Page 1

PMA Prozeß- und Maschinen-Automation GmbH

r

Universal controller for burners

KS40-1 burner

KS40-1 burner

expertline

KS40-1 burne

Operating manual

English

9499-040-66011

Valid from:8473

Page 2

Description of symbols

in the text: on the device:

g General information a Follow the operating instructions

a General warning

l Attention: ESD-sensitive devices

© PMA Prozeß- und Maschinen-Automation GmbH • Printed in Germany (0207)

All rights reserved. No part of this document may bereproduced or published in any form or by any means

without prior written permission from the copyright owner.

A publication of PMA Prozeß- und Maschinen Automation

P.O.Box 310229

D-34058 Kassel

Germany

Page 3

Contents

1 Mounting .............................. 5

2 Electrical connections ....................... 6

3 Operation.............................. 7

3.1 Front view.............................. 7

3.2 Operating level ........................... 8

3.3 Self-tuning ............................. 10

3.4 Manual tuning ........................... 11

3.5 Operating structure ........................ 13

4 Configuration level ........................14

4.1 Configuration with qUIC ..................... 14

4.2 Configuration without qUIC ( qUIC= OFF) ..........18

4.3 Configuration survey:....................18

5 Parameter setting level ...................... 24

5.1 Input scaling (only visible with qUIC = OFF)..........26

6 Calibration level ......................... 27

7 Programmer ........................... 30

8 Technical data .......................... 32

9 Safety hints ............................ 36

9.1 Resetting to factory setting .................... 38

3 KS40-1 burner

Page 4

KS40-1 burner 4

Page 5

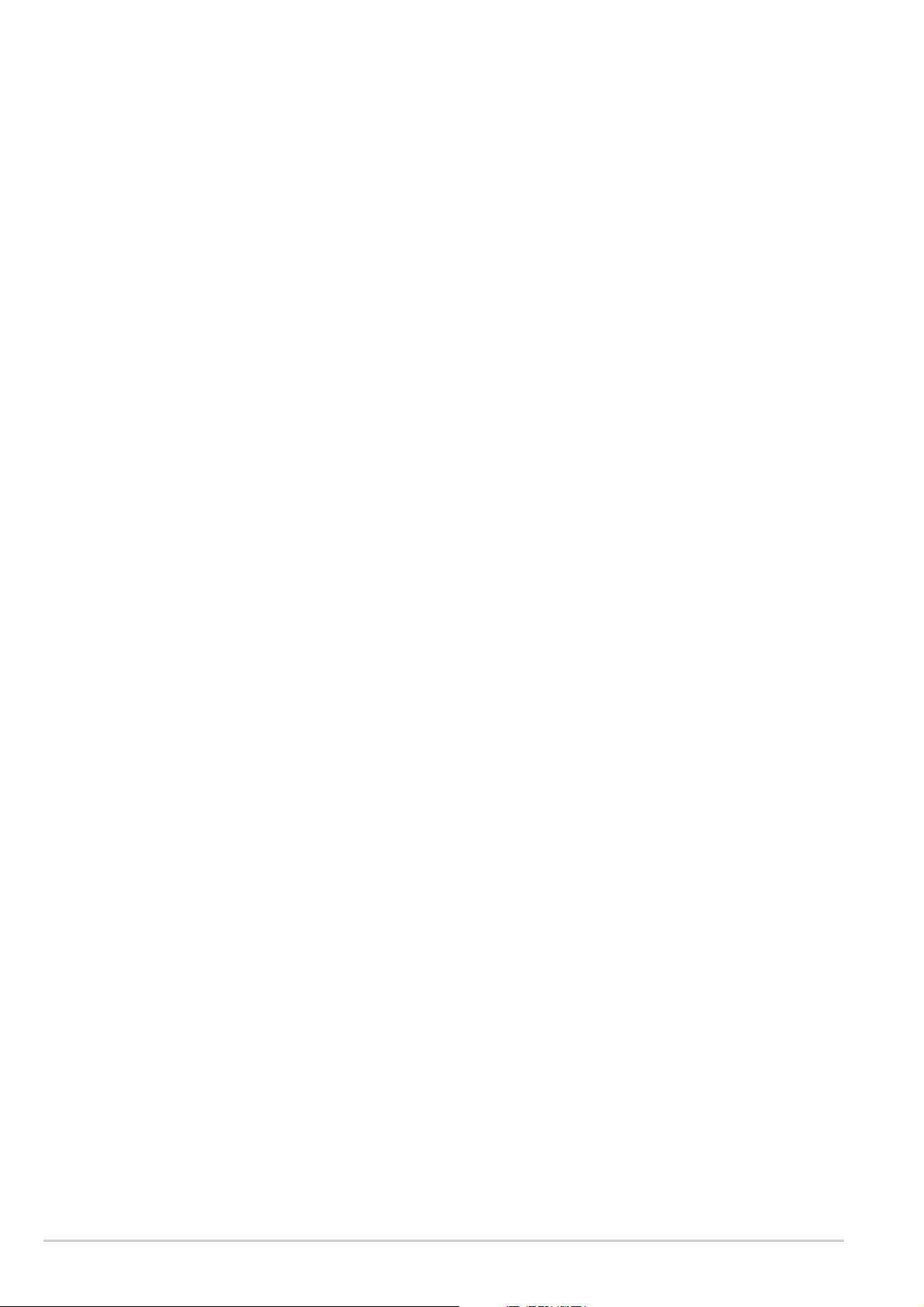

1 Mounting

Mounting

(0.4")

10

118

SP.X

F

96 (3.78")

KS 40-1 burner

48 (1.89")

(4.65")

126

125

min.48

SG

Ada

Err

Loc

Safety switch

Ü

(1.89")

1..10

(0.04..0.4")

+0,6

45

+0.02

(1.77" )

10V i mA/Pt

or:

+0,8

+0.03

92

max.

60°C

0°Cmin.

(3.62" )

max.

95% rel.

%

Loc 10V mA/Pt

Loc 10V mA/Pt

Loc 10V mA/Pt

Ü

*

*

Safety switch:

For access to the safety switches, the controller must be withdrawn from the hou

sing. Squeeze the top and bottom of the front bezel between thumb and forefinger

and pull the controller firmly from the housing.

10V i mA/Pt mA/Pt 1 Thermocouple / Pt100 or transducer at InP.1

10V Pressure transmitter (0..10V) at InP.1

Loc open Access to the levels is as adjusted by means of

BlueControl (engineering tool)

closed 1 all levels accessible wihout restriction

1 Factory setting 2 Default setting: display of all levels

suppressed, password PASS = OFF

2

-

a

l

Safety switch 10V i mA/Pt always in position left or right. Leaving the

safety switch open may lead to faulty functions!

Caution! The unit contains ESD-sensitive components.

5 KS40-1 burner

Page 6

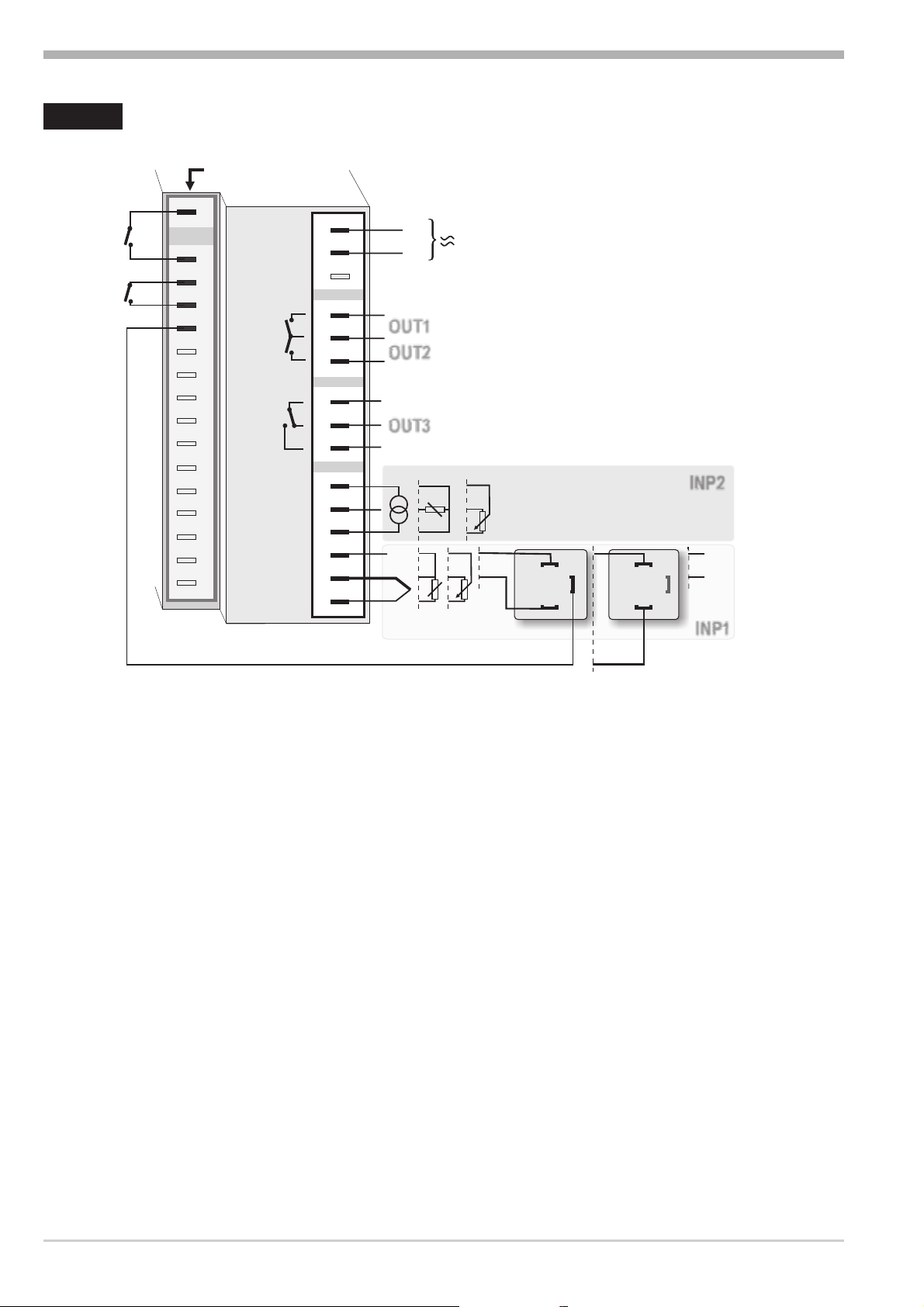

Electrical connections

g

O

2 Electrical connections

di2

di3

U(+)

t

P

1

(2)

3

4

5

6

10

11

12

13

14

15

A

1

2

3

4

5

6

7

8

9

L

N

OUT1

OUT2

OUT3

g

+

+

90...250V

gh

c

100%

0%

++

10V *

0%

--

100%

1

3

2

INP2

2

20mA **

1

INP1

ption

abbc

edf

* Safety switch INP1 (mA i 10V) in position 10V

** Safety switch INP1 (mA i 10V) in position mA/Pt

Connection of input INP1

Input for variable x1 (process value)

a thermocouple

b resistance thermometer (Pt100/ Pt1000/ KTY/ ...)

c Transducer 50-30-50 W

d voltage (0/2...10V)

e pressure transmitter (3-wire connection)

f pressure transmitter (2-wire connection)

g current (0/4...20mA)

Connection of input INP2

See input INP1.

