Page 1

DataVU 5 - Operating Manual

59480

Page 2

Page 3

Contents

1 Introduction 7

1.1 Preface .......................................................................................................... 7

1.2 Arrangement of the documentation ........................................................... 8

1.2.1 Structure of this operating manual ................................................................. 8

1.3 Typographical conventions ......................................................................... 9

1.3.1 Warning signs ................................................................................................. 9

1.3.2 Note signs ...................................................................................................... 9

1.3.3 Representation modes ................................................................................. 10

2 Device description 11

2.1 Displays and controls ................................................................................ 11

2.2 Operating principle and graphic elements .............................................. 12

2.3 Analog inputs .............................................................................................. 14

2.4 Digital signals (event traces) ..................................................................... 15

2.5 Counters / integrators / operating time counter ..................................... 16

2.5.1 Reporting period of the counts .................................................................... 18

2.5.2 Resetting the counters / integrators / operating time counters ................... 18

2.5.3 Response to instrument reconfiguration ...................................................... 19

2.5.4 Response at end of summer time ................................................................ 20

2.6 Math/logic module ..................................................................................... 20

2.7 Operating modes ........................................................................................ 23

2.8 Storing data ................................................................................................ 24

2.9 Read-out of data ........................................................................................ 27

2.10 Evaluating data ........................................................................................... 27

2.11 Webserver ................................................................................................... 28

3 Operation and visualization 31

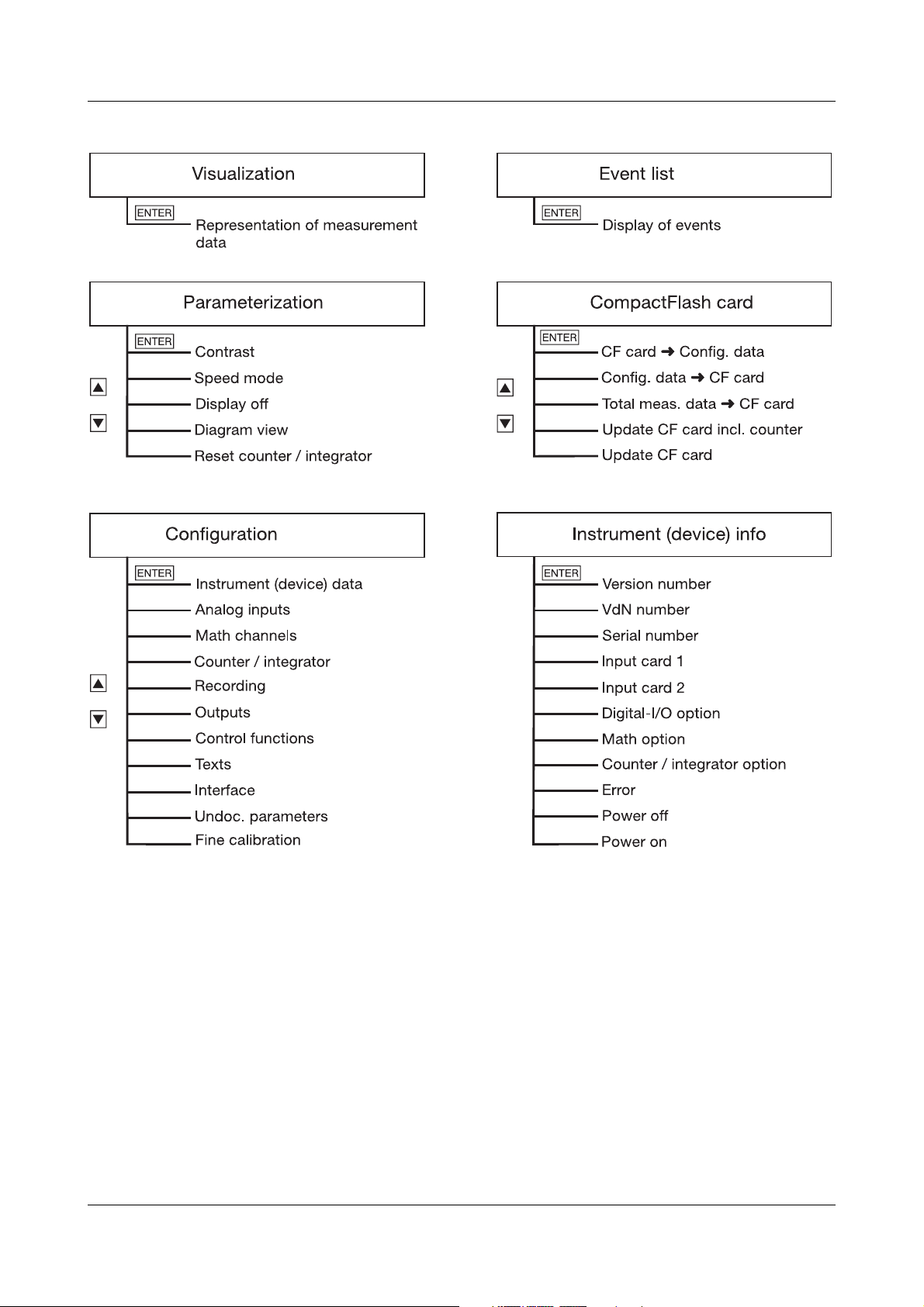

3.1 Basic menu ................................................................................................. 32

Page 4

Contents

3.2 Visualization ................................................................................................ 33

3.2.1 Diagram representation with digital display (small measurements) ............. 34

3.2.2 Diagram representation with scaling ............................................................ 35

3.2.3 Diagram representation with bar graph ........................................................ 35

3.2.4 Large digital display (large measurements) .................................................. 36

3.2.5 Curve representation (header switched off) ................................................. 37

3.2.6 Evaluation of the stored measurement data ................................................ 38

3.2.7 Counters / integrators / operating time ........................................................ 41

3.3 Parameterization ........................................................................................ 43

3.4 Configuration .............................................................................................. 46

3.5 Event list ...................................................................................................... 47

3.6 CompactFlash card .................................................................................... 50

3.7 Device info .................................................................................................. 53

3.8 Text entry ..................................................................................................... 55

3.9 Entering values ........................................................................................... 56

3.10 Code number (password query) ............................................................... 57

4 Configuration parameters 59

4.1 Operating example ..................................................................................... 59

4.2 Table of configuration parameters ........................................................... 60

4.2.1 Parameterization .......................................................................................... 60

4.2.2 Configuration - Instrument (device) data ...................................................... 62

4.2.3 Configuration - Analog inputs ...................................................................... 64

4.2.4 Configuration - Math channels ..................................................................... 66

4.2.5 Configuration - Counter/integrator (extra code) ........................................... 66

4.2.6 Configuration - Recording ............................................................................ 70

4.2.7 Configuration - Outputs (extra code) ........................................................... 73

4.2.8 Configuration - Control functions ................................................................. 74

4.2.9 Configuration - Texts .................................................................................... 74

4.2.10Configuration - Interfaces ............................................................................ 75

4.2.11Configuration - Undocumented parameters ............................................... 76

4.2.12Configuration - Fine calibration ................................................................... 76

5 Setup program 77

5.1 Hardware and software requirements ...................................................... 77

5.2 Installation .................................................................................................. 78

Page 5

Contents

5.3 User interface ............................................................................................. 79

5.4 Configuration .............................................................................................. 81

5.5 Teleservice .................................................................................................. 84

5.6 Data transfer from and to the instrument ................................................ 86

5.6.1 Transfer via CompactFlash memory card .................................................... 86

5.6.2 Transfer via interface .................................................................................... 89

5.7 Connection between the PC and the recorder ........................................ 91

5.7.1 Assistant for device settings ........................................................................ 91

5.7.2 Device list ..................................................................................................... 95

5.8 Menu functions ........................................................................................... 96

5.8.1 File ................................................................................................................ 96

5.8.2 Edit ............................................................................................................... 97

5.8.3 Data transfer ................................................................................................. 98

5.8.4 Extras ........................................................................................................... 98

5.8.5 Window ...................................................................................................... 103

5.8.6 Info ............................................................................................................. 104

5.9 Math/logic ................................................................................................. 105

5.10 Character set ............................................................................................ 109

6 Rights 111

6.1 Rights with regard to the setup program ............................................... 111

7 PC programs 113

7.1 PC evaluation software (PCA3000) ......................................................... 113

7.2 PCA communication software (PCC) ..................................................... 114

8 Identifying the instrument version 115

8.1 Type designation ...................................................................................... 115

8.2 Standard accessories .............................................................................. 116

8.3 Optional accessories ............................................................................... 116

9 Installation 117

9.1 Installation site and climatic conditions ................................................ 117

9.2 Fitting ......................................................................................................... 117

Page 6

Contents

10 Electrical connection 121

10.1 Installation notes ...................................................................................... 121

10.2 Technical data ........................................................................................... 121

10.3 Connection diagram ................................................................................ 122

11 Index 125

Page 7

1.1 Preface

E

B

1 Introduction

Please read these operating instructions before commissioning the

instrument. Keep the operating instructions in a place that is accessible to all

users at all times.

Please assist us to improve these operating instructions, where necessary.

Your comments will be appreciated.

All necessary settings are described in this manual. If any

difficulties should arise during commissioning, you are asked not

to carry out any manipulations that could endanger your rights

under the instrument warranty!

Please contact the nearest subsidiary or the head office in such a

case.

When returning modules, assemblies or components, the

regulations of EN 61340-5-1 and EN 61340-5-2 “Protection of

electronic devices from electrostatic phenomena” must be

observed. Use only the appropriate ESD packaging for transport.

Please note that we cannot accept any liability for damage caused

by ESD.

ESD=electrostatic discharge

7

Page 8

1 Introduction

1.2 Arrangement of the documentation

The documentation for this instrument consists of the following parts:

Operating

Manual

59480

Interface

Description

59482

This operating manual comes with the delivery. It is addressed to the

equipment manufacturer and the user with appropriate technical expertise.

In addition to installation and electrical connection, it contains information on

commissioning, operation and parameter setting on the instrument, as well as

on the optional PC setup program and the optional evaluation program (PCA).

It provides information on the serial interface (RS232 and RS485), which can

be supplied as an extra code. The interface description can be used to

develop specific programs which can, for instance, read out current

measurement data.

1.2.1 Structure of this operating manual

This manual is arranged in a way which permits the user to enter directly into

operation and configuration of the instrument. Consequently, chapters dealing

with items that normally arise only once are placed at the end of the manual.

These include instrument description, type designation, installation and

electrical connection.

8

Page 9

1.3 Typographical conventions

V

E

v

1.3.1 Warning signs

The signs for Danger and Caution are used in this manual under the following

conditions:

Danger

This symbol is used when there may be danger to personnel if the

instructions are ignored or not followed correctly!

Caution

This symbol is used when there may be damage to equipment or data if the

instructions are ignored or not followed correctly!

Caution

This symbol is used where special care is required when handling

components liable to damage through electrostatic discharge.

1 Introduction

1.3.2 Note signs

1

abc

h

Note

This symbol is used when your special attention is drawn to a remark.

Reference

This symbol refers to further information in other manuals, chapters or

sections.

Footnote

Footnotes are remarks that refer to specific points in the text. Footnotes

consist of two parts:

A marker in the text, and the footnote text.

The markers in the text are arranged as continuous superscript numbers.

Action instruction

This symbol indicates that an action to be performed is described.

The individual steps are marked by this asterisk, e.g.

h Press the

h key

h Confirm with

E

9

Page 10

1 Introduction

1.3.3 Representation modes

Keys

h + E

Program

Manager

Edit

Device data

Keys are shown in a box. Both symbols and text are possible. If a key has a

multiple function, then the text shown is the one that corresponds to the

function that is active at the moment.

Screen texts

Texts that are displayed in the setup program are indicated by italic script.

Menu items

Menu items in the setup program which are referred to in this manual are

shown in italics. Menu name, menu item and submenu item are separated

from each other by “

”.

