Page 1

1

-DIN

8

DUAL COLOUR DISPLAY

TEMPERATURE INDICATOR

Product Manual

59135-2

Page 2

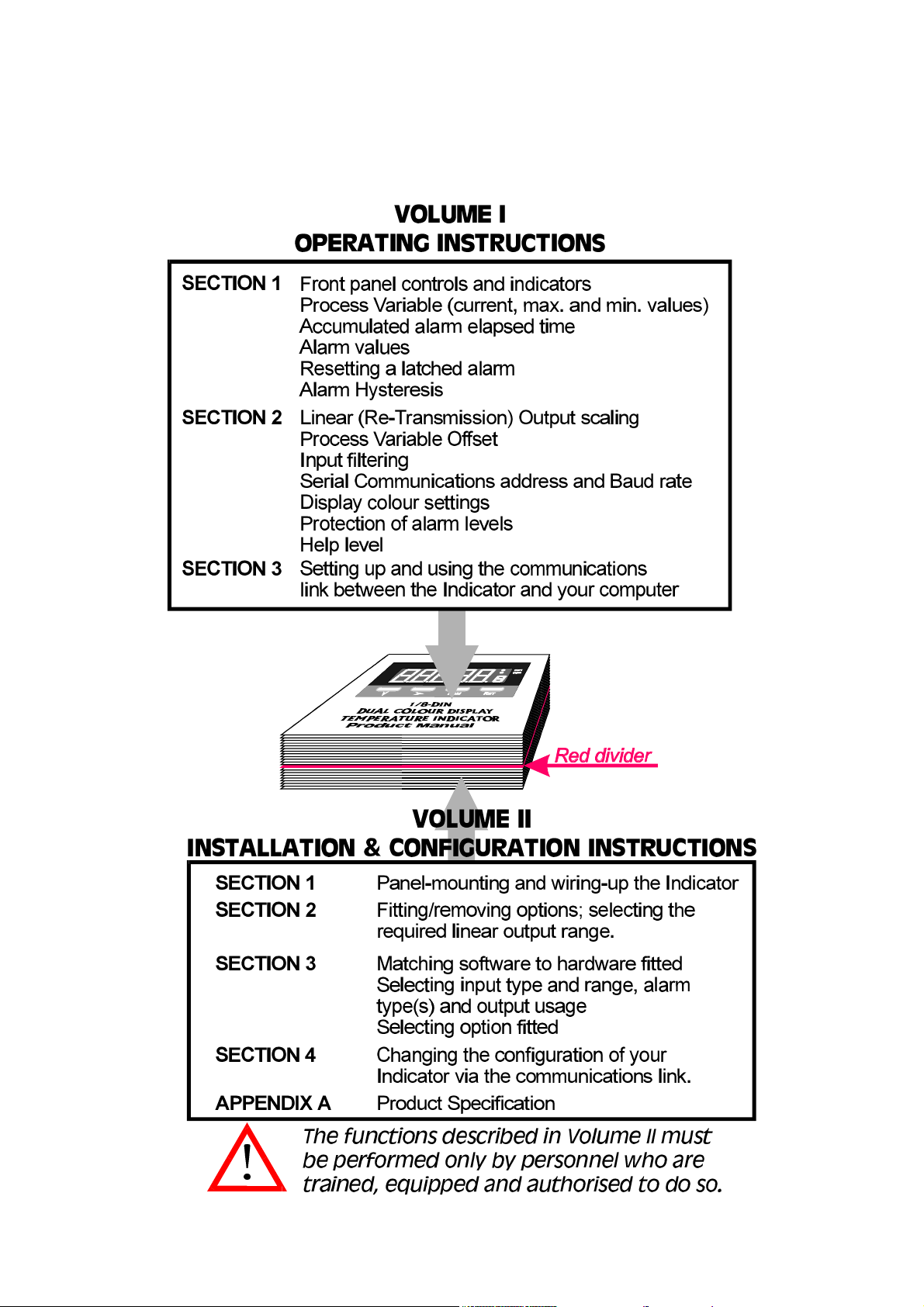

HOW TO USE THIS MANUAL

This manual comprises two volumes:

Page 3

59135

1

-DIN DUAL COLOUR DISPLAY

8

TEMPERATURE INDICATOR

Product Manual

Contents - Volume I

1 OPERATION MODE 1-1

1.1 FRONT PANEL 1-1

1.2 PARAMETER SEQUENCE 1-2

1.3 INPUT OVER-RANGE OR UNDER-RANGE 1-3

1.4 SENSOR BREAK 1-3

1.5 CHANGING AN ALARM VALUE 1-3

1.6 RESETTING A LATCHED ALARM 1-4

1.7 ALARM HYSTERESIS 1-4

1.8 SUMMARY OF PARAMETER IDENTIFIERS (SECONDARY DISPLAY) 1-4

2 PROGRAM MODE 2-1

2.1 ENTRY/EXIT 2-1

2.2 PARAMETER SELECTION 2-1

2.3 EDITING THE DISPLAYED PARAMETER (EDIT MODE) 2-2

2.4 PARAMETER SEQUENCE 2-3

3 SERIAL COMMUNICATIONS 3-1

3.1 DATA FORMAT/BAUD RATE 3-1

3.2 PROTOCOL 3-1

3.3 MESSAGE FORMAT 3-1

3.4 ERROR CONDITIONS 3-4

OM090-FM Volume I (iii)

Page 4

1 OPERATION MODE

This mode covers day-to-day operation of the Indicator.

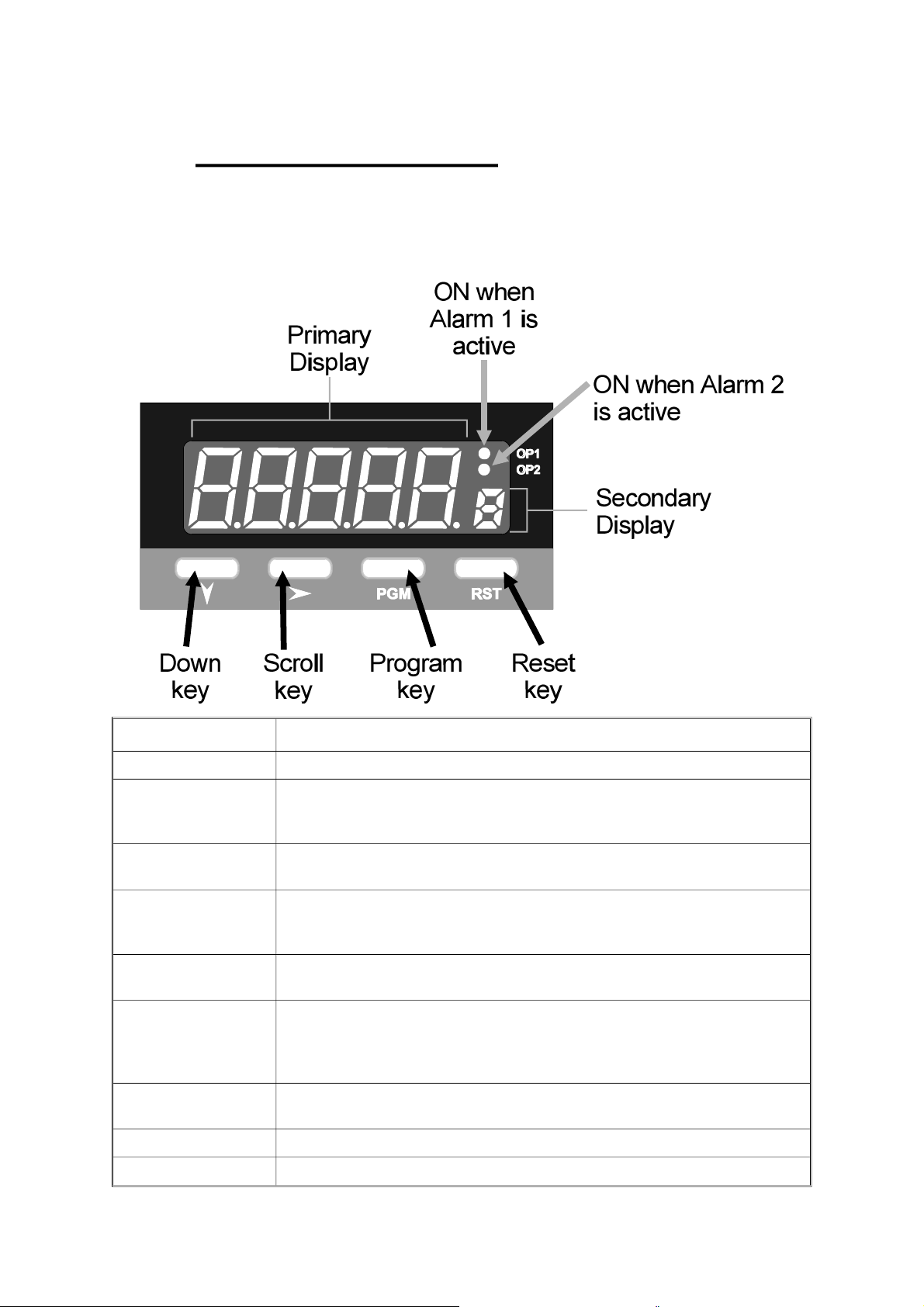

1.1 FRONT PANEL

59135

Key/Display/Indicator Function

Down key (Ú ) In Edit Mode, decrements the flashing digit in the Primary Display.

