Page 1

PMA Prozeß- und Maschinen-Automation GmbH

UNIFLEX CI 45

universal transmitter

rail

line

UNIFLEX

CI 45

UNIFLEX

Operating manual

English

9499-040-71711

Valid from: 06/2009

CI 45

Page 2

û

More efficiency in engineering,

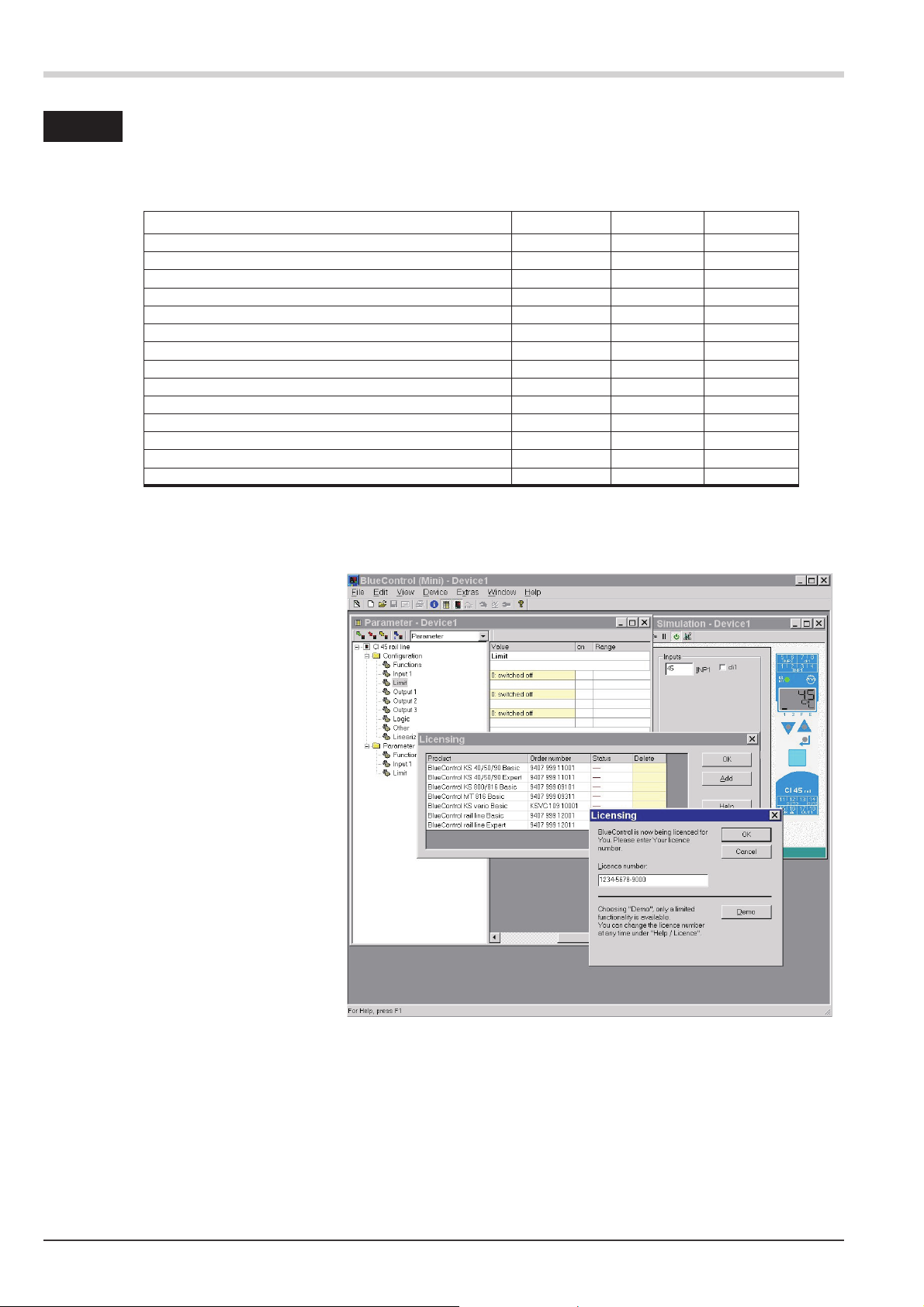

The projecting environment for the BluePort

rail line and measuring converter, controller, temperature limiter

BlueControl

more overview in operating:

Ò

â

controllers, indicators

ATTENTION!

g

a

l

+

Mini Version and Updates on

Description of symbols:

General information

General warning

Attention: ESD sensitive devices

Caution: read the operating instructions

Read the operating instructions

Hint

© 2004 PMA Prozeß- und Maschinen-Automation GmbH · Printed in Germany

All rights reserved. No part of this document may be reproduced or published in any form

or by any means without prior written permission from the copyright owner.

