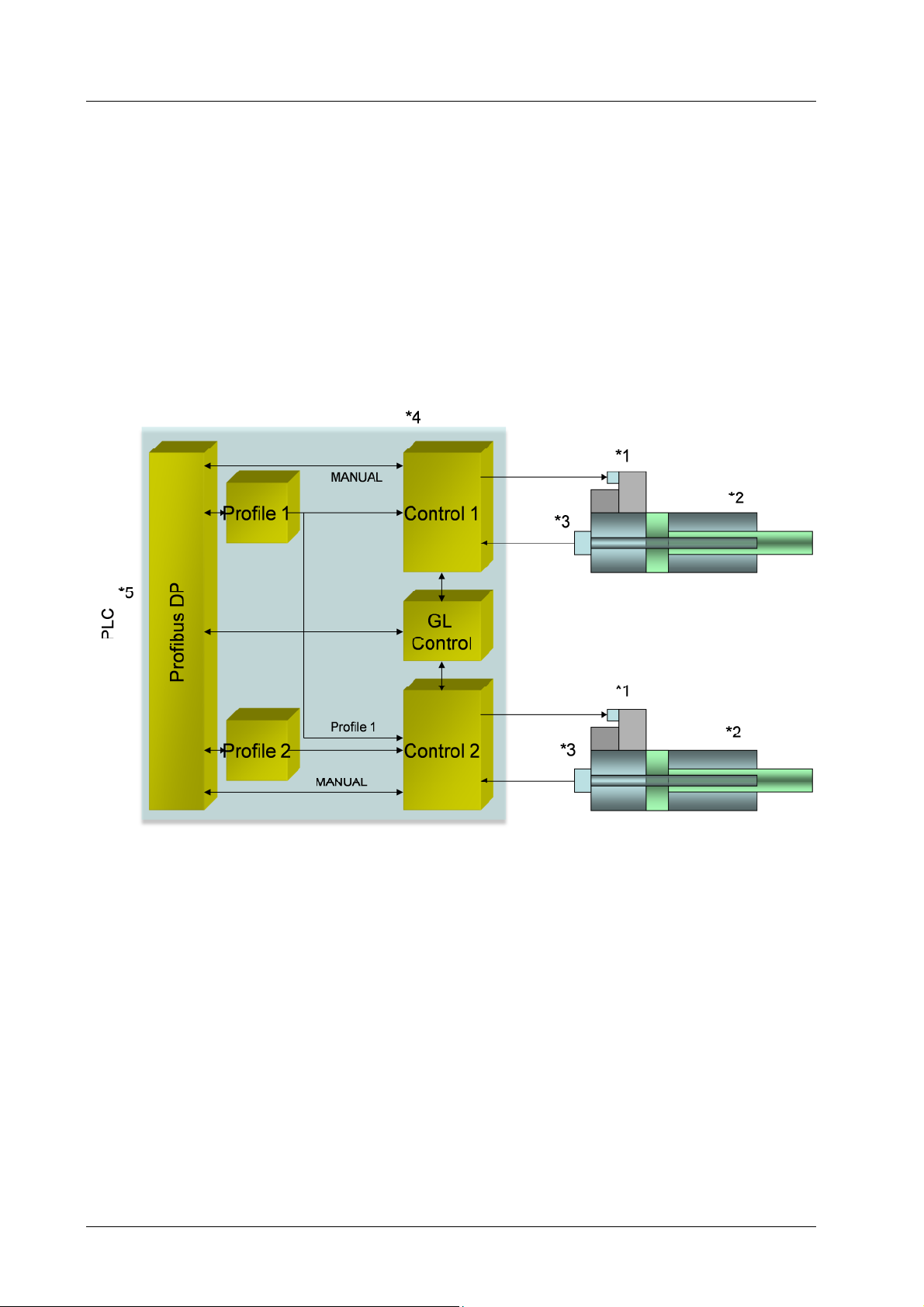

3.2 Typical system structure

This minimal system consists of the following components:

(*1) proportional valve

(*2) hydraulic cylinder

(*3) position sensor

(*4) POS-124-PDP control module

(*5) interface to PLC with analogue and digital signals

3.3 Method of operation

This control module supports simple point-to-point positioning with hydraulic drives. The system works

based on the principle of stroke-dependent deceleration, i.e. the control gain (deceleration stroke) is set

via parameters D:A and D:B. Alternatively the loop gain will be used in NC mode.

The deceleration characteristics can be set linearly (LIN) or approximately quadratically (SQRT1) via the

CTRL parameter. For normal proportional valves SQRT1 is the input setting.

For control valves with a linear flow curve it depends on the application. If LIN is selected for these valves

a significantly shorter deceleration distance can often be set (D:A and D:B).

Page 10 of 45 POS-124-*-PDP-1121 13.02.2013

Page 11

W.E.ST.

Elektronik GmbH

Positioning sequence:

The positioning is controlled via Profibus. After releasing (ENABLE input), the command

position is set to the actual position of the sensor and the axis stays in closed loop position control

mode. The READY output indicates that the system is generally ready for operation. When setting the

START-signal, the preset command value will be taken over. The axis immediately will drive to this new

command position and indicates reaching it by setting the InPos output.

The InPos output stays active as long as the axis is within the preset InPos window and the START input

is active. The driving velocity is forced by preset parameter, too.

The axis can be driven in manual mode (START is off) using the control bits HAND+ or HAND-. The

velocity is programmable. When the HAND signal is deactivated, the command position is set to the actu-

al position and the system stays in closed loop position control mode.

Setting the synchronous bit (GL) will synchronize both axes and the synchronization controller is overrid-

ing the position controller of axis 2. Axis 2 is now following axis 1 according to the master-slave-principle.

Influences on positioning accuracy:

The positioning accuracy is determined by the hydraulic and mechanical conditions. The right choice of

valve is therefore a decisive factor. In addition, two mutually contradictory requirements (short position

time and high accuracy) must be taken into account when designing the system.

The electronic limitations lie mainly in the resolution of the analogue signals, although with our modules a

resolution of < 0.01% only needs to be considered with long positions. In addition, the linearity of the individual signal points (PLC, sensor and control module) must be considered. The worst-case scenario is

that a system-specific absolute fault occurs.

The repeat accuracy is, however, not affected by this.

V+

A:A D:A

D:B

V+

volumetric flow

MAX:A

control direction

driving out

control direction

driving in

MAX:B

P-A

and B-T

A:B

Page 11 of 45 POS-124-*-PDP-1121 13.02.2013

Page 12

W.E.ST.

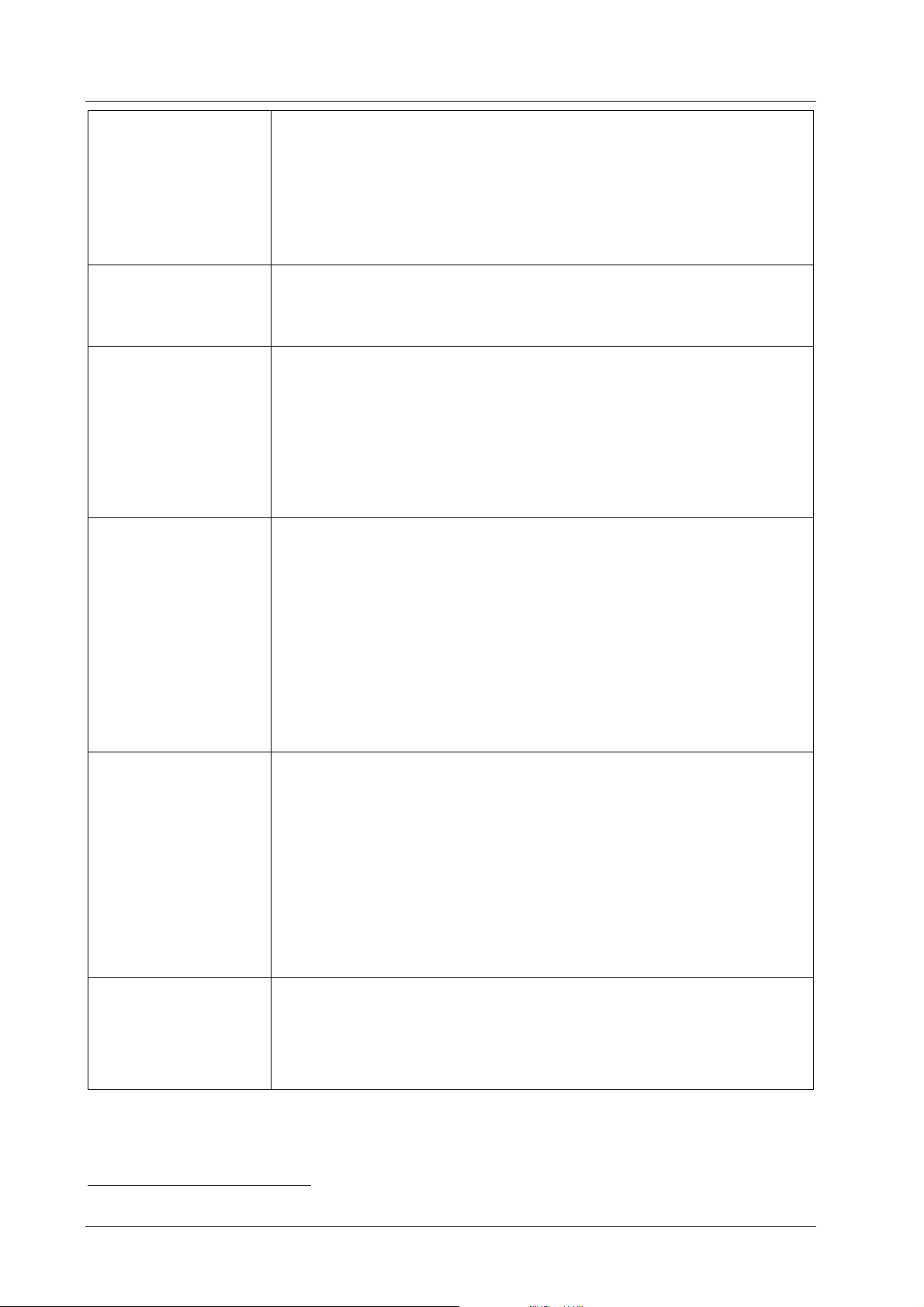

3.4 Commissioning

Step Task

Elektronik GmbH

Installation

Switching on for the first

time

Setting up communication

Pre-parameterisation

Control signals

Install the device in accordance with the circuit diagram. Ensure it is wired correctly and that the signals are well shielded. The device must be installed in a metal

protective housing (control cabinet or similar).

