Page 1

Industrial controller KS 94

Operating Instruction

9499 040 44211

S94

Gültig ab: 8363

Page 2

Inhalt

1. Front view ..............5

2. Safety notes .............5

3. Electromagnetic compatibility . . . 5

4. Technical data r data sheet,

order no. 9498 737 28233 ......5

5. Maintenance / Behaviour in case

of trouble ...............6

6. Further information.........6

7. Mounting ...............6

8. Electrical connections ........7

8.1 Notes . . . . . . . . . . . . . . . . . 7

8.2 Connecting input INP1 . . . . . . . . 7

8.3 Connecting input INP6 . . . . . . . 8

8.4 Connecting input INP5 . . . . . . . 8

8.5 Connecting the power supply . . . . 8

8.6 Connecting the outputs OUT2/4/5 . . 8

8.7 Connecting output OUT1 . . . . . . 8

8.8 Digital inputs and outputs (di / do) . 8

8.9 Connecting the bus interface . . . . 9

8.10 Connecting the inputs INP3 / INP4 . 9

8.11 Connecting the output OUT3 . . . . 9

8.12 Versions with integr. supply voltage 10

9. Operation (survey) .........11

9.1 The menues 1...3 . . . . . . . . . . 11

9.2 The operating level . . . . . . . . . 11

9.3 Operating the programmer: . . . . . 12

9.4 Calibration: ............12

9.5 DAC – motor actuator monitoring . .

(Digital Actor Control DAC®) . . . . .13

9.6 Self-tuning (automatic optimization of

control parameters) . . . . . . . . .13

9.7 Parameter and configuration level . 14

10. Configuration............15

10.1 General . . . ............15

10.2 Basic structure. . . . . . . .....15

10.3 Main groups . . . . . . . . .....18

10.4 CONTR: Controller . . . . . . . . . 19

10.5 SOURCE: Input signal allocation . . 21

10.6 INPUT: inputs . . . . . . . .....23

10.7 OUTPT: outputs. . . . . . . . . . . 27

10.8 ALARM: alarms ..........31

10.9 TUNE:self-tuning ..........32

10.10 DISP: User interface for operation . 32

10.11 AUX: Additional functions . . . . . 33

10.12 Examples of configuration . . . . . 35

11. Parameters .............36

11.1 General . . . ............36

11.2 Set-point function ..........38

11.3 Time function . . . . . . . .....38

11.4 Programmer functions . . . . . . . 38

11.5 Alarm function . . . . . . . . . . . 39

11.6 Self-tuning. . . . . . . . . . . . . . 39

11.7 Control algorithm ..........40

11.8 Input processing . . . . . . . . . . . 41

11.9 Miscellaneous . . . . . . . .....42

11.10 Signals . . . . . . . . . . . . . . . . 42

12. Versions ...............43

13. ....................43

13.1 Input and output allocation with . . .

pre-configured units. . . . . . . . .....44

Symbol definition:

a

K

J

DAC

General warning (caution, following the warnings in the instruction)

Protective earth

Earth connection

®

is a patented method and a registered trademark of Regeltechnik Kornwestheim GmbH.

All rights reserved. No part of this documentation may be reproduced or published in any form

or by any means without prior written permission from the copyright owner

A publication of PMA Proze- und Maschinen-Automation. Subject to alterations without notice.

PMA Prozess- und Maschinen-Automation GmbH 2000, Printed in Germany (2003).

PMA Prozess- und Maschinen-Automation GmbH • P.O.Box 310 229 • D-34058 Kassel - Germany

Page 3

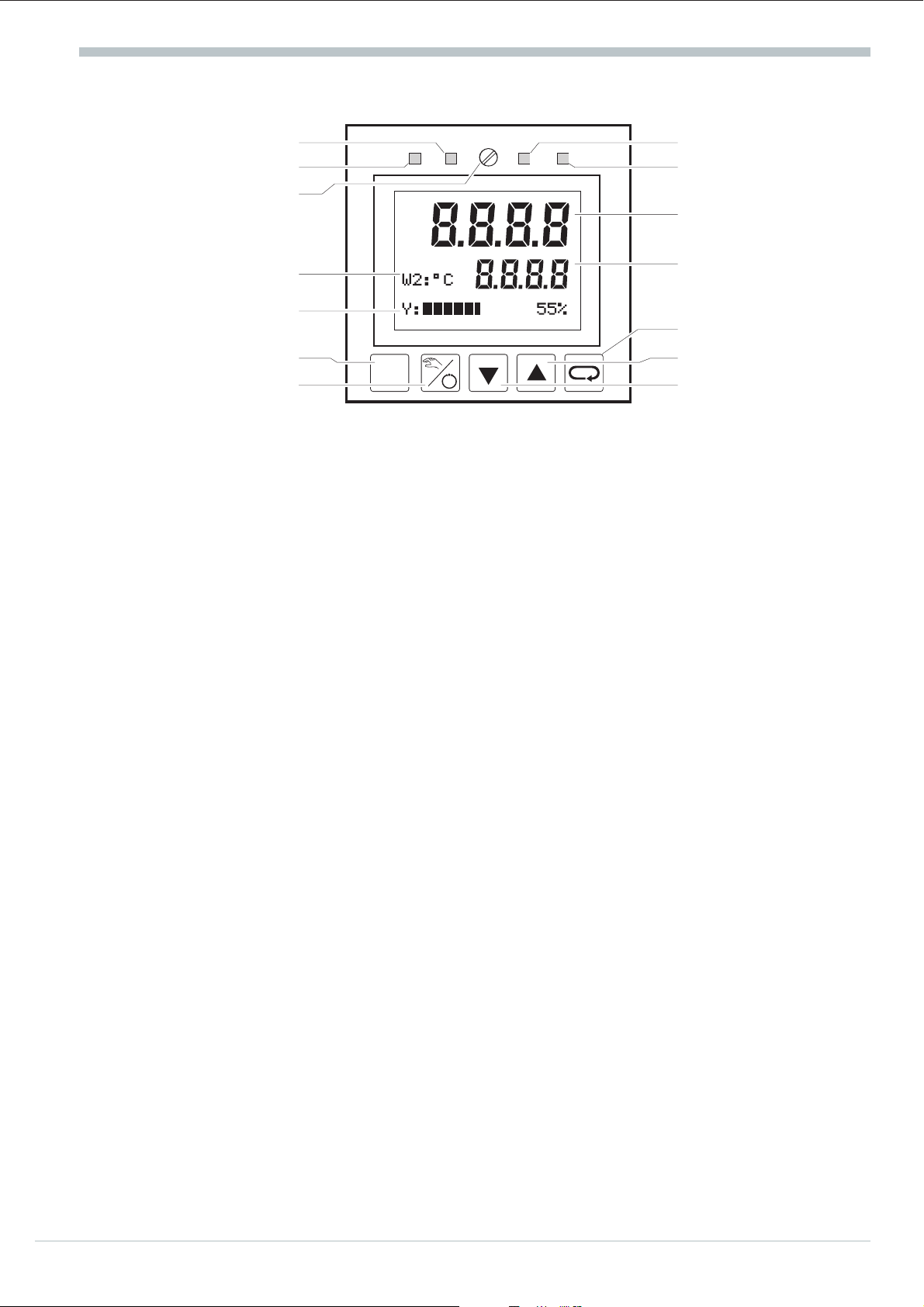

1. Front view

English

LED 2 e.g. Cooling LED 3 e.g. Alarm 1

LED 1 e.g. Heating LED 4 e.g. Alarm 2

Text 1 e.g. physical unit Display 2 e.g. Set-point

Text 2 e.g. Bargraph / Dialogue

Manual/Automatic key Decrement key (u)

Locking screw: Locks the controller module in the housing.

w

Front view

Locking screw

Display 1 e.g. Process value

Selection key

PC interface Increment key (z)

LEDs: indicates the statuses of controller outputs Y1, Y2 and alarms LIM1, LIM2 (other settings at

w

configuration level C.800 r page 30).

Display 1: indicatess process value at operating and parameter level, or the configuration code at

w

configuration level.

Display 2: indicates the set-point (automatic mode) or the correcting value (manual mode) in operating

w

level. The values are adjustable directly with ID. Further displays at operating level r page 9. In

parameter and configuration level, values and codes described with text1 are indicated (r page 12).

w

Text 1: indicates the short-form dialogue or the unit of display 2.

w

Text 2: indicates the output bargraph (other selections possible in configuration level C.800).

Keys HDIM: For the certain function r pages 9 and 12.

w

PC interface: PC connection for configuration/parameter setting/operation with an engineering tool.

2. Safety notes

Following the enclosed safety instructions 9499 047 07101 is indispensable!

The insulation of the instrument conforms to EN 61 010-1 with pollution degree 2, overvoltage

category III, operating voltage 300 V and protection class I. Additional with horizontal installation, a

protection to prevent live part, e.g. wire ends, from dropping into the open housing of a withdrawn

controller must be fitted.

3. Electromagnetic compatibility

The instrument conforms to European Directive 89/336/EEC and will be provideed with the

CE-marking. The following European Generic Standards are met: Emission: EN 50081-2 and

Immunity: EN 50082-2. The unit is suitable for use in industrial areas (in residential areas, RF

interference may occur). The electromagnetic radiation can be reduced decisively by installing the

unit in a grounded metal switch cabinet.

4. Technical data r data sheet, order no. 9498 737 28233

5 Operating instruction KS94

Page 4

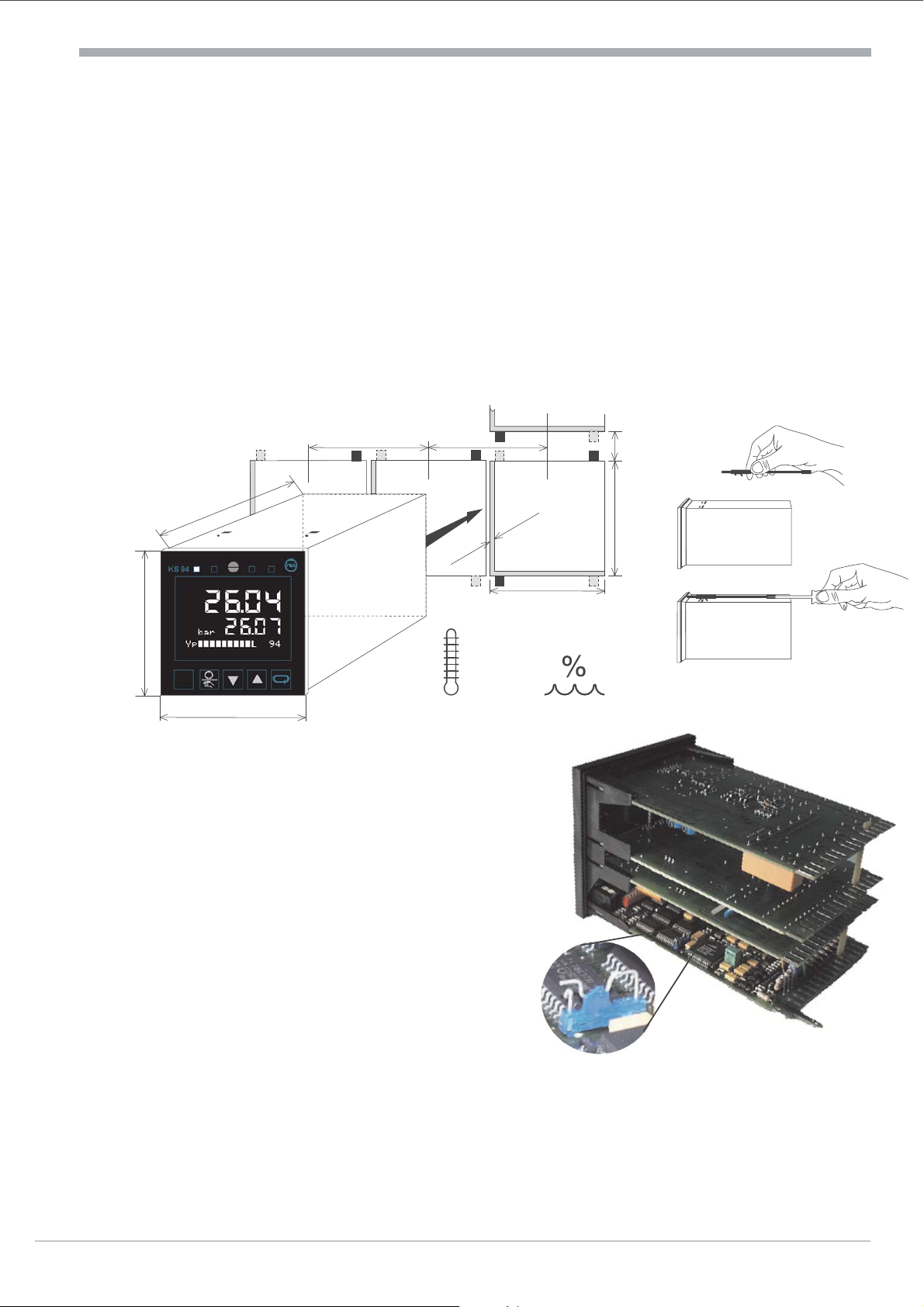

Maintenance / Behaviour in case of trouble

96

96

96 96

92

+0,8

92 ?24

+0,8

1...16

160

2

1

8.8.8.8

8.8.8.8

min. 0°C

50°Cmax.

max.

95% rel.

W2:ÀC

Y:ыыыыыо 55%

5. Maintenance / Behaviour in case of trouble

The controller needs no maintenance. The rules to be followed in case of trouble are:

Check mains (voltage, frequency and correct connections),wcheck, if all connections are correct,

w

check the correct funktion of the sensors and final elements,wcheck the configuration words for

w

required functions andwcheck the adjusted parameters for required operation. If the controller still

does not work properly after these checks, shut down the controller and replace it.

Cleaning:Housing and Front can be cleaned by means of a dry, lint-free cloth. No use of solvents or

cleansing agents!

6. Further information

A manual with the order no. 9499 040 44811 gives further information to the chapters of this

operating notes.