www.pma-online.de

or on PMA-CD

A publication of PMA Prozeß- und Maschinen Automation

P.O.Box 310229

D-34058 Kassel

Germany

Page 3

Table of content

1. General ............................................5

2. Safety hints ..........................................6

2.1 Maintenance, repair, modification ...........................6

2.2 Cleaning .........................................7

2.3 Spare parts .......................................7

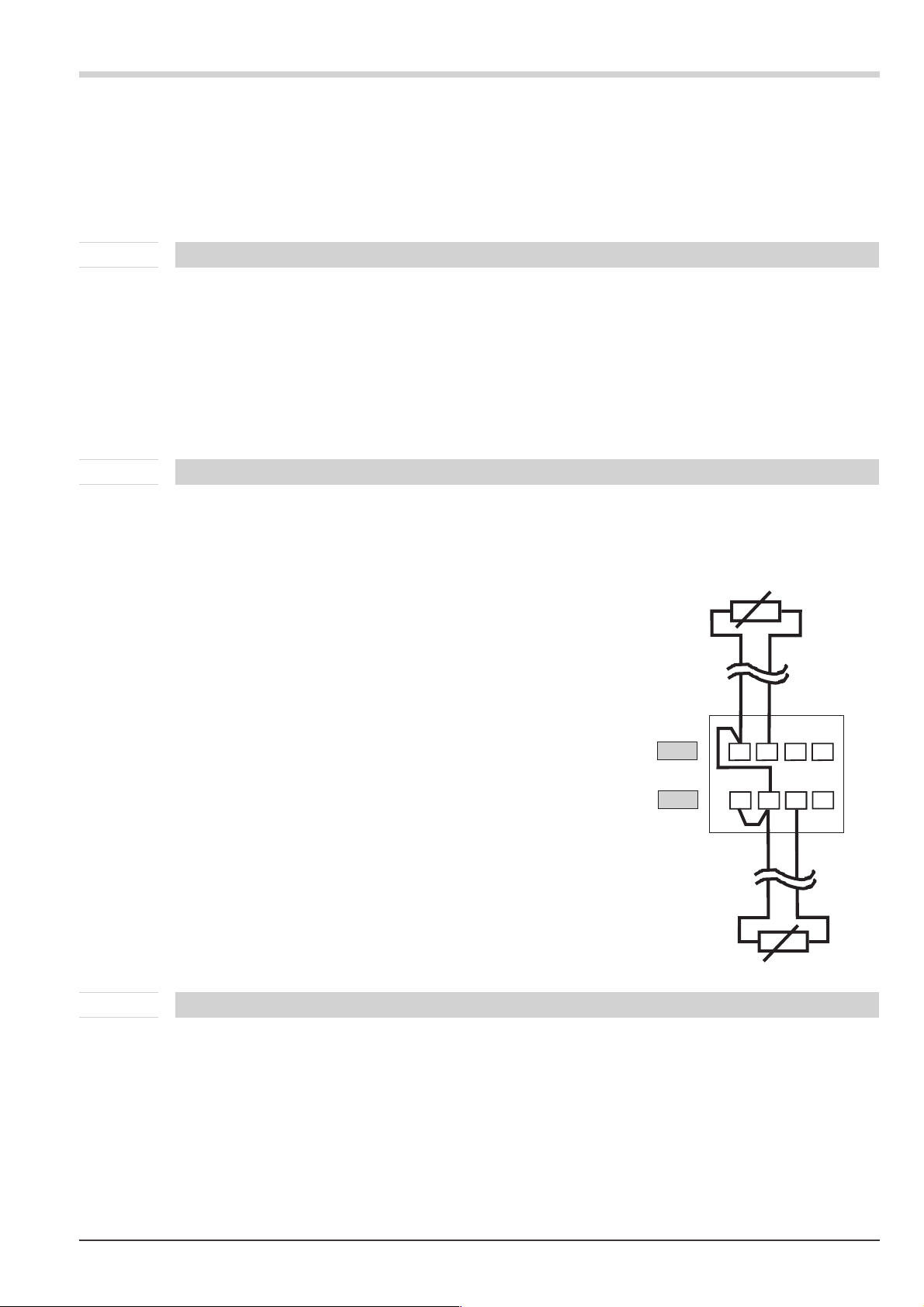

3. Mounting ...........................................8

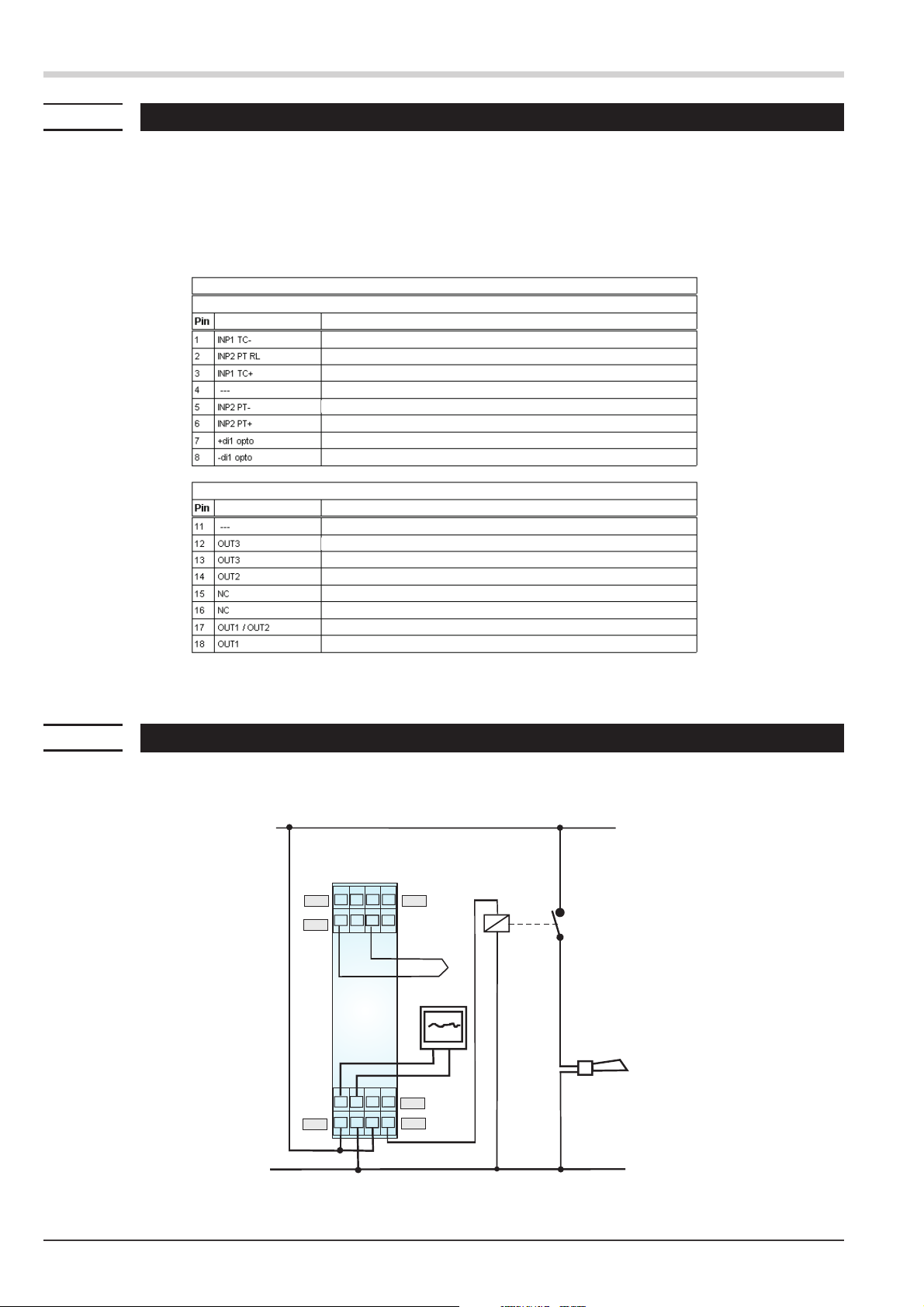

3.1 Connectors........................................9

4. Electrical connections ..................................10

4.1 Connecting diagram ..................................10

4.2 Terminal connections .................................10

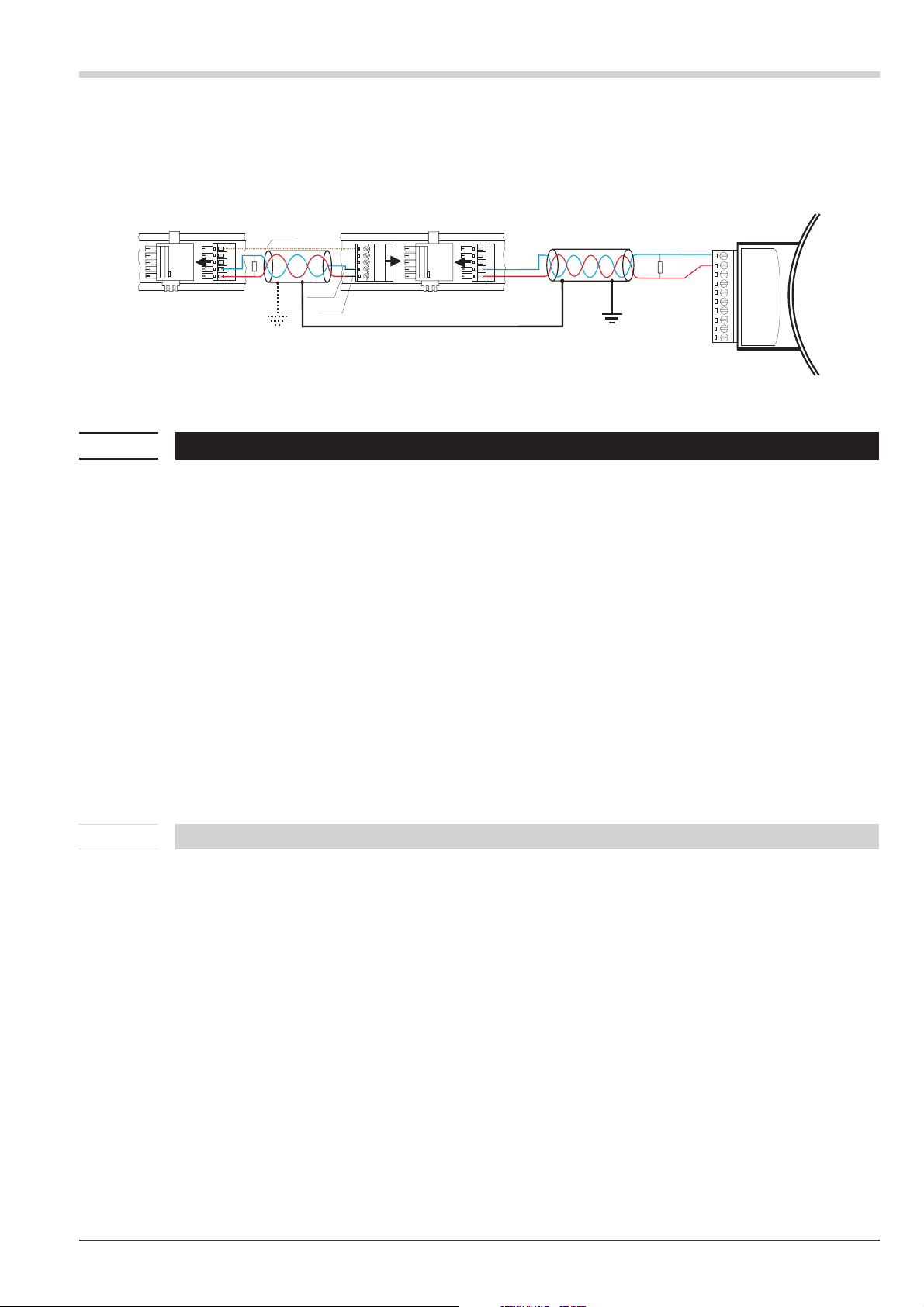

4.3 Connecting diagram ..................................12

4.4 Connection examples .................................12

4.5 Hints for installation ..................................13

4.5.1 cULus approval ..............................13

5. Operation ..........................................14

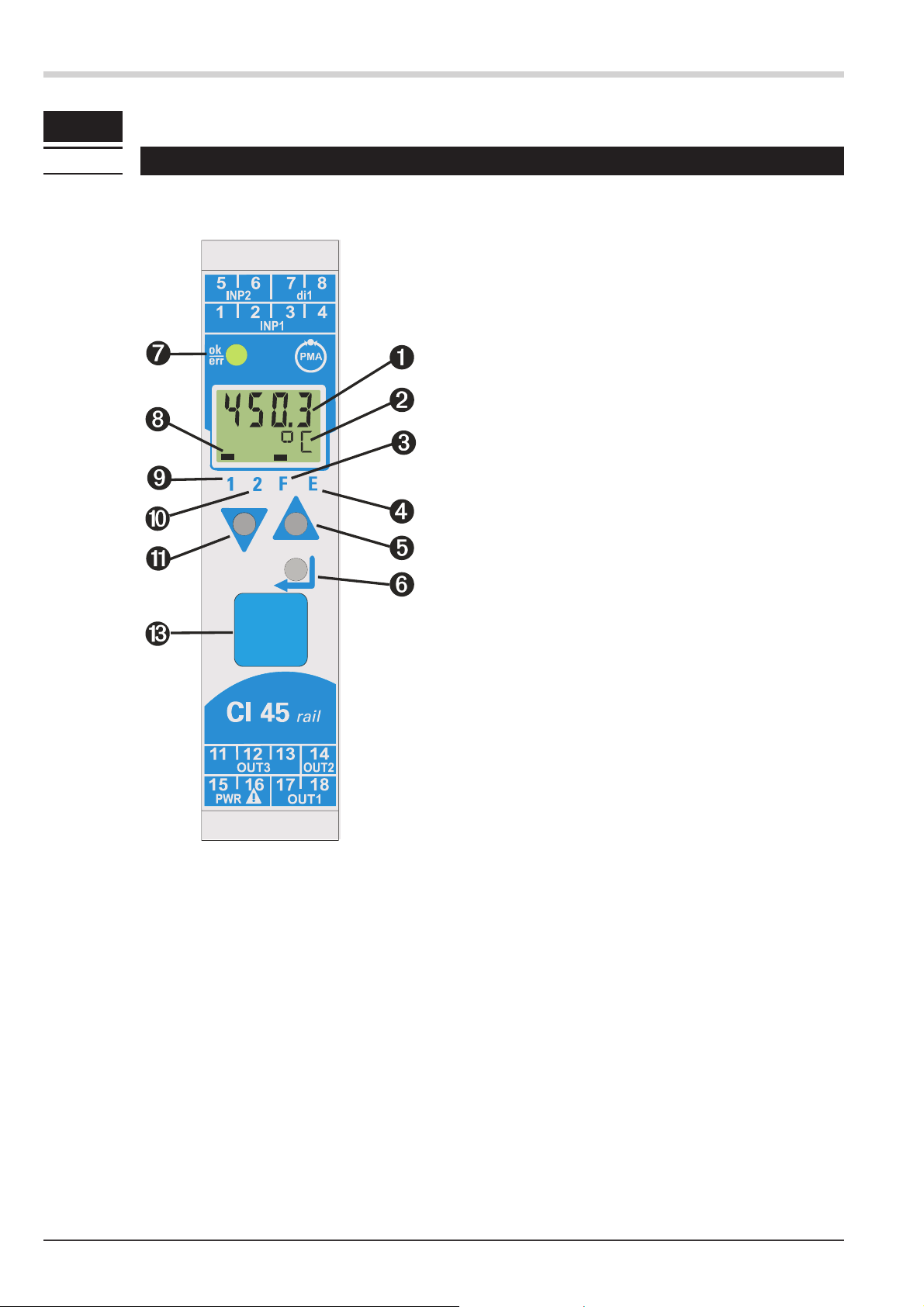

5.1 Front view .......................................14

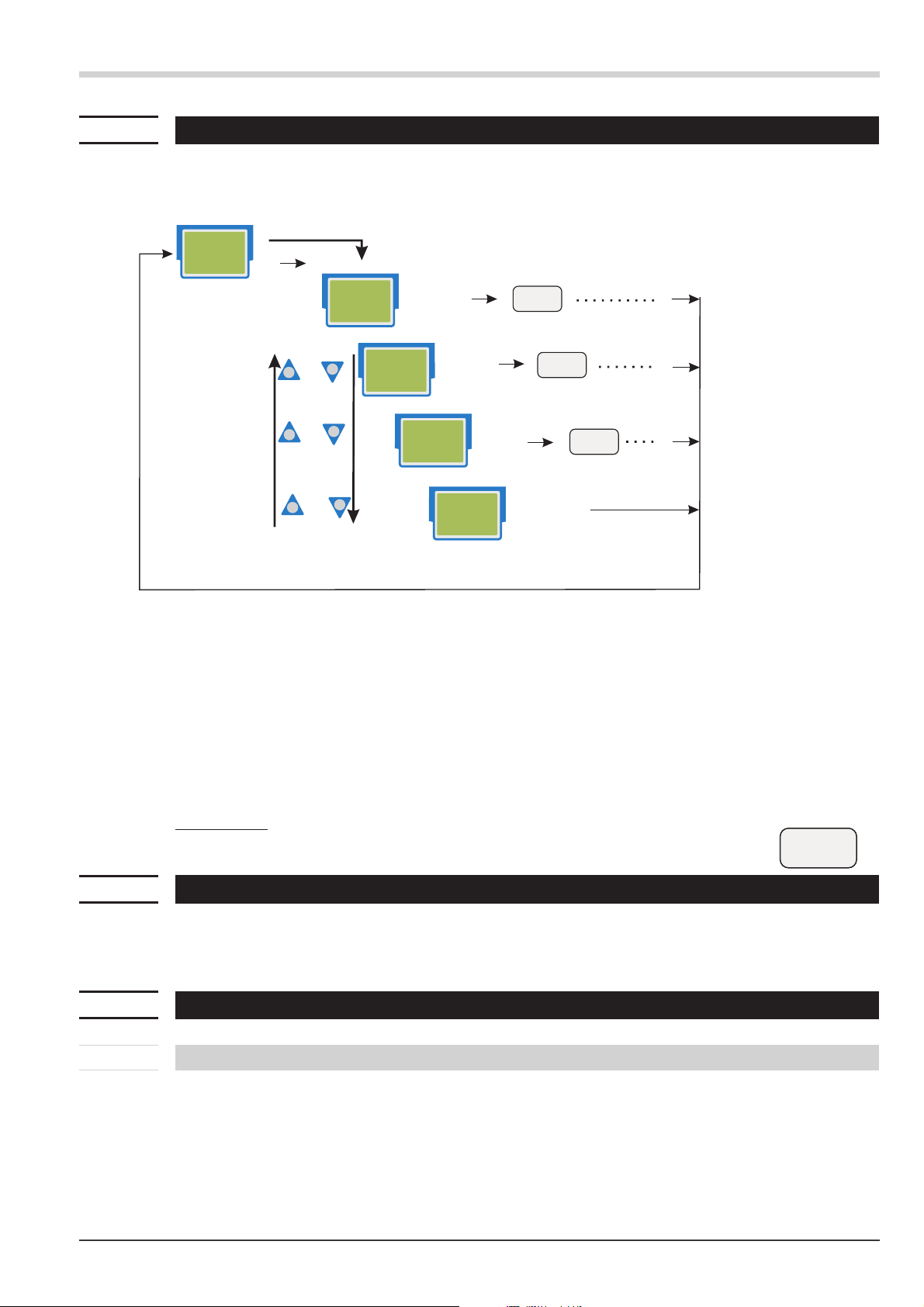

5.2 Operating structure ..................................15

5.3 Behaviour after supply voltage switch-on.......................15

5.4 Operating level .....................................15

5.4.1 Display line1................................15

5.4.2 Display line 2 ...............................16

5.4.3 Switching over by means of the Enter key ................16

5.4.4 Slave pointer function...........................17

5.4.5 Selecting the units ............................17

5.4.6 Extended operating level .........................18

6. Functions ..........................................19

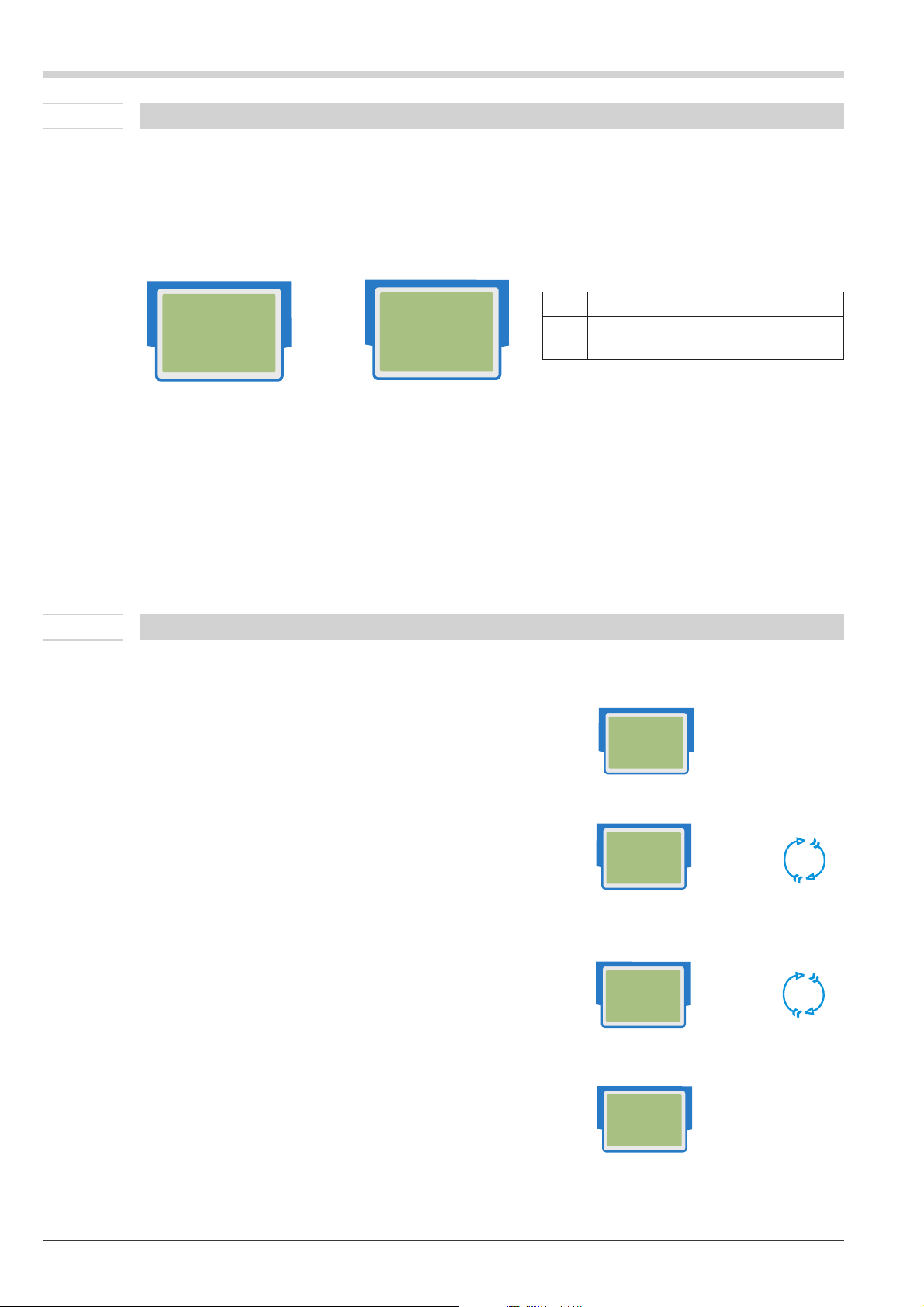

6.1 Linearization ......................................19

6.2 Input scaling ......................................20

6.2.1 Input fail detection ............................21

6.2.2 Two-wire measurement..........................21

6.2.3 Scaling with potentiometer measurement ................21

6.3 Temperature compensation, measured via INP2 (optional)..............22

6.4 Filter ..........................................23

6.5 Substitue value for inputs ...............................23

6.6 Input forcing ......................................23

6.7 O

2 measurement (optional) ..............................23

6.8 Counter (optional) ...................................25

6.9 Frequency input (optional) ...............................26

6.10 Arithmetic functions ..................................27

6.11 Tare function (optional) ................................28

6.12 Sample&hold amplifier (optional) ...........................28

6.13 Integrator function ...................................29

6.14 Limit value processing .................................29

6.14.1 Measured value monitoring........................30

6.14.2 Monitoring the number of operating hours and switching cycles ....32

UNIFLEX CI 45 3

Page 4

6.15 Analog output configuration..............................33

6.15.1 Analog output ...............................33

6.15.2 Logic output ................................34

6.15.3 Transmitter power supply.........................34

6.15.4 Frequency output (optional) ........................35

6.15.5 Analog output forcing ...........................35

6.16 Maintenance manager / error list ...........................36

6.17 Reset to factory setting ................................37

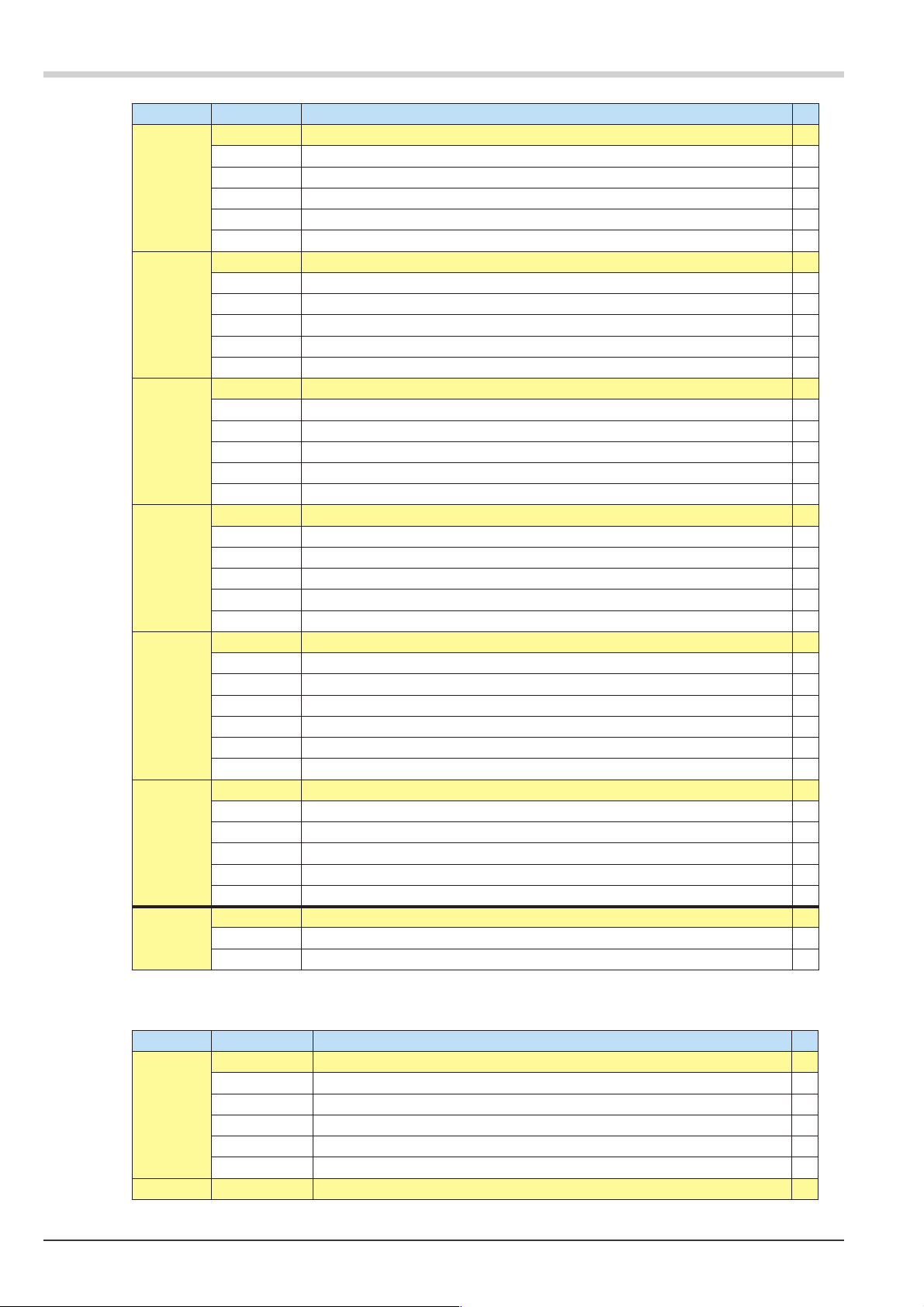

7. Configuration level.....................................38

7.1 Configuration survey ..................................38

7.2 Configurations .....................................39

8. Parameter setting level ..................................47

8.1 Parameter survey....................................47

8.2 Adjustment .......................................47

8.3 Parameters .......................................48

9. Calibrating level ......................................49

9.1 Offset correction ....................................50

9.2 2-point correction ...................................51

10.BlueControl

Ò

engineering tool ..............................52

11.Versions ...........................................53

12.Technical Data .......................................54

13.Index ...........................................59

4 UNIFLEX CI 45

Page 5

- preliminary - General

1

.

General

Thank you very much for buying a Universal Transmitter UNIFLEX CI 45.

UNIFLEX CI 45 transmitters are suitable for precise, cost-efficient signal detection and processing. Every CI 45 is

equipped with at least one universal input, one universal output and a relay. Optionally, the transmitter can be fitted

with an additional relay.

Galvanic isolation is provided between inputs and outputs as well as from the supply voltage and the communication

interfaces.

Applications

CI 45 is used for measurement, scaling and separation of electrical signals, e.g. for

Heat treatment plants

w

Drying equipment

w

Furnace builders

w

Metallurgy

w

Kilns

w

General machine building

w

Research and development

w

Energy measurement

w

Signal conversion

w

...

At-a-glance survey of advantages

Compact construction, only 22,5 mm wide

Clips onto top-hat DIN rail

Plug-in screw terminals or spring clamp connectors

Dual-line LC display with additional display elements

Process values always in view

Convenient 3-key operation

Direct communication between rail-mounted transmitters

Universal input with high signal resolution (>15 bits) reduces stock keeping

Universal output with high resolution (14 bits) as combined current / voltage output

Quick response, only 100 ms cycle time, i.e. also suitable for fast signals

One or two relay outputs

Customer-specific linearization

Measurement value correction (offset or 2-point)

Min/max indicator ('slave pointer')

Logical linking of digital outputs, e.g. for common alarms

Preset of output value

*

This documentation includes already several options which will be available only with

operating version 2 instruments.

Further documentation for universal transmitter CI 45:

–

Data sheet CI 45 9498 737 48313

–

Operating note CI 45 9499 040 71441

–

Interface description 9499 040 72011

UNIFLEX CI 45 5

Page 6

Safety hints

2

.

a

a

Safety hints

This instrument was built and tested in accordance with VDE 0411-1 / EN 61010-1 and was shipped in safe condition.

The unit complies with European guideline 89/336/EEC (EMC) and is provided with the CE-marking.

The instrument was tested before delivery and has passed the tests required in the test plan. In order to maintain this

condition and to ensure safe operation, the user must follow the hints and warnings given in these operating

instructions and operate this instrument in compliance with the instructions given in this manual.

The unit is intended exclusively for use as a measuring and control instrument in technical installations.

Warning

If the instrument is so heavily damaged that safe operation seems impossible, the instrument must not be taken into

operation.

ELECTRICAL CONNECTIONS

The electrical connections must conform to local standards (e.g. VDE 0100). The input leads must be kept separate

from signal and mains leads.

A circuit breaker or a power switch must be provided for the instrument and marked accordingly in the installation. The

circuit breaker or power switch must be installed near the instrument and easily accessible for the operator.

COMMISSIONING

Before instrument switch-on, ensure that the rules given below were followed:

Ensure that the supply voltage corresponds to the specification on the type label.

w

All covers required for contact safety must be fitted.

w

Before instrument switch-on, check, if other equipment and/or facilities connected in the same signal loop is / are

w

not affected. If necessary, appropriate protective measures must be taken.

The instrument may be operated only when mounted in its enclosure.

w

The temperature limits specifed for operation of the unit must be met before and during operation.

w

a

a

Warning

During operation, the ventilation slots of the housing must not be covered.

The measurement inputs are designed for measurement of circuits which are not connected directly with

the mains supply (CAT I). The measurement inputs are designed for transient voltage peaks up to 800V

against PE.

SHUT-DOWN

For permanent shut-down, disconnect the instrument from all voltage sources and protect it against accidental

operation.

Before instrument switch-off, check that other equipment and / or facilities connected in the same signal loop is / are

not affected. If necessary, appropriate measures must be taken.

2.1 Maintenance, repair, modification

The instruments need no particular maintenance.

No operable controls are mounted inside the instrument, i.e. the operator must not open the unit.

Modification, maintenance and repair may be carried out only by trained, authorized persons. For this purpose, the user

is invited to contact the PMA service.

6 Maintenance, repair, modification UNIFLEX CI 45

Page 7

Safety hints

a

l

g

Warning

When opening the instruments, or when removing covers and components, live parts or terminals can be exposed.

Caution

When opening the instruments, electrostatically sensitive components can be exposed.

The PMA service can be contacted as follows:

PMA Prozeß- und Maschinen-Automation GmbH

Miramstraße 87

D-34123 Kassel

Tel. +49 (0)561 / 505-1257

Fax +49 (0)561 / 505-1357

e-mail: mailbox@pma-online.de

2.2 Cleaning

g

Housing and front panel of the instrument can be cleansed using a dry, lintfree cloth.

2.3 Spare parts

The following accessories are permitted as spare parts for the transmitter:

Description Order no.

Connector set with screw terminals 9407-998-07101

Connector set with spring clamp terminals 9407-998-07111

Bus connector for fitting in top-hat rail 9407-998-07121

UNIFLEX CI 45 Cleaning 7

Page 8

- preliminary - Mounting

A

3

.