Connection of inputs di2/di3

Digital input di2 for external switching between SP and SP.2 (SP/SP2).

Digital input di3 for external switching between 3-point-stepping controller and

on/off controller (DPS/SG).

KS40-1 burner 6

Page 7

125

126.

SP.x

SG

Err

Ada

123OK

3

1

2

3

7

!

"

4

8

5

6

9

0

$

%

è

§

&

KS 40-1

burner

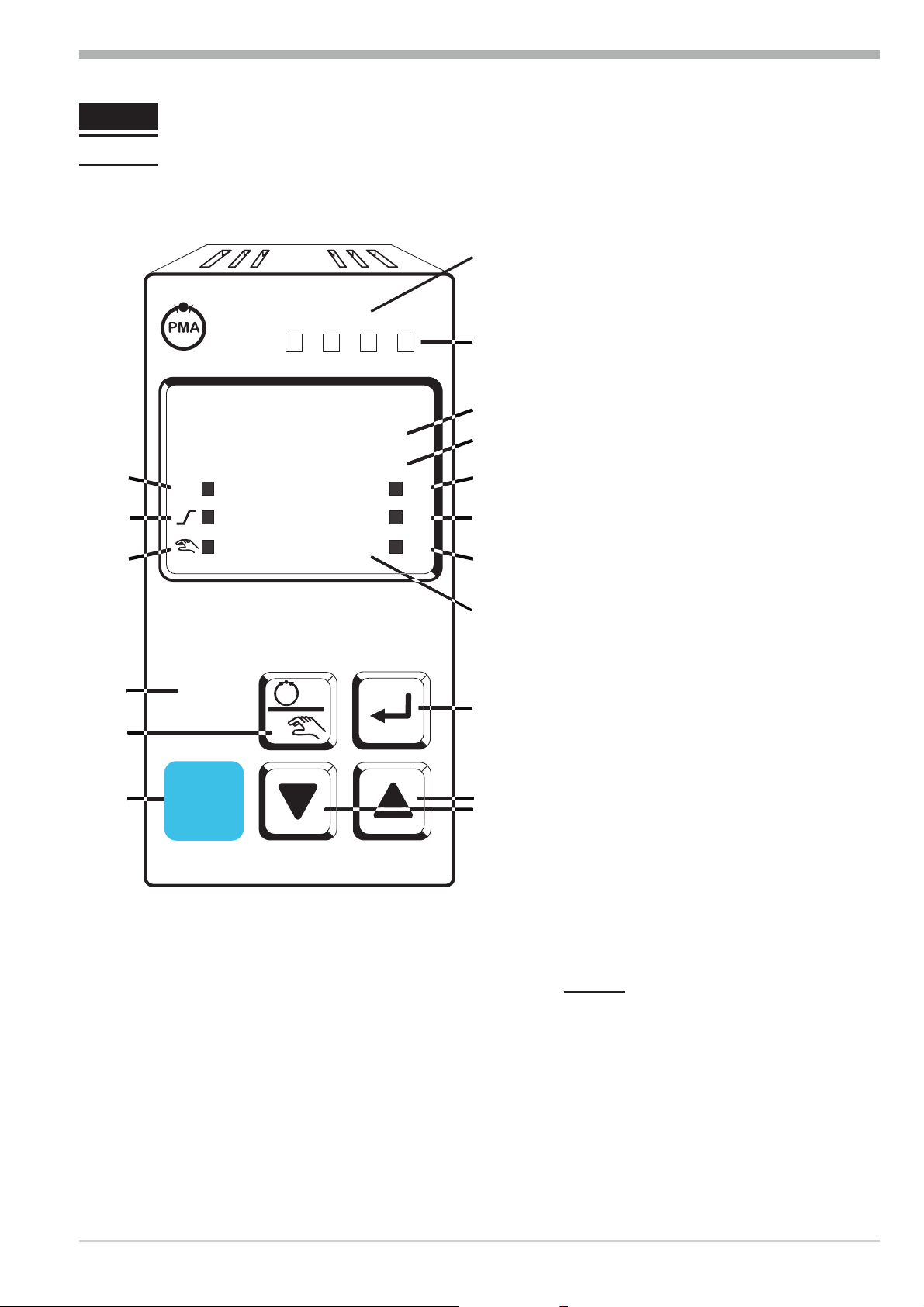

3 Operation

3.1 Front view

Operation

1 Status of switching outputs

OuT.1... 3

2 Lit with limit value 1 not

exceeded

3 Process value display

4 Controller works as on/off

controller

5 Self-tuning active

6 Entry in error list

7 Set-point, controller output

8 Enter key:

calls up extended operating

level / error list

9 Up/down keys:

changing the set-point or the

controller output value

0 Set-point SP.2 or SP.E is

effective

! Set-point gradient effective

" Manual mode

§ Function key

$ Manual-automatic-mode

switching ( " )

% PC connection for BlueControl

(engineering tool)

& Signalization

PArA level (burns)

ConF level (blinks)

g

In the upper display line, the process value is always displayed. At parameter,

configuration, calibration as well as extended operating level, the bottom display

line changes cyclically between parameter name and parameter value.

Front view 7 KS40-1 burner

Page 8

Operation

A

M

l

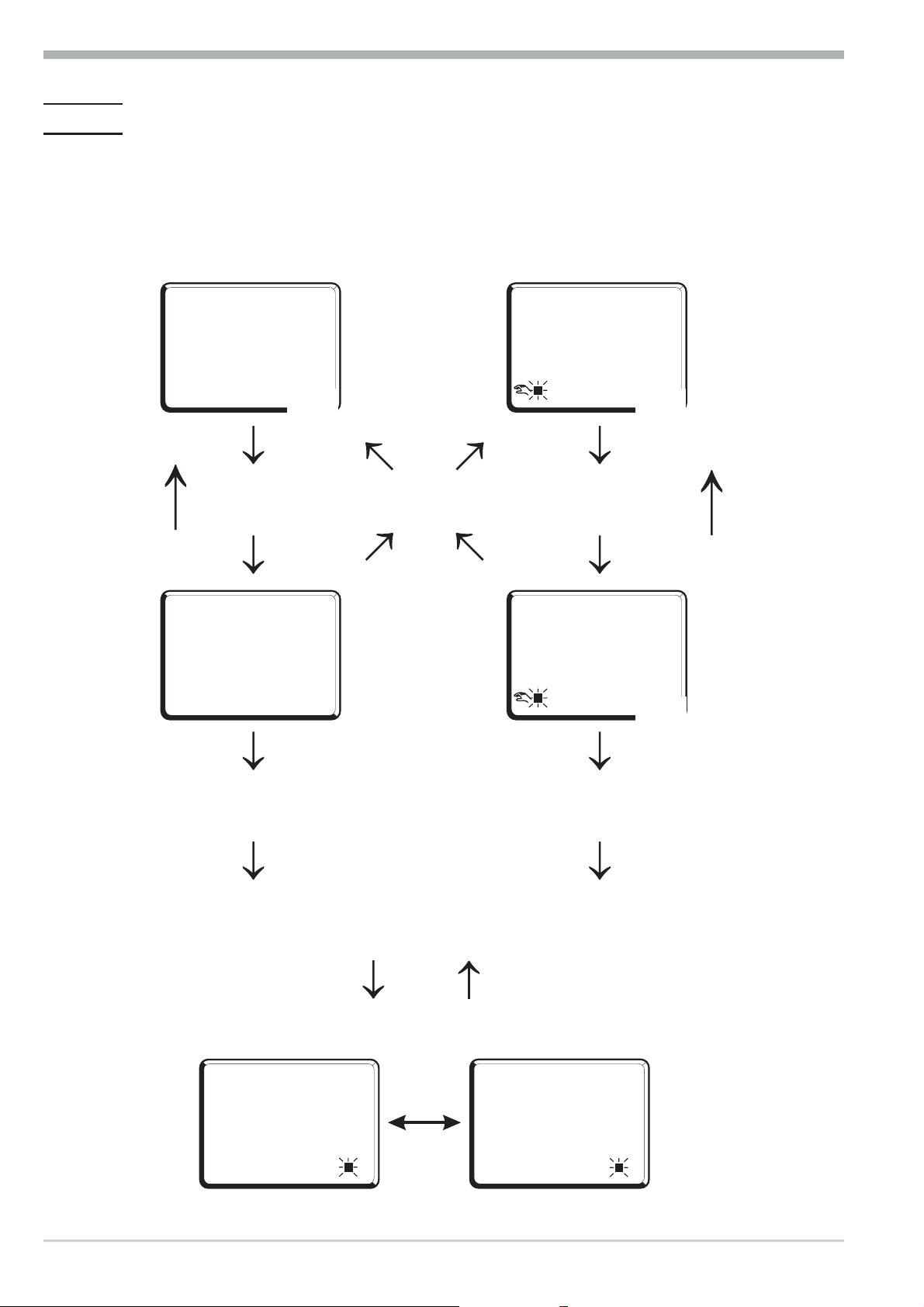

3.2 Operating level

The content of the extended operating level is determined by means of BlueCon

trol (engineering tool). Parameters which are used frequently or the display of

which is important can be copied to the extended operating level.

time

out

utomatic

126

125

È

Ì

Ù

i

Ò

Ò

i

anua

126

y21

È

Ì

Ù

time

out

-

126

y21

only

display

Ù

126

125

È

Ì

Ù

Extended operating level

time

out

Errorliste (if error exists)

126

FbF.1

KS40-1 burner 8 Operating level

display

switching

Err

126

2

Err

Page 9

Maintenance manager / Error list

With one or several errors, the extended operating level

always starts with the error list. Signalling an actual en

try in the error list (alarm, error) is done by the Err LED

-

SP.X

in the display. To reach the error list press Ù twice.