Ensure that no unwanted movement is possible in the drive (e.g. switch off the

hydraulics). Connect an ammeter and check the current consumed by the device.

If it is higher than specified there is an error in the cabling. Switch the device off

immediately and check the cabling.

Once the power input is correct the PC (notebook) should be connected to the serial interface. Please see the WPC-300 program documentation for how to set up

communication.

Further commissioning and diagnosis are supported by the operating software.

Now set up the following parameters (with reference to the system design and circuit diagrams):

The STROKE, POSITION, SENSOR SETTING, POLARITY, ACCELERATION

and DECELERATION.

Pre-parameterisation is necessary to minimise the risk of uncontrolled movements.

Parameterise specific settings for the control element (MIN for following error

compensation and MAX for maximum velocity).

Reduce the speed limitation to a value which is uncritical for the application.

Check the control signal with a voltmeter. The control signals (PIN 15 to PIN16

and PIN19 to PIN20) lies in the range of ± 10V. In the current state it should be

0V. Alternatively, if current signals are used, approx. 0 mA should flow.

CAUTION! This signal depends on the EOUT setting.

Profibus communication

Switching on the hydraulics

Activating ENABLE

Activating START

Manual (HAND) operation

Optimise controller

Activate the profibus communication and check whether the right values and bits

are send to the module.

The hydraulics can now be switched on. Since the module is not yet generating a

signal the drive should be at a standstill or drift slightly (leave its position at a slow

speed).

CAUTION! The drive can now leave its position and move to an end position at

full speed. Take safety measures to prevent personal injury and damage.

The drive is in the current position (with ENABLE the actual position is accepted

as the required position). Should the drive move to an end position the polarity is

probably wrong.

With the start signal the demand value on the analogue demand value input is accepted and the axis moves to the predefined target position.

If START is disabled the axis stops in the preset deceleration distance D:S.

If START is disabled the axis can be moved manually with HAND+ or HAND- .

After disabling the HAND signal, the axis stops in a controlled manner at the current position.

Now optimise the controller parameters according to your application and your

requirements.

Page 12 of 45 POS-124-*-PDP-1121 13.02.2013

Page 13

W.E.ST.

4 Technical description

4.1 Input and output signals

Connection Supply

Elektronik GmbH

PIN 3, PIN 31

and PIN 35

PIN 4, PIN 32

and PIN 36

Power supply (see technical data)

0 V (GND) connection.

Caution, PIN 4 is connected internally to PIN 11 (and also possibly to PIN 12 depending on

the model). These connections serve as a reference potential for the analogue sensor or

demand value signals.

Connection Analogue signals

PIN 13

PIN 14

PIN 15 / 16

PIN 19 / 20

Analogue position actual value (X1), range 0… 100% corresponds to 0… 10V or 4… 20 mA

Analogue position actual value (X2), range 0… 100% corresponds to 0… 10V or 4… 20 mA

Analogue differential output for activation of the axis 1:

-100...100% corresponds to -10...10V.

Analogue differential output for activation of the axis 2:

-100...100% corresponds to -10...10V.

Connection SSI sensors

PIN 37-40

PIN 33, 34

PIN 41-44

PIN 47, 48

Interface 1 to the SSI sensor. RS422 interface and power supply

Interface 2 to the SSI sensor. RS422 interface and power supply

Connection Digital inputs and outputs

PIN 8

PIN 2

PIN 1

Enable input:

This digital input signal initializes the application. The signal will be approved in connection

with the software enable the corresponding axis.

Synchronous error output (only active in synchronous mode):

ON: Slave axis within the error window (GL:E)

OFF: Slave axis outside the error window (GL:E)

READY output:

ON: The module is enabled; there are no discernable errors.

OFF: Enable (PIN 8) is disabled or an error (sensor or internal error) has been detected.

Page 13 of 45 POS-124-*-PDP-1121 13.02.2013

Page 14

W.E.ST.

Elektronik GmbH

4.2 LED definitions

LEDs Description of the LED function

GREEN

YELLOW

GREEN

(right side)

Identical to the READY output.

OFF: no power supply or ENABLE is not activated

ON: System is ready for operation

Flashing: Error discovered (valve solenoid or 4… 20 mA).

The error of one axis results to a flashing LED.

Only active in synchronous mode:

OFF: Slave axis outside the error window

ON: Slave axis within the error window

Profibus connection.

OFF: No Profibus communication

ON: Profibus communication in prozess

Page 14 of 45 POS-124-*-PDP-1121 13.02.2013

Page 15

W.E.ST.

4.3 Circuit diagram

Elektronik GmbH

Profibus DP

ANA Feedback

Position 1

0 V

SSI Feedback

Position 1

0..10V

4..20mA

0 V

DC

24 V

0 V

35

31

3

4

24 V

0 V

PELV

32

36

15

Differentialinput

16

Profibus

SUBD

9

9polig

ws1

v1

Speed

Profil Generator

Commands:

- STROKE

VMODE = NC

Speed

via Feldbus

Position

via Feldbus

POS-124-A/I-PDP

Control Function

xd1w1

Commands:

- A:A and A:B

- D:A and D:B

-

Internal Power

VMODE = SDD

Output

limitation

Output Adaptation

Commands:

- MIN: A and B

- MAX: A and B

- TRIGGER

- OFFSET

- POL

DC

Output: A

u1

Output: B

12

Input Scaling

13

Commands:

11

AIN:W

33

24 V

SSI Sensor

Commands:

34

0 V

SSI:RES

SSI:BITS

SSI:CODE

37

CLK+

SSI:POL1

SSI:OFFSET1

38

CLK-

39

DATA+

40

DATA-

VMODE = SDD

INPX = ANA

INPX = SSI

x1

x1

x2

AXIS 1

Synchronous Controller

Commands:

- GL:P

- GL:T1

- GL:E

Enable Sync.

via Feldbus

I-Version: 4... 20 mA

PIN 15 = +, PIN 12 = GND

ANA Feedback

Position 2

0 V

SSI Feedback

Position 2

Enable

0..10V

4..20mA

0 V

Input Scaling

14

Commands:

11

AIN:W

47

24 V

SSI Sensor

Commands:

48

0 V

SSI:RES

SSI:BITS

SSI:CODE

41

CLK+

SSI:POL2

SSI:OFFSET2

42

CLK-

43

DATA+

44

DATA-

8

24 V input

x2

INPX = ANA

x2

INPX = SSI

Commands:

- TS (sample time)

- MODE (Expert or Standard)

- EOUT (Error Mode)

- INPOS (InPos output)

AXIS 2

Control program

RS232 C

9600 Baud

1 Stopbit

no parity

3,5 mm JISC-6560 Buchse

u2

24 V output

24 V output

Output: A

Output: B

PE via DIN-RAIL

19

Differentialinput

20

18

I Version: 4... 20 mA

PIN 19 = +, PIN 18 = GND

Ready

1

2

Synchron

Error

Page 15 of 45 POS-124-*-PDP-1121 13.02.2013

Page 16

W.E.ST.

4.4 Typical cabling

ENABLE

4321

Elektronik GmbH

20191817

power

24V

0V

supply

+/- 10 V (4...20mA)

to control valve 2

+24 V DC

GND

SSI 1

36353433

sensor interface

CLK+

CLKDATA+

DATA-

PE

0..10V, 4..20mA

sensor position

13 = X1, 14 = X2

+/- 10 V (4...20mA)

to control valve 1

4.5 Connection examples

SPS / PLC 0... 10 V speed input signal

+In PIN 10

-In PIN 9

GND PIN 11

24

8765

1211109

16151413

232221

Profibus

9pol Buchse

32313029

393837

40

44434241

48474645

GND

power supply

communication modul

+24 V DC

PE Klemme

DATADATA+

CLKCLK+

SSI 2

sensor interface

GND

+24 V DC

z. B. 24 V

PLC or sensor with 4... 20 mA (two wire connection)

+In PIN 13 or 14

PIN 12 (GND)

AIN:W 2000 1600 2000 C ( für 0... 100%)

SPS / PLC 0... 10 V command and feedback signal

+In PIN 13 or PIN 14

In PIN 12 (GND)

z. B. 24 V

PLC or sensor with 4... 20 mA (three wire connection)

+In PIN 13 or 14

PIN 12 (GND)

AIN:W 2000 1600 2000 C ( für 0... 100%)

Valve (6 + PE plug) with OBE electronics

Module

PIN 12

PIN 15

PIN 16

A : 24 V supply

B : 0 V supply

C : GND or enable

D : + differential input

E : - differential input

F : diagnostics

PE -

Page 16 of 45 POS-124-*-PDP-1121 13.02.2013

Page 17

W.E.ST.