Scroll key (Ø ) Puts Indicator into Edit Mode; in Edit Mode, selects digit to be altered

(selected digit is flashing) in Primary Display. Wrap-around occurs from

right-most digit to left-most digit.

Program Key (PGM ) Selects parameter to be viewed/edited. In Edit Mode, confirms changed

parameter value.

Reset key (RST ) If the process variable is displayed, resets the latched Alarm 1. If the

Maximum (High) Value, Minimum (Low) Value or Alarm 1 Elapsed Time is

displayed, resets the displayed parameter.

Down (Ú ) and Scroll

(Ø ) keys

Primary Display Normally displays the process variable value. Displays other Operation

Secondary Display Shows a single-character identifier for the parameter value being

OP1 indicator ON when Alarm 1 is active.

OP2 indicator ON when Alarm 2 is active.

If pressed simultaneously in Edit Mode, will abort the Edit operation and

will restore the parameter to its initial value.

Mode parameters when the Program (PGM) key is used. If the Help

Facility is enabled (see Subsection 2.4), this display shows the parameter

description for three seconds before displaying the parameter value.

displayed (blank for process variable).

1-1 Volume I OM090-1

Page 5

59135

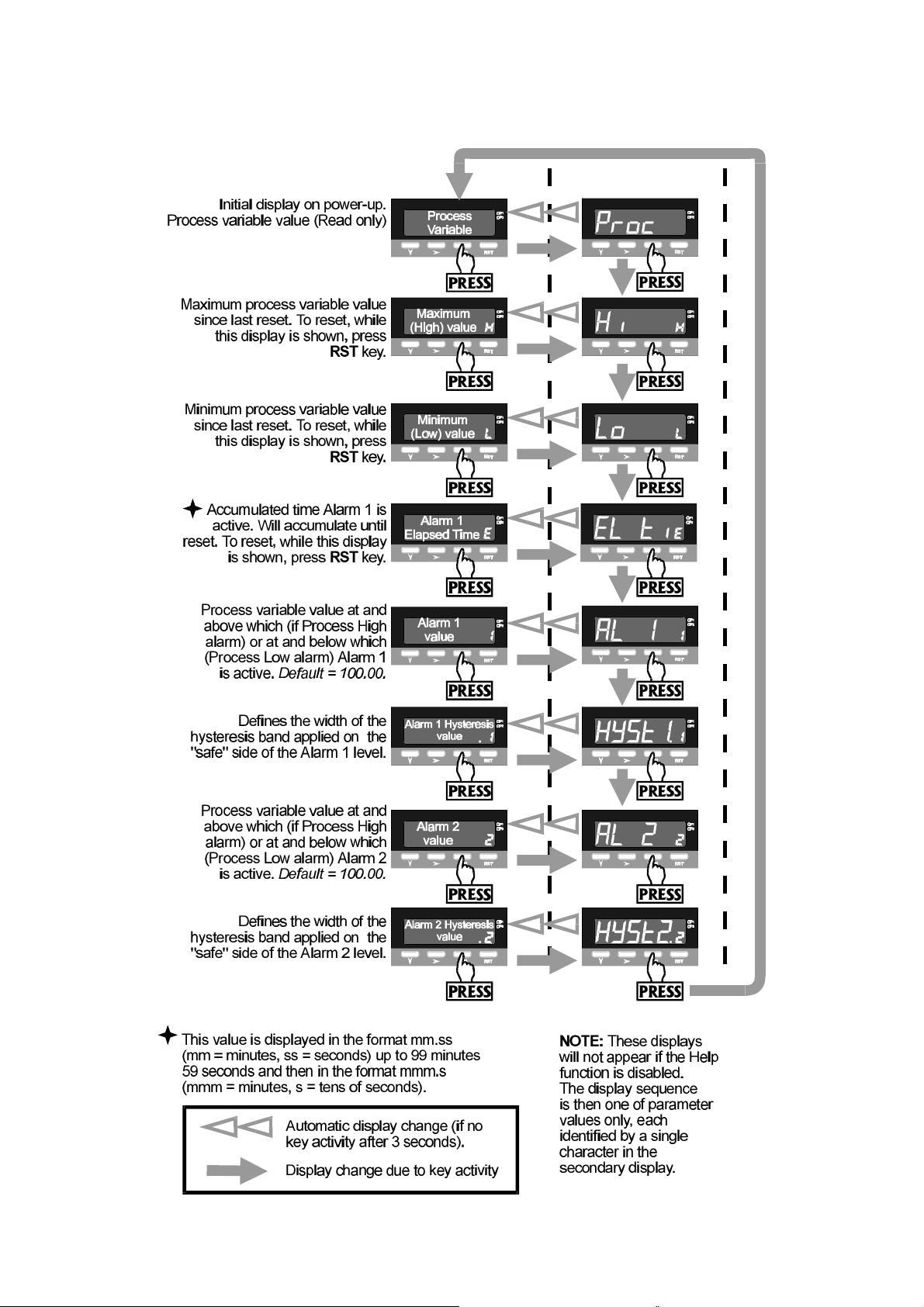

1.2 PARAMETER SEQUENCE

OM090-1 Volume I 1-2

Page 6

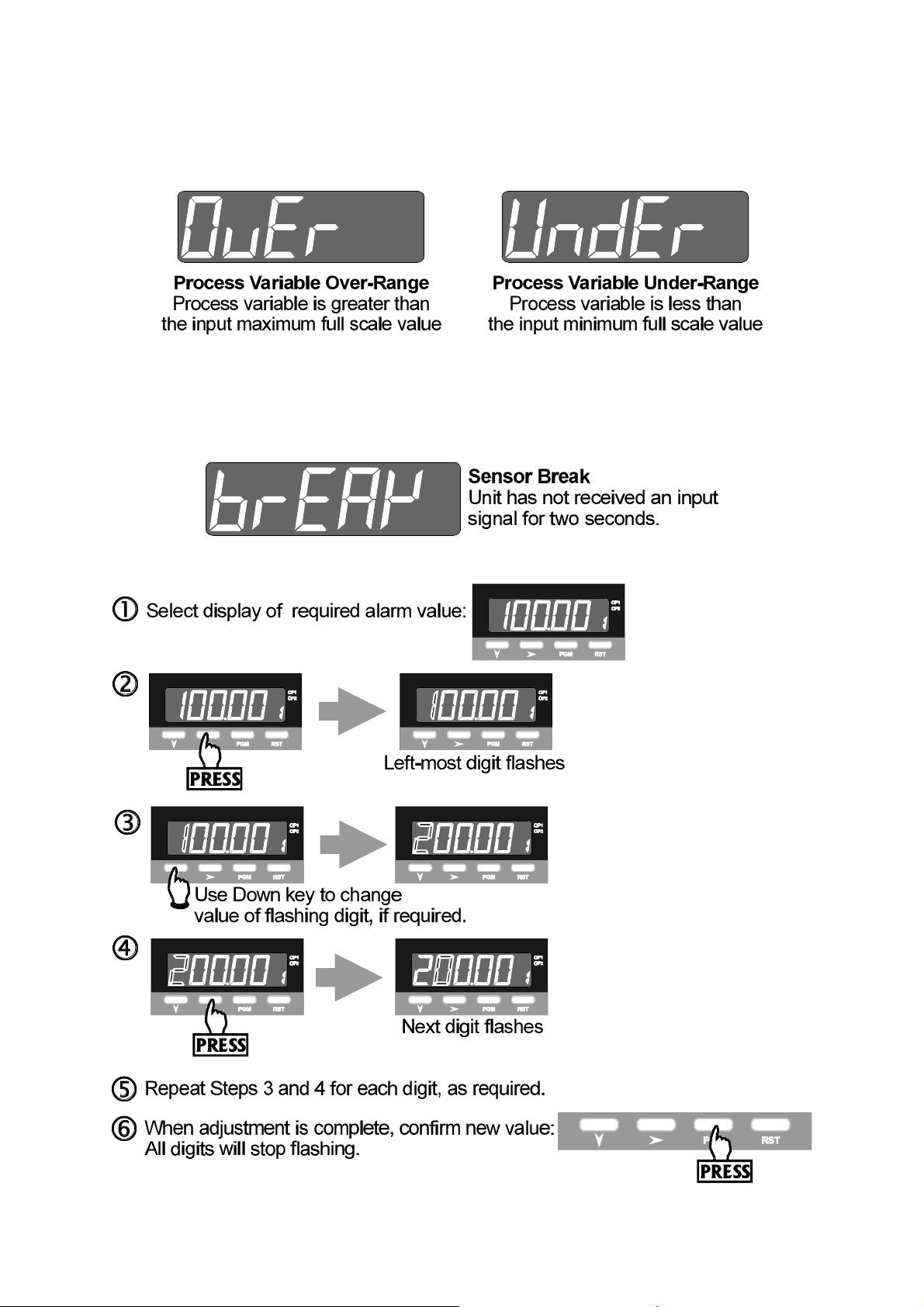

1.3 INPUT OVER-RANGE OR UNDER-RANGE

If the input becomes over-range or under-range, the primary display will show:

The display will disappear when the input returns within the input scale range.

