Page 1

Process controller 8800

Operating manual

English

9499-040-70611

Valid from: 8405

Page 2

8800/8840 Configurator

More efficiency in engineering, more overview in operating:

The projecting environment for the West controllers 8800/8840

ATTENTION!

Mini Version and Updates on

www.westinstruments.com

Description of symbols:

g General information

a General warning

l Attention: ESD sensitive devices

© West Instruments • Printed in Germany

All rights reserved. No part of this document may bereproduced or published in

any form or by any means without prior written permission from the copyright

owner.

A publication of West Instruments, The Hyde Business Park,

Brighton BN2 4JU, England

Page 3

Contents

1 Mounting ..............................6

2 Electrical connections .......................7

2.1 Connecting diagram .......................7

2.2 Terminal connection.........................8

3 Operation .............................12

3.1 Front view ............................12

3.2 Behaviour after power-on .....................13

3.3 Operating level ...........................13

3.4 Error list / Mainenance manager .................14

3.5 Self-tuning .............................17

3.5.1 Preparation for self-tuning .......................17

3.5.2 Optimization after start-up or at the set-point ..............18

3.5.3 Selecting the method ( ConF/ Cntr/ tunE).............18

3.5.4 Self-tuning start .............................22

3.5.5 Self-tuning cancellation ........................22

3.5.6 Acknowledgement procedures in case of unsuccessful self-tuning . 23

3.5.7 Examples for self-tuning attempts ..................24

3.6 Manual self-tuning .........................25

3.7 Second PID parameter set .....................26

3.8 Alarm handling...........................27

3.9 Operating structure.........................29

4 Configuration level ........................30

4.1 Configuration survey ....................30

4.2 Configuration parameters ....................31

4.3 Set-point processing ........................49

4.3.1 Set-point gradient / ramp ........................49

4.4 Switching behaviuor ........................50

4.4.1 Standard ( CyCl= 0 ) .........................50

4.4.2 Switching attitude linear ( CyCl= 1 ).................50

4.4.3 Switching attitude non-linear ( CyCl= 2 )...............51

4.4.4 Heating and cooling with constant period ( CyCl= 3 )........52

8800 process controller 3

Page 4

4.5 Configuration examples ......................53

4.5.1 On-Off controller / Signaller (inverse) .................53

4.5.2 2-point controller (inverse) .......................54

4.5.3 3-point controller (relay & relay) ....................55

4.5.4 3-point stepping controller (relay & relay) ...............56

4.5.5 Continuous controller (inverse) .....................57

4.5.6 ∆ - Y - Off controller / 2-point controller with pre-contact ......58

4.5.7 8800 process controller with measured value output ..........59

4.5.8 Continuous controller with integrated positioner ( Cntr/ C.Fnc = 6 )60

5 Parameter setting level ......................61

5.1 Parameter survey ........................61

5.2 Parameters .............................62

5.3 Input scaling ............................65

5.3.1 Input Inp.1 and InP.3 .............65

5.3.2 Input InP.2...............................66

6 Calibration level .........................67

7 Special functions .........................70

7.1 DAC®– motor actuator monitoring ...............70

7.2 O2measurement ..........................72

7.2.1 Connection ...............................72

7.2.2 Configuration: ..............................73

7.3 Linearization ............................74

7.4 8800 process controller as Modbus master ............75

8 8800/8840 configurator ......................76

9 Versions ..............................77

10 Technical data ..........................78

11 Safety hints ............................81

11.1 Resetting to factory setting.....................82

12 Notes ................................83

4 8800 process controller

Page 5

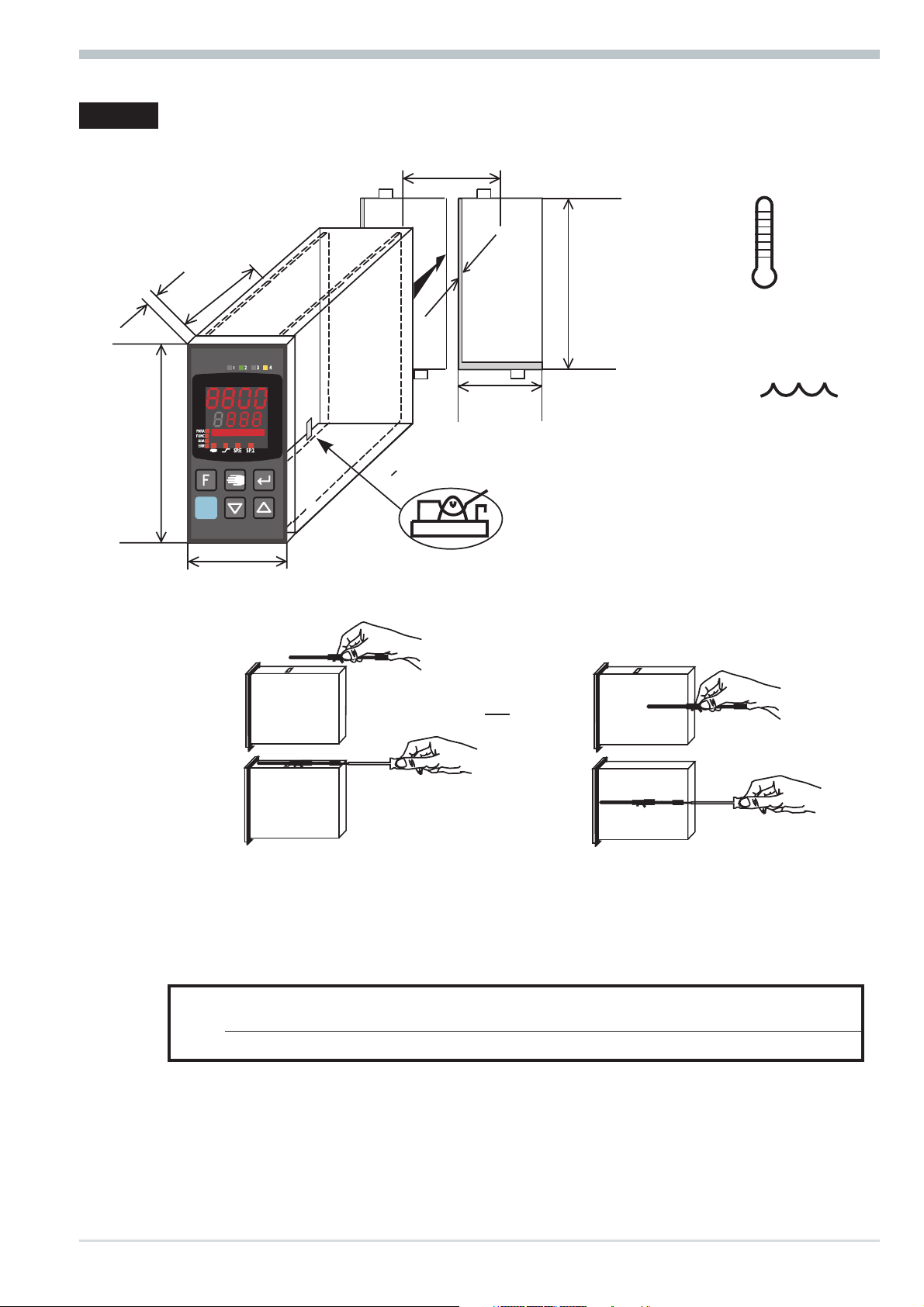

1 Mounting

*

Mounting

min.48 (1.89")

(0.4")

10

118

WEST

96 (3.78")

Process Controller

48 (1.89")

(4.65")

8800

1..10

(0.04..0.4")

+0,6

45

(1.77" )

+0.02

Loc

security switch

+0,8

+0.03

92

max.

(3.62" )

max.

95% rel.

60°C

0°Cmin.

%

Ü

or

Ü

*

Safety switch:

For access to the safety switch, the controller must be withdrawn from the

housing. Squeeze the top and bottom of the front bezel between thumb and

forefinger and pull the controller firmly from the housing.

Loc open Access to the levels is as adjusted by means of 8800/8840 configurator

(engineering tool) 2

closed 1 all levels accessible wihout restriction

1 Factory setting 2 Default setting: display of all levels

suppressed, password PASS = OFF

l

8800 process controller 5

Caution! The unit contains ESD-sensitive components.

Page 6

Electrical connections

3

2 Electrical connections

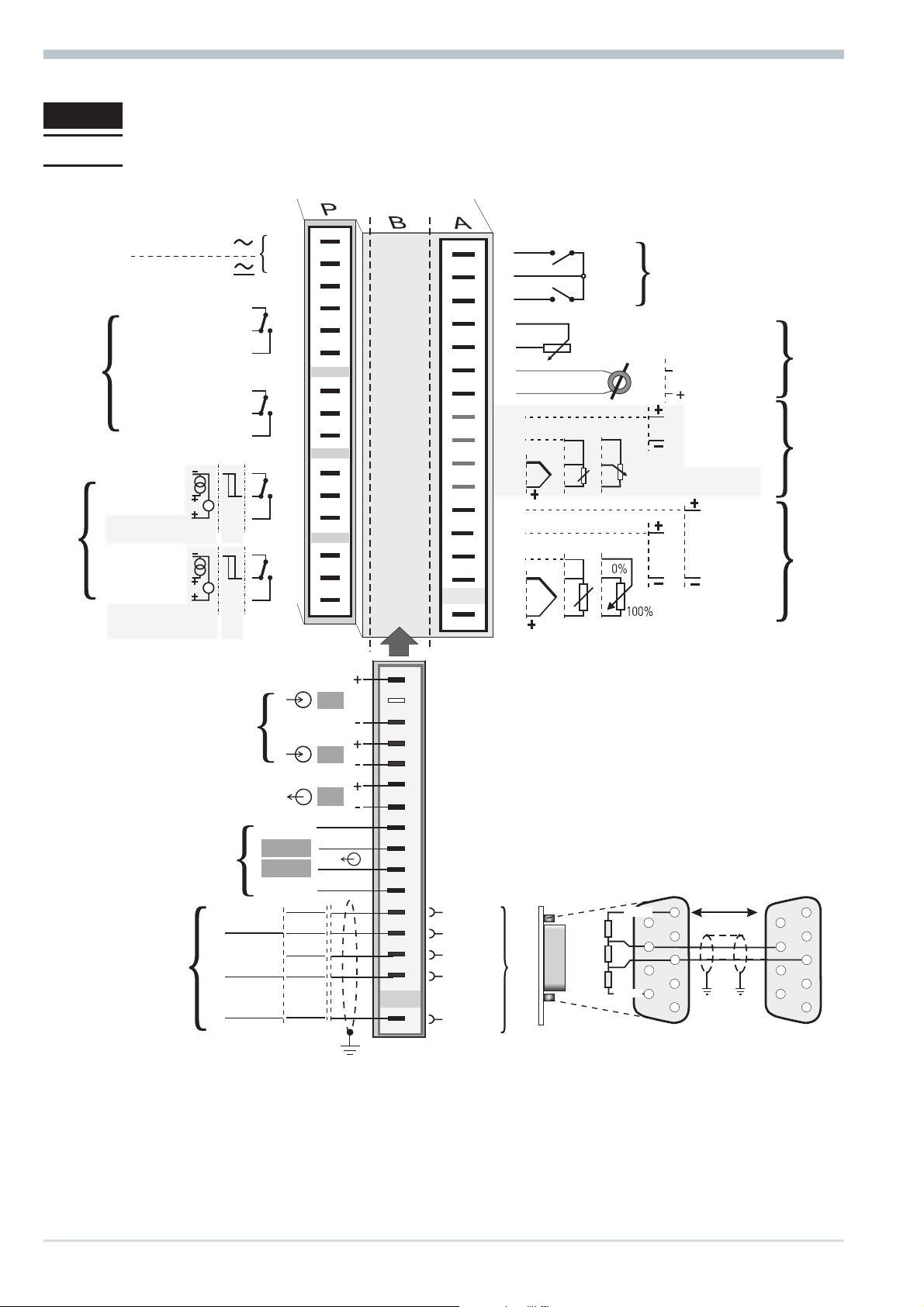

2.1 Connecting diagram

1

2

90...250V

24 V UC

OUT1

OUT2

OUT3

OUT4

!

V

V

d

b

c

e

8

9

0

RGND

DATA B

DATA A

RS485 RS422

Modbus RTU

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

a

+24V DC

OUT5

OUT6

24V GND

RXD-B

RXD-A

TXD-B

TXD-A

GND

di2

di3

U

1

2

3

di1

7

di2

4

5

6

7

g

HC

mA

INP2

f

5

8

9

10

11

(mV)

0%

100%

mA

INP3

6

12

13

14

15

mA

Volt

INP1

4

(16)

Option

1

(2)

3

4

5

10

11

12

13

14

15

(16)

17

6

7

8

9

VP (5V)

DGND

RxD/TxD-N

RxD/TxD-P

Schirm/

Screen

T

17

PROFIBUS-DP

(mV)

a

b

390 [

220 [

Adapter

390 [

cd

DGND

9

8

7

VP (5V)

6

Profibus DP

e

max.

1200m

5

4

3

2

1

5

9

4

8

3

7

2

6

1

g

Dependent of order, the controller is fitted with :

flat-pin terminals 1 x 6,3mm or 2 x 2,8mm to DIN 46 244 or

w

screw terminals for 0,5 to 2,5mm²

w

Connecting diagram 6 8800 process controller

Page 7

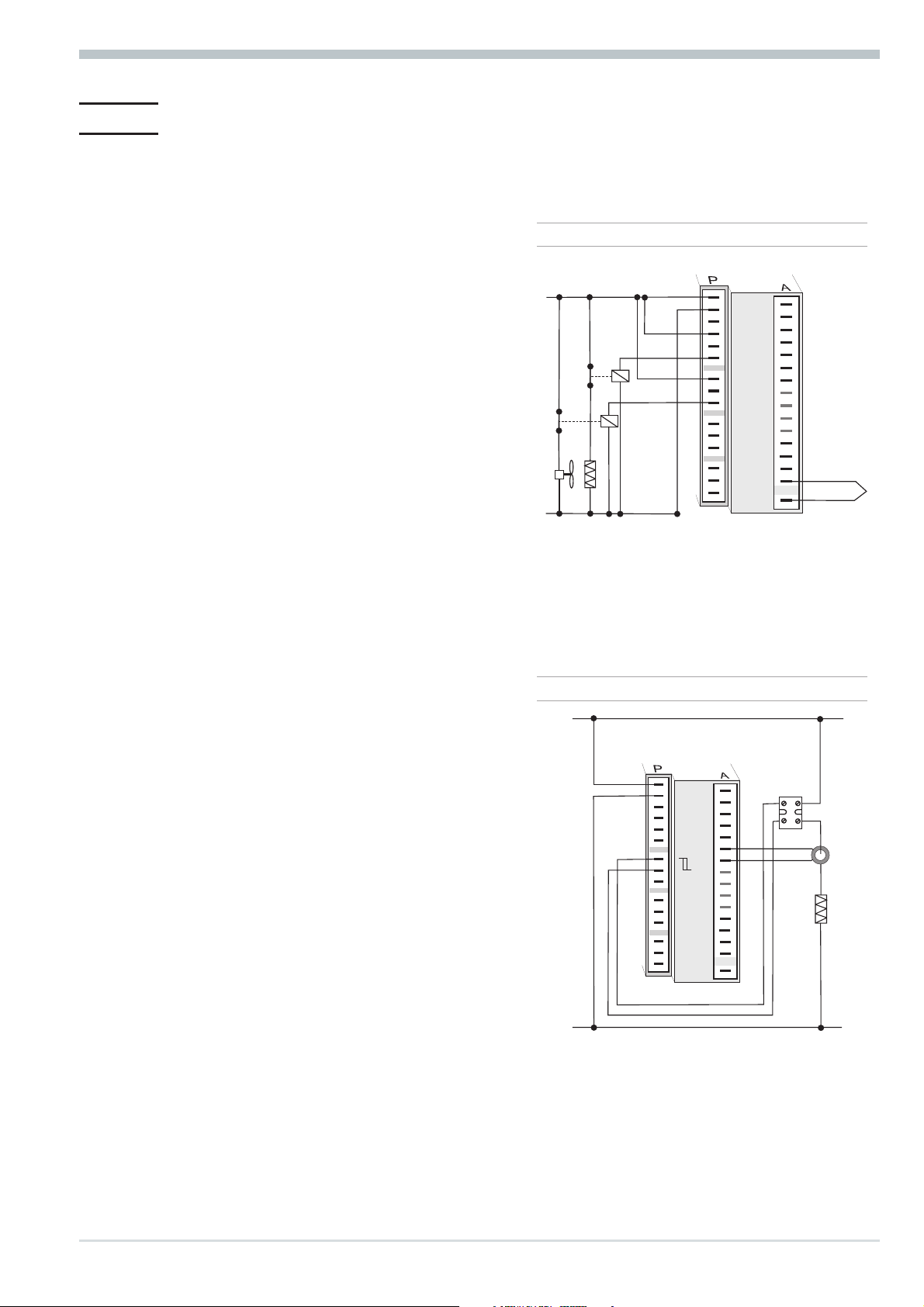

2.2 Terminal connection

Power supply connection 1

See chapter 10 "Technical data"