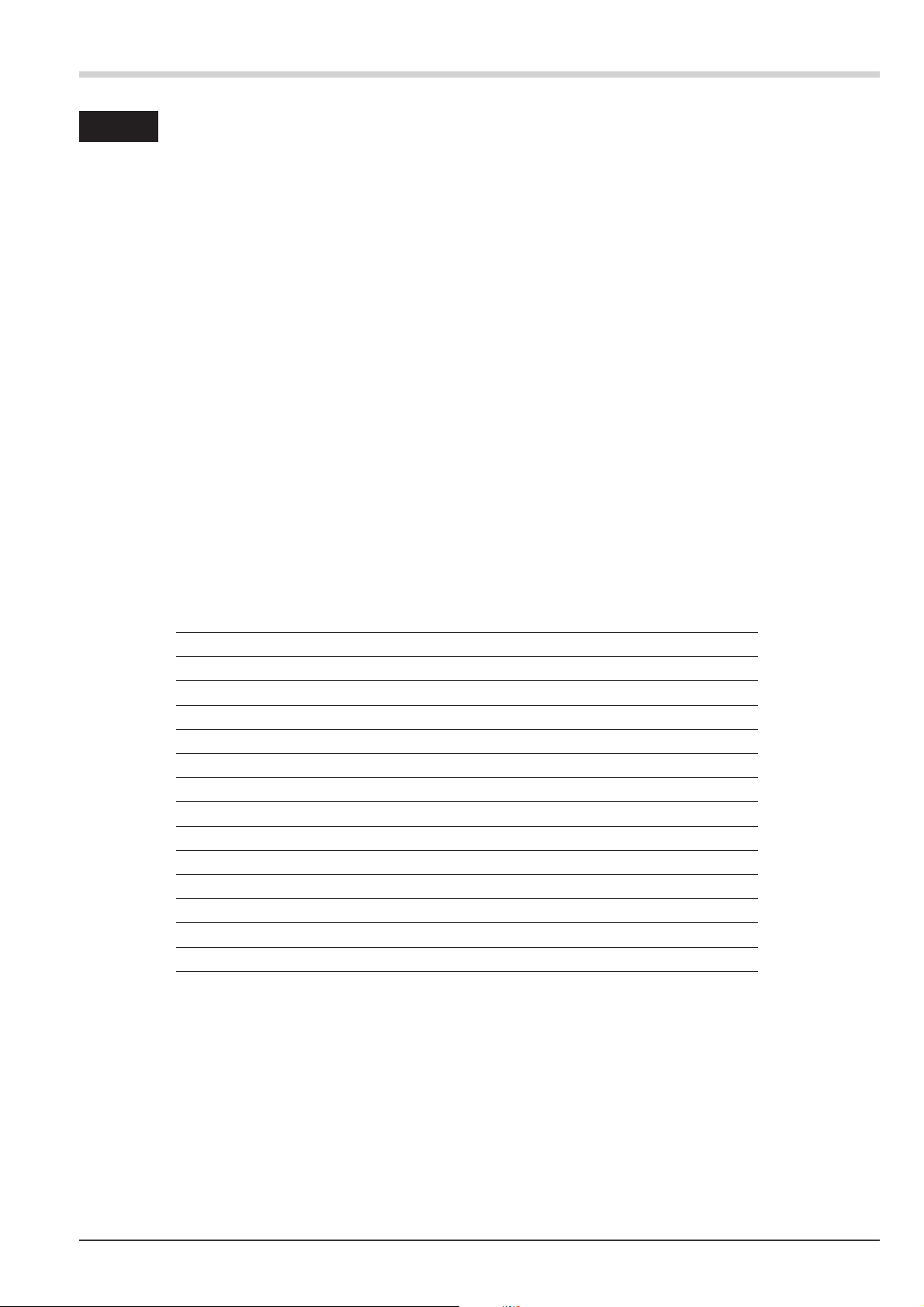

Mounting

bmessungen / dimensions

56

7

Klemme /

8

terminal

12

Montage / mounting

5.5

(0,20”)

4

3

2.3

(0,08”)

click

99 (3,90”)

Demontage / dismantling

1

22.5

(0,87”)

max.

117.5 (4,63”)

55°C

-10°Cmin.

111 (4, 37” )

max.

95% rel.

1516

17

18

Klemme /

terminal

%

11 1 2

14

13

g

a

a

a

l

a

a

The unit is provided for vertical mounting on 35 mm top-hat rails to EN 50022.

If possible, the place of installation should be exempt of vibration, aggressive media (e.g. acid, lye), liquid, dust or

aerosol.

The instruments of the rail line series can be mounted directly side by side. For mounting and dismounting, min. 8 cm

free space above and below the units should be provided.

For mounting, simply clip the unit onto the top-hat rail from top and click it in position.

To dismount the unit, pull the bottom catch down using a screwdriver and remove the unit upwards.

Transmitter CI 45 does not contain any maintenance parts, i.e. the unit need not be opened by the

customer.

The unit may be operated only in environments for which it is suitable due to its protection type.

The housing ventilation slots must not be covered.

In plants where transient voltage peaks are susceptible to occur, the instruments must be equipped with

additional protective filters or voltage limiters!

Caution! The instrument contains electrostatically sensitive components .

Please, follow the instructions given in the safety hints.

To maintain contamination degree 2 acc. to EN 61010-1, the instrument must not be installed below

contactors or similar units from which conducting dust or particles might trickle down.

UNIFLEX CI 45 8

Page 9

3.1 Connectors

The four instrument connectors are of the plug-in type. They plug into the housing from top or bottom and click in

position. Releasing the connectors should be done by means of a screwdriver.

Two connector types are available:

Screw terminals for max. 2,5 mm2conductors

•

Spring-clamp terminals for max. 2,5 mm2conductors

•

Mounting

g

a

Before handling the connectors, the unit must be disconnected from the

supply voltage.

Tighten the screw terminals with a torque of 0,5 - 0,6 Nm.

With spring-clamp terminals, stiff and flexible wires with end crimp can be

introduced into the clamping hole directly. For releasing, actuate the (orange)

opening lever.

Contact protection: Terminal blocks which are not connected should remain in the socket.

UNIFLEX CI 45 Connectors 9

Page 10

Electrical connections - preliminary -

4

.

Electrical connections

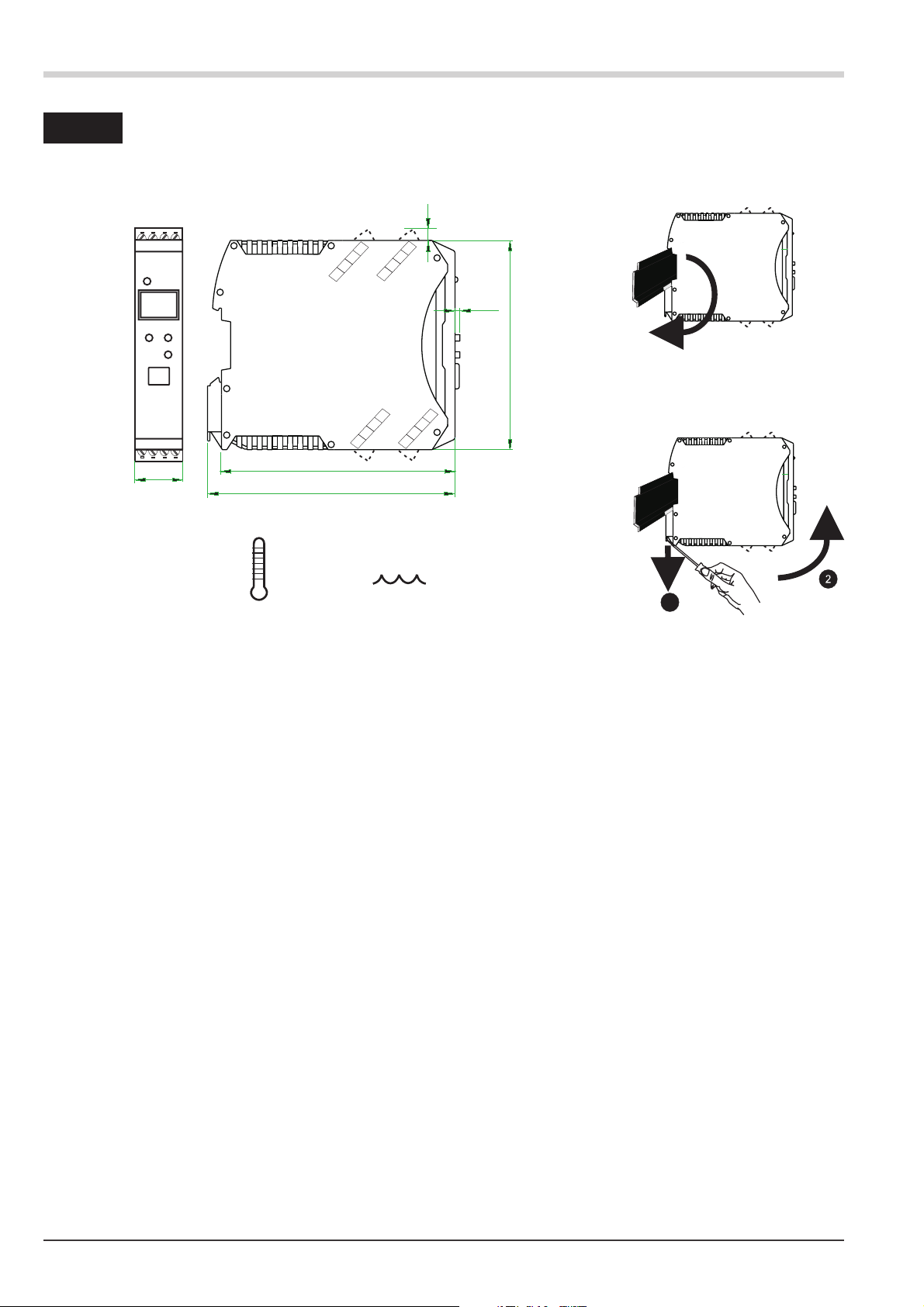

4.1 Connecting diagram

7

2

5

INP2

INP1

k

OUT3

(mV)

a

e

b

c

d

5

1

76

3

3

2

b

a

8

di1

4

3

1234

1234

a

b

c

d

e

g

mV

f

Logic

V

RS 485

RGND

Data A

Data B

top

RGND

Data A

Data B

6

h

i

j

V

12

13

11

14

PWR

1

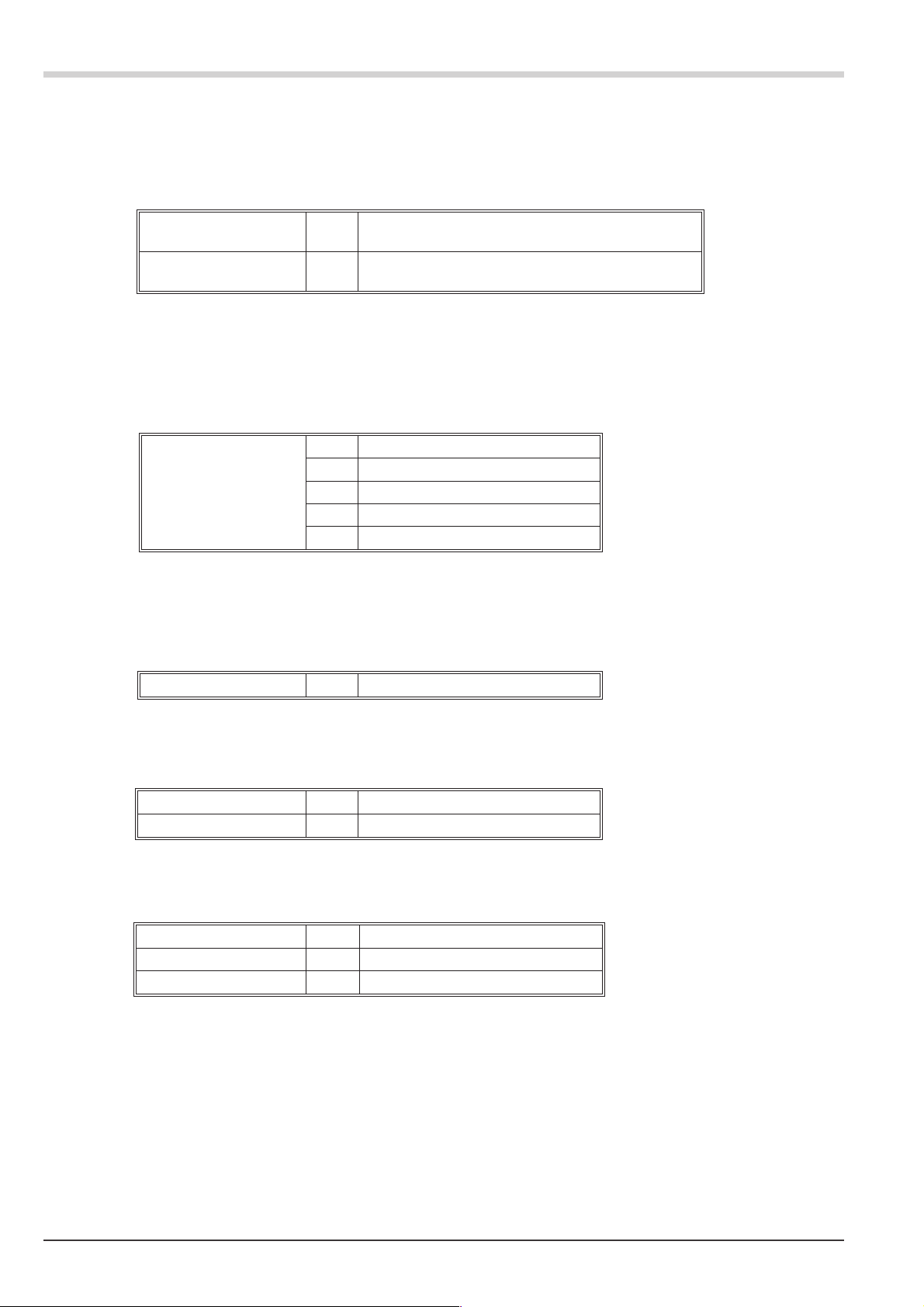

4.2 Terminal connections

a

g

Faulty connection might cause destruction of the instrument !

1 Connecting the supply voltage

Dependend on order

90 … 260 V AC terminal: 15, 16

w

24 V AC / DC terminal: 15, 16

w

For further information, see section "Technical data"

Instruments with optional system interface:

Energization is via the bus connector of field bus coupler or power supply module. Terminals 15, 16 must

not be used.

15

16

L

90...260V AC

24V AC/DC

N

17

18

OUT1

OUT2

4

11 12 13 14

11 12 13 14

15 16 17 18

15 16 17 18

10 Connecting diagram UNIFLEX CI 45

Page 11

Electrical connections

2 Connecting input INP1

Input for the measurement value

a resistance thermometer (Pt100/ Pt1000/ KTY/ ...), 3-wire connection terminal: 1, 2, 3

b resistance thermometer (Pt100/ Pt1000/ KTY/ ...), 4-wire connection terminal: 2, 3, 5, 6

c potentiometer terminal: 1, 2, 3

d current (0/4...20mA) terminal: 2, 3

e voltage (-2,5...115/-25...1150/-25...90/ -500...500mV) terminal: 1, 2

f voltage (0/2...10V/ -5...5V) terminal: 2, 4

g thermocouple terminal: 1, 3

3 Connecting input di1

Digital input,

a control input (as a contact) terminal: 7, 8

b control input (as an opto-coupler)(optional) terminal: 7, 8

c counter input (optional) terminal: 7, 8

d frequency input (optional) terminal: 7, 8

4 Connecting outputs OUT1 / OUT2 (optional)

Relay outputs max. 250V/2A NO contacts with a common terminal.

OUT1 terminal: 17, 18

w

OUT2 terminal: 17, 14

w

5 Connecting output OUT3

Universal output

h logic (0..20mA / 0..11,5V) terminal: 11, 12

i current (0...20mA) terminal: 11, 12

j voltage (-10/0...10V)) terminal: 12, 13

k transmitter power supply terminal: 11, 12

l frequency output terminal: 12, 13

6 Connecting the bus interface (optional)

RS 485 interface with MODBUS RTU protocol

* see interface description MODBUS RTU: (9499-040-72011)

7 Connecting input INP2 (optional)

Input for the second variable INP2.

a thermocouple terminal: 5, 6

b resistance thermometer (Pt100/ Pt1000/ KTY/ ...), 3-wire connection terminal: 2, 5, 6

c potentiometer terminal: 2, 5 6

d current (0/4...20mA) terminal: 2, 6

e voltage (-2,5...115/-25...1150/-25...90/ -500...500mV) terminal: 5, 6

UNIFLEX CI 45 Terminal connections 11

Page 12

Electrical connections

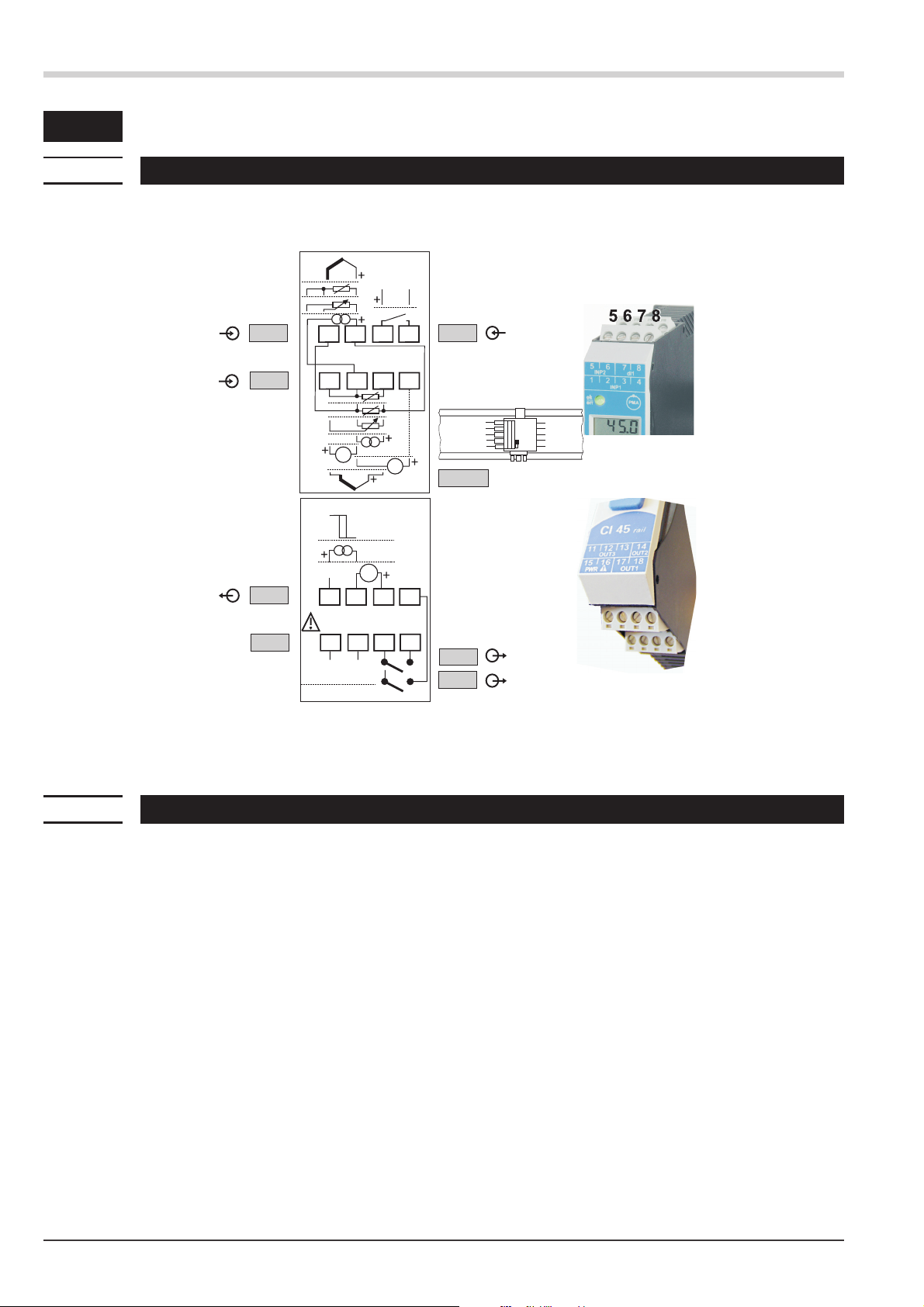

4.3 Connecting diagram

The instrument terminals used for the engineering can be displayed and printed out via BlueControlÒ( menu File \ Print

preview - Connection diagram).