1.4 SENSOR BREAK

This indicates that there is a break in the input sensor circuit.

59135

1.5 CHANGING AN ALARM VALUE

1-3 Volume I OM090-1

Page 7

59135

1.6 RESETTING A LATCHED ALARM

If Relay 1 is configured to act as a latched Alarm 1 relay, when this alarm is

active, it can be reset by selecting the process variable display and then pressing

the Reset (RST) key. The alarm will not be reset if the alarm condition exists at the

time reset is attempted.

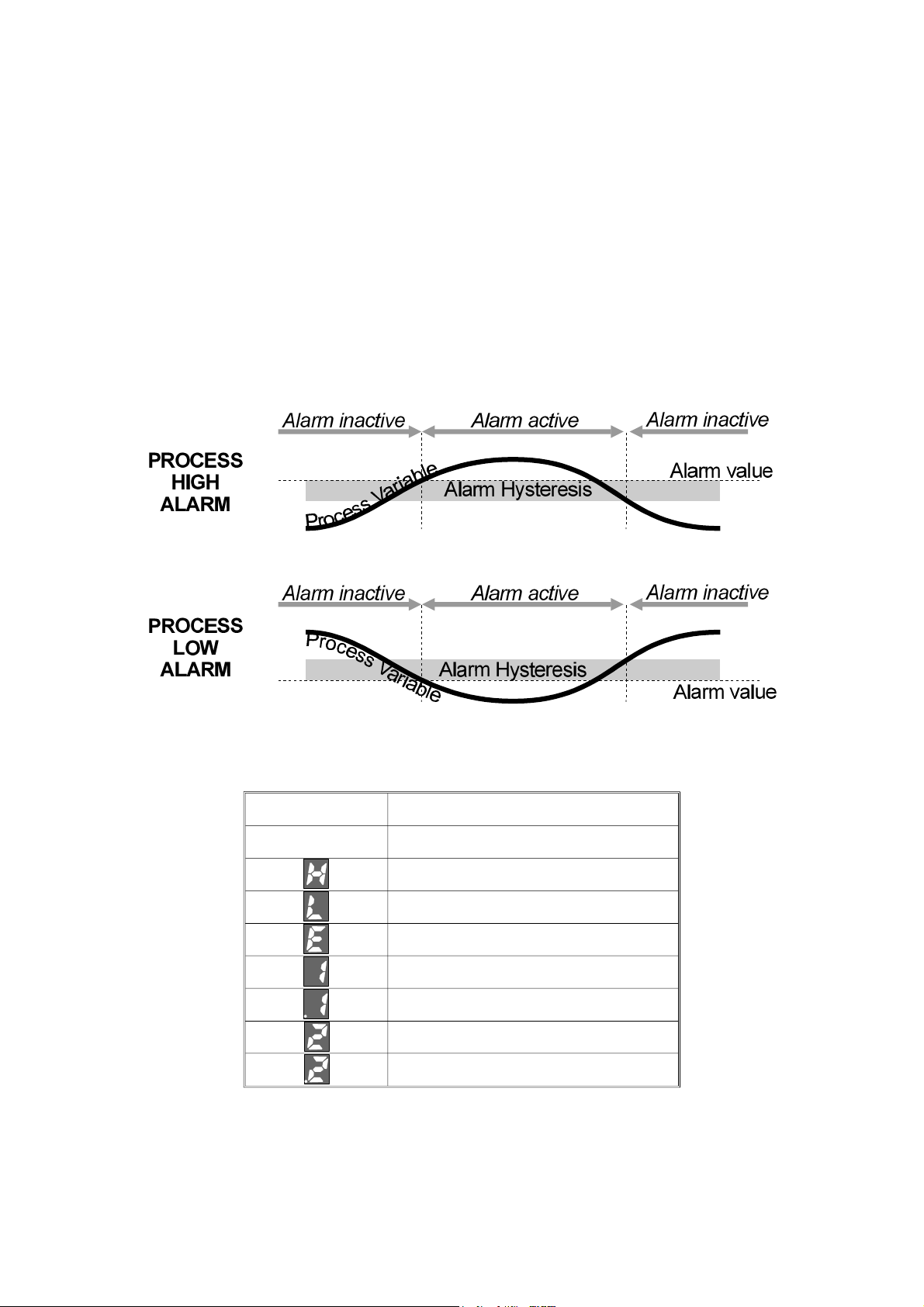

1.7 ALARM HYSTERESIS

The Alarm Hysteresis parameter applies a hysteresis band on the “safe” side of the

Alarm value. The effect of the hysteresis value (a percentage of input span) on the

operation of the different types of alarm is illustrated below:

