Page 1

1

-DIN,

4

1

-DIN &

8

1

-DIN

16

TEMPERATURE CONTROLLERS

Product Manual

59125-3

Page 2

PREFACE

This manual comprises two volumes:

Volume 1: This supports normal operation of the

1

-DIN,

4

1

-DIN and

8

1

16

-DIN

Temperature Controllers. In normal operation, all actions taken

by the user are to be in front of the panel.

Volume 2: This supports the installation, commissioning and configuring of

the

1

-DIN,

4

1

-DIN and

8

1

-DIN Temperature Controllers. It is

16

intended for use only by personnel who are trained, equipped

and authorised to carry out these functions.

Page 3

59125

1

-DIN,

4

1

-DIN &

8

1

1 6

-DIN

TEMPERATURE CONTROLLERS

PRODUCT MANUAL

VOLUME 1

OPERATING INSTRUCTIONS

In normal operation, the operator must not remove the

Controller from its housing or have unrestricted access to

the rear terminals, as this would provide potential contact

with hazardous live parts.

Installation and configuration must be undertaken by

technically-competent servicing personnel. This is covered

in Volume 2 of this manual.

Contents - Volume 1

1 OPERATOR MODE 1-1

1.1 INTRODUCTION 1-1

1.2 DISPLAYS AVAILABLE 1-2

1.3 ADJUSTING THE SETPOINT/SETPOINT RAMP RATE 1-3

1.4 ALARM STATUS DISPLAY 1-3

1.5 OVER-RANGE/UNDER-RANGE DISPLAYS 1-4

1.6 SENSOR BREAK INDICATION 1-4

1.7 MANUAL CONTROL MODE 1-4

1.8 PRE-TUNE FACILITY 1-5

1.9 SELF-TUNE FACILITY 1-6

1.10 VIEWING THE HARDWARE DEFINITION CODE 1-7

O054-V1 (iii)

Page 4

59125

2 SET UP MODE 2-1

2.1 ENTRY INTO SET UP MODE 2-1

2.2 SET UP MODE PARAMETERS 2-2

2.3 OPERATOR MODE DISPLAYS 2-13

2.4 TUNING THE CONTROLLER MANUALLY 2-13

2.5 SELF-TUNE AND PRE-TUNE FACILITIES 2-14

2.6 EXIT FROM SET UP MODE 2-15

3 RS485 SERIAL COMMUNICATIONS 3-1

3.1 COMMUNICATIONS ENABLE/DISABLE 3-1

3.2 PHYSICAL REQUIREMENTS 3-1

3.3 INDIVIDUAL PARAMETERS 3-5

3.4 ERROR RESPONSE 3-10

(iv ) O054-V1

Page 5

59125

1 OPERATOR MODE

1.1 INTRODUCTION

This Section covers the routine operation of the Controller, once it has been

installed and configured as described in Volume 2 of this manual. The Controller

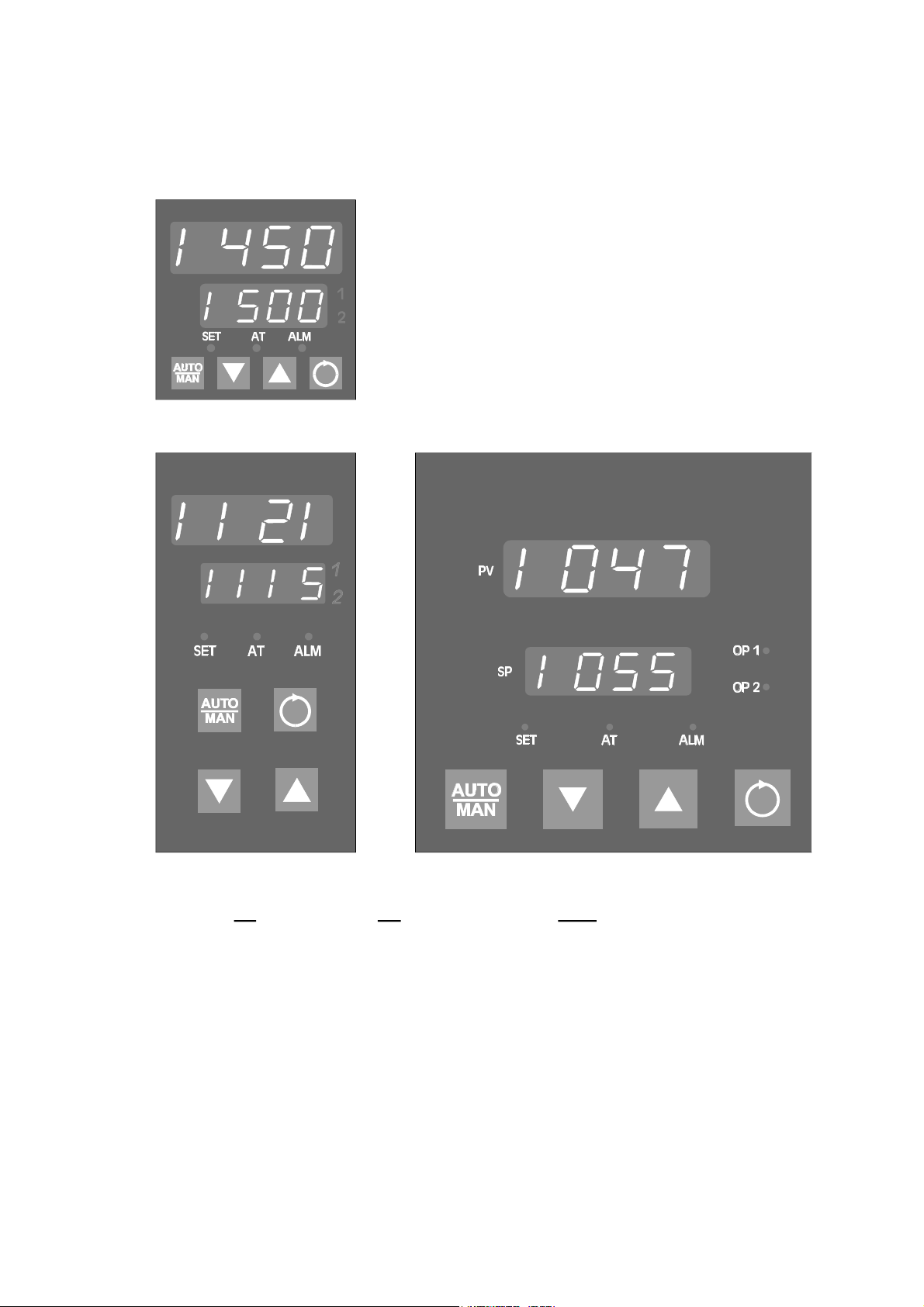

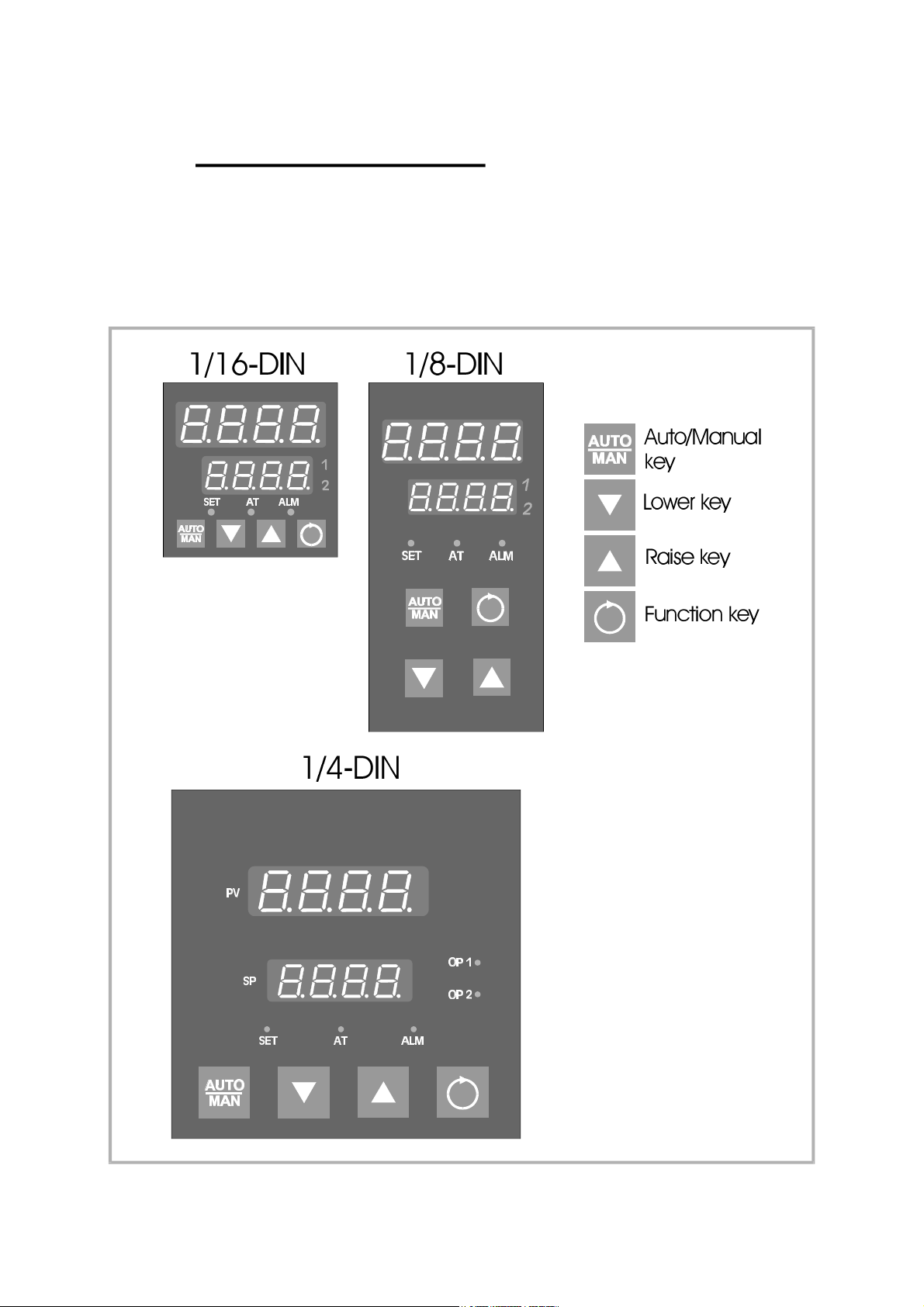

front panel indicators and keys are shown in Figure 1-1.

Figure 1-1 Front Panel Controls and Indicators

O054-1 1-1

Page 6

59125

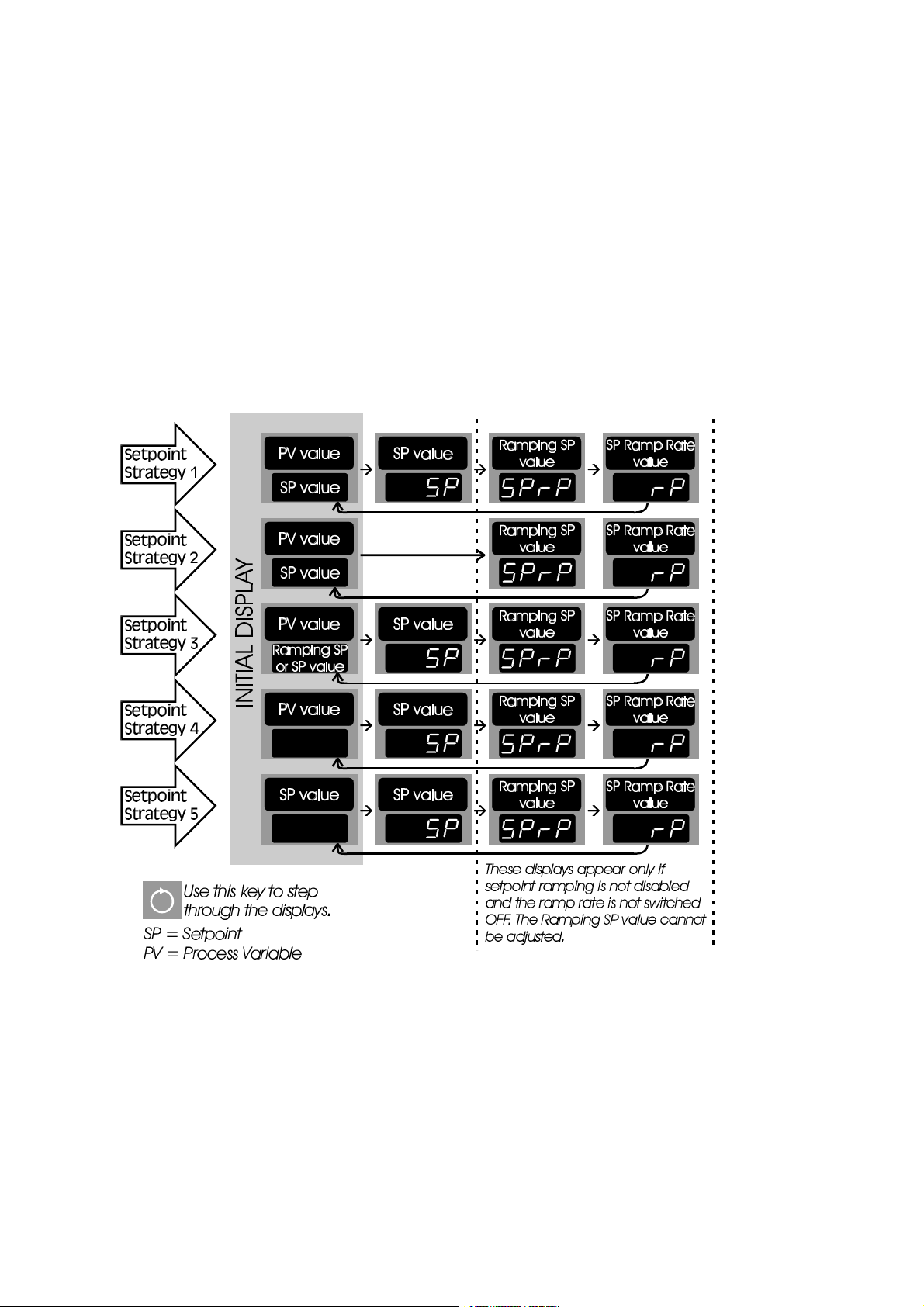

1.2 DISPLAYS AVAILABLE

After the Controller has performed its power-up self-test (during which, if the

Function key is held down during power-up, the current Controller firmware

revision is displayed), the initial displays appear. The available displays are

dependent upon (a) whether the Controller has been configured for Single

Setpoint operation or Dual Setpoint operation and (b) the setting of the Setpoint

Strategy parameter in Set Up Mode.