Example

Connecting diagram

Connector 1

Connector 2

Name

Name

Description

Process value x1

Measurement

Frequency measurement

Description

4.4 Connection examples

Example: Signal converter with output on indicator and alarm signal

L

Frequency

Limit value 2 signalling, INP2 error signalling

Limit value 1 signalling, INP1 error signalling

5

7

6

INP2

INP1

1

8

di1

4

3

2

+

11

15

PWR

PWR

N

14

13

12

16

OUT2

18

17

OUT1

12 Connecting diagram UNIFLEX CI 45

Page 13

Example: RS 485 interface with RS 485-RS 232 converter

See documentation 9499-040-72011

RGND

3

LT 1

Data A

Data B

2

Data A

Data B

Electrical connections

Master z.B. / e.g.

Converter RS 232-RS 485

(ADAM-4520-D)

DATA+ 1

(RS-485)

LT 1

DATA-

TX+

TXRX+

RX-

(R)+Vs

(B)GND 10

(RS-422)

4.5

a

a

a

a

Hints for installation

Measurement and data lines should be kept separate from control and power supply cables.

w

Sensor measuring cables should be twisted and screened, with the screening connected to earth.

w

External contactors, relays, motors, etc. must be fitted with RC snubber circuits to manufacturer specifications.

w

The unit must not be installed near strong electric and magnetic fields.

w

The temperature resistance of connecting cables should be selected in accordance with the local conditions.

w

The unit is not suitable for installation in explosion-hazarded areas.

Faulty connection can lead to the destruction of the instrument.

The measurement inputs are designed for measurement of circuits which are not connected directly with

the mains supply (CAT I). The measurement inputs are designed for transient voltage peaks up to 800V

against PE.

Please, follow the instructions given in the safety hints.

4.5.1 cULus approval

For compliance with cULus regulations, the following points must be taken into account:

q

Use only copper (Cu) wires for 60 / 75 °C ambient temperature.

q

The connecting terminals are designed for 0,5 – 2,5 mm2Cu conductors.

q

The screw terminals must be tightened using a torque of 0,5 – 0,6 Nm.

q

The instrument must be used exclusively for indoor applications.

q

For max. ambient temperature: see technical data.

q

Maximum operating voltage: see technical data.

UNIFLEX CI 45 Hints for installation 13

Page 14

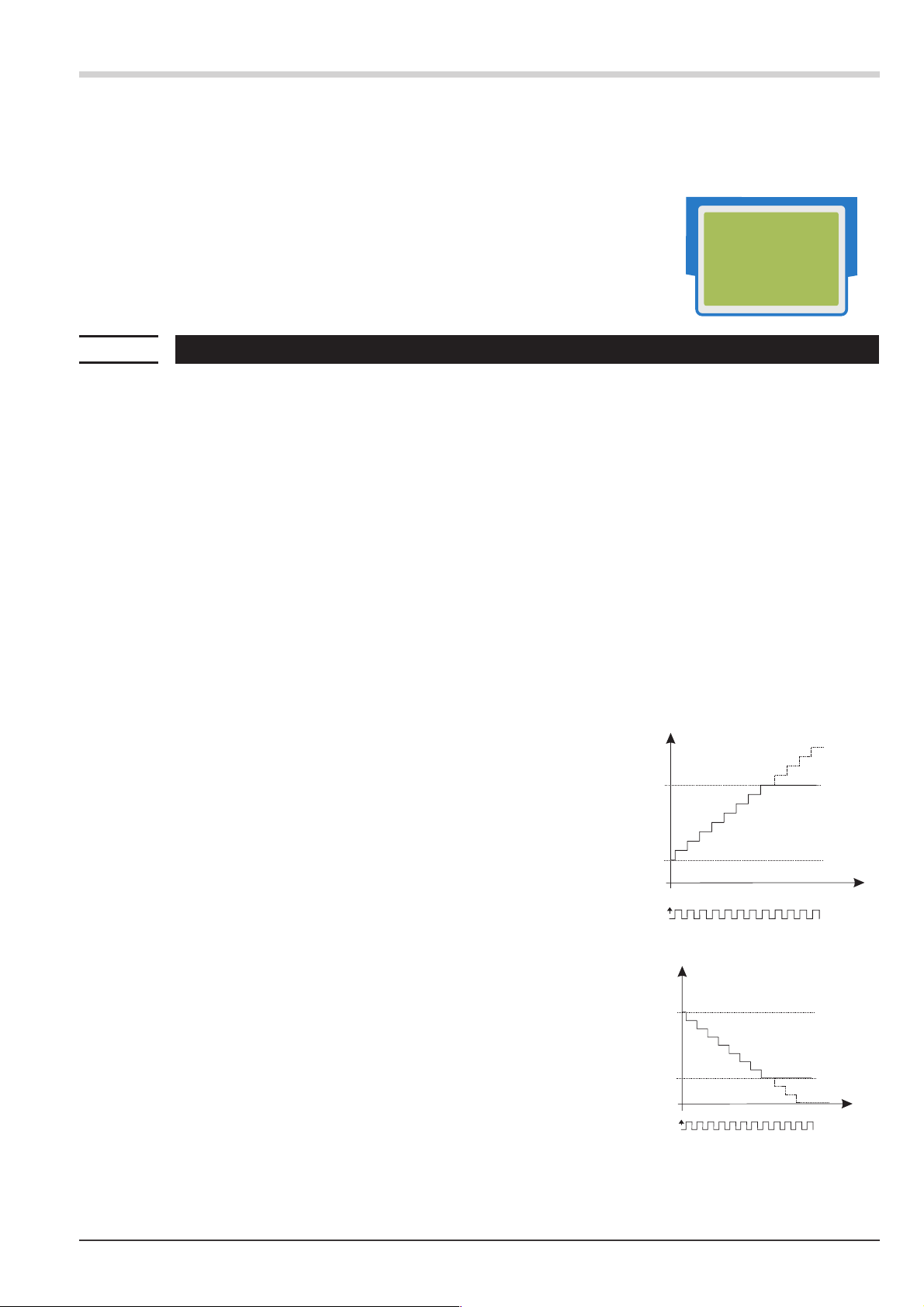

Operation

5

.

5.1 Front view

Operation

1 Line 1: process value display

2 Line 2: display of unit / extended operating level / error list /

Conf and PArA level values

3 Tare / sample & hold activated

4 Error list (2 x ô ), e.g.

· Fbf. x sensor fault INP. X

· sht. x short circuit INP. X

· Pol. x wrong polarity INP. X

· Lim. x limit value alarm

· ...

5 Increment key / slave pointer, maximum value

6 Enter key to select extended operating level or error list

7 LED indication of instrument status

· green: OK

· green blinking: no data exchange with bus coupler

(only on instruments with optional

system interface)

· red: limit value I triggered

· red blinking: instrument fault

8 Display elements, active as bars

9 Status of switching output OUT1 / INP1 active

0 Status of switching output OUT2 / INP2 active

! Decrement key / slave pointer, minimum value

§ PC connection for the BlueControl

Ò

engineering tool

g

+

14 Front view UNIFLEX CI 45

The measurement value is displayed in LCD line 1. In the second line, the selected unit is displayed as

standard. When changing over to the parameter setting, configuration or calibration level and at the

extended operating level, the parameter name and value are displayed alternately.

§ : To facilitate withdrawal of the PC connector from the instrument, please, press the cable left.

Page 15

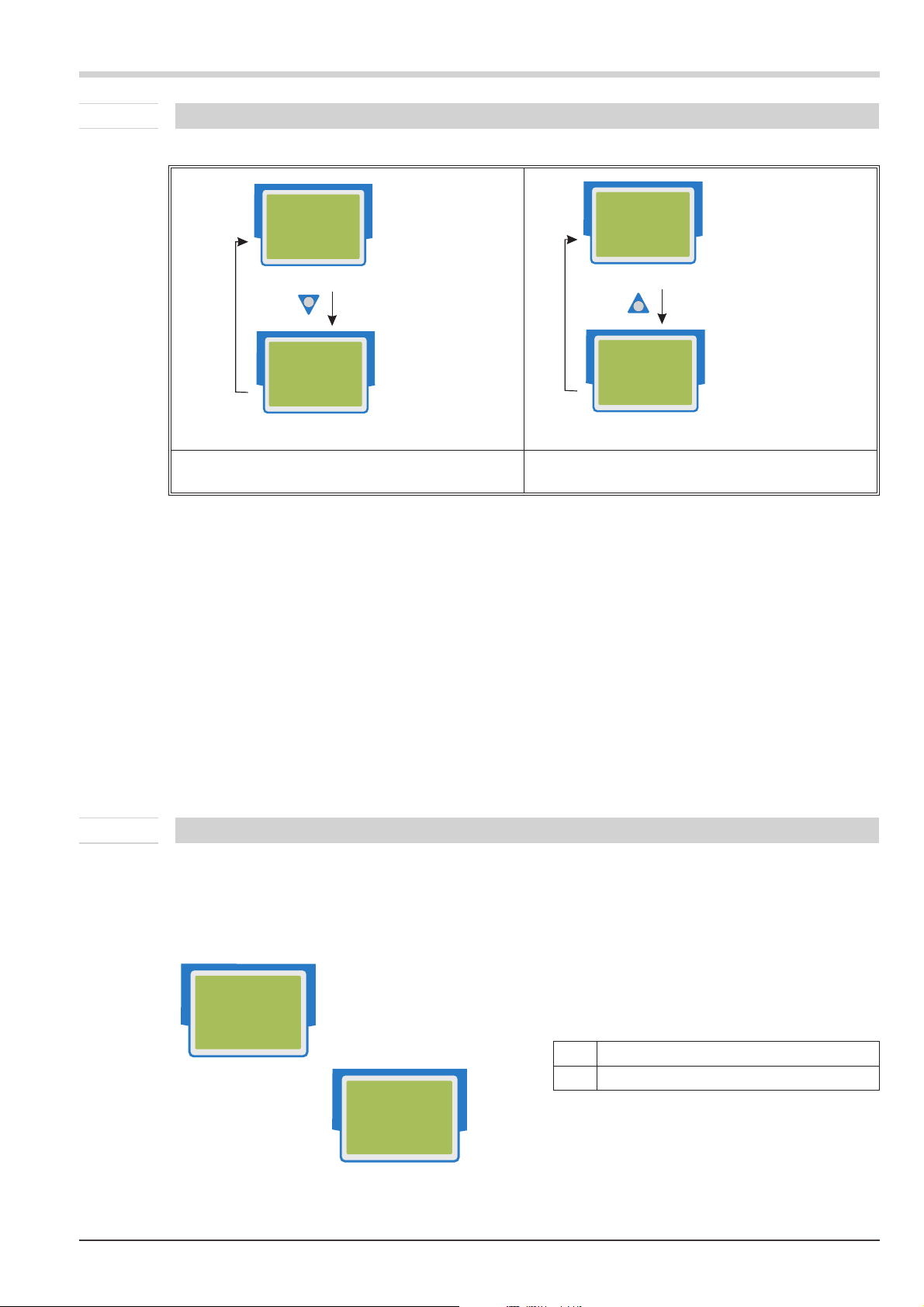

5.2 Operating structure

The instrument operation is divided into four levels:

Operation

450.3

ûC

äüüü

FE

1

2

The access to the parameter, configuration and calibrating level can be disabled using the following two methods:

Level disabling by adjustment in the engineering tool (IPar, ICnf, ICal). Display of disabled levels is suppressed.

w

ô

3s

450.3

PARA

äüüü

FE

1

2

450.3

CONF

äüüü

1

ô

FE

2

450.3

CAL

äüüü

1

ô

FE

2

450.3

END

äüüü

1

2

ô

FE

PASS

PASS

PASS

ô

Operating level

Parameter level

Configuration level

Calibrating level

The access to a level can be disabled by entry of a pass number (0 … 9999). After entry of the adjusted pass

w

number, all values of the level are available.

With faulty input, the unit returns to the operating level.

Adjusting the pass number is done via BlueControl

Individual parameters which must be accessible without pass number, or from a disabled

parameter level, must be copied into the extended operating level.

Factory-setting:

all levels are accessible without restrictions,

pass number PASS = OFF

5.3 Behaviour after supply voltage switch-on

After switching on the supply voltage, the instrument starts with the operating level.

The operating status is as before power-off.

5.4 Operating level

5.4.1 Display line1

The display value is the value resulting from function.1, function.2, function.3 handling.

It is also called process value (see also section/page 6-19.)

Ò

.

PASS

UNIFLEX CI 45 Operating structure 15

Page 16

Operation

5.4.2 Display line 2

The value to be displayed continuously in the second LCD line can be selected via the BlueControlÒengineering

tool.

As default, the adjusted engineering unit is displayed.

1

450.3

ûC

äüüü

2

FE

1

g

g

g

5.4.3 Switching over by means of the Enter key

The values in display line 2 can only be displayed, but not changed.

Reset to display of the engineering unit is possible by deleting the entry for line 2..

With faulty input values, signals dependent on the inputs (e.g. Inp1, Inp2, display value, Out3) also

indicate FAIL.

By pressing key Enter, various values can be indicated on display line 2.

450.3

äüüü

1

2

2

55.0

FE

1 Engineering unit as default setting

2 Display of output OUT3 in % (with

corresponding scaling)

1 Display of the defined display line 2 value

w

2 Display of the error list, if it includes entries.

w

3 Display of the extended operating level, if

w

4 Return to the initial display

w

(via BlueControl

Limit value LC is set by default

With several inputs, the following value is

displayed when pressing the Enter key.

entries were made. With several inputs, the

following value is displayed when pressing the

enter key.

Unless a key is pressed during 30 s, the

instrument returns to the initial display.

®

);

1

2

3

4

278.3

äüüä

1

ô

278.3

FbF.1

äüüä

12FE

ô

278.3

L.1

дььдь

1

ô

278.3

äüüä

1

°C

2FE

FE

2

°C

2FE

ô

ô

16 Operating level UNIFLEX CI 45

Page 17

5.4.4 Slave pointer function

The minimum and maximum input values are stored in the unit.

Operation

450.3

ûC

äüüü

FE

1

2

min

450.3

26.7

äüüü

FE

1

2

The minimum input value is displayed as long as key Ì is

pressed.

Deleting the minimum value

The minimum value is deleted by pressing key È whilst key Ì is kept pressed.

Whether the minimum value should be deleted also by the digital input (rES.L) can be determined during

configuration.

Deleting the maximum value

To delete the maximum value, press key Ì whilst keeping key È pressed.

Whether the maximum value should be deleted also by the digital input (rES.H) can be determined during

configuration.

The maximum input value is displayed as long as key È

is pressed.

450.3

ûC

äüüü

2

max

FE

1

450.3

502.4

äüüü

2

FE

1

Deleting the minimum and maximum values is possible also via interface.

g

g

5.4.5 Selecting the units

When de-energizing UNIFLEX CI 45, the minimum and maximum values are deleted.

In case of error of the display value (e.g. input fail behaviour), the minimum and maximum values are also

set to FAIL. When a valid value is displayed again, the minimum and maximum value are deleted.

The unit to be displayed is determined via configuration D.Unt.

With selection “1 = temperature unit” , the displayed unit is determined by configuration Unit with the relevant

conversions for Fahrenheit and Kelvin.

By selecting D.Unt = 22, display of any max. 5-digit unit or text can be determined.

4.5

kWh

äüüü

2

FE

1

1

450.3

TI451

äüüü

2

FE

1

2

1 Unit (example): kilowatt hour

2 Text (example): TAG no.

UNIFLEX CI 45 Operating level 17

Page 18

Operation

5.4.6 Extended operating level

The operation of important or frequently used parameters and signals can be allocated to the extended operating level.

This facilitates the access, e.g. travelling through long menu trees is omitted, or only selected values are operable, the

other data of the parameter level are e.g. disabled.

Display of the max. 8 available values of the extended operating level is in the second LCD line.

The content of the extended operating level is determined by means of the BlueControl

select entry "Operation level" in the "Mode" selection menu. Further information is given in the on-line help of the

engineering tool.

450.3

ûC

äüüü

2

ô

FE

1

Ò

engineering tool. For this,

Press key ô to display the first value of the extended

operating level (after display of error list, if necessary).

The selected parameters can be changed by

pressing keys Ì and È .

450.3

H.I

äüüü

2

FE

1

ô press to display the next parameter

450.3

500.0

äüüü

2

FE

1

ô

450.3

L.I

äüüü

2

ô

FE

ô return to normal display after the last parameter

1

Unless a key is pressed within a defined time (timeout = 30 s), the operating level is displayed again.

450.3

100.0

äüüü

2

FE

1

18 Operating level UNIFLEX CI 45

Page 19

Functions

6

.

Functions

The signal data flow of transmitter CI 45 is shown in the following diagram:

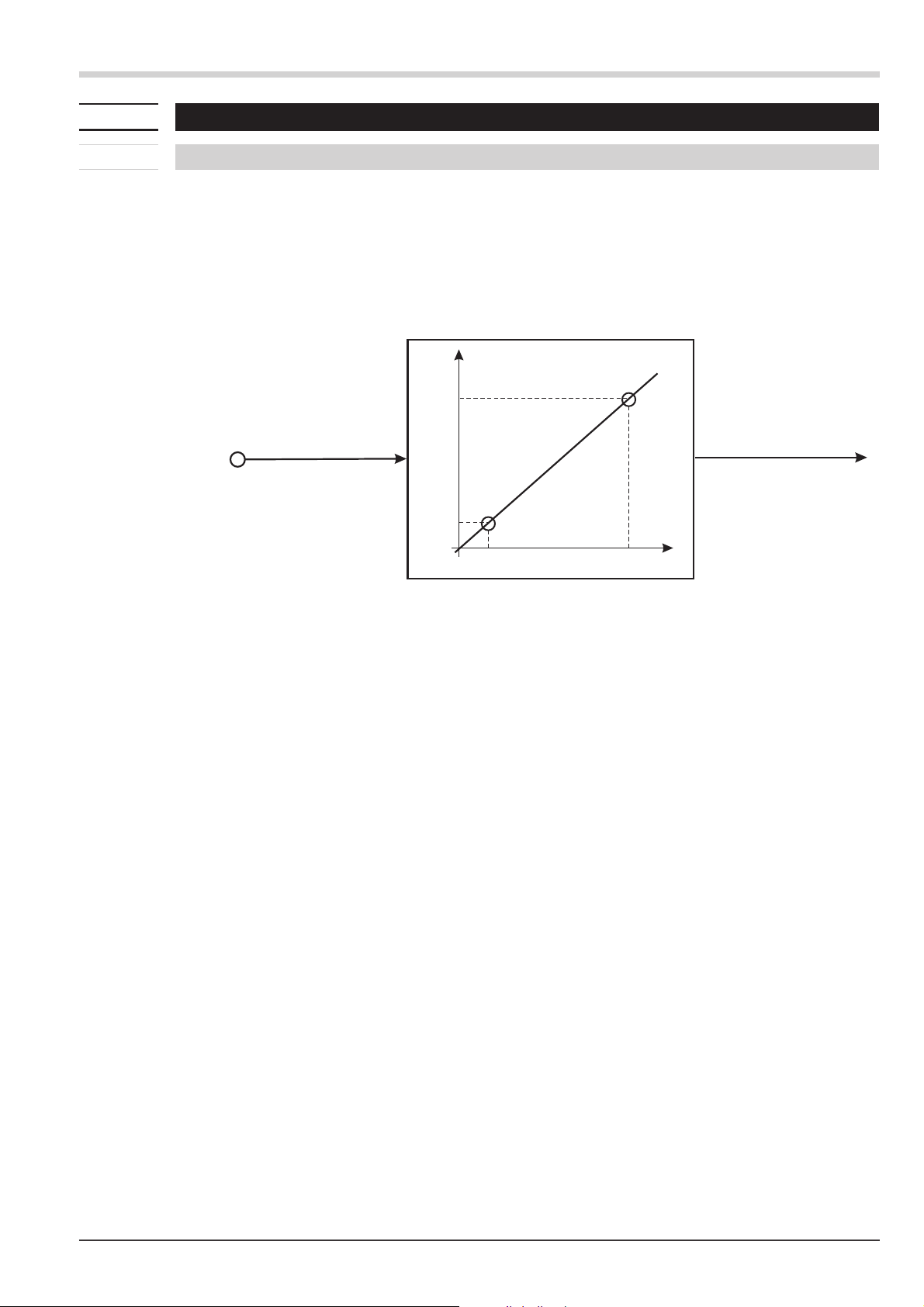

6.1 Linearization

The input values of input INP1 or INP2 can be linearized via a table.