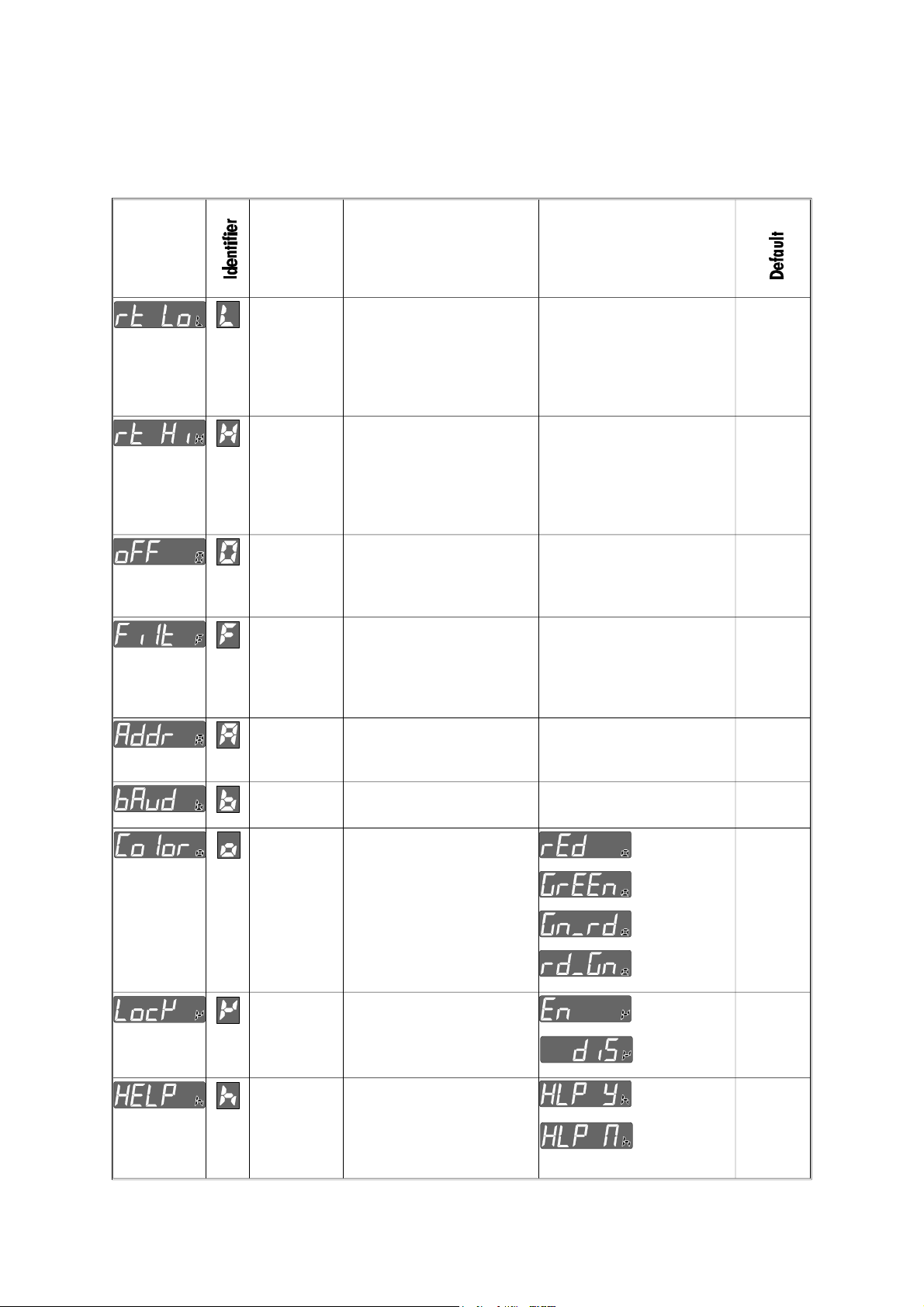

1.8 SUMMARY OF PARAMETER IDENTIFIERS (SECONDARY DISPLAY)

Secondary Display Displayed Parameter

Blank Process variable

Maximum (High) value

Minimum (Low) value

Alarm 1 Elapsed Time

Alarm 1 value

Alarm 1 Hysteresis value

Alarm 2 value

Alarm 2 Hysteresis value

OM090-1 Volume I 1-4

Page 8

59135

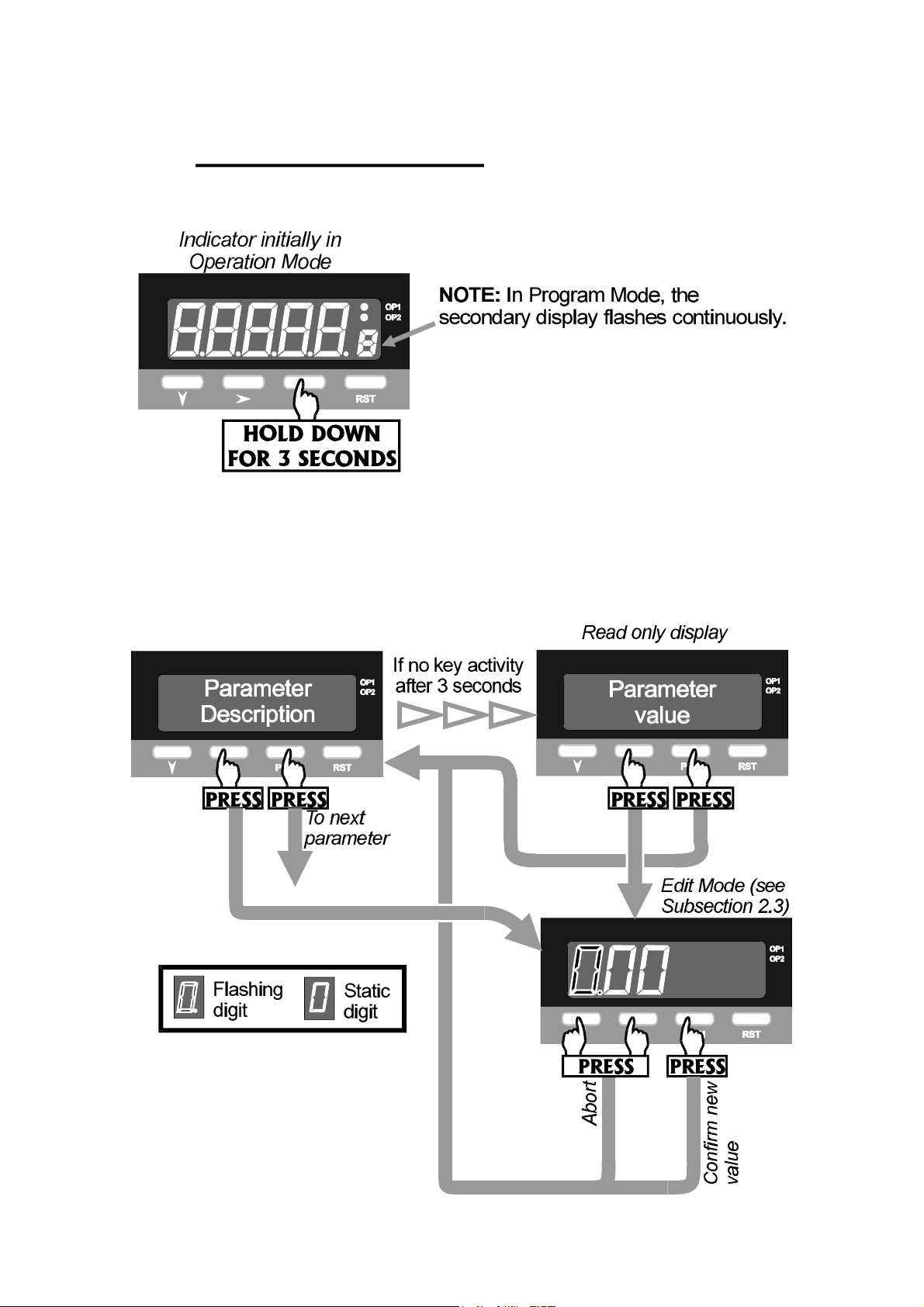

2 PROGRAM MODE

2.1 ENTRY/EXIT

Use the Program (PGM) key in the same way to exit Program Mode (i.e. return to

Operation Mode).

2.2 PARAMETER SELECTION

2.2.1 With Help Facility Enabled

2-1 Volume I OM090-2

Page 9

59135

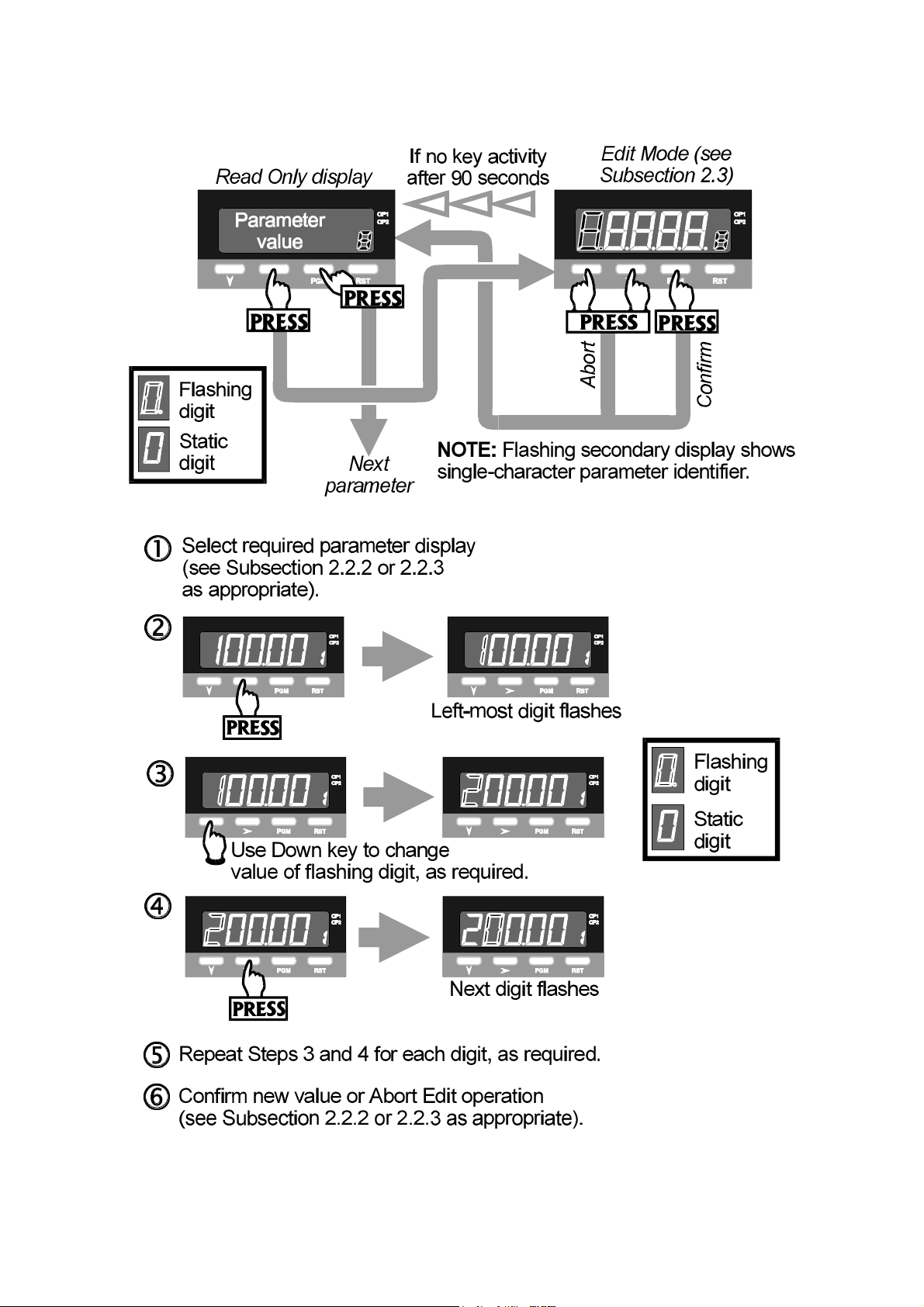

2.2.2 With Help Facility Disabled

2.3 EDITING THE DISPLAYED PARAMETER (EDIT MODE)

OM090-2 Volume I 2-2

Page 10

2.4 PARAMETER SEQUENCE

The Program Mode parameter sequence is as follows:

