Page 1

User Manual

Relay C

3PH from 60A to 210A

Rev. 01/2019

PMA-C3-60-210A

www.west-cs.co.uk

Page 2

A publication of:

PMA

Prozeß- und Maschinen-Automation GmbH

P.O.Box 310 229 • D-34058 Kassel • Germany

All rights reserved.

No part of this document may be reproduced or published in any form or by any means without

prior written permission from the copyright owner.

Liability and warranty

Any information and notes in these operating instructions were composed under consideration of

the applicable regulations, the present state of the art and our extensive know-how and experience.

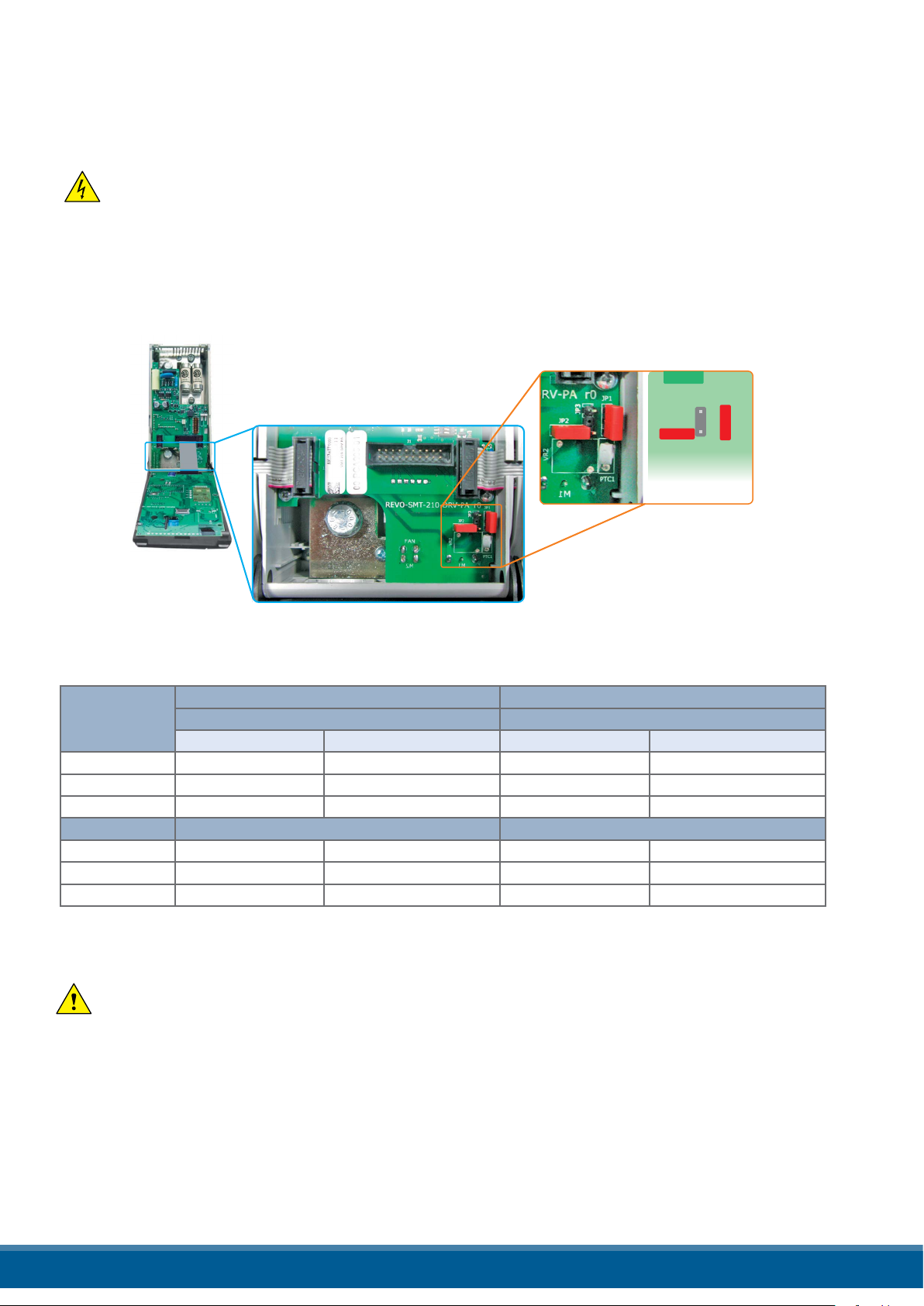

With special versions, additional ordering options or due to the latest technical modications, the

actual scope of delivery may vary from the descriptions and drawings in this manual.

For questions, please, contact the manufacturer.

Before starting to work with the instrument and before commissioning, in particular, these

operating instructions must be read carefully! The manufacturer cannot be held responsible

for damage and trouble resulting from failure to comply with the information given in this

manual.

This product may be subject to change due to improvements of the product features in the

course of further development.

Copyright

This operating manual should be considered as condential information, intended only for persons

who work with the instrument.

Contraventions are subject to payment of damages. Further claims reserved.

www.west-cs.co.uk 2

Page 3

Contents

1. Important warnings for safety .............................................................................................................................. 5

2. Maintenance ........................................................................................................................................................... 10

3. Introduction ............................................................................................................................................................ 11

A thyristor unit is semiconductor device which acts as a switch formed by two thyristors in ant parallel. .... 11

3.1. Advantages compared with analog thyristor unit ........................................................................................... 11

3.2. Overview ............................................................................................................................................................. 12

4. Software Congurator ........................................................................................................................................... 13

Thyristor congurator software is free and is Thyristor congurator software is free and is .......................... 13

5. Quick Start ............................................................................................................................................................. 14

6. Basic Connections and sizing.............................................................................................................................. 15

7. Identication .......................................................................................................................................................... 16

7.1. Identication of the unit ..................................................................................................................................... 16

8. Order Code ............................................................................................................................................................. 17

8.1. Notes on the options: ......................................................................................................................................... 18

8.1.1 I LIMIT (CURRENT LIMIT) ............................................................................................................................... 18

8.1.2. Heaterbreak Alarm (HB) .................................................................................................................................... 18

8.1.3. Datalogger ......................................................................................................................................................... 18

8.1.4. Energy totalizer .................................................................................................................................................. 18

9. Technical specications ....................................................................................................................................... 19

9.1. General features ................................................................................................................................................. 19

9.2. Input features ...................................................................................................................................................... 19

9.3. Output features (power device)......................................................................................................................... 19

9.4. Fan Specication (only from 90 to 210A) ......................................................................................................... 19

9.5. Environmental installation conditions ............................................................................................................. 20

9.6. Derating curve .................................................................................................................................................... 20

9.7. Calculating ow capacity of the fan ................................................................................................................. 20

10. Installation............................................................................................................................................................ 21

10.1. Dimensions and weight ................................................................................................................................... 22

10.2. Fixing holes ........................................................................................................................................................ 22

11. Wiring instructions .............................................................................................................................................. 23

11.1. Terminal Positions ............................................................................................................................................ 23

11.2. Power Terminals ............................................................................................................................................... 23

11.3. Control Terminals ............................................................................................................................................. 24

11.3.1. Terminal block M1 ............................................................................................................................................ 24

11.3.2. Terminal block M3 ........................................................................................................................................... 24

11.4. Schematic .......................................................................................................................................................... 25

11.4.1 SSR Control Input Schematic .......................................................................................................................... 26

11.5 Connection Diagram for 3 phases ................................................................................................................... 27

12. Control Panel ...................................................................................................................................................... 28

12.1. Menu navigation ............................................................................................................................................... 29

12.2. Control Panel Led ............................................................................................................................................. 30

12.3. Displayed alarms .............................................................................................................................................. 30

12.4. Parameter list .................................................................................................................................................... 31

12.4.1 Operator Menu .................................................................................................................................................. 31

12.5 Setup Menu ........................................................................................................................................................ 32

12.5.2 Advanced Setup Menu ..................................................................................................................................... 32

12.5.3 Hardware Menu ................................................................................................................................................ 34

12.5.4. Communication Menu ..................................................................................................................................... 37

12.5.5 Monitoring Menu .............................................................................................................................................. 38

13. Using the Congurator ....................................................................................................................................... 41

13.1 Typical Uses ..................................................................................................................................................... 41

13.2 Communicating with Power Controllers ......................................................................................................... 41

13.3 Recipes ............................................................................................................................................................... 41

13.3.1 Upload a recipe ................................................................................................................................................ 41

13.3.2 Download a recipe............................................................................................................................................ 41

13.4 How To ................................................................................................................................................................ 41

13.4.1 Install and communication with the power controller ...................................................................................... 41

13.5 Using the Congurator ..................................................................................................................................... 42

13.5.1 To view or save a power controller’s settings ................................................................................................... 42

using “Simple” view section: ........................................................................................................................................ 42

13.5.2 To edit a setting in a recipe: ............................................................................................................................. 43

13.5.3 To download a recipe le into a power controller: ............................................................................................ 43

13.5.4 To monitor a power controller with the Test view: ............................................................................................ 43

www.west-cs.co.uk 3

Page 4

13.5.5 To log in on the test view to change the digital input and analog input functions: ............................................ 43

13.5.6 To log out the test view: .................................................................................................................................... 43

13.5.7 To view data on the scope: ............................................................................................................................... 44

13.5.8 To reset the power totals: ................................................................................................................................. 44

13.5.9 Setting Up and Using Data Logging ................................................................................................................. 44

13.5.10 To retrieve a data log le from the power controller: ...................................................................................... 45

13.6 Software General information .......................................................................................................................... 45

13.6.1 Program Window .............................................................................................................................................. 45

13.6.2 Simple Section ................................................................................................................................................. 45

13.6.3 Test Section ...................................................................................................................................................... 46

13.6.4. Load Analyzer .................................................................................................................................................. 48

13.6.5 Data Log Window ............................................................................................................................................. 49

13.6.6 Data Log Conguration window ....................................................................................................................... 49

13.6.7 MSG view ......................................................................................................................................................... 50

13.6.8 Settings window ............................................................................................................................................... 50

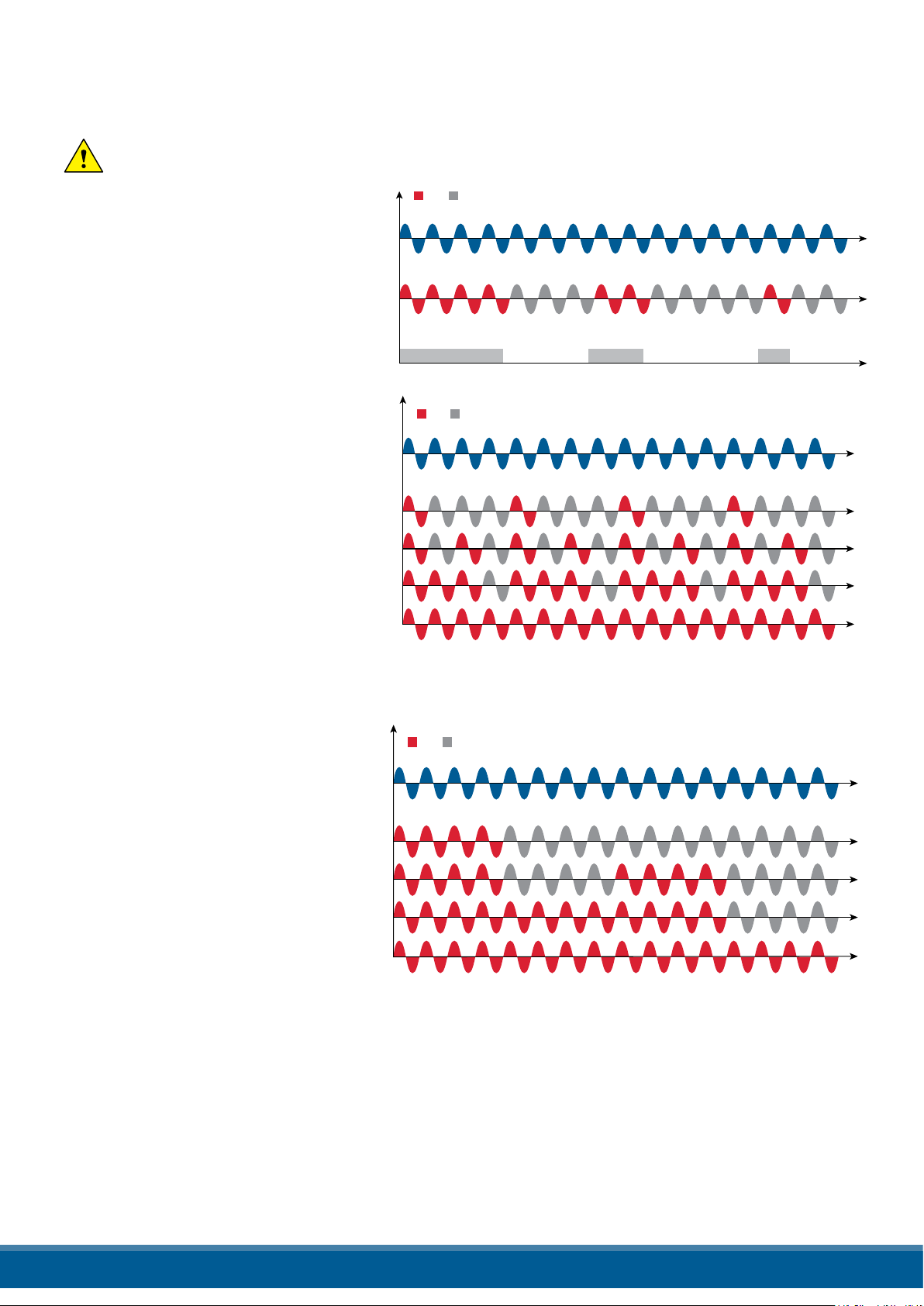

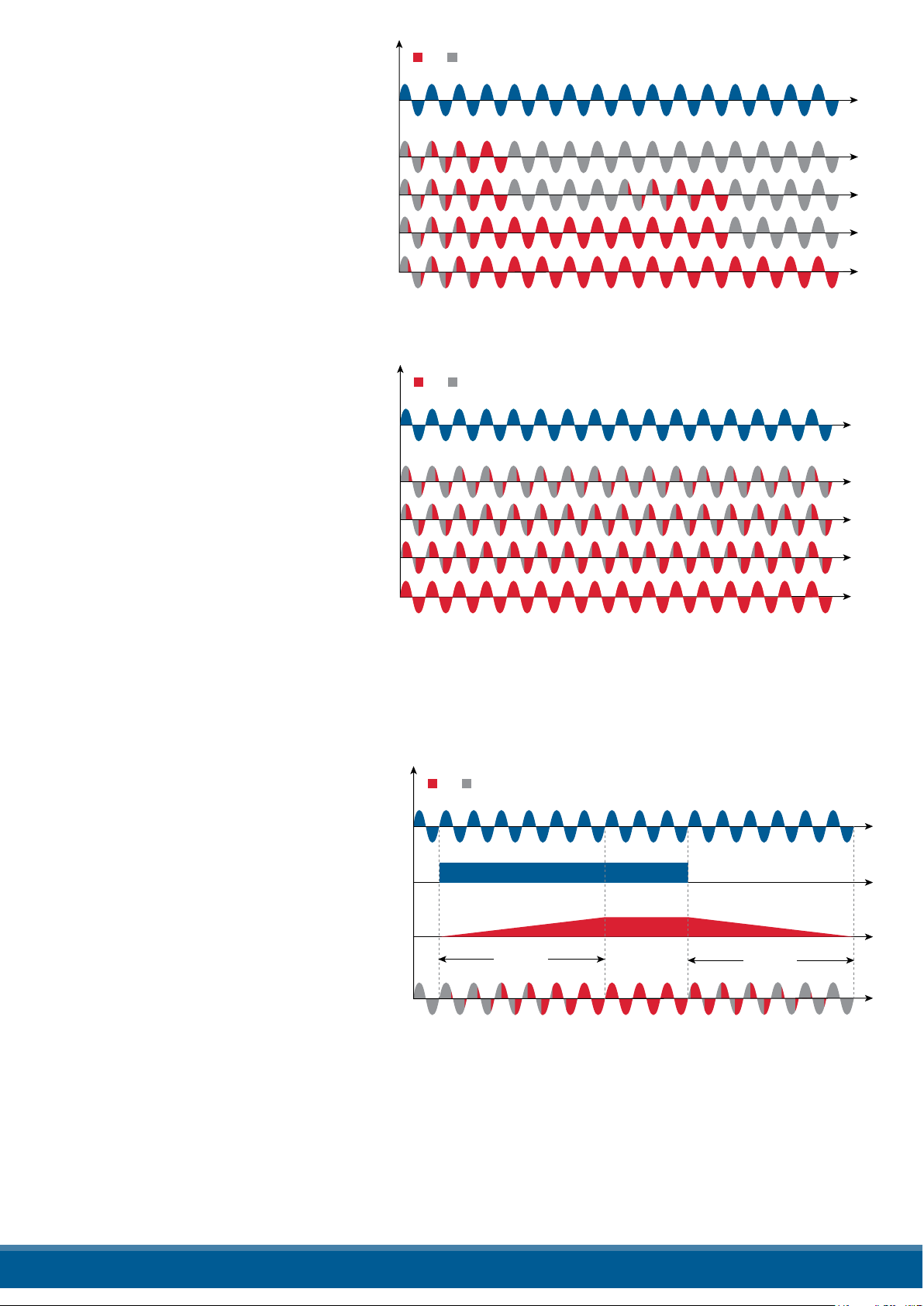

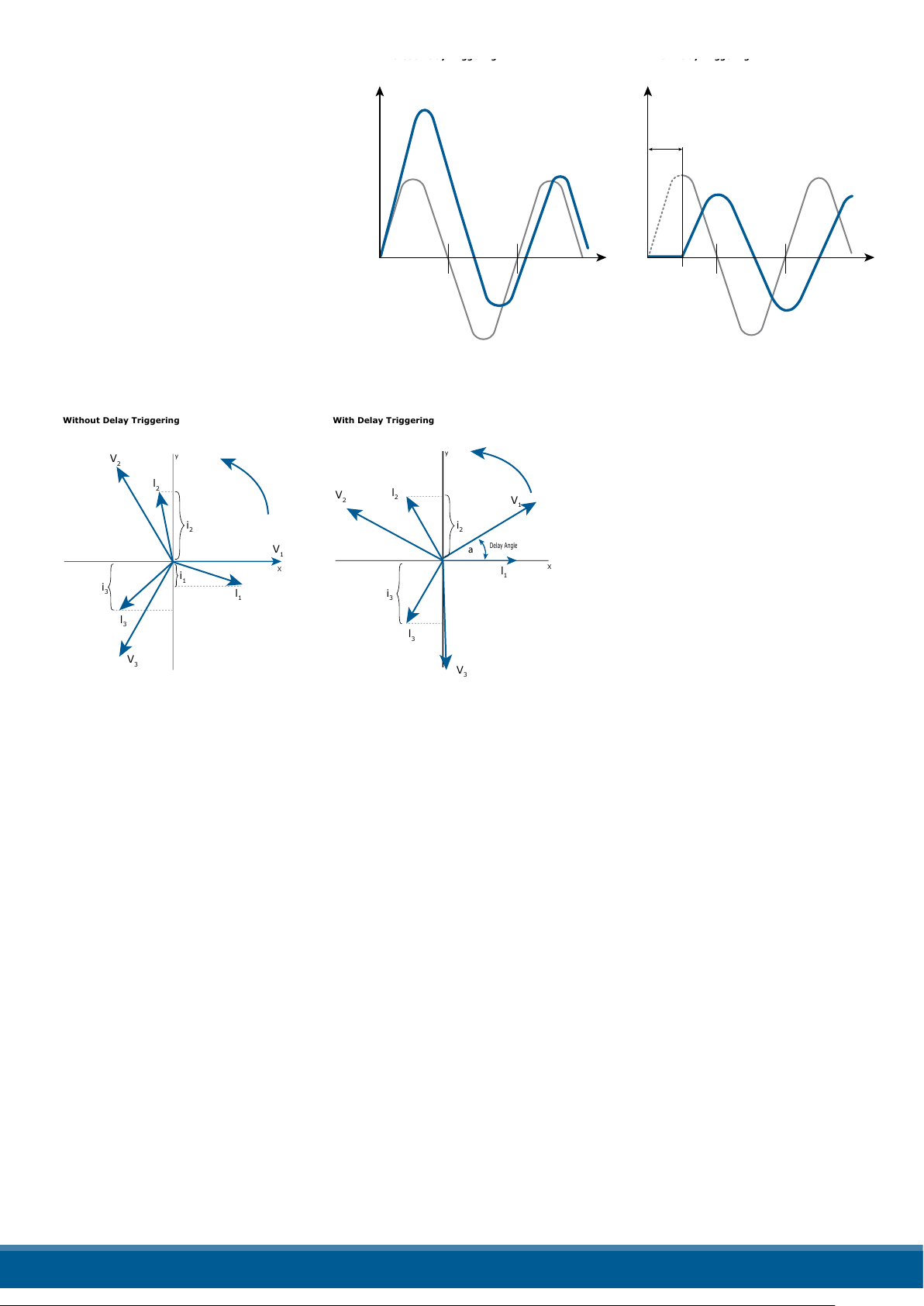

14. Firing type ............................................................................................................................................................ 51

14.1 Zero Crossing .................................................................................................................................................... 51