Err LED status Signification Proceed as follows

blinks Alarm due to existing error

lit Error removed,

Alarm not acknowledged

off No error,all alarm entries deleted

Determine the error type in the error list via the error number

Remove the error

Acknowledge the alarm in the error list pressing key È or Ì

The alarm entry was deleted.

-

Error list:

Operation

126

125

SG

Ada

Err

Name

E.1

E.2

FbF.1

/ 2

Sht.1

/ 2

POL.1

LooP

AdA.H

LiM.1/

2 / 3

Inf.1

Description Cause Possible remedial action

Internal error,

cannot be

removed

Internal error,

can be reset

Sensor break

INP1 / 2

Short circuit

INP1 / 2

INP1 polarity

error

Control loop

alarm (LOOP)

Self-tuning

heating alarm

(ADAH)

stored limit

alarm1/2/3

time limit value

message

E.g. defective EEPROM

-

- e.g. EMC trouble - Keepmeasurement andpower supply cables in

- Sensor defective

- Faulty cabling

- Sensor defective

- Faulty cabling

- Faulty cabling - Reverse INP1 polarity

- Input signal defective or not

connected correctly

-

Output not connected correctly

-

See Self-tuning heating error

status

-

adjusted limit value1/2/3

exceeded

-

adjusted number of operating

hours reached

Contact PMA service

-

- Return unit to our factory

separate runs

- Ensure that interference suppression of contactors is

provided

- Replace INP1 / 2 sensor

- Check INP1 / 2 connection

- Replace INP1/ 2 sensor

- Check INP1 / 2 connection

- Check heating or cooling circuit

-

Check sensor and replace it, if necessary

-

Check controller and switching device

-

see Self-tuning heating error status

-

check process

-

application-specific

Operating level 9 KS40-1 burner

Page 10

Operation

Error status (error status 3 - 9 only with error AdA.H / AdA.C ):

Error status Signification

0 No error/message not visible, except with acknowledgement

1 Stored error Change to error status 0 after acknowledgement in error list

2 Existing error Change to error status 1 after error removal

3

Faulty control action Re-configure controller (inverse i direct)

4

No response of process

variable

5

Low reversal point Increase ( ADA.H) max. output limiting Y.Hi or decrease

6

Danger of exceeded

set-point (parameter

determined)

7

Output step change too

small (dy > 5%)

8

Set-point reserve too

small

9

Impulse tuning failed The control loop is perhaps not closed: check sensor, connections and process

The control loop is perhaps not closed: check sensor, connections and process

( ADA.C) min. output limiting Y.Lo

If necessary, increase (inverse) or reduce (direct) set-point

Increase ( ADA.H) max. output limiting Y.Hi or reduce

( ADA.C) min. output limiting Y.Lo

Increase set-point (invers), reduce set-point (direct) or increase set-point

range (r PArA / SEtp / SP.LO and SP.Hi )

3.3 Self-tuning

After starting by the operator, the controller makes a self-tuning attempt. The

controller uses the process characteristics for quick line-out to the set-point without overshoot.

g

ti and td are taken into account only, if they were not set to

OFFpreviously.

Self-tuning start

The operator can start self-tuning at any time. For this, keys Ù and È must be

pressed simultaneously. The AdA LED starts blinking.

The controller outputs 0% or Y.Lo, waits until the process is at rest and starts

self-tuning (AdA LED lit permanently).

The self-tuning attempt is started when the following prerequisite is met:

The difference between process value i set-point must be ³ 10% of the

w

set-point range ( SP.Hi - SP.LO) (with inverse action: process value smaller

than set-point, with direct action: process value higher than set-point).

After successful self-tuning, the AdA-LED is off and the controller continues

operating with the new control parameters.

Self-tuning cancellation by the operator:

Self-tuning can always be cancelled by the operator. For this, press Ù and È

key simultaneously. The controller continues operating with the old parameters in

automatic mode in the first case and in manual mode in the second case.

KS40-1 burner 10 Self-tuning

Page 11

Operation

3

Self-tuning cancellation by the controller:

If the Err LED starts blinking while self-tuning is running, successful self-tuning

is prevented due to the control conditions. In this case, self-tuning was cancelled

by the controller. The controller switches off its outputs (controller output 0%).

Acknowledgement procedures in case of unsuccessful self-tuning:

1. Press keys Ù and È simultaneously:

The controller continues controlling using the old parameters in automatic

mode. The Err LED continues blinking, until the self-tuning error was

acknowledged in the error list.

2. Press key Ù :

Display of error list at extended operating level. After acknowledgement of

the error message, the controller continues control in automatic mode

using the old parameters.

Cancellation causes:

r page 9: "Error status self-tuning heating ( ADA.H) and cooling ( ADA.C)"

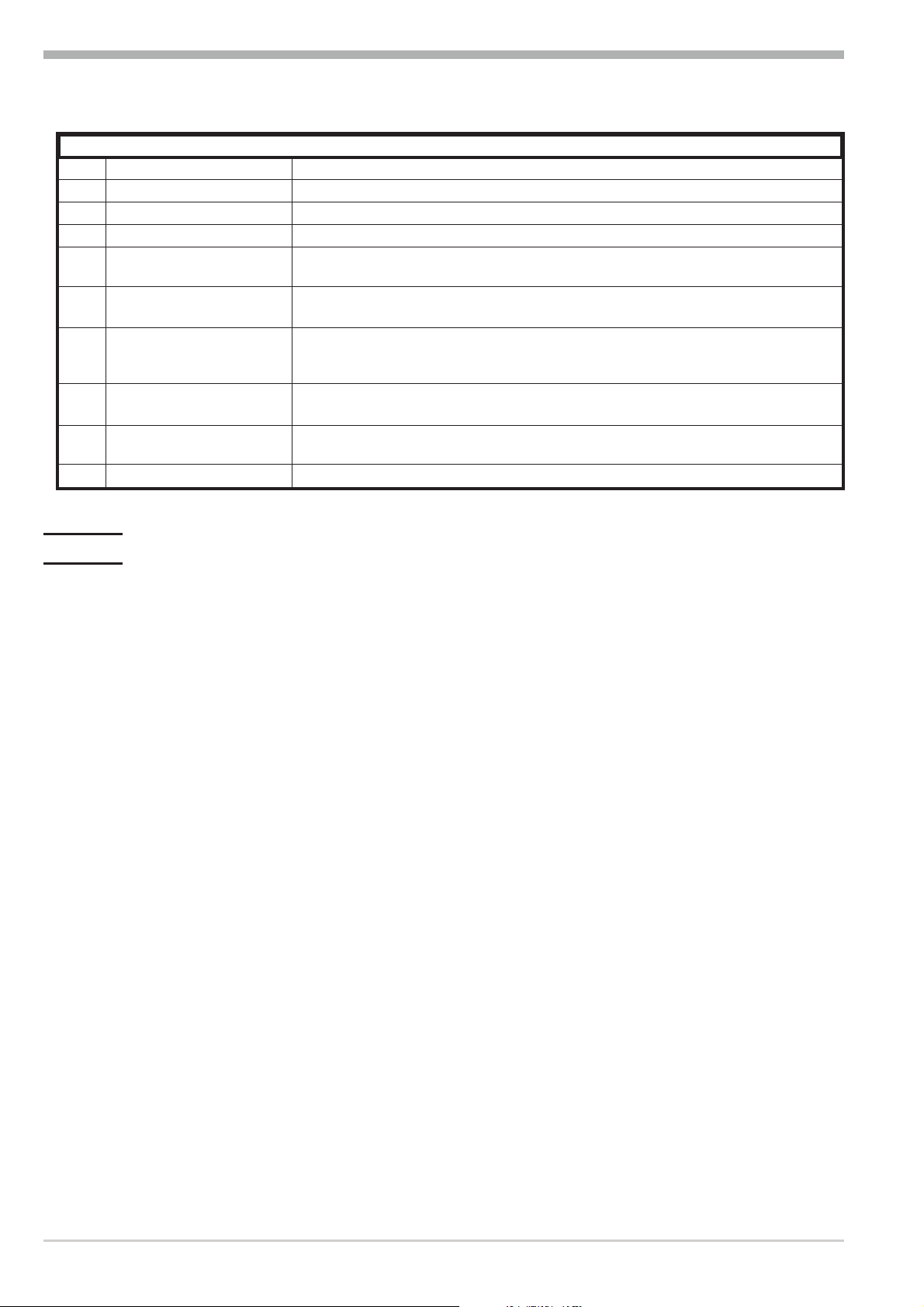

Examples for self-tuning attempt 3-point-stepping controller

After the start (1) the controller

closes the actuator (2 Out.3).

W

X

When the difference between

process value and set-point is

big enough (3), the changing of

the process value is monitored

for 1 min. (4). Afterwards the

actuator is opened (5 Out.1).

If the reversal point is reached

1 min

(6) or there are made enough

measurements, the parameters

are detected and are adopted.

