Page 1

Multi Temperaturecontroller KS800

PID

PID

KS800

PID

PID

PID

PID

PID

PID

KS800KS800

PROFIBUS-DP

KS800

KS800

Interface description

PROFIBUS-DP

9499 040 50511

Valid from: 8395

Page 2

SIMATIC

STEP

®

is a registered trademark of Siemens AG

®

is a registered trademark of Siemens AG

®

is a registered trademark of the

PROFIBUS user organization (PNO)

© PMA Prozeß- und Maschinen-Automation GmbH Printed in Germany

All rights reserved. No part of this documentation may be reproduced or published in any form or by

any means without prior written permission

from the copyright owner.

A publication of PMA Prozeß- und Maschinen Automation

Postfach 310229

D-34058 Kassel

Germany

Page 3

Contents

1 General ..................................5

1.1 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . ..........6

2 Hints on operation............................7

2.1 Interface connection . . . . . . . . . . . . . . . ...................7

2.1.1 Installation of cables . . . . . . . . . . . . . . . . . . . ...........7

2.2 Forcing .........................................7

3 Process data ...............................8

3.1 Defined as status byte are: . . . . . . . . . . . . . . ................12

3.2 Status and diagnosis messages . . . . . . . . . . . . ................15

3.3 Disabling mechanism with changes . . . . . . . . . . . ..............15

3.4 Process data transmission . . . . . . . . . . . . . . ................15

3.5 Parameter transmission . . . . . . . . . . . . . . . . . . . . . . ..........16

3.5.1 Message elements . . . . . . . . . . . . . . ................16

3.5.2 General communication structure . . . . . . . . . . . . . . . .......17

3.5.3 Data write sequence . . . . . . . . . . . . . ................17

3.5.4 Data read procedure . . . . . . . . . . . . . ................18

3.6 Examples . . . . . . . . . . . . . . . . . . . . . . . ................18

3.6.1 Function block protocol principles . . . . . . . . . . . . . . . .......18

3.6.2 Individual access . . . . . . . . . . . . . . . ................18

3.6.3 Block access (tens block). . . . . . . . . . . . . ..............19

3.6.4 Block acces (overall block) . . . . . . . . . . . . . . . . . .......19

3.7 Data types. . . . . . . . . . . . . . . . . . . . . . . ................21

4 Quick entrance .............................22

4.1 Quick entrance with S5. . . . . . . . . . . . . . . . . . . . . . ..........22

4.1.1 Example of a test environment: . . . . . . . . . . .............22

4.2 Quick entrance with S7. . . . . . . . . . . . . . . . . . . . . . ..........24

4.2.1 Example of a test environment: . . . . . . . . . . .............24

5 Function block protocol ........................26

5.1 Data structuring. ...................................26

5.2 CODE tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ........27

5.2.1 Structure of configuration words (C.xxxx). . . . . . . . . . ........27

5.2.2 INSTRUMENT (FB no.: 0 type no.: 0) . . . . . . . . . . .......27

5.2.3 Special accesses (FB no.: 10 ... 17 type no.: 10) . . . . . . . . . . . . 33

5.2.4 Freely configurable (FB no.: 20 ... 27 type no.: 20) . . . . . . . . . . 34

5.2.5 INPUT (FB no.: 60 ... 67 Type no.: 112) . . . . . . . . . . . . . . . . 36

5.2.6 CONTR (FB no.: 50 ... 57 Type no.: 91) . . . . . . . . . . . . . . . . 37

5.2.7 ALARM (FB no.: 70 ... 77 Type no.: 46) . . . . . . . . . . . . . . . . 41

3 9499 040 50511

Page 4

6 Function modules ...........................43

6.1 Function module for SIMATIC®S5 ........................43

6.1.1 Structure . . . . . . . . . . . . . . . . . . . . ...............43

6.1.2 Function module call . . . . . . . . . . . . . ................45

6.2 Function module for SIMATIC®S7 ........................46

6.2.1 Structure . . . . . . . . . . . . . . . . . . . . ...............46

7 Annex ..................................49

7.1 Terms .........................................49

7.2 GSD file . . . . . . . . . . . . . . . . . . . . . . . ................49

9499 040 50511 4

Page 5

1 General

The KS800 multi-temperature controller versions (9407-480-30001) are equipped with a PROFIBUS-DP

interface for transmission of process parameter and configuration data. Connection is via the 9-pole sub-D

connector socket. The serial communication interface permits connections to supervisory systems,

visualization tools, etc.

Another interface, which is always provided as standard, is the PC interface. This interface serves for

connecting an engineering tool, which runs on a PC.

Communication is according to the master/slave principle. KS800-DP is always slave.

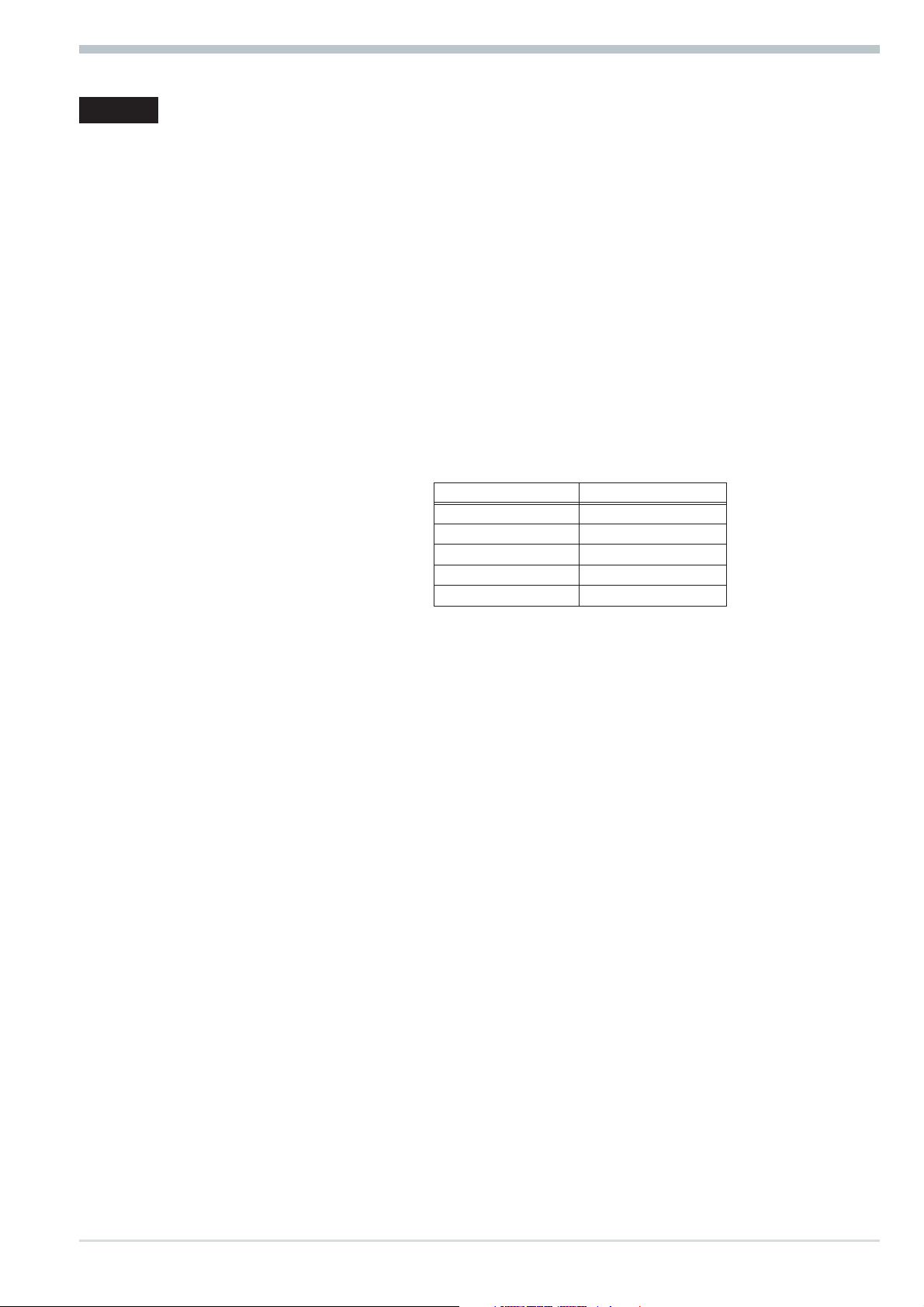

Cable medium as well as physical and electrical interface proporties:

Network topologie

w

Linear bus with active bus termination at both ends. Stub lines are possible (dependent of cable type, a

maximum overall stub line length of 6,6m with 1,5Mbit/s and of 1,6m with 3-12Mbit/s is possible).

Transmission medium

w

screened, twisted 2-wire cable (Ä EN 50170 vol.2).

Baudrates and cable lengths (without repeater)

w

The maximum cable length is dependent of transmission rate.

The Baudrate is determined by the master configuration.

General

Automatic Baudrate

detection

Interface

w

RS485 connectable with sub-D connector (9-pole).

Address settings

w

Address setting is possible as follows:

- Adjustment via coding switches, range 00 ... 99, default 00

- adjustment via software, range 0 ... 126, default 126

With the coding switches set to ‘00’, the adjusted software address is valid.

A modified coding switch address is active only after switching on the supply voltage again.

32 instruments in one segment. Extension to 127 by means of a repeater is possible.

w

KS800 with PROFIBUS-DP interface offers many advantages with respect to handling and integration into a

PROFIBUS network.

Diagnosis and monitoring via COM-LED

w

LED off: error identification for ‘no bus access’ (so far not addressed by the master)

LED on: OK, cyclic data exchange running

LED blinks: (2Hz) Data exchange interrupted

LED blinks: (4Hz) PROFIBUS parameter setting and configuration error.

Particularities

w

Configurable process data modules

Direct input and output reading and writing

Output forcing

Easy connection to PLCs

Baudrate Maximum cable length

9,6 / 19,2 / 93,75 kbit/s 1200 m

187,5 kbit/s 1000 m

500 kbit/s 400 m

1,5 Mbit/s 200 m

3 ... 12 Mbit/s 100m

5 9499 040 50511

Page 6

General

1.1 Scope of delivery

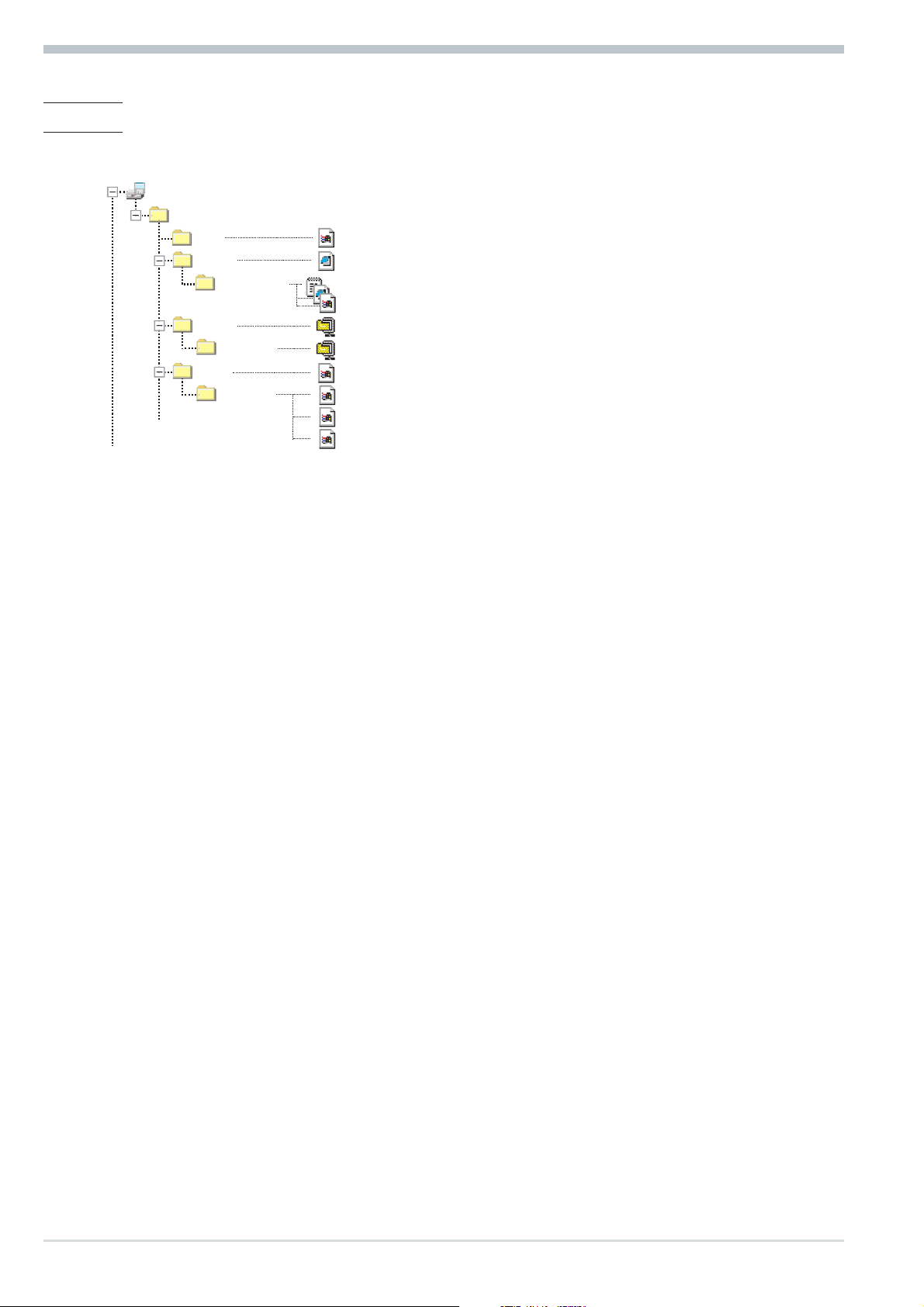

The engineering set comprises:

Disk

w

3,5-Diskette (A:)