Electrical connections

Connection of outputs OUT1/2 2

2 OUT1/2 heating/cooling

Relay outputs (250V/2A), potential-free

changeover contact

L

Connection of outputs OUT3/4 3

a relay (250V/2A), potential-free

changeover contact universal output

b current (0/4...20mA)

c voltage (0/2...10V)

d transmitter supply

e logic (0..20mA / 0..12V)

Connection of input INP1 4

N

Input mostly used for variable x1

(process value)

a thermocouple

b resistance thermometer (Pt100/ Pt1000/ KTY/ ...)

c current (0/4...20mA)

d voltage (0/2...10V)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

10

11

12

13

14

(16)

1

2

3

4

5

6

7

8

9

15

17

+

Connection of input INP2 5

f heating current input (0..50mA AC)

or input for ext. set-point (0/4...20mA)

g potentiometer input for position

feedback

Connection of input INP2 5

a Heating current input (0...50mA AC)

or input for ext. Set-point (0/4...20mA)

b Potentiometer input for position

feedback

Connection of input INP3 6

As input INP1, but without voltage

Connection of inputs di1, di2 7

Digital input, configurable as switch or

push-button

5 INP2 current tansformer

L

1

2

3

4

5

6

7

8

Logik

9

10

11

12

13

14

15

10

11

12

13

14

15

(16)

17

1

2

3

4

5

6

7

8

9

SSR

_

+

8800 process controller 7 Terminal connection

Page 8

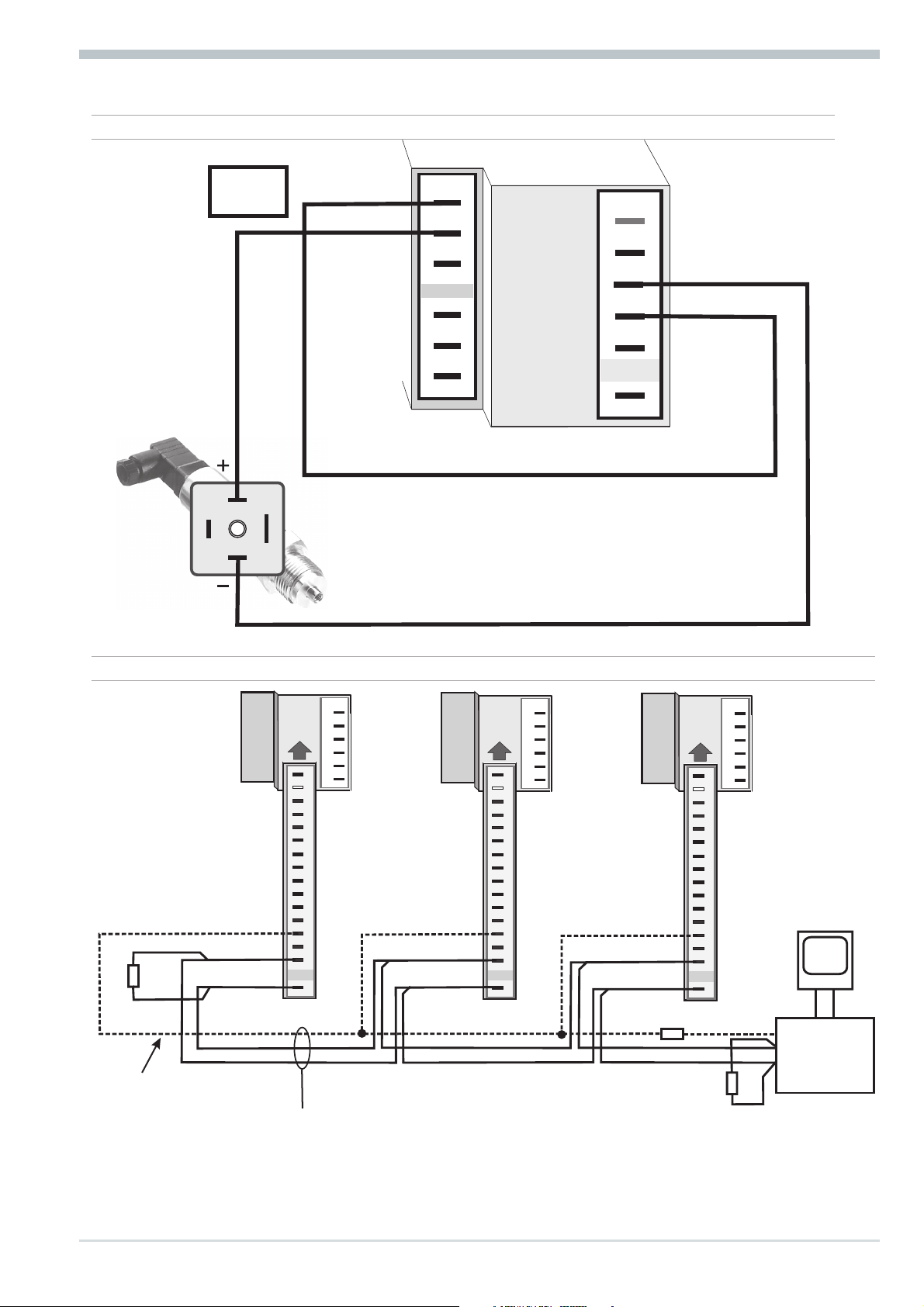

Electrical connections

Connection of inputs di2/3 8 (option)

Digital inputs (24VDC external), galvanically isolated, configurable as switch or

push-button

Connection of output U

9 (option)

T

Supply voltage connection for external energization

Connection of outputs OUT5/6 0 (option)

Digital outputs (opto-coupler), galvanic isolated, common positive control

voltage, output rating: 18...32VDC

Connection of bus interface ! (option)

PROFIBUS DP or RS422/485 interface with Modbus RTU protocol

89 di2/3, 2-wire transmitter supply

OUT3

J

10

11

12

13

14

15

Option

15

(16)

17

13

14

+

-

g

+24VDC

3

0V

+

1

2

-

17,5V

22mA

K

5mA

5mA

+

-

1

(2)

3

4

5

6

7

8

9

10

11

12

13

14

15

(16)

17

J

If the universal output OUT3 or OUT4 is used there may be no external galvanic

connection between measuring and output circuits!

Terminal connection 8 8800 process controller

Page 9

3 OUT3 transmitter supply

Electrical connections

3

13V

22mA

1

K

2

-

+

10

11

12

13

14

15

11

12

15

(16)

17

13

14

+

-

9 RS485 interface (with RS232-RS485 interface converter) *

R = 120...200 OhmT

RT

RGND connection optional

RGND

DATA B

DATA A

option

1

(2)

3

4

5

6

7

8

9

10

11

12

13

14

15

(16)

17

J

10

11

12

13

14

15

RGND

DATA B

DATA A

option

1

(2)

3

4

5

6

7

8

9

10

11

12

13

14

15

(16)

17

10

11

12

13

14

15

max. 1000m

"Twisted Pair” cable

RGND

DATA B

DATA A

R=100 Ohm

option

1

(2)

3

4

5

6

7

8

9

10

11

12

13

14

15

(16)

17

RT

R = 120...200 OhmT

10

11

12

13

14

15

PC

RS485-RS232

converter

* Interface description Modbus RTU in speperate manual: see page 75.

8800 process controller 9 Terminal connection

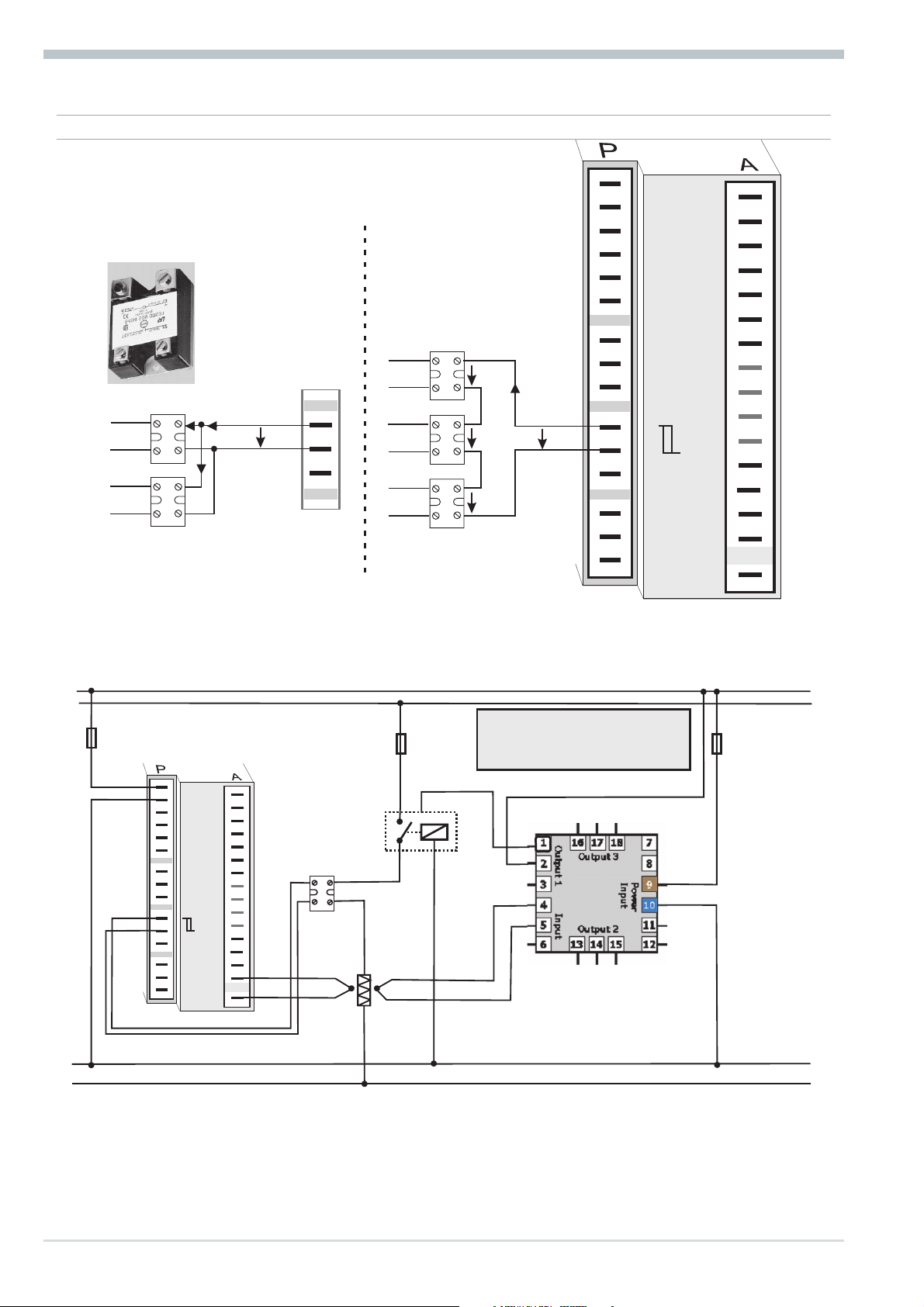

Page 10

Electrical connections

3 OUT3 as logic output with solid-state relay (series and parallel connection)

Series connection

SSR

I =22mA

max

_

4V

+

SSR

_

4V

+

SSR

_

4V

+

12V

10

11

12

Logic

SSR

SSR

Parallel connection

I =22mA

max

_

+

_

+

12V

10

11

12

8800 process controller connecting example:

L1

L2

fuse

8840 profiler

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Logic

10

11

12

13

14

(16)

1

2

3

4

5

6

7

8

9

15

17

SSR

_

+

fuse

contactor

+

heating

1

6700 Limit controller

Standard version:

N6700Z21

00

other versions on requestr

1

6700

Limit

controller

fuse

N1

N2

a

CAUTION: Using a Limit controller is recommendable in systems

where overtemperature implies a fire hazard or other risks.

Terminal connection 10 8800 process controller

Page 11

3 Operation

1

2

3

4

5

6

$

7

8

%

&

(

/

9

0

§"

!

3.1 Front view

Operation

1 Status of switching outputs

OuT.1... 6

2 Process value display

3 Set-point, controller output

4 Signals display on °C or °F

5 Signals ConF and PArA level

6 Signals aktive function key

7 Self-tuning active

8 Entry in error list

9 Bargraph or clear text display

0 SP.2 is effective

! SP.E is effective

" Set-point gradient effective

§ Manual/automatic switch-over:

Off: Automatic

On: Manual (changing possible)

Blinks:Manual (changing not

possible

(r ConF/ Cntr/ MAn)

$ Enter key:

calls up extended operating

level / error list

% Up/down keys:

changing the set-point or the

controller output value

& Manual mode /spec. function

(→ ConF / LOGI )

LED colours:

LED 1, 2, 3, 4: yellow

Bargraph: red

other LEDs: red

/ Freely programmable function

key

( PC connection for

8800/8840 configurator

(engineering tool)

g

In the upper display line, the

process value is always

At parameter, configuration,

calibration as well as extended

operating level, the bottom

display line changes cyclically between parameter name and parameter value.

displayed.

8800 process controller 11 Front view

Page 12

Operation

A

M

l

3.2 Behaviour after power-on

After supply voltage switch-on, the unit starts with the operating level.

The unit is in the condition which was active before power-off.

If the 8800 process controller was in manual mode at supply voltage switch-off,

the controller will re-start with the last output value in manual mode at power-on.

