Page 1

Page 2

Pro-EC44

2-Loop Graphical Profile

Controller & Recorder

Pro-EC44 User Guide 59540-1

Page 3

Page 4

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

WARNING: THE INTERNATIONAL HAZARD SYMBOL IS INSCRIBED

ADJACENT TO THE REAR CONNECTION TERMINALS. IT IS IMPORTANT

TO READ THIS MANUAL BEFORE INSTALLING OR COMMISSIONING THE

UNIT.

WARNING: THIS SYMBOL MEANS THE EQUIPMENT IS PROTECTED

THROUGHOUT BY DOUBLE INSULATION.

WARNING: PRODUCTS COVERED BY THIS MANUAL ARE SUITABLE FOR

INDOOR USE, INSTALLATION CATEGORY II, POLLUTION CATEGORY 2

ENVIRONMENTS.

Note: It is strongly recommended that applications incorporate a high or low limit

protective device, which will shut down the equipment at a pre-set process

condition in order to prevent possible damage to property or products.

This manual supplements the Concise Product manual supplied with each instrument at the

time of shipment. Information in this installation, wiring and operation manual is subject to

change without notice.

Copyright © October 2013, Danaher Corporation, all rights reserved. No part of this

publication may be reproduced, transmitted, transcribed or stored in a retrieval system, or

translated into any language in any form by any means without the written permission of

Danaher/West Control Solutions.

Copies of this manual are available in electronic format on the West Control Solutions web

site (www.west-cs.com) Printed versions may be purchased from West Control Solutions or

its representatives.

This user guide covers all versions of the West Pro-EC44 controller.

©WCS – Product & specifications may be subject to change without notice - E&OE

Pro-EC44 Product Manual - 59540-1 October 2013 Page i

Page 5

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

Warranty and Returns Statement

These products are sold by West Control Solutions under the warranties set forth in the

following paragraphs. Such warranties are extended only with respect to a purchase of these

products, as new merchandise, directly from West Control Solutions or from a West Control

Solutions distributor, representative or reseller and are extended only to the first buyer

thereof who purchases them other than for the purpose of resale.

Warranty

These products are warranted to be free from functional defects in material and workmanship

for three years from the time the products leave West Control Solutions factory and to

conform at that time to the specifications set forth in the relevant West instruction manuals

sheet or sheets.

THERE ARE NO EXPRESSED OR IMPLIED WARRANTIES, WHICH EXTEND BEYOND THE

WARRANTIES HEREIN AND ABOVE SET FORTH. NO WARRANTY IS MADE OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT TO THE

PRODUCTS.

Limitations

West Control Solutions shall not be liable for any incidental damages, consequential

damages, special damages, or any other damages, costs or expenses excepting only the

cost or expense of repair or replacement as described above. Products must be installed and

maintained in accordance with West Control Solutions instructions. There is no warranty

against damage to the product resulting from corrosion. Users are responsible for the

suitability of the products to their application.

For a valid warranty claim, the product must be returned carriage paid to the supplier within

the warranty period. The product must be properly packaged to avoid damage from

electrostatic discharge or other forms of harm during transit.

Page ii Pro-EC44 Product Manual - 59540-1 October 2013

Page 6

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

How to use this manual

This manual is structured to give easy access to the information required for all aspects of

the installation and use and of the controller. The main sections are shown here, with a full

table of contents at the end.

Warranty and Returns Statement ..................................................................................................... ii

1 Introduction............................................................................................................................. 1

2 Installation .............................................................................................................................. 2

3 Field Upgrade Options ........................................................................................................... 4

4 Electrical Installation .............................................................................................................. 9

5 Powering Up .......................................................................................................................... 29

6 Messages & Error Indications.............................................................................................. 31

7 Application Setup ................................................................................................................. 33

8 Operation and Configuration Menus ................................................................................... 36

9 Input Calibration & Multi-point Scaling ............................................................................... 70

10 Digital Inputs ......................................................................................................................... 75

11 Cascade Control ................................................................................................................... 78

12 Ratio Control ......................................................................................................................... 81

13 Redundant Input ................................................................................................................... 83

14 Valve Motor Drive / 3-Point Stepping Control ..................................................................... 84

15 Setpoint Sources .................................................................................................................. 86

16 Profiler ................................................................................................................................... 87

17 USB Interface ........................................................................................................................ 96

18 Data Recorder ................................................................ ....................................................... 97

19 Controller Tuning.................................................................................................................. 99

20 Serial Communications ...................................................................................................... 109

21 Glossary .............................................................................................................................. 204

22 PC Software ........................................................................................................................ 235

23 Specifications ..................................................................................................................... 245

24 Pro-EC44 Product Coding .................................................................................................. 255

25 Table of Contents ................................................................ ............................................... 257

Pro-EC44 Product Manual - 59540-1 October 2013 Page iii

Page 7

Page 8

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

1 Introduction

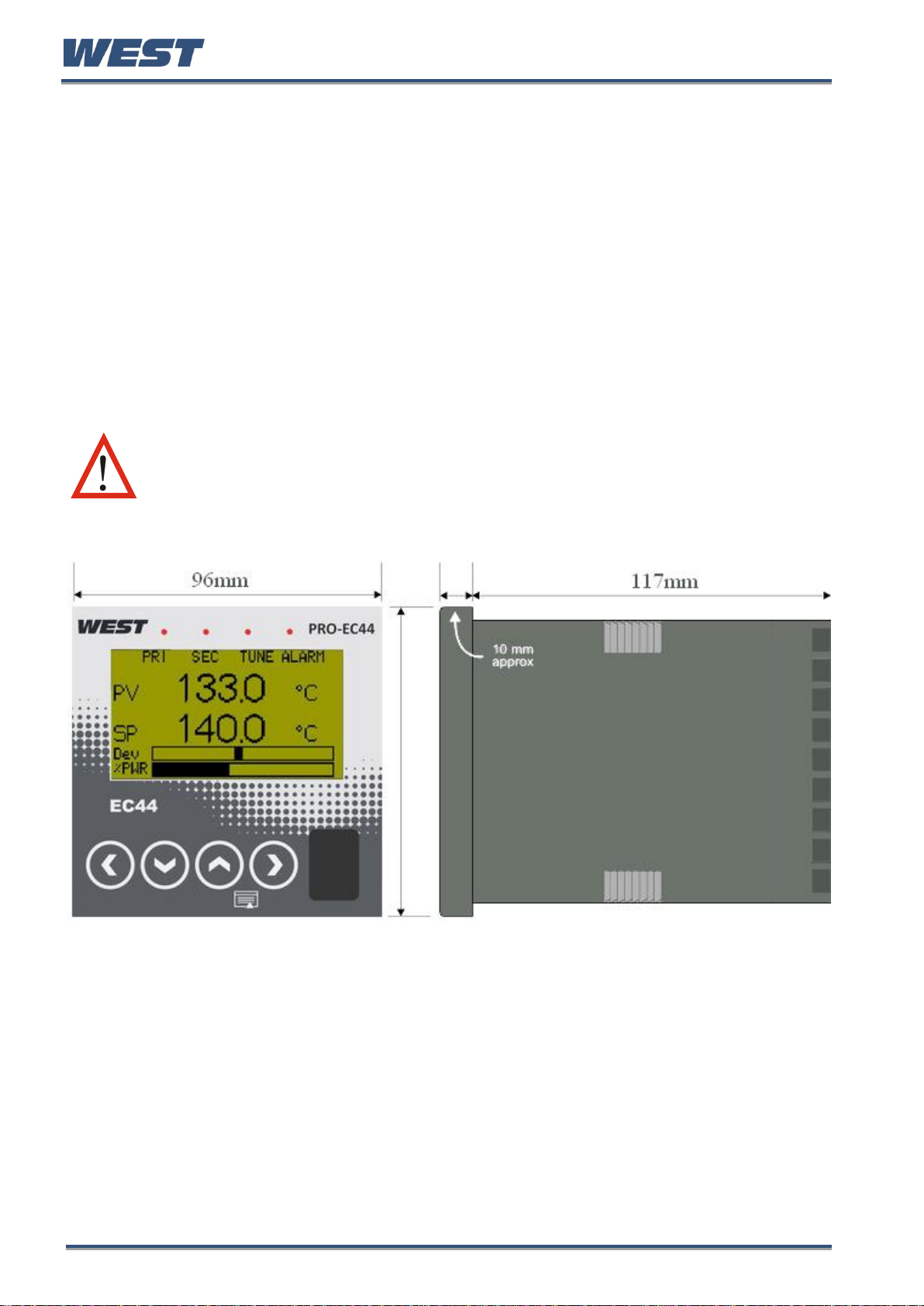

This product is a 1/4 DIN size (96 x 96mm front) microprocessor based graphical process

controller, featuring a 160 x 80 pixel, monochrome LCD with dual colour (red/green)

backlight. It operates from 100-240V at 50/60 Hz or 24V-48V AC/DC, depending on the

model purchased. It can measure and control up to two process variables from a variety of

sources such as temperature, pressure, flow and level. Primary and secondary control

outputs are possible for each loop.

Optional features include a second process input, USB interface, remote setpoint inputs

RS485 or Ethernet communications, profile control and data recording. Control options

include cascade, ratio and 3-point stepping valve control. Automatic tuning or 5 stage gainscheduling are also available.

The USB Interface option allows uploading or downloading instrument configuration settings

to/from a USB memory stick, for easy configuration of multiple instruments or transfer to/from

the PC configuration software. If the data recorder or profiler options are fitted, recordings

and profile information can be transferred via the memory stick.

The data recorder option allows the user to make recordings of the processes over time.

Recordings can be transferred to a memory stick using the USB interface or downloaded via

one of the communications options.

The Profiler option allows the user to predefine up 255 segments, shared amongst up to 64

Setpoint Profiles. These control the setpoint levels for the control loop(s) over time,

increasing, decreasing or holding their values as required. When combined with the real-time

clock (part of the Data Recorder option) the profiling capabilities are expanded to allow

automatic program start at a defined time and day.

Inputs are user configurable for thermocouple and RTD probes, as well as linear process

signal types such as mVDC, VDC or mADC. Two-point calibration or multipoint scaling can

compensate for errors or non-linear signals. Output options include single or dual relays,

single or dual SSR drivers, triacs or linear mA/V DC. These can be used for process control,

alarms/events or retransmission of the process variable or setpoint to external devices.

Transmitter power supply options can provide an unregulated 24V DC (22mA) auxiliary

output voltage, or a 0 to 10VDC stabilised excitation for external signal transmitters.

Up to 7 alarms can be defined as process high or low, deviation (active above or below

controller setpoint), band (active both above and below setpoint), rate of input change,

control loop, PID power or signal break types. Alarm status can be indicated by lighting an

LED, changing the display backlight colour or viewing the active alarm status screen. These

alarms can be linked to any suitable output.

Configuration for basic applications is possible using the easy Setup Wizard run

automatically at first power-up or manually later. Access to the full range of parameters is via

a simple menu driven front panel interface, or the PC based configuration software.

Pro-EC44 Product Manual - 59540-1 October 2013 Page 1

Page 9

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

CAUTION: Installation should be only performed by technically competent

personnel. It is the responsibility of the installing engineer to ensure that

the configuration is safe. Local Regulations regarding electrical installation

& safety must be observed (e.g. US National Electrical Code (NEC) or

Canadian Electrical Code).

2 Installation

Unpacking

1. Remove the product from its packing. Retain the packing for future use, in case it is

necessary to transport the instrument to a different site or to return it to the supplier for

servicing.

2. The instrument is supplied with a panel gasket and push-fit mounting clamp. A multi-page

concise manual is supplied with the instrument, in one or more languages. Examine the

delivered items for damage or defects. If any are found, contact your supplier

immediately.

Installation

Figure 1. Main dimensions

Panel-Mounting

The controller should be mounted in a properly earthed metal cabinet. The mounting panel

must be rigid and may be up to 6.0mm (0.25 inches) thick. The cut-out size is:

92mm x 92mm (+0.5mm / -0.0mm).

Pro-EC44 Product Manual - 59540-1 October 2013 Page 2

Page 10

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

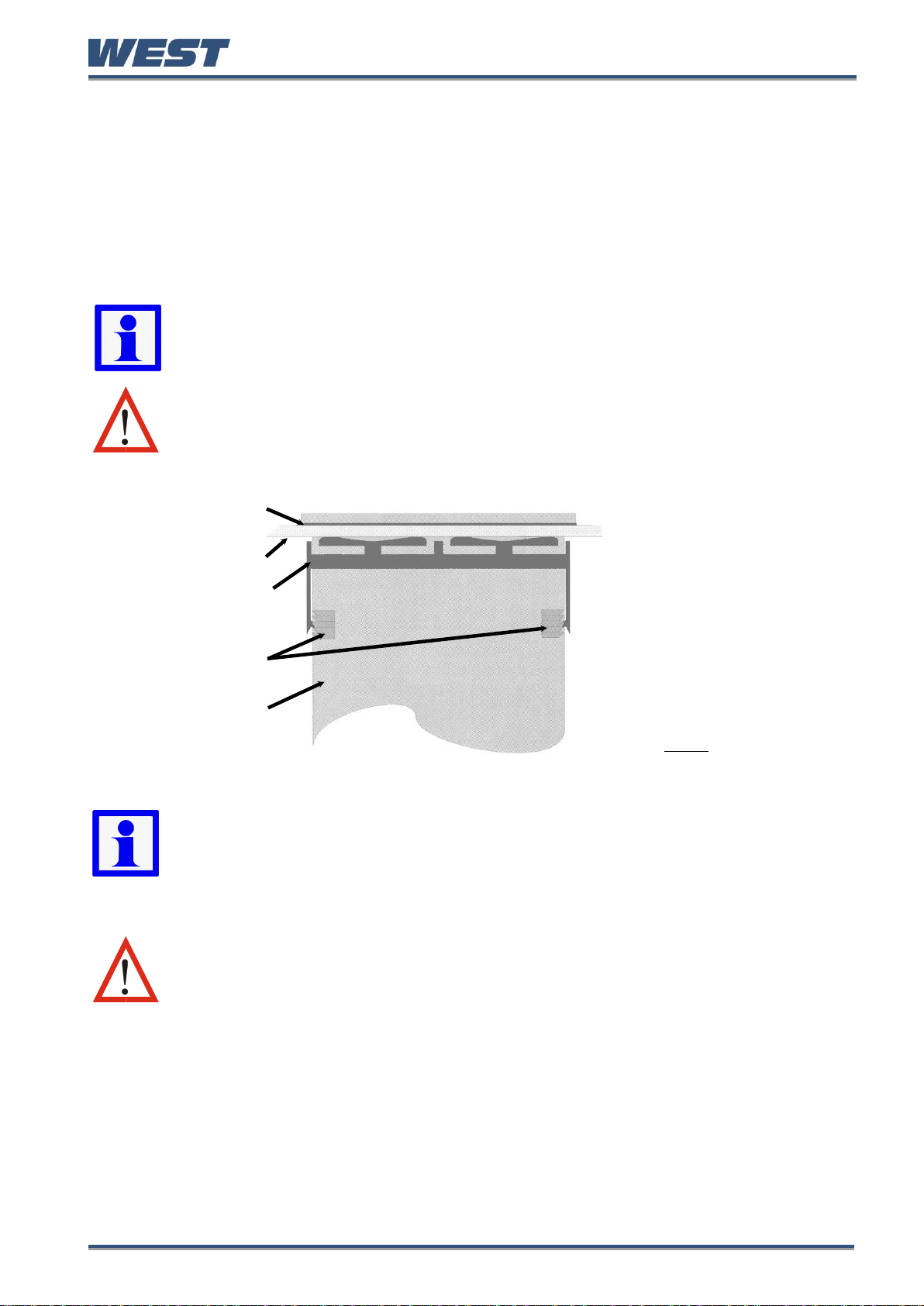

Note: The mounting clamp tongues may engage the ratchets either on the sides

or the top/bottom faces of the Instrument housing. When installing several

Instruments side-by-side in one cut-out, use the ratchets on the top/bottom faces.

CAUTION: Ensure the inside of the panel remains within the instrument

operating temperature and that there is adequate airflow to prevent

overheating.

Gasket

Mounting Panel

Clamp

Ratchets

Instrument

Housing

1. Insert instrument into the

panel cut-out.

2. Hold front bezel firmly

(without pressing on the

display area), and re-fit

mounting clamp. Push the

clamp forward, using a tool if

necessary, until gasket

compresses and instrument

is held firmly in position.

CAUTION: Do not remove the panel gasket, as this may result in inadequate

clamping and sealing of the instrument to the panel.

Note: For an effective IP66 seal against dust and moisture, ensure gasket is well

compressed against the panel, with the 4 tongues located in the same ratchet

slot.

Instruments may be mounted side-by-side in a multiple installation, but instrument to panel

moisture and dust sealing will be compromised. Allow a 20mm gap above, below and behind

the instrument for ventilation. The cut-out width (for n instruments) is:

(96n - 4) mm or (3.78n - 0.16) inches

If panel sealing must be maintained, mount each instrument into an individual cut-out with

10mm or more clearance between the edges of the holes.

Figure 2. Panel-Mounting the instrument

Once the instrument is installed in its mounting panel, it may be subsequently removed from

its housing if necessary, as described in the Fitting and Removing Plug-in Modules section.

Cleaning

Clean the front panel by washing with warm soapy water and dry immediately. If the USB

option is fitted, close the USB port cover before cleaning.