14.2 Single Cycle ....................................................................................................................................................... 51

14.3 Burst Firing ........................................................................................................................................................ 51

14.4 Soft Start with Burst Firing ............................................................................................................................... 52

14.5 Phase Angle ....................................................................................................................................................... 52

14.6 Soft Start with Phase Angle .............................................................................................................................. 52

14.7 Delay Triggering with Burst Firing ................................................................................................................... 53

15. Current Limit ........................................................................................................................................................ 54

15.1 Current Limit Setting ......................................................................................................................................... 54

15.2 Current Limit tuning procedure ....................................................................................................................... 54

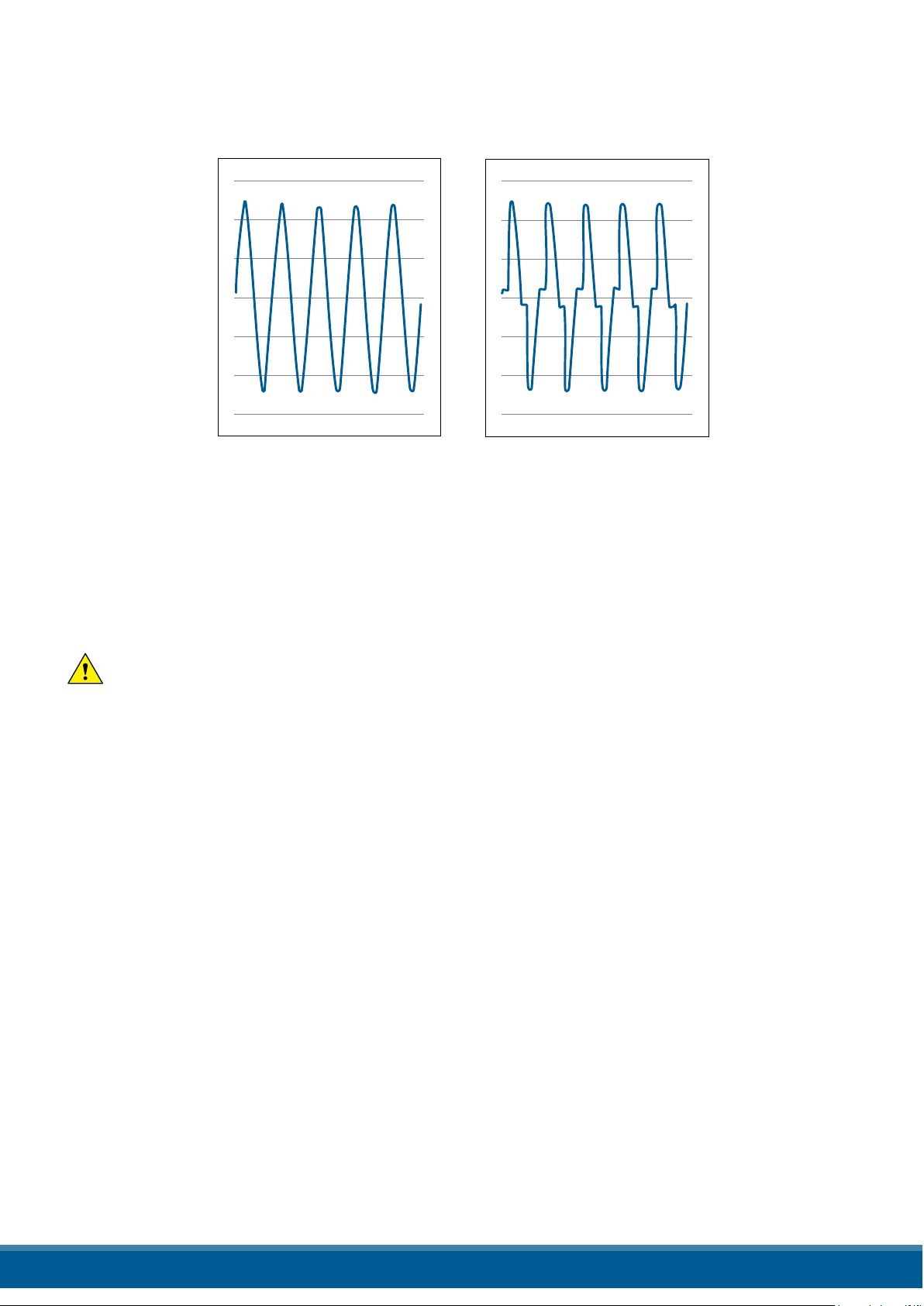

16. Bakeout in function ............................................................................................................................................. 55

16.1 What is heater bakeout? ................................................................................................................................... 55

16.2 How does heater bakeout work? ..................................................................................................................... 55

17. Control Mode (feed-back) ................................................................................................................................... 56

18. Supply the Electronic Board .............................................................................................................................. 57

19. RS485 Serial port ................................................................................................................................................. 58

20. Fieldbus communication option ....................................................................................................................... 58

21. Internal Fuse ........................................................................................................................................................ 59

www.west-cs.co.uk 4

Page 5

1. Important warnings for safety

IND. CONT. EQ.

E231578 2RD5

This chapter contains important information for the safety. The not observance of these instructions may result

in serious personal injury or death and can cause serious damages to the Thyristor unit and to the components

system included.

The installation should be performed by qualied persons.

In the manual are used symbols to give more evidence at the notes of safety and operativity for the attention

for the user:

This icon is present in all the operational procedures where the Improper operation may result in serious

personal injury or death by Electrical Shock Hazard Symbol (a lightning bolt in a triangle) precedes an

electric shock hazard CAUTION or WARNING safety statement.

Warning or Hazard that needs further explanation than the label on unit can provide. Consult User’s Guide

for further information.

Unit is compliant with European Union directives.

See Declaration of Conformity for further details on Directives and Standards used for Compliance.

If available, unit is a Listed device per Underwriters Laboratories. It has been investigated to ANSI/UL®

508 standards for Industrial Control Switches and equivalent to CSA C22.2 #14.

For more detail search for File E505847 on www.ul.com

ESD Sensitive product, use proper grounding and handling techniques when installing or servicing product.

Do not throw in trash, use proper recycling techniques or consult manufacturer for proper disposal.

www.west-cs.co.uk 5

Page 6

A “NOTE” marks a short message to alert you to an important detail.

A “CAUTION” safety alert appears with information that is important for protecting your equipment and performance.

Be especially careful to read and follow all cautions that apply to your application.

A “WARNING” safety alert appears with information that is important for protecting you, others and equipment

from damage. Pay very close attention to all warnings that apply to your application.

1.1. Safety notes

WARNING! To avoid damage to property and equipment, injury and loss of life, adhere to applicable electrical

codes and standard wiring practices when installing and operating this product. Failure to do so could result in

damage, injury and death.

WARNING! All service including inspection, installation, wiring, maintenance, troubleshooting, fuse or other user

serviceable component replacement must be performed only by properly qualied personnel. Service personnel

must read this manual before proceeding with work. While service is being performed unqualied personnel

should not work on the unit or be allowed in the immediate vicinity.

WARNING! When in use the power controller is connected to dangerous voltages. Do not remove the protective

covers without rst disconnecting and preventing power from being restored while servicing the unit.

WARNING! Do not use in aerospace or nuclear applications.

WARNING! The power controller’s protection rating is IP20 with all covers installed and closed. It must be

installed in an enclosure that provides all the necessary additional protections appropriate for the environment

and application.

WARNING! Ground the power controller via the provided protective earth grounding terminal. Verify ground is

within impedance specications. This should be veried periodically.

WARNING! Electric Shock Hazard: when the power controller has been energized, after shutting o the power,

wait at least one minute for internal capacitors to discharge before commencing work that brings you in to

contact with power connections or internal components.

WARNING! The installation must be protected by electromagnetic circuit breakers or by fuses. The

semiconductor fuses located inside the power controller are classied for UL as supplementary protection for

semiconductor devices. They are not approved for branch circuit protection.

WARNING! When making live voltage or current measurements, use proper personal protective equipment for

the voltages and arc-ash potentials involved.

WARNING! Verify the voltage and current ratings of the power controller are correct for the application.

www.west-cs.co.uk 6

Page 7

CAUTION: To avoid compromising the insulation, do not bend wire or other components beyond their bend

radius specications.

CAUTION: Protect the power controller from high temperature, humidity and vibrations.

CAUTION: The power controller warranty is void if the tested and approved fuses are not used.

CAUTION: Only trained and authorized personnel should access and handle the internal electronics and they

must follow proper electro-static prevention procedures.

CAUTION: Install an appropriately sized RC lter across contactor coils, relays and other inductive loads.

NOTE! Provide a local disconnect to isolate the power controller for servicing.

NOTE! The nominal current is specied for ambient temperatures at or below 40° C. Ensure the application

design allows for adequate cooling of each power controller. The power controller must be mounted vertically.

The cooling design must prevent air heated by one power controller from causing power controllers mounted

above to exceed the ambient operating temperature limit. When power controllers are mounted side by side

allow a minimum spacing of 15mm between them.

NOTE! Use only copper cables and wires rated for use at 90°C or greater.

www.west-cs.co.uk 7

Page 8

2. Maintenance

In order to have a corrected cooling, the user must clean the heat-sink and the protective grill of the fans. The frequency of this servicing depends on environmental pollution.

Also check periodically if the screw for the power cables and safety earth are tightened correctly

(See Connection Diagram).

www.west-cs.co.uk 8

Page 9

3. Introduction

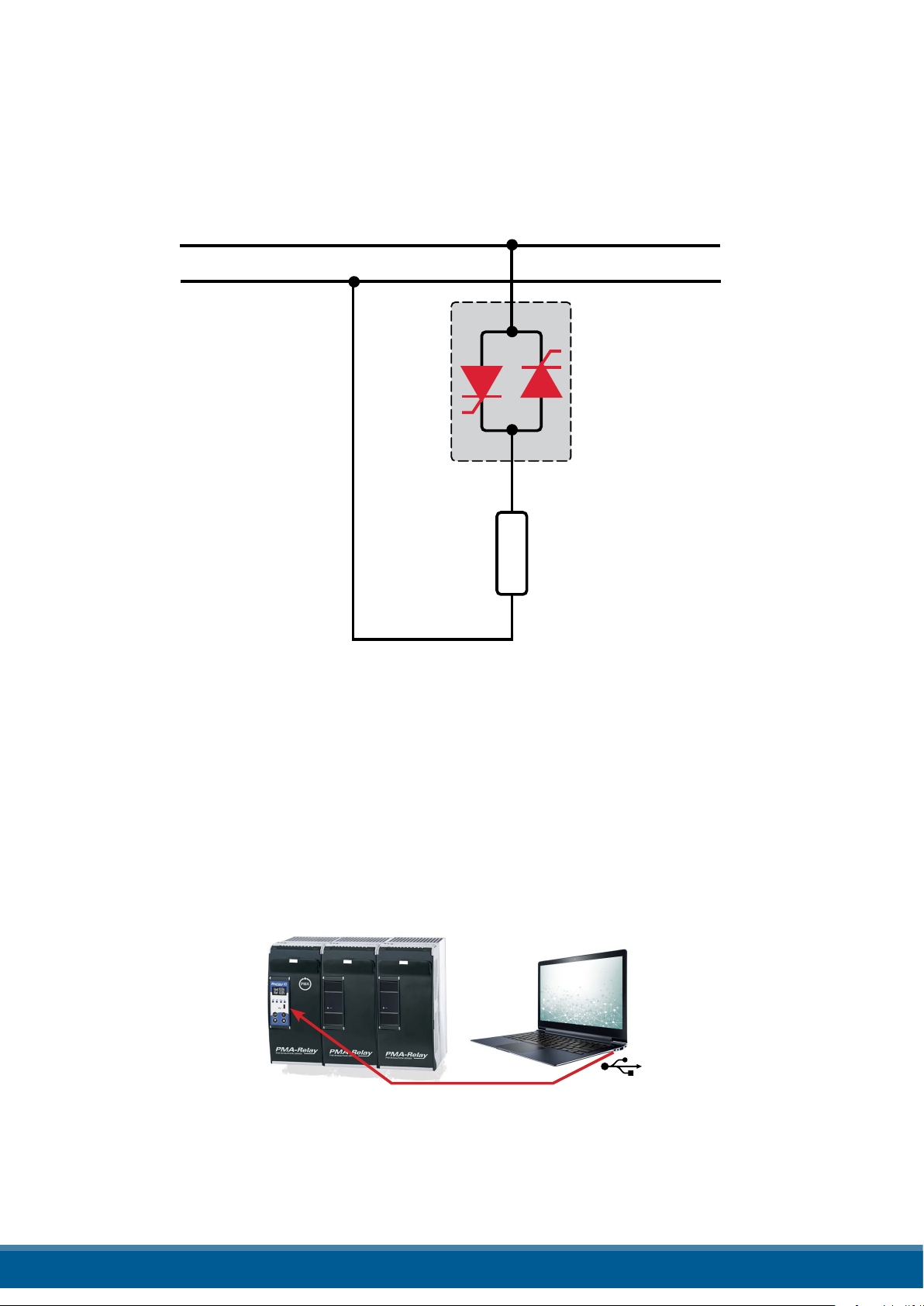

A thyristor unit is semiconductor device which acts as a switch formed by two thyristors in ant parallel.

To switch on the alternating current the input signal will be on and the thyristor will switch o at rst Zero Crossing

voltage with no input signal.

The benets of thyristor units compared with electromechanical contactors are numerous: no moving parts, no

maintenance and capacity to switch very fast. Thyristors are the only solution to control transformers and special

loads that change resistance with temperature and with age.

L1

L2

Thyristor

Load

3.1. Advantages compared with analog thyristor unit

Communication RS485 is a standard feature of Relay C. this allows the use of many information like: current, power,

load state and all the parameters for diagnostic and conguration. Ulterior advantages of the digital system vs the

analogical is the exibility and the possibility of implement special characteristics without change the hardware.

Several strategies can be implemented and selected through the conguration parameters.

With the software Thyristor Congurator, you can have access to the conguration parameters.

To connect the Thyristor unit to the computer use a micro USB cable.

www.west-cs.co.uk 9

Page 10

3.2. Overview

Heater bakeout

• Protects heater upon start up

• Eliminates labour and time associated with checking for wet heaters

Integrated semiconductor fusing, current transformer and user interface

• Saves installation time and eases setup and commissioning

• Delivers a user-friendly, intuitive interface

Industry-leading design and serviceability

• Oers a robust SCR design to meet a rugged industrial environment’s high quality and

reliability needs

• Provides quick and easy access to maintain and service fuses and individual legs

in minimal time

• Enables fast troubleshooting by providing helpful thermal system diagnostics

Comprehensive power controller range

• Provides wide range of options from simple single phase to complex three-phase loads to

69 0V.

100KA short circuit current rating (SCCR) (Not reviewed by UL®)

• Enables greater protection in the event of a short circuit

c-UL® 508 listed

• Shortens project schedules, agency testing and expenses

Control modes: contactor, voltage, current or power

• Satises a wide range of demanding thermal applications

Load ring modes: zero-cross, burst re, phase angle, soft start, single-cycle, delayed triggering

• Handles a wide range of load types including nichrome, medium and long waveform infrared

lamps, moly, transformers, silicon carbide, UV lamps and tungsten

• Protects and extends the life of connected loads

Wide range of communication protocols

• Enable factory and process automation with connectivity to process and equipment data via

Modbus® RTU, Modbus® TCP, Probus, Pronet, USB device (conguration and data le

transfers)

Open heater and shorted SCR indication

• Minimizes production downtime with easy to understand, intelligent, troubleshooting

diagnostics

Integrated USB and user interface for conguration

• Easily and safely program conguration settings as the user interface can be powered through

USB connection

• Eliminates need to work in a high voltage hazard environment. High voltage to the power

controller and system panel can be shut o and locked out for safety while conguring

controller.

www.west-cs.co.uk 10

Page 11

4. Software Congurator

Thyristor congurator software is free and is Thyristor congurator software is free and is

possible download it from our site.

If the Order Code is in line with requirement,

then unit has been already congured in

Factory and it’s ready to use.

You need the software only to modify the

ordered conguration. Anyway, we suggest

to check the unit on the machine with the

“Test unit” section.

For install the software, launch the program

and follow the instructions on the screen.

Run the software congurator and set the

correct serial port number by menu setting ->

Serial Port -> por t numbe r.

L/R EN Com AL

To connect the unit at the PC, it’s necessary to

use the micro USB 2.0 Modbus RTU cable.

USB connection need a driver to work properly,

you can nd it from our site.

However the conguration software installer will

install as default the correct driver.

Micro USB

www.west-cs.co.uk 11

Page 12

5. Quick Start

Attention: this procedure must be carried out by skilled people only.

If your Relay C code is in line with what you really need, then the main conguration is already done by Producer and

you just need to do the following steps:

1. Verify Relay C current sizing. Be sure that:

• the load current is equal or less than the nominal one of Relay C

• the main voltage is equal or less than the nominal voltage of Relay C

2. Verify the Installation

3. Verify the Wiring:

• all auxiliary connections must be done in line with wirings on this manual

• verify that there isn’t a short circuit on the load

4. Supply the auxiliary voltage of the unit in the Set menu

Set the parameters Operative Load Voltage and Nominal Current of the load using the frontal keypad or Thyristor con-

gurator software.

The auxiliary voltage supply of the Relay C unit must be synchronized with load voltage power supply.

If the Auxiliary Voltage (written on the identication label) is dierent from Supply Voltage (to the load), use an

external transformer.

If your Relay C code is NOT in line with what you really need, use the congurator software tool to set-up the

unit. Install the software on your PC, select Relay C and click on test unit changing what you need.

www.west-cs.co.uk 12

Page 13

6. Basic Connections and sizing

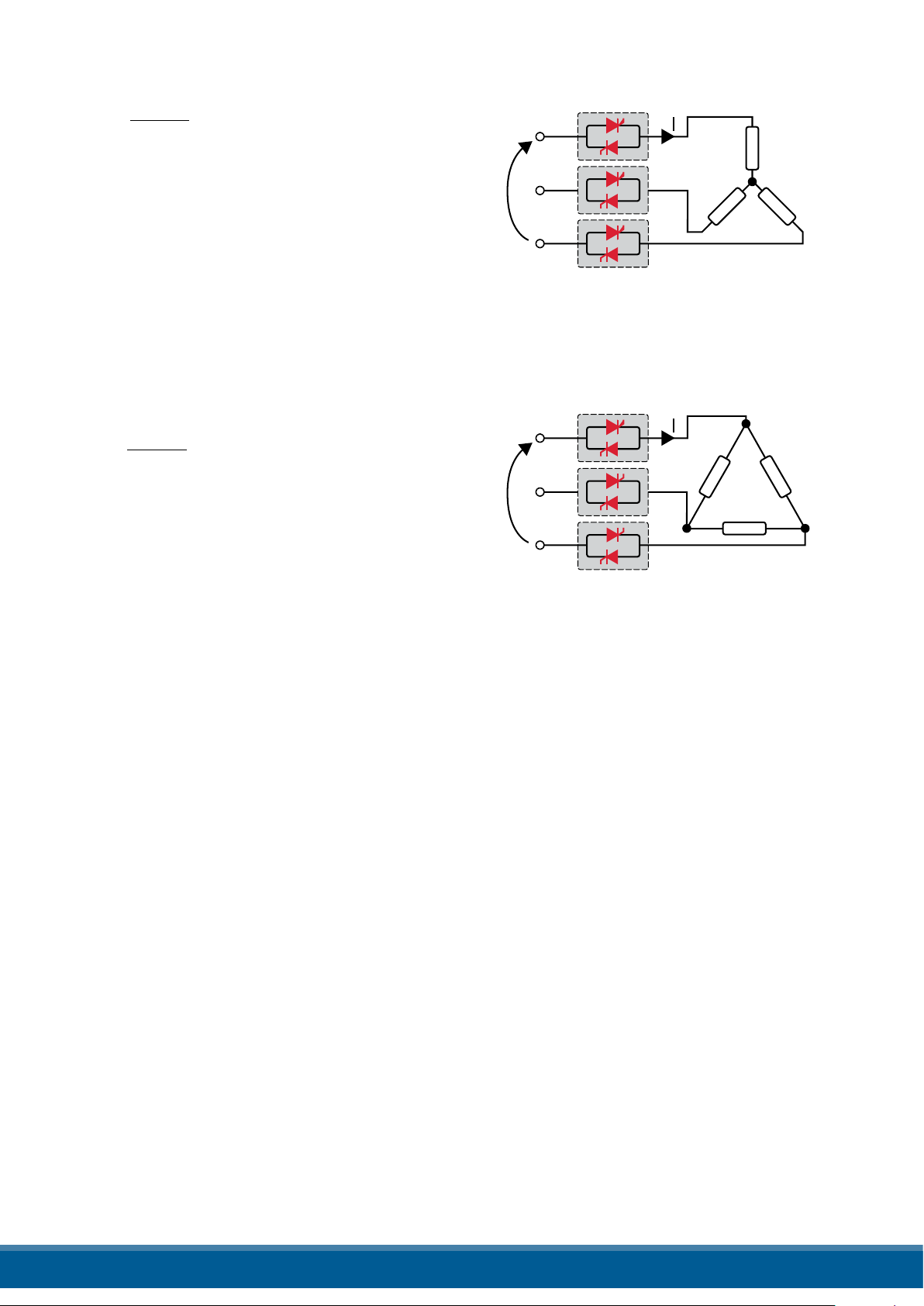

Star wiring with resistive load (control on two phases with PMA-Relay C-3PH)

P

I=

1,73V

V

V = Nominal voltage of the load

I = Nominal current of the load

P = Nominal power of the load

Delta wiring with resistive load (control on two phases with PMA-Relay C-3PH)

P

I=

1,73V

V

V = Nominal voltage of the load

I = Nominal current of the load

P = Nominal power of the load

www.west-cs.co.uk 13

Page 14

7. Identication

7.1. Identication of the unit

Caution: Before to install, make sure that the Thyristor unit have not damages. If the product has a

fault, please contact the dealer from which you purchased the product.