Ks800dp

Gsd

S5_fb

Example.fix

S7_fb

Example

Type

Example

Interface description for PROFIBUS-DP

w

Pma_0800.gsd

Pmadp1st.s5d

Pmadm3*.*

Pma_parm.arj

Ks800dmo.arj

Ks800_1x.200

Demo308i.et2

Demo95ui.et2

Ks800dem.et2

GSD file

STEP®5-FB for parameter channel

project example in STEP®5 for FixPoint

STEP®7-FB for parameter channel

project example in STEP®7

type file

configuration example COM PROFIBUS for

IM308-C

configuration example COM PROFIBUS for S5 CPU

95U

configuration example COM PROFIBUS for

PC-Karte

9499 040 50511 6

Page 7

2 Hints on operation

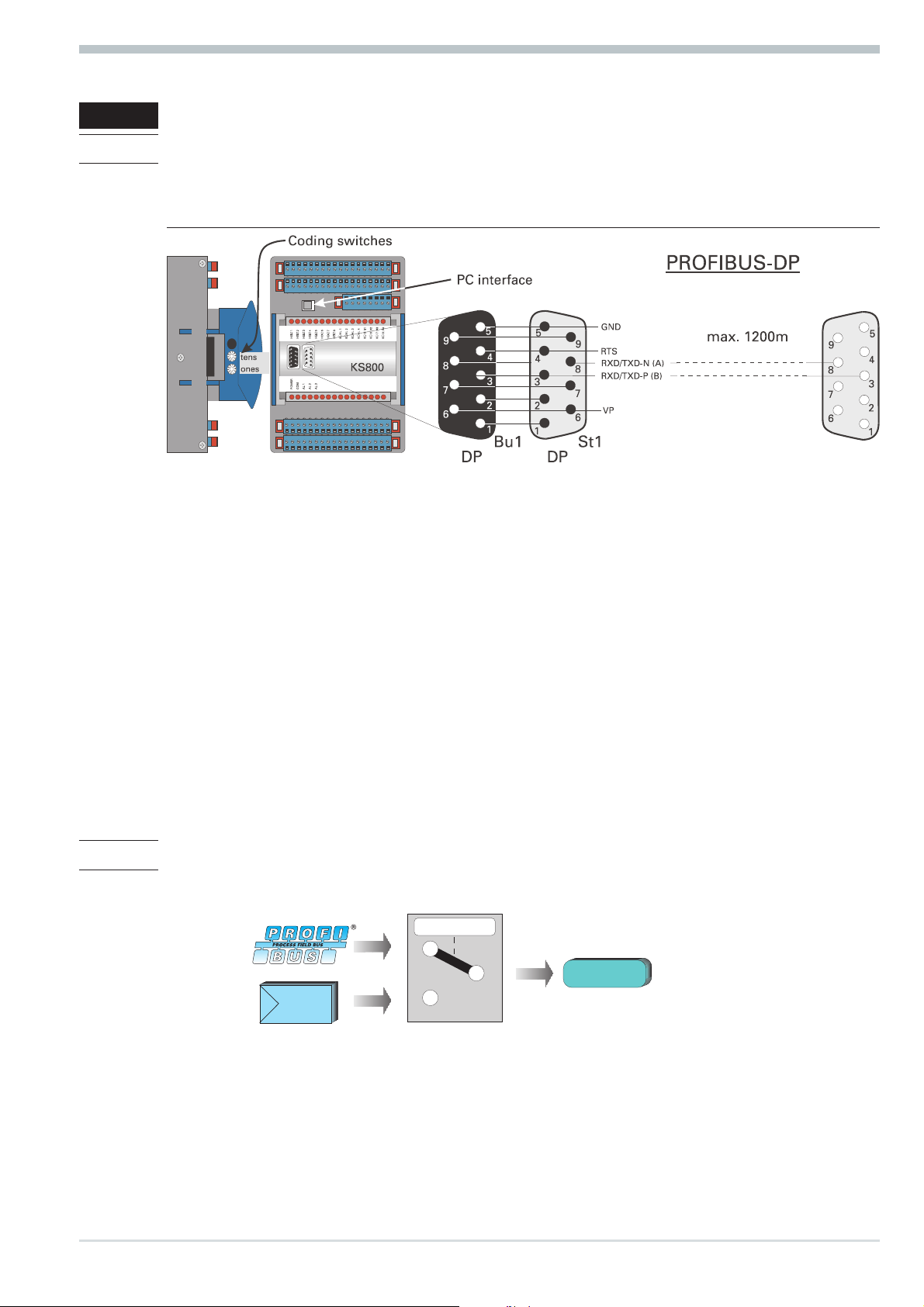

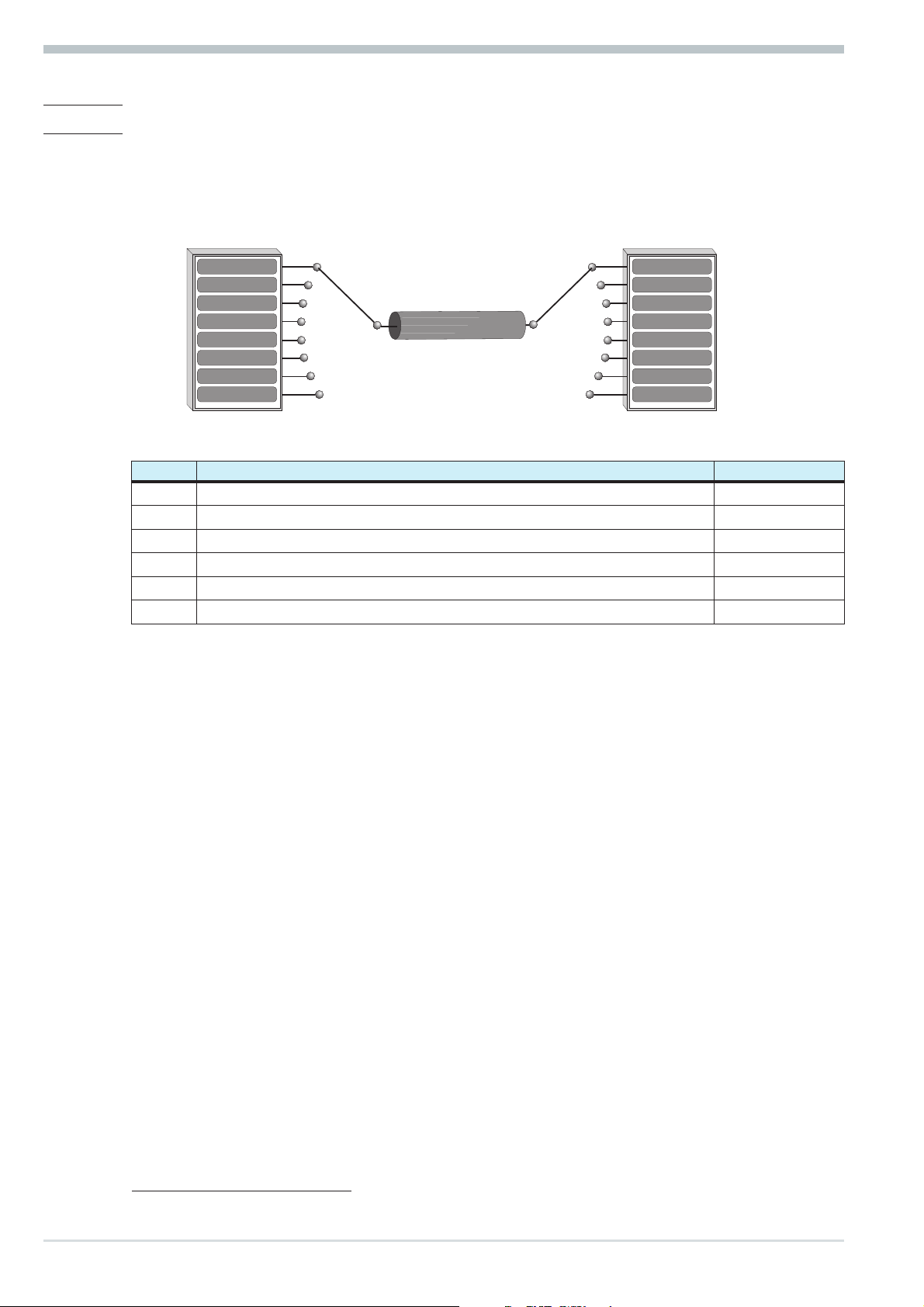

2.1 Interface connection

The PROFIBUS must be connected to the 9-pole sub-D socket.

Serial interface, physical RS485-based signals.

Fig.: 1 Connecting PROFIBUS-DP

Hints on operation

The construction of suitable cabling must be provided by the user, whereby the general cable specifications

to EN 50170 vol.2 must be taken into account.

2.1.1 Installation of cables

When laying the cables, the general hints for cable installation given by the supplier of the master module

must be followed:

Cable run in buildings (inside and outside cabinets)

w

Cable run inside and outside buildings

w

Potential compensation

w

Cable screening

w

Measures against interference voltages

w

Stub line length

w

Bus termination resistors are not contained in KS800-DP, but must be realized via the connector, if

w

necessary.

Earthing

w

Special hints for installation of PROFIBUS cables are given in the PNO technical guideline “Installation

g

guidelines for PROFIBUS-DP/FMS” (Order no. 2.111 [dt]; 2.112 [engl.]).

2.2 Forcing

Digital outputs can be written directly after configuring them accordingly.

C.100 C.500/

do

7 9499 040 50511

Page 8

Process data

3 Process data

Process data

module A:

Process data

module B:

Process data

module C:

Process data

module D:

Process data

module E:

Process data

module F:

Process data

module G:

Process data

module H:

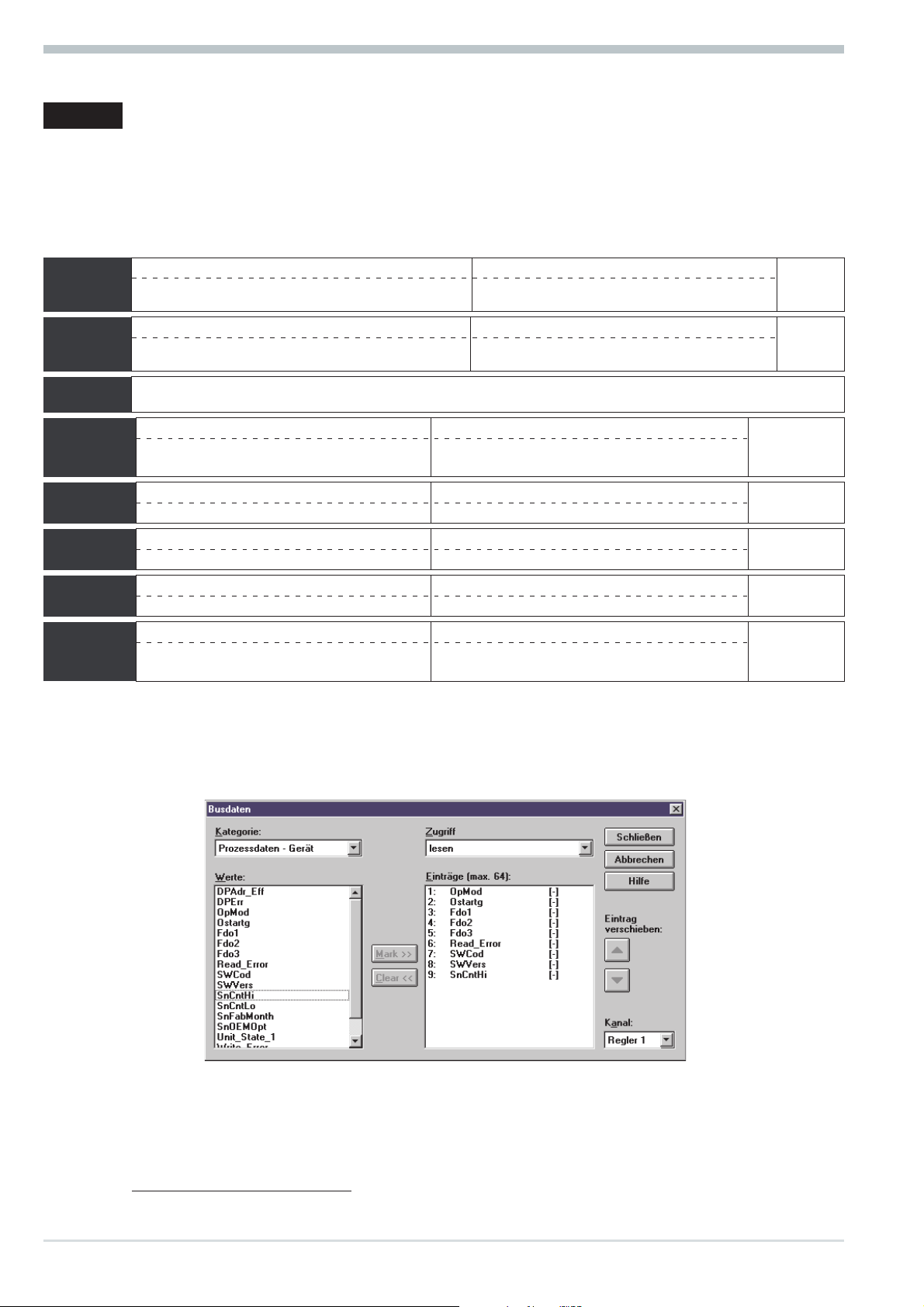

During data transmission, distinction of process data to be transmitted cyclically and parameter /

configuration data to be transmitted acyclically is made. The I/O data field is structured modularly for

matching it to the requirements of the control task.

Selection of the process data module is via configuration tools of the master circuits (e.g. with Siemens S5

via COM PROFIBUS).

The following process data modules can be configured:

read (66 bytes)

1)

Instrument status, (process value, output value, status, ..) Instrument control, (set-point, output value, ...)

write1)(52 bytes) without

parameter

channel

read (74 bytes)

Instrument status, (process value, output value, status, ..) Instrument control, (set-point, output value, ...)