Pro-EC44 Product Manual - 59540-1 October 2013 Page 3

Page 11

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

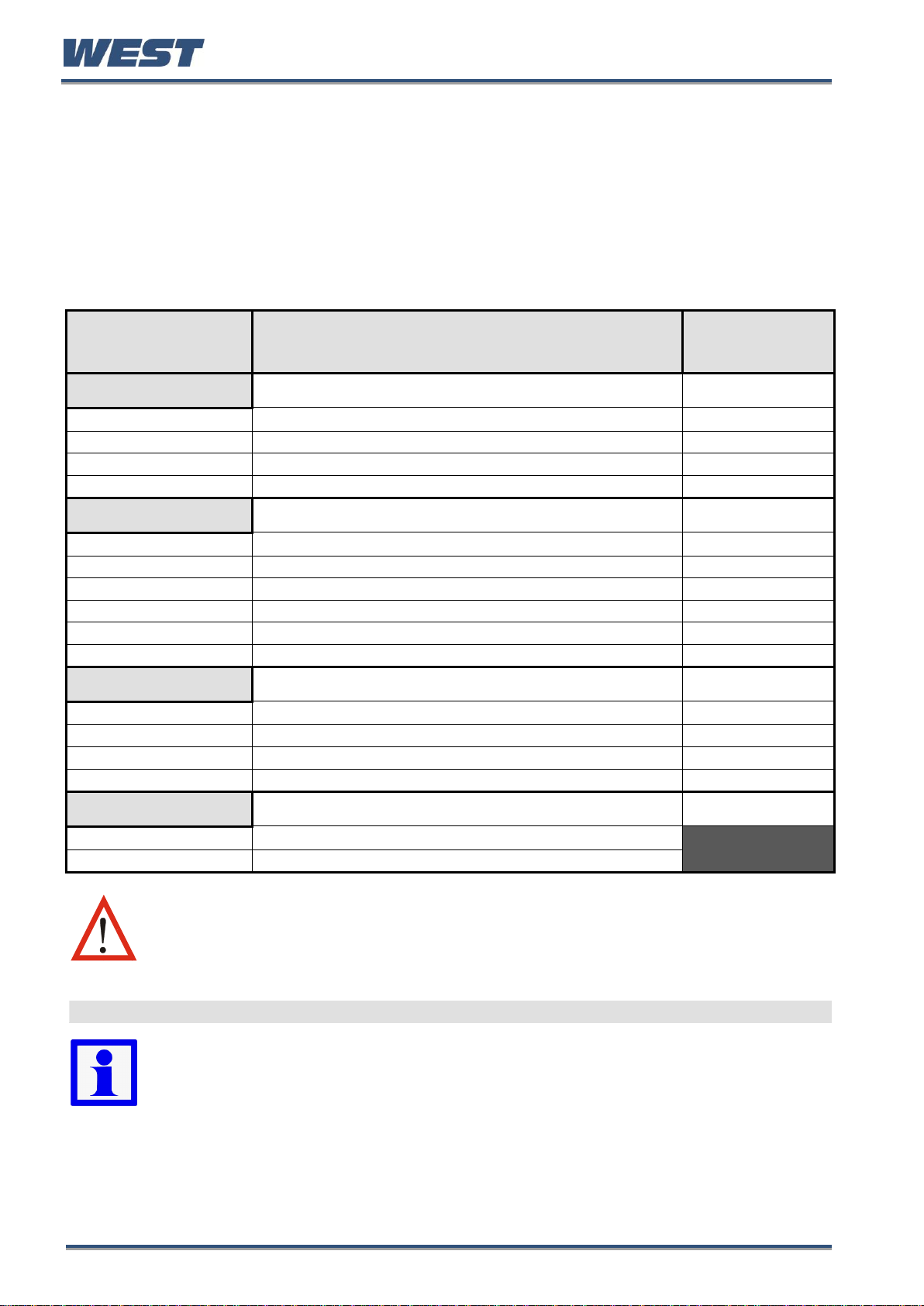

PART

NUMBER

AVAILABLE OPTIONS & ACCESSORIES

BOARD

IDENTIFICATION

NUMBER

MODULE SLOT 1

PO1-R10

Single Relay Output for plug-in module slot 1

716/01

PO1-S20

Single SSR Driver Output for plug-in module slot 1

716/02

PO1-T80

Triac Output for plug-in module slot 1

716/03

PO1-C21

Linear mA / Voltage Output for plug-in module slot 1

639/01

MODULE SLOT 2 or 3

PO2-R10

Single Relay Output for plug-in module slot 2 or 3

717/01

PO2-W09

Dual Relay Output for plug-in module slot 2 or 3

644/01

PO2-S20

Single SSR Driver Output for plug-in module slot 2 or 3

717/02

PO2-S22

Dual SSR Driver Output for plug-in module slot 2 or 3

644/02

PO2-T80

Triac module Output for plug-in module slot 2 or 3

647/01

PO2-W08

24VDC Transmitter Power Supply for module slot 2 or 3

642/01

MODULE SLOT A

PA1-W03

Digital Input for plug-in module slot A

641/02

PA1-W04

Basic Auxiliary Input for plug-in module slot A

653/01

PA1-W06

RS485 Serial Communications for plug-in module slot A

680/01

PA1-ETH

Ethernet Communications for plug-in module slot A

707/01

ACCESSORIES

PS1-PRF

Profiler Enable Key-code

PS1-PRW

Blue Control PC Configuration Software & Lead

CAUTION: Plastic pegs prevent fitting of older non-reinforced single relay

modules (board identification numbers 637/01 and 638/01). Fitting the older

relay modules reduces the isolation rating to Basic 240V isolation and is

therefore not recommended.

Remove this peg when fitting Dual Relay Modules.

Board Positions

Note: All dual relay modules have reinforced isolation.

3 Field Upgrade Options

Plug-Modules and Upgradeable Functions

Plug-Modules can be either pre-installed at the time of manufacture, or retrofitted in the field

to expand the capabilities of the controller. Contact your supplier to purchase these items.

Part numbers and circuit board identification numbers for the plug-in modules and

accessories are shown in below:

Pro-EC44 Product Manual - 59540-1 October 2013 Page 4

Page 12

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

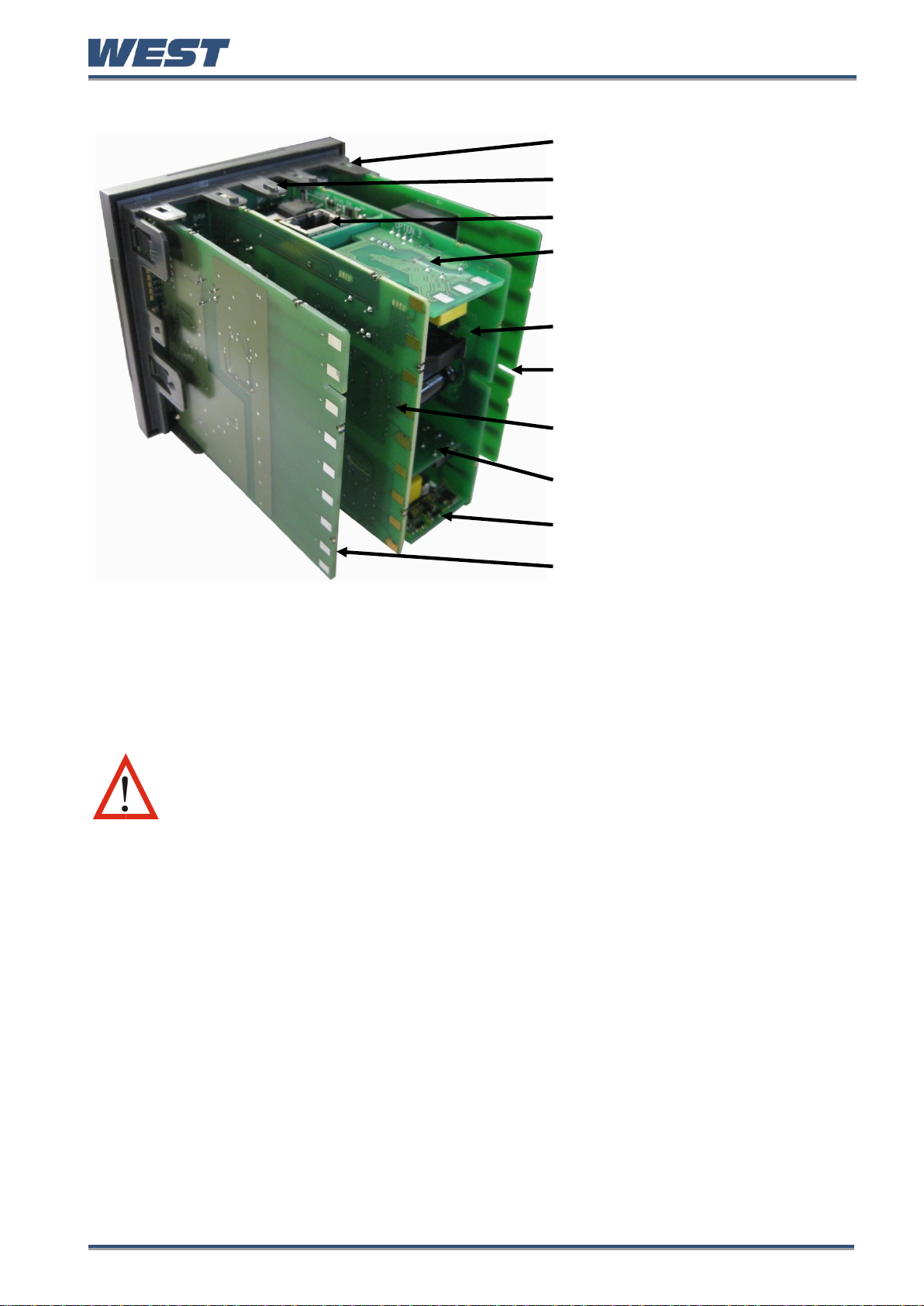

Board Mounting Struts (x4)

Front Panel Removal Latch (x1)

Plug-in Module A

Plug-in Module 3

Power Supply Board

2nd Universal Input & Base

Option 2 Board

1st Universal Input & Base

Option 1 Board

Plug-in Module 1

Plug-in Module 2

USB/Digital Input C Option

Board

CAUTION: Before removing the instrument from its housing, ensure that all

power has been removed from the rear terminals. Modules / boards should

be replaced by a technically competent technician.

Figure 3. Rear view (uncased) & board positions

Preparing to Install or Remove Plug-in Modules

1. Grip the edges of the front panel (there is a finger grip on each edge) and pull it forwards

approximately 10mm, until the Front Panel Removal Latch prevents further movement.

The purpose of the latch is to prevent removal of the instrument without the use of a tool.

2. The Front Panel Removal Latch must be pushed down to allow removal of the instrument.

Using a tool (e.g. screwdriver or pen tip), press down it down through the front central

ventilation hole. This will release the instrument from the case.

3. The internal boards can now be accessed. Take note of the orientation of the instrument

and boards for subsequent replacement into the housing. The positions of the boards,

their mountings and the Front Panel Removal Latch are shown above.

Pro-EC44 Product Manual - 59540-1 October 2013 Page 5

Page 13

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

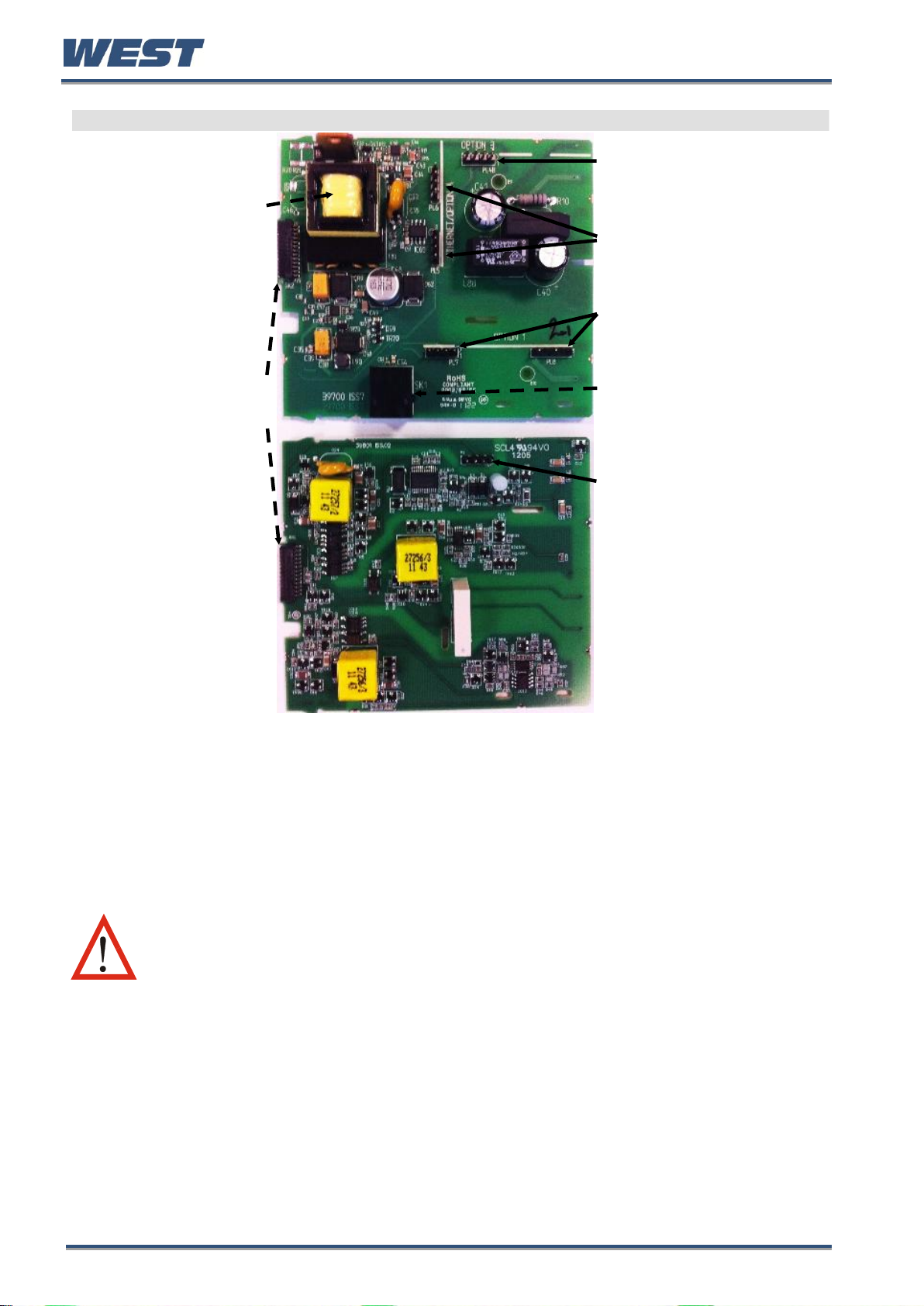

Main Board Connectors

POWER SUPPLY

BOARD

Transformer Colour

Code

100-240V (Yellow)

24-48V(Blue)

Display Board

Connections

1st UNIVERSAL

INPUT / BASE

OPTION 1 BOARD

Module Slot 3

Connector PL4B

Module Slot A

Connectors PL5, & PL6

Module Slot 1

Connectors PL7 & PL8

PC Configurator

Socket SK1

Module Slot 2

Connector PL4A

CAUTION: Replacement of boards must be carried out by a technically

competent technician. If the Power Supply board does not match the

labelling, users may apply incorrect voltage resulting in irreparable

damage.

This product is designed to allow the user to reconfigure some hardware options in the field

by changing the plug-in modules in slots 1, 2, 3, & A located on the power supply and 1st

universal input boards. The main boards (display/CPU, power supply, inputs 1 & 2 and digital

input/USB) are factory fitted, but may be removed while reconfiguring the plug-in modules.

Take care when re-fitting these boards. Observe the power supply board transformer colour,

and case labelling to check the supply voltage, otherwise irreparable damage may occur.

Figure 4. Main board connectors

Pro-EC44 Product Manual - 59540-1 October 2013 Page 6

Page 14

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

CAUTION: Check for correct orientation of the modules and that all pins

are located correctly.

CAUTION: Before replacing the instrument in its housing, ensure that all

power has been removed from the rear terminals.

CAUTION: Ensure that the instrument is correctly orientated. A mechanical

stop will operate if an attempt is made to insert the instrument in the wrong

orientation, this stop MUST NOT be over-ridden.

Removing/Replacing Option Modules

1. To remove or replace Plug-in Modules 1, 2, 3 or A it is necessary to detach the power

supply and input boards from the front panel by lifting first the upper and then lower

mounting struts.

2. Remove or fit the modules to the connectors on the power supply and input boards. The

location of the connectors is shown below. Plastic pegs prevent fitting of older nonreinforced single relay modules – Remove the peg to fit dual relay modules

3. Assemble the Power Supply and Input boards together. Tongues on each option module

locate into slots cut into the main boards, opposite each of the connectors. Hold the Power

and Input boards together and relocate them back on their mounting struts.

4. Push the boards forward to ensure correct connection to the front Display/CPU board and

re-check the installation of the Option C and/or 2nd Input / Base Option 2 boards if present.

Replacing the Instrument in its Housing

With the required option modules correctly located into their respective positions the

instrument can be replaced into its housing as follows:

1. Hold the Power Supply and Input boards together.

2. Align the boards with the guides in the housing.

3. Slowly and firmly, push the instrument into position in its case.

Auto Detection of Plug-in Modules

The instrument automatically detects which plug-in modules have been fitted into each slot.

The menus and screens change to reflect the options compatible with the hardware. The

modules fitted can be viewed in the product information menu, as detailed in the Product &

Service Information Mode section of this manual.

Pro-EC44 Product Manual - 59540-1 October 2013 Page 7

Page 15

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

CAUTION: Servicing of the Data Recorder/RTC circuit and replacement of

the lithium battery should only be carried out by a technically competent

technician.

Data Recorder Board

If installed, the Data Recorder memory and Real Time Clock (RTC) components are located

on a plug-in daughter board attached to the front Display/CPU board.

Profiler Enabling

If you purchased a controller with the Profiler option installed, these features will be enabled

during manufacture.

Controllers supplied without the Profiler option installed can be upgraded in the field by

purchasing a licence code number from your supplier. A unique code must be purchased to

enable profiling on each controller that requires it.

Entering the Profiler Enable Code

Hold down the L and D keys during the power-up “splash screen”.

Using the D or U keys, enter the 16-character licence code in the displayed screen.

Press R to move on to the next character. Press L to move back to the previous

character.

Press R after entering the final character.

To confirm if profiling is installed in your instrument, check the Controller Feature Information

in Product & Service Information Mode.

Pro-EC44 Product Manual - 59540-1 October 2013 Page 8

Page 16

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

CAUTION: Installation should be only performed by technically competent

personnel. It is the responsibility of the installing engineer to ensure that

the configuration is safe. Local Regulations regarding electrical installation

& safety must be observed (e.g. US National Electrical Code (NEC) or

Canadian Electrical Code).

CAUTION: The only wires that should run together are those of the same

category.

4 Electrical Installation

Avoiding EMC Problems

This controller has passed EMC compliance tests to EN61326. There should be no difficulty

achieving this level of compliance in use, but it should be borne in mind that the wiring of the

installation can significantly reduce the efficiency of instrumentation immunity due to the ease

with which high frequency RF can enter via unprotected cables.

The following general recommendations can reduce the possibility of EMC problems.

1. If the instrument is being installed in existing equipment, wiring in the area should be

checked to ensure that good wiring practices have been followed.

2. The controller should be mounted in a properly earthed metal cabinet. All round metal

shielding is important, so the cabinet door may require a conductive sealing strip.