7. Mounting

S.I.L. switch: with the switch closed, transition to

parameter and configuration level is disabled.

When making an attempt to change over to the

parameter level, ”ParaL” is displayed (text1).

Correcting variable, set-point and parameters at

the ”extended operating level” remain available

for selecting and changing. For access to the S.I.L.

switch, release the locking screw and withdraw the

instrument module from the housing. Subsequently,

re-insert the controller module into the housing and

mount it with screws.

Protection mode IP65: 4 fixing clamps must be

used. The instruments insert must be placed strongly

an locked strongly by means of the locking screw.

l

Operating instruction KS94 6

Caution! The instrument contains ESD-hazarded

components.

Page 5

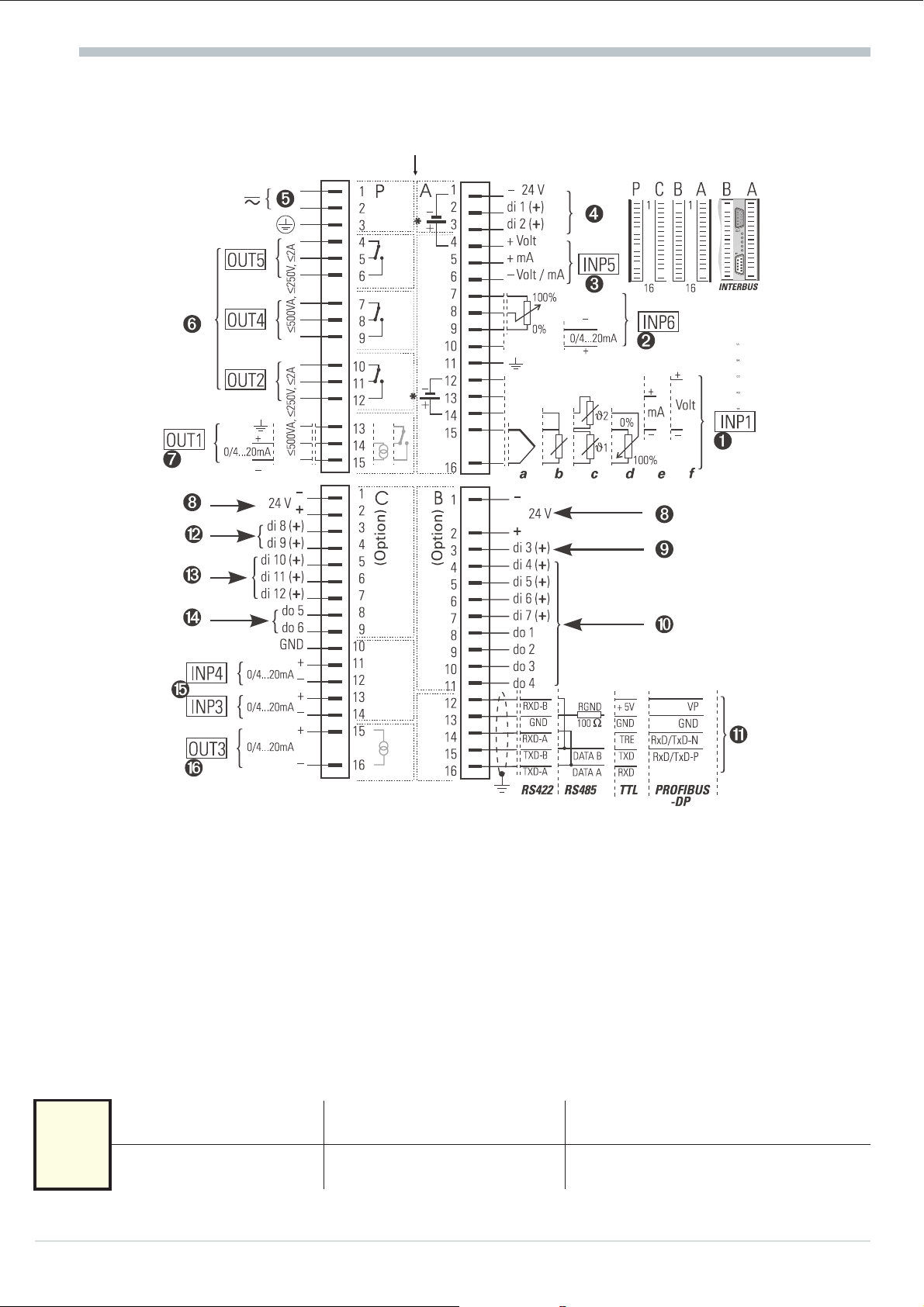

8. Electrical connections

Electrical connections

galvanic isolation

* Versions with integrated supply voltage (connection example look at page 10)

8.1 Notes

q

q

q

The ground connection of earth terminal A11 (terminal P13 with continuous controllers, too) should

be kept separate from the mains and as short as possible (15 cm during test). Keep mains cables

separate from signal and measurement input leads. We recommend twisted and screened

measurement input leads (screen contacted to measurement earth).

When connecting a contactor to a relay output, an RC protective circuit is necessary, to avoid voltage

peaks which can cause trouble to the controller.

Individual or common fuse protection must be fitted (1 A per instrument).

8.2 Connecting input INP1 1

Input for main process value x1 (actual value).

Thermocouple

x1

a

d

Potentiometric transducer

b

e

Resistance thermometer

(Pt 100)

Current (0/4...20mA)

7 Operating instruction KS94

Temperature difference (}1-}2)

c

(2x Pt 100)

f

Voltage (0/2...10V)

Page 6

Electrical connections

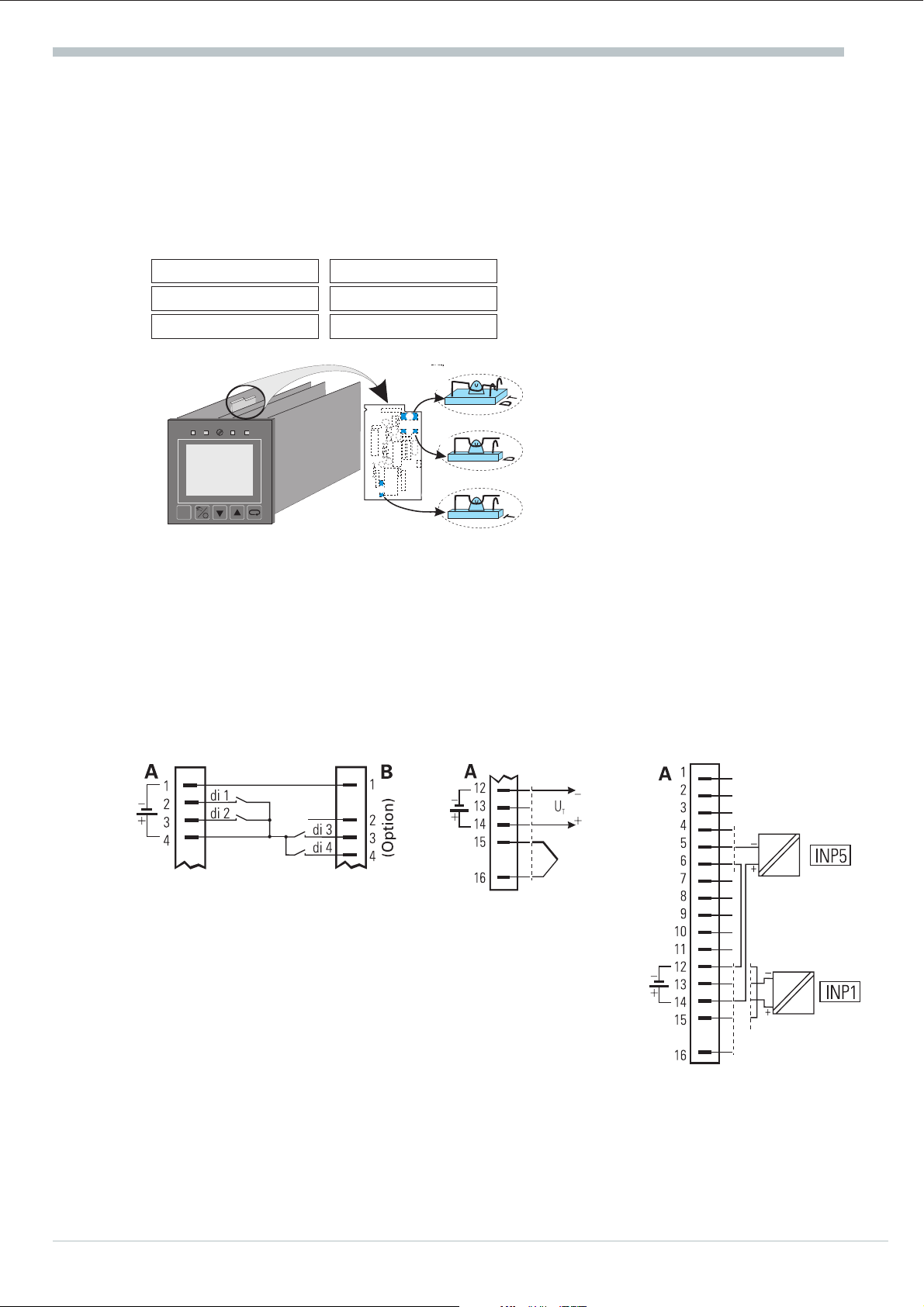

8.3 Connecting input INP6 2

For position feedback with 3-point stepping controller

(other selections possible in configuration level C.180).

8.4 Connecting input INP5 3

Input for process value x2 or external set-point or external

set-point offset (configuration level C.180). With voltage signals,

x2

8.5 Connecting the power supply 5

8.6 Connecting the outputs OUT2/4/5 6

8.7 Connecting output OUT1 7

A6 must be connected to the reference potential at A9.

Depending on the version, the instrument is supplied with: 90...250 V AC or 24 V UC. The

24 V UC version is for 19,2...30 V DC or 20,4...26,4 V AC. The indicated values are the limits. The

protective earth must be connected to terminal P3.

Relay outputs, corresponding to the controller output Y2 or the alarms LIM1 / LIM2 (other selections

possible in configuration level rfrom page 26).

Depending on the version, OUT1 is a relay, logic or continuous output corresponding to the

controller output Y1 (other selections in configuration level). With logic and continuous outputs, P13

must be connected to the earth terminal. The logic signal is 0 / >20 mA (load ß600 [)or0/>12V

(load ?600 [).

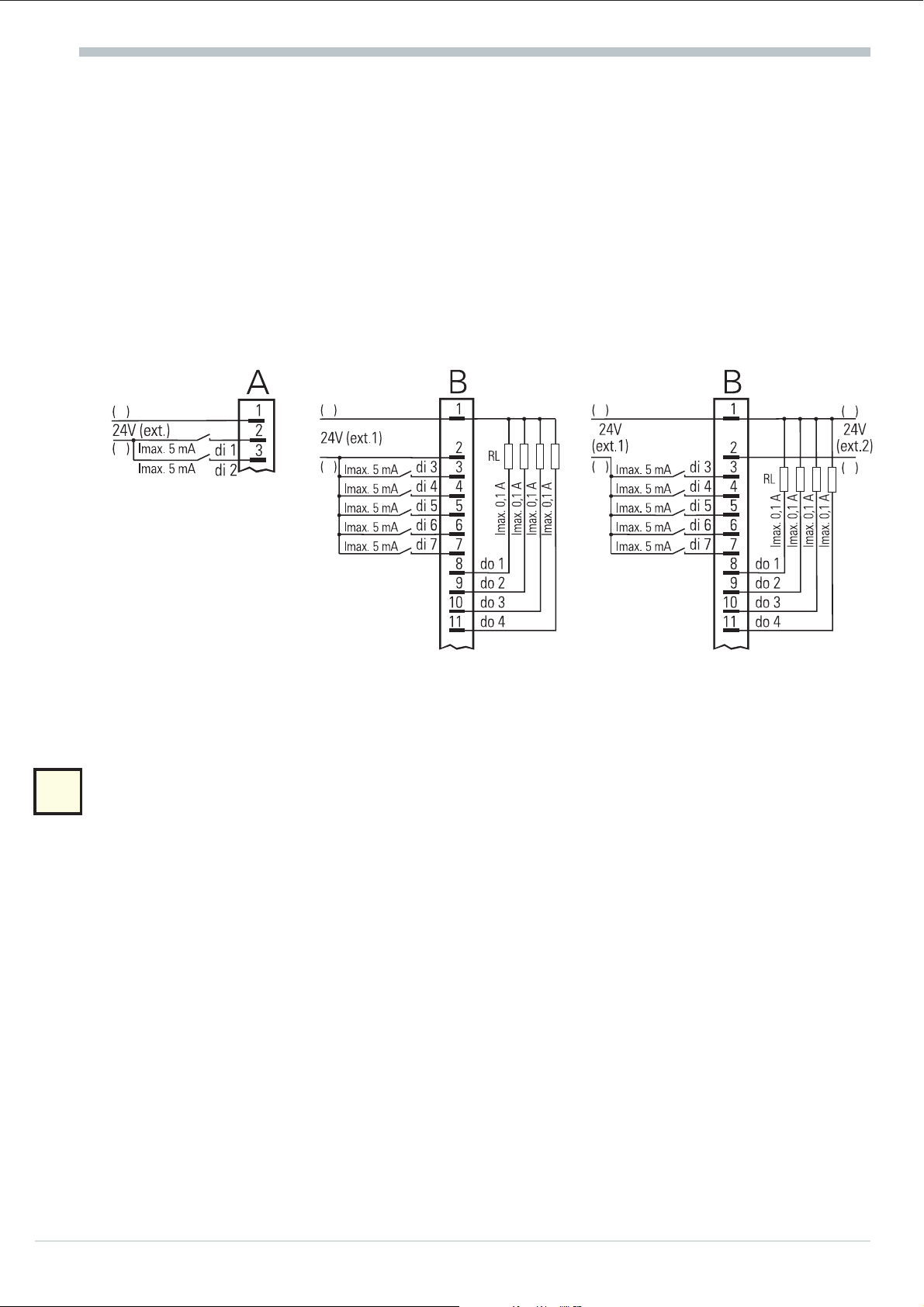

8.8 Digital inputs and outputs (di / do) 4890"§$

The inputs operate as current sink (IEC 1131 type1), logic „0" = -3...5 V, logic “1" = 15...30 V.