10

Page 11

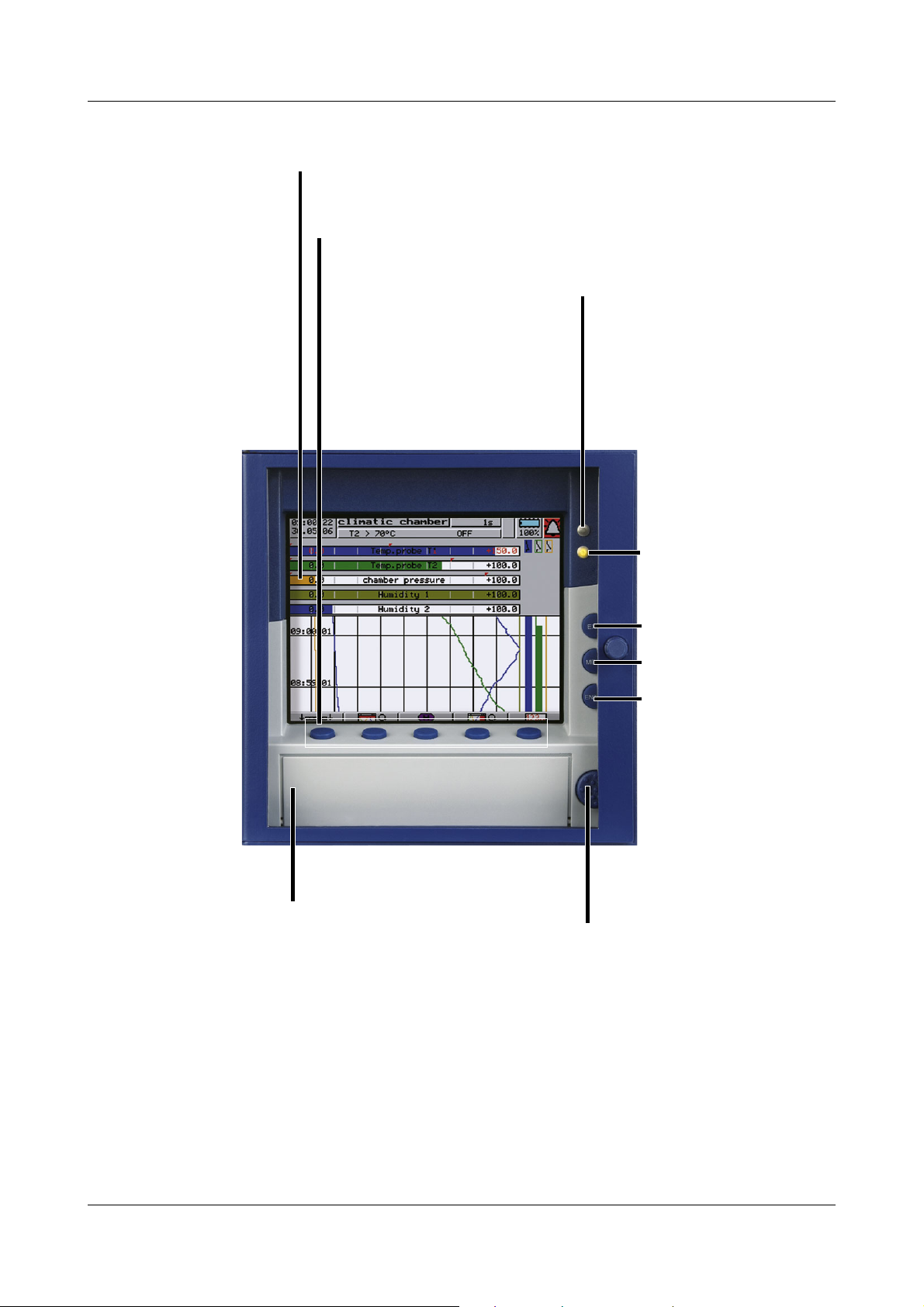

2.1 Displays and controls

Status LED (red)

is on continuously while

an alarm is present

Enter

- select menu item

- enter selection

Menu

return to the basic menu

1

Exit

- previous window

- cancel the

present action

Menu-dependent function keys (softkeys)

screen-dependent functions, represented by text or symbols

Color display

320 x 240 pixels, 27 colors

Cover

for the CompactFlash

®

slot

2

to open the cover of the

CompactFlash slot

Power LED (green)

This is lit continuously as

soon as power is applied.

It blinks when the screen

saver is active.

2 Device description

1

Not from the configuration level if a parameter has already been modified there.

2

CompactFlash® is a registered trademark of the SanDisk Corporation.

The life of the background illumination can be prolonged by

making use of the screen saver.

v Chapter 4 “Configuration parameters”,

Parameterization

Display off

11

Page 12

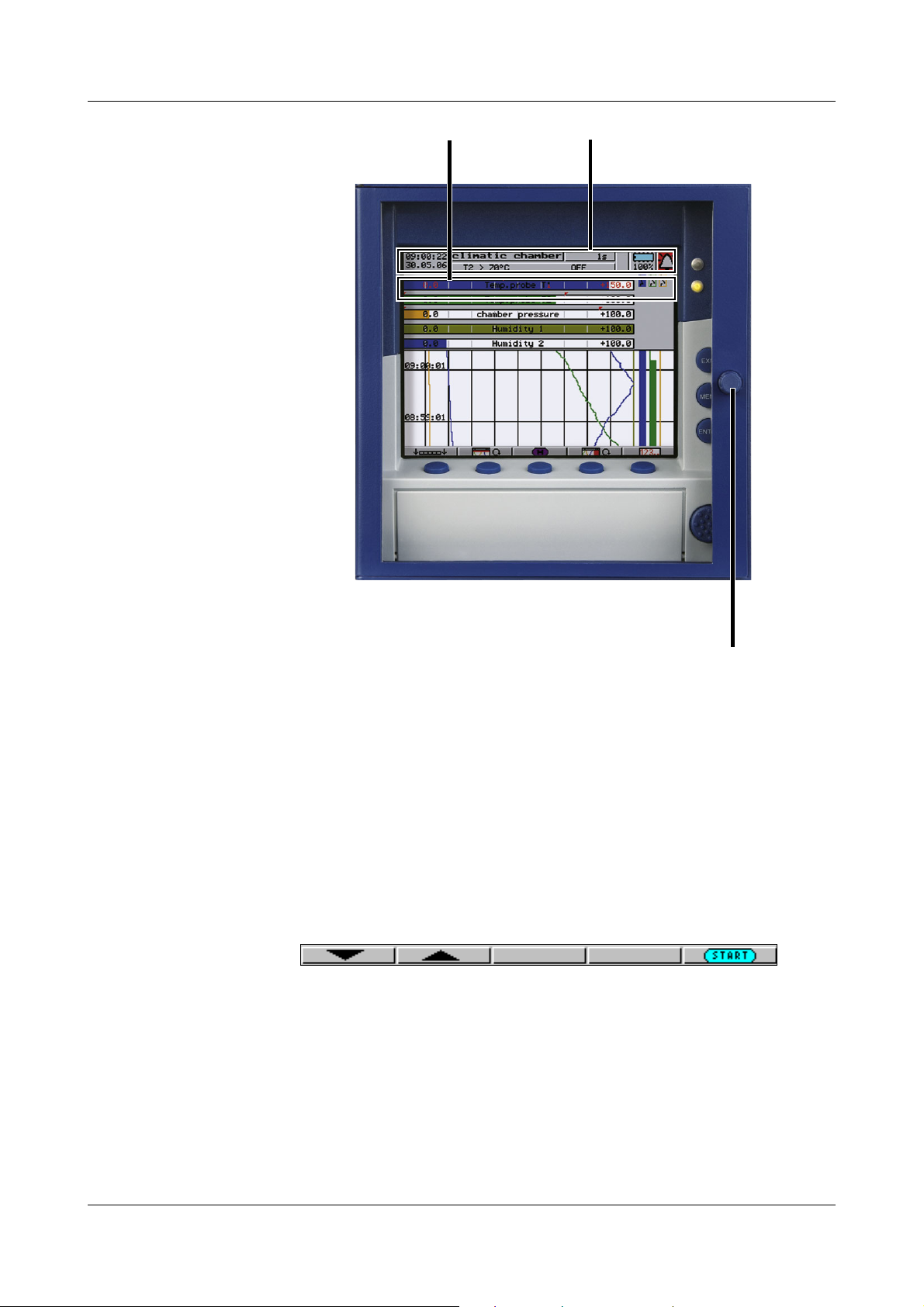

2 Device description

To open or close the door of the

instrument, turn the knob

Status line

Header

Opening and

closing the door

of the

instrument

2.2 Operating principle and graphic elements

Keys The recorder is operated from eight keys. Three of these keys have fixed

Softkeys The functions of the softkeys appear in the bottom line of the display, as

functions, the other five (softkeys) have menu-dependent functions.

v Chapter 2.1 “Displays and controls”

symbols or in plain text.

12

Page 13

2 Device description

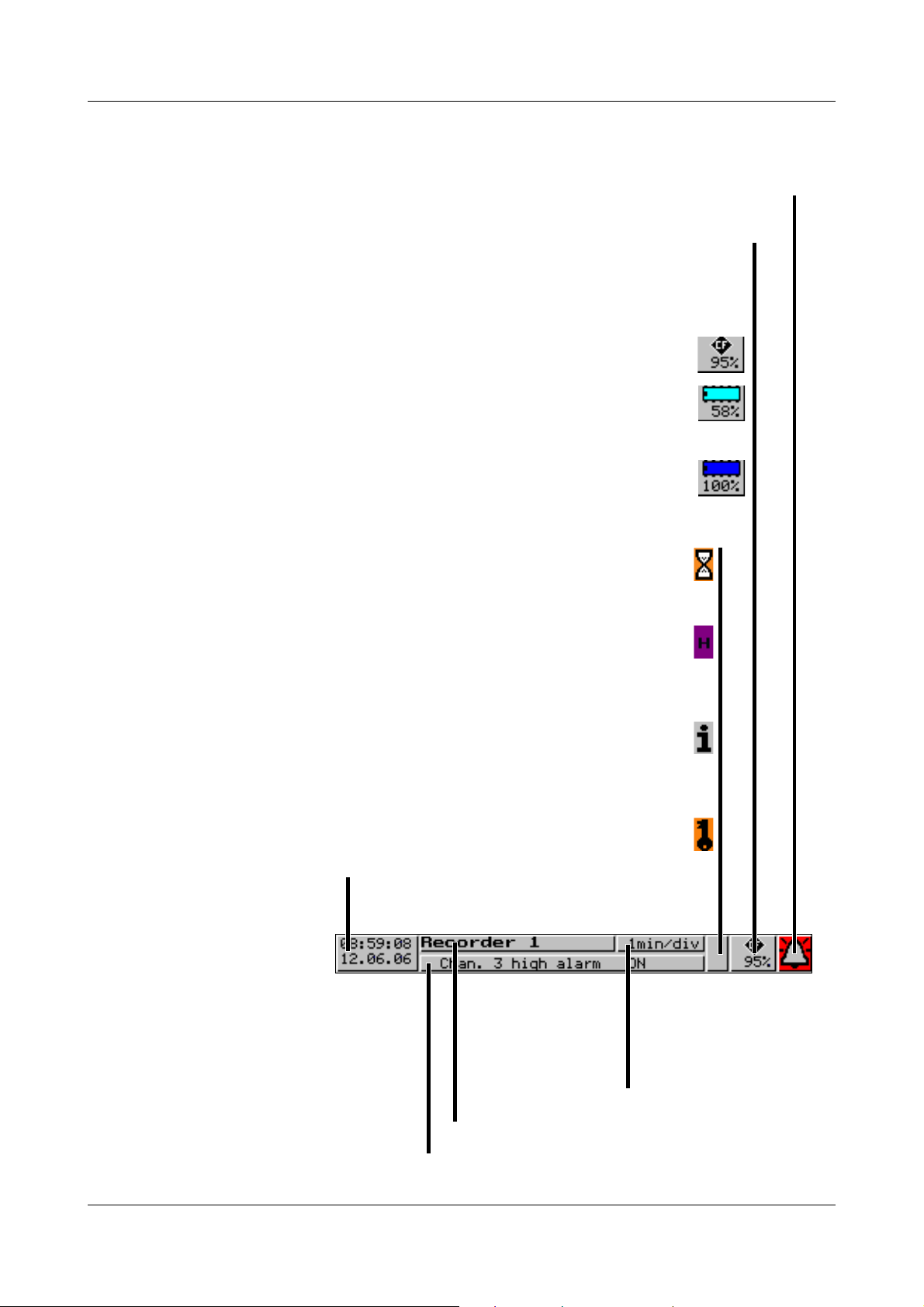

Time & Date

Display of the current time

and date

The egg timer appears whenever the instrument cannot be

operated because it is busy.

The “H” indicates that the measurements which are displayed

are derived from the past (history). The display shows

the data saved in the FLASH memory.

If a fault occurs, an “i” will flash in this position.

In the device info window (v Chapter 3.7 “Device info”)

you can ask for the cause of the fault.

If the keys are inhibited, a key will flash in this position.

Alarm

If an alarm occurs (e.g. out-of-limit), the bell (alarm) will flash in this field.

Shows the last entry in the event list

Instrument name (maximum 16 characters).

Present diagram speed

Background color:

gray = normal operation,

blue = timed operation,

orange = event operation

CF card / internal memory

Shows the free storage of the CompactFlash card or the internal memory, as

a percentage. In the event of a “memory alarm” or a fault on the CF card, the field is

shown with a yellow background and the symbol will flash. The error message

can be checked in the CF card menu (Chapter 3.6 “CompactFlash card”).

Storage capacity of the CF card

Available internal memory for read-out via CF card

(the diagram shows a turquoise-colored memory chip)

Available internal memory (for read-out via interface)

(the diagram shows a dark blue memory chip)

Status line The status line is shown in the top section of the display. It provides

information on important actions and states. The status line is always visible,

irrespective of the level (operation, parameters, configuration).