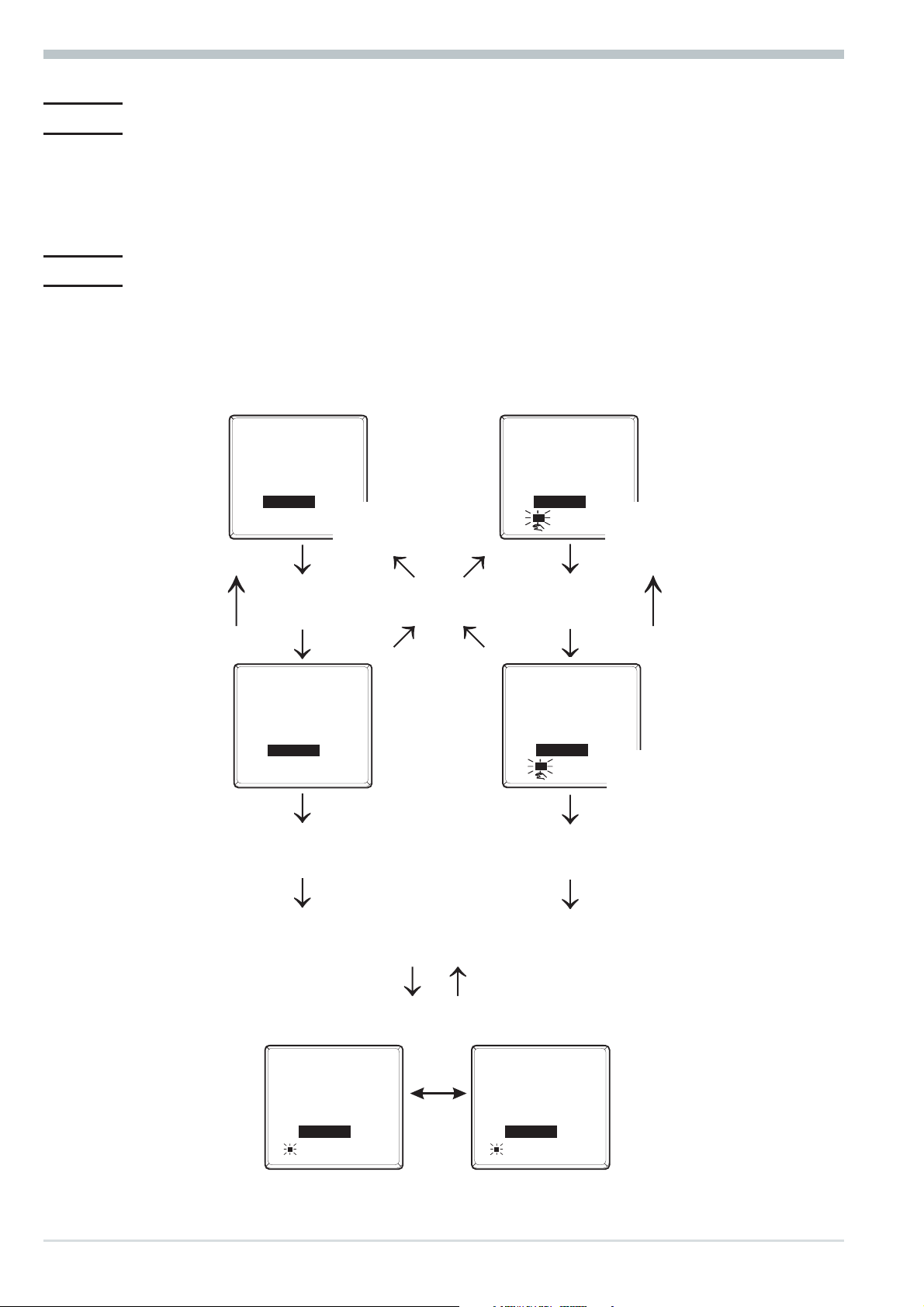

3.3 Operating level

The content of the extended operating level is determined by means of 8800/8840

configurator (engineering tool). Parameters which are used frequently or the

display of which is important can be copied to the extended operating level.

time

out

utomatic

1199

1200

È

Ì

Ù

1199

Y21

only

display

i

Ò

Ò

i

anua

1199

Y21

È

Ì

Ù

1199

1200

È

Ì

time

out

Ù

Ù

Extended operating level

time

out

Error list (if error exists)

126

FbF.1

Err

Behaviour after power-on 12 8800 process controller

Display

switching

126

2

Err

Page 13

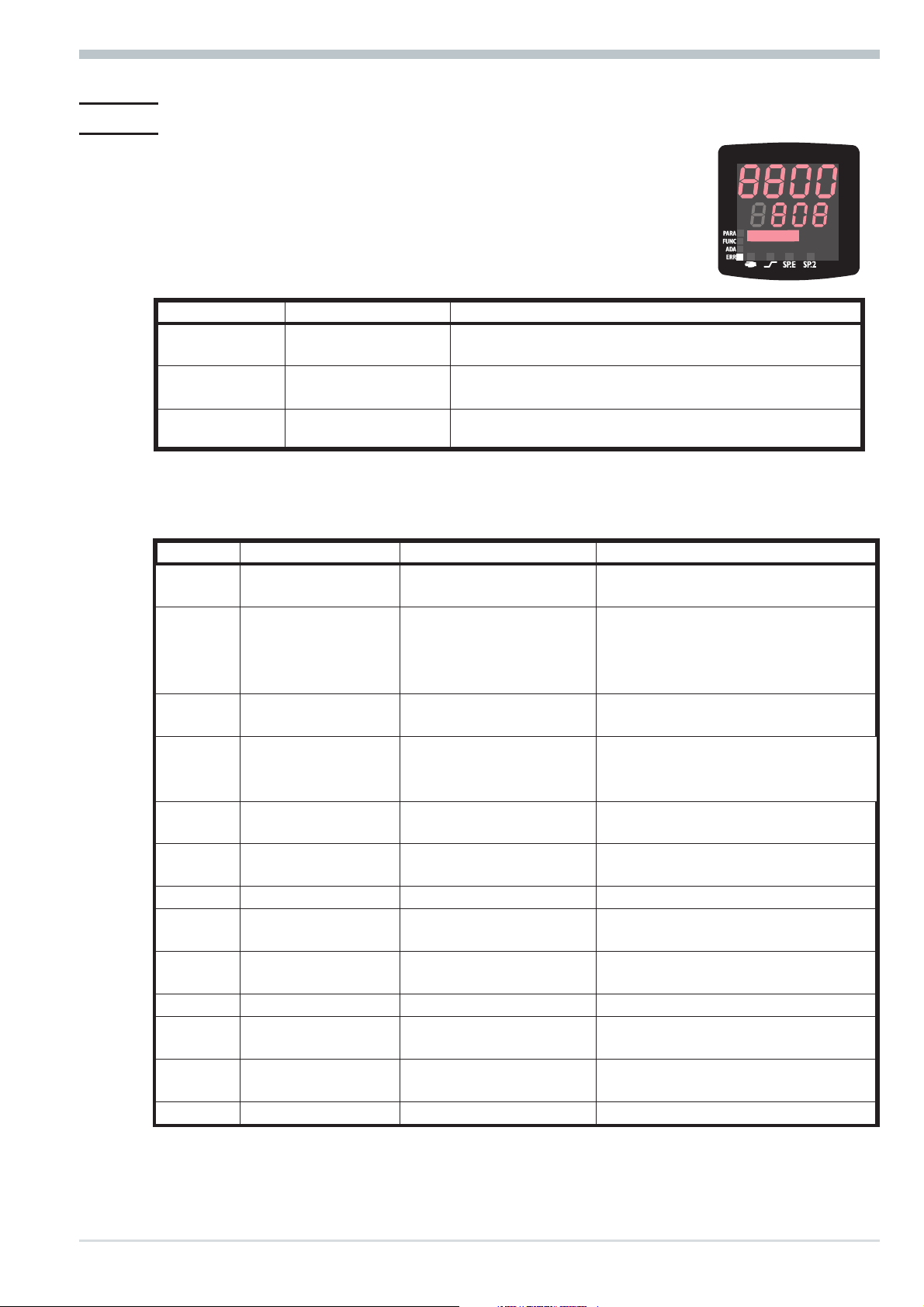

3.4 Error list / Mainenance manager

With one or several errors, the extended operating level

always starts with the error list. Signalling an actual entry

in the error list (alarm, error) is done by the Err LED in the

display. To reach the error list press Ù twice.

Err LED status Signification Proceed as follows

blinks

(status 2)

lit

(status 1)

off

(status 0)

Alarm due to existing

error

Error removed, alarm

not acknowledged

No error, all alarm

entries deleted

Determine the error type in the error list

-

After error correction the unit changes to status 1

-

Acknowledge the alarm in the error list pressing key ÈorÌ

-

The alarm entry was deleted (status 0).

-

-Not visible except when acknowledging

-

Operation

°C

°F

Error list:

Name

E.1

E.2

E.3

E.4

FbF.1

Sht.1

POL.1

FbF.2

Sht.2

POL.2

FbF.3

Sht.3

POL.3

Internal error,

cannot be removed

Internal error, can be

reset

Configuration error,

can be reset

Hardware error - Codenumber and

Sensor break INP1

Short circuit INP1-Sensor defective

INP1polarity error

Sensor break INP2-Sensor defective

Short circuit INP2-Sensor defective

INP2 polarity

Sensor break INP3-Sensor defective

Short circuit INP3-Sensor defective

INP3 polarity

Description Reason Possible remedial action

- E.g. defective EEPROM - Contact West service

- Return unit to our factory

- e.g. EMC trouble - Keep measurement and power supply

cables in separate runs

- Ensure that interference suppression

of contactors is provided

- wrong configuration

- missing configuration

- Check interaction of configuration /

parameters

- Contact West service

hardware are not

identical

-

Sensor defective

-

Faulty cabling

-

Faulty cabling

-

Faulty cabling

-

Faulty cabling

-

Faulty cabling

-

Faulty cabling

-

Faulty cabling

-

Faulty cabling

-

Faulty cabling

- Elektronic-/Optioncard must be

exchanged

-

Replace INP1 sensor

-

Check INP1 connection

-

Replace INP1 sensor

-

Check INP1 connection

-

Reverse INP1 polarity

-

Replace INP2 sensor

-

Check INP2 connection

-

Replace sensor INP2

-

Check INP2 connection

-

Reverse INP2 polarity

-

Replace INP3 sensor

-

Check INP3 connection

-

Replace sensor INP3

-

Check INP3 connection

-

Reverse INP3 polarity

8800 process controller 13 Error list / Mainenance manager

Page 14

Operation

Name

HCA

SSr

LooP

AdA.H

AdA.C

LiM.1

Lim.2

Lim.3

Inf.1

Inf.2

E.5

dp.1

dp.2

dp.3

Description Reason Possible remedial action

Heating current

alarm (HCA)

Heating current circuit

-

interrupted, I< HC.A or

Check heating current circuit

If necessary, replace heater band

-

I> HC.A (dependent of

configuration)

Heater band defective

-

Heating current

short circuit (SSR)

Current flow in heating

circuit with controller

Check heating current circuit

If necessary, replace solid-state relay

-

off

SSR defective

-

Control loop alarm

(LOOP)

Input signal defective or

not connected correctly

Output not connected

correctly

Check heating or cooling circuit

Check sensor and replace it, if

necessary

Check controller and switching

device

Self-tuning heating

alarm

See Self-tuning heating

error status

see Self-tuning heating error status

-

(ADAH)

Self-tuning heating

alarm cooling

(ADAC)

stored limit alarm 1 - adjusted limit value 1

See Self-tuning cooling

error status

see Self-tuning cooling error status

-

- check process

exceeded

stored limit alarm 2 - adjusted limit value 2

- check process

exceeded

stored limit alarm 3 - adjusted limit value 3

- check process

exceeded

time limit value

message

duty cycle message

(digital ouputs)

Internal error in DP

module

- adjusted number of

operating hours reached

- adjusted number of duty

cycles reached

-

self-test error

-

internal communication

- application-specific

- application-specific

-

Switch on the instrument again

-

Contact West service

interrupted

No access by bus

master

-

bus error

-

connector problem

-

no bus connection

Faulty configuration-Faulty DP

configuration telegram

Inadmissible

parameter setting

telegram sent

-

Faulty DP parameter

setting telegram

-

Check cable

-

Check connector

-

Check connections

-

Check DP configuration telegram in

master

-

Check DP parameter setting

telegram in master

-

Check cable connection

-

Check address

-

Check master setting

dp.4

No data

communication

-

Bus error

-

Address error

-

Master stopped

Error list / Mainenance manager 14 8800 process controller

Page 15

Operation

g

g

Saved alarms (Err-LED is lit) can be acknowledged and deleted with the digital

input di1/2/3, the è-key or the Ò-key.

Configuration, see page 37: ConF / LOGI / Err.r

If an alarm is still valid that means the cause of the alarm is not removed so far

(Err-LED blinks), then other saved alarms can not be acknowledged and deleted.

Self-tuning heating ( ADA.H) and cooling ( ADA.C) error status:

Error

status

Description Behaviour

0

No error

3

Faulty control action

4

No response of process

variable

5

Low reversal point Increase ( ADA.H) max. output limiting Y.Hi or decrease

Re-configure controller (inverse i direct)

The control loop is perhaps not closed: check sensor, connections

and process

( ADA.C) min. output limiting Y.Lo

6

Danger of exceeded

If necessary, increase (inverse) or reduce (direct) set-point

set-point (parameter

determined)

7

Output step change

too small (∆y > 5%)

8

Set-point reserve too

small

Increase ( ADA.H) max. output limiting Y.Hi or reduce

( ADA.C) min. output limiting Y.Lo

Acknowledgment of this error message leads to switch-over to

automatic mode.If self-tuning shall be continued,

increase set-point (invers), reduce set-point (direct)

or decrease set-point range

(r PArA / SEtp / SP.LO and SP.Hi )

9

Impulse tuning failed The control loop is perhaps not closed: check sensor, connections

and process

DAC function ( DAC) error status:

Error

status

0

3

4

5

6

No error

Output is blocked Check the drive for blockage

Wrong method of operation Wrong phasing, defect motor capacitor

Fail at Yp measurement Check the connection to the Yp input

Calibration error Manual calibration necessary

Description Behaviour

8800 process controller 15 Error list / Mainenance manager

Page 16

Operation

3.5 Self-tuning

For determination of optimum process parameters, self-tuning is possible.

After starting by the operator, the controller makes an adaptation attempt,

whereby the process characteristics are used to calculate the parameters for fast

line-out to the set-point without overshoot.

The following parameters are optimized when self-tuning:

Parameter set 1:

Pb1 - Proportional band 1 (heating) in engineering units [e.g. °C]

ti1 - Integral time 1 (heating) in [s]

r only, unless set to OFF

td1 - Derivative time 1 (heating) in [s]

r only, unless set to OFF

t1 - Minimum cycle time 1 (heating) in [s]

r only, unless Adt0 was set to “no self-tuning” during

configuration by means of 8800/8840 configurator

®

.