The outputs operate as „grounded load“. They are short circuit protected and contain recovery diodes.

The digital input and supply voltage (24V) must be connected on each circuit board.

4 di1 / di2 control various actions (set in configuration level C.190/ C.191 and

parameter Blck1 / Blck2)

9 di3 is used for changeover Local mode(0) i Remote mode(1).

0 di4...di7 and do1...do4 are correlated to the programmer as follows:

di4 Program STOP (0) i RUN (1) do1 Status fo control output 1

di5 Program normal (0) i RESET (1) do2 Status fo control output 2

di6 Program number (LSB) do3 Status fo control output 3

di7 Program number (MSB) do4 Status fo control output 4

di6 0 1 0/1 di8 0101

di7 0 0 1 di9 0011

program 1 2 3 parameterset 0123

" di8 / di9 is used for selecting the parameter set (bei C.700 = xx.x.3, di9 = MSB).

Operating instruction KS94 8

Page 7

Electrical connections

§ di10 is the input for override control OVC+ (three-point stepping).

di11 is the input for override control OVC- (three-point stepping) or the correction of the

effective set-point OFF (0) i ON (1) (configuration level C.190 / C.191).

di12 switches the bumpless transfer of the internal set-point (tracking) OFF (0) i ON (1) or

switches from set-point w (0) i w2 (1) (configuration level C.190 / C.191).

$ do5 or do6 indicates the status automatic i manual or internal i external set-point or the

status of the controller outputs Y1 / Y2 with switching controllers (configurations C.596 / C.597).

8 The digital inputs and outputs must be supplied from one or several external 24 V dc sources

(current consumption 5 mA/input, max. load = 0,1 A/output). Examples:

Digital inputs (connect. A) Digital inputs and outputs with

one dc source (e.g. connector B)

-

+

-

+

8.9 Connecting the bus interface !

TTL level or RS422, RS485, PROFIBUS or INTERBUS. With TTL level, an interface module for

conversion to RS422/RS485 is required. 4 units may be connected to an interface module.

8.10 Connecting the inputs INP3 / INP4 %

Digital inputs and outputs with

two dc sources (e.g. connector B)

-

+

-

+

Selectable in configuration level as e.g. process variable x2, process variable x3, auxiliary variable z,

x3

ext. set-point or over ride control (OVC). The reference potential of the inputs is at C10.

8.11 Connecting the output OUT3 &

Depending on the version, OUT3 is a logic or continuous output (C.560). The logis signal is

0 / >20 mA (load ß600 [) or 0 / >12 V (load ?600 [). The signals are available, see page 28.

The function can be selected with configuration code C.560. By means of code C.565, the output

can be connected to a post processing (e.g. linearisation).

9 Operating instruction KS94

Page 8

Electrical connections

8.12 Versions with integrated supply voltage

The supply voltage can be used only for energization of a 2-wire transmitter or for energization of

max. 4 control inputs. The supply voltage is potential-free and can also be used for energizing inputs

INP3 ... INP6 or for other units. Selection of supply voltage or digital inputs is by S.I.L. switches (see

figure opposite).

Transmitter

supply voltage

Ü

Position T Position D

* open

Ö

closed (T)

8.8.8.8

W2:ÀC

8.8.8.8

Y:ыыыыыо 55%

a

The supply voltage is only applied to terminals A12 and A14 with INP1 configured for

current or thermocouple (C.200; type) and the S.I.L. switches set for transmitter supply

(factory setting)! With the S.I.L. switches set to digital input, the voltage is applied to

terminals A1 and A4 independent of the configuration of input INP1. In this case, the voltage

input of INP5 is not available.

Digital input

closed (D)

open

Ü

T

Ü

D

D

*

*

Ö

T

Ö

Supply voltage for energization of

digital input (e.g. di1...di4)

External use of the supply

voltage

Connection of a 2-wire

transmitter on example of

INP1 or INP5

Operating instruction KS94 10

Page 9

9. Operation (survey)

Operation (survey)

+

The user manual (order no. 9499 040 44811) is required for the complete operation.

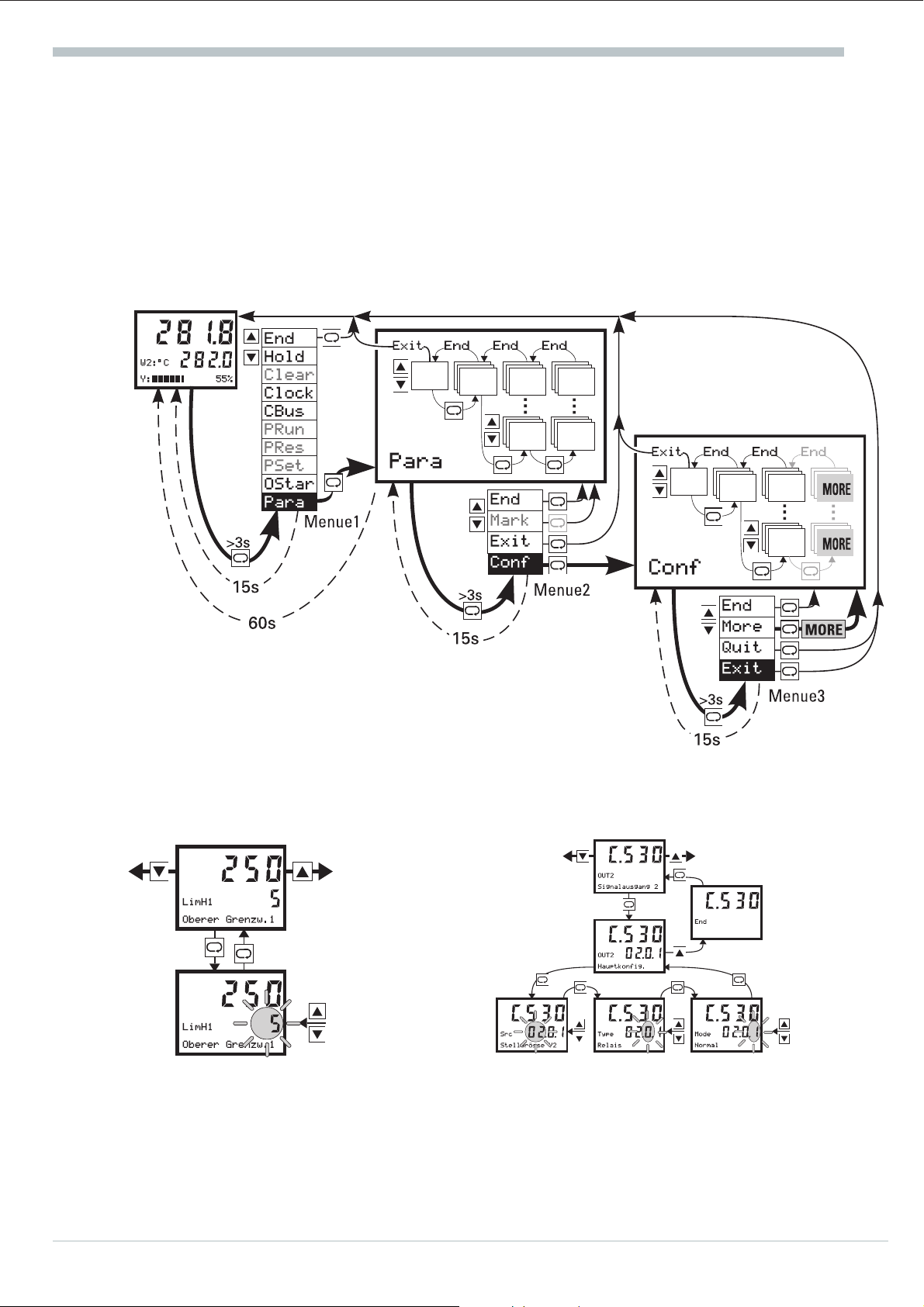

9.1 The menues 1...3

Apart from the parameter and configuration words, the following dialogue words are used (Text1):

Text1 Signification

CBus CFrnt

Clear

Clock

Conf

End

Exit

Hold

Mark

More

OStar OStop

Para

PRun PStop

PSet PRes

Quit

PC communication via interface at terminals B12...B16 or connection on the unit front

The additional display selected at operating level is deleted (r Mark)

Adjust the clock

Transition to configuration level

Return to the previous selection menu

Return to operating level (main display)

The displayed parameter is determined as standard indication.

The displayed parameter is stored as additional display at operating level (r Clear)

The configuration level area described with MORE is accesible

Self-tuning will be started or stopped

Transition to parameter level

Programmer will be started or stopped

Programmer will be set to a specified program point or reset to the reset point

Return to operating level (main display) without storage of the values changed last