1

2

4

5

6

3.4 Manual tuning

t

t

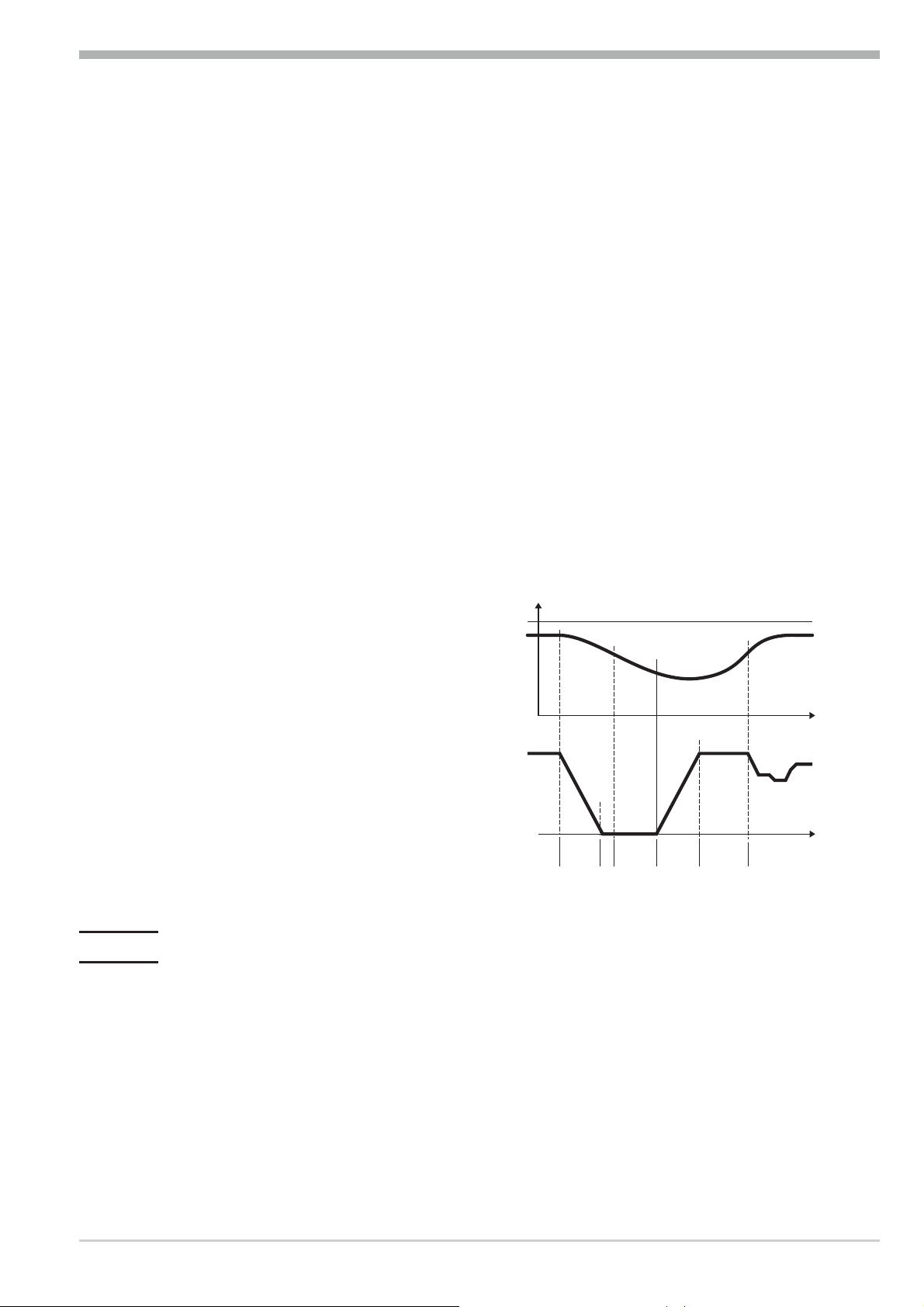

The optimization aid should be used with units on which the control parameters

shall be set without self-tuning.

For this, the response of process variable x after a step change of correcting va

riable y can be used. Frequently, plotting the complete response curve (0 to

100%) is not possible, because the process must be kept within defined limits.

Manual tuning 11 KS40-1 burner

Page 12

Operation

y

Values Tgand x

(step change from 0 to 100 %) or Dt and Dx (partial step re

max

sponse) can be used to determine the maximum rate of increase v

100%

Y

h

0%

x

X

max

Tg

y =correcting variable

Y

= control range

h

Tu = delay time (s)

Tg = recovery time (s)

X

V

= maximum process value

max

{{x

=

t

max

Xmax

=

Tg

Tu

= max. rate of increase of process value

{t

max

{X

-

.

t

t

The control parameters can be determined from the values calculated for delay

time T

, maximum rate of increase v

u

, control range Xhand characteristic K ac-

max

cording to the formulas given below. Increase Xp, if line-out to the set-point oscillates.

Parameter adjustment effects

Parameter Control Line-out of disturbances Start-up behaviour

Pb1 higher increased damping slower line-out slower reduction of duty cycle

lower reduced damping faster line-out faster reduction of duty cycle

td1 higher reduced damping faster response to disturbances faster reduction of duty cycle

lower increased damping slower response to disturbances slower reduction of duty cycle

ti1 higher increased damping slower line-out slower reduction of duty cycle

lower reduced damping faster line-out faster reduction of duty cycle

Formulas

K = Vmax * Tu controller behavior Pb1 [phy. units] td1 [s] ti1 [s]

With 2-point and

3-point controllers,

the cycle time must be

adjusted to

t1 / t2 £ 0,25 * Tu

PID 1,7*K 2*Tu 2*Tu

PD 0,5 * K Tu OFF

PI 2,6 * K OFF 6*Tu

PKOFF OFF

3-point-stepping 1,7 * K Tu 2 * Tu

KS40-1 burner 12 Manual tuning

Page 13

3.5 Operating structure

After supply voltage switch-on, the controller starts with the operating levels.

The controller status is as before power off.

Operation

g

g

126

Ù

125

PArA - level: At PArA - level, the right decimal point of the

ConF - level: At ConF - level, the right decimal point of upper

3sec.

upper display line is lit continuously.

display line blinks

126

PArA

Ì

Ù

126

ConF

Ì

PASS

Ù

126

CAL

Ì

PASS

Ù

126

End

PASS

Ù

a

PASS

To get access to the configuration and the parameters the saftey switch Loc must

be closed (factory setting).

Safety switch

Loc

closed OFF / password disabled / enabled

open OFF / password disabled

open OFF enabled

open Password enabled

All levels are accessible only by entering the Password (PASS). If

the safety switch Loc is open all levels are disabled

Password entered

with BluePort®

Function disabled or

enabled with BluePort®

Access via the instrument front

panel:

enabled

disabled

enabled

enabled after password entry

Operating structure 13 KS40-1 burner

Page 14

Configuration level

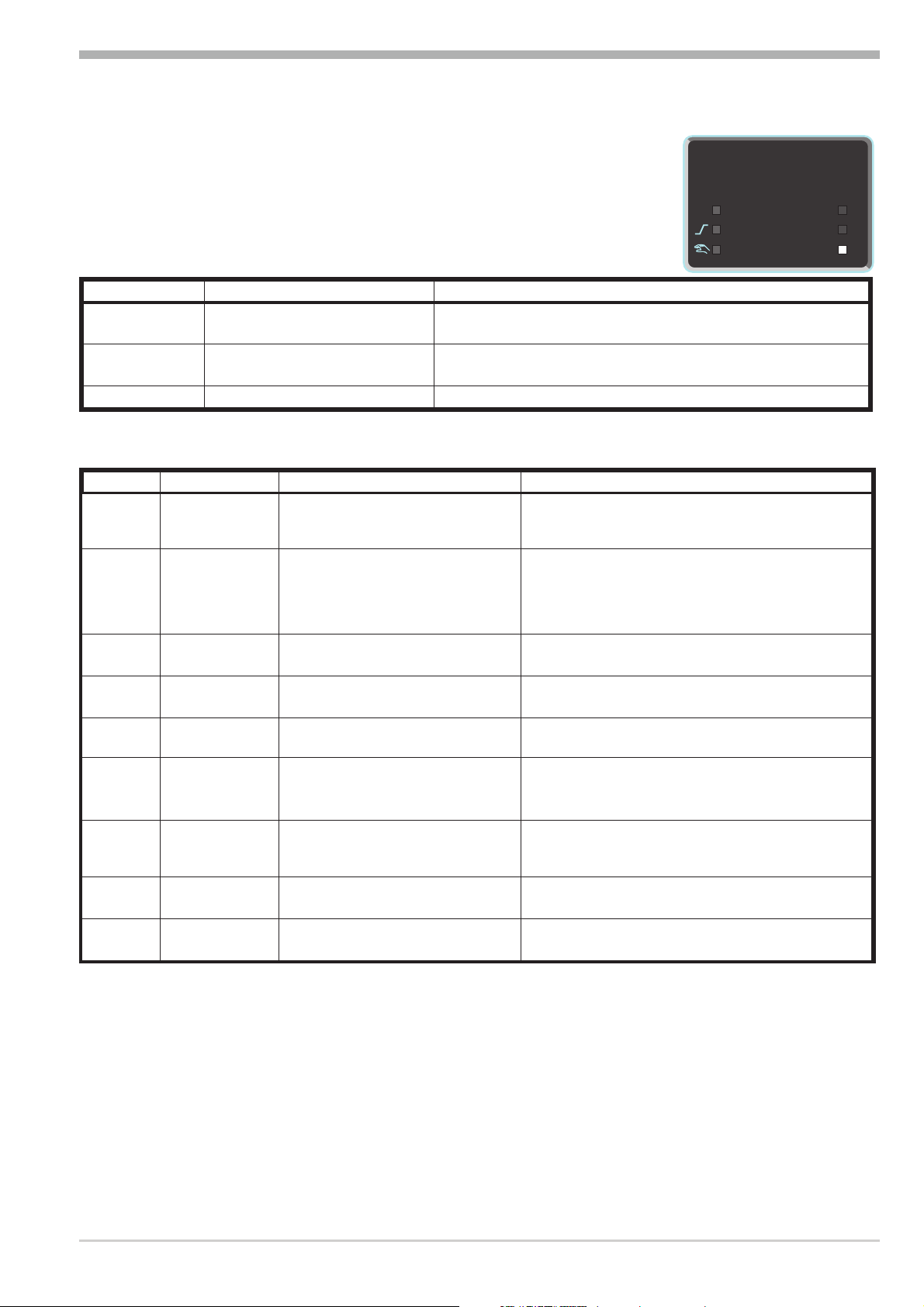

4 Configuration level

4.1

Configuration with qUIC

At configuration level, the controller function is determined by changing configu

ration word Con1 . Con1 and the code adjusted for Con1 are displayed al

ternately on the lower display line.

r

126

SP.X

125

Code signification:

A 0 Reaction at sensor break as process value higher than set-point.