3. It is good practice to ensure that the AC neutral is at or near ground (earth) potential.

A proper neutral will help ensure maximum performance from the instrument.

4. Consider using a separate isolation transformer to feed only the instrumentation. A

transformer can protect instruments from noise found on the AC power supply.

Cable Isolation & Protection

Four voltage levels of input and output wiring may be used with the unit:

1. Analogue inputs or outputs (for example thermocouple, RTD, VDC, mVDC or mADC)

2. Relays & Triac outputs

3. Digital Inputs & SSR Driver outputs

4. AC power

If any wires need to run parallel with any from another category, maintain a minimum space

of 150mm between them. If wires MUST cross each other, ensure they do so at 90 degrees

to minimise interference.

Keep signal cables as short as possible. If an earthed thermocouple is used or if the sensor

has a screened cable, it should be earthed at one point only, preferably at the sensor

location or cabinet entry point, by means of a metal gland. Ideally all analogue and digital

signals should be shielded like this, but for unscreened cables, large diameter ferrite sleeves

at the cabinet entry point are an effective method of reducing RF interference. Looping

cables through the ferrite sleeves a number of times improves the efficiency of the filtering.

For mains input cables the fitting a suitable mains filter can provide good results.

Pro-EC44 Product Manual - 59540-1 October 2013 Page 9

Page 17

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

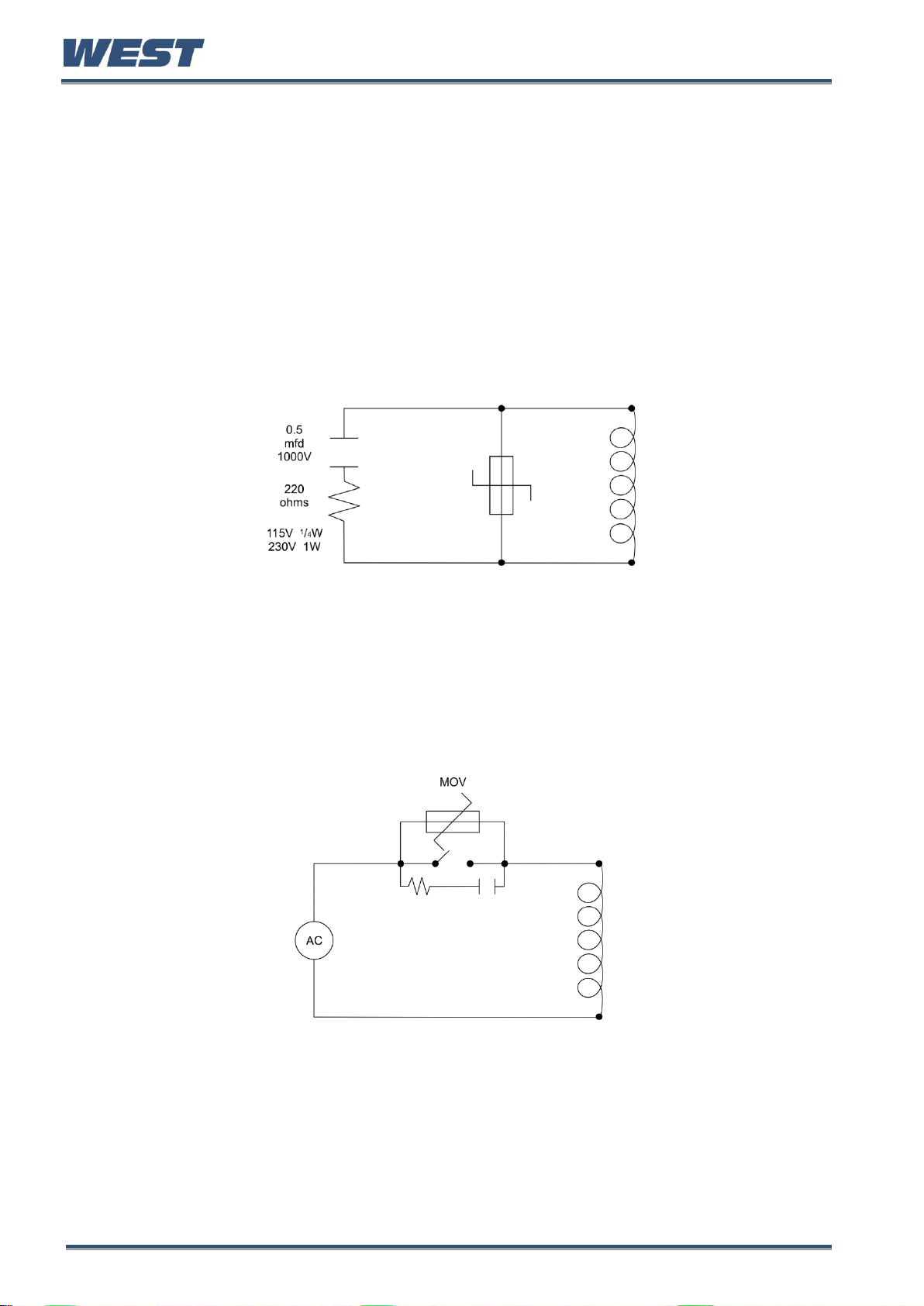

Noise Suppression at Source

If possible, eliminate mechanical contact relays and replace with solid-state relays.

Noise-generating devices such as Ignition transformers, arc welders, motor drives, relays

and solenoids should be mounted in a separate enclosure. If this is not possible, separate

them from the instrumentation, by the largest distance possible.

Many manufacturers of relays, contactors etc supply 'surge suppressors' to reduce noise at

its source. For those devices that do not have surge suppressors supplied, ResistanceCapacitance (RC) networks and/or Metal Oxide Varistors (MOV) may be added.

Inductive coils:- MOVs are recommended for transient suppression in inductive coils.

Connect as close as possible, in parallel to the coil. Additional protection may be provided by

adding an RC network across the MOV.

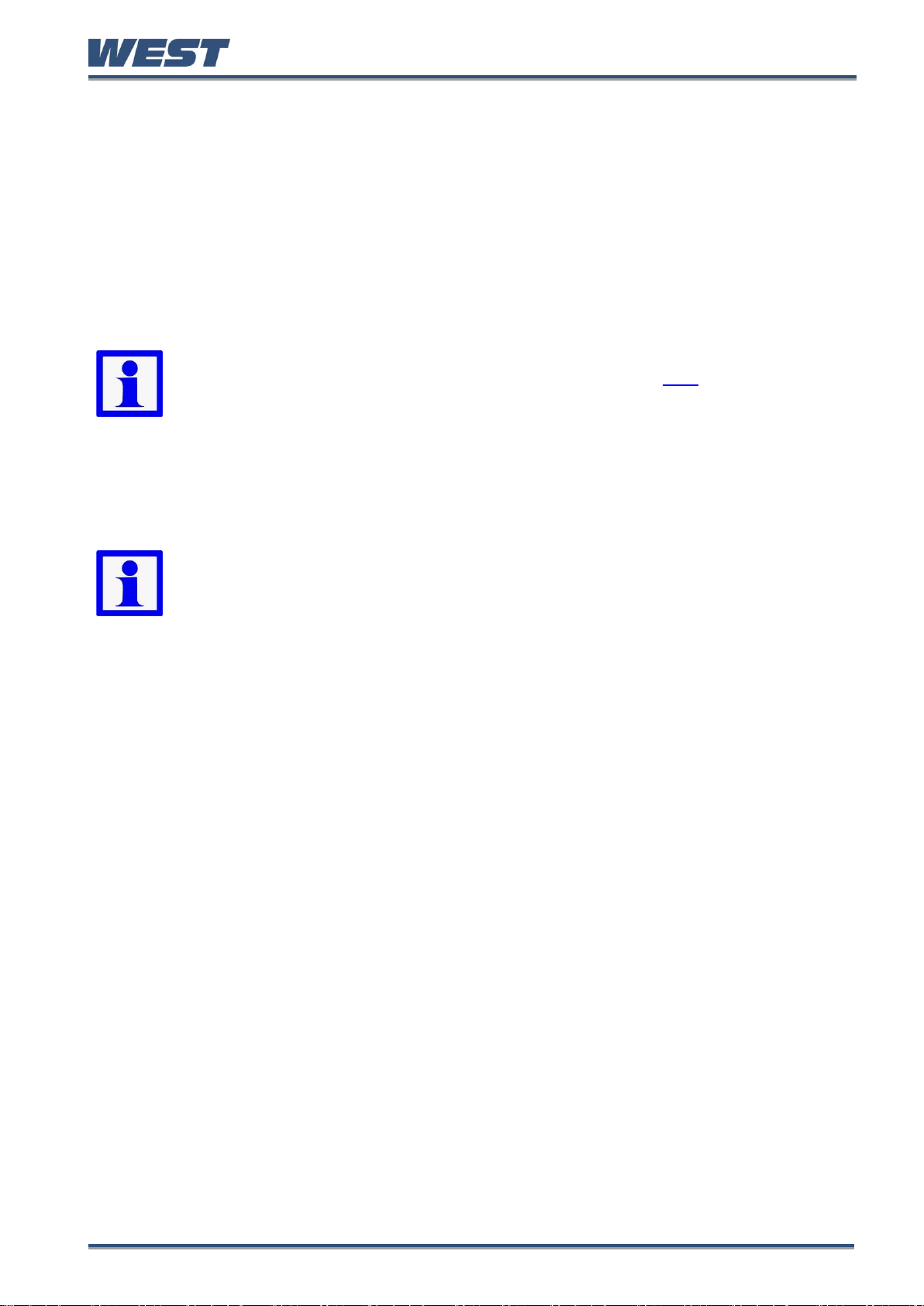

Figure 5. Transient suppression with inductive coils

Contacts:- Arcing may occur across contacts when they open and close. This results in

electrical noise as well as damage to the contacts. Connecting a properly sized RC network

can eliminate this arc.

For circuits up to 3 amps, a combination of a 47 ohm resistor and 0.1 microfarad capacitor

(1000 volts) is recommended. For circuits from 3 to 5 amps, connect two of these in parallel.

Figure 6. Contact noise suppression

Pro-EC44 Product Manual - 59540-1 October 2013 Page 10

Page 18

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

CAUTION: The placement of probes into pipe work some distance from the

heating vessel leads to transport delay, which results in poor control.

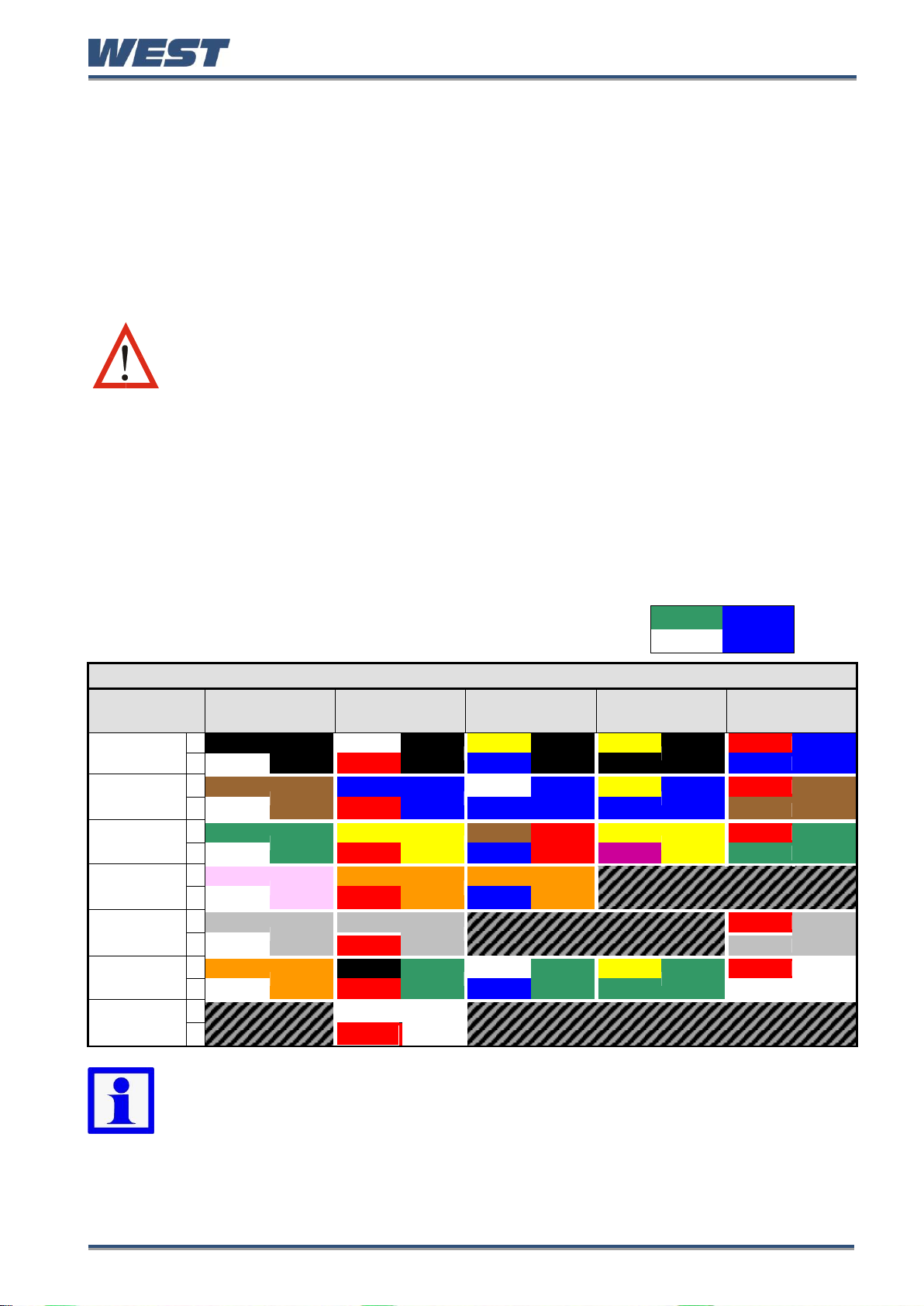

THERMOCOUPLE WIRE COLOUR CHART

Type

International

IEC584-3

USA ANSI

MC 96.1

British

BS1843

French

NFC 42-324

German

DIN 43710

J

+*

Black

Black

White

Black

Yellow

Black

Yellow

Black

Red

Blue

-

White

Red

Blue

Black

Blue

T

+

Brown

Brown

Blue

Blue

White

Blue

Yellow

Blue

Red

Brown

-

White

Red

Blue

Blue

Brown

K

+

Green

Green

Yellow

Yellow

Brown

Red

Yellow

Yellow

Red

Green

-*

White

Red

Blue

Purple

Green

N

+

Pink

Pink

Orange

Orange

Orange

Orange

-

White

Red

Blue

B

+

Grey

Grey

Grey

Grey

Red

Grey

-

White

Red

Grey

R & S

+

Orange

Orange

Black

Green

White

Green

Yellow

Green

Red

White

-

White

Red

Blue

Green

White

C (W5)

+

White

White

-

Red

Note: * = Wire is magnetic – a magnet can be used to assist with correctly

identifying the type and polarity of the conductors

+ Wire

Sheath

- Wire

Sensor Placement (Thermocouple or RTD)

If a temperature probe is to be subjected to corrosive or abrasive conditions, it must be

protected by an appropriate thermowell.

Probes must be positioned to reflect the true process temperature:

1. In a liquid media - the most agitated area

2. In air - the best circulated area

For a two wire RTD, a wire link should be used in place of the third wire (see the wiring

section for details). Two wire RTDs should only be used with lead lengths less than 3 metres.

Use of three wire RTDs is strongly recommended to reduce errors do to lead resistance.

Thermocouple Wire Identification

The different thermocouple types are identified by their wires colour, and where possible, the

outer insulation as well. There are several standards in use throughout the world, but most

regions now use the International IEC584-3 standard.

The table below shows the wire and sheath colours used for most

common thermocouple types. The format used in this table is:

Pro-EC44 Product Manual - 59540-1 October 2013 Page 11

Page 19

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

CAUTION: Installation should be only performed by technically competent

personnel. It is the responsibility of the installing engineer to ensure that

the configuration is safe. Local Regulations regarding electrical installation

& safety must be observed (e.g. US National Electrical Code (NEC) or

Canadian Electrical Code).

CAUTION: This equipment is designed for installation in an enclosure that

provides adequate protection against electric shock. The isolation switch

should be located in close proximity to the unit, in easy reach of the

operator and appropriately marked.

WARNING: This symbol means the equipment is protected throughout by

double insulation. All external circuits connected must provide double

insulation. Failure to comply with the installation instructions may impact

the protection provided by the unit.

Pre-wiring – Cautions, Warnings & Information

WARNING:

TO AVOID ELECTRICAL SHOCK, AC POWER WIRING MUST NOT BE CONNECTED TO THE

SOURCE DISTRIBUTION PANEL UNTIL ALL WIRING PROCEDURES ARE COMPLETED.

CHECK THE INFORMATION LABEL ON THE CASE TO DETERMINE THE CORRECT

VOLTAGE BEFORE CONNECTING TO A LIVE SUPPLY.