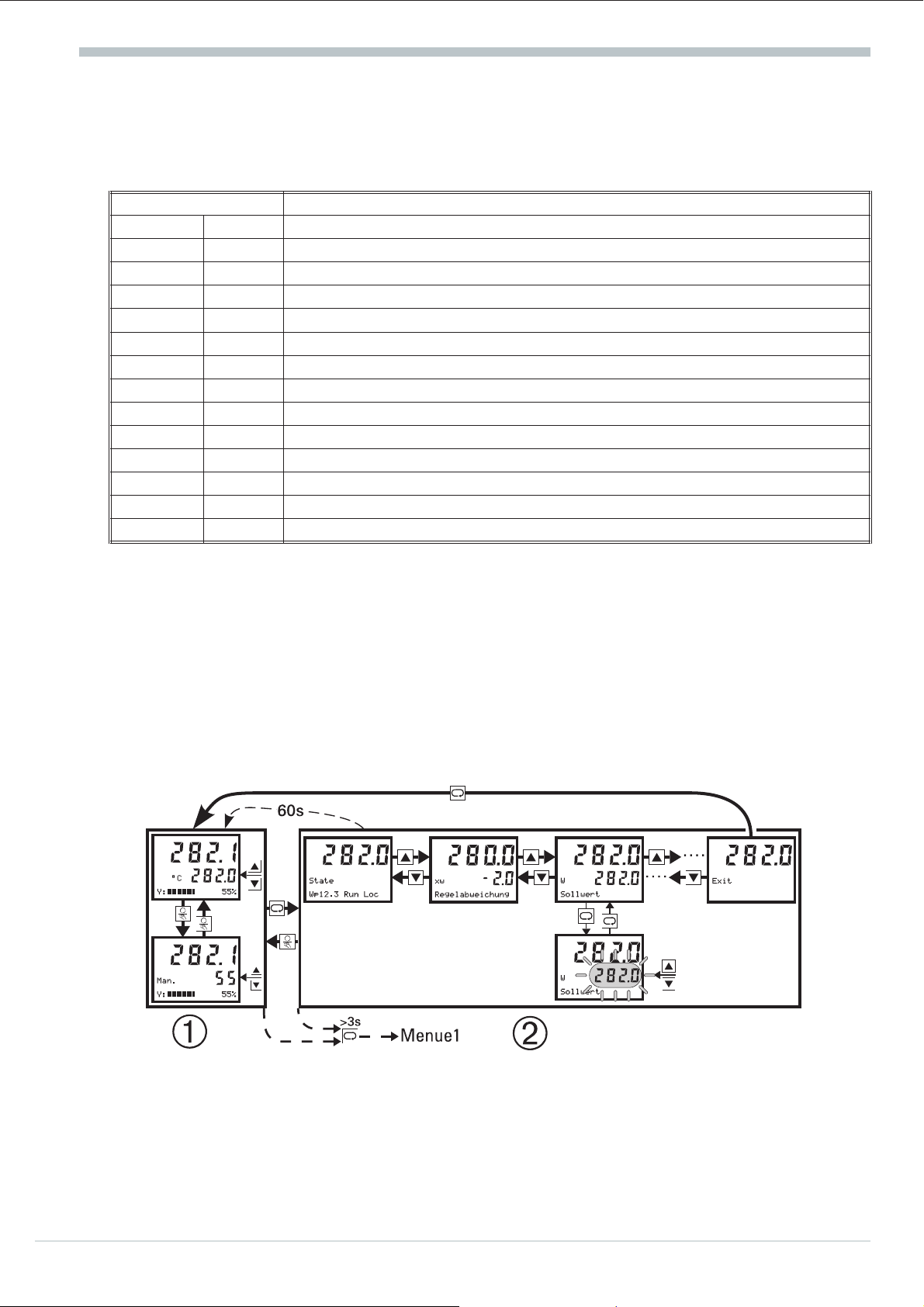

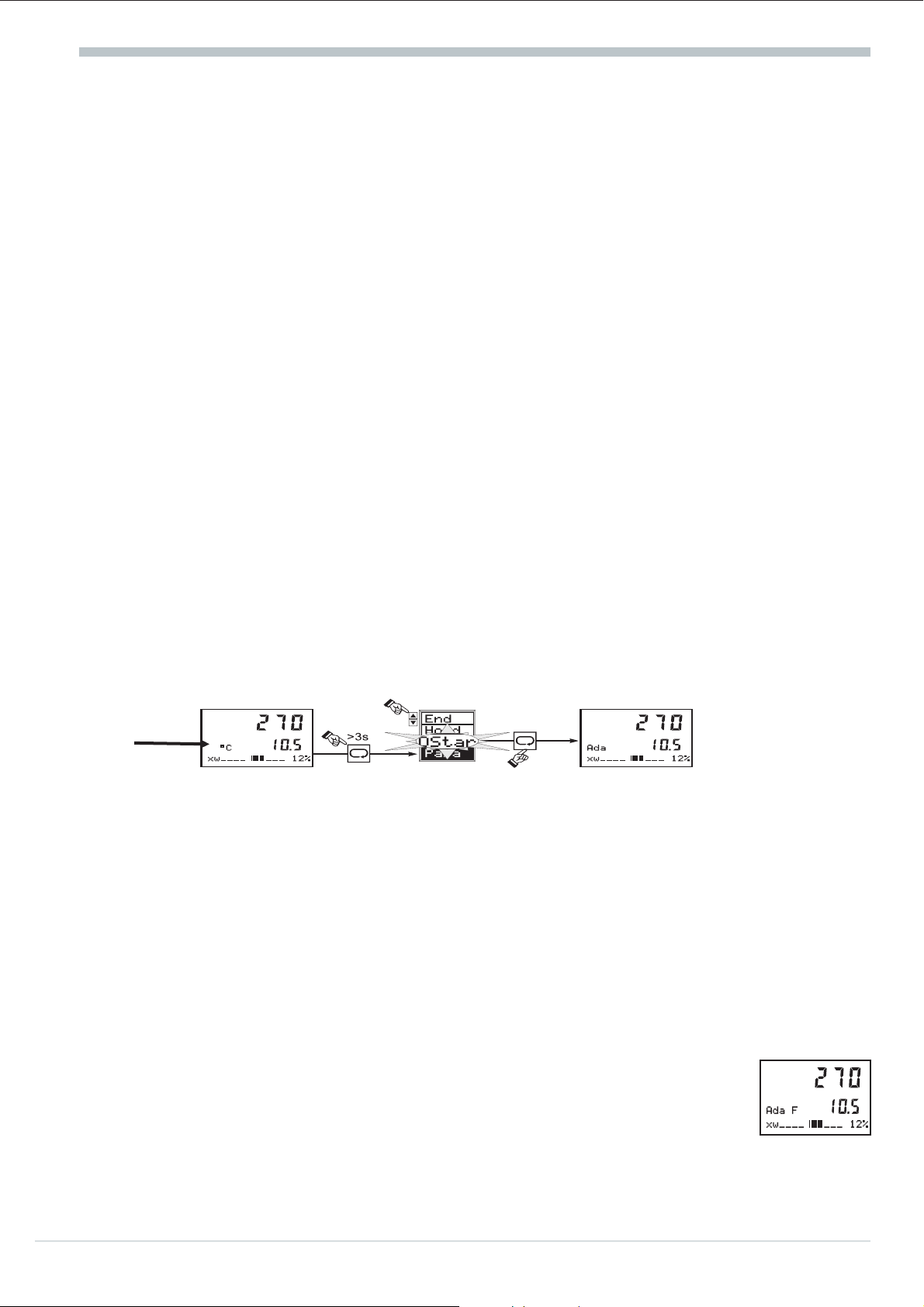

9.2 The operating level

The operating level comprises main display Ü and extension *. During the main display, automatic

or manual operation can be selected (H). With automatic, the set-point, and with manual, the

correcting value can be adjusted directly (ID). In the extension, the number and sequence of

displays is dependent of selected functions. Max. 12 parameters from the parameter level can be

displayed (Mark i Clear). Some of these parameters are directly adjustable (ID). A parameter

can be displayed continuously with the Hold function. (PressM <3sÄ Select parameter (press

ID) ÄM>3sÄ Select Hold (Press ID) ÄM). The extension can be left with Exit and M

or after a timeout of 60 s or with H. With H, the other operating mode is also selected.

+

If the set-point is set to ‘——‘ by means of D, the controller is switched off!!

Menu 1 is always selectable at operating level: deletion of additional display (Clear),

communication interface switch-over (CBus i CFrnt) and starting (OStar) or stopping

(OStop) the self-tuning, setting the clock (Clock), operate the programmer (PRun i PStop;

PRes; PSet) and transition to parameter level (Para).

11 Operating instruction KS94

Page 10

Operation (survey)

+

c

0

Status display: In the extended operation of KS94, ‘Text2’ indicates the

controller status. The following table shows the possible

displays:

Set-point

Meaning Status Meaning Status Meaning

Symbol)

.....

We

Wp

xx.

y

W2

Internal set-point

External set-point

Program set-point

Segment number

Program number

2nd set-point

....

Band

End

Grw

Rset

Run

Stop

9.3 Operating the programmer:

The programmer can be operated (run, stop, reset, preset) with menu 1, via digital inputs or via the

interface (process management system).

Operating Level

No bandalarm and no

programmer active

Band width control has stopped

programmer or set-point ramp.

End of program is reached

Set-point gradient is limiting the

speed of change

Programmer in reset mode

Programmer is running

Programmer has been stopped

Menu 1

(flashes)

...

Rem

KS94 in local mode

(Front operation

possible)

KS94 in remote mode

(Front operation

blocked)

When entering the preset time (parameter setting: Pmode = 1) the time can be entered up to 99.59 in

hours . minutes, or only in hours with longer times.

9.4 Calibration:

+

a

Calibation is only possible with the controller set to manual mode. Calibration from INP1/6 (Typ=

40; Potentiometric transducer) is in two steps.

w

Select x0c Ä Press M (c blinking) Ä set transducer to 0%, wait 6s and confirm with M.

w

Select x100c Ä Press M (c blinking) Ä set transducer to 100%, wait 6s and confirm with M.

Manual calibration of INP6 is only possible with the DAC function switched off. With the DAC

function switched on, automatic calibration is possible (r DAC page 11 ).

w

For selecting YpCal , press ÄM(0 blinks) change to 1 with I and acknowledge with M

r automatic calibration is started.

Operating level

270

Man.

xw____áûô___ 12%

The parameter X0c and X100c can be allocated to the extended operating level.

10.5

+

>3s

M

I

D

End

Hold

OStar

Para

M

End

I

Signl

D

Aux

Input

Contr

Tune

Limit

Setp

M

+

I

D

I

D

End

Cal

End

INP6

INP1

+

M

M

+

I

D

I

D

End

X100c

X0c

YpCal

End

X100c

X0c

+

M

M

+

0

X0c

Operating instruction KS94 12

Page 11

Operation (survey)

9.59.5 DAC – motor actuator monitoring (Digital Actor Control DAC®)

With all controllers with position feedback Yp, the motor actuator can be monitored for functional

troubles.

CFunc = 08 = 3-point stepping controller with position feedback as a potentiometer

CFunc = 09 = continuous with position feedback as a potentiometer

CFunc = 12 = continuous with current feedback via Yp (INP6)

The system detects the following stepping controller errors:

defective motor

w

defective capacitor (wrong rotating direction),

w

wrong phase followers

w

defective force transmission at spindle or drive,

w

excessive backlash due to wear

w

jamming of the control valve e.g. due to foreign body

w

With the continuous controllers, monitoring if output signal and position feedback exceed a

difference of 10 % after elapse of a 20 s filter time is provided. The DAC® function can be switched

on or off at parameter setting level (DAC = 0/1). A detected trouble is indicated, the controller

switches to manual mode and no pulses are output any more.

a

During Yp calibration, the DAC® function is activated! Otherwise, disabling would be

detected when reaching the limits and the controller would be switched to “off” (r

calibration).

9.6 Self-tuning (automatic optimization of control parameters)

After starting by the operator, the controller makes an attempt for optimization by determining the

parameters for fast line-out at the set-point without overshoot from the process characteristics.

Optimization start:the operator can start the optimization attempt at any time (see opposite drawing).

Preparation for self-tuning:

•

PID, PI, PD or P control behaviour can

be selected by the user by switching off

Tn=0 or Tv=0 before self-tuning start.

•

Determine which parameter set shall be

optimized (POpt).

Self-tuning cancelation:

The operator can cancel the optimization attempt at any time. This is possible by pressing key H

(Äcontroller switches to ‘manual’) or via OStop in menu1 (Ä controller switches to `automatic’).

The controller continues operating with the old parameter values.

•

Determine the output step change (dYopt).

•

Determine the stable correcting variable (YOptm).

•

Determine the `process-at-rest’ mode ( C.700 ; OCond)

•

Is the set-point reserve (x-w) > 10% of W100-W0?

Optimization problems:

With process conditions which prevent successful optimization, the controller cancels

the attempt for optimization (Ada F is displayed). The controller outputs are

switched off to prevent the set-point from being exceeded. Afer self-tuning

cancelation, controlling is continued with the old parameter values.

13 Operating instruction KS94

Page 12

Operation (survey)

9.7 Parameter and configuration level

Menu 1 is always selectable at operating level: several operations (r 7.2) and transition to parameter

level (Para).

Menu 2 is always selectable at parameter level: selection of additional displays (Mark), return to

parameter level (End), return to operating level (Exit), transition to configuration level (Conf).

Menu 3 is always selectable at configuration level: permitting the MORE area (More), return to

configuration level (End), return to operating level without storage of the last changes (Quit)or

with storage of the changes (Exit).

Value adjustment is as follows (parameter values / configuration codes):

Example for a single value Example for combined data (e.g. C-codes)

Operating instruction KS94 14

Page 13

10. Configuration

10.1 General

The KS94 controller configuration for quick and easy function selection during subsequent operation

is described in this section. During configuration, the required functions are selected from a large

variety of available functions. The configuration determines the basic structure for solution of an

application.

The configuration structure is designed so that determination of the required functions for a large

number of applications is possible by adjustment of as few configuration words as possible.

Moreover, the structure was designed flexible enough to permit additional configurations also for

realization of special applications.

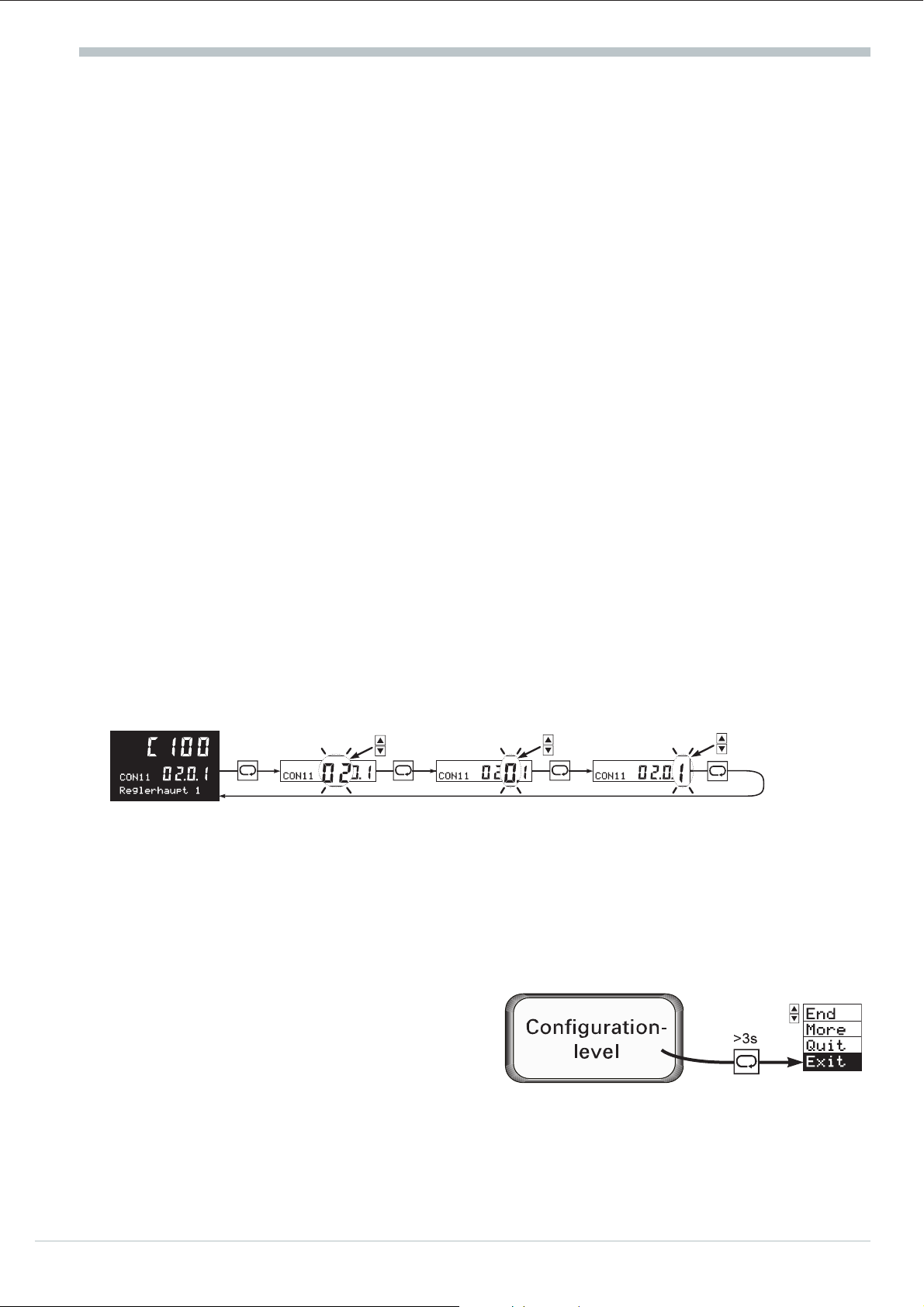

10.2 Basic structure

The first menu level permits selection of the main configuration group.

The user can be guided through all function configurations, or he can configure the specific functions

required for his application directly.

Configuration

For all ‘complex’ main groups, a two-level configuration concept which enables the user to select the

‘correct’ setting for his application by defining only one configuration word was determined. If

necessary, special functions can be determined separately. For the ‘normal user’, however, the

configuration words are preset to purposeful default values! For simplification, the hierarchic

configuration dialogue is structured so that the user can and must adjust only the ‘required’

configuration words.

The user configuration dialogue is started via selector key M and ‘increment’ / ‘decrement’ keys

ID, like with the other KS92/94 operating levels:

w

Press the selector key to select menu items / input values / input positions within a ‘level’ and to

change over to the next higher level at the end of a ‘level’.

w

Press the ‘increment’ / ‘decrement’ keys for returning to a lower level and for modification of input

values.