4.6 Technical data

Supply voltage

Current requirement

External protection

Digital inputs

Input resistance

Digital outputs

Analogue inputs (sensor and

demand value signal)

Signal resolution

[VDC]

[mA]

[A]

[V]

[V]

[kOhm]

[V]

[V]

[V]

[mA]

[%]

24 (±10 %)

500

1 medium time lag

logic 0: < 2 V

logic 1: > 10 V,current consumption

< 0,1 mA

25

logic 0: < 2 V

logic 1: > 12 V; max. 10 mA

0… 10. 33 kOhm

4… 20. 250 Ohm

0.01(internally 0.0031) inc. oversampling

Elektronik GmbH

[V]

[mA]

[%]

[mA]

[%]

[ms]

[°C]

[°C]

[%]

[kg]

2 x 0… 10; Differential output

5 (max. load)

0.024

4… 20; 390 Ohm maximum load

0.024

-

RS-422 Spezifikation, 150 kBaud

1

RS 232C, 9600… 57600 Baud, 1 stop

bit, no parity, Echo Mode

9.6,19,2,93.75,187.5,500,1500,3000

6000, 12000 kbits/s

1810h

Snap-on module to EN 50022

PA 6.6 polyamide

Flammability class V0 (UL94)

IP20

-10… 50

-20... 70

<95 (non-condensing)

RS232: 3,5mm JISC-6560

11 x 4-pole terminal blocks

Profibus DP, D-Sub 9 pol.

PE: via the DIN mounting rail

EN 61000-6-2: 8/2002

EN 61000-6-3: 6/2005

0,375

Analogue outputs

Voltage

Signal resolution

Current

Signal resolution

SSI interface

Controller sample time

Serial interface

Profibus DP

Baud rate

ID Number

Housing

Protection class

Temperature range

Storage Temperature

Humidity

Connections

EMC

Weight

Page 17 of 45 POS-124-*-PDP-1121 13.02.2013

Page 18

W.E.ST.