By means of tables, e.g. special linearizations for thermocouples or other non-linear input signals, e.g. a container

filling curve, are possible.

Table “ Lin” is always used with sensor type S.TYP= 18: "Special thermocouple" in INP1 or INP2, or if linearization

S.Lin = 1: “Special linearization” are adjusted.

The input signals must be specified in mV, V, mA, % or Ohm dependent on input type.

w

For special thermocouples (S.tYP = 18), specify the input values in mV, and the output values in the temperature

w

unit adjusted in U.LinT .

For special resistance thermometer (KTY 11-6) (S.tYP = 23), specify the input values in Ohm, and the output values

w

in the temperature unit adjusted in U.LinT.

Non-linear signals can be linearized using up to 32 segment points. Each segment point comprises an input (In.1

… In.32) and an output (Ou.1 … Ou.32). These segment points are interconnected automatically by straight

lines. The straight line between the first two segment points is extended downwards and the straight line between the

two highest segment points is extended upwards, i.e. a defined output value for each input value is provided.

With an In.x value switched to OFF, all further segments are switched off.

+

g

Condition for the input values is an ascending order.

In.1 < In.2 < ...< In.32.

For linearization of special thermocouples, the ambient temperature range should be defined exactly,

becauseit is used to derive the internal temperature compensation.

See also page 46.

UNIFLEX CI 45 Linearization 19

Page 20

Functions

Ou.32

.

.

.

.

.

.

Ou.1

In.1In.32

g

The same linearization table is used for input 1 and input 2.

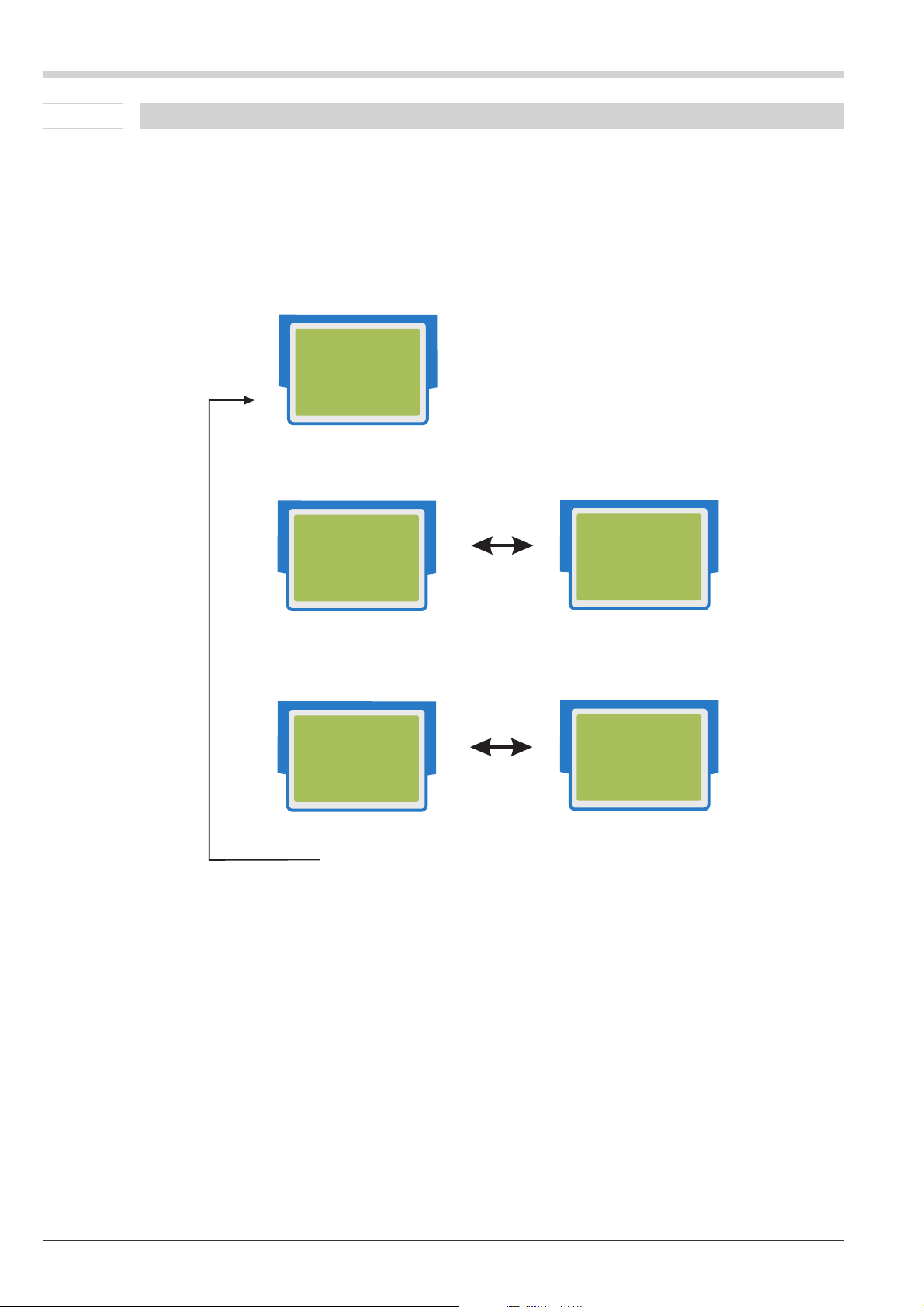

6.2 Input scaling

Scaling of input values is possible. After any linearization, measurement value correction is according to the offset or

two-point method.

g

When using current or voltage signals as input variables for InP.x, the input and display values should

be scaled at the parameter level. Specification of the input value of the lower and upper scaling point is in

units of the relevant physical quantity.

Example for mA/V

mA / V

phys.

size

OuH.x

OuL.x

InL.x

InH.x

phys. size

mA/V

g

20 Input scaling UNIFLEX CI 45

Parameters InL, OuL, InH and OuH are visible only with ConF / InP / Corr = 3 selected.

Parameters InL and InH determine the input range.

Example with mA:

InL= 4 and InH = 20 means that measuring from 4 to 20 mA is required (life zero setting).

Page 21

Functions

a

+

For using the pre-defined scaling with thermocouples and resistance thermometers (Pt100), the settings

for InL and OuL as well as for InH and OuH must correspond with each other.

For resetting the input scaling, the settings for InL and OuL as well as InH and OuH must

correspond.

6.2.1 Input fail detection

For life zero detection of connected input signals, variable adjustment of the response value for FAIL detection is

possible according to formula:

Fail response value £ In.L - 0,125 * (In.H - In.L)

Example 1: In.L = 4 mA, In.H = 20 mA Fail response value £ 2mA

Example 2: In.L =2V,In.H = 6 V Fail response value £ 1,5 V

6.2.2 Two-wire measurement

Normally, resistance and resistance thermometer measurement is in three-wire connection, whereby the resistance of

all leads is equal.

Measurement in four-wire connection is also possible for input I. With this method, the lead resistance is determined

by means of reference measurement.

With two-wire measurement, the lead resistance is included directly as a falsification in the measurement result.

However, determination of the lead resistances by means of is possible.

g

+

Besides the connection of the both leads of the RTD / R sensor the

3rd connector has to be short-circuited.

Procedure with Pt100, Pt1000

Connect a Pt100 simulator or a resistance decade instead of the sensor at

the test point so that the lead resistance is included and calibrate the

values by means of 2-point correction.

By means of measurement value correction the resulting

temperature value will be corrected, but not the resistance input

value. In this case the linearization error can increase.

Procedure with resistance measurement

Measure the lead resistance with an ohmmeter and subtract it from the

measured value via the scaling.

6.2.3 Scaling with potentiometer measurement

With potentiometer measurement (S.tYP = 50 … 53), a display value in 0% (lower stop value) to 100 % (upper stop

value) is normally expected.

For this, 2-point calibration at calibrating level (rp. 49) Is necessary.

2

INP2

INP1

1

8

5

1

76

4

3

3

2

Turn your potentiometer to the lower stop and specify value “0” for OuL.x. Now, turn the potentiometer to the upper

stop and set value OuH.x to “100”.

UNIFLEX CI 45 Input scaling 21

Page 22

Functions - preliminary -

6.3 Temperature compensation, measured via INP2 (optional)

With thermocouple measurement via INP1, the required temperature compensation is possible by internal

measurement of the compensation temperature via an external reference (external TC) or by measurement via INP2.

With TC measurement via INP2, the following settings must be done:

setting in the function for: ConF / Func / Fnc.1 = 10

•

input 1 for thermocouple input : ConF / InP.1 / S.tYP = 0 … 18

•

Switch on input 2 for measurement : ConF / InP.2 / I.Fnc = 1

•

Select suitable sensor element for input 2: ConF / InP.2 / S.tYP

•

Example:

For saving compensating cable, or unless suitable cables for special thermocouples are available, the

–

termperature at the thermocouple connecting terminal must be measured exactly by means of a resistance

thermometer (e.g. Pt100).

g

Unless input 2 is enabled for measurement, the unit generates error E.3 (configuration error).

Please, note that there may be increased errors or even polarity errors with a thermocouple measuring range starting

only at 0°C (32°F), when the outside temperature is low.

Connection example

5

7

6

INP2

INP1

1

8

di1

4

3

2

+

22 Temperature compensation, measured via INP2 (optional) UNIFLEX CI 45

Page 23

- preliminary - Functions

6.4 Filter

A 1st order mathematical filter with adjustable time constant and bandwidth is built in.

x

Output

Input

b.F

t

The filter bandwidth b.Fx is the adjustable tolerance around the measured value within which the filter is active.

Measurement value changes in excess of the adjusted bandwidth are not filtered.

6.5 Substitue value for inputs

If a substitute value for an input is activated, this value is used for further calculation with a sensor fault, independent

of the selected input function. The selected controller output reaction on sensor fault, configuration FAIL, is omitted.

With factory setting, the substitute value is switched off.

a

Before activation of a substitute value In.F, the effect on the control loop must be considered.

6.6 Input forcing

Setting f.AIx = 1 (only via BlueControl®) can be used for configuring the input for value entry via the interface

(=forcing).

a

Please, check the effect on the control loop in case of failure of input value / communication and

exceeded measuring range.

6.7 O2 measurement (optional)

This function is available only on instrument versions with INP2 .

Lambda probes (l probes) are used as input signals. The electromotive force (in volt) delivered by lambda probes is

dependent on the instantaneous oxygen content and on the temperature. Therefore, transmitter CI 45 can only display

accurate measurement results, if the probe temperature is known.

Distinction of heated and non-heated lambda probes is made.

Signals from both types can be handled by CI 45.

Heated lambda probes

Heated l probes are fitted with a controlled heating, which ensures a continuous temperature. This temperature must

be specified in parameter Probe temperature in transmitter CI 45.

Parameters ® Functions ® Pro be temperature tEmP ® ...°C (/°F/K - dependent on configuration)

Non-heated lambda probes

When the probe is always operated at a fixed, known temperature, the procedure is as with a heated probe.

UNIFLEX CI 45 Filter 23

Page 24

Functions - preliminary -

A non-heated l probe is used, if the temperature is not constant. In this case, the temperature in addition to the

probe mV value must be measured. For this purpose, any temperature measurement with analog input INP2 can be

used. During function selection, input INP2 must be set for measurement (CONF/InP.2/I.Fnc=1).

Configuration:

O

-measurement must be adjusted in function 1 :

2

g

Func r Fnc.1 7

Connection

Connect the input for the lambda probe to INP1 . Use terminals I and 2.

If necessary, temperature measurement is connected to INP2.

Input 1 is used to adjust one of the high-impedance voltage inputs as sensor type:

Inp.1r S.tYP

These high-impedance inputs are without break monitoring. If necessary, input signal monitoring is possible via the

limit values.

Further recommendations for adjustment:

Input 1 must be operated without linearization:

Inp.1r S.Lin 0

O2-measurement with constant probe temperature

(heated probe)

O2-measurement with probe temperature measurement

8

(non-heated probe)

special ( -2,5...115 mV)

41

special ( -25...1150 mV)

42

special ( -25...90 mV)

43

special ( -500...500 mV)

44

special ( -200...200 mV)

47

no linearization

g

g

With O2 measurement, specification if parameters related to the measured value should be output in ppm

or % is required. This is done centrally during configuration.

1

2

3

Unit: ppm

Unit: %

°C

°F

K

othrr O2 0

Whether the temperature of the non-heated l probe is entered in °C, °F or K can be selected during

configuration.

othrr Unit 1

24 O2 measurement (optional) UNIFLEX CI 45

Page 25

Functions

Displays

With configuration for O2 measurement (see above), the oxygen content is displayed as process value with the selected

unit (see above) on line 1. Max. 4 characters can be displayed.

With display range overflow, “EEEE” is displayed .

Example: the ppm range is selected, but the value is a % value.

When exceeding the display span start, 0 is displayed.

20.95

+

Tip: the unit can be displayed on line 2.

6.8 Counter (optional)

Digital input di1 can be configured as a counter input (dependent on ordering code).

The function operating as a pulse counter is set as

Up counter ( ConF / Cn.Fr / I.Fnc = 1, 2 )

•

Down counter ( ConF / Cn.Fr / I.Fnc = 3, 4 )

•

Active edge is configurable

•

g

a

The counter state is updated continuously in the background with the sample & hold function activated

(r p. ) .

The counter state is not stored permanently. It is reset to the counter start value (Cnt.S) after supply

voltage switch-on.

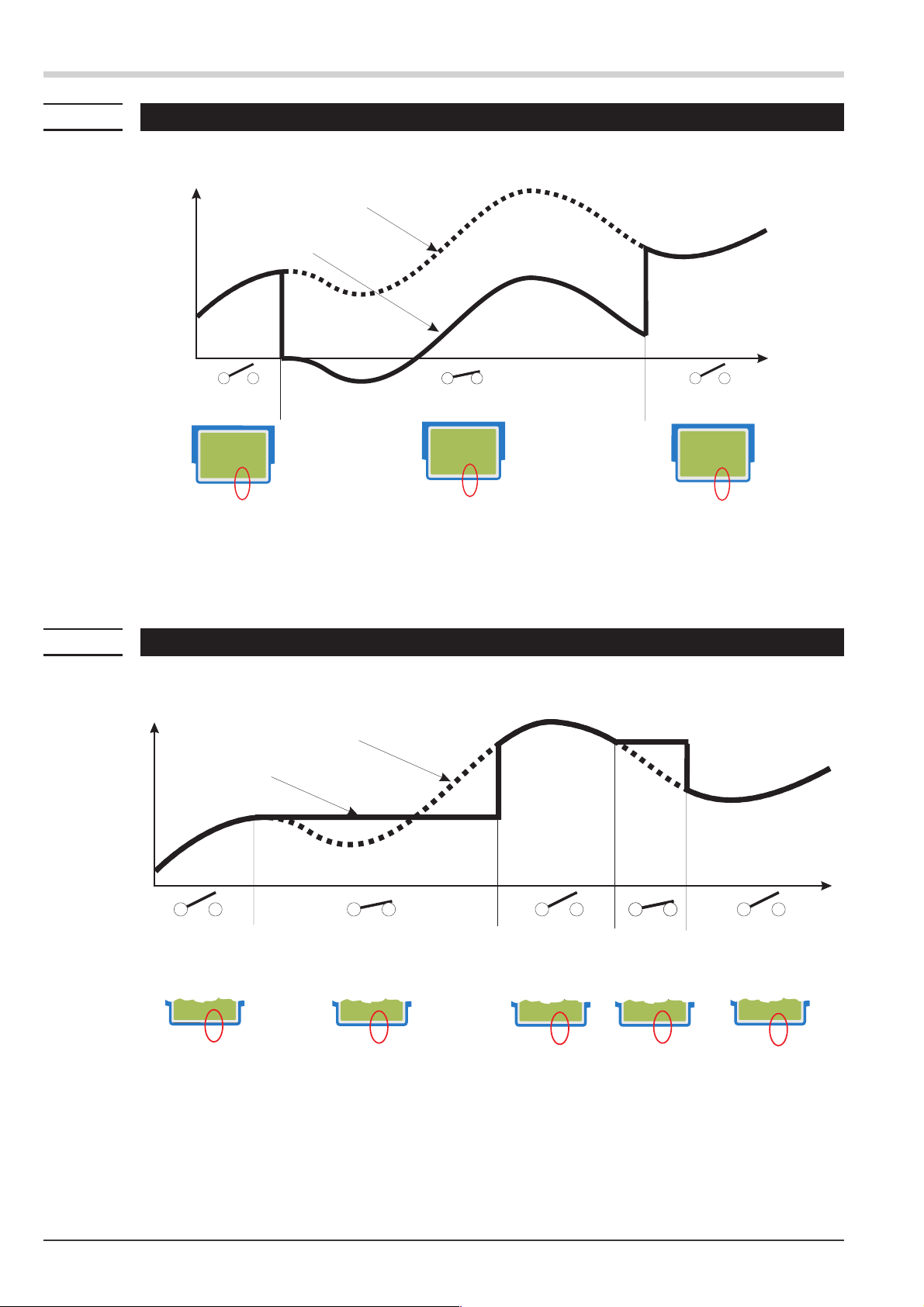

Up counter function

The counter starts with start value Cnt.S,

•

adjustable via ConF / Cn.Fr / Cnt.S.

With every edge at input di1, the counter is incremented by 1.

•

A counter end value can be defined via ConF / Cn.Fr / Cnt.E.

•

Pulses in excess are not counted.

With the counter end value switched off, incrementing is done up to

the max. coun ter value.

üû/o

cnt

Cnt.E = off

Cnt.E

g

UNIFLEX CI 45 Counter (optional) 25

Please, note that the counter end value must be higher than the

counter start value (Cnt.E > Cnt.S).

Down counter

The counter starts at counter start value Cnt.S,

•

adjustable via ConF / Cn.Fr / Cnt.S.

The counter is decremented by 1 with every edge at input di1.

•

The counter end value can be defined via ConF / Cn.Fr /

•

Cnt.E.

Pulses in excess are not counted.

With the counter end value switched off, decrementing is done down

to 0.

Cnt.S

Cnt.S

Cnt.E

cnt

Cnt.E = off

Page 26

Functions

g

+

+

Note that the counter end must be set to a lower value than the counter start (Cnt.S > Cnt.E)

Resetting the counter

The counter can be reset to the start value by

Reset via key combination Enter + increment key

w

(keep the Enter key pressed and actuate the increment key)

An activated limit value Lim1 … Lim3.

w

Tip: When resetting the counter via a limit value, cyclic counting can be realized. Thereby, a pulse divider

is created when the limit value is provided at an output.

Counter divisor

The incoming pulses can be stepped down using parameter Cnt.d . This function is used for

Scaling the display range, e.g. to prevent display overflow, or for

•

Display value dimensioning.

•

With a counter divisor of 1000.0 and integration of the least significant digits of the counter value at

extended operating level, e.g. value 9999.9999 can be displayed.

450

cnts

1

2

E

F

Example:

– Adjusted counter divisor Cnt.d = 100.0 (100 pulses increment the process value by

1)

– Line 1: process value display

– Line 2: display of the least significant digits of the counter value (Cnt.L) at extended

operating level

– Example value: 24 / 56 = 24x 100 + 56 = 2456

Display overflow

An overflow of the display range is shown by EEEE on the display. Hoverever, the unit continues incrementing until

reaching the maximum counter width.