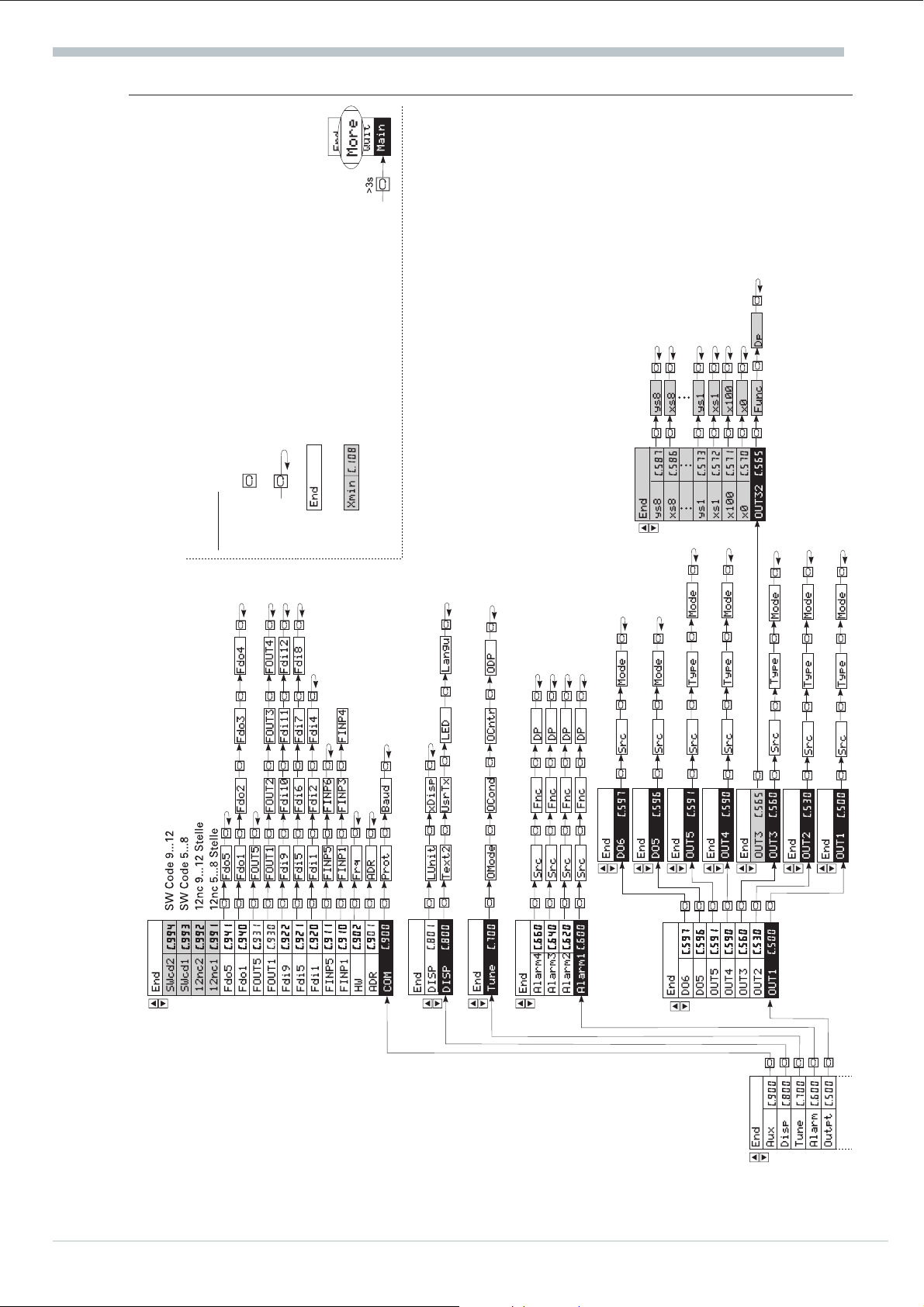

The configuration structure is shown on the two following pages (16 and 17). All possible

configuration words are listed. Configuration words which are irrelevant for a function are not

displayed during the dialogue!

Switch-over to a selection menu is possible from anywhere during configuration by pressing key M >3s.

End: Return to configuration level

More: Activating the More function

Quit: Return to operating level

(configuration changes are not effective)

Exit: Return to operating level (configuration

changes are effective and the controller

is re-initialized).

15 Operating instruction KS94

Page 14

Configuration

Fig.1: Configuration-Overview

Selector key:

Key for selection of menu item, input value and input

position

Acknowledgement and returnto menu item

Return to the previous selection menu is by

acknowledgement and End.

All configuration data shown with gray

background on the drawing are only

accessible after selection of the More

function.

Legend:

Operating instruction KS94 16

Page 15

Fig.2: Configuration-Overview

Configuration

17 Operating instruction KS94

Page 16

Configuration

10.3 Main groups

The following main configuration groups are available for KS9x controller configuration:

Contr

Sourc

Input

Outpt

Alarm

Tune

Disp

Aux

The main configuration groups are structured in a hierarchical order, whereby determination of a

dialogue for prompting only the really relevant configurations is possible.

ENGINEERING TOOL ‘ET/KS 94’

g

Engineering Tool ET/KS94 permits realization of all operations which are possible via the KS94

front panel on a PC, whereby controller configuration and parameter setting are facilitated

considerably.

Controller function

Input allocation

Input function

Output function

Alarm function

Self-tuning

User interface

Additional function

C.100

C.180

C.200

C.500

C.600

C.700

C.800

C.900

...

...

...

...

...

...

C.139

C.192

C.487

C.597

C.660

C.994

Ä page 19

Ä page 21

Ä page 23

Ä page 27

Ä page 31

Ä page 32

Ä page 32

Ä page 33

The engineering tool offers the following functions:

q

q

q

q

q

Connection of PC and KS94 controller is via an RS232/TTL adaptor cable, which must be ordered

separately (ordering information r see page 43 section 12 ). In conjunction with the ‘SIM/KS 94’

controller simulation, a graphic trend display of the real process data is available!

Operating instruction KS94 18

Creation and modification of the parameter set

Transmission of a parameter set to KS94

Read-out of a parameter set from a KS94

Long-term storage of various parameter sets on hard disk or floppy

Display of operating data

Page 17

10.4 CONTR: Controller

This main group determines the controller structure and function, which is used as starting point for

controller configuration for a particular application. The main controller configuration C.100 leads to

an input and output pre-adjustment (C.180.. C.190, C.500.. C591). This ‘proposal’ must always be

checked before commissioning and corrected, if necessary. After determination of this word, no

further settings are required for a large number of applications. Additional function adaptions are

possible via configuration words C.105 and the following configurations.

Main controller configuration 1:

CFunc CType WFunc

(Control behaviour) (Controller type) (Set-point function)

00: signaller 1 output

01: signaller 2 outputs

02: 2-pnt.controller

03: 3-pnt.controller

(heating switching and cooling switching)

04: 3-pnt.controller

(heating continuous and cooling switching)

05: 3-pnt.controller

(heating switching and cooling continuous)

06: {/Y-off

07: 3-pnt.stepping

08: 3-pnt.stepping with Yp (INP6)

09: continuous with position controler

10: continuous

11: continuous split-range

(only with Optin C; OUT1 and OUT3)

12: continuous with current feedback via Yp (INP6)

0: standard controller

1: ratio controller

(Ä C.107)

2: 3-element controller

x

= x1+aw(x2-x3)

eff

3: mean value

x

= (1-b)wx1+bwx2

eff

Configuration

0: set-point

1: set-point / cascade

2: programmer

3: set-point with ext. offset

4: set-point / cascade with

internal offset

5: set-point / cascade with

external offset

6: programmer with

internal offset

7: programmer with

external offset

Main controller configuration 2:

CMode CDiff CFail

(Output action) (Differentiation) (Controller behaviour with main variable sensor break)

0: inverse

1: direct

0: differentiate Xw

1: differentiate X

0: neutral (controller outputs switched off)

1: Ypid = Ymin (0)

2: Ypid = Ymax (100)

3: Ypid = Y2 (adjustment via front panel not possible)

4: Ypid = Y2 (adjustment via front panel possible)

19 Operating instruction KS94

Page 18

Configuration

More

00: no

01: X+Z in conjunction with the process value without differentiation

02: X+-dZ/dt in conjunction with the process value with differentiation

in both directions

03: X+dZ/dt in conjunction with the process value with differentiation

and positive change

04: X-dZ/dt in conjunction with the process value with differentiation

and negative change

05: Y+Z in conjunction with the correcting variable without

differentiation

06: Y+-dZ/dt in conjunction with the correcting variable with

differentiation in both directions

07: Y+dZ/dt in conjunction with the correcting variable with

differentiation and positive change

08: Y-dZ/dt in conjunction with the correcting variable with

differentiation and negative change

Use of an auxiliary variable and external y limiting:

CAux COVC

(Auxiliary variable z via INP3/6) (Output limiting)

0: no external limiting

1: OVC+

2: OVC-

Set-point functions:

(only with option C, Wext and not with 3-element controller)

More

C.106

CON1

Reglerzusatz 2

0.0.0.0

WTrac dW W Sel

(Behaviour of Wint when switching over from Wext to

Wint with the w tracking input switched on )

0: Set-point tracking

1: Process value tracking

Ratio functions: (only with ratio controller)

More

C.107

CON1

Reglerzusatz 3

1.00.2

Ratio XDp

(Ratio control function) (Process value decimal point)

1: (x1 + N0) / x2

2: (x1 + N0) / (x1 + x2)

3: (x2-x1+N0)/x2

0: no digit behind decimal point

1: 1 digit behind decimal point

2: 2 digits behind decimal point

3: 3 digits behind decimal point

(Type of set-point

tracking.)

0: additive

1: factor

(MIN/MAX selection)

0: no selection

1: Max selection Weff

2: Min selection Weff

Operating instruction KS94 20

Page 19

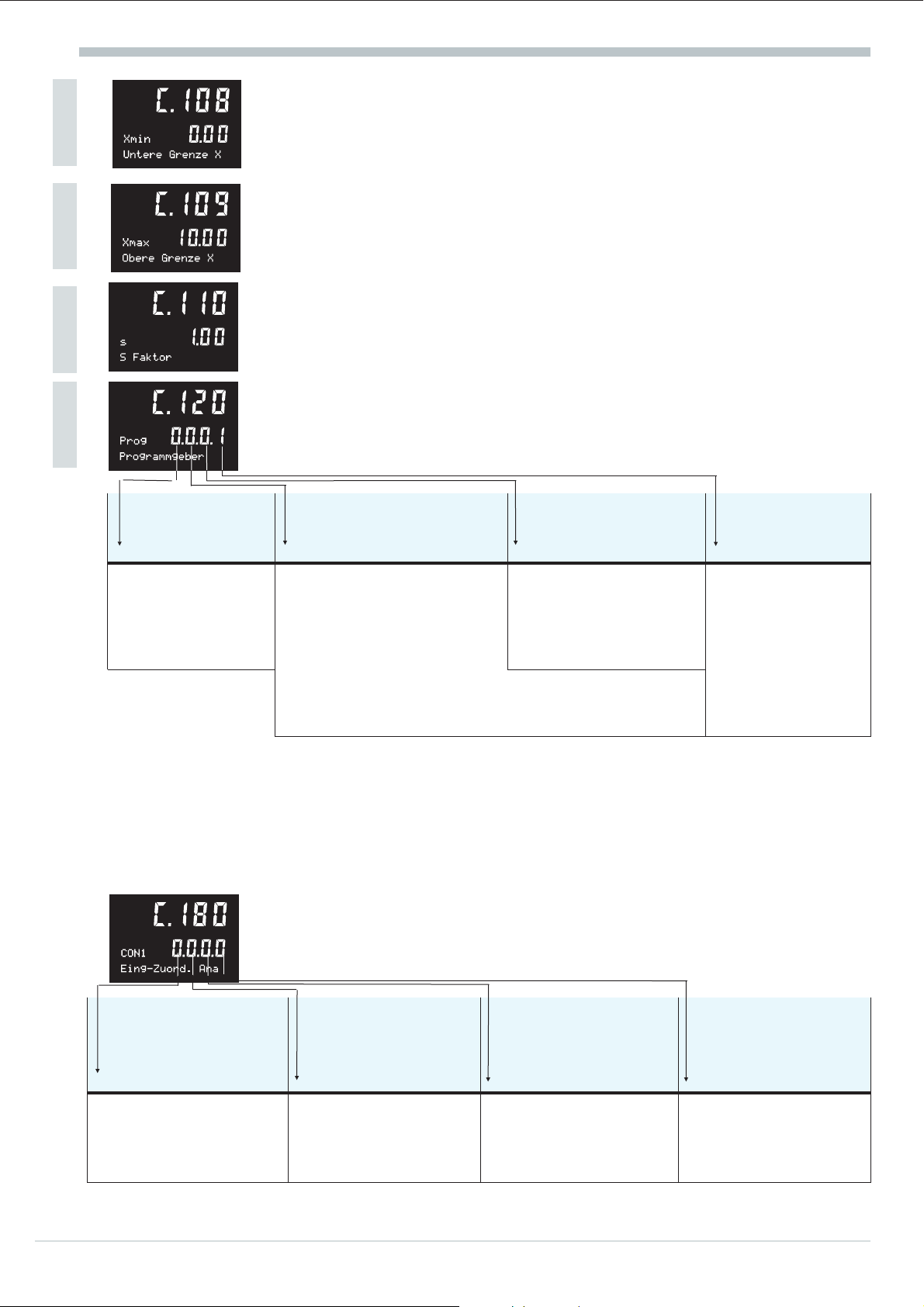

More MoreMore More

Configuration

Span start X0: (only with ratio controller)

Xmin:(min. process value limiting Xmin)

Numeric value: -999 ... 9999

Span end X100: (only with ratio controller)

Xmax:(max. process value limiting Xmax)

Numeric value: -999 ... 9999 and Xmin Xmax

Factor for stoichiometric ratio s: (only with ratio controller)

S:stoichiometric ratio

Numeric value: 00.00 ... 99.99 (2 fixed digits behind decimal point)

Programmer configuration:

(only with programmer configured)

PSel PwrUp PEnd PStrt

(Source for program

selection)

0: program selection

via operation

1: program selection

via control input

*C.190; SWi/e select the source for int/ext-switching.