13

Page 14

2 Device description

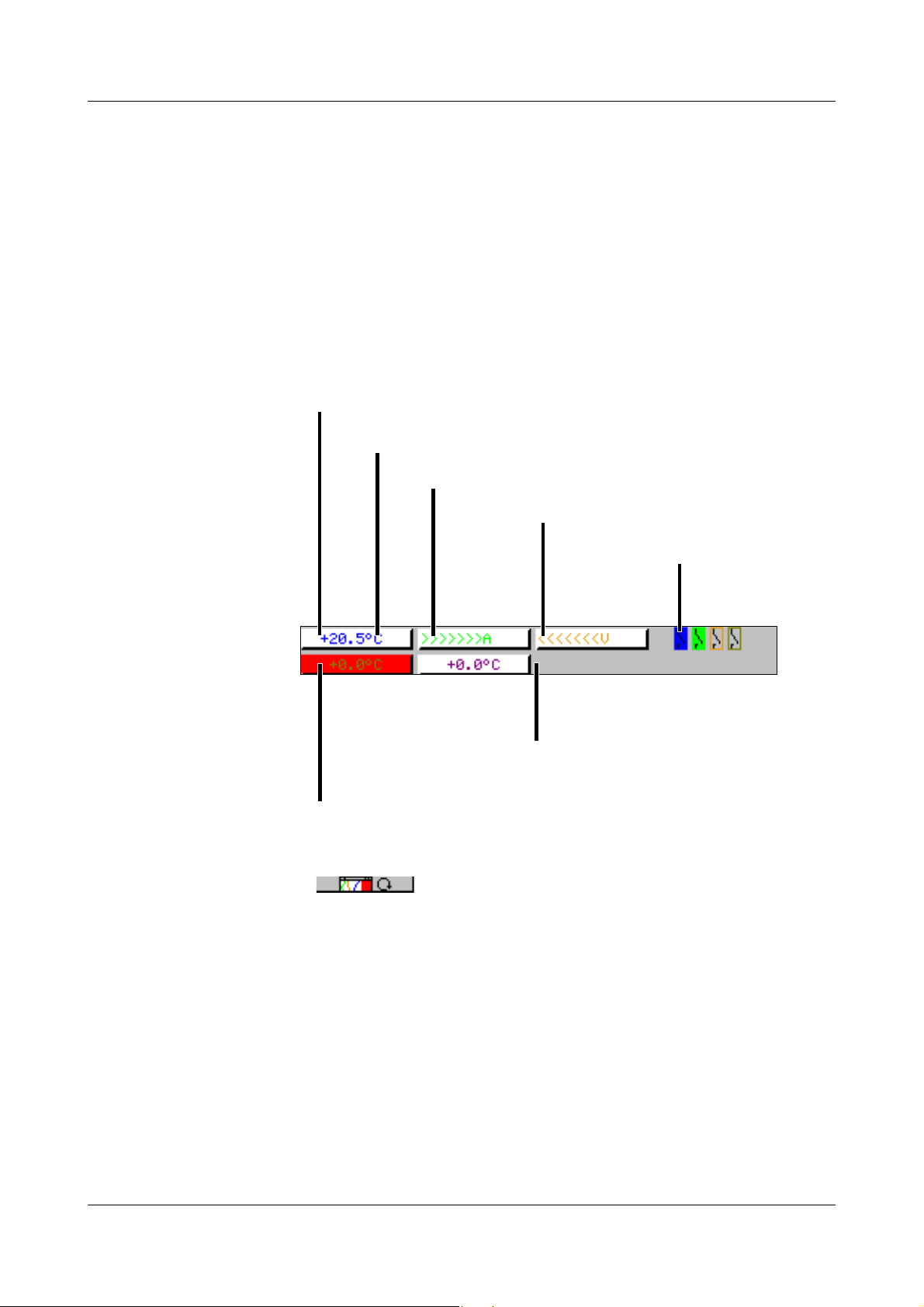

Numerical display

The measurements are shown in numerical form.

OFF

If a channel has been switched off, then

there will be no indication at all.

Unit of measurement

Alarm

If an alarm (e.g. out-of-limit) is present,

the measurement of the channel is shown on a red background.

Overrange

Underrange

(underrange)

State of the

event traces

Channel line

(channel

representation)

The channel line shows the measurements of the active channels and their unit

as

- a measurement

-scale or

-bar graph.

Alternatively, the header can be switched off altogether.

In addition, alarms and out-of-limit conditions are made directly visible,

depending on the display mode.

Example: Measurement (small meas.)

Selection and visual presentation of the channel line can be controlled through

the parameter Parameterization ➔ Diagram view ➔ Channel represent. or by

using the key.

With the help of the parameter Parameterization ➔ Diagram view ➔ Channel

indication ➔ Channel 1 — 6, it is possible to suppress the display of individual

channels in the channel line. This is especially useful for scale or bar graph

display, where more space is needed to show the diagram. The channels that

have been suppressed in the display will nevertheless be recorded, and shown

on the diagram.

2.3 Analog inputs

Internal

analog inputs

The paperless recorder can be equipped with 3 or 6 analog inputs. When

configuring the analog inputs (Chapter 4.2 “Table of configuration

parameters”), these are designated as analog input 1 — 3 (1 — 6).

14

Page 15

2 Device description

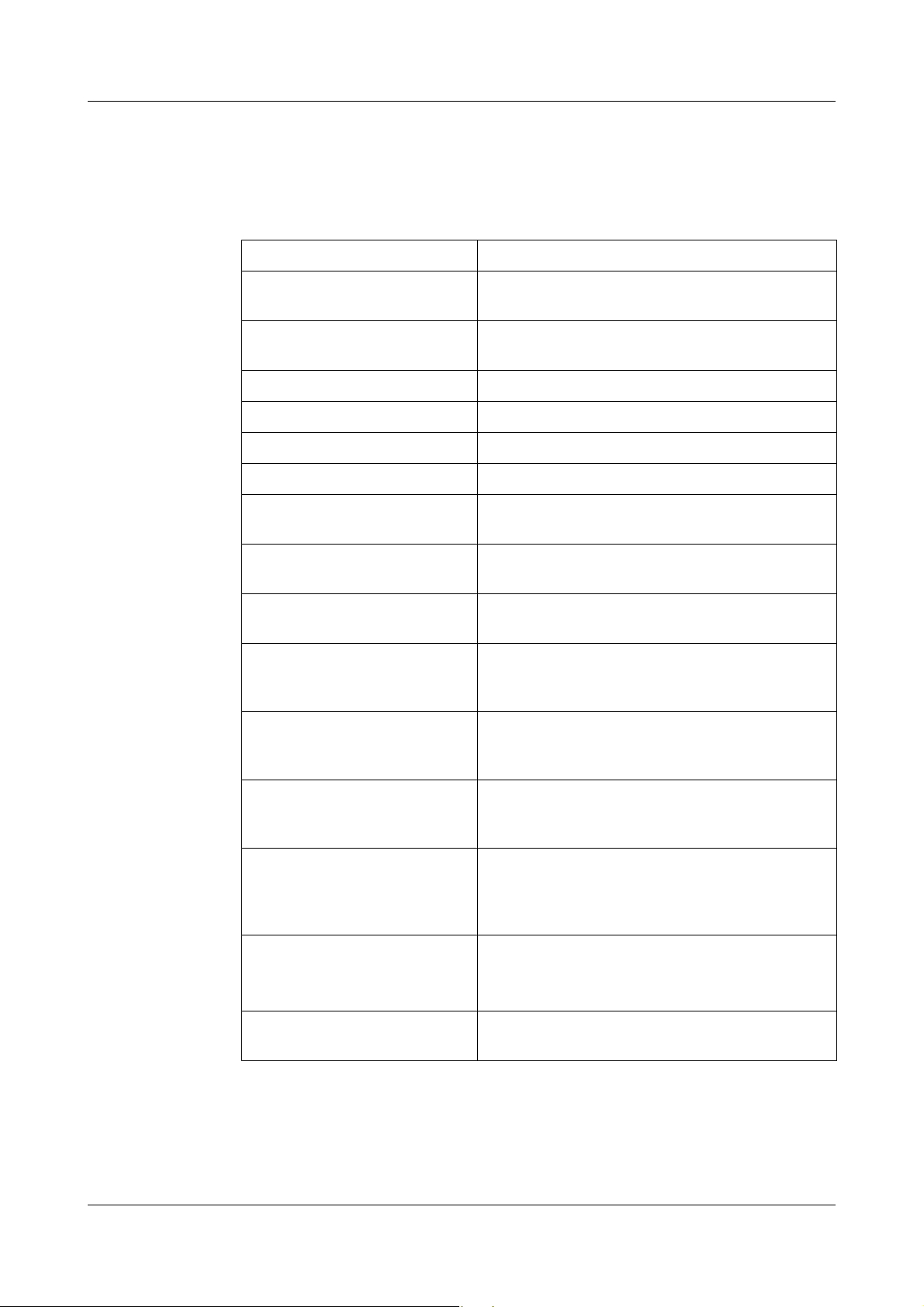

2.4 Digital signals (event traces)

Signal types In addition to the four binary inputs (extra code), digital signals generated by

the instrument itself can also be displayed in the six digital traces (event

traces):

signal Description

Binary input 1 — 4 Four binary inputs available as hardware

(extra code)

Logic channel 1 — 6 Channels which are created by using the math

and logic module (extra code required)

Low alarm 1 — 6 Underrange of the channels

Low combination alarm OR linkage of all low alarms

High alarm 1 — 6 Overlimit of channels

High combination alarm OR linkage of all high alarms

Counter/integrator alarm 1 — 6 Limit infringements of counter and

integrator channels (extra code required)

Counter/integrator combination

alarm

Combination alarm OR linkage of all low, high and counter/inegrator

CF card inserted The signal is set when a CF card is inserted in the

Int. mem. alarm/CF card The alarm is triggered when the internal storage

Int. mem. alarm/serial The alarm is triggered when the internal storage

Mem. alarm/CF card The alarm is triggered when the storage memory

Error Alarm when the battery is empty, or the time has

OR linkage of all counter/integrator

alarms (extra code required)

alarms

instrument. It remains active until the card is

removed.

memory available for read-out via the CF card

card has fallen below a certain value

memory available for read-out via the interface

has fallen below a certain value

available on the CF card that has been plugged in

falls below a certain value

plugged in.

to be set.

Chapter 3.7 “Device info”

1

, or no CF card is

1

.

1

.

MODbus flag Control flag, which can be activated through one

of the interfaces.

1

The limit for all memory alarms is the same, and is set by the parameter

Configuration Device data Memory alarm.

15

Page 16

2 Device description

Representation Representation on the screen is as follows:

Representation

as symbol On/off represented as switch:

as diagram Representation as a record over time:

Outputs The digital signals can be used to operate three relays (extra code). The action

can be configured as a break (SPST-NC) or make (SPST-NO) contact

(Configuration ➔ Outputs).

External texts External texts can be called up via four binary inputs or the logic channels. If a

binary input is closed or a logic channel makes a 0-1 transition, then the

preconfigured text will be entered in the event list. Either a standard text or one

of the 18 definable texts can be used. The instrument automatically

supplements the texts in order to distinguish between the appearance and

disappearance of the signal. The external texts are configured on the

instrument, under Configuration ➔ Control functions.

v Chapter 3.5 “Event list”

Event operation The digital signals can be used to activate event operation. In event operation,

the measurements are stored with a storage cycle that is different from normal

operation.