1)

write1)(60 bytes)* with

parameter

channel

1)

only parameter channel

read (74 Byte)

1)

Instrument status, (process value, output value,

(8/8 bytes)

write (60 Byte)

1)

Instrument control, (set-point, output value, ...)

with parameter

channel

status, ..)

read (116 Byte)

1)

write (116Byte)

Instrument status, (52 variable process data) Instrument control, (52 variable process data)

read (92 Byte)

1)

write (92 Byte)

Instrument status, (40 variable process data) Instrument control, (40 variable process data)

read (28 Byte)

1)

write (28 Byte)

Instrument status, (8 variable process data) Instrument control, (8 variable process data)

read (16 Byte)

Instrument status, (multiplexing 64 variable

process data)

1)

write (16 Byte)

Instrument control, (multiplexing 64 variable process

data)

1)

with parameter

channel

1)

with parameter

channel

1)

with parameter

channel

1)

with parameter

channel

The parameter channel is used for sequential transmission of parameter and configuration data. The values to

be adjusted and data significations are given in the following tables:

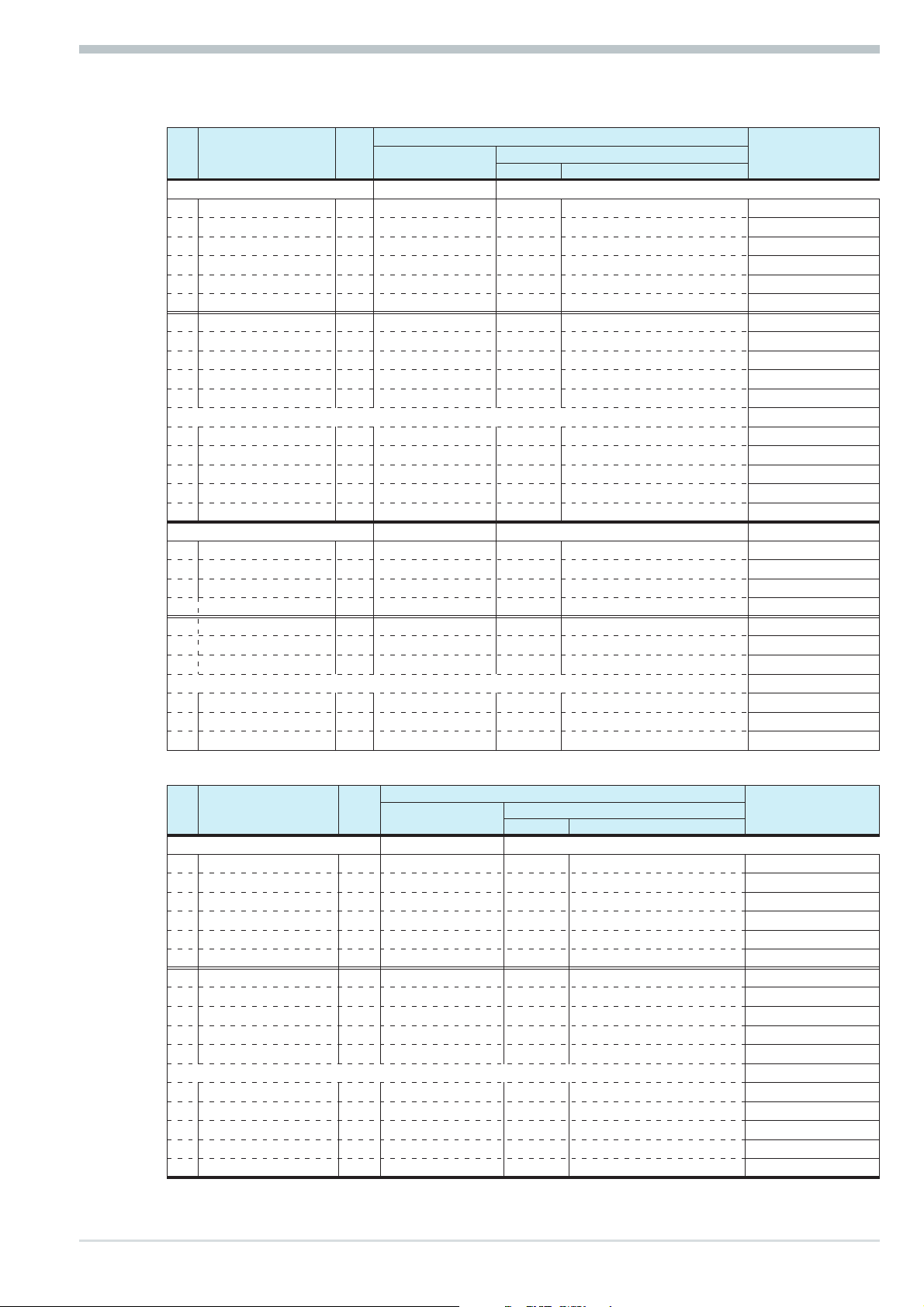

For the process data modules (module E - H), the cyclical transmission data must be selected by means of

the ‘KS800’ engineering tool via General instrument settings r

Communication r Bus data.

Max. 64 data for reading and 64 data for writing can be selected. Dependent of selected process data

module, the first 52 data (module E), the first 40 data (module F), the first 8 data (module H) or all

data are used (module G).

1) Number of required bytes in the I/O field

9499 040 50511 8

Page 9

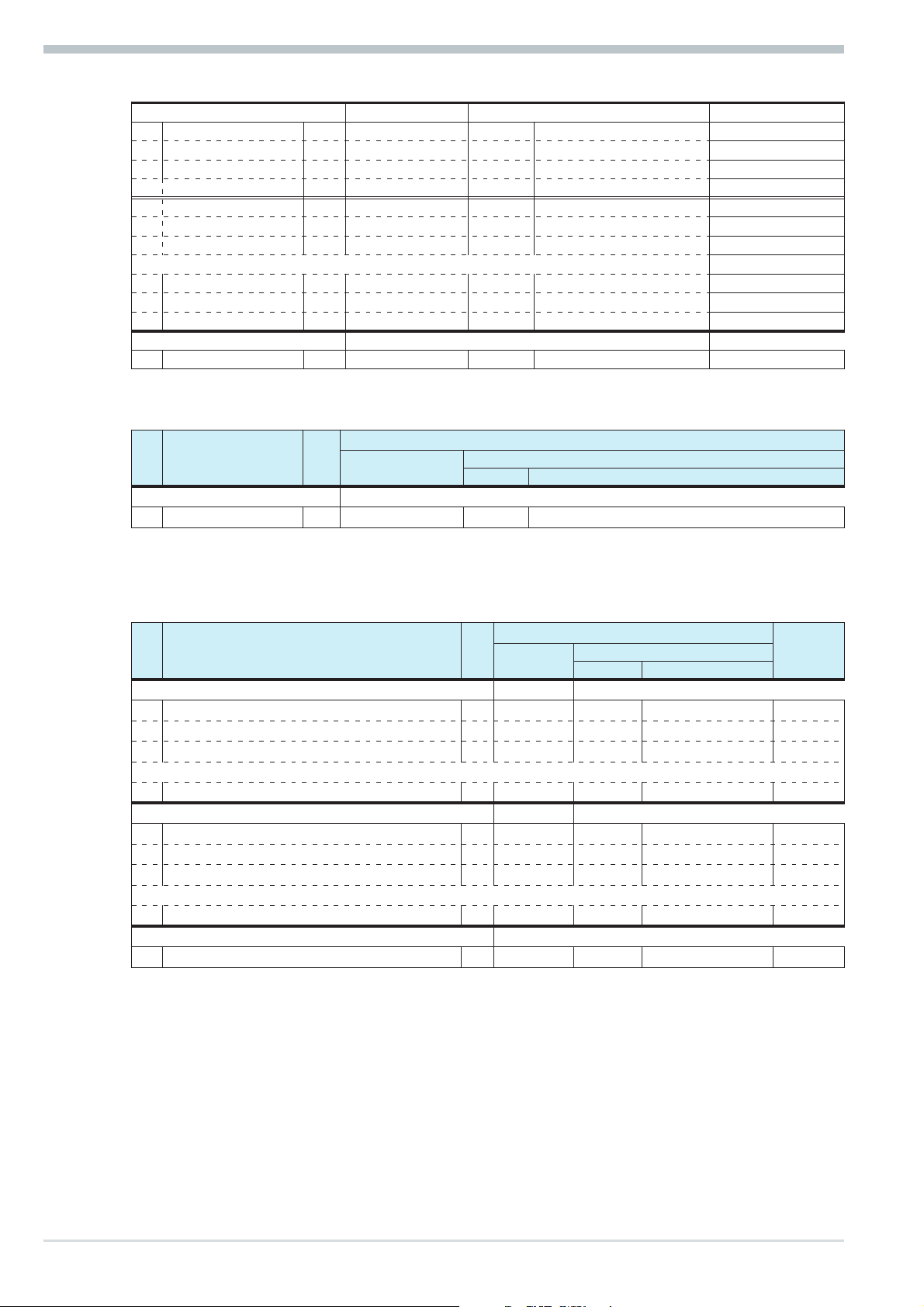

Module A (process data of all 8 channels)

q

FIX point format

No. Descr. R/W

Inputs ] 66

0 Unit_State R 2 11 16DE

1 Xeff_1 R 2 50 1AE

2 Yeff_1 R 2 50 1AE

3 HC_1 R 2 50 1AE

4 Alarm_1 R 1 10 8DE

5 Status_1 R 1 10 8DE

6 Xeff_2 R 2 50 1AE

7 Yeff_2 R 2 50 1AE

8 HC_2 R 2 50 1AE

9 Alarm_2 R 1 10 8DE

10 Status_2 R 1 10 8DE

...

36 Xeff_8 R 2 50 1AE

37 Yeff_8 R 2 50 1AE

38 HC_8 R 2 50 1AE

39 Alarm_8 R 1 10 8DE

40 Status_8 R 1 10 8DE

Outputs ] 52

41 Unit_Cntrl W 4 23 32DA

42 Wvol_1 W 2 60 1AA

43 Yman_1 W 2 60 1AA

44 Cntrl_1 W 2 21 16DA

45 Wvol_2 W 2 60 1AA

46 Yman_2 W 2 60 1AA

47 Cntrl_2 W 2 21 16DA

...

63 Wvol_8 W 2 60 1AA

64 Yman_8 W 2 60 1AA

65 Cntrl_8 W 2 21 16DA

Number of bytes

Hex COM PROFIBUS

Value

Process data

Rem.

A

B

C

B

C

B

C

D

E

E

E

q

Module B (process data of all 8 channels + parameter channel)

FIX point format

No. Descr. R/W

Inputs ] 66

0 Unit_State R 2 11 16DE

1 Xeff_1 R 2 50 1AE

2 Yeff_1 R 2 50 1AE

3 HC_1 R 2 50 1AE

4 Alarm_1 R 1 10 8DE

5 Status_1 R 1 10 8DE

6 Xeff_2 R 2 50 1AE

7 Yeff_2 R 2 50 1AE

8 HC_2 R 2 50 1AE

9 Alarm_2 R 1 10 8DE

10 Status_2 R 1 10 8DE

...

36 Xeff_8 R 2 50 1AE

37 Yeff_8 R 2 50 1AE

38 HC_8 R 2 50 1AE

39 Alarm_8 R 1 10 8DE

40 Status_8 R 1 10 8DE

Number of bytes

Hex COM PROFIBUS

Value

Rem.

A

B

C

B

C

B

C

9 9499 040 50511

Page 10

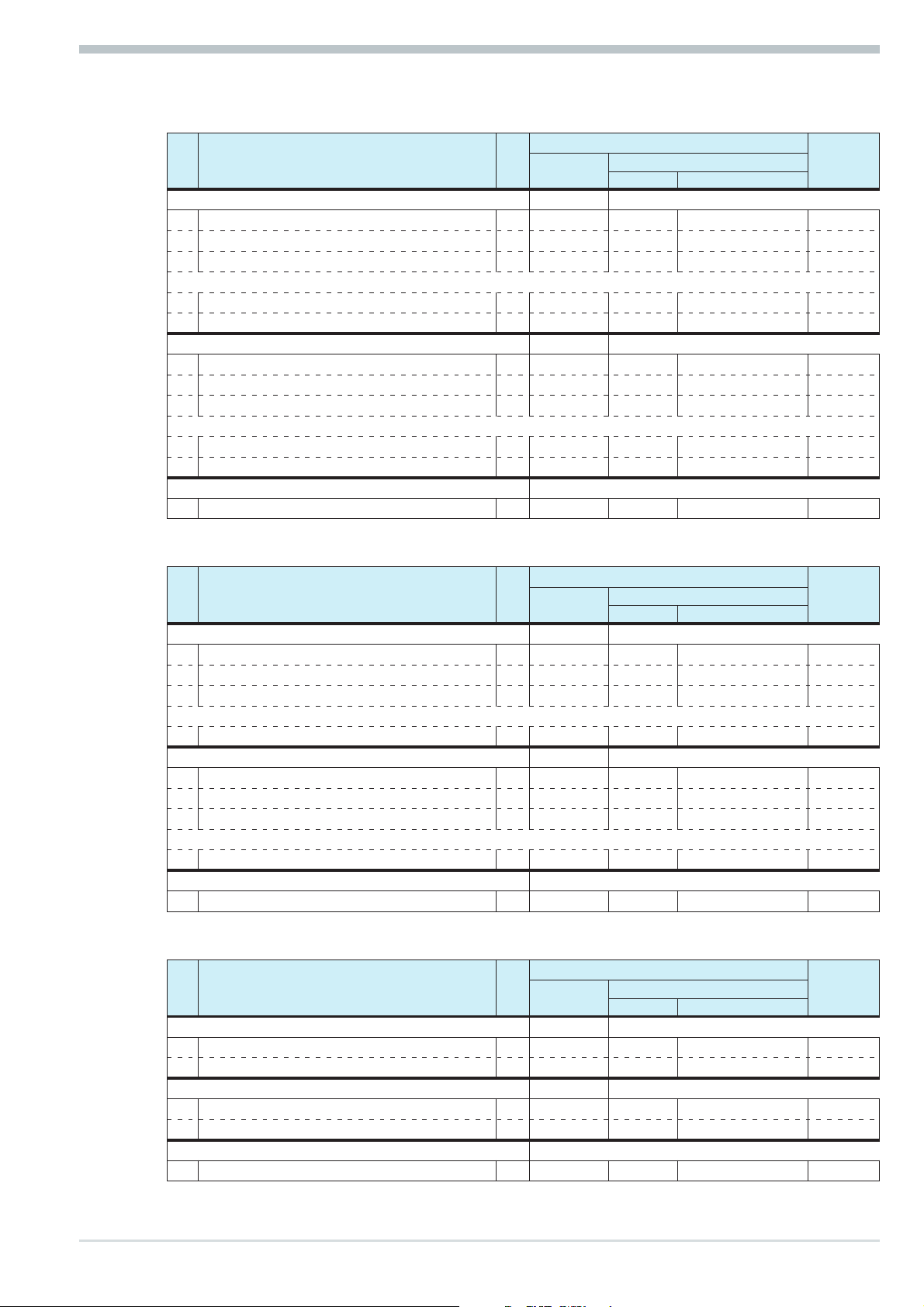

Process data

Outputs ] 52

41 Unit_Cntrl W 4 23 32DA

42 Wvol_1 W 2 60 1AA

43 Yman_1 W 2 60 1AA

44 Cntrl_1 W 2 21 16DA

45 Wvol_2 W 2 60 1AA

46 Yman_2 W 2 60 1AA

47 Cntrl_2 W 2 21 16DA

...