(Behaviour with mains

recovery)

0: continue program

1: stop program and switch over

to Wint

2: continue program after

automatic research

3: continue program after successful automatic research

otherwise switch over to Wint

4: continue program at the time mark of mains recovery

10.5 SOURCE: Input signal allocation

Input signal allocation is dependent of main controller configuration ‘C.100‘. this proposal must

always be checked before commissioning and corrected, if necessary. Therefore, input signal

allocation ‘SOURCE’ is no independent main item and considered as additional configuration of

‘CONTR’.

Signal allocation analog signals:

(Behaviour with

program end)

0: continue with following

program

1: following program and

reset (start required)

(Source for

Run/Stop)

0: start/stop and

reset together*.

control with

int/ext (without

Option B)

1: start/stop and

reset separate.

(Option B)

S X2 SWext S dW S Z

(Signal source for X2

with ratio and

three-element controller)

0: X2 switched off

1: X2 of INP5

2: X2 of INP3

(Signal source for Wext

with controller with

external set-point)

0: Wext switched off

1: Wext of INP5

2: Wext of INP6

3: Wext of INP4

21 Operating instruction KS94

(Signal source for W

with controller with

set-point offset

0: dW switched off

1: dW of INP5

2: dW of INP6

3: dW of INP4

(Signal source for

auxiliary variable)

0: z switched off

1: z of INP3

2: z of INP6

3: z of INP4

Page 20

Configuration

Allocation of digital signals for set-point processing:

SWi/e STrac SdWon Sw/W2

(Set-point switch-over

from internal to external)

0: only internal set-point

1: W/Wext via front

2: di1=external set-point

3: di2=external set-point

4: di1= internal set-point

5: di2= internal set-point

Allocation of digital signals for the controller functions:

S A/M SPI/P SY2on SCoff

(Automatic / manual

(manual switch-over)

0: auto/manual via front

1: fixed to manual

2: di1 = manual

3: di2 = manual

4: Backup run

5: di1 = auto

6: di2 = auto

(Bumpless switch-over

to int. set-point with

1)

int./ext. switch-over )

0: no tracking

2)

1: tracking on

2: di2 = tracking on

3: di12 = tracking on

4: di2 = tracking off

5: di12 = tracking off

(3.pnt.stepping controller:

feedback off, otherwise

PI / P switch-over)

0: PI fixed

2)

1: fixed to P action

2: di1 = P action

3: di2 = P action

4: di1 = PI action

5: di2 = PI action

(Effective set-point

offset)

0: no offset

2)

1: offset on

2: di1 = offset on

3: di2 = offset on

4: di11 = offset on

5: di1 = offset off

6: di2 = offset off

7: di11 = offset off

(Output of safe

correcting value)

0: Y no Y2)

2)

1: fixed to Y2

2: di1 = Y2

3: di2 = Y2

4: timer = Y2

5: di1 = Y

6: di2 = Y

(Switch-over to

set-point w2)

0: no W2

2)

1: fixed to W2

2: di1 = W2

3: di2 = W2

4: di12 = W2

5: Timer = W2

6: di1 = W

7: di2 = W

8: di12 = W

(Switch-off controller)

0: controller on/off via

front (W = ‘——’)

1: controller fixed to off

2: di1 = controller off

3: di2 = controller off

4: timer= controller off

5: di1= controller on

6: di2= controller on

Allocation of digital signals for the programmer:

(only with programmer configured)

More

SPrSt

(Signal source for programmer run/stop)

0: Run/Stop: Front

1: Run/Stop: di4

2: Run/Stop: di4 and timer 1

1) With the programmer configured, switch-over is between internal and external program set-point.

2) Can be switched over via interfaces (e.g. engineering tool; operating data)

Operating instruction KS94 22

Page 21

10.6 INPUT: inputs

The signal inputs for the previously selected controller configuration are determined in this main

group. The signal inputs required for the selected controller function are displayed in the menu for

configuration. As during control function configuration, a large number of applications can also be

covered by determining the main configuration. At the second level, special cases can be matched and

adjusted by additional, optional configuration.Max. 5 signal inputs are provided on KS94. Analog

inputs INP1, INP5 and INP6 are always provided; INP3 and INP4 are optional inputs.

All analog inputs (whether or not used for control) can be used for monitoring purposes

(e.g. alarm processing).

10.6.1 Signal input 1 / INP1 (main variable x1)

Configuration is for main variable x1. This signal input is a universal input for which extensive

functions can be configured.

Main configuration:

The main configuration word is used for determination of input sensor type and

physical unit. Additional input configurations can be determined using the

additional configuration.

Configuration

Type Unit Dp

(Sensor type) (Unit)* (Number of decimals)

Thermocouple:

00: Type L 0 ... 900 °C

01: Type J 0 ... 900 °C

02: Type K 0 ... 1350 °C

03: Type N 0 ... 1300 °C

04: Type S 0 ... 1760 °C

05: Type R 0 ... 1760 °C

06: Type T 0 ... 400 °C

07: Type W 0 ... 2300°C

08: Type E 0 ... 900 °C

09: Type B ( 0) ... 400

...1820°C

* Unit settings for scaling of Typ 00...26. With Typ 30...40 the value is fixed to 0. For this case the unit to be displayed will be configured by C.801.

x0:

(physical value at 0%)

numeric value -999 ... 9999

select only with type = 30 ... 40

Resistance thermometer:

20: Pt 100 -99.9 ... 850.0 °C

21: Pt 100 -99.9 ... 250.0 °C

25: 2 x Pt 100 -99.9 ... 850.0

°C

26: 2 x Pt 100 -99.9 ... 250.0

°C

Standard signals:

30: 0 ... 20 mA

31: 4 ... 20 mA

32: 0 ... 10 V

33: 2 ... 10 V

Potentiometric transducer:

40: 0 ... 500 Ohm

0: at

30...40

1: °C

2: °F

Typ

0: no decimal point

1: 1 digit behind the

decimal point

2: 2 digits behind the

decimal point

3: 3 digits behind decimal point

only with type: 20 ... 40

x100:

(physical value at 100%)

numeric value -999 ... 9999 , X0≠X100!

select only with type = 30 ... 40

23 Operating instruction KS94

Page 22

Configuration

Additional configuration:

Via the additional configuration, the default setting for the signal input can be

changed or matched dependent of sensor type class.

Fail STk XKorr

(Signal behaviour with

sensor fault)

1: upscale(X100)

2: downscale(X0)

3: XFail (C.213)

Type: 00...26, 31, 40 type: 00 ... 09

Non-selectable digits are marked by ‘0’

0: not effective

1: internal TC

2: external TC

Tkref:

(external TC)

numeric value:-99 ... 100 °C or °F

select only with type: 00...08 and STk = 2

XFail:

(substitute value with sensor error)

numeric value: -999 ... 9999

(Temperature

compensation)

(TC fixed in C.210!)

(Process value correction enable)

0: not effective

1: with process value correction (adjustable via

parameters x1in,x1out,x2in,x2out)

Tfm:

(filter time constant for input value processing)

numeric value: 0.0 ... 999.9

Optional configuration 1:

The optional configuration can be used to determine the functions

for two signal pre-processing levels.

Func1, Func2 LDp

(Function selection for signal pre-processing) (decimal point for gain, Xeff and yki)

0: no function, signal is output directly

1: scaling (parameters: m,b)

2: linearization (segment points xs1,ys1 ...)

3: filter (parameter: Tf)

4: square root extraction with factor (parameter:gain)

0: no decimal point

1: 1 digit behind the decimal point

2: 2 digits behind the decimal point

3: 3 digits behind decimal point

Operating instruction KS94 24

Page 23

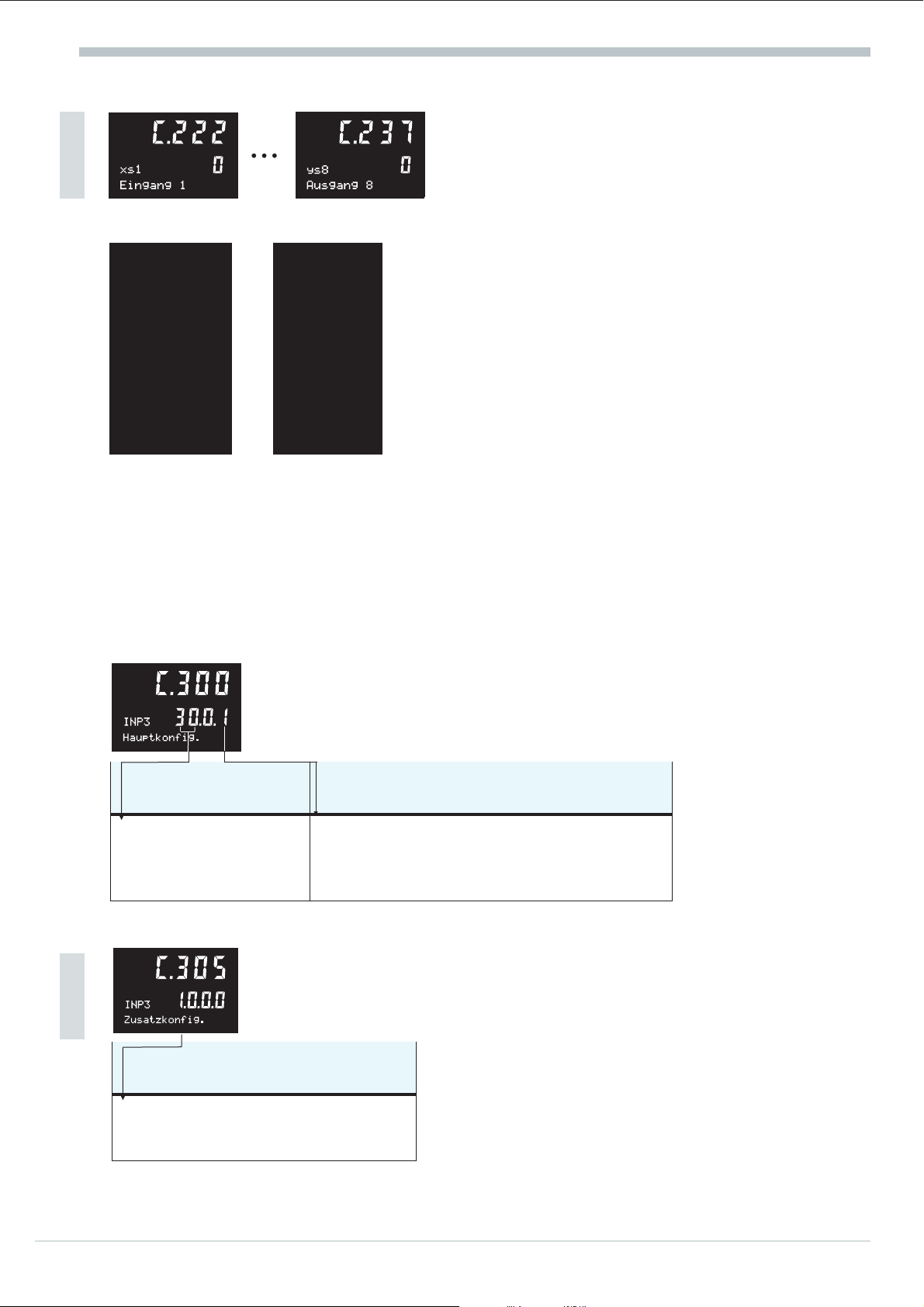

Linearization parameters:

More

The configuration parameters for linearization are stored as follows.

Configuration

C.222 xs1 C.223 ys1

C.224 xs2 C.225 ys2

C.226 xs3 C.227 ys3

C.228 xs4 C.229 ys4

C.230 xs5 C.231 ys5

C.232 xs6 C.233 ys6

C.234 xs7 C.235 ys7

C.236 xs8 C.237 ys8

The range for these configuration words is within -999 and 9999 or ‘——’ (switched off)!

For limiting the number of parameters, these functions can be used only once during pre-processing levels

g

1 or 2! Linearization segment points which are not required can be switched off by setting ‘——‘.

value pair 1

value pair 2

value pair 3

value pair 4

value pair 5

value pair 6

value pair 7

value pair 8

a

Note that the input values

(x-values) must be entered in

ascending order.

(xs1<xs2<xs3...)

10.6.2 Signal input 3 / INP3 (ratio variable x2 or auxiliary variable z)

In this case, the signal is configured for ratio variable x2 or auxiliary variable z, provided that option

p.c.b. C is fitted in the controller and the function was selected during controller configuration.

Main configuration:

Selection is only possible with option p.c.b. C provided.

(Sensor type) (Number of digits behind the decimal point)

Standard signals:

30: 0 ... 20 mA

31: 4 ... 20 mA

More

(Signal behaviour with sensor error)

1: upscale (X100)

2: downscale (X0)

3: XFail (C.313)

Type Dp

0: no decimal point

1: 1 digit behind the decimal point

2: 2 digits behind the decimal point

3: 3 digits behind decimal point

Additional configuration:

The additional configuration can be used for changing or matching the signal

input default setting for the sensor type.

Select only with type = 31 option p.c.b. C and ratio or auxiliary variable selected.

Fail

25 Operating instruction KS94

Page 24

Configuration

The other configuration words for INP3 are explained in section (see following table).

C.301

X0

C.302

X100

C.313

XFail

C.314

Tfm

optional configuration 1

C.320

10.6.3 Signal input 4 / INP4 (variable x3, ext. set-point Wext, override control ovc+/-)

The signal for three-element variable x3 or the galvanically isolated external set-point Wext or

the override control signal ovc+/- are configured with option p.c.b. C fitted in the controller

and the function selected during controller configuration.

The configuration words for INP4 are explained in section and (see following table).

Main configuration

Additional configuration

Optional configuration 1

Optional configuration 2

Linearization table

C.350

C.351

X0

C.352

X100

C.355

C.363

XFail

C.364

Tfm

C.370

C.371

C.372

.. ..

C.387 C.237

see

„

„

„

„

see

„

„

„

„

„

„

„

„

C.201

C.202

C.213

C.214

C.220

C.300

C.201

C.202

C.305

C.213

C.214

C.220

C.221

C.222

without linearization (Func1/2: 2)

10.6.4 Signal input 5 / INP5 (ratio variable x2, ext. set-point Wext)

The signal for ratio variable x2 or external set-point Wext is configured with option p.c.b. not fitted in

the controller and the function selected during controller configuration. The configuration words for

INP5 are explained in section and (see following table).