1.2.1 Single Setpoint Operation

In single setpoint operation, the available displays are:

1 -2 O054-1

Page 7

59125

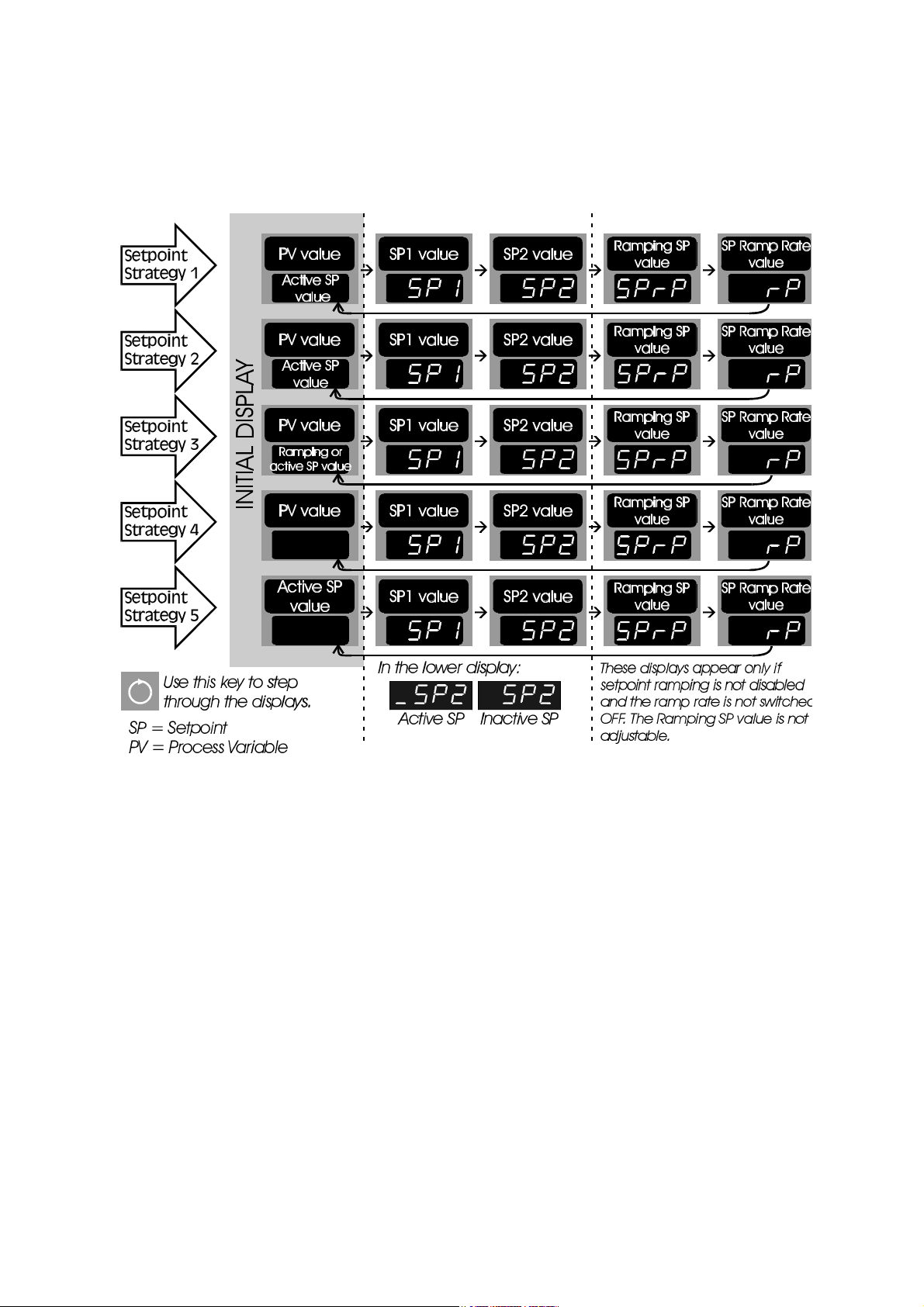

1.2.2 Dual Setpoint Operation

In dual setpoint operation, the available displays are:

1.3 ADJUSTING THE SETPOINT/SETPOINT RAMP RATE

The setpoint/setpoint ramp rate (whichever is selected - see previously) may be

adjusted using the Raise/Lower keys. The ramp rate may be adkusted in the range

1 to 9999. Any attempt to increase the ramp rate value beyond 9999 will cause

the upper display to go blank and setpoint ramping to be switched OFF. Setpoint

ramping can be resumed by decreasing the ramp rate value to 9999 or less.

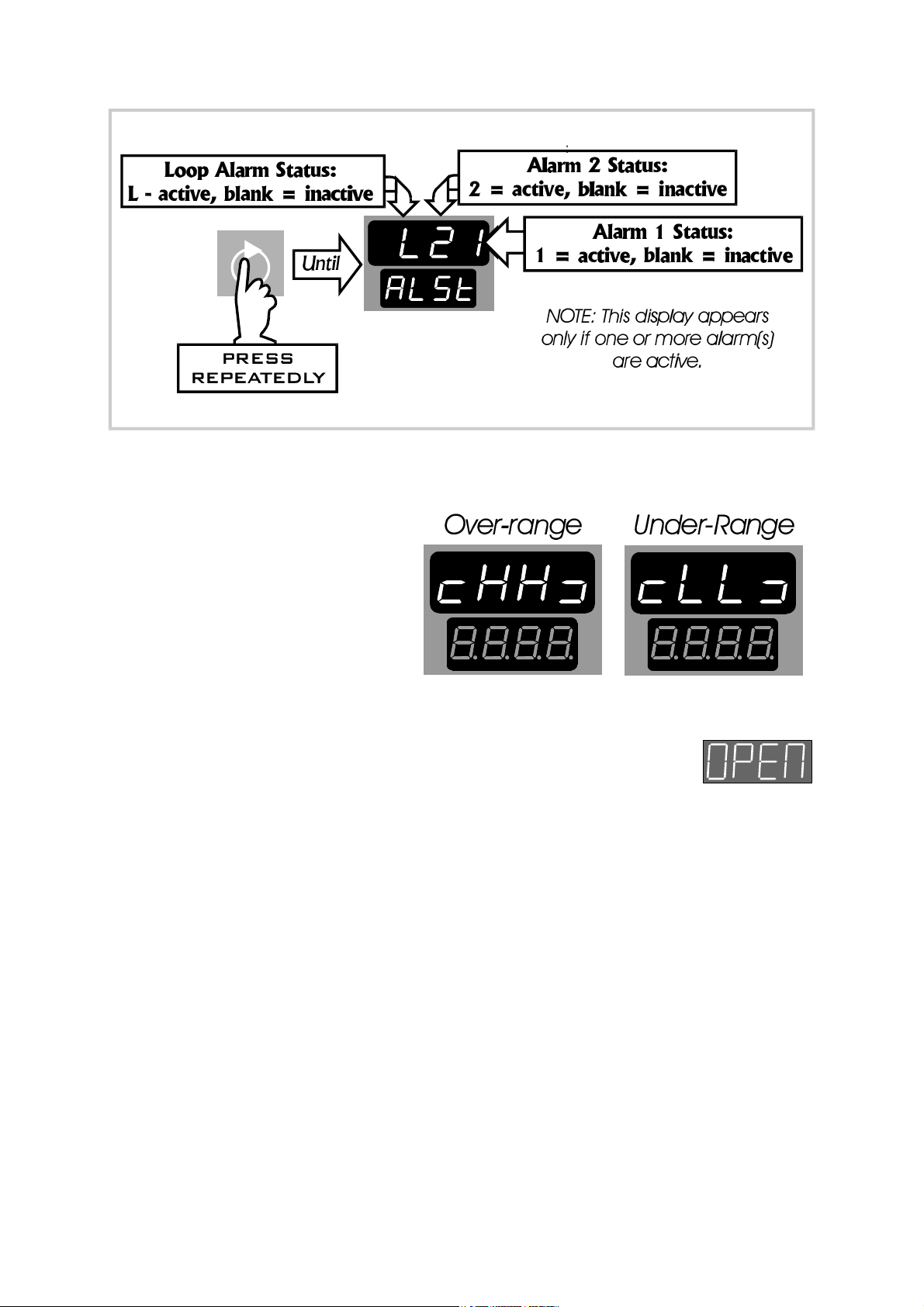

1.4 ALARM STATUS DISPLAY

If one or more of the Controller’s alarms is (are) active, the alarm status display is

included in the available display sequence. The Alarm Status display is selected

by depressing the Function key repeatedly until the display appears (see Figure

1-2).

O054-1 1-3

Page 8

Figure 1 -2 Alarm Status Display

1.5 OVER-RANGE/UNDER-RANGE DISPLAYS

59125

The upper display will indicate if

the process variable is higher

than the input scale maximum

limit (over-range), or lower than

the input scale minimum limit

(under-range) as shown on the

right.

1.6 SENSOR BREAK INDICATION

If a break is detected in the sensor circuit, the upper display shows:

The reaction of the outputs and alarms to a detected sensor break is dependent

upon the input type and is defined in Appendix A.

1.7 MANUAL CONTROL MODE

If selection of Manual Control Mode is enabled, the Manual Control Mode may

be entered (via a bumpless transfer) by depressing the Auto/Manual key. The SET

indicator will then flash continuously whilst the Controller is in Manual Control

Mode. The output power will then be displayed and may be adjusted with the

Raise/Lower keys.A return can be made to Automatic Control Mode (via a

bumpless transfer) by simply depressing the Auto/Manual key again, which causes

the usual process variable display to appear.