Pro-EC44 Product Manual - 59540-1 October 2013 Page 12

Page 20

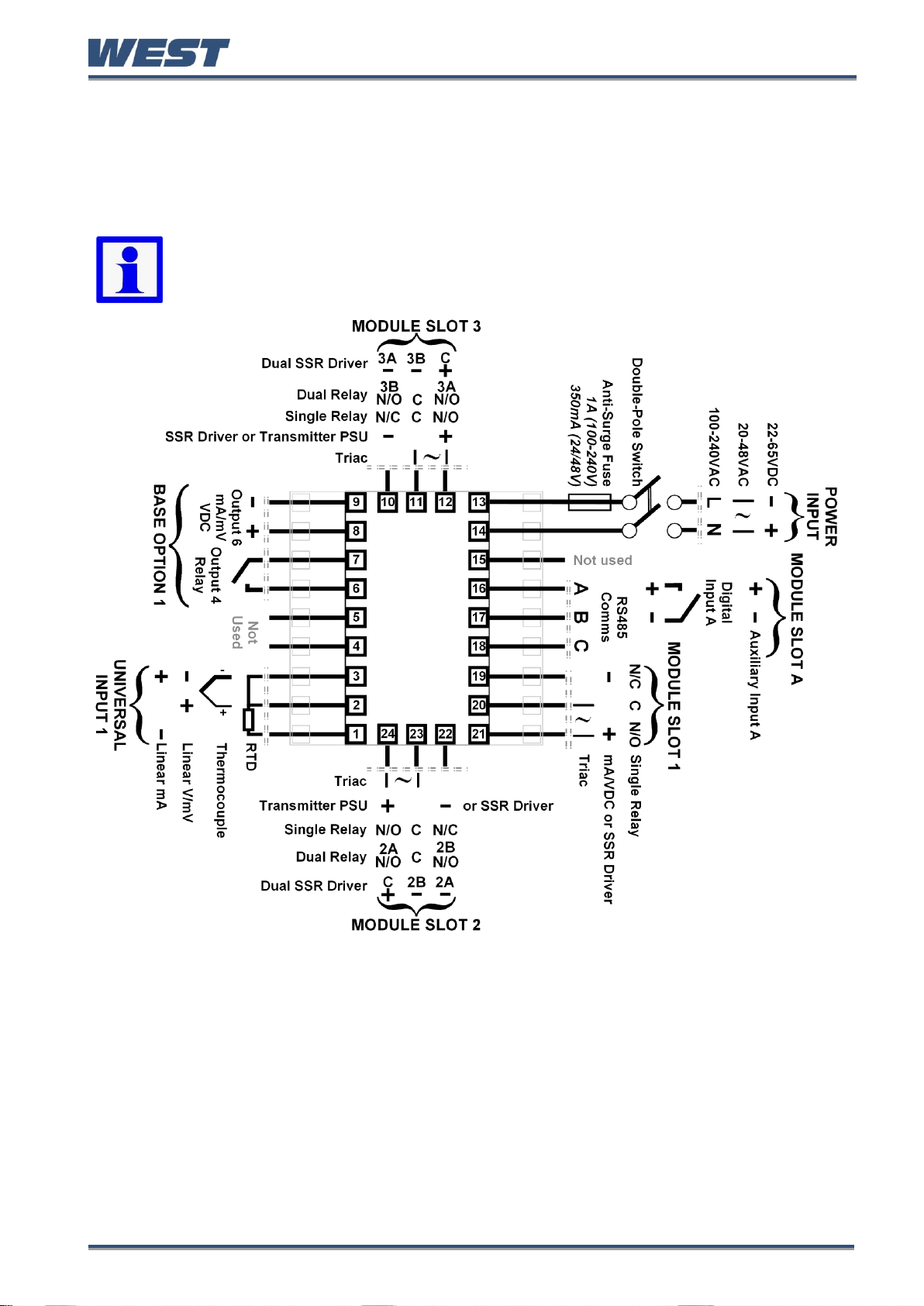

Connections and Wiring

Note: The wiring diagram below shows all possible combinations to the main

connections (numbered 1 to 24) in the centre of the case rear. The actual

connections required depends upon the features and modules fitted.

Central Terminal Connections

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

.

Figure 7. Central Terminals 1 to 24

WARNING:

CHECK THE INFORMATION LABEL ON THE CASE TO DETERMINE THE CORRECT VOLTAGE

BEFORE CONNECTING TO A LIVE SUPPLY.

Pro-EC44 Product Manual - 59540-1 October 2013 Page 13

Page 21

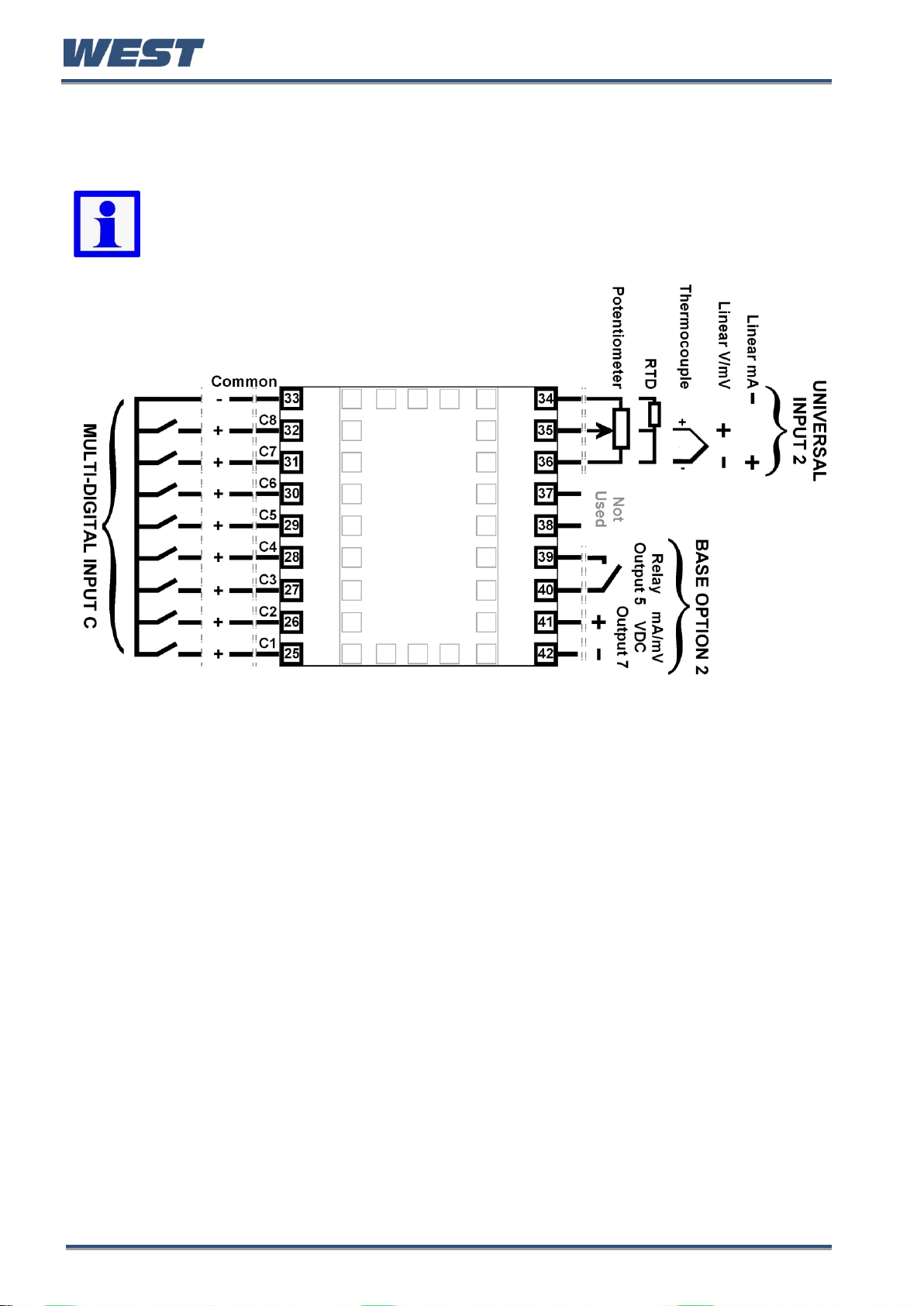

Outer Terminal Connections

Note: The wiring diagram below shows the Central Terminals (numbered 25 to

42) at the sides of the case rear. Connections for the 2nd Input, Base Option 2

and Digital Input C are shown. The actual connections required depends upon

the features and modules fitted.

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

Figure 8. Outer Terminals 25 to 42

Pro-EC44 Product Manual - 59540-1 October 2013 Page 14

Page 22

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

CAUTION: This equipment is designed for installation in an enclosure that

provides adequate protection against electric shock. An isolation switch

should be located in close proximity to the unit, in easy reach of the

operator and appropriately marked.

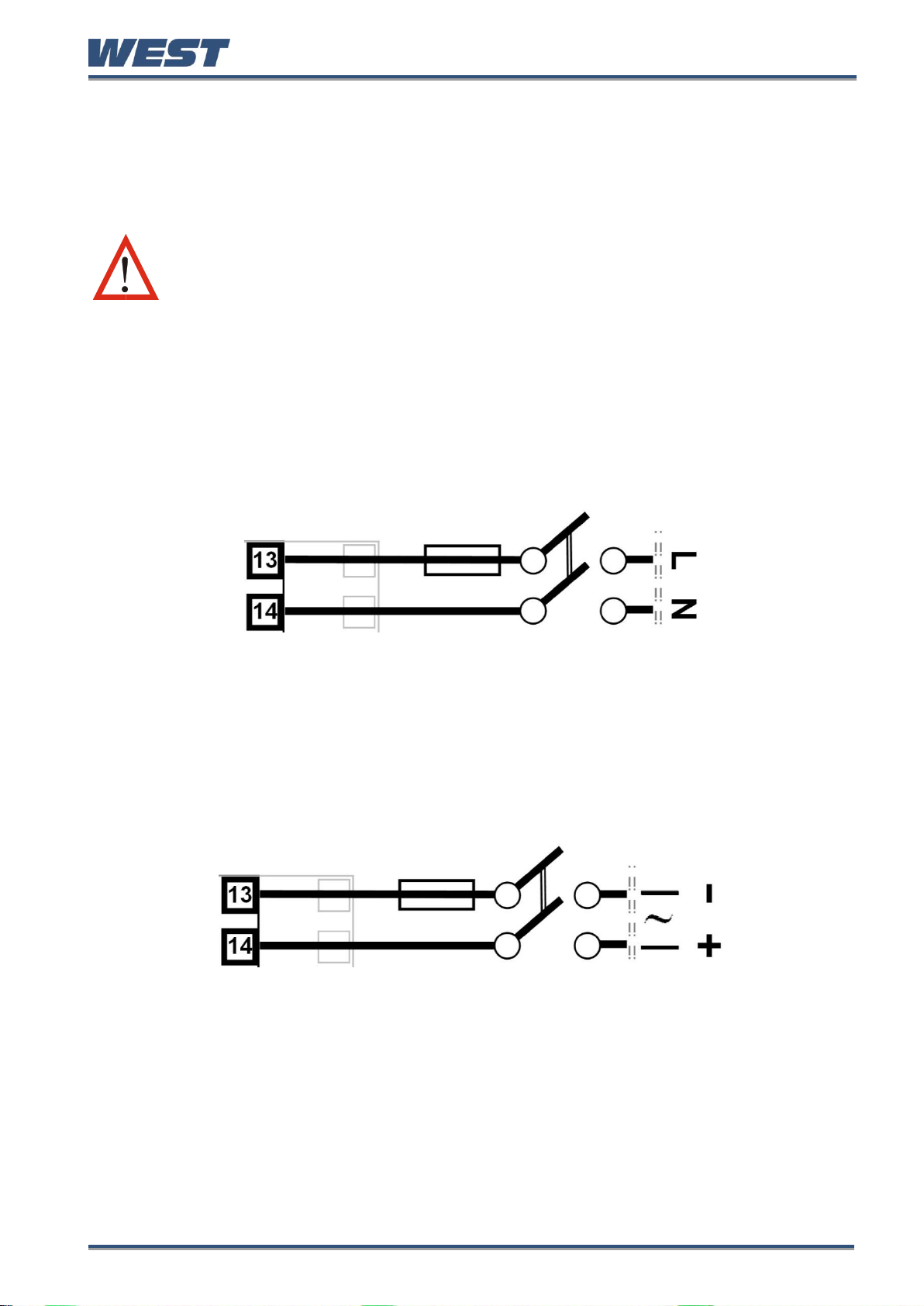

Power Connections

WARNING:

CHECK THE INFORMATION LABEL ON THE CASE TO DETERMINE THE CORRECT VOLTAGE

BEFORE CONNECTING TO A LIVE SUPPLY.

Power Connections - Mains Powered Instruments

Mains powered instruments operate from a 100 to 240V (±10%) 50/60Hz supply. Power

consumption is 20VA. Connect the line and neutral as illustrated via a UL listed fuse type:

250V AC 1Amp anti-surge and a two-pole IEC60947-1 & IEC60947-3 compliant isolation

switch / circuit breaker located within easy reach of the operator and appropriately marked.

If relays switch mains voltage this should be separate from the instruments mains supply.

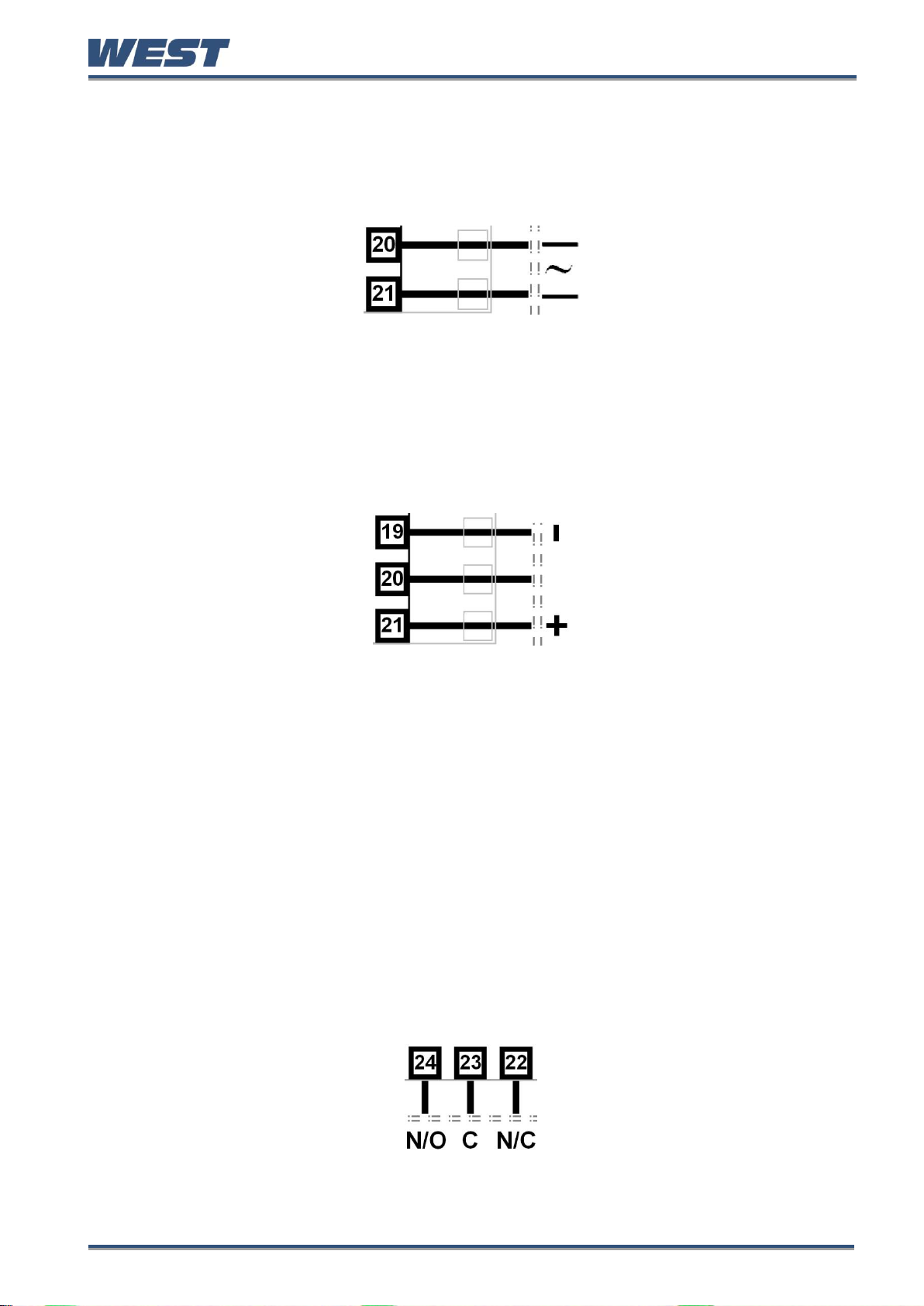

Figure 9. Mains Power Connections

Power Connections - 24/48V AC/DC Powered Instruments

24/48V AD/DC powered instruments will operate from a 20 to 48V AC or 22 to 55V DC

supply. AC power consumption is 15VA max, DC power consumption is 12 watts max.

Connection should be via a UL listed fuse type: 65v dc 350mAamp anti-surge and a two-pole

IEC60947-1 & IEC60947-3 compliant isolation switch / circuit breaker located within easy

reach of the operator and appropriately marked.

Figure 10. 24/48V AC/DC Power Connections

Pro-EC44 Product Manual - 59540-1 October 2013 Page 15

Page 23

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

Universal Input 1 Connections

Universal Input 1 is present on all models. This input is normally used for the measured

variable signal from a process to be controlled. It can be connected to thermocouples;

resistance temperature detectors; analogue mA; mV or V DC signals. The input settings are

in the Input 1 Configuration sub-menu. Connections for the various types are shown below.

Ensure that the signal is correctly connected, paying particular attention to the polarity.