Simulation

For simulation of the counter input in the BlueControl®engineering tool, a counter pulse can be simulated using the

checkbox of digital input di1 or via input window “Freq”. The input value must be specified in kHz.

6.9 Frequency input (optional)

Digital input di1 can be configured as a frequency input (dependent on ordering code). The frequency is a function of

the number of pulses counted during the gate time.

24

56

The display value is updated at the earliest after elapse of the gate time.

Settings:

Frequency measurement ( ConF / Cn.Fr / I.Fnc = 5 )

•

Gate time ( ConF / Cn.Fr / Frq.t)

•

+

26 Frequency input (optional) UNIFLEX CI 45

During frequency measurement, measurements can be realized, monitored and output via universal inputs

INP1 / INP2, if necessary.

Page 27

Scaling

The frequency input value can be scaled to a physical value in two points.

1st value:

input Frq.L (value specified in kHz)

–

physical value Ou.L

–

2nd value:

input Frq.H (value specified in kHz)

–

physical value Ou.H

–

Example:

5Hz = 2 l/min

20 Hz = 30 l/min

Settings: Frq.L = 0,002; Ou.L =5

Frq.H = 0,020; Ou.H =30

Filter

The frequency input value can be filtered (Parameter Frq.F).

Exceeded frequency range

Functions

g

When exceeding the frequency input range end, measurements are switched off during approx. 1 s.

Out-of-range signalling is possible via an output signal: ConF / Out.x / FAi.F =1

Simulation

A special “Freq” input window is provided for simulation of the frequency input in the BlueControl®engineering tool.

It should be specified in kHz.

6.10 Arithmetic functions

The following arithmetic functions are available in configuration setting CONF / Fnc.2 :

Square function

Formula: x

•

The display value which is squared is output.

Square root extraction

Formula: Öx

•

For output, the square root of the display value is extracted.

For values x £ 0 , value 0 is output.

2

UNIFLEX CI 45 Arithmetic functions 27

Page 28

Functions - preliminary -

6.11 Tare function (optional)

Switching on the tare function sets the instantaneous input value to zero and measurement is continued with this

offset. By switching off the tare function, the actual measurement value is displayed again.

Measurement value

Effective value

t

450.3

ûC

äüüü

FE

1

2

The tare function is enabled during configuration (Func r Fnc.3 = 1).

Dependent on configuration, the tare function can be activated by digital input di1 or interface (LOGI r

tArA).

An active tare function is displayed as an active bar for display element ‘F’ .

6.12 Sample&hold amplifier (optional)

With the sample & hold function activated, the measured value is held on the display. After de-activating the sample &

hold function, the actual measurement value is displayed again.

Measurement value

Effective value

75.9

ûC

äüäü

FE

1

2

617.2

ûC

äüüü

FE

1

2

t

450.3

ûC

äüüü

FE

1

2

The sample&hold amplifier function can be activated during configuration (Func r Fnc.3 = 2).

Dependent on configuration, the sample&hold function can be made effective via digital input di1 or via the interface

(LOGI r HOLd).

An active sample&hold amplifier function is displayed as an active bar for display element ‘F’ .

28 Tare function (optional) UNIFLEX CI 45

450.3

ûC

äüäü

FE

1

2

450.3

ûC

äüüü

FE

1

2

450.3

ûC

äüäü

FE

1

2

450.3

ûC

äüüü

FE

1

2

Page 29

6.13 Integrator function

The input signal can be totalized by means of a selectable integrator (ConF \ Func \ Fnc.3 = 3).

Function:

Integrator with adjustable time constant (PArA \ Func \ t.I) [specified in minutes] and adjustable input offset

(PArA \ Func \ P.I)

Formula:

y(t) = y(t-Tr) + Tr/t * (x +P.I)

y(t) = integrator output

y(t-Tr) = integrator output of the last cycle

Tr = cycle time (100ms INP1, 140ms INP1 + INP2)

t = time constant

x = integrator input

P.I = input offset (zero offset)

With a constant input value, the integrator output reaches the specified value after elapse of the adjusted time

g

constant t.I.

Reset:

Dependent on selection (ConF\Logi\rES.I), the integrator can be reset via:

Functions

Digital input di1

w

Key combination Enter + increment key

w

(keep the Enter key pressed and actuate the increment key)

Limit values Limit1 to Limit3

w

Example 1:

A flow in m3/h is measured. The integrator should measure the overall flow quantity. The measured flow is related to

time unit hours, i.e. time constant t.I = 1 hour = 60 min must be used. Parameter P.I can be used for zero correction.

Example 2: pulse output

The integrator is activated. The resulting process value is monitored using a limit value (without memory) , e.g. Lim1.

Lim.1 is defined as integrator reset function. Limit value Lim.1 is output e.g. on ouput 1 (OUT.1).

When exceeding limit value Lim1, there is a signal change at OUT1 during a period (100ms INP1, 140ms INP1 + INP2).

x

H.1

P. I

t (cycle)

Lim.1

Out.1

6.14 Limit value processing

Max. three limit values can be configured for the outputs. Generally, each one of outputs Out.1... Out.3 can be

used for limit value or alarm signalling. Several signals allocated to an output are linked by a logic OR function.

UNIFLEX CI 45 Integrator function 29

Page 30

Functions

6.14.1 Measured value monitoring

g

The signal to be monitored can be selected separately for each alarm in the configuration. The following

signals are available:

Process value (display value)

•

Measurement value INP1

•

Measurement value INP2 (option)

•

Counter / frequency measurement value (optional)

•

Each of the 3 limit values Lim.1 … Lim.3 has 2 trigger points H.x (Max) and L.x (Min), which can be switched off

individually (parameter = “OFF”). The hysteresis HYS.x of each limit value is adjustable.

Input value monitoring

Input value monitoring is as shown below:

Operating principle with absolute alarm (ex. Lim.1)

L.1 = OFF

Display range

Limit value 1

Outputs

-1999

H.1

H.1

HYS.1

LED rot / red

9999

H.1 = OFF

-1999

L.1

Display range

L.1

Limit value 1

HYS.1

Outputs

LED rot / red

-1999

L.1

H.1

Display range

H.1

Limit value 1

Outputs

L.1

LED

rot / red

HYS.1 HYS.1

Normally open: ( ConF / Out.x/O.Act = 0 ) (as shown in the example)

Normally closed: ( ConF / Out.x/O.Act = 1 ) (inverted output relay action)

9999

9999

LED

rot / red

30 Limit value processing UNIFLEX CI 45

Page 31

Functions

Alarm delay

An alarm can become effective with a delay: the alarm output is set only after elapse of the adjusted delay time,

provided that the limit value is still exceeded. Shorter alarms than the adjusted delay are ignored.

Example: Alarm delay

Signal change monitoring

Another limit value processing function is signal change monitoring (per minute).

Behaviour with signal change (Ex. Lim1)

L.1 = Off

x

{{x

>H.1

t

LED

rot / red

t [min]

Lim.1

{{x

>H.1

t

LED

rot / red

UNIFLEX CI 45 Limit value processing 31

Page 32

Functions

g

{{x

<L.1

t

LED

rot / red

H.1 = OFF

t [min]

x

Lim.1

With measurement value or signal change with latch selected ( ConF / Lim / Fnc.x=2, 4),

the alarm relay remains set, until the alarm was reset in the error list, via di1 or via the

interface (Lim1 ... Lim3 = 1).

For this, reset value 0 must be specified in the error list or via the interface.

g

After power on or an engineering download an used input filter has an effect on the gradient of the input

signal. Therefore a valid alarm monitoring can only be processed after a certain rise up time. This time

depends on the value of the filter time constant t.F.

For t.F = 0 the monitoring results are valid immediately.

6.14.2 Monitoring the number of operating hours and switching cycles

Operating hours

The number of operating hours can be monitored. When reaching or exceeding the adjusted value, signal InF.1 is

activated (in the error list and via an output, if configured).

The monitoring timer starts when setting limit value C.Std. Reset of signal InF.1 in the error list will start a new

monitoring timer. Monitoring can be stopped by switching off limit value C.Std.

Adjusting the limit value for operating hours C.Std can be done only via BlueControl®.

g

The current counter state can be displayed in the BlueControl

The number of operating hours is saved once per hour. Intermediate values are lost when switching off.

g

Number of switching cycles

The output number of switching cycles can be monitored. When reaching or exceeding the adjusted limit value, signal

InF.2 is activated (in the error list and via an output, if configured).

The monitoring timer starts when setting limit value C.Sch. Reset of signal InF.2 in the error list will start a new

monitoring timer. Monitoring can be stopped by switching off limit value C.Sch.

®

expert version.

A switching cycle counter is allocated to each output. Limit value C.Sch acts on all switching cycle counters.

g

Adjusting the limit value for the number of switching cycles C.Sch can be done only via BlueControl®.

g

The current counter state can be displayed in the BlueControl

The number of switching cycles is saved once per hour. When switching off, intermediate values are lost.

g

32 Limit value processing UNIFLEX CI 45

®

expert version.

Page 33

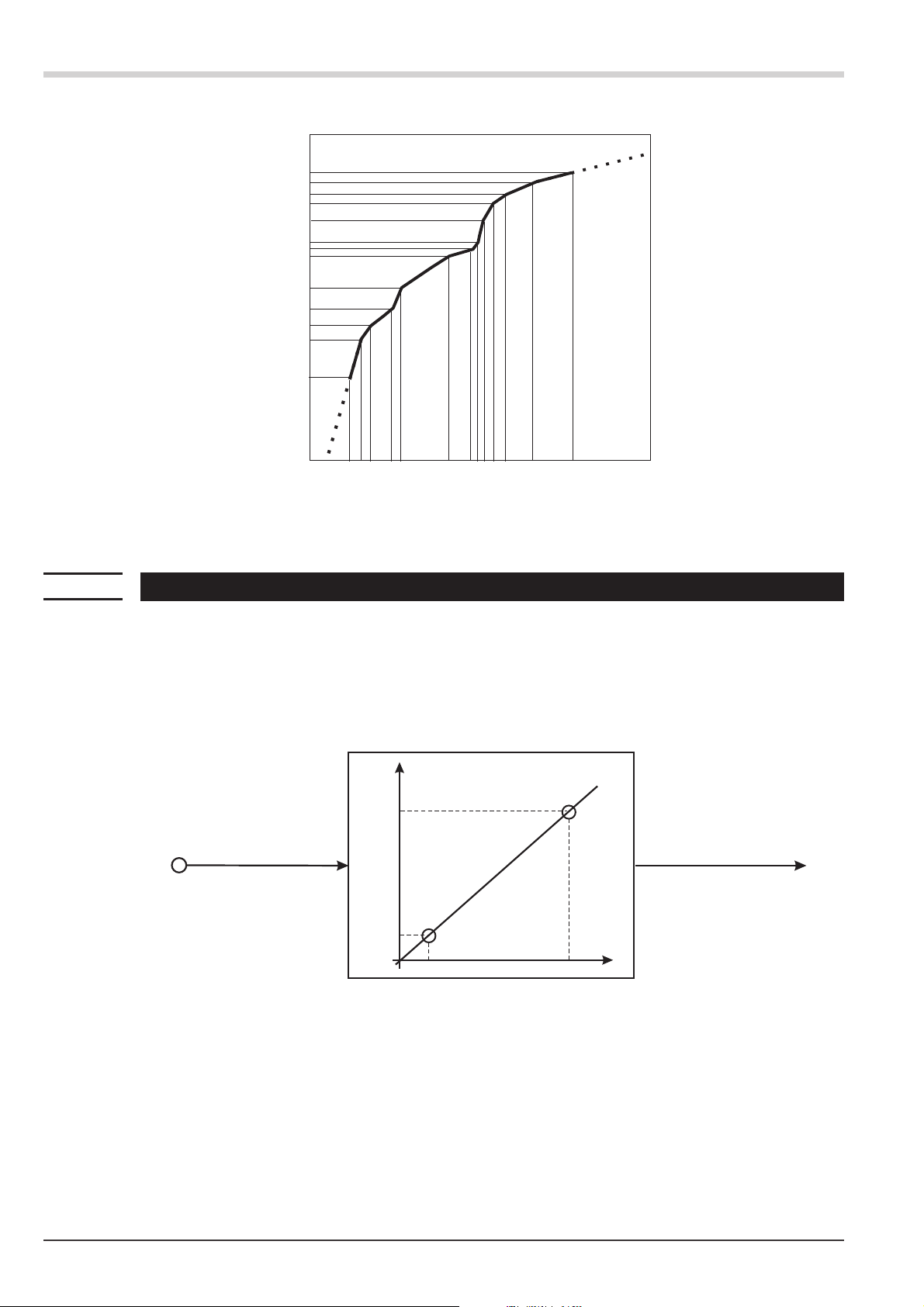

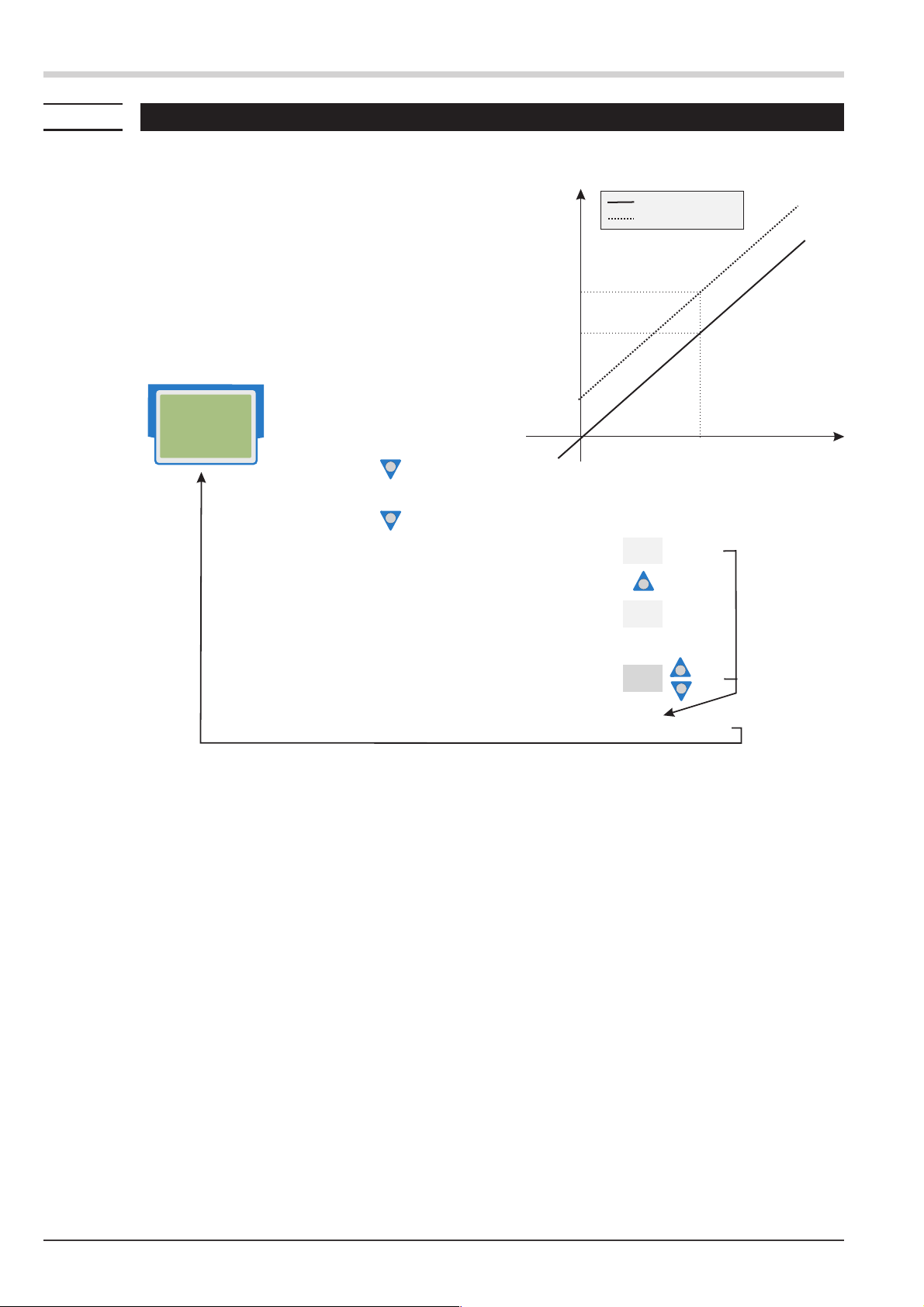

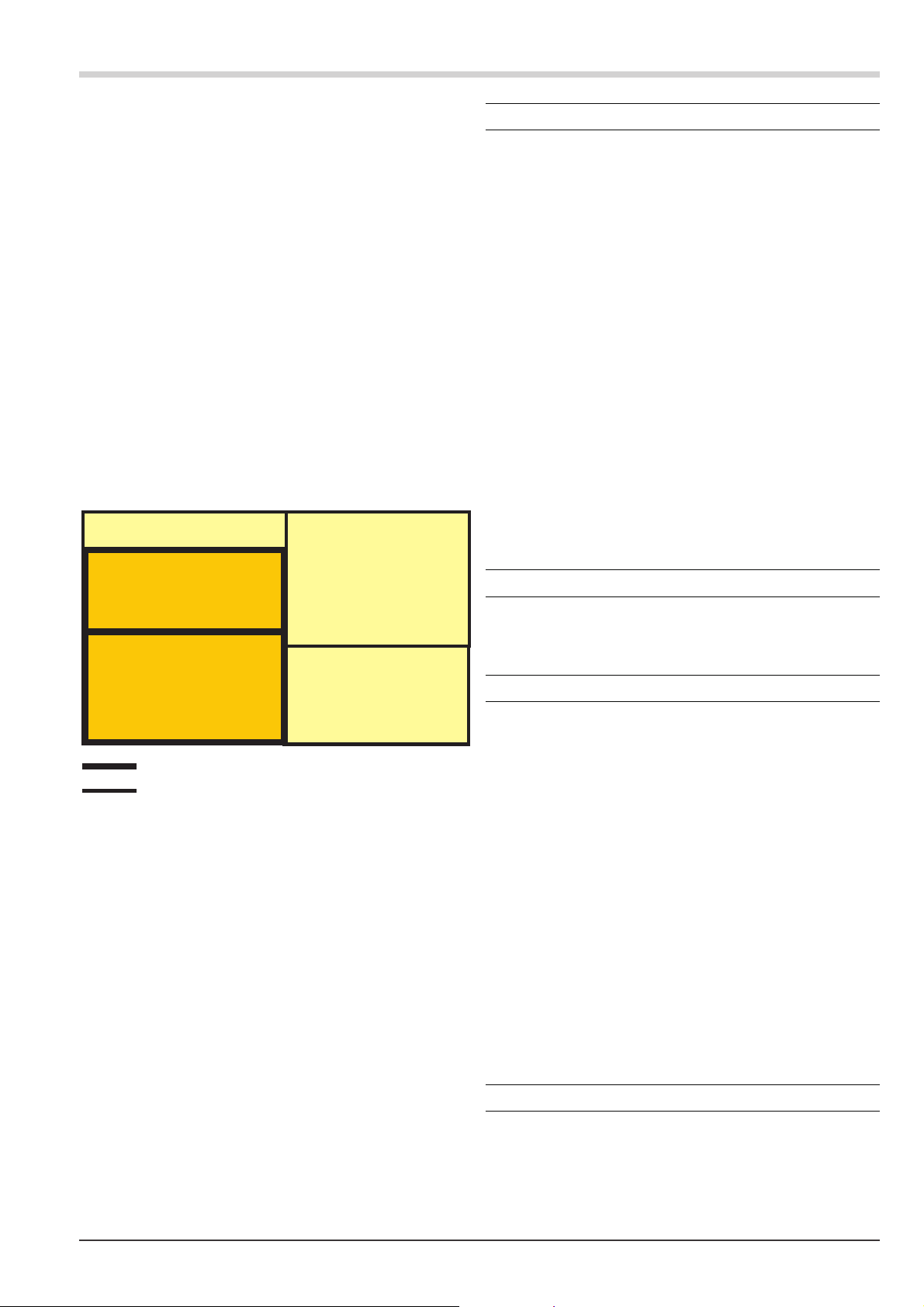

6.15 Analog output configuration

6.15.1 Analog output

The two output signals (current and voltage) are available simultaneously. Adjust ConF / Out.3 / O.tYP to

select the output type which should be calibrated.