5 Parameters

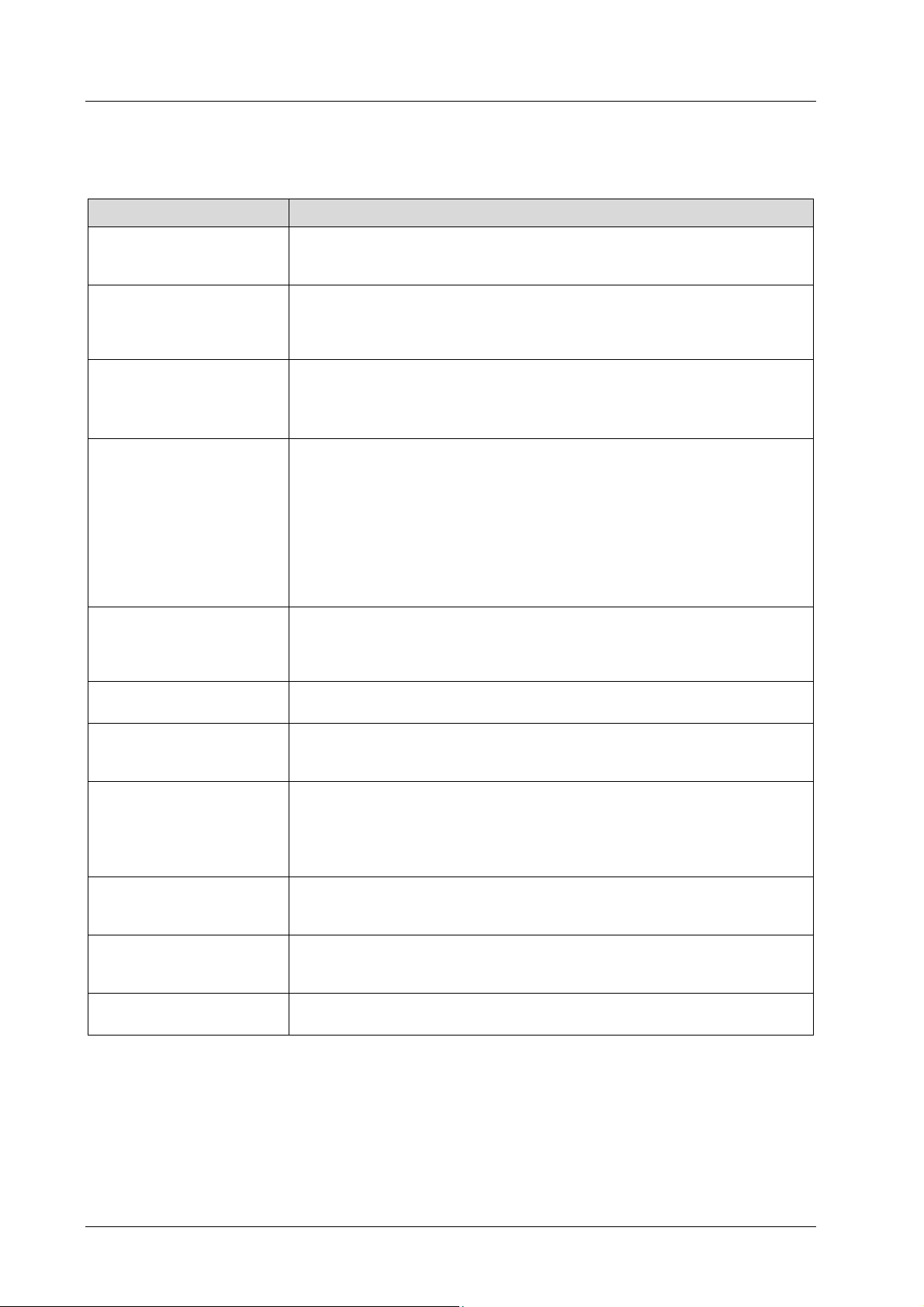

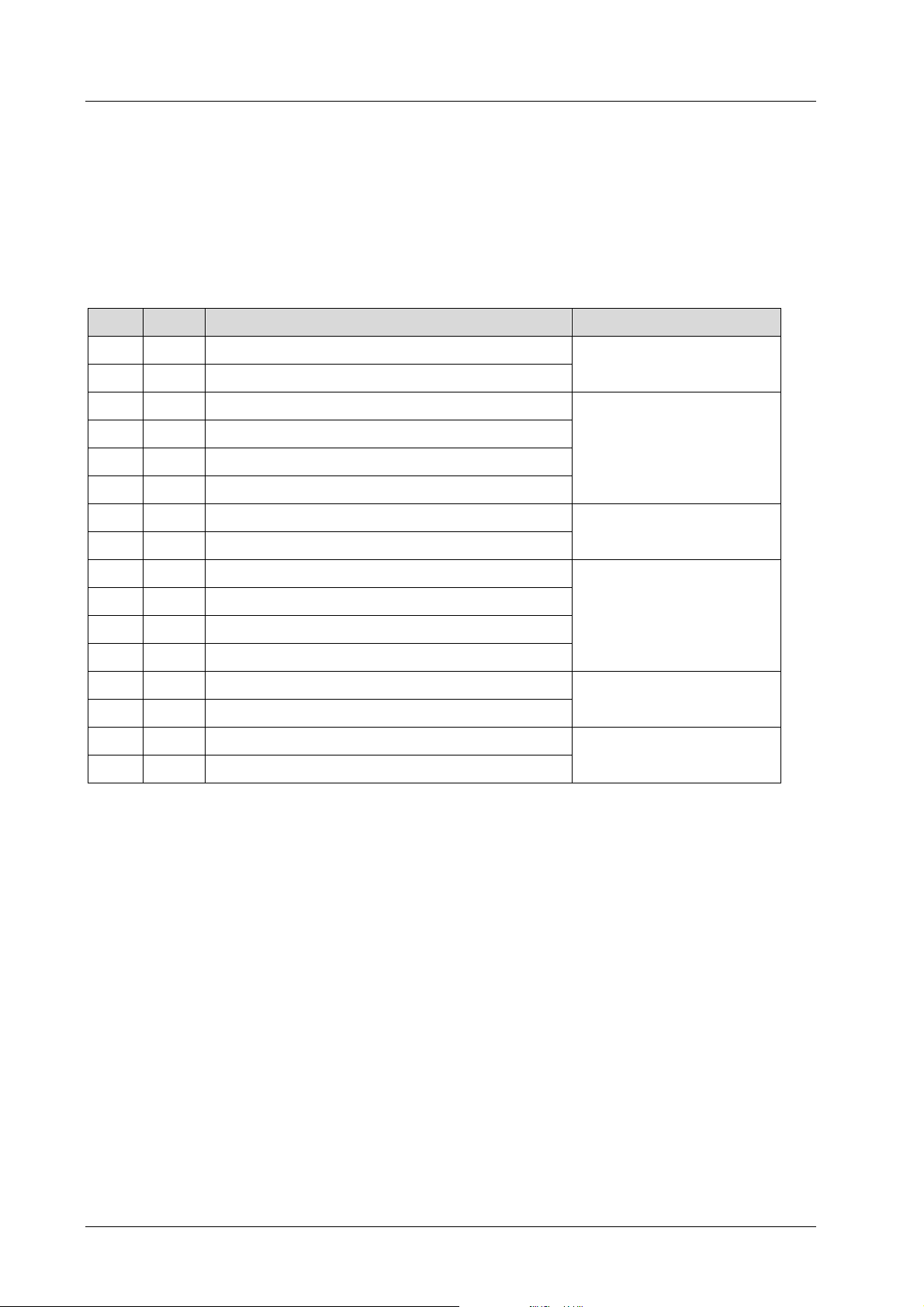

5.1 Parameter overview

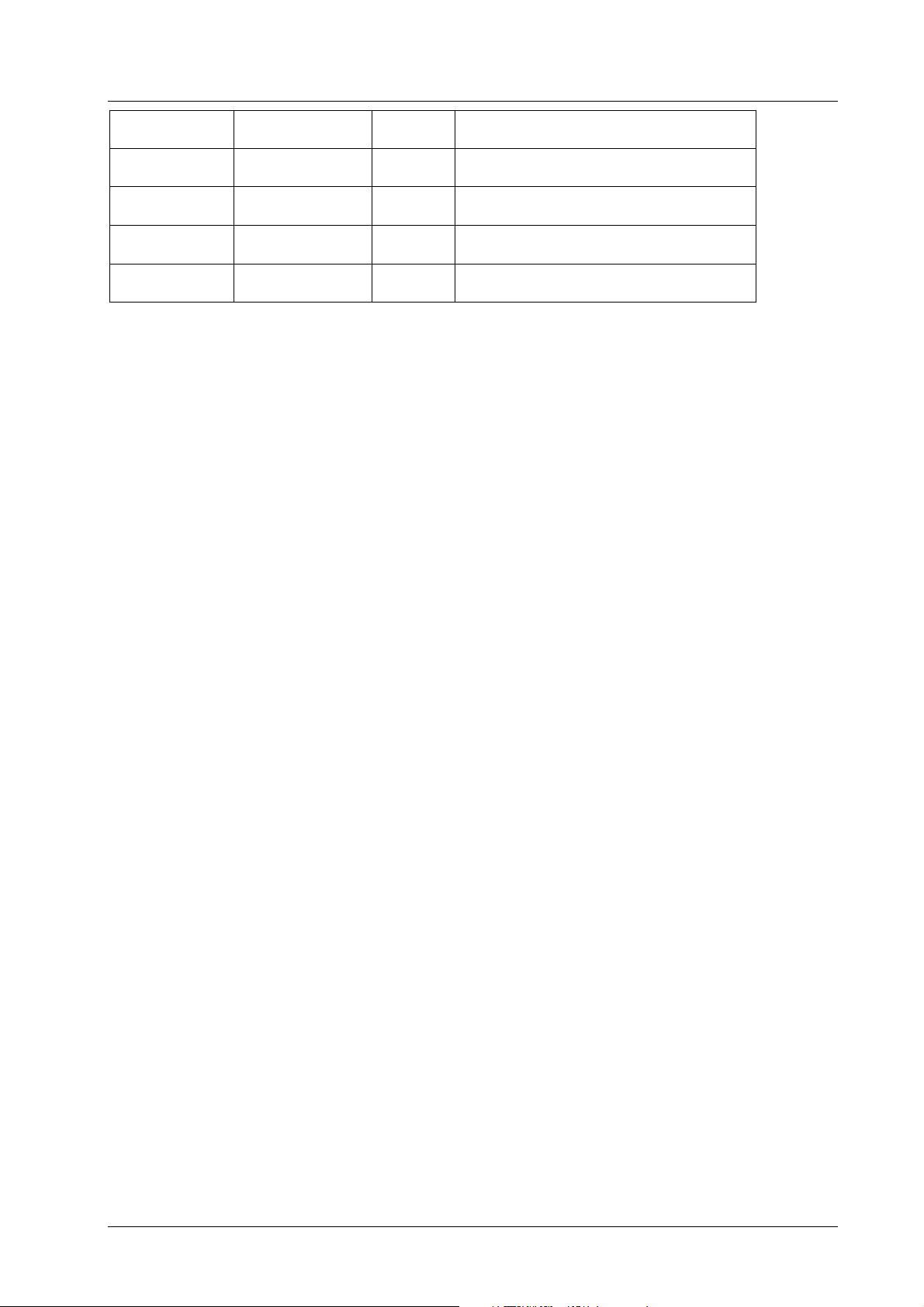

Command

Default

Unit

Elektronik GmbH

Description

LG

PDPADR

MODE

SENS

INPX

STROKE1

STROKE2

VRAMP1

VRAMP2

VMODE1

VMODE2

VMAX1

VMAX2

POL1

POL2

EOUT1

EOUT2

SSI:OFFSET1

SSI:OFFSET2

SSI:POL1

SSI:POL2

SSI:RES

SSI:BITS

SSI:CODE

AIN:I

A

B

C

X

A1:I

A2:I

D1:I

D2:I

V01:I

V02:I

CTRL 1

CTRL 2

GL:P

GL:T1

GL:E

HAND1:I

HAND2:I

GB -

126 -

STD -

ON -

SSI -

X = 10...10000 mm

100 ms

SDD -

50 mm/s

+ -

0 0,01%

0 10 nm

+ -

500 10 nm

24 -

GRAY -

10000

10000

10000

:A 100

:B 100

:A 25

:B 25

:S 10

:A 10

:B 10

sqrt1 -

:A 3330

:B -3330 0,01%

V

48

80

200

-

0,01 %

-

ms

mm

mm

mm

1/s

1/s

0,01

ms

µm

Changing language help texts.

Address of the unit at the Profibus.

Mode parameter.

Activation and disabling of internal failure monitoring functions.

Switching between SSI and analog sensors.

Working stroke of the sensor.

Ramp function for external speed input.

Control structure for positioning process.

Maximum speed in NC mode.

Reversal of output polarity.

Error output signal.

Position offset

Sensor polarity

Resolution of the sensors (the same for both)

Number of transmitted bits (the same for both)

transfer Encoding (the same for both)

Analogue input scaling for X1 and X2.

Acceleration times.

Deceleration distance

Deceleration distance

Emergency deceleration distance

Loop gain setting.

Specification of control characteristics.

Definition of the synchronization actuator. GL:P

adjusted the gain, GL:T1 effects a decelerated action of the actuator (revised stability) and .GL:E for

error-window in synchronous run (out of window

GL-Error-Bit is set on the Profibus)

Output signal in manual mode.

Page 18 of 45 POS-124-*-PDP-1121 13.02.2013

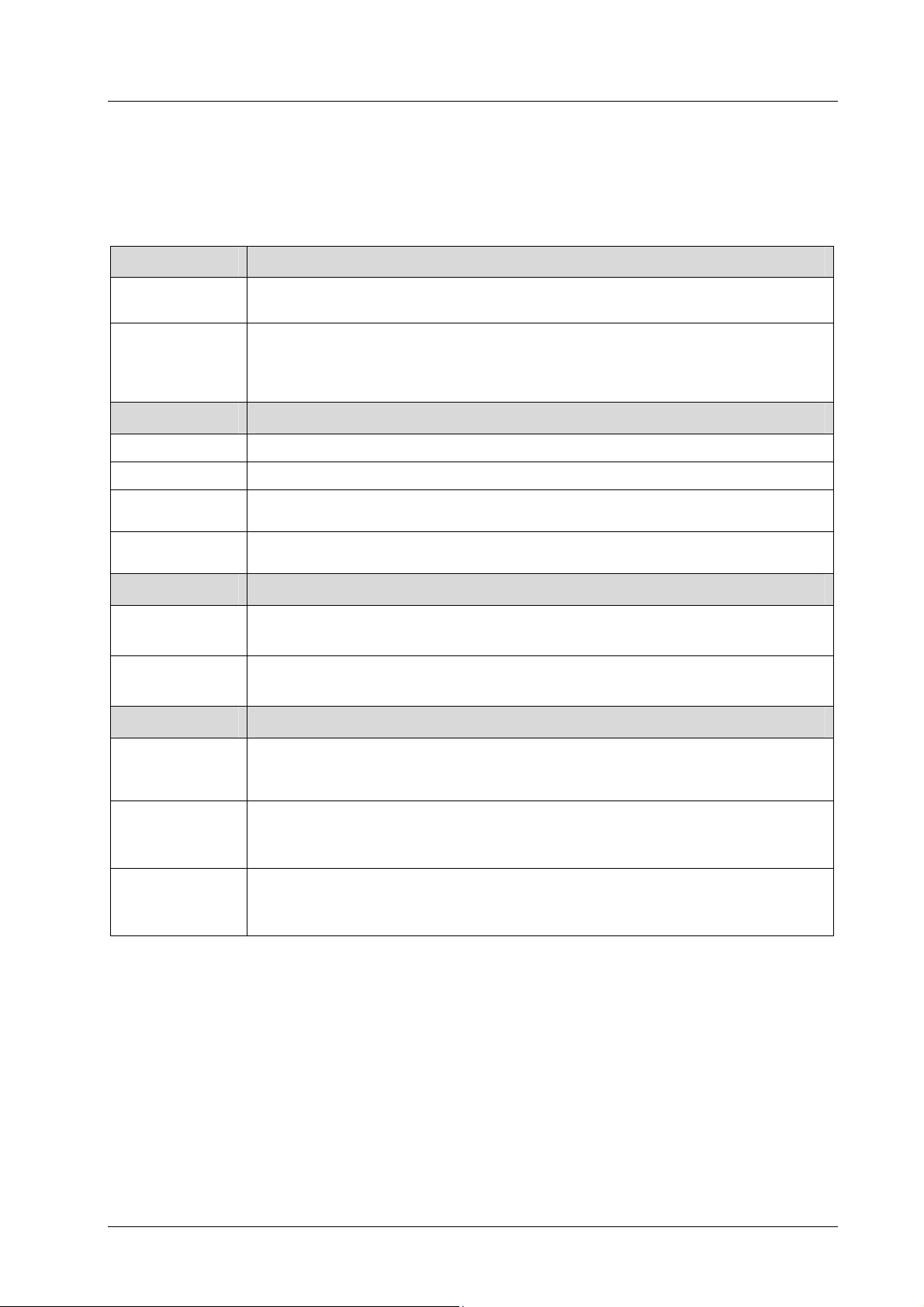

Page 19

W.E.ST.