The identication’s label gives all the information regarding the factory settings of the Thyristor unit, this label is on the

unit, like represented in gure.

Verify that the product is the same thing as ordered.

www.west-cs.co.uk 14

Page 15

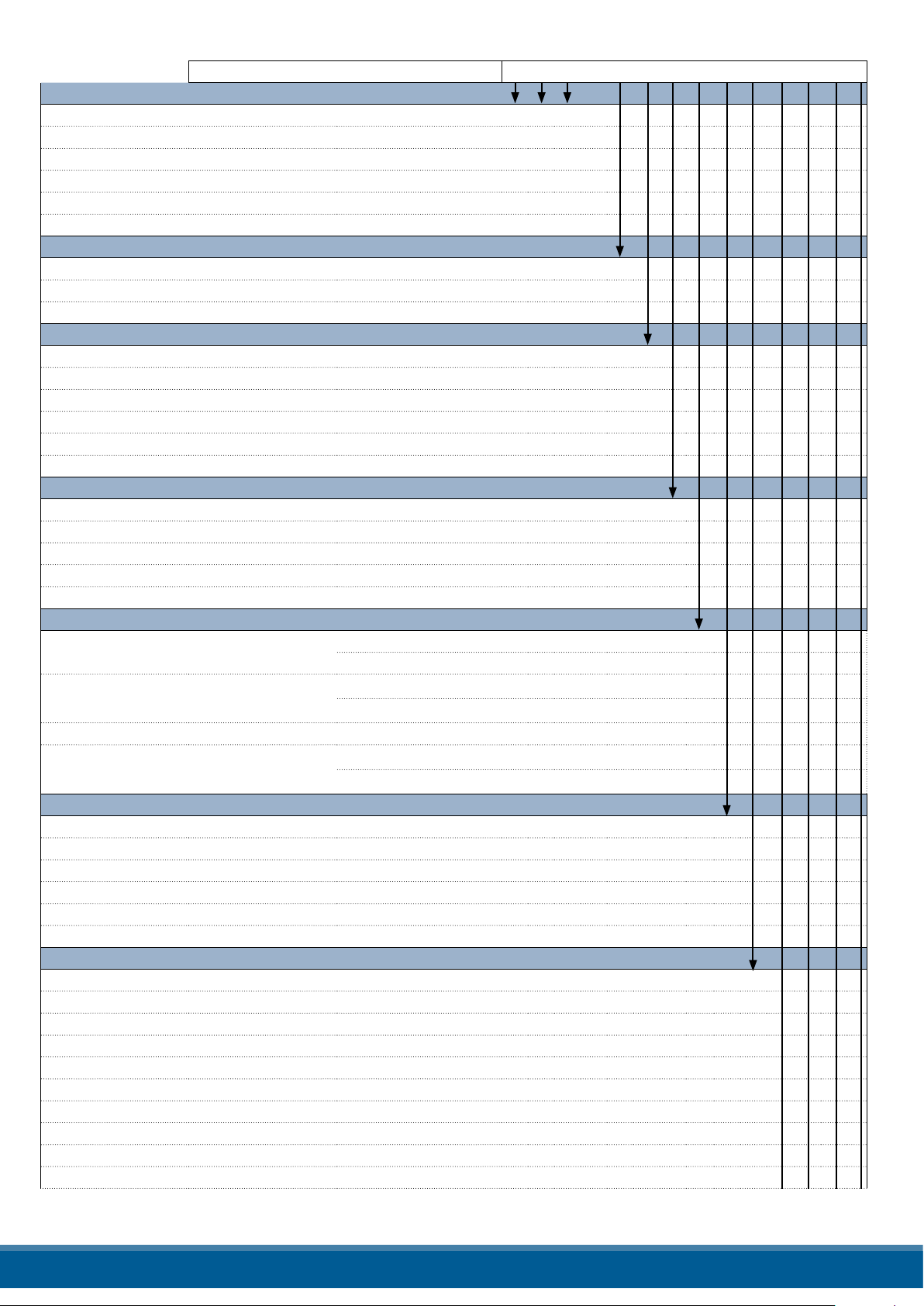

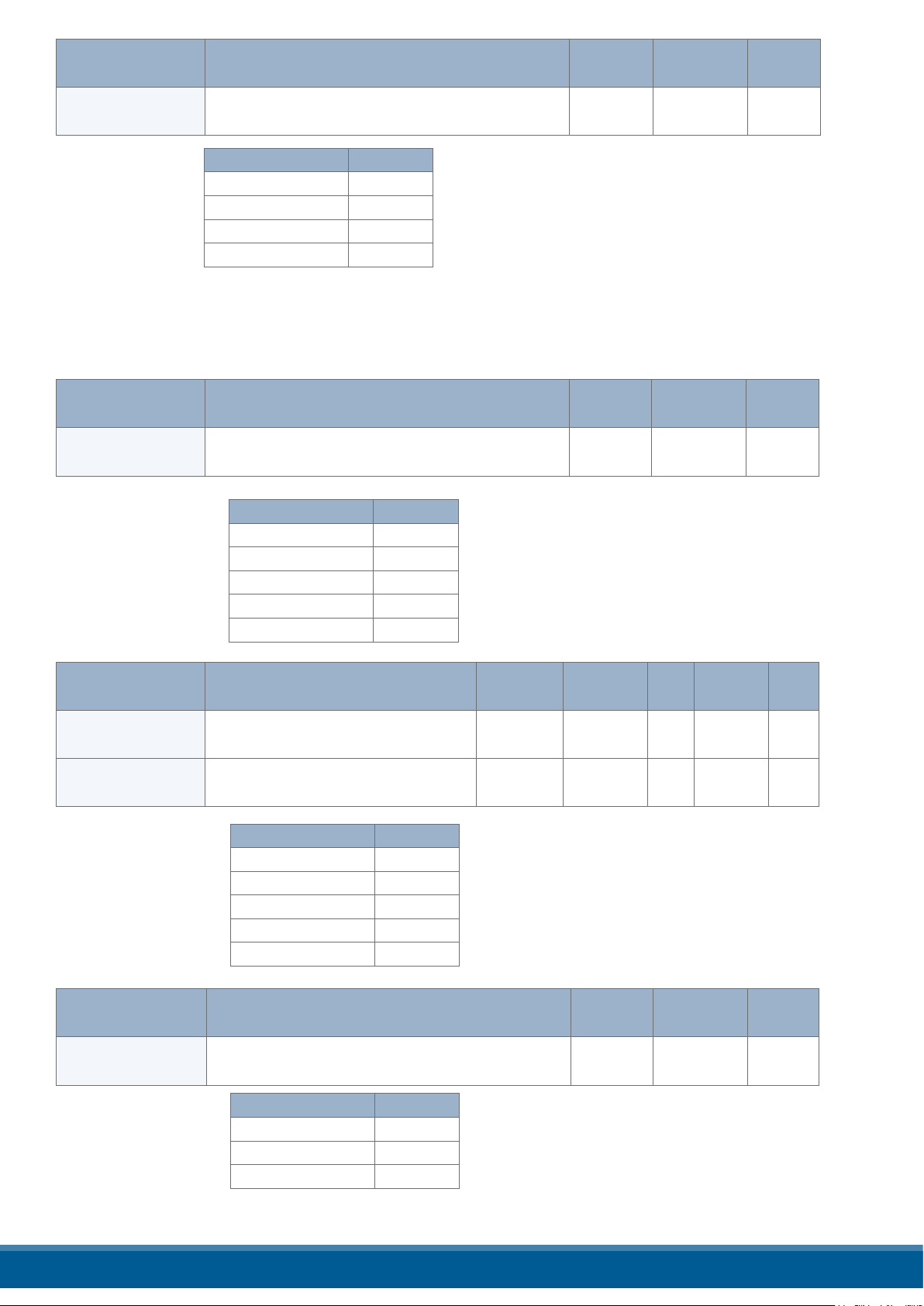

8. Order Code

RC3 x x x - x x x x x x x x x x

Current - Fuses

60 A - Fixed Fuses Included 0 6 0

90 A - Fixed Fuses Included 0 9 0

120 A - Fixed Fuses Included 1 2 0

150 A - Fixed Fuses Included 1 5 0

180 A - Fixed Fuses Included 1 8 0

210 A - Fixed Fuses Included 2 1 0

MAX VOLTAGE MAIN SUPPLY VOLTAGE 1*

480 V

600 V

690 V

MAIN SUPPLY VOLTAGE 1* Aux Voltage range

100/120 Vac

200/208/230/240 Vac

277 Vac

380/415/480 Vac

60 0 Vac

690 Vac 540 to 759 Vac

INPUT

SSR S

0:20 mA B

4:20 m A A

0:10 V (DC) V

10 kΩ potentiometer K

START OPTION

FIRING

Burst Firing (BF)

Phase Angle

Delayed Triggering No Soft Start D

Zero Crossing

CONTROL MODE

Open Loop O

Volt age U

Voltage Square U² Q

Current I

Current Square I² A

Power (U x I) W

OPTION

No Option 0

Energy totalizer 1

Datalogger 2

Datalogger + Energy totalizer 3

Heaterbreak Alarm (HB) 8

Heaterbreak Alarm (HB) + Energy totalizer 9

Heaterbreak Alarm (HB) + Datalogger A

Heaterbreak Alarm (HB) + Datalogger + Energy totalizer B

Current Limit G

Current Limit + Energy totalizer H

90 to 135 Vac

180 to 265 Vac

238 to 330 Vac

342 to 528 Vac

540 to 759 Vac

No soft start B

Linear Soft Starter J

No Soft Start P

Linear Soft Starter E

No soft start Z

Linear Soft Starter R

4

6

7

1

2

3

5

6

7

www.west-cs.co.uk 15

Page 16

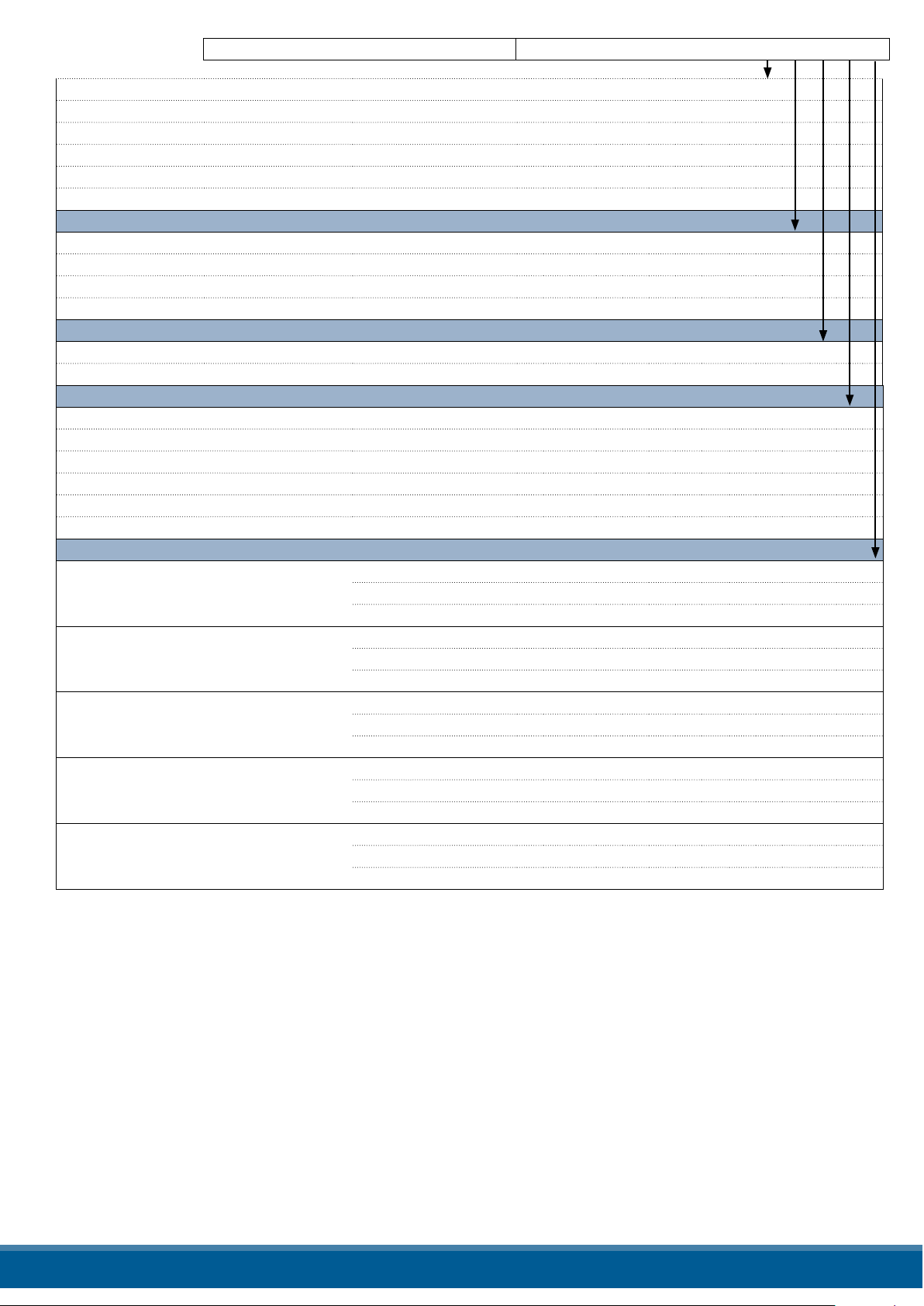

RC3 x x x - x x x x x x x x x x

Current Limit + Datalogger I

Current Limit + Datalogger + Energy totalizer J

Current Limit + Heaterbreak Alarm (HB) O

Current Limit + Heaterbreak Alarm (HB) + Energy totalizer P

Current Limit + Heaterbreak Alarm (HB) + Datalogger Q

Current Limit + Heaterbreak Alarm (HB) + Datalogger + Energy totalizer R

FAN VOLTAGE

No fan < 90A 0

Fan 110Vac (≥ 90A) 1

Fan 230Vac (≥ 90A) – standard version 2

24Vdc (≥ 90A) - standard version 3

APPROVALS

CE 0

cULus L

LOAD T YPE

Normal Resistive Load with 3 Phase Star with neutral Connection 0

Normal Resistive Load with 3 Phase Delta Connection 1

IRSW Infrared Short wave with 3 Phase Star Connection with neutral 2

IRSW Infrared Short wave with 3 Phase Delta Connection 3

3 Phase Transformer coupled with normal resistance 4

3 Phase Transformer coupled with cold resistance 5

COMMUNICATION AND RETRANSMISSION

No.1 Modbus RTU No Retransmission 0

Retransmission 4:20 mA 1

Retransmission 0:10 V 2

No.2 Modbus RTU No Retransmission 3

Retransmission 4:20 mA 4

Retransmission 0:10 V 5

No.2 Probus DP + No. 1 Modbus RTU No Retransmission 6

Retransmission 4:20 mA 7

Retransmission 0:10 V 8

No.2 Pronet + No. 1 Modbus RTU No Retransmission 9

Retransmission 4:20 mA

Retransmission 0:10 V

No.2 Modbus TCP + No. 1 Modbus RTU No Retransmission

Retransmission 4:20 mA

Retransmission 0:10 V

*1 Since the supply voltage of the electronics is used for synchronization, it must be in phase with the load voltage.

A

B

C

D

E

8.1. Notes on the options:

8.1.1 I LIMIT (CURRENT LIMIT)

This option is used to keep the overcurrent inside setted limit. It’s necessary to drive primary transformers and cold

resistance. This option is not available on 30-35-40A units.

8.1.2. Heaterbreak Alarm (HB)

HB Alarm for partial or total load failure and Short Circuit on SCR (relay output).

8.1.3. Datalogger

This feature is important to see the historical data of parameter like Current, Voltage and Power and can be useful to

diagnose a fault.

8.1.4. Energy totalizer

This function totalizes the energy consumption of the load allowing the calculation of heat treatment.

www.west-cs.co.uk 16

Page 17

9. Technical specications

9.1. General features

Cover and Socket

material

Utilization Category AC-51 AC-55b

IP Code 20

Method of Connecting Load in Delta, Load in Star

Auxiliary voltage Order Code RC3_ _ _-_1 = line voltage 100/120V voltage range 90:135V (8 VA Max)

Relay output for Heater Break Alarm

(only with HB option)

PolymericV2

Order Code RC3_ _ _-_2 = line voltage 200/208/220/230/240V voltage range 180:265V

(8 VA Max)

Order Code RC3_ _ _-_3 = line voltage 277 voltage range 238:330V (8 VA Max)

Order Code RC3_ _ _-_5 = line voltage 380/400/415/440/480V voltage range 342:528V

(8 VA Max)

Order Code RC3_ _ _-_6 = line voltage 600V voltage range 540:759V (8 VA Max)

Order Code RC3_ _ _-_7 = line voltage 690V voltage range 540:759V (8 VA Max)

0.5A a 125VAC

9.2. Input features

Analog Input V: 0 to 10 Vdc impedance 15 kΩ

Analog Input I: 4 to 20 mA Impedance 100 Ω

Potentiometer 10 kΩ min.

Digital Input 4 to 30Vdc 5mA Max (ON ≥ 4Vdc OFF < 1Vdc)