SG

r

Ada

Err

Ù

3sec.

r

PArA

Ì

ConF

r

Ù

r

qUIC

123.8

r

Ù

Con1

r

Con1

123.8

1520

C

B

A

È

Ì

D

r

Ù

-

-

1 Reaction at sensor break as process value smaller than set-point

2 Only P30/W connection, always process value smaller than set-point *

B 0 Potentiometric transducer 50-30-50 [ / pressure sensor 0..10V, display range

0,0...100,0 (%)

1 Potentiometric transducer 50-30-50 [ / pressure sensor 0..10V, display range

0,00...1,00 (bar)

2 Potentiometric transducer 50-30-50 [ / pressure sensor 0..10V, display range

0,0...16,0 (bar)

3 Potentiometric transducer 50-30-50 [ / pressure sensor 0..10V, display range

0,0...40,0 (bar)

4 Resistance thermometer Pt 100 [ , range 0...200°C

5 Resistance thermometer Pt 100 [ , range 0...400°C

6 Thermocouple type L, range 0...900°C

7 Thermocouple type K, range 0...1350°C

C 0 Signaller with switching

1 3-point signaller

2 3-point stepping controller (DPS) switchable to signaller (SG)

3 3-point stepping controller (DPS) switchable to 3-point signaller (SG)

D 0 Not changeable

* Only possible with A = 2 and B = 0 … 3

KS40-1 burner 14 Configuration with qUIC

Page 15

Configuration level

g

After exit from the configuration level (see page 43, the controller is re-initiali

zed (all display elements are lit) and changes over to normal operation (operating

level).

Leading zeros are not displayed (ex.: display 400 with code 0400)

Configuration example 1 (code 0400):

KS40-1 as a signaller with

switch-over contact for 2-stage burner:

Measuring range 0...200°C,

Resistance thermometer Pt 100,

Reaction at sensor break

as process value higher than set-point.

Configuration example 2 (code 2120):

KS40-1 as 3-point stepping controller:

Connection to pressure transmitter P30/W,

Measuring range 0,00...1,00 bar,

Reaction at sensor break as process value

smaller than set-point.

123.8

Con1

123.8

Con1

123.8

400

123.8

2120

-

Function: Signaller with switch-over contact

CAUTION: The two relays

1 and 2 are coupled, i.e.

the contacts have

switch-over function. Ensure that the two relays are

not energized or de-energized simultaneously. Ex

ception: de-energized

condition.

Settings:

Switching differences: Sd1: in physical values

Limit value OUT3: The relay is de-energized when exceeding the limit.

-

-X

W

Upper limit value H.1 : in units of phys. quantity.

Switching difference HYS.1 : in units of phys.quantity

ON

OUT1

Sd1 Sd2=

OUT2

OFF

ON

W

OFF

ON

H.1

Limit OUT3

OFF

HYS.1

X

W

Signalling LEDs: LED1: lit when OUT1 is energized

LED2: lit when OUT2 is energized

LED3: lit when OUT3 is energized

OK-LED: lit, unless the limit value is reached

Parameter: see chapter 5 “Parameter level”

Configuration with qUIC 15 KS40-1 burner

Page 16

Configuration level

Function: 3-point signaller

OFF

ON

Sd2

OUT1

d.SP

OUT2

Sd1

ON

W

-X

W

OFF

X

W

H.1

ON

Limit OUT3

OFF

HYS.1

Settings:

OUT1: Switch-on point is coupled with the set-point.

Switching difference Sd1: in units of phys. quantity.

OUT2: Switch-off point is always below the set-point!

Adjustment range d.SP : in units of phys. quantity

Switching difference Sd2: in units of phys. quantity.

Limit value OUT3: With the limit value exceeded, the relay is de-energized.

High limit value H.1: in units of phys. quantity.

Switching difference HYS.1: in units of phys.quantity.

Signal LEDs: LED1: lit, when OUT1 is energized

LED2: lit, when OUT2 is energized

OK LED: lit, when limit value not reached

Parameters: see chapter 5 “Parameter level”

KS40-1 burner 16 Configuration with qUIC

Page 17

Function: 3-point stepping controller

Configuration level

W

OUT2

-X

W

OUT1

ON

OFF

XSd

-A A

SH

H.1

ON

Limit OUT3

HYS.1

Settings:

Controller: SH: in units of phys. quantity

Response threshold A: 0,5 w SH

Switching difference XSd : 0,06 w SH + 0,08

Actuator travel time tt: 3...9999 s

Min.duty cycle: fixed, TEmin = 100 ms

ON

OFF

X

W

Control parameters: Pb1 = 0,01...9999 : in unit of phys. quantity °C or °F

(number of digits behind the decimal point is determined

by CON1)

Ti = 1...9999 s ( OFF = no I-action)

td = 1...9999 s ( OFF = no D-action)

Limit value OUT3: With exceeded limit value, the relay is de-energized.

High limit value H.1 : in units of phys. quantity

Switching difference HYS.1 : in units of phys. quantity

Signalling LEDs: LED1: lit when OUT1 is energized

LED2: lit when OUT2 is energized

OK LED: lit, unless limit value is reached

De-energized condition: all relays de-energized, contacts open

Parameters: see chapter 5 “Parameter level”

Configuration with qUIC 17 KS40-1 burner

Page 18

Configuration level

4.2 Configuration without qUIC ( qUIC= OFF)

When key Ù is kept pressed during controller supply voltage switch-on, the

configuration is switched off with qUIC.

Now, all configuration settings are available to the user.

For changing back to configuration with qUIC , the two keys ÌÈmust be

kept pressed during controller supply voltage switch-on.

a

Hereby, the controller is reset to the factory-set default values !

4.3

Configuration survey:

Con1

Name Value range Description Default

Con1

0000...2330 qUIC - Configuration

Wire hook switches (on electronic card)

Name Value range Description Default

Loc

InP.1

open or closed Wire hook switch for locking the ConF- and PArA- level (if

enabled with BlueControl)

mA/Pt or 10V Wire hook switch for chosing InP.1 signal type

Cntr

Name Value range Description Default

SP.Fn

0 set-point controller can be switched over to external set-point (->

1 programmer

8 standard controller with external offset (SP.E)

C.Fnc

0

1

2

3

4

7

8

9

mAn

0

1

C.Act

0

1

Basic configuration of setpoint processing

LOGI/ SP.E)

Control behavior (algorithm)

2-point signaller

PID controller (2-point and continuous)

D/ Y/Off, or 2-point controller with partial/full load switch-over

2 x PID (3-point and continuous)

3-point stepping controller

3-point signaller

3-point stepping controller switchable to signaller

3-point stepping controller switchable to 3-point signaller

Manual operating permitted

no

yes (see also LOGI/ mAn)

Method of controller operation

Inverse, e.g. heating

Direct, e.g. cooling

Own

setting

0000

Own

setting

closed

mA/Pt

Own

setting

0

0

1

0

KS40-1 burner 18 Configuration without qUIC ( qUIC= OFF)

Page 19

Configuration level

Name Value range Description Default

FAIL

0

1

2

Behavior at sensor break

Controller outputs switched of

y=Y2

y = mean output. The maximum permissible output can be adjusted with

parameter Ym.H. To prevent determination of inadmissible values, mean value

formation is only if the control deviation is lower than parameter L.Ym.

rnG.L

rnG.H

-1999...9999

-1999...9999

X0 (low limit range of control) 1

X100 (high limit range of control) 1

100

1 rnG.L and rnG.H indicate the control range to which e.g. self-tuning is related.

InP.1

Name Value range Description Default

S.tYP

S.Lin

Corr

0

1

2

3

4

5

20

21

22

23

30

40

50

51

52

0

1

0

1

2

3

Sensor type selection

Thermocouple type L (-100...900°C) , Fe-CuNi DIN

Thermocouple type J (-100...1200°C) , Fe-CuNi

Thermocouple type K (-100...1350°C), NiCr-Ni

Thermocouple type N (-100...1300°C), Nicrosil-Nisil

Thermocouple type S (0...1760°C), PtRh-Pt10%

Thermocouple type R (0...1760°C), PtRh-Pt13%

Pt100 (-200,0 ... 100,0 °C)

Pt100 (-200,0 ... 850,0 °C)

Pt1000 (-200,0...200,0 °C)

KTY 11-6 (special 0...4500 Ohm)

0...20mA / 4...20mA 2

0...10V / 2...10V 2

Potentiometer 0...160 Ohm 2

Potentiometer 0...450 Ohm 2

Potentiometer 0...1600 Ohm 2

Linearization (only at S.tYP = 30 (0..20mA) and 40

(0..10V) adjustable)

None

Linearization to specification. Creation of linearization table

with BlueControl (engineering tool) possible. The characteristic

for KTY 11-6 temperature sensors is preset.