63 Wvol_8 W 2 60 1AA

64 Yman_8 W 2 60 1AA

65 Cntrl_8 W 2 21 16DA

Inputs/outputs

66 Parameter channel R/W 8 / 8 F3 4AX

Module C (only parameter channels)

q

FIX Point-Format

No. Descr. R/W

Inputs/outputs

0 Parameter channel R/W 8 / 8 F3 4AX

Number of bytes

Hex COM PROFIBUS

Value

D

E

E

E

Transmission of the analog values is in the 16-bit fix point format (FIX). In FIX format, all values are

interpreted with one digit behind the decimal point (range -3000,0 to 3200,0).

Module D (Like Module B, but more compact Configurationformat)

q

FIX Point-Format

No. Descr. R/W

Inputs ] 74

0 Unit_State R 2 11 16DE

1 Xeff_1, Yeff_1, HC_1, Alarm_1, Status_1 R 8 53 4AE

2 Xeff_2, Yeff_2, HC_2, Alarm_2, Status_2 R 8 53 4AE

...

8 Xeff_8, Yeff_8, HC_8, Alarm_8, Status_8 R 8 53 4AE

Outputs ] 60

9 Unit_Cntrl W 4 23 32DA

10 Wvol_1, Yman_1, Cntrl_1 W 6 62 3AA

11 Wvol_2, Yman_2, Cntrl_2 W 6 62 3AA

...

17 Wvol_8, Yman_8, Cntrl_8 W 6 62 3AA

In- /Outputs

18 Parameterchannel R/W 8 / 8 F3 4AX

Number of

Bytes

Hex COM PROFIBUS

Value

Rem.

A

B

9499 040 50511 10

Page 11

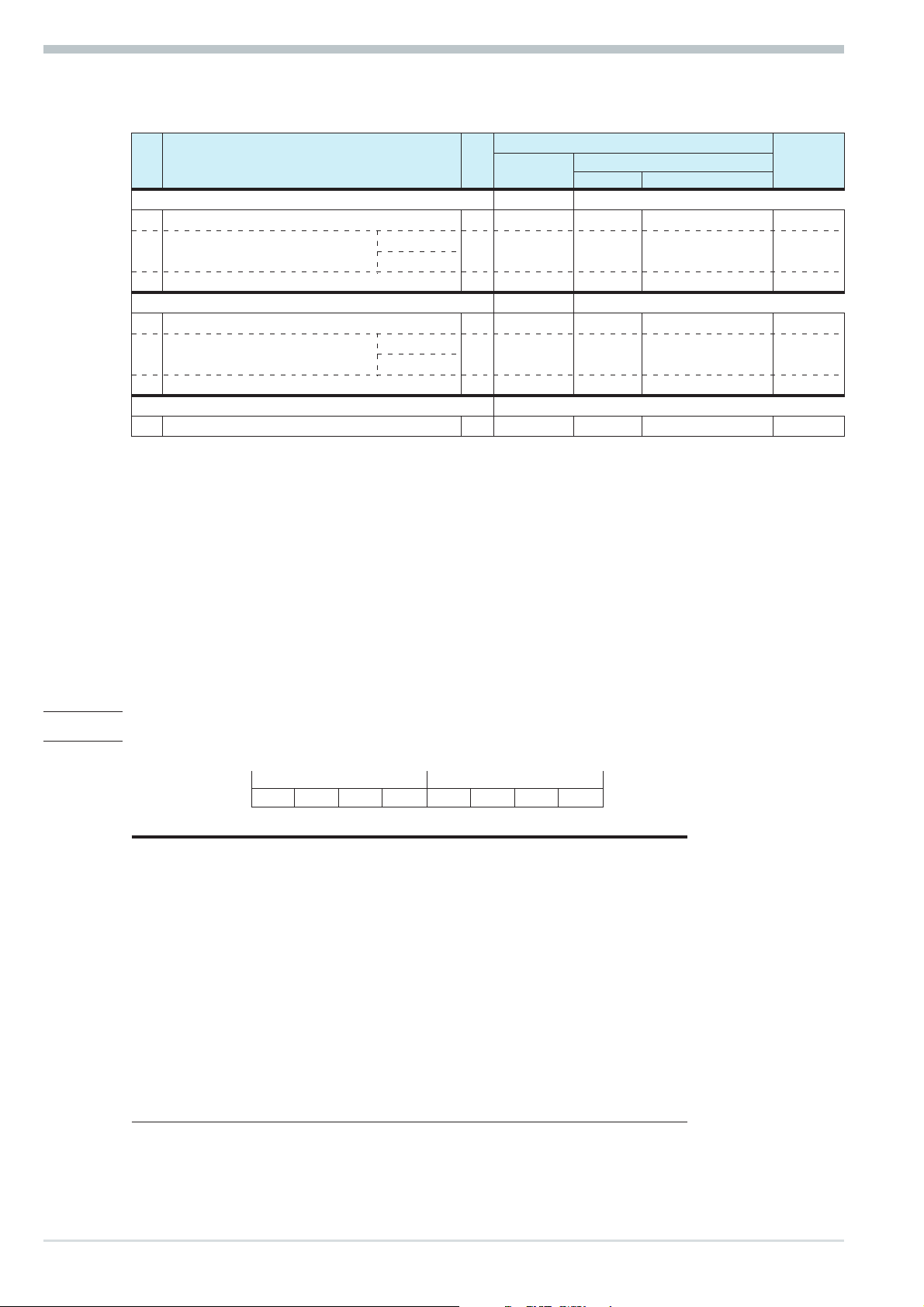

Module E (52 variable processdata and parameterchannel)

q

FIX Point-Format

No.. Descr.. R/W

Inputs ] 116

0 Unit_State, Digital_Outputs R 4 13 32DE

1 IN_1 … IN_8 R 16 57 8AE

2 IN_9 … IN_16 R 16 57 8AE

...

6 IN_41 … IN_48 R 16 57 8AE

7 IN_49 … IN_52 R 8 53 4AE

Outputs ] 116

8 Unit_Cntrl I, Unit_Cntrl II W 4 23 32DA

9 OUT_1 … OUT_8 W 16 67 8AA

10 OUT_9 … OUT_16 W 16 67 8AA

...

14 OUT_41 … OUT_48 W 16 67 8AA

15 OUT_49 … OUT_52 W 8 63 4AA

In- /Outputs

16 Parameterchannel R/W 8 / 8 F3 4AX

Number of

Bytes

Hex COM PROFIBUS

Value

Process data

Rem.

A, F

B

Module F (40 variable processdata and parameterchannel)

q

FIX Point-Format

No.. Descr.. R/W

Inputs ] 92

0 Unit_State, Digital_Outputs R 4 13 32DE

1 IN_1 … IN_8 R 16 57 8AE

2 IN_9 … IN_16 R 16 57 8AE

...

5 IN_33 … IN_40 R 16 57 8AE

Outputs ] 92

6 Unit_Cntrl I, Unit_Cntrl II W 4 23 32DA

7 OUT_1 … OUT_8 W 16 67 8AA

8 OUT_9 … OUT_16 W 16 67 8AA

...

11 OUT_33 … OUT_40 W 16 67 8AA

In- /Outputs

12 Parameterchannel R/W 8 / 8 F3 4AX

q

Module G (8 variable processdata and parameterchannel)

No.. Descr.. R/W

Inputs ] 28

0 Unit_State, Digital_Outputs R 4 13 32DE

1 IN_1 … IN_8 R 16 57 8AE

Outputs ] 28

2 Unit_Cntrl I, Unit_Cntrl II W 4 23 32DA

3 OUT_1 … OUT_8 W 16 67 8AA

In- /Outputs

4 Parameterchannel R/W 8 / 8 F3 4AX

Number of

Bytes

Number of

Bytes

Hex COM PROFIBUS

FIX Point-Format

Hex COM PROFIBUS

Value

Value

Rem.

A, F

B

Rem.

A, F

B

11 9499 040 50511

Page 12

Process data

g

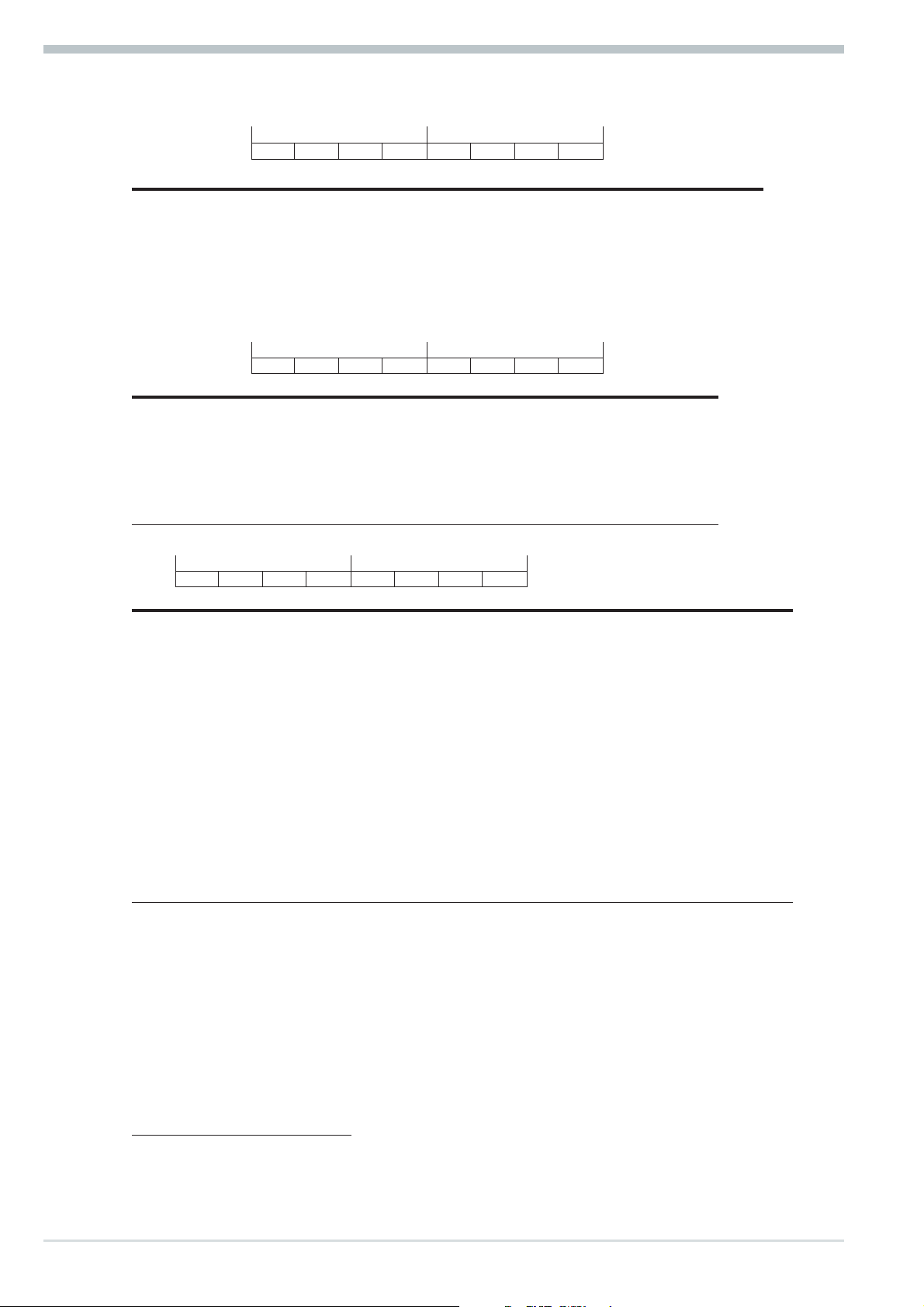

Module H (Multiplexing of all 64 variable processdata and parameterchannel)

q

FIX Point-Format

No.. Descr. R/W

Inputs ] 16

0 Unit_State, Digital_Outputs R 4 13 32DE

1

Index IN

2 Read Value R 2 50 1AE

Outputs ] 16

3 Unit_Cntrl I, Unit_Cntrl II W 4 23 32DA

4

Index OUT

5 Write Value W 2 60 1AA

In- /Outputs

6 Parameterchannel R/W 8 / 8 F3 4AX

Operating principle (reading):

Enter the index number into ‘Index OUT’ (Read).

w

After the index number is mirror-inverted in ‘Index IN’ (Read), the read value is stored in

w

‘Read Value’ .

Operating principle (writing):

Enter the index number into ‘Index OUT’ (Write)

w

Enter the value to be written into ‘Write Value’.

w

After the index number is mirror-inverted in ‘Index IN’ (Write), the value was transmitted.

w

To ensure consistent data transmission, ‘Index OUT’ (Write) and ‘Write Value’ must have been updated

safely before a PROFIBUS data cycle. If this cannot be ensured, proceed as follows: ‘0’ in ‘Index OUT’

(Write), write the value to be transmitted into ‘Write Value’ and write the index number into ‘Index OUT’

(Write). With entry ‘0’ in ‘Index OUT’ (Read) / ‘Index OUT’ (Write), no data are transmitted.