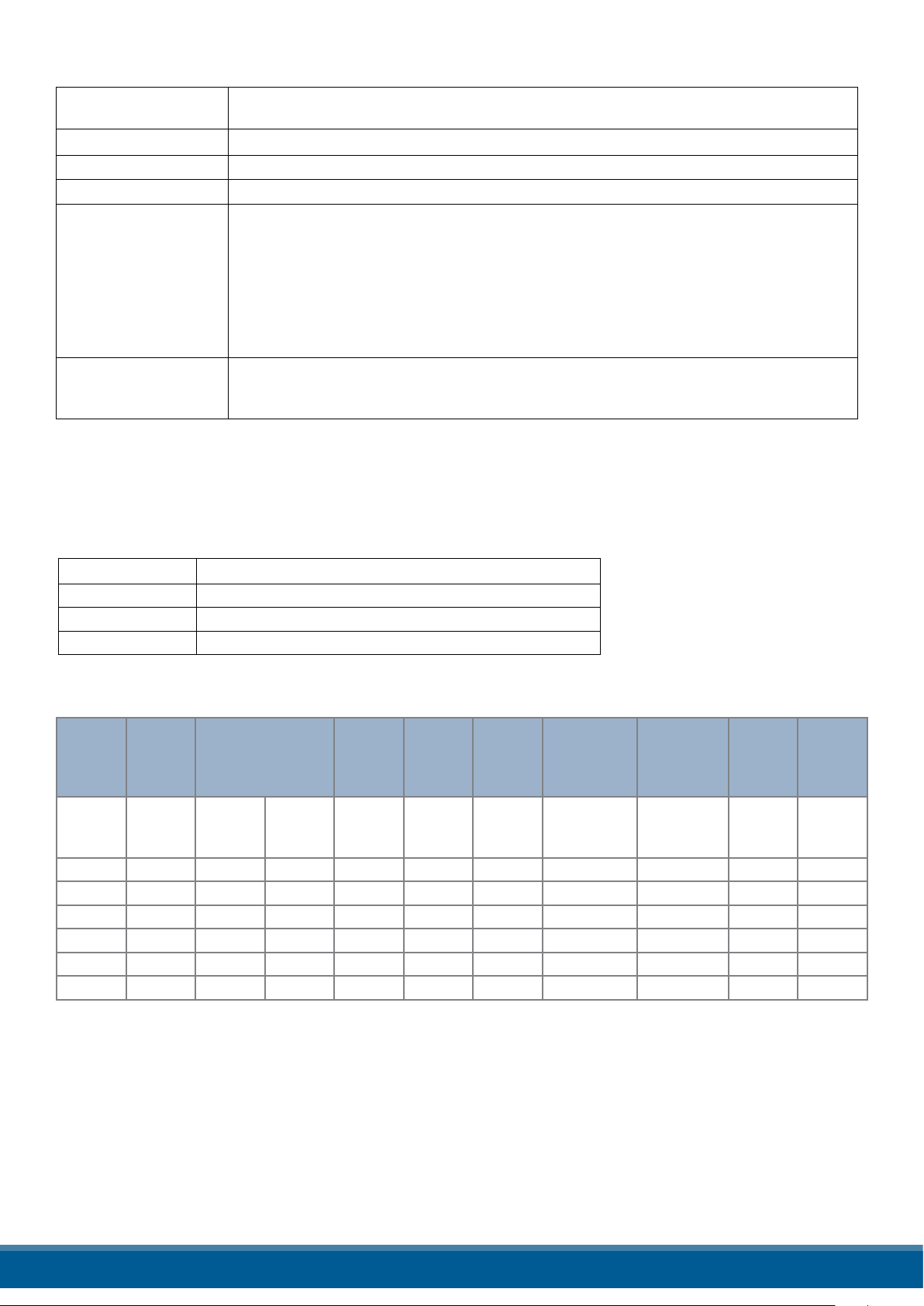

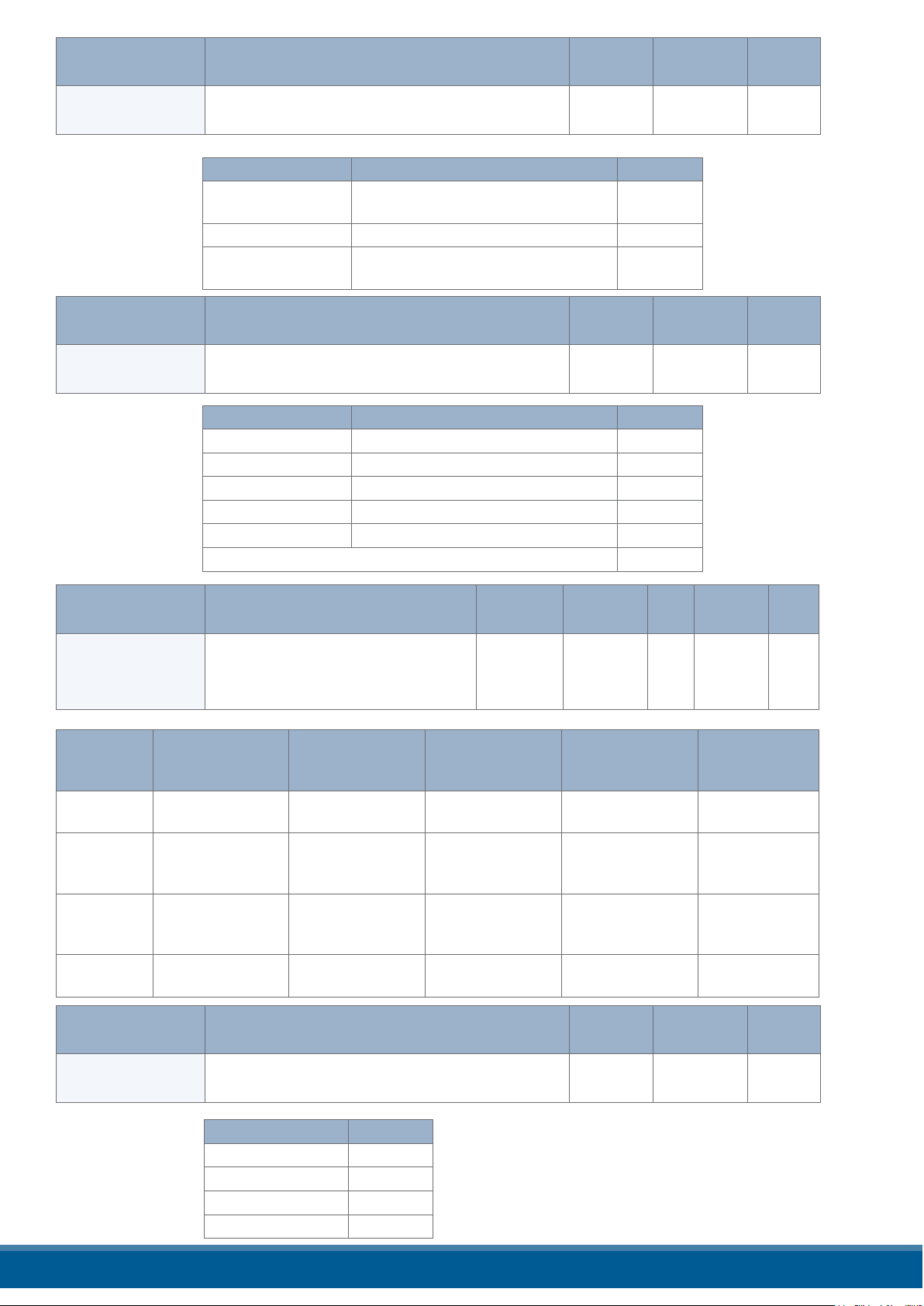

9.3. Output features (power device)

Nominal

Current

(A) (V) (480V) (600V) (mAe) (10

60 24÷600 1200 1600 600 1900 15 10780 47÷70 290 3000

90 24÷600 1200 1600 600 1900 15 10780 47÷70 580 3000

120 24÷600 1200 1600 600 1900 15 14280 47÷70 598 3000

150 24÷600 1200 1600 300 5000 15 17500 47÷70 594 3000

180 24÷600 1200 1600 300 5000 15 30800 47÷70 740 3000

210 24÷600 1200 1600 300 5000 15 53900 47÷70 898 3000

Voltage

range

(Ue)

Repetitive peak

reverse voltage

(Uimp)

Latching

current

Max

peak

one cycle

msec.)

(A)

Leakage

current

(mAe) tp=

FUSE

I2T value

Suggested

A2s (at500V)

10msec

Frequency

range

(Hz) I =Inom

Thyristor

Power

loss

+ Fuse

(W)

Isolation

Voltage

(Ui)

(A)

9.4. Fan Specication (only from 90 to 210A)

Supply: 230V Standard Power 48W (16W for 3 Fan)

Supply: 115V Option Power 42W (14W for 3 Fan)

www.west-cs.co.uk 17

Page 18

9.5. Environmental installation conditions

Ambient temperature 0-40°C (32-104°F) at nominal current.

Over 40°C-104°F use the derating curve.

Storage temperature -25°C to 70°C -13°F to 158°F

Installation place Don’t install at direct sun light, where there are conductive dust, corrosive gas, vibration or

water and also in salty environmental.

Altitude Up to 1000 meter over sea level. For higher altitude reduce

the nominal current of 2% for each 100m over 1000m

Humidity From 5 to 95% without condense and ice

Pollution Level Up to 2nd Level ref. IEC 60947-1 6.1.3.2

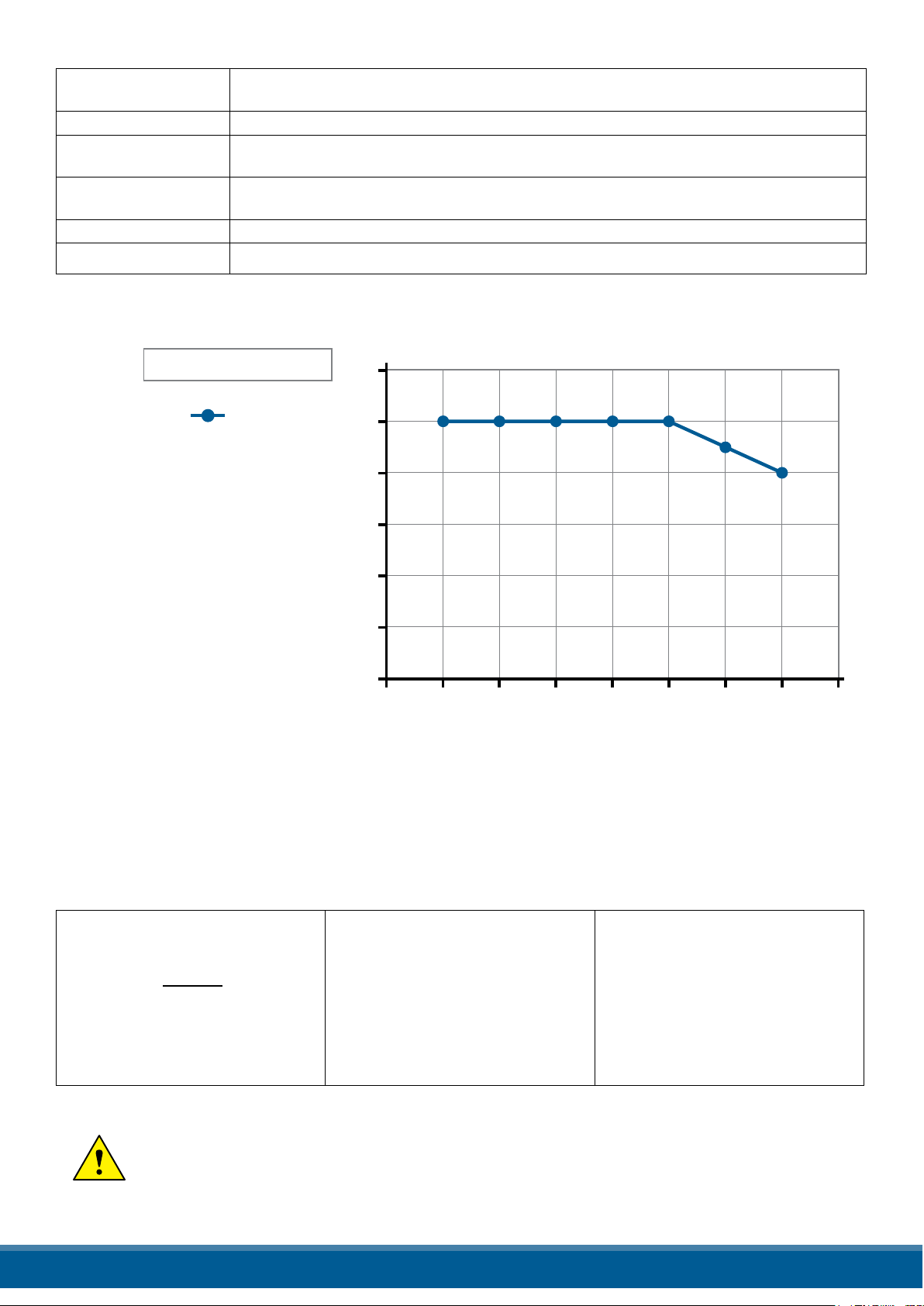

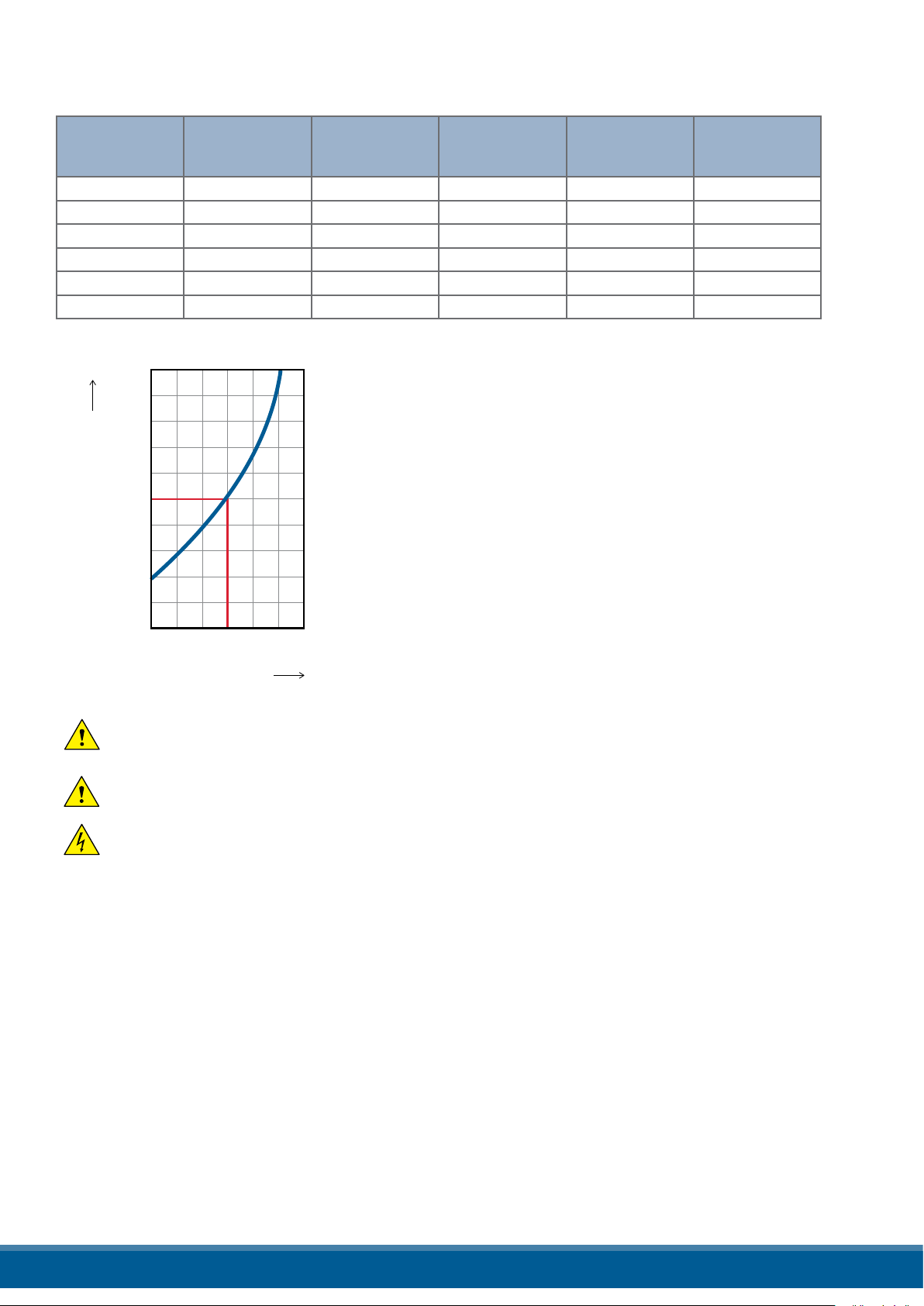

9.6. Derating curve

l max = l nominal x K

Derating

1,2

1

0,8

0,6

K

0,4

0,2

1

1 1 1 1

0,9

0,8

For higher cabinet

temperature

contact the producer

of the unit

0

15 20 25 30 35 40 45 50 55

CABINET TEMPERATURE °C

9.7. Calculating ow capacity of the fan

All the thyristor units when are in conduction produces power loss that is dissipated inside cubicle in terms of

heating. Due to this fact the internal temperature of cubicle is higher than ambient temperature. To be cooled the

thyristor need of fresh air cooling and to do it is normally used a fan mounted on the front door or on the roof of the

cabinet.

Procedure to size Fan air mass ow (V): see power loss for each thyristor and fuse mounted indicated in the

manual related to the current (Output feature and Internal fuse Chapter).

V = f *

The formulas used are for information only and is not a substitute for a proper thermal rating

done by a qualied person.

Qv

tc-ta

Qv = total power losses (w)

(thyristor + fuse power loss)

ta = ambient temperature (°C)

tc = cabinet temperature (°C)

V = fan air mass ow (m³/h)

f = altitude coecient (see

table on right)

Altitude

0:100 meters f = 3.1 m³K/Wh

100:250 meters f = 3.2 m³K/Wh

250:500 meters f = 3.3 m³K/Wh

500:750 meters f = 3.4 m³K/Wh

www.west-cs.co.uk 18

Page 19

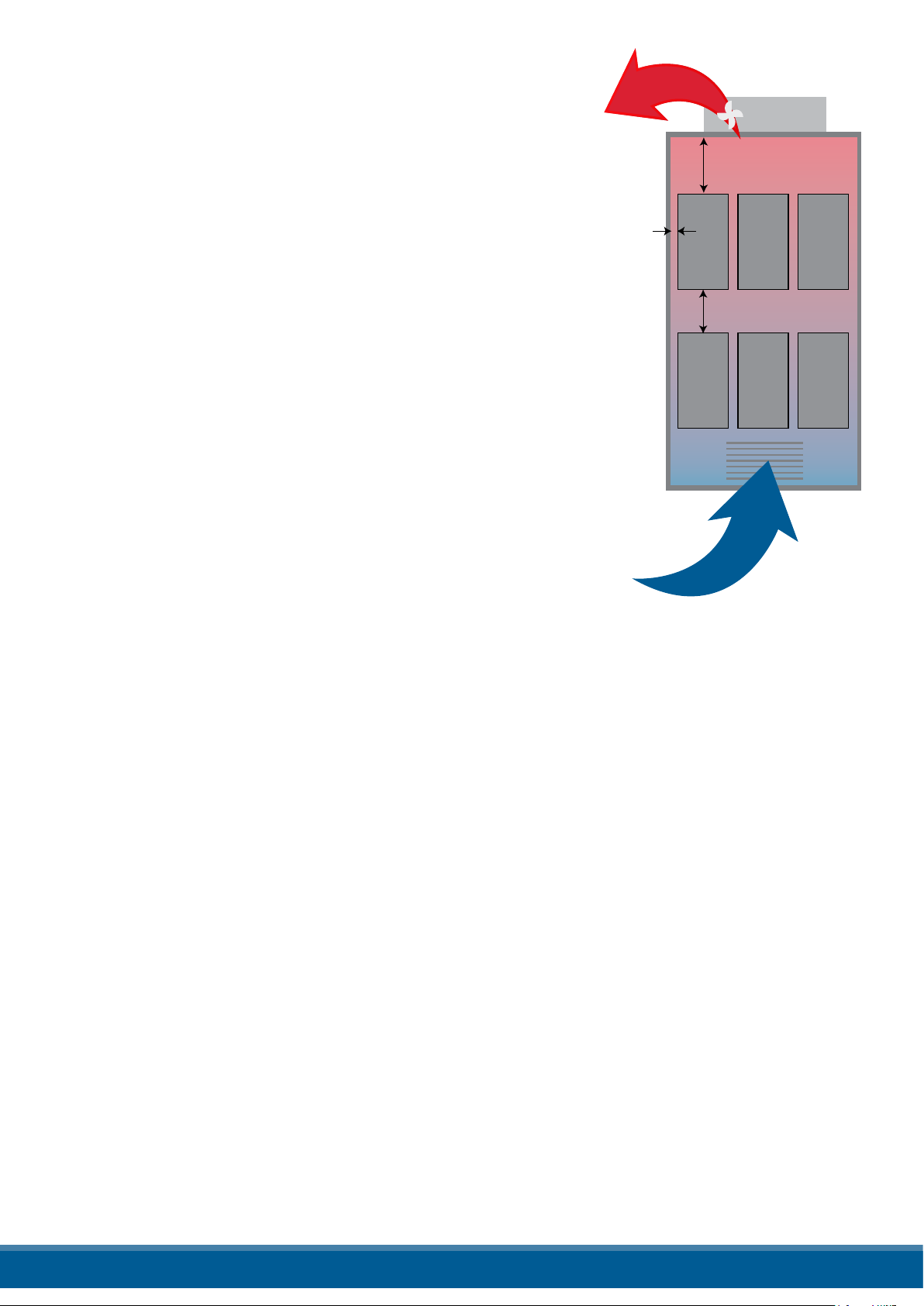

*30 cm

*20 cm

*2 cm

AIR FLOW IN (V)

AIR FLOW OUT (V)

FAN

in aspiration

Air Grid

10. Installation

Before to install, make sure that the Thyristor unit have not damages.

If the product has a fault, please contact the dealer from which you

purchased the product. Verify that the product is the same thing as

ordered.

The Thyristor unit must be always mounted in vertical position to improve air cooling on heat-sink. Maintain the minimum distances (*)

in vertical and in Horizontal as represented, this area must be free

from obstacle (wire, copper bar, plastic channel).

When more unit has mounted inside the cabinet maintain the air cir-

culation like represented in gure without obstacle for the air ow. Is

necessary to install a fan to have better air circulation as calculated

previously.

The V Air ow must be equal or more than the value calculated.