Pb2 - Proportional band 2 (cooling) in engineering units [e.g. °C]

ti2 - Integral time 2 (cooling) in [s]

r only, unless set to OFF

td2 - Derivative time 2 (cooling) in [s]

r only, unless set to OFF

t2 - Minimum cycle time 2 (cooling) in [s]

r only, unless Adt0 was set to “no self-tuning” during

configuration by means of 8800/8840 configurator

Parameter set 2: analogous to parameter set 1 (see page25)

3.5.1 Preparation for self-tuning

Adjust the controller measuring range as control range limits. Set values

w

rnG.L and rnG.H to the limits of subsequent control.

(ConfigurationrControllerrlower and upper control range limits)

ConF r Cntr r rnG.L and rnG.H

Determine which parameter set shall be optimized.

w

-The instantaneously effective parameter set is optimized.

r Activate the relevant parameter set (1 or 2).

®

.

Determine which parameter set shall be optimized (see tables above).

w

Select the self-tuning method

w

see chapter 3.5.3

-Step attempt after start-up

-Pulse attempt after start-up

-Optimization at the set-point

Self-tuning 16 8800 process controller

Page 17

3.5.2 Optimization after start-up or at the set-point

The two methods are optimization after start-up and at the set-point.

As control parameters are always optimal only for a limited process range,

various methods can be selected dependent of requirements. If the process

behaviour is very different after start-up and directly at the set-point, parameter

sets 1 and 2 can be optimized using different methods. Switch-over between

parameter sets dependent of process status is possible (see page 25).

Optimization after start-up: (see page25 )

Optimization after start-up requires a certain separation between process value

and set-point. This separation enables the controller to determine the control

parameters by evaluation of the process when lining out to the set-point.

This method optimizes the control loop from the start conditions to the set-point,

whereby a wide control range is covered.

We recommend selecting optimization method “Step attempt after start-up”

with tunE = 0 first. Unless this attempt is completed successfully, we

recommend a “Pulse attempt after start-up”.

Operation

Optimization at the set-point: (see page 18)

For optimizing at the set-point, the controller outputs a disturbance variable to the

process. This is done by changing the output variable shortly. The process value

changed by this pulse is evaluated. The detected process parameters are

converted into control parameters and saved in the controller.

This procedure optimizes the control loop directly at the set-point. The advantage

is in the small control deviation during optimization.

3.5.3 Selecting the method ( ConF/ Cntr/ tunE)

Selection criteria for the optimization method:

Step attempt after start-up Pulse attempt after start-up Optimization at the set-point

tunE =0

tunE =1

tunE =2

sufficient set-point reserve is

provided

sufficient set-point reserve is

provided

always step attempt after

start-up

Sufficient set-point reserve:

inverse controller: (with process value < set-point- (10% of rnGH - rnGL)

direct controller: (with process value > set-point + (10% of rnGH - rnGL)

sufficient set-point reserve is not

provided

sufficient set-point reserve is not

provided

Step attempt after start-up

Condition: - tunE = 0 and sufficient set-point reserve provided or

- tunE =2

The controller outputs 0% correcting variable or Y.Lo and waits, until the process

is at rest (see start-conditions on page 16).

Subsequently, a correcting variable step change to 100% is output.

8800 process controller 17 Self-tuning

Page 18

Operation

The controller attempts to calculate the optimum control parameters from the

process response. If this is done successfully, the optimized parameters are taken

over and used for line-out to the set-point.

With a 3-point controller, this is followed by “cooling”.

After completing the 1st step as described, a correcting variable of -100% (100%

cooling energy) is output from the set-point. After successfull determination of

the “cooling parameters”, line-out to the set-point is using the optimized

parameters.

Pulse attempt after start-up

Condition: - tunE = 1 and sufficient set-point reserve provided.

The controller outputs 0% correcting variable or Y.Lo and waits, until the process

is at rest (see start conditions page 16)

Subsequently, a short pulse of 100% is output (Y=100%) and reset.

The controller attempts to determine the optimum control parameters from the

process response. If this is completed successfully, these optimized parameters

are taken over and used for line-out to the set-point.

With a 3-point controller, this is followed by “cooling”.

After completing the 1st step as described and line-out to the set-point, correcting

variable "heating" remains unchanged and a cooling pulse (100% cooling energy)

is output additionally. After successful determination of the “cooling

parameters”, the optimized parameters are used for line-out to the set-point.

Optimization at the set-point

Conditions:

A sufficient set-point reserve is not provided at self-tuning start (see page 17).

w

tunE is0or1

w

With Strt = 1 configured and detection of a process value oscillation by

w

more than ± 0,5% of (rnG.H - rnG.L) by the controller, the control

parameters are preset for process stabilization and the controller realizes an

optimization at the set-point (see figure “Optimization at the set-point”).

when the step attempt after power-on has failed

w

with active gradient function ( PArA/ SETP/ r.SP≠ OFF), the set-point

w

gradient is started from the process value and there isn't a sufficient set-point

reserve.

Self-tuning 18 8800 process controller

Page 19

Operation

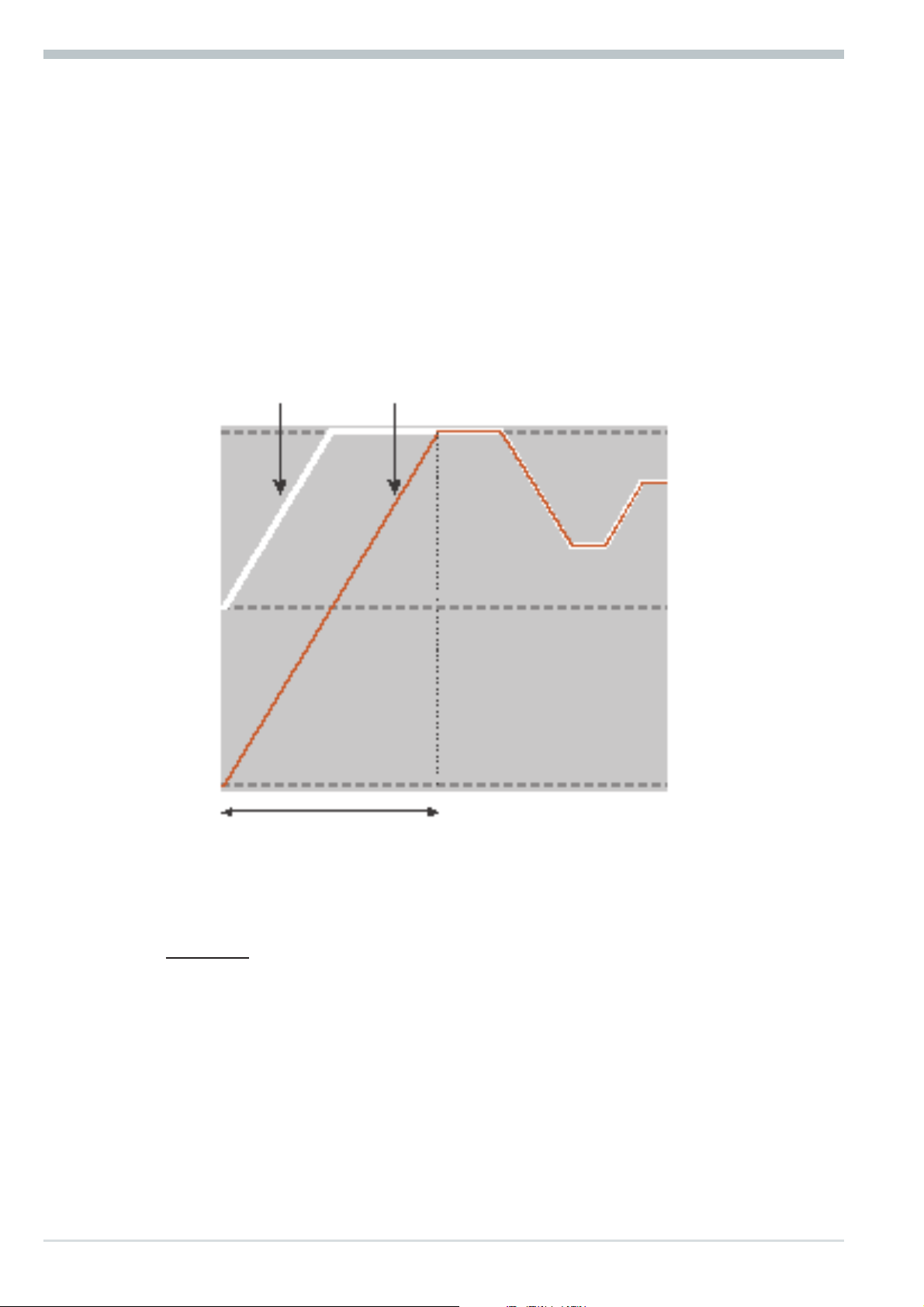

Optimization-at-the-set-point procedure:

The controller uses its instantaneous parameters for control to the set-point. In

lined out condition, the controller makes a pulse attempt. This pulse reduces the

correcting variable by max. 20% 1, to generate a slight process value

undershoot. The changing process is analyzed and the parameters thus calculated

are recorded in the controller. The optimized parameters are used for line-out to

the set-point.

Optimization at the set-point

set-point

process value

correcting

variable

With a 3-point controller, optimization for the “heating“ or “cooling” parameters

occurs dependent of the instantaneous condition.

These two optimizations must be started separately.

1 If the correcting variable is too low for reduction in lined out condition it is

increased by max. 20%.

8800 process controller 19 Self-tuning

Page 20

Operation

Optimization at the set-point for 3-point stepping controller

With 3-point stepping controllers, the pulse attempt can be made with or without

position feedback. Unless feedback is provided, the controller calculates the

motor actuator position internally by varying an integrator with the adjusted

actuator travel time. For this reason, precise entry of the actuator travel time

(tt), as time between stops is highly important. Due to position simulation, the

controller knows whether an increased or reduced pulse must be output. After

supply voltage switch-on, position simulation is at 50%. When the motor actuator

was varied by the adjusted travel time in one go, internal calculation occurs, i.e.

the position corresponds to the simulation:

Simulation actual position

Internal calculation

tt

Internal calculation always occurs, when the actuator was varied by travel time

tt in one go

variation, internal calculation is cancelled. Unless internal calculation occurred

already after self-tuning start, it will occur automatically by closing the actuator

once.

Unless the positioning limits were reached within 10 hours, a significant

deviation between simulation and actual position may have occurred. In this case,

the controller would realize minor internal calculation, i.e. the actuator would be

closed by 20 %, and re-opened by 20 % subsequently. As a result, the controller

knows that there is a 20% reserve for the attempt.

, independent of manual or automatic mode. When interrupting the

Self-tuning 20 8800 process controller

Page 21

3.5.4 Self-tuning start

Start condition:

For process evaluation, a stable condition is required. Therefore, the

w

controller waits until the process has reached a stable condition after

self-tuning start.

The rest condition is considered being reached, when the process value

oscillation is smaller than ± 0,5% of (rnG.H - rnG.L).

For self-tuning start after start-up, a 10% difference from (SP.LO ... SP.Hi)

w

is required.

Operation

g

Self-tuning start can be blocked via 8800/8840 configurator®(engineering tool)

( P.Loc).

Strt = 0 Only manual start by pressing keys Ù and È

simultaneously or via interface is possible.

Strt = 1 Manual start by press keys Ù and È simultaneously

via interface and automatic start after power-on and detection

of process oscillations.

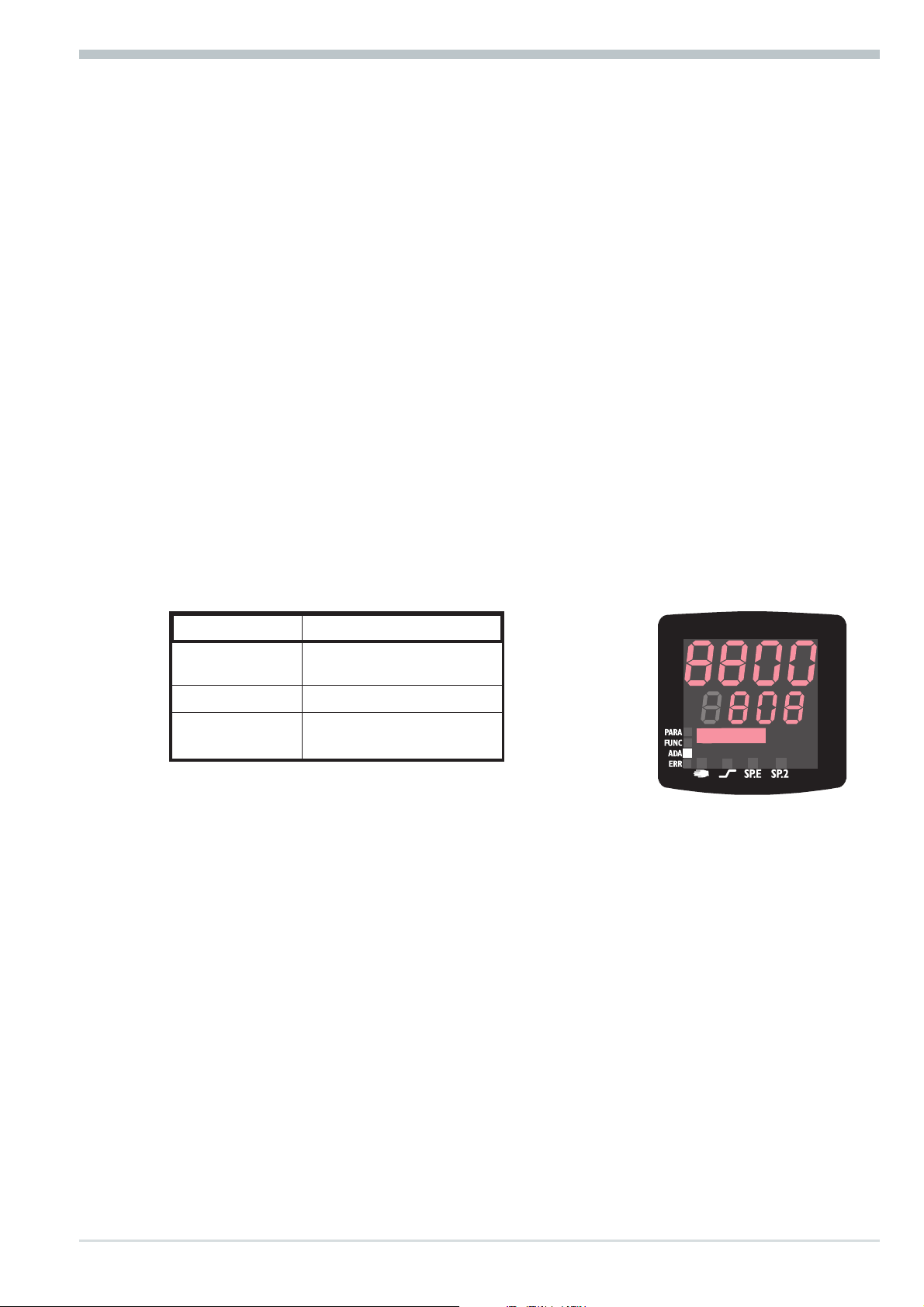

Ada LED status Signification

blinks Waiting, until process

calms down

lit Self-tuning is running

off Self-tuning not activ

or ended

°C

°F

3.5.5 Self-tuning cancellation

By the operator:

Self-tuning can always be cancelled by the operator. For this, press Ù and È

key simultaneously.With controller switch-over to manual mode after self-tuning

start, self-tuning is cancelled. When self-tuning is cancelled, the controller will

continue operating using the old parameter values.