Elektronik GmbH

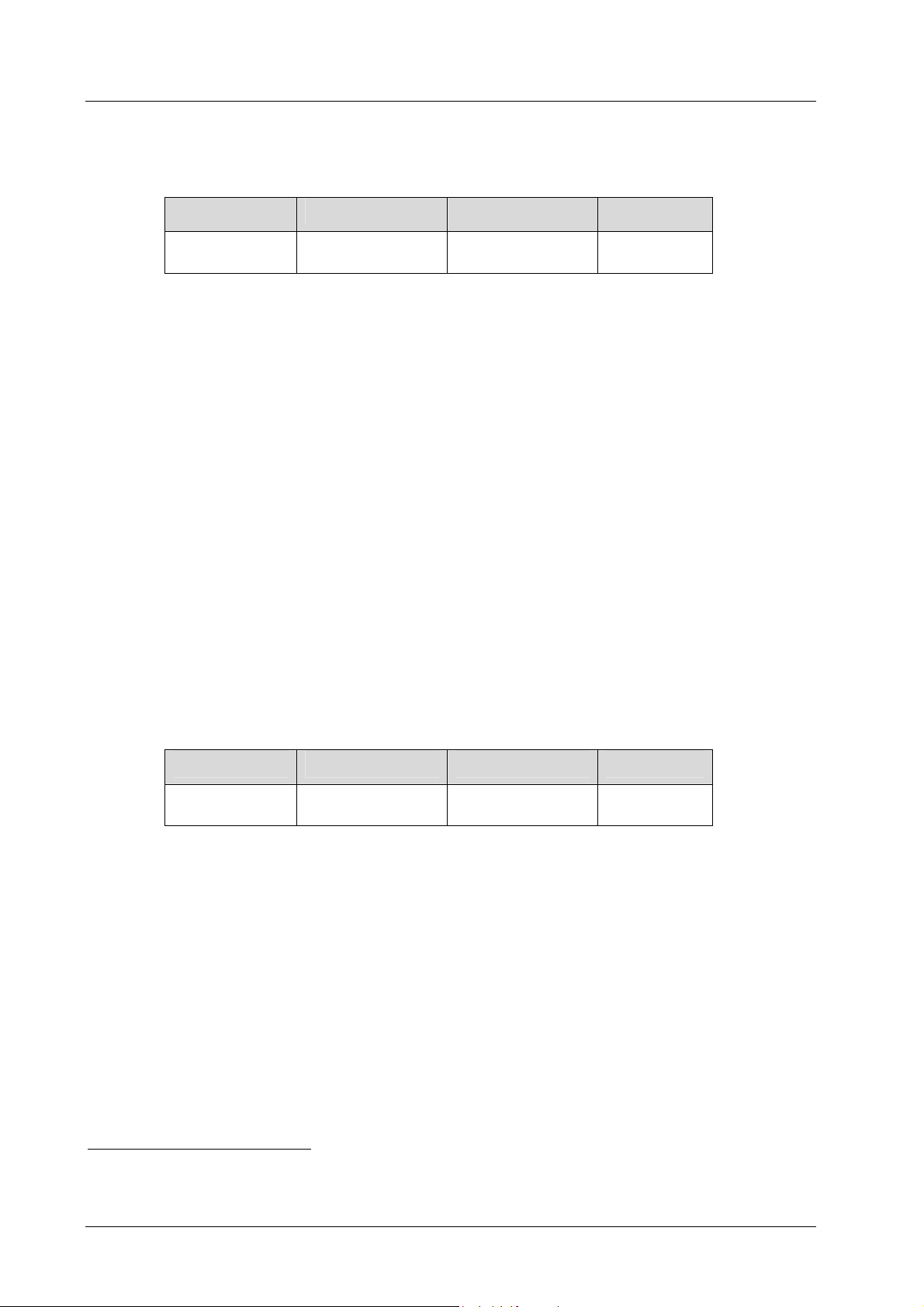

MIN1:I

MIN2:I

MAX1:I

MAX2:I

TRIGGER1

TRIGGER2

OFFSET1

OFFSET2

INPOS1:I

INPOS2:I

0

0

10000

10000

200

200

0

0

200

200

0,01 %

0,01 %

0,01 %

0,01 %%

0,01 %

0,01 %%

0,01 %

0,01 %%

µm

µm

Zero point setting /following error compensation.

Maximum output signal limitation.

Trigger threshold for activating the following error

compensation (MIN).

Offset value (added to the output signal).Axis 1 and

axis 2 separate definable.

Range for InPos signal.

Page 19 of 45 POS-124-*-PDP-1121 13.02.2013

Page 20

W.E.ST.

Elektronik GmbH

5.2 Parameter description

5.2.1 LG (Changing the language for the help texts)

Command

LG x x= DE|GB -

Either German or English can be selected for the help texts.

CAUTION: After changing the language settings the ID button (SPEED BUTTON) in the menu

bar (WPC-300) must be pressed (module identification).

Parameters

Unit

5.2.2 PDPADR (Profibus adress)

Command

PDPADR X x= 1...126 -

Slave address in the Profibus network.

Parameters

Unit

5.2.3 MODE (Switching between parameter groups)

Group

STD

Group

STD

Command

MODE x x= STD|EXP -

This command changes the operating mode. Various commands (defined via STD/EXP) are blanked out

in Standard Mode. The commands in Expert Mode have a more significant influence on system behaviour

and should accordingly be changed with care.

Parameters

Unit

Group

STD

Page 20 of 45 POS-124-*-PDP-1121 13.02.2013

Page 21

W.E.ST.

5.2.4 SENS (Module monitoring)

Elektronik GmbH

Command

SENS x x= ON|OFF -

Parameters

Unit

Group

STD

This command is used to activate and disable monitoring functions (4… 20 mA sensors and internal

module monitoring).

ON: Monitor function is activ.

OFF: Failures are ignored.

Normally, monitoring is always active as otherwise no errors are signalled via the PIN 1

(READY) output. It can, however, be disabled for fault finding.

5.2.5 STROKE1 /STROKE2 (Full stroke)

Command

STROKE1 X

STROKE2 X

Parameters

x= 10… 10000 mm

Unit

Group

STD

This command defines the full stroke, which corresponds to 100% of the input signal. If the demand is set

incorrectly, this leads to incorrect system settings, and the dependent parameters such as speed and

gain cannot be calculated correctly.

5.2.6 VRAMP1 /VRAMP2 (Ramp time for external speed demand)

Command

VRAMP1 X

VRAMP2 X

The rate of change of the external speed demand can be limited by this ramp time. The command is only

active if external speed demand (VS = EXT) has been parametrised.

Parameters

x= 1… 2000 ms

Unit

Group

STD

Page 21 of 45 POS-124-*-PDP-1121 13.02.2013

Page 22

W.E.ST.

Elektronik GmbH

5.2.7 VMODE1 / VMODE2 (Switching over the control mode)

Command

VMODE1 X

VMODE2 X

Parameters

x= SDD|NC

Unit

Group

EXP

The fundamental control structure can be changed with this parameter.

SDD: Stroke-Dependent Deceleration. In this mode, stroke-dependent deceleration is activated. This

mode is the default mode and is suitable for most applications. With stroke-dependent deceleration the drive comes to a controlled stop at the target position. From the set deceleration

point the drive then switches to control mode and moves accurately to the desired position.

This control structure is very robust and reacts insensitively to external influences such as fluctuating pressures.

One disadvantage is that the speed varies with the fluctuating pressure as the system runs

under open-loop control.

NC: Numerically Controlled. In this mode a position profile is generated internally. The system al-

ways works under control and uses the following error to follow the position profile. The magnitude of the following error is determined by the dynamics and the set control gain. The advantage is that the speed is constant (regardless of external influences2) due to the profile

demand. Because of continuous control, it is necessary not to run at 100% speed, as otherwise the errors cannot be corrected. 80% of the maximum speed is typical although especially

the system behaviour and the load pressure should be taken into account when specifying the

speed.

5.2.8 VMAX1 / VMAX2 (Maximum speed in NC Mode)

Command

VMAX1 X

VMAX2 X

Specification of the maximum speed in NC Mode. This value is defined by the drive system and should be

specified as precisely as possible (not too high under any circumstances)3. The maximum speed is

scaled by means of the VELO value or via the external speed demand. The command is only active if the

VMODE has been parametrised to NC.

2

There are deviations due to external influences which are then compensated for. The time response is defined by

the system dynamics.

3

If the retraction speed and the outward speed are different, the smaller one has to be used

Parameters

x= 1… 5000 mm/s

Unit

Group

VMODE = NC

Page 22 of 45 POS-124-*-PDP-1121 13.02.2013

Page 23

W.E.ST.

Elektronik GmbH

5.2.9 POL1 / POL2 (Output polarity)

Command

POL1 X

POL2 X

Parameters

x= +|- -

Unit

Group

STD

This command enables the output signal polarity to be reversed.

5.2.10 EOUT1 / EOUT2 (Output signal in case of error)

Command

EOUT1 X

EOUT2 X

Error output value. A value (degree of valve opening) for use in the event of a sensor error can be defined

here. This function can be used if, for example, the drive is to move to one of the two end positions (at the

specified speed) in case of a sensor error.

|EOUT| = 0 The output is switched off in the event of an error. This is normal behaviour.

CAUTION! If the output signal is 4… 20 mA, the output is switched off if |EOUT| = 0. If a

null value = 12 mA is to be output in the event of an error, EOUT must be set to 14.

CAUTION! The output value defined here is stored permanently (independently of the parameter set). The effects should be analysed by the user for each application from the

point of view of safety

CAUTION! If EOUT is activated, the HAND mode should not be used. After deactivating

the HAND mode the output will be set to the programmed EOUT value.

.

Parameters

x= -10000… 10000 0,01%

Unit

Group

EXP

4

This is necessary if using valves without error detection for signals lower than 4 mA

Page 23 of 45 POS-124-*-PDP-1121 13.02.2013

Page 24

W.E.ST.

5.2.11 INPX (Sensor type define)

Elektronik GmbH

Command

INPX X x= SSI|ANA

Parameters

Unit

Group

STD

With this parameter the appropriate sensor type can be activated.

SSI: The SSI sensor interfaces are active. The SSI sensors have to be adjusted via the SSI com-

mands to the sensors. The relevant sensor data must be available.

ANA: The analog sensor interfaces (0 ... 10 V or 4 ... 20 mA) are active. The sensors are scaled with

the commands AIN: X

The SSI interface is suitable for digital position sensor. The internally processed accuracy is 1 micron.

CAUTION: It can only be used SSI sensors of the same type, ie the resolution of the sensor,

the number of bits transmitted and the transmission coding must be the same!