Measured value correction ( scaling

Without scaling

Offset correction (at CALlevel)

2- point correction (at CALlevel)

Scaling (at PArA level)

50

0

2

Own

setting

1

0

Own

setting

2 With current, voltage or potentiometer input signals, scaling is required (see section 5.1).

19 KS40-1 burner

Page 20

Configuration level

InP.2

Name Value range Description Default

I.Fnc

0

2

S.tYP

20

21

22

30

50

51

52

Function selection of INP2

No function

External set-point SP.E (switching -> LOGI/ SP.E)

Sensor type selection

Pt100 (-200,0 ... 100,0 °C)

Pt100 (-200,0 ... 850,0 °C)

Pt1000 (-200,0...200,0 °C)

0...20mA / 4...20mA 1

Potentiometer ( 0...160 Ohm) 1

Potentiometer ( 0...450 Ohm) 1

Potentiometer ( 0...1600 Ohm) 1

Corr Measured value correction / scaling 0

0 Without scaling

1 Offset correction (at CALlevel)

2 2-point correction (at CALlevel)

3 Scaling (at PArA level)

1 With current or potentiometer input signals, scaling is required (see section 5.1).

Own

setting

0

30

Lim

Name Value range Description Default

Fnc.1

Fnc.2

Fnc.3

Src.1

Src.2

Src.3

LP.AL

Function of limit1/2/3

0

1

2

Switched off

Measured value monitoring

Measured value monitoring + alarm status storage. A stored

limit value can be reset via error list, Ò-key or a digital input (

-> LOGI/ Err.r)

Source of limit1/2/3

0

1

2

Process value = absolut alarm

Control deviation Xw (process value - set-point) relativ alarm

Control deviation Xw (relativ alarm) with suppression after

start-up and set-point change

6

7

Effective set-point Weff

Correcting variable (controller output)

Monitoríng of control loop interruption

0

1

Switched off

LOOP alarm active

1/0/0

1/0/0

Own

setting

0

KS40-1 burner 20

Page 21

Out.1 / 2 / 3

Configuration level

Name Value range Description Default

O.Act

Y.1

Y.2

Lim.1

Lim.2

Lim.3

LP.AL

FAi.1

FAi.2

Method of operation of output OUT1

0

1

Direct / normally open

Inverse / normaly closed

Controller output Y1 / Y2

0

1

Not active

Active

Limit1/2/3signal

0

1

Not active

Active

Interruption alarm signal (LOOP)

0

1

Not active

Active

INP1 / INP2 error signal

0

1

Not active

Active

Out.1:0

Out.2:0

Out.3:1

Out.1: 1/0

Out.2: 0/1

Out.3: 0/0

Out.1: 0/0/0

Out.2: 0/0/0

Out.3: 1/0/0

Out.1:0

Out.2:0

Out.3:0

Out.1: 0/0

Out.2: 0/0

Out.3: 1/0

LOGI

Own

setting

Name Value range Description Default

L_r

Local / Remote switching (Remote: adjusting of all values by

0

front keys is blocked)

0

1

3

4

No function

Always active

DI2 switches *

DI3 switches *

5 è key switches *

SP.2

Switching to second set-point SP.2

0

3

4

No function

DI2 switches *

DI3 switches *

3

5 è key switches *

SP.E

Switching to external set-point SP.E

0

1

3

4

No function

Always active

DI2 switches *

DI3 switches *

0

5 è key switches *

Y2

Y/Y2 switching

0

3

4

5

6

No function

DI2 switches *

DI3 switches *

è key switches *

Ò key switches *

0

Own

setting

21 KS40-1 burner

Page 22

Configuration level

Name Value range Description Default

mAn

0

1

3

4

5

6

C.oFF

0

3

4

5

6

m.Loc

0

3

4

Automatic/manual switching

No function

Always active

DI2 switches *

DI3 switches *

è key switches *

Ò key switches *

Switch of the controller

No function

DI2 switches *

DI3 switches *

è key switches *

Ò key switches *

Blocage of the Ò key

No function

DI2 switches *

DI3 switches *

5 è key switches *

Err.r

0

3

4

5

6

SG

Reset of all error list entries

No function

DI2 switches *

DI3 switches *

è key switches *

Ò key switches *

Switching of the controller behavior between 3-point-stepping

controller and signaller

0

3

4

No function

DI2 switches *

DI3 switches *

5 è key switches *

P.run

0

3

4

Programmer Run/Stop

No function

DI2 switches *

DI3 switches *

5 è key switches *

di.Fn

0

1

2

Function of digital inputs (valid for all inputs)

Direct

Inverse

Toggle key function

Own

setting

6

0

0

0

4

5

0

* Multiple switching is possible and should be excluded on demand.

KS40-1 burner 22

Page 23

othr

Configuration level

Name Value range Description Default

Unit

dP

C.dEl

0

1

2

0

1

2

3

0...200

Unit

Without unit

°C

°F

Decimal point (max. number of digits behind the decimal point)

No digit behind decimal point

1 digit behind decimal point

2 digits behind decimal point

3 digits behind decimal point

Modem delay [ms]

Own

setting

1

0

0

23 KS40-1 burner

Page 24

Parameter setting level

5 Parameter setting level

Cntr

Visible

with qUIC

f

f

f

f

f

f

f

f

f

Name Value range Description Default

Pb1

1...9999

Proportional band 1 (heating) in phys.

10

dimensions (e.g. °C)

Pb2

1...9999

Proportional band 2 (cooling) in phys.

10

dimensions (e.g. °C)

ti1

ti2

td1

td2

t1

1...9999

1...9999

1...9999

1...9999

0,4...9999

Integral action time 1 (heating) [s]

Integral action time 2 (cooling) [s]

Derivative action time 1 (heating) [s]

Derivative action time 2 (cooling) [s]

Minimal cycle duration 1 (heating) [s]. The

10

10

10

10

10

minimum impulse is 1/4 x t1

t2

0,4...9999

Minimal cycle duration 2 (heating) [s]. The

10

minimum impulse is 1/4 x t2

SH

0...9999

Dead zone or switching differential for

1

on-off control [phys. dimensions)

Sd1

0,0...9999

Switching differntial relais 1 for signaller

0,1

with partial/full load switch-over

Sd2

0,0...9999

Switching differntial relais 2 for 3-point

0,1

signaller

d.SP

tP

tt

Y.Lo

Y.Hi

Y2

Y.0

-1999...999

9

0,1...9999

3...9999

-120...120

-120...120

-120...120

-120...120

Trigger point speration for series contact D

/ Y / Off [phys. dimensions]

Minimum impulse [s]

Actuator response time for servo-motor [s]

Lower output limit [%]

Upper output limit [%]

2. correcting variable

Working point for the correcting variable

0

OFF

60

0

100

0

0

[%]

Ym.H

L.Ym

-120...120

0...9999

Limitation of the mean value Ym [%]

Max. deviation xw at the start of mean

5

8

value calculation [phys. dimensions]

Own

setting

SETP

Visible

with qUIC

f

KS40-1 burner 24

Name Value range Description Default Own setting

SP.LO

SP.Hi

SP.2

r.SP

-1999...9999

-1999...9999

-1999...9999

0...9999

Set-point limit low for Weff

Set-point limit high for Weff

Set-point 2.

Set-point gradient [/min]

0

100

20

OFF

Page 25

ProG

Parameter setting level

Visible

with qUIC

InP.1

Visible

with qUIC

Name Value range Description Default Own setting

SP.01

Pt.01

SP.02

Pt.02

SP.03

Pt.03

SP.04

Pt.04

Name Value range Description Default

InL.1

OuL.1

-1999...9999

0...9999

-1999...9999

0...9999

-1999...9999

0...9999

-1999...9999

0...9999

-1999...9999

-1999...9999

Segment end set-point 1

Segment time 1 [min]

Segment end set-point 2

Segment time 2 [min]

Segment end set-point 3

Segment time 3 [min]

Segment end set-point 4

Segment time 4 [min]

Input value for the lower scaling point

Displayed value for the lower scaling

100

10

100

10

200

10

200

10

Own

setting

38,5

0

point

InH.1

OuH.1

-1999...9999

-1999...9999

Input value for the upper scaling point

Displayed value for the lower scaling

61,5

100

point

t.F1

-1999...9999

Filter time constant [s]

0,5

InP.2

Visible

with qUIC

Lim

Visible

with qUIC

f

f

Name Value range Description Default

InL.2

OuL.2

-1999...9999

-1999...9999

Input value for the lower scaling point

Displayed value for the lower scaling

point

InH.2

OuH.2

-1999...9999

-1999...9999

Input value for the upper scaling point

Displayed value for the upper scaling

point

Name Value range Description Default

L.1

H.1

HYS.1

L.2/3

H.2/3

HYS.2/

-1999...9999

-1999...9999

0...9999

-1999...9999

-1999...9999

0...9999

Lower limit 1

Upper limit 1

Hysteresis limit 1

Lower limit2/3

Upper limit2/3

Hysteresis limit2/3

OFF

OFF

OFF

3

Own

setting

0

0

100

100

Own

setting

20

0,1

0,1

25 KS40-1 burner

Page 26

Parameter setting level

5.1 Input scaling (only visible with qUIC = OFF)

When using current or voltage signals as input variables for InP.1 or InP.2,

scaling of input and display values at parameter setting level is required. Specifi

cation of the input value for lower and higher scaling point is in the relevant elec

trical unit (mA/ V).

phys.

quantity

OuH.x

-

-

mA / V

5.1.1 Input Inp.1

g

Parameters InL.1 , OuL.1, InH.1 and OuH.1 are only visible if

ConF / InP.1 / Corr = 3 is chosen.

S.tYP Input signal InL.1 OuL.1 InH.1 OuH.1

30

(0...20mA)

40

(0...10V)

phys. quantity

OuL.x

InL.x

0…20mA 0 any 20 any

4…20mA 4 any 20 any

0…10V 0 any 10 any

2…10V 2 any 10 any

InH.x

mA/V

In addition to these settings, InL.1 and InH.1 can be adjusted in the range

(0...20mA / 0...10V) determined by selection of S.tYP .

a

For using the predetermined scaling with thermocouple and resistance

thermometer (Pt100), the settings for InL.1 and OuL.1 and for InH.1 and

OuH.1 must have the same value.

g

Input scaling changes at calibration level (r page 27) are displayed by input

scaling at parameter setting level. After calibration reset (OFF), the scaling

parameters are reset to default.

5.1.2 Input InP.2

As input InP.1, but only S.Typ = 30 adjustable!