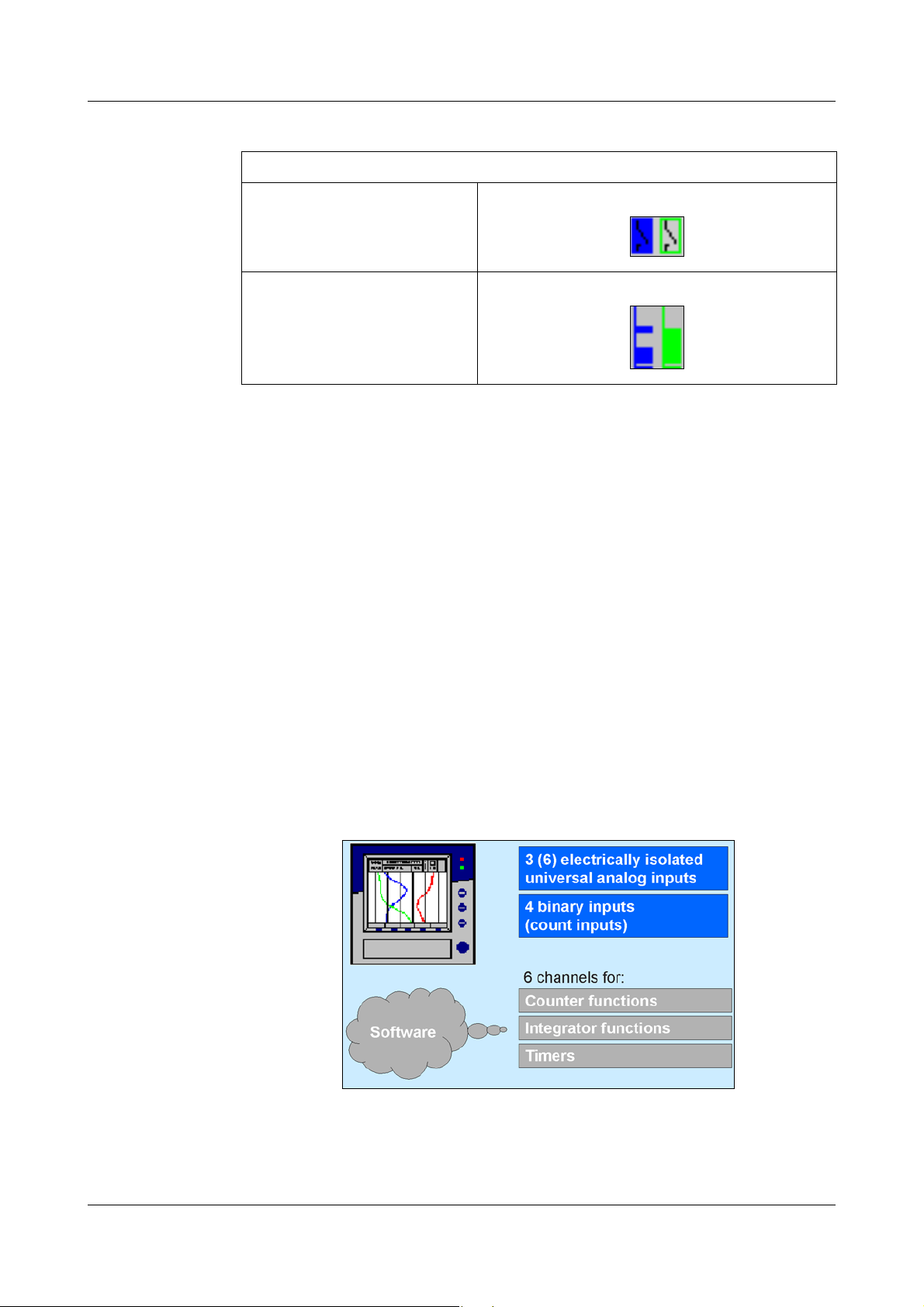

2.5 Counters / integrators / operating time counter

16

These are not electrical measurement inputs (hardware), but channels which

are calculated by the paperless recorder (software).

Page 17

2 Device description

Counters

Counter inputs Any of the digital signals can be used as input signals for the counters.

v Chapter 2.4 “Digital signals (event traces)”

Example:

- binary inputs

- logic channels

-alarms

- memory alarms

- Modbus flag (signal via interface)

Counter

frequency

Evaluation The count pulses can be evaluated (weighted). A down counter can be

30Hz max.

implemented by entering a negative weighting (e.g. weighting factor -1).

Each count change can be documented with an entry in the event list. The

new count is attached to the message.

Integrators

Integrator

inputs

Integrator

time base

Evaluation You can also enter a weighting for the integrators.

Weighting

example

Analog inputs 1 — 3 or 1 — 6 and math channels 1 — 6

sec, min, hr and day

- measurement of flow volume

- input signal of 0 — 20mA (corresponds to 0 — 500 liters/sec)

- time base 1sec

Minimum size

of the input

signal

- weighting 0.001

Result: display of the integration value (volume) in m³.

Entering a threshold value (amount of the threshold value) has the effect that

integration takes place only when the value has been exceeded. No

integration will occur on falling below this value. The advantage of integration

with a threshold value larger than 0 is that possible noise from a transducer

can be suppressed in this way.

If there is an overrange or underrange on an integrator input, then

integration is stopped (the latest valid value is retained), and will

only continue when the input signal is correct again.

17

Page 18

2 Device description

Operating time counter

The operating time counter will count how long a selected binary input or one

of the digital signals is closed (set). The time can be displayed in sec, min, hr

or days.

2.5.1 Reporting period of the counts

After an adjustable time (reporting period), the counts are stored for all

counters/integrators/operating time counters. The counts for the current and

the previous 7 completed reporting periods will be displayed. The following

counter/integrator types are possible:

-periodic

In addition, the time period (between 1 min and 12 hrs) must be selected in

the parameter Period.

-external

In this case, the counter/integrator is updated only when the selected

control signal is active (e.g. binary input is closed). When the control signal

is deactivated (e.g. binary input is opened), the counter/integrator value is

saved and reset to 0.

- daily

-weekly

-monthly

-yearly

-total

- daily, from ... to

The period also has to be selected, by means of the parameters “Daily start

time” and “Daily end time”. The counter/integrator will then be updated

from the start time only. When the end time has been reached, the counter/

integrator value is saved and reset to 0.

2.5.2 Resetting the counters / integrators / operating time counters

Periodic reset There is a reporting period for each counter/integrator/operating time counter.

At the end of this period, the current data (value and time) are saved and the

value reset to 0. Subsequently, the next period can be recorded.

An exception is the totalizer/integrator. It is saved whenever any count/

integration has been completed, but it is not reset to 0. It enables the totalizer

to be evaluated in the evaluation software PCA as well.

18

Page 19

2 Device description

External reset You can configure one control signal for all 6 counters/integrators together,

with the result that the counters/integrators are reset to 0 without any saving

of the previous values. The period for the counter/integrator summation will be

restarted at this point. This means that after the test run of an installation, for

instance, the recording can be freshly started; the test run values that are not

required are eliminated.

v see Page 69 “Generate reset”

Reset from

keys

Reset from

CompactFlash

card menu

Another option for resetting the counter/integrator values is provided at the

parameter level. After entering the password, you can define a value for each

of the 6 channels. The counter/integrator will then be set to this value. When

the value is entered, after editing, a message with the new and the old count is

entered in the event list.

The time period for the counter/integrator summation will not be restarted. The

previous counter/integrator values will also not be saved.

If you wish to save the previous counter/integrator values, you

must execute the function “Update CF incl. counters ...” in the

menu for the CompactFlash card.

In this way, the recording can be freshly started for individual counters/

integrators, e.g. after the test run of an installation; the test run values that are

not required will be eliminated in the process.

You can select a password that is different from that for accessing the

configuration. The password is set up in Configuration ➔ Device data ➔ Code

No. (password) ➔ Reset counter / int.

If, in the menu CompactFlash card, the function CF update incl. counters

is carried out, then the counter states will also be saved and then reset.

v See “CompactFlash card” on Page 50.

2.5.3 Response to instrument reconfiguration

When the instrument is reconfigured, the current counter/integrator reporting

periods remain unaffected. The counter/integrator values will not be reset to 0

and the reporting period will not be restarted.

The values can only be deliberately reset through the

Parameterization menu.

19

Page 20

2 Device description

2.5.4 Response at end of summer time

If a period of less than one hour has been set for counters/

integrators, and the change from summer time to winter time falls

precisely within this period, then the PC evaluation software

(PCA3000) will forcibly set the end time to be the same as the start

time. This prevents a negative period arising, and ensures that

further processing is error-free.

2.6 Math/logic module

The math and logic module is available as an extra code. Like the counter/

integrator/operating time counters, the math and logic module is implemented

as channels that are not available as hardware but are calculated by the

instrument software.

The math and logic module consists of 2 parts:

- the math module for calculating analog values and

- the logic module for calculating Boolean values (0 or 1).

Math module With the help of the math module, measurement inputs can be used for the

calculation of “virtual” math channels.

A total of 6 channels can be recorded (stored) in the instrument. In the

configuration, you will find an option under Configuration

Analog channels Analog channel 1 — 6 Input signal for selecting which

of the analog inputs or math channels should be stored.

If more than 6 channels are to be active in the instrument (e.g. 4 analog inputs

and 3 active math channels), then you can also use the visualization in the

presentation mode “Large digital display (large measurements)” to see the

measurements that are not stored.

v Chapter 3.2.4 “Large digital display (large measurements)”

Recording

20

Page 21

2 Device description

The following variables are used for the formulae:

- analog inputs (AE1 — AE6)

- math channels (MAT1 — MAT6)

- counter/integrator channels (ZI1 — ZI6)

- binary inputs (BE1 — BE4)

-alarms

-errors

- Modbus flag (signal via interface)

- instrument-specific data (only after consultation with the manufacturer)

If counter/integrator values are used for calculation, then please note that their

accuracy is reduced, since, in this case, two different data formats have to be

used for calculation. The counters/integrators are calculated in the doublefloat format, whereas the math module employs a single-float format that

follows the IEEE 754 standard. Nevertheless, it is possible to include these

values in the math module.

The following fixed functions are available:

-difference

-ratio

- relative humidity (psychrometric measurement)

- moving average

For the moving average, the reference channel has to be entered (in most

cases, the analog input number) and the time period (in minutes) for

calculating the moving average.

The following operators and functions are available for the formulae: +, -, *, /,

(, ), SQRT(), MIN(), MAX(), SIN(), COS(), TAN(), **, EXP(),

ABS(), INT(), FRC(), LOG(), LN().

On going above or falling below the scalable values, the math channel is

treated as for “out-of-range”.

The formulae are entered in the PC, in the setup program. The mathematical

formulae cannot be edited by using the keys on the instrument.

For further information, refer to

Chapter 5.9 “Math/logic”

21

Page 22

2 Device description

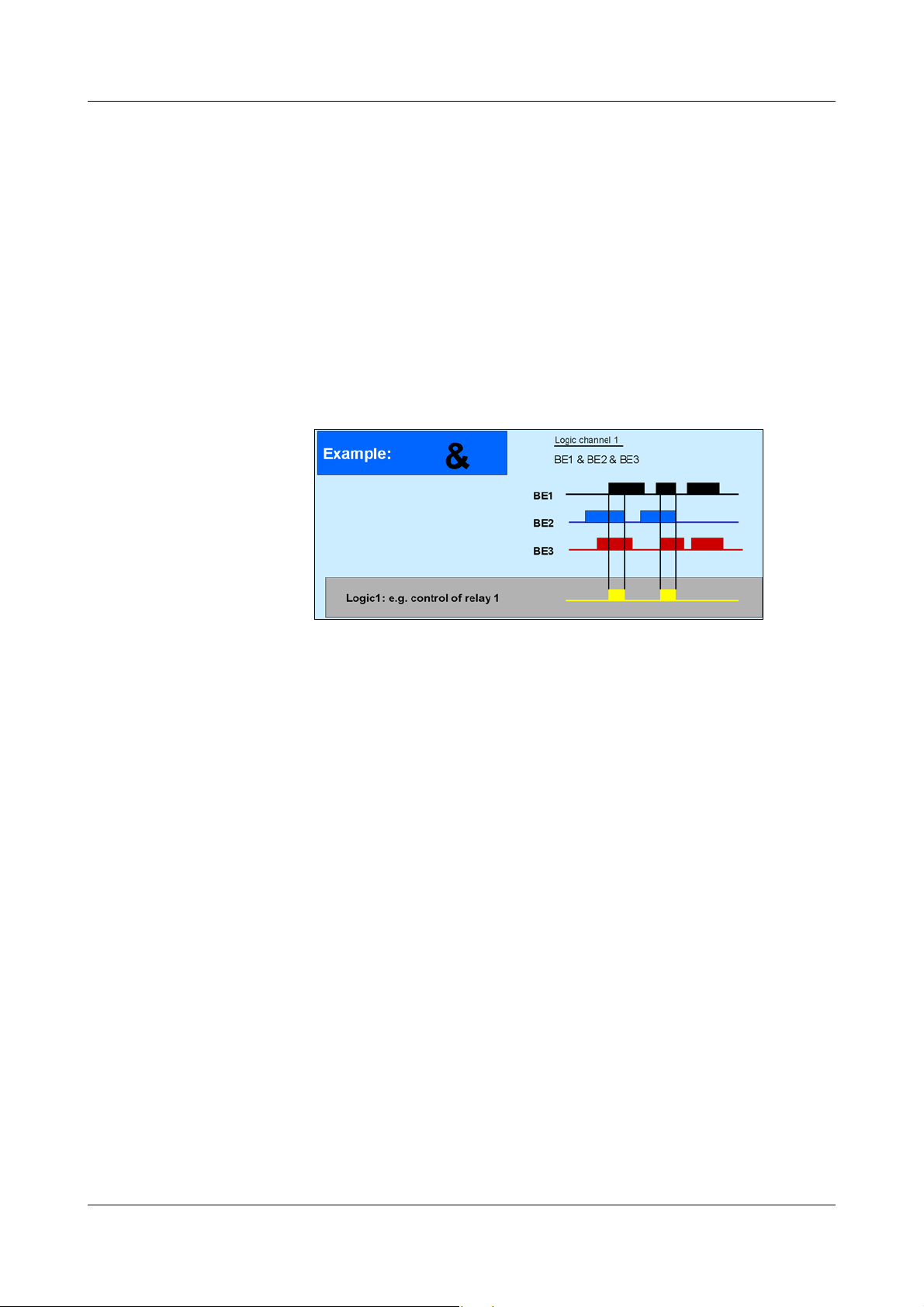

Logic module You also have up to 6 channels available as logic channels.

As is the case with all the other digital signals, the calculated digital (Boolean)

values can be used for different functions:

- recording in the event traces,

- as a control signal for display switch-off,

- clock time synchronization,

- operating time counter,

- externally controlled counters / integrators

- counter/integr. reset

- event operation and key inhibit,

- for output to a relay and

- as count input for a counter.