5.2.12 SSI:OFFSET (Sensor offset)

Command

SSI:OFFSET1 X

SSI:OFFSET2 X

Parameters

x= -1000000… 1000000 µm

Unit

Group

INPX = SSI

This command is a sensor offset (zero point of the sensor).

5.2.13 SSI:POL (Direction of the sensor signal)

Command

SSI:POL1 X

SSI:POL2 X

To reverse the working direction of the sensor, with this command, the polarity can be changed.

Example: Sensor Length = 200 mm, reverse the direction of work is required.

Set SSI: POL to "-" (internally, the sensor position is subtracted from the stroke ).

Parameters

x= +|- -

Unit

Group

INPX = SSI

Page 24 of 45 POS-124-*-PDP-1121 13.02.2013

Page 25

W.E.ST.

5.2.14 SSI:RES (Signal resolution)

Elektronik GmbH

Command

SSI:RES X x= 100… 10000 0,01 µm

Parameters

Unit

Group

INPX = SSI

This command defines the signal resolution of the sensor. Data entry has a resolution of 10 nm (nanometers or 0.01 micron). If the sensor has one micron resolution, the value must be set to 100. This makes it

possible to scale rotational sensors.

Take the data from the sensor data sheet.

Caution: The signal resolution for both SSI sensors must be equal.

5.2.15 SSI:BITS (Number of bits)

Command

SSI:BITS X x= 8… 31 bits

With this command the number of data bits can be set.

Take the data from the sensor data sheet.

Caution: The number of bits for both SSI sensors must be equal.

Parameters

Unit

Group

INPX = SSI

5.2.16 SSI:CODE (Signal coding)

Command

SSI:CODE X x= GRAY|BIN -

With this command the signal coding can be set.

Take the data from the sensor data sheet.

Caution: The signal coding for both SSI sensors must be equal.

Page 25 of 45 POS-124-*-PDP-1121 13.02.2013

Parameters

Unit

Group

INPX = SSI

Page 26

W.E.ST.

5.2.17 AIN (Analogue input scaling)

Elektronik GmbH

Command

AIN:I

A

B

C

X

Parameters

i= X1|X2

a= -10000… 10000

b= -10000… 10000

c= -700… 10000

x= V|C

Unit

-

-

0.01%

-

Group

STD

This command can be used to scale the individual inputs. The following linear equation is used for

scaling.

=

∙

−

The “c” value is the offset (e.g. to compensate the 4 mA in the case of a 4… 20 mA input). The variables a

and b define the gain factor.

e.g.: 2.345 correspond to: a = 2345, b =1000

The internal measuring resistor for measuring the current (4… 20 mA) is activated via the x value and the

evaluation switched over accordingly.

Typical settings:

Command

AIN:X1 1000 1000 0 V

AIN:X1 10 8 1000 V

OR

AIN:X1 1000 800 1000 V

AIN:X1 10 4 500 V

OR

AIN:X1 1000 400 500 V

AIN:X1 20 16 2000 C

OR

AIN:X1 2000 1600 2000 C

Input

0… 10V

1… 9V

0,5… 4,5V

4… 20mA

Description

Range: 0… 100%

Range: 0… 100%; 1 V = 1000 used for the offset and gained by 10 /

8 (10V divided by 8 V (9V -1V)

Range: 0… 100%; 0,5 V = 500 used for the offset and gained by 10 /

4 (10V divided by 4 V (4,5V -0,5V)

Range: 0… 100%

The offset will be compensated on 20% (4 mA) and the signal (16 mA

= 20mA – 4 mA) will be gained to 100% (20 mA).

Page 26 of 45 POS-124-*-PDP-1121 13.02.2013

Page 27

W.E.ST.

5.2.18 A1 / A2 (Acceleration time)

Elektronik GmbH

Command

A1:I X

A2:I X

Parameters

i= A|B

x= 1… 5000

Unit

ms

ms

Group

STD

Ramp function for the 1st and 3rd quadrants.

The acceleration time for positioning is dependent on the direction. A corresponds to connection 15 and B

corresponds to connection 16 (if POL = +).

Normally A = flow P-A, B-T and B = flow P-B, A-T.

For quadrants 2 and 4, parameters D:A and D:B are used as the deceleration distance demand.

5.2.19 D1 / D2 (Deceleration / braking distance)

Command

D1:I X

D2:I X

This parameter is specified in mm5.

The deceleration distance is set for each direction of movement (A or B). The control gain is calculated

internally depending on the deceleration distance. The shorter the deceleration distance, the higher the

loop gain. A longer deceleration distance should be specified in the event of instability.

Parameter D:S is used as the emergency stopping ramp when disabling the START signal. After disabling, a new target position (current position plus D:S) is calculated in relation to the speed and is specified as a demand value.

G =

Intern

STROKE

D

i

CAUTION: If the maximum position (POSITION command) is changed, the deceleration distance must also be adjusted. Otherwise this can result in instability and uncontrolled movements.

Parameters

i= A|B|S

x= 1… 10000

Calculation of control gain

Unit

mm

mm

mm

Group

VMODE = SDD

VMODE = SDD

SDD + NC

5

CAUTION! With older modules this parameter was specified in % of the maximum path. Since data specification for

this module has now been converted to mm the relationship between the path (PATH command) and these parameters must be taken into account.

Page 27 of 45 POS-124-*-PDP-1121 13.02.2013

Page 28

W.E.ST.

5.2.20 V01 / V02 (Loop gain setting)

Elektronik GmbH

Command

V01:I X

V02:I X

Parameters

i= A|B

x= 1… 200

Unit

s-1

s-1

Group

VMODE = NC

This parameter is specified in s-1 (1/s).

In NC Mode the loop gain is normally specified rather than the deceleration distance6.

The internal gain is calculated from this gain value together with the VMAX and POSITION parameters.

v

i

V

STROKE

max

0

D

Calculation of the internal control gain

i

G

D==

Intern

In NC Mode the following error at maximum speed is calculated by means of the loop gain. This following

error corresponds to the deceleration distance with stroke-dependent deceleration. The conversion and

therefore also the correct data demands related to the control system are relatively simple if the relationship described here is taken into account.

6

The loop gain is alternatively defined as a KV factor with the unit (m/min)/mm or as Vo in 1/s. The conversion is KV

= Vo/16.67.

Page 28 of 45 POS-124-*-PDP-1121 13.02.2013

Page 29

W.E.ST.

Elektronik GmbH

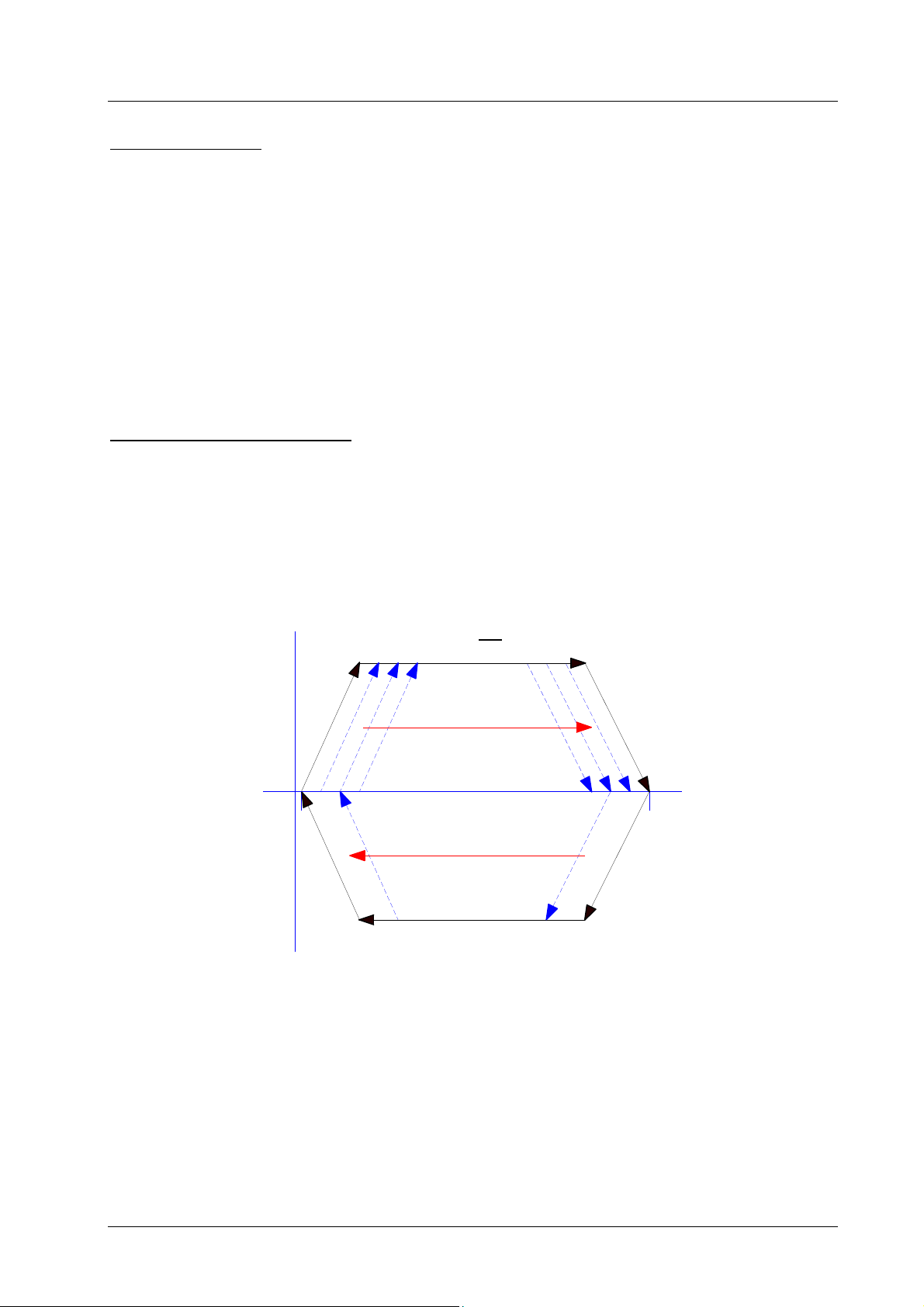

5.2.21 CTRL1 / CTRL2 (Deceleration function characteristic)

Command

CTRL1 X

CTRL2 X

Parameters

x= lin|sqrt1

|sqrt2

Unit

-

Group

STD

The deceleration characteristic is set with this parameter. In the case of positively overlapped proportional

valves the SQRT function should be used. The non-linear flow function of these valves is linearised by the

SQRT7 function.