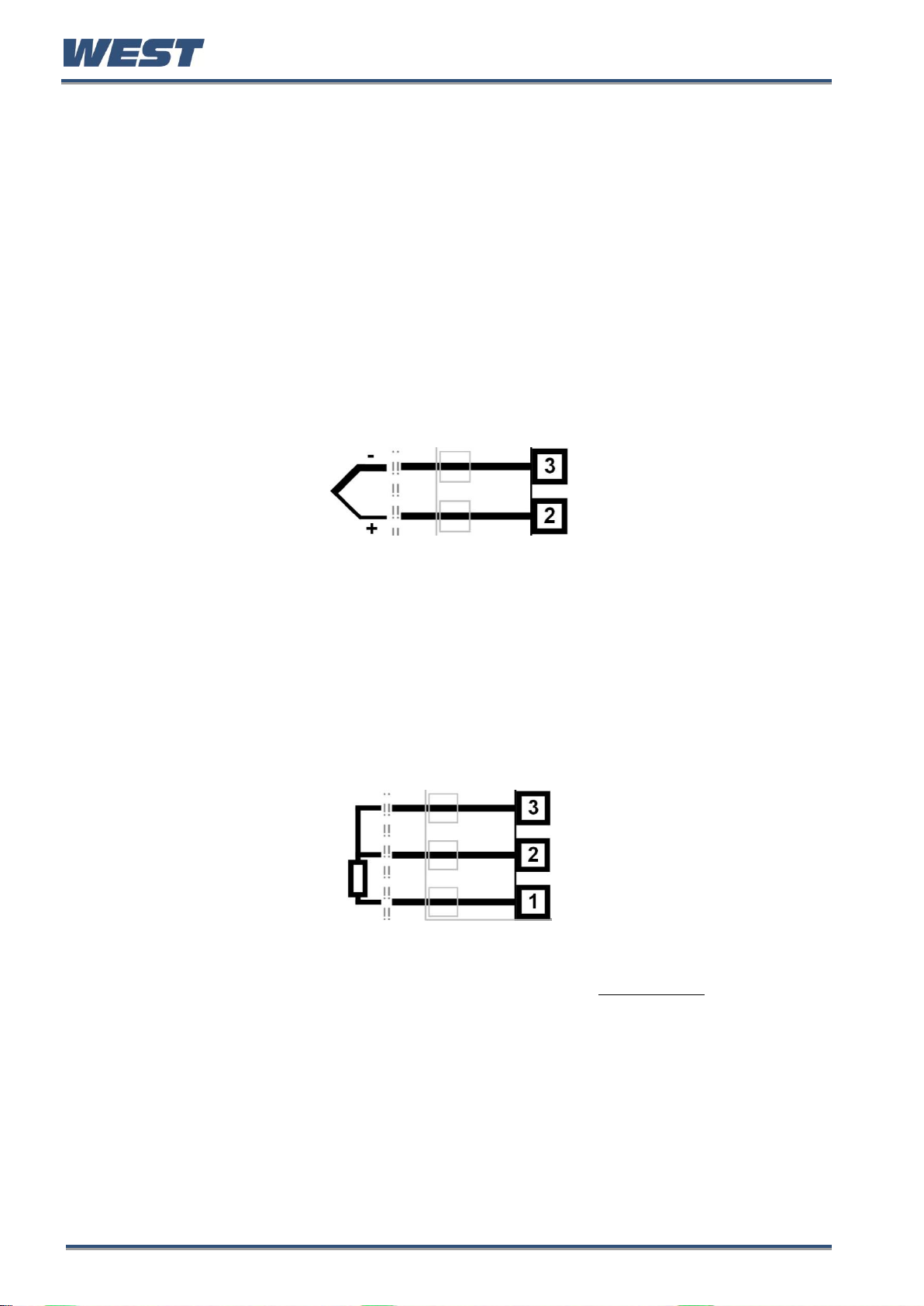

Universal Input 1 Connections - Thermocouple (T/C)

Supported thermocouple types & ranges are listed in the input specifications section on page

245. Only use the correct thermocouple wire or compensating cable from the sensor to the

instrument terminals avoiding joints in the cable if possible. Where joints are made, special

thermocouple connectors must be used. Failure to use the correct wire type and connectors

will lead to inaccurate readings. Ensure correct polarity of the wires by cross-referencing the

colours with the thermocouple reference table above.

Figure 11. Input 1 - Thermocouple Connections

Universal Input 1 Connections – PT100 / NI120 (RTD) input

The inputs supports two types of RTD. PT100 (platinum sensor, 100Ω at 0°C). For three wire

RTDs, connect the resistive leg and the common legs of the RTD as illustrated. For a two

wire RTD a wire link should be fitted across terminals 2 & 3 (in place of the third wire). Two

wire RTDs should only be used when the leads are less than 3 metres long. Avoid cable

joints.

Figure 12. Input 1 - RTD Connections

Four wire RTDs can be used, provided that the fourth wire is left unconnected. This wire

should be cut short or tied back so that it cannot contact any of the terminals on the rear of

the instrument.

Pro-EC44 Product Manual - 59540-1 October 2013 Page 16

Page 24

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

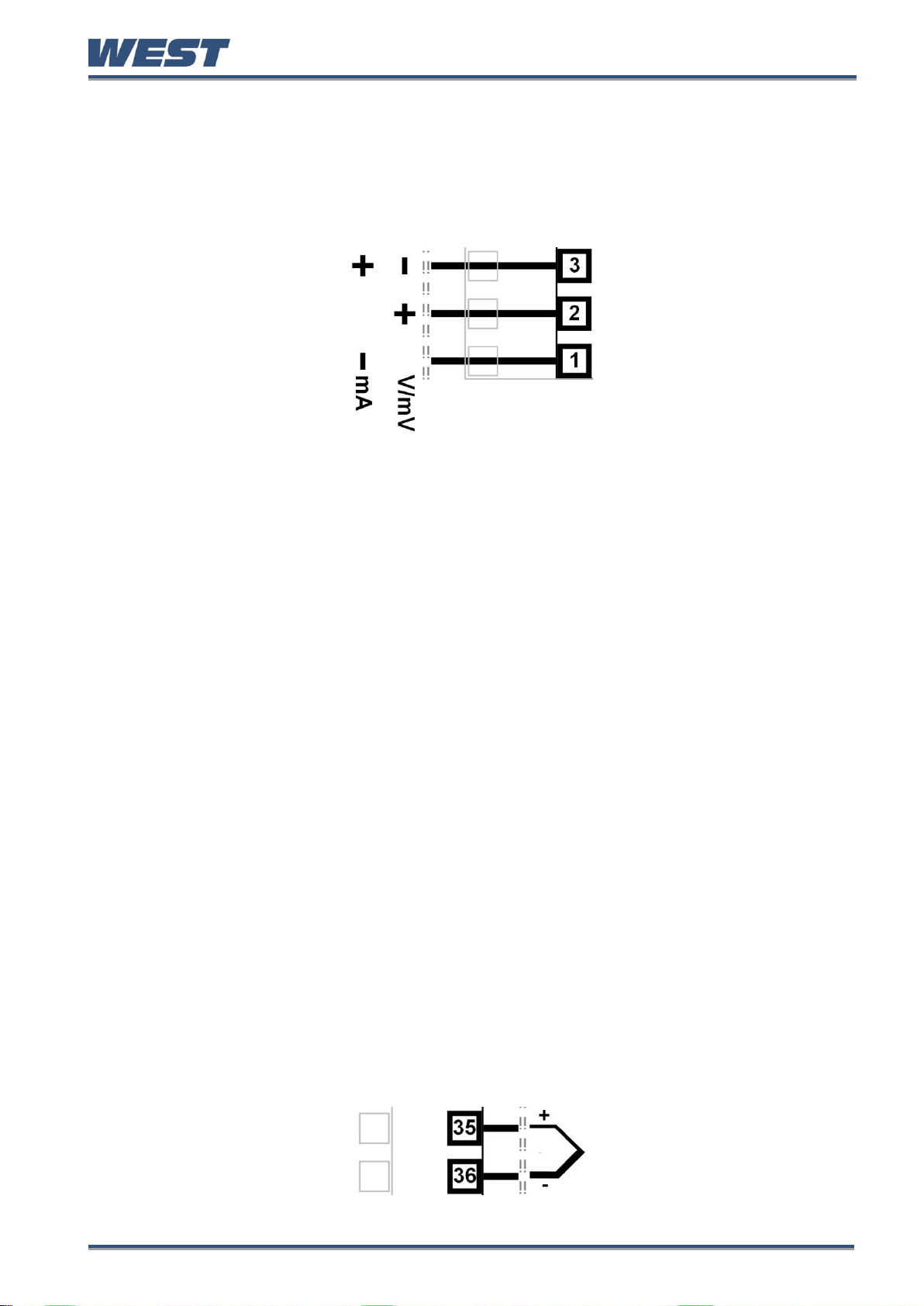

Universal Input 1 Connections - Linear Volt, mV or mA input

The input supports the following linear/analogue signals: 0 to 50mV; 10 to 50mV; 0 to 5V; 1

to 5V; 0 to 10V; 2 to 10V; 0 to 20mV; 4 to 20mA from any suitable source. Voltage & millivolt

signals are connected to terminals 2 & 3, milliamp signals are connected to 1 & 3. Carefully

observe the position & polarity of the connections.

Figure 13. Input 1 - DC Volt, mV & mA Connections

Universal / Auxiliary Input 2 Connections

An Auxiliary Input 2 option is fitted to some models. This can connect to a potentiometer;

analogue mA; mV or V DC signal for a remote setpoint input signal, or for flow/valve position

feedback information.

Alternatively, a second Universal Input 2 option may be fitted. In addition to the remote

setpoint input signal or feedback information possible with the auxiliary input, the 2nd

Universal Input can be used as a second process control loop for two control loops, or used

in conjunction with input one in more complex single control loops. Universal Input 2 can be

connected to thermocouples; resistance temperature detectors; potentiometers; analogue

mA; mV or V DC signals.

The settings are in the Input 2 Configuration sub-menu. Connections for the various types

are shown below. Ensure that the signal is correctly connected, paying particular attention to

the polarity.

Universal Input 2 Connections - Thermocouple (T/C)

The optional 2nd universal input, supports various thermocouple types. Supported types &

ranges are listed in the input specifications section on page 245.

Only use the correct thermocouple wire or compensating cable from the sensor to the

instrument terminals avoiding joints in the cable if possible. Where joints are made, special

thermocouple connectors must be used. Failure to use the correct wire type and connectors

will lead to inaccurate readings. Ensure correct polarity of the wires by cross-referencing the

colours with a thermocouple reference table.

Figure 14. Input 2 - Thermocouple Connections

Pro-EC44 Product Manual - 59540-1 October 2013 Page 17

Page 25

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

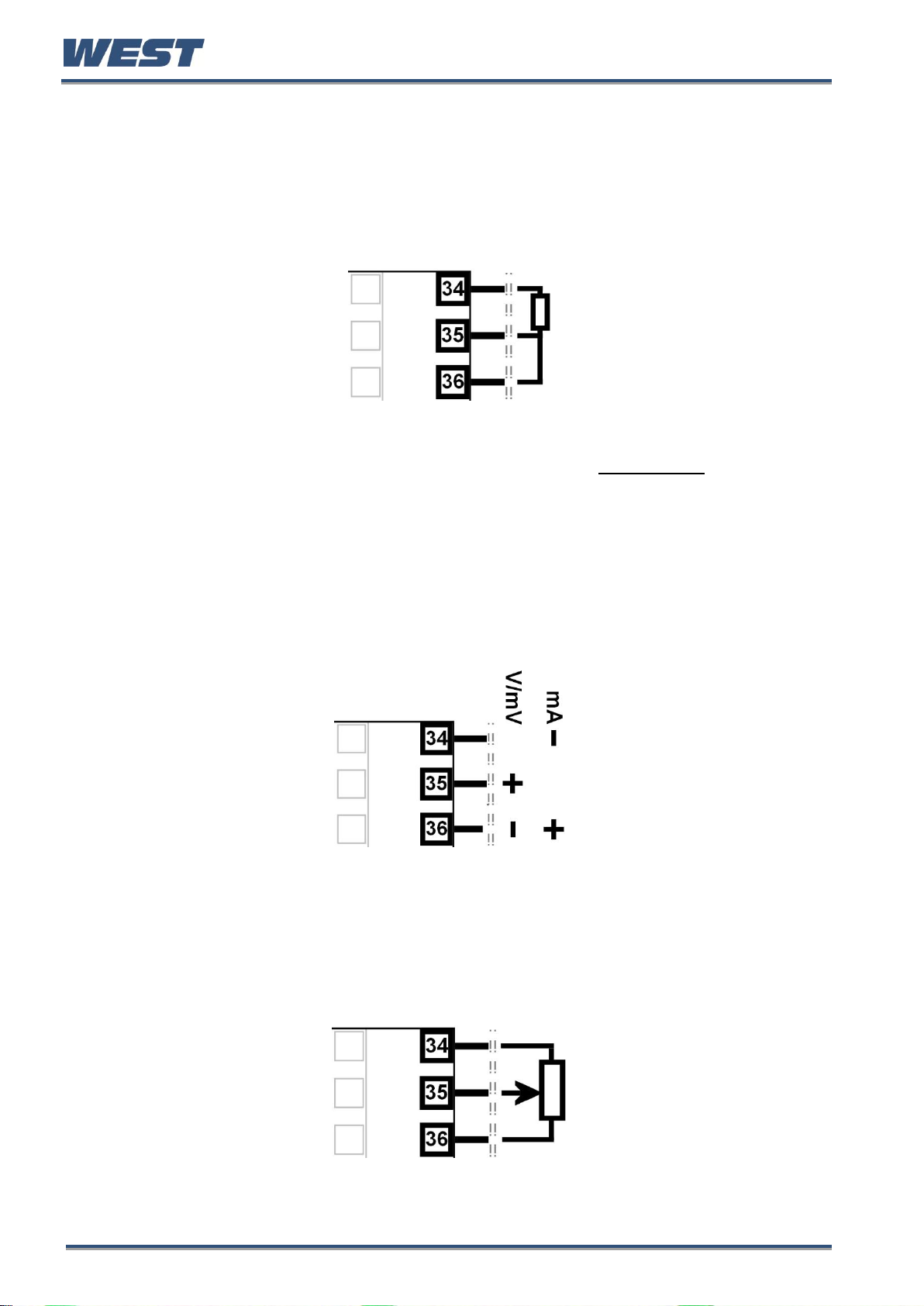

Universal Input 2 Connections – PT100 / NI120 (RTD) input

The optional 2nd universal input, supports two types of RTD. PT100 (platinum sensor, 100Ω

at 0°C). For three wire RTDs, connect the resistive leg and the common legs of the RTD as

illustrated. For a two wire RTD a wire link should be fitted across terminals 35 & 36 (in place

of the third wire). Two wire RTDs should only be used when the leads are less than 3 metres

long. If possible, avoid cable joints.

Figure 15. Input 2 - RTD Connections

Four wire RTDs can be used, provided that the fourth wire is left unconnected. This wire

should be cut short or tied back so that it cannot contact any of the terminals on the rear of

the instrument.

Universal / Auxiliary Input 2 Connections - Linear Volt, mV or mA input

The optional auxiliary or 2nd universal input supports the following linear/analogue signals: 0

to 50mV; 10 to 50mV; 0 to 5V; 1 to 5V; 0 to 10V; 2 to 10V; 0 to 20mV; 4 to 20mA from any

suitable source. Voltage & millivolt signals are connected to terminals 2 & 3, milliamp signals

are connected to 1 & 3. Carefully observe the polarity of the connections.

Figure 16. Input 2 - DC Volt, mV & mA Connections

Universal / Auxiliary Input 2 Connections – Potentiometer

The optional auxiliary or 2nd universal input, the terminals detailed below can be used to

connect a feedback potentiometer. Minimum potentiometer resistance is ≥100Ω.

Figure 17. Input 2 - Potentiometer Connections

Pro-EC44 Product Manual - 59540-1 October 2013 Page 18

Page 26

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

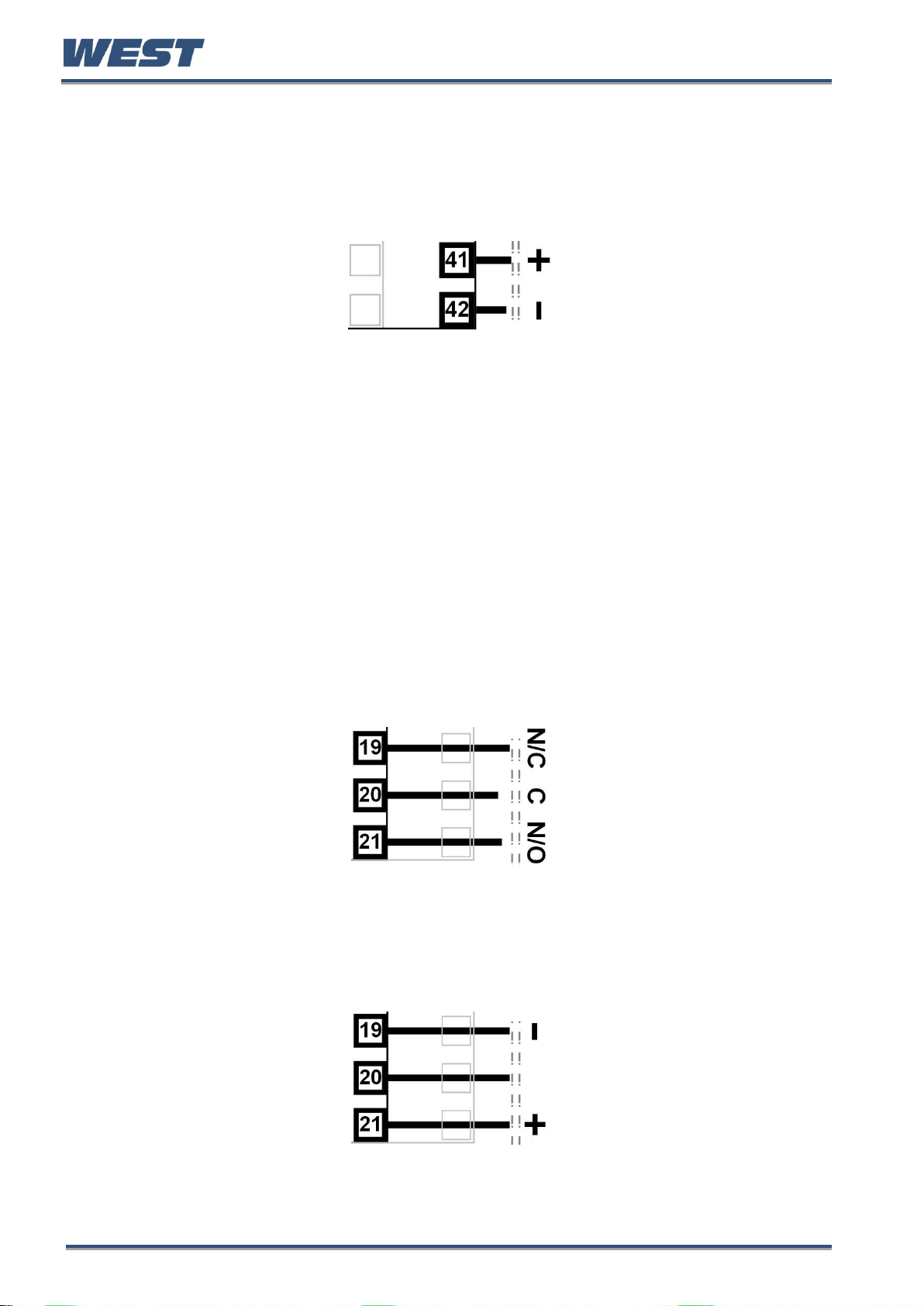

Base Option 1

Base Option 1 provides one or two factory fitted outputs. A relay designated as Output 4 is

fitted on all models, and an optional linear mA/V DC designated as Output 6. Base options

cannot be added after manufacture. The functions of outputs 4 & 6 are set in the Output

Configuration sub-menu. Connect as illustrated below.

Base Option 1 Relay Output 4

Present on all instruments, Output 4 is a SPST relay, rated at 2 amps at 240 VAC resistive. If

it is used to switch mains voltages, the supply should be separate from the instrument supply

and should be correctly switched and fused.

Figure 18. Relay Output 4 Connections

Base Option 1 Linear Output 6

Part of base option 1, Output 6 is an optional linear mV/V DC analogue output. The type &

range are selectable from 0 to 5, 0 to 10, 2 to 10V & 0 to 20 or 4 to 20mA.