Parameter

Description

(Primary

Display)

Parameter Description Adjustment Range

59135

Retransmission

Scale

Minimum

Retransmission

Scale

Maximum

Process

Variable

Offset

Input Filter

Time

Constant

Communications

Address

The lower end of the linear

scale for the

re-transmission output,

expressed as the value

corresponding to the

minimum output signal.

The upper end of the

linear scale for the

re-transmission output,

expressed as the value

corresponding to the

maximum output signal.

Corrects a known offset of

the input in order to

display more accurately

the process value.

Filters the input over a

user-definable time period

to minimise the effect on

the process variable of

any extraneous impulses

The unique serial

communications address

of the instrument.

−19999 to 99999 −19999

−19999 to 99999

− 19999 to 99999

0.0 (OFF) to 100.0 2.0

1 to 99 1

99999

0.00

Baud Rate Serial communications

speed

Display

Colour

Change

Alarm Lock Enables/disables the

Help Prompt Determines whether the

Defines the colour of the

primary and secondary

displays prior to/after the

preset value (e.g. Alarm

level) is reached.

changing of alarm values

via the front panel.

Primary Display shows the

parameter description for

3 seconds before a

parameter value is shown.

1200, 2400, 4800 or 9600 4800

Red

Green

Green

to Red

Red to

Green

Enabled

Disabled

Yes

No

Green to

Red

Enabled

Yes

2 -3 Volume I OM090-2

Page 11

59135

3 SERIAL COMMUNICATIONS

The Serial Communications option is a standard RS485 communications link. Up to

32 standard RS485 loads may be presented to a single loop on this link. Each

Indicator presents ¼ standard, therefore up to 128 may be connected to a single

loop (ignoring the load presented by the master device). However, addresses are

restricted to the range 1 to 99.

3.1 DATA FORMAT/BAUD RATE

Data format is fixed at one start bit, seven data bits, 1 parity bit (even parity) and

1 stop bit i.e. a 10-bit data word. Baud rates supported are 1200, 2400, 4800 and

9600. The half-duplez line turn-round time is fixed at 6ms regardless of Baud rate.

The maximum inter-character delay is 120ms. The No Reply timeout is 2 seconds.

Data is expressed as a five-digit signed hexadecimal number in which the

following characters are permitted:

0 1 2 3 4 5 6 7 8 9 A B C D E F

Note that all the non-numeric characters are upper case. The detection of any

characters other than these will be regarded as a syntax error. Where a value

carries a decimal point, the point position is implicit and the responsibility for

interpreting it lies with the user.

3.2 PROTOCOL

The protocol operates on a single master basis only. All communication is initiated

by the master device.

The communications addresses available are in the range 1 - 99. Address 0 is

used for broadcast Parameter Write operation messages. When a message is

broadcast, the receiving instruments will attempt to implement the instruction but

will not reply.

3.3 MESSAGE FORMAT

Each message starts with a Start of Message character (L) and finishes with an End

of Message character (*). A reply from the addressed instrument will contain either

a positive acknowledgement or a negative acknowledgement. A positive

acknowledgement has the character A immediately preceding the End of

Message character; a negative acknowledgement has the character N

immediately preceding the End of Message character.

There are three message formats; they permit instrument identification, Parameter

Read operations and Parameter Write operations.

OM090-3 Volume I 3-1

Page 12

59135

3.3.1 Form 1 Message

The master device sends a Form 1 message to ascertain whether a specific

communications address is occupied by an instrument. If there is an instrument at

that address, a reply (with a positive acknowledgement) is received. If there is no

instrument at that address or if there is a communications link failure, no reply is

received. The message from the master device is of the form:

Laa??*

where aa is the address (a two-digit hexadecimal number). The reply from the

addressed instrument is of the form:

Laa?A*

where aa is the same address as in the received message.

3.3.2 Form 2 Message

This message implements a Parameter Read operation. The message from the

master device is of the form:

Laap?*

where aa is the address (a two-digit hexadecimal number)

p is a single-character parameter identifier (see Table 3-1)

The reply, if the Parameter Read operation is successful, is of the form:

LaapnnnnnA*

where aa is the same address as in the received message

p is a single-character parameter identifier (see Table 3-1)

nnnnn is the data (a five-digit hexadecimal number)

If the specified parameter is invalid (e.g. not applicable to the addressed

instrument), the reply is of the form:

Laap00000A*

where aa is the same address as in the received message

p is a single-character parameter identifier (see Table 3-1)

3-2 Volume I OM090-3

Page 13

59135

3.3.3 Form 3 Message

This message implements the Parameter Write operation either on a single

addressed instrument (address in the range 1 - 99) or broadcast to all instruments

connected to the master device (i.e. using address 00). Note that, with the

broadcast message, each slave instrument does not generate a reply. The

message from the master device is of the form:

Laapnnnnn*

where aa is the address (a two-digit hexadecimal number)

p is a single-character parameter identifier (see Table 3-1)

nnnnn is the value to be written (a five-digit hexadecimal

number)

The reply for a successful Parameter Write operation is of the form:

LaapnnnnnA*

where aa is the same address as in the received message

p is a single-character parameter identifier (see Table 3-1)

nnnnn is the value written (a five-digit hexadecimal number). In

cases in which this parameter does not exist or is not

applicable for the slave instrument, this value is 00000.

Iif a valid parameter is specified with an invalid value or an error condition is

encountered, the reply is of the form:

LaapnnnnnN*

where aa is the same address as in the received message

p is a single-character parameter identifier (see Table 3-1)

nnnnn indicates the error condition:

Value Error Condition

FFFFF Value under-range

7FFFF Value over-range

7FFFE Sensor Break detected

00001 Read Only parameter

00000 Illegal value

OM090-3 Volume I 3-3

Page 14

Table 3 -1 Parameter Identifiers and Adjustment Ranges

Identifier Hex. Parameter Adjustment Range

59135

: 3A Process Variable

< 3C Maximum Process Variable

= 3D Minimum Process Variable

Read Only (−19999 to 9999)

Read Only (−19999 to 9999)

Read Only (−19999 to 9999)

> 3E Elapsed Alarm 1 Time Read Only (0 to 60000)

@ 40 Reset Max. PV Write resets; Read always 0

A 41 Reset Min. PV Write resets; Read always 0

B 42 Reset Elapsed Alarm 1 Time Write resets; Read always 0

D 44 Reset Latched Alarm 1 Write resets; Read always 0

E 45 Alarm 1 value Range Max. To Range Min.

F 46 Alarm 2 value Range Max. To Range Min.

] 5D Re-transmitted Scale Min.

−19999 to Re-trans. Scale Max.

^ 5E Re-transmitted Scale Max. Re-trans. Scale Min. To 99999

_ 5F Process Variable Offset 0 to Range Span

‘ 60 Input Filter 0 to 1000 (0.0 to 100.0s)

a 61 Colour 0 to 3 (0 = Red, 1 = Green,

2 = Green/Red, 3 = Red/Green)

b 62 Alarm Lock 0 (lock enabled), 1 (lock disabled)

c 63 Help level 0 (Help enabled), 1 (Help disabled)

3.4 ERROR CONDITIONS

If a slave device detects a syntax error or parity error, it will not reply to the

message; the master device should make up to two retries, applying the

two-second No Reply timeout in each case.

Parameter Read operations with parameter identifiers which are in the legal

range but which are not applicable to the addressed instrument will have no

effect on any parameter values and a positive acknowledgement will be

returned.

Parameter Write operations with parameter identifiers which are outside the legal

range will be considered to be syntax errors; no reply will be generated.