KS40-1 burner 26 Input scaling (only visible with qUIC = OFF)

Page 27

6 Calibration level

Calibration level

g

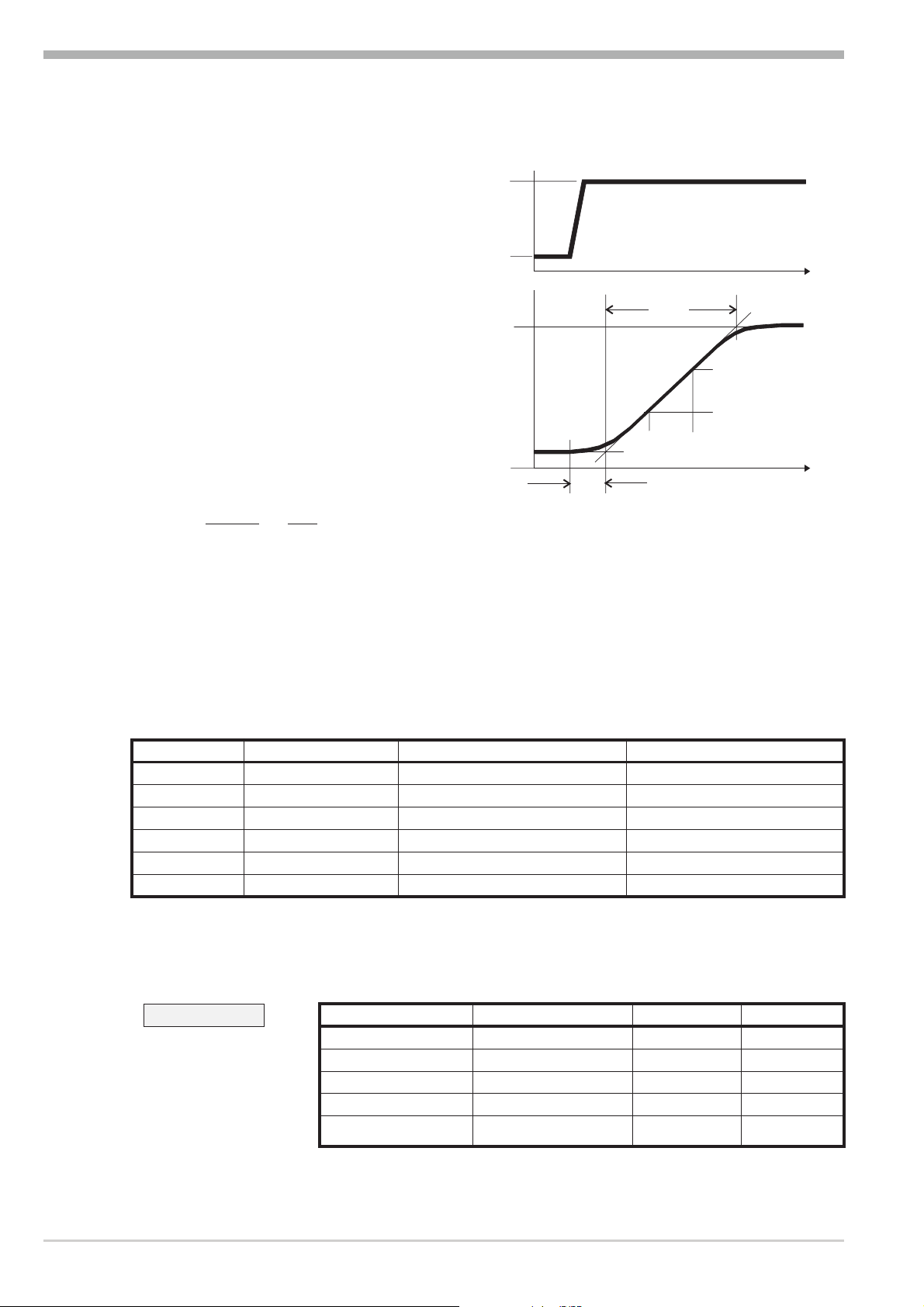

Measured value correction ( CAL) is only visible if ConF / InP.1 / Corr = 1

or 2 and qUIC = OFF is chosen.

The measured value can be matched in the calibration menu ( CAL). Two me

-

thods are available:

Offset correction

( ConF/ InP.1 / Corr =1 ):

possible on-line at the

w

display

standard setting

offset correction

process

OuL.1

new

OuL.1old

2-point correction

( ConF/ InP.1 / Corr = 2 ):

w

is possible off-line with

process value simulator

display

OuH.1

OuH.1

OuL.1

new

OuL.1old

old

new

InL.1

InL.1

standard setting

2-point correction

InH.1

X

X

27 KS40-1 burner

Page 28

Calibration level

Offset correction ( ConF/ InP.1 / Corr =1 ):

r

SP.X

126

125

r

run

Ada

Err

Ù

3sec.

r

PArA

Ì

:

CAL

r

InL.1: The input value of the scaling point is displayed.

The operator must wait, until the process is at rest.

Subsequently, the operator acknowledges the input value by pressing

key Ù.

OuL.1: The display value of the scaling point is displayed.

Before calibration, OuL.1 is equal to InL.1.

The operator can correct the display value by pressing keys ÈÌ .

Subsequently, he confirms the display value by pressing key Ù.

Ù

r

InP.1

r

Ù

r

r

r

InL.1

OuL.1

End

r

r

È

Ì

Ù

r

Ù

Ù

KS40-1 burner 28

Page 29

2-point correction ( ConF/ InP.1 / Corr =1 ):

r

Calibration level

SP.X

126

125

run

r

Ada

Err

Ù

3sec.

r

PArA

Ì

:

CAL

r

InL.1: The input value of the lower scaling point is displayed.

The operator must adjust the lower input value by means of a

process value simulator and confirm the input value by pressing key Ù.

OuL.1: The display value of the lower scaling point is displayed.

Before calibration, OuL.1 equals InL.1.

The operator can correct the lower display value by pressing the ÈÌ

keys. Subsequently, he confirms the display value by pressing key Ù.

InH.1: The input value of the upper scaling point is displayed. .

The operator must adjust the upper input value by means of the

process value simulator and confirm the input value by pressing key Ù.

OuH.1: The display value of the upper scaling point is displayed.

Before calibration OuH.1 equals InH.1.

The operator can correct the upper display value by pressing keys ÈÌ

Subsequently, he confirms the display value by pressing key Ù.

Ù

r

InP.1

r

Ù

r

r

r

r

r

InL.1

OuL.1

InH.1

OuH.1

End

r

È

Ì

r

È

Ì

r

Ù

r

Ù

r

Ù

Ù

Ù

g

The parameters (OuL.1, OuH.1) changed at CAL level can be reset by adjusting

the parameters below the lowest adjustment value (OFF) by means of decrement

key Ì .

29 KS40-1 burner

Page 30

Programmer

7 Programmer

W,X

W,X

Pt.01

SP.01

Pt.02

SP.02

Pt.03

SP.03

Pt.04

SP.04

W

t

Programmer set-up:

For using the controller as a programmer, select parameter SP.Fn = 1 in the

ConF menu. The programmer is started via one of digital inputs di2..3 or the è

key. Which input shall be used for starting the programmer is determined by selecting parameter P.run = 3 / 4 / 5 in the ConF menu accordingly.

For assigning the program end as a digital signal to one of the relay outputs, parameter P.End = 1 must be selected for the relevant output OUT.1...OUT.3 in the

ConF menu.

Programmer parameter setting:

A programmer with 4 segments is available to the user. Determine a segment duration Pt.01 .. Pt.04 (in minutes) and a segment target set-point SP.01 ..

SP.04 for each segment in the PArA menu.

Starting/stopping the programmer:

Starting the programmer is done by a digital signal at input di2..3 or by pressing

the è key selected by parameter P.run .

The programmer calculates a gradient from segment end setpoint and segment

time. This gradient is always valid. Normaly, the programmer starts the first seg

ment at process value. Because of this the effective run-time of the first segment

may differ from the at PArA level setted segment time (process value ¹ set

point).

After program end, the controller continues controlling with the target set-point

set last.

If the program is stopped during execution (signal at digital input di2..3 or the è

key is taken away), the programmer returns to program start and waits for a new

start signal.

-

KS40-1 burner 30

Page 31

Programmer

+

Program parameter changing while the program is running is possible.

Changing the segment time:

Changing the segment time leads to re-calculation of the required gradient. When

the segment time has already elapsed, starting with the new segment is done di

rectly, where the set-point changes with a step.

Changing the segment end setpoint:

Changing the set-point leads to re-calculation of the required gradient, in order to

reach the new set-point during the segment rest time, whereby the required gra

dient polarity sign can change.

-

-

31 KS40-1 burner

Page 32

8 Technical data

INPUTS

PROCESS VALUE INPUT INP1

Resolution: > 14 bits

Decimal point: 0 to 3 digits behind the

decimal point

Dig. input filter: adjustable 0,000...9999 s

Scanning cycle: 100 ms

Measured value

correction:

Thermocouples

r Table 2 (page 58 )

Input resistance:

Effect of source resistance: 1 mV/W

Cold-junction compensation

Maximal additional error: ± 0,5 K

Sensor break monitoring

Sensor current:

Configurable output action

2-point or offset correction

1M

³

W

A

£1m

SUPPLEMENTARY INPUT INP2

Resolution: > 14 bits

Scanning cycle: 100 ms

Accuracy: < 0,5 %

Current measuring range

Technical data as for INP1

Potentiometer

r Table 2 (page 58 )

Connection: 3-wire

Lead resistance: max. 30 Ohm

Input circuit monitor: break

CONTROL INPUT DI2/DI3

Configurable as switch or push-button!

Connection of a potential-free contact suitable

for switching “dry” circuits.

Switched voltage: 5 V

Current: 160mA

Resistance thermometer

r Table 2 (page 58 )

Connection: 2 or 3-wire

Lead resistance: max. 30 Ohm

Input circuit monitor: break and short circuit

Potentiometric transducer 50-30-50 W

Current and voltage signals

r Table 3 (page 58 )

Span start, end of span: anywhere within measuring

range

Scaling: selectable -1999...9999

Linearization: 16 segments, adaptable

with BlueControl

Decimal point: adjustable

Input circuit monitor: 12,5% below span start

(2mA, 1V)

TRANSMITTER SUPPLY UT (OPTION)

Power: 22 mA /³18 V

GALVANIC ISOLATION

Safety isolation

Function isolation

Power supply

connections

Relay outputs OUT 1,2

Relay output OUT3

Process value input INP1

Supplementary input INP2

Digital inputs di2, 3

Transmitter supply U

T

KS40-1 burner 32

Page 33

OUTPUTS

ENVIRONMENTAL CONDITIONS

RELAY OUTPUTS OUT1, OUT2

Contact type: 2 NO contacts with

common connection

Max. contact rating: 500 VA, 250 V, 2A at

48...62 Hz,

resistive load

Min. contact rating: 6V, 1 mA DC

Operating life (electr.): 800.000 duty cycles with

max. rating

RELAY OUTPUT OUT3

Contact type: potential-free changeover

contact

Max.contact rating: 500 VA, 250 V, 2A at 48...62

Hz,

resistive load

Min. contact rating: 5V, 10 mA AC/DC

Operating life (electr.): 600.000 duty cycles with

max. contact rating

Note:

If the relays OUT1...OUT3 operate external

contactors, these must be fitted with RC

snubber circuits to manufacturer specifications

to prevent excessive switch-off voltage peaks.