The following variables are used for the formulae:

- binary inputs

- logic channels

-alarms

-errors

- Modbus flag (signal via interface)

-TRUE

-FALSE

- device-specific data (only after consultation with the manufacturer)

These functions can be used for the formulae:

-! (NOT)

-& (AND)

-| (OR)

-^ (XOR)

- / (rising edge)

- \ (falling edge)

-( (open bracket)

-) (close bracket)

22

For further information, refer to

Chapter 5.9 “Math/logic”

Page 23

2.7 Operating modes

2 Device description

3 operating

modes

The instrument has 3 operating modes:

- normal operation

- timed operation

- event operation

The following settings can, among others, be made for each of the three

operating modes:

-stored value

-storage cycle

Stored value The stored value setting determines what is stored: average, minimum,

maximum or momentary value between two storage cycles, or the peak value

(envelope). The setting “peak value” means that the maximum and minimum

values from the last storage cycle are saved.

Storage cycle The storage cycle determines the interval between two stored values. The

diagram speed corresponds to the storage cycle, which means that with a

storage cycle of 5sec, for example, the stored value is entered in the diagram

every 5sec.

Normal

Normal operation is active whenever event or timed operation is not active.

operation

Timed

operation

For timed operation, a period of time can be defined (up to 24 hrs) within

which a specific stored value and a specific storage cycle are active.

Event operation Event operation is active as long as its control signal (v Chapter 4.2.6

“Configuration - Recording”) is active. Event operation can be used, for

example, to shorten the storage cycle when an alarm is present.

Priority The respective priorities of the operating modes are allocated as follows:

Operating mode Priority

Active

operating mode

Normal

operation

Timed operation average

Event operation high

The active operating mode is shown in the diagram by the background color

for the diagram speed:

Operating mode Color

Normal

operation

Timed operation turquoise

low

gray

Event operation orange

v Chapter 2.2 “Operating principle and graphic elements”

23

Page 24

2 Device description

2.8 Storing data

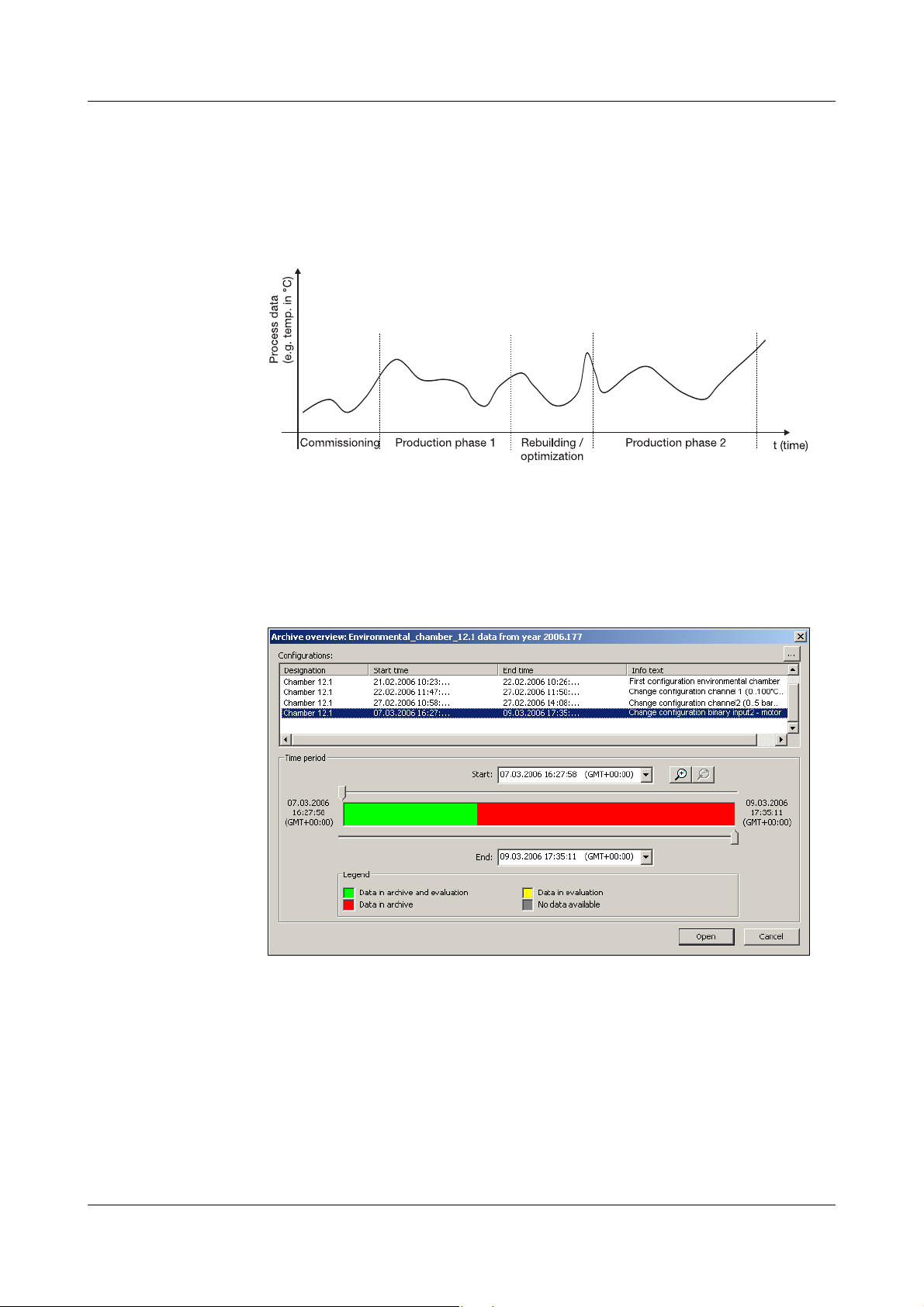

Life-cycle data

management

The integrated life-cycle data management puts users in the position of being

able to save all the process data from the system that is being monitored in an

archive file on their PCs or a server system.

The recovery of configuration-dependent system data, which may be required

for commissioning, maintenance or optimization during the life-cycle of a

system, is now enabled by the associated PC evaluation software (PCA3000)

in a dialog window.

24

Page 25

Operating

principle

2 Device description

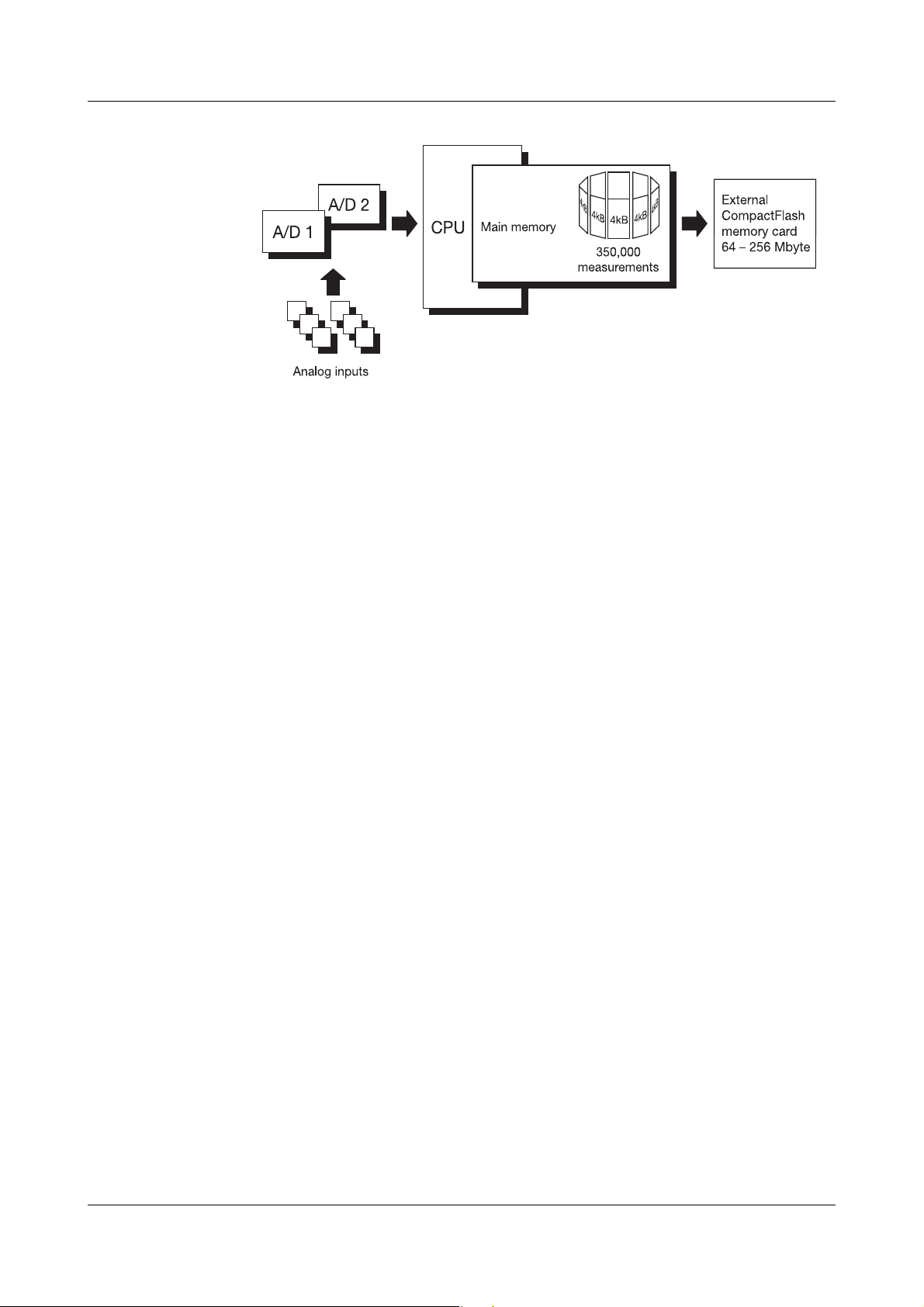

The measurements from the analog inputs are acquired continuously in a

250msec sampling cycle, and then stored in the main memory. These

measurements also serve as the basis for limit monitoring.

Main memory

(FLASH

memory)

CompactFlash

card

Data security The data are stored in coded form in a proprietary format. If the CompactFlash

Storage cycle Different storage cycles, ranging from 1sec to 32,767sec can be configured

The data stored in the main memory are regularly copied to the CompactFlash

card in 4 kbyte blocks. The main memory is written to as a ring memory, i.e.

when it is full, the oldest data will automatically be overwritten by new data.

The capacity of the main memory is sufficient for approximately 350,000

measurements. The instrument monitors the capacity of the main memory and

activates the “Memory alarm (internal)” signal if the level falls below a

configurable residual capacity.

For saving the data, CompactFlash cards (industrial grade) can be used with

the following storage capacities: 64/128/256MB.

The instrument monitors the capacity of the CompactFlash card, and activates

the “Memory alarm (CF card)” signal if the level falls below a configurable

residual capacity. This signal can be used, for instance, to operate a relay

(warning signal “Swap CF card”).

card is removed from the instrument, no data will be lost immediately, as these

data are still stored in the FLASH memory. A loss of data will only occur if, after

the CompactFlash card has been removed, the FLASH memory is completely

rewritten as well, and no data have been read out through the interface.

for normal, event and timed operation under “configuration”.

The storage cycle determines the time intervals at which the measurements

are stored.

Stored value Under this parameter, separate configurations are made for normal, event and

timed operation, to decide which value is stored (average, momentary,

minimum, maximum, peak values).

25

Page 26

2 Device description

Recording

duration

The recording duration depends on various factors:

- number of analog channels and event traces being recorded

-storage cycle

- number of events in the event list.