By the controller:

If the Err LED starts blinking whilst self-tuning is running, successful self-tuning

is prevented due to the control conditions. In this case, self-tuning was cancelled

by the controller. The controller continues operating with the old parameters in

automatic mode. In manual mode it continues with the old controller output

value.

3.5.6 Acknowledgement procedures in case of unsuccessful self-tuning

8800 process controller 21 Self-tuning

Page 22

Operation

1. Press keys Ù and È simultaneously:

2. Press key Ò (if configured):

3. Press key Ù :

Cancellation causes:

r page 15: "Error status self-tuning heating ( ADA.H) and cooling ( ADA.C)"

The controller continues controlling using the old parameters in automatic

mode. The Err LED continues blinking, until the self-tuning error was

acknowledged in the error list.

The controller goes to manual mode. The Err LED continues blinking,

until the self-tuning error was acknowleged in the error list.

Display of error list at extended operating level. After acknowledgement

of the error message, the controller continues control in automatic mode using

the old parameters.

Self-tuning 22 8800 process controller

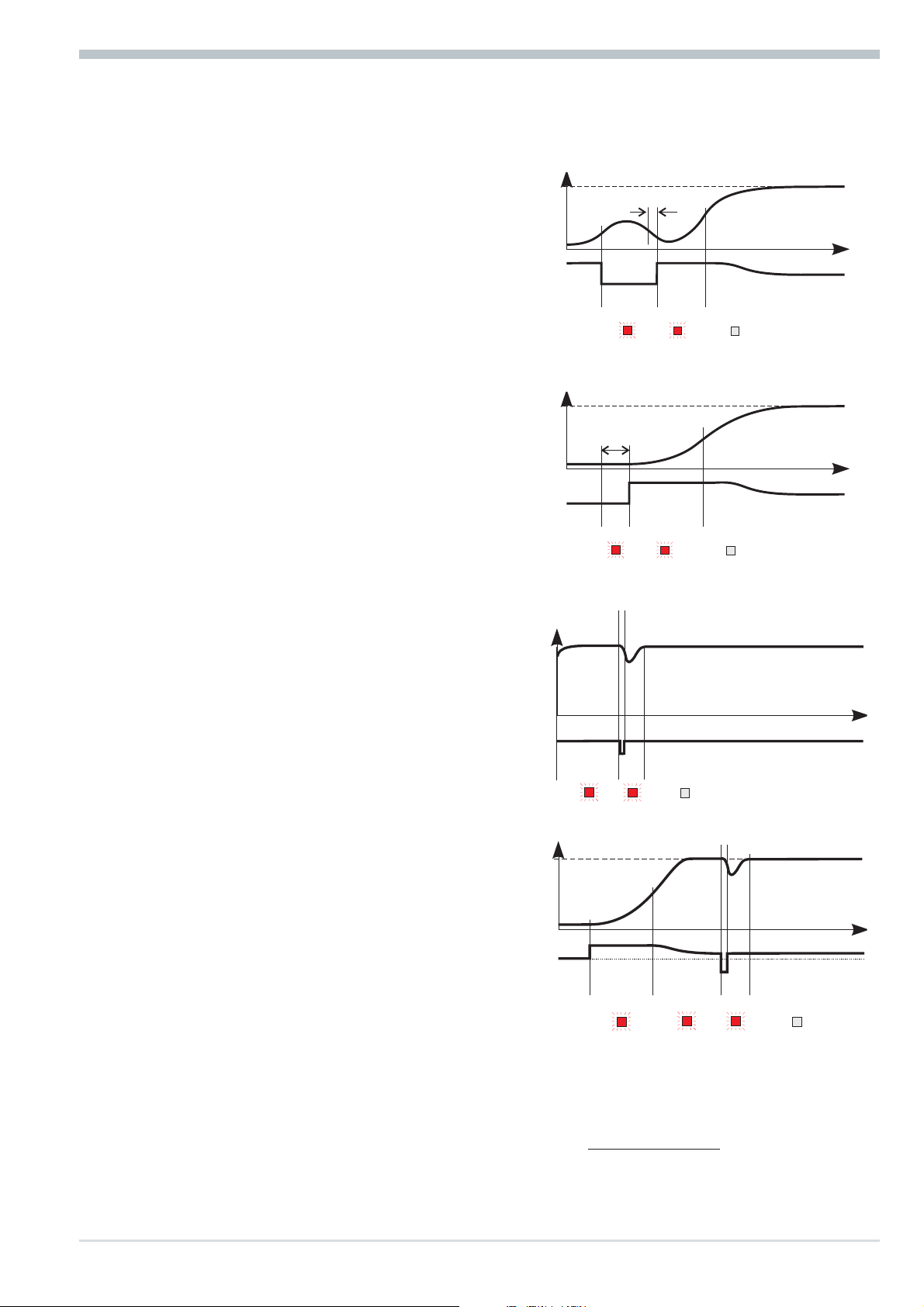

Page 23

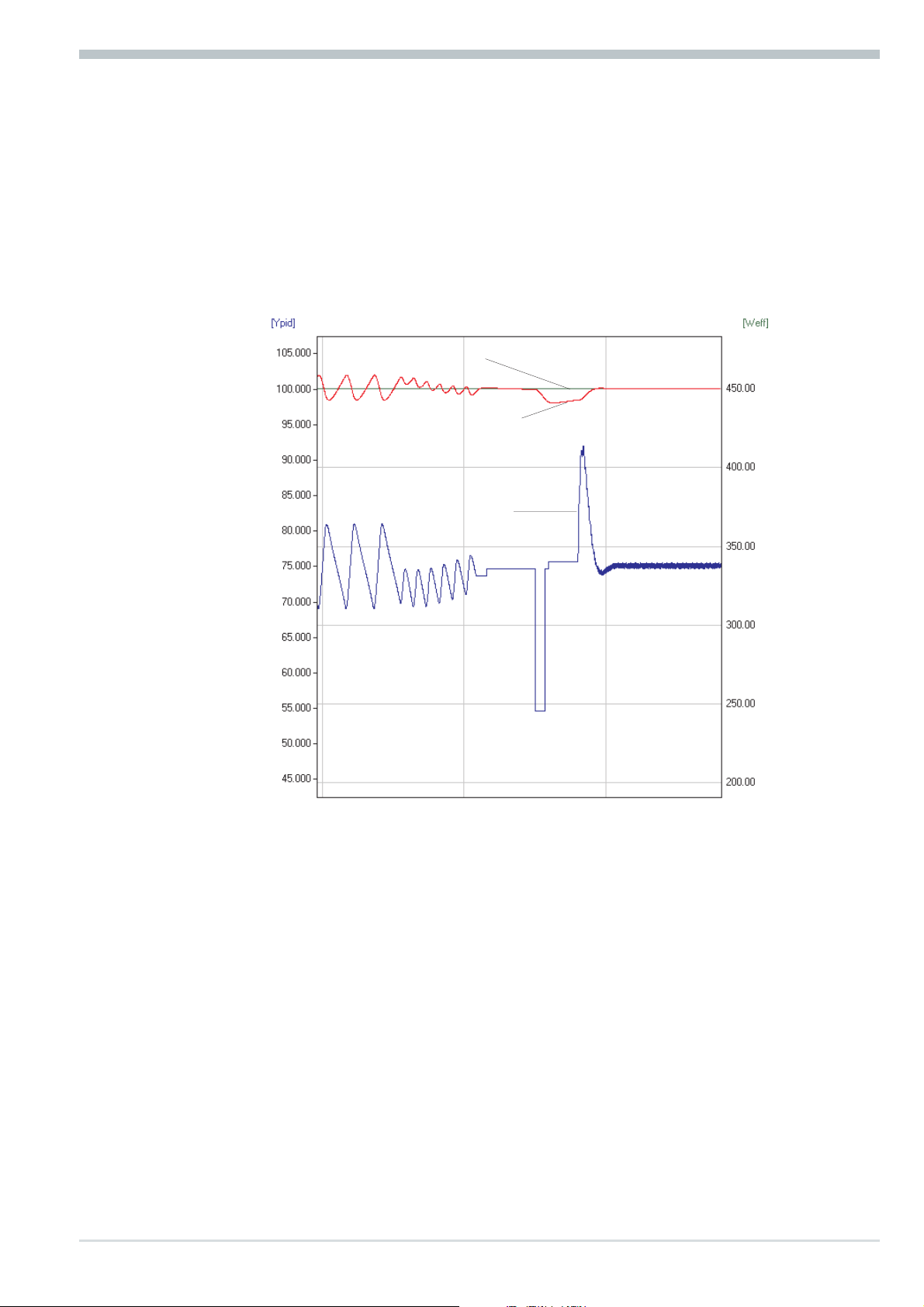

3.5.7 Examples for self-tuning attempts

(controller inverse, heating or heating/cooling)

Operation

Start: heating power switched on

Heating power Y is switched off (1).

X

W

2

When the change of process value X

was constant during one minute (2),

the power is switched on (3).

At the reversal point, the self-tuning

100%

0%

Y

Star t r

1

3

t reversal point

attempt is finished and the new

parameter are used for controlling to

blinks

set-point W.

Start: heating power switched off

X

W

The controller waits 1,5 minutes (1).

Heating power Y is switched on (2).

At the reversal point, the self-tuning

attempt is finished and control to the

set-point is using the new parameters.

Self-tuning at the set-point a

100%

0%

Y

start r

1

blinks

2

t reversal point

The process is controlled to the

set-point. With the control deviation

constant during a defined time (1)

(i.e. constant separation of process value

X

W

r

2

t

and set-point), the controller outputs a

reduced correcting variable pulse (max.

20%) (2). After determination of the

control parameters using the process

characteristic (3), control is started

using the new parameters (4).

Three-point controller a

The parameter for heating and cooling are

100%

0%

Start r

X

W

Y

1

blinks

3

4

3

rt

determined in two attempts. The heating

power is switched on (1). Heating

parameters Pb1, ti1, td1 and t1 are

determined at the reversal point. Control to

the set-point occurs(2). With constant

control deviation, the controller provides a

+100%

Y0%

-100%

Start r

1

t reversal

point

2

4

cooling correcting variable pulse (3).

After determining its cooling parameters

Pb2, ti2, td2 and t2 (4) from the

process characteristics , control operation is started using the new parameters (5).

t

t

t

t

5

a

During phase 3, heating and cooling are done simultaneously!

8800 process controller 23 Self-tuning

Page 24

Operation

y

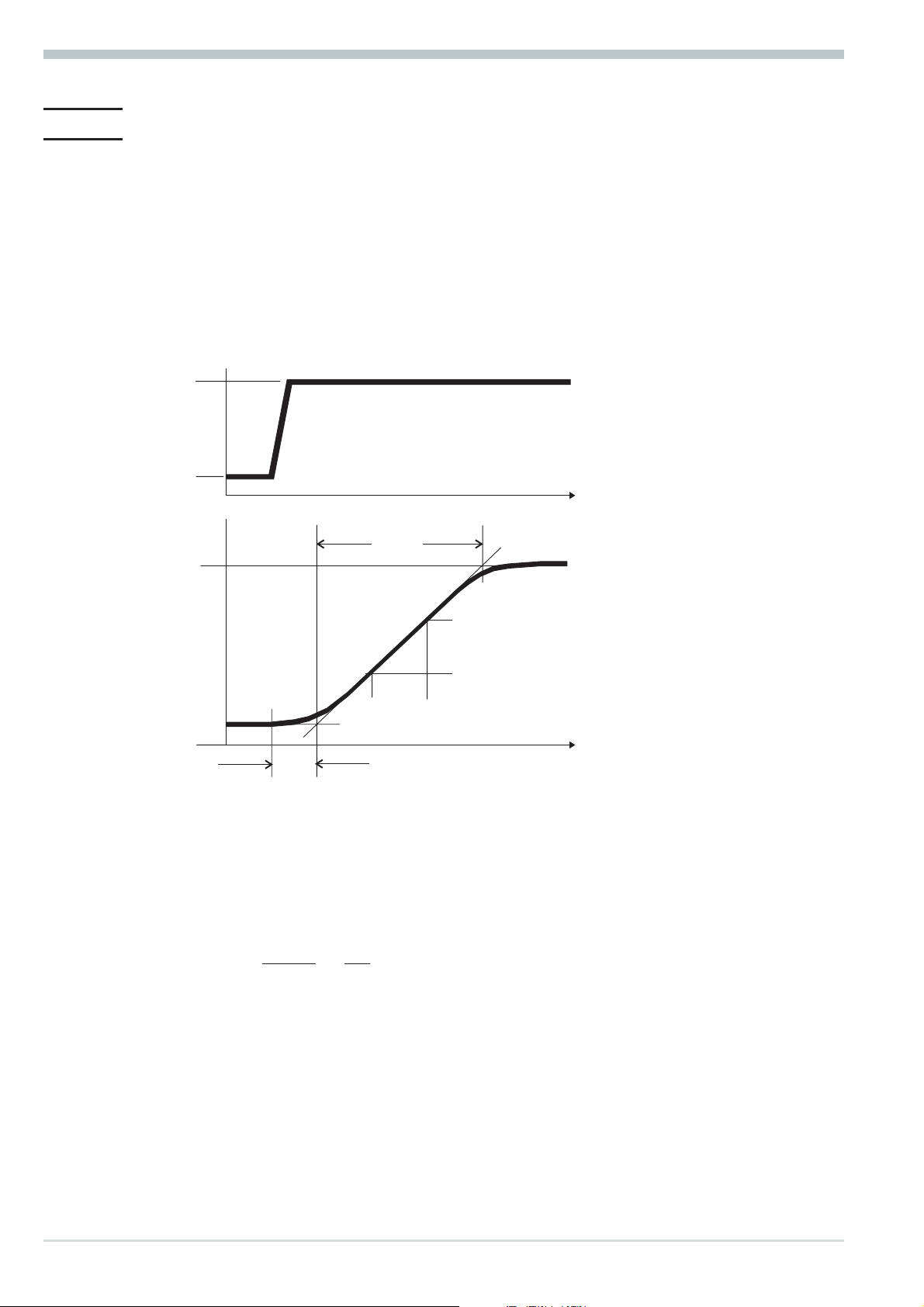

3.6 Manual self-tuning

The optimization aid can be used with units on which the control parameters shall

be set without self-tuning.

For this, the response of process variable x after a step change of correcting

variable y can be used. Frequently, plotting the complete response curve (0 to

100%) is not possible, because the process must be kept within defined limits.

Values T

and x

g

(step change from 0 to 100 %) or ∆t and ∆x (partial step

max

response) can be used to determine the maximum rate of increase v

100%

Y

h

0%

x

t

Tg

X

max

{X

{t

max

.

Tu

t

y = correcting variable

Y

h

= control range

Tu = delay time (s)

Tg = recovery time (s)

X

V

max

max

= maximum process value

Xmax

=

Tg

∆∆x

=

= max. rate of increase of process value

t

The control parameters can be determined from the values calculated for delay

time T

, maximum rate of increase v

u

, control range Xhand characteristic K

max

according to the formulas given below. Increase Pb1, if line-out to the set-point

oscillates.