1 -4 O054-1

Page 9

59125

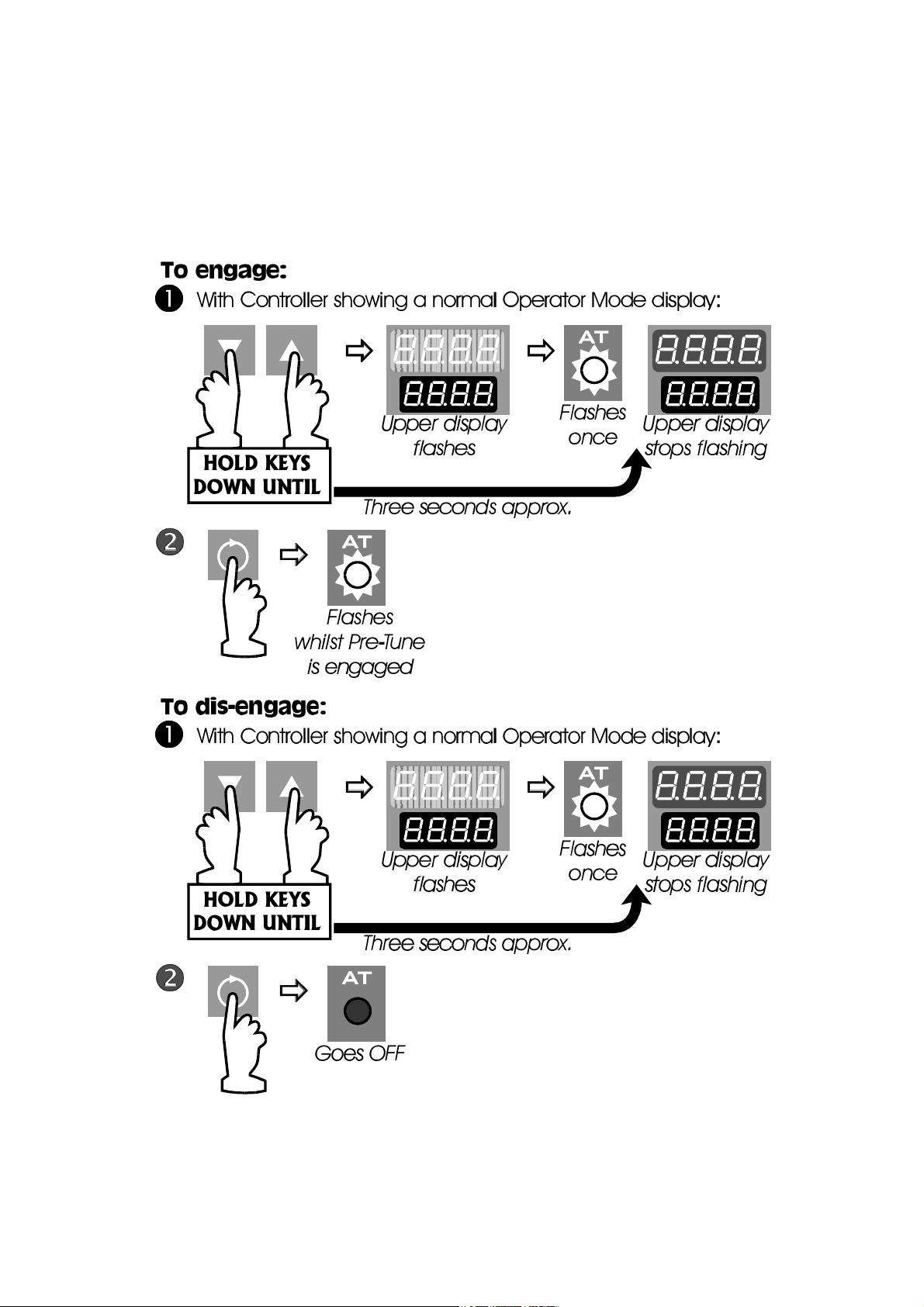

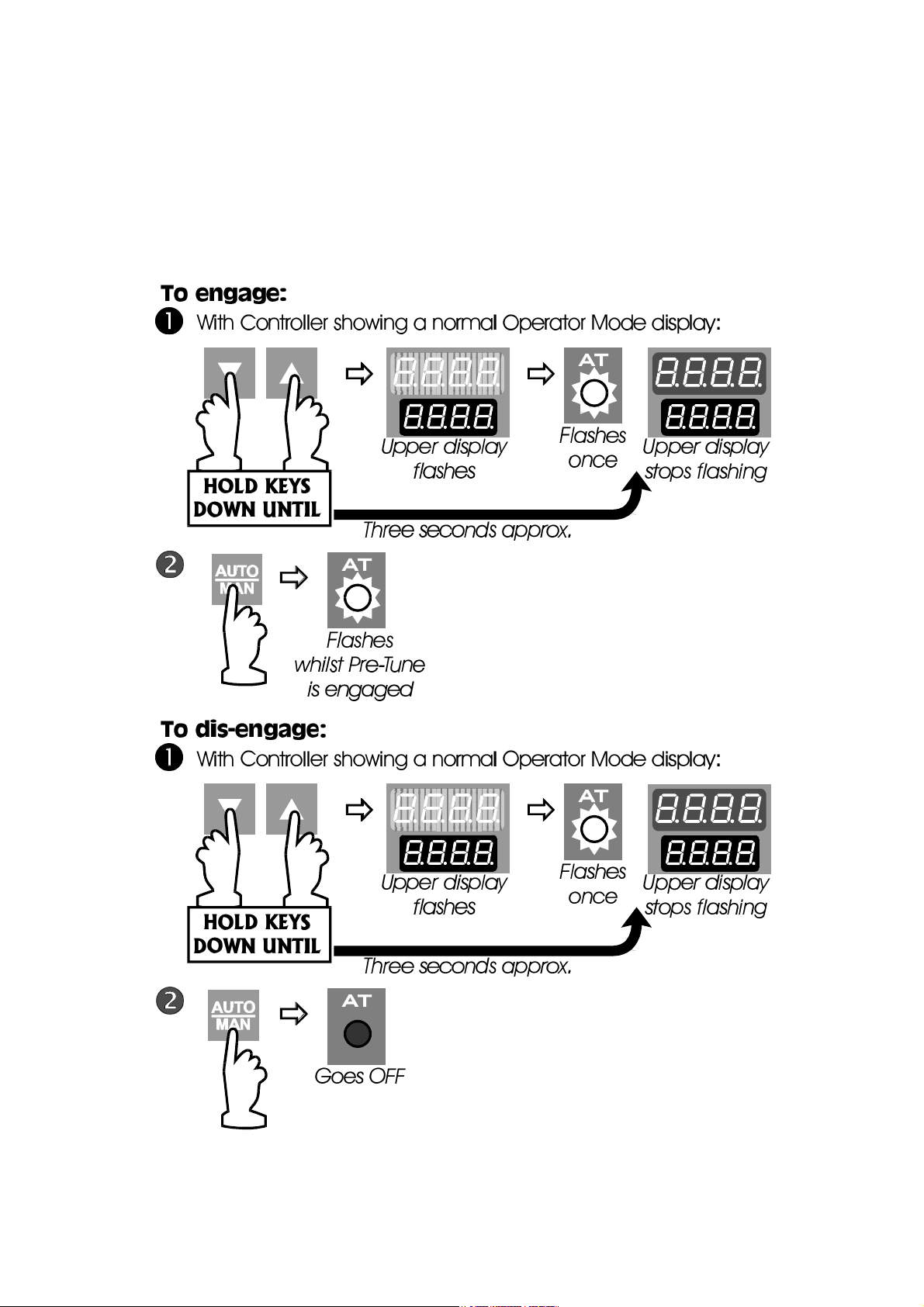

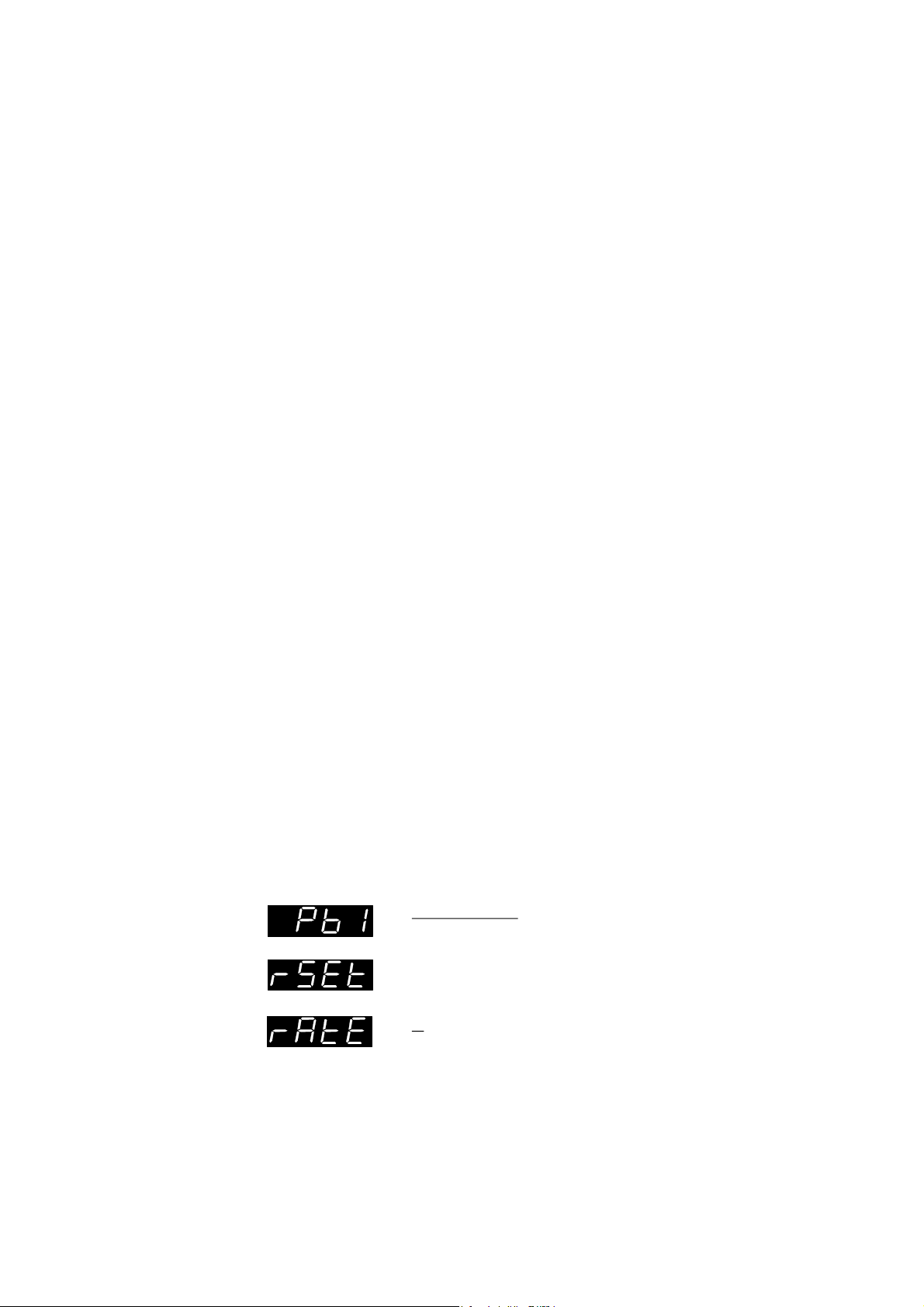

1.8 PRE-TUNE FACILITY

This facility may be used to set the Controller’s PID parameters to values which are

approximately correct, in order to provide a base from which the Self-Tune facility

may subsequently optimise tuning. Pre-Tune may be engaged (and subsequently

dis-engaged) as follows:

NOTE: The Pre-Tune facility will not engage if (a) the setpoint is currently

ramping, (b) the process variable is within 5% of input span of the setpoint,

or (c) an erroneous key sequence is used.

O054-1 1-5

Page 10

59125

Since Pre-Tune is a single-shot operation, it will automatically dis-engage

itself once the operation is complete.

1.9 SELF-TUNE FACILITY

This facility is be used to optimise tuning whilst the Controller is operating. Self-Tune

may be activated as follows:

1-6 O054-1

Page 11

59125

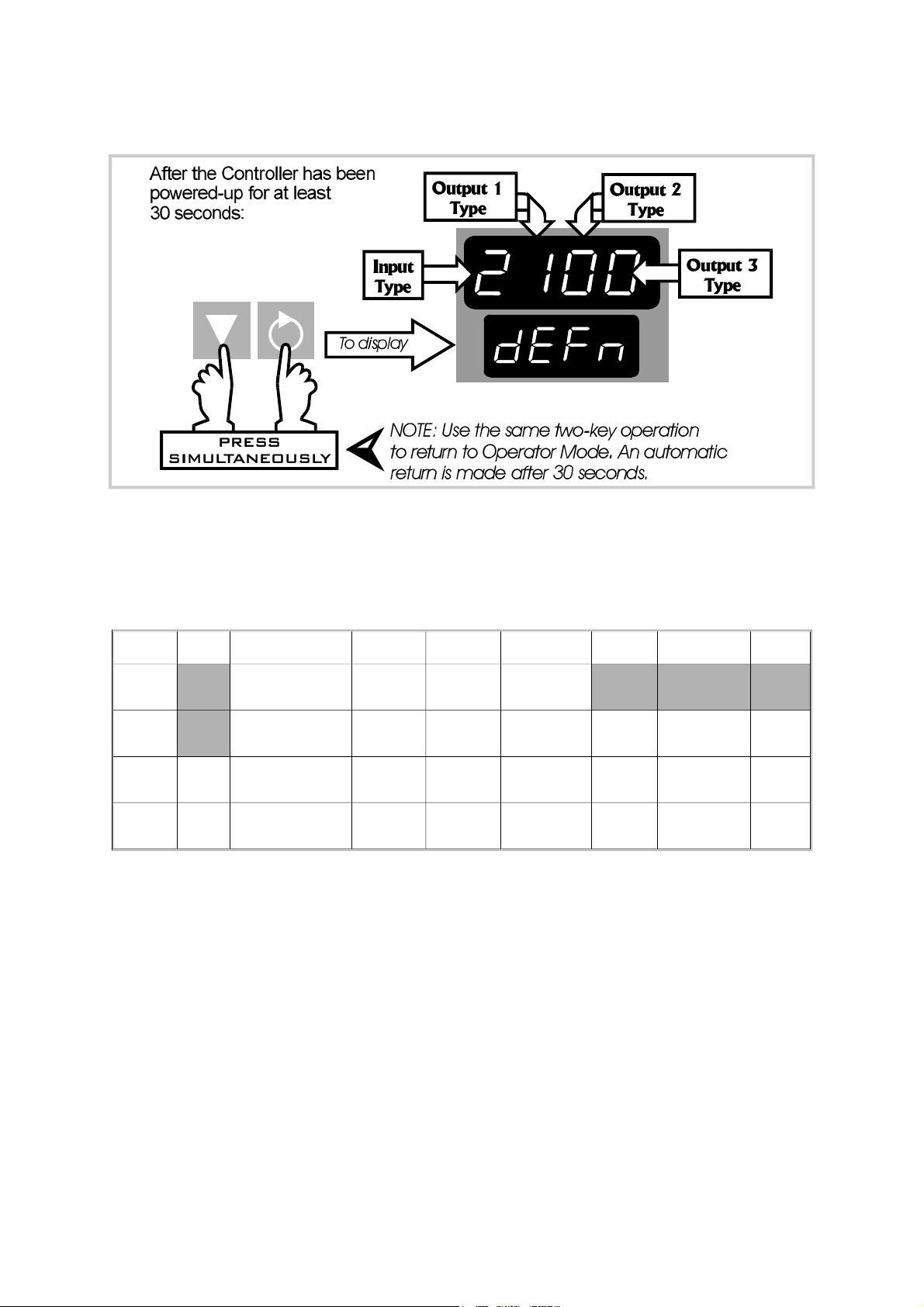

1.10 VIEWING THE HARDWARE DEFINITION CODE

Figure 1 -3 Viewing the Hardware Definition Code

NOTE: An automatic return is made to the normal Operator Mode

display after 30 seconds.

The Hardware Definition Code has the following significance:

Value 0 1 2 3 4 5 7 8

Input RTD/

Linear DC (mV)

Output

1

Output 2Not

fitted

Output 3Not

fitted

Relay SSR

Relay SSR

Relay SSR

Thermo-

couple

DriveDC(0 - 10V)DC(0 - 20mA)DC(0 - 5V)DC(4 - 20mA)

DriveDC(0 - 10V)DC(0 - 20mA)DC(0 - 5V)DC(4 - 20mA)

DriveDC(0 - 10V)DC(0 - 20mA)DC(0 - 5V)DC(4 - 20mA)

Linear

DC (mA)

Linear DC

(V)

Solid

State

Solid

State

Solid

State

O054-1 1-7

Page 12

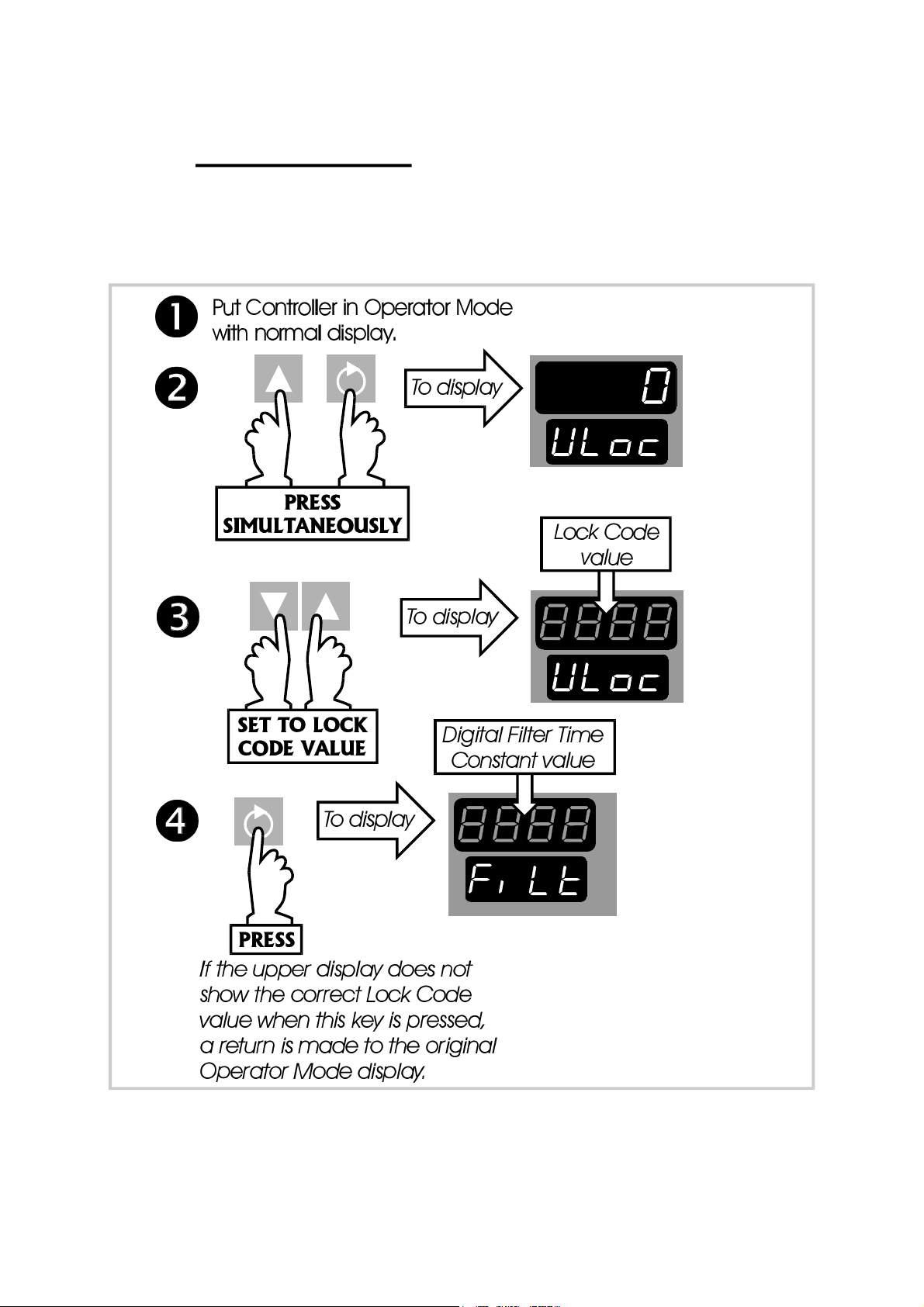

2 SET UP MODE

2.1 ENTRY INTO SET UP MODE

See Figure 2-1.

59125

Figure 2-1 Entry into Set Up Mode

2-1 O054-2

Page 13

59125

NOTE: If, on entry into Set Up Mode, the upper

display initially shows all decimal point

positions illuminated), this indicates that one

or more of the critical configuration

parameters - typically input range or output

use/type - have been altered in value/setting and, as a consequence, all

Set Up Mode parameters have been automatically set to their default

values/settings. To clear this display, simply alter the value/setting of any Set

Up Mode parameter (see below).