In the case of zero lapped valves (control valves and servo valves) the LIN or SQRT1 function should be

used regardless of the application. The progressive characteristic of the SQRT1 function has better positioning accuracy but can also lead to longer positioning times in individual cases.

LIN: Linear deceleration characteristic (gain is increased by a factor of 1).

SQRT1: Root function for braking curve calculation. The gain is increased by a factor of 3 (in the target

position). This is the default setting.

SQRT2: Root function for braking curve calculation. The gain is increased by a factor of 5 (in the target

position). This setting should only be used with a significantly progressive flow through the

valve.

Braking stroke

D:A or D:B

Deceleration time

D:A or D:B

Velocity

CTRL = SQRT

Velocity

CTRL = SQRT

CTRL = LIN

CTRL = LIN

7

The SQRT function generates constant deceleration and thus reaches the target position faster. This is achieved by

increasing the gain during the deceleration process.

Stroke

1 Braking function with respect to stroke and time

Time

Page 29 of 45 POS-124-*-PDP-1121 13.02.2013

Page 30

W.E.ST.

Elektronik GmbH

5.2.22 GL: P (gain of the synchronization in SDD mode)

5.2.23 GL: V0 (gain of the synchronization in NC mode)

5.2.24 GL:T1 (Time constant of the synchronisation control)

5.2.25 GL:E (Window for the synchronization error)

Command

GL:P X

GL:V0 X

GL:T1 X

GL:E X

Parameters

X = 1… 10000

X = 1… 200

X = 1… 200

X = 2… 10000

Unit

mm

s-1

ms

µm

Group

VMODE = SDD

VMODE = NC

STD

STD

These parameters are used to optimize the synchronization controller The SYNC-controller works as a

PT1 compensator for optimized controlling of hydraulic drives. The parameter T1 effects a delayed action

of the SYNC Controller. The stability of the compensator could be increased in critical cases with the up

streamed T1 Filter.

In

SDD-mode

distance is calculated internally. In short braking distance, the high gain is calculated.

is specified with GLP, the braking distance in mm. The gain will depend on the stopping

In the case of instability should be given a longer stopping distance.

In

NC-mode

In this mode, the loop gain is entered.

parameters of the GL: V0 is in s-1 (1 / s) specified.

The parameter GL: T1 causes a delayed action of the synchronized controller. The stability of the controller can be increased by the upstream T1-filter in critical cases.

The GL:E command defines a monitoring window in which the GL-Error message is displayed. The monitoring window is placed centrally on the required position value. The actual position value within this window is signalled by the GL-Error message at the status output (see signal description PROFIBUS). The

positioning process is not influenced by this message. The control remains active.

Master/Slave

Profibus

w

x2

x1

Rampfunction

Page 30 of 45 POS-124-*-PDP-1121 13.02.2013

w

x2

x1

xw

-

-

xk2

A:A, A:B

D:A, D:B

GL:P, GL:V0

GL:T1

u2

Page 31

W.E.ST.

Elektronik GmbH

5.2.26 HAND1 / HAND2 (Manual speed)

Command

HAND1:I X

HAND2:I X

The manual speeds are set with these parameters. Entering the speed and direction at will enables any

switch input to be assigned.

The drive moves in a controlled manner in the defined direction when the manual signal is active. After

the manual signal has been disabled, the drive remains under closed loop control in the current position.

In the event of a fault (position sensor fault) the drive can still be moved with the manual function. The

output is zero after the manual signals have been disabled.

The manual speed is limited by the speed demand (MIN evaluation) via the Profibus.

Parameters

i= A|B

x= -10000… 10000

Unit

0,01%

0,01%

Group

STD

Page 31 of 45 POS-124-*-PDP-1121 13.02.2013

Page 32

W.E.ST.

Elektronik GmbH

5.2.27 MIN / MIN2 (Overlap compensation)

5.2.28 MAX1 / MAX2 (Limitation)

5.2.29 TRIGGER (Response threshold for the MIN parameter)

Command

MIN1:I X

MAX1:I X

TRIGGER1 X

MIN2:I X

MAX2:I X

TRIGGER2 X

Parameters

i= A|B

x= 0… 6000

x= 3000… 10000

x= 0… 4000

x= 0… 6000

x= 3000… 10000

x= 0… 4000

Unit

-

0,01%

0,01%

0,01%

0,01%

0,01%

0,01%

Group

STD

The output signal to the valve is adjusted by means of these commands. A kinked volume flow characteristic is used instead of the typical overlap step for the position controls. The advantage is better and more

stable positioning behaviour. At the same time, non linear volume flow characteristics can also be adjusted with this compensation8.

CAUTION: If there should also be adjustment options for dead zone compensation on

the valve or valve amplifier, it must be ensured that the adjustment is performed either at

the power amplifier or in the module.

If the MIN value is set too high this has an effect on the minimum speed, which can then

no longer be adjusted. In extreme cases this leads to oscillation around the controlled

position.

MAX:A

flow linearization

Output

standard deadband compensation

MIN:A

Input

MIN:B

MAX:B

TRIGGER value

8

Various manufacturers have valves with a defined linear curve: e.g. a kink at 40 or 60 % (corresponding to 10% input signal) of the nominal volume flow. In this case the TRIGGER value should be set to 1000 and the MIN value to

4000 (6000).

If zero lapped or slightly underlapped valves are used, the volume flow gain in the zero range (within the underlap) is

twice as high as in the normal working range. This can lead to vibrations and jittery behaviour. To compensate for

this, the TRIGGER value should be set to approximately 200 and the MIN value to 100. The gain in the zero point is

thus halved and a higher overall gain can often be set.

Page 32 of 45 POS-124-*-PDP-1121 13.02.2013

Page 33

W.E.ST.

Elektronik GmbH

5.2.30 OFFSET1 / OFFSET2 (Zero correction)

Command

OFFSET1 X

OFFSET2 X

Parameters

x= -4000… 4000 0,01%

Unit

Group

STD

This parameter is entered in 0.01% units.

The offset value is added to the control element signal at the output. Control element (valve) zero offsets

can be compensated with this parameter.

5.2.31 INPOS:S1 / INPOS:S2 (In position window)

Command

INPOS:S1 X

INPOS:S2 X

This parameter is entered in µm.

The INPOS:S command defines a monitoring window in which the INPOS:S message is displayed. The

monitoring window is placed centrally on the required position value. The actual position value within this

window is signalled by the INPOS:S message at the status output (see signal description PROFIBUS).

The positioning process is not influenced by this message. The control remains active.

Parameters

x= 2… 10000 µm

Unit

Group

STD

5.2.32 INPOS:D1 / INPOS:D2 (following error window)

Command

INPOS:D1 X

INPOS:D2 X

This parameter is entered in µm.

The INPOS:D command defines a monitoring window in which the INPOS:D message is displayed. The

monitoring window is placed centrally on the required position value. The actual position value within this

window is signalled by the INPOS message at the status output (see signal description PROFIBUS). The

positioning process is not influenced by this message. The control remains active.

In NC Mode this message is used to monitor the following error (depending on the parameterisation).

Parameters

x= 2… 100000 µm

Unit

Group

STD

Page 33 of 45 POS-124-*-PDP-1121 13.02.2013

Page 34

W.E.ST.

Elektronik GmbH

5.2.33 PROCESS DATA (Monitoring)

Command

WA1/WA2

W1/W2

X1/X2

XD1/XD2

XK2

V1/V2

U1/U2

Parameters

Actual command position axis 1 / 2

External command position axis 1 / 2

Feedback positon axis 1 / 2

Control error axis 1 / 2

Synchronisation error at axis 2

Speed set point 1 / 2

Control signal axis 1 / 2

Unit

0,01 mm

0,01 mm

0,01 mm

0,01 mm

0,01 mm

0,01 %

0,01 %

The process data are the variables which can be continuously observed on the monitor or on the oscilloscope.

Page 34 of 45 POS-124-*-PDP-1121 13.02.2013

Page 35

W.E.ST.

Elektronik GmbH

6 Appendix

6.1 Failure monitoring

Following possible error sources are monitored continuously:

Source Fault Characteristic

Command signal PIN 13

4... 20 mA

Feedback signal PIN 14

4… 20 mA

SSI-VERSION

Sensor value

EEPROM

(at switching on)

CAUTION: Take care of the EOUT command. Changes will influense the behaviour.

Out of range or broken wire. The output will be switched off.

Out of range or broken wire. The output will be switched off.

Out of range or broken wire. The output will be switched off.

Data error The output is deactivated.

The module can be activated by

saving new parameters (pressing of the SAVE Button).

6.2 Troubleshooting

It is assumed that the device is in an operable state and there is communication between the module and

the WPC-300. Furthermore, the valve control parametrisation has been set with the assistance of the

valve data sheets.

The RC in monitor mode can be used to analyse faults.

CAUTION: All safety aspects must be thoroughly checked when working with the RC (Remote Control) mode. In this mode the module is controlled directly and the machine control

cannot influence the module.

FAULT CAUSE / SOLUTION

ENABLE is active, the

module does not respond, and the READY

LED is off.

Page 35 of 45 POS-124-*-PDP-1121 13.02.2013

There is presumably no power supply or the ENABLE signal (PIN 8) or ENABLE signal via Profibus is not present.