Manual self-tuning 24 8800 process controller

Page 25

Operation

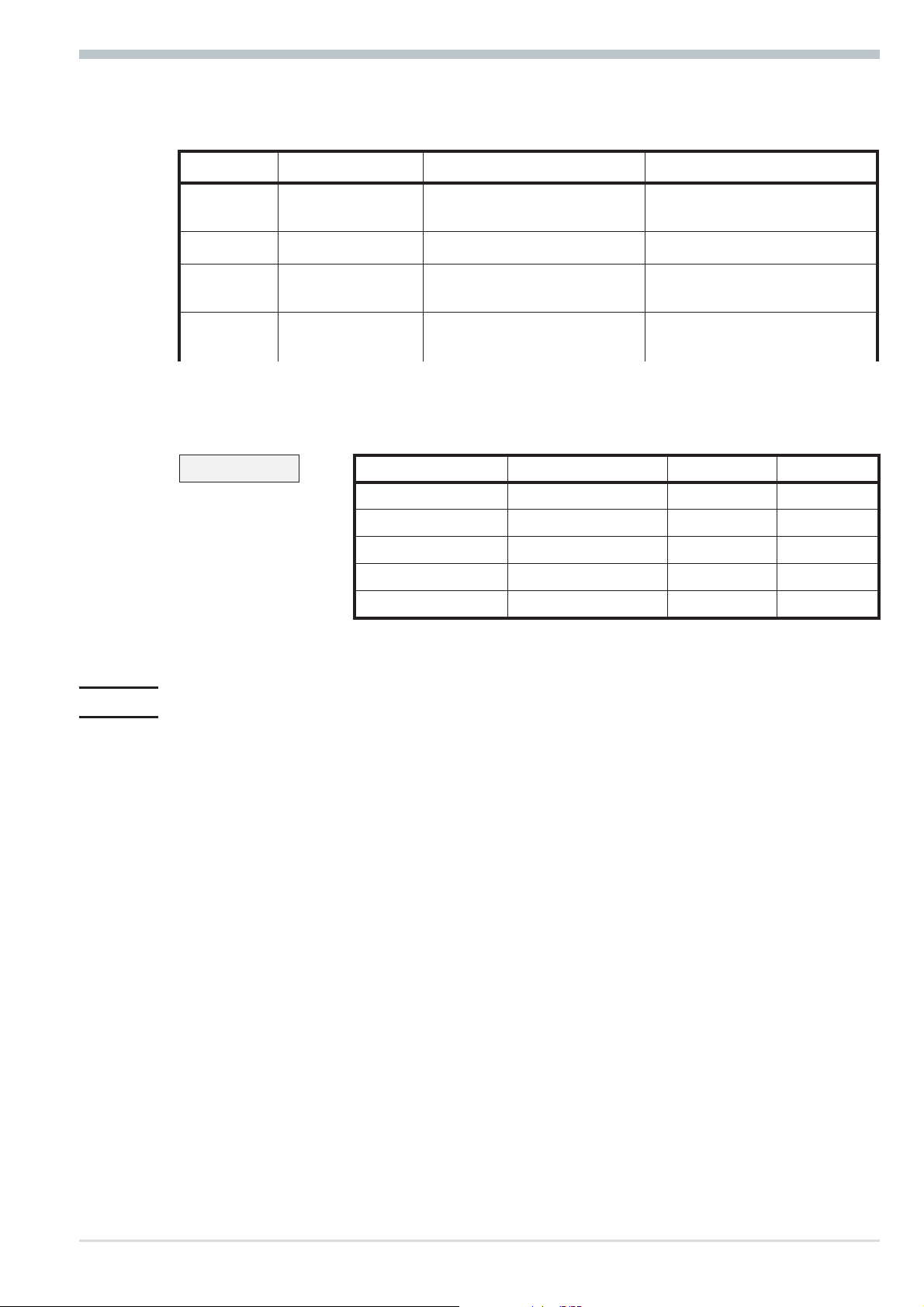

Parameter adjustment effects

Parameter Control Line-out of disturbances Start-up behaviour

Pb1 higherincreased damping slower line-out slower reduction of duty cycle

lower reduced damping faster line-out faster reduction of duty cycle

td1 higherreduced damping faster response to disturbances faster reduction of duty cycle

lower increased

damping

slower response to

disturbances

slower reduction of duty cycle

Formulas

K = Vmax * Tu controller behavior Pb1 [phy. units] td1 [s] ti1 [s]

PID 1,7*K 2*Tu 2*Tu

With 2-point and

3-point controllers,

the cycle time must be

adjusted to

t1 / t2 ≤ 0,25 * Tu

PD 0,5 * K Tu OFF

PI 2,6 * K OFF 6*Tu

PKOFF OFF

3-point-stepping 1,7 * K Tu 2 * Tu

3.7 Second PID parameter set

The process characteristic is frequently affected by various factors such as

process value, correcting variable and material differences.

To comply with these requirements, the 8800 process controller can be switched

over between two parameter sets.

Parameter sets PArA and PAr.2 are provided for heating and cooling.

Dependent of configuration ( ConF/LOG/Pid.2), switch-over to the second

parameter set ( ConF/LOG/Pid.2) is via one of digital inputs di1, di2, di3,

key è or interface (OPTION).

g

Self-tuning is always done using the active parameter set, i.e. the second

parameter set must be active for optimizing.

8800 process controller 25 Second PID parameter set

Page 26

Operation

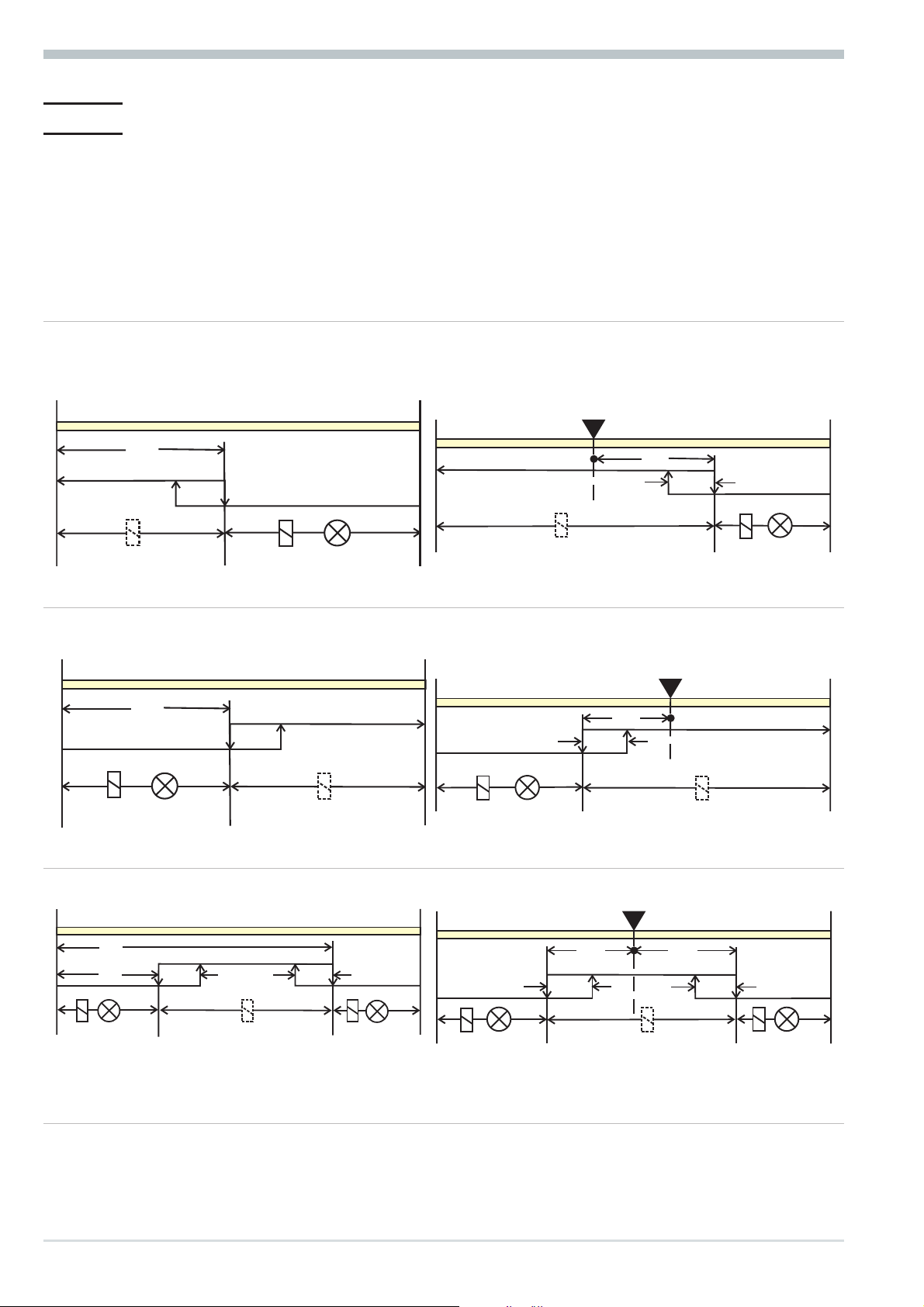

3.8 Alarm handling

Max. three alarms can be configured and assigned to the individual outputs.

Generally, outputs OuT.1... OuT.6 can be used each for alarm signalling. If

more than one signal is linked to one output the signals are OR linked. Each of

the 3 limit values Lim.1 … Lim.3 has 2 trigger points H.x (Max) and L.x (Min),

which can be switched off individually (parameter = “OFF”). Switching

difference HYS.x and delay dEl.x of each limit value is adjustable.

Ü Operaing principle absolute alarm

L.1 = OFF

InL.1

1

H.1

HYS.1

2

InH.1

LED

H.1 = OFF

InL.1

2

L.1

HYS.1

LED

1

InH.1

* Operating principle relative alarm

L.1 = OFF

SP

InL.1

H.1

HYS.1

1

2

H.1 = OFF

SP

InL.1

L.1

HYS.1

LED

2

1

InH.1

LED

InH.1

L.1

SP

1

InH.1

H.1

HYS.1

LED

2

InL.1

2

H.1

L.1

HYS.1 HYS.1

LED

1

2

InH.1

LED

InL.1

HYS.1

LED

2

1: normally closed ( ConF/ Out.x/O.Act=1 )

2: normally open ( ConF/ Out.x/O.Act= 0 )

Alarm handling 26 8800 process controller

Page 27

Operation

g

The variable to be monitored can be selected seperately for each alarm via

configuration

The following variables can be monitored:

process value

w

control deviation xw (process value - set-point)

w

control deviation xw + suppression after start-up or set-point change

w

After switching on or set-point changing, the alarm output is suppressed,

until the process value is within the limits for the first time. At the latest after

expiration of time 10 ti1, the alarm is activated. (ti1 = integral time 1;

parameter r Cntr)

If ti1 is switched off (ti1 = OFF), this is interpreted as Î, i.e. the alarm

is not activated, before the process value was within the limits once.

Measured value INP1

w

Measured value INP2

w

Measured value INP3

w

effective set-point Weff

w

correcting variable y (controller output)

w

Deviation from SP internal

w

Process value - x2

w

g

If measured value monitoring + alarm status storage is chosen ( ConF / Lim /

Fnc.x=2/4), the alarm relay remains switched on until the alarm is resetted in

the error list ( Lim 1..3 = 1).

8800 process controller 27 Alarm handling

Page 28

Operation

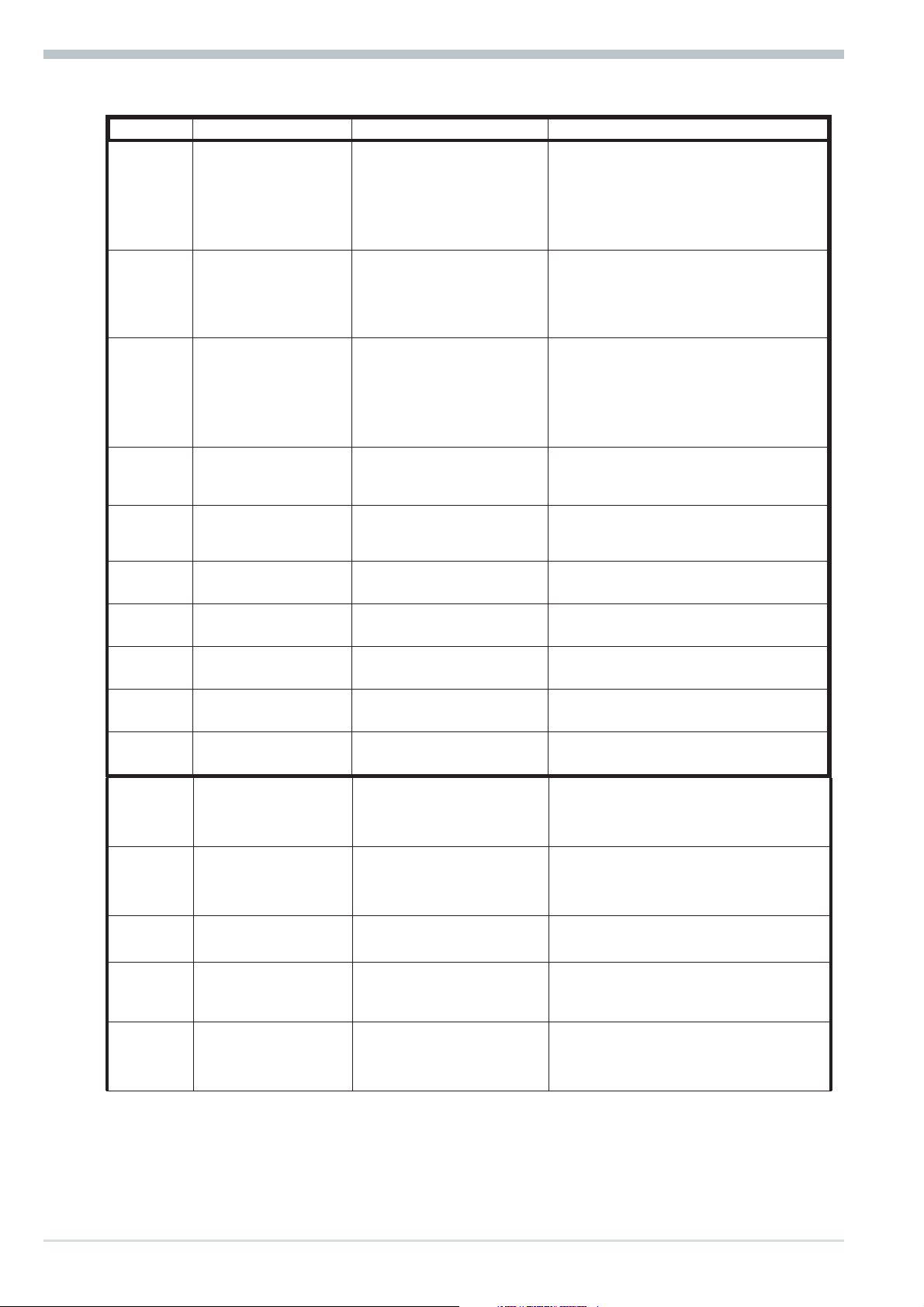

3.9 Operating structure

After supply voltage switch-on, the controller starts with the operating levels.

The controller status is as before power off.

g

g

1199

1200

Ù

3 sec.

1199

PArA

para

Ì

Ù

1199

ConF

para

Ì

PASS

Ù

1199

CAL

PASS

Ù

PASS

1199

Ù

Ì

PArA - level: At PArA - level, the right decimal point of the bottom

display line is lit continuously.