Parameter Write operations in which the specified parameter is valid but the

specified value is invalid will generated a negative acknowledgement.

3 -4 Volume I OM090-3

Page 15

59135

1

-DIN DUAL COLOUR DISPLAY

8

TEMPERATURE INDICATOR

Product Manual

Contents - Volume II

The procedures described in this Volume must be undertaken only by

technically-competent servicing personnel.

1 INSTALLATION 1-1

1.1 UNPACKING 1-1

1.2 PANEL-MOUNTING 1-1

1.3 CONNECTIONS AND WIRING 1-3

2 INTERNAL LINKS AND SWITCHES 2-1

2.1 REMOVING THE INDICATOR FROM ITS HOUSING 2-1

2.2 REMOVING/REPLACING THE RELAY 2/LINEAR OUTPUT OPTION PCBs 2-3

2.3 REMOVING/REPLACING THE RS485 SERIAL COMMUNICATIONS

OPTION PCB/DIGITAL INPUT OPTION PCB 2-3

2.4 REPLACING THE INSTRUMENT IN ITS HOUSING 2-4

2.5 SELECTION OF LINEAR (RE-TRANSMISSION) OUTPUT RANGE 2-4

3 CONFIGURATION MODE 3-1

3.1 ENTRY/EXIT 3-1

3.2 PARAMETER SELECTION 3-1

3.3 EDITING THE DISPLAYED PARAMETER 3-2

3.4 PARAMETER SEQUENCE 3-3

4 SERIAL COMMUNICATIONS - CONFIGURATION MODE 4-1

PM090-FM Volume II (i)

Page 16

59135

Appendices

A PRODUCT SPECIFICATION A-1

A.1 DISPLAY A-1

A.2 SENSOR INPUT A-1

A.3 DIGITAL INPUT (OPTION) A-3

A.4 TRANSISTOR OUTPUTS A-3

A.5 RELAY 1 OUTPUT A-3

A.6 RELAY 2 OUTPUT (OPTION) A-4

A.7 LINEAR (RE-TRANSMITTED PV) OUTPUT (OPTION) A-4

A.8 SERIAL COMMUNICATIONS (OPTION) A-4

A.9 PERFORMANCE A-5

A.10 ENVIRONMENTAL A-7

A.11 PHYSICAL A-7

(ii) Volume II PM090-FM

Page 17

59135

1 INSTALLATION

1.1 UNPACKING

1. Remove the Indicator from its packing. The indicator is supplied with a

panel gasket and push-fit fixing strap. Retain the packing for future use.

2. Examine the delivered items for damage or deficiencies. If any is found,

notify the carrier immediately.

1.2 PANEL-MOUNTING

The panel on which the Indicator is to be

mounted must be rigid and may be up to

6mm (0.25 inches) thick. The cut-out

required for a single Indicator is shown in

Figure 1-1. Several indicators may be

mounted side-by-side in a single cut-out.

For n Indicators mounted side-by-side,

the cut-out dimensions would be (48n - 4)

millimetres or (1.89n - 0.16) inches. The

main dimensions of the Indicator are

shown in Figure 1 -2 .

Figure 1-1 Panel Cut-out

Figure 1-2 Main Dimensions

The panel-mounting procedure is shown in Figure 1 -3 .

CAUTION: Do not remove the panel gasket, as this may result in

inadequate clamping of the instrument in the panel.

PM090-1 Volume II 1-1

Page 18

59135

Figure 1-3 Panel-mounting

1.3 CONNECTIONS AND WIRING

The rear terminal connections are shown in Figure 1 -4 .

1 -2 Volume II PM090-1

Page 19

59135

Figure 1-4 Rear Terminal Connections

PM090-1 Volume II 1-3

Page 20

59135

1.3.1 Mains (Line) Supply

The Indicator will operate on 90 - 264V AC 50/60Hz mains (line) supply. The power

consumption is approximately 4 watts.

CAUTION: This equipment is designed for installation in an enclosure

which provides adequate protection against electric shock. Local

regulations regarding electrical installation should be rigidly

observed. Consideration should be given to prevention of access to

the power terminations by unauthorised personnel. Power should be

connected via a two-pole isolating switch (preferably situated near

to the equipment) and a 1A fuse, as shown in Figure 1 -4 .

If the Indicator has relay outputs in which the contacts are to carry mains (line)

voltage, it is recommended that the relay contact mains (line) supply should be

switched and fused in a similar manner but should be separate from the Indicator

mains (line) supply.

1.3.2 20 - 50V AC/DC Supply

Power should be connected via a two-pole isolating switch and a315mA

slow-blow (anti-surge Type T) fuse. With this option fitted, the Indicator will accept

20 - 50V AC @ 50/60Hz or 20 -50V DC in the polarity shown in Figure 1-4.

1.3.3 Thermocouple Input

The correct type of thermocouple extension leadwire or compensating cable

should be used for the entire distance between the Indicator and the

thermocouple, ensuring that the correct polarity is observed throughout. The

positive leg should be connected to Terminal 3 and the negative leg to Terminal

4. Joints in the cable should be avoided, if possible.

NOTE: Do not run thermocouple cables adjacent to power-carrying

conductors. If the wiring is run in a conduit, use a separate conduit

for the thermocouple wiring. If the thermocouple is grounded, this

must be done at one point only. If the thermocouple extension lead

is shielded, the shield must be grounded at one point only.

1.3.4 RTD Inputs

Three-wire or four-wire RTDs may be used. For three-wire RTDs, connect the resistive

leg of the RTD to Terminal 2, the common legs to Terminals 3 and 4 and a link

between Terminals 1 and 2. For four-wire RTDs, connect the resistive legs to

Terminals 1 and 2 and the common legs to terminals 3 and 4.

1 -4 Volume II PM090-1

Page 21

59135

1.3.5 Digital Input Option

Terminals 16 and 17, when this option is fitted, may be used for external selection

of the Security facility) which allows/prevents entry into Program Mode from the

front panel. These terminals may be connected to (a) the voltage-free contacts of

a switch or relay, or (b) a TTL-compatible voltage. With the Security option

configured (see Subsection 3.4), security selection is as follows:

Voltage-free Operation: Contacts open - Entry into Program Mode

prohibited

Contacts closed - Entry into Program Mode

permitted

TTL-compatible Operation: >2.0V - Entry into Program Mode

prohibited

<0.8V - Entry into Program Mode

permitted.

NOTE: This option and the Serial Communications option are

mutually exclusive.

1.3.6 Relay Outputs

Relay 1 is a standard feature; it is tied to Alarm 1. Relay 2 is an option; when fitted,

it is tied to Alarm 2. The contacts are rated at 2A resistive @ 120/240V AC.

1.3.7 Linear Output

This option provides a 10-bit linear output signal representing the process

variable. The range of this output is selectable in Configuration Mode (see

Subsection 3.4).

1.3.8 Serial Communications Option

The cable used should be suitable for data transfer at the selected rate (1200,

2400, 4800 or 9600 Baud) over the required distance. Transmitters/receivers

conform to the recommendations in the EIA Standard RS485.

The “A” terminal on the Indicator (Terminal 17) should be connected to the “A”

terminal on the master device; the “B” terminal on the Indicator (Terminal 16)

should be connected to the “B” terminal on the master device; the “Common”

terminal on the Indicator (Terminal 18) should be connected to the “Common”

terminal on the master device.

PM090-1 Volume II 1-5

Page 22

59135

Where several Indicators are connected to one master port, the master port

transceiver in the active state should be capable of driving a load of 120k Ω per

Indicator; the master port transceiver in the passive state must have

pull-up/pull-down resistors of sufficiently low impedance to ensure that it remains in

the quiescent state whilst supplying up to ± 100µA each to the Indicator

transceivers in the high impedance state.

NOTE This option and the Digital Input option are mutually exclusive.

1-6 Volume II PM090-1

Page 23

59135

2 INTERNAL LINKS AND SWITCHES

2.1 REMOVING THE INDICATOR FROM ITS HOUSING

CAUTION: Before removing the Indicator from its housing, ensure that

all power has been removed from the rear terminals.

To remove the Indicator from its housing, simply grip the side edges of the front

panel (there is a finger grip on each edge) and pull the instrument forward. This

will release the rear terminals from their connectors in the housing and will give

access to the PCBs. Take note of the orientation of the instrument for subsequent

replacement in the housing. The positions of the PCBs in the Indicator are shown in

Figure 2-1.