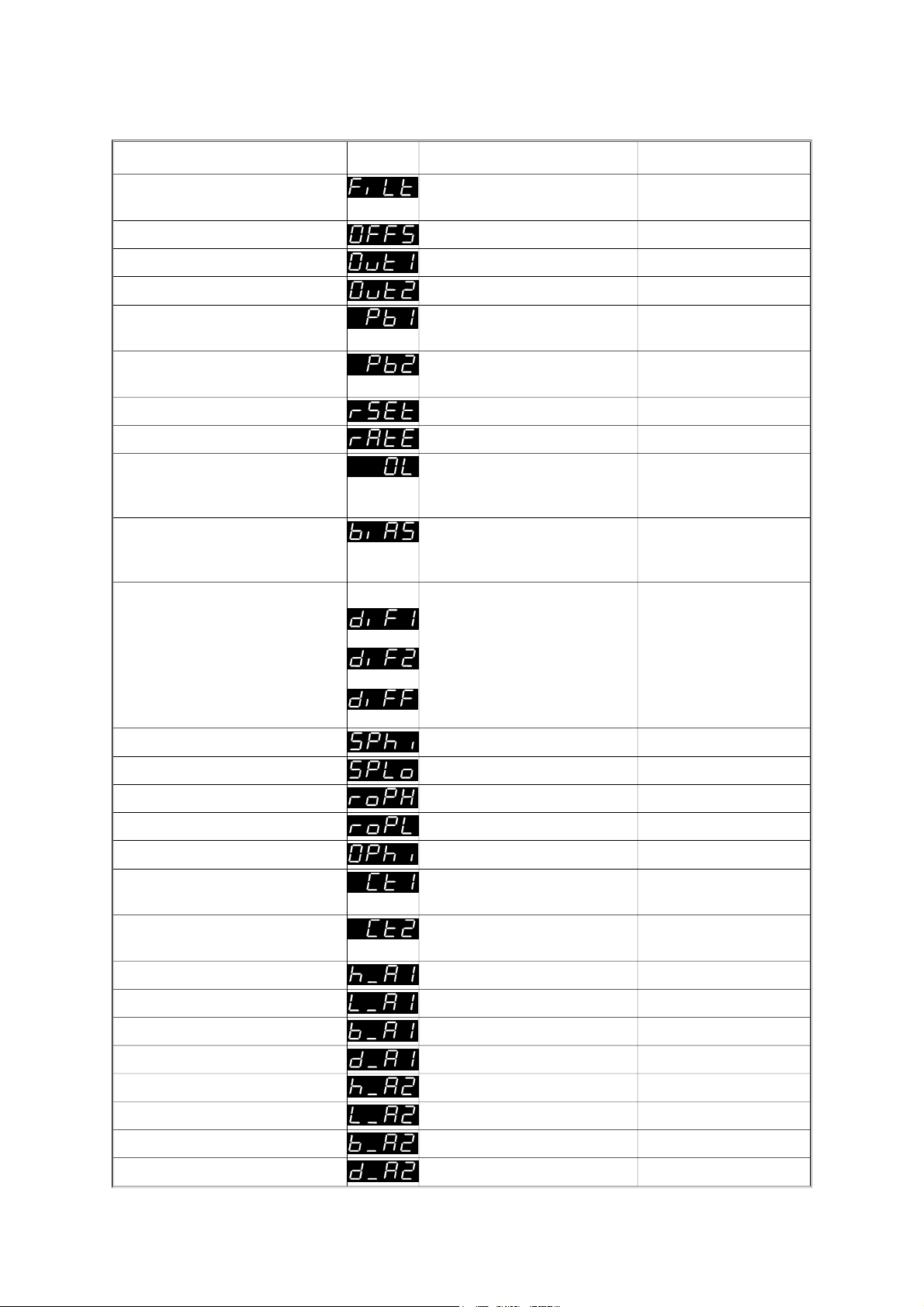

2.2 SET UP MODE PARAMETERS

The parameter sequence for view/adjustment in Set Up Mode is shown in Table

2 -1 . Use the Function key to step through the parameters. In each case, the

legend will be shown in the lower display and the current value/setting will be

shown in the upper display. The value/setting may be altered using the

Raise/Lower keys. A detailed description of each of these parameters is given in

the following Subsections.

2.2.1 Input Filter Time Constant

The Controller input is equipped with a digital filter which is used to filter out any

extraneous impulses on the process variable. This filtered PV is used for all

PV-dependent functions (control, alarms etc.).

CAUTION: If this parameter value is set excessively high, the control quality

may be significantly impaired. The value chosen should be sufficiently

large to attenuate stray noise on the process variable signal but no larger.

2.2.2 Process Variable Offset

This parameter is used to modify the actual process variable value (measured at

the Controller’s input terminals) in the following manner:

Offset PV value = Actual PV value + Process Variable Offset value.

For Controllers fitted with a linear input, the displayed process variable value is

limited by Scale Range Maximum (see Subsection 2.2.30) and Scale Range

Minimum (see Subsection 2.2.31). The offset process variable value is used for all

PV-dependent functions (control, display, alarm, recorder output etc.).

NOTE: This parameter value should be chosen with care. Any

adjustment to this parameter is, in effect, a calibration adjustment.

Injudicious application of values to this parameter could lead to the

displayed process variable value bearing no meaningful

relationship to the actual process variable value. There is no front

panel indication when this parameter is in effect (i.e. has been set

to a non-zero value).

O054-2 2-2

Page 14

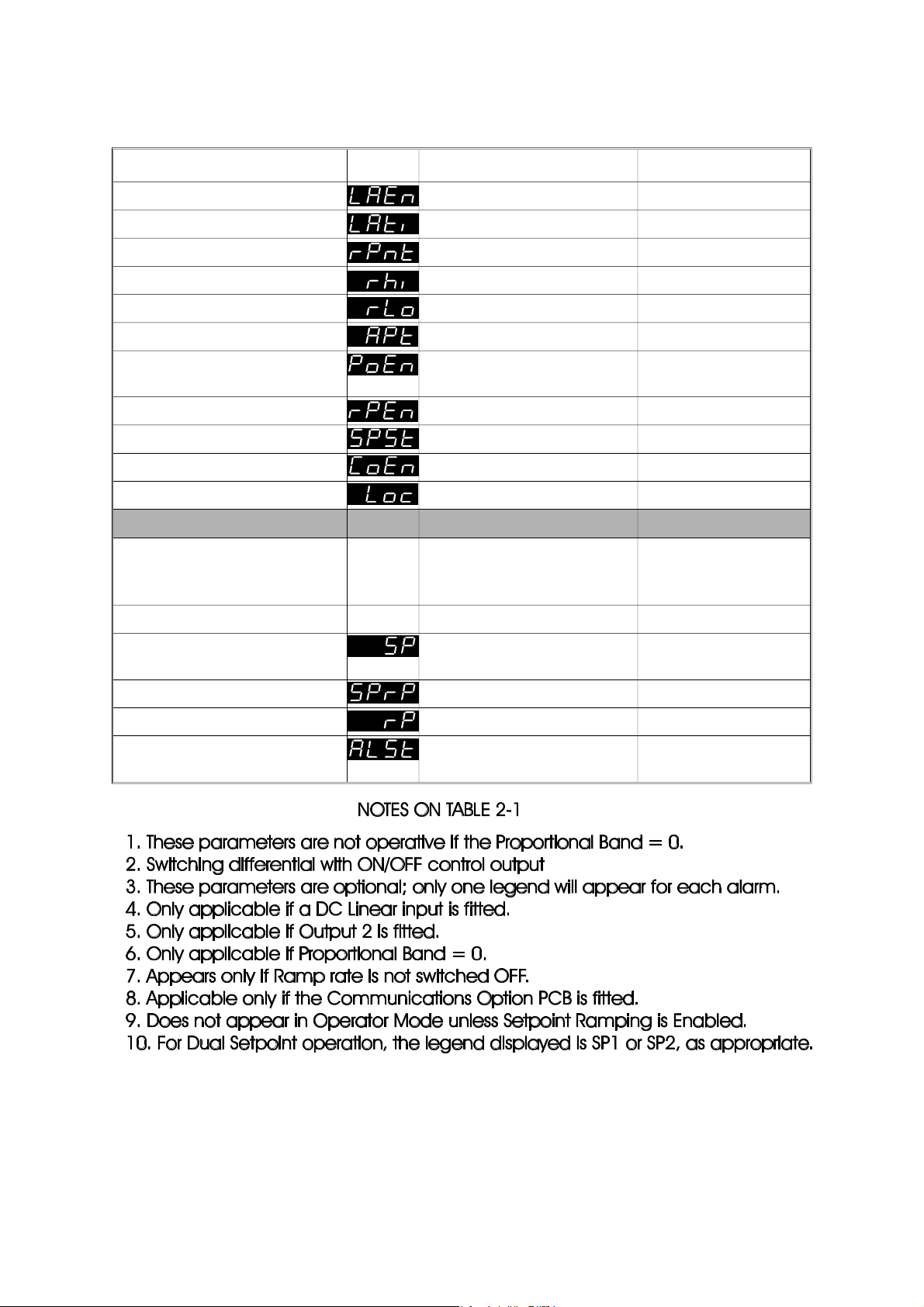

Table 2 -1 Set Up Mode Parameters

Parameter Legend Adjustment Range Default Value

59125

Digital Filter Time Constant OFF, 0.5 to 100.0 secs. In

2.0 seconds

0.5 sec. increments

Process Variable Offset

Span of Controller 0

±

Output Power 0 to 100% Read only

Output Power 2

Proportional Band 1 0.0 (ON/OFF control) to

5

0 to 100% Read only

10.0%

999.9% of input span

Proportional Band 2

15,

0.0 (ON/OFF control) to

10.0%

999.9% of input span

Reset (Integral Time Const.)

Rate (Derivative Time Const.)

Overlap/Deadband

15,

1

1

1s to 99m 59s and OFF 5m 00s

00s to 99m 59s 1m 15s

-20% to +20% (of

0%

Proportional Band 1 +

Proportional Band 2)

Manual Reset (Bias)

1

0% to 100% (Output 1 only)

25%

-100% to +100% (Output 1

& Output 2)

ON/OFF Differential

2

0.1% to 10.0% of input span 0.5%

Output 1 only

Output 2 only

Output 3 only

5

5

Setpoint High Limit Setpoint to Range Maximum Range Maximum

Setpoint Low Limit Range Minimum to Setpoint Range Minimum

Recorder Output Scale Max. -1999 to 9999 Range Maximum

Recorder Output Scale Min. -1999 to 9999 Range Minimum

Output 1 Power Limit

Output 1 Cycle Time 0.5, 1, 2, 4, 8, 16, 32, 64,

1

0% to 100% of full power 100%

32 secs.

128, 256 or 512 secs.

Output 2 Cycle Time 0.5, 1, 2, 4, 8, 16, 32, 64,

32 secs.

128, 256 or 512 secs.

Process High Alarm 1 value

Process Low Alarm 1 value

Band Alarm 1 value

3

Deviation Alarm 1 value

Process High Alarm 2 value

Process Low Alarm 2 value

Band Alarm 2 value

3

Deviation Alarm 2 value

3

3

Range Min. To Range Max. Range Max.

Range Min. To Range Max. Range Min.

0 to span from Limit SP 5 units

3

3

3

±Span from Limit SP 5 units

Range Min. To Range Max. Range Max.

Range Min. To Range Max. Range Min.

0 to span from Limit SP 5 units

3

±Span from Limit SP 5 units

2-3 O054-2

Page 15

59125

Table 2 -1 Set Up Mode Parameters (cont.)

Parameter Legend Adjustment Range Default Value

Loop Alarm Enable 0 (Disabled) or 1 (Enabled) 0

Loop Alarm Time

Scale Range Decimal Point

Scale Range Maximum

Scale Range Minimum

Auto Pre-Tune Enable/Disable 0 (Disabled) or 1 (Enabled) 0

6

4

4

4

1s to 99m 59s 99m 59s

0, 1, 2 or 3 1

-1999 to 9999 1000

-1999 to 9999 0000

Manual Control

0 (Disabled) or 1 (Enabled) 0

Enable/Disable

Setpoint Ramp Enable/Disable 0 (Disabled) or 1 (Enabled) 0

Setpoint Strategy 1, 2, 3, 4 or 5 1

Communications Enable

8

0 (Disabled) or 1 (Enabled) 1 (Enabled)

Lock Code 0 to 9999 10

Operator Mode Displays

(still accessible in Set Up

Mode):

Process Variable Read Only -

Setpoint

10

Setpoint Low Limit to Setpoint

Setpoint Low Limit

High Limit

Ramping Setpoint value

Setpoint Ramp Rate

Alarm Status Read Only (see Subsection

7

9

Read only

1 to 9999 and OFF OFF (blank)

-

1.3)

O054-2 2-4

Page 16

59125

2.2.3 Output Power 1

This parameter is the current Output 1 power level. It is a “Read Only” parameter

and is not adjustable.

2.2.4 Output Power 2

This parameter is the current Output 2 power level (if Output 2 is fitted). It is a

“Read Only” parameter and is not adjustable. If Output 2 is not fitted, this

parameter display is not applicable.

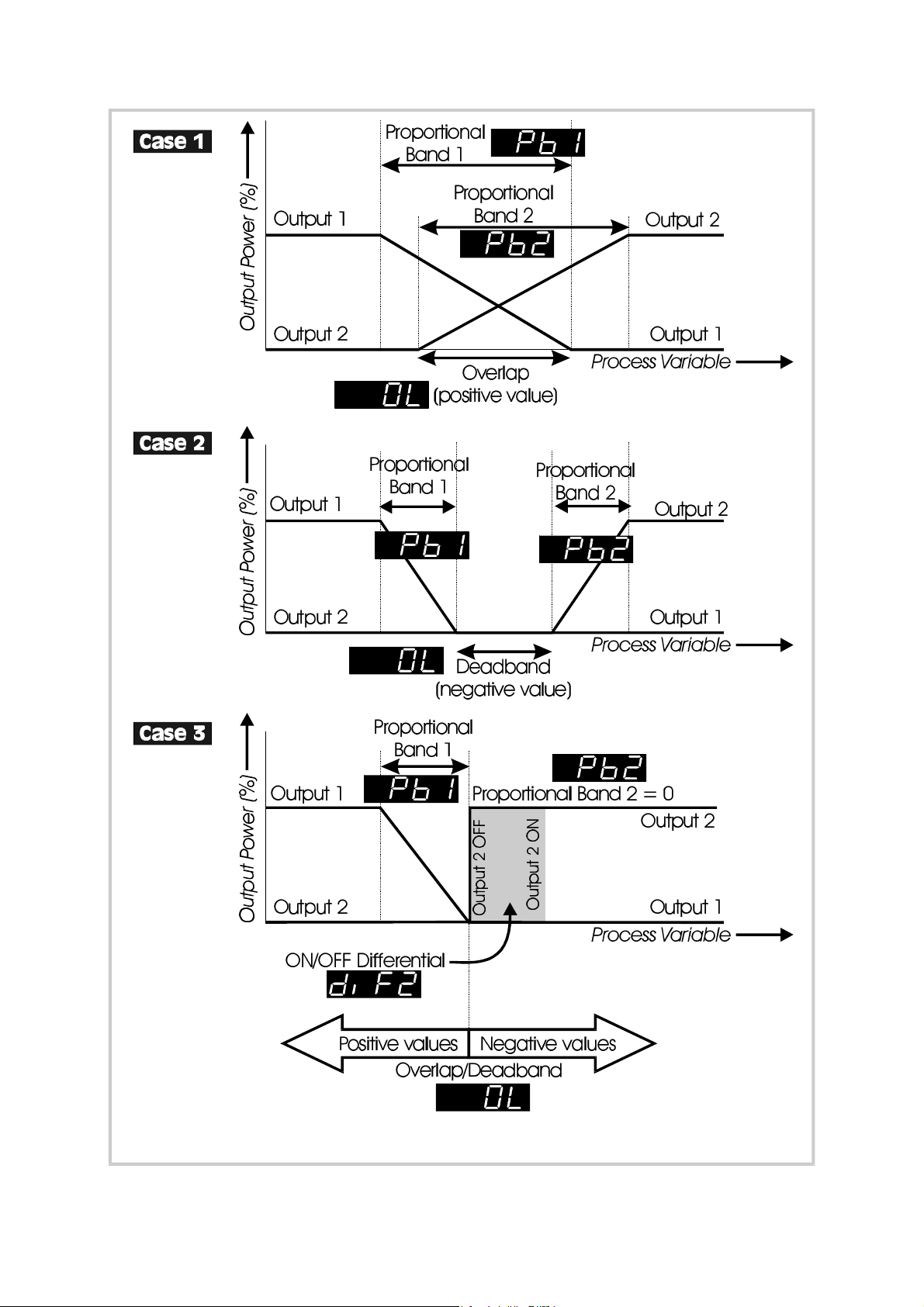

2.2.5 Proportional Band 1

This parameter is the portion of the input span of the Controller over which the

Output 1 power level is proportional to the displayed process variable value. The

function of the Proportional Band 1 is illustrated in Figure 2 -2 .