Main configuration

X0

X100

Additional configuration

XFail

Tfm

Optional configuration 1

C.400

C.401

C.402

C.405

C.413

C.414

C.420

see

„

„

„

„

„

„

C.300

C.201

C.202

C.305

C.213

C.214

C.220

additional 0/2...10V (type: 32/33)

without linearization (Func1/2: 2)

10.6.5 Signal input 6 / INP6 (auxiliary variable Yp, feedback Yp)

The signal for the auxiliary variable Yp or for the position feedbackk is configured, if this was

selected during controller configuration.

The configuration words for INP6 are explained in section and (see following table).

Main configuration

X0

X100

Additional configuration

XFail

Tfm

Optional configuration 1

C.450

C.451

C.452

C.455

C.463

C.464

C.470

see

„

„

„

„

„

„

C.300

C.201

C.202

C.305

C.213

C.214

C.220

additional potentiometric transducer for Yp (type: 40)

without linearisierung (Func1/2: 2)

Operating instruction KS94 26

Page 25

10.7 OUTPT: outputs

10.7.1 Signal output 1 / OUT1

Used for configuring the source of output OUT1. This signal output is a universal

output which can be configured for extensive functions.

Main configuration:

Src Type Mode

(Signal source) (Output stage) (Motor actuator output action)

00: output switched of

01: controller output Y1/Yout1

02: controller output Y2/Yout2

03: output Ypid

04: position feedback Yp

05: controlling deviation Xw

10: process value Xeff

11: X1

12: X2

13: X3

20: set-point W

21: external set-point Wext

22: external offset dWe

23: set-point Weff

24: programmer set-point Wprg

25: alarm 1 (limit1)

26: alarm 2 (limit2)

27: alarm3 (limit3)

28: alarm 1 (limit4)

0: relay (switching)

1: 0 ... 20 mA (continuous output)

2: 4 ... 20 mA (continuous output)

3: 0 / 20 mA (logic)

Configuration

0: not selectable

1: direct / normally open

2: inverse / normally closed

Additional configuration Out1:

Via the options configuration, the functionality for a signal post-processing stage

C.505

OUT1 0.0.0.0

More

Zusatzkonfig.

(Function selection for signal

output processing)

0: no function, signal is output

without change (0%...100%)

1: scaling (reference values C.510

and C.511 are effective)

C.510

x0

Bezugswert 0%

C.511

x100

Bezugswert 100%

100

can be determined.

This configuration word is displayed only with the option enabled.

Func Dp

X0:

(physical value at 0%)

Numeric value -999 ... 9999

0

x100:

(physical value at 0%)

Numeric value -999 ... 9999

(decimal point for xsi,x0,x100)

0: no decimal point

1: 1 digit behind decimal point

2: 2 digits behind decimal point

3: 3 digits behind decimal point

27 Operating instruction KS94

Page 26

Configuration

10.7.2 Signal output 2 / OUT2

Used for configuring the source of output OUT2. This signal output is a universal output and can be

configured for extensive functions.

Main configuration:

Src Type Mode

(Signal source) (Output stage) (Motor actuator output action)

00: output switched off

01: controller output Y1/Yout1

02: controller output Y2/Yout2

25: alarm1 (limit1)

26: alarm2 (limit2)

27: alarm3 (limit3)

28: alarm4 (limit4)

10.7.3 Signal output 3 / OUT3

0: relay (switching) 0: not selectable

1: direct / normally open

2: inverse / normally closed

Used for configuring the source of output OUT3. This signal output is a universal

C.560

OUT3

Hauptkonfig.

00: none (output switched off)

01: controller output Y1/Yout1

02: controller output Y2/Yout2

03: controller output Ypid

04: position feedback Yp

05: control deviation xw

10: process value xeff

11: process value x1

Additional configuration:

The optional configuration can be used for determining the functions for signal post-processing.This

10.1.1

output and can be configured for extensive functions.

Main configuration:

Selection is only possible with option C fitted.

Src Type Mode

(Signal source) (Output stage)

12: process value x2

13: process value x3

20: set-point Wint

21: ext. set-point Wext

22: ext. Offset dWe

23: set-point Weff

24: programmer Wprg

configuration word is displayed only with the option enabled.

0: switched off

1: 0 ... 20 mA

(continuous

output)

2: 4 ... 20 mA

(continuous

output)

3: 0 / 20 mA (logic)

(Motor actuator output

0: not selectable

1: direct / normally open

2: inverse / normally closed

action)

C.565

OUT3

More

Zusatzkonfig.

0: no function, signal is output directly (0%...100%)

1: scaling (reference values C.570 and C.571 are effective)

2: linearization (segment points xs1,ys1 ...)

Operating instruction KS94 28

1.0.0.0

Func Dp

(Function selection for signal output processing) (decimal point for xsi,x0,x100)

0: no decimal point

1: 1 digit behind the decimal point

2: 2 digits behind the decimal point

3: 3 digits behind decimal point

Page 27

a

x0:

(physical value at 0%)

numeric value -999 ... 9999

x100:

(physical value at 100%)

numeric value -999 ... 9999

Note that the input values (x-values)

must be entered in ascending order.

(xs1<xs2<xs3...)

Configuration

The configuration parameters for linearization are stored as

follows.

C.572 xs1 C.573 ys1

C.574 xs2 C.575 ys2

C.576 xs3 C.577 ys3

C.578 xs4 C.579 ys4

C.580 xs5 C.581 ys5

C.582 xs6 C.583 ys6

C.584 xs7 C.585 ys7

C.586 xs8 C.587 ys8

value pair 1

value pair 2

value pair 3

value pair 4

value pair 5

value pair 6

value pair 7

value pair 8

10.7.4 Signal output 4 / OUT4

Used for configuring the source of output OUT4. This signal output can be

configured for extensive functions.

Main configuration:

Src Type Mode

(Signal source) (Output stage) (Actuator output action)

00: output switched off

01: controller output Y1/Yout1

02: controller output Y2/Yout2

25: alarm 1 (limit1)

26: alarm 2 (limit2)

27: alarm 3 (limit3)

28: alarm 4 (limit4)

29: programmer output 1

30: programmer output 2

31: programmer output 3

32: programmer output 4

33: program end

The range for these configuration words is within -999 and

9999 or ‘——’ (switched off)!

0: relay (switching) 0: not selectable

1: direct / normally open

2: inverse / normally closed

29 Operating instruction KS94

Page 28

Configuration

10.7.5 Signal output 5 / OUT5

Used for configuring the source of output OUT1.. This signal output can be configured for extensive

functions.

Main configuration:

Src Type Mode

(Signal source) (Output stage) (Actuator output action)

00: output switched off

01: controller output Y1/Yout1

02: controller output Y2/Yout2

25: alarm 1 (limit1)

26: alarm 2 (limit2)

27: alarm 3 (limit3)

28: alarm 4 (limit4)

29: programmer output 1

30: programmer output 2

31: programmer output 3

32: programmer output 4

33: program end

0: relay (switching) 0: not selectable

1: direct / normally open

2: i nverse / normally closed

10.7.6 DO5,6 (digital control outputs)

Additional digital control outputs are configured!

Main configuration:

(digital control signal DO5)

Selection is possible with option C fitted.

Src Mode

(Digital control signal DO5) (Actuator output action)

00: output switched off

01: controller output Y1

34: status automatic=0 / manual=1

Main configuration:

(Digital control signal DO6)

Selection is possible with option C fitted.

0: not selectable

1: direct / normally open

2: inverse / normally closed

Src Mode

(Digital control signal DO6)

00: output switched off

02: controller output Y2

35: status external=0 / internal=1

Operating instruction KS94 30

(Motor actuator output

0: not selectable

1: direct / normally open

2: inverse / normally closed

action)

Page 29

10.8 ALARM: alarms

10.8.1 Alarm 1 / (limit 1)

The function for alarm 1, (output via output OUT 4) is configured.

Configuration

C.600

ALRM1

Alarm 1

00: no source

01: Xeff

02: Xw*

03: x1

04: x2

05: x3

06: auxiliary

variable z

07: Wext

08: {w

09: Weff

10: Yp

*Limit comparator (refered to set-point), all other versions are fitted with limit contact.

00.0.0

(Alarm signal source) (Alarm function)

Main configuration:

Src Fnc Dp

(Decimals for alarm

11: Ypid

12: OVC

13: WMIN/MAX (Wsel)

14: INP1

16: INP3

17: INP4

18: INP5

19: INP6

20: program time (net)

21: program time (gross)

22: program rest time

23: Status PROFIBUS-DP

24: faulty actor

0: no alarm (don’t care)

1: sensor fail

2: sensor fail or measurement

value alarm

3: sensor fail or measurement

value

alarm with suppression with

set-point switch-over or

start-up

4: measurement value alarm

5: measurement value alarm with

suppression with set-point

change

or start-up

6: Bus error (PROFIBUS-DP)

0: no decimal point

1: 1 digit behind the

decimal point

2: 2 digits behind the

decimal point

3: 3 digits behind the

decimal point

limits)

10.8.2 Alarm 2 (limit 2)

The function for alarm 2 (output via OUT 5) is configured.

Main configuration

10.8.3 Alarm 3 (limit 3)

The function for alarm 3 (output via OUT 1) is configured.

Main configuration

Selection is possible with OUT1 configured as alarm output.

10.8.4 Alarm 4 (limit 4)

The function for alarm 4 (output via OUT 2) is configured.

Main configuration

Selection is possible only with OUT2 configured as alarm output

C.620

C.640

C.660

see

see

see

C.600

C.600

C.600

4 31 Operating instruction KS9

Page 30

Configuration

10.9 TUNE:self-tuning

The type of controller self-tuning and the type of controlled self-tuning can be

adjusted!

Main configuration:

OMode OCond OCntr ODP

(Controller

self-tuning)

0: Standard 0: grad = 0

10.10 DISP: User interface for operation

(Process-at-rest mode) (Controlled self-tuning mode)

1: grad < 0

with inverse controller

or grad > 0

with direct controller

2: grad≠0

0: no function

1: selectable control / disturbance behaviour

2: switch-over via operation

3: switch-over via control input

4: switch-over controlled by Weff

5: switch-over controlled by Xeff

6: switch-over controlled by Ypid

7: switch-over controlled by X-W

(Decimals for

OCntr)

0: no decimal point

1: 1 digit behind

the decimal point

2: 2 digits behind

the decimal point

3: 3 digits behind

the decimal point

Configuration of display function signification via front panel

L1 process operation:

Text2 UsrTx LED Langu

(Signification of display text2)

0: Y (correcting variable display)

bargraph (-100% ...) 0% ...+100%

1: Xw (control deviation) bargraph

-10% ... 0% ... +10% span

2: Tprog bargraph (elapsed

program time) 0 ... tmax

3: Status display

Unit display:

(User text

selection)

0: no user text

1: user text via

control input

2: user text via

function

statuses

(Front LED function)

0: logic output levels

Y1,Y2,LIM1,LIM2

1: logic output levels LIM1...LIM4

2: programmer control outputs D1 ... D4

3: logic output levels LIM1,Y1, Y2, LIM2

4: PROFIBUS-DP errors

5: logic output levels Y2, Y1, LIM1, LIM2

6: logic output levels LIM1,Y2, Y1, LIM2

(Language selection

of text displays)

0: German

1: English

2: French

LUnit xDisp wDisp

(Unit selection for text 1) (select process value for disp.) (select set-point for disp.)

00: no unit

01: °C

02: °F

03: %

04: mbar

05: bar

Operating instruction KS94 32

06: t/h

07: m3/h

08: 1/min

99: freely selectable

Engineering toolnecessary

0: Process value =xeff

1: Process value =x1

2: Process value =x2

3: Process value =x3

0: set-point disp. = Standard

1: set-point disp. = Weff

Page 31

10.11 AUX: Additional functions

The interface function and operating frequency for suppression of interference on inputs are

configured.

10.11.1 COM (serial interface)

Mainconfiguration:

C.900

COM

Schnittstelle

0: IS0174 00: not adjustable

*PROFIBUS: automatic baud rate detection

0.03.0

Prot Baud Addr

(Interface protocol) (Baud rate)* (Interface address)

(IS01745, PROFIBUS)

Only with HW option B

01: 2400 Bd

02: 4800 Bd

03: 9600 Bd

04: 19200 Bd

10.11.2 Hardware

The hardware-related functions are configured.

Main configuration:

Operating frequency for suppression of interference on inputs is configured.

Configuration

ISO1745

0 ... 99 (default 0)

PROFIBUS-DP

1...128 (default 128)

Frq (Mains frequency)

0: 50 Hz

1: 60 Hz

10.11.3 Forcing signal input

All configuration for forcing ar only

present by PROFIBUS-DP

FINP1 FINP3 FINP4 FINP5 FINP6

(Forcing input 1) (Forcing input 3) (Forcing input 4) (Forcing input 5) (Forcing input 6)

0: Controller value

1: Forcing

0: Controller value

1: Forcing

10.11.4 Forcing digital input

10.11.5

Fdi1 Fdi2 Fdi4

(Forcing digital input 1) (Forcing digital input 2) (Forcing digital input 4)

0: Controller value

1: Forcing

0: Controller value

1: Forcing

0: Controller value

1: Forcing

0: Controller value

1: Forcing

0: Controller value

1: Forcing

0: Controller value

1: Forcing

4 33 Operating instruction KS9

Page 32

Configuration

(Forcing dig. Eingang 5) (Forcing dig. Eingang 6) (Forcing dig. Eingang 7) (Forcing dig. Eingang 8)

0: Controller value

1: Forcing

(Forcing dig. input 9) (Forcing dig. input 10) (Forcing dig. input 11) (Forcing dig. input 12)

0: Controller value

1: Forcing

Fdi5 Fdi6 Fdi7 Fdi8

0: Controller value

1: Forcing

Fdi9 Fdi10 Fdi11 Fdi12

0: Controller value

1: Forcing

0: Controller value

1: Forcing

0: Controller value

1: Forcing

0: Controller value

1: Forcing

0: Controller value

1: Forcing

10.11.6 Forcing signal output

FOUT1 FOUT2 FOUT3 FOUT4 FOUT5

(Forcing signl.

outp. 1)

0: Controller value

1: Forcing

2: Release signal

(Forcing signl.

outp. 1)

0: Controller value

1: Forcing

2: Release signal

10.11.7 Forcing digital output

Fdo1 Fdo2 Fdo3 Fdo4 Fdo5/6

(Forcing dig.

outp.1)

0: Controller value

1: Forcing

2: Release signal

(Forcing dig.

outp.2)

0: Controller value

1: Forcing

2: Release signal

(Forcing signl.

outp. 1)

0: Controller value

1: Forcing

2: Release signal

(Forcing dig.

outp.3)

0: Controller value

1: Forcing

2: Release signal

(Forcing signl.

outp. 1)

0: Controller value

1: Forcing

2: Release signal

(Forcing dig.

outp.4)

0: Controller value

1: Forcing

2: Release signal

(Forcing signl.

outp. 1)

0: Controller value

1: Forcing

2: Release signal

(Forcing dig.

outp.5/6)

0: Controller value

1: Forcing

2: Release signal

Operating instruction KS94 34

Page 33

10.11.8 Hard-/Software Codenumber

The following configuration dates are not changeable. They show the hardware version

(C.991 u. C.992) and the software version (C.993 u. C.994) of the instrument.