Figure 2-1 PCB Positions

PM090-2 Volume II 2-1

Page 24

59135

Figure 2-2 Removing the Relay 2/Linear Output Options PCBs

2-2 Volume II PM090-2

Page 25

59135

2.2 REMOVING/REPLACING THE RELAY 2/LINEAR OUTPUT

OPTION PCBs

With the Indicator removed from its housing:

1. Gently push the rear ends of the CPU PCB and Power Supply PCB apart

slightly, until the to tongues on each of the Relay 2 Option PCB and the

Linear Output Option PCB become disengaged - see Figure 2 -2 B; the Relay

2 Option PCB tongues engage in holes in the Power Supply PCB and the

Linear Output Option PCB tongues engage in holes in the CPU PCB.

2. Carefully pull the required Option PCB (Relay 2 or Linear Output) from its

connector (the Relay 2 Option PCB is connected to the CPU PCB and the

Linear Output PCB is connected to the Power Supply PCB) - see Figure 2 -2 C.

Note the orientation of the PCB in preparation for its replacement.

Adjustments may now be made to the link jumpers on the Linear Output Option

PCB (to select the output range - see Subsection 2.5).

2.3 REMOVING/REPLACING THE RS485 SERIAL

COMMUNICATIONS OPTION PCB/DIGITAL INPUT

OPTION PCB

The Serial Communications Option PCB or the DC Input Option PCB (the two are

mutually exclusive) is mounted on the inner surface of the Power Supply PCB and

can be removed from the unhoused Instrument by pulling the Option PCB towards

the rear of the Power Supply PCB. Figure 2 -3 illustrates the removal/replacement

procedure. It is not necessary to remove the Relay 2/Linear Output Option PCBs to

perform this procedure.

Figure 2-3 Removing/Replacing the Serial Communications/Digital

Input Option PCB

PM090-2 Volume II 2-3

Page 26

59135

2.4 REPLACING THE INSTRUMENT IN ITS HOUSING

To replace the instrument in its housing, simply align the CPU PCB and Power

Supply PCB with their guides and connectors in the housing and slowly but firmly

push the instrument into position.

CAUTION: Ensure that the instrument is correctly orientated. A stop will

operate if an attempt is made to insert the instrument in the wrong

orientation i.e. upside-down. This stop must not be over-ridden.

2.5 SELECTION OF LINEAR (RE-TRANSMISSION) OUTPUT

RANGE

If the Linear Output Option PCB is fitted, link jumpers on that PCB are used to select

the output range (see Figure 2 -4 and Table 2 -1 ).

Table 2 -1 Linear Output Range

Selection

Figure 2-4 Linear Output Option PCB

Output Range Link Jumper Fitted

0 - 10V DC LJ8

0 - 20mA DC LJ9

0 - 5V DC LJ8

4 - 20mA DC LJ9

2 -4 Volume II PM090-2

Page 27

59135

3 CONFIGURATION MODE

3.1 ENTRY/EXIT

Use these keys in the same way to exit from Configuration Mode.

3.2 PARAMETER SELECTION

3.2.1 With Help Facility Enabled

PM090-3 Volume II 3-1

Page 28

3.2.2 With Help Facility Disabled

59135

3.3 EDITING THE DISPLAYED PARAMETER

3-2 Volume II PM090-3

Page 29

59135

3.4 PARAMETER SEQUENCE

Parameter

Description

(Primary

Display)

Parameter Description Adjustment Range

Input

Range

Range

Trim High

Range

Trim Low

Power

Supply

Frequency

Alarm 1

Type

Selects the input sensor

type, resolution and

display scale (°C or °F)

by means of a code

number.

Adjusts the maximum

range value of the input

type selected.

Adjusts the minimum

range value of the input

type selected.

Applicable to

DC-powered units only,

this must be set to the

mains (line) frequency

for the site in order to

ensure proper filtering of

the input signal.

Defines the action of

Alarm 1

See Table 3 -1 .

Range Trim Low (see below) to

Range Max. (see Table 3-1).

Range Min. (See Table 3-1) to

Range Trim High (see above)

50Hz

60Hz

Process High

Process Low

No alarm

Range

Max.

Range

Min.

60Hz

Process

High

Alarm 2

Type

Output 1

Usage

Defines the action of

Alarm 2

Determines how NPN

Output 1 and Relay 1

operate.

Process High

Process Low

No alarm

Alarm 1, nonlatching, direct

action

Alarm 1, nonlatching, reverse

action

Alarm 1, latching,

direct action

Alarm 1, latching,

reverse action

Logical OR Alarm

1 & 2, direct

action

Logical OR Alarm

1 & 2, reverse

action

No

alarm

Alarm 1

nonlatching

direct

action

PM090-3 Volume II 3-3

Page 30

Parameter

Description

(Primary

Display)

59135

Parameter Description Adjustment Range

Output 2

Usage

Re-transmission

(Linear)

Output

Determines how NPN

Output 2 and Relay 2

operate.

Selects the scale for the

Re-transmission (Linear)

Output

Alarm 2, direct

action

Alarm 2,

reverse action

Logical OR

Alarm 1 & 2,

direct action

Logical OR

Alarm 1 & 2,

reverse action

None

0 - 5V

1 - 5V

0 - 10V

2 - 10V

0 - 20mA

4 - 20mA

Alarm 2,

direct

action

None

Option

Selection

Determines whether the

Serial Communications

Option or Digital Input

Option is fitted

None

Serial Comms.

Digital Input

None

3-4 Volume II PM090-3

Page 31

59135

Table 3 -1 Input Range Codes

Input Type Range Code Range Minimum Range Maximum

Thermocouple Inputs

J

100 (°C)

101 (°F)

110 (°C)

111 (°F)

T

200 (°C)

201 (°F)

210 (°C)

211 (°F)

K

300 (°C)

301 (°F)

310 (°C)

311 (°F)

N

400 (°C)

401 (°F)

B

500 (°C)

501 (°F)

R

600 (°C)

601 (°F)

–200

–328

–128.0

–198.4

–240

–400

–128.0

–198.4

–240

–400

–128.0

–198.4

0

32

100

212

0

32

1200

2192

537.0

998.6

400

752

400.0

752.0

1372

2502

537.0

998.6

1399

2550

1824

3315

1760

3200

S

3-wire

4-wire

700 (°C)

701 (°F)

800 (°C)

801 (°F)

810 (°C)

811 (°F)

900 (°C)

901 (°F)

910 (°C)

911 (°F)

RTD Inputs

0

32

–200

–328

–128.0

–198.4

–200

–328

–128.0

–198.4

1760

3200

800

1472

537.0

998.6

800

1472

537.0

998.6

PM090-3 Volume II 3-5

Page 32

59135

4 SERIAL COMMUNICATIONS -

CONFIGURATION MODE

This section is a supplement to the information provided in Volume I, Section 3 and

describes the Read/Write communications operations which can be performed in

Configuration Mode.

Table 4 -1 Parameter Identifiers and Adjustment Ranges - Configuration Mode

Identifier Hex. Parameter Adjustment Range

d 64 Enter Configuration Mode Read:0 - Not in Configuration Mode

1 - In Configuration Mode

Write:1 - Enter Configuration Mode

e 65 Exit Configuration Mode Read:0 - In Configuration Mode

1 - Not in Configuration Mode

Write:1 - Exit Configuration Mode

f 66 Input Type For range of values, see Table 4-2.

g 67 Range Trim Maximum Range Trim Minimum to Range

Maximum (see Table 4-2)

h 68 Range Trim Minimum Range Minimum (see Table 4-2) to

Range Trim Maximum

i 69 Mains (Line) Frequency.

(Applicable to

DC-powered units only)

j 6A Alarm 1 Type 0 No alarm

k 6B Alarm 2 Type 0 No alarm

NOTE: All Configuration Mode parameters are Read Only when

the instrument is not in Configuration Mode, Read/Write

when the instrument is in Configuration Mode.

0 (50Hz) or 1 (60Hz)

1 Process High

2 Process Low

1 Process High

2 Process Low

Continued on next page ⇒⇒⇒⇒⇒

4-1 Volume II PM090-4

Page 33

59135

Table 4 -1 Parameter Identifiers and Adjustment Ranges - Configuration Mode

Identifier Hex. Parameter Adjustment Range

l 6C Output 1 Use 0 Alarm 1 non-latching,

direct action

1 Alarm 1 non-latching,

reverse action

2 Alarm 1 latching, direct action

3 Alarm 1 latching, reverse

action

4 Logical OR Alarm 1 & 2,

direct action

5 Logical OR Alarm 1 & 2,

reverse action

m 6D Output 2 Use 0 Alarm 2, direct action

1 Alarm 2, reverse action

2 Logical OR Alarm 1 & 2,

direct action

3 Logical OR Alarm 1 & 2,

reverse action

n 6E Select Re-transmission

(Linear) Output Range

0 None

1 0 - 5V

2 1 - 5V

3 0 - 10V

4 2 - 10V

5 0 - 20mA

6 4 - 20mA

NOTE: All Configuration Mode parameters are Read Only when

the instrument is not in Configuration Mode, Read/Write

when the instrument is in Configuration Mode.