2.2.6 Proportional Band 2

This parameter is the portion of the input span of the Controller over which the

Output 2 power level is proportional to the displayed process variable value. In

Figure 2-2 , Proportional Band 2 is shown (a) with a non-zero value (Case 1 and

Case 2) - PID control, and (b) with a zero value (Case 3) - ON/OFF control.

2.2.7 Reset ( Integral Time Constant)

This parameter is not applicable if Proportional Band 1 (see Subsection 2.2.5 ) is set

to 0 (ON/OFF control).

2.2.8 Rate ( Derivative Time Constant)

This parameter is not applicable if Proportional Band 1 (see Subsection 2.2.5 ) is set

to 0 (ON/OFF control).

2.2.9 O verlap/Deadband

This defines the portion of the Proportional Band (Proportional Band 1 +

Proportional Band 2) over which both outputs are active (or, in the case of a

deadband, neither output is active). The function of the overlap/deadband is

illustrated in Figure 2 - 2 . This parameter is not applicable if Proportional Band 1 = 0

or if Output 2 is not fitted. Note that, with Output 2 set to ON/OFF control (Figure 2-2

Case 3), the Overlap/Deadband parameter has the effect of moving the ON

Differential band of Output 2 to create an overlap (positive values) or a

deadband (negative values). When Overlap/Deadband = 0, the “Output 2 OFF”

edge of the Output 2 ON/OFF Differential band coincides with the point at which

Output 1 reaches 0%.

2-5 O054-2

Page 17

59125

Figure 2-2 Proportional Band and Deadband/Overlap

O054-2 2-6

Page 18

59125

2.2.10 Bias (Manual Reset)

This bias to the output power is expressed as a percentage of output power. This

parameter is not applicable if Proportional Band 1 = 0.

2.2.11 ON/OFF Differential

This is a switching differential used when one or both outputs have been set to

ON/OFF control (i.e. Proportional Band 1 or Proportional Band 2 or both = 0).

2.2.12 Setpoint High Limit

This is the maximum limit for setpoint adjustment. It should be set to a value which

prevents the setpoint being given a value which will cause damage to the

process being controlled.

2.2.13 Setpoint Low Limit

This is the minimum limit for setpoint adjustment. It should be set to a value which

prevents the setpoint being given a value which will cause damage to the

process being controlled.

2.2.14 Recorder Output Scale Maximum

This parameter defines the value of process variable or setpoint (whichever is

applicable) at which the Recorder Output reaches its maximum value; for

example, for a 0 - 5V Recorder Output, this value corresponds to 5V. The decimal

point position for the Recorder Output is always the same as that for the process

variable input range. This parameter is not applicable if the Recorder Output

option is not fitted.

NOTE: If this parameter is set to a value less than that for the Recorder

Output Scale Minimum (see Subsection 2.2.15 ), the relationship between

the process variable/setpoint value and the Recorder Output is reversed.

2.2.15 Recorder Output Scale Minimum

This parameter defines the value of the process variable or setpoint (whichever is

applicable) at which the Recorder Output reaches its minimum value; for

example, for a 0 - 5V Recorder Output, this value corresponds to 0V. The decimal

point position for the Recorder Output is always the same as that for the process

variable input range. This parameter is not applicable if the Recorder Output

option is not fitted.

NOTE: If this parameter is set to a value greater than that for the Recorder

Output Scale Maximum (see Subsection 2.2.14 ), the relationship between

the process variable value and the Recorder Output is reversed.

2 -7 O054-2

Page 19

59125

2.2.16 Output 1 Power Limit

This parameter is used to limit the power level of Output 1 and may be used to

protect the process being controlled. If no protection is required, this parameter

may be set to 100%. IThis parameter is not applicable if Proportional Band 1 is set

to 0.

2.2.17 Output 1 Cycle Time

The cycle time value required is dependent upon the process being controlled

and the type of output being used for Output 1. For a Relay Output, the cycle

time should be as large as possible (whilst remaining compatible with the process

control requirements) in order to maximise relay life. For an SSR Output, the cycle

time may have a lower value (and thus satisfy the requirements of a fast-changing

process variable e.g. flow or pressure). This parameter is not applicable if

Proportional Band 1 is set to 0 or if Output 1 is a DC linear output..

2.2.18 Output 2 Cycle Time

The cycle time value required is dependent upon the process being controlled

and the type of output being used for Output 2. For a Relay Output, the cycle

time should be as large as possible (whilst remaining compatible with the process

control requirements) in order to maximise relay life. For an SSR Output, the cycle

time may have a lower value (and thus satisfy the requirements of a fast-changing

process variable e.g. flow or pressure). This parameter is not applicable if

Proportional Band 1 or Proportional Band 2 is set to 0 or if Output 2 is a DC linear

output.

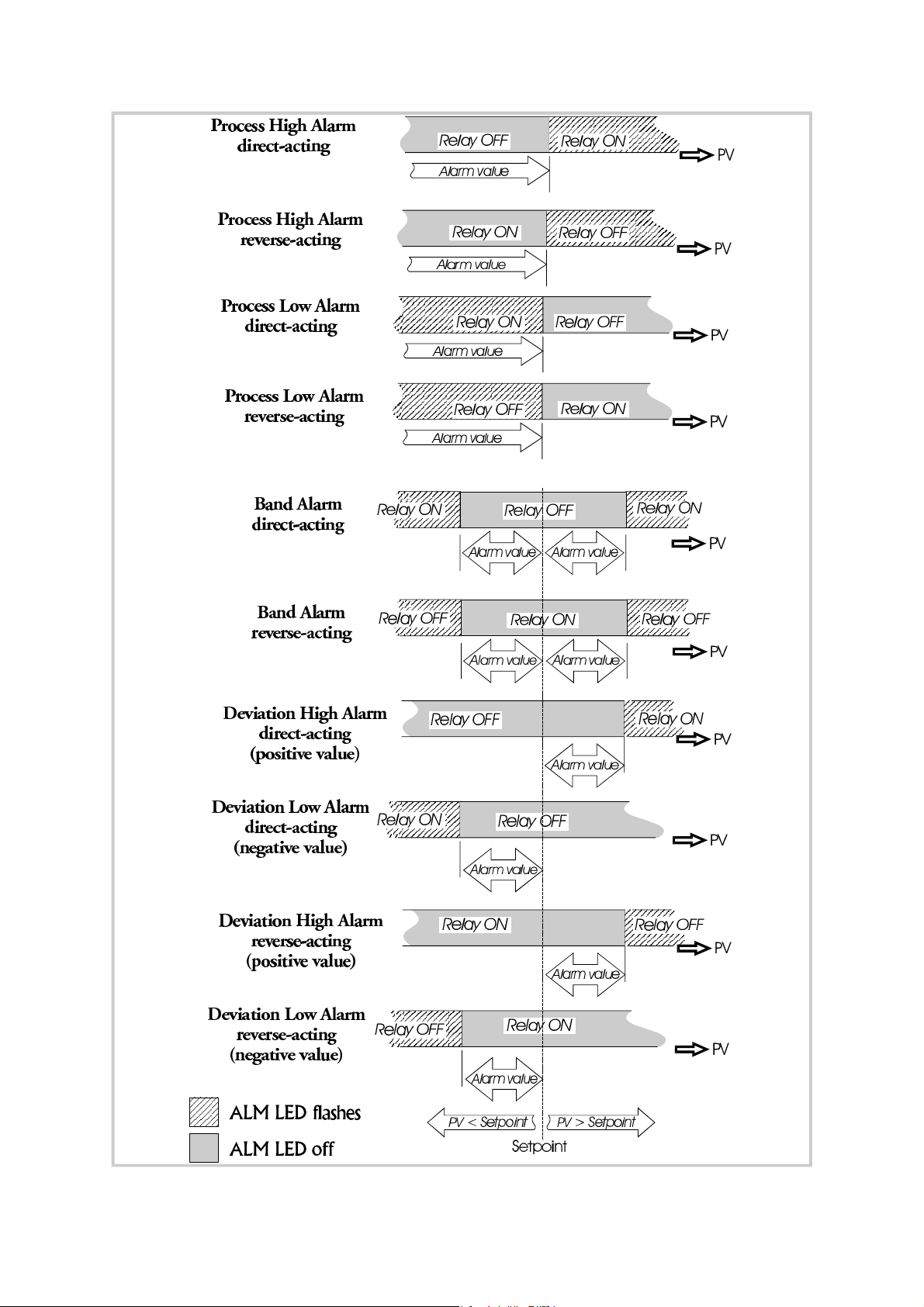

2.2.19 Process High Alarm 1 Value

This parameter, applicable only when Alarm 1 is selected to be a Process High

alarm, defines the process variable value at or above which Alarm 1 will be

active. The operation of a process high alarm is illustrated in Figure 2-3.

2.2.20 Process Low Alarm 1 Value

This parameter, applicable only when Alarm 1 is selected to be a Process Low

alarm, defines the process variable value at or below which Alarm 1 will be

active. The operation of a process low alarm is illustrated in Figure 2-3.

2.2.21 Band Alarm 1 Value

This parameter, applicable only if Alarm 1 is selected to be a Band Alarm, defines

a band of process variable values, centred on the setpoint value. If the process

variable value is outside this band, the alarm will be active. The operation of a

band alarm is illustrated in Figure 2-3.

O054-2 2-8

Page 20

59125

Figure 2-3 Alarm Operation

2-9 O054-2

Page 21

59125

2.2.22 Deviation (High/Low) Alarm 1 Value

This parameter, applicable only if Alarm 1 is selected to be a Deviation High/Low

Alarm, defines a value above (positive value - Deviation High alarm) or below

(negative value - Deviation Low alarm) the setpoint; if the process variable

deviates from the setpoint by a margin greater than that defined by this

parameter, Alarm 1 goes active. The operation of Deviation Alarms is illustrated in

Figure 2-3.

2.2.23 Process High Alarm 2 Value

This parameter, applicable only when Alarm 2 is selected to be a Process High

alarm, defines the process variable value at or above which Alarm 2 will be

active. The operation of a process high alarm is illustrated in Figure 2-3.

2.2.24 Process Low Alarm 2 Value

This parameter, applicable only when Alarm 2 is selected to be a Process Low

alarm, defines the process variable value at or below which Alarm 2 will be

active. The operation of a process low alarm is illustrated in Figure 2-3.

2.2.25 Band Alarm 2 Value

This parameter, applicable only if Alarm 2 is selected to be a Band Alarm, defines

a band of process variable values, centred on the setpoint value. If the process

variable value is outside this band, the alarm will be active. The operation of a

band alarm is illustrated in Figure 2-3.

2.2.26 Deviation (High/Low) Alarm 2 Value

This parameter, applicable only if Alarm 2 is selected to be a Deviation High/Low

Alarm, defines a value above (positive value - Deviation High alarm) or below

(negative value - Deviation Low alarm) the setpoint; if the process variable

deviates from the setpoint by a margin greater than that defined by this

parameter, Alarm 2 goes active. The operation of Deviation Alarms is illustrated in

Figure 2-3.

2.2.27 Loop Alarm Enable

This parameter is the means by which the user can enable or disable the Loop

Alarm. The Loop Alarm is a special alarm which detects faults in the control

feedback loop by continuously monitoring process variable response to the

control output(s).

The Loop Alarm facility, when enabled, repeatedly checks the control output(s) for

saturation i.e. either or both outputs being at the maximum or minimum limit. If an

output is found to be in saturation, the Loop Alarm facility starts a timer; thereafter,

O054-2 2-10

Page 22

59125

if the saturated output has not caused the process variable to be corrected by a

pre-determined amount V after a time T has elapsed, the Loop Alarm goes active.

Subsequently, the Loop Alarm facility repeatedly checks the process variable and

the control output(s). When the process variable starts to change value in the

correct sense or when the saturated output comes out of saturation, the Loop

Alarm is de-activated.

For PID control, the Loop Alarm Time T is always set to twice the value of the Reset

(Integral Time Constant) parameter. For On/Off control, the user-defined value of

the Loop Alarm Time Set Up parameter (see Subsection 2.2.28) is used.

The value of V is dependent upon the input type:

°C ranges: 2°C or 2.0 °C

°F ranges: 3°F or 3.0 °F

Linear ranges: 10 least significant display units

For single output Controllers, the saturation limits are 0% and Out1Max%. For dual

output Controllers, the saturation limits are –100% and Out1Max%.

NOTES

1. Correct operation of the Loop Alarm depends upon reasonably

accurate PID tuning.

2. The Loop Alarm is automatically disabled during Manual Control Mode

and during execution of the Pre-Tune facility. Upon exit from Manual

Control Mode or after completion of the Pre-Tune routine, the Loop Alarm is

automatically re-enabled.

2.2.28 Loop Alarm Time

When full ON/OFF control is selected (i.e. Proportional Band 1 is set to 0) and Loop

Alarm is enabled, this parameter determines the duration of the saturation

condition after which the Loop Alarm will be activated. This parameter is omitted

from the Set Up display sequence if ON/OFF control is not selected or Loop Alarm

is disabled.

2.2.29 Scale Range Decimal

Value Decimal Point Position

Point

0 xxxx

This parameter, applicable only if a linear

input is fitted, defines the position of the

decimal point in values of the process

variable, setpoint, alarm levels and

recorder outputs as shown on the right.

2 -11 O054-2

1 xxx.x

2 xx.xx

3 x .xxx

Page 23

59125

2.2.30 Scale Range Maximum

This parameter, applicable only if a linear input is fitted, defines the scaled input

value when the process variable input hardware is at its maximum value. This

parameter can be set to a value less than (but not equal to) Scale Range

Minimum, in which case the sense of the input is reversed. Decimal point position

is defined by the Scale Range Decimal Point parameter (see Subsection 2.2.29 ).

2.2.31 Scale Range Minimum

This parameter, applicable only if a linear input is fitted, defines the scaled input

value when the process variable input hardware is at its minimum value. This

parameter can be set to a value greater than (but not equal to) Scale Range

Maximum, in which case the sense of the input is reversed. Decimal point position

is defined by the Scale Range Decimal Point parameter (see Subsection 2.2.29 ).

2.2.32 Auto Pre-Tune Enable/Disable

This parameter determines whether or not the Controller’s Pre-Tune facility is

activated automatically on power-up or not.

2.2.33 Manual Control Enable/Disable

This parameter determines whether operator selection of manual control is

enabled or disabled.

2.2.34 Setpoint Ramp Enable/Disable

This parameter enables/disables use of the setpoint ramping feature at user level.

2.2.35 Setpoint Strategy

This parameter enables the user to select the required Operator Mode setpoint

display strategy - see Subsections 1.2.1 (Single Setpoint operation) and 1.2.2 (Dual

Setpoint operation).

2.2.36 Communications Enable/Disable

This parameter enables/disables Write operations (i.e. the changing of parameter

values/settings) via the RS485 communications link, if the Communications Option

PCB is fitted. Parameters can be interrogated via the link, regardless of the setting

of this parameter.