Internal recording duration (without external CF card)

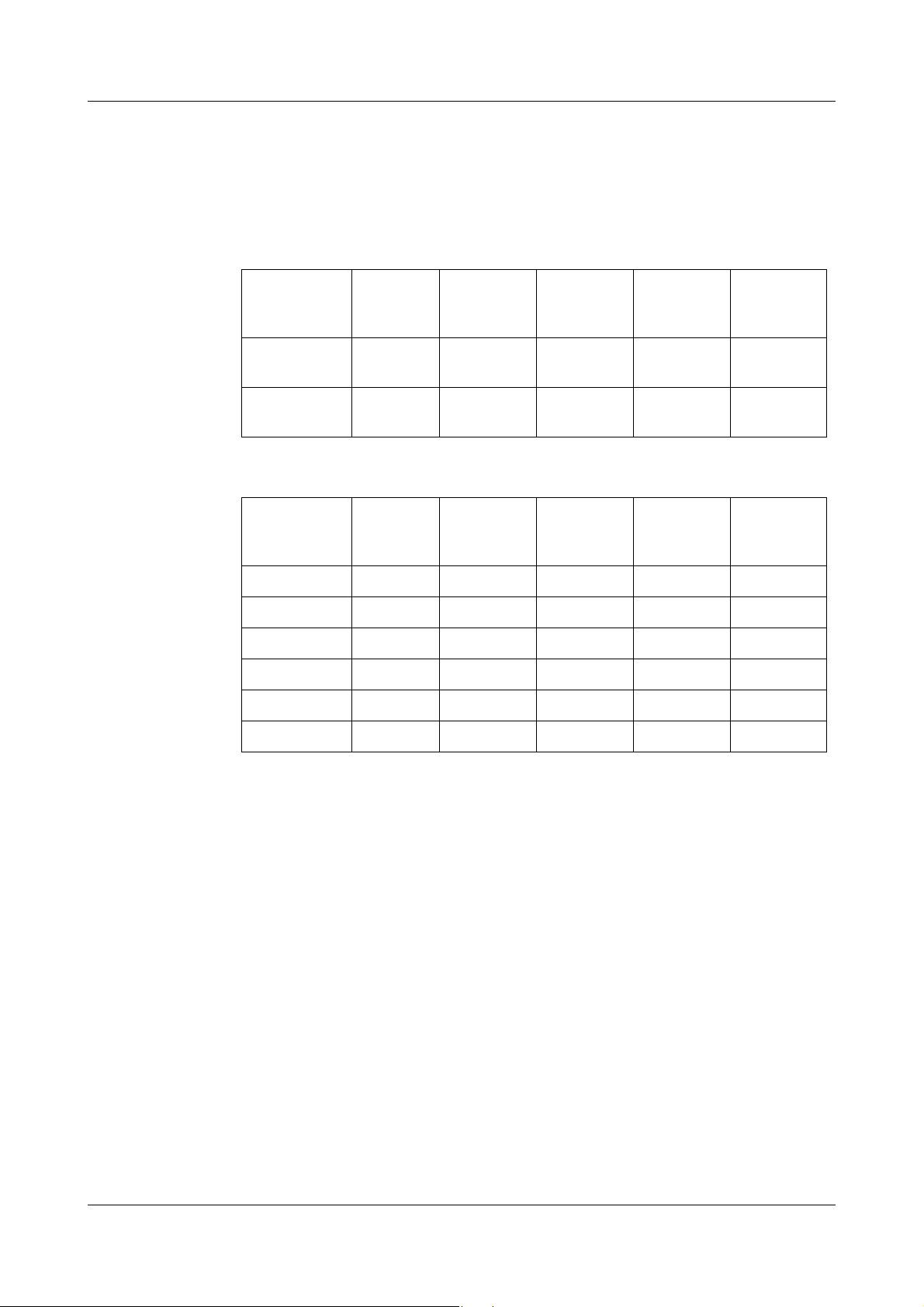

Number of

channels

3approx.

6approx.

Memory

size

1MB

1MB

Storage

cycle

1 min

42.2 days 21.1 days 7 days 17 hours

29.5 days 14.8 days 4.9 days 12 hours

Storage

cycle

30 sec

Storage

cycle

10 sec

Storage

cycle

1 sec

Recording duration with CF card

Number of

channels

3 64 MB 8.8 years 4.4 years 1.5 years 1.8 months

Memory

size

Storage

cycle

1 min

Storage

cycle

30 sec

Storage

cycle

10 sec

Storage

cycle

1 sec

Optimization of

recording

duration

3 128 MB 17.6 years 8.8 years 2.9 years 3.5 months

3 256 MB 35.3 years 17.6 years 5.9 years 7.1 months

6 64 MB 6.2 years 3.1 years 1.0 years 1.2 months

6 128 MB 12.3 years 6.2 years 2.1 years 2.5 months

6 256 MB 24.7 years 12.3 years 4.1 years 4.9 months

The calculation of the recording duration is made for the storage of

momentary, minimum, maximum or average values. If peak values are

recorded, then the times are shorter, since a maximum and minimum value is

recorded each time.

The recording capacity will be further reduced if a large number of event

messages are also stored.

The recording duration can be optimized by process-oriented selection of the

storage cycle.

In normal operation (no error, no alarm, ...) a storage cycle that is as long as

possible (e.g. 60sec, 180sec, …) should be selected, depending on the

particular application.

In the event of an alarm or error, the storage cycle can be shortened via event

operation, with the effect that the measurement data are recorded with a high

time resolution.

26

Page 27

2 Device description

2.9 Read-out of data

In addition to automatic read-out via the external CompactFlash memory card,

measurement data can also be read out through one of the interfaces (RS232,

RS485, setup, Ethernet).

Both read-out options (card/interface) work in parallel. For this reason, there

are also two “digital signals”, which indicate when the available storage space

has fallen below a certain configurable value.

Memory alarm The limit for alarms can be set by the parameter Configuration ➔ Device data

➔ Memory alarm in the configuration level.

The parameter Configuration ➔ Memory upload can be used to determine

which storage space indication should be shown in the status line. The “digital

signals” for storage space detection function independently of the indication in

the status line.

Digital signals IntMemAlm/CF

If this signal is set, it means that no data have been fetched by the CF card for

a long time, and the available capacity of the internal memory has fallen below

the configured level.

IntMemAlm/ser

If this signal is set, it means that no data have been fetched by the interface for

a long time, and the available capacity of the internal memory has fallen below

the configured level.

MemAlmCFcard

If this signal is set, it means that not enough space is avialable on the CF card.

The program PCA3000 can help here. Use PCA3000 to read in the data, save

them to the hard disk on a network, and free up the space on the CF card.

Alternatively, you can use a new CF card.

Data lost A loss of data is only imminent if all three of the above signals are set.

Read-out via

interface

Use the PCA Communications Server software (PCC) to read out

measurement data via the serial, setup or Ethernet interface. The software has

been developed especially for the paperless recorder.

v Please refer to the Operating Manual 59500 for further information.

Use the same archive (in the PC) for reading out via the interface

as for reading out with the CF card. This saves having to put

together data from different files at a later date.

2.10 Evaluating data

Please use the PC Evaluation Software (PCA3000) for evaluating the data on

the PC. The software has been developed especially for the paperless

recorder.

v Please refer to the Operating Manual 59498 for further information.

27

Page 28

2 Device description

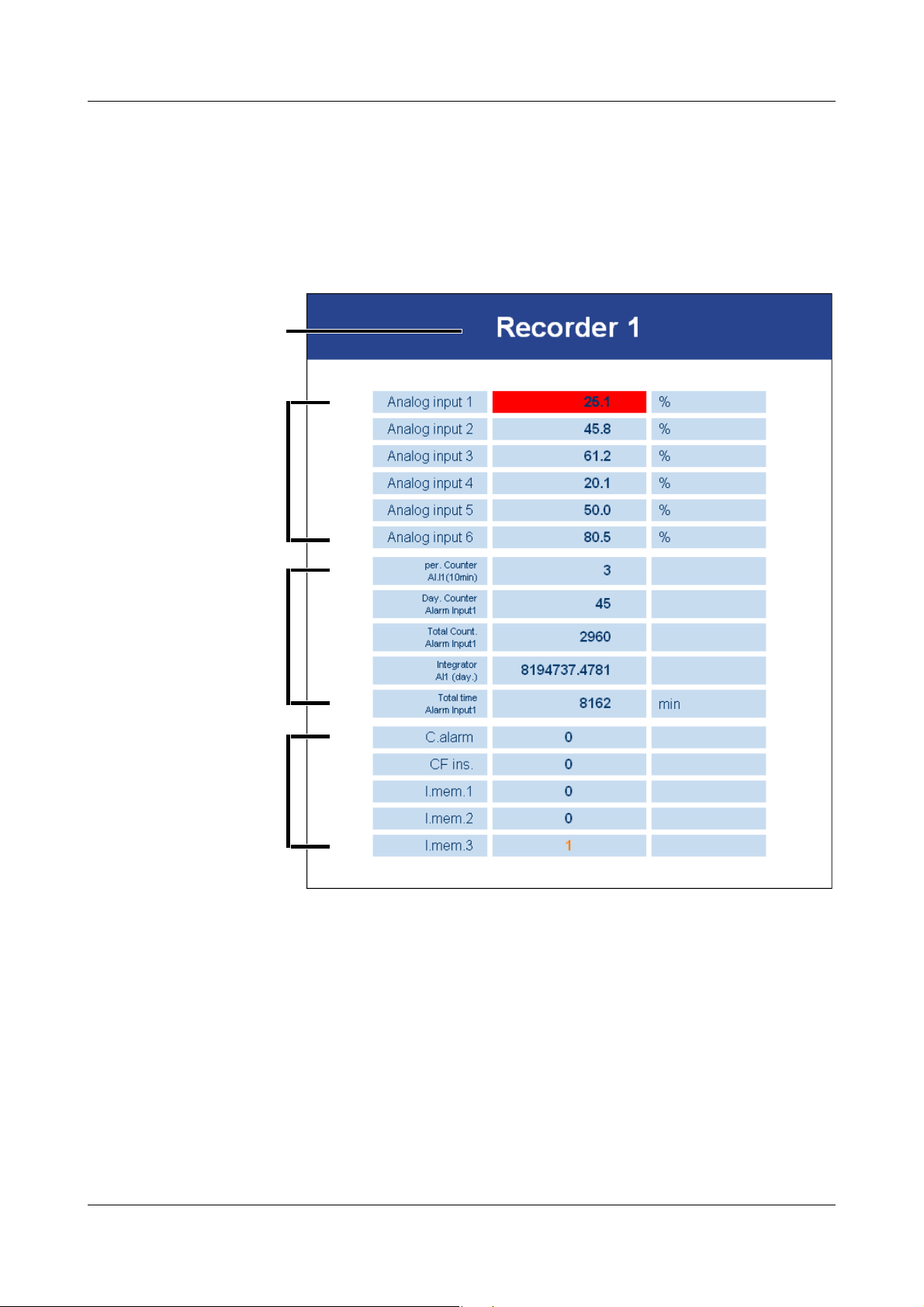

Device nameAnalog channelsCounters / integratorsEvent traces

2.11 Webserver

If the paperless recorder is equipped with the extra code “Ethernet interface”,

and the device-internal Ethernet software (“Ethernet version“) has the number

183.02.03 or higher, then the paperless recorder has an inbuilt webserver. The

webserver can be started by entering the IP address in an Internet browser on

the PC (e.g. http://10.10.90.45).

The variables that are shown are acquired and displayed automatically by the

webserver. The latest data are read out of the instrument every 5 seconds. Any

limit infringements show a red background. A maximum of 6 channels (analog

or math channels), up to 6 counters or integrators, and a maximum of 6 event

traces.

28

Page 29

2 Device description

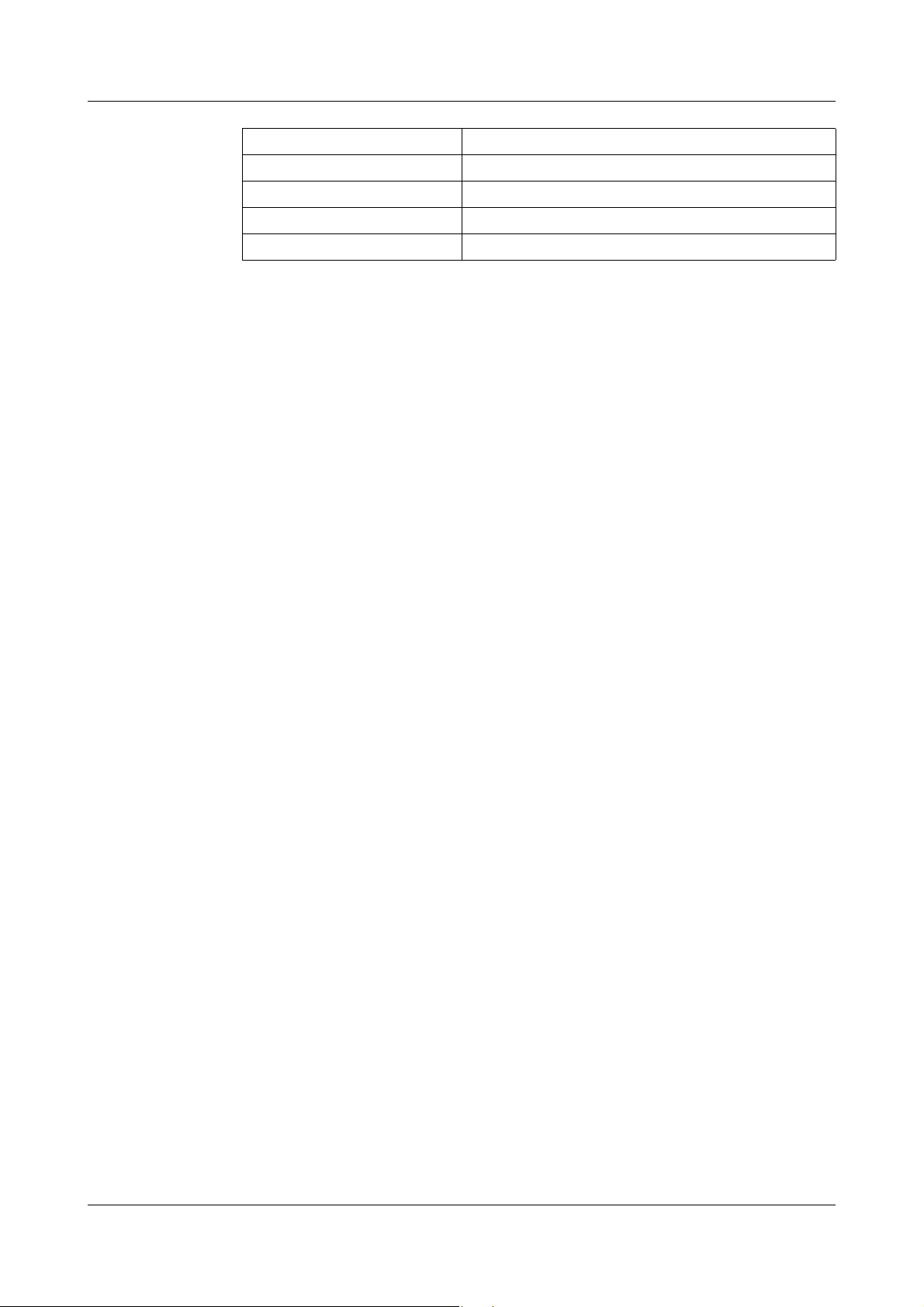

Display of ... Activated through menu ...