Read

Write

Read

Write

Number of

Bytes

R 2 50 1AE

W 2 60 1AA

Hex COM PROFIBUS

Value

Rem.

A, F

B

3.1 Defined as status byte are:

Unit_State

MSB LSB

D15 D14 D13 .. .. D2 D1 D0

Bit no. Name Allocation Status ‘0’ Status ‘1’

D0

D1

D2

D3

D4

D5

D6, D7

D8

D9

D10

D11

D12

D13

D14

D15

IN13 Digital input IN13 (ParNo) off on

IN14 Digital input IN14 (Coff) off on

IN15 Digital input IN15 (Leck) off on

IN16 Digital input IN16 (w/w2) off on

always ‘0’

Dex Changed ComRead or ComWrite data no yes

Always ‘0’

Err1 Transmission error channel 1 no yes

Err2 Transmission error channel 2 no yes

Err3 Transmission error channel 3 no yes

Err4 Transmission error channel 4 no yes

Err5 Transmission error channel 5 no yes

Err6 Transmission error channel 6 no yes

Err7 Transmission error channel 7 no yes

Err8 Transmission error channel 8 no yes

9499 040 50511 12

Page 13

Rem. B1 Alarm_x

MSB LSB

D7 D6 D5 D4 D3 D2 D1 D0

Bit no. Name Allocation Status ‘0’ Status ‘1’

Lim HH Alarm HH off on

D0

Lim H Alarm H off on

D1

Lim L Alarm L off on

D2

Lim LL Alarm LL off on

D3

Fail Alarm Sensor Fail no yes

D4

HCAl Heating current alarm off on

D5

LeckAl Leakage current alarm off on

D6

do1_8Al Alarm OUT1 ... 8 off on

D7

Rem. C Status_x

MSB LSB

D7 D6 D5 D4 D3 D2 D1 D0

Bit no. Name Allocation Status ‘0’ Status ‘1’

w/W2 w/W2 switch-over w W2

D0

We/w External/internal switch-over external internal

D1

w/Wanf Start-up set-point switch-over w Wanf

D2

Orun Optimization active no yes

D3

A/M Automatic/manual switch-over auto manual

D4

Coff Controller switched off no yes

D5

Y1 Switching output 1 off on

D6

Y2 Switching output 2 off on

D7

Rem. D Unit_Contrl I

MSB LSB

D31 D30 D29 ... ... D2 D1 D0

Process data

Bit no. Name Allocation Status ‘0’ Status ‘1’

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15

OUT1 Forcing of output OUT1 off on

OUT2 Forcing of output OUT2 off on

OUT3 Forcing of output OUT3 off on

OUT4 Forcing of output OUT4 off on

OUT5 Forcing of output OUT5 off on

OUT6 Forcing of output OUT6 off on

OUT7 Forcing of output OUT7 off on

OUT8 Forcing of output OUT8 off on

OUT9 Forcing of output OUT9 off on

OUT10 Forcing of output OUT10 off on

OUT11 Forcing of output OUT11 off on

OUT12 Forcing of output OUT12 off on

OUT13 Forcing of output OUT13 off on

OUT14 Forcing of output OUT14 off on

OUT15 Forcing of output OUT15 off on

OUT16 Forcing of output OUT16 off on

13 9499 040 50511

Page 14

Process data

Rem. E Unit_Contrl II

MSB LSB

D31 D30 D29 ... ... D2 D1 D0

Bit no. Name Allocation Status ‘0’ Status ‘1’

D0

D1

D2

D3

D4

D5

D6- D15

OUT17 Forcing of output OUT17 off on

OUT18 Forcing of output OUT18 off on

OUT19 Forcing of output OUT19 off on

OstartG Start optimizing all group controllers no start start

OStopG Forcing of output OUT5 no stop stop

Dval Forcing of output OUT6 flank 0->1

always "0"

Rem. F Cntrl_x

MSB LSB

D15 D14 D13 ... ... D2 D1 D0

Bit no. Name Allocation Status ‘0’ Status ‘1’

D0

D1

D2

D3

D4

D5

D6 .. D15

A/M Automatic/manual switch-over auto manual

Coff Controller switched off no yes

w/W2 w/W2 switch-over w W2

We/w External/internal switch-over external internal

OStart Start optimization

OStop Stop optimization

1)

1)

no start start

no stop stop

unused, always ‘0’

Rem. G Digital_Outputs

MSB LSB

D15 D14 D13 ... ... D2 D1 D0

Bit-No. Name Allocation Status ‘0’ Status ‘1’

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15

Y1_7 Y1-Output Channel 7 off on

Y2_7 Y2-Output Channel s 7 off on

Y1_6 Y1-Output Channel 6 off on

Y2_6 Y2-Output Channel 6 off on

Y1_5 Y1-Output Channel 5 off on

Y2_5 Y2-Output Channel 5 off on

Y1_4 Y1-Output Channel 4 off on

Y2_4 Y2-Output Channel 4 off on

Y1_3 Y1-Output Channel 3 off on

Y2_3 Y2-Output Channel 3 off on

Y1_2 Y1-Output Channel 2 off on

Y2_2 Y2-Output Channel 2 off on

Y1_1 Y1-Output Channel 1 off on

Y2_1 Y2-Output Channel 1 off on

Y1_0 Y1-Output Channel 0 off on

Y2_0 Y2-Output Channel 0 off on

1) Signals are active only with change from 0 Ä 1. The signal must be available, until a change of Orun

(see Status_x) has occurred.

2)See chapter 3.3 page 15 "Disabling mechanism with changes".

9499 040 50511 14

Page 15

3.2 Status and diagnosis messages

For KS800 instrumwent status signalling, the external (user-specific) diagnosis must be used. The format

corresponds to the instrument-related diagnosis (EN50170 volume 2 PROFIBUS).

Instrument-specific diagnosis Octet 1

MSB LSB

D7 D6 D5 D4 D3 D2 D1 D0

Bit no. Name Allocation Status ‘0’ Status ‘1’ Type

D0

D1

D2

D3

D4 .. D7

Instrument-specific diagnosis Octet 2

Bit no. Name Allocation Status ‘0’ Status ‘1’ Type

D0

D1

D2

D3

D4

D5

D6

D7

Online/Conf On-line / configuration on-line configuration status

DO1_12Fail Error do1 ... do12 no yes diagnosis

D=13_16Fail Error do13 ... do16 no yes diagnosis

HCFail Heating current short circuit no yes diagnosis

unused, always ‘0’

MSB LSB

D7 D6 D5 D4 D3 D2 D1 D0

InpF1 Input fail channel 1 no yes diagnosis

InpF2 Input fail channel 2 no yes dianosis

InpF3 Input fail channel 3 no yes diagnosis

InpF4 Input fail channel 4 no yes diagnosis

InpF5 Input fail channel 5 no yes diagnosis

InpF6 Input fail channel 6 no yes diagnosis

InpF7 Input fail channel 7 no yes diagnosis

InpF8 Input fail channel 8 no yes diagnosis

Process data

3.3 Disabling mechanism with changes

Changing the reference to a datum to be transmitted during operation, e.g. on-line via parameter channel

or via the engineering interface, implies a hazard of value misinterpreting by bus master and KS800.

This can be prevented by a disabling mechanism.

When changing a reference, the controller module sets bit Dex = 1.

w

The master must evaluate bit Dex.

w

Acknowledgement and a statement that there are only valid write data also on the master side, are

w

generated via a positive flank for bit Dval.

When receiving a positive flank, the controller module sets Dex = 0 and stores the data which were

w

sent.

Resetting Dex is also possible by switching the voltage off and on again.

w

3.4 Process data transmission

Process data are transmitted cyclically by the controller, whereby compliance with the minimum poll time of

570ms is ensured, if no simultaneous access via the parameter channel is made. Output data sent to KS800

are compared with the previously transmitted values and processed by the controller with deviation. If one of

the data is faulty, bit 8 with error in channel 1, bit 9 with error in channel 2 ... or bit 15 with error in channel

8 is set in the ‘Unit_State’, until no faulty accesses are pending any more.

15 9499 040 50511

Page 16

Process data

3.5 Parameter transmission

For parameter transmission, the ‘parameter channel’ via which data can be exchanged transparently via the

function block protocol is available. Thereby, all possible protocol access modes are supported (individual

access, tens block and overall block). Communication to the controller is transparent, i.e. the user himself is

responsible for monitoring ranges, operating modes (auto/hand) etc.

The parameter channel is designed for large amounts of data with low requirements on the transmission

speed.

3.5.1 Message elements

Some terms which are used in the following text are explained below:

Element Description Rem.

ID

ID1

Code

FB no.

Fct no.

Type

Rem. A ID

This element identifies the telegram type:

Rem. B ID1

This element identifies the file format:

Parameter 1 Parameter 1

Parameter 2 Parameter 2

.... ....

.... ....

.... ....

.... ....

.... ....

Parameter n Parameter n

Parameterkanal

Telegram mode identification

Format of data to be transmitted or to be received

Addressing code of a datum

Function block number

Function number

d.c. (always ‘0’)

ID = 0x10 = start telegram

1)

ID = 0x68 = data telegram

ID = 0x16 = end telegram

ID1=0= Integer

ID1 = 1 = Real value as fixpoint

A

B

C

D

E

Rem. C Code

The code identification is decimal and the range includes ‘00’...’99’ as well as ‘178’ = B2 and ‘179’ = B3.

Rem. D FB no. (function block number)

A function block is addressed with a function block number. It is within ‘0’ and ‘250’. Channel addressing is

also via the function block number.

Function block number ranges:

0general data for the overall instrument

w

1 - 99 fixed function blocks

w

Rem. E Fct. no. (function number)

A function as a partial address of a function block is also addressed with a function number. It is within ‘0’

and ‘99’.

Function number ranges:

0function general

w

1 - 99 other functions

w

1) 0x10 means 10 in hexadecimal

9499 040 50511 16

Page 17

3.5.2 General communication structure

For transmission of the parameters required for the function block protocol via an 8-byte data window, the

access is composed of three parts:

Order header with specification of code, FB no., fct. no., type and the following real and integer values.

w

Start telegram structure:

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

ID ID1 Code FB no. Fct._no. Type Numb.real values Numb.integer values

n data blocks with the data to be transmitted

w

Data telegram structure:

Transmission of real data as fixedpoint and of integer values

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

ID Count Integer

An end block provides the operation result

w

Structure of the end telegram:

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

ID Result

Signification of result

0OK

4 NAK

The read or write operation is always started by the master. With the number of real and integer values≠0, a

write service, otherwise, a read service is started.

The code determines the access type:

Code < 100, no multiple of 10 Ä individual access

Code < 100, multiple of 10 Ä tens block access

Code > 100 Ä overall block access

Process data

3.5.3 Data write sequence

Start telegram:

Master sends: Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x10 ID1 Code FB no. Fct._no. Type Numb.real values Numb.integer values

Controller

replies:

Master sends:

Master sends:

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x10

Data telegrams:

Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7 Controller replies: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7

0x68 count Value 0x68 count

Thereby, the first value is sent with Count = 1. For flow control, Count is reflected by KS800 (? once). The

values are transmitted in the order real - integer.

End telegram:

Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7 Controller replies: Byte 0 Byte 1 Byte 2-3 Byte4-7

0x16 0x16 Result

17 9499 040 50511

Page 18

Process data

3.5.4 Data read procedure

Start telegram:

Master sends: Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x10 ID1 Code FB no. Fct._no. Type 0 0

Controller

replies:

Master sends: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7 Controller replies: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7

Master sends: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7 Controller replies: Byte 0 Byte 1 Byte 2-3 Byte4-7

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x10 Numb. real values

Data telegrams:

0x68 count 0x68 count Value

Thereby, the first value is sent with Count = 1. For flow control, count is reflected by KS800 (? once). The

values are transmitted in the order real - integer.

End telegram:

0x16 0x16 Result

1)

Numb. integer values

3.6 Examples

3.6.1

3.6.2 Individual access

Function block protocol principles

A function block has input and output data (process data) as well as parameter and configuration data. It is

addressable via a function block number.

The following access mechanisms are used:

This access (code xx) can be used for reading or writing an individual value of a function.

Valid values for ID1:

Configuration as

FixPoint:

Example 1: (message structure with data sending)

Transmission of parameter set number (ParNr = 1) to the controller (channel 2).

0 = integer real values are transmitted as integer (without digits behind the decimal point)

1 = real real values are transmitted as FixPoint (1 digit behind the decimal point)

1)

Master sends:

Controller

replies:

Master sends:

Master sends:

Start telegram:

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x10 0 31 52 5 0 0 1

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x10

Data telegrams:

Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7 Controller replies: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7

0x68 1 1 0x68 1

End telegram:

Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7 Controller replies: Byte 0 Byte 1 Byte2-3 Byte4-7

0x16 0x16 0

1) If a Read Service was refused, these values = 0

9499 040 50511 18

Page 19

Process data

Example 2: (message structure with data request)

Reading the error code of self-tuning heating (MSG1) of controller (channel 2).

Start telegram:

Master sends: Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x10 0 35 52 5 0 0 0

Controller

replies:

Master sends:

Master sends:

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x10 0 1

Datentelegramme:

Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7 Controller replies: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7

0x68 1 0x68 1 2 (ok)

End telegram:

Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7 Controller replies: Byte 0 Byte 1 Byte2-3 Byte4-7

0x16 0x16 0

3.6.3 Block access (tens block)

This access (code x0) can be used for reading max. nine process values (always as REAL values) of a

function.