2.2.37 Lock Value

This parameter defines the four-digit code required to enter Set Up Mode.

O054-2 2-12

Page 24

59125

2.3 OPERATOR MODE DISPLAYS

Once the complete cycle of Set Up Mode parameters has been displayed, the

user may then step through the Operator Mode displays (see Subsection 1.2),

making adjustments where required, before re-starting the Set Up Mode

parameter cycle, as shown in Table 2-1.

2.4 TUNING THE CONTROLLER MANUALLY

2.4.1 Controllers Fitted with Output 1 Only

Before starting to tune the Controller to the load, check that the Setpoint High and

Low Limits (SPhi and SPLo) are set to safe levels - see Subsections 2.2.12 and

2.2.13 .

The following simple technique may be used to determine values for proportional

band (Pb1), derivative time constant (rAtE) and integral time constant (rSEt).

NOTE: This technique is suitable only for processes which are not harmed by

large fluctuations in the process variable. It provides an acceptable basis

from which to start fine tuning for a wide range of processes.

1. Set the setpoint to the normal operating process value (or to a lower

value if overshoot beyond this value is likely to cause damage).

2. Select ON/OFF Control (i.e. set Pb1 = 0).

3. Switch on the process. The process variable will oscillate about the

setpoint. Note (a) The peak-to-peak variation (P) of the first cycle i.e. the

difference between the highest value of the first overshoot and the lowest

value of the first undershoot, and (b)tThe cycle time (T) of this oscillation in

minutes (see Figure 2-4)

4. The control parameters should then be set as follows:

=

= T minutes

P

x 100

ScaleRange

T

=

minutes

6

NOTE: After setting up the parameters, set the Controller to Operator Mode

(see Subsection 2.6) to prevent unauthorised adjustment to the values.

2 -13 O054-2

Page 25

59125

Figure 2 -4 Manual Tuning Parameters - Output 1 only

2.4.2 Controllers Fitted with Output 1 and Output 2

Before starting to tune the Controller to the load, check that the Setpoint High and

Low Limits (SPhi and SPLo) are set to safe levels - see Subsections 2.2.12 and

2.2.13 .

The following simple technique may be used to determine values for proportional

band (Pb1), derivative time constant (rAtE) and integral time constant (rSEt).

NOTE: This technique is suitable only for processes which are not harmed by

large fluctuations in the process variable. It provides an acceptable basis

from which to start fine tuning for a wide range of processes.

1. Tune the Controller using Output 1 only as described in Subsection 2.4.1.

2. Set Pb2 to the same value as Pb1 and monitor the operation of the

Controller in dual output mode. If there is a tendency to oscillate as control

passes into the Output 2 proportional band, increase the value of Pb2. If

the process appears to be over-damped in the region of the Output 2

proportional band, decrease the value of Pb2.

3. When values of proportional bands, integral time constant and derivative

time constant have been determined for tuning, if there is a “kick” as

control passes from one output to the other, set OL to a positive value to

introduce some overlap. Adjust the value of OL by trial and error until

satisfied.

2.5 SELF-TUNE AND PRE-TUNE FACILITIES

Once the Controller has been manually tuned, the Self-Tune and Pre-Tune

facilities may be used in Operator Mode to enhance further the response of the

Controller (see Subsections 1.9 and 1.8 respectively).

O054-2 2-14

Page 26

59125

2.6 EXIT FROM SET UP MODE

To leave Set Up Mode, select the initial Operator Mode display (normally process

variable) then depress the Raise and Function keys simultaneously, whereupon

the Controller will return to Operator Mode. NOTE: An automatic return to Operator

mode will be executed if there is no key activity in Set Up Mode for two minutes.

2-15 O054-2

Page 27

59125

3 RS485 SERIAL COMMUNICATIONS

The Controller may be equipped with a two-wire RS485-compatible serial

communications facility, by which means communication may occur between

the Controller and a master device (e.g. a computer or terminal).

3.1 COMMUNICATIONS ENABLE/DISABLE

When Communications are enabled (in Set Up Mode - see Subsection 2.2.36), the

Controller parameters may be adjusted by the master device via the serial

communications link. If communications are disabled, the Controller will not adjust

or change any parameters in response to commands received from the master

device and will send a negative acknowledgement in response to such

commands. Whether communications are enabled or disabled, the Controller will

return the requested information in response to a Type 2 Interrogation message

(see Subsection 3.2.5 ) from the master device.

3.2 PHYSICAL REQUIREMENTS

3.2.1 Character Transmission

Data format is fixed to be even parity, seven data bits and one stop bit. The Baud

rate may be selected to be 1200, 2400, 4800 (default) or 9600 Baud.

3.2.2 Line Turn-Round

The communications link is operated as a multi-drop half duplex system. When a

device is transmitting, it drives the transmission lines to the appropriate levels;

when it is not transmitting, its outputs are set to a high impedance in order that

another device can transmit. It is important that a transmitter releases the

transmission lines before another device starts transmission. This imposes the

following restraints on the master device:

(a) The transmitter must release the transmission lines within 6ms of

the end of the last character of a message being transmitted. Note

that delays due to buffers such as those used in universal

asynchronous receivers/trans-mitters (UARTs) within the master device

must be taken into account.

(b) The transmitter must not start transmission until 6ms has elapsed

since the reception of the last character of a message.

All Controllers in this range having an RS485 communications facility adhere to this

standard; thus, provided that the master device conforms similarly to the

standard, there should be no line contention problems.

O054-3 3-1

Page 28

59125

3.2.3 Communications Protocol

The protocol assumes half duplex communications. All communication is initiated

by the master device. The master sends a command or query to the addressed

slave and the slave replies with an acknowledgement of the command or the

reply to the query. All messages, in either direction, comprise:

(a) A Start of Message character

(b) One or two address characters (uniquely defining the slave)

(c) A parameter/data character string

(d) An End of Message character

Messages from the master device may be one of four types:

Type 1: L {N} ? ? *

Type 2: L {N} {P} {C} *

Type 3: L {N} {P} # {DATA} *

Type 4: L {N} {P} I *

Table 3 -1 {DATA} Element - Sign

and Decimal Point

where all characters are in ASCII code and:

L is the Start of Message

character (Hex 4C)

{N} is the slave Controller

address (in the range 1 -

32); addresses 1 - 9 may be

{DATA} Content Sign/Decimal Point

abcd0 +abcd

abcd1 +abc.d

abcd2 +ab.cd

abcd3 +a.bcd

abcd5 -abcd

abcd6 -abc.d

represented by a single digit

(e.g. 7) or in two-digit form,

the first digit being zero (e.g.

abcd7 -ab.cd

abcd8 -a.bcd

07).

{P} is a character which identifies the parameter to be

interrogated/modified.

{C} is the command (see below)

# indicates that {DATA} is to follow (Hex 23)

{DATA} is a string of numerical data in ASCII code (see Table 3 -1 )

* is the End of Message character (Hex 2A)

No space characters are permitted in messages. Any syntax errors in a received

message will cause the slave controller to issue no reply and await the Start of

Message character.

3-2 O054-3

Page 29

59125

3.2.4 Type 1 Message

L {N} ? ? *

This message is used by the master device to determine whether the addressed

slave Controller is active. The reply from the slave Controller, if it is active, is

L {N} ? A *

An inactive Controller will give no reply.

3.2.5 Type 2 Message

L {N} {P} {C} *

This type of message is used by the master device to interrogate or modify a

parameter in the addressed Controller. {P} identifies the parameter and {C}

represents the command to be executed, which may be one of the following:

+ (Hex 2B) - Increment the value of the parameter defined by {P}

– (Hex 2D) - Decrement the value of the parameter defined by {P}

? (Hex 3F) - Determine the current value of the parameter defined by {P}

The reply from the addressed Controller is of the form:

L {N} {P} {DATA} A *

where {DATA} comprises five ASCII-coded digits whose format is shown in Table

3-1. The data is the value requested in a query message or the new value of the

parameter after modification. If the action requested by the message from the

master device would result in an invalid value for that parameter (either because

the requested new value would be outside the permitted range for that

parameter or because the parameter is not modifiable), the Controller replies with

a negative acknowledgement:

L {N} {P} {DATA} N *

The {DATA} string in the negative acknowledgement reply will be indeterminate. If

the process variable or the deviation is interrogated whilst the process variable is

outside the range of the Controller, the reply is L{N}{P}<??>0A* if the process

variable is over-range, or L{N}{P}<??>5A* if the process variable is

under-range.

Scan Tables

A parameter identifier character “]” in the message from the master device

indicates that a “Scan Table” operation is required. This provides a facility for

O054-3 3-3

Page 30

59125

interrogating the values of a group of parameters and status in a single message

from the master device. The reply to such a command would be in the form:

L {N} ] xx aaaaa bbbbb ccccc ddddd eeeee A *

where xx is the number of data digits to follow; this is 20 for a single-control-output

instrument and 25 for a dual-control-output instrument. The digits are expressed as

shown in Table 3 -1 . For further information, refer to Subsection 3.3.6 .

3.2.6 Type 3 Message

L {N} {P} # {DATA} *

This message type is used by the master device to set a parameter to the value

specified in {DATA}. The command is not implemented immediately by the slave

Controller; the slave will receive this command and will then wait for a Type 4

message (see below). Upon receipt of a Type 3 message, if the {DATA} content

and the specified parameter are valid, the slave Controller reply is of the form:

L {N} {P} {DATA} I *

(where I = Hex 49) indicating that the Controller is ready to implement the

command. If the parameter specified is invalid or is not modifiable or if the

desired value is outside the permitted range for that parameter, the Controller

replies with a negative acknowledgement in the form:

L {N} {P} {DATA} N *

3.2.7 Type 4 Message

L {N} {P} I *

This type of message is sent by the master device to the addressed slave

Controller following a successful Type 3 message transmission and reply to/from

the same slave Controller. Provided that the {DATA} content and the parameter

specified in the preceding Type 3 message are still valid, the slave Controller will

then set the parameter to the desired value and will reply in the form:

L {N} {P} {DATA} A *

where {DATA} is the new value of the parameter. If the new value or parameter

specified is invalid, the slave Controller will give a negative acknowledgement:

L {N} {P} {DATA} N *

where {DATA} is indeterminate. If the immediately-preceding message received

by the slave Controller was not a Type 3 message, the Type 4 message is ignored.

3-4 O054-3

Page 31

59125

3.3 INDIVIDUAL PARAMETERS

The individual parameters and how they may be interrogated/modified are

described below. Unless otherwise stated, the {DATA} element will follow the

standard five-digit format and the decimal point position must be correct for the

new value to be accepted and for modification to occur.

3.3.1 Input Parameters

Parameter Identifier Description

Process Variable

Process Variable Offset

Scale

Range

Max.

Scale

Range

Min.

M Read (Type 2 message) Only; If out of range, {DATA} will

contain <??>0 (over-range) or <??>5 (under-range).

v May be read (Type 2 message) or modified (Type 3/Type 4

message sequence). Modifies actual process variable

value (as measured at the input terminals):

Modified PV value

= Actual PV value + PV offset value

Modified value is limited by Range Maximum and Range

Minimum and is used for display/alarm purposes and for

recorder outputs. Choose this value with care. In effect, it

modifies the Controller’s calibration. Lack of care could

result in the displayed PV value having no meaningful

relationship to the actual PV value.

G Adjustable only on DC inputs. May be read (Type 2

message) or modified (Type 3/Type 4 message sequence).

Decimal point position is as for the input range. If less than

Scale Range Min. Value, sense of input is reversed.

H Adjustable only on DC inputs. May be read (Type 2

message) or modified (Type 3/Type 4 message sequence).

Decimal point position is as for the input range. If greater

than Scale Range Max. Value, sense of input is reversed.

Scale

Range

Decimal

Point

Input Filter Time Constant

O054-3 3-5

Q Adjustable on DC inputs only. May be read (Type 2

message) or modified (Type 3/Type 4 mesage sequence).

Defines the decimal point position:

0 = abcd 1 = abc.d 2 = ab.cd

3 = a.bcd

m May be read or modified using a Type 2 message or a

Type 3/Type 4 message sequence.

Page 32

3.3.2 Output Parameters

Parameter Identifier Description

59125

Power Output value

Output 1 Power Limit

Output 1 Cycle Time

Output 2 Cycle Time

W If Manual Control is not selected, may be read

only (Type 2 message). If Manual Control is

selected, may be read (Type 2 message) or

modified (Type 3/Type 4 message sequence).

B May be read (Type 2 message) or modified (Type

3/Type 4 message sequence). Defines power limit

for Output 1.

N May be read (Type 2 message) or modified (Type

3/Type 4 message sequence). NOTE: Value must

be a power of 2 in the range 0.5 - 512 (i.e. 0.5, 1,

2, 4, 8 etc.). For a Relay Output, cycle time should

be as large as possible (whilst remaining

compatible with the process control requirements)

in order to maximise relay life. For an SSR Output,

the cycle time may have a lower value (and thus

satisfy the requirements of a fast-changing

process variable e.g. flow or pressure).

O May be read (Type 2 message) or modified (Type

3/Type 4 message sequence). NOTE: Value must

be a power of 2 in the range 0.5 - 512 (i.e. 0.5, 1,

2, 4, 8 etc.). For a Relay Output, cycle time should

be as large as possible (whilst remaining

compatible with the process control requirements)

in order to maximise relay life. For an SSR Output,

the cycle time may have a lower value (and thus

satisfy the requirements of a fast-changing

process variable e.g. flow or pressure).

Recorder Output

Scale Max.

[ May be read/modified by a Type 2 message or a

Type 3/Type 4 message sequence. Corresponds to

Input Scale Max. with decimal point position as for

input. If less than Recorder Output Scale Min.

sense of recorder output is reversed.

Recorder Output

Scale Min.

\ May be read/modified by a Type 2 message or a

Type 3/Type 4 message sequence. Corresponds to

Input Scale Min. with decimal point position as for

input. If greater than Recorder Output Scale Max.

sense of recorder output is reversed.

3-6 O054-3

Page 33

59125

3.3.3 Setpoint Parameters

Parameter Identifier Description

Setpoint value

Setpoint Ramp Rate

Setpoint High Limit

Setpoint Low Limit

S May be read (Type 2 message) or modified (Type

3/Type 4 message sequence). Limited by Setpoint High

Limit and Setpoint Low Limit (see below).

^ May be read (Type 2 message) or modified (Type

3/Type 4 message sequence). May be set in the range

1 - 9999 increments/hour or OFF ({DATA} =0000).

Decimal point position is as for input range.

A May be read (Type 2 message) or modified (Type

3/Type 4 message sequence). Defines maximum value

for setpoint (in the range setpoint - Input Range

Maximum). Decimal point position is as for input

range.

T May be read (Type 2 message) or modified (Type

3/Type 4 message sequence). Defines minimum value

for setpoint (in the range Input Range Minimum setpoint). Decimal point position is as for input range.

3.3.4 Alarm Parameters

Parameter Identifier Description

Alarm 1 value C May be read/modified by a Type 2 message or a

Type 3/Type 4 message sequence. Decimal point

position is as for input range.

Alarm 2 value E May be read/modified by a Type 2 message or a

Type 3/Type 4 message sequence. Decimal point

position is as for input range.

For descriptions of the operation of the different alarm types, see Figure 2-3 .

O054-3 3-7

Page 34

3.3.5 Tuning Parameters

Parameter Identifier Description

59125

Rate (Derivative Time Constant)

Reset (Integral Time Constant)

Manual Reset (Bias)

ON/OFF Differential

D May be read/modified using a Type 2 message or a

Type 3/Type 4 message sequence. Defines the

derivative time constant for the control algorithm.