Figure 19. Linear Output 6 Connections

Base Option 2

Base Option 2 provides one or two factory fitted outputs. An optional relay designated as

Output 5, and an optional linear mA/V DC designated as Output 7. Base options cannot be

added after manufacture. The functions of outputs 5 & 7 are set in the Output Configuration

sub-menu. Connect as illustrated below.

Base Option 2 Relay Output 5

Part of base option 2, Output 5 is a SPST relay, rated at 2 amps at 240 VAC resistive. If it is

used to switch mains voltages, the supply should be separate from the instrument supply and

should be correctly switched and fused.

Figure 20. Relay Output 5 Connections

Pro-EC44 Product Manual - 59540-1 October 2013 Page 19

Page 27

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

Base Option 2 Linear Output 7

Part of base option 2, Output 7 is an optional linear mV/V DC analogue output. The type &

range are selectable from 0 to 5, 0 to 10, 2 to 10V & 0 to 20 or 4 to 20mA.

.

Figure 21. Linear Output 7 Connections

Plug-in Module Slot 1 Connections

A selection of plug-in modules are available for Module Slot 1. They can be fitted during

manufacture, or purchased and fitted later by the user. Modules in slot 1 are designated

Output 1. They are not interchangeable with those in slot 2 or 3. Their function is set in the

Output Configuration sub-menu. Connect as illustrated below.

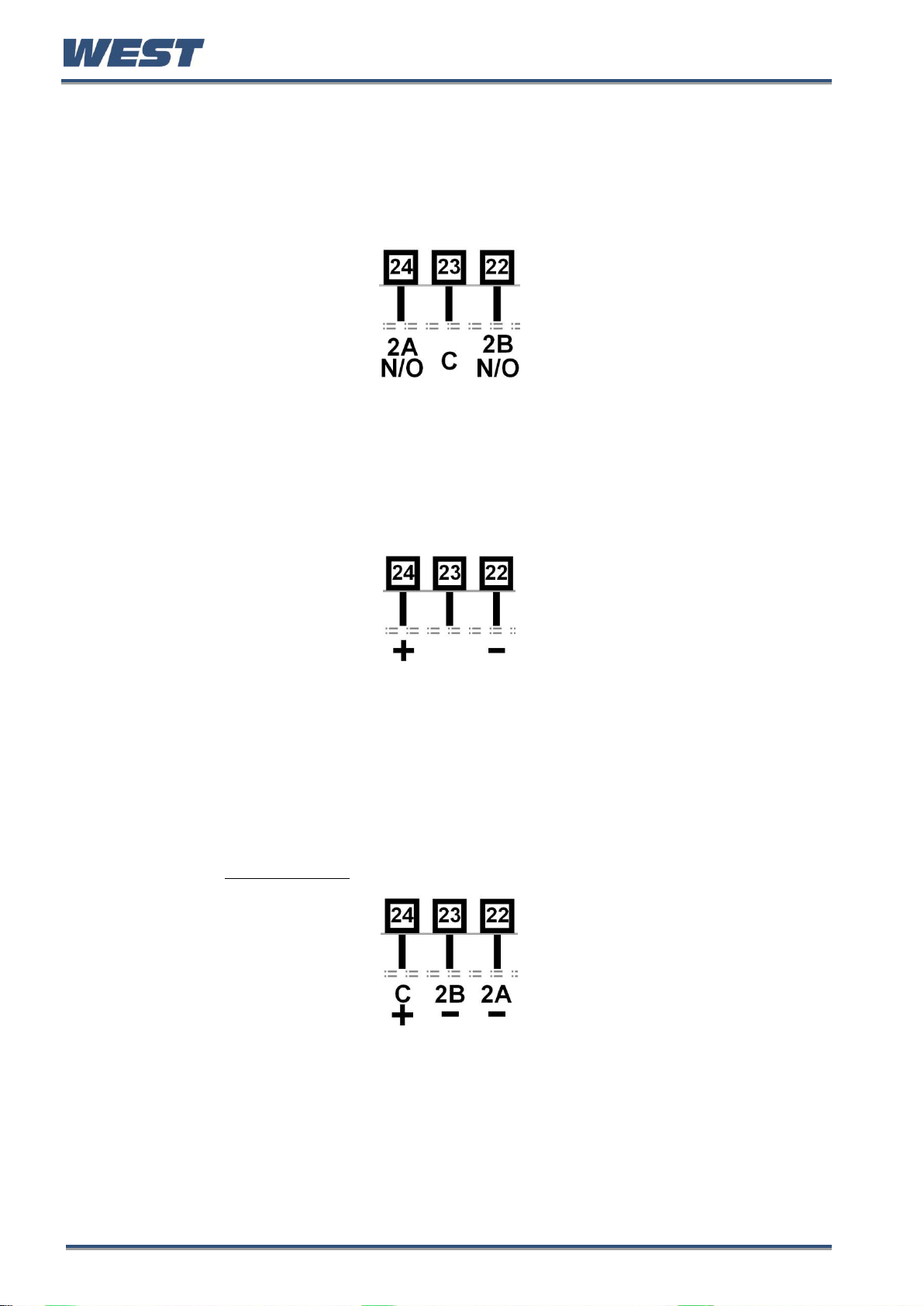

Plug-in Module Slot 1 – Single Relay Output Module

If fitted with a single relay output module, connect as shown. The relay contacts are SPDT

and rated at 2 amps resistive, 240 VAC. If it is used to switch mains voltages, the supply

should be separate from the instrument supply and should be correctly switched and fused.

Figure 22. Plug-in Module Slot 1 – Single Relay Module

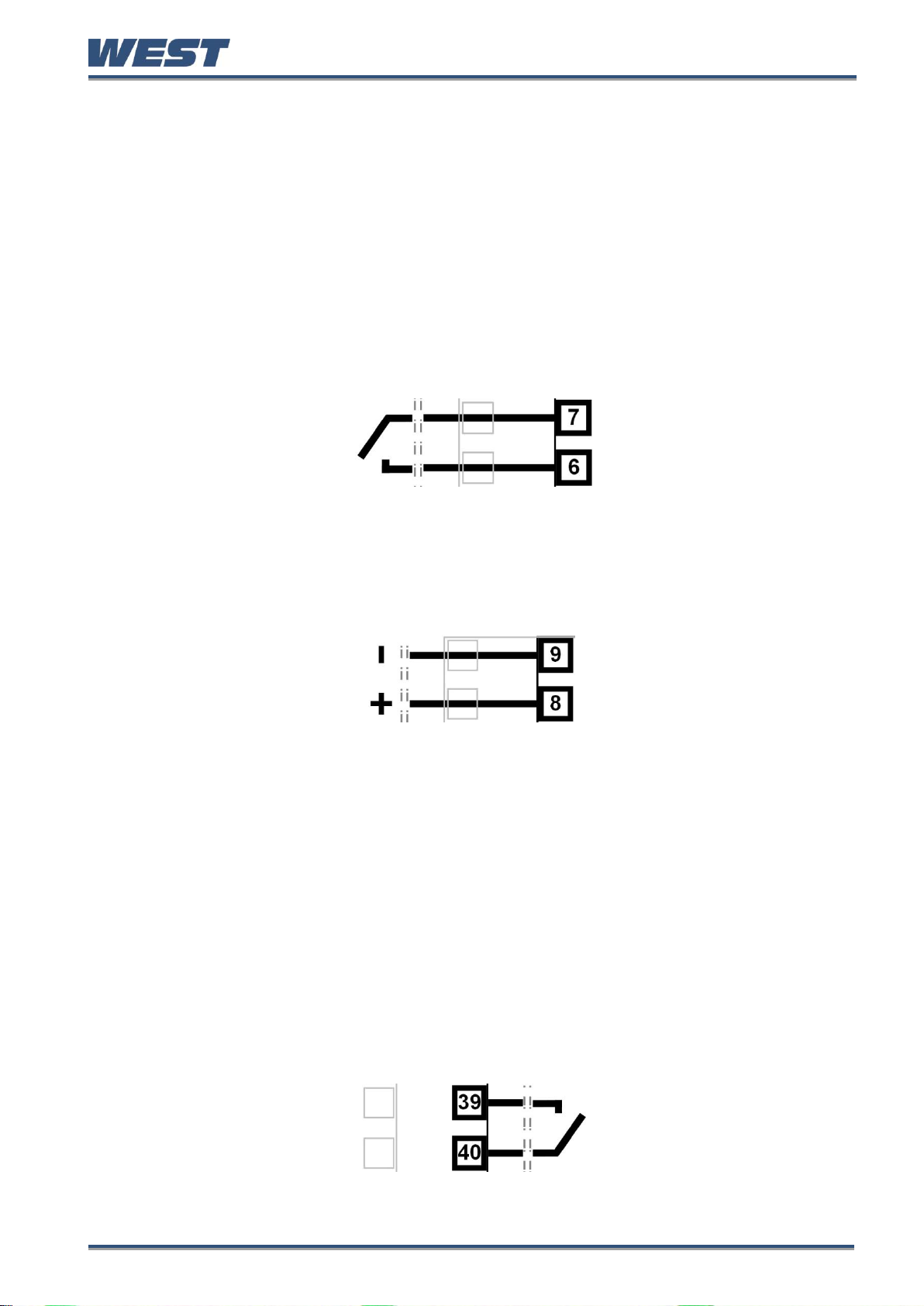

Plug-in Module Slot 1 – Single SSR Driver Output Module

If fitted with a single SSR Driver output module, connect as shown. The 10V DC pulse signal

(load ≥500 ohms) is isolated from all inputs/outputs except other SSR drivers.

Figure 23. Plug-in Module Slot 1 – Single SSR Driver Module

Pro-EC44 Product Manual - 59540-1 October 2013 Page 20

Page 28

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

Plug-in Module Slot 1 - Triac Output Module

If fitted with a triac output module, connect as shown. This output is rated at 0.01 to 1 amp @

280V AC 50/60Hz. Isolated from all other inputs and outputs. A snubber should be fitted

across inductive loads to ensure reliable switch off of the Triac.

Figure 24. Plug-in Module Slot 1 - Triac Module

Plug-in Module Slot 1 - Linear Voltage or mADC Output module

If fitted with a DC linear output module, connect as shown. Output type & range are

selectable from 0 to 5, 0 to 10, 2 to 10V & 0 to 20 or 4 to 20mA. Isolated from all other inputs

and outputs.

Figure 25. Plug-in Module Slot 1 - Linear Voltage & mADC Module

Plug-in module slot 2 Connections

A selection of plug-in modules are available for Module Slot 2. They are interchangeable with

slot 3, but not slot 1.They can be fitted during manufacture, or purchased and fitted later by

the user. Modules in slot 2 are designated Output 2, and for dual modules Output 2A and 2B.

Their functions are set in the Output Configuration sub-menu. Connect as illustrated below.

Plug-in Module Slot 2 – Single Relay Output Module

If fitted with a single relay output module, connect as shown. The relay contacts are SPDT

and rated at 2 amps resistive, 240 VAC. If it is used to switch mains voltages, the supply

should be separate from the instrument supply and should be correctly switched and fused.

Figure 26. Plug-in Module Slot 2 – Single Relay Module

Pro-EC44 Product Manual - 59540-1 October 2013 Page 21

Page 29

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

Plug-in Module Slot 2 - Dual Relay Output Module

If fitted with a dual relay output module, connect as shown. This module has two independent

SPST relays for outputs 2A and 2B, with a shared common terminal. The contacts are rated

at 2 amp resistive 240 VAC. If used to switch mains voltages, the supply should be separate

from the instruments mains supply and the contacts should be correctly switched and fused.

Figure 27. Plug-in Module Slot 2 - Dual Relay Module

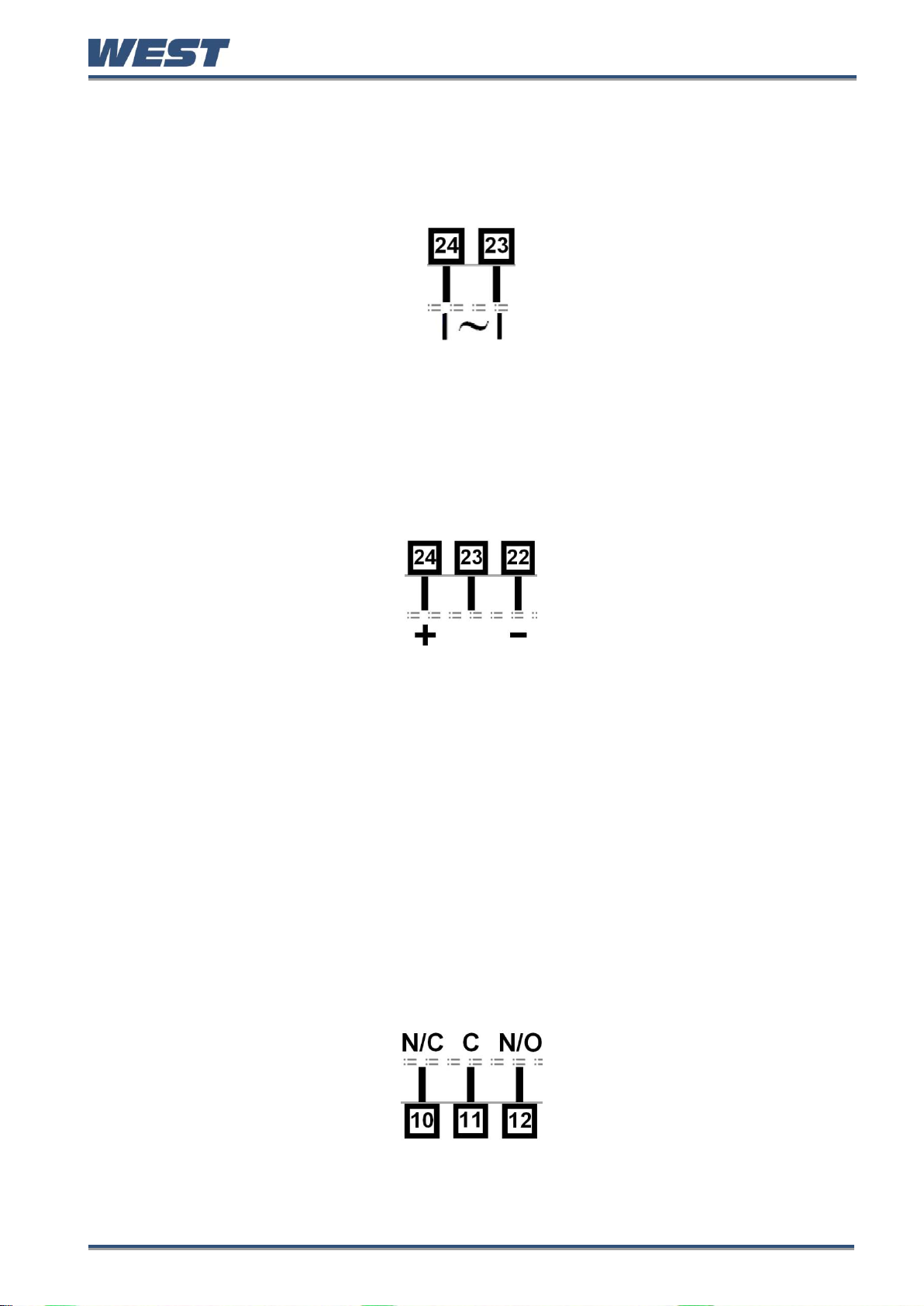

Plug-in Module Slot 2 – Single SSR Driver Output Module

If fitted with a single SSR Driver output module, connect as shown. The 10V DC pulse signal

(load ≥500 ohms) is isolated from all inputs/outputs except other SSR drivers.

Figure 28. Plug-in Module Slot 2 – Single SSR Driver Module

Plug-in Module Slot 2 – Dual SSR Driver Output Module

If fitted with a dual SSR Driver output module, the two solid-state relay driver outputs are

designated as Output 2A and 2B. The outputs are 10V DC pulse signals, (load ≥500 ohms).

They are isolated from all inputs/output except other SSR driver outputs. Connect as shown

making note of the shared positive common terminal.

Figure 29. Plug-in Module Slot 2 – Dual SSR Driver Module

Pro-EC44 Product Manual - 59540-1 October 2013 Page 22

Page 30

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

Plug-in Module Slot 2 - Triac Output Module

If fitted with a Triac output module, connect as shown. This output is rated at 0.01 to 1 amp

@ 280V AC 50/60Hz. Isolated from all other inputs and outputs. A snubber should be fitted

across inductive loads to ensure reliable switch off of the Triac.

Figure 30. Plug-in Module Slot 2 - Triac Module

Plug-in Module Slot 2 - Transmitter Power Supply Module

If fitted with a transmitter power supply module (TxPSU), connect as shown. The output is a

24V nominal (unregulated, 19 to 28V DC), supply at 22mA max. Only one TxPSU is

supported, do not fit in slot 2 if one is already fitted in slot 3.

Figure 31. Plug-in Module Slot 2 - Transmitter Power Supply Module

Plug-in Slot 3 Connections

A selection of plug-in modules are available for Module Slot 3. They are interchangeable with

slot 2, but not slot 1.They can be fitted during manufacture, or purchased and fitted later by

the user. Modules in slot 3 are designated Output 3, and for dual modules Output 3A and 3B.

Their functions are set in the Output Configuration sub-menu. Connect as illustrated below.