ConF - level: At ConF - level, the right decimal point of bottom

display line blinks

.

When safety switch Loc is open, only the levels enabled by

PASS

of 8800/8840 configurator (engineering tool). Individual parameters accessible

without password must be copied to the extended operating level.

means of 8800/8840 configurator (engineering tool) are visible

and accessible by entry of the password also adjusted by means

End

g

g

Operating structure 28 8800 process controller

Factory setting:Safety switch Loc closed: all levels accessible without

restriction, password PASS = OFF.

All levels locked with a password are locked only if safety switch Loc is closed.

Page 29

4 Configuration level

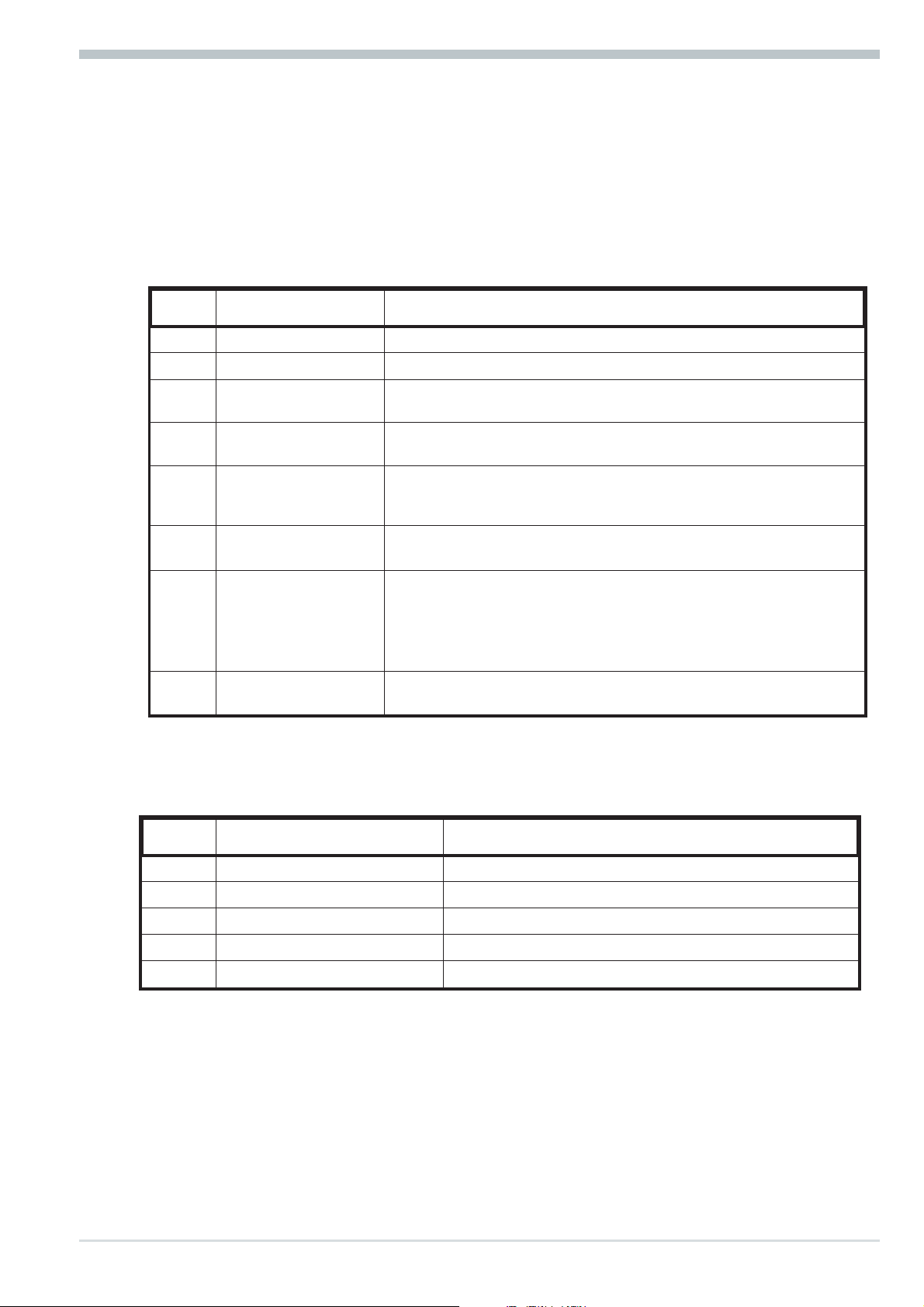

4.1 Configuration survey

ConF Configuration level

Configuration level

Control and self-tuning

Cntr

È

SP.Fn I.Fnc I.Fnc I.Fnc Fnc.1 O.Act

Ì

C.tYP StYP StYP S.Lin Src.1 Y.1 O.Act O.Act SP.2 Addr

C.Fnc S.Lin Corr S.Typ Fnc.2 Y.2 Y.1 Y.1 SP.E PrtY

C.dif Corr In.F Corr Src.2 Lim.1 Y.2 Y.2 Y.2 dELY

mAn In.F Fnc.3 Lim.2 Lim.1 Lim.1 Y.E dp.Ad

C.Act Src.3 Lim.3 Lim.2 Lim.2 mAn bc.up

FAIL HC.AL dAc.A Lim.3 Lim.3 C.oFF O2

rnG.L LP.AL LP.AL dAc.A dAc.A m.Loc Unit

rnG.H dAc.A HC.AL LP.AL LP.AL Err.r dP

CYCL HC.SC HC.AL HC.AL Pid.2 LEd

tunE P.End HC.SC HC.SC I.Chg dISP

Strt FAi.1 P.End P.End di.Fn C.dEl

Input 1

InP.1

InP.2

Input 2

Input 3

InP.3

Limit value functions

Lim

OUt.1

Output 1

OUt.2

Output 2

O.tYP O.tYP

See output 1

FAi.2 FAi.1 FAi.1

FAi.3 FAi.2 FAi.2

FAi.3 FAi.3

OuT.0 OuT.0

Out.1 Out.1

O.Src O.Src

OUt.3

Output 3

OUt.4

Output 4

Out.5

Output 5

See output 1

Out.6

Output 6

LOGI

L_r bAud

See output 1

Digital inpu ts

Othr

Display, operation,

interface

Adjustment:

The configuration can be adjusted by means of keys ÈÌ .

w

Transition to the next configuration is by pressing key Ù .

w

After the last configuration of a group, donE is displayed and followed by

w

automatic change to the next group

Return to the beginning of a group is by pressing the Ù key for 3 sec.

8800 process controller 29 Configuration survey

Page 30

Configuration level

4.2 Configuration parameters

Cntr

Name Value range Description Default

SP.Fn

C.tYP

C.Fnc

C.dif

mAn

C.Act

FAIL

Basic configuration of setpoint processing

0

set-point controller can be switched over to external set-point

(-> LOGI/ SP.E)

8

standard controller with external offset (SP.E)

Calculation of the process value

0

1

2

3

standard controller (process value = x1)

ratio controller (x1/x2)

difference (x1 - x2)

Maximum value of x1and x2. It is controlled with the bigger

value. At sensor failure it is controlled with the remaining

actual value.

4

Minimum value of x1and x2. It is controlled with the smaller

value. At sensor failure it is controlled with the remaining

actual value.

5

Mean value (x1, x2). With sensor error, controlling is

continued with the remaining process value.

6 Switching between x1 and x2 (-> LOGI/ I.ChG)

7O

8O

function with constant sensor temperature

2

function with measured sensor temperature

2

Control behaviour (algorithm)

0

1

2

on/off controller or signaller with one output

PID controller (2-point and continuous)

∆ / Y / Off, or 2-point controller with partial/full load

switch-over

3

4

5

6

2 x PID (3-point and continuous)

3-point stepping controller

3-point stepping controller with position feedback Yp

continuous controller with integrated positioner

Output action of the PID controller derivative action

0

1

Derivative action acts only on the measured value.

Derivative action only acts on the control deviation

(set-point is also differentiated)

Manual operation permitted

0

1

no

yes (r LOGI / mAn)

Method of controller operation

0

1

inverse, e.g. heating

direct, e.g. cooling

Behaviour at sensor break

0

1

2

controller outputs switched off

y=Y2

y = mean output. The maximum permissible output can be

adjusted with parameter Ym.H. To prevent determination of

inadmissible values, mean value formation is only if the

control deviation is lower than parameter L.Ym.

0

0

1

0

0

0

1

Configuration parameters 30 8800 process controller

Page 31

Configuration level

Name Value range Description Default

rnG.L

rnG.H

CYCL

tunE

Strt

Adt0

-1999...9999

-1999...9999

X0 (low limit range of control) 1

X100 (high limit range of control) 1

Characteristic for 2-point- and 3-point-controllers

0

1

2

3

standard

water cooling linear

water cooling non-linear

with constant cycle (see page 51)

Auto-tuning at start-up (see page 16 )

0

At start-up with step attempt, at set-point with impulse

attempt

1

At start-up and at set-point with impulse attempt. Setting for

fast controlled systems (e.g. hot runner control)

2 Always step attempt at start-up

Start of auto-tuning

0

1

Manual start of auto-tuning

Manual or automatic start of auto-tuning at power on or

when oscillating is detected

Optimization of T1, T2 (only visible with 8800/8840

configurator!)

0

1

Automatic optimization

No optimization

-100

1200

0

0

0

0

1 rnG.L and rnG.H are indicating the range of control on which e.g. the

self-tuning is refering

InP.1

Name Value range Description Default

I.fnc

INP1 function selection

0

1

2

3

4

5

No function (following INP data are skipped)

Heating current input

External set-point SP.E (switch-over -> LOGI/ SP.E)

Position feedback Yp

Second process value x2 (ratio, min, max, mean)

External positioning value Y.E

(switch-over r LOGI / Y.E)

6

7

No controller input (e.g. limit signalling instead)

Process value x1

7

8800 process controller 31 Configuration parameters

Page 32

Configuration level

Name Value range Description Default

S.tYP

S.Lin

Corr

In.f

fAI1

-1999...9999

10

18

20

21

22

23

24

30

40

41

42

50

51

52

53

Sensor type selection

0

1

2

3

4

5

6

7

8

9

thermocouple type L (-100...900°C) , Fe-CuNi DIN

thermocouple type J (-100...1200°C) , Fe-CuNi

thermocouple type K (-100...1350°C), NiCr-Ni

thermocouple type N (-100...1300°C), Nicrosil-Nisil

thermocouple type S (0...1760°C), PtRh-Pt10%

thermocouple type R (0...1760°C), PtRh-Pt13%

thermocouple type T (-200...400°C), Cu-CuNi

thermocouple type C (0...2315°C), W5%Re-W26%Re

thermocouple type D (0...2315°C), W3%Re-W25%Re

thermocouple type E (-100...1000°C), NiCr-CuNi

1

thermocouple type B (0/100...1820°C), PtRh-Pt6%

special thermocouple

Pt100 (-200.0 ... 100,0 °C)

Pt100 (-200.0 ... 850,0 °C)

Pt1000 (-200.0 ... 850.0 °C)

special 0...4500 Ohm (preset to KTY11-6)

special 0...450 Ohm

0...20mA / 4...20mA 1

0...10V / 2...10V 1

special -2,5...115 mV 1

special -25...1150 mV 1

potentiometer 0...160 Ohm 1

potentiometer 0...450 Ohm 1

potentiometer 0...1600 Ohm 1

potentiometer 0...4500 Ohm 1

Linearization (only at S.tYP = 23 (KTY 11-6), 24

0

(0...450 ), 30 (0..20mA), 40 (0..10V), 41 (0...100mV) and

42 (special -25...1150 mV))

0

1

none

Linearization to specification. Creation of linearization table

with 8800/8840 configurator (engineering tool) possible.

The characteristic for KTY 11-6 temperature sensors is

preset.

Measured value correction / scaling

0

1

2

3

Without scaling

Offset correction (at CAL level)

2-point correction (at CAL level)

Scaling (at PArA level)

Alternative value for error at INP1

Forcing INP1 (only visible with 8800/8840 configurator!)

0

1

No forcing

Forcing via serial interface

0

OFF

0

1 with current and voltage input signals, scaling is required (see chapter 5.3)

Configuration parameters 32 8800 process controller

Page 33

Configuration level

InP.2

Name Value range Description Default

I.Fnc

S.tYP

Corr

In.F

fAI2

Function selection of INP2

0

1

2

3

4

5

no function (subsequent input data are skipped)

heating current input

External set-point SP.E (switch-over -> LOGI/ SP.E)

Position feedback Yp

Second process value x2 (ratio, min, max, mean)

External positioning value Y.E

(switch-over r LOGI / Y.E)

6

7

no controller input (e.g. transmitter input instead)

Process value x1

Sensor type selection

30

31

50

51

52

53

0...20mA / 4...20mA 1

0...50mA AC 1

Potentiometer ( 0...160 Ohm) 1

Potentiometer ( 0...450 Ohm) 1

Potentiometer ( 0...1600 Ohm) 1

Potentiometer ( 0...4500 Ohm) 1

Measured value correction / scaling 0

0 Without scaling

1 Offset correction (at CAL level)

2 2-point correction (at CALlevel)

3 Scaling (at PArA level)

-1999...9999

Alternative value for error at INP2

Forcing INP2 (only visible with 8800/8840 configurator!)

0

1

No forcing

Forcing via serial interface

1

30

OFF

0

1 with current and voltage input signals, scaling is required (see chapter 5.3)

InP.3

Name Value range Description Default

I.Fnc

Function selection of INP3

0

1

2

3

4

5

no function (subsequent input data are skipped)

heating current input

External set-point SP.E (switch-over -> LOGI/ SP.E)

Yp input

Second process value X2

External positioning value Y.E

(switch-over r LOGI / Y.E)

6

7

no controller input (e.g. transmitter input instead)

Process value x1

1

8800 process controller 33 Configuration parameters

Page 34

Configuration level

Name Value range Description Default

S.tYP

S.Lin

Corr

In.F

fAI3

-1999...9999

10

18

20

21

22

23

24

30

41

42

50

51

52

53

Sensor type selection

0

1

2

3

4

5

6

7

8

9

thermocouple type L (-100...900°C) , Fe-CuNi DIN

thermocouple type J (-100...1200°C) , Fe-CuNi

thermocouple type K (-100...1350°C), NiCr-Ni

thermocouple type N (-100...1300°C), Nicrosil-Nisil

thermocouple type S (0...1760°C), PtRh-Pt10%

thermocouple type R (0...1760°C), PtRh-Pt13%

thermocouple type T (-200...400°C), Cu-CuNi

thermocouple type C (0...2315°C), W5%Re-W26%Re

thermocouple type D (0...2315°C), W3%Re-W25%Re

thermocouple type E (-100...1000°C), NiCr-CuNi

30

thermocouple type B (0/100...1820°C), PtRh-Pt6%

special thermocouple

Pt100 (-200.0 ... 100,0 °C)

Pt100 (-200.0 ... 850,0 °C)

Pt1000 (-200.0 ... 850.0 °C)

special 0...4500 Ohm (preset to KTY11-6)

special 0...450 Ohm

0...20mA / 4...20mA 1

special -2,5...115 mV 1

special -25...115 0mV 1

potentiometer 0...160 Ohm 1

potentiometer 0...450 Ohm 1

potentiometer 0...1600 Ohm 1

potentiometer 0...4500 Ohm 1

Linearization

0

(only at S.tYP = 23,24,30,41 and 42 adjustable)

0

1

none

Linearization to specification. Creation of linearization table

with 8800/8840 configurator (engineering tool) possible.