Example:(message structure with data request)

Reading the set-points (W

Start telegram:

Master sends: Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x10 0 30 53 1 0 0 0

Controller

replies:

Master sends: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7 Controller replies: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7

Master sends: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7 Controller replies: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7

Master sends: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7 Controller replies: Byte 0 Byte 1 Byte2-3 Byte4-7

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x10 2 0

Data telegrams:

0x68 1 0x68 1 150

0x68 2 0x68 2 140

End telegram:

0x16 0x16 0

nvol

and W

) of controller (channel3).

vol

3.6.4 Block acces (overall block)

This access can be used for reading or writing all parameter (code 178) and configuration data (code 179) of

a function. The following conditions are applicable to this access:

For writing the data with ‘code B3 = 179’, the instrument must be switched to the configuration mode

w

(Ä see page 27 ‘OpMod’). All entered new configuration data and parameters are effective only,

when the instrument was switched back to on-line.

All data of a message must be defined, omissions are not permissible.

w

The complete message must be transmitted also, if parts of a message in the controller are not used

w

(HW and SW options). Checking of the non-existing data is omitted.

With faulty block write accesses, the following is valid: a message is replied with NAK, if at least one

w

datum is faulty. Already valid values are accepted.

19 9499 040 50511

Page 20

Process data

The message structure with block accesses with code B2/B3 is shown using two examples below. The order

of data to be transmitted is given in the relevant code table.

Valid values for ID1:

Configuration as FixPoint: 0, 1 Transmission of real values each as a FixPoint value

Example 1: (message structure with data request)

Reading set-point parameters (W0, W100, W2, Grw+, Grw- and Grw2) of controller (channel 7).

Start telegram:

Master sends: Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x10 0 0xB2 57 1 0 0 0

Controller

replies:

Master sends: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7 Controller replies: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7

Master sends: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7 Controller replies: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7

Master sends: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7 Controller replies: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7

Master sends: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7 Controller replies: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7

Master sends: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7 Controller replies: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7

Master sends: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7 Controller replies: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x10 6 0

Data telegrams:

0x68 1 0x68 1 0

0x68 2 0x68 2 700

0x68 3 0x68 3 100

0x68 4 0x68 4 -32000

0x68 5 0x68 5 -32000

0x68 6 0x68 6 -32000

End telegram:

Master sends: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7 Controller replies: Byte 0 Byte 1 Byte2-3 Byte4-7

0x16 0x16 0

Example 2: (Message structure with data specification)

Writing the alarm configuration (C.600, C.601) to the controller (channel 1).

Start telegram:

Master sends: Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x10 0 0xB3 70 0 0 0 2

Controller

replies:

Master sends: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7 Controller replies: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7

Master sends: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7 Controller replies: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7

Master sends: Byte 0 Byte 1 Byte 2 Byte 3 Byte4-7 Controller replies: Byte 0 Byte 1 Byte2-3 Byte4-7

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x10 0 0

Data telegram:

0x68 1 0120 0x68 1

0x68 2 0110 0x68 2

End telegram:

0x16 0x16 0

9499 040 50511 20

Page 21

3.7 Data types

Data values are classified in data types for transmission.

FP

w

Floating point number (Real)

Range:as integer (in individual access) -9999 ... 0 ... 9999

as fix point-3000,0 ... 0,0 ... 3200,0

Exception:switch-off value ‘-32000’

INT

w

positive integer number

Range: 0 ... 32767

Range with configuration words: 0000 ... 9999 (Ä Page 27)

Exception: Switch-off value ‘-32000’

ST1

w

Status, bit-oriented, 1 byte Length

Range: 00H ... 3FH, transmitted: 40H...7FH

Only 6 bits can be used for information transmission, i.e. bit 0...5 (LSB = bit 0). Bit 6 must always be

set to ‘1’, in order to avoid confusion with the control characters. Bit 7 contains the parity bit.

ICMP (Integer Compact)

w

Bit information as integer transmission, max. 15 bits

Range: 0...32767; integer transmission is in ASCII format.

Process data

fixed to ‘0’ Bit signification

Bit 15 14 13 12 11 10 9876543210

Value - 16384 8192 4096 2048 1024 512 256 128 64 32 16 8421

Example:

Bit 13 = 1 and bit 1 = 1, all remaining bits are ‘0’

internal hex value: 0x2002, as integer value: 8194, transmitted ASCII value: ‘8194’

990914 21 9499 040 50511

Page 22

Quick entrance

4 Quick entrance

The disk enclosed in the engineering set includes the GSD file, project examples for a SIMATIC®S5 / S7,

the type file and configuration examples for COM PROFIBUS. Communication with a KS800-DP can be

built up easily by means of the configuration and a project.

4.1 Quick entrance with S5

Test environment

The following components are required for the test set-up:

Programming unit (PG740 recommended)

w

Automation unit

w

w

w

w

4.1.1 Example of a test environment:

A KS800-DP with address 5 is to be connected to an IM 308-C via PROFIBUS-DP. Process data module B

is selected (8 process data channels and parameter channel). Data shall be transmitted in fix point format.

The I/O addresses in the S5 start with 0 in the P area.

Before taking the test environment into operation, ensure that the automation units do not contain user

g

software (“initial clear”). The same applies to the IM 308-C memory card.

S5-115U, S5-135U or S5-155U with IM 308-C

-

KS800-DP

Engineering set (order no. 9407 999 09x11)

Cable

PROFIBUS cable automation unit / IM 308-C i KS800-DP

-

programming unit i automation unit

-

Procedure:

Establishing the communications

w

Instrument configuration

w

- Adjust address 5 on KS800-DP (via coding switches or engineering tool) and connect it to the

network.

- Activate bus termination resistors at the controller connector and at the (S5) PLC connector.

PROFIBUS network configuration

w

- Insert the disk (engineering set) into programming unit.

- Call up COM PROFIBUS and load example (A:\KS800dp\type\example\Demo308i.et2)

- Select the correct CPU type with IM308C.

-

If necessary, adapt addressings and DP network and transmit them to the DP master (Ä Fig.: ).

Load S5 program

w

-

Insert disk (engineering set) into the programming unit.

-

Call up STEP

-

Load program example, e.g. (A:\KS800dp\s5_fb\example.fix\...)

-

If necesary, match the addresses for send / receive window (A-A/E-A in FB) and transmit them to

the automation unit.

-

Switch automation unit to run

®

5.

9499 040 50511 22 990914

Page 23

Quick entrance

After taking the test set-up into operation, testing of the I/O area and parameter channel call-up are possible

by means of the graphic modules enclosed in the project.

Operanden: Signalzustände:

-Unit_Sta EW 0 KM=00000000 00000000

Graphic module 1:

Shows all process data of channel 1 (fix point).

Example: (specified set-point = 30)

Value 300 is written in AW 4.

-UnitCntA AW 0 KM=00000000 00000000

-UnitCntB AW 2 KM=00000000 00000000

-Xeff_1 EW 2 KF=+290

-Yeff_1 EW 4 KF=+400

-HC_1 EW 6 KF=+0

-Alarm_1 EB 8 KM=00001100

-Status_1 EB 9 KM=00010010

-Wvol_1 AW 4 KF=+300

-Yman_1 AW 6 KF=+400

-Cntrl_1 AW 8 KM=00000000 00000001

Graphic module 2:

Access to the function module parameters for parameter

channel mapping is possible by means of this graphic

module.

Specify e.g. when reading values:

Code

w

Fbno

w

FCTno

w

•

Setting

Specify “1" when reading with Specify ”1" when reading with

Operanden: Signalzustände:

-DWLR MW 52 KF=+1

-DWLI MW 54 KF=+0

-DWLC MW 56 KF=+0

-Read/Wr MW 58 KH=0001

-Code MW 60 KF=+32

-FBno. MW 62 KF=+50

-FCTno. MW 64 KF=+1

-Type MW 66 KF=+0

-ANZW MW 68 KM=00000000 00000010

-Setting MB 0 KM=00000000

......... DB 12

-DBval1 DW 11 KF=+300

Integer Real Integer Real

00 00

ANZW gives the status and the result after completing the FB handling.

w

DWLR, DWLI, DWLC indicates the number of read values.

w

Graphic module 3:

This graphic module indicates the first data of the data

module into which data of the parameter channel are

written, or from which values are read.

23 9499 040 50511

Page 24

Quick entrance

4.2 Quick entrance with S7

Test environment

The following components are required for the test set-up:

Programming unit (PG740 recommended)

w

Automation unit

w

w

w

w

4.2.1 Example of a test environment:

A KS800-DP with address 5 shall be connected to a CPU315-2 DP via PROFIBUS-DP. Process data module

B is selected (8 process data channels and parameter channel). Data shall be transmitted in fix point format.

Before taking the test environment into operation, you should ensure that the automation units do not contain

g

user software (“initial clear”).

Procedure:

w

w

w

CPU315-2 DP

-

KS800-DP

Engineering set (order no. 9407 999 09x11)

Cable

PROFIBUS cable automation unit i KS800-DP

-

programming unit i automation unit

-

Establishing the communications

Configuring the instruments

Adjust address 5 on KS800-DP (via coding switch or engineering tool) and connect it to the

-

network.

- Activate bus terminating resistors at the controller connector and at the (S7) PLC connector.

PROFIBUS network configuration

- Insert the disk (engineering set) into

the programming unit.

- De-archive the project example.

(A:\KS800DP\S7_FB

\EXAMPLE

\KS800dmo.arj)

- Open project KS800dmo

- If necessary, match addressings and

CPU hardware configuration and

transmit them to the DP master

(CPU315-2 DP).

-

Switch the automation unit to

run.

After taking the test set-up into operation, I/O

testing and calling up the parameter channel

are possible by means of the variable tables (VAT x) enclosed in the project.

9499 040 50511 24

Page 25

VAT 1:

Shows the process data of all channels (fix

point). Only channel 1 can be seen in the

figure opposite.

Example channel 1:

(set-point specification = 30

output variable = 40 %

manual operation)

VAT 2:

Access to the function module parameters

for parameter channel mapping is possible

by means of this variable table.

Quick entrance

Specify e.g. when reading fix point values:

CodeNo, FBNo, FKTNo, Type = 0

w

(Ä Chapter )

Service = 0x 0001

w

Start_FixP = 1

w

ANZW_FixP indicates the status and

w

the result after completing the FB

handling.

DWLR, DWLI, indicate the number

w

of read values.

The bottommost figure shows the first

data of a data module into which the

parameter channel data are written, or

from which values are read.

25 9499 040 50511

Page 26

Function block protocol

5 Function block protocol

5.1 Data structuring

Due to the variety of information to be processed in KS800, logically related data and actions are grouped

into function blocks. A function block has input data, output data, parameters and configuration data. 25

function blocks are defined for KS800. They are addressed via fixed block addresses (FB no.). Each block is

also grouped in individual functions. Functions are addressed via function numbers (fct. no.). Function

number 0 addresses function-specific data.

9499 040 50511 26

Page 27

5.2 CODE tables

5.2.1

Structure of configuration words (C.xxxx)

The configuration words given in the following code tables comprise several partial components, which can

be transmitted only in common.

The data in the table must be interpreted as follows:

Example (C100): Code Descr. R/W Type Description Range

71 C100 R/W INT CFunc: Controller function

WFunc:Set-point function

Description CFunc WFunc

Thousands Hundreds Ones

Range

xxz

00 ... 07 0...1

(T,H)

(E)

Function block protocol

0..xx0z

Example: 2-pnt. controller;

Set-point / cascade

- For transmission of configuration words, see chapter page 19.

g

- The possible settings of the configuration words are given in the KS800

function description (order no.: 9499 040 49218)

5.2.2 INSTRUMENT (FB no.: 0 type no.: 0)

All data which are valid for the overall instrument are grouped in function block ‘INSTRUMENT’.

Process data

General

Code Descr. R/W Type Description Range Rem.

01 Unit_State 1 R ST1 Status 1

10 Block 13..15, 18 R Block

13 Write Error R INT Error during last write access 0, 100...127

14 Write Error

Position

15 Read Error R INT Error during last read access 0, 100...127

16 DPErr R ICMP Error messages from DP module

17 DPAdr_eff R INT Effective PROFIBUS address 0...126

18 Type R INT Type no. of function block 0

20 Block 21...27 R Block

21 HWbas R INT Basic HW options: module A, P

23 SWopt R INT SW options 1

24 SWcod R INT SW code no. 7th-10th digit of 12NC wxyz

25 SWvers R INT SW code no. 11th-12th digit of 12NC 00xy

26 OPVers

27 EEPVers

31 OpMod R/W INT Instrument switch-over to configuration mode (only after 1) 0

32 Ostartg R/W INT Stop/start self-tuning for all group controllers 0..1

33 UPD R/W INT Acknowledgement of local data change 0..1

34 HC_reset R/W INT Heating-current-reset / Quicktest 0...3

1)

1)

R INT Position of last write access error 0...99

R INT Operating version

R INT EEPROM version

Instrument switch-over to online mode (only after 0) 1

Cancellation of configuration mode (only after 0) 2

0204

(Function no.: 0)

A

B

C

D

E

F

G

G2

1) Data are reserved for distinction of internal versions in future applications.

27 9499 040 50511

Page 28

Function block protocol

Rem. A Unit_State1

Bit no. Name Allocation Status ‘0’ Status ‘1’

D2...D4

Rem. B DPErr

MSB LSB

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Bit no. Name Allocation Status ‘0’ Status ‘1’

D4...D15

Rem. C HWbas

MSB LSB

D7 D6 D5 D4 D3 D2 D1 D0

‘0’ always ‘0’

D0

CNF Instrument status online configuration

D1

‘0’ always ‘0’

UPD Parameter update no yes

D5

‘1’ always ‘1’

D6

D7

D0

D1

D2

D3

Parity

Bus access not successful no error error

Faulty parameter setting telegram no error error

Faulty configuration no error error

No more data exchange no error error

always ‘0’

COM2 0 0

TH Z E

Basic version without COM2

COM2 with CANopen

COM2 with PROFIBUS-DP

COM2 with ISO1745

Example: Value ‘HWbas = 0200‘ means that the addressed instrument has a COM2 interface with

PROFIBUS connection.

Rem. D SWopt

Basic version

Water cooling (so far not available)

Rem. E SWCod

THZE

7th digit 8th digit 9th digit 10th digit

Example: Value ‘SWCod= 7239’ means that the software for the addressed instrument contains code

number 4012 157 239xx.