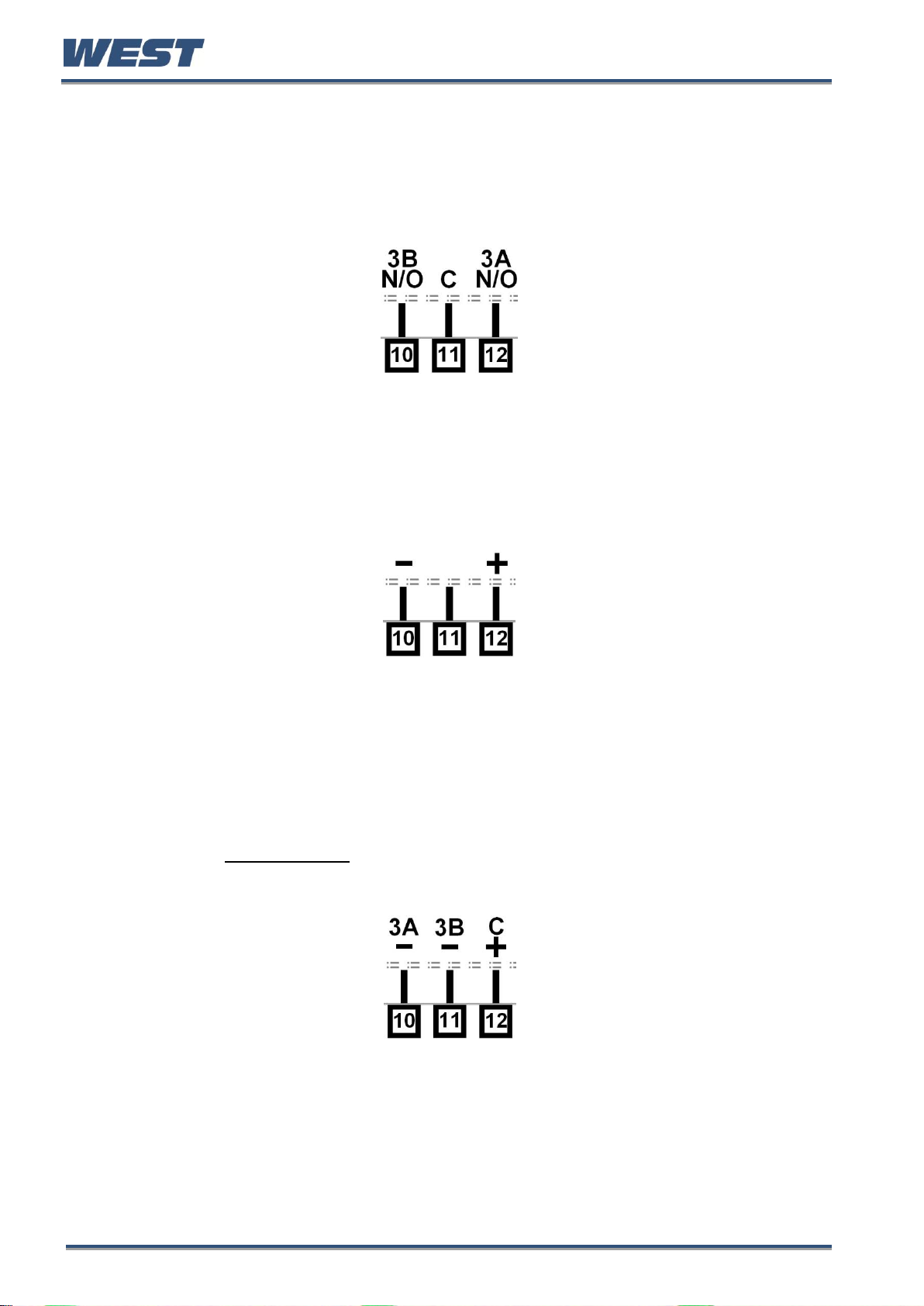

Plug-in Module Slot 3 – Single Relay Output Module

If fitted with a single relay output module, connect as shown. The relay contacts are SPDT

and rated at 2 amps resistive, 240 VAC. If it is used to switch mains voltages, the supply

should be separate from the instrument supply and should be correctly switched and fused.

Figure 32. Plug-in Module Slot 3 – Single Relay Module

Pro-EC44 Product Manual - 59540-1 October 2013 Page 23

Page 31

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

Plug-in Module Slot 3 - Dual Relay Output Module

If fitted with a dual relay output module, connect as shown. This module has two independent

SPST relays for outputs 3A and 3B, with a shared common terminal. The contacts are rated

at 2 amp resistive 240 VAC. If used to switch mains voltages, the supply should be separate

from the instruments mains supply and the contacts should be correctly switched and fused.

Figure 33. Plug-in Module Slot 3 - Dual Relay Module

Plug-in Module Slot 3 – Single SSR Driver Output Module

If fitted with a single SSR Driver output module, connect as shown. The 10V DC pulse signal

(load ≥500 ohms) is isolated from all inputs/outputs except other SSR drivers.

Figure 34. Plug-in Module Slot 3 – Single SSR Driver Module

Plug-in Module Slot 3 – Dual SSR Driver Output Module

If fitted with a dual SSR Driver output module, the two solid-state relay driver outputs are

designated as Output 3A and 3B. The outputs are 10V DC pulse signals, (load ≥500 ohms).

They are isolated from all inputs/output except other SSR driver outputs. Connect as shown

making note of the shared positive common terminal.

Figure 35. Plug-in Module Slot 3 – Dual SSR Driver Module

Pro-EC44 Product Manual - 59540-1 October 2013 Page 24

Page 32

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

Plug-in Module Slot 3 - Triac Output Module

If fitted with a Triac output module, connect as shown. This output is rated at 0.01 to 1 amp

@ 280V AC 50/60Hz. Isolated from all other inputs and outputs. A snubber should be fitted

across inductive loads to ensure reliable switch off of the Triac.

Figure 36. Plug-in Module Slot 3 - Triac Module

Plug-in Module Slot 3 - Transmitter Power Supply Module

If fitted with a transmitter power supply module (TxPSU), connect as shown. The output is a

24V nominal (unregulated, 19 to 28V DC), supply at 22mA max. Only one TxPSU is

supported, do not fit in slot 3 if one is already fitted in slot 2.

.

Figure 37. Plug-in Module Slot 3 - Transmitter Power Supply Module

Plug-in Slot A Connections

A selection of plug-in modules are available for Module Slot A. They can be fitted during

manufacture, or purchased and fitted later by the user. Depending on their functions, they

are setup Input or Communications configuration sub-menus. Connect as illustrated below.

Plug-in Module Slot A – Basic Auxiliary Input Module

If fitted with a basic auxiliary mA/V DC analogue input module, connect as shown. Isolated

from all inputs/outputs. Consider using the 2nd auxiliary input (if available) instead, as this has

additional features and leaves plug-in module slot A free for other modules.

Figure 38. Plug-in Module Slot A – Basic Auxiliary Input Module

Pro-EC44 Product Manual - 59540-1 October 2013 Page 25

Page 33

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

CAUTION: External computing devices connected to the communications

port should comply with the standard, UL 60950.

Plug-in Module Slot A - Ethernet Communications Module

If fitted with the Ethernet communication module, the communications protocol available is

Modbus TCP. Isolated from all inputs/outputs. If necessary, cut out the removable panel to

access the RJ45 connector through the top of the case. No rear connections are required.

Plug-in Module Slot A - RS485 Serial Communications Module

If fitted with the RS485 serial communication module, the protocol used is Modbus RTU.

Isolated from all inputs/outputs. Carefully observe the polarity of the A (Rx/Tx +ve) and B

(Rx/Tx -ve) connections.

Figure 39. Plug-in Module Slot A – RS485 Serial Communications Module

Plug-in Module Slot A – Single Digital Input Module

If a digital input module is fitted, it provides a fully isolated input that is held high via a pull-up

resistor. The input can be connected to either to voltage free contacts (e.g. from a switch), or

a TTL compatible signal.

Logic High = Open contacts (>5000Ω) or 2 to 24VDC signal.

Logic Low = Closed contacts (<50Ω) or -0.6 to +0.8VDC signal.. Connect as shown.

Figure 40. Plug-in Module Slot A – Digital Input A Module

Pro-EC44 Product Manual - 59540-1 October 2013 Page 26

Page 34

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

Option C Connections

Option C offers a factory fitted multiple digital input option. The board also accommodates

the USB port if that is option is fitted. The USB port does not have connections on the rear

terminal, it is accessed via the front panel.

Option C Connections – Multiple Digital Input Module

If the Multiple Digital Input option is fitted, the connections are as illustrated. The 8 optoisolated inputs each have a positive input terminal and share a common negative terminal.

The inputs are held high with internal pull-up resistors, so may be connected to either voltage

free contacts (e.g. from a switch), or TTL compatible signals:

Logic High = Open contacts (>5000Ω) or 2 to 24VDC signal.

Logic Low = Closed contacts (<50Ω) or -0.6 to +0.8VDC signal.

Figure 41. Option C - Multiple Digital Inputs C1 to C8

Pro-EC44 Product Manual - 59540-1 October 2013 Page 27

Page 35

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

CAUTION: The windings of a valve motor effectively form an

autotransformer. This has a voltage doubling effect when power is applied

to either the Open or Close terminal, causing twice the supplied voltage at

the other terminal. For this reason, switching devices directly connected to

the valve motor must only be used up to half of their rated voltage. The

maximum motor voltage when using the internal relays/triacs is therefore

120V unless interposing relays are used. Interposing relays or other devices

used to control the valve must themselves be rated for twice the motor

supply voltage.

Open Valve Winding

Close Valve Winding

Valve Common

“OPEN” RELAY

N/O

C

N/C

N/C C N/O

“CLOSE” RELAY

N/C C N/O

120VAC SUPPLY

2 x 120V = 240V

120V

Special Wiring Considerations for Valve Motor Control

Valve Motor Drive (VMD) controllers require two identical outputs to be assigned to position

the valve. One to open and one to close the valve. These outputs can be two single relays,

two triacs, two SSR drivers or one dual relay, but it is recommended to use two single relays

(SPDT change-over contacts), and to interlock the relay wiring as shown. This prevents both

motor windings from being driven at the same time, even under fault conditions.

Switching actuators directly connected to the valve motor must only be used up to half of

their rated voltage (see CAUTION below). The internal relay and triac outputs are rated at

240VAC, so the maximum motor voltage when using them in this way is therefore 120V

unless interposing relays are used. Interposing relays or other devices used to control the

valve must themselves be rated for twice the motor supply voltage.

Figure 42. Interlocking of Valve Motor Drive Relays

Pro-EC44 Product Manual - 59540-1 October 2013 Page 28

Page 36

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

CAUTION: Ensure safe wiring practices have been followed. When powering

up for the first time, disconnect the output connections. The instrument

must be powered from a supply according to the wiring label on the side of

the unit. The supply will be either 100 to 240V AC, or 24/48V AC/DC

powered. Check carefully the supply voltage and connections before

applying power

5 Powering Up

Powering Up Procedure

At power up, a self-test procedure is automatically started, during which a splash screen is

displayed and the LED indicators are lit. At the first power up from new, a Setup Wizard runs

to assist configuration of basic applications (refer to the Setup Wizard section on page 43).

At all other times, the instrument returns to the normal operation mode once the self-test

procedure is complete.

Front Panel Overview

The illustration below shows an instrument fitted with the optional USB socket located to the

right of the four keypad buttons. Clean the front panel by washing with warm soapy water

and dry immediately. If the USB option is fitted, close the port cover before cleaning.

Figure 43. A Typical Front Panel

Display

The instrument has a 160 x 80 pixel monochrome graphical display with dual colour

(red/green) backlight. The main display typically shows the process variables, setpoints,

power / deviation bar graphs or graphical trends during normal operation. There are recorder

and profile status screen. The top line of the display has labels for the 4 LED indicators. If

desired, the backlight colour can be changed to indicate the presence of an active alarm or

latched output. Refer to the Display Configuration section - page 59

Pro-EC44 Product Manual - 59540-1 October 2013 Page 29

Page 37

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

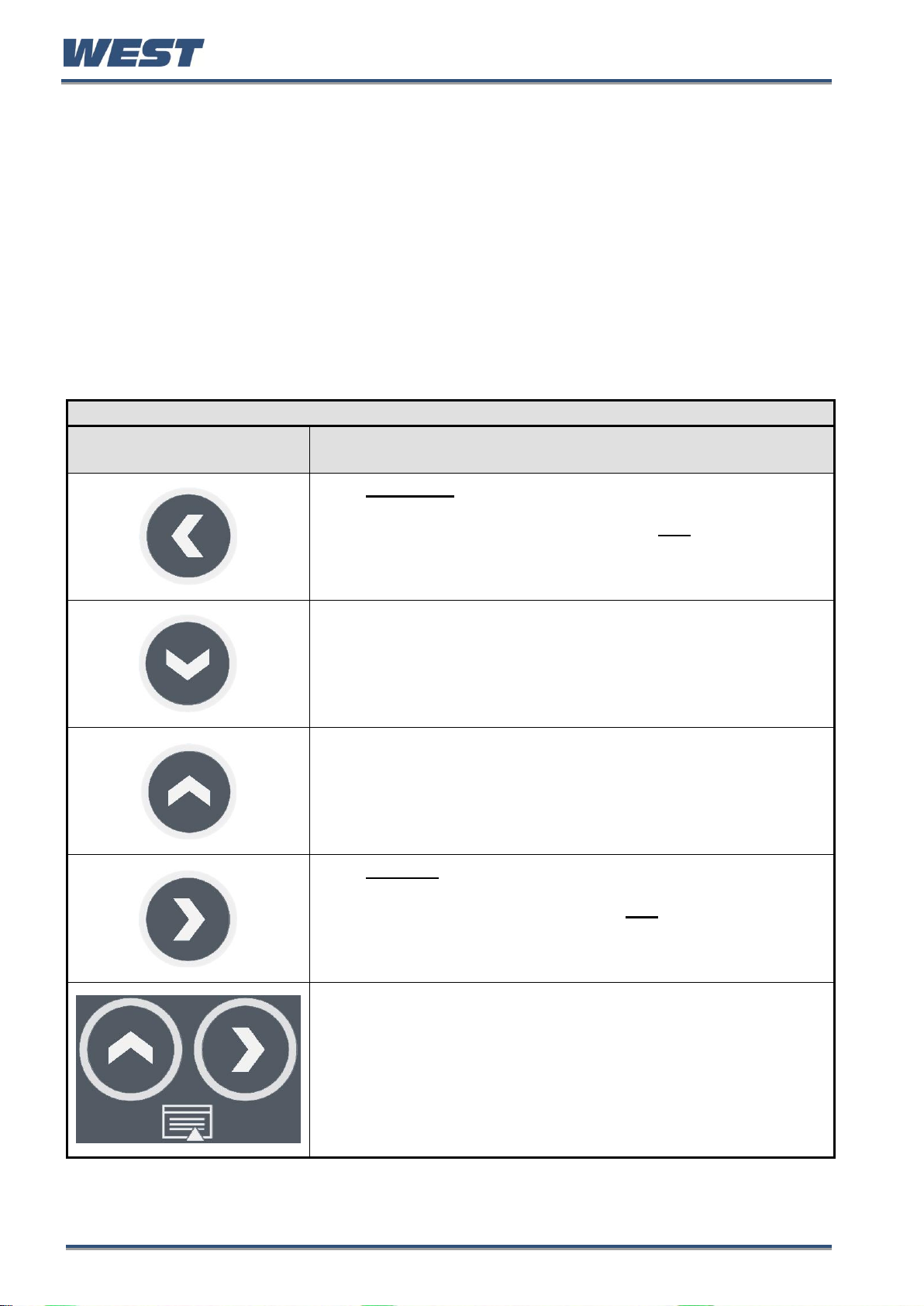

Keypad Button Functions

Button

Function

Moves backwards to the previous parameter or screen in the

current mode. Holding this key down for more than 1 second skips

immediately to the previous screen accepting ALL values as shown.

CAUTION: If editing a parameter, ensure that the current

(highlighted) parameter value is correct before pressing the key as

this action will update and store the value displayed.

In menus and configuration choice screens, this key moves to the

next item on the list.

Editable values can be decreased by pressing this key. Holding the

key down speeds up the change.

In Trend views this key moves the Cursor Line back through the

stored data points

In menus and configuration choice screens, this key moves to the

previous item on the list.

Editable values can be increased by pressing this key. Holding the

key down speeds up the change.

In Trend views this key moves the Cursor Line forward through the

stored data points

Moves forwards to the next parameter or screen in the current

mode. Holding this key down for more than 1 second skips

immediately to the next screen accepting ALL values as shown.

CAUTION: If editing a parameter, ensure that the current

(highlighted) parameter value is correct before pressing the key as

this action will update and store the value displayed.

Pressing the U key while holding down the R key causes the

instrument to move up one menu level. From Operation Mode and in

most menus, this will result in entry to the Main Menu.

From sub-menus, it is necessary to carry out this sequence more

than once to reach the main menu.

CAUTION: If editing a parameter, ensure that the current

(highlighted) parameter value is correct before pressing the key as

this action will update and store the value displayed.

LED Functions

There are four red LEDs that by default indicate the status of the primary & secondary

outputs, automatic tuning and alarm status. The top line of the graphical display has four

labels for LED indicators. The function of these LEDs and their display labels can be

changed using the PC configuration software. The information in this manual assumes

standard functions for these LEDs.

Keypad Functions & Navigation

Each instrument has four keypad switches, which are used to navigate through the user

menus and adjust the parameter values. In configuration screens, a context sensitive

scrolling help text is displayed that guides the user about the function of the keys.

Pro-EC44 Product Manual - 59540-1 October 2013 Page 30

Page 38

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

CAUTION: Do not continue using the product until the the error is resolved.

CAUTION: Correct the signal/wiring problem to continue normal operation.

CAUTION: Perform a full base calibration of the input before continuing

normal operation (see page 72). If the problem persists, return the

instrument for servicing.

6 Messages & Error Indications

Plug-in Module Problems

If an invalid or unknown module is detected in one of the plug-in module slots during the

power-up self-test, the message “Fault Found, Press R, for details” is shown. This is

followed by “Replace faulty module in Module Slot n, Press R,” (where n is the faulty slot

location). The Service Contact information is displayed next showing details of who to

contact if a fault persists

Replace the module in slot “n”. If this does not solve the problem, return the instrument for

investigation.

Sensor Break Detection

Whenever a problem is detected with a process variable or auxiliary input connection, the

displayed value for that input is replaced with the word “OPEN”; except in Ratio control

where an open input 1 or 2 is shown as “x1-Open” or “x2-Open”. See Redundant Input

(page 83) to protect critical processes from sensor faults.

This may be the result of a failed sensor, a broken connection or an input circuit fault.

In this condition, the control outputs go to the pre-set power value (see Control Configuration

– page 50).

Un-Calibrated Input Detection

The instrument is fully calibrated during manufacture. If a fault occurs and calibration data is

lost, the process input displays are replaced with the word “ERROR” and error is shown

instead of “Calibrated” for effected inputs in Service & Product Information mode.

In this condition, the control outputs go to the pre-set power value (see Control Configuration

– page 50).

PV Over-range or Under-range Indication

If a measured process input value is more than 5% above than the Scaled Input Upper Limit,

its value is replace by the word “HIGH” to indicate that it is out of range.

If a measured process input value is more than 5% below than the Scaled Input Lower Limit,

its value is replaced by the word “LOW” to indicate that it is out of range.

Pro-EC44 Product Manual - 59540-1 October 2013 Page 31

Page 39

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

Auxiliary Input Over-range or Under-range Indication

If the auxiliary Remote Setpoint input is more than 5% above than the Auxiliary Input Upper

Limit, its value is replaced by the word “HIGH” to indicate that it is out of range.