The characteristic for KTY 11-6 temperature sensors is

preset.

Measured value correction / scaling

0

(only at S.tYP = 23,24,30,41 and 42 adjustable)

0

1

2

3

4

0

1

Without scaling

Offset correction (at CAL level)

2-point correction (at CAL level)

Scaling (at PArA level)

Automatic calibration (DAC)

Alternative value for error at INP3

Forcing INP3 (only visible with 8800/8840 configurator!)

No forcing

Forcing via serial interface

OFF

0

1 with current and voltage input signals, scaling is required (see chapter 5.3)

Configuration parameters 34 8800 process controller

Page 35

Configuration level

Lim

Name Value range Description Default

Fnc.1

Src.1

Fnc.2

Function of limit 1

0

1

2

switched off

measured value monitoring

Measured value monitoring + alarm status storage. A stored

limit value can be reset via error list,

è-key, Ò-key or a

digital input ( -> LOGI/ Err.r)

3

4

signal change (change/minute)

signal change and storage (change/minute)

Source of imit 1

0

1

2

process value

control deviation xw (process value - set-point)

control deviation xw (with suppression after start-up and

set-point change)

After switch-on or set-point changing, the alarm output is

suppressed, until the process value is within the limits for the first

time. At the latest after elapse of time 10 ti1the alarm is

activated (ti1 = integral time 1; parameter r Cntr)

If ti1 is switched off (ti1 = 0), this is interpreted as Î , i.e.

the alarm is not activated, before the process value was within the

limits once.

3

4

5

6

7

measured value INP1

measured value INP2

measured value INP3

effective setpoint Weff

correcting variable y (controller output)

8 control variable deviation xw (actual value - internal setpoint)

= deviation alarm to internal setpoint

9

difference x1 - x2 (utilizable e.g. in combination with process

value function “mean value” for recognizing aged

thermocouples

Function of limit 2

0

1

2

switched off

measured value monitoring

Measured value monitoring + alarm status storage. A stored

limit value can be reset via error list,

è-key, Ò-key or a

digital input ( -> LOGI/ Err.r)

3

4

signal change (change/minute)

signal change and storage (change/minute)

1

1

0

8800 process controller 35 Configuration parameters

Page 36

Configuration level

Name Value range Description Default

Src.2

Fnc.3

Source of limit 2

0

1

2

process value

control deviation xw (process value - set-point)

control deviation xw (with suppression after start-up and

set-point change)

After switch-on or set-point changing, the alarm output is

suppressed, until the process value is within the limits for the

first time. At the latest after elapse of time 10 ti1the alarm

is activated (ti1 = integral time 1; parameter r Cntr)

If ti1 is switched off (ti1 = 0), this is interpreted as Î ,

i.e. the alarm is not activated, before the process value was

within the limits once.

3

4

5

6

7

measured value INP1

measured value INP2

measured value INP3

effective setpoint Weff

correcting variable y (controller output)

8 control variable deviation xw (actual value - internal setpoint)

= deviation alarm to internal setpoint

9

difference x1 - x2 (utilizable e.g. in combination with process

value function “mean value” for recognizing aged

thermocouples

Function of limit 3

0

1

2

switched off

measured value monitoring

Measured value monitoring + alarm status storage. A stored

limit value can be reset via error list,

è-key, Ò-key or a

digital input ( -> LOGI/ Err.r)

3

4

signal change (change/minute)

signal change and storage (change/minute)

0

0

Configuration parameters 36 8800 process controller

Page 37

Configuration level

Name Value range Description Default

Src.3

HC.AL

LP.AL

dAc.A

Hour

Swit

Source of limit 3

0

1

2

process value

control deviation xw (process value - set-point)

control deviation xw (with suppression after start-up and

set-point change)

After switch-on or set-point changing, the alarm output is

suppressed, until the process value is within the limits for the

first time. At the latest after elapse of time 10 ti1 the alarm

is activated (ti1 = integral time 1; parameter r Cntr)

If ti1 is switched off (ti1 = 0), this is interpreted as Î ,

i.e. the alarm is not activated, before the process value was

within the limits once.

3

4

5

6

7

measured value INP1

measured value INP2

measured value INP3

effective setpoint Weff

correcting variable y (controller output)

8 control variable deviation xw (actual value - internal setpoint)

= deviation alarm to internal setpoint

9

difference x1 - x2 (utilizable e.g. in combination with process

value function “mean value” for recognizing aged

thermocouples

Alarm heat current function (INP2)

0

1

2

switched off

Overload short circuit monitoring

Break and short circuit monitoring

Monitoring of control loop interruption for heating

0

1

switched off / inactive

active.

If ti1=0 LOOP alarm is inactive!

DAC alarm function

0

1

OFF...999999

OFF...999999

DAC alarm switched off / inactive

DAC alarm active

Operating hours (only visible with 8800/8840 configurator!)

Output switching cycles (only visible with 8800/8840

configurator!)

0

0

0

0

OFF

OFF

Out.1

Name Value range Description Default

O.Act

0

1

Y.1

0

1

Method of operation of output OUT1

direct / normally open

inverse / normally closed

Controller output Y1

not active

active

8800 process controller 37 Configuration parameters

0

1

Page 38

Configuration level

Name Value range Description Default

Y.2

Lim.1

Lim.2

Lim.3

dAc.A

LP.AL

HC.AL

HC.SC

FAi.1

FAi.2

FAi.3

fOut

Controller output Y2

0

1

not active

active

Limit 1 signal

0

1

not active

active

Limit 2 signal

0

1

not active

active

Limit 3 signal

0

1

not active

active

Valve monitoring (DAC)

0

1

not active

active

Interruption alarm signal (LOOP)

0

1

not active

active

Heat current alarm signal

0

1

not active

active

Solid state relay (SSR) short circuit signal

0

1

not active

active

INP1 error signal

0

1

not active

active

INP2 error signal

0

1

not active

active

INP3 error signal

0

1

not active

aktiv

Forcing OUT1 (only visible with 8800/8840 configurator!)

0

1

No forcing

Forcing via serial interface

0

0

0

0

0

0

0

0

0

0

0

0

Out.2

Configuration parameters Out.2 = Out.1 except for: Default Y.1 =0 Y.2 =1

Configuration parameters 38 8800 process controller

Page 39

Configuration level

Out.3

Name Value range Description Default

O.tYP

O.Act

Y.1

Y.2

Lim.1

Lim.2

Lim.3

dAc.A

LP.AL

HC.AL

HC.SC

Signal type selection OUT3

0

1

relay / logic (only visible with current/logic voltage)

0 ... 20 mA continuous (only visible with

current/logic/voltage)

2

4 ... 20 mA continuous (only visible with

current/logic/voltage)

3

4

5

0...10 V continuous (only visible with current/logic/voltage)

2...10 V continuous (only visible with current/logic/voltage)

transmitter supply (only visible without OPTION)

Method of operation of output OUT3 (only visible when

O.TYP=0)

0

1

direct / normally open

inverse / normally closed

Controller output Y1 (only visible when O.TYP=0)

0

1

not active

active

Controller output Y2 (only visible when O.TYP=0)

0

1

not active

active

Limit 1 signal (only visible when O.TYP=0)

0

1

not active

active

Limit 2 signal (only visible when O.TYP=0)

0

1

not active

active

Limit 3 signal (only visible when O.TYP=0)

0

1

not active

active

Valve monitoring (DAC) (only visible when O.TYP=0)

0

1

not active

active

Interruption alarm signal (LOOP) (only visible when

O.TYP=0)

0

1

not active

active

Heating current alarm signal (only visible when O.TYP=0)

0

1

not active

active

Solid state relay (SSR) short circuit signal (only visible

when O.TYP=0)

0

1

not active

active

0

1

0

0

1

0

0

0

0

0

0

8800 process controller 39 Configuration parameters

Page 40

Configuration level

Name Value range Description Default

FAi.1

FAi.2

FAi.3

Out.0

Out.1

O.Src

fOut

0

1

0

1

0

1

-1999...9999

-1999...9999

0

1

2

3

4

5

6

7

8

9

0

1

INP1 error (only visible when O.TYP=0)

not active

active

INP2 error (only visible when O.TYP=0)

not active

active

INP3 error (only visible when O.TYP=0)

not active

aktiv

Scaling of the analog output for 0% (0/4mA or 0/2V, only

visible when O.TYP=1..5)

Scaling of the analog output for 100% (20mA or 10V, only

visible when O.TYP=1..5)

Signal source of the analog output OUT3 (only visible when

O.TYP=1..5)

not used

controller output y1 (continuous)

controller output y2 (continuous)

process value

effective set-point Weff

control deviation xw (process value - set-point)

measured value position feedback Yp

measured value INP1

measured value INP2

measured value INP3

Forcing OUT3 (only visible with 8800/8840 configurator!)

No forcing

Forcing via serial interface

1

0

0

0

100

1

0

Out.4

Name Value range Description Default

O.tYP

O.Act

Signal type selection OUT4

0

1

relay / logic (only visible with current/logic voltage)

0 ... 20 mA continuous (only visible with

current/logic/voltage)

2

4 ... 20 mA continuous (only visible with

current/logic/voltage)

3

4

5

0...10 V continuous (only visible with current/logic/voltage)

2...10 V continuous (only visible with current/logic/voltage)

transmitter supply (only visible without OPTION)

Method of operation of output OUT4 (only visible when

O.TYP=0)

0

1

direct / normally open

inverse / normally closed

0

0

Configuration parameters 40 8800 process controller

Page 41

Configuration level

Name Value range Description Default

Y.1

Y.2

Lim.1

Lim.2

Lim.3

dAc.A

LP.AL

HC.AL

HC.SC

FAi.1

FAi.2

FAi.3

Out.0

Out.1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

-1999...9999

-1999...9999

Controller output Y1 (only visible when O.TYP=0)

not active

active

Controller output Y2 (only visible when O.TYP=0)

not active

active

Limit 1 signal (only visible when O.TYP=0)

not active

active

Limit 2 signal (only visible when O.TYP=0)

not active

active

Limit 3 signal (only visible when O.TYP=0)

not active

active

Valve monitoring (DAC) (only visible when O.TYP=0)

not active

active

Interruption alarm signal (LOOP) (only visible when

O.TYP=0)

not active

active

Heat current alarm signal (only visible when O.TYP=0)

not active

active

Solid state relay (SSR) short circuit signal (only visible

when O.TYP=0)

not active

active

INP1 error (only visible when O.TYP=0)

not active

active

INP2 error (only visible when O.TYP=0)

not active

active

INP3 error (only visible when O.TYP=0)

not active

aktiv

Scaling of the analog output for 0% (0/4mA or 0/2V, only

visible when O.TYP=1..5)

Scaling of the analog output for 100% (20mA or 10V, only

visible when O.TYP=1..5)

0

0

0

0

0

0

0

0

0

0

0

0

0

100

8800 process controller 41 Configuration parameters

Page 42

Configuration level

Name Value range Description Default

O.Src

fOut

Out.5

Configuration parameters Out.2 = Out.1 except for: Default Y.1 =0 Y.2 =0

Signal source of the analog output OUT4 (only visible when

0

O.TYP=1..5)

0

1

2

3

4

5

6

0

1

not used

controller output y1 (continuous)

controller output y2 (continuous)

process value

effective set-point Weff

control deviation xw (process value - set-point)

measured value position feedback Yp

Forcing OUT1 (only visible with 8800/8840 configurator!)

No forcing

Forcing via serial interface

0

Out.6

Configuration parameters Out.2 = Out.1 except for: Default Y.1 =0 Y.2 =0

g

Method of operation and usage of output Out.1 to Out.6:

Is more than one signal chosen active as source, those signals are

OR-linked.

LOGI

Name Value range Description Default

L_r

SP.2

Local / Remote switching (Remote: adjusting of all values

by front keys is blocked)

0

1

2

3

4

5

no function (switch-over via interface is possible)

always active

DI1 switches

DI2 switches (only visible with OPTION)

DI3 switches (only visible with OPTION)

è - key switches

Switching to second setpoint SP.2

0

2

3

4

5

no function (switch-over via interface is possible)

DI1 switches

DI2 switches (only visible with OPTION)

DI3 switches (only visible with OPTION)

è - key switches

0

0

Configuration parameters 42 8800 process controller

Page 43

Configuration level

Name Value range Description Default

SP.E

Y2

Y.E

mAn

C.oFF

m.Loc

Switching to external setpoint SP.E

0

1

2

3

4

5

no function (switch-over via interface is possible)

always active

DI1 switches

DI2 switches (only visible with OPTION)

DI3 switches (only visible with OPTION)

è - key switches

Y/Y2 switching

0

2

3

4

5

6

no function (switch-over via interface is possible)

DI1 switches

DI2 switches (only visible with OPTION)

DI3 switches (only visible with OPTION)

è - key switches

Ò - key switches

Switching to fixed control output Y.E

0

1

2

3

4

5

6

no function (switch-over via interface is possible)

always activated (manual station)

DI1 switches

DI2 switches (only visible with OPTION)

DI3 switches (only visible with OPTION)

è - key switches

Ò - key switches

Automatic/manual switching

0

1

2

3

4

5

6

no function (switch-over via interface is possible)

always activated (manual station)

DI1 switches

DI2 switches (only visible with OPTION)

DI3 switches (only visible with OPTION)

è - key switches

Ò - key switches

Switching off the controller

0

2

3

4

5

6

no function (switch-over via interface is possible)

DI1 switches

DI2 switches (only visible with OPTION)

DI3 switches (only visible with OPTION)

è - key switches

Ò - key switches

Blockage of hand function

0

2

3

4

5

no function (switch-over via interface is possible)

DI1 switches

DI2 switches (only visible with OPTION)

DI3 switches (only visible with OPTION)

è - key switches

0

0

0

0

0

0

8800 process controller 43 Configuration parameters

Page 44

Configuration level

Name Value range Description Default

Err.r

Pid.2

I.Chg

di.Fn

fDI1

fDI2

fDI3

Reset of all error list entries

0

2

3

4

5

6

no function (switch-over via interface is possible)

DI1 switches

DI2 switches (only visible with OPTION)

DI3 switches (only visible with OPTION)

è - key switches

Ò - key switches

Switching of parameter set (Pb, ti, td)

0

2

3

4

5

no function (switch-over via interface is possible)

DI1 switches

DI2 switches (only visible with OPTION)

DI3 switches (only visible with OPTION)

è - key switches

Switching of the actual process value between Inp1 and X2

0

2

3

4

5

no function (switch-over via interface is possible)

DI1 switches

DI2 switches (only visible with OPTION)

DI3 switches (only visible with OPTION)

è - key switches

Function of digital inputs (valid for all inputs)

0

1

2

direct

inverse

toggle key function

Forcing di1 (only visible with 8800/8840 configurator!)

0

1

No forcing

Forcing via serial interface

Forcing di2 (only visible with 8800/8840 configurator!)

0

1

No forcing

Forcing via serial interface

Forcing di3 (only visible with 8800/8840 configurator!)

0

1

No forcing