If the cabinet fan mounted by the customer have an air ow lower

than the correct value the warranty will decay.

www.west-cs.co.uk 19

Page 20

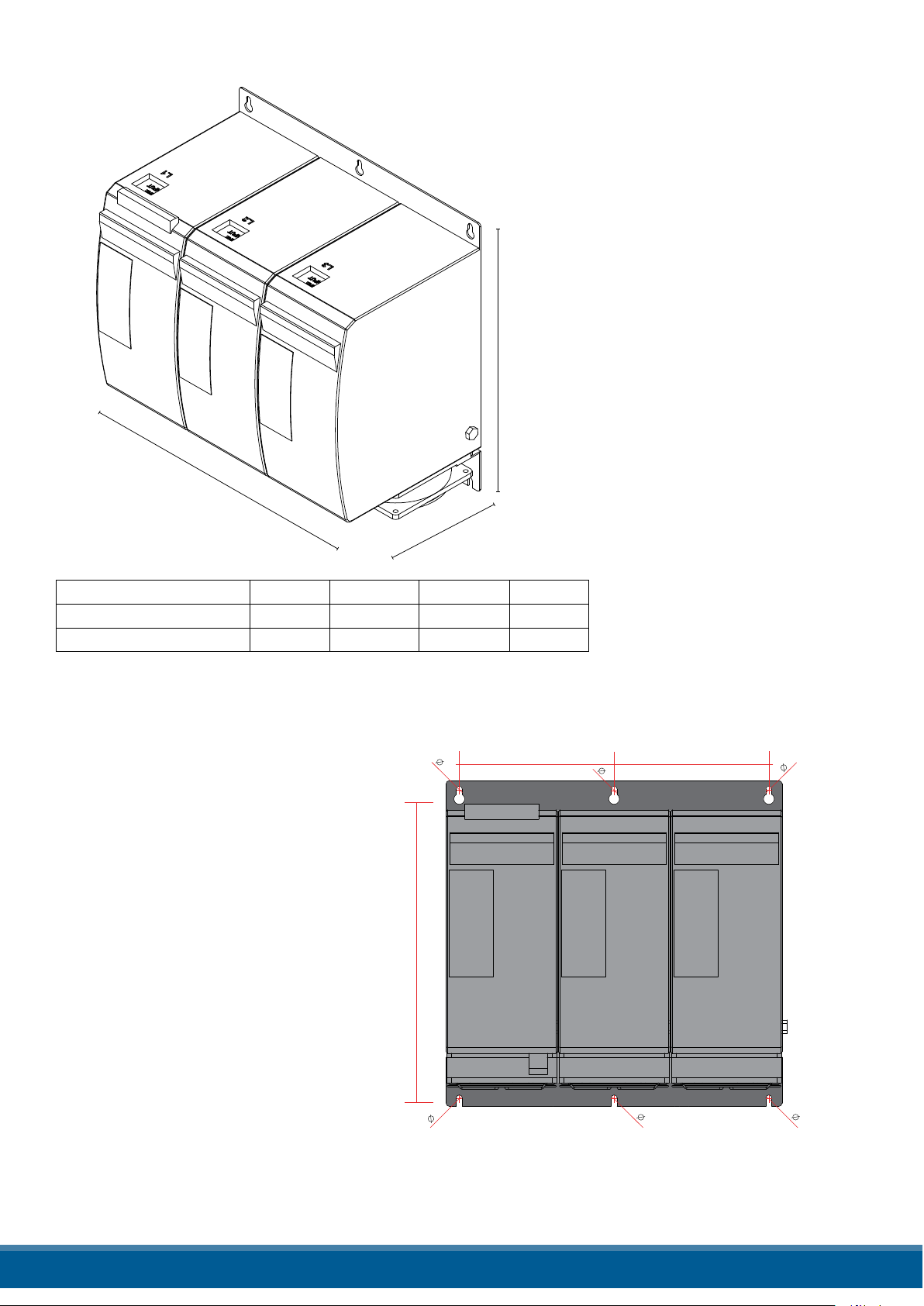

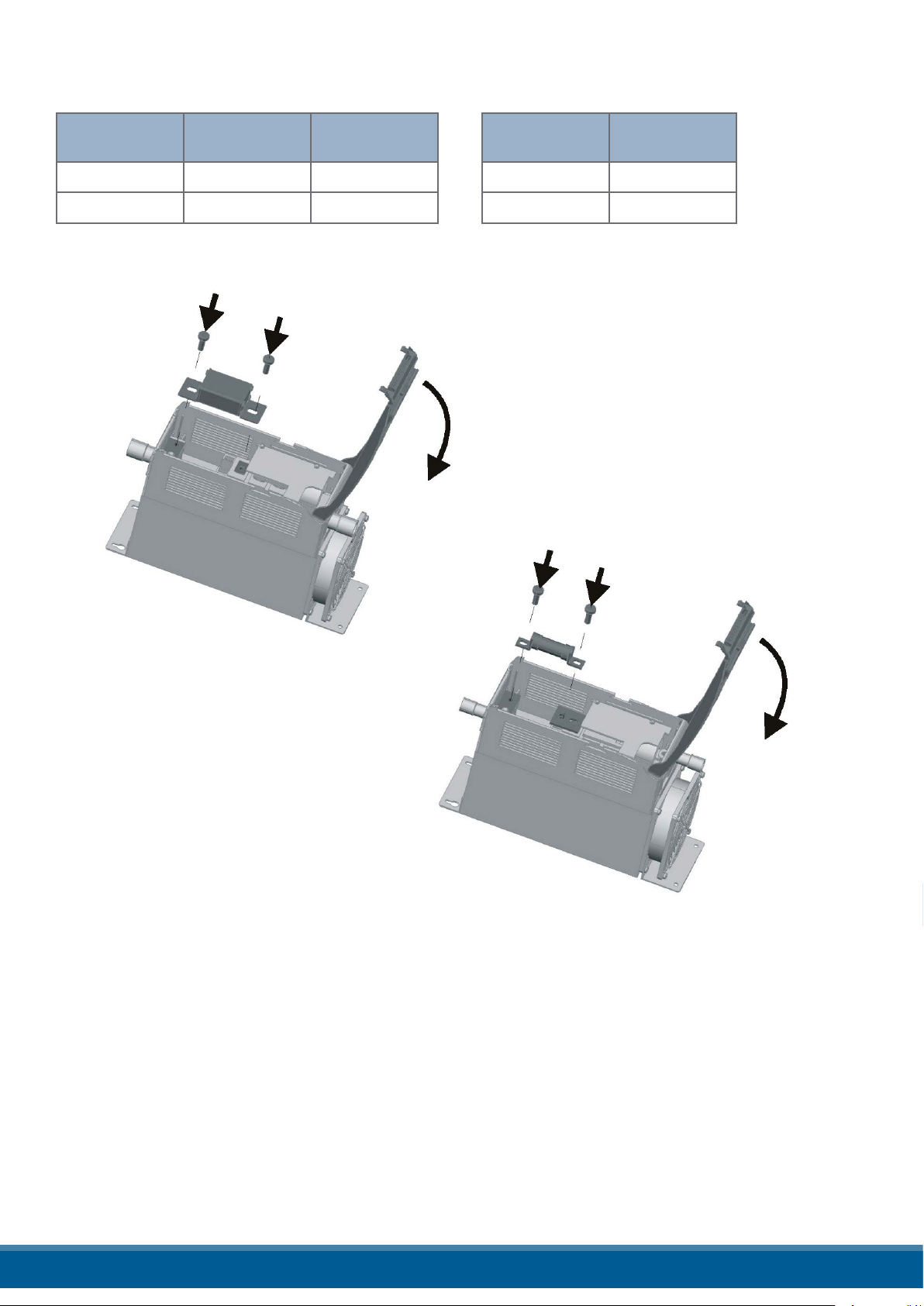

10.1. Dimensions and weight

W

D

H

5

5

5

5

5

5

129,5 129,5

H1

Type W H D Weight

3PH 60A no Fan 279 mm 269 mm 170 mm 10.2 kg

3PH 90-210A with Fan 279 mm 273 mm 170 mm 10.6 kg

10.2. Fixing holes

H1:

3PH (60A no Fan): 256

3PH (90-210A with Fan): 260

www.west-cs.co.uk 20

Page 21

11. Wiring instructions

The Thyristor unit could be susceptible to interferences lost by near equipments or by the power supply, for this

reason in accord to the fundamental practices rules is opportune take some precautions:

• The coil contactor, the relays and other inductive loads must be equipped with opportune RC lter.

• Use shielded bipolar cables for all the input and output signals.

• The signal cables must not be near and parallel to the power cables.

• Local regulations regarding electrical installation should be rigidly observed.

Use 75°C copper (CU) conductor only, wire ranges (AWG), wire terminal type (ZMVV), terminal tightening

torque in the table below.

Power cable torque (suggested)

Type Connector

Type

060

090

120

150

180

210

Cable dimensions of the Command Terminals 0.5 mm² (AWG 18)

Cable dimensions of the Earth (suggested) 16 mm² (AWG 6) up to 120A

25 mm² (AWG 4) up to 210A

Screw M6 70.8 (8.0)

Screw M8 141, 6 (16.0)

Torque Lb-in

(N - m)

Wire Range

mm² (AWG)

16(5)

25(3)

35(2)

50(0)

70(00)

90(000)

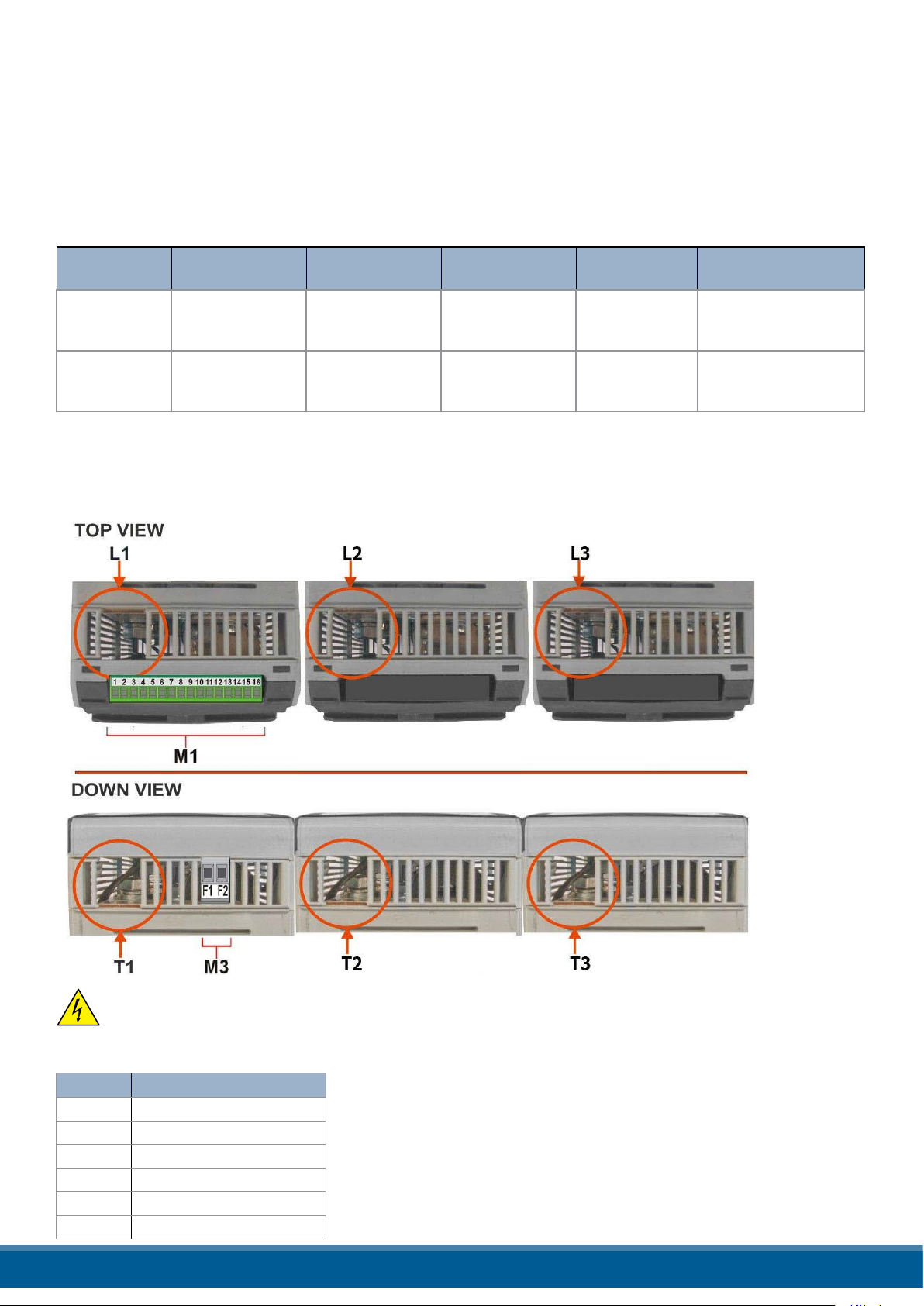

11.1. Terminal Positions

MAX Current

Terminals

150

250

Wire Terminals UL

Listed (ZMVV)

Fork/Spade Terminal

Copper Tube Crimp.

Lug

Fork/Spade Terminal

Copper Tube Crimp.

Lug

Warning: Before connecting or disconnecting the unit check that power and control cables

are isolated from voltage sources.

11.2. Power Terminals

Terminal Description

L1 Line Input Phase 1

T1 Load Output Phase 1

L2 Line Input Phase 2

T2 Load Output Phase 2

L3 Line Input Phase 3

T3 Load Output Phase 3

www.west-cs.co.uk 21

Page 22

11.3. Control Terminals

Warning: Before connecting or disconnecting the unit check that power and control cables

are isolated from voltage sources.

11.3.1. Terminal block M1

Terminal Description

1 0V GND

2 COM I - Common Digital Input

3 DI 2 – Enable Digital Input

4 DI 1 - Congurable Input

5 + Analog Input1 (0-10Vdc/4-20mA Analog Setpoint)

6 - Analog Input1 (0-10Vdc/4-20mA Analog Setpoint)

7 Output +10Vdc stabilized 1 mA MAX

8 + Analog Input2 (0-10Vdc/4-20mA Reference/ext.feed-back)

9 Slave Output

10 Retransmission Output

11 RS485 A

12 RS485 B

13 0V GND

14 C - Common contact alarm relay output

15 NO - Normally Open contact alarm relay output (Thermal or SC/HB/CL)

16 NC - Normally Close contact alarm relay output (Thermal or SC/HB/CL)

11.3.2. Terminal block M3

Terminal Description

F1 Fan supply (230V Standard – 115 Option - for DC Fan Option +24Vdc)

F2 Fan supply (230V Standard – 115 Option - for DC Fan Option -24Vdc)

www.west-cs.co.uk 22

Page 23

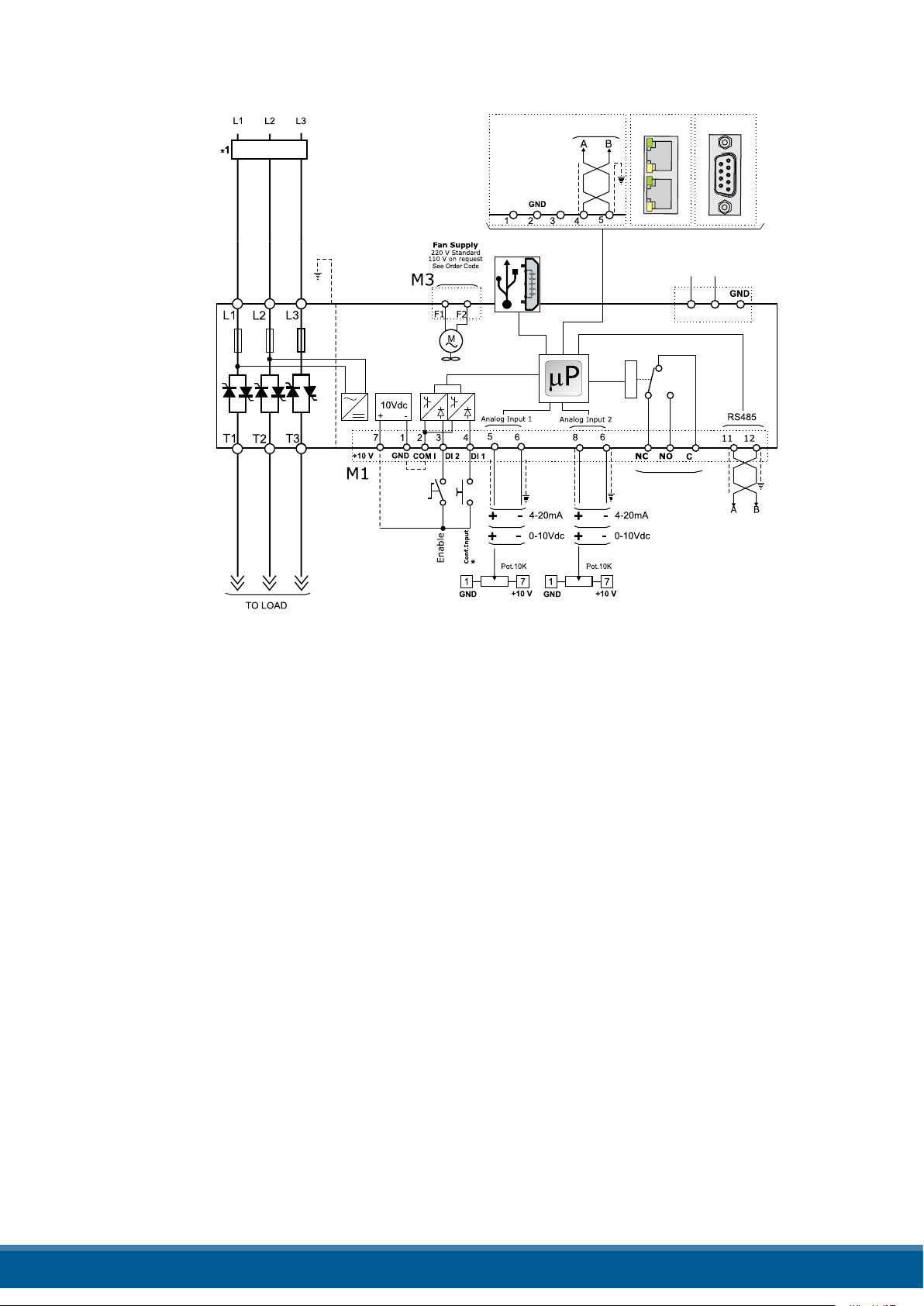

11.4. Schematic

Branch Circuit

Protection

M4

+24V

MICRO

USB 2.0

Second

Serial RS485

+

Option

Ethernet

-

M1

Function

Thermal

SC/HB

Profibus

OUT

RETRANS.

OUT

SLAVE

139 10

141615

2

Analog Inp.1

Analog SetPoint

Analog Inp.2

Reference

Ext.FeeDBack

NOTE:

*1 The user installation must be protecting by electromagnetic circuit breaker or by fuse isolator. The Fuse

must be branch circuit protection. For UL any listed UL branch circuit fuse would be acceptable as an

external fuse, following national electric code guide for resistive heating of 125% load current rating to protect

external wires.

*2 For SSR input connection follow next page schematic

www.west-cs.co.uk 23

Page 24

11.4.1 SSR Control Input Schematic

For SSR input follow the schematic below and congure Digital Input 1 as Fast enable.

Analog Input 1

M1

SSR

INPUT

www.west-cs.co.uk 24

Page 25

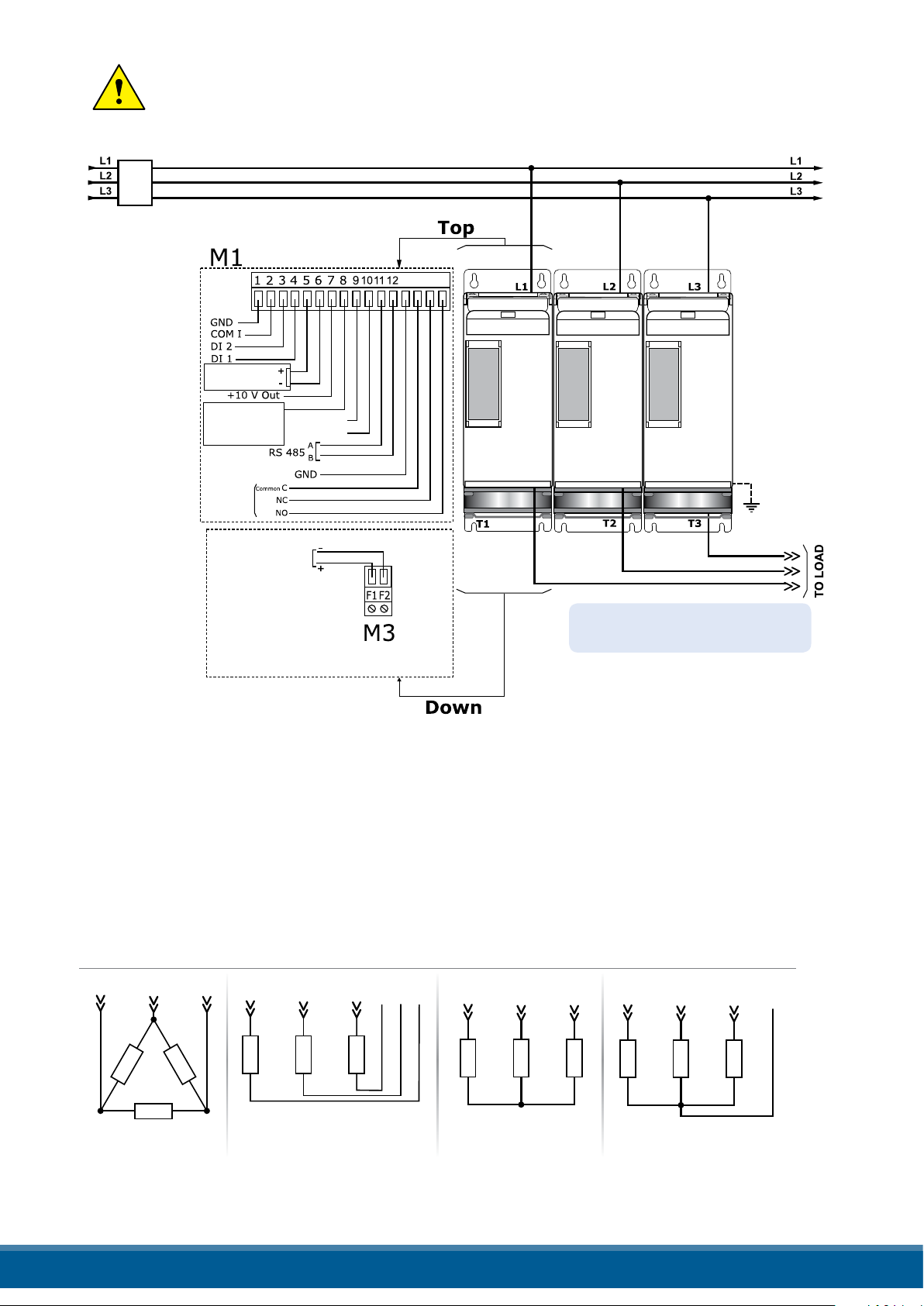

11.5 Connection Diagram for 3 phases

Load Type

Delta Star

T1 T2 T3

T1 T2 T3

Star + Neutral

T1 T2 T3 N

Open Delta

T1

L1 L3 L2

T2 T3

Relay

Thermal or

SC/HB

Analog Inp.2

0-10VDC /4-20mA

Reference

Ext.FeeDBack

Analog Inp.1

0-10VDC /4-20mA

ANALOG SET POINT

SLAVE OUT

RETRANS. OUT

1314 1516

Fan Supply

(only from 90 to 210A)

See order code for the Value

Caution: this procedure must be performed only by qualied persons.