Rem. F SWvers

THZE

0 0 11th digit 12th digit

Example: Value ‘SWVers= 11‘ means that the software for the addressed instrument contains code number

4012 15x xxx11.

Rem. G UPD

Changing a parameter value or a configuration value via an interface is indicated in the UPD flag. After

power recovery, this bit is also set. The flag which can be read also via code UPD can be reset (value =0).

Rem. G2 HC_reset

Hc_reset = 0 normal

= 1 Reset of all heating currents

= 2 Starting a quicktest

= 3 Reset of all heating currents with following quicktest

After finishing of the chosen softwareroutine, the value of HC_reset is set 0 automatically.

00 0 0

01 0 0

02 0 0

03 0 0

Version 0 0

TH Z E

00 0 0

01 0 0

9499 040 50511 28

Page 29

Function block protocol

I/O connection

Code Descr. R/W Type Description Range Rem.

0 Block 1...2 R Block

1 State_alarm_out R ST1 Status alarm outputs

2 State_dio R ST1 Status digital inputs/outputs

20 Block 21...24 R Block

21 SnOEMOpt R INT Serialnumber OEM-Field

22 SnFabMonth R INT Serialnumber Produktion month

23 SnCntHi R INT Serialnumber Counter High

24 SncntLo R INT Serialnumber Counter Low

30 Block 31...33 R Block

31 Fdo1 R/W INT Forced digital outputs: OUT1 ... OUT8

32 Fdo2 R/W INT Forced digital outputs: OUT9 ... OUT16

33 Fdo3 R/W INT Forced digital outputs: OUT17 ... OUT19

Rem. H State_alarm_out

MSB LSB

D7 D6 D5 D4 D3 D2 D1 D0

Bit no. Name Allocation Status ‘0’ Status ‘1’

R1 Relay 1 off on

D0

R2 Relay 2 off on

D1

R3 Relay 3 off on

D2

do1_12 AL Alarm outputshort circuit OUT1 ... OUT12 off on

D3

HCscAL Alarm message heating current short circuit off on

D4

‘0’ always ‘0’

D5

‘1’ always ‘1’

D6

D7

Rem. I State_dio

Parity

MSB LSB

D7 D6 D5 D4 D3 D2 D1 D0

(function no.: 2)

H

K

L

I

J

Bit no. Name Allocation Status ‘0’ Status ‘1’

Par_Nr Parameter set number set 0 set 1

D0

w/w2 w/w2 switch-over w w2

D1

Coff Controller off off on

D2

Leck Leakage current off on

D3

‘0’ always ‘0’

D4

do13_16f OUT13 ... OUT16 Fail no yes

D5

‘1’ always ‘1’

D6

D7

Rem. J Data structure

Bit 1514131211109876543210

Signification 00000000OUT8 OUT7 OUT6 OUT5 OUT4 OUT3 OUT2 OUT1

Rem. K Data structure

Bit 1514131211109876543210

Signification 00000 000OUT16 OUT15 OUT14 OUT13 OUT12 OUT11 OUT10 OUT9

Rem. L Data structure

Bit 1514131211109876543210

Signification 00000000 00000OUT19 OUT18 OUT17

Parity

29 9499 040 50511

Page 30

Function block protocol

GProcessVal

Code Descr.. Channel R/W Type Description Range Rem.

B2 Xeff 1 R INT Effective process value of channel 1

Yeff 1 R INT Effective correcting variable of channel 1

HC 1 R INT Heating current of channel 1

Xeff 2 R INT Effective process value of channel 2

Yeff 2 R INT Effective correcting variable of channel 2

HC 2 R INT Heating current of channel 2

...

Xeff 8 R INT Effective process value of channel 8

Yeff 8 R INT Effective correcting variable of channel 8

HC 8 R INT Heating current of channel 8

State_alarm_out 1 R ST1 Alarm output status of channel 1

State_alarm_out 2 R ST1 Alarm output status of channel 2

...

State_alarm_out 8 R ST1 Alarm output status of channel 8

GProcessPar

Code Descr.. Channel R/W Type Description Range Rem.

B2 Wvol 1 R/W INT Volatile set-point of channel 1

W2 1 R/W INT Additional set-point of channel 1

Yman 1 R/W INT Absolute correcting variable of channel 1

Wboost 1 R/W INT

Tboost 1 R/W INT

Wvol 2 R/W INT Volatile set-point of channel 2

W2 2 R/W INT Additional set-point of channel 2

Yman 2 R/W INT Absolute correcting variable of channel 2

Wboost 2 R/W INT

Tboost 2 R/W INT

...

Wvol 8 R/W INT Volatile set-point of channel 8

W2 8 R/W INT Additional set-point of channel 8

Yman 8 R/W INT Absolute correcting variable of channel 8

Wboost 8 R/W INT

Tboost 8 R/W INT

(Funktions-Nr: 10)

H

H

H

(Funktions-Nr: 11)

9499 040 50511 30

Page 31

Function block protocol

GControlPar

Code Descr. Channel R/W Type Description Range Rem.

B2 A/M 1 R/W INT Automatic / manual switch-over of channel 1

Coff 1 R/W INT Controller on/off of channel 1

w/W2 1 R/W INT Switch-over w/W2 of channel 1

Ostart 1 R/W INT Self-tuning start of channel 1

SoftStartEnable 1 R/W INT

BoostStartEnable 1 R/W INT

A/M 2 R/W INT Automatic / manual switch-over of channel 2

Coff 2 R/W INT Controller on/off of channel 2

w/W2 2 R/W INT Switch-over w/W2 of channel 2

Ostart 2 R/W INT Self-tuning start of channel 2

SoftStartEnable 2 R/W INT

BoostStartEnable 2 R/W INT

...

A/M 8 R/W INT Automatic / manual switch-over of channel 8

Coff 8 R/W INT Controller on/off of channel 8

w/W2 8 R/W INT Switch-over w/W2 of channel 8

Ostart 8 R/W INT Self-tuning start of channel 8

SoftStartEnable 8 R/W INT

BoostStartEnable 8 R/W INT

(Funktions-Nr: 12)

GAlarmPar

Code Descr. Channel R/W Type Description Range Rem.

B2 LimL 1 R/W INT Low Alarm of channel 1

LimH 1 R/W INT High Alarm of channel 1

LimLL 1 R/W INT Low Low Alarm of channel 1

LimHH 1 R/W INT High High Alarm of channel 1

LimL 2 R/W INT Low Alarm of channel 2

LimH 2 R/W INT High Alarm of channel 2

LimLL 2 R/W INT Low Low Alarm of channel 2

LimHH 2 R/W INT High High Alarm of channel 2

...

LimL 8 R/W INT Low Alarm of channel 8

LimH 8 R/W INT High Alarm of channel 8

LimLL 8 R/W INT Low Low Alarm of channel 8

LimHH 8 R/W INT High High Alarm of channel 8

(Funktions-Nr: 13)

31 9499 040 50511

Page 32

Function block protocol

GPIDPar

(Funktions-Nr: 14)

Code Descr. Channel R/W Type Description Range Rem.

B2 Xp1 1 R/W INT Proportional band of channel 1

Tn1 1 R/W INT Integral time of channel 1

Tv1 1 R/W INT Derivative time of channel 1

T1 1 R/W INT min. cycle time of channel 1

Xp1 2 R/W INT Proportional band of channel 2

Tn1 2 R/W INT Integral time of channel 2

Tv1 2 R/W INT Derivative time of channel 2

T1 2 R/W INT min. cycle time of channel 2

...

Xp1 8 R/W INT Proportional band of channel 8

Tn1 8 R/W INT Integral time of channel 8

Tv1 8 R/W INT Derivative time of channel 8

T1 8 R/W INT min. cycle time of channel 8

Parameter a. configuration data

General

Code Descr. R/W Type Description Range Rem.

B3 71 C900

72 Adr1

COM1

1)

R/W INT Prot: Protocol type

Baud: Baudrate

1)

R/W INT COM1: Instrument address: 0..99

(T)

(H,Z)

(function no.: 0)

0..xyy0

73 C904 R/W INT Freq: Mains frequency 50/60

Alm-Ver: Alarm version

(T)

(H)

0..x000

Mode-out:Configuration-version of the

(Z)

(E)

(T)

(H,Z)

0..wxyz

0..99

0..255

0..126

(function no.: 2)

1)

74 C902

R/W INT Prot: Protocol type

COM2

1)

75 Adr2

R/W INT COM2: Instrument address: ISO1745 (def. 0)

I/O connection

analog outputs (old/new)

Mode-out current zero 0/4 mA

Baud: Baudrate (omitted with PROFIBUS)

CAN-BUS

PROFIBUS (def. 126)

Code Descr. R/W Type Description Range Rem.

B3 71 HC100 R/W FP Span end for HC 1...9999

72 C500 R/W INT Main configuration IN1/OUT13 ... IN4/OUT16

Fkt_dio1: IN1 / OUT13

Fkt_dio2: IN2 / OUT14

Fkt_dio3: IN3 / OUT15

Fkt_dio4: IN4 / OUT16

(T)

(H)

(Z)

(E)

0..wxyz

73 C530 R/W INT Main configuration OUT17 ... OUT19

mode_do17

mode_do18

mode_do19

(T)

(H)

(Z)

0...xyz0

74 C151 R/W INT Allocation HC/leakage current Alarm

DestHC

DestLeck

DestOutError

(T)

(H)

(Z)

0...xyz0

75 HCycl R/W INT Heating current cycle time 0...999

1) Baudrate and address setting are effective only after initialization, e.g. protocol switch-over.

9499 040 50511 32

Page 33

5.2.3 Special accesses (FB no.: 10 ... 17 type no.: 10)

Alternatively, access to the KS800 data is possible via function block ‘Special accesses’ .

In this case, access is only via code B2.

Function block protocol

ProcessVal

Code Descr. R/W Type Description Range Rem.

B2 Xeff R INT Effective process value

Yeff R INT Effective correcting variable

HC R INT Heating current

State_alarm_out R ST1 Alarm output status

ProcessPar

Code Descr. R/W Type Description Range Rem.

B2 Wvol R/W INT Volatile set-point

W2 R/W INT Additional set-point

Yman R/W INT Absolute correcting variable

Wboost R/W INT Momentarily no funktion

Tboost R/W INT Momentarily no funktion

ControlPar

Code Descr. R/W Type Description Range Rem.

B2 A/M R/W INT Automatic/manual switch-over

Coff R/W INT Controller on/off

w/W2 R/W INT Switch-over w/W2

Osart R/W INT Start selftuning

SoftStartEnable R/W INT Momentarily no funktion

BoostStartEnable R/W INT Momentarily no funktion

(Funktions-Nr: 0)

(Funktions-Nr: 1)

(Funktions-Nr: 2)

AlarmPar

Code Descr. R/W Type Description Range Rem.

B2 LimL R/W INT Low Alarm

LimH R/W INT High Alarm

LimLL R/W INT Low Low Alarm

LimHH R/W INT High High Alarm

PIDPar

Code Descr. R/W Type Description Range Rem.

B2 Xp1 R/W INT Proportional band 1

Tn1 R/W INT Integral time1

Tv1 R/W INT Derivative time 1

T1 R/W INT min. cycle time

(Funktions-Nr: 3)

(Funktions-Nr: 4)

33 9499 040 50511

Page 34

Function block protocol

5.2.4 Freely configurable (FB no.: 20 ... 27 type no.: 20)

Function block ”Freely definable” defines data, which can be read only by block access 20 or 30. The

ComWrite data can also be changed by mean of keys 31 – 38. Additionally, this Profibus interface setting

provides the values for the relevant data modules.

ComRead

Code Descr. R/W Type Description Range Rem.

20 Block R Block 21... 28

21 Val 1 R dataspecific Value 1

22 Val 2 R dataspecific Value 2

23 Val 3 R dataspecific Value 3

24 Val 4 R dataspecific Value 4

25 Val 5 R dataspecific Value 5

26 Val 6 R dataspecific Value 6

27 Val 7 R dataspecific Value 7

28 Val 8 R dataspecific Value 8

ComWrite

Code Descr. R/W Type Description Range Rem.

30 Block R Block 31... 38

31 Val 1 R/W dataspecific Value 1

32 Val 2 R/W dataspecific Value 2

33 Val 3 R/W dataspecific Value 3

34 Val 4 R/W dataspecific Value 4

35 Val 5 R/W dataspecific Value 5

36 Val 6 R/W dataspecific Value 6

37 Val 7 R/W dataspecific Value 7

38 Val 8 R/W dataspecific Value 8

(Funktions-Nr: 0)

(Funktions-Nr: 1)

A

A

Rem. A Data-specific

Dependent of the adjusted parameter, the value is output as INT or status. Undefined values are output

in INT format with –31000.

9499 040 50511 34

Page 35

Parameter- a. Configuration-Data

Function block protocol

ComRead

Code Descr. R/W Type Description Range Rem.

B2 41 ComReadBlock1 R/W INT Functionblocknumber for value 1 0 … 77

42 ComReadFctKey1 R/W INT Funktionnumber and code for value 1 0 … 2999

43 ComReadBlock1 R/W INT Functionblocknumber for value 2 0 … 77

44 ComReadFctKey1 R/W INT Funktionnumber and code for value 2 0 … 2999

45 ComReadBlock1 R/W INT Functionblocknumber for value 3 0 … 77

46 ComReadFctKey1 R/W INT Funktionnumber and code for value 3 0 … 2999

47 ComReadBlock1 R/W INT Functionblocknumber for value 4 0 … 77

48 ComReadFctKey1 R/W INT Funktionnumber and code for value 4 0 … 2999

49 ComReadBlock1 R/W INT Functionblocknumber for value 5 0 … 77

51 ComReadFctKey1 R/W INT Funktionnumber and code for value 5 0 … 2999

52 ComReadBlock1 R/W INT Functionblocknumber for value 6 0 … 77

53 ComReadFctKey1 R/W INT Funktionnumber and code for value 6 0 … 2999

54 ComReadBlock1 R/W INT Functionblocknumber for value 7 0 … 77

55 ComReadFctKey1 R/W INT Funktionnumber and code for value 7 0 … 2999

56 ComReadBlock1 R/W INT Functionblocknumber for value 8 0 … 77

57 ComReadFctKey1 R/W INT Funktionnumber and code for value 8 0 … 2999

ComRead

Code Descr. R/W Type Description Range Rem.