If there is no power supply there is also no communication via our operating program. If a connection has been made to the WPC-300, then a power supply is also

available

If the power supply exists, an attempt should be made to see whether the system

can be moved by means of the HAND+ and HAND- signals (measuring the output

signal to the valve helps).

Page 36

W.E.ST.

Elektronik GmbH

ENABLE is active, the

READY LED is flashing.

ENABLE is active; the

READY LED is on, the

system moves to an

end position.

ENABLE is active, the

READY LED is on, the

STATUS LED is not

flashing, the system

moves to the target position but doesn’t reach

it (positioning error).

ENABLE is active, the

READY LED is on, and

the system oscillates on

the spot.

Speed too low

Speed too high

The flashing READY LED signals that a fault is been detected by the module. The

fault could be:

• A broken cable or no signal at the input (PIN 10/9 or PIN 14/13), if 4… 20

mA signals are parametrised.

• Internal data error: press the command/SAVE button to delete the data er-

ror. The system reloads the DEFAULT data.

With the WPC-300 operating program the fault can be localised directly via the monitor.

The control circuit polarity is incorrect. The polarity can be changed with the POL

command or by reversing the connections to PIN 15 and PIN 16 or

PIN 19 and PIN 20.

Serious positioning errors can result from incorrect parametrisation or incorrect system design.

• Is the cylinder position specified correctly?

• Are the deceleration distances correct (to start the system the deceleration

distances should be set to approx. 20… 25 % of the cylinder position9)?

• Is the valve a zero lapped control valve or a standard proportional valve?

In the case of a proportional valve, the valve overlap which may be present

should be compensated for with the MIN parameters. Typical values are to

be found in the valve data sheet.

The system is working and also actuating the valve.

Various potential problems could be:

• The parametrisation is not yet adjusted to the system (gain too high).

• There is severe interference on the power supply.

• Very long sensor cables (> 40 m) and sensor signal interference.

• The MIN setting to compensate the valve overlap is too high.

As a basic principle, the parametrisation of the sensor data and the controller settings must be carried out first (before switching on). An incorrect demand is equivalent to incorrect system design which then leads to incorrect operation. If the system

oscillates, the gain should first be reduced (longer deceleration distances for D:A and

D:B) and in the case of overlapped valves the MIN parameter should also be reduced.

The drive may be able to move to position but the speed is too low.

• Check the control signal to the valve.

• Via the integrated oscilloscope (U variable).

• Measure the signal to the valve with an external oscilloscope /

voltmeter.

• If the control is within the range of ± 100% (± 10V), the fault must be sought

in the hydraulics.

• If the control signal is relatively low, the following points should be checked:

• Is the internal/external speed signal limiting the speed?

• Which setting has been specified for the deceleration distance in

relation to the POSITION?

The drive should move to position. The drive moves in and out too fast leading to uncontrolled behaviour. Reducing the speed (MAX or VELO parameter) has very little

or no effect.

• The hydraulic system is over-sized. The entire parametrisation of the

movement cycle cannot be reproduced (overlap and deceleration distance

settings)

9

The stability criterion of the hydraulic axes must be taken into account.

Page 36 of 45 POS-124-*-PDP-1121 13.02.2013

Page 37

W.E.ST.

Elektronik GmbH

6.3 Description of the command structure

The command structure:

[nnnn:i x] or

[nnnn x]

Meaning:

nnnn - used for an arbitrary command name

nnnn: - used for an arbitrary command name, expandable by an index.

i oder I - a dummy is for the index. E. g. an index can be „A“ or „B“, depending on the direction.

x - parameter value, in case of special commands more than one parameter are possible.

Examples:

MIN:A 2000 nnnn = “MIN”, i = “A” and x = “2000”

OFFSET 50 nnnn = „OFFSET“ and x = „50“

C:IC 2000 nnnn = “C”, i = “IC” and x = “2000”

Page 37 of 45 POS-124-*-PDP-1121 13.02.2013

Page 38

W.E.ST.

Elektronik GmbH

7 Profibus DP interface

7.1 Profibus functions

The module supports all baud rates from 9,6 kbit/s up to 12000 kbit/s with auto detection of the baud rate.

The functionality is defined in IEC 61158. The Profibus address can be programmed by a terminal program, WPC-300 or online via the Profibus. A diagnostic LED indicates the online status.

7.2 Installation

A typical screened Profibus plug (D-Sub 9pol with switchable termination) is mandatory. Every Profibus

segment must be provided with an active bus termination at the beginning and at the end. The termination is already integrated in all common Profibus plugs and can be activated by DIL switches. The Profibus cable must be screened. PIN 17 have to be connected with PE (low impedance).

7.3 GSD Configuration File

The GSD data are available on our homepage: http://www.w-e-st.de/files/software/hms_1810.gsd

The communication parameters are 16 bytes (8 words) for IN/OUT variables.

Page 38 of 45 POS-124-*-PDP-1121 13.02.2013

Page 39

W.E.ST.

Elektronik GmbH

7.4 Description Profibus DP interface

The resolution (data via Profibus) of the command position is defined in µm (0,001 mm) independent on

the real sensor resolution.

The scaled speed is defined by 0x3fff (16373) for 100% of the maximum programmed speed.

The module will be controlled by the control word, with the following bits:

• ENABLE1 (2): Must be activated in addition to the hardware signal

• START1 (2): the new command position is taken over by a signal change from low to high (from

0 to 1). By deactivation of this bit, the system stops via a programmed deceleration ramp or held

controlled in target position.

• HANDA1 (2): Manual mode, speed and direction on internal parameters "HAND1 (2): A". If the

velocity is limited by the command velocity, only the maximum command velocity can be used

for movement

• HANDB1 (2): Manual mode, speed and direction on internal parameters "HAND1 (2): B". If the

velocity is limited by the command velocity, only the maximum command velocity can be used

for movement

• GL: Activation of synchronism, synchronization of axis 2 to axis 1.

• DIRECT: The target position is directly overtaken (not just on the leading edge of the START

signal). This bit applies to both axes.

Command values:

• Command position1 (2): In positioning mode this is the target position, which is approached

with "START".

• Command velocity1 (2): 100 % corresponds to 0x3fff. To traverse the axes a default value

(even in manual mode) is necessary.

Feedback of the status words and the actual positions:

• READY1 (2): System is ready. If the sensor monitoring is enabled, a sensor fault will disable the

READY signal.

• INPOS1:S (2): In position window. This bit is used for display only (no effect)

• INPOS1:D (2): Following error window. This bit is used for display only (no effect)

• GL-ERROR: the synchronization error is displayed dependent on the parameter "GL: E". This

bit is used for display only (no effect).

• Feedback position1 (2): corresponding to the current position in µm (0.001 mm) of the respec-

tive axis.

Page 39 of 45 POS-124-*-PDP-1121 13.02.2013

Page 40

W.E.ST.

7.5 Commands via PROFIBUS

7.5.1 Command map

16 data bytes are sent to the module.

Elektronik GmbH

Nr. Byte

1 0 Control word Hi

2 1 Control word Lo

3 2 Command position axis 1 Hi

4 3 Command position axis 1

5 4 Command position axis 1

6 5 Command position axis 1 Lo

7 6 Velocity axis 1 Hi

8 7 Velocity axis 1 Lo

9 8 Command position axis 2 Hi

10 9 Command position axis 2

11 10 Command position axis 2

12 11 Command position axis 2 Lo

13 12 Velocity axis 2 Hi

14 13 Velocity axis 2 Lo

15 14

16 15

Function

unsigned int

Signal resolution independent

on the real sensor resolution

1 µm (0,001 mm)

Signal range = 0x3fff (16373)

= 100 % of the nominal speed

Signal resolution independent

on the real sensor resolution

1 µm (0,001 mm)

Signal range = 0x3fff (16373)

= 100 % of the nominal speed

Remake

Page 40 of 45 POS-124-*-PDP-1121 13.02.2013

Page 41

W.E.ST.

7.5.2 Definition of the control bits:

Byte 0 – Control word Hi-Byte

Nr. Bit Function

Elektronik GmbH

1 0 DIRECT

2 1 GL

3 2 HandB1

4 3 HandA1

5 4 -

6 5 -

7 6 START1

8 7 ENABLE1

Bit for direct control of the commando position. If this bit is set,

every change of the command position is taken over as a new

command position.

This bit is used for both axes.

1: Axis B is synchronized. HANDB2, HANDA2 and START2

are inactive.

0: Both axis working independently.

1: Manual speed B is active. START must be inactive.

0: OFF

1: Manual speed A is active. START must be inactive.

0: OFF

0: No new command position can be send

0-1: Signal change from 0 to 1; the new command position is

taken over.

1: Positioning mode is active. In case of DIRECT = 1 new

command positions can be sending continuously.

1-0: Signal change from 1 to 0; an emergency stop ramp is calcu-

lated and the positioning process is stopped via this ramp.

1: Axis is active (together with hardware enable)

0: Axis is inactive, output is OFF.

Nr. Bit Function

1 0 -

2 1 -

3 2 HandB2

4 3 HandA2

5 4 -

6 5 -

7 6 START2

8 7 ENABLE2

Byte 1 – Control word Lo-Byte

-

-

1: Manual speed B is active. START must be inactive.

0: OFF

1: Manual speed A is active. START must be inactive.

0: OFF

0: No new command position can be send

0-1: Signal change from 0 to 1; the new command position is

taken over.

1: Positioning mode is active. In case of DIRECT = 1 new

command positions can be sending continuously.

1-0: Signal change from 1 to 0; an emergency stop ramp is calcu-

lated and the positioning process is stopped via this ramp.

1: Axis is active (together with hardware enable)

0: Axis is inactive, output is OFF.

Page 41 of 45 POS-124-*-PDP-1121 13.02.2013

Page 42

W.E.ST.

7.6 DATA send to PROFIBUS

7.6.1 Feedback map

Totally, 16 Bytes will be sent to the Profibus.

Elektronik GmbH

Nr. Byte