Device name Configuration - Instrument data - Device name

Analog or math channels Configuration - Recording - Analog channels

Counters or integrators Configuration - Counter/integrator

Event traces Configuration - Recording - Event traces

Only the activated signals will be displayed.

The information about the “Ethernet version” can be found in the “Device info”

menu.

v Chapter 3.7 “Device info”

H

Since the paperless recorder is only polled by the Internet browser every 5 seconds, it is possible that, for instance, the PCC data transfer software takes

over control of the paperless recorder during this interval. After securing the data, PCC will end access to the recorder, so that the Internet browser can read

out data again.

Only 1 PC (client) at a time can access the device (server) via the

Ethernet interface.

29

Page 30

2 Device description

30

Page 31

3 Operation and visualization

After starting up the paperless recorder by switching on the supply (power

ON), you will see the start logo.

During screen build-up, the recorder is initialized with the data of the last

configuration.

After the initialization phase, the measurement diagram

(visualization level) is displayed.

By using the setup program, an individual start logo (bitmap with a

maximum of 16 colors) can be loaded into the instrument, through

the function Extras

Start screen.

31

Page 32

3 Operation and visualization

h Select the required level

h Enter selection with E

3.1 Basic menu

The basic menu is the central point from which the various instrument levels

branch out.

The following levels are available:

v Chapter 3.2 “Visualization”

v Chapter 3.3 “Parameterization”

v Chapter 3.4 “Configuration”

v Chapter 3.5 “Event list”

v Chapter 3.6 “CompactFlash card”

v Chapter 3.7 “Device info”

32

The basic menu is displayed after pressing the

1

Not from the configuration level,

if a parameter has already been modified there.

Mkey

1

.

Page 33

3.2 Visualization

Evaluation of the stored

measurement data (history)

Hide function keys (softkeys)

Alter signal type (representation)

- analog inputs

- analog inputs and

event traces

Alter channel representation (header)

- diagram representation with digital display (small

measurements)

- diagram representation with scaling

- diagram representation with bar graph

- large digital display (large measurements)

- diagram representation (header switched off)

Show event

list

Show counters / integrators / operating

time counters

As already mentioned in Chapter 2.2 “Operating principle and graphic

elements”, the softkeys are arranged at the bottom of the screen. They change

their function according to the menu and are shown as symbols or plain text.

3 Operation and visualization

If the paperless recorder is equipped with “Counters/Integrators” (extra code),

the symbol for indicating the counts will now appear below the softkey on the

right, the symbol for showing the event list is shifted to the counter display.

33

Page 34

3 Operation and visualization

- current measurements of the analog inputs, including dimensional unit

- measurement on a red background out of limit

3.2.1 Diagram representation with digital display (small measurements)

Diagram representation can be reached from the basic menu, by calling up the

“Visualization” menu or by pressing the

D key.

By using the parameter Parameterization ➔ Diagram view ➔ Signal type (or

the button), it is possible to select whether, in addition to the

analog channels, the event traces are to be displayed as well. The contents of

the header are determined by means of the parameter Parameterization ➔

Diagram view ➔ Channel representation (or the button).

34

Page 35

3 Operation and visualization

Scaling start of the selected channel

Lower limit index of the selected channel

(no display when alarm is off)

Upper limit index

(no display when alarm

is off)

Current measurement

Channel name

Scaling end

of the selected channel

Scaling start of the selected channel

Lower limit index of the selected channel

(no display when alarm is off)

Upper limit index

(no display when alarm

is off)

Scaling end

of the selected channel

Current measurement

Channel name

3.2.2 Diagram representation with scaling

Which scaling (on which channel) is to be displayed can be selected through

the parameter Parameterization ➔ Diagram view ➔ Channel indication.

3.2.3 Diagram representation with bar graph

Use the parameter Parameterization ➔ Diagram view ➔ Channel indication to

select which bar graph (from which channel) is to be displayed.

35

Page 36

3 Operation and visualization

3.2.4 Large digital display (large measurements)

This display type is limited to the digital display.

If more than 6 signals are active (for instance, 6 analog inputs and 3 math

channels), the button is switched into the display. It can be used

to switch between the individual signals.

- recorded analog channels (channels selected through the parameter

Configuration

- all analog inputs

- all math channels

Recording Analog channels)

36

Page 37

3 Operation and visualization

3.2.5 Curve representation (header switched off)

This display type is limited to the curve display.

37

Page 38

3 Operation and visualization

Cursor (violet)

Current zoom

(magnification)

Scroll forwards fast

(one screen)

Scroll forwards slowly (one pixel line)

History

activated

Switch to

softkey functions

Zoom/Search

Date and time of measurements at

the cursor position

Scroll backwards slowly (one pixel line)

Scroll backwards fast (one screen)

Measurement at the

cursor position

3.2.6 Evaluation of the stored measurement data

History The softkey function changes during evaluation. In addition, the current zoom

factor and cursor position (date and time) will be shown.

Scroll operation

Using these softkeys, the measurement data display can be scrolled (shifted)

on the screen within the measurement data stored in the internal memory.

38

Measurement acquisition remains active during history

representation.

Page 39

3 Operation and visualization

Cursor (violet)

Zoom +

Position cursor on time (selectable)

Switch to

softkey

function

“Scroll”

Only for peak-value acquisition:

switch channel line between MIN

and MAX display

Zoom -

Scrolling backwards within the internally stored measurement data

is possible up to the last changeover from summer time to normal

time.

Zoom If the zoom factor has to be adjusted, or specific times have to be searched,

then it is necessary to switch the softkey functions.

h Press softkey

The degree of compression of the measurement data on the screen is given as

a ratio in steps (1:1, 1:2, 1:5, 1:10, 1:20, 1:50 and 1:100).

For instance, a ratio of 1:100 means that 1 screen pixel corresponds to 100

measurements, i.e. only every hundreth stored measurement is displayed.

39

Page 40

3 Operation and visualization

Cursor

positioning

Peak-value

acquisition

After activating the button, the following dialog appears for positioning the

cursor on a specific time:

After entering the date and time and activating , the cursor is

positioned on the selected time.

If no measurement data have been stored for the selected time, then the

cursor is positioned on the next possible time.

If the data have been recorded in the “peak value” mode, then two different

measurements (one minimum and one maximum value) may be displayed

graphically for one instant of time (storage cycle). Using the key,

it is possible to switch between minimum and maximum value display within

the “measurement” display mode.

Function key Channel line

Minimum

Maximum

Peak value acquisition is programmed (activated) through the parameters:

- Configuration ➔ Measurement storage ➔ Normal display ➔ Stored value

- Configuration ➔ Measurement storage ➔ Event operation ➔ Stored value

- Configuration ➔ Measurement storage ➔ Timed operation ➔ Stored value

For further information about the “measurement” display mode, see Chapter

3.2.1 “Diagram representation with digital display (small measurements)” and

Chapter 3.2.4 “Large digital display (large measurements)”.

40

Page 41

3 Operation and visualization

Show curves

Expanded representation

Programmed

alarm limit

was exceeded

Overrange

3.2.7 Counters / integrators / operating time

Count display is optionally available (extra code). If it is available, a screen

such as the following will appear after the softkey has been pressed, in which

the current counts are shown in a numerical form.

Press the softkey to activate the expanded representation.

41

Page 42

3 Operation and visualization

Normal representation

Event list

see

Chapter 3.5

“Event list”

Current count

Concluded reporting period

Show next concluded

reporting period

The last 7 concluded reporting periods can be

shown, one after another, by pressing the key.

Expanded

representation

42

Page 43

3.3 Parameterization

3 Operation and visualization

The Parameter level is available to set

-contrast,

- speed indication

-display off

- diagram view and

- counter/integrator reset.

All parameters are selected using the and

or and keys.

Contrast The contrast of the screen can be set here. This ensures that the screen is

always highly legible, even under difficult light conditions.

Speed

indication

“mm/h”, “time/div” or “storage cycle” is selected here for the speed display in

the diagram.

Example: a diagram speed of 1hr/div correspond to approx. 22mm/hr.

43

Page 44

3 Operation and visualization

Display off

(screen saving)

Diagram view Diagram view ➔ Signal type

Switch-off event = waiting time

For screen saving, a time between 0 and 32,767min can be set under the

parameter “Waiting time”. If no key on the recorder is operated during this

time, then the screen goes dark. The power LED blinks during screen saving.

Screen saving can be canceled by pressing any key on the recorder.

If 0min is set, then screen saving is deactivated.

Switch-off event = control signal

In this case, screen saving is performed through one binary input (extra code)

or a different control signal. The binary input is selected via the parameter

“Control signal”.

As long as the signal is present, the screen remains switched off. A waiting

time is not allowed for.

Screen saving is deactivated when “Off” is selected.

Only one type of screen saving can be active at any time.

The representation mode of the measurements and event traces are

determined here:

- analog inputs

- analog inputs and event traces.

Diagram view ➔ Channel representation

The contents of the channel bar is selected here:

- small measuremenst

-scaling

-bar graph

- large measurements

-switched off.

Diagram view ➔ Channel indication

The channels which are displayed in the channel line, in the representation

mode “Small measurement“ “Scaling” and “Bar graph” are selected here.

Diagram view ➔ Paper perforations

This can only be selected if only the analog channels and no event traces are

displayed. When Yes is set, paper perforations appear in the diagram, thus

giving the picture the appearance of a conventional chart recorder.

44

Page 45

3 Operation and visualization

Counter/

integrator

reset

After the password has been successfully entered, the counts for each of the 6

channels can be set to 0 or a defined value in this menu.

When a value has been entered (confirm with the

new and old count is entered in the event list. The time period for the counter/

integrator summation will not be restarted. The previous counter/integrator

values will also not be saved. If you wish to do so, you have to carry out

Update CF card incl. counters in the CompactFlash card menu before

resetting.

In this way, the recording can be freshly started for counters/integrators, e.g.

after the test run of an installation. The test run values that are not required will

be eliminated in the process.

You can select a password that is different from that for accessing the

configuration. The default value is also 09200.

The password can be set in the menu Configuration ➔ Device data ➔ Code

No. (password) ➔ Reset counter/int.

E key), a message with the

45

Page 46

3 Operation and visualization

Window title

Parameter is inhibited

Parameter can be selected/edited

Current setting

3.4 Configuration

When you call up the configuration level, you will be asked to enter the

password (factory setting: 09200). This also serves to prevent unauthorized

alteration of the configuration.

After entering the password, a warning appears, which must be

acknowledged with the

v Chapter 3.10 “Code number (password query)”

E key.

Window

technology

As for the other levels, the configuration principle is also based on menu-led

window technology. Individual menu items can be selected in the windows.

The window title describes the contents of the window.

If a menu item is selected, a further window is opened with new menu items,

until the required parameter is finally reached. If several windows are open, the

window title assists in orientation.

46

Page 47

3 Operation and visualization

The configuration of the recorder is sub-divided into the following levels:

v Chapter 4 “Configuration parameters”

3.5 Event list

Events Various events can initiate texts which are incorporated in the event list and

saved to the internal memory or CF card. Events may include:

- alarms triggered by out-of-limit conditions on individual channels,

Event

definition

Te xt

assignment

Freely definable

texts

- external texts triggered through binary inputs or logic channels,

- system messages (e.g. power ON/OFF, summer/winter time changeover),

- count-up of a counter,

- any message text of up to 20 characters that was transmitted to the device

via one of the interfaces.

For all events, except for system messages, it is possible to configure

whether:

- the message text is to be included in the event list,

- the device-internal standard text

- or one of the texts (see below) is used.

The texts (standard texts or 18 freely definable texts) are assigned to events at

the operating level “Configuration” (v Chapter 4 “Configuration parameters”).

18 texts can be freely defined, up to a length of 20 characters.