Note: Aux Voltage and Load

Voltage must be synchronized

NOTE:

*1 A suitable device must ensure that the unit can be electrically isolated from the supply, this allows the qualied

people to work in safety.

www.west-cs.co.uk 25

Page 26

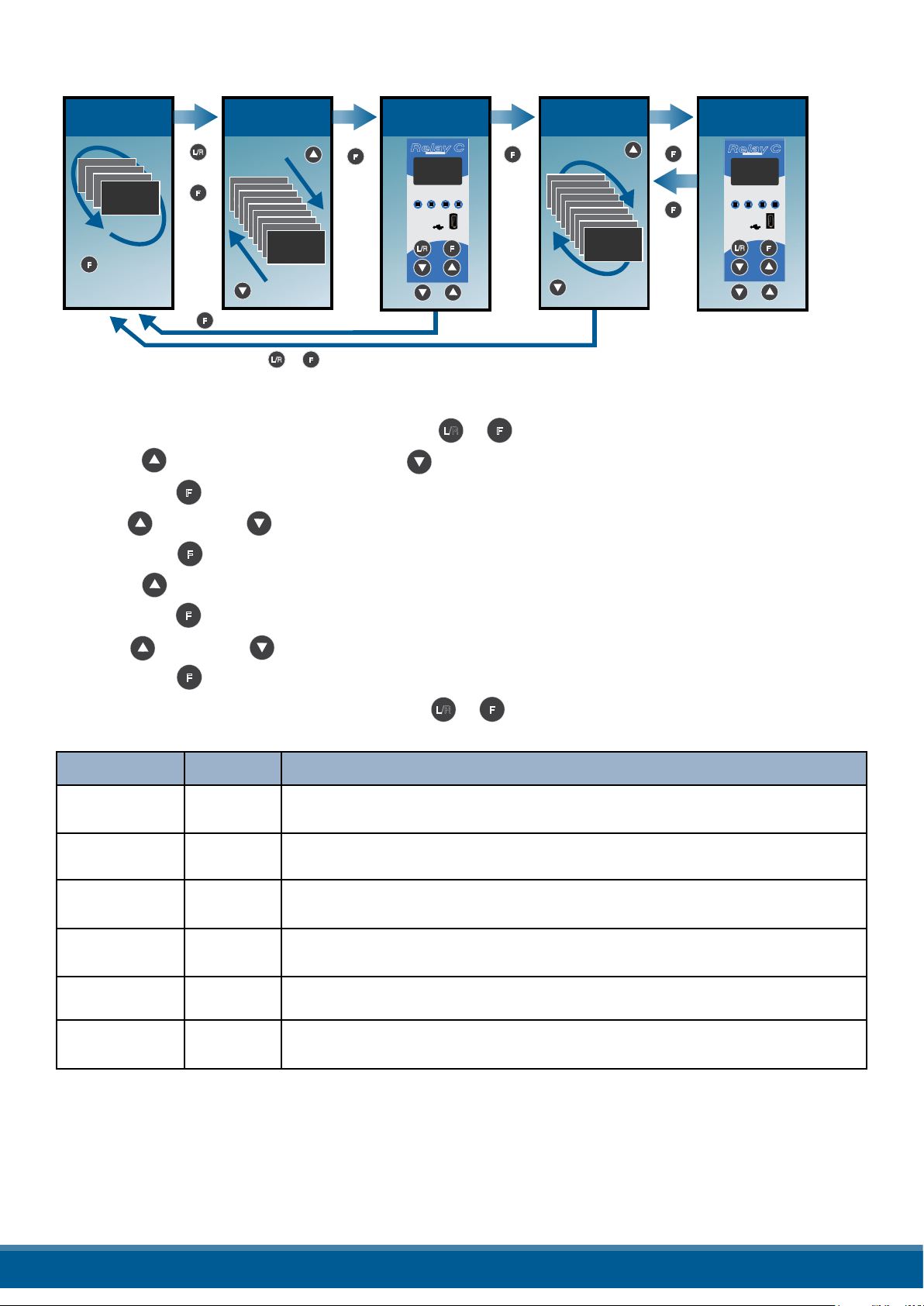

12. Control Panel

F

F

L/R

F

F

F

L/R

F

F

The Control Panel is placed on the front of the thyristor unit, on his display you can visualize the alarms, the

input and output signals and all the conguration parameters.

Relay C

Iout0.0A

SP 100%

L/R

Output Current RMS

F

Relay C

Iout0.0A

SP 100%

L/R EN Com ALL/R EN Com AL

L/R

Output Voltage (RMS)

F

On the home page the keys are used as follows:

Press.. To...

F

L/R

Function Scroll through the parameters on the home page

Local/Remote Switch between local and remote set point for power demand

Relay C

Pout0%

SP 100%

L/R EN Com AL

L/R

Output Power

(Average)

F

Relay C

Aux High

SP 100%

L/R EN Com AL

L/R

F

Alarms

Up Increment power demand set point when set to local

Down Decrement power demand set point when set to local

F

+

L/R

Press and hold for about two seconds to access the menus

To view the status parameters:

• Press Function once to advance from one parameter to the next

F

To set the set point locally:

• Press Local/Remote (Note: indicator 1 ashes steadily when set point is set locally)

• Use Down and/or Up to set the local set point.

L/R

www.west-cs.co.uk 26

Page 27

12.1. Menu navigation

F

L/R

F

F

F

L/R

F

F

F

L/R

F

F

The menus are accessible using the control panel keypad and display.

HOME PAGE

Iout0.0A

Iout0.0A

SP 100%

Iout0.0A

SP 100%

Iout0.0A

SP 100%

SP 100%

F

L/R

+

F

(~2 sec)

F

Choose

Menu

Menu

Menu

Operator

Menu

Operator

Menu

Operator

Menu

Operator

Menu

Operator

Menu

Operator

Menu

Operator

Menu

Operator

Operator

(wrong password)

L/R

+

F

F

(~2 sec)

Enter

Password

Relay C

Relay C

Password

0

L/R EN Com AL

1 2 3 4

L/R

F

L/R

F

F

Choose

Parameter

Set Point

Set Point

100%

Set Point

100%

Set Point

100%

Set Point

100%

Set Point

100%

Set Point

100%

Set Point

100%

Set Point

100%

100%

Parameter

F

F

Edit

Relay C

Relay C

Set Point

100%

L/R EN Com AL

1 2 3 4

L/R

L/R

To access a menu and edit a setting:

1. Press and hold Local/Remote and Function together + until the upper display ashes Menu.

L/R

2. Press Up to choose the menu. (Press down if you overshoot the menu you want).

3. Press function to advance to the password prompt.

F

4. Use up and/or down to set the password (see the table).

5. Press function to enter the password and advance to the rst parameter of the menu.

F

F

F

F

6. Press Up to advance tot he next parameter and repeat to reach the desired parameter.

7. Press function to start editing the parameter. The parameter name ashes in the upper display.

F

8. Use Up and/or down to edit the parameter setting.

9. Press function to enter the new setting. The parameter name stops ashing.

10. Press and hold local/remote and function together + for about two seconds to exit the menus.

F

L/R

F

Menu Password Parameter used to..

Operator 0 View measured values and basic settings including current, voltage

and set point

Setup 2 Congure the power controller for the load

Adv Setup 10 Congure the operation and performance of the power controller in

the application

Hardware 5 Congure the functions of the analog and digital inputs and outputs,

and the retransmission parameters

Comm 3 Congure eld bus communicating parameters

Monitoring 0 View measured and calculated values and other read-only parame-

ters

www.west-cs.co.uk 27

Page 28

12.2. Control Panel Led

The four indicators on the control panel show the general state of the power controller.

Relay C

Aux High

SP 100%

L/R EN Com AL

1 Local/Remote Flashing Power output set locally or via

2 Enable On Output enabled

3 Communications Flashing Active communications

L/R

F

4 Alarm On Active alarm

12.3. Displayed alarms

Alarm or message Description

Heater Break Heater Break

communications

O Power output set remotely (via

analog input)

O Output disabled

O No alarm

Aux High Aux voltage too high

Aux Low Aux voltage too low

Bakeout Heater Bakeout function active

Watchdog Communication Watchdog error

Line Loss Line power not detected

I Limit Output limited by current limit feature (only single phase)

SD Card Error SD card error

Short Circuit Short Circuit on SCR

SCR Over Temp Thermal Switch over temperature

www.west-cs.co.uk 28

Page 29

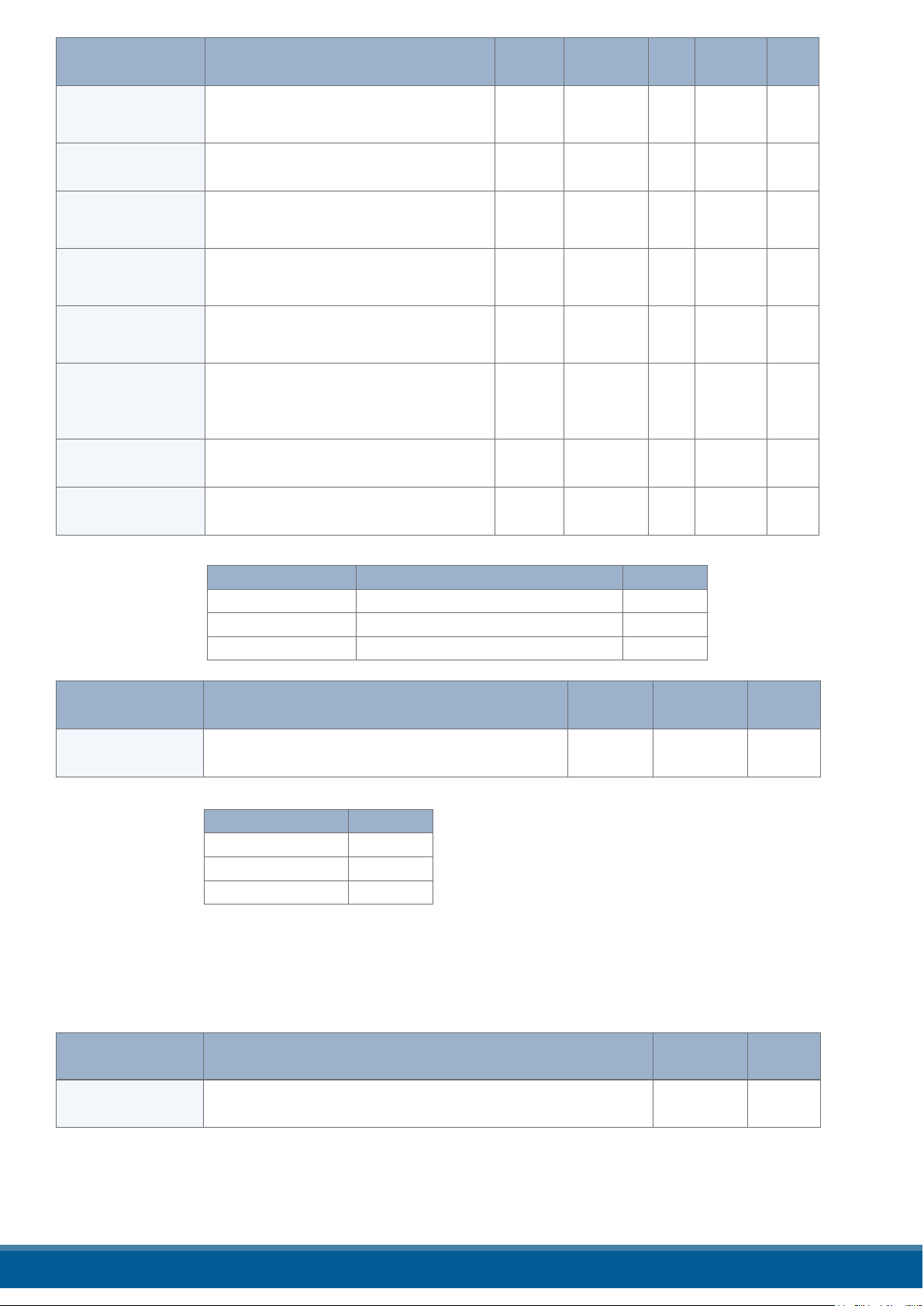

12.4. Parameter list

This chapter describes the parameter on the menus accessed via the control panel and Congurator software.

To learn how to access the menus described below see “Menu navigation” chapter.

12.4.1 Operator Menu

This section describes each item on the operator menu. Use this menu to view the measured values and

basic settings of the power controller. The password to access this menu is 0.

Parameter

Name

Description Range Unit Modbus

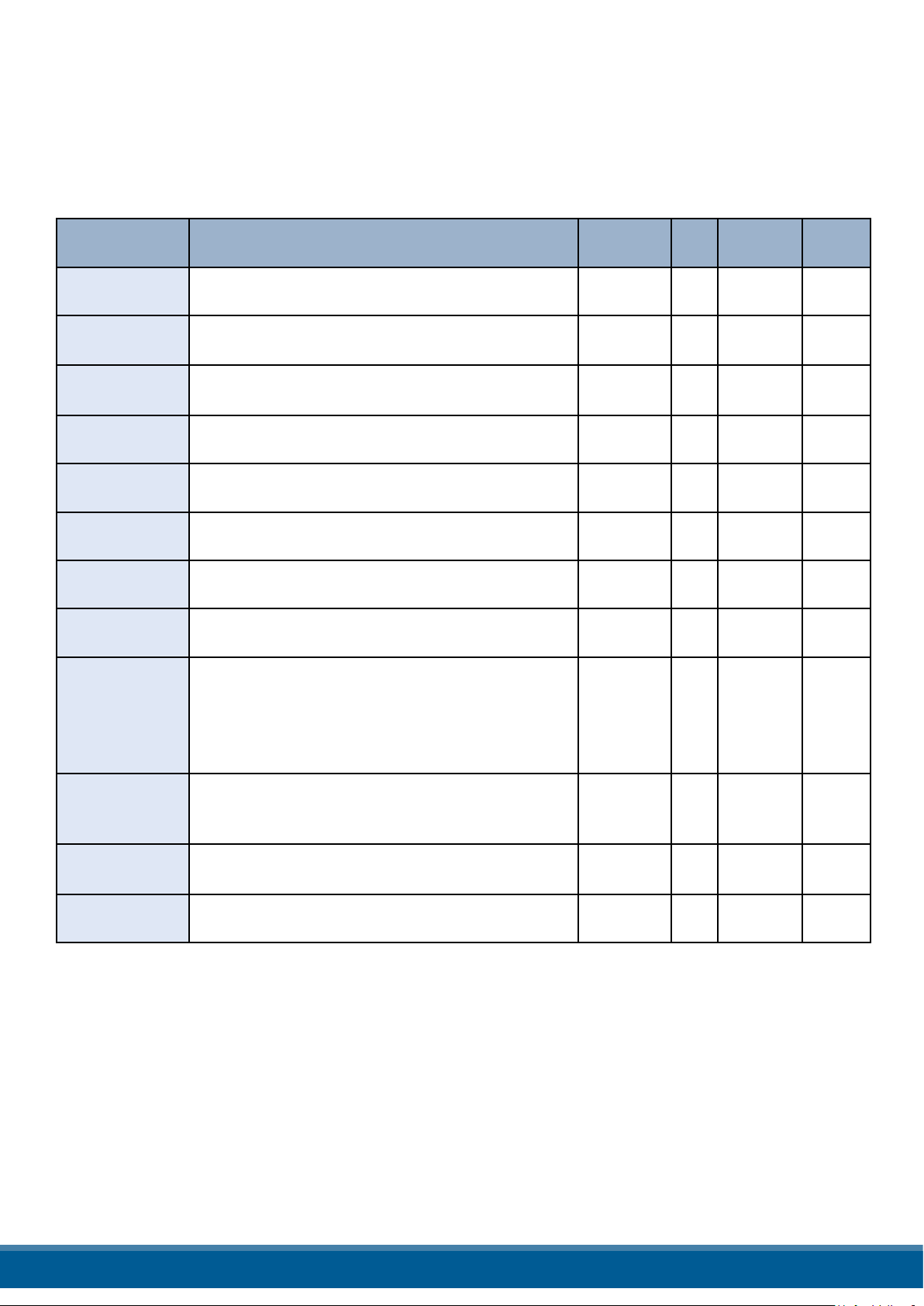

Address

Par.

Typ e

SET POINT View the set point 0 to 100 % 15 Read

Only

V Output Indicates the average (RMS) voltage of all

phases

I Output Indicates the average (RMS) current of all

phases

0 to 1023 V 10 Read

Only

0 to 1023 V 11 Read

Only

Power Indicates the average (RMS) power output 0 to 100 % 12 Read

Only

V Input Indicates the average (RMS) voltage input 0 to

65535

Frequency Indicates frequency of the power input 0 to

655.35

V 47 Read

Only

Hz 9 Read

Only

Power Factor Indicates power factor of the output power 0 to 1000 102 Read

Only

Load Ω Indicates the resistance of the load 0 to

655.35

I Limit Indicates the maximum percent of the nomi-

0 to 100 % 17 Read

nal current that the power control allows. This

Ω 46 Read

Only

Only

parameter indicates RMS current by default.

When parameter 52 is set to 1, this parameter

indicates peak current

Out Scale Indicates the percentage by which the power

demand set point is scaled

Nominal V Indicates the user-set, nominal value for the

0 to

100.0

0 to 1023 V 37 Read

line voltage input

Nominal I Indicates the user-set, nominal load current 0 to

999.9

% 16 Read

Only

Only

A 38 Read

Only

www.west-cs.co.uk 29

Page 30

12.5 Setup Menu

This section describes each item on the setup menu. Use this menu to congure the power controller for the

load. The password to access this menu is 2.

Parameter

Name

Description Range Unit

Set the percentage by which the set point is scaled. For example, if a

Out Scale

0 to 10V analog input providing the set point is 5V and output scaling

is 80% then the eective set point is 40%

100

80

60

40

Parameter

Name

Scaled Set Point

20

0

0 20 40 60 80 100

Description Default Range Unit

Output Scaling = 100%

Output Scaling = 80%

Output Scaling = 40%

Input

Set the maximum percent of the nominal current that

I Limit

the power control allows. This parameter indicates RMS

current by default. When parameter 52 is set to 1, this

0%

parameter indicates peak current

Nominal V Set the nominal value for the line voltage input 220V

0 to

100.0

0 to

100.0

0 to

1023

Modbus

Address

% 16

Modbus

Address

% 17

V 37

Par.

Type

Read

Write

Par.

Type

Read

Only

Read

Write

Nominal I Set the nominal load current

Maximum

current

Set the duration of the soft start in increment of 50mSec.

Soft Start

The power controller ramps set to point changes over

the time set here. For more information see “Soft Start”

100

(5 sec)

page on this manual

Remote SP Choose the source for the remote set point 61

0 to

999.9

0 to 255

(0 to

12,75

sec)

A 38

23

Read

Write

Read

Write

Read

Write

Option Value

Analog Input 1 0

Analog Input 2 1

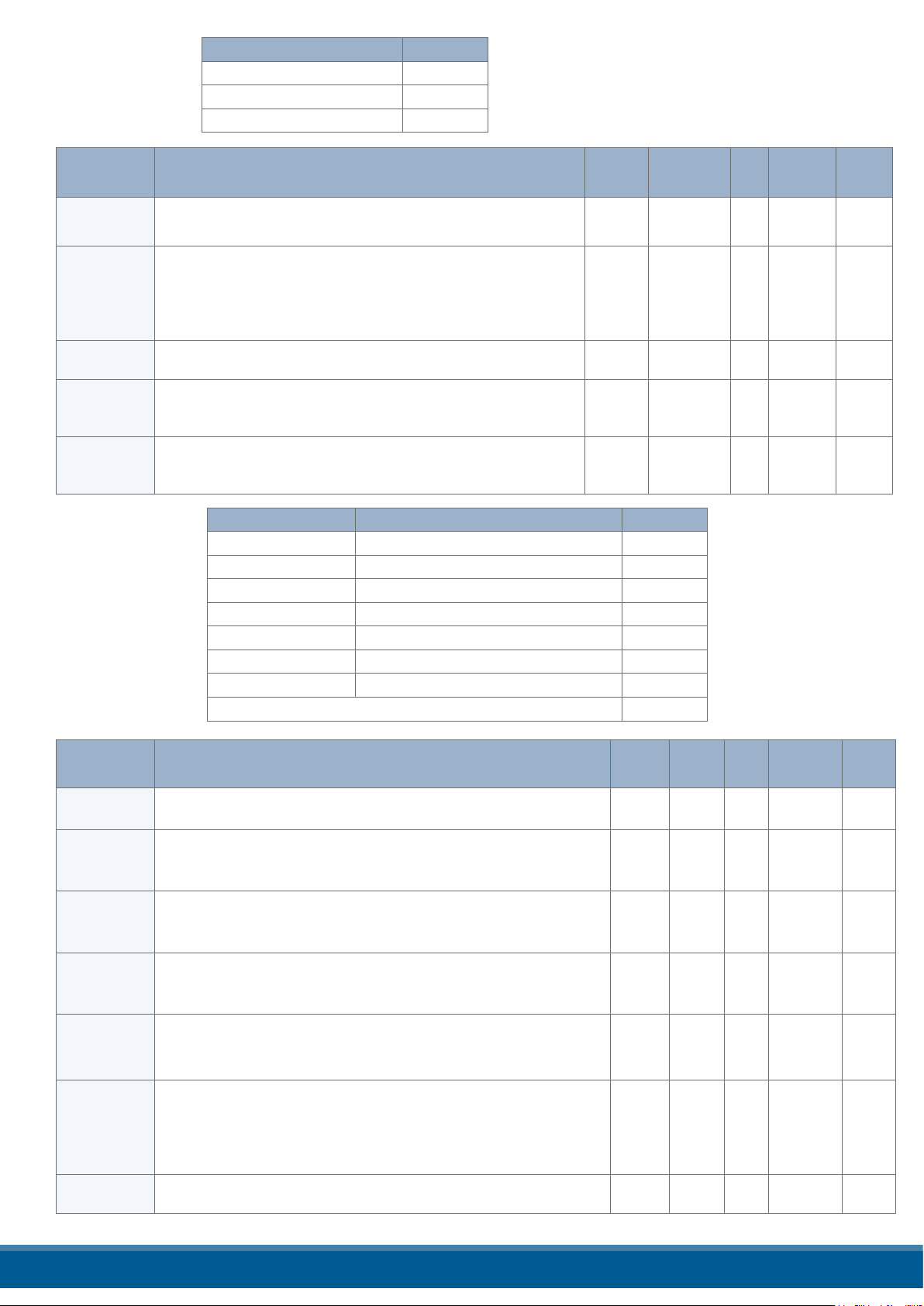

12.5.2 Advanced Setup Menu

This section describes each item on the advanced setup menu. Use this menu to congure the power switching, closed loop control of power and adjustable settings for data logging and heater bakeout. The password to access this

menu is 10.