Example: 9407 923 31201 Example: 4012 157 25320

More

10.12 Examples of configuration

Block diagram Configuration, different from default

9407-9x4-xxxxx

INP1

INP5

INP6

INP3

INP4

Continuous controller

1 xw- alarm, 2 process value alarms

9407-9xx-xxxxx

INP1

INP5

INP6

INP3

INP4

2-pnt. controller +

2 process value alarms

9407-9xx-xxxxx

INP1

INP5

INP6

INP3

INP4

3-pnt. stepping controller +

process value alarm

9407-9x4-xxxxx

INP1

INP5

INP6

INP3

INP4

Ratio controller (continuous)

1 xw- alarm, 2 process value alarms

9407-9x4-1x2xx

INP1

INP5

INP6

di4

di5

Programmer (continuous)

1 xw- alarm

9407-9x4-x1xxx

INP1

INP5

INP6

INP3

INP4

Continuous contr. ‘split-range’

1 xw- alarm, 1 process value alarm

x

x Heizen

x AUF

yp

x1

x2

xeff

x

start/stop

reset

x

xw

xw

wp

xw

xw

ZU

Ende

y1

y2

OUT1

OUT2

OUT4

OUT5

OUT3

OUT1

OUT2

OUT4

OUT5

OUT3

OUT1

OUT2

OUT4

OUT5

OUT3

OUT1

OUT2

OUT4

OUT5

OUT3

OUT1

OUT2

OUT4

OUT5

OUT3

OUT1

OUT2

OUT4

OUT5

OUT3

C.100

C.200

C.500

C.530

C.100

C.200

C.500

C.590

C.100

C.200

C.530

C.590

C.100

C.180

C.200

C.500

C.100

C.192

C.200

C.500

C.100

C.200

C.500

C.560

CFunc

CTyp

WFunc

Typ

Src

Src

CFunc

CTyp

WFunc

Typ

Src

Src

CFunc

CTyp

WFunc

Typ

Src

Src

CFunc

CTyp

WFunc

SX2

Typ

Src

CFunc

CTyp

WFunc

SPrSt

Typ

Src

CFunc

CTyp

WFunc

Typ

Src

Src

= 10 (continuous)

= 0 (standard controller)

=0,1,4or5

= sensor type

= 01(controller output y1)

= 28 (alarm 4)

= 02 (2-pnt.controller)

= 0 (standard controller)

=0,1,4or5

= sensor type

= 01(controller output y1)

= 25 (alarm 1)

= 03 (3-pnt.stepping)

= 0 (standard controller)

=0,1,4or5

= sensor type

= 01 (controller output y1)

= 02 (controller output y2)

= 10 (continuous)

= 1 (ratio controller)

=0,1,4or5

= 1 (INP5)

= sensor type

= 01(controller output y1)

= 10 (continuous)

= 1 (standard controller)

= 3 (programmer)

= 1 (di4)

= sensor type

= 01(controller output y1)

= 11 (continuous split-range)

= 1 (standard controller)

=0,1,4or5

= sensor type

= 01(controller output y1)

= 02(controller output y2)

C.590

C.591

C.600

C.660

C.640

C.591

C.660

C.640

C.591

C.620

C.530

C.590

C.591

C.600

C.660

C.640

C.530

C.591

C.600

C.590

C.591

C.600

C.660

Src

Src

Src

Src

Src

Src

Src

Src

Src

Src

Src

Src

Src

Src

Src

Src

Src

Src

Src

Src

Src

Src

Src

Configuration

= 25 (alarm 1)

= 26 (alarm 2)

= 02 (xw-alarm)

= 03 (process value x1)

= 03 (process value x1)

= 26 (alarm 2)

= 03 (process value x1)

= 03 (process value x1)

= 26 (alarm 2)

= 03 (process value x1)

= 28 (xw-alarm)

= 25 (alarm 1)

= 26 (alarm 2)

= 02 (xw-alarm)

= 01 (xeff)

= 03 (process value x1)

= 28 (alarm 4)

= 33 (program end)

= 02 (xw-alarm)

= 25 (alarm 1)

= 26 (alarm 2)

= 02 (xw-alarm)

= 03 (process value x1)

35 Operating instruction KS94

Page 34

Parameters

11. Parameters

11.1 General

This section gives a survey of the KS92/94 parameter data and general hints for parameter handling.

The parameter operation and effect on the controller operation are described with the operating

principle.

The parameter setting dialogue is realized via selector key M and ‘increment’ / ‘decrement’ keys

ID, like at the other operating levels:

Press the selector key to select menu items / input values within one level and to change to the next

w

higher level.

Press the ‘increment’ / ‘decrement’ keys to return to a lower level or to change input values.

w

11.1.1

The controller parameter structure is given on the following page. All

Parameters which are not relevant for a function (configuration-dependent) are not displayed!

A selection menu can be displayed anywhere at parameter level by pressing key M >3s.

End: return to parameter level

Mark: mark the selected parameter for

display at ‘extended’ configuration level.

Exit: return to operating level.

Conf: transition to configuration level.

parameters are listed.

Allocation of parameters to the ‘extended operating level’

Up to 12 parameters can be allocated to the ‘extended operating level’ (see Fig.3: ), whereby the

controller operation is simplified, since changing over to parameter level whenever one of these

parameters must be changed is omitted.

Allocation: select required parameter, press

‘selection’ key M during >3s (Para blinks)

Select Mark with ‘up’ key I and acknowledge with

‘selection’ key M (see Fig.3: ).

Delete: select the required parameter at the extended

operating level, press ’selection’ key M during >3s

(Para blinks) and acknowledge with ’up’ key I.

Fig.3 : selecting a parameter

Select Clear and acknowledge with ‘selection’

key M (see Fig.4: ).

Hold: The Hold function can be used for selecting

a parameter from the extended operating level for

being visible continuously. For this, select the

required parameter at the extended operating level,

press ‘selection’ key M during >3s (Para blinks)

select Hold with ‘up’ key I and confirm with

’selection’ key M (see Fig.4:).

Applications:

w

During optimization, frequent access to defined parameters (Xp1, Xp2, Tn and Tv) is required.

w

During commissioning, limit value ( LimH1, LimH2, ...) or measurement value corrections must be

changed frequently.

w

With the parameter level disabled, access to the selected parameters is possible for the operator.

Deleting a parameter from the ‘extended operating level’ must be done at this level (see Fig.4: )

Operating instruction KS94 36

Fig.4: deleting a parameter

Page 35

Selection menus KS 94 parameters

Parameters

changing a parameter

37 Operating instruction KS94

Page 36

Parameters

11.2 Set-point function

Text 1 Description Range Default

Setpt

LC+

LCW0

W100

W2

Grw+

GrwGrw2

11.3 Time function

Text 1 Description Range

Timer

TS.Y

TS.MD

TS.HM

TE.Y

TE.MD

TE.HM

Set-point parameter

Band width upper limit 0...9999 ‘——’ (switched off)

Band width lower limit 0...9999 ‘——’ (switched off)

lower set-point limit for Weff -999 ... 9999 0

upper set-point limit for Weff -999 ... 9999 100

additional set-point -999 ... 9999 100

set-point gradient plus with W[w/min] 0.01 ... 99.99 ‘——’ (switched off)

set-point gradient minus with W[w/min] 0.01 ... 99.99 ‘——’ (switched off)

set-point gradient with W2[w/min] 0.01 ... 99.99 ‘——’ (switched off)

Timer-parameters

Start value: Year 0...255

Start value: Month and day Month:1...12; Day: 1...31

Start value: Hour and minutes Hour:0...23; Minutes: 0...59

Final value: Year 0...255

Final value: Month and day Month:1...12; Day: 1...31

Final value: Hour and minutes Hour:0...23; Minutes: 0...59

11.4 Programmer functions

Recp1

Analog Digital

Text 1 Description Range Def. Text 1 Description Range Def.

Wmode

Pmode

Pnext

LCLC+

Wp0

TP1

WP1

...

TP20

WP20

Programmer recipe 1

Change mode 0: Ramp 0

Preset mode 0: Segment start 1

Successive program 1..3 or ‘——’ ‘——’

Band width lower limit 0...9999 ‘——’

Band width upper limit 0...9999 ‘——’

Reset value W0 -999...9999 0

Time segment1 0...9999 [min] ‘——’

Set-point segment 1 -999...9999 0

Time segment 20 0...9999 [min] ‘——’

Set-point segment 20 -999...9999 0

1: Step

2: Ramp (Time

priority

1: Program time

D0

Td1

D1

...

Td20

D20

Reset value control output 1..4 0000..1111 0000

Time segment 1 0...9999[min] ‘——’

control output 1..4 for segm. 1 0000..1111 0000

Time segment 20 0...9999[min] ‘——’

control output 1..4 for segm. 20 0000..1111 0000

Recp2

Recp3

Operating instruction KS94 38

see programmer recipe 1

see programmer recipe 1

Page 37

11.5 Alarm function

Text 1 Description Range Default

LIM1

LimL1

LimH1

Lxsd1

LIM2

LimL2

LimH2

Lxsd2

LIM3

LimL3

LimH3

Lxsd3

LIM4

LimL4

LimH4

Lxsd4

Alarm 1

Low limit -999 ... 9999 ‘——’ (switched off)

High limit -999 ... 9999 ‘——’ (switched off)

Switching difference -999 ... 9999 0

Alarm 2

Low limit -999 ... 9999 ‘——’ (switched off)

High limit -999 ... 9999 ‘——’ (switched off)

Switching difference -999 ... 9999 0

Alarm 3

Low limit -999 ... 9999 ‘——’ (switched off)

High limit -999 ... 9999 ‘——’ (switched off)

Switching difference -999 ... 9999 0

Alarm 4

Low limit -999 ... 9999 ‘——’ (switched off)

High limit -999 ... 9999 ‘——’ (switched off)

Switching difference -999 ... 9999 0

Parameters

11.6 Self-tuning

Text 1 Description R/W Range Def.

Tune

YOptm

dYopt

POpt

Trig1

Trig2

Trig3

ORes1

ORes2

Tu1

Vmax1

Kp1

Tu2

Vmax2

Kp2

Optimization

Correcting variable whilst

process at rest

Step width during identification

Parameter set to be optimized

trigger point 1 (set 1i set 2)

trigger point 2 (set 2 i set 3)

trigger point 3 (set 3 i set 4)

Self-tuning result during heating

Self-tuning result during cooling

Delay time heating

Vmax heating

Process amplification heating

Delay time cooling

Vmax cooling

Process amplification cooling

-105 ... 105 0

R/W

5 ... 100 100

R/W

0 ... 3 1

R/W

-999 ... 9999 (Decimal point as configured in C.700; ODP)

R/W

-999 ... 9999 (Decimal point as configured in C.700; ODP)

R/W

-999 ... 9999 (Decimal point as configured in C.700; ODP)

R/W

0: Cancellation (during optimization preparation)

1: Cancellation (wrong output action)

2: Finished (successful optimization; reversal point found)

3: Cancellation (process does not react or is too slow)

4: Cancellation (reversal point found; estimation unsafe)

5: Cancellation (reversal point not found; estimation unsafe)

R

6: Finished (optimization cancelled due to exceeded set-

point risk; reversal point not reached so far;

estimation unsafe)

7: Cancellation (correcting variable too low {Y < 5%)

8: Cancellation (set-point reserve too low)

0 ... 8 (see ORes1)

R

000,0 ... 999,9 s

R

000,0 ... 999,9 /s

R

000,0 ... 999,9

R

000,0 ... 999,9 s

R

000,0 ... 999,9 /s

R

000,0 ... 999,9

R

39 Operating instruction KS94

Page 38

Parameters

11.7 Control algorithm

Text 1 Description Range Default

CPara

Tpuls

Tm

Y2

Ymin

Ymax

Y0

ParNr

Xsd2

LW

Xsd1

Xsh2

Xsh1

Xsh

Set 0

Xp1 0

Xp2 0

Tn1 0

Tv1 0

T1 0

T2 0

Set1

Xp1 1

Xp2 1

Tn1 1

Tv1 1

T1 1

T2 1

Set2

Xp1 2

Xp2 2

Tn1 2

Tv1 2

T1 2

T2 2

Set3

Xp1 3

Xp2 3

Tn1 3

Tv1 3

T1 3

T2 3

Recov

XwOnY

XwOnX

GrwOn

* Decimal point position of adjustment range as for main variable X1.

Controller parameters

Min. pulse length 0.1 ... 999.9 s 0.3

Actuator response time 10 ... 9999 s 30

Additional correcting value -105 ... 105 % 0

Min. correcting variable limiting -105 ... 105 % 0

Max. correcting variable limiting -105 ... 105 % 100

Correcting variable working point -105 ... 105 % 0