PM090-4 Volume II 4-2

Page 34

Table 4 -2 Input Type Selection - Available Values

Input Type Range Code Range Minimum Range Maximum Hex. Value

Thermocouple Inputs

59135

J

100 (°C)

101 (°F)

110 (°C)

111 (°F)

T

200 (°C)

201 (°F)

210 (°C)

211 (°F)

K

300 (°C)

301 (°F)

310 (°C)

311 (°F)

N

400 (°C)

401 (°F)

B

500 (°C)

501 (°F)

R

600 (°C)

601 (°F)

–200

–328

–128.0

–198.4

–240

–400

–128.0

–198.4

–240

–400

–128.0

–198.4

0

32

100

212

0

32

1200

2192

537.0

998.6

400

752

400.0

752.0

1372

2502

537.0

998.6

1399

2550

1824

3315

1760

3200

0

1

2

3

4

5

6

7

8

9

0A

0B

0C

0D

0E

0F

10

11

S

3-wire

4-wire

700 (°C)

701 (°F)

800 (°C)

801 (°F)

810 (°C)

811 (°F)

900 (°C)

901 (°F)

910 (°C)

911 (°F)

0

32

RTD Inputs

–200

–328

–128.0

–198.4

–200

–328

–128.0

–198.4

1760

3200

800

1472

537.0

998.6

800

1472

537.0

998.6

12

13

14

15

16

17

18

19

1A

1B

4-3 Volume II PM090-4

Page 35

59135

APPENDIX A PRODUCT SPECIFICATION

A.1 DISPLAY

Type: Red/green, seven-segment LED, five-digit

primary display, one-digit secondary

display.

Height: 0.71 inches (18mm) primary display

0.3 inches (7mm) secondary display

Annunciators: Alarm 1 and Alarm 2 status.

A.2 SENSOR INPUT

Types: Type B, J, K, N, S and T thermocouples

Three-wire and four-wire RTD

Accuracy: 0.1% of span

Sample Rate: Every 250mS.

Resolution: 14 bits.

Sensor Break Detection: Detected within two seconds.

Input Ranges Available: See Table A -1.

PM090-A Volume II A-1

Page 36

Table A -1 Input Type Selection - Available Values

Input Type Range Code Range Minimum Range Maximum

Thermocouple Inputs

59135

J

100 (°C)

101 (°F)

110 (°C)

111 (°F)

T

200 (°C)

201 (°F)

210 (°C)

211 (°F)

K

300 (°C)

301 (°F)

310 (°C)

311 (°F)

N

400 (°C)

401 (°F)

B

500 (°C)

501 (°F)

R

600 (°C)

601 (°F)

–200

–328

–128.0

–198.4

–240

–400

–128.0

–198.4

–240

–400

–128.0

–198.4

0

32

100

212

0

32

1200

2192

537.0

998.6

400

752

400.0

752.0

1372

2502

537.0

998.6

1399

2550

1824

3315

1760

3200

S

3-wire

4-wire

700 (°C)

701 (°F)

800 (°C)

801 (°F)

810 (°C)

811 (°F)

900 (°C)

901 (°F)

910 (°C)

911 (°F)

RTD Inputs

0

32

–200

–328

–128.0

–198.4

–200

–328

–128.0

–198.4

1760

3200

800

1472

537.0

998.6

800

1472

537.0

998.6

A-2 Volume II PM090-A

Page 37

59135

A.3 DIGITAL INPUT (OPTION)

Type: Voltage-free or TTL-compatible operation.

May be connected to: External switch/relay contacts or

TTL-compatible logic signal.

Maximum Input delay

(open - closed or “1" - “0"

transition):

Minimum Input delay

(closed - open or “0" - “1"

transition):

External Switch/Relay Contacts

Maximum Contact

Resistance (Closure):

Minimum Contact

Resistance (Open):

External TTL-Compatible Logic Signal

Maximum Voltage (TTL) for

“0”:

1 second

1 second

50

5000

0.8V

Minimum Voltage (TTL) for

“0":

Minimum Voltage (TTL) for

“1":

Maximum Voltage (TTL) for

“1":

-0.6V

2.0V

24.0V

A.4 TRANSISTOR OUTPUTS

Type: NPN open collector. Output tied to Alarm 1,

Output 2 tied to Alarm 2.

A.5 RELAY 1 OUTPUT

Contact Type: Single pole double throw.

Rating: 5A resistive @ 120/240V AC

PM090-A Volume II A-3

Page 38

Lifetime: >500,000 operations at rated

voltage/current.

Isolation: Inherent

A.6 RELAY 2 OUTPUT (OPTION)

Contact Type: Single pole double throw.

Rating: 5A resistive @ 120/240V AC

Lifetime: >500,000 operations at rated

voltage/current.

Isolation: Inherent

A.7 LINEAR (RE-TRANSMITTED PV) OUTPUT (OPTION)

59135

Ranges available: 0 - 5V, 1 - 5V, 0 - 10V, 2 - 10V, 0 - 20mA

and 4 - 20mA.

Accuracy: 0.25% (mA @ 250W, V @ 2kW); degrades

linearly to 0.5%.

Resolution: 8 bits in 250mS (10 bits in 1 second

typically).

Update Rate: 4/second approximately.

Load Impedance: mA ranges - 500W max.

V ranges - 500W min.

A.8 SERIAL COMMUNICATIONS (OPTION)

Type: Serial asynchronous, UART to UART.

Data Format: Open ASCII; One start bit, even parity,

seven data bits, one stop bit.

Physical Layer: RS485.

Maximum Number of

Zones:

Baud Rate: Selectable from 1200, 2400, 4800 and

A-4 Volume II PM090-A

99.

9600 Baud.

Page 39

59135

A.9 PERFORMANCE

Reference Conditions

Ambient Temperature:

Relative Humidity: 60 - 70%

Supply Voltage: 90 - 264V AC 50Hz

Source Resistance: <10Ω for thermocouple input

Lead Resistance: <0.1Ω/lead balanced (Pt100)

20°C ±2°C

Performance Under Reference Conditions

Common Mode Rejection: >120dB at 50/60Hz giving negligible effect

at up to 264V 50/60Hz.

Series Mode Rejection: >500% of span (at 50/60Hz) causes

negligible effect.

Thermocouple Inputs

Measurement Accuracy:

±0.05% typical, ±0.1% maximum, of span

±1LSD. NOTE: Reduced performance with

Type “B” Thermocouple below 600°C

(1112 °F).

Linearisation Accuracy:

Cold Junction

Compensation:

RTD Inputs

Measurement Accuracy:

Linearisation Accuracy:

Operating Conditions

Ambient Temperature:

High resolution ranges - better than ±0.5°C

Low resolution ranges - better than ±0.05 °C

±0.3% typical, ±0.5% maximum.

±0.02% typical, ±0.06% maximum, of span

±1LSD

High resolution ranges - better than ±0.5°C.

Low resolution ranges - better than

±0.05 °C.

0°C to 55 °C

PM090-A Volume II A-5

Page 40

Relative Humidity: 20% - 95% non-condensing

Source Resistance: 1000 Ω maximum (thermocouple)

Lead Resistance: 50Ω per lead maximum balanced (Pt100)

Performance Under Operating Conditions

59135

Temperature Stability:

Cold Junction

Compensation

(thermocouple only):

0.005% of span/°C change in ambient

temperature.

Better than ±1°C.

A.10 ENVIRONMENTAL

EMI Susceptibility: Complies with EN50082-1:1992,

EN50082-1:1995. NOTE: For RF

electromagnetic fields (10V/m 80% AM

1kHz), the reading accuracy may be

impaired by up to 3oC in the frequency

band 273 to 470MHz and by up to 1.4oC

in the frequency band 785 to 1000MHz.

EMI Emmissions: Complies with EN50081-1:1992,

EN50081-2:1993.

Safety: Complies with EN61010-1.1993.

Supply Voltage: 90 - 264V, 50/60Hz (standard)

20 - 50V AC/DC (option)

Power Consumption: 4watts approximately

Front Panel Sealing: To IP66 (Nema 4)

A.11 PHYSICAL

Dimensions: Height - 48mm

Width - 96mm

Depth - 100mm

Mounting: Panel-mount; press-fit fixing strap supplied.

Panel cut-out - 45mm x 92mm

Terminals: Screw type; combination head.

Weight: 0.21kg maximum.

A-6 Volume II PM090-A

Loading...

Loading...