Parameter Name Description Default Modbus Address Par. Type

Firing Choose the ring mode 3 18

Option Value

Zero Cross 1

Single Cycle 2

Burst Firing 3

Phase Angle 4

Burst ring start ramp 19

Read

Write

www.west-cs.co.uk 30

Page 31

Option cont. Value

Phase angle Soft Start 20

Burst Firing Delay Trigger 35

DEFAULT: Burst Firing 3

Parameter

Name

Min Cycles

Soft Start

Delay

Cycle time

Control

Mode

(Feed-back)

Description Default Range Unit

Set the minimum number of On cycles and o cycles for

burst ring

Set the duration of the soft start in increment of 50mSec. The

power controller ramps set to point changes over the time

set here. For more information see “Soft Start” page on this

manual

Set the ring delay degrees. Applies to burst ring with delay

trigger

Set the duration of one on-o cycle in increments of 50mSec.

Applies to zero crossing

Choose the feed-back type 1 19

Option Description Value

Voltage ² Voltage squared 0

None No feed-back 1

Current ² Current squared 2

Voltage Voltage 32

Current Current 64

Power Power 128

External External signal via analog input 2 256

DEFAULT: None 1

8 0 to 999.9 n° 20

100

(5 sec)

1 1 to 255 ° 23

60

(3 sec)

0 to 255

(0 to

12,75 sec)

0 to 255

0 to 12,75

sec)

Modbus

Address

23

24

Par.

Type

Read

Write

Read

Write

Read

Write

Read

Write

Read

Write

Parameter

Name

Prop band

power

Integral

power

Prop band

current

Integral

current

Htr Break

sensitivity

Htr Break

delay

Logging Enable or disable data logging on the internal SD card 0 139

Set the gain for the main loop. A smaller proportional band yields

a larger adjustment for a given deviation

Set how aggressively the integral part of the control algorithm

acts. A smaller settings yields a larger adjustment for a given

deviation over a given time

Set the gain for the main loop. A smaller proportional band yields

a larger adjustment for a given deviation

Set how aggressively the integral acts in the current loop. A

smaller settings

Set the threshold of resistance that activates the Heater

Break alarm. This setting is in percentage of the nominal load

resistance

Set a delay between when the resistance drops below the value set

for a heater break sensitivity and when the heater break alarm is

indicated. This set increments of 50mSec

Description Default Range Unit

10%

50

10%

50

100%

50 (2,5

sec)

0 to

255

0 to

255

0 to

255

0 to

255

0 to

100.0

0 to

255

(0 to

12,75

sec)

Modbus

Address

% 26

% 63

% 29

27

64

28

Par.

Type

Read

Write

Read

Write

Read

Write

Read

Write

Read

Write

Read

Write

Read

Write

www.west-cs.co.uk 31

Page 32

Option Value

O 0

On 1

DEFAULT: O 0

Parameter Name Description Default Range Unit

Logging interval Set how often data is logged 5 sec 0 to 255 sec 70

Heater Bakeout Enable or disable the heater bakeout feature 0 140

Option Value

O 0

On 1

DEFAULT: O 0

Modbus

Address

Par.

Type

Read

Write

Read

Write

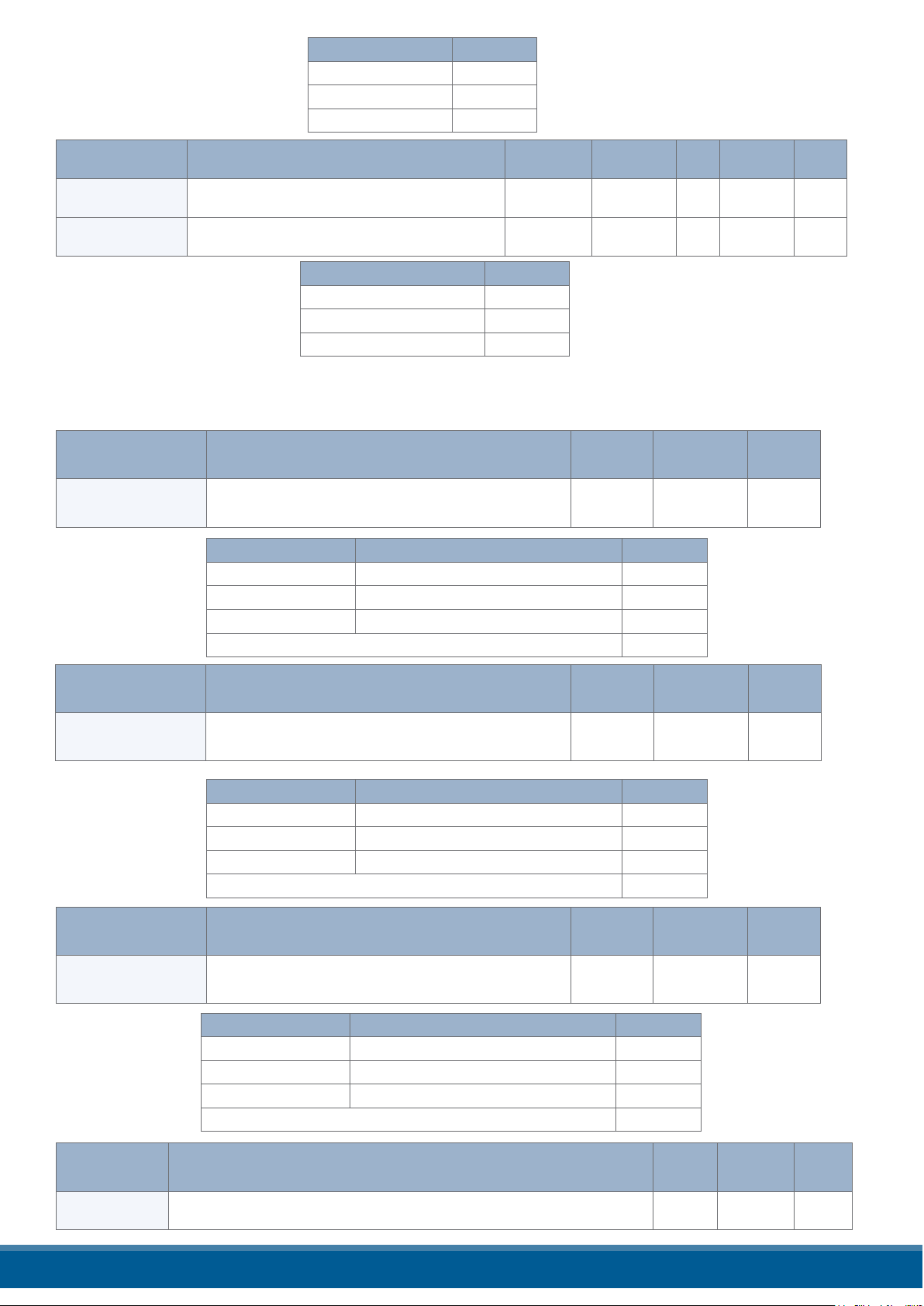

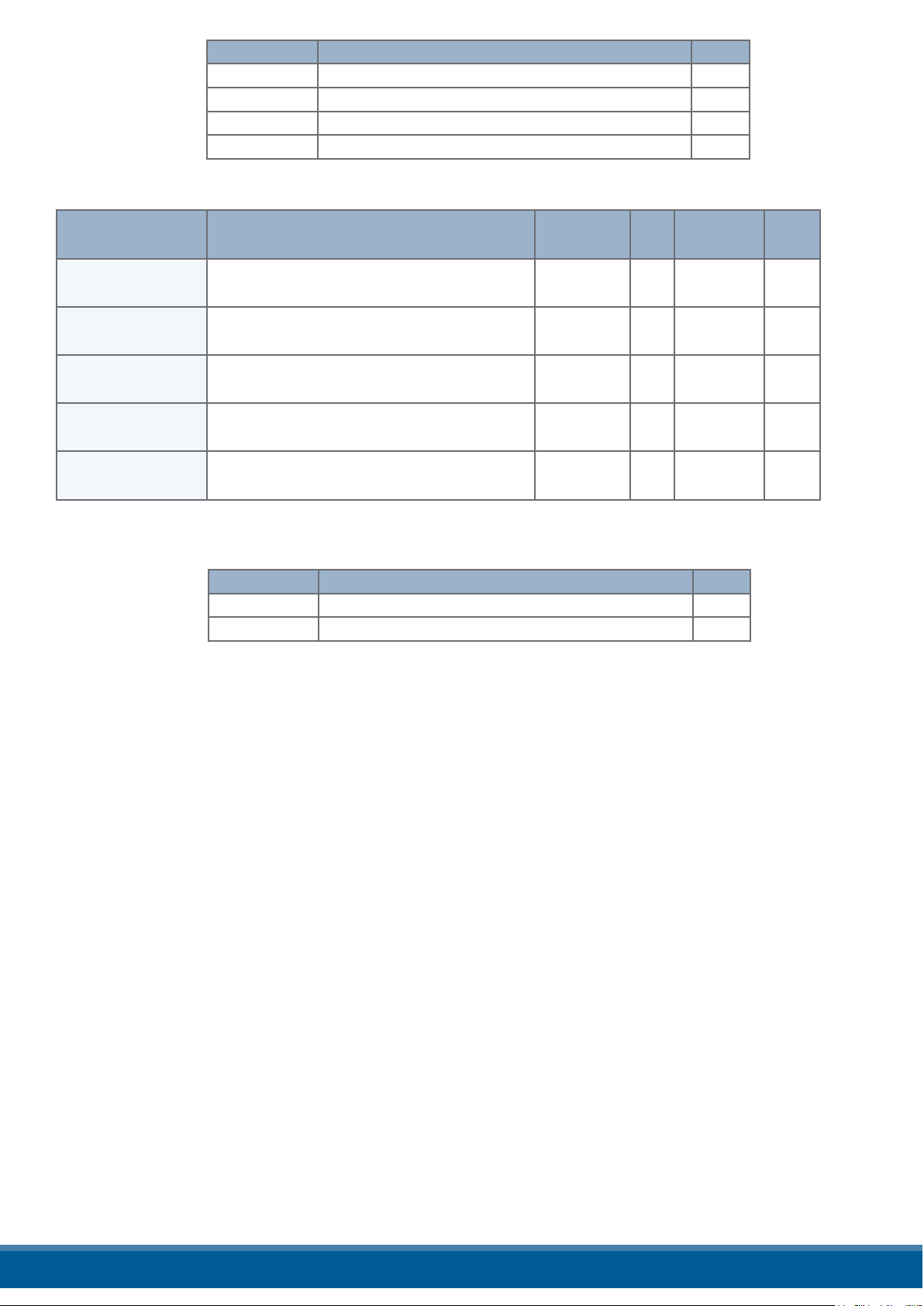

12.5.3 Hardware Menu

This section describes each item on the hardware menu. Use this menu to congure how the inputs and outputs

are used in the application. The password to access this menu is 5.

Parameter Name Description Default

Analog In 1

Choose the type of signal to be measured by analog input 1

Option Description Value

0-10V / 10k Pot 0 to 10 Vdc or 10,000Ω 1

4-20mA 4 to 20 mAdc 2

0-20mA 0 to 20 mAdc 3

DEFAULT: 0-10V / 10k Pot 1

1 44

Modbus

Address

Par.

Type

Read

Write

Parameter Name Description Default

Analog In 2

Parameter Name Description Default

Analog In 2

Function

Choose the type of signal to be measured by analog input 2

Option Description Value

0-10V / 10k Pot 0 to 10 Vdc or 10,000Ω 1

4-20mA 4 to 20 mAdc 2

0-20mA 0 to 20 mAdc 3

DEFAULT: 0-10V / 10k Pot 1

Choose how the signal measured by analog input 2

is used

Option Description Value

I Limit Current Limit Set point 0

Feed-back External feed-back 1

Set Point Power Demand set point 2

DEFAULT: I Limit 0

1 105

0 or 1 116

Modbus

Address

Modbus

Address

Par.

Type

Read

Write

Par.

Type

Read

Write

Parameter

Name

Digital In 1

Function

Description Default

Choose how the signal detected by digital input 1 is used 0 32

Modbus

Address

Par.

Type

Read

Write

www.west-cs.co.uk 32

Page 33

Option Description Value

Enable Enable power output 0

Voltage Feed-back Use voltage feed-back when on 2

Local / Remote Local when on / Remote when o 3

Phase Angle Use phase angle ring when on 4

Set point Analog In 1/2 Select remote set point source: analog input 1 when o or analog

input 2 when on

Logging Enable logging 6

Heater Bakeout Enable heater bakeout 7

FastEn Fast Enable, power on up to 10msec (only with phase angle ring) 8

DEFAULT: Voltage Feed-back 2

5

Parameter Name Description Default

Digital In 2

Function

Option Description Value

Enable Enable power output 0

Voltage Feed-back Use voltage feed-back when on 2

Local / Remote Local when on / Remote when o 3

Phase Angle Use phase angle ring when on 4

Set point Analog In 1/2 Select remote set point source: analog input 1 when o or analog input 2 when on 5

Logging Enable logging 6

Heater Break Enable heater break 7

FastEn Fast Enable, power on up to 10msec (only with phase angle ring) 8

DEFAULT: Enable 0

Parameter

Name

Choose for which conditions the digital output indicates alarm. The output

always indicate an alarm when the heat sink is over temperature. The digital

Alarm

Function

output is energized for normal operating condition and de-energized when

the power controller is o or when there is an alarm.

Note!: The power controller monitors for heater break or short circuit

condition only when included in the option selected for Alarm Output Function

Choose how the signal detected by digital input 2 is used 33

Description Default

Modbus

Address

1 34

Par.

Type

Read

Write

Modbus

Address

Par.

Type

Read

Write

Option Description Value

None SCR is over temperature only 0

Heater Break Heater Break or SCR is over temperature 1

Short Circuit Short circuit or SCR is over temperature 2

Current Limit Current Limit or SCR is over temperature 4

HB / SC Heater Break or Short circuit 3

HB / IL Heater Break or Current Limit 5

SC / IL Short circuit or Current Limit 6

HB / SC / IL Heater Break, Short circuit or Current Limit 7

Communication watchdog error 16

Communication watchdog error or Heater Break 17

Communication watchdog error or Short circuit 18

These option may be set

via communication only

DEFAULT: Heater Break 1

Communication watchdog error, Heater Break or Short circuit 19

Communication watchdog error or Current Limit 20

Communication watchdog error, Heater Break or Current Limit 21

Communication watchdog error, Short circuit or Current Limit 22

Communication watchdog error, Heater Break, Short circuit or Current Limit 23

www.west-cs.co.uk 33

Page 34

Parameter Name Description Default

Modbus

Address

Par.

Type

I Limit Local /

Remote

Parameter Name Description Default

Retransmit

Choose how the current limit is set 0 14,bit 4

Option Description Value

Local Set point set via keypad or commu-

nication

Analog In2 Set point set via analog input 1

DEFAULT:

Local

Choose wich parameter is retransmitted by the

analog output

Option Description Value

None Do not retransmit value 0

Set Point Set point 15

V Output RMS voltage output 10

I Output RMS current output 11

Power Average output power 12

DEFAULT: Power 12

RMS voltage output 0

12 68

0

Modbus

Address

Read

Write

Par.

Type

Read

Write

Parameter Name Description Default Range Unit

Set the value of retransmitted

Retransmit Sale

Retransmit

Set Point 100

xV where x is

V Output

I Output

Power 100

Parameter Name Description Default

the Nominal Line

Voltage

xA where x is

the Nominal Line

Current

parameter to be represented by the

full scale of the analog output.

See the table below

Recommended

Retransmission

Scaling

Resulting Signal

(4 to 20 mADC)

4mADC = 0%

20mADC = 100%

4mADC = 0V

20mADC = xV

4mADC = 0A

20mADC = xA

4mADC = 0%

20mADC = 100%

0 0 to 9999 124

Resulting Signal

(0 to 20 mADC)

0mADC = 0%

20mADC = 100%

0mADC = 0V

20mADC = xV

0mADC = 0A

20mADC = xA

0mADC = 0%

20mADC = 100%

Resulting Signal

(0 to 10 VDC)

0VDC = 0%

10VDC = 100%

0VDC = 0V

10VDC = xV

0VDC = 0A

10VDC = xA

0VDC = 0%

10VDC = 100%

Modbus

Address

Modbus

Address

Par.

Type

Read

Write

Max Value

100.0

999.9

999.9

100

Par.

Type

Retransmit Type Choose type of signal for the retransmission output 1 69

Option Value

0-10V 1

4-20mA 0

0-20mA 2

DEFAULT: 0-10V 1

Read

Write

www.west-cs.co.uk 34

Page 35

Parameter Name Description Default

Modbus

Address

Par.

Type

Startup Display

Choose wich parameter is displayed on the home

page at power-up

Option Value

Current 0

Voltage 1

Power 2

DEFAULT: Voltage 1

1 60

Read

Write

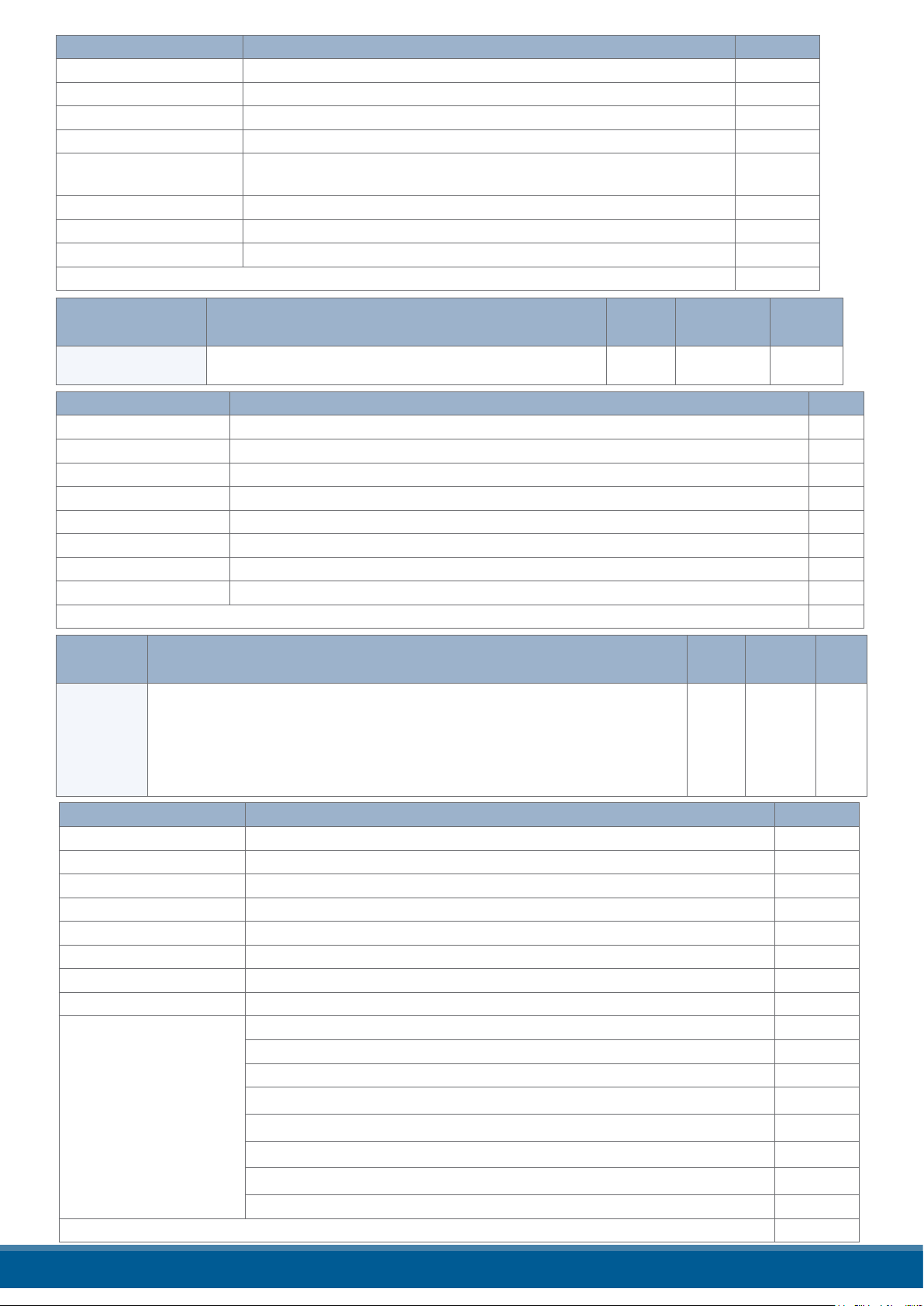

12.5.4. Communication Menu

This section describes each item on the communication menu. Use this menu to congure the communication options. The password to access this menu is 3.