47

Page 48

3 Operation and visualization

Standard texts The recorder offers standard texts as listed in the following table:

Standard text Comment

Channelx low alarm ON

Channelx low alarm OFF

Channelx high alarm ON

Channelx high alarm OFF

Counter/int. alarm x ON

Counter/int. alarm x OFF

Binary input y ON

Binary input y OFF

Logic channel y ON

Logic channel y OFF

Counter x: yx = counter channel number

Power ON

Power OFF

Data lost

Summer time start

Summer time end

New configuration

Counter/int. x reset from y to z

“Text 1 — 18” 18 freely definable texts

x = channel number

y = input number

y = counter value (9 digits)

x = counter/int. channel number

y = old counter/int.value (9 digits)

z = new counter/int. value (9 digits)

with 20 characters each

Supplementary

text

The recorder automatically supplements the texts by “ON” or “OFF” in order to

distinguish between the appearance and disappearance of the signal.

Example:

Standard text Supplementary

text

Binary input 2 ON Binary input 2 ON

Binary input 2 OFF Binary input 2 OFF

Entry in event list

48

Page 49

3 Operation and visualization

h Select operating level Event list

h Enter selection with E

jump back directly into diagram presentation

Basic menu ➔

Event list

The event list is called up via the basic menu:

Event list

49

Page 50

3 Operation and visualization

h Select operating level CompactFlash card

h Enter selection with E

3.6 CompactFlash card

Automatic

storage of

measurement

data

Loading and

saving the

configuration

data

Basic menu ➔

CompactFlash

card

The data stored in the measurement data memory (FLASH) of the paperless

recorder are saved at regular intervals to the CompactFlash card

instrument. The PC evaluation program (v Chapter 7 “PC programs”) reads

the data from the CF card and provides user-friendly functions for evaluation.

The configuration data can be downloaded from the CF card and saved to the

CF card. A configuration can thus be copied from one instrument to another,

or it can be transferred from and to the PC setup program.

Only one configuration file can be saved to the CF card at any

time. If there is a configuration on a CF card, this will be

overwritten without any further query through the function

CompactFlash card ➔ Config. data➔CF card.

The CompactFlash menu is called up via the basic menu:

1

in the

The functions

- Update CF incl. counters ...,

- Compl. meas. data ➔ CF,

- Config. data ➔ CF card and

- CF card ➔ Config. data

are protected against unauthorized access by a password query (factory

setting: 09200).

1

PC Card access made available by CSM FAT File System

Copyright © 1997-2002 CSM GmbH Filderstadt, Germany

50

Page 51

CompactFlash

Residual capacity of CF card in percent

Background flashes on error (e. g. “CF

card full”, “no CF card”,

or in the event of a memory alarm

Start action

The configuration data are read from the CF card

The configuration data are written to the CF card

All measurement data in the memory are written to CF card

Measurement data not yet saved are written to the CF card.

Select action

Counter/integrator reporting periods are concluded and

written to the CF card, together with the measurement data

not yet saved. Counters/integrators are reset (to 0) and

restarted.

card

3 Operation and visualization

The function CF card Update reads out data that have not been

read out yet. After read-out, the data are marked as read in the

recorder.

The function Total meas. data

the internal memory, including those that had already been read

out.

CF card reads all the data from

51

Page 52

3 Operation and visualization

Status

messages

Status messages from the CompactFlash manager are shown in the

corresponding action window. The following status messages are possible:

Status message Description

CF CARD UPDATED Directly before removing the CF card from the

instrument, it is necessary to call up Update CF

card so that all measurement data up to the time

of removal are contained on the CF card. The data

not yet stored since the last automatic saving are

written to the CF card.

NO CF CARD If there is no CF card in the instrument, the CF

card symbol flashes in the status line.

CF CARD FAULT An error has occurred while writing to the CF card.

The CF card is faulty.

Remedy:

Insert new (FAT16-formatted) CF card.

CF CARD FULL If the CF card is full, the CF card symbol flashes in

the status line. No more data will be written to the

CF card.

Remedy:

Insert a blank CF card before the measurement

data memory of the recorder is also full. If this is

not done, measurement data will be lost.

NO CONFIG. FILE ON CF An attempt was made to read a configuration from

the CF card, but there is no suitable configuration

file on the CF card.

52

Page 53

3.7 Device info

h Select operating level Device info

h Enter selection with E

The device info window displays general information about the instrument. It

also includes the errors “Battery empty” and “Data lost”. If one of the

instrument errors occur, the info symbol flashes in the status line.

3 Operation and visualization

Basic menu ➔

Device info

The device info is called up from the basic menu:

Device info

53

Page 54

3 Operation and visualization

- This menu also includes the version number (e.g. 208.01.04). This is the

version number of the device software. It is important because some

functions are only available from a certain version number onwards.

- If the “Digital I/O option” is available (Yes), then the recorder also includes

an RS232/RS485 interface.

- If the Ethernet interface is available, then the field “Vers. No. Ethernet”

includes a number combination (e.g. 183.02.02). If this option is not

available, the field is filled with “-”.

Error The following errors may occur:

Error Description

none no error in instrument

Data lost A discharge of the battery or storage capacitor

occurred during the last lengthy power

interruption.

The clock was set to 01.01.00 00:00:00.

Remedy:

Reset the time (v Chapter 4.2.2 “Configuration Instrument (device) data”) and use a new

CF card for data storage.

Battery empty This message appears on instruments with a

lithium battery, when the time was reset after a

loss of data but the battery is still empty

Please return the instrument to the supplier for a

change of battery.

Data may be lost after separating the instrument from the supply:

after more than 10 years (on instruments with a lithium battery) or

after approx. 2 weeks (at ambient temperature 15 to 25°C) with a

storage capacitor.

54

Page 55

3 Operation and visualization

Switch to character set matrix

Select the character to be altered using the softkeys

Accept character

Select new character

3.8 Text entry

Entry options The configurable texts can be entered either through the setup program or on

the instrument itself. This section describes the entry on the instrument.

Character

selection

The display below is shown when a text (e. g. Configuration ➔ Text s) has been

selected at the configuration level for editing using

E.

After the character to be altered has been selected and the switch made to

character set matrix, the cursor is positioned on the current character in the

character set matrix.

Character entry The softkeys change their function, as can be seen from the picture below:

After the entire text has been entered, it can either be accepted or all

alterations canceled.

h Enter text with

or

h cancel text entry with

E

D

55

Page 56

3 Operation and visualization

Increase (+1) or

decrease (-1) selected

digit or change the sign

Select the digit to

be altered

Alter the number

of decimal places

3.9 Entering values

The softkeys are also used to enter values in the instrument – the example

shows fine calibration being carried out.

56

The sign can only be altered if the value is not “0”. This means that

you cannot start the value entry with an alteration of the sign if the

current value is “0”.

The entry can be concluded with

E or canceled with D.

Page 57

3 Operation and visualization

Increase (+1) or

decrease (-1) selected

digit

Select the digit to

be altered

3.10 Code number (password query)

The following functions are protected ex-factory against unauthorized access

by a password query:

-the Configuration menu

-parts of the CompactFlash card menu

-the Parameterization ➔ Reset counter / int. menu.

The factory default setting for the passwords is 09200.

You can also use a password to secure access to the recorder via one of the

interfaces (with the exception of the setup interface). However, the factory

default setting here is 0 (no password query). If you enter a value other than 0,

please take into account that this number must also be sent to the recorder by

an attached communications program.

Further information about the password query for the interfaces

can be found in the Interface description 59482.

Password query

All passwords can be programmed differently (see Chapter 4.2.2

“Configuration - Instrument (device) data”).

When you have finished the entry (e.g. +09200), use the

Use

D if you want to cancel the password query and quit the menu.

E key to confirm it.

57

Page 58

3 Operation and visualization

Password query

in the

configuration

menu

After the password has been entered in the Configuration menu, an additional

security query will appear. You will only be able to gain access to the

parameters when you have confirmed the the query with

E.

58

Page 59

4.1 Operating example

4 Configuration parameters

1

If required, the code number must be entered here

(factory setting: 09200)

2

Cancel entry; the old settings are retained

3

Accept entry

59

Page 60

4 Configuration parameters

4.2 Table of configuration parameters

The table below lists all the instrument parameters. The order in which the

parameters are explained corresponds to the order in which they appear on

the instrument (in the menu structure).

The first column describes the path to the particular parameter, via the menus

and windows.

The second column lists the possible settings for the parameters or the

possible selections. The factory default setting in this column is shown bold.

The third column contains a description of the parameter, or the possible

selections, if the parameter and its function or selection is not self-evident.

4.2.1 Parameterization

Parameter Value/Selection Description

Contrast Parameterization

➔ Contrast

Speed indication Parameterization

➔ Speed indic. mode

Switch-off event Parameterization

➔ Display off

➔ Switch-off event

Waiting time Parameterization

➔ Display off

➔ Waiting time

Control signal Parameterization

➔ Display off

➔ Ctrl signal

Signal type Parameterization

➔ Diagram view

➔ Signal type

0—16 — 31 Display contrast

in mm/h,

time/div,

storage rate

Waiting time,

Cntrl signal

0 — 32767min Time after which the

Off,

Bin. inp. 1 — 4,

Logic channel 1 — 6,

Low alarm 1 — 6,

Low comb.al.,

High alarm 1 — 6,

High comb.al.,

Count/Int/Al 1 — 6,

C/i. comb.al.,

Comb. alarm,

CF inserted,

IntMemAlmCF,

IntMemAlmSer,

MemAlmCFcard,

Error, Modbus flag,

Analog inp.,

Analog&Event

The selected display mode

is shown in the diagram

representation

The type of display

switch-off (screen saving)

is selected here

display is switched off. Any

key stroke will re-activate

the display. The parameter

can only be entered if the

parameter Switch-off event

is set to “Waiting time”.

0 = display not off

If one of the 4 binary inputs

(extra code) or one of the

other control signals is set

to “off” and activated, then

the display will be switched

off. The parameter can only

be entered if the parameter

Switch-off event is set to

“Control signal”.

This determines which

measurements are

graphically displayed

60

Page 61

4 Configuration parameters

Parameter Value/Selection Description

Channel

representation

Channel indication Parameterization

Paper perforations Parameterization

Counter/int. reset Parameterization

Parameterization

➔ Diagram view

➔ Chan. represent.

➔ Diagram view

➔ Channel indication

➔ Channel 1 — 6

➔ Diagram view

➔ Paper perforations

➔ Reset counter/int.

➔ Channel 1 — 6

Meas. small,

Scaling

Bar graph

Meas. large,

Off

Yes,

No

No,

Yes

-999999999 to 0 to

+999999999

This determines the

contents of the channel

line (header)

“Yes” means that the

selected channels are

shown in the header

“Yes” means that paper

perforations are shown

within the graphic display,

on the left and right

margins of the screen.

Paper perforations can

only be activated and

shown if no event traces

have been selected (signal

type = analog input)

The start value for the

counter or integrator can

be entered here. The

current value is not saved.

Count changes are

documented in the event

list.

v Chapter 3.3

“Parameterization”

If the password query

is active (password “Reset

counter/int.” > 0), the start

values can only be set if

the password has been

entered correctly.

61

Page 62

4 Configuration parameters

4.2.2 Configuration - Instrument (device) data

Parameter Value/Selection Description

Device name Configuration

➔ Device data

➔ Device name

Date Configuration

➔ Device data

➔ Date and time

➔ Date

Time Configuration

➔ Device data

➔ Date and time

➔ Time

Time

synchronization

Summer time

(switch)

Summer time

(start date)

Summer time

(start time)

Summer time

(end date)

Summer time

(end time)

Configuration

➔ Device data

➔ Date and time

➔ Time

synchroniz.

Configuration

➔ Device data

➔ Summer time

➔ Switch

Configuration

➔ Device data

➔ Summer time

➔ Start date

Configuration

➔ Device data

➔ Summer time

➔ Start time

Configuration

➔ Device data

➔ Summer time

➔ End date

Configuration

➔ Device data

➔ Summer time

➔ End time

16 characters

any date Entry of the current

date

any time Entry of the current

time

Off,

Bin. inp. 1 — 4,

Logic channel 1 — 6,

Low alarm 1 — 6,

Low comb.al.,

High alarm 1 — 6,

High comb.al.,

Count/Int/Al 1 — 6,

C/i. comb.al.,

Comb. alarm,

CF inserted,

IntMemAlmCF,

IntMemAlmSer,

MemAlmCFcard,

Error, Modbus flag,

Off,

User timed,

Automatic

any date Can only be set if

any time Can only be set if

any date Can only be set if

any time Can only be set if

With the help of this

parameter (function), the

system clocks of several

paperless recoders can be

simultaneously

synchronized.

When a binary input has

been selected and is

activated (transition from

“Low” to “High”), then the

time can be synchronized.

The seconds are decisive

in the time change. They

are used for rounding the

time up or down.

Example:

12:55:29 -> 12:55:00

12:55:30 -> 12:56:00

Automatic:

2:00 hrs or 3:00 hrs on the

last Sunday in March or

October

switch is set

to user timed

switch is set

to user timed

switch is set

to user timed

switch is set

to user timed

62

Page 63

4 Configuration parameters

Parameter Value/Selection Description

Language Configuration

➔ Device data

➔ Language

Temperature unit Configuration

➔ Device data

➔ Temperature unit