ConF / Out.3: O.tYP = 1 Out.3 0...20mA continuous

= 2 Out.3 4...20mA continuous

= 3 Out.3 0...10V continuous

= 4 Out.3 2...10V continuous

phys.

size

Out.1

Functions

phys. size

Out.0

0/4mA

0/2V

Parameter O.Src defines the signal source of the output value.

Example:

O.Src = 3 signal source for Out.3 is

Scaling of the output range is done via parameters Out.0 and Out.1. The values are specified in units of the

physical quantity.

Out.0 = -1999...9999 scaling Out.3

Out.1 = -1999...9999 scaling Out.3

Example: output of the full input range of thermocouple type J (-100 … 1200 °C)

Out.0 = -100

Out.1 = 1200

Example: output of a limited input range, e.g. 60.5 … 63.7 °C)

Out.0 = 60.5

Out.1 = 63.7

20mA

10V

the process value

for 0/4mA or 0/2V

for 20mA or 10V

mA / V

+

g

g

g

UNIFLEX CI 45 Analog output configuration 33

Please, note: the smaller the span, the higher the effect of input variations and resolution.

Using current and voltage output in parallel is possible only in galvanically isolated circuits.

Configuration O.tYP = 2 (4 … 20mA) or 4 (2...10V) means only allocation of the reference value (4 mA or 2V)

for scaling of output configuration Out.0. Therefore, output of smaller values is also possible rather than

output limiting by reference value 4mA / 2V.

Configuration O.tYP = 0/1 (0/4...20mA) or 2/3 (0/2...10V) determines, which output should be used as a

calibrated reference output.

Page 34

Functions

6.15.2 Logic output

The output can be used also as a logic output (O.typ = 0). In this case, e.g. alarms or limit values can be output.

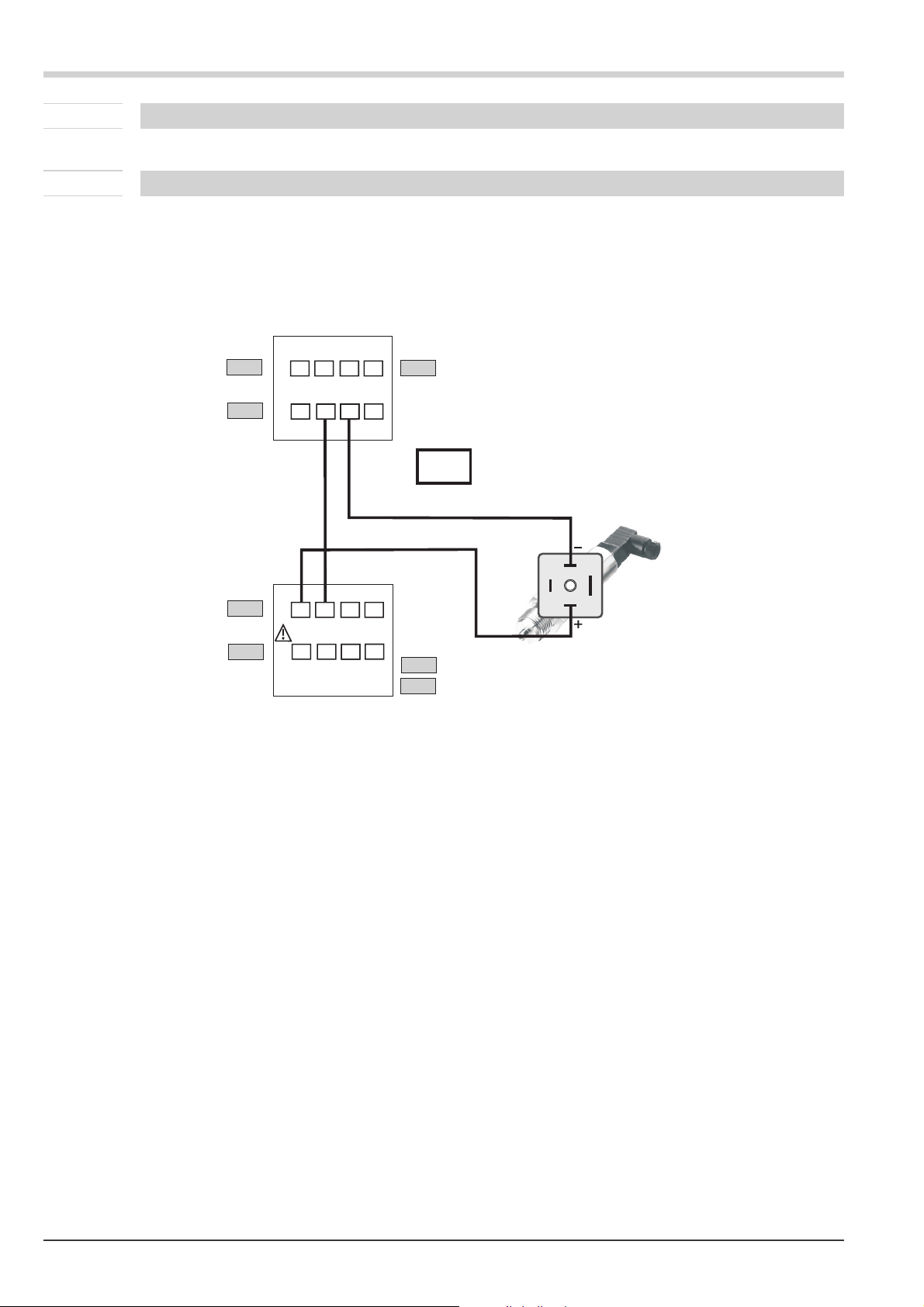

6.15.3 Transmitter power supply

Two-wire transmitter power supply can be selected by adjusting O.typ =5.

In this case, the analog output of UNIFLEX CI 45 is not available any more, but the input signal can be monitored or

read out via the interface.

Connection example:

INP2

INP1

OUT3

PWR

8

5

1

76

3

3

2

+

-

di1

4

13V

22mA

2

-

+

12

13

17

14

18

OUT1

OUT2

11

15

16

3

K

1

34 Analog output configuration UNIFLEX CI 45

Page 35

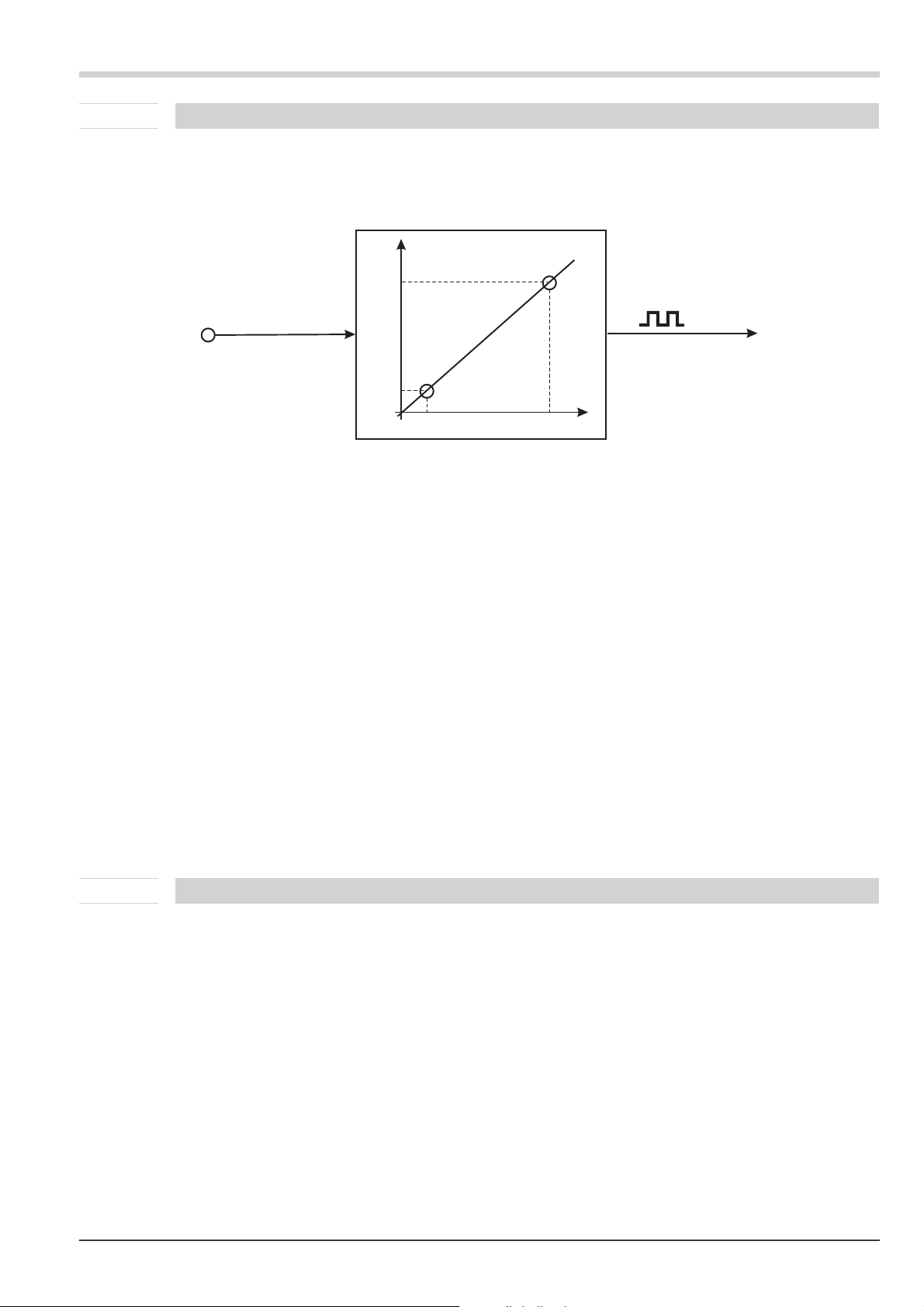

6.15.4 Frequency output (optional)

The analog output signal for voltage can be selected also as a frequency output with setting:

ConF / Out.3: O.tYP = 6 Out.3 0...10V frequency output

Frq.H

Functions

f[Hz]

Quelle

source

Frq.L

Out.L

Setting O.Src defines the signal source of the frequency output value.

Example: O.Src = 3 signal source for Out.3 is the process value

Output range scaling is done via parameter pairs Out.L/ FrQ.L and Out.H/ FrQ.H. Values Out.L and

Out.H are specified in physical units, FrQ.L and FrQ.H are specified in Hz.

Example:

20°C = 5Hz

200°C = 500 Hz

Settings: Ou.L = 20; Frq.L = 5,0

Ou.H = 200; Frq.H = 500,0

The output behaviour in case of input value error can be defined via O.FAI .

Out.H

phys. Größe

phys. size

(V)

g

g

Please, note that the lower the span the higher the effect of input variations and resolution steps

Signals exceeding the permissible frequency range cause deviations from the square shape of frequency

waves.

6.15.5 Analog output forcing

By adjusting f.Out = 1 (only via BlueControl), the output can be configured for value input via interface, or by means of

an input value at extended operating level (=Forcing).

g

g

This setting can be used also for e.g. testing the cables and units connected in the output circuit.

This function can also realize a setpoint potentiometer.

UNIFLEX CI 45 Analog output configuration 35

Page 36

Functions

2

6.16 Maintenance manager / error list

In case of one or several errors, the error list is always displayed at the

beginning of the extended operating level .

A current input in the error list (alarm or error) is always indicated by display of

letter E .

450.3

ûC

For display of the error list, press key ô once.

E- display element Signification Further procedure

blinks Alarm is pending, error - The error number in the error list indicates the error type

-Remove the error.

on Error was removed, alarm not

acknowledged

off No error, all alarm entries are deleted

Error list:

Name Description Cause Possible remedial action

E.1 Internal error,

cannot be corrected

E.2 Internal error, resettable E.g. EMC trouble Keep measuring and supply cables

E.3 Configuration error,

resettable

E.4 Hardware error Code number and hardware not

FbF.1 INP1 sensor break Defective sensor

Sht.1 INP1 short circuit Defective sensor

POL.1 INP1 polarity error Wiring error Change INP1 polarity

FbF.2 INP2 sensor break Defective sensor

Sht.2 INP2 short circuit Defective sensor

POL.2 INP2 polarity error Wiring error Change INP2 polarity

Lim.1 Latched limit value alarm 1 Adjusted limit value 1 exceeded Check process

Lim.2 Latched limit value alarm 2 Adjusted limit value 2 exceeded Check process

Lim.3 Latched limit value 3 Adjusted limit value 3 exceeded Check process

Inf.1 Time limit value message Preset number of operating hours

Inf.2 Switching cycle message

(digital outputs)

E.g. defective EEPROM Contact PMA service

Missing or faulty configuration Check interdependencies for

identical

Wiring error

Wiring error

Wiring error

Wiring error

reached

Preset number of switching

cycles reached

- Acknowledge the error in the error list by pressing

È or Ì - key.

- The alarm entry is deleted.

Return instrument to manufacturer

separate. Protect contactors by means of

RC snubber circuits

configurations and parameters

Contact PMA service

Replace electronics/options card

Replace INP1 sensor

Check INP1 connection

Replace INP1 sensor

Check INP1 connection

Replace INP2 sensor

Check INP2 connection

Replace INP2 sensor

Check INP2 connection

Application-specific

Application-specific

äüüä

1

FE

36 Maintenance manager / error list UNIFLEX CI 45

Page 37

Functions

1

g

g

g

Latched alarms Lim1/2/3 (E element displayed) can be acknowledged, i.e. reset via digital alarm di1.

For Configuration, see page 46: ConF / LOGI / Err.r

When an alarm is still pending, i.e. unless the error cause was removed ( E display blinks), latched alarms

cannot be acknowledged and reset.

Error-state Signification

2 Pending error Change to error status 1after error removal

1 Stored error Change to error status 0 after acknowledgement in error list 0

0 no error/message Not visible, except during acknowledgement

If sensor errors should not be on the error list any more after error correction without manual reset in the

error list, suppression via BlueControl is possible by means of setting ILat.

CONF / othr / ILat 1

This setting is without effect on limit values Lim.1 … 3 configured for storage.

6.17 Reset to factory setting

In case of faulty configuration, UNIFLEX CI 45 can

be reset to its factory setting.

blocked

g

g

g

For this, the operator must keep the keys

Ü

increment and decrement pressed during

power-on.

*

For confirmation, press key increment to

select

YES

Ö

Confirm factory resetting with Enter and the

copy procedure isl started (display COPY).

ä

Afterwards the device restarts.

In all other cases, no reset will occur(timeout

abortion).

If one of the operating levels was blocked,

reset to factory setting is not possible.

If a pass number was defined (via

BlueControl

blocked, enter the correct pass number

when prompted in 3. A wrong pass numbers

aborts the reset action.

The copy procedure (COPY) can take some

seconds.

Now, the transmitter is in normal operation.

®

) but no operating level was

2

3

+ Power on

FAC

torY

FAC

no

FAC

yEs

ô

FAC

COPY

8.8.8.8

#:#:#:#:#

ääää

4

UNIFLEX CI 45 Reset to factory setting 37

Page 38

Configuration level

7

.