If the auxiliary Remote Setpoint input is more than 5% below than the Auxiliary Input Lower

Limit, its value is replace by the word “LOW” to indicate that it is out of range.

Cascade-Open

“Cascade Open” is shown on the main screen if the internal link has be severed between

cascaded master and slave control loops. This mode should only be used for diagnostics and

slave tuning. Close the cascade for proper operation. Refer to the Cascade Control section

(page 78) for more information.

Profile Not Valid

If the user attempts to run a profile that would take the setpoint beyond the current setpoint

limits, the profile will not run and the message “Profile Not Valid” is displayed at the bottom

of the profile status screen.

USB Data Transfer Failure message

If the instrument cannot successfully write to the USB memory stick, the message “Data

Transfer Failure” will be displayed. Check that there is adequate disk space on the memory

stick, then retry.

If the instrument cannot successfully read data from the USB memory stick, the message

“Data Transfer Failure” will also appear. Check that this operation would not cause the

maximum number of profiles and/or segments to be exceeded then retry.

Getting Help

First Level Support

If the errors persist or other problems are encountered, refer your supplier for first level

support. This includes help with configuration, tuning, servicing and replacement modules.

Second Level Support

If your supplier is unable to assist or cannot be contacted, check the Service & Product

Information screen on the main menu for details of who to contact.

Third Level Support

If further assistance is required, contact the nearest company from those listed on the back

page of this manual.

Servicing

If you need to return your instrument for servicing, contact your supplier or check the Service

& Product Information screen on the main menu for instructions for its return.

Pro-EC44 Product Manual - 59540-1 October 2013 Page 32

Page 40

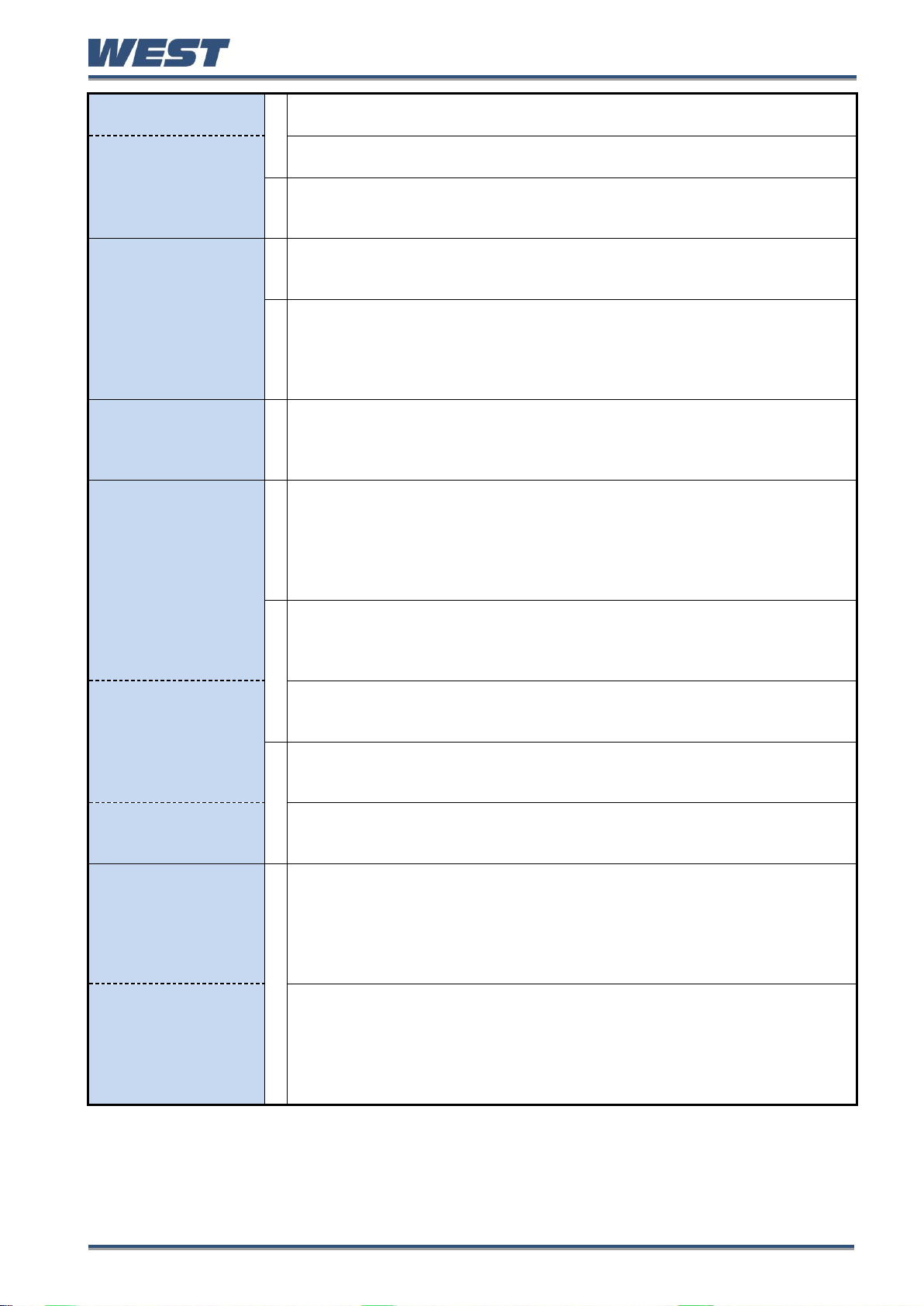

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

Process Type*

Loop 1 / Master

Loop 2 / Slave

(only if 2nd

input fitted)

Control

Configuration:

Control Select

Control

Configuration:

Control Type

Control

Configuration:

Control Select

Control

Configuration:

Control Type

One Loop*

Input 2

Configuration |

Input 2 Usage

= Not Used

Standard PID

Control Select

= Control Standard

Primary Only

Control Type

= Single

Primary / Secondary

Control Type

= Dual

Valve Motor Drive

Control Select

= VMD (TPSC)

Control

7 Application Setup

Before beginning configuration, consider how the controller will be used in your application.

For instance, how many control loops are needed, is cascade or ratio control required, will

the unit control a valve motor, do you need setpoint profiling etc. Consideration should also

be given to the output types, alarms and tuning method.

This section is intended to help with this process, guiding you through the major configuration

settings. Additional information can be found in the relevant sections of this manual, including

the glossary, configuration menus, and dedicated sections for major features. These are

listed in the table of contents.

Pre-commissioning Considerations

An easy Setup Wizard is available for basic applications (see page 43) where the most

commonly required parameters are present for adjustment in turn. The wizard has a sub-set

of the full configuration menu options. For more complex applications where the wizard is not

sufficient, consideration must be given to the following fundamental questions:

If fitted, how will the 2nd input be used?

One loop only (if the 2nd input not fitted or not used in this application)

Two independent control loops (see page 50).

Valve feedback for loop 1 (see page 85Error! Bookmark not defined.).

A “redundant” backup for the 1st input (see page 83).

Cascaded with the first control loop (see page 78).

A reference input for ratio control (see page 81).

How will the instrument physically control the process?

Primary only or primary & secondary control outputs (see page 210).

Direct valve motor drive outputs (see page 84).

The table below shows the main input and control configuration settings for these application

types (see page 45 for the configuration menus).

Pro-EC44 Product Manual - 59540-1 October 2013 Page 33

Page 41

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

Process Type*

Loop 1 / Master

Loop 2 / Slave

(only if 2nd

input fitted)

Control

Configuration:

Control Select

Control

Configuration:

Control Type

Control

Configuration:

Control Select

Control

Configuration:

Control Type

Two Loops*

Input 2

Configuration |

Input 2 Usage

= Standard

Standard PID

Control Select

= Control Standard

Primary Only

Control Type

= Single

Standard PID

Control Select

= Control Standard

Primary Only

Control Type

= Single

Primary / Secondary

Control Type

= Dual

Primary / Secondary

Control Type

= Dual

Valve Motor Drive

Control Select

= VMD (TPSC)

Control

Valve Motor Drive

Control Select

= VMD (TPSC)

Control

+Feedback*

Input 2

Configuration |

Input 2 Usage

= Feedback

Valve Motor Drive

Control Select

= VMD (TPSC)

Control

Redundant*

Input 2

Configuration |

Input 2 Usage

= Redundant

Input

Standard PID

Control Select

= Control Standard

Primary Only

Control Type

= Single

Primary / Secondary

Control Type

= Dual

Valve Motor Drive

Control Select

= VMD (TPSC)

Control

Cascade*

Input 2

Configuration |

Input 2 Usage

= Standard

AND

Loop 1 / Master

Configuration |

Control Mode

= Cascade

Standard PID

Control Select

= Control Standard

Primary Only

Control Type

= Single

Primary / Secondary

Control Type

= Dual

Valve Motor Drive

Control Select

= VMD (TPSC)

Control

Ratio*

Input 2

Configuration |

Input 2 Usage

= Standard

AND

Loop 1 / Master

Configuration |

Control Mode

= Ratio

Standard PID

Control Select

= Control Standard

Valve Motor Drive

Control Select

= VMD (TPSC)

Control

Which outputs will be used for control, and are alarms or event outputs needed?

Output configuration (see page 56).

Alarms & Profile Events (see page Alarm Types207 & 225).

Pro-EC44 Product Manual - 59540-1 October 2013 Page 34

Page 42

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

CAUTION: Configuration & commissioning must be completed before

proceeding to Operation Mode. It is the responsibility of the installing

engineer to ensure that the configuration is safe.

What are the sources for the setpoints?

Local setpoint(s) only, or a remote setpoint input (see page 216 & 227).

Profile Control (see page 87).

Is Input re-configuration required?

Analogue input calibration & scaling (see page 70).

Digital input functions (see page 75).

Which other features are to be used?

Data Recorder (see page 97).

Serial Communications (see page 109).

USB Interface (see page 96).

Once you have an understanding of your application and how the controller will be used,

continue on to the configuration and use section below.

Pro-EC44 Product Manual - 59540-1 October 2013 Page 35

Page 43

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

CAUTION: Set all Configuration parameters as required before starting

normal operations. It is the responsibility of the installing engineer to

ensure that the configuration is safe for the intended application.

8 Operation and Configuration Menus

This section contains information on all of the controller’s modes and the configuration

menus.

Operation Mode

This is the mode used during normal operation of the instrument. It can be accessed from the

Main Menu, and is the usual mode entered at power-up. The available displays are

dependent upon the features/options fitted and the way in which it has been configured.

The Base screen is the usual screen displayed during operation. It provides “at a glance”

information about the process. The Profile Status screen shows similar information when

using profiles.

Subsequent screens allow the display and selection/adjustment* of the setpoints. From

display configuration, a selection of other parameter screens can be made available for

operator selection/adjustment*. These include: profile control; cascade open/close;

auto/manual control; setpoint ramp rate; setpoint source; control enable; clear latched

outputs; data recording & status trend views. Optional operator mode screens are marked ◘

in the screen lists.

Some screens will persist until the user navigates away, others will ‘time-out’ back to the

base screen.

* If required, all Operation Mode parameters can be made read only (see Display

Configuration on page 59Error! Bookmark not defined.). Otherwise parameters such as

setpoints can be adjusted within their configured limits.

WARNING:

DURING NORMAL USE, THE USER MUST NOT REMOVE THE CONTROLLER FROM ITS

HOUSING OR HAVE UNRESTRICTED ACCESS TO THE REAR TERMINALS, AS THIS WOULD

PROVIDE POTENTIAL CONTACT WITH HAZARDOUS LIVE PARTS.

Navigating and Adjusting Values in Operator Mode

Press R to move forward or L to move backwards through the available screens.

When a displayed value can be adjusted, use D or U to change its value.

The next/previous screen follows the last parameter. If no further changes are needed,

hold down R or L for >1sec to skip straight to the next/previous screen accepting

ALL values shown.

In Trend Views, pressing D or U moves the cursor line back and forward through the

last 240 data points.

Pro-EC44 Product Manual - 59540-1 October 2013 Page 36

Page 44

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

OPERATION MODE SCREEN SEQUENCE

All possible screens are listed below. The sequence shown depends on the configuration and status.

E.g. settings for “Loop 2” only apply if 2nd input is fitted and configured for 2-loop control.

◘ Some screens are only shown if set to do so in Display Configuration.

After 2 minutes without key activity, the most screens revert to the Base Operating Screen. Screens

marked do not revert automatically. They remain displayed until the user navigates away.

Calibration Check Due Warning

If a Calibration Reminder is set and the due date has passed this will be shown at every power up,

and repeated once per day. Press R to acknowledge and continue using the instrument temporarily

without recalibration. Change the due date or disable the reminder to cancel the warning.

This feature is only possible if the recorder is fitted. It is enabled in Input Configuration.

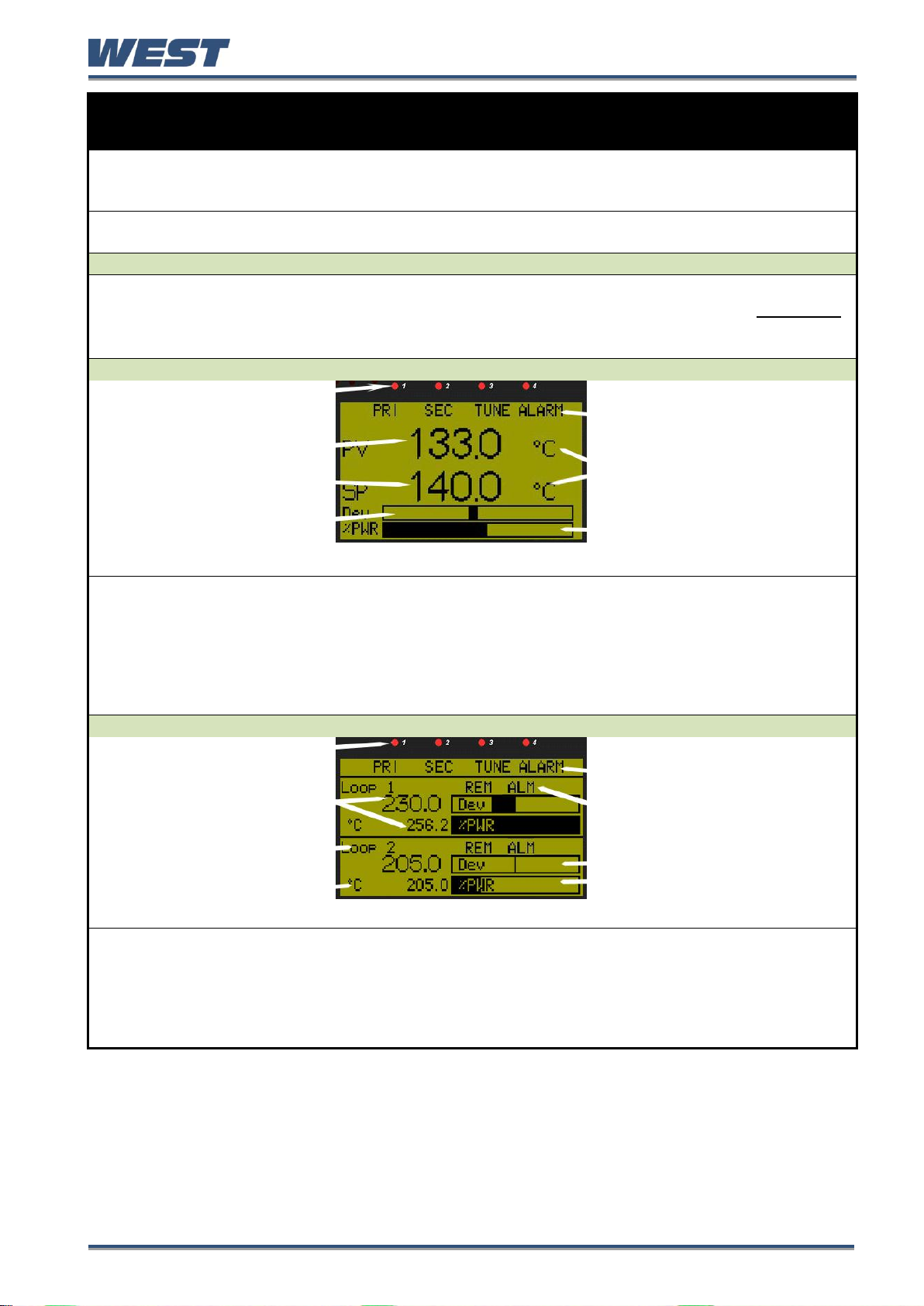

Single Control Loop: Normal Operation

LED Indicators

LED Function Labels

Process Variable Value

Effective Actual Setpoint

Value

Engineering Units

Control Deviation Graph

(scaled ±5% of input span)

Power Graph (0-100% primary,

±100% primary & secondary)

1-LOOP OPERATION

Default LED indicator functions are PRI, SEC, TUNE & ALARM - the functions and their labels can be

altered only with the PC configuration software.

In valve motor drive mode, the power bar-graph is replaced by valve Open / Stop / Close unless the

2nd input is used for position feedback, where it shows 0 to 100% valve position.

In manual mode the effective setpoint is replaced by the %Manual Power and the label “MAN”.

In manual mode with valve motor drive the setpoint is replaced by valve Open / Stop / Close.

If control is disabled the effective setpoint value is replaced by “OFF”.

Two Control Loops: Normal Operation

LED Indicators

LED Function Labels

Process Variable* & Actual

Setpoint Values*

Indicators for Alarm and

Remote Setpoint active*

Loop Description*

Control Deviation (±5% of

span) & Power Graphs*

Engineering Units*

* = in loop 1 & 2 screen area

2-LOOP OPERATION

Default LED indicator functions are PRI 1, PRI 2, TUNE & ALARM - the functions and their labels can

be altered only with the PC configuration software.

In valve motor drive mode, the power bar-graph is replaced by valve Open / Stop / Close.

In manual mode the effective setpoints are replaced by the %Manual Power and the label “MAN”.

In manual mode with valve motor drive the setpoint is replaced by valve Open / Stop / Close.

If control is disabled the effective setpoint value of that loop is replaced by “OFF”.

Pro-EC44 Product Manual - 59540-1 October 2013 Page 37

Page 45

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

Cascade Control: Normal Operation

LED Indicators

LED Function Labels

Cascade Status

Master Process Value

Slave Process Value

Master Setpoint (Slave SP if

Cascade Open)

Control Deviation (±5% of

span) & Power Graphs

CASCADE CONTROL