Parameter Name Description Default

Port 1 Baud Choose the baud rate for the primary serial port 2 30

Option Value

9600 0

19200 1

38400 2

115200 3

DEFAULT: 38400 2

Modbus

Address

Par.

Type

Read

Write

Parameter Name Description Default Range Unit

Port 1 Address

Port 2 Baud

Parameter Name Description Default

Watchdog

Set the address for the primary serial

port

Choose the baud rate for the primary

serial port

Option Value

9600 0

19200 1

38400 2

115200 3

DEFAULT: 38400 2

Enable or disable the watchdog on the primary

serial port

Option Value

O 0

On 1

DEFAULT: O 0

1 0 to 255 31

2 45

Modbus

Address

0 142

Modbus

Address

Par.

Type

Read

Write

Read

Write

Par.

Type

Read

Write

www.west-cs.co.uk 35

Page 36

Parameter Name Description Default Range Unit

Watchdog Reset

Time

Wi-Fi Address

Ethernet Address

Ethernet Subnet

Ethernet Gateway

Host Name

Port 2 Address

Set the amount of time to wait for a

message before triggering the watchdog

error

Indicate the IP address of the WiFi

connection in the power controller

Indicate the IP address of the power

controller with the Modbus TCP or

Pronet option

Indicate the subnet mask of the the

power controller with the Modbus TCP or

Pronet option

Indicate the gateway address of the the

power controller with the Modbus TCP or

Pronet option

Indicate the WiFi hotspot name also

known as the Service Set IDentiner

(SSID). Two (one byte) character per

register, 16 Character total

Set the address for the secondary serial

port or the Probus Address

5 0 to 255 Sec 143

0 to 255

0 to 255

0 to 255

0 to 255

0 to 65535

0 0 to 1024 122

Modbus

Address

94-95

96-97

71-72

73-74

75-76

77-78

79-80

81-82

83-84

85-86

87-88

89-90

Par.

Type

Read

Write

Read

Only

Read

Only

Read

Only

Read

Only

Read

Only

Read

Write

Port 2

Parameter Name Description Default

Wi-Fi Enable or disable WiFi communication 0 120

Indicates the type of secondary

communication port

Option Description Value

Disabled No secondary communication port 0

Ethernet Modbus TCP or ProNet 1

RS-485 RS-485 2

Option Value

O 0

On 1

DEFAULT: O 0

119

Modbus

Address

Read

Write

Par.

Type

Read

Write

12.5.5 Monitoring Menu

This section describes each item on the monitoring menu. Use this menu to view the states of digital input, values

of analog input and information about the power controller such as serial number and software version. The

password to access this menu is 0.

Parameter Name Description

Digital In 1 Indicate the state of the signal to digital input 1 13 bit8

Modbus

Address

Par.

Type

Read

Only

www.west-cs.co.uk 36

Page 37

Option Value

O 0

On 1

Parameter Name Description

Digital In 2 Indicate the state of the signal to digital input 2 13 bit9

Option Value

O 0

On 1

Parameter Name Description

Indicate whether or not the power controller is enabled.

Enable

The enable signal must be on for the unit to output power

to the load

Option Value

O 0

On 1

Modbus

Address

Modbus

Address

14 bit2

Par.

Type

Read

Only

Par.

Type

Read

Only

Parameter Name Description

Set Point Source

Parameter Name Description Range Unit

Analog In 1

Analog In 2

Version Indicates the software version number (x.xx.x) 0 to 65535 48

Release

Unit Type Indicates the type of power controller 36

Indicate whether the power controller is local or remote set

point mode

Option Description Value

Remote Set Point via analog input 0

Local Set Point via keypad or communication 1

Indicates the percent of full scale measured

by analog input 1

Indicates the percent of full scale measured

by analog input 2

Indicates the software release date year and

week (yyww)

0 to 100.0 % 138

0 to 100.0 % 137

0 to 65535 49

Modbus

Address

14 bit1

Modbus

Address

Par.

Type

Read

Only

Par.

Type

Read

Only

Read

Only

Read

Only

Read

Only

Read

Only

www.west-cs.co.uk 37

Page 38

Option Description Value

1 Leg Single Phase 7

2 Leg Two Leg, three phase 8

3 Leg Three Leg, three phase 9

3 Leg PA Three Leg, three phase with phase angle capability 9999

Parameter Name Description Range Unit

Max Voltage

Max Current

Aux Voltage Indicates the measured line voltage 0 to 1023 V 43

Serial Number

SCR Temperature

Indicates the maximum voltage rating of the

power controller

Indicates the maximum current capacity of the

power controller

Indicates the serial number of the power

controller

Indicates whether the SCR is below or above

the factory-set trip point

Option Description Value

Disabled No sensor present / temperature below limit 0

Over Temp Over temperature 130

0 to 1023 V 41

0 to 9999 A 62

0 to 9999

Modbus

Address

149-150

151-152

127

Par.

Type

Read

Only

Read

Only

Read

Only

Read

Only

Read

Only

www.west-cs.co.uk 38

Page 39

13. Using the Congurator

Congurator software can be used like an alternative of the power controller’s keypad and set the advanced

features not available via the power controller’s onboard user interface.

Here will explain how use it.

13.1 Typical Uses

The software may be used during commissioning to:

• set internal parameter do determine how the power controller operates and performs;

• save and restore a setup, copy or clone one power controller to another;

• on a day-to-day basis to monitor operation and power usage;

• to examine performance in more detail to determine if any corrective actions are needed.

13.2 Communicating with Power Controllers

When commissioning the power controller, may be useful to connect via the USB port located below the

control panel’s display a computer, is so possible congure and examine the settings of controller.

The controller’s electronics is powered vis USB cable, so is possible inspect it before applying power.

NOTE! the power of the USB port is limited and not designed to power industrial cards, so it manages

to feed only the essential parts of the electronics. For complete control, you need to power up the

auxiliaries of the power controller.

13.3 Recipes

A recipe is a le that store the settings of power controller internal parameter.

Is used to save a power controller conguration or restore an existing conguration in a power controller.

13.3.1 Upload a recipe

A recipe is created using upload function Congurator software and saving it as a le on the computer.

13.3.2 Download a recipe

An existing recipe can be download to a power controller using download function in Congurator software

13.4 How To

Here it is described step-by-step the procedures for common task.

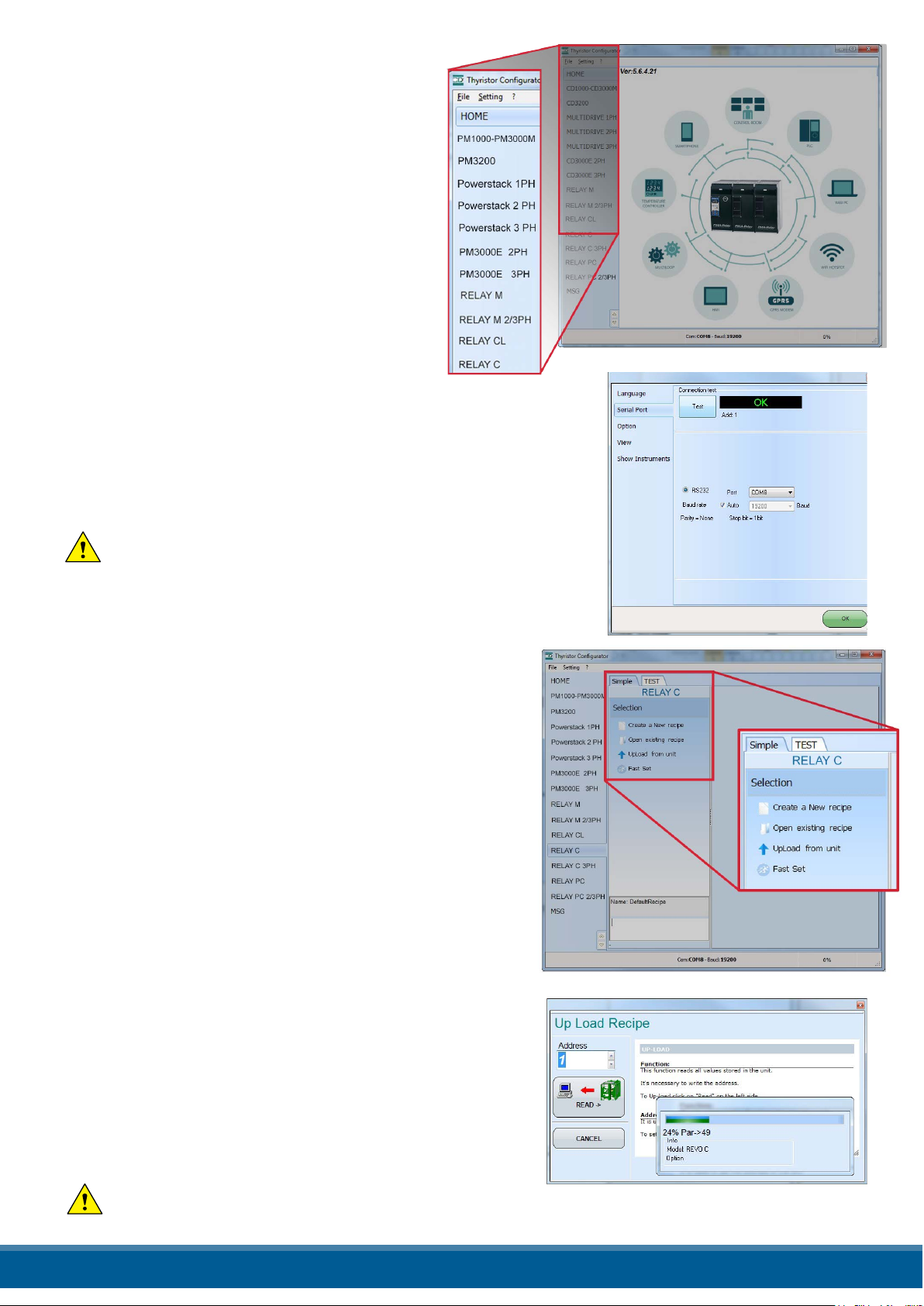

13.4.1 Install and communication with the power controller

Procedure to install the Congurator:

1) Locate the installer:

- On https://www.west-cs.com

link is possible Download it

2) Double-click on the installer program to start installation.

3) Follow the on-screen instructions.

www.west-cs.co.uk 39

Page 40

Procedure to communicate with a power controller:

1) if used direct USB connection:

- Connect the USB cable between the computer

and the micro USB connector on the power

controller’s keypad

- if necessary, Wait for the USB driver to install.

2) if used RS-485 connection connect the power

controller terminal to computer RS485 port. Usually

the standard pc do not have a RS485 port so a

USB-to-485 converter is required.

Note: for connection detail See “Communication

Connections” paragraph.

3) Launch the Congurator software an select

- Relay C: for single phase

- Relay C: 3PH for 3 phase power controller

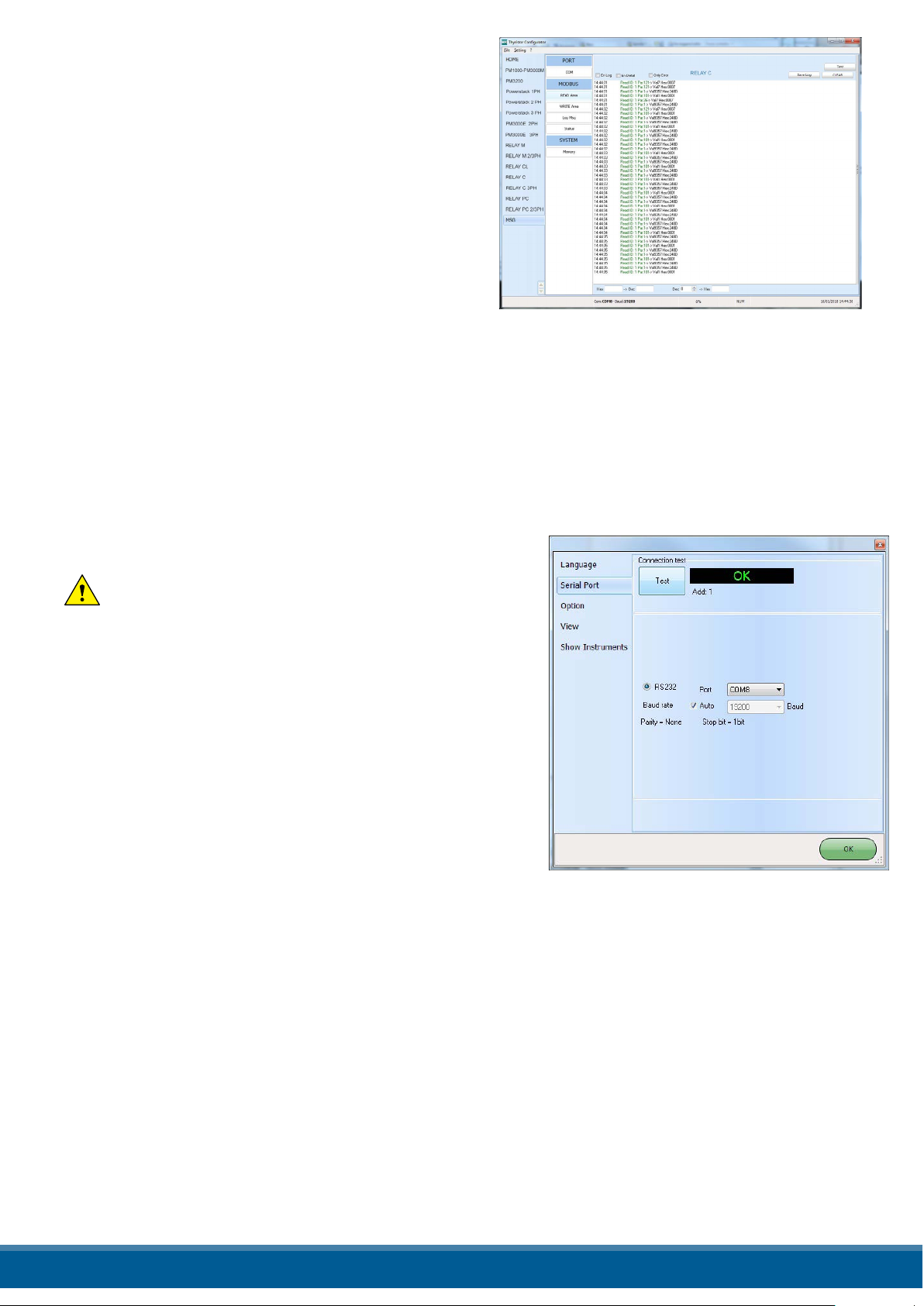

4) Choose Serial Port From the Setting -> Serial Port

menu

5) In value Port, select the connected COM port to the power

controller (see the note below)

6) To verify communications, click Test

7) Click OK

NOTE! to determine which port is connected to the power

controller, you can:

• In the Windows¨ Device Manager under Ports (COM & LPT), looking

for the COM port named “LPC USB VCOM Port (COMx)” where x is

the port number

• In the congurator software:

- open the software without connect the unit and see the

available com port on con port window setting,

- close the com setting window,

- connect the USB cable to the power controller (wait for the

USB driver to install if necessary), - open the com setting

window and see the added com number and select it.

13.5 Using the Congurator

After software has been installed, communication has been

set up and model type selected, is possible operate with

power controller.

13.5.1 To view or save a power controller’s settings using “Simple” view section:

1) Click Simple, if not already on the simple view

2) Click Upload from unit

3) Set the address, if necessary

4) Click READ->

5) Wait for the software to read the parameter settings

6) Click OK

7) If need save the settings in a recipe le:

- Click Save

- Name the recipe

- Click Save button

NOTE! In the simple view the change are not “live”, so

to take eect the change in simply section is necessary

download it with download procedure.

www.west-cs.co.uk 40

Page 41

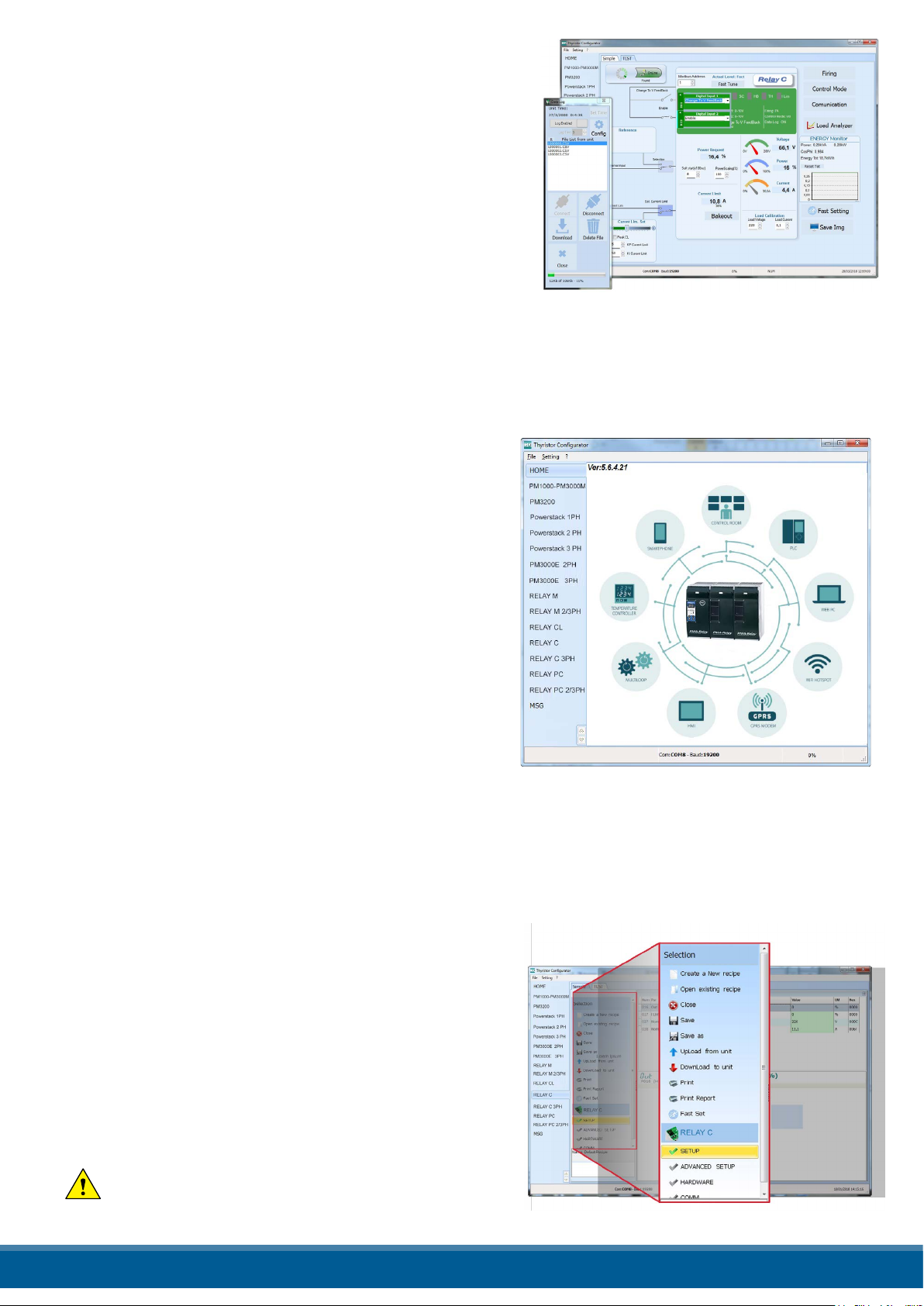

13.5.2 To edit a setting in a recipe:

1) Click Simple, if not already on the simple view

2) Click Open existing recipe

3) Locate and select the recipe le and click Open

4) Click OK

5) Click the menu with the setting you want to change

- SETUP

- ADVANCED SETUP

- HARDWARE

- COMMUNICATIONS

6) Select the value you want to change