B2 41 ComWriteBlock1 R/W INT Functionblocknumber for value 1 0 … 77

42 ComWriteFctKey1 R/W INT Funktionnumber and code for value 1 0 … 2999

43 ComWriteBlock1 R/W INT Functionblocknumber for value 2 0 … 77

44 ComWriteFctKey1 R/W INT Funktionnumber and code for value 2 0 … 2999

45 ComWriteBlock1 R/W INT Functionblocknumber for value 3 0 … 77

46 ComWriteFctKey1 R/W INT Funktionnumber and code for value 3 0 … 2999

47 ComWriteBlock1 R/W INT Functionblocknumber for value 4 0 … 77

48 ComWriteFctKey1 R/W INT Funktionnumber and code for value 4 0 … 2999

49 ComWriteBlock1 R/W INT Functionblocknumber for value 5 0 … 77

51 ComWriteFctKey1 R/W INT Funktionnumber and code for value 5 0 … 2999

52 ComWriteBlock1 R/W INT Functionblocknumber for value 6 0 … 77

53 ComWriteFctKey1 R/W INT Funktionnumber and code for value 6 0 … 2999

54 ComWriteBlock1 R/W INT Functionblocknumber for value 7 0 … 77

55 ComWriteFctKey1 R/W INT Funktionnumber and code for value 7 0 … 2999

56 ComWriteBlock1 R/W INT Functionblocknumber for value 8 0 … 77

57 ComWriteFctKey1 R/W INT Funktionnumber and code for value 8 0 … 2999

(Funktionsnr: 0)

(Funktionsnr: 0)

B

B

Rem. B Data structure

Definition to which data an access is made, the following entries are required:

Function block number r ComReadBlock or ComWriteBlock

w

Function number + individual code r ComReadFctKey or ComWriteFctKey

w

Example::

If the Wvol value for controller 2 (controller description1-8)forComRead must be selected,

the values are composed as follows:

Functionblocknumber Controller 2 = 51 ComReadBlock = 51

Funktionnumber Wvol = 01

Single-Code Wvol = 32

ComReadFctKey = 0132

35 9499 040 50511

Page 36

Function block protocol

5.2.5 INPUT (FB no.: 60 ... 67 Type no.: 112)

All data which concern acquisition and processing of all input values (analog/digital) are grouped in function

block ‘INPUT’. The data are available once per controller channel.

Process data

General

Code Descr. R/W Type Description Range Rem.

00 Block R Block Block access (1, 3)

1 Input_x_Fail R ST1 Signal input x fail

3 x1 R FP Main variable

10 Block R Block Block access (13, 18)

13 INP1 R FP Raw measurement value before measured value correction

18 Function Type R INT Type no. of function block 112

Rem. A Status byte Input_X_Fail:

MSB LSB

D7 D6 D5 D4 D3 D2 D1 D0

Bit no. Name Allocation Status ‘0’ Status ‘1’

INP1F Input 1 fail no yes

D0

D1...D5

‘0’ always ‘0’

‘1’ always ‘1’

D6

D7

Parity

input processing of analog signals (function no.: 0)

A

Parameter a. configuration data

ME/V1

Code Descr. R/W Type Description Range Rem.

B2 41 X1

42 X1

43 X2

44 X2

B3 71 X0 R/W FP Phys. value at 0% -999..9999

72 X100 R/W FP Phys. value at 100% -999..9999

73 X

Fail

74 T

fm

75 T

kref

76 C200 R/W INT Type: sensor type

77 C205 R/W INT Fail: sensor break behaviour

78 C190 R/W INT Signal allocation of digital signals:

R/W FP Measured value correction X1 input -999..9999

in

R/W FP Measured value correction X1 output -999..9999

out

R/W FP Measured value correction X2 input -999..9999

in

R/W FP Measured value correction X2 output -999..9999

out

R/W FP Substitute value with sensor fail -999..9999

R/W FP Filter time const. measured value process. 0.0 .. 999.9

R/W FP Reference TC 0...60 °C / 32...140°F

Measured value INP1 : acquisition and processing (function no.: 1)

(T,H)

0..xxy0

Unit: unit

STk: Source Tk

XKorr: enable process value corr.

Controller off

w/w2

(Z)

(T)

(H)

(Z)

(Z)

(E)

1..wxy0

0...00xy

9499 040 50511 36 990914

Page 37

5.2.6 CONTR (FB no.: 50 ... 57 Type no.: 91)

All data which concern the controller are grouped in function block ‘CONTR’. They are available once for

each controller channel.

Process data

General

Code Descr. R/W Type Description Range Rem.

00 Block R Block Block access (1...9)

1 Status 1 R ST1 Status 1

3 W R FP Eff. set-point

4 X R FP Eff. process value

5 Y R FP Effective output value

6 xw R FP Control deviation

13 Status Alarm x R INT Status x and Alarm x B1

18 Type R INT Type no. of function block 90

20 Block R Block Block access (21...26)

21 Xeff R FP Eff. process value

22 Yeff R FP Effective output variable

23 HC R FP Heating current measureement value

24 Unit_State R ICMP Input values (di) Ä page 12

25 Alarm_x R ICMP Alarm values Ä page 13 B2

26 Status_x R ICMP Status information Ä page 13

30 Block R Block Block access (31...38)

33 A/M R/W INT Automatic/manual switch-over 0..1

34 OStart R/W INT Optimization start 0..1

35 We/i R/W INT Wext/Wint switch-over 0..1

36 w/w2 R/W INT w/w2 switch-over 0..1

38 Coff R/W INT Controller off/on 0..1 C

Rem. A Status1: (code 01)

MSB LSB

D7 D6 D5 D4 D3 D2 D1 D0

Bit no. Name Allocation Status ‘0’ Status ‘1’

Y1 Switching output off on

D0

Y2 Switching output off on

D1

A/M Auto/manual auto manual

D2

CFail Controller status ok not ok

D3

Coff Controller switched off no yes

D4

XFail Sensor fail no yes

D5

‘1’ always ‘1’

D6

D7

Rem. B1 Status_alarm_x: Code 13

MSB LSB

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Parity

Function block protocol

(function no.: 0)

A

Bit no. Name Allocation Status ‘0’ Status ‘1’

w/w2 w/w2 switch over w w2

D0

we/wi extern/intern switch over extern intern

D1

w/wanf Start-setpoint switch over w wanf

D2

Orun Optimisation activ no yes

D3

A/M Automatic/Manuel switch over Auto Man

D4

Coff Controller off no yes

D5

Y1 Switchung output 1 off on

D6

Y2 Switching output 2 off on

D7

Lim HH Alarm HH off on

D8

Lim H Alarm H off on

D9

D10

D11

D12

D13

D14

D15

Lim L Alarm L off on

Lim LL Alarm LL off on

Fail Alarm sensor fail no yes

HCAl Heating current alarm off on

LoopAl Loop alarm off on

"0" always "0"

37 9499 040 50511

Page 38

Function block protocol

Rem. B2 Cntrl_x: (Code 39)

MSB LSB

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Bit no. Name Allocation Status ‘0’ Status ‘1’

D6...D15

Set-point

Code Descr. R/W Type Description Range Rem.

00 Block R Block Block access (1, 3)

01 WState R ST1 Set-point status

03 Wint R FP Effective internal set-point

30 Block R Block Block access (31...32)

31 Wnvol R/W FP Int. set-point, non-volatile -999..9999

32 Wvol R/W FP Int. set-point, volatile -999..9999

Rem. C WState: (code 01)

A/M Automat/Manuel Auto Manuel

D0

Coff Switch the controller off no yes

D1

w/w2 w/w2 switch over w w2

D2

we/wi wext/wint wext wint

D3

OStart Start the optimisation no start start

D4

Ostop Stop the optimisation no stop stop

D5

"0" Always "0"

MSB LSB

D7 D6 D5 D4 D3 D2 D1 D0

Set-point processing (function no.:1)

B

Bit no. Name Allocation Status ‘0’ Status ‘1’

w/w2 w/w2 switch-over w W2

D0

we/wi wext/wint wext wint

D1

w/wanf start-up set-point switch-over w wanf

D2

GRW Gradient function active no yes

D3

Weff_fail Error effective set-point no yes

D4

‘0’ always ‘0’

D5

‘1’ always ‘1’

D6

D7

Output variable

Code Descr. R/W Type Description Range Rem.

30 Block R Block Block access (31, 35)

31 dYman R/W FP Difference output variable -210..210

32 Yman R/W FP Absolute output variable -105..105

33 Yinc R/W INT Increment. output variable 0, 1

34 Ydec R/W INT Decrement. output variable 0, 1

35 Ygrw_ls R/W INT Speed for incr./decr. output variable offset 0, 1

Tuning

Code Descr. R/W Type Description Range Rem.

00 Block R Block Block access (1, 3)

1 State_Tune1 R ST1 Status Tuning D

3 ParNeff R INT Eff. parameter set number 0...1

30 Block R Block Block access (31...39)

31 ParNr R/W INT Parameter set number effective 0 .. 1

32 Tu1 R FP Delay time heating 0...9999 s

33 Vmax1 R FP Rate of increase heating 0,000...9,999 %/s

34 Kp1 R FP Process gain heating 0,000...9,999

35 MSG1 R INT Error code of self-tuning heating 0...8

36 Tu2 R FP Delay time cooling 0...9999 s

37 Vmax2 R FP Rate of increase cooling 0,000...9,999 %/s

38 Kp2 R FP Process gain cooling 0,000...9,999

39 MSG2 R INT Error code of self-tuning cooling 0...8

Parity

Output variable processing(function no.:4)

Self-tuning(function no.:5)

9499 040 50511 38

Page 39

Rem. D Status 1 Tuning ‘State_Tune1’

MSB LSB

D7 D6 D5 D4 D3 D2 D1 D0

Bit no. Name Allocation Status ‘0’ Status ‘1’

OStab Process at rest no yes

D0

Orun Optimization run off on

D1

Oerr Optimization result Ok error

D2

D3...D5

‘0’ always ‘0’

‘1’ always ‘1’

D6

D7

Parity

Parameter a. configuration data

Function block protocol

General

Code Descr. R/W Type Description Range Rem.

0..xxyz

B3 71 C100 R/W INT CFunc: Controller function

CType: Controller type

WFunc:set-point function

72 C101 R/W INT CMode:Controller output action

CDiff: x/x-w Differentiat.

CFail: Behaviour with sensor fail

CAnf: Start-up circuit

73 C700 R/W INT OMode:Optimization mode

OCond: Process at rest.

OGrp: Allocation group opt.

OCntr: Controlled adaptation mode

74 C180 R/W INT SWext: Source for Wext (T) 0..x000

Set-point

Code Descr. R/W Type Description Range Rem.

B2 41 W0 R/W FP Min. set-point limit f. Weff -999..9999

42 W100 R/W FP Max. set-point limit f. Weff -999..9999

43 W2 R/W FP Additional set-point -999..9999

44 Grw+ R/W FP Set-point gradient plus >0..9.999

45 Grw- R/W FP Set-point gradient minus >0..9.999

46 Grw2 R/W FP Set-point gradient W2 >0..9.999

(T,H)

(Z)

(E)

0..wxyz

(T)

(H)

(Z)

(E)

0..wxyz

(T)

(H)

(Z)

(E)

Set-point processing(function no.: 1)

(function no.: 0)

1)

Algo

Code Descr. R/W Type Description Range Rem.

B2 41 Xsh R/W FP Neutral zone 0.2 .. 20,0 %

42 Tpuls R/W FP Min. pulse length 0.1..2,0 s

43 Tm R/W FP Actuator response time 10..300 s

44 Xsd1 R/W FP Switching difference signaller 0,1..9999 %

45 LW R/W FP Trigger point separation add. cont. -999..9999

46 Xsd2 R/W FP Switching difference add. cont. 0,1..9999 %

47 Xsh1 R/W FP Neutral zone 0.0 .. 999.9%

48 Xsh2 R/W FP Neutral zone 0.0 .. 999.9 %

1) Datum has swich-off function; additional data value ‘-32000’

Control algorithm (function no.: 3)

39 9499 040 50511

(1)

Page 40

Function block protocol

Output variable

Code Descr. R/W Type Description Range Rem.

B2 41 Y

42 Y

43 Y0 R/W FP Working point f. output variable -105..105 %

44 Yh R/W FP Max. mean value of output 5..100%

45 LYh R/W FP Limit for mean value formation 0,1 .. 10,0

R/W FP Min. output limiting -105..105 %

min

R/W FP Max. output limiting -105..105 %

max

Tuning

Code Descr. R/W Type Description Range Rem.

B2 41 YOptm R/W FP Output variable during process at rest -105..105

42 dYopt R/W FP Step height during identification 5..100

43 POpt R/W INT Parameter set to be optimized 0...1

44 OXsd R/W FP Hysteresis with parameter switch-over 0.0..9999

45 Trig1 R/W FP Trigger point 1 0.0..9999

Paramset x

Code Descr. R/W Type Description Range Rem.

B2 41 Xp1 R/W FP Proportional band 1 0.1..999.9

42 Tn1 R/W FP Integral time 1 0..9999

43 Tv1 R/W FP Derivative time 1 0..9999

44 T1 R/W FP Min. cycle time 1 0.4..999.9

45 Xp2 R/W FP Proportional band 2 0.1..999.9

46 Tn2 R/W FP Integral time 2 0..9999

47 Tv2 R/W FP Derivative time 2 0..9999

48 T2 R/W FP Min. cycle time 2 0.4..999.9

Output variable processing(function no.: 4)

Self-tuning(function no.: 5)

Control parameter set1/2(function no.: 6,7)

Start-up circuit

Code Descr. R/W Type Description Range Rem.

B2 41 Ya R/W FP Maximum output value 5 .. 100 %

42 Wa R/W FP Start-up set-point -999 .. 9999

43 TPa R/W FP Start-up holding time 0 .. 9999 min