{DATA} is of the form mm.ss where mm = minutes

and ss = seconds. The decimal point position must

specify two decimal places, otherwise modification

will not occur.

I May be read/modified using aType 2 message or a

Type 3/Type 4 message sequence. Defines the

integral time constant for the control algorithm.

{DATA} is of the form mm.ss where mm = minutes

and ss = seconds. The decimal point position must

specify two decimal places, otherwise modification

will not occur.

1

J May be read/modified using a Type 2 message or a

Type 3/Type 4 message sequence. Decimal point

position is as for input range.

F May be read/modified using a Type 2 message or a

Type 3/Type 4 message sequence. Defines the

switching hysteresis for controllers with an ON/OFF

control output. Decimal point position = 1.

Overlap

/Deadband

Proportional Band 1 value

Proportional Band 2 value

K May be read/modified using a Type 2 message or a

Type 3/Type 4 message sequence. May be set to a

positive (overlap) or negative (deadband) value.

Decimal point position = 0.

2

P May be read/modified using a Type 2 message or a

Type 3/Type 4 message sequence. May be set to

0.0 (ON/OFF control) or within the range 0.5% -

999.9% of Output 1 power range. Decimal point

position = 1.

U May be read/modified using a Type 2 message or a

Type 3/Type 4 message sequence. May be set to

0.0 (ON/OFF control) or within the range 0.5% -

999.9% of Output 2 power range. Decimal point

position = 1.

2

3-8 O054-3

Page 35

59125

3.3.6 Status Parameters

Parameter Identifier Description

Controller Status

Arithmetic Deviation

Scan Tables

L Read Only (Type 2 message). Status information is

encoded in four digits as the decimal representation of a

binary number; each bit in the binary number has a

particular significance (see Figure 3-1 ).

V Read Only (Type 2 message). The difference between the

process variable value and the Limit Setpoint value.

] Read Only (Type 2 message). Response:

L{N}xxaaaaabbbbbcccccdddddeeeeeA*

where:

xx = Number of data digits in {DATA}

element (20 for single control output,

25 for dual control outputs)

aaaaa = Current setpoint value

bbbbb = Current process variable value

ccccc = Current value of Output 1 Power

(0 - 100%)

ddddd = Current value of Output 2 Power

(0 - 100%) - if applicable.

eeeee = Controller Status (see Figure 3-1)

3.3.7 Controller Commands

Parameter Identifier Description

Controller Commands

Z Implemented by Type 3/Type 4 message sequence only.

In the Type 3 message, {DATA} must be one of eight

five-digit numbers:

00010 Activate Manual Control

00020 Activate Automatic Control

00030 Activate Self-Tune

00040 De-activate Self-Tune

00050 Request Pre-Tune*

00060 Abort Pre-Tune

00130 Activate Loop Alarm

00140 De-activate Loop Alarm

The response from the Controller also contains the same

{DATA} content, as does the response to the Type 4

message.

O054-3 3-9

Page 36

59125

Figure 3-1 Controller Status Byte

3.4 ERROR RESPONSE

The circumstances under which a message received from the master device is

ignored are:

Parity error detected

Syntax error detected

Timeout elapsed

Receipt of a Type 4 message without a preceding Type 3 command

message.

Negative acknowledgements will be returned if, in spite of the received message

being notionally correct, the Controller cannot supply the requested information

or perform the requested operation. The {DATA} element of a negative

acknowledgement will be indeterminate.

3-10 O054-3

Page 37

59125

Alphabetic Index - Volume 1

A

Alarm 1 Value

Band Alarm 2-3

Deviation Alarm 2-3

Process High Alarm 2-3

Process Low Alarm 2-3

Alarm 2 Value

Band alarm 2-3

Deviation alarm 2-3

Process High alarm 2-3

Process Low alarm 2-3

Alarm Operation

Illustration of2-9

Alarm Status

Display of 1-3

Displaying (Set Up mode)2-4

Auto Pre-Tune Enable/Disable 2-12

H

Hardware Definition Code

Explanation of 1-7

Viewing 1-7

I

Input Filter Time Constant 2-2

Input Over-Range

Indication of 1-4

Input Scale Range

Decimal point position 2-4

Input Scale Range Maximum 2-4

Input Scale Range Minimum 2-4

Input Under-Range

Indication of 1-4

Integral Time Constant (Reset) 2-5

B

Band Alarm 1 2-8

Band Alarm 2 2-10

Bias (Manual Reset) 2-7

C

Communications Line Release Time

Maximum Value 3-1

Communications Message

Format 3-2

D

Deadband 2-5

Decimal Point Position

Input scale range 2-4

Derivative Time Constant (Rate) 2-5

Deviation Alarm 1 2-10

Deviation Alarm 2 2-10

Digital Filter Time Constant 2-3

L

Lock Value 2-12

Loop Alarm 2-10

Loop Alarm Enable 2-10

Loop Alarm Time 2-11

M

Manual Control Mode

De-selection of 1-4

Indication of 1-4

Selection of 1-4

Manual Control Selection

Enable/Disable 2-12

Manual Reset (Bias) 2-7

Manual Tuning

Controllers with Output 1 and

Output 2 2-14

Controllers with

Output 1 only 2-13

O056-IDX 1

Page 38

59125

O

ON/OFF Differential 2-7

Output 1 Cycle Time 2-8

Output 1 Power Limit 2-8

Output 2 Cycle Time 2-8

Output Power 1 2-5

Output Power 2 2-5

Overlap 2-5

P

Pre-Tune Facility

Activation of 1-5

Process High Alarm 1 2-8

Process High Alarm 2 2-10

Process Low Alarm 1 2-8

Process Low Alarm 2 2-10

Process Variable Offset 2-2

Proportional Band 1 2-5

Proportional Band 2 2-5

R

Rate (Derivative Time Constant)2-5

Recorder Output Scale Maximum

2-7

Recorder Output

Scale Minimum 2-7

Reset2-5

Reset (Integral Time Constant) 2-5

End of Message

character 3-2

Error response 3-10

Line turn-round time 3-1

Message Types 3-2

Protocol 3-2

Scan Tables command 3-3

Start of Message

character 3-2

Type 2 message 3-3

Type 3 message 3-4

Type 4 message 3-4

Set Up Mode

Entry into 2-1

Exit from 2-15

Lock code 2-4

Set Up Parameters at default

Indication of 2-2

Setpoint

Adjustment of 1-3

Setpoint Display Strategy

Single Setpoint operation1-2

Setpoint High Limit2-7

Setpoint Low Limit 2-7

Setpoint Ramp Rate

Viewing/adjusting 1-3

Setpoint Ramping

Adjusting the

ramping rate 1-3

Enabling/disabling 2-12

Setpoint Strategy 2-12

Dual Setpoint operation 1-3

S

Scale Range Decimal Point 2-11

Scale Range Maximum 2-12

Scale Range Minimum 2-12

Self-Tune Facility

Activation of 1-6

Sensor Break

Indication of 1-4

Serial Communications

Data Format 3-1

Enabling/disabling2-4, 2-12

2 O056-IDX

Page 39

59125

1

-DIN,

4

1

-DIN &

8

1

1 6

-DIN

TEMPERATURE CONTROLLERS

PRODUCT MANUAL

VOLUME 2

INSTALLATION & CONFIGURATION

INSTRUCTIONS

The procedures described in this Volume must be undertaken only

by technically-competent servicing personnel.

Contents - Volume 2

1 INSTALLATION 1-1

1.1 UNPACKING 1-1

1.2 PANEL-MOUNTING 1-1

1.3 CONNECTIONS AND WIRING 1-4

2 INTERNAL LINKS AND SWITCHES 2-1

2.1 REMOVING THE CONTROLLER FROM ITS HOUSING 2-1

2.2 REMOVING/REPLACING THE OUTPUT 2/OUTPUT 3 OPTION PCBs 2-3

2.3 REMOVING/REPLACING THE RS485 COMMUNICATIONS OPTION PCB

OR DUAL SETPOINT OPTION PCB 2-3

2.4 REPLACING THE CONTROLLER IN ITS HOUSING 2-3

2.5 SELECTION OF INPUT TYPE 2-4

2.6 SELECTION OF OUTPUT 1 TYPE 2-5

2.7 OUTPUT 2 TYPE/OUTPUT 3 TYPE 2-5

3 CONFIGURATION MODE 3-1

3.1 ENTRY INTO CONFIGURATION MODE 3-1

S056-V2 (i)

Page 40

59125

3.2 HARDWARE DEFINITION CODE 3-2

3.3 OPTION SELECTION 3-3

3.4 CONFIGURATION MODE PARAMETERS 3-4

3.5 ALARM HYSTERESIS OUTPUTS 3-8

3.6 EXIT FROM CONFIGURATION MODE 3-9

Appendices

A PRODUCT SPECIFICATION A-1

A.1 UNIVERSAL INPUT A-1

A.2 DUAL SETPOINT SELECTION INPUT (OPTION) A-3

A.3 OUTPUT 1 A-4

A.4 OUTPUT 2 A-5

A.5 OUTPUT 3 A-7

A.6 LOOP CONTROL A-8

A.7 ALARM CONTROL A-9

A.8 PERFORMANCE A-9

A.9 ENVIRONMENTAL A-11

A.10 PHYSICAL A-12

(ii) S056-V2

Page 41

59125

1 INSTALLATION

1.1 UNPACKING

1. Remove the Controller from its packing. The Controller is supplied with a

panel gasket and push-fit fixing strap. Retain the packing for future use,

should it be necessary to transport the Controller to a different site or to

return it to the supplier for repair/testing.

2. Examine the delivered items for damage or deficiencies. If any is found,

notify the carrier immediately.

1.2 PANEL-MOUNTING

The panel on which the Controller is to be mounted must be rigid and may be up

to 6.0mm (0.25 inches) thick. The cut-out required for a single Controller is as

shown in Figure 1 -1 .

Figure 1-1 Cut-out Dimensions

Several controllers may be installed in a single cut-out, side-by-side. For n

Controllers mounted side-by-side, the width of the cut-out would be:

1

-DIN &

16

1

-DIN: (96n - 4) millimetres or (7.56n - 0.16) inches

4

1

-DIN: (48n - 4) millimetres or (3.78n - 0.16) inches

8

The main dimensions of the Controller are shown in Figure 1 -2 .

O054-1 1-1

Page 42

59125

Figure 1-2 Main Dimensions

The procedure to panel-mount the Controller is shown in Figure 1 -3 .

CAUTION: Do not remove the panel gasket, as this may result in inadequate

clamping of the instrument in the panel.

NOTE: The mounting clamp tongues may engage the ratchets either on the

sides of the Controller housing or on the top/bottom faces of the Controller

housing. Therefore, when installing several Controllers side-by-side in one

cut-out, use the ratchets on the top/bottom faces.

1-2 O054-1

Page 43

59125

Figure 1-3 Panel-Mounting the Limit Controller

Once the Controller is installed in its mounting panel, it may be subsequently

removed from its housing, if necessary, as described in Subsection 2.1.

O054-1 1-3

Page 44

1.3 CONNECTIONS AND WIRING

59125

The rear terminal connections are illustrated in Figure 1-4 (

controllers) and Figure 1-5 (

1

-DIN controllers).

16

1

-DIN and

4

1

-DIN

8

Figure 1 -4 Rear Terminals (

1

-DIN &

4

1

-DIN Controllers)

8

1 -4 O054-1

Page 45

59125

Figure 1 -5 Rear Terminals (

1

-DIN Controllers)

16

O054-1 1-5

Page 46

59125

1.3.1 Mains (Line) Input

The Controller will operate on 96 - 264V AC 50/60Hz mains (line) supply. The power

consumption is approximately 4 VA.

CAUTION: This equipment is designed for installation in an enclosure which

provides adequate protection against electric shock. Local regulations

regarding electrical installation should be rigidly observed. Consideration

should be given to prevention of access to the power terminations by

unauthorised personnel. Power should be connected via a two-pole

isolating switch (preferably situated near the equipment) and a 1A fuse, as

shown in Figures 1 -4 and 1 -5 .

If the Controller has relay outputs in which the contacts are to carry mains

(line) voltage, it is recommended that the relay contact mains (line) supply

should be switched and fused in a similar manner but should be separate

from the Controller mains (line) supply.

1.3.2 24V (Nominal) AC/DC Supply

The supply connections for the 24V AC/DC option of the Controller are as shown in

Figures 1-4 and 1 -5 . Power should be connected via a two-pole isolating switch

and a 315mA slow-blow (anti-surge Type T) fuse. With the 24V AC/DC supply option

fitted, these terminals will accept the following supply voltage ranges:

24V (nominal) AC 50/60Hz - 20 - 50V

24V (nominal) DC - 22 - 65V

1.3.3 Thermocouple Input

The correct type of thermocouple extension leadwire or compensating cable

must be used for the entire distance between the Controller and the

thermocouple, ensuring that the correct polarity is observed throughout. Joints in

the cable should be avoided, if possible. The Controller’s CJC facility must be

enabled (normal conditions) for this input (see Page 3-8 ).

NOTE: Do not run thermocouple cables adjacent to power-carrying

conductors. If the wiring is run in a conduit, use a separate conduit for the

thermocouple wiring. If the thermocouple is grounded, this must be done at

one point only. If the thermocouple extension lead is shielded, the shield

must be grounded at one point only.

1.3.4 RTD Inputs

The compensating lead should be connected to Terminal 4 (

Terminal 3 (

1

(

-DIN controllers) or Terminals 2 and 3 (

16

1

-DIN and

4

1

-DIN controllers). For two-wire RTD inputs, Terminals 4 & 5

8

1

-DIN and

4

1

-DIN controllers) should be

8

linked. The extension leads should be of copper and the resistance of the wires

1 - 6 O054-1

1

-DIN controllers) or

16

Page 47

59125

connecting the resistance element should not exceed 5 ohms per lead (the leads

should be of equal resistance).

1.3.5 Linear Inputs

For linear mA input ranges, connection is made to Terminals 4 and 6 (

controllers) or Terminals 4 and 1 (

1

-DIN &

4

1

-DIN controllers) in the polarity shown in

8

16

1

-DIN

Figures 1-4 and 1-5. For linear mV and V ranges, connection is made to Terminals

4 and 5 (

1

-DIN controllers) or Terminals 3 and 2 (

16

1

-DIN &

4

1

-DIN controllers) in the

8

polarity shown in Figures 1-4 and 1-5. For details of the linear input ranges

available, refer to Appendix A.

1.3.6 Dual Setpoint Selection Input

With the Dual Setpoint option fitted, Terminals 11 and 12 (

Terminals 16 and 17 (

1

-DIN &

4

1

-DIN controllers) are used for external selection of

8

the active setpoint. These terminals may be connected to (a) the voltage-free

contacts of a switch or relay, or (b) a TTL-compatible voltage. Setpoint selection is

as follows:

Voltage-Free: Contacts open - Setpoint 1 selected

Contacts closed - Setpoint 2 selected

TTL-compatible: >2.0V - Setpoint 1 selected

<0.8V - Setpoint 2 selected

1

-DIN controllers) or

16

NOTE: The Dual Setpoint option and the RS485 Serial Communications

option are mutually exclusive.

1.3.7 Relay Outputs

The contacts are rated at 2A resistive at 120/240V AC.

1.3.8 SSR Drive Outputs

These outputs produce a time-proportioned non-isolated DC signal (0 - 4.2V

nominal into 1kΩ minimum).