Configuration level

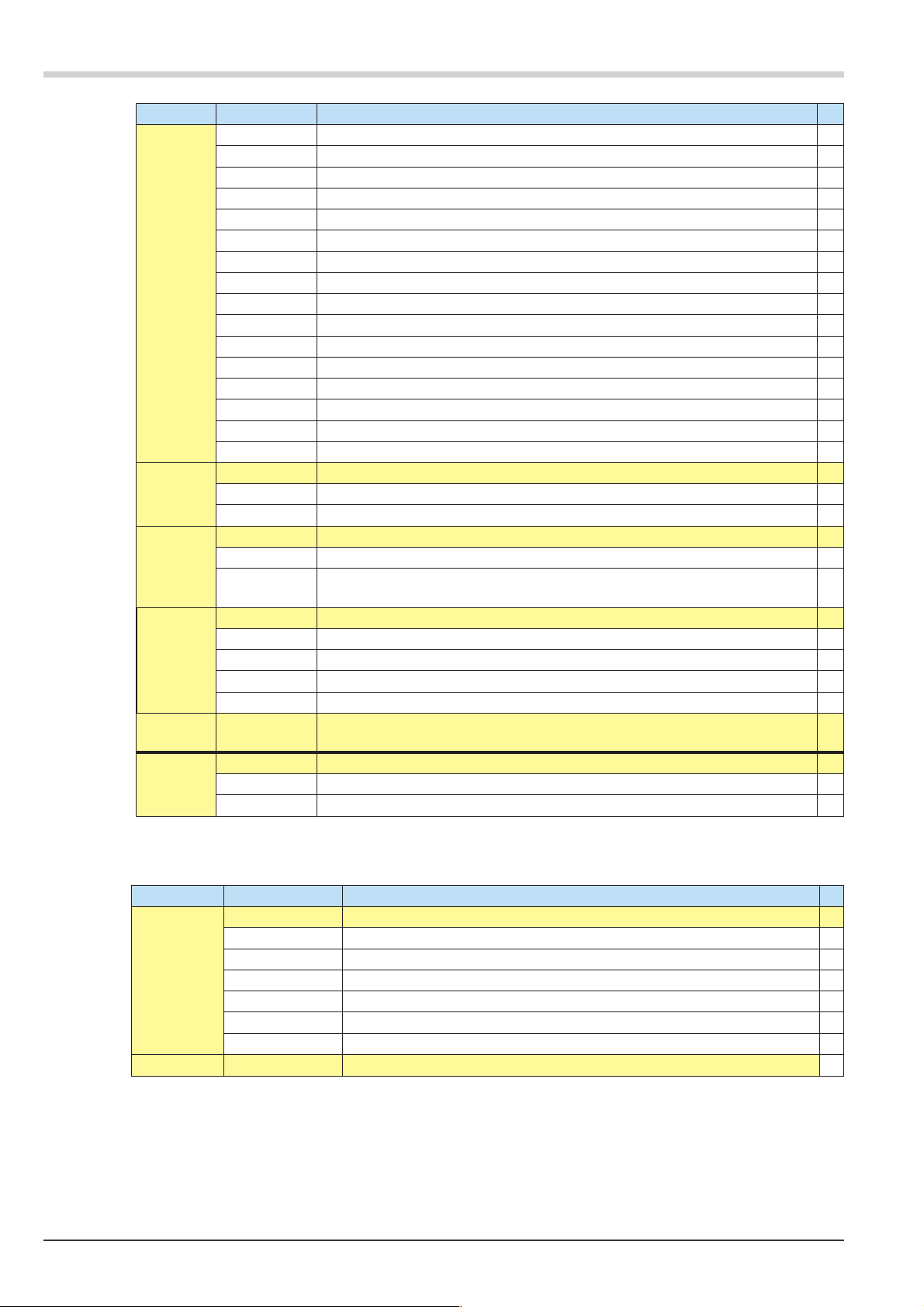

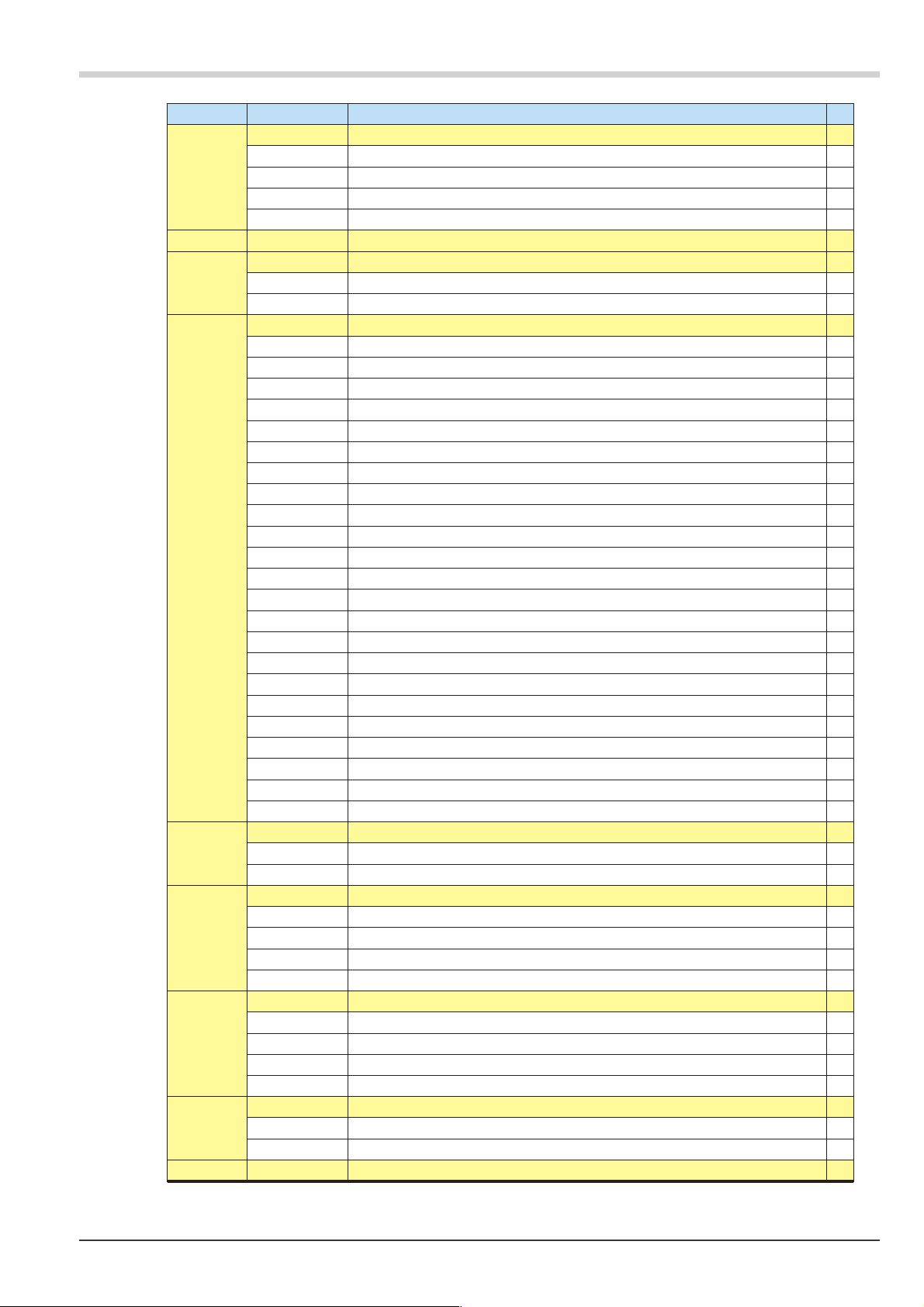

7.1 Configuration survey

Dependent on the device version and further adjusted configurations, configurationdata can be hidden.

Data operable via the instrument front panel are shown in the following figure.

ô

ô

Fnc.1

Fnc.1

Fnc.2

Fnc.2

Fnc.3

Fnc.3

ô

ô

s

s

t

t

Inp.1

Inp.1

ô

ô

StYP

StYP

4wir

4wir

S.Lin

S.Lin

Corr

Corr

In.F

In.F

ô

ô

s

s

t

t

Inp.2

Inp.2

ô

ô

I.Fnc

I.Fnc

StYP

StYP

S.Lin

S.Lin

Corr

Corr

In.F

In.F

ô

ô

t

t

s

s

Lim OUt.1 OUt.2

Lim OUt.1 OUt.2

Fnc.1

Fnc.1

Src.1

Src.1

Fnc.2

Fnc.2

Src.2

Src.2

Fnc.3

Fnc.3

Src.3

Src.3

t

t

s

s

ô

ô

ô

ô

ô

ô

0.Act

0.Act

Lim.1

Lim.1

Lim.2

Lim.2

Lim.3

Lim.3

FAi.1

FAi.1

FAi.2

FAi.2

ô

ô

s

s

t

t

ô

ô

0.Act

0.Act

Lim.1

Lim.1

Lim.2

Lim.2

Lim.3

Lim.3

FAi.1

FAi.1

FAi.2

FAi.2

ô

ô

s

s

t

t

OUt.3

OUt.3

ô

ô

O.tYP

O.tYP

0.Act

0.Act

Lim.1

Lim.1

Lim.2

Lim.2

Lim.3

Lim.3

FAi.1

FAi.1

FAi.2

FAi.2

Out.0

Out.0

Out.1

Out.1

O.src

O.src

s

s

t

t

LOGI

LOGI

ô

ô

di.Fn

di.Fn

L_r

L_r

Err.r

Err.r

I.ChG

I.ChG

tArA

tArA

HOLd

HOLd

rES.L

rES.L

rES.H

rES.H

ô

ô

s

s

t

t

othr

othr

ô

ô

bAud

bAud

Addr

Addr

PrtY

PrtY

dELY

dELY

d.Unt

d.Unt

02

02

Unit

Unit

dP

dP

SEGm

SEGm

C.dEL

C.dEL

s

s

t

t

EndFunc

End

EndFunc

End

ô

ô

g

g

ô

O.FAI

O.FAI

ô

ô

Setting:

The configurations can be adjusted by means of keys ÈÌ .

•

Transition to the next configuration element is by pressing key ô .

•

After the last configuration of a group, donE is displayed and an automatic change to the next group is made.

•

Return to the start of a group is by pressing key ô during 3 sec.

With configuration changes, please, check all dependent parameters for validity.

ô

38 Configuration survey UNIFLEX CI 45

Page 39

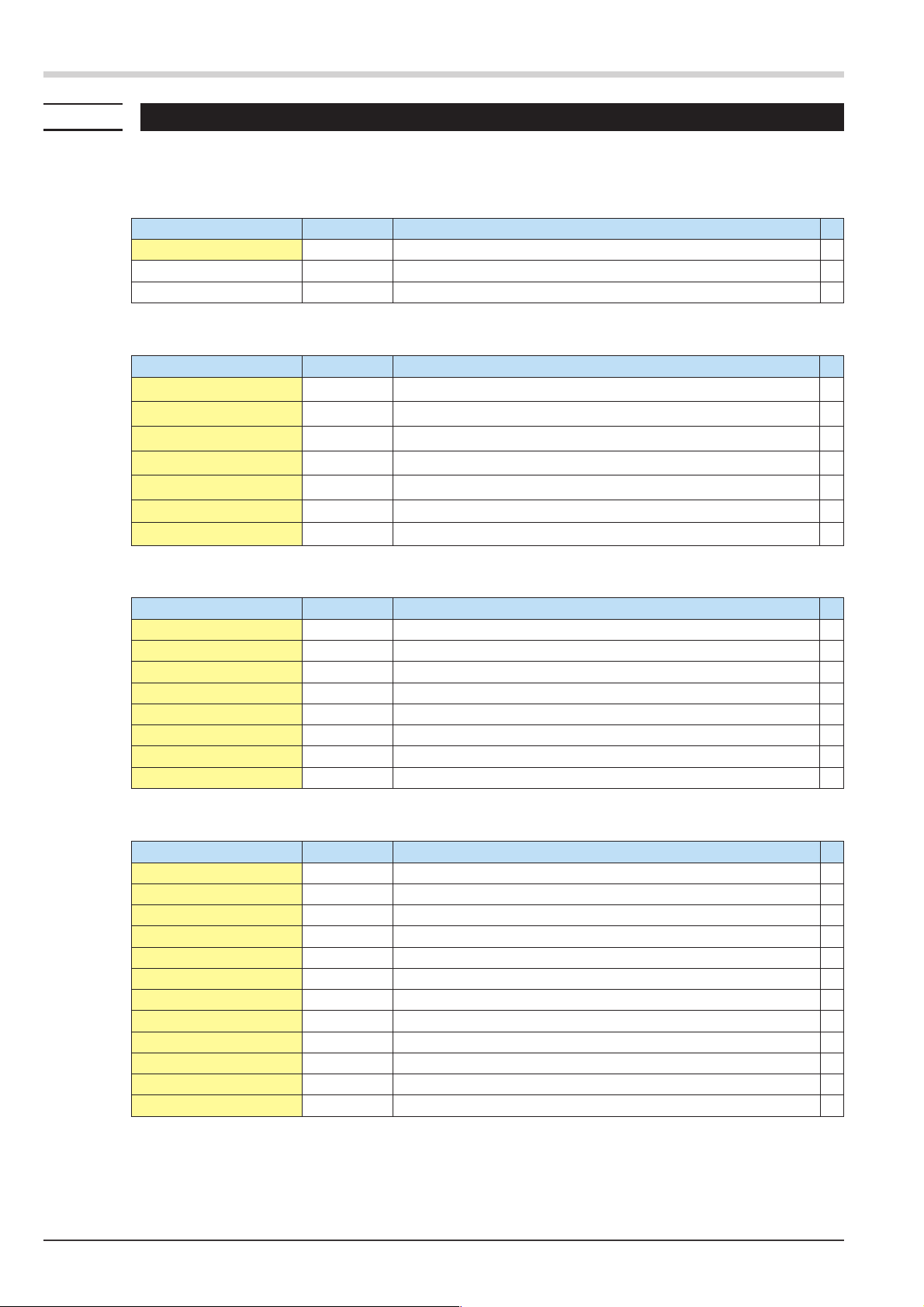

7.2 Configurations

Dependent on instrument version and configuration settings, display of values which are not required is suppressed.

µ The entries marked with this symbol are selectable only, if the instrument option is fitted.

Function selection Func

Name Value range Description

Fnc.1

Fnc.2

Fnc.3

Function 1 µ

0 Process value = INP1

2 Difference (INP1 -INP2)

3 Max (INP1, INP2)

4 Min (INP1, INP2)

5 Mean value (INP1, INP2)

6 Switch-over (INP1, INP2)

7O

8O

9 Counter / frequency

10 Process value = INP1 ( TC of INP2)

0 No function

1 Squarer

2 Square root

0 No function

1 Tare

2 Sample & Hold

-Function with constant probe temperature

2

-Function with measured probe temperature

2

Function 2

Function 3 µ

Configuration level

Inputs InP.1 and InP.2 (µ)

Name Value range Description

I.Fnc

0 No measurement

1 measurement

S.tYP

0 Thermocouple type L (-100...900°C), Fe-CuNi DIN

1 Thermocouple type J (-100...1200°C), Fe-CuNi

2 Thermocouple type K (-100...1350°C), NiCr-Ni

3 Thermocouple type N (-100...1300°C), Nicrosil-Nisil

4 Thermocouple type S (0...1760°C), PtRh-Pt10%

5 Thermocouple type R (0...1760°C), PtRh-Pt13%

6 Thermocouple type T (-200...400°C), Cu-CuNi

7 Thermocouple type C (0...2315°C), W5%Re-W26%Re

8 Thermocouple type D (0...2315°C), W3%Re-W25%Re

9 Thermocouple type E (-100...1000°C), NiCr-CuNi

10 Thermocouple type B (0/100...1820°C), PtRh-Pt6%

18 Special thermocouple (linearization necessary)

20 Pt100 (-200.0 ... 100,0 °C) (150°C with reduced lead resistance)

21 Pt100 (-200.0 ... 850,0 °C)

22 Pt1000 (-200.0...850.0 °C)

23 Special 0...4500 Ohm (preset KTY11-6)

Input function (µ with 2nd universal input only )

Sensor type

UNIFLEX CI 45 Configurations 39

Page 40

Configuration level

Name Value range Description

4wir

S.Lin

Corr

In.F

fAI1

(fAI2)

24 Special 0...450 Ohm

25 Special 0...1600 Ohm

26 Special 0...160 Ohm

30 0...20mA / 4...20 mA

40 0...10V / 2...10 V (Inp.1 only)

41 Special (-2,5...115 mV)

42 Special (-25...1150 mV)

43 Special (-25...90 mV)

44 Special (-500...500 mV)

45 Special (-5...5 V) (Inp.1 only)

46 Special (-10...10 V) (Inp.1 only)

47 Special (-200..200 mV)

50 Potentiometer 0...160 Ohm

51 Potentiometer 0...450 Ohm

52 Potentiometer 0...1600 Ohm

53 Potentiometer 0...4500 Ohm

Resistance connection type (Inp.1 only)

0 3-wire connection

1 4-wire connection

Linearization only adjustable with S.tYP:18, 23 ... 47

0 none

1 Special linearization. Producing a linearization table is possible via BlueControl

(Engineering-Tool). Preset is the characteristic for KTY 11-6 temperature sensors.

Measured value correction / scaling

0 No correction

1 Offset correction (at CAL -level)

2 2-point correction (at CAL -level)

3 Scaling (at PArA -level)

OFF,

-1999...9999

0 Not active

1 The value for this analog input is preset via interface

Substitute value in case of a fault. This value is used for calculations, if there is a

fault at the input (e.g. FAIL).

Forcing of analog input INP1, INP2 µ (only visible with BlueControl!)

Counter / frequency input µ

Name Value range Description

I.Fnc

0 Control input

1 Up counter, positive edge

2 Up counter, negative edge

3 Down counter, positive edge

4 Down counter, negative edge

5 Frequency measurement

Frq.t

40 Configurations UNIFLEX CI 45

0,1…20 Frequency gate time [s] µ

Function selection µ

Page 41

Limit values Lim1 … Lim3

Name Value range Description

Fnc.1

(Fnc.2)

(Fnc.3)

0 Switched off

1 Measured value monitoring

2 Measured value monitoring + alarm status latch. A stored limit value can

3 Signal change (in minutes).

4 Signal monitoring for rate of change (per minute) + storage of the alarm

Src.1

(Src.2)

(Src.3)

C.Std OFF; 1 … 9999999 Monitoring operating hour (only visible with BlueControl!)

C.Sch OFF; 1 … 9999999 Monitoring duty cycle (only visible with BlueControl!)

0 Process value= displayed value

3 Measured value of the analog input INP1

4 Measured value of the analog input INP2

10 Counter/frequency measurement value

Function of limit 1 (2, 3)

be reset via error list or a digital input ( -> LOGI/Err.r)

status. A stored limit value can be reset via error list or a digital input (

->LOGI/Err.r)

Source of limit 1 (2, 3)

Configuration level

Outputs Out.1 and Out.2 µ (Relay)

Name Value range Description

O.Act

0 Direct / normally open

1 Inverse / normally closed

Lim.1

0 Not active

1 Active

Lim.2

0 Not active

1 Active

Lim.3

0 Not active

1 Active

FAi.1

0 Not active

1 Active

FAi.2

0 Not active

1 Active

FAi.F

0 Not active

1 Active

Sb.Er

0 Not active

1 Active

fOut Forcing of analog output OUT 1 (only visible with BlueControl!)

0 Not active

1 The value for this output is preset via interface

Inf.1 Status message Inf.1 (operating hours) (only visible with BlueControl!)

0 Not active

1 active

Direction of operation OUT1

Signal limit 1

Signal limit 2

Signal limit 3

Signal INP1 fail

Signal INP1 fail µ

Frequency error µ message

System bus error µ message

UNIFLEX CI 45 Configurations 41

Page 42

Configuration level

Name Value range Description

Output Out.3 (analog)

Name Value range Description

O.tYP

O.Act

Lim.1

Lim.2

Lim.3

FAi.1

FAi.2

FAi.F

Sb.Er

Out.0

Out.1

Out.L

FrQ.L

Out.H

FrQ.H

Inf.2 Status message Inf.2 (number of switching cycles) (visible only with BlueControl!)

0 Not active

1 Active

Type of OUT3

0 Relay / logic (only visible with current/logic/voltage)

1 0 ... 20 mA continuous (only visible with current/logic/voltage)

2 4 ... 20 mA continuous (only visible with current/logic/voltage)

3 0...10 V continuous (only visible with current/logic/voltage)

4 2...10 V continuous (only visible with current/logic/voltage)

5 Transmitter supply (only visible with current/logic/voltage)

6 Frequency µ

Direction of operation OUT3 (only visible with O.TYP=0 )

0 Direct / normally open

1 Inverse / normally closed

Signal limit 1 (only visible with O.TYP=0 )

0 Not active

1 Active

Signal limit 2 (only visible with O.TYP=0 )

0 Not active

1 Active

Signal limit 3 (only visible with O.TYP=0 )

0 Not active

1 Active

Signal INP1 fail (only visible with O.TYP=0 )

0 Not active

1 Active

Signal INP2 fail (only visible with O.TYP=0 ) µ

0 Not active

1 Active

Frequency error µ message

0 Not active

1 Active

System bus error µ message

0 Not active

1 Active

-1999

...9999

-1999

...9999

-1999

...9999

-1999

...9999

-1999

...9999

0.0...9999 Max. output frequency in Hz (visible only with O.TYP=6)µ

Lower scaling limit of the analog output (corresponds to 0% (0/4mA bzw. 0/2V, only

visible with O.TYP=1..4)).

Upper scaling limit of the analog output (corresponds to 100% (20mA bzw. 10V,

only visible with O.TYP=1..4 )).

Input value for min. output frequency (visible only with O.TYP=6)µ

Min. output frequency in Hz (visible only with O.TYP=6)µ

Input value for max. output frequency (visible only with O.TYP=6)µ

42 Configurations UNIFLEX CI 45

Page 43

Configuration level

Name Value range Description

O.Src

0 Not active

3 Process value

7 Measured value INP1

8 Measured value INP2 µ

O.FAI

0 Upscale

1 Downscale

Inf.1 Status message Inf.1 (operating hours) (visible only with BlueControl!)

0 Not active

1 Active

Inf.2 Status message Inf.2 (number of switching cycles) (visible only with BlueControl!)

0 Not active

1 Active

fOut Forcing OUT3 (only visible with BlueControl!)

0 Not active

1 The value for this output is preset via interface

Signal source for analog output OUT3 (only visible with O.TYP=1..4 )

Fail behaviour

Logic LOGI

Name Value range Description

di.Fn

0 Direct

1 Invers

2 toggle key function (adjustable for 2-point-operation with interface and di1)

L_r

0 No function (switch-over via interface is possible)

1 Always active.

2 Di1 switches.

7 Limit 1 switches

8 Limit 2 switches

9 Limit 3 switches

Err.r

0 No function (switch-over via interface is possible)

2 Di1 switches.

7 Limit 1 switches

8 Limit 2 switches

9 Limit 3 switches

I.ChG

0 No function (switch-over via interface is possible).

2 Di1 switches.

7 Limit 1 switches

8 Limit 2 switches

9 Limit 3 switches

Function of inputs (valid for all inputs)

Local / remote switchover

(Remote: Adjustment of all values via the front panel is blocked)

Source for resetting all stored entries in the error list

Switching the effective process value between INP1 and INP2.

µ (input 2 must be released (CONF / Inp.2 / I.Fnc = 1))

UNIFLEX CI 45 Configurations 43

Page 44

Configuration level

Name Value range Description

tArA

HoLd

rES.L

rES.H

rES.I

rES.C

Tare-function µ (function must be activated (CONF /FUNC / Fnc.3 = 1))