Protection modes

Front panel: IP 65 (NEMA 4X)

Housing: IP 20

Terminals: IP 00

Permissible temperatures

For specified

0...60°C

accuracy:

Warm-up time: ≥ 15 minutes

For operation: -20...65°C

For storage: -40...70°C

Humidity

75% yearly average, no condensation

Altitude

To 2000 m above sea level

Shock and vibration

Vibration test Fc (DIN 68-2-6)

Frequency: 10...150 Hz

Unit in operation: 1g or 0,075 mm

Unit not in operation: 2g or 0,15 mm

Shock test Ea (DIN IEC 68-2-27)

POWER SUPPLY

AC SUPPLY

Voltage: 90...250 V AC

Frequency: 48...62 Hz

Power consumption approx. 7,3 VA

BEHAVIOUR WITH POWER FAILURE

Configuration, parameters and adjusted

set-points, control mode:

Non-volatile storage in EEPROM

Shock: 15g

Duration: 11ms

Electromagnetic compatibility

Complies with EN 61 326-1

(for continuous, non-attended operation)

33 KS40-1 burner

Page 34

GENERAL

Housing

Material: Makrolon 9415

flame-retardant

Flammability class: UL 94 VO, self-extinguishing

Plug-in module, inserted from the front

Safety test

Complies with EN 61010-1 (VDE 0411-1):

Overvoltage category II

Contamination class 2

Working voltage range 300 V

Protection class II

Certifications

Type tested to EN 14597 (replaces DIN

3440)

With certified sensors applicable for:

Heat generating plants with outflow

w

temperatures up to 120°C to DIN 4751

Hot-water plants with outflow temperatures

w

above 110°C to DIN 4752

w Thermal transfer plants with organic transfer

media to DIN 4754

w

Oil-heated plants to DIN 4755

cULus-certification

(Type 1, indoor use)

File: E 208286

Electrical connections

Flat-pin connectors 1 x 6,3 mm or 2 x 2,8 mm

to DIN 46 244

Mounting

Panel mounting with two fixing clamps at

top/bottom or right/left,

High-density mounting possible

Mounting position: uncritical

Weight: 0,27kg

Accessories delivered with the unit

Operating manual

Fixing clamps

KS40-1 burner 34

Page 35

Technical data

Table 1 Thermocouples measuring ranges

Type Range Accuracy Resolution (Ô)

L Fe-CuNi (DIN) -100...900°C -148...1652°F ß 2K 0,1 K

J Fe-CuNi -100...1200°C -148...2192°F ß 2K 0,1 K

K NiCr-Ni -100...1350°C -148...2462°F ß 2K 0,2 K

N Nicrosil/Nisil -100...1300°C -148...2372°F ß 2K 0,2 K

S PtRh-Pt 10% 0...1760°C 32...3200°F ß 2K 0,2 K

R PtRh-Pt 13% 0...1760°C 32...3200°F ß 2K 0,2 K

T Cu-CuNi -200...400°C -328...752°F ß 2K 0,05 K

C W5%Re-W26%Re 0...2315°C 32...4199°F ß 2K 0,4 K

D W3%Re-W25%Re 0...2315°C 32...4199°F ß 2K 0,4 K

E NiCr-CuNi -100...1000°C -148...1832°F ß 2K 0,1 K

B * PtRh-Pt6% 0(100)...1820°C 32(212)...3308°F ß 2K 0,3 K

* Specifications valid for 100°C

Table 2 Resistance transducer measuring ranges

Type Sensor current Range Accuracy Resolution (Ô)

Pt100

Pt100 -200...850°C -140...1562°F ß 1K 0,1K

Pt1000 -200...200°C -140...392°F ß 2K 0,1K

KTY 11-6 * -50...150°C -58...302°F ß 2K 0,05K

0,2 mA

Spezial 0...4500

Spezial 0...450

Poti 0...160

Poti 0...450

Poti 0...1600

* Or special

-200...100°C -140...212°F ß 1K 0,1K

ß 0,1 % 0,01 %

Table 3 Current and voltage measuring ranges

Range Input resistance Accuracy Resolution (Ô)

0-10 Volt

0-20 mA

~ 110 kW

49 W (voltage requirement ß 2,5 V)

ß 0,1 % ß 0,6 mV

ß 0,1 %

35 KS40-1 burner

ß 1,5 mA

Page 36

Safety hints

9 Safety hints

This unit was built and tested in compliance with VDE 0411-1 / EN 61010-1 and

was delivered in safe condition.

The unit complies with European guideline 89/336/EWG (EMC) and is provided

with CE marking.

The unit was tested before delivery and has passed the tests required by the test

schedule. To maintain this condition and to ensure safe operation, the user must

follow the hints and warnings given in this operating manual.

The unit is intended exclusively for use as a measurement and control instrument

in technical installations.

a

Warning

If the unit is damaged to an extent that safe operation seems impossible, the unit

must not be taken into operation.

ELECTRICAL CONNECTIONS

The electrical wiring must conform to local standards (e.g. VDE 0100). The input

measurement and control leads must be kept separate from signal and power

supply leads.

COMMISSIONING

Before instrument switch-on, check that the following information is taken into

account:

Ensure that the supply voltage corresponds to the specifications on the type

w

label.

All covers required for contact protection must be fitted.

w

If the controller is connected with other units in the same signal loop, check

w

that the equipment in the output circuit is not affected before switch-on. If

necessary, suitable protective measures must be taken.

The unit may be operated only in installed condition.

w

Before and during operation, the temperature restrictions specified for

w

controller operation must be met.

w

SHUT-DOWN

For taking the unit out of operation, disconnect it from all voltage sources and

protect it against accidental operation.

If the controller is connected with other equipment in the same signal loop, check

that other equipment in the output circuit is not affected before switch-off. If ne

cessary, suitable protective measures must be taken.

KS40-1 burner 36

-

Page 37

MAINTENANCE, REPAIR AND MODIFICATION

The units do not need particular maintenance.

Safety hints

a

l

Warning

When opening the units, or when removing covers or components, live parts and

terminals may be exposed.

Before starting this work, the unit must be disconnected completely.

After completing this work, re-shut the unit and re-fit all covers and components.

Check if specifications on the type label must be changed and correct them, if ne

cessary.

Caution

When opening the units, components which are sensitive to electrostatic dischar

ge (ESD) can be exposed. The following work may be done only at workstations

with suitable ESD protection.

Modification, maintenance and repair work may be done only by trained and authorized personnel. For this purpose, the PMA service should be contacted.

-

-

37 KS40-1 burner

Page 38

Safety hints

9.1 Resetting to factory setting

In case of faultyconfiguration, KS4x-1 can be reset to the default condition.

For this, the operator must keep the keys increment and decrement pressed during

power-on.

Then, press key increment to select YES.

Confirm factory resetting with Enter and the copy procedure is started

(display COPY).

Afterwards the device restarts.

1

ÌÈ + Power on

FAC

SP.x

torY

1.

g

g

In all other cases, no reset will occur (timeout abortion).

If one of the operating levels was blocked and the safety lock is open, reset to

factory setting is not possible.

If a pass number was defined (via BlueControl®) and the safety lock is open, but

no operating level was blocked, enter the correct pass number when prompted in

3. A wrong pass number aborts the reset action.

run

Ada

Err

FAC

SP.x

2.

no

2

È

FAC

run

Ada

Err

SP.x

YES

run

Ada

Err

3

Ù

FAC

SP.x

COPY

run

Ada

Err

4

8.8.8.8.

SP.x

8.8.8.8.

run

Ada

Err

g

The copy procedure ( COPY) can take some seconds.

Now, the transmitter is in normal operation.

KS40-1 burner 38 Resetting to factory setting

Page 39

Index

0-9

2-point correction .............27

C

Calibration (CAL).............27

Calibration level (CAL)........27-29

Configuration with

Configuration without

Control inputs di1, di2, di3

Technical data ..............32

Current signal measuring range ......32

QUIC ......14-17

QUIC .......18

D

Digital inputs di1, di2, di3

Technical data ..............32

E

Error list ...................9

Example

3-point signaller .............16

3-point stepping controller .......17

Signaller with switch-over contact . . . 15

M

Maintenance manager ............9

Manual tuning .............11-12

Mounting ..................5

O

Offset correction ..............27

Output OUT1

Technical data ..............33

Output OUT2

Technical data ..............33

P

Programmer

Changing segment end setpoint .....31

Changing segment time .........31

Parameter setting ............30

Set-up ..................30

Starting/Stopping ............30

Q

QUIC Codes ................14

F

Front view ..................7

I

Input INP1

Parameters................25

Technical data ..............32

Input INP2

Parameters................25

Input scaling ................26

L

LED

Ada-LED................7

Err-LED.................7

ì -LED.................7

ò -LED.................7

run-LED.................7

SP.x-LED................7

R

Resetting to factory setting.........38

Resistance thermometer measuring range . 32

S

Safety hints ..............36-38

Safety switch ................5

Safety test .................34

Self-tuning

Cancelation .............10-11

Cancelation causes ...........11

Start ...................10

T

Thermocouple measuring range ......32

V

Voltage signal measuring range ......32

39 KS40-1 burner

Page 40

9499- 040- 66011

2

Subject to alterations without notice © PMA Prozeß- und Maschinen-Automation GmbH

Änderungen vorbehalten P.O.B. 310 229, D-34058 Kassel, Germany

Sous réserve de toutes modifications Printed in Germany 9499-040-66011 (08/2013)

A6

A5 auf A6 gefaltet, 2-fach geheftet, SW-Druck Normalpapier weiß 80g/m

Loading...

Loading...