1.3.9 Solid State Outputs

These outputs provide up to 1A AC drive with a longer lifetime than an

electromechanical relay. For further details, refer to Appendix A.

1.3.10 DC Outputs

See Appendix A.

O054-1 1-7

Page 48

59125

1.3.11 RS485 Serial Communications Link

The cable used should be suitable for data transfer at the selected rate (1200,

2400, 4800 or 9600 Baud) over the required distance. Transmitters/receivers

conform to the recommendations in the EIA Standard RS485.

The “A” terminal on the Controller should be connected to the “A” terminal on the

master device; the “B” terminal on the Controller should be connected to the “B”

terminal on the master device. Where several Controllers are connected to one

master port, the master port transceiver in the active state should be capable of

driving a load of 12k Ω per Controller; the master port transceiver in the passive

state must have pull-up/pull-down resistors of sufficiently low impedance to ensure

that it remains in the quiescent state whilst supplying up to

Controller transceivers in the high impedance state.

NOTE: The RS485 Serial Communications option and the Dual

Setpoint option are mutually exclusive.

100µA each to the

±

1-8 O054-1

Page 49

59125

2 INTERNAL LINKS AND SWITCHES

NOTE: The operations described in this Section should be performed only by

personnel trained and authorised to do so.

2.1 REMOVING THE CONTROLLER FROM ITS HOUSING

CAUTION: Before removing the Controller from its housing, ensure that all

power has been removed from the rear terminals.

To withdraw the Controller from its housing, simply grip the side edges of the front

panel (there is a finger grip on each edge) and pull the Controller forwards. This

will release the Controller from its rear connectors in the housing and will give

access to the Controller PCBs. Take note of the orientation of the Controller for

subsequent replacement into the housing.The positions of the PCBs in the

Controller are shown in Figure 2-1.

Figure 2-1 PCB Positions

S054-2 2-1

Page 50

59125

Figure 2-2 Removing the Output 2/Output 3 Option PCBs

2-2 S054-2

Page 51

59125

2.2 REMOVING/ REPLACING THE OUTPUT 2/OUTPUT 3

OPTION PCBs

With the Controller removed from its housing:

1. Gently push the rear ends of the CPU PCB and Power Supply PCB apart

slightly, until the two tongues on each of the Output 2/Output 3 Option PCBs

become dis-engaged - see Figure 2-2B; The Output 2 Option PCB tongues

engage in holes in the Power Supply PCB and the Output 3 Option PCB

tongues engage in holes on the CPU PCB.

2. Carefully pull the required Option PCB (Output 2 or Output 3) from its

connector (Output 2 Option PCB is connected to the CPU PCB and Output 3

Option PCB is connected to the Power Supply PCB) - see Figure 2-2C. Note

the orientation of the PCB in preparation for its replacement.

Adjustments may now be made to the link jumpers on the CPU PCB, the Output

2/Output 3 Option PCBs (if DC output) and (on

1

-DIN Controllers, if fitted) the DC

16

Output 1 PCB. The replacement procedure is a simple reversal of the removal

procedure.

2.3 REMOVING/REPLACING THE RS485

COMMUNICATIONS OPTION PCB OR DUAL SETPOINT

OPTION PCB

This Option PCB is mounted on the inner surface of the Power Supply PCB and can

be removed when the Controller is removed from its housing (see Subsection 2.1 ).

Figure 2 -3 illustrates the removal/replacement procedure. It is not necessary to

remove the Output 2/Output 3 Option PCBs to perform this procedure.

2.4 REPLACING THE CONTROLLER IN ITS HOUSING

To replace the Controller, simply align the CPU PCB and Power Supply PCB with

their guides and connectors in the housing and slowly but firmly push the

Controller into position.

CAUTION: Ensure that the instrument is correctly orientated. A stop will

operate if an attempt is made to insert the instrument in the wrong

orientation (e.g. upside-down). This stop must not be over-ridden.

S054-2 2-3

Page 52

59125

Figure 2-3 Removing the RS485 Communications Option PCB

or the Dual Setpoint Option PCB

2.5 SELECTION OF INPUT TYPE

2.5.1

The selection of input type is

accomplished on link jumpers on the

CPU PCB. The CPU PCB may be either

of two forms: (a) for a relay or SSR

Output 1 (see Figure 2-4) or for a DC

Output 1 (see Figure 2-5). Input type

selection is as shown on the right.

2.5.2

1

-DIN Controllers

16

1

-DIN and

4

1

-DIN

8

Controllers

The selection of input type is

accomplished on link jumpers on the

CPU PCB (see Figure 2-6). Input type

selection is as shown on the right.

Input Type Link Jumpers Fitted

RTD or DC (mV) None (Parked)

Thermocouple LJ3

DC (mA) LJ2

DC (V) LJ1

Input Type Link Jumpers Fitted

RTD or DC (mV) None (Parked)

Thermocouple LJ3

DC (mA) LJ2

DC (V) LJ1

2 -4 S054-2

Page 53

59125

2.6 SELECTION OF OUTPUT 1 TYPE

2.6.1

1

-DIN Controllers

16

The required type of Output 1 is

selected by Link Jumpers LJ4, LJ5,

LJ6 and LJ7 on the Relay/SSR Output

1 CPU PCB (see Figure 2-4) or, on the

DC Output 1 CPU PCB, Link Jumpers

LJ8 and LJ9 (see Figure 2 -5 ). Output

type selection is as shown on the

right.

2.6.2

1

-DIN and

4

1

-DIN

8

Controllers

The required type of Output 1 is

selected by Link Jumpers LJ4, LJ5,

LJ6, LJ7, LJ8 and LJ9 on the PSU PCB

(see Figure 2 -7 ). Output type

selection is as shown on the right.

Output 1 Type Link Jumpers Fitted

Relay or Solid State LJ5 & LJ6

SSR Drive LJ4 & LJ7

DC (0 - 10V) LJ8

DC (0 - 20mA) LJ9

DC (0 - 5V) LJ8

DC (4 - 20mA) LJ9

Output 1 Type Link Jumpers Fitted

Relay or Solid State LJ5 & LJ6

SSR Drive LJ4 & LJ7

DC (0 - 10V) LJ8

DC (0 - 20mA) LJ9

DC (0 - 5V) LJ8

DC (4 - 20mA) LJ9

2.7 OUTPUT 2 TYPE/ OUTPUT 3 TYPE

The type of output for Output 2 and Output 3 is determined by the Option PCB

fitted in the appropriate position (see Figure 2 -1 ). There are four types of option

PCB which may be used for Output 2 and Output 3:

1. Relay Output Option PCB (no link jumpers)

2. Solid State Output Option PCB (no link jumpers)

3. SSR Output Option PCB (no link jumpers)

4. DC Output Option PCB (link jumpers as shown in Figure 2-8)

In the case of the DC Output Option

PCB being fitted, DC output range is

selected using link jumpers LJ8 and

LJ9, as shown on the right.

DC Output Range Link Jumpers Fitted

DC (0 - 10V) LJ8

DC (0 - 20mA) LJ9

DC (0 - 5V) LJ8

DC (4 - 20mA) LJ9

S054-2 2-5

Page 54

59125

Figure 2-4 CPU PCB (Relay/SSR Drive/Solid State Output 1) -

Figure 2 -5 CPU PCB (DC Output 1) -

1

-DIN Controllers

16

1

-DIN Controllers

16

2 -6 S054-2

Page 55

59125

Figure 2 -6 CPU PCB -

1

-DIN &

4

1

-DIN Controllers

8

Figure 2 -7 PSU PCB -

1

-DIN &

4

1

-DIN Controllers

8

S054-2 2-7

Page 56

59125

Figure 2 -8 DC Output Option PCB PCB (Output 2/Output 3)

2 -8 S054-2

Page 57

59125

3 CONFIGURATION MODE

3.1 ENTRY INTO CONFIGURATION MODE

See Figure 3 -1 .

Figure 3 -1 Entry into Configuration Mode

NOTE: Changes to the value/setting of certain Configuration Mode

parameters (e.g. input range, output use and type) will cause the Set Up

Mode parameters to be automatically set to their default values the next

time Set Up Mode is entered (see also Volume 1, beginning of Section 2 ).

S054-3 3-1

Page 58

3.2 H ARDWARE DEFINITION CODE

This parameter is a special facility in Configuration Mode, which is used to

represent the hardware fitted (input type, Output 1 type, Output 2 type and

Output 3 type); this must be compatible with the hardware actually fitted. For

access to, and adjustment of, the Hardware Definition Code, see Figure 3-2.

59125

Figure 3-2 Hardware Definition Code - Access and Adjustment

3-2 S054-3

Page 59

59125

Table 3 -1 Hardware Definition Code - Input/Output Type Selection

Value 0 1 2 3 4 5 7 8

Input RTD/

Linear

Thermocouple

Linear

DC mA

Linear

DC V

DC mV

Output

1

Output

2/3

Not

fitted

Relay SSR

Drive

Relay SSR

Drive

DC

0 - 10VDC0 - 20mADC0 - 5VDC4 - 20mA

DC

0 - 10VDC0 - 2-mADC0 - 5VDC4 - 20mA

Solid

State

Solid

State

NOTES: 1. If Output 2 is set to be a relay/SSR drive/solid state

output, it may be a control output (COOL) or an

alarm output; if it is set to be a DC output, it can only

be a control output (COOL).

2. If Output 3 is set to be a relay/SSR drive/solid state

output, it can only be an alarm output; if it is set to

be a DC output, it can only be a recorder (i.e.

re-transmitted process variable or setpoint) output.

The maximum setting available for this code is 4888. For example, the code for a

thermocouple input, DC 4 - 20mA primary output (Output 1) and relay Output 3

would be 2701.

NOTE: It is essential that this code is changed promptly whenever there is a

change to the Controller’s hardware configuration (change of input/output

type, alarm/recorder output added/removed etc.). The Controller software

depends upon this code to ensure that the Controller operates correctly.

This code may be viewed as a Read Only display in Operator Mode (see Volume

1, Subsection 1.10).

3.3 OPTION SELECTION

This indicates the option fitted (Communications Option, Dual Setpoint Option no

option at all). It is accessed whilst the Hardware Definition Code is displayed (see

Figure 3-3 ).

S054-3 3-3

Page 60

59125

Figure 3 -3 Option Selection

3.4 CONFIGURATION MODE PARAMETERS

Parameter Identifier Description

Input Range

Output 1 Action

Alarm 1 Type

A four-digit code (see Appendix A). Default settings:

Thermocouple - 1419 (Type J, 0 - 761 °C)

RTD/Linear mV - 7220 (RTD Pt100 0 - 800°C)

Linear mA - 3414 (4 - 20mA)

Linear V - 4446 (0 - 10V)

Reverse-acting

Direct-acting

Process High Alarm

Process Low Alarm

Deviation Alarm

Band Alarm

No alarm

3-4 S054-3

Page 61

59125

Parameter Identifier Description

Alarm 2 Type

Alarm Inhibit

Process High Alarm

Process Low Alarm (default)

Deviation Alarm

Band Alarm

No alarm

No alarms inhibited

Alarm 1 inhibited

Alarm 2 inhibited

Both Alarm 1 & Alarm 2 inhibited

S054-3 3-5

Page 62

Parameter Identifier Description

59125

Output 2 Usage

Output 2 secondary control (COOL) output

Alarm 2 hardware output, direct-acting. Available only if relay/SSR drive/solid state output.

Alarm 2 hardware output, reverse-acting. Available only if relay, SSR drive or solid state output.

Direct-acting output for Logical OR of Alarm 1

and Alarm 2. Available only if relay, SSR drive,

or solid state output.

Reverse-acting output for Logical OR of Alarm 1

and Alarm 2. Available only if relay, SSR drive,

or solid state output.

Direct-acting output for Logical AND of Alarm 1

and Alarm 2. Available only if relay, SSR drive,

or solid state output.

Reverse-acting output for Logical AND of Alarm

1 and Alarm 2. Available only if relay, SSR drive,

or solid state output.

Loop Alarm output, direct-acting. Available only

if relay, SSR drive or solid state output.

Loop Alarm output, reverse-acting. Available

only if relay, SSR drive or solid state output.

Alarm Hysteresis output, direct-acting. Available

only if relay, SSR drive or solid state output.

Alarm Hysteresis output, reverse-acting.

Available only if relay, SSR drive or solid state

output.

Example of Logical Combination of Alarms - Logical OR of Alarm 1 & Alarm 2

Direct-acting Reverse-acting

AL1 OFF, AL2 OFF: Relay de-energised AL1 OFF, AL2 OFF: Relay energised

AL1 ON, AL2 OFF: Relay energised AL1 ON, AL2 OFF: Relay de-energised

AL1 OFF, AL2 ON: Relay energised AL1 OFF, AL2 ON: Relay de-energised

AL1 ON, AL2 ON: Relay energised AL1 ON, AL2 ON: Relay de-energised

3-6 S054-3

Page 63

59125

Parameter Identifier Description

Output 3 Usage

Alarm 1 hardware output, direct-acting. Available only if relay/SSR drive/solid state output.

Alarm 1 hardware output, reverse-acting. Available only if relay, SSR drive or solid state output.

Direct-acting output for Logical OR of Alarm 1

and Alarm 2. Available only if relay, SSR drive,

or solid state output.

Reverse-acting output for Logical OR of Alarm 1

and Alarm 2. Available only if relay, SSR drive,

or solid state output.

Direct-acting output for Logical AND of Alarm 1

and Alarm 2. Available only if relay, SSR drive,

or solid state output.

Reverse-acting output for Logical AND of Alarm

1 and Alarm 2. Available only if relay, SSR drive,

or solid state output.

Loop Alarm output, direct-acting. Available only

if relay, SSR drive or solid state output.

Loop Alarm output, reverse-acting. Available

only if relay, SSR drive or solid state output.

Alarm Hysteresis output, direct-acting. Available

only if relay, SSR drive or solid state output.

Alarm Hysteresis output, reverse-acting.

Available only if relay, SSR drive or solid state

output.

Recorder Output - Setpoint (DC output only)

Recorder Output - Process Variable

(DC Output only)

Example of Logical Combination of Alarms - Logical AND of Alarm 1 & Alarm 2

Direct-acting Reverse-acting

AL1 OFF, AL2 OFF: Relay de-energised AL1 OFF, AL2 OFF: Relay energised

AL1 ON, AL2 OFF: Relay de-energised AL1 ON, AL2 OFF: Relay energised

AL1 OFF, AL2 ON: Relay de-energised AL1 OFF, AL2 ON: Relay energised

AL1 ON, AL2 ON: Relay energised AL1 ON, AL2 ON: Relay de-energised

S054-3 3-7

Page 64

Parameter Identifier Description

59125

Comms. Baud

Selectable: 1200, 2400, 4800, 9600 Baud

Rate

Comms. Address Unique address assigned to the controller;

in the range 1 - 32.

Cold Junction

Enabled (default)

Compensation

Enable/Disable*

Disabled

Lock Code Read Only display of current four-digit Set Up

Mode Lock Code.

3.5 ALARM HYSTERESIS OUTPUTS

An alarm hysteresis output is active only when both alarms are active; it becomes

subsequently inactive only when both alarms become inactive. Thus, the status of

the Alarm Hysteresis output when one alarm is active and the other is inactive

depends upon the alarm status immediately prior to that alarm being activated;

thus, with two process high alarms:

3 -8 S054-3

Page 65

59125

3.6 EXIT FROM CONFIGURATION MODE

NOTE: An automatic exit to Operator

Mode will be made if, in Configuration

Mode, there is no front panel